Turquoise

Energy Ltd. News #66

Victoria BC

by Craig Carmichael - August 2nd, 2013

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Feature:

Permanganate-manganese Battery Breakthrough! High voltage, high energy

cells now work consistently and should hold their charge.

Month In Brief

(Project Summaries)

- Electric Mazda: batteries again - MnMn: Best Battery Chemistry

Ever! (the short version!) - Wiring up PbPb interface to solar PV

system - Evacuated tube with ammonia test seemed to work except it

leaked - a couple of better photos of the Electric Hubcap motor.

In Passing (Miscellaneous

topics, editorial comments & opinionated rants)

- continued erosion of financial system - USA war on journalists claims

another one - Cassini photo: Earth as seen from Saturn

Electric Transport - Electric

Hubcap Motor

Systems

* Turquoise Motor controller realizations: 80 amps DC means maybe ~240

amps

peak with a motor stopped or at very low RPM,

helping to explain why I can't seem to get higher currents without

blowing dual 120 amp rated mosfets.

Other "Green" Electric Equipment Projects

* Summer Thermoelectric Fridge Notes: It's struggling to keep cool in

the heat. More insulation helps.

Electricity Generating

* Wave Power for Boat Propulsion?

Electricity Storage - Turquoise

MnMn Battery Project etc.

* Calcium hydroxide

prevents gassing on overcharging.

* MnMn chemistry & construction seems "good enough" for solar use

if "prismatic" constructions are employed.

* MnMn never "dies": the voltages just keep gradually getting lower.

* Theoretically infinite cycle life.

* Electrode compaction with

hammer works if there's no press.

* Simple cases that don't leak for stationary applications! -- wide

mouth jars, plastic or glass.

* Low temperature is the key to charging manganese to metal, and to it

holding its charge. Cool room or fridge works.

* -Mn additive: zirconium silicate raises hydrogen overvoltage - Now

cells work at 'normal'

temperatures!

* NiMH pipe battery Connection

Problem Tracked Down -- beware of

unspringy, high resistance

spring clips in battery tubes!

No Project Reports on: DSSC

solar cells, LED Lighting, Pulsejet steel

plate cutter, Magnetic

Motion Machine,

CNC Gardening/Farming Machine (sigh, maybe summer 2014?),

Woodstove/Thermal Electricity Generator, Peltier & vacuum pipe heat

pumping.

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

-

Electric Hubcap Motor - Turquoise Motor

Controller - 36 Volt Electric

Fan-Heater (say, this heater is now obsolete! Use Peltier module heat

pump!)

- Nanocrystalline glaze to enhance Solar

Cell performance - Ersatz 'powder coating' home process for

protecting/painting metal

Products Catalog:

- Electric Hubcap Motor Kit - also please inquire about Electric

Caik

3KW Motor Kit

- Sodium Sulfate - Lead-Acid battery longevity/renewal

- NiMH Handy Battery Sticks, 12v battery trays & Dry

Cells (cheapest NiMH

prices in Victoria BC)

- LED Light Fixtures

Will accept BITCOIN digital currency

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

Permanganate-Manganese:

Best

Battery

Chemistry

Ever!

Key to manganese metal charging & holding charge: cool temperature.

My Cells - Good Enough for Solar Energy Storage?

(A short version of this story is in July in Brief,

below, for busier readers)

At the start of July, there

seemed to be still three longstanding major problems preventing

practical use of my cells:

high self discharge, low current capacity and low active substance

utilization of the permanganate-manganese

electrodes and cells.

I did more

new chemie battery making

work than I'd planned, but by the end of the month some key questions

had been answered. By about the 20th I decided I had practical

batteries at

least for low rate solar applications... by modifying my expectations

rather

than the chemistry. Then on the last day of the month I discovered a

key factor in my mixed results and high self discharge in charging

manganese to the metallic state: it worked at cool temperatures but not

at warm summer temperatures. That's how close Mn is to having the

highest possible voltage and energy that can be held in an aqueous

battery. On August 2nd I decided to try another additive to raise the

hydrogen overvoltage, zirconium silicate. It worked! The batteries

charge readily at 2.9 volts to hold 2.5 volts and above as tested at

29°c. It hadn't taken enough charge and there wasn't time to do an

hours-long self discharge test before sending this newsletter, but it

would appear the cells will now work acceptably, at 'normal'

temperature ranges.

This is fabulous of course! -- It appears I've

accomplished one of the main objectives set in 2008 -- a higher

voltage, incredibly high energy density aqueous battery! But it led to

some last minute

newsletter revisions, and there are some somewhat inconsistent writings

within

this text crossing paths with each other.

Usually I stop load tests when the voltage drops lower

than seems reasonable, eg, at 1.75 or 1.5 volts for a 2+ volt cell. And

the low

amp-hours are usually disappointing. But I ran a

long 50 ohm load test on cell PP#6. The voltage dropped very rapidly at

first, maintaining 1.75 volts for under 20 minutes, and usually I'd

have shut it off there and said "fooey!" But I left it on, and it put

out

good current for a full 24 hours --

22 of

them at voltages below 1.5. Total transfer of electrons from '-' to '+'

was over .55 amp-hours. Even

then it was putting out and the voltage drop had become very gradual.

But it was down to .885 volts. It might

have run even another whole day at even lower voltages and passed an

amp-hour. Cells PP#2 and PP#3 held

higher voltages longer - eg, 1.75V for 2.5 hours - but below that point

they too must have

had the bulk of their

charge still remaining.

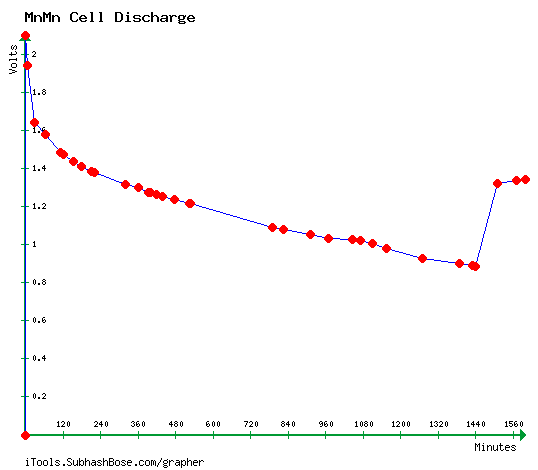

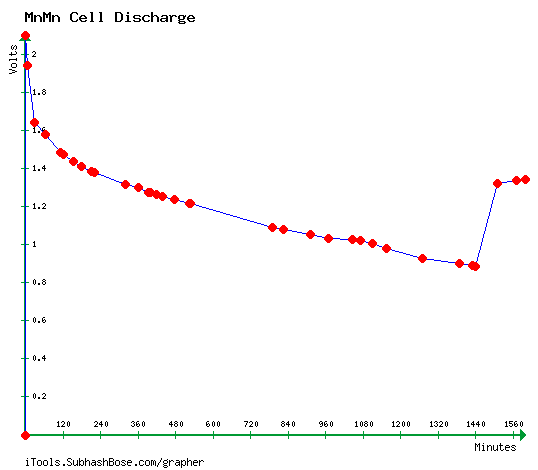

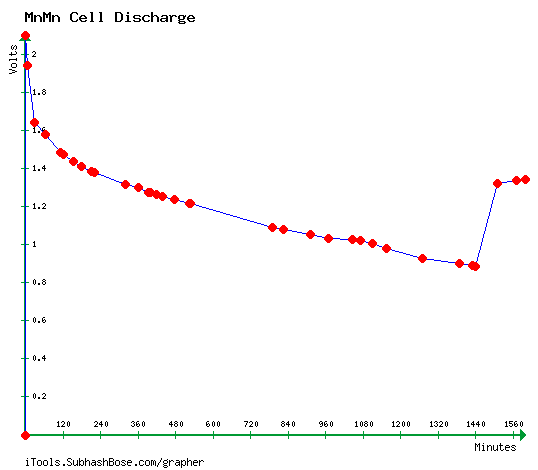

50Ω discharge test of cell PP#6, starting just over 2 volts and hitting

.885 volts after 24 hours.

When the load was removed it recovered to 1.34 volts - probably with

Mn2O3

in the "+" side.

(This is rather similar to a chart done in March 2012 when I first got

the chemistry working

[TE News #50], but I didn't run that test long enough to see the

changing valence states.)

BTW the graph software at the indicated link is very nice: enter your

x,y values into a text file,

then go to the site, upload it, enter a few things, and download the

graph image.

(I had to enter one dummy value at zero to get the graph to start at

zero

volts instead of .885.)

I

started to re-think how a

battery is expected to

perform. We're used to seeing battery voltages that may vary by 10 or

20% - perhaps 30% at the outside - between full charge and low. But

people talk about

"ultracapacitors" to hold energy with ridiculously variable, constantly

changing output

voltage. This is supposedly to be compensated for by elaborate

electronics. What's wrong then with a high capacity storage battery

that

goes down to 1/2 the fully charged voltage before it's considered

spent? If that's too much variation for the intended use, we have DC to

DC converters that can easily handle such ranges, and output a

regulated

constant voltage. Or it could be charged just to 1.9 volts (to MnO2 but

not to KMnO4) and use terminated at 1.3v or wherever.

If lower

cell voltages were considered acceptable I could

cross "low substance utilization" off the main list of complaints. And

perhaps "high self discharge": it ends with decreasing

voltage. A cell that won't hold over 2 volts overnight might hold

around 1.8 volts, still accounting for much of

its total

charge, for weeks - contrary to appearances, the cells still have lots

of stored energy. As a

battery from which only 1 to 1.6 volts is expected (varying

considerably with state of charge), only

the low current capacity is a major objection. Perhaps I'd

created great low-rate energy storage batteries without realizing it?

There's no apparent reason to think that a manganese cell

won't continue working 'forever'. It's the

amazing electrochemical element that can, with chelation of potassium

permanganate, moderately alkaline pH, antimony sulfide to raise

hydrogen overvoltage, and (evidently) a cool temperature, charge in

either direction from

valence 7 (permanganate) through various oxidation states to valence 0

(metallic particles) or from 0 to 7, without at any point becoming a

passive

insulator,

dissolving, or rapidly self discharging.

Changing oxidation states is where the amp-hours get

multiplied, at the expense

of having a more variable voltage than other cells with single

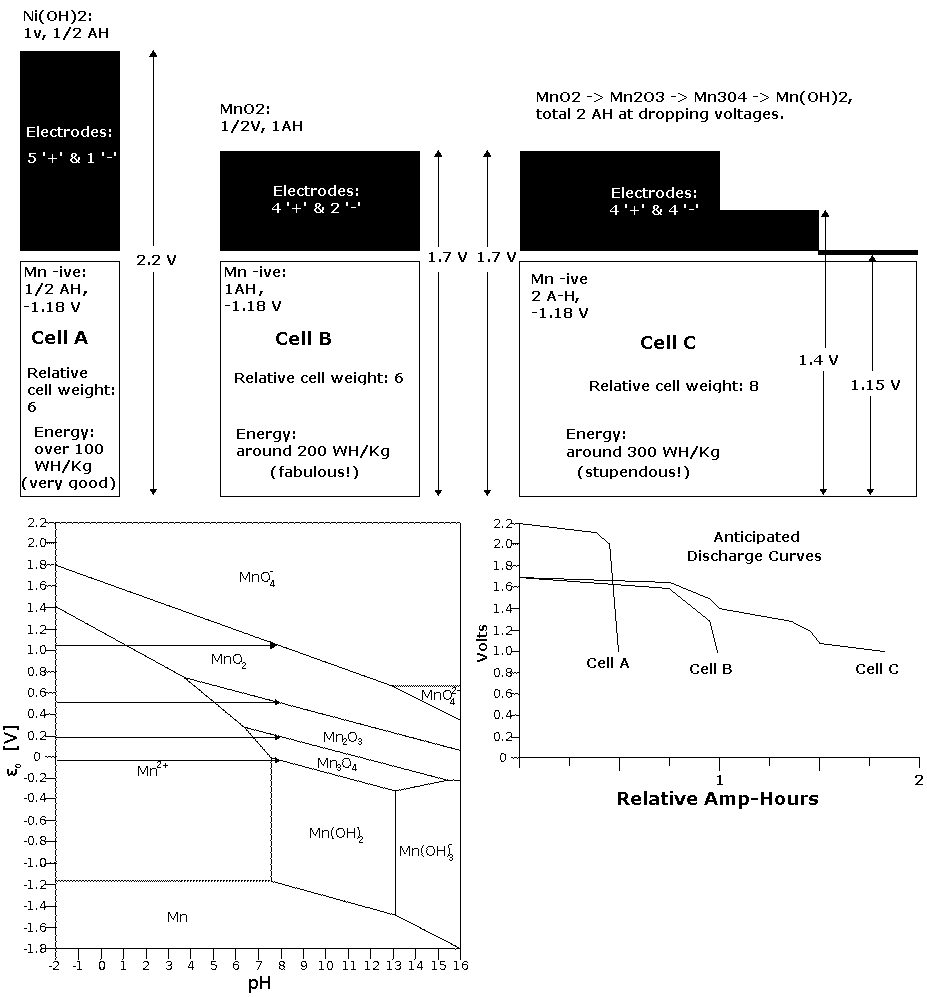

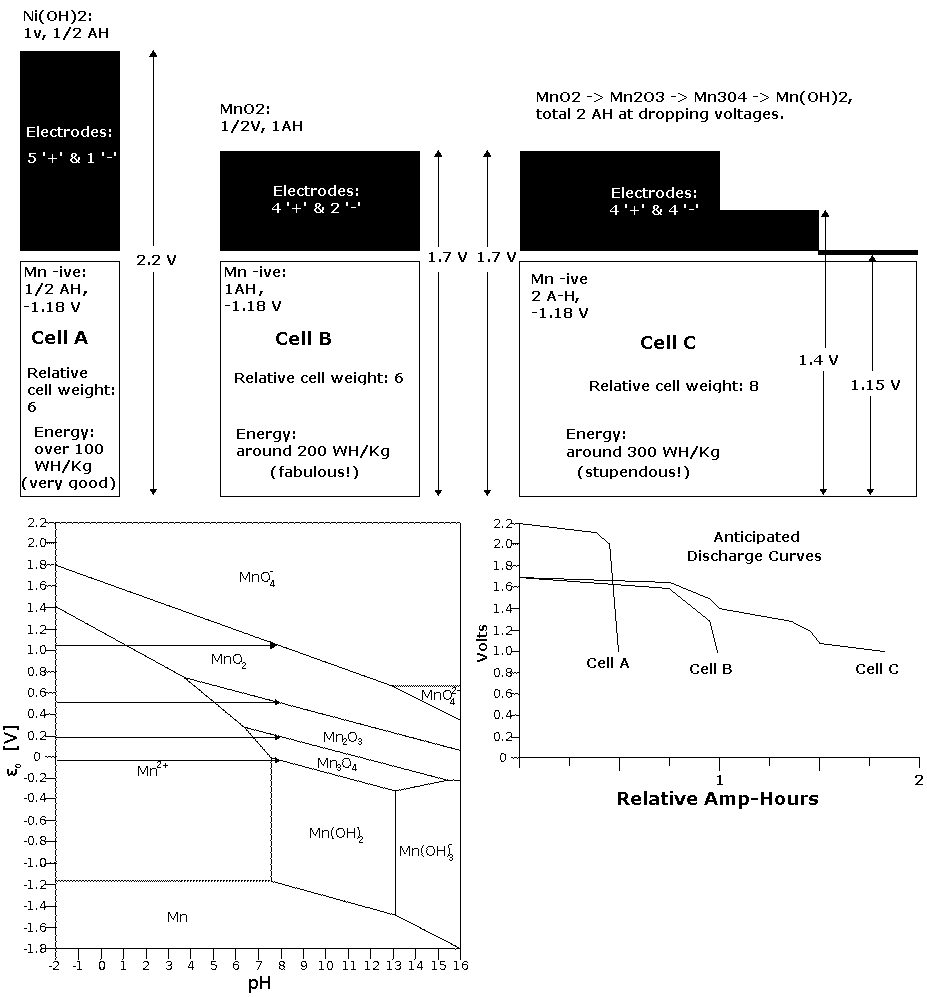

reactions. Here I'll refer

back to a chart I made over a year ago for its general idea of the step

voltages:

(Arrow for valence 7, "MnO4-" voltage added)

(The amp-hours per kilogram values assume high utilization of the

active materials and

constructions without

excess weight and water. To actually get 20% utilization,

in jars of water, would be okay for solar/stationary uses.)

Apparently I had the right idea then, shortly before I

realized the cells were charging to permanganate, which led me to put

the lower

oxides out of my mind. For the actual posodes I chose a mix of

manganese and nickel (~60:40). If the nickel oxyhydroxide and the

permanganate or nickel manganate do hold their high voltage charge, one

has roughly the equivalent of cell "A" added to the left side of cell

"C". If they

don't, one still has cell "C".

Some expert will doubtless say here that manganese metal

as a negative is known to spontaneously discharge itself within an hour

or two. But that's at pH 14

where its reaction voltage is highest (-1.57v), and with no additive

such as antimony

sulfide to raise the electrode's hydrogen overvoltage. The reaction

voltage of metallic manganese evidently drops faster between pH 14 and

pH 7.5 than the hydrogen overvoltage does, so my theory has all along

been that there's a "moderately alkaline" range where it can stay

charged if sufficient overvoltage raising can be attained.

Of course the -Mn voltage, in pushing the limits of the

amount of energy that can be stored in an aqueous negative electrode,

does also push the limits of chargability, and some of my cells held

their charge better than others. Reviewing TE News #50 from when I

first got

permanganate-manganese cells working, I noted that a test cell with a

'pure

manganese' negative held 2.13 volts for 24 hours. That's 'good enough'

for solar use, since it gets recharged daily. I recall cell PP#3 also

maintaining over 2 volts overnight on at least a couple of occasions.

These would be pretty high voltages to account for unless the

Mn negative was holding at least some metallic charge.

But in PP#6, the Mn negative wouldn't stay charged above

about 1.8 volts overnight -- the voltage for the Zn additive, not the

Mn.

That's not the best. It gave the .55 amp-hours, and it's good enough to

use if the 20% concentration of zinc doesn't form dendrites and short

the cell. (This does seem probable, especially given the lower pH where

the Pourbaix diagrams show no soluble state... if one can trust that.)

I stirred in some hydroxide [Ca(OH)2 & KOH] to

alkalize the electrolyte from about neutral to a higher value and the

charge voltage quickly went up 30mV, but it didn't help get the Mn

charged to metal.

The cells that worked were done in winter and spring. This

is summer. The temperature in my house isn't well regulated. Could

temperature (23°c that day) be the reason? I put the cell in the

fridge (8°) and continued charging it. By morning its voltage was

up to 2.45, much the highest yet, and it held something like 2.15 volts

open circuit for around an hour

indicating Mn metallic charge. I

took it out of the fridge and left it on charge several hours

(22°c), but the voltage dropped to 2.4 and when the charge was

removed, the self discharge was about 6 times faster dropping through

the 2.18 volt area (1mV drop per 5 seconds instead of per 30 seconds).

Apparently it works much better in a cooler. I put it back in and back

on charge, and it passed 2.5 volts by evening. The charging current had

dropped off with the higher voltage, and I put in a smaller resistor to

bring it back up to 25mA. It hit 2.68 volts after a day, holding a

while over 2.3 with the charge off.

Once much of the manganese has charged to metallic state,

higher cell conductivity may be expected, reducing or perhaps

eliminating the last major electrochemical problem with the cells.

Whether it can work at room temperature and above would be

a subject for further experimentation. Probably continued practice and

experimentation would disclose and hopefully raise the fine edge

between

manganese gaining and holding its very energetic charge, and not.

On August 2nd I decided to try an identical electrode but

with 3% zirconium silicate as an overvoltage raising additive before

sending this newsletter. Like the calcium dioxide on the

positive side, the reaction voltage of zirconium is just a bit too high

to retain a charge. It might interact favorably with the manganese.

I made it, pried open cell PP#3 and replaced the negative

electrode. I stuck a back on it, strapped it on with cable ties, and

put it in the jar in place of PP#6.

It worked. In a test at 29°c (dropping gradually to 26

as the bucket of water now holding the battery jar cooled) the cell

attained a charge voltage of about 2.9 volts after a few hours and held

2.4 volts for 1/4 hour. It was obviously going to go higher when the

charge was put back on, and this result will surely be found to be

replicable.

Permanganate-manganese batteries are now a viable battery

type, and a

higher energy aqueous battery can scarcely be imagined.

Even when the cells

hold a 2.4+ volt charge, much more energy is still available at lower

voltages as the permanganate becomes manganese

dioxide and progressively lower oxides. 5 or 6 cells will give a fine

12 volt battery, but one that can be run down to perhaps 8 or 9 volts

still happily putting out power instead of rapidly dying if it's called

on to "work overtime"...

and sit at any state of charge for any length of time with no damage or

loss of 'forever' cycle capacity.

A bonus chemistry feature is a

calcium hydroxide layer painted onto the positive current

collectors. Instead of bubbling oxygen if overcharged, the calcium

charges to dioxide, CaO2, or perhaps

one might say "calcium peroxide". The energetic voltage (+1.55 volts)

of this substance will spontaneously discharge it back to Ca(OH)2,

releasing hydroxide ions to discharge the negative electrode, so that

the excess charge discharges itself (making heat) without generating

hydrogen gas - or at least less of it.

The present low current capacity cells

seem

pretty hopeless for high current electric transport applications... but

they are real batteries, and the long load test shows they hold

very useful amounts of charge.

For stationary, low rate solar PV use, poor performance can be overcome

by making cells with as much electrode substance as it takes to get the

desired

power and storage capacity. The cells yield good amp-hours if driven

from

their fully charged state down to 1 volt or lower. If

necessary they can be tied in with flexible input DC to DC

converters to supply a constant voltage.

Hopefully also the performance

will

improve with time, practice, and

figuring out better ways to do things. They also seem to improve with

cycling, and more testing of this aspect is required.

On the 28th, I

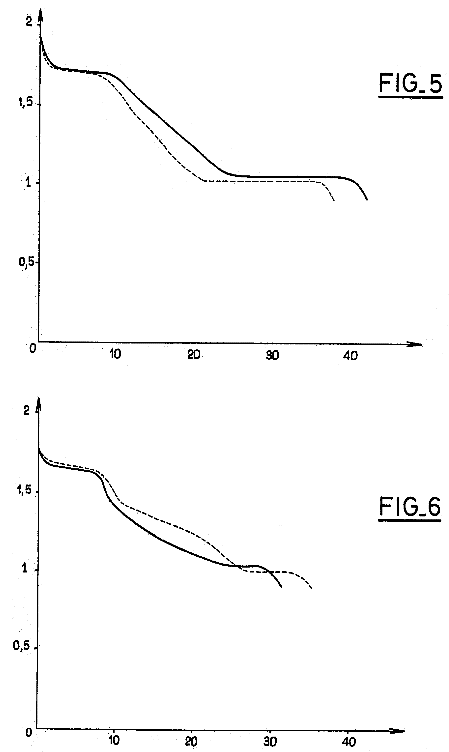

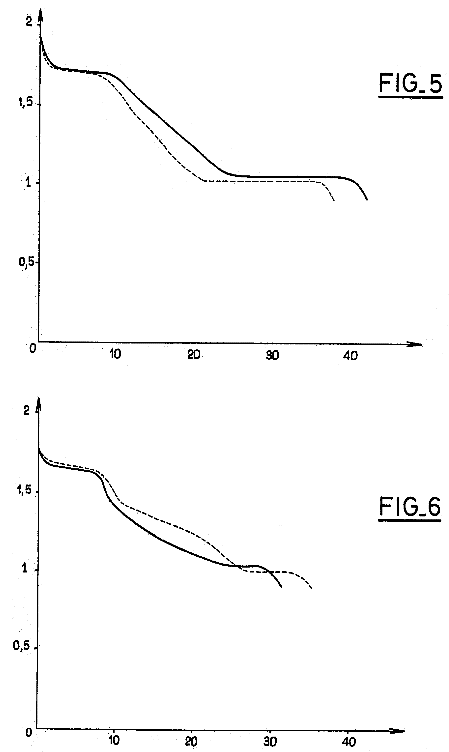

ran across an interesting patent from 1985. It was for a

graphite-manganese chloride compound for battery positive electrodes.

It had much in common with PP#6. Fig.5 from the patent showed the

discharge curve of a cell with this and a zinc negative. The voltages

obtained were rather similar, and the performance improved from cycle 1

(dotted) to cycle 4, as my cells have done. They also noted some

charging to permanganate, and also that their electrode substance would

work at any pH from acid to alkali.

On the 28th, I

ran across an interesting patent from 1985. It was for a

graphite-manganese chloride compound for battery positive electrodes.

It had much in common with PP#6. Fig.5 from the patent showed the

discharge curve of a cell with this and a zinc negative. The voltages

obtained were rather similar, and the performance improved from cycle 1

(dotted) to cycle 4, as my cells have done. They also noted some

charging to permanganate, and also that their electrode substance would

work at any pH from acid to alkali.

Their discharge voltages are a little higher and voltage

steps with

charge states are more evident - presumably the low conductivity in my

cell caused it to be more loaded down.

It would seem my chelation with Sunlight dishsoap

technique has achieved much the same thing as their rather elaborate

method of combining graphite and manganese in a chlorine gas

environment at 500°c... but maybe with less conductivity... or is

it my negatives?

The patent's Fig.6 shows the performance of regular MnO2

and graphite mix in a dry cell, without chelation. The voltages drop

more quickly with identical Mn content (poorer utilization), and

performance from cycle 1 to 4 deteriorates instead of improving.

One questions why long life batteries utilizing their

'manganese

inserted' C(5.6)-MnCl(2.4) substance never became available. It's

possible it was too difficult to produce the substance. Of course,

chelation is much the simpler technique, but this answer is

unsatisfying, since

the inventors managed to make it in the lab, and industry will set up

whatever process it takes to produce what it needs in bulk. Or a

manganese electrode may have sounded too common, 'mundane', or the

voltage steps too impractical, to even be seriously considered. DC to

DC converters were a new and uncommon technology back then.

But

when one looks at the way battery technology has been suppressed, now

for a whole

century, one suspects it was really because it was against the plans of

the

gangsters who run our economy to allow production of something that

might have resulted in practical, low cost electric vehicles and killed

their

petroleum sales.

Before the end of the month, some construction loose ends

were being

tied up towards making practical cells for solar/stationary energy

storage use. And probably without a 3D

printer or too much else in the way of special tools.

For stationary uses where an excess of weight and volume

isn't a concern, my perennial case headache can be solved

simply by using glass or plastic jars filled with electrolyte. I found

some nice plastic "20 oz cosmetic jars" big enough to hold a stack of

electrodes and lots of electrolyte. They have plastic lids that screw

on tightly. These can be slotted for the terminals to poke through, and

the slots can be sealed with heat glue as at present. Nothing attaches

to the body of the jar - visualize the jar turning to screw to a

stationary lid with everything attached to it.

What remains is some way to hold that stack of electrodes,

plates and separators together in a sandwich to immerse in those jars.

Hopefully with venting of gasses between each electode pair.

Materials and techniques for doing this is becoming the focus as July

turns into

August.

Making zinc foil rough for better contact with drum rasp.

If making stacks of electrodes as discrete units works

out,

then if I get back to trying to make cells for electric

transport, perhaps I could square off plastic plumbing tubes in the

oven, as I

had planned a couple of years ago. Tops of

flat plastic with slots for the electrode terminals could simply be

glued on, and again heat glue around the slots. The glass ball in a

smooth hole with a 3D printed retainer would still make a good filler

cap and pressure release.

A 7 or 8 cell, "12 volt" battery for my solar collector

system

would be a great start to test and measure performance over time.

July in Brief

Electric Mini - Tesla Model S

Someone came to buy a few bits of wood from me on the 3rd,

the day of the VEVA-Islands monthly meeting. He remarked on the long

extension cord coming out my upstairs window, which I said was charging

my electric Mazda from the solar panels. It turned out that he had

driven here in a Tesla and he gave me a ride. It was fabulous... and

terrifyingly powerful. When he stomped on the pedal, the car leapt

forwards and it was like going straight up, and we were doing 50 Km/h

or more in the space of 50 feet or so. all without squealing a tire.

But he had more... he had converted his wife's mini to

electric before buying the Tesla. I told him about the meeting and he

came in the Mini. It had lithium batteries in the back and a range of

something like 70 Km.

What a synchronicity to have met him that very morning!

Electric converted Austin Mini

Electric

Mazda

After removing 1 battery of

11 from the Mazda RX7, hence dropping from 132 to 120 volts, the

currents seemed to go up enough to shorten the range appreciably,

probably, I thought,

owing as much to batteries having lower amp-hours as the amps rise, as

to the actual reduction in nameplate watt-hours - hence 'losing double'

with each

battery removed. On the 10th I bought two more 'reconditioned'

batteries (so 144v) hoping to 'gain double' and improve range

substantially, plus get more power with lower amps. Low voltages and

higher amps aren't wrong in principle, but they're wrong for this car

as converted, since it's not possible to fit two batteries in parallel

for each position, which would go from at least 8 batteries to 16, or

to

fit larger, higher current batteries of any common configuration. I put

one of them in immediately, but the other was still sitting around at

month's end. It turned out I had another battery problem than just one

less.

On the evening of the 18th I noticed that the voltage was

too low - by about 8 volts - for what should have been a fully charged

car. On checking, I found a problem with a charger to one of the NiMH

batteries, which was down to about 6 volts. That's battery damage

range, and it probably hadn't been charged for two trips or more.

It also turned out that this 6-pipe NiMH battery was "losing"

pipes by bad connections and so was responsible for much of the "losing

double". It was the very low voltage that had caused the charger

trouble - the solder holding the wire to the (very hot) current

limiting resistor melted. Here

once again is a problem that would have been caught in good time by the

individual battery monitor, which would have been beeping "red alert"

long since. I really need to get that going before I start losing my

pricey

NiMH batteries!

I fixed the battery - it was the one with twelve 6v NiMH D

cell pipes - by

breaking the pipes open and remaking it in six 12v pipes. Chief

problem with these 6v pipes was that I had put in nickel-brass "U"

clips at one end of each to give some spring tension to hold the cells.

Nickel-brass isn't the best conductor

and the currents were high enough that these got hot and softened the

plastic around the terminal bolts, causing bad connections, more heat,

and melted plastic. There were also cells, randomly distributed through

the tubes, that had solder on them from previous soldered battery

packs. As I had found, the solder becomes corroded and also makes for

bad connections. I scraped it

all off.

MnMn: Best Battery Chemistry Ever! (short version)

"Slapped together" cell PP#3 with new negode containing 3%

zircon.

Notwithstanding my plan to

do "outdoor" and "active" things over the summer, I did a bit more

battery making

work - and then fell into ongoing new chemistry battery testing and

designs. And by about the 20th I decided I had practical batteries at

least for solar applications... by modifying my expectations rather

than the chemistry. Then on the 31st I figured out the reason for the

nagging problem

of inconsistent results charging manganese to metal and its high self

discharge: it worked below about 17°c - but not at 23°. The

MnMn

battery

worked great in a fridge!

Notwithstanding my plan to

do "outdoor" and "active" things over the summer, I did a bit more

battery making

work - and then fell into ongoing new chemistry battery testing and

designs. And by about the 20th I decided I had practical batteries at

least for solar applications... by modifying my expectations rather

than the chemistry. Then on the 31st I figured out the reason for the

nagging problem

of inconsistent results charging manganese to metal and its high self

discharge: it worked below about 17°c - but not at 23°. The

MnMn

battery

worked great in a fridge!

Cooled batteries might have been practical enough for

solar use, but at the last moment came a major chemistry breakthrough.

On August 2nd I decided to try one more thing, that might be very

significant, before sending this newsletter. I made an otherwise

identical electrode with 3% zirconium silicate in it to try to raise

the hydrogen overvoltage to a workable level, and slapped a cell

together. At 29°c it charged readily to 2.5 volts and appeared it

would continue to charge and to hold a high voltage charge in the time

I had to test it before sending the newsletter. The results will

doubtless be replicable. I think I've finally completed the chemistry

side of what I set out to do in 2008 and made a fantastic high voltage,

very high energy density aqueous battery, far beyond what anyone else

has done.

If the story following isn't a coherent as it might be,

it's because of the vital late breaking developments.

Tired of battery cases that somehow always seem to leak, I

found a large plastic jar, filled it half way with electrolyte, and put

cell PP#6 inside it. The jar wouldn't leak. I made a hole in the center

of the lid and brought the wires out through that. A jar makes a simple

case for stationary cells where size and weight are of little

consequence.

Instead of shutting off at a cutoff voltage that seemed

reasonable for a 2 volt cell, I ran a discharge test for a whole day on

the 24th (& 25th). The battery kept putting out current, at lower

and lower voltages, as perhaps only manganese is able to do as its

oxidation state drops a level at a time from valence 7 to 2. After 24

hours it was still putting out, but it had finally dropped below .9

volts and I shut it off. If one accepts voltage swings of 2

to 1 with much of the discharge available at lower voltages, it stores

a

fantastic amount of energy - far more than any single reaction

electrode such as nickel hydroxide. A DC to DC converter can take such

voltages

and put out a constant DC voltage to make a "voltage regulated

battery". And because the chelated Mn oxide substances never dissolve

or become a passive insulator in any state, it should be rechargeable

'forever'. And manganese is cheap.

When I ran the test, the manganese in the negative

electrode wouldn't hold a charge, so it was really

operating off the zinc 'conductivity additive', making the battery

Mn-Zn rather than

Mn-Mn. The breakthrough in thinking came first and remains valid; the

breakthrough in charging the negative to Mn metal particles came later.

50Ω discharge test of cell PP#6, starting just over 2 volts and hitting

.885 volts after 24 hours.

When the load was removed it recovered to 1.34 volts - probably Mn2O3

in the "+" side.

With the present low

current capacity the cells

seem

pretty hopeless for high current electric transport applications... but

for stationary, low rate solar PV use, poor performance can be overcome

by making cells with as much electrode substance as it takes to get the

desired power and storage capacity.

I visualize a horizontal stack of electrodes, current

collectors and separator sheets, with pieces of plastic at the ends to

sandwich them all together, wrapped up with cable ties, tape, or

whatever. The terminal extensions

of the collector sheets will stick up and protrude through slots in the

lid, separately or bunched up. Heat glue can seal the slots as now.

Materials and techniques for making these stacks is the focus as July

turns into

August. Coarse embroidery cloth (accordion folded?) may replace the 3D

printed vertical bar baskets to provide a gas vent between each pair of

electrodes.

For cell construction for stationary uses where an excess

of weight and volume

isn't a concern, my perennial case headache can be solved

simply by using glass or plastic jars filled with electrolyte. I found

some nice plastic "20 oz cosmetic jars" big enough to hold a cube stack

of

electrodes and lots of electrolyte. ABS I think - but as usual they

don't say. They have plastic lids that screw

on tightly. These can be slotted for the terminals to poke through.

Nothing attaches

to the body of the jar - visualize the jar turning to screw to a

stationary lid with everything attached to it.

A 7 or 8 cell, "12 volt" battery for my solar collector

system

would be a great start to test and measure performance over time.

The first MnMn in February/March 2012 worked and held

its charge. PP#3 in April 2013 worked, but had higher self discharge.

PP#6 in July wouldn't stay charged to Mn metallic. The difference

was... winter versus spring versus summer? On the night of the 30th I

put the battery in the fridge (8°c) and by morning, on the last day

of

July, I had the answer. The battery had at last, for the first time,

charged up to 2.45 volts and stayed over 2.2 with the charge removed.

Removed from the fridge, the voltages dropped, and put back in, the

charge voltage hit 2.5 volts by evening. It'll take some days of

charging at the present low rate to charge most of the Mn substance to

metal, and I'll probably increase the rate. It has to be higher than

the self discharge, which is doubtless still well above zero. Once it's

charged to metallic state, I look forward hopefully to much higher

conductivity.

A load test showed even lower drive at 8° than at room

temperature. Apparently fridge temperatures are cooler than needed to

hold charge - and too cool for good performance. Perhaps somewhere

around 15° might be 'optimum'. I suspect it's the plus side

objecting to the fridge temperature.

Temperature was, then, the key to my inconsistent results

charging the

negatives to Mn metal particles and keeping them charged. The Mn is so

energetic that it's borderline whether it charges and stays charged or

not, and a cool temperature of perhaps 15°c versus 23° makes

the whole

difference between success and failure. The cheap batteries with an

energy density higher than lithium work great in a cool place! I can

visualize making battery enclosures in the style of my shallow chest

Peltier module refrigerator, but cooled just enough for the manganese

to hold its charge.

Preferably, electrode additives will be found to bring the

operating temperature up into at least the mid 20s, and of course the

higher the better. Otherwise, the cooler idea is practical. It's

nothing like sodium batteries that have to be heated to an extreme

temperature to melt the electrolyte.

The project occupied more of July 2013 than I'd planned,

and I

didn't get very far on any other projects. On the other hand, after

5-1/2 years the Mn-Mn/moderately alkaline battery chemistry has been

found: the best, highest energy battery attainable. And its somewhat

obscure workings are at last basically

understood and the results are replicable. It's the end of the search

for a better battery chemistry. Progress on them can at last truly

proceed from the experimental research to the product development level.

Solar PV System: PbPb storage

Of course I wanted to hook some of my lead-acid batteries

to the

solar panel system, both to increase its storage capacity for now, and

to put the renewed batteries originally intended for the Mazda into

use, where their capacity might gradually increase with cycling. In

order

not to have a bunch of batteries with differing characteristics in

parallel and feeding into each other (especially mixing NiMH and PbPb),

I

decided to diode isolate each one in both directions. Since PbPb s

charge slowly, I decided to do it like the car, through small value

resistors from a constant voltage. The NiMH s and the main house supply

already have 14 volts on them when the sun is out. This goes to 5

diodes and resistors, one set for each lead-acid battery.

Coming the other way is a heatsink block with 5 heavy

current car alternator resistors. Each battery attaches to one diode

anode, and the block attaches to the common cathode side, which

supplies the main house power if it falls below the voltage of the

lead-acids less one diode forward drop (~.6v) at night or in clouds.

Okay, it just doesn't have that "professional" look to it.

(needs some sort of cupboard/shelf with roof.)

Then, it would seem from a

'battery renewal' discussion list that pulse charging is a requisite

for bringing 'renewed' batteries back up to maximum capacity. I decided

to make a pulse charger with a 24 volt transformer and a single

rectifier diode. Since one diode only rectifies 1/2 wave, the pulse is

under 50% duty cycle. I wasn't satisifed with that, and I attached a

computer control I made about 3 years ago when I was first doing

battery renewal, but didn't get much use out of then. I programmed it

to

turn on for short periods, so the strong 60Hz pulses are only going to

the battery 1/16th of the time every couple of seconds - another form

of pulsing. I set this up on the back patio where the batteries taken

from the Mazda were sitting, and started charging them. One that

wouldn't

charge up still wouldn't. I decided it should be shorted out again and

"reset" to zero, then I'd try the pulse charging again and see if that

resurected it. I'm pretty sure most batteries can in fact be brought

back to life and good capacity, little success tho I've had so far.

Pulse charging is probably the way to do it. Perhaps these will regain

their capacity and can go back into the car, or into the boat for the

electric outboard.

Evacuated tube with ammonia

I made an attempt to evacuate a tube with ammonia in it

instead of pure water, hoping for a lower boiling point. I still hadn't

bought the pipe fitting and copper end plug I'd been meaning to get for

the top end, and "made do" with another fitting with a galvanized plug.

At first it seemed successful. I wasn't sur eof the boiling point, but

by the next day the vacuum was gone - it leaked. The only other

accomplishment on this project was to finally make a special trip to

buy the fittings I kept forgetting to pick up.

Electric Hubcap Motor Pictures

Looking for one, I noticed that I'd never taken any decent

pictures of the latest (2012) model of Electric Hubcap motor, so here

are a couple. It is of course set up for mounting in the Chev Sprint

and driving the planetary gear torque converter.

Rotor side

Coil side with air filter unwrapped showing ilmenite painted coils.

Profile view

In Passing

Incidental news, editorial comments & opinionated rants

Continued Collapse of the Financial

System

According to Max Keiser and others, a key indicator of the

coming crisis will be the rise of interest rates from near zero in

spite of anything the US "Fed" can do, with a consequent collapse of

the highly inflated "bond bubble". Another will be the collapse of the

"on-paper" bullion markets, comex and LBMA. The price of gold and

silver has been manipulated down to make the US dollar look stronger,

and those doing the manipulating must have expected people to dump

there precious metals as the price dropped. Instead there has been

unprecidented demand, and the physical supply held by the manipulating

banks must be about exhausted.

The sequences appear to be proceeding apace,

with bond selloffs recently accelerating at dropping values. (Okay,

Detroit municipal bonds were probably not the best investment, but

there'll be much more to come!) Some are talking about complete

financial system collapse and wiping out of all debts as well as

financial assets this autumn. Like the most dire predictions for

'Earth's population 12 billion by the year 2000' (IIRC) and now one for

something like '95% of Americans dead within next few years', it's

probably premature and exaggerated. It's also probably got enough truth

to it to be worth noting. And the world as a whole is overpopulated and

everything is highly dependent on everything else. There'll surely be

serious trouble in any lasting interruption of the

flow of goods and services. Everyone would be wise to have a good stock

of durable foods and perhaps access to food production - gardens,

chickens, fishing equipment... and savings and assets outside of the

banks.

And of course we should all try to contribute to social sustainability

in whatever ways we personally find that seem harmonious and useful. It

seems to me there are too many who only want to take from 'the system'

whatever it'll give them. This results from their own unfortunate

decisions and tendencies, but such are fed by a system that no longer

appears to

care about ensuring practical and reasonably fair opportunity for

individuals and families to better their circumstances and live a

decent life. The gross inequality and rampant corruption, the uncaring

about the populace by those in charge, breeds a populace of uncaring

individuals. This is the fatal, self perpetuating trend.

Today 'the system' is hostile to change,

but it will become open to it in the increasingly chaotic period soon

to come and indeed already underway in various ways in various part of

the world. The economical and social system needs

to be reframed in sustainable ways, and that needs a lot of creative

thought, caring, by a lot of people.

US War On Journalism update

From "dumbing down" the main news channels, to harassment

and threatening of Americans reporting or putting on websites news or

views contrary to propaganda or exposing crimes 'the establishment'

wants kept quiet, to gunning down Reuters journalists from a helicopter

in Baghdad, to arresting people videoing police actions, it is

increasingly apparent that an energetic war is being waged against

journalists and freedom of the press by the US government. They're

still trying to get revenge on Julian Assange and Ed Snowden. (After

the

rampant US espionage program revealed by Ed Snowden, charging him with

"espionage" is ironic.)

This month the war took another savage turn with the booby

trapping of the car of 'mainstream' journalist Michael Hastings,

apparently by government employees. Hastings had done a candid

interview with a top US general in Afghanistan that was printed in

Rolling Stone. The general said some things about "we're losing" that

he evidently hoped would lead to the US sending more troops there, but

instead he ended up being sacked.

In the days before he was killed, Hastings told those

around him that he was about to release a big exposé on the CIA.

A few hours before his death, he e-mailed to Wikileaks that he thought

the FBI was 'investigating' him. It would seem that they or whoever

were actually busy booby trapping his car. As best I understand it the

car suddenly accelerated wildly, caught fire, and then,

already burning, hit a tree at high speed. This was deemed

"an accident" by the police. They must have been hard pressed to ignore

witness testimony and look the other way, when the engine was blown

something like 300 feet into the air and landed 75 feet away. People

who knew Hastings well said he was an exceptionally careful driver.

The story was reported on The Corbett Report,

"Crashes of Convenience". James Corbett is an American who does his

news reports on Youtube from Japan. He's not alone among American

journalists living and working abroad, where they doubtless hope to

avoid meeting some sort of fate akin to Hastings'.

In the west it used to just be unsuspecting inventors who

were at such risk, being quietly removed from the scene of action by

murder or somewhat more subtle underhanded techniques by corrupt

corporate interests - not by the government. Welcome to the club,

journalists! Before the internet, such criminal tactics used to work

and usually no one was the wiser. They can't be hidden any more, and

the backlash against such crimes works to destabilize the whole of

society. If they continue, martyrs like Michael Hastings will be

definite factors in inciting whole populaces to rise up to overthrow

their 'governments'.

Here's a couple of samples of things this month you

probably won't see in the American mainstream news:

* Former US president Jimmy Carter said the USA has no functioning

democracy today.

* There's a book out about how the US has become the USSR. (I don't

recall the title - something like "role reversal".)

To find the real journalists and news, try youtube,

RT[.com], Aljazeera, news & magazine websites, etc.

There it is! There's the planet where all the trouble's coming from!

No, not the big one with the rings... the teensy little blob to the

lower right:

"Earth", 1.6 terrameters from the Cassini's camera. We are all on it.

Electric

Hubcap Motor Systems - Electric Transport

Blown motor controller fixed - Realizations: To see 120 amps, Max

amps would be ~= 360?

The controller worked again after replacing just two power

MOSFETs. I tried all the "?" IR2133s from previous controller blowings.

To my surprise only one of them, the first one, was good out of five.

But at least, running the controller off the lab power supply with the

supply current limited to under 10 amps, I didn't blow anything more

with testing. (One of the chips tried its best to blow everything. Two

had a phase drive

missing, and the last seemed to do nothing at all.)

Now... any chance I could just get back to the Sprint car?

No, I decided to look at the other controller while I was at it. Then I

didn't even get to that.

But I also started to consider that at low RPMs or stopped

with no back EMF,

the peak current to the coils must ramp up to a level much

higher than

the

average DC current from the battery. Perhaps 3 times as high. In

that

case, seeing the "rated" 127 amps from the battery on the meter would

actually mean about 380 amps peak to

each set of coils. Here I've been thinking I'm limiting them to 1/2

the MOSFETs' rated continuous current, when in fact to see such a

current on the meter, it would be 1.5x! So if the current cut-out is

set to my normal 127 amps max, the most the meter may show is around

40-45 amps with the motor stopped or at very low RPM. So apparently I

shouldn't be wondering why I see maximum current readings much lower

than the current trip-out setting. Obvious after realizing it, of

course!

Furthermore, the amps ramp

up more and more slowly as the

motor RPM increases. If the max has been set to 380 amps, that may read

as 127 amps DC with a stalled motor, but at some

point of RPM and load, they could ramp up to 350 amps and never hit

380, so the

average current would be very high, and the controller would probably

blow.

These realizations give me

better appreciation of what the MOSFETs in the controllers are

contending with, and why it doesn't seem to take a lot to blow them -

actually it does, but they're getting a lot more than it looks

like on

the DC ampmeter.

Chev Sprint

At the risk of having insufficient power to move the car

instead

of just enough, I took one of the batteries out and just had 24 volts.

I really didn't relish the chance of blowing the motor controller

again, and they seem more reliable at 24 volts. Of course, it shouldn't

take a lot of

power to move the car if everything is working the way it's supposed to.

Next a means was needed to keep the flat belt from sliding off the

pulleys sideways when it's slipping. (When it's not slipping it tracks

well enough.) I supposed raised sides on the pulleys would be best and

simplest, and

I took off the top pulley in order to glue plastic sides onto it. Then

somehow the month slid by without getting anything more done.

Pitot Tube

Speedometer for low-speed Boats

When I was doing the Electric Caik Outboard in February, I

was looking for an economical water speed indicator. (TENews#61) The

pitot tube seemed ideal, but all the speedometers that connected to

pitot tubes went up to very high speeds and didn't even read below 10

or 15 MPH. That's pretty useless for most boats besides high-speed

planing hull

speedboats.

I found a table that showed the height that the pitot tube

would raise water to at various speeds, and it varied with the square

of the speed. At one MPH it's just a centimeter, but 4.3cm at 2 MPH

(table in TENews61 has this figure wrong), and at 15 knots it'll

overflow an open ended tube sticking 1 meter above the water line.

It occurred to me later that a closed ended tube would be

much better, giving a more linear calibration and extending the range,

since air pressure in the tube would counter the pitot pressure as the

water rises higher in the tube. This should also help stabilize the

readings somewhat in waves and turbulence. It would still bounce around

a bit no doubt, but the boater should get some quite decent indication

of speed between about 2 or 3 and 15 or 20 MPH. The low end speed is

dictated by the accuracy and precision of readings on a moving boat in

waves. For example, (for an open tube) if the water column wavers up

and down 4cm, that's the whole height of the reading for 2 MPH. But

only 1/4 of the reading for 4 MPH.

Of course, figuring out the calibration would involve a

bit of math with the rising pitot pressure causing rising air pressure.

I looked on the web for one that has already been done, but found

nothing. I find it hard to believe no one would have done it for

displacement hull boats, or indeed that no one makes such closed end

tubes ready to use for that purpose. But I haven't found anything. All

it needs is a clear tube with a plug in one end and speed markings -

just about like a thermometer.

In lieu of that, I really ought to make an open ended one

before my next boat excursion. Open ended does have the advantage that

the calibration is available in standard tables.

To keep the "zero" mark at the

waterline, I'd have the whole thing outside the boat on a float. And at

that point,

maybe it could be a lightweight unit that's towed on a light line. That

way it would also be out of the way when launching and landing. It

might

be a bit hard to read at a distance... then again, maybe there

could be a small colored float inside the measurement tube to help with

that.

Then I thought that better than towing with a rope would

be hinged arms, upper and lower, holding the unit to the transom/stern.

It would be free to float up and down to stay at the waterline, but the

tube would be held vertical and couldn't tip, and it would be close to

the stern for reading.

Electric Equipment Projects

Summer

Thermoelectric Fridge Notes

I thought that in the

summer the longer sunny hours would mean the fridge could run almost

purely on solar power. Instead, with warm summer weather, it could run

24 hours and not get even the coldest area below the ice tray down to

5°c. Mostly it was 5.5 to 6.5°. There was no point worrying

about the control when it was best if it should never shut off.

On the 10th I bought another piece of 1" extruded styrene insulation.

I cut it in half and put one piece under the fridge and simply set the

other on top of the lid. It made a difference. Temperatures dropped to

5° in the day and 4° or lower at night. When I finally tried

turning it off overnight, there was more ice and a lower temperature

than usual in the morning.

This trend reversed itself when I put both extra sheets

underneath (giving 5" of foam on the bottom) and at the same time took

out or moved some of the food, making more open air flow from the

cooling unit to the

other side of the fridge. I verified it was the air flow by stacking up

some cans to block it, and the temperature near the ice tray went down

below 5 again. Of course, the warmer side of the fridge away from the

ice tray is obviously cooler with better air flow.

I also found that with the warmer weather the fridge would

get up to 7 or 8 degrees near the ice tray when it was turned off

overnight, even with a little ice still floating in the tray.

At this point I'm considering the thermoelectric fridge

idea to be marginal in practicality. I'd recommend using at least 4" of

extruded styrofoam insulation on the top, bottom, back and sides. (If

the front is thinner, 3",

you don't have to reach in as far.) Obviously even more insulation,

and fridge shapes such as the octagon and or the stepped floor to

reduce external surface area per inside volume, would be beneficial.

I've gone to 5" in the floor, which is the coldest surface, and where

thickness makes no difference to space occupied except that underneath,

which isn't very useful space.

I've been running with the 8-volt and 15-volt, 8.5 amp Cui

Peltier modules in series on the 12 volt supply, using perhaps 45-50

watts. I haven't yet tried hooking up the two 15-volt modules in series

(35-40 watts) to see if they'd perform as well or better. (There may

have been a piece of grit preventing good thermal contact when I tried

it before.)

I evacuated a pipe with ammonia-water to make a radiator

that

would start to boil at room temperature to replace the warm side

heatsink and fan, but it seemed to leak - it quit working by the next

day. I got better pipe fittings for the next try, but didn't get to it.

It's possible that an evacuated pipe radiator for warm

side heat dispersal will make the somewhat marginal performance of such

fridges more acceptable.

Electricity (Energy) Production

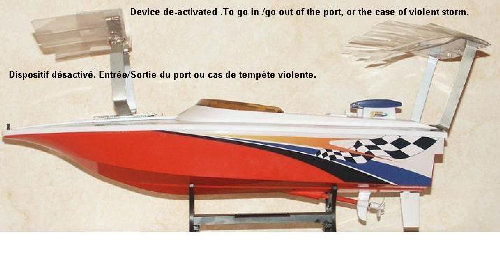

Wave Power for Boat Propulsion

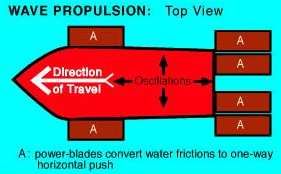

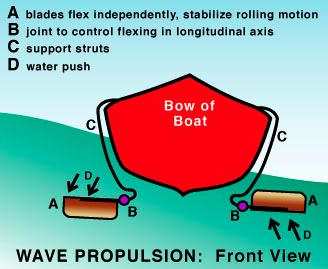

I've had the idea that one could use wave power on a boat

to make electricity. Of course, one could then use the electricity to

propel the boat. Here's another idea I've run across: Francois Kneider

skips the 'middleman' and has the waves propel the boat directly.

http://www.rexresearch.com/kneiderwave/kneider.htm

The waves move "power blades", up and down, and these act

as fins to push the boat. (Considering how small oars or paddles are

compared to the blades in these diagrams, I suspect that smaller blades

might work better. But that may depend on wave size.)

However, wave power on a boat making electricity can

charge

a battery even while at anchor, and the electricity can then be used at

a

future time to provide any desired velocity with a regular electric

inboard or outboard motor.

Electricity Storage - Turquoise Battery Project (etc.)

Production Prototype Cell #6 ("PP6")

I started this and made the posode in June. A new feature

is a piece of carbon fiber cloth across the front and wrapped around

one edge behind the graphite current collector sheet. This is intended

to increase the overall conductivity of the electrode by connecting

everything across the front face, in addition to the current collector

connection across the rear face.

Negode

I mixed some materials for the negode. It was pretty

similar to cell PP3 (TENews62) except I used a lot more granular

manganese. I added a little VeeGum, Sunlight dishsoap, and water to the

42.5g portion I compacted. The electrode was a bit short. (45g

next time was slightly long.)

50g Granular Mn

50g fine (<300) Mn powder

50g Mn oxides powder (MnO2, Mn2O3...)

22g Zn flakes

22g Zn fine powder

2g Sb2S3

---

196g (Hey, that was supposed to be 200!)

When I was mixing it I noticed a lot of fine fibers in the

mix. Either something I bought was contaminated with something or I had

put carbon fiber in with some manganese oxide I used. Under a

magnifying

glass it looked to me like carbon/graphite fibers, all single fine

strands of a uniform thickness. Ouch! There isn't supposed to be any

graphite in the negode - it might bubble hydrogen. It would be good in

a plus side, except I'd mixed in the zinc and stibnite for a minus. I

decided to try it anyway, having mixed 200g of substance.

I dried it on

porous brick and torched it only about 4 seconds instead of double

that, with a small propane torch. Next I decided to match the other

side and put a perforated zinc foil current collector sheet behind the

separator sheets.

Yikes! - at no time did I think to check the conductivity

of the briquette, and I assembled the cell without having done so.

Considering that poor conductivity is probably the chief problem,

that's

a poor step to miss! Nor did I take pictures of the perforated zinc

sheet arrangement.

The cell didn't charge as expected. Instead

of 2.6 volts, it charged up to about 2.0 or 2.1. Well, what was

different from PP#3? Two fundamental things - maybe three. First, I put

some ferric

chloride onto the posode briquette, and since it didn't quickly soak

in, I brushed it around over the entire surface. Second were those

graphite/carbon fibers in the negode. Thirdly I just might have put a

layer of calcium hydroxide at the posode current collector in #3. I

didn't think of it this time. (Methodical I'm not!)

At first I was suspicious of the first item, but then I

thought

that the cell was charging up to the voltage one might expect from

permanganate-zinc. Continued charging after that made a lot of tiny

bubbles and

loss of electrolyte. It could make sense that the abundant carbon

fibers were bubbling hydrogen throughout the negode before it was up to

the charge voltage of metallic Mn, so the Mn would neither charge nor

stay charged.

This points to the probable need for quite pure

ingredients in the negodes to prevent self-discharge. Any little

metallic- or conductive carbon-based bits of 'stuff' could gradually

bubble hydrogen and steal away the charge. In fact, I think I won't

worry about self discharge until I'm sure I have all "lab grade"

materials in a negode.

Either that, or some way of 'masking' any offending grains

of powder is needed. Here once again borax in the electrolyte might be

useful to form borohydride and hopefully neutralize such sites. (As for

neutralizing a whole mesh of carbon fiber, I have my doubts.)

Since 20% of the electrode was zinc

powder for conductivity, and the current collector sheets were also

zinc, it would function quite well as a Mn-Zn cell. It didn't have much

current drive, but driving a 50 ohm load, it hung around 1.5 volts (so

driving 30mA) for over 13 hours, showing at least .4 AH of capacity. A

stable drive voltage and useful if not high capacity

definitely made it a real battery. At that point the voltage was

starting to fade and had dropped to 1.41. It may well have had quite a

while yet, but I shut it off since I'd be asleep. That

it was probably KMnO4-Zn and not MnO2-Zn was only

indicated by the fact that if the load was disconnected the voltage

headed quickly for 1.8 volts and beyond - at least for the first few

hours. Doubtless the carbon fibers, as well as the two zinc

current collector sheets, contributed much towards getting a lot of the

zinc properly connected to the terminal in spite of the bulk of Mn(OH)2

that (possibly) couldn't charge, or stay charged, to Mn metal

particles.

With only 20% of the negode being the effective

active substance, perhaps it's not very surprising that the current

drive was pretty low. On the other hand, the current collector sheets

themselves were zinc. They should at least be very, very low electrical

resistance. That points to the posode as the main problem - or the

electrolyte. KCl is much less soluble than KOH and the electrolyte's

specific gravity can only be raised to about 1.12 instead of 1.25 or

1.3. But should that make a 30 or 50 times conductivity difference?

It's perplexing to have seemingly good cells that suffer significant

voltage drop with less than 1mA/sq.cm of current flowing, where perhaps

20 to 50mA/sq.cm would be expected figures for maximum usable loads...

or surely at least 10. But then I have had 10 or 20 with some of my

cells. Later with a 10 ohm load, voltage settled around just 1.2 volts:

120mA and 3ma/Sq.cm. (Opening the battery later revealed that less than

1/2 the back of the negode was in contact with the current collector.)

With good current, I'd be happy with Mn-Zn except for

zinc's well known

characteristic of gradually migrating and losing capacity with cycling,

and in so

doing sometimes forming dendrite bridges that short out the cell across

the electrodes.

These make for short cycle life. There

are many patents for ways to

make zinc work better, but none seem entirely effective. (One company

does make Ni-Zn AA cells, which are rated at 1.6 volts.) This is

possible in my cells because of the zinc current collector sheet and

zinc powder electrode additive, but it's probably not enough zinc to

cause problems, and the zinc current collector looked pretty good when

I opened the cell.

I decided the first thing to try would be to add some

borax to the electrolyte and see if it helped the cell charge more

towards the voltage of cell PP#3. If there was any notable improvement

it

would support the borax/borohydride 'impurity masking' idea.

That didn't seem to work. Then the conductivity of the

cell dropped remarkably. However, it did seem to be holding voltage

pretty well when left off of charge for 32+ hours. On the 10th I opened

it, expecting to see a badly corroded zinc current collector sheet. But

it looked good. It looked like it wasn't making a good connection to

the electrode, and on reassembling it with some more rubber backing

behind it to push it against the electrode, it worked much better.

However, it was leaking badly, and the zinc sheet probably still wasn't

touching the electrode briquette over more than 1/2 the surface. It

would seem that mechanical things are still the lion's share of the

problems, rather than chemical things.

Second Negode

Since the borax didn't seem to make some miraculous

improvement, I decided to

make a new mix, virtually identical but without the carbon

fibers, and replace the negode. The two

small jars of Mn oxides, one of which must have had the

carbon fibers mixed in, were empty, so it wouldn't happen again. (I

remind myself to carefully label my containers, but it doesn't

always happen.)

50g Granular Mn

50g fine (<#300) Mn powder

52g Mn oxides powder (MnO2, Mn2O3...)

20g Zn flakes

20g Zn fine powder

3g Sb2S3

---

195g (well, each electrode takes a bit less than 50g anyway)

Theoretically

(ahem - *theoretically*) the 45g electrode

has over 25 amp-hours of manganese. I wouldn't expect to actually get

half of that. The granular Mn has low surface area with most of the

metal locked inside, and the rest won't be perfect either. It'd be

great if it's 10 amp-hours, but that's probably still a pipe dream -

and more than the

positive side has.

Theoretically

(ahem - *theoretically*) the 45g electrode

has over 25 amp-hours of manganese. I wouldn't expect to actually get

half of that. The granular Mn has low surface area with most of the

metal locked inside, and the rest won't be perfect either. It'd be

great if it's 10 amp-hours, but that's probably still a pipe dream -

and more than the

positive side has.

This time forgot to add Vee-gum but I remembered to check

the surface resistance at

a few points. Before torching it was from several K ohms to several

tens of K ohms, notwithstanding being perhaps the toughest briquette

I've made (so forget the Vee-gum). Afterwards it was tens of megohms,

either side up - oops, overdid it again!

That would doubtless explain poor current capacity right there. ...But

even with

all that zinc powder, zinc flakes, and both fine and granular metallic

manganese?

I don't even like the kilohms figures, much less megohms.

Maybe I should try lead or bismuth, or powders thereof, in place of

zinc after all? Permanganate-manganese is a cell

that'll keep going and going like the reputed Eveready battery bunny,

at ever lower voltages, until all the zinc is oxide and all the

manganese in both electrodes is in the same state.

I can of course hope that the manganese oxides start

charging to Mn metal or that things become more conductive with use on

the microscopic level, and the whole thing will become more conductive

with charging, cycling or just time. Cell PP#3 showed just such

ongoing, but gradual, improvement until it quit.

As was probably the case with the carbon fiber, many or

most impurities would

bubble

hydrogen at the

high reaction voltage of Mn metal to Mn hydroxide. High purity Mn and

Mn oxides would seem to be required, perhaps

eliminating pottery supply MnO2, and it has to be graphite-free, so

salvaging it from dry cells is also out. If this surmise is correct,

I've had the chemistry right since the end of February 2012 and really

just need purer ingredients.

Or perhaps the borax, forming borohydride where the

hydrogen bubbles are, might gradually 'glaze over' the impurities and

passivate them.

But after a day, the cell with the new electrode again

refused

to rise over about 2.24 volts (eventually reaching 2.33 volts a day or

two later) with a

27mA charge running. It sat there

hour after hour. It stayed higher and higher when the charge was

removed, eventually approaching 2.2 volts, but the on-charge voltage

didn't rise much. There was no more carbon in the negode, but the

voltage

was similar with or without it.

So where did that fabulous 2.6 volts, and 2.4 volts under

load, of

PP#3

go? Admittedly it was a higher voltage than expected from MnMn. I

finally decided I must have put calcium hydroxide into the

PP#3 posode, as a layer painted onto the current collector, and that

the

extra voltage must have been attributable to the Ca(OH)2 (or "CaO:H2O")

charging to CaO2 -- a reaction of +1.55 volts I had once considered

might make a great high voltage posode. I then decided that it was such

a high voltage it was bound to self discharge, releasing OH- ions.

(CaO2 + 2 H2O => Ca(OH)2 + 2 OH-) But I decided to paint it onto the

positive collector plate as something to inhibit oxygen gas generation

during charging. That would seem to explain many things:

* the cell voltage (2.6v) was higher than I had expected (2.2v) because

of the calcium charging up to dioxide.

* the discharge curves matched the actual case: discharge began around

2.4 volts - the

CaO2 voltage plus the Mn negode - but fairly rapidly dropped to about 2

volts - about where cell PP#6 is. It seemed like 'disappointing

performance' at the time, but it would be inevitable because there

wasn't very much

calcium. There's lots of amp-hours of permanganate for extended

discharge times once

the voltage is below 2.1 or so.

* the overnight self-discharge was high for the very reason I hadn't

chosen calcium as the main ingredient: high self discharge was expected

from calcium dioxide.

PP#6 doesn't charge to such a high voltage because I

didn't paint any Ca(OH)2 onto the positive current collector in it.

(Methodical and consistent I'm not.) Instead it starts to bubble gasses

when the charge voltage gets up to

around 2.33 volts. So all along I've had working MnMn chemistry, making

a cell that might be rated (pretty optimistically) as 2 volts under

load. If

it's charging up above 2.35 volts or so, it's already 'full' and is now

charging up the calcium dioxide anti-gassing additive (if present),

which may be expected to self

discharge itself in a few hours, leaving about 2.2 open circuit volts.

If the temperature is down around freezing, calcium

dioxide may hold its charge a long time.

In fact, the hours it takes to discharge may point to

potential for research into ways to raise the oxygen overvoltage so it

can

hold charge reliably, for a higher voltage electrode needing only 5

cells to make a 12 volt battery. Like the potassium

permanganate, Ca(OH)2 is slightly soluble, but this should be

controllable by the same chelation technique.

However, the MnMn with calcium hydroxide ('slaked lime')

as a

gassing inhibitor and alkalizer seems very nice - even "elegant" as

computer programmers used to say - and I'm going with it.

In all this thinking about voltage, I hardly noted that in

one 50 ohm load test on the third day (7th), the cell gave amazing

performance. It ran 13 hours before I shut it off, heading for 400mAH.

It dropped to just over 1.4 volts after an hour, then went back up to

hit 1.5 from hour 7 to 10, then went down again to a bit over 1.4 by

hour 13. The only reason I shut it off then was that it was 3 AM. But

in subsequent tests - 10 ohms - it didn't seem to work very well, and I

wanted to try without the carbon fibers and see if it had less self

discharge.

Discounting that one test, the second negode performed

much better than the first

one. Notwithstanding the high resistance readings, it delivered the

same milliamps at substantially higher voltages in load tests. It could

drive a 10 ohm load at 1.3 volts for 18 minutes instead of at 1.0 volts

for 3 minutes. Since the chemicals were the same except for eliminating

the fine carbon fibers, that doesn't say much for the efficacy of those

fibers in improving conductivity. (Could the Vee-gum have reduced

performance? There was only 1% of it. But the second electrode seemed

just as tough as the first, so there seems no reason to add it anyway.)

Notwithstanding the better electrode, in a test with a 50

ohm load the voltage dropped to 1.73 volts after 20 minutes, while in a

10 ohm load test it dropped to 1.28 volts in the same period (and 1.25v

after 25 minutes). There's no doubt that these tests could have been

run much longer and would have disclosed at least a few hundred

milliamp-hours of capacity, but I was saving long tests for later.

After the 25 minute, 10 ohm load test, delivering an

average of about 1.34 volts (& hence 134mA), it took 4 hours of

charging at about 23mA to bring the charge voltage back to the same

point, 1.323 volts. 25 minutes at 134mA is 56mAH of discharge. 4 hours

of 23mA is 92mAH of charge - 1.65 times as much. It's not high charge

efficiency, but it's not completely disproportionate either. Of course,

136mA is a pretty hefty (hence inefficient) discharge rate for this

little cell. A low rate discharge would probably show better charging

efficiency and is something to monitor following the next lower current

load test.

In a 20 ohm load test on the 18th, the cell was well below

1.5 volts for most of the test, ending after an hour at 1.2 volts.

On the 19th I ran a long 50 ohm load test, starting from

about 2 volts and finally dropping below 1.1 volts after 370 minutes

(6 hrs 10min). At least it was over a volt throughout.

Total electrons moved was about 150mA-hours. It recovered to about 1.55

volts, which may well have mostly been MnO2 + Zn. I'm pretty sure it

would have performed better if it hadn't been leaking. When charging

was resumed, it shot almost instantly above 1.8 volts. It took about 9

or 10 hours (past my bed time) to charge up to its previous charging

voltage. As it was charging more slowly than it had discharged for the

first three hours, the charging efficiency must have been pretty decent.

On the 21st I ran a second 20 ohm test, with the cell

having been well charged the previous day and overnight. At first it

seemed to perform much better than the first time. It started at 2.3v

no load, and was hundreds of millivolts higher than on the first 20 ohm

test for the first few minutes. But by 15 minutes the advantage had

dropped under 100mA (and the voltage to 1.5v), to 50mV after 25, and

went lower after 45. That meant it was discharging the same(?) amount

of substance faster into the same resistance - ie, with better

conductivity. If I could make cells that would last and not leak, they

might start performing quite well by 10 or 20 cycles. Hopefully the

substance utilization is also increasing.

On the 24th I tried to glue a plastic face onto the cell,

but it leaked. After several attempts to stop the leaks (there was just

a small one left... somewhere), I gave up and found a plastic jar that

would hold the whole cell. I put it inside and filled the whole jar to

the appropriate level with KCl electrolyte, drilled a hole in the

center of the lid, put the test leeds through the hole and connected

them, and screwed the lid on. (mostly of the way - the terminals stuck

out just a bit.)

Then after charging a just few hours I tried a 50 ohm load

test, which I ended up running for exactly 24 hours at ever lower

voltages, starting just over 2, dropping to 1.6 within and hour, and

then running for ages from 1.5 volts gradually down to .889 at the 1

day mark. I calculated it put out 551.5 milliamp-hours. By that time

the voltage was dropping very, very slowly, and it obviously would have

put out more at still lower voltages - maybe even another day or more.

Some time I'll have to try really running it down, like to 1/2

a volt or so. I'll bet it has a couple of amp-hours in it.

It recovered

quickly to almost 1.3 volts, and to 1.35 volts over about 3 hours.

It'll take over a day of charging at 22mA (with the usual 50 ohms) to

recover to over 2.3 volts, even with efficient charging.

After the test and

some time for recovery, internal voltages were: +.664 & -1.138 WRT

a graphite electrode, total 1.802v. (The meter read 1.799v) However, it

turned out the graphite electrode seemed to be around +.3 volts, not

zero. I started using a zinc electrode. It showed the the negative

voltage was about the same as zinc, -1 or so, so the positive was

higher, maybe .8 or so. I sense that I should have a reference

electrode with some known voltage to measure from.

Different Circuit Designs for a Different Battery?

Most batteries put out a relatively steady voltage, which

rapidly drops off to nothing when their charge is exhausted. But as

I've said, MnMn really has no reason to suddenly run out of charge and

die. Instead it can continue putting out current at ever lower voltages

as the oxidation levels of the Mn change, until both electrodes are in

the same oxidation state, somewhere between 7 (permanganate) and 0

(metallic).

In the above test, 6 cells in series would have gradually

gone from

being a 12 volt battery to a 6 volt one, no doubt with potential for

running as

long again down to 4 volts. The variable voltage can be seen as being

an interesting circuit design challenge instead of as a battery

chemistry problem. If the battery was fed straight to a

circuit, the voltage would either be too high at first, or too low as

the charge got lower. It could however be fed to circuits such as a DC

to DC converter or an EV motor and controller, which can accept a wide

range of input voltage. The EV will get gradually less energetic. The

converter will continue to put out a constant output voltage to supply

loads. In the Mazda RX7 as an example EV, the motor and controller can

accept a considerable range -- about 65 volts to 160 or more. (It's

crawling at 65 volts.) The Zahn DC to DC converter will accept 18 to 44

volts input and put out an exact (adjustable) voltage in the range of

14 volts.

But the varying input voltage challenge from a battery

whose voltage can vary by more than 2 to 1 is almost trivial compared

to the idea of using "supercapacitors" for energy storage, where the

voltage output from the capacitor could range from thousands of volts

down to almost zero.

One can always charge the battery only to a certain

voltage if that's the desired maximum, eg, staying below 1.8 volts or

so and forming MnO2 but not permanganate in the posode, and one can

always discharge only to a given desired minimum voltage. And probably

I can get the higher voltages to last for longer periods with

improved constructions -- or even just with cycling. PP#3 held higher

voltages much longer than PP#6, perhaps because of the calcium

hydroxide.

Pos.React.