Turquoise

Energy Ltd. News #67

Victoria BC

by Craig Carmichael - September 4th, 2013

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Headline

MnMn batteries: Self discharge is the last problem; cause identified

Month In Brief

(Project Summaries)

- Improved(?) Peltier module camping cooler

In Passing (Miscellaneous

topics, editorial comments & opinionated rants)

- Book: Limits to Growth - a financial educational documentary;

Hungary, doing it right - USA to

attack Syria?: "DHS" to be deployed there? - Cold PNW winter ahead? -

Challenge for the next civilization.

Electric Transport - Electric

Hubcap Motor Systems

* Improved rotor magnet attachment?

* Electric motorcycle with belt clutch?

* More Mazda/Battery tidbits.

Other "Green" Electric Equipment Projects

* Improved Thermoelectric Camping Cooler

Electricity Generating

* Magnet machines: Spiral(s), More Magnets!

* Vertical Axis Wind Turbines

Electricity Storage - Turquoise

(MnMn) Battery Project etc.

* 20 ton hydraulic press with

gauge - indicates my electrode compaction until now has been wholly

insufficient

* "Pin Frog" AKA "Flower Frog" from florists to perforate zinc and

graphite sheets

* Manganese electrodes with stibnite & zircon additives

appear to hold valence 0 metallic charge, at room temperature and below

pH 14.

* Last Major Problem: self discharge is via an internal cell reaction

is causing both electrodes, the whole cell, to discharge overnight.

* Solutions? (1) trap permanganate ions within +ode container (2) make

Ni(OH)2 +ode... Various tries to trap permanganate.

No Project Reports on:

DSSC

solar cells, LED Lighting, Pulsejet steel

plate cutter, CNC Gardening/Farming Machine (sigh, maybe summer 2014?),

Woodstove/Thermal Electricity Generator, Peltier & vacuum pipe heat

pumping, Ultra-efficient torque converter transmission.

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers -

Nanocrystalline glaze to enhance Solar

Cell performance - Ersatz 'powder coating' home process for

protecting/painting metal

Products Catalog:

- Electric Hubcap 4.6KW BLDC Pancake Motor Kit

- Electric

Caik

3KW BLDC Pancake Motor Kit

- Sodium Sulfate - Lead-Acid battery longevity/renewal

- NiMH Handy Battery Sticks, 12v battery trays & Dry

Cells (cheapest NiMH

prices in Victoria BC)

- LED Light Fixtures

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

August in Brief

I went camping

from August 5th to 9th, so not much R & D work was

done near the beginning of the month except an MnMn battery experiment

or two in the first few days, and on the 3rd I bought a 20 ton

hydraulic press. I saw this unique unit while browsing in Barclay's

Exchange: it had a hydraulic pump cylinder with a

long handle separate from the press cylinder... and a pressure gauge!

I went camping

from August 5th to 9th, so not much R & D work was

done near the beginning of the month except an MnMn battery experiment

or two in the first few days, and on the 3rd I bought a 20 ton

hydraulic press. I saw this unique unit while browsing in Barclay's

Exchange: it had a hydraulic pump cylinder with a

long handle separate from the press cylinder... and a pressure gauge!

I've always

suspected many of my battery troubles were from insufficient compaction

(verified with the gauge)

and or poor connection between the electrode briquettes and the current

collector plates. Here was a unit to not only apply very high

compacting pressure for the edge compactor and maybe for munching the

electrode and current collector together, but also to know how just

much pressure was in fact being applied.

For the camping trip itself I took the original Peltier

Module cooler I had bought to initially investigate thermoelectric

devices for the refrigerator, and re-assembled it but in a slightly

modified form: I used two 8.5A peltiers in series (electrically)

instead of the original single 5A peltier. Owing to the increased

efficiencies of Peltier modules when driven at lower currents, this

arrangement is theoretically superior, cooling to similar or lower

temperatures with

lower current (~3A versus ~4.2A) from the battery. In fact the unit

cools poorly. The warm side

heatsink does get too warm (~35°c), but I'm still puzzled that it

does no better, the cold side only dropping to about 10°. My fridge

does much better with almost the same arrangement, and it's much

larger. The difference would seem to be two 15v

peltiers in the cooler versus a 15v + an 8v in the fridge. I'll try

some modifications next time - the lower voltage peltier, and a

better heatsink or an evacuated tube radiator.

As long

as the weather was sunny and direct sunlight was accessible (which it

was the whole time), a 65 watt solar panel ran the cooler all day. I

had to move it

around the camp a couple of times every day to keep the collector in

the

sunlight and pointed towards it. Whatever voltage the collector put out

was fine because the cooler had no delicate electronic smarts to burn

out.

Next time I'll

bring a very long extension cord so the cooler can be kept stationary

in the cool shade instead of dragging it around in the hot sun with the

collector.

After I got

back I kept reminding myself that I had other

projects besides trying to make batteries, some best done in summer

weather, but the cell seemed to be almost

working and I

kept thinking "maybe if I just..." and I kept plugging away at it.

After I got

back I kept reminding myself that I had other

projects besides trying to make batteries, some best done in summer

weather, but the cell seemed to be almost

working and I

kept thinking "maybe if I just..." and I kept plugging away at it.

I had thought the

batteries were about there by the end of July, but although the

permanganate-manganese cells would now charge at summer temperatures as

well as winter,

and if heavily charged began delivering worthwhile amounts of current

for many minutes at levels of 2.0 to 2.5 volts (even up to about 450mA,

which is over 10mA/sq.cm, or 225mA for over half an hour), they still

had unacceptably high self discharge, losing most of their energy

overnight and sitting at about 2.0 volts by morning. I expect that the

self discharge is the only remaining problem, and that without it

higher currents and much more energy storage giving long discharge

times would be attained.

I made the important step of identifying the discharge

mechanism.

Neither electrode will discharge when immersed in electrolyte by

itself. What happens (I believe) is that a few ions from the slightly

soluble

permanganate dissolve into the electrolyte (contrary to my

previous assertions of having chelated them into position) where they

travel to the other electrode and mutually discharge against the Mn

metal without an external circuit connection. Then, being turned into

solid manganese oxide particles no longer dissolved in the solution,

more permanganate ions dissolve to continue the process.

I'm trying various

measures to block the ions and hence reduce the discharge, with some

improvement but so far no very effective real solution. The other

solution might be to make a simple nickel hydroxide posode. That would

have much

lower amp hours per weight than permanganate and the cells might not

beat lithium ion for energy density.

It does seem that if discharge proceeds under about 1.9

volts that the zinc current collector starts to deteriorate, so the

idea of letting the cells run to lower and lower voltages and putting

them through a DC to DC converter to get a regulated output is out.

They seem to run best from about 2.4 volts draining to 2.0 volts under

load.

I did give other projects some small consideration. I spent a couple more

days trying fruitlessly to repair my 3D printer with the help of an "Arduino Guru"... who

got no farther than I had. I

started in on a V-belt drive for the motorbike and put a 10" V-belt

pulley on the back wheel to replace the chain sprocket. Next it needs a

new (or the same resurrected) motor on the front and a belt tensioning

clutch of

some sort.

Bike wheel with V-belt pulley.

Belts can slip to provide clutch action. Chains can't.

Wind

turbines seem like something others have done, and done pretty well,

and I'm not in an area with frequent strong winds. So

I haven't tried tackling one myself. But looking again, vertical

axis wind turbines (VAWTs) evidently work much better in the

unsteady

winds with gusts and shifting directions that are most common here when

there is wind, than

horizontal axis propeller

types, and they seem so simple it seems

almost silly not to make one. I'm planning one out. Apparently the

speed is more self-limiting than for propeller types, but if it should

tend to over-rev in strong winds, I have a couple of ideas for gravity

retracted centrifugal fins that will swing out at high speeds to act as

air brakes,

limiting the top speed.

I think I have all the

parts necessary already. I hope to get some other free energy zealot to

put it together.

There's probably some "optimum" blade shape, but unlike propeller

types, all sorts of VAWT blade shapes can be made and will spin well.

This one promises easy connection of guy wires at the top (which

requires a bearing up there since the shaft spins).

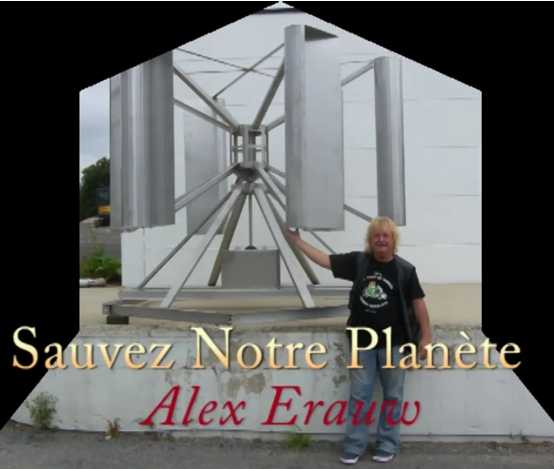

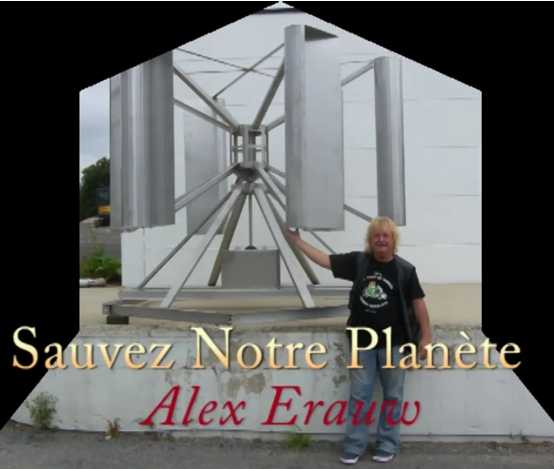

Alex Erauw says he has "Les meilleur du Monde" ("world's best")

vertical

axis wind turbines (VAWTs).

They start turning in a very light breeze. Evidently he sells them.

Everything above the stand spins so all support must be underneath, but

the unsupported axle section is fairly short.

Presumably the distorted half elipse is an "optimum" blade profile.

I'll try to incorporate such features.

www.youtube.com/watch?v=Mc6JrtpQz34

The thing about doing one

is that much of the system

complexity is in what is done with the rather unpredictable and varying

electrical output, and this little different than for solar, ocean

waves,

or woodstove thermoelectric power generation, so doing a wind turbine

will help

advance the techniques and equipment for the other types as well. The

output can go to the same 12v distribution panel as the solar PV

panels, occasionally providing power including when the sun isn't

shining. I'm not expecting big energy from this (especially in the

occasional winds here), but it's all a part:

everything generated locally is power that doesn't have to be made at

some big plant elsewhere, often by polluting sources, and transported

along long power lines with losses.

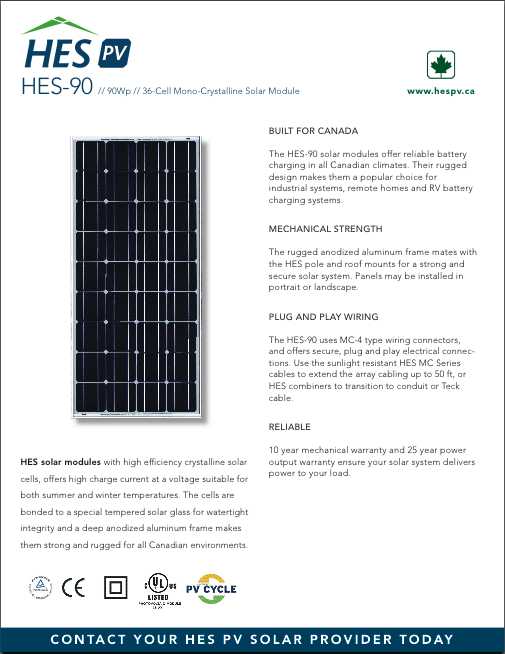

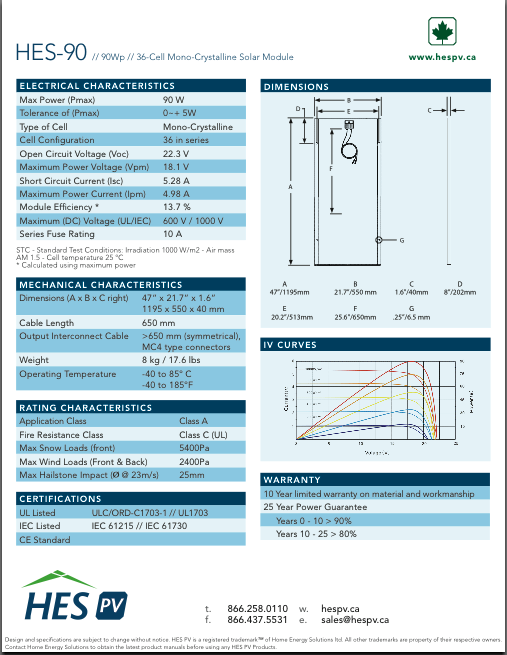

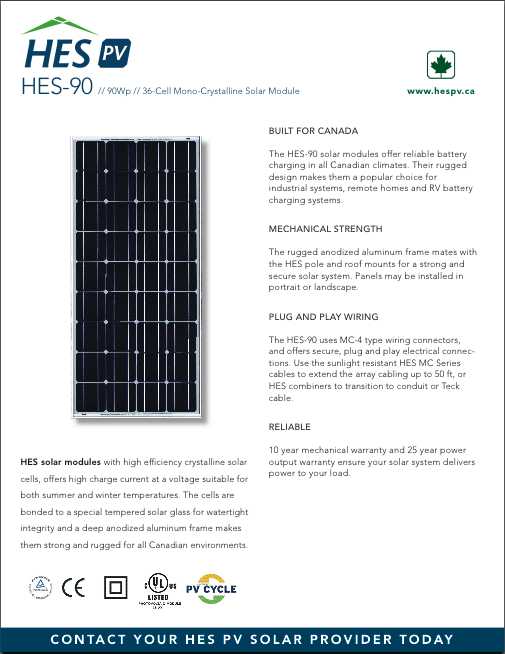

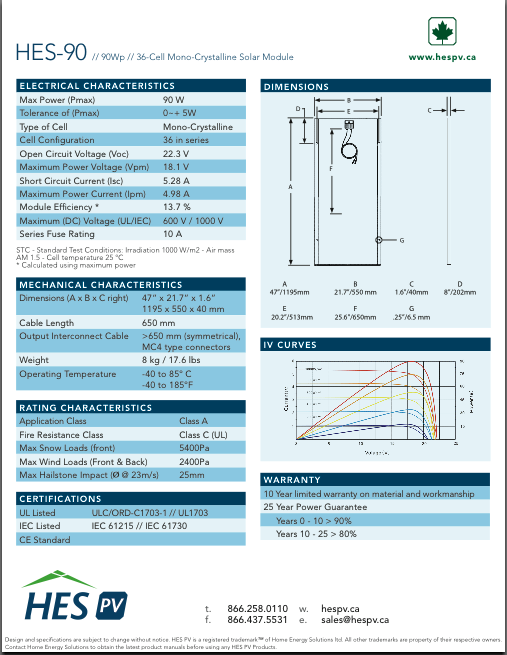

I did a fair bit of shopping, and I saw some juicy 90

watt solar PV panels at HES wholesale that I couldn't resist - just

what I've been wanting for EV use - so (being

a dealer with them) I bought some to use or to resell, and I put them

in the TE

Catalog at 225$. Personally I think that compares well with a 60 watt

panel discounted in a recent Canadian Tire flier to $350. (If I sell

any

I'll buy more for myself.) I could use three on the roof of the Sprint

car assuming I get that going (36 volts), or two on the boat for the

electric outboard (24 volts).

They're just a bit long and I suspect they'll be good for

bumping your head on getting out of the car. Solution: have them stick

out on the passenger side, not my side. Looking now at the

voltage/current graphs, I'd say that instead of using them with charge

controllers, I'd try just putting two of them in series, simply

connected across the

batteries with an isolation diode. This looks just about perfect for

float charging 36 volts of NiMHs or lead-acids, avoiding all

electronics and losses and providing almost the same charging as three

connected through all the 'stuff'. (and they could then be turned the

other way to

avoid bumping of heads.) Of course, that would probably work best with

the collectors facing directly at the sun, which won't be the usual

case on a car roof. Unless maybe they were mounted raised and could

pivot left or right from the center axis.

On the boat I'd have to make a frame and use them for a

roof. (and at that point, should I put in windows and make it a cabin?

then move the outboard controls to the front, inside? all on a 14'

aluminum

boat?)

If anybody around here wants anything items www.HESPV.ca

has

available, for local (Esquimalt) pickup 'cash and carry', I'll pick it

up for a 10% markup plus GST and PST if applicable (no PST

on solar panels). (I may ask for payment in advance.) E-mail or call

me: Craig, 250 384 2626.

In Passing

Incidental news, editorial comments & opinionated rants

Limits to Growth

A celestial being (named Serara, IIRC) suggested to his

audience that for their enlightenment about the coming collapse they

might want to check out a book: Limits

to Growth, by Donella H. Meadows, Dennis L. Meadows, Jørgen

Randers, and William H. Behrens III. This controversial 1972

work, Funded by the Volkswagen Foundation and commissioned by the Club

of Rome, used computer modeling to

explore what happens on a planet of limited resources confronted by

exponential growth of human population and economic activities.

"Five variables were examined in the original model. These variables

are: world population, industrialization, pollution,

food production and resource depletion."

[Wikipedia]

Evidently most scenarios for unguided growth, with various

reasonable values plugged in,

ended up not with simply rising to some equilibrium, but instead rising

to an "overshoot" peak followed by a major collapse. At no time since

the book's 1972 has there been any political will to guide our growth

(other than

China's marginally effectual 'one child' policy), and many of the

projections for peaking evidently bear an uncanny resemblance to the

world today.

The same authors did a 20 year update Beyond

the

Limits in 1993, and a

final update Limits to Growth: the 30 Year Update in 2004. I

confess I've only read articles and abstracts about the books using a

web search, such as the article on Wikipedia.

But even without having read these works, I have the sense

that, having done no population planning, we are very near the apex of

the "overshoot" zone, with a world population (7.3 billion) probably

triple what it

should be over many regions of the globe (...and 2-1/2 times greater

overall than when I was a child myself). The effects are certainly

being magnified and exacerbated by the greed and corruption. Without

that, considering the dropping birth rates in what were "more

civilized" lands, and the more lands advancing, we just might as a

species have managed to plan

better and maintain an even keel. That which hasn't been learned the

easy way must now be learned the hard way.

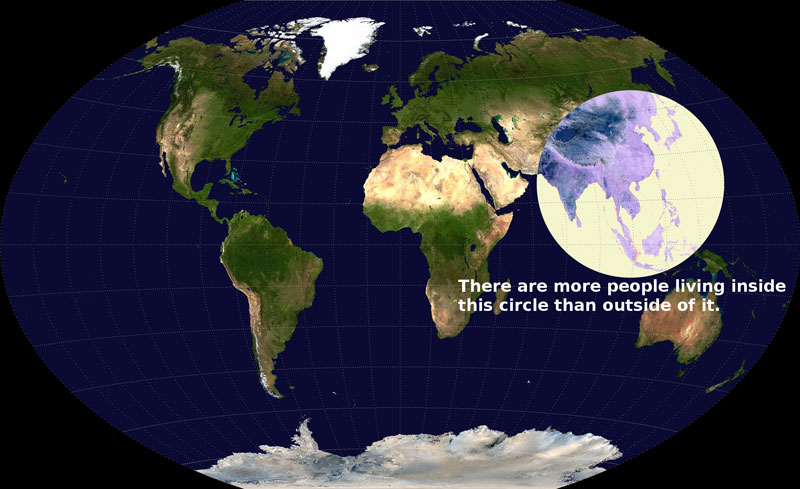

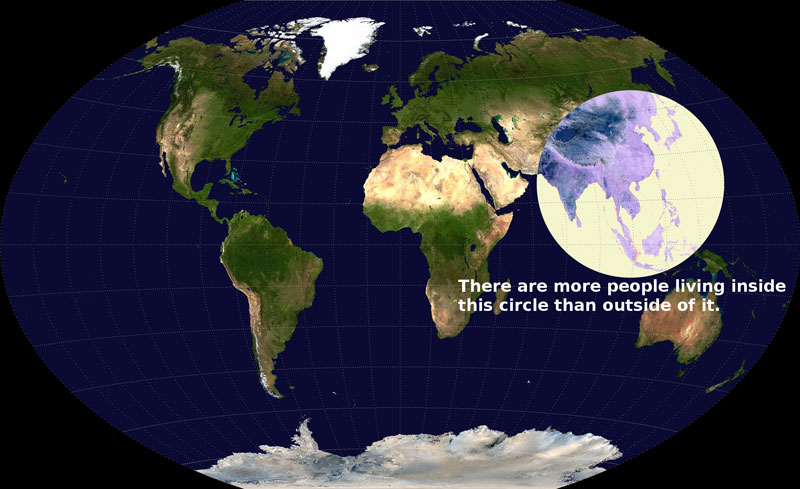

An interesting comment on global population distribution!

An Educational Documentary

I watched a 2 hour documentary that had a lot of excellent

background on why our society is just now coming apart at the seams,

with 1% of the population having half the wealth and 80% having not

much or even less. First it goes into the diabolical workings of the

pyramid

scheme of the financial system, how the banksters control and enslave

the people and nations of the world by inflicting debt. Then it

explains about

America's

'clandestine empire' which insidiously installs the "leaders" the USA

wants in every country where the resources are coveted and inflicts

crippling debt to control and enslave it, and about the corporatocracy.

I saw it on youtube.com, titled "Life Hidden Truth - 2013

Global Financial

Crisis", but the title when it came on was "Zeitgeist: Addendum". At

the end it brings it back to individual responsibility and

the coming age of greater... humanity. It mentions "The Venus Project"

as a venue to help work towards a sustainable future. [

www.youtube.com/watch?v=Aq-FSI9x6fo]

I don't see how their idea of doing away with money is

supposed to work, unless there's something to replace it with (could I

be too indoctrinated to understand?), but I'm in harmony with many of

their ideas. For example, I've written myself that automation should

shorten everyones' work hours, not cause layoffs and unemployment. And

they mention that

there's no effective democracy, and furthermore, when you step into a

workplace you step into a dictatorship. (My own suggestions that shop

foremen should be elected for a two year term in the Greater Victoria

School District, and that that would bring out the talented and prevent

the indolent or incompetent from rising to such positions by seniority

and holding

them until they retire, didn't go anywhere. It would have been a

start.) Another point is that politicians pass a restrictive law to

solve most any immediate problem (and it would seem with no thought

about the broader consequences of what they're banning or prohibiting),

when improved technology could better solve that problem, because they

know nothing about technology. Those who might deliver technical

solutions have no power to implement them.

Few except banksters understood the financial pyramid

scheme -- until people recently started explaining it on youtube, and

still

most people don't get it: You put 1000$ in the bank, and the bank is

required to keep a 10% reserve. So you think they have 900$ to loan out

at a higher interest rate than they pay you, the depositor, and that

that rate difference is how they make their money. This would be

reasonable.

Instead, they keep all your money and enter on their books

that they have 9000$ to lend out, and they lend it. They have their 10%

reserve - your 1000$. With your 1000$ deposit, the bank has created

9000$ of potential debt out of thin air, which is soon made actual.

The recipient of the loaned money (eg,

the seller of a house)

usually deposits it in a bank, so the bank has 1000+9000 = 10000$ on

deposit and is owed 9000$ (by the house buyer). The interest from the

fictitious 9000$ loan

comes in, and the principal is gradually repaid, so the bank gains more

and

more money on deposit, which they treat the same as your deposit and

lend out nine times as much as they have. The money, created as debt,

inflates the money supply and robs value from your 1000$, said to

amount to 98% of the value since 1913: what cost ten cents back then

now costs five dollars. And the money that exists, all created as debt

to

be paid back with

interest, can never equal the amount owed, so the debts can never

be

repaid. In this game of musical chairs, unless the money supply

continues to expand, defaults are inevitable, and in today's shrinking

economy the banks in many lands have seized major portions of the whole

real estate

'inventory' through foreclosures while tens of millions go without.

If you or I lent money the same way the banks do, we would

quickly find ourselves in jail. Therefore this "ponzy" scheme creates a

two-tiered justice system with a powerful unfair leverage given to the

banking institutions over the citizens. The price of the house was 10

times higher than it could otherwise have become owing to 'cheap', easy

bank credit - supplied from money that didn't exist. The

citizens become economic

slaves to the parasitic banks for decades, effectively on an almost

life-long "rent to purchase" plan - as if it was the bank that had

built and sold them the house! And the financial sector has now grown

far larger

than the real

economy, on the backs of the productive. Only "the 1%" can buy a house

for cash without involving a bank, which accrues a fortune off each

transaction, off each purchaser, with the debt they created out of thin

air.

Again, nations should control, create and print their own

currency, not print

bonds and and sell them to borrow money from a private central bank

that creates the

money out of thin air privately. No private institution should be

permitted to

loan out money it doesn't have - it is in fact (even if not in present

laws)

a criminal offense and

banksters responsible for it should be personally punished the same way

you or I would be. Perhaps there should be no private banks, only

public financial trusts. It's almost beyond belief that unprincipled

politicians have

permitted this insidious, heinous pyramid scheme to be installed

everywhere in the world,

against the interests of their own people. On the other hand, someone

has pointed out that every politician that has tried to end the banking

system's fleecing of the public has been murdered. (This isn't quite

true, as the assassination attempt on Andrew Jackson failed and the US

treasury printed the USA's money for 80 years following his "takeout"

of the First Central Bank, until in 1913 the bankers reasserted their

overlordship.)

The article quoted from below, seen just while I was doing

a

final editing of this newsletter, appears to be a great example of what

can happen when it's done the right way.

Hungary Tells Banksters To Get Out Of Their Country And Take The

IMF With You. (excerpt from article:)

"According to a report on the German-language website “National

Journal,” Orbán has now moved to unseat the usurers from their

throne. The popular, nationalistic prime minister told the IMF that

Hungary neither wants nor needs further “assistance” from that proxy

of the Rothschild-owned Federal Reserve Bank. No longer will Hungarians

be forced to pay usurious interest to private, unaccountable central

bankers.

"Instead, the Hungarian government has assumed sovereignty over its own

currency and now issues money debt free, as it is needed. The results

have been nothing short of remarkable. The nation’s economy, formerly

staggering under deep indebtedness, has recovered rapidly and by means

not seen since National Socialist Germany."

http://americanfreepress.net/?p=12418

.

The

ruling political group was in fact elected on its promise to

nationalize the currency supply as stated. Will this be squashed, or

can it spread to become the herald of a more sustainable way of doing

things? Anyway, congratulations to Orbán, his group, and to

Hungary as a whole!

USA's DHS headed for Syria, Iran?

US president Obama said, seemingly out of the blue last

year, that

if Syria - the Syrian government - used chemical weapons to defend

itself, the USA wouldn't tolerate it. There was no threat or promise

expressed or implied that the USA would help Assad put down the

insurgents if they used chemical weapons, and they were found

by the UN to have used them at least twice with no moves or even verbal

condemnation

from the USA. The statement was thus

purely a threat against the

Syrian government, not a statement of principle against the use of

chemical weapons. And it came after the USA itself had been selling

chemical weapons to the Syrian military. It would appear that the USA

has been supplying arms

and training to any insurgents willing to go into Syria for several

years, and while Assad is

perhaps no more popular than other middle-eastern dictators, the

current problems in Syria seem to be largely "Made In USA". And even if

there was no other criminal intent, Obama is culpable just for

aggravating the situation with his inflammatory statement, which would

obviously tempt the rebels to use chemical weapons and try to frame the

Syrian government for it.

This month's nerve gas event that killed hundreds of

people

just after UN inspectors had arrived on the scene at the invitation of

Syria and Russia,

then,

came as no surprise, and had every appearance of being a stage-managed

propaganda stunt to get the American and western public behind an

invasion of

Syria, similar to Hitler's staged "Poland Attacks Germany" attack just

before

Germany invaded Poland "in retaliation" in 1939, incidentally starting

world war two. A lady in Syria near the scene said it was done by the

rebels and she named a rebel leader who she alleged had ordered the

attack. (See Corbett Report of

August 21st on youtube.com explaining how little rhyme or reason there

would have been to Assad launching this gas attack on his own people,

especially at this time.) Israel claimed to have heard "radio chatter"

pinning the blame on Assad's brother. Is that the best "proof" they

could find? Nor was it a surprise

to hear a rumour

a day later there were American paid mercenaries already next to or

even in

Syria, and within a week that the USA could be expected to attack "any

time".

A bunch of other stuff suddenly started to add up, too.

Why did the American "DHS", "TSA" and expanded "FEMA" really exist, why

did they have

such a huge personnel, and why did they need (according to various

reports) 400,000,000 or 1,200,000,000 rounds of "dum-dum" hollow point

bullets, placing orders to the point that not only the public but the

police can't buy bullets? And why did they need state-of-the-art

armoured vehicles? Why were they said to be using pop-up silhouettes of

civilians for target practice? What was the purpose of them being

ordered (a week or so before the nerve gas attack) to complete various

training programs and, essentially, mobilize, by October, with

placement of large food ration orders? What were the various hints

being dropped that "something big" is afoot for October?

What it seems to add up to to all appearances, is that the

"homeland" forces are going to be sent to Syria. They were never

intended to be employed within the USA - the names were just blinds,

perhaps for the recruits as well as the world. (This blind has worked

well: even the ardent critics of the US government thought they were

meant for imposing martial law at home. I don't how and whether they

were

included in foreign calculations of US military muscle.) The first step

would be

invasion and occupation of Syria, and that's probably all that will be

hinted at while it's happening. That would give the USA a port in the

Eastern Mediterranean. But all these violent weapons and all this force

can hardly be necessary to subdue Syria alone. The obvious next step is

to march from Syria through Iraq and invade Iran - the other country

the USA has been targeting with threats, propaganda and sanctions for

some years now. I wonder how many of those who joined the "DHS" and

"TSA"

had any inkling that they would be headed overseas to invade foreign

countries?

If they are successful they'll

have a "secure" route for transport and oil and natural gas pipelines

to the

Mediterranean through Syria, Iraq, Iran and Afghanistan.

But such plans are

madness. Russian deliveries of missiles to Syria

and Russian naval movements in the Eastern Mediterranean would suggest

they aren't to roll over and take it. Furthermore, the US government

won't

get away with

it at home. American protests that will gradually turn into bloody

uprisings as people wake up to what's being done and why are almost

inevitable. We may look at Egypt as a template.

Speaking of which... it also seems there may well have

been

American influence in the overthrow of Morsi, Egypt's first

democratically elected leader, where they seem to be trying to pull a

repeat of slandering and overthrowing Iran's first elected leader in

the 1950's and installing the Shah as a USA-friendly puppet who would

give them Iran's oil instead of selling it at a fair price, and the

many repetitions of that theme since in South America for resources

there.

But this ain't the 1950's no more. As Zbigneuw Brzezinsky

says, there seems to be a raising of consciousness around the world,

with people everywhere having an increased sense of political

awareness. People are starting to catch on, and government and business

are starting to have a hard time pulling the wool over their eyes.

Furthermore, some critics argue that the US economy will implode,

either simply under the strain or because some countries will cease

shipping their commodities to the US. They say that the other countries

will win this way instead of trying to fight the militarily powerful

USA with weapons, "without firing a shot."

Why is Obama now asking for Congressional approval? Some

think it's a face-saving way of stepping back from the brink, others

think approval through blackmail will assure that the juggernaut will

roll on and give the appearance of solidarity. The latter idea seems

more in keeping with the rest of a plan put into motion well before

Obama's time.

There is of course no hint of the USA wanting to actually

take the steps required to exit the oil dependency that is at the root

of all

this in order to move towards a peaceful world. not even the most basic

step

(taken most everywhere but in North America) of electrifying the

railroads. That doesn't fit the part of the "business model" of the

clique of

gangsters who rule the world from behind the scenes (and for whom Obama

is "an asset") of sapping wealth

from the public (in case there is any left) via petroleum. As

Jesus said, "A

corrupt tree can't bear good fruit."

I'm starting to think that the fearsome collapse of the

global

financial system, and the global chaos and dislocation of plans and

supplies it will cause, can't come a moment too soon! So far, the can

has been kicked down the road farther than many (lately including me)

have expected, but at

some point "the can" will turn into "the bucket". I'm in tune

with those who

advise "Get your money out of the banks!", "Use local banks and credit

unions.", "Become your own central

banker.", and "Have cash, gold, silver, bitcoins, assets, commodities,

food, energy, for the day the banks close their doors." It's not like

banks pay interest any more, and with the threat of "bail-ins", money

in the bank is starting to look less safe than cash in a jar buried in

a field. As Max Keiser recently put it, the world's people are now

not just being fleeced but plucked like chickens.

BC Winter?

Last winter was very cold in many parts of North America.

We were spared here in the PNW, but somehow I have a sense that after

this

great summer there's likely to be an exceptional winter with mountains

of snow here on the coast. Heavy snow may block roads, and bring down

power lines

causing lengthy power failures. It's another reason besides potential

monetary system collapse to have some food, fuel and any vital meds

stocked up. I've bought snowshoes, which I missed having in 1996.

(Remember the 1996

snowstorm when nothing was moving for 3 weeks in Victoria?) We are now

globally seeing various weather extremes and the PNW may not be immune.

People did freeze in the Quebec ice storms a few years ago, and in

Russia last winter. The flooding in Russia's far East this summer

doubtless brought most everything to a halt there, too, and just now

unseasonable early spring snow and bitter cold (-20°c) is killing

livestock and

people in Peru, which is in the tropics. Victoria wouldn't

fare well at -20°c either. The shrinking of the Arctic icecaps

might produce glaciers and colder temperatures elsewhere, especially at

higher elevations. Could it all be

related to HAARP? Who can tell?

I could just be a worrier and Victoria's winter will have

it's usual rain and clouds with occasional frost and a few flakes of

snow that soon melt. Look at all the nasty weather there's been, and

all

the crop failures last year (2012), and decide for yourself whether

it's too much bother or takes up too much storage space to be prepared

just in case there's a nasty weather event here too. Just before

hurricane Sandy, NYC grocery store shelves were emptied in something

like an hour or two.

Challenge for the Next Civilization

Formerly lands were ruled by kings and dictators, then the

concept that people could rule themselves evolved, and democracy and

representative government followed. However, these concepts were new,

untried, and while the greatest minds of the day framed the new

systems, they couldn't see ahead far enough to see the more distant

ramifications of the choices they were making. Their frameworks had

serious flaws that are now proving fatal to peaceful evolution of

society.

In most countries, parliament acted as a

legislative branch under a king, but assumed the powers of both the

executive and legislative branches of governance as soon as there was

an incompetent king. Mostly the judicial

branch was properly separated from the other two. In the new United

States of America, the founders wisely realized that the executive

branch was separate from the legislative (as any high school political

textbook will tell you today), and created the elected

office of president to replace the hereditary executive office of king.

But in no cases did anyone proceed farther with the

actual selection mechanism than the idea of marking the "illiterate's

X" on the ballots for the offices to be filled. (After all, there were

plenty of people who couldn't read or write.) It seemed - and was - a

tremendous advance over elections with swords and spears.

But I've written before about how this primitive voting system is

unfair,

and how it polarizes and politicizes our governing systems and our

whole societies.

In this unfairness, permanent political partisan groups,

"parties", soon begin to form. Quickly power exits the elected

legislatures and becomes concentrated in party hands and it is seen

that "independents" in the legislature can accomplish little when

confronted by organized voting

blocks,

and the voter begins to feel they must vote for a "party" rather than

for a person, and that voting for the best person is a "wasted vote".

It is a fear based voting system where one votes instead for the "most

likely to win" alternative to the "least wanted" likely outcome. As the

polarization proceeds one party gains power over all others combined,

and the legislature becomes merely a rubber stamp for the decisions of

the largest party's leader, who in most nations is also the "Prime

Minister". (a

term first applied derisively to Robert Walpole for his staid,

churchman-like leadership. [Walpole is also of "Bob's your

uncle!" fame for giving his relatives the choice jobs.])

Ambitious people, greedy or hungry for power over

others, start finding their way to the top of the parties, and thence

by default to the top of the political system. And since they have no

guiding ideals or ideas for social progress nor principles except "What

can I get out of it?", but occupy the seats of power wherein such

new ideas and progressive forms are implemented, sociopolitical

progress grinds to a halt, and as events of the new century have shown,

go into

reverse. Former "bastions of freedom" are rapidly becoming brutal

dictatorships.

Similarly minded people who have connived their way to the

top of the economic system are also able to get what they want

politically,

by rewards to the unprincipled party politicians. And now with their

vast stolen fortunes they lavishly support all

political sides - any who may perhaps form the next government must be

beholden

to them. This is why there are

two laws: one for those with the money who get the politicians elected,

and one for the rest of the people. We see today the transfer of the

entire wealth of nations to wholly corrupt bankers and commerce based

people (often the same people, as a handful of families controls 70 or

80% of the world's commerce) by various obscure fraudulent and

underhanded processes, best

described as brazen theft on a grand scale, that would land any of

"the 99%" in jail, with politicans in connivance, aiding and abetting

the crime -- and then choosing not to arrest or prosecute.

A major challenge for the next civilization will be to

frame its democratic and representative governmental institutions in

such a way as to foster election of talented and morally qualified

individuals to governing offices, people with ideals and ideas for

further improving society, while giving the greedy and power hungry

no foothold. Along with treason, betrayal of public trust in

any form

by anyone in any position of political or economic power, must come to

be treated as the culpable offense and capital crime that it really is.

Today getting involved in political processes seems

virtually futile, and the "political class" is more and more separated

from society and reality. The seeming apathy of the masses is due

partly to powerlessness more than to lack of desire or interest in

effecting change. The choice ranking voting system, separation of the

executive and legislative branches, power to control the political

process and agenda through referendums, and (IMHO) the Department of

Progress, are all basic components to fixing this. These things will

empower people to be effective when they get involved in governing

processes, able to provide input and influence to make needed changes

and advance society and culture.

Electric

Hubcap Motor Systems - Electric Transport

Better Rotor Magnet Attachment?

I considered or started in on some things that were going

to need Electric Hubcap type motors or generators. I had been trying to

think of a stronger way to put the magnets on the rotors, and I think

I've come up with something simple: a better pattern of polypropylene

strapping. The biggest problem with the existing method is that the

outer end of the magnet isn't covered. The magnet can simply slide out

if it doesn't adhere well to the epoxy, and this happened to my first

(so far only) Electric Caik rotor at some very low speed. I re-did

the rotor after I sanded the slick coated magnets. I'm still afraid to

run

it above around 2000 RPM, when my intended design speed was 3000.

But I didn't want to add another layer that would make the

cloth thicker on top of the magnets. Axial flux magnet gap is quite

wide, but having placed a wall between the magnets and the coils, the air

gap isn't very big... and I don't want it to become zero or negative

with the magnets rubbing the wall owing to extra layers.

The new idea is to put a first layer of strapping over the

outer end and wrapping it around the sides of the magnet. It would just

be the thickness of the magnet tall and hence add no material on top.

An aluminum clip can hold it in place while the epoxy sets.

When the "regular" strapping is laid on, it would be the

same height, one material thickness over the magnet, but it would

enclose the material now underlying around the sides. The material now

covering the outer end would thus be supported all the way up the

sides. It

could also extend down the edge of the rotor and even wrap around the

back if I feel disposed to cut more complex shapes and extend the

epoxying down and around.

Maybe then I'd feel confident of testing the Caik motor up

to 3500 or 4000 RPM and (assuming it holds together) calling it a 3000

RPM motor as I had planned.

The Electric Motorcycle - with V-belt & clutch

Having somehow not got the Chev Sprint with the

ultra-efficient torque converter transmission working this summer, I

decided I should try out the belt-clutch idea in a simple way: by

resurrecting the electric motorcycle project. This rather heavy frame

machine (plus the rider)

had needed about 80 amps out of an Electric Hubcap motor to start

moving on level ground with a 4 or 4.6 to one chain sprocket reduction.

It was like trying to start a car moving in 3rd gear, and it was pretty

disappointing.

This time I decided to try a 4 or 5 to one reduction with

a V-belt, with an idler operated by a clutch pedal to tension the belt.

On the 27th I made the drive to Princess Auto (and other destinations

in the Langford direction) and picked up another of their flat-plate

10" V-belt pulleys, and a cast steel 2.5" one for the motor end. I

didn't see any ready-made idlers, but that wouldn't be hard to make.

The next day I drilled the bolt holes, turned the center hole larger on

the lathe, and (with considerable filing to fit) mounted the big pulley

on the back wheel of the bike. I'll use a link belt in order to get the

belt through the frame.

The 10" V-belt pulley - with center hole expanded and bolt holes

drilled - on the back wheel.

With the bicycle rim motor unmade, the Sprint car still

sitting, and all the other things I could be doing, I'm not sure this

project is the most effective use of my time. But once it's working, I

see no particular use for it myself, so I won't be fitting it all up

with battery chargers, weatherproof equipment covers, signal lights and

so forth to make it a practical vehicle. I tell myself it should be a

short project. Haha! Anyway,

putting the pulley on was just part of one afternoon.

Mazda: Battery #12

I was told the Mazda would run with 8 to 12 twelve volt

batteries. And so it does. But using regular "marine-RV deep cycle"

batteries, with sodium silicate or not, has shown a problem: they're

not really made for delivering such high continuous currents, often

well over 100 amps on an up slope, except maybe for a moment to start

an engine, and so they run down rather quickly under heavy EV loads,

reducing the expected driving range. Golf cart batteries would be

better, but only uncommon 8-volt ones fit in the Mazda. Also, my 70

amp-hour NiMH "D" cell batteries aren't charging right up to 14 volts

owing to somewhat weak chargers, and they run down prematurely.

Every battery that's added raises the voltage and thus

reduces the current required to attain a given power, and the lower

currents make for more gain than just the added percentage of storage

capacity. I finally got around to juggling some batteries around and

putting in battery #12 on August 31st. (with Tom's help lifting them.)

I expect to go from about 5 miles range with what I think is reasonable

voltage drop to at least 6. Speaking of which, the "Cycle Analyst"

won't say the voltage is above 155.3, and I was worried about why it

wasn't charging higher. But I finally noticed that the other meter says

166 volts, so the Cycle Analyst is wrong.

But the batteries that run out of charge first are the

NiMH ones -- because they aren't charging up to the full 14.0 volts.

I've found Toshiba 15 volt, 8 amp power adapters that aren't too

costly. I have one now. I put it on the lowest NiMH battery with a

smaller value current limit resistor on September 1st, and it looks

like it's charging faster. (I'll order a bunch of them soon but the

cheapest store is presently out of stock.) That'll probably add another

mile or two of range as well, and faster charge recovery although it's

still a slow float-charge system.

But I haven't have time to put the improvements to the distance test

yet.

I picked the float charge

as surely being the easiest on the batteries and hence having them last

longest, with overnight charging. I still think that. But it can limit

driving if you want to drive two fairly good distances on the same day.

But evidently I shouldn't have left the new charger on overnight: it

was still pumping in heavy current and overheating the battery the next

day. I'm worried its capacity may have been reduced or that some of the

cells may be ruptured. It turned out to be 15.5 volts instead of 15.0,

so it needed another diode in series to output the proper voltage.

(Starting with a 14 volt supply would be better, if such a thing can be

found at an economical price.)

Of course, an inefficient automotive transmission is a big

part of the problem. Without its 30% [typical manual transmission]

losses, the currents would be 30% lower and the vehicle would have much

greater range with the same batteries. In spite of all my failures and

setbacks, I trust I'll be able to get back to the variable torque

converter "ultra efficient" transmission project and bring it to a

successful conclusion - hopefully as an "Electric Hubcap" add-on motor

system.

Electric Equipment Projects

Improved(?)

Thermoelectric Camping Cooler

For the camping trip

I took

the original Peltier Module cooler I had bought to initially

investigate thermoelectric devices for the refrigerator, and

re-assembled it but in a slightly modified form: I used two 8.5A, 15V

peltiers in series (electrically) instead of the original single 5A,

15V

peltier. Of course, running the modules below 1/2 voltage, they lose

considerable capacity if the voltage goes down to 10 or 11 volts. But

my plans were for higher voltages if anything, rather than lower.

There was a spot on the warm side heat sink machined flat

for the peltier module. To fit the two modules, I machined it a little

longer (it was too short by all of 2mm or so) on the milling machine.

After putting it off for weeks, I started putting it together on the

evening of the 4th, and finished the assembly on the morning of the 5th

before I set out camping.

Performance during the campout was meager. It was better

than nothing, but not a whole lot. I think the 4 liters of ice lasted a

day or so longer. I didn't have time to look at it while camping. After

I got home, I started checking and found that the two bolts clamping

the warm and cold heatsinks together onto the faces of the Peltier

modules weren't very tight, and the cold side fan was jammed by a part

that was out of place.

With the problems fixed, the doubled module cooling should

be

superior - especially with the limited power usually available while

camping - pumping more heat with less current from the battery

(~3.0A vs. ~4.2A = ~70%). But in a couple of attempts, I haven't proved

it so far. Perhaps I should try the 12v-8v series peltier arrangement

I'm using in the fridge.

A second component to this project was to power the cooler

directly off a 65 watt solar

collector intended for 12 volt applications (putting out probably 12-17

volts while powering the cooler). As long as the weather was sunny and

direct sunlight was accessible (which it was for the whole campout

while the sun was above the trees surrounding the clearing), this ran

the cooler all day from about 8:30AM to 6PM (That's DST, so 7:30 to 5PM

local solar time). I had to move it around a couple of times every day

to keep the collector in the sunlight and pointed towards it. Whatever

voltage the collector put out was fine because the cooler had no smarts

to burn out. I had put a resistor in series with the outer fan to

reduce its speed/noise, and the two 15 volt Peltier modules were in

series

and could tolerate up to 30 volts. The only fan that could be run at

somewhat more than its rated voltage was the inner one. It was a small

quiet fan and I doubt it cares much about voltage.

The one important change I'll make next time is to bring a

very long

extension cord so the cooler can be kept stationary in the cool shade

instead of having to drag it around with the collector in the hot sun.

Electricity (Energy) Production

Magnet Machines: More Magnets?

The type of magnet machine that seems most likely to

succeed might just be the "magnetic ramp" type, with the ramp formed

into a circle. I now envision one where instead of a ramp with two rows

of magnets that gradually get farther apart, it would have just one

row, around the outside as a stator where the magnets gradually get

farther from the rotor, in a one-turn shallow spiral.

Either by repulsion or attraction the rotor magnet would

spin the rotor for one turn until it came back to the start and end of

the spiral. We'll consider repulsion. Normally there it would encounter

the equal and opposite magnetism that would bring it to a halt.

Instead, at the optimum moment some sort of cam would push the last

magnet from the outside of the spiral to the inside, so that the rotor

magnet, instead of being at the end of the spiral, is at its start and

will spin another turn. Some will hold that the force required to push

the magnet into position will be equal to that gained in the rest of

the circuit. If it's less, the machine will be obtaining nuclear energy

from the magnets via their magnetism.

I had some sort of mental block against this type of

machine because one magnet on a rotor pushed by one ramp doesn't make

for much force. But obviously as many magnets as practical can be

placed around the rotor at the best angle, and all of them will be

pushed. The cam will be activated as each one passes the start and end

point... with the others still pushing. The unbalanced component of the

force driving the rotation, which will doubtless be quite small, will

be multiplied by the number of magnets on the rotor, and will be

smoothed out if the magnets don't all line up at once at certain

points, ie if the numbers of magnets on the rotor are slightly

different than the number on the stator.

Hopefully several magnets would overcome inertia and

friction and also be able to do a useful amount of work.

Another Video of Alex Erauw's Vertical Axis Wind Turbines (Aug

26th)

I've been convinced by Erauw's videos that If I ever make

a wind turbine, it'll be a vertical axis one. They seem so

simple, and are apparently more effective in shifting winds and

turbulence: ie, at any location shorter than a tower that sticks up

above

everything else around. (Or as I previously proposed, strung along a

cable between two mountains.) Erauw has some impressive units and

equipment to make them, but

it should be simple to do a small unit with some of the same shafts and

bearings I've been using for motors, a piece of plywood or two

(depending on the unit's size), sheets of aluminum, and perhaps just

connect it to a lawnwower motor or one of my own motors with a flat

belt (or V-belt), rather than build coils and a magnet rotor into the

unit itself.

Since I already have too many projects, I got the idea to

offer to create a design, buy someone the parts, and have them put it

together. This does have the danger of drawing me into assisting with

various aspects, doing charge controllers and hookups, and so on. But

these are things I'm doing anyway, presumably for various types of

power generation. And I have a couple of prospects of interested people.

Let's see... maybe an aluminum and 3/4" plywood rotor

about 3' diameter by 3' tall, unit mounted on an angle iron frame, with

a 1" shaft and bearings below the rotor and a V-belt or flat belt

step-up drive to a lawnmower motor for a generator.

Electricity Storage - Turquoise Battery Project (etc.)

Plastic Jar Cell #1

Self discharge: is interaction between the two electrodes

On August 3rd I ran a load test on the 'new' PP#3-b cell

with the zircon in the negative electrode.

It started with the cell having charged to over 2.5 volts, and ran for

30 minutes until the voltage of the manganese negode dropped to that of

the zinc 'test/reference electrode'. Beyond this, the zinc would start

to oxidize. Since PP#3's original zinc terminal strip had corroded off,

I decided that lower voltage operation was a bad idea after all, and

that discharge to under 2 volts should be avoided. Obviously if the

zinc was allowed to oxidize, the cell wouldn't last long.

A piece of zinc sheet makes a crude reference electrode.

At the pH, 13, it should be ~ -1.20 volts according to the zinc

Pourbaix diagram. (That can only be considered quite approximate. The

diagram is suspect because it doesn't seem to match standard dry cell

voltage near neutral pH, showing ~ -.84 versus the actual ~ -1.07.)

Before

discharge, the Mn negode tested as about 1/3 volt more negative than

the Zn, ie, around -1.5 volts. That meant the nickel

hydroxide:potassium

permanganate posode was about +1.0 volts.

The cell recovered strongly to ~ 2.35 volts. Unfortunately

I didn't get a reference electrode test at that time. After almost 4

hours, it had dropped to 2.15. The negode was still .280 volts more

negative than the zinc reference, or ~ -1.48 volts. This meant the "+"

side was down to around .67 volts, probably accounting for much or even

most of the self discharge and the lower cell voltage. I later realized

the the discharge was interaction between the electrodes.

I charged it up over 2.5 volts again, and put it in the

fridge.

20 Ton Press

"Window shopping" downtown on the 3rd I noticed a "King"

20 ton hydraulic

press with some nice features at Barclay's Exchange. One of its nice

features was a gauge saying the pressure being applied. It was about

380$. After thinking about it I went back later and bought it. I've

long

suspected that

that insufficient compaction might be the reason for the poor

conductivity of my cells, and that I could do a better job of

compacting electrodes. With the edge compactor, 20 tons should be

sufficient, and hopefully more than sufficient.

A key point was the gauge. Previously I suspected that

I wasn't compacting enough, but I didn't even know how much I was

compacting. With the slot in the compactor 3.2mm * 64mm, the area being

compacted is known (2.048 sq.cm) and so from the pressure, the pressure

per square centimeter can be calculated. (Ie, divide by 2.)

Knowing the compaction pressure may be as valuable as greater

compaction itself, because then it's replicable instead of haphazard.

I carried the pieces (it came unassembled) upstairs in about 5 trips,

and completed assembling the beast in the battery lab on the evening of

the 10th - not without having to drill an extra 1/2" hole and mount the

pump cylinder askew to have it on the left side. (Can't move one hole

position and drill 3 extra holes to enable proper left-handed pump

mounting? Come on, guys, 12% of men are left handed!) I pressed some

steel blocks

to about 11

megagrams (Mg, "tonnes", a bit more than a 2000 pound "ton") and it

seemed to work fine.

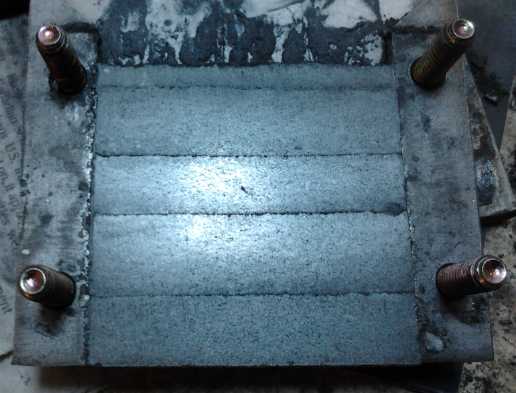

The new press from above

I then looked up the "optimum" compaction for an Fe 'trode

from the 2004 Bangalore research paper and found it was only "675

Kg/sq.cm". My memory was that the pressure worked out to a very high

figure --

which was probably based on compacting electrodes on the flat. To

compact the 64x64mm electrodes (41 sq.cm) on the flat would take 28Mg.

[megagrams]

But for edge compacting, only 1.35Mg! Had I wasted my money on the

press? But every electrode element would be different, and I can now

try everything from 1 to 20Mg for the Mn and Ni:Mn electrodes.

Perhaps I should consider the possibility that I was

compacting them too much and the impedance problem was that they

weren't porous enough for the electrolyte to enter freely? That seemed

a bit far fetched, but again without a gauge I didn't even know what

pressure I'd been exerting. Using the gauge on the press compacting a

few test electrodes should tell the story!

Late at night on the 10th I thought of a simpler test. I

closed the valve and pumped the press a bit, put in some steel blocks,

and used them as a fulcrum for the same pry bar I had been compacting

electrodes with. I levered up on the press cylinder, with the same sort

of leverage and force I had used to compact electrodes. I could hardly

get the pointer to move on the dial. It must have been less than 250Kg

- at best 1/5th of the force recommended for the iron electrodes, and

perhaps as little as 1/10th!

There was the answer. Much more pressure, easily obtained

with the press, would doubtless make much better electrodes.

When I tried the press on the 12th it turned out the

suggested figure was good: 1.5 Mg was the most force it was prudent to

apply. At 2 Mg the die sheet suddenly bent and had to be hammered

straight again. Later at 1.75Mg there was a "bang" - one of the bolts

holding the press together had stripped its threads. It was also

impossible after applying such pressures to get the bolts out

afterwards with the nutdriver - holding the compactor in a vice and a

good wrench was required. I drilled out the threaded holes in the

compactor and put through longer bolts with nuts.

In theory the book press should be able to provide enough

pressure if it had a working swivel on the end of the threaded press

rod - and it was much faster to operate. Evidently I had wasted my

money on the heavy press - at least for the way I was presently making

electrodes - except for the precious gauge. I finally know how much

actual pressure I'm applying. I now know the lever arrangement I've

been using lately has entirely insufficient pressure.

On the other hand, I could press electrodes up to about 25

or 30 square centimeters on the flat with pressures up to 20 Mg. (hmm,

45 x 45mm = 20 sq.cm = 1/2 the present size, ~13 Mg of press. That

might be a convenient size. The smaller they are the less likely they

are to crack during handling - just stack more of them.) Then they

could be pressed straight onto/into a perforated collector sheet for

best contact, and double sided electrodes with the current collector in

the middle could be pressed, all in one go.

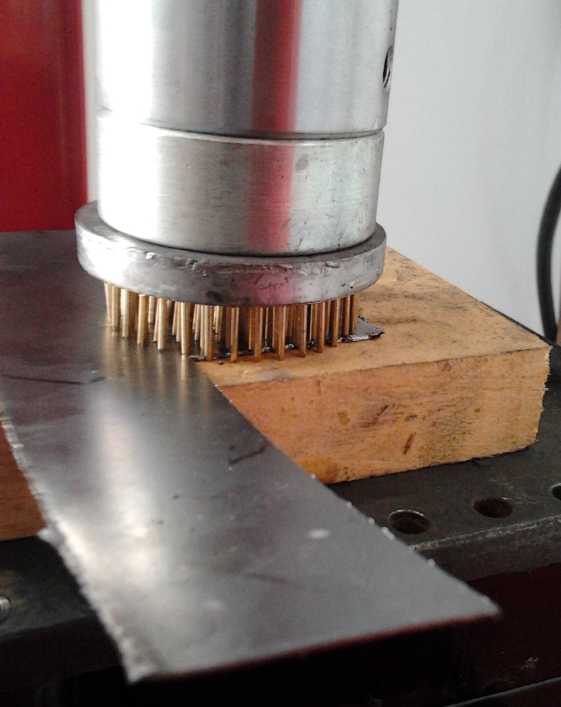

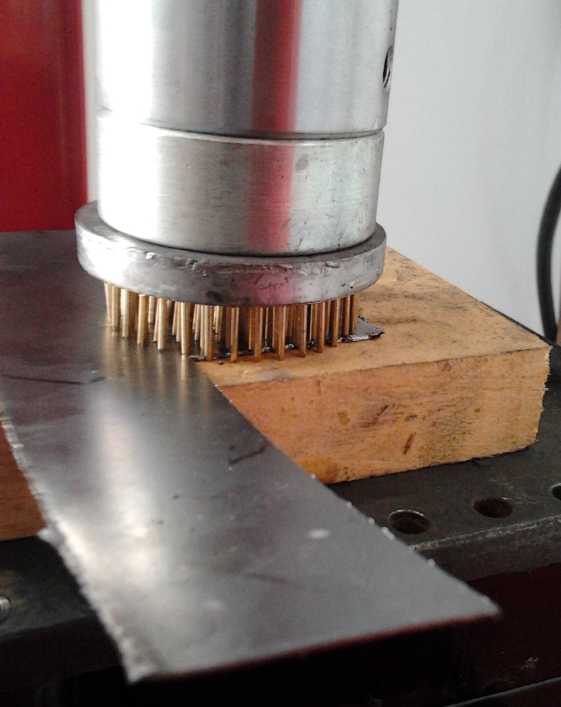

How to Perforate Sheet Metal: Pin Frog?

I

wasn't satisfied with the roughing up of the zinc sheets

with the rasps - they weren't really perforating - and I kept thinking

about how to properly perforate the metal to obtain a high surface area

grid for better connection. I haven't found such sheets in zinc or

graphite anywhere. I looked on line and found perforating machines, but

they looked like they'd cost many thousands of dollars, even tho from

China.

I

wasn't satisfied with the roughing up of the zinc sheets

with the rasps - they weren't really perforating - and I kept thinking

about how to properly perforate the metal to obtain a high surface area

grid for better connection. I haven't found such sheets in zinc or

graphite anywhere. I looked on line and found perforating machines, but

they looked like they'd cost many thousands of dollars, even tho from

China.

Then I had an inspiration: Take a plate of aluminum and

use the CNC drill-router (or finally install the CNC kit in the milling

machine) to drill out the desired hole pattern. Then take a bunch of

small finishing nails, grind off the points, and stuff them into the

holes. Screw a solid plate over the heads of the nails so they can't

come out. Drill another aluminum plate, with slightly larger holes, as

a die to press through the zinc sheet and into. Voila! One could drill

a third plate that can left on while puncturing and pried up to push

the zinc sheet evenly off the nails.

Even simpler, just drill one plate and pound the nails

with a hammer (in bunches) through the zinc into a soft wooden block

under. Pry the wood, then the zinc, off the nails - or pound the nails

out again, backwards.

My thought then is to place the perforated zinc (or

graphite) sheet in the compactor and press with it in place, expanding

the thickness of the space a bit and having the die come down next to

it. If it doesn't fold up or crush, this should hopefully make for well

connected electrodes and current collectors.

And if I do smaller size electrodes, it should get easy

enough to make the simple 'bed of nails' with a drill in the hand

operated milling machine: just turn the crank the same number of turns

for each hole position.

I made a 1/4" aluminum test plate with 5 rows of about 30

holes. On the 15th, a friend saw the new creation, and later he

e-mailed suggesting I try a "flower frog" or "pin frog". These are a

block of lead or solder with the pointed ends of nails sticking up from

them. They're used in flower arranging: the stems of the flowers are

stuck into the nails to hold them in place.

The nails proved to be steel and didn't bend when I

hammered on it or put it in the press to punch the holes in the thin

zinc metal (which took about 3/4 of a ton of force, since many holes

are being punched at once). By pressing several times I covered the

electrode area, mostly with multiple offset copies of the pattern, and

had jagged perforations sticking out both sides for good contacts to

both briquettes of a double sided electrode.

Zinc sheet perforated several times with the pin frog and a hammer.

It easily perforated the graphite sheets, barely moving

the needle on the pressure gauge if at all.

Now the only thing I could wish for would be a larger,

square pin frog to cover the entire electrode area in one pass -

preferably with a denser pin pattern. I checked the web, and found they

do come in various shapes, sizes and materials. Denser pins might be

problematic. Some are wholly unsuitable, eg, some have holes instead of

pins to stick the stems into, so I was lucky Michaels had the right

thing.

Now the only thing I could wish for would be a larger,

square pin frog to cover the entire electrode area in one pass -

preferably with a denser pin pattern. I checked the web, and found they

do come in various shapes, sizes and materials. Denser pins might be

problematic. Some are wholly unsuitable, eg, some have holes instead of

pins to stick the stems into, so I was lucky Michaels had the right

thing.

But now that I know

what they are, I could probably make one easily enough if I decide it's

worth while. Easier to make than

melting lead might be to cast the nails into epoxy - assuming a thick

slab of epoxy would be strong enough not to crack in the press. ...Or

PP-epoxy composite?

I checked local florist shops. One had quite large round

pin frogs. They wouldn't quite get the corners, but I paid 40$ to

reduce the number of times I have to press for each electrode

(hydraulic presses are anything but fast), or to save having to get

into making a big square one myself.

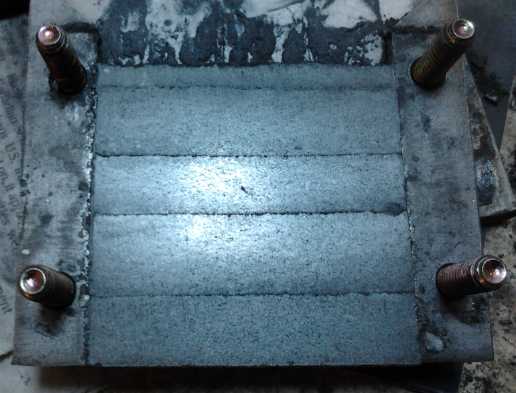

Plastic Jar Cell #1 (PJC1)

On the 17th I put together the first cell in a (ABS?)

plastic jar. I

cut slots in the lid for the terminals to stick out of. I glued on a

1/4" ABS tab to protect the graphite of the positive current collector.

I "sealed" the slots with modelling clay, since I might want to

disassemble things. My first idea was to do a two-face negode with a

posode on each side, doubling what I had been doing for higher current

and storage capacity, then I decided to just do single electrodes and

see how it worked. The negode was 48g and the posode 30g.

Theoretically, it should have 20 or 30 amp-hours of material.

I backed the electrode briquettes, which had been better

compacted by the hydraulic press than previous ones, with the

perforated zinc and graphite current collector sheets. The posode's

graphite got painted with osmium doped acetaldehyde and calcium

hydroxide. I wrapped each electrode in polypropylene fabric, a thicker

white variety. (called "Crop Cover" of some such name.) Between the

electrodes I also placed a piece of fat, rough embroidery cloth as a

holey place for gasses to bubble out. On the outside of the sandwich I

used two pieces of 3/16" ABS plastic, cut about the same size as the

electrodes. I wrapped this with cable tie wraps then inserted the

terminals through the slots in the lid. I didn't fill it above the tops

of the electrodes - probably they weren't even entirely immersed. I

figure the top will wick up water and work as something of a dry cell.

I made a little metal tray to dump eectrode materials into the slot in

the compactor.

I pulled the first piece of hydraulic pressed briquette out to see what

it looked like:

almost like a chunk of metal with that zinc sheen.

I tried compacting an electrode with considerable material dumped in

for each press.

One can see that the lower end material of each press isn't as well

compacted.

So... it's back to 'one teaspoon at a time'.

Negode on perfed zinc sheet - still very fragile in spite of high

compacting pressure.

It started out reading over 1.7 volts. This would

basically be the zinc (-) and permanganate (+), with the Mn and MnO2

(in the minus side) having discharged each other to some intermediate

state when I mixed the electrode powder and wetted it. After a day's

charging at 25mA, 50mA and then 65mA, I went up to 90mA. After a while

the charge voltage was about 2.9 volts. I put it in the fridge part of

the time. It seemed to make some difference to the charging voltage,

but it didn't make "the" difference between charging up to higher

voltage and not, as it had without the zircon.

I tried a 1 ohm load test and found it would deliver about

1.2 amps (= 1.2V) after 30 seconds. Doubtless this was draining the

zinc as well as the manganese, but I think it's easily the best figure

so far with MnMn. It's 30mA/sq.cm, which if not high is at least into

real battery territory.

Later I tried it in the fridge and it would only put out

.9 amps. Higher resistance when it's cold probably explains the higher

charging voltages as well as the lower discharge voltage. Apparently

MnMn prefers it warm, at least above fridge temperatures -- as long as

the negode has the antimony sulfide and the zirconium silicate to raise

the hydrogen overvoltage so it charges at "room temperature". (at least

up to about 30°c.)

I tried a short load test and compared it to the first few minutes of

one with cell PP#3. It didn't seem to be faring quite as well, but

close. Well, it wasn't very charged yet. Then I realized I was using a

25 ohm load where the PP#3 test had been a 50 ohm load, so the new cell

definitely had better current. With 50 ohms a bit later it seemed to

fare slightly better than the best test with PP#3 - and after only a

day, I trusted it had a lot more charge to charge up to.

The Mn negode was about .3 to .4

volts more negative than a zinc one, depending on the state of

charge.

It wasn't charging up to the now expected 2.6 open circuit

volts, hovering around 2.4 to 2.5 depending on the charging current,

and dropping relatively quickly. It fared somewhat better in the fridge.

I started to consider that if the cell really had 10 or 20

or more amp-hours in it, tens of milliamps was pretty small peanuts,

and the discharge currents were always puzzlingly low. If indeed I had

a good cell I might not be exceeding the natural self discharge rate,

and so not really charging up most of the manganese. On the 19th I

raised the charging current again, to 220mA. Charge voltage rose to

almost 3.1 volts... then dropped back to just over 3.0. It's such high

voltages that make me flinch - they're ridiculous for any other battery

cell. But why should should they bother me when I've created such a

high voltage cell, with its own unknown characteristics? I went up to

300mA (at 3.15 volts).

I did a 25 ohm load test after 3 or 4 hours, with

the best results so far - marginally: 33 minutes at over 2.0 volts,

46mAH. Later the water was purple (& pH ~7). I replaced the

electrolyte and reduced the charge to 185mA to reduce bubbling.

The next day gave, again marginally, the best results I've

had. But after another day I got fed up with that and tried 670mA. The

water was purple anyway, and the cell *should* have at least 10

amp-hours, not milliamp hours, so why should it be charged with less

than pretty high current? The bubbling was audible and the charge

voltage, 3.6 volts, seemed ludicrous, but when it was taken off charge

after only 1/2 an hour, it stayed well over 2.6 volts for a bit, and

under load delivered the highest voltages yet. I put it back on. But

the graphite terminal had got munched when I had the cell in the fridge

(when I closed the door it pushed it back against a shelf which broke

off the protective plastic tab), and now it finished breaking off.

Attempts to tape another piece of graphite to it were unsuccessful and

it broke off right at the electrode. I disassembled the cell and stuck

a new graphite terminal tab behind the current collector sheet. It

seemed to work okay.

It later turned out that one alligator clip leed or its

contacts had a rather high resistance, almost an ohm, and that the

charging voltage at the actual battery terminals was around 3.1 volts

(not 3.6), with a current of 700mA. Another 50 ohm load test in the

early evening (21st) gave incrementally the best results yet. Most

exciting was that the voltage previously started dropping typically

from under 2.4 in less than a minute, and now it was all but 2.5 volts,

dropping to 2.4 only after 15 minutes of discharge, and it stayed above

2.0 volts for over 90 minutes. That's about 70 mAH at above 2 volts -

not much but improving.

It continued improving. A while later after some more

charging a short 50 ohms load test stayed over 2.5 volts(!) for 5

minutes, and it put out nearly 2 amps into 1 ohm for a few seconds,

instead of under 1.5 amps. Before bed a test with a 10 ohm load stayed

over 2.0 volts (average ~2.3v, 230mA) for 16 minutes (61mAH), and 17

minutes near noon the next day (22nd). This current actually warmed up

the six 1/4W resistors making up the 10 ohms.

I let the cell sit overnight and in the morning (23rd) it

was under 2 volts - essentially discharged, notwithstanding that it was

in the fridge where I had hoped self discharge would be lower. But I

charged it up for some hours, mostly at lower current then at ~700mA

for an hour, and in the evening tried the 10 ohms test again. This time

it ran for 36 minutes (134mAH). This was double, more than

"incremental" improvement!

Evidently it's true: I've been too timid all along,

charging at currents much too low to really start charging the

bulk of the manganese to metal. If it keeps improving with every cycle

until it has a few amp-hours of capacity per pair of electrodes and

good current drive - and if the self discharge becomes manageable -

it's not so important how long it takes to get there.

In the whole discharge region from the highest (2.55v?) to

around 2.05 volts, voltage drop is gradual. From there it sinks rapidly

to about 1.94 volts, then slows again - at that level the zinc starts

to discharge as well as any remaining manganese.

pH is staying around neutral, and the electrolyte is

staying black, obviously with a substantial level, perhaps saturation

level, of permanganate. If it works, do I really care about these

things? Neutral pH is safest to the humans using the batteries.

Self Discharge: Cause... Cure?

Towards the end of the month it was becoming evident that

the self discharge wasn't being overcome. With both stibnite and zircon

additives it would now take charge at room temperature, and one

could

get some real energy out of the cell by charging it hard, but wherever

it started it would still be discharged down to 2 volts overnight.

The mechanism started to look less mysterious, too. One

thing noted was that it seemed both electrodes were discharging, and at

something like the same rate. And on one occasion I stuffed some bits

of plastic under the tie wraps to press the electrodes together more

firmly, and the self discharge then became much higher.

From this one could conclude that the electrodes appeared

not to be each or either one *self* discharging, but discharging

together internally without an external connection.

Then, the separator sheets became black, and the water was black,

but it mostly wasn't permanganate, it was black particles which could

be filtered out - evidently manganese oxides. I had been assuming this

had leaked out of the electrodes somehow... but in cell after cell?

White PP cloth full of black MnO2 oxide.

New separators. Could the migration of permanganate be stopped?

This was

in fact heartening: neither the

permanganate electrode nor the manganese metal appeared disposed to

discharge by itself. The electrodes, per se, hold charge fine.

It would seem that it'd be necessary either to use some

kind of containment within or around the posode that the permanganate

ions can't penetrate, or else to abandon permanganate and make purely

nickel hydroxide posodes. The containment of the ions isn't without

precedent, but I seem to have somewhat miscalculated somewhat with the

chelation

by organic ligands, as chelation normally traps positively

charged

ions, in which category MnO4- doesn't qualify. But MnO4 is a fairly

large ion, with an atomic weight of 119, so surely there's small holes

it can't fit through.

But cell #3 seemed to hold charge better as time went on.

I decided to try wrapping the electrodes in things that might be not

just micorporous, but almost nanoporous. The first one was packaging

tape.

Electrodes wrapped with packaging tape. This was a flop.

This made the battery a virtual insulator. The voltage

could be read, but it would drop to virtually zero with the slightest

current draw. I guess it wasn't even nanoporous. Then I tried masking

tape. After a few hours, the cell would supply just a very small

current, with substantial voltage drop, and it could be charged very