Turquoise

Energy Ltd. News #71

(December 2013)

Victoria BC

by Craig Carmichael - January 6th, 2014

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Highlights:

Lambda Ray Collector Experiments

Month In Brief

(Project Summaries)

- Battery Making Book -

centrifugal torque converter - lambda ray collector - evacuated steam

radiator tubes - a forgotten planetary gear torque converter video from

Sept. 2012 shows it was working better than I remembered (but still

needed a clutch - a part I couldn't seem to make decently!)

6 Years In Review

- oodles of projects!

In

Passing

(Miscellaneous

topics, editorial comments & opinionated rants)

Electric Transport - Electric

Hubcap Motor Systems

* Planetary Gear Centrifugal Variable Torque

Converter Transmission

Other "Green" Electric Equipment Projects

(No reports)

* Evacuated steam radiator pipes - Experiment with 12V Peltier module

refrigerator.

Electricity Generating

* Lambda Ray Collector - Brazilian Lambda Ray Collector

* Magnet Machines

Electricity Storage - Turquoise

(NiMn) Battery Project etc.

* Battery Making Book, URL: See December in Brief. (no separate report)

No Project Reports on:

DSSC

solar cells (will probably abandon), LED Lighting, Pulsejet steel

plate cutter, CNC Gardening/Farming Machine (sigh, maybe summer 2014?),

Woodstove/Thermal Electricity Generator (will probably abandon),

individual EV

battery monitor (will probably cancel).

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers -

Ersatz 'powder coating' home process for

protecting/painting metal

Products Catalog:

- Electric Hubcap 4.6KW BLDC Pancake Motor Kit

- Electric

Caik

3KW BLDC Pancake Motor Kit

- NiMH Handy Battery Sticks, 12v battery trays & Dry

Cells (cheapest NiMH

prices in Victoria BC)

- LED Light Fixtures

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

December in Brief

December turned

into a month of things that sounded good in principle, but didn't work

out well in practice. The centrifugal torque converter bumped the Chevy

Sprint into motion, barely - but with more vibration than motion. I'm

starting

to wonder if it's a workable idea with my meager machine skills. I

can try to get the same converter to run more smoothly in spite of

seeing that it needs to be wider to reduce the loads on the plastic

parts, or I can start over with a wider unit.

The essential mechanism.

The essential mechanism.

Springs were added to the shoes later.

The first version of a lambda ray collector whined at the

(audible)

pulse frequency and put out 32 volts into a 400 watt electric heater

(36 ohms). The two brief times this happened (2 or 3 seconds each) were

its last two runs

because it was using far too much current and the power mosfet burned

out.The

heater would take 28 watts to get to 32 volts, so with 35 watts driving

the control coil it doesn't sound like

much of a success -- but there was no path for the input energy, which

was the same as on previous unsuccessful attempts, to couple more than

about 4 volts through to

the output coil by transformer action. And the "secondary" windings

were at right angles to the "primary", not in-line, so it wasn't even

configured as a transformer. So, as far as I can figure it, the 32

volts and 28 watts had to be coming from somewhere

else: presumably from lambda ray energy. The success came when I moved

a wire from 'ground' to the floating 'minus' on the power supply. The

other end of that wire didn't quite touch the collector coil wire, so

the appearance was of making it work by moving an unconnected wire.

This unit had used an external square wave from a signal

generator. In order to reduce the input currents, I redesigned the

circuit with its own short pulse generator, and used the whole coil

instead of 1/2 the turns. (circuits

are in the project report.) This version seemed to do nothing much in

initial testing. However, I'm not finished trying

various things out.

The collector - in a bread pan with a

nickel-brass cover.

The collector - in a bread pan with a

nickel-brass cover.

I strongly suspect dangerous radiations are possible with something

that converts rays from the high energy end of the spectrum.

Below lambda rays are gamma rays, x-rays, ultraviolet, visible,

infra-red,

microwave and radio waves, not to mention the charged particles

generated.

On an impulse looking at one of my evacuated radiator

pipes at the start of January, and thinking perhaps to get something

to

actually work right for this newsletter, I tried making an evacuated

pipes

with ammonia in it. I tried testing it on the fridge, but it didn't

work well. Sigh! But the biggest

problem was that the aluminum block, absorbing the heat from the

peltier module warm sides, wasn't transferring heat well to the pipe.

So the the block got up to 50°c and the pipe (under 40°) never

had a good chance. Even so, there were just a few little pings of the

ammonia

boiling a bit. I must do something about the block-to-pipe heat

transfer, try to get a stronger vacuum in the pipe with a bigger torch,

and test again soon. The

lures of silent refrigeration, with lower loss of coldness through the

unit when it's not cooling, and the potential of thermoelectric heat

pumping for home and EV heating with 1/2 the watts, are still there.

"Evacuated"(?) radiator pipe clamped onto

Peltier modules of refrigerator.

"Evacuated"(?) radiator pipe clamped onto

Peltier modules of refrigerator.

Ni-Mn 2.6v Battery Making Book

Having what appears at last to be a reliable, working

battery chemistry, I decided I should try and put some battery making

instructions on line. But the tome, which I started long ago and

revised and revised several times as things changed, was a large

undertaking. I settled for editing the first two chapters and part of

the third, and directing people to Turquoise Energy News #60 to #69 for

more up to date battery fabrication information.

At the same time, I cautioned readers that while the

chemistry (at last!) all appears to work, I still haven't got batteries

that perform up to anything like the current and amp-hours capacities

they ought to have. That applies to batteries I make of any chemistry,

not just nickel-manganese. I think they need stronger briquette

compaction and better "grille" type current collectors within the

briquettes instead of just plates pressed onto the faces, to attain

better internal conductivity.

The Book may be found here:

http://www.saers.com/recorder/craig/TurquoiseEnergy/BatteryMaking/BatteryMaking.html

Energy Generation

When the weather turned cold a few days into December

I looked on youtube and found a video about magnet machines with a link

to a website, www.magnetmotorhojo.com

, where they were selling detailed instructions for making Howard

Johnson type self-turning magnet machines. I paid my 47$US, and found

not only the book but instructional videos. There was considerable

material but after scanning it I seemed no farther ahead. I've seen the

Johnson patent before. It seems to me the

biggest problem with the Johnson design is it uses magnets shaped in

cross section like crescent moons magnetized between the two "horns",

which shape and magnetization is evidently critical

and which I've never seen for sale.

That's probably a barrier that's

kept most people from making one. The design shown in the videos was

different, and they did list supply sources, but it looked rather hokey

to me - made by cannibalizing some small motor. It didn't look like

something to make much of a start at eliminating hydro with.

On the 10th I checked my e-mail... evidently for the first

time since I sent the November newsletter... and found someone had sent

me info on what could only be Lambda ray collectors ("Earth Electron

Capture Units") being made in Brazil, and a couple of

people had sent thoughts on torque converters. I wrote to the

Brazilians hoping for more info. An excellent design in the hand might

be better than months of my own experiments to get something to work at

all. I considered buying one, but 5500$ was a lot of money. The design

patents were on line, and while they had some

interesting features, they weren't all that different than others. I

didn't get a reply, and their units were seized and they were arrested

- really, kidnapped - then released. But they may be being prevented by

the corrupt from continuing their work.

Centrifugal Torque Converter

I made a new drum from a 10" O.D., 9" I.D. brake drum,

cutting 5 slots with

end walls at 45° angles. Then I made an inner rotor from a 7.5"

disk rotor I

had cut for an Electric Caik motor a year ago. I got 1.5" thick UHMW

polyethylene and made five shoes with bandsaw, drill press, belt

sander, and a small 5.5" circular plywood blade mounted in the wood

lathe.

As I worked I got better ideas and more of a feel for how

it should go together and work. The 45° angles weren't really

45° because

the pivot pin of the shoes was an inch inward from the drum and not in

line with the slot wall angles. Pointing from the pivot pin to the

forward end wall, the angle was almost 90°, which meant the pawl of

the shoe might jam against it (stalling the motor) after the hit,

instead of bouncing inward. But the closer it was to 90° without

actually stalling, the more motor energy would be transferred to the

drum as output torque bumps. An optimum angle to hit at had to be

determined. With too glancing a blow the motor would just speed up

freely without imparting much torque to the drum. With too heavy a

blow, the motor would be too loaded down to pick up much speed, and the

"reduction ratio" from the slow motor to the car would also make for

insufficient torque to move it.

In reverse the 45° slots were also wrong. The pawls

would be being pulled away from the drum and would barely strike it.

The angle for reverse had to be greatly increased, perhaps to an actual

backwards hook beyond 90°. I decided to just leave extra material

on the pawls for reverse and shape them later.

On the 16th I had everything together to try out on the

table. Sure enough, it jammed going forward and hardly brushed the drum

going backward.

I then considered that the shafts had to be held securely

in alignment in the car, and accomplished that with a

sintered bronze bushing held in an SD coupling extending a little past

the end of the motor shaft, with the output shaft running inside the

bushing. Good enough for testing purposes, but even so it cracked.

I finally tried it on the car at the end of the month. It

kept jamming (extra cutting to even things up made for problems), so I

took it off and put springs on the shoes. That helped, but the hits

were lumpy and uneven. Some did little. Others bumped the car slightly

ahead (which probably took only 50 foot-pounds from where it was

sitting) but in doing so, momentarily brought the motor almost to a

stop. The car did more shaking around than moving. There's one or two

more things I can try with only modest changes.

After that, I confess I pale at the thought of having to

redo

everything again, perhaps more than once, to arrive at a really

satisfactory design. I hope this one is at least sufficient for a good

proof of concept!

To top it all off, I left the video camera in the rain,

and for the the last tests, I had to get out my old one, which I can't

edit the videos of. In reviewing the tests, I went back a little

farther and found the last one from September 2012. In that video, I

had managed to drive the Chevy Sprint forward several feet from where

it was into the shed, and had to stop before it hit the bench. I don't

remember having been that successful with the planetary gear

torque converter, but there it was on video! Once the PG torque

converter starts the car moving, it does work. I've described it as a

"divide by zero error", but really I still don't really understand why

it doesn't work until the car is in motion.

Perhaps a flywheel on the motor really was all that was

needed to get it going. Even if not, the PG converter concept worked,

except my crappy flat belt clutch construction wasn't up to the task.

Maybe a more "regular" sort of plate clutch to engage the chain drive

sprocket would make it work.

If I don't get the centrifugal converter working better in

a couple more tries, I may revert to that idea. So far, then, the

magnetic impulse, slipping planetary gear, and centrifugal torque

converters have all come close to working without quite making it,

evidently owing mainly to me "underbuilding" some of the pieces. It's

pretty frustrating!

Six Years in Review

I must be making a mistake somewhere... SIX years of

doing renewable energy projects? Let's see... 2008, 2009, 2010, 2011,

2012,

2013. That's only... hmm, six! That's not counting the early ocean wave

power ideas and designs of 2006 and 2007. My 59th birthday struck with

this new year.

What renewable energy things have I done or tried to do in

those six years? Going through the newsletter indexes is a pretty

boring read. Certain intransigent projects appear over and over again

in most issues for the whole time or much of it, with seeming promises

of success just around the corner being dashed an issue or two later,

and often the expectations of performance or function not being met.

Many might say I took on too much without knowing enough about the

subjects. Certainly my efforts have been spread very thin.

Yet over the time, main objectives have been creeping

along, and for relief, interesting projects and progress have been

accomplished in many energy related fields.

There have been some main projects, and some derivative

projects resulting from them. Some have achieved success, others have

been little more than concepts, or projects that haven't gone very far

- at least so far. A few I've sidelined because I started working on

other, more promising lines of progress that would make them obsolete

anyway.

List of Projects

* Ocean wave power

* An electric motor for car wheels

* Better batteries

* Some sort of efficient torque converter transmission - many tries to

get anything that would work:

- inertial

- magnetic

- magnetic impulse

- slipping planetary gear

- centrifugal

* Nanocrystaline "ultra-efficient" motor coil cores

* Nanocrystalline titanium dioxide borosilicate glaze frit to improve

solar collector performance

* Dye sensitized solar cells

* Lead-acid battery renewal with sodium sulfate

* An electric car heater

* NiMH dry cell car battery (in car almost 3 years now, still works

great)

* Building bigger batteries from NiMH dry cells (several constructions)

* Simple battery tab spot welder

* Pulsejet steel plate cutter

* An electric outboard motor - 3 projects (a working transport

application for my motors!)

* Huge torque "Electric Weel" motor for vehicles

* LED lighting

* Solar panels and low voltage house wiring

* A thermoelectric refrigerator

* Magnetic heat pumping

* CNC farming and gardening machine

* Electric Caik motor - a smaller version of the Electric Hubcap

* More efficient outboard propeller - aluminum casting.

* Woodstove/heat source

thermoeletric power

* A thermoelectric heat pump using less electricity than a regular

electric heater

* Evacuated steam tube heat or coldness radiators

* Magnetic machines, magnetic

spacecraft drives - my theory of thermomagnetism

* Vertical axis wind turbine

*

A radio wave energy collector

* Lambda ray collector (after identifying the source of the unknown

radiant energy people seem to have been capturing for a century)

In regard to generating electricity, I have

become quite convinced from many sources that people actually do get

power from self rotating magnet machines, and actually do 'collect' the

incredibly energetic lambda rays which are all around us and get

kilowatts of power from them. In fact, judging from the wide variety of

designs on the web, this last is rather easily done. To paraphrase a

phrase, such devices would "create solutions rather

than fix problems." Solar, wind and thermoelectric power generation

pale beside these grand possibilities, so there seems to be little

point in continuing with them.

For those still useful projects and ideas that

I can't bring to a successful conclusion myself, and there

obviously will be some if only because there have grown to be so many,

I

hope writing about them in these newsletters will inspire others to

take up the projects, or even more worthy successors to them, and make

their fruits available to the world. (My latest idea is to see if the

Victoria

"maker community" would like to have something along the lines of a

monthly "energy night" where people build an energy project of their

choice. If I could help guide this, it might speed design evolution as

well as dissemination and adoption of some of the projects and designs.)

Getting down to specifics,

the four main projects related to car "hybridization" have been

the main focus throughout these six years. The Electric Hubcap and

Electric Caik motors are probably the most complete projects. The

Electric Hubcap took a long time before I had a really excellent

motor, being one of the three I started in January 2008. Since the Caik

was derived from the Hubcap and uses mostly the same parts and

constructions, I developed it in just 3 months at the end of 2012. I

can now make a great motor whenever I need

one, and I hope to teach others how to do so as well.

And yet, I have in mind a couple of ideas for improved

jigs,

and even this month I've had an idea for a motor improvement: a

metal rotor-end cover plate, which should be better for attaching the

bearing and a solid mounting to than the PP-epoxy composite. The

Electric Weel and bicycle rim motor should be little harder to make in

principle, but require input of design time to make the molds and

templates/jigs before they can be produced.

Next up also from January 2008 is the BLDC "Turquoise

motor

controller". They've been working reasonably well since 2011, but they

still aren't totally reliable unless limited to 24 volts or to too low

a current for street vehicles. (Next I'll try shielded gate drive wires

to prevent glitches, and move the PC board a little farther from the

high power MOSFETs - little things like this are critical to prevent

spurious switching leading to failures at high power in such fast

switching, high powered circuits.)

The final project with that same start time is the

Turquoise Battery Project, in which the last pieces of the

electrochemical puzzle have at last come together to yield an excellent

battery chemistry: Ni-Mn with KCl electrolyte, "moderately alkaline"

cells. There've been many puzzling failures and successes that proved

to be only partial along the way, so they limped along always holding

out the elusive

promise of fabulous, cheap batteries. The chemistry at last seems to

be complete and working, with cells holding that great 2.6 volt charge,

in 'any' weather and with repeated charging. They now need to be

constructed so that they fulfill theoretical expectations, with good

current capacity and good utilization of the active

chemicals. I've decided that that's not my priority for now - or

probably ever if others like Changhong Batteries start making them. If

not (they didn't reply to my e-mail), perhaps I'll have a go at

production quality cells someday. But that I've spent

six years on these projects to get this far are a reminder that life on

this planet is

finite, and realistically, the day may not come.

The fourth main project, the torque converter, was started

in

May or June 2009 when

I finally realized that a motor that could directly drive a car wheel

would be too heavy and bulky to mount on that wheel. To my surprise,

even

with a 4 to 1 reduction the motors would barely get a heavy frame

motorbike

going (and only with batteries and a controller capable of powering it

strongly, without fading or blowing).

Any fixed gear ratio that would allow a vehicle to start from a stop

and

accelerate well at low speed, seemed like a good way to waste

electricity with high RPM.s at driving speeds, especially on the

highway. A compact, efficient, variable torque converter that would fit

between the motor and the wheel became another "holy grail" project

that would go on and on, with some frustrating "almost works" magnetic,

planetary gear and centrifugal units that weren't quite practical. So

far.

So far, the only really successful electric transport

achieved by my motors and controllers are two versions of an electric

outboard motor for boats - the original November 2010 conversion of a

Honda 7.5HP with a primitive version of the motor, and the February

2013 launch of the same Honda outboard with the newly created Electric

Caik motor. Yet conversion of an existing outboard has its

frustrations. With land transport, I can't seem to get enough gear

reduction efficiently. With outboards too much reduction is built in,

down at the propeller. And the propellers, it would appear, could be

much more efficiently shaped.

In some frustration, I took on an old "regular" converted

electric car in 2013, generously offered by Jim Harrington,

which turned into a considerable - and ongoing - project in itself.

(...now it's short two PbPb batteries again, and the hydraulic clutch

pedal

has died and

its removal bolts are virtually inaccessible.) But it runs, I drive it

on the street, and I've learned some things from it. On the other hand,

it has taken up a lot of time that might have been better spent getting

a working torque converter, making thermoelectric heating, and other

projects.

Skipping to 2013, the highlights are doubtless:

* the finish of the short development of the Electric Caik motor

* the successful running of the Electric Caik Outboard

* the final links to get the new and better NiMn battery chemistry

working

properly after so many years

* the findings about the lambda rays: of the existence and nature of

free, powerful radiant energy that really is all around us, day and

night. This extension to the electromagnetic spectrum beyond gamma rays

has been "known" for over 10 years, but hasn't made it into the general

knowledge stream - it hadn't even been given a name and people haven't

been waking up to its radiative characteristics or its potential for

energy generation.

Also worthy of mention are:

* I created click-lock versions of the "CAT Standard" 12 VDC plugs and

sockets,

* I started in (but didn't get very far) on thermoelectric heat pumping

for space heating to double the effectiveness of whatever electricity

was used for heating,

* and on evacuated steam tubes for heat radiation for the above,

* I made 3D printed 12 volt NiMH "D" cell battery cases (and improved

my techniques for soldered-together battery packs),

* I got the electric Mazda RX7 with all its seized-up parts running and

back on the street.

* I've been working on a centrifugal torque converter. This is a

promising converter type that does everything automatically (no clutch

or gear shifting), and I'm getting more of a

handle on the requirements and parameters. It ought to propel

cars.

*

The 'shallow chest' thermoelectric fridge made in summer 2012 continues

to work nicely and I keep food in it, albeit I *still* haven't made any

automatic control for it and operate it manually, more on than off, on

a daily cycle.

Since energy issues are so closely tied to social issues

in our dead-end and failing civilization, my idea for a referendum

web site where anyone can propose and vote on a referendum on any

topic, by interactive creation of choices and choice ranking voting, of

any geographical or other scope, should probably be

mentioned. In addition, I plan to narrate my booklet Fundamental

Principles of Democratic Government - towards utopian systems of

governance and put it on youtube, where it will doubtless reach

a far larger audience than it appears to have so far.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Unicorns

In TE News #69

I recounted the discovery of fossils of the

giant flying bird Argentavis, probably in the "teratorn" family of huge

flying birds. It could carry people or livestock, and is probably the

'roc',

'fandor', maybe the 'griffin'. It was written about as still living in

historic times in Southeast Asia by Marco Polo and by naturalists, but

until the discovery of the fossils, their accounts were dismissed as

'legends' by more recent scientists.

In TE News #69

I recounted the discovery of fossils of the

giant flying bird Argentavis, probably in the "teratorn" family of huge

flying birds. It could carry people or livestock, and is probably the

'roc',

'fandor', maybe the 'griffin'. It was written about as still living in

historic times in Southeast Asia by Marco Polo and by naturalists, but

until the discovery of the fossils, their accounts were dismissed as

'legends' by more recent scientists.

To carry on with the theme, it appears that the

'legendary' unicorn was probably a species of fleet footed rhinoceros

- or perhaps more than one species - with a single long horn, that were

once very common but went extinct (overhunted?) around

10000 years ago, of genus Elasmotherium. The legs of this tall

species were more akin in length to horse

legs than to the short legs of extant rhinoceros species.

Hidden Secrets of Money - Video Series

This is a plug for Mike Maloney's five part video series, Hidden

Secrets

of

Money. As Maloney points out, people who understand how

the money system works, who understand how banks and governments

may collude to scam us and steal our wealth, and who understand what's

coming upon us, will prepare accordingly and be better off than those

who don't. So the best thing you can do for your own future is to

educate yourself. And the more people there are who understand, the

more

pressure there'll be to end the stealthily pilfering financial system

and put something sustainable and fair in its place.

Maloney isn't the only person saying these things, but Hidden

Secrets

of

Money does it with good clarity in an entertaining,

watchable style. Search for "Michael Maloney" on Youtube. (He does not,

in this series, touch on Bitcoin, and the viewer should realize he

threw himself into gold and silver before Bitcoin existed. Nor does he

touch on related matters such as the need to put away food for a period

when the supply chain may be disrupted for an extended period by the

chaos of the

financial collapse he expects. But it's a great video series about

money!)

1. Gold and silver: Money versus Currency

2. Gold and silver: 7 Stages of Empire

3. Demise of the Dollar (and every other fiat currency in history -

thousands of them)

4. When Money is Corrupted

5. The Biggest Scam in the History of Mankind

Free Energy Inventors - Suppressed?

The Brazilian inventors of the lambda ray collectors have

run into flak, to say the least. One would hope peoples' natural

reaction might be one of wonder, and enthusiasm as they realize how the

fact of almost free energy in abundance will change the

world forever for the better. Instead the people sent saw the simple

answer to the world's perplexing,

entrenched energy problems of a century and more, right before their

eyes -- and they were indignant. Maybe they already had their orders.

They stole ("confiscated") the

installed devices and had the inventors arrested in what amounts pretty

much to a kidnapping. (They were later released. Now I hear a rumor

that unlike the ever-frauding big banks, they've been charged with

"fraud".)

Here's some questions for those who think that if Barbosa

and Leal were charged with fraud, they must have had no actual success

and been trying to defraud:

* If they had no real product, if they really were running a scam, why

were they willing to sell only locally, using their real names, so

their

intended victims could see and try out the merchandise before buying,

and "know where they live" if they found they had been cheated? It

would be more natural to sell over the internet only, to points abroad,

under pseudonyms, and avoid local sales.

* If they really were trying to run a scam, amidst all the scams being

run and succeeding for a while before the police catch up, if they ever

do, how is it that the authorities came prepared with power company

officials to immediately disconnect and seize the equipment, and

seemingly "threw the book at them" -- no warnings and evidently without

even a

customer complaint to justify pressing of charges? At that point, it

was only a potential fraud. And they were first arrested not for fraud

but for having "stolen" electric power meters. No one bothered to ask

how it was they had them (they were given them by a utility employee)

before carting them off to jail.

* If their inventions don't work, how did

they get two or three patents on them?

Nobody seems to like

the inventors or their product... except probably the 99.99%, who would

immensely benefit. But the way this world is being run today, their

feelings, wishes and needs - our

feelings, wishes and needs - and the planet's future, count for naught.

A news report about it (see on youtube) noted at the end that many

promising

energy inventions such as this have come along, made the news, and then

disappeared and

nothing more is

ever heard, noting that one petroleum

saving inventor's last words as he collapsed in a parking lot were

"I've been poisoned!"

This is a reason why we need the coming global collapse

and

"reset". Today the

internet is preventing the corrupt from controlling the dialog, and

manipulative false flag events are being seen for the lies that they

are, for example thwarting at least for now the US led attack on Syria

(intended to help dominate and control the middle east for its

resources). Even now, global consciousness is rising. Hopefully these

Brazilian inventors may be able to continue their work in

peace.

Peace, forgiveness and love are the attitudes that will

loosen the grip of evil on this world and see it progress. Corrupt

overcontrol by a few family cliques of "reprobates" is what has been.

It will soon be a part of history, not of the planet's utopian future.

I've heard that when the time comes (probably within our lifetimes)

the top "reprobates" are to be "unceremoniously removed

from the planet so they can work no more harm", and taken - their souls

taken -

for special rehabilitation. Thus, problems that seem beyond human

solution

will be solved nonetheless. The

bunkers, island or fortified homes and fallout shelters won't help

those who would enslave humanity and who have made working of evil into

an art form. What would help them is turning around and living a

righteous life.

Some

of them will choose oblivion over eternal life owing to the way they

lived their Earth life. Forgive them. Pray for them.

Of course, partly the reaction of the power company people

may be a natural human reaction to having one's view of the world

jarred.

All our lives we've "understood" that energy is scarce and costly, and

easiest to get from oil. To find that energy can be freely and easily

collected from the air changes everything we thought we knew - the

whole way the world works and relates to energy. As one scientist put

it in a book (stop me if I've told this one already), the way to get

your theories accepted is:

1. Publish your work.

2. Wait for the current generation of skeptics to die off. They will

never believe regardless of anything. It is surprising to find that

this is as true today as it was in 1610 when Galileo was placed under

house arrest for discovering Jupiter had four previously unknown

planets orbiting it, made plainly visible with the telescope. And

again, if Galileo was just spouting fantasies, he would have been

dismissed as a nutcase, not arrested. It's those that have something

new that are feared.

If the work is true, the next generation will incorporate

it into humanity's knowledge database. In the case of lambda ray energy

and probably magnet machines

however, the time is coming that people are increasingly

not going to be paying hefty monthly fees to a power grid to run their

homes and businesses, and then even the skeptics won't want to be still

doing so.

Nasty Iran: a continuing threat to peace

Here's a little

diagram I found of American military bases near Iran, which has just

democratically elected a new president. For decades now we've been told

that Iran is a crazy country that is almost ready to make nuclear

weapons, and as soon as it does, mayhem will break loose.

Iran is

surrounded by nations holding nuclear weapons on their soils. So what's

it

really all about? Iran is selling its oil for currencies other than the

US dollar, and more especially for gold. The last two countries to try

that were Iraq and Libya - look what happened to them. But having been

invaded by Iraq, and

then threatened for so long, Iran has built up a considerable military

and

would be no pushover. Before the USA could invade it, it would need a

short,

secure supply route via the Mediterranean, through Syria and Iraq.

In the 1950s (1952?) the CIA paid some malcontents to

stage demonstrations, and managed to oust the first and newly elected

president of Iran, and have a puppet, the shah, installed in his place.

It was the easiest takeover of a country ever, and became a model for

the corporatocracy's "banana republics" treatment of Latin America for

the rest of the century. The book Confessions of an Economic Hit Man

shines some light on this dark era.

That doesn't seem to

work on Iran any more. I must say the diagram reminds me of a map of

Poland just before Germany invaded it from all sides to start World War

Two.

from Keiser Report ...#5XX

from Keiser Report ...#5XX, December 2013

Electric

Hubcap Motor Systems - Electric Transport

Centrifugal

torque converter transmission

Notwithstanding the poor results in November - and I

suppose owing to my failure to make a working clutch for the planetary

gear converter - I became

convinced the centrifugal torque converter was the best way to go. So I

started looking for more suitable parts - mainly something better than

an old frying pan for a drum rotor.

I got an 8"

I.D. aluminum pipe, 3" long and wondered how

to mount it without machining a whole end plate to exacting specs. I

got out an old brake drum to see how it would fit in it. The fit might

have worked if I cut the aluminum pipe to 2" width or less. But then I

thought,

why not just use the brake drum? A chief reason in my mind was that

being steel it

would rust mounted on a car wheel. The abrasive rust would wear out the

plastic "shoes" (which I was calling "fingers" in last month's issue).

Well, I wasn't putting it on a wheel now, and anyway proof of concept

was the objective at this point. The brake drum was of course properly

machined smooth and round, 9" I.D., 10" O.D., and the center hole size

(as luck would have it)

was just right to fit an SDS taper lock bushing to mount it on the

shaft.

The drum inside walls would allow for up to 1.25" wide plastic "shoes".

I still only had 1" thick plastic, but that would at least give some

slack

for misalignment. (After finding one used drum of this type in a brake

shop garbage bin, I had bought this one new in a much much earlier

failed attempt to make a converter, and if it's so perfect I want more

of them, I trust I can find the part number in some old issue of

Turquoise Energy News.)

I got an 8"

I.D. aluminum pipe, 3" long and wondered how

to mount it without machining a whole end plate to exacting specs. I

got out an old brake drum to see how it would fit in it. The fit might

have worked if I cut the aluminum pipe to 2" width or less. But then I

thought,

why not just use the brake drum? A chief reason in my mind was that

being steel it

would rust mounted on a car wheel. The abrasive rust would wear out the

plastic "shoes" (which I was calling "fingers" in last month's issue).

Well, I wasn't putting it on a wheel now, and anyway proof of concept

was the objective at this point. The brake drum was of course properly

machined smooth and round, 9" I.D., 10" O.D., and the center hole size

(as luck would have it)

was just right to fit an SDS taper lock bushing to mount it on the

shaft.

The drum inside walls would allow for up to 1.25" wide plastic "shoes".

I still only had 1" thick plastic, but that would at least give some

slack

for misalignment. (After finding one used drum of this type in a brake

shop garbage bin, I had bought this one new in a much much earlier

failed attempt to make a converter, and if it's so perfect I want more

of them, I trust I can find the part number in some old issue of

Turquoise Energy News.)

I cut the slots 1.75" long (inside length) and at 45°

on the 8th. Since I was using an angle grinder rather than precision

equipment, that was followed the next day by several hours of grinding

and filing to get things as straight and true as my stamina and time

allowed. The slots were 2" long or slightly more (and not very evenly

spaced) by the time I was done.

As suggested by Eric Jenkins at the VEVA electric car

club, I might try steeper slot angles. If the motor didn't have enough

coupling to the wheels and just spun up easily without making much

torque, as happened with the frying pan version, I could steepen the

angles by grinding away the outsides more. I could see going up to 60

or 70° - maybe even 80° or more - to increase the force of each

blow. This would also change the angle of the resulting force vector,

becoming more of a straight on smash, the forces of which would slow

the motor more and speed up the drum more - more torque transfer. But

the angle

would still be enough that the "fingers" on the shoes would bounce out

and not stall motor rotation. The more I thought about it, the more I

suspected I'd had the blinders on about the 45° angles. Finding the

optimum fairly steep angle might well be the key to getting optimum

coupling force between motor and wheels.

On the other hand, having twice as many 45° slots

would provide twice as many lighter hits per rotation and hence twice

the torque transfer without changing the angle. At that point, with 2"

long

slots, there'd be more slot than wall, and triple or quadruple slots

would be out of the question. The question of angles soon became the

main point, when I considered the shape to make the shoes.

A 1/4" x 7.5"

O.D. rotor cut nearly a year ago for an

Electric Caik motor (I had four rotors done when I made the first Caik)

seemed pretty much ideal for the inner (driving) rotor to mount the

"shoes" on. That made a 3/4" space between the outside of the driving

disk and the inside of the driven drum. I had sized the disks' center

holes for smaller taper lock

bushings, size "H" instead of "SDS". I had "H" bushings

for 7/8" and 1" shafts, but the motor had a 1-1/16" shaft end. I didn't

relish changing the motor shaft, so the next day had a shopping trip.

Somehow I was already sure that would be all I got done that day, and

sure enough, no one had one and I had to buy one with a 1-1/8" center

and make a sheet steel insert, a shim. Not before trying all the places

that just might have one.

A 1/4" x 7.5"

O.D. rotor cut nearly a year ago for an

Electric Caik motor (I had four rotors done when I made the first Caik)

seemed pretty much ideal for the inner (driving) rotor to mount the

"shoes" on. That made a 3/4" space between the outside of the driving

disk and the inside of the driven drum. I had sized the disks' center

holes for smaller taper lock

bushings, size "H" instead of "SDS". I had "H" bushings

for 7/8" and 1" shafts, but the motor had a 1-1/16" shaft end. I didn't

relish changing the motor shaft, so the next day had a shopping trip.

Somehow I was already sure that would be all I got done that day, and

sure enough, no one had one and I had to buy one with a 1-1/8" center

and make a sheet steel insert, a shim. Not before trying all the places

that just might have one.

(Later I found a "7.8 inch brake disk" with a center for a

keyed 1 inch shaft at Princess Auto. This would have made an ideal

inner rotor for a motor with a 1" shaft. In fact, it might make a very

good "ready made" magnet rotor for Electric Caik motors!)

On the 11th I bought some 1.5" thick UHMW-PE plastic (and

some 2.0") and on the 12th I started in on a design for the 'shoes'. I

started to consider the strike angles not by themselves but as vectors

in relation to the shoe's pivot point. If only the small mass of the

shoe was considered, the hit was 45° and the shoe's bounce was

inward.

But the angle of the bounce could only be the angle from

the pivot pin, which would only be straight in if the pivot pin was

somehow just outside of the drum rim. That pin, which drives the shoe

around the drum, is about 50° around the rim from the impact and an

inch inward from the drum wall, resulting in a bounce angle of

almost 45° from straight in. it appeared that even with an optimum

length shoe, the 45° angle would in fact already be almost a

90° hit knocking the shoe against the pin, if the shoes faced

forward from the pin. It would be forced to bounce off at a very high

speed compared to the speed of the impact. If the shoe tip wasn't

rounded off, or if the slot angle was say 50° instead of 45, the

shoe might actually jam against the slot wall and stop the motor.

Tolerances being what they are, it might actually happen. A very steep

strike angle is evidently inherent in the design. In fact, in theory

the slot end walls ought to be slightly curved concave to match the

sweep of the pivot. The cog end wall would be slightly convex to match.

If on the other hand the shoes faced backward, or for

driving in reverse, the same shoe tip and slot wall angles would brush

by each other very lightly, with the pivot pin already pulling the shoe

away from the drum. Evidently the angles for the

shoe tips and slot ends should be completely asymmetrical between

forward and reverse, the reverse requiring almost a reverse hook in

order to effectively transfer the rotary forces from the disk to the

drum.

Little torque difference between

forward and reverse was seen with the frying pan. That made me nervous

about these surmises, but then it could hardly

be said to have been working properly, with the slots obviously too

narrow and flaking little chips off the

plastic in both directions. I decided to go with the steep angles idea

and leave some extra material on the shoes tips to shape the 'reverse'

sides later. If the car would drive only forward, it would still prove

the centrifugal torque converter concept -- the shapes for the other

direction could be worked out later.

On the 14th I finally decided on a shape for the shoes and

roughly cut them out from my block of plastic with the band saw. I left

some extra on the "pawl" end for adjustments and for shaping them for

the reverse direction later. On the 15th I drilled 5 holes in the rotor

disk for the pivots and shaped 2 of the 5 shoes. Doing the shoes was

slow going. I needed a better way.

As I did this, I started thinking there wasn't much free

play, and that it would be much better to somehow tie the two shafts

together to keep the disk and drum aligned, rather than just to rely on

lining up the motor approximately with the output shaft.

On the 16th I

found an old 5.5" plywood blade and mounted

it on my wood lathe to cut the remaining slots, butting the pieces on

the tool rest. It worked quite well and I had them all nicely cut and

adjusted in an hour or so. They all needed deeper slits than the

original shape allowed for, and it was nice to just dig into them

however much was required.

On the 16th I

found an old 5.5" plywood blade and mounted

it on my wood lathe to cut the remaining slots, butting the pieces on

the tool rest. It worked quite well and I had them all nicely cut and

adjusted in an hour or so. They all needed deeper slits than the

original shape allowed for, and it was nice to just dig into them

however much was required.

I made the pivot pin holes so that the 1/4" bolts slid

into one side, and threaded into the other side. It didn't seem they

were likely to turn loose, but it left the metal screw shafts pivoting

on the steel rotor, so they'd need oiling.

In spite of the loose driving V-belt and the slow speed,

the thought of my fingers perhaps touching the nearby saw blade wasn't

very appealing. I was very careful and only had 5 shoes to do, but it

certainly needed some thought about setting up for any sort of

production. Some sort of CNC tool might be best? Or at least a clamp

and screws to hold the pieces and move them around against the blade,

keeping fingers well clear.

Then I put the rotor together and fitted it on a shaft

with the drum. As I by now expected, the cogs usually jammed in the

forward direction. But even at hand speeds each cog hammered the drum

with notable force and made it turn a bit. This was encouraging. The

cogs breezed breezed by the slots in reverse with little force to the

drum. I made a little video of it. For the first time in this whole

project I felt like I was starting to get a good grip on the parameters

and requirements to make a centrifugal torque converter work. I thought

it would work if I got everything about right... and if the plastic

shoes didn't disintegrate.

Later I went to Princess Auto and got some sintered bronze

bushings. (None exactly the size I wanted - I shaped one on the lathe.)

The plan is to fit the

motor end of the bushing fixed under the "H" bushing, with the outer

end sticking out past the motor shaft. (And oil it!) When installing, I

would loosen the fittings and then push the output shaft end into the

open end of the bushing. This would hold the shafts in alignment while

allowing them to rotate independently.

Finally, I had noticed during the bench rotations that the

5 cogs didn't line up with the 5 slots evenly. Really, they were pretty

bad. The pivot holes were pretty evenly spaced, as were the shoe

lengths. Then I measured around the outside of the drum and found that,

careful as I had been measuring and drawing the angles, the slots were

quite unevenly spaced. I should have done the outside measures before I

cut the slots - and again during grinding and filing. (I should have

measured the distances between all the pivot hole points, too, but that

worked out pretty well regardless.) Also I got a 45° angle measure

and found some of the angles weren't very close - some were about

50° towards right angles. These would be the ones that jammed - or

jammed worst.

The total distance around the outside of the drum was

790mm, so 790/5=158mm from one slot front face to the next one. They

were actually from 153 to 163mm. One was 5mm short, one was 5mm long,

two of them were right WRT each other and the last was pretty close...

but all but one would need regrinding to even out all 5 spacings - and

that one needed its angle reground anyway - ouch! So the drum required

another day and a lot more grinding and filing to rectify.

It wasn't until almost the end of the month that I tried

the unit out. It jammed. I took it inside and put springs on the shoes.

Then it ran very roughly. The car moved ahead a few inches from a spot

where low torque was needed, but mostly it just shook.

One guess which spring I wound myself

One guess which spring I wound myself

Other Green Electricity Projects

Fridge with evacuated(?) heat pipe radiator

clmaped onto

Fridge with evacuated(?) heat pipe radiator

clmaped onto

Peltier modules & copper "cold bar" going to ice tray inside.

Evacuated Pipes Attempt - for thermoelectric fridges and heat

pumping

On an impulse looking at one of my

evacuated radiator pipes at the start of January, and thinking perhaps

to get any something to actually work right for this newsletter, I

tried

making an evacuated pipe, this time with ammonia in it instead of plain

water. The first pipe had a leak.

The second one didn't sound like much of a vacuum, but it sounded

different than one with no vacuum. Maybe ammonia didn't behave quite

the

same as water? I put the radiator fins back on it and tried it on the

peltier fridge. I got the following temperatures:

- Peltier hot side (aluminum block): 47°c

- Base of pipe (inside aluminum block): 37°

- Top of pipe (after all the radiator fins): 27°

- Room : 17°

- Peltier cold side (to fridge): 7°

If the unit was turned off, the cold side (there was some

ice

in the

tray in the fridge) dropped to 5°. Needless to say, all this was

pretty

unsatisfactory and I had to reconnect the fan and heatsink (which gave

good performance:

- Heatsink: 27°

- Room: 17°

- Cold side: -1°. (The cold side would get no colder until it

froze all the water in the ice tray.)

However, I noticed in the days that followed that the unit

drew somewhat less current and cooled more slowly than before I started

- effects of poorer heat transfer. This would mean that I didn't get

the Peltier modules seated as well as they were before the experiment,

which in turn shows how critical it is to transfer the heat and cold

from the modules as effectively as possible. But I digress...

The first problem, before even getting to the evacuation,

was how on earth a pipe clamped into a hole inside an aluminum block,

and even the liquid inside that pipe, could have a temperature so much

different than the block. The heat transfer should keep them virtually

the same temperature. I took it apart and stuffed in aluminum foil,

added heatsink compound, and then tried copper foil, almost to no

avail. The copper foil helped a bit, reducing the difference to about

7°. Unfortunately the diagonal hole in the aluminum for the pipe

wasn't very smooth and even.

Perhaps I should get a copper block to put on the hot side

of the peltiers, and solder copper fittings to it to physically and

thermally connect the radiator pipe to it. Or sand the block down some

and re-drill the hole. But I would need a plan for getting it smoother

this time. The trouble is trying to hold the block on an angle.

Then there's the seemingly poor vacuum. Like last time,

pipe temperature was well up into the 30 s celsius before any small

'tings'

of steaming were heard. As I think about it, when I was trying to

evacuate the pipe, the propane torch didn't have as strong a flame as

usual -- likely the slower steam makes less vacuum.

This led to the thought that maybe if I want a better

vacuum I should use a powerful naphtha gas torch and have the steam

whistling out much harder before closing off the end cap. (And then get

the torch away quick before bursting the pipe. And with better vacuum

maybe I could use plain water.)

On January 3rd the friend who had given

me the two naphtha gas torches (quite some time ago) came over, so I

had him

go over how they were supposed to work and what I should expect.

Neither of them did what it was supposed to, but assuming I can adjust

the better one properly, I should be able to get a whopping powerful

flame to do

the pipe evacuations with. Then maybe the vacuum will be good

enough that the liquid will boil at or below room temperature. Maybe

even with plain water.

Evacuated tubes should work. It's not just the fridge - I

don't want to start in on the heat pumping for house and EV heating

until - and probably unless - I have them working well.

Electricity (Energy) Production

Lambda Ray Collector

Lambda Ray Collector in Bread Pan with

Nickel-Brass Lid

Lambda Ray Collector in Bread Pan with

Nickel-Brass Lid

- to contain any dangerous radiations or energies.

As electric rates here have just been jacked up 24%, the race is on to

find

truly effective alternatives to the offerings of the government, the

utility, and the 'for profit' "Independent Power Producer" companies.

Four big solar collectors haven't made much of a dent, winds here are

generally light, and I don't have waterfront or waves even if I was

permitted to set up an ocean wave power station across a beach, which

is doubtful. Geothermal would also seem to be out, and again a

woodstove thermoelectric generator would be a small dent in the total

bill.

That leaves lambda rays, powerful unseen energy coming

from across the sky and all around us, and magnet machines.

I can't pretend to know with any clarity myself what

happens inside a lambda ray collector. As per the table last month,

lambda rays are the only radiant energy energetic enough to produce "a

stream of particles and antiparticles" on interaction with matter.

But what exactly does this mean? The wires or other parts

of the collectors don't disintegrate as far as anyone has reported, so

from where are these particles derived?

One day, Physicist Jakovak came over and spent a couple of

hours in dissertation introducing me to the incredible world of

subatomic particles, of which there seem to be dozens if not hundreds

of types, and their interactions. There are indeed aspects of reality

undreampt of in my philosophies!

According to Jacovak,

apparently out of "empty space", electrons and positrons (positively

charged electrons) can form in pairs. This is apparently the potential

"vacuum" energy Fineman spoke of when he said the energy in an empty

cup could boil all the water in all the oceans of the world.

So perhaps the "vacuum energy" theory is right... but it's

brought from potentiality into actuality by the lambda ray energy. In

the

magnetic field of the coil, the electrons and positrons spin off in

opposite directions, preventing them from canceling each other and

returning to 'potential'. The needle-hook wire (below - see

developments December 18th onward) looped around one end of the

collector loop wire may have something to do with separating them and

developing a large voltage across what ought to be nearly a short

circuit coil of wire - just one to four turns.

Gold or Silver?

The file on the collector I started copying and the

experiments leading up to it found solder was better than copper for

collection coils, and mentioned that aluminum doesn't work. The solder

might work better than copper either because it had higher resistance

and so allowed a higher internal voltage to build up within the wire

(in which case the higher voltage was a negative thing), or because it

actually "collected" the rays' energy better.

If it was the latter as I started to suspect, it was

probably because the elements, tin and lead, were denser with high

atomic weights. That fits

with aluminum, being very undense and atomically light, "not working"

(or perhaps working

quite poorly). And denser elements might cause the rays to interact

with matter proportionally or disproportionately to the density - for

example, maybe by the square of the density. Or maybe it's proportional

to the atomic weight. Put together, there's more, bigger nucleuses to

hit in less space. For dense elements that also conduct electricity

very well, silver and gold should be good choices. For conductive

elements of high atomic weight, there's nothing else half as good as

gold. Understandably, gold wires weren't one of the types tried. If it

works

best as I suspect, it's not going to make the collectors any cheaper!

Silver would be more affordable since the amount of wire in the

collector coil is small. But it may be that all that's needed of the

heavy metal is a needle point near the collector wire. Even gold would

be affordable for that... at least at its current manipulated low price.

I started thinking that if they were getting a kilowatt

from a simple "moebius strip" loop of double wire that was probably

poorly efficient, the energy must be

even more concentrated than I thought. I started thinking a collector

"plate" such as Tesla had used would probably do better in a very small

space. I started thinking in terms of something like a "bread pan" for

the plate, and also as a cover for the unit to keep the energies safely

inside.

A friend wanted to get together and work on the energy

collector with me. This devolved down to looking at some info on line,

especially looking up some Brazilian units (below), and I borrowed a

signal

generator from him to make square waves up to 2MHz. This was the

missing piece to activate my unit. The Brazilians' high performance

unit appeared to be about the simplest design yet, with just one

control coil and a couple of loops of wire for the capture coil, and a

ground wire not quite touching the collector coil at one end. They

appeared to be using ordinary transformer laminates - which another

patenter, Tom Bearden, claimed wouldn't work. There were a couple of

puzzling features and their patent drawings might not tell the whole

story.

On Saturday the 14th, some friends and I sat around

discussing the energy and devices. The feeling of the others was that

since it sounded like there actually was energy there... they would

believe it when they saw it. That's a good step up from prejudiced

rejection, and stems from having a rational explanation of what such

radiant energy is and where it comes from. But I realized I would have

to demonstrate working energy collection, preferably very easy to

replicate, before most people would give my words much credence.

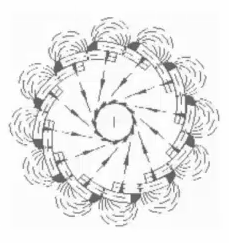

So now we have one patented design using unspecified

nanocrystalline material, and another using transformer laminates. Like

the crescent-moon shaped magnets required to make the Howard Johnson

magnet machine, neither of these core types are available for purchase

from any source I'm aware of. What sort of cores could be had? Of

course there's air core like the unit I started copying. Then, I have

the 2" x 1" toroidal iron powder cores that I wound the control coils

from. If I wound a couple of loops of wire around in the "regular"

direction through the center of the toroid, it should meet the

essential requirements of two magnetic circuits at right angles to each

other, and the frequency (around 100000 Hz is the plan) should be

plenty high enough to work with the low permeability of the iron powder

cores. And it would be very simple.

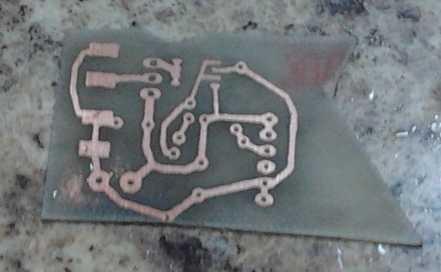

On the night of the 17th I wired up my

newly simplified circuit, and on the morning of the 18th I tried it

out. The driver board didn't work. Aside from an easily corrected

wiring mistake, somehow I had the P-channel and N-channel pre-driver

mosfets reversed. The mistake was elementary. I

must have been working too late at night when I made the schematic! The

miniature SSOP packages were the one component that would be very hard

to rewire without making a whole new circuit board, and I spent the day

designing and making a new board.

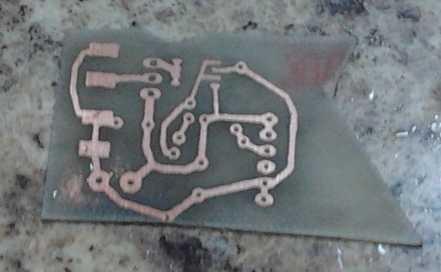

The thin glossy magazine paper jammed in the laser

printer, and after finally clearing it out, the second sheet wrinkled

up. But I had put 6 images of the board on it, and 3 of them were okay.

Again the "really fast" PCB etching techniques espoused on

web sites looked to take 1/2 hour and more - even with new etchant

chemicals. After 15 minutes of rapid agitation at elevated temperature

with no evident results, I threw down the gloves and safety glasses

and quit in frustration... and forgot all about it for a couple of

hours. When I came back a good part of it was etched through. I left

again and had supper. When I came back it was pretty much done. I

decided that was the way I'd etch PCB s from now on - just let it take

its own time, and hope I didn't forget about it for too long. It's

possible my circuit board (a big sheet of single sided epoxy board

someone gave me around 1980) has a thicker copper layer than the boards

people claim they're etching so fast.

Commercial Units?

Someone sent

me a link to a Brazilian

company - inventors Barbosa and Leal - that is evidently offering a

commercial unit

- or,

trying to... their machines were seized. As

usual not knowing the source of the energy, they say it captures

"Earth electrons", but it doubtless is collecting lambda rays which get

the

electrons moving. (which is pretty similar in principle to the

photons moving the

electrons in a solar collector.) They look very well made. And I

appreciate the energies being kept inside a box! Their units make 6, 40

and 282 kilowatts.

Someone sent

me a link to a Brazilian

company - inventors Barbosa and Leal - that is evidently offering a

commercial unit

- or,

trying to... their machines were seized. As

usual not knowing the source of the energy, they say it captures

"Earth electrons", but it doubtless is collecting lambda rays which get

the

electrons moving. (which is pretty similar in principle to the

photons moving the

electrons in a solar collector.) They look very well made. And I

appreciate the energies being kept inside a box! Their units make 6, 40

and 282 kilowatts.

http://www.libertariannews.org/2013/11/05/brazilian-firm-goes-to-market-with-free-energy-generator-capable-of-powering-two-average-size-houses/

(English news article)

http://energiauniversal.eco.br/

(Portuguese)

Also, on youtube there's a video of the inventors demonstrating the

units (Portuguese) and the news article (English) mentioned above. (I

don't have the links handy.)

On the 11th I wrote for more information. That evening I

even considered buying one of their machines, but they were quite

costly. The next day I looked up their

first patent. The actual workings weren't that different from some

others, but there were a couple of odd things. I can try a couple of

their twists in my experiments and see how they work out. I have

received no reply. They are running into flak, to say the least. I

fear for their safety and liberty.

The Free Energy Book

In my searching I ran into a link to an updated web

copy of the free energy book that I already have, which has added the

Brazilian devices, with some explanations of the patents, to the many

other circuits that presumably capture lambda rays. I can only

wince at the descriptions of "capturing electrons from the Earth" or

from the air "by induction" through essentially unconnected wires.

Obviously the energy is coming from lambda rays. In fact, I think the

'unconnected' "electron capturing" wires are

why they're getting such great results (I assume that they

actually are): http://www.free-energy-info.tuks.nl/Chapt3.html

In fact, I suspect that Tesla's needle point serves the

same

function and will work better than the

loop of ground wire around the collection wire. I think that's a

'connection' that'll improve the performance. Now... would the gold be

limited to the needle point, or should the whole collection wire loop

be gold? Gold at the point where the lambda rays interact with matter

(wherever that is) could be a big boost.

Initial Test

The etched PCB

The etched PCB

After

designing and making the new PC board on the 18th,

on the 19th I hooked up the wires and tried it out. I

hooked up a power supply, a signal generator (TTL level square wave),

an oscilloscope on the control coil, and a 400W electric heater (36

ohms) with a

voltmeter across it set to AC. It initially drew no appreciable

current, but if the drive waveform was on at all, it drew 5 amps almost

regardless of signal frequency (ouch!), at only about 7 volts supply

(35W - the

supply was running current limited). I tried various signal frequencies

from 1KHz to 1MHz. Nothing seemed to happen. Coil voltages went up to

about 100 volts, but dropped off rapidly when the signal went above

100KHz or so.

After

designing and making the new PC board on the 18th,

on the 19th I hooked up the wires and tried it out. I

hooked up a power supply, a signal generator (TTL level square wave),

an oscilloscope on the control coil, and a 400W electric heater (36

ohms) with a

voltmeter across it set to AC. It initially drew no appreciable

current, but if the drive waveform was on at all, it drew 5 amps almost

regardless of signal frequency (ouch!), at only about 7 volts supply

(35W - the

supply was running current limited). I tried various signal frequencies

from 1KHz to 1MHz. Nothing seemed to happen. Coil voltages went up to

about 100 volts, but dropped off rapidly when the signal went above

100KHz or so.

Roughly following a design of the Brazilian device, I had

clipped an alligator clip leed onto one side of the collector coil. The

coil wire was insulated so there was no electrical connection. Normal

circuit design would say that little effect should be expected almost

regardless of where the other end was connected. The other end

went to "ground" on power supply. But the DC coil supply was

ungrounded, floating.

I now moved the connected end from "ground" to "minus" on

the power supply. This time, when I turned it on and swept the signal

frequency up, suddenly the whole assembly seemed to start squealing at

the signal frequncy, and the heater voltage for the first time came to

life, reading 32 volts.

After two tests of a couple of seconds with

about the same results, the power transistor feeding the coil went up

in smoke. I had definitely been driving it to its limits,

according to its datasheets, and beyond as it heated up.

It was an amazing change -- from reconnecting a wire with

no

actual connection at the other end! When I calculated the power to the

heater at 32 volts, it was just 28W, and I was feeding the coil driving

circuit with 35W, so it can't be claimed that I'd got more power out

than in. But it had been using 35W in all the previous tests as well -

and there was no way to couple that input energy to the output. So

there seemed to be some extra energy arriving from

somewhere. It seemed pretty promising for a first try.

I didn't have a chance to replace the transistor, use more

turns of the coil to lower the current, change the "unconnected"

aligator clip to a needle point, and try again before I got the flu. In

a way, the signal generator is a problem, because I really want to

drive the coil with a narrow pulse rather than a square wave. The pulse

would have the same sharp transitions and the driver would use far less

power. Perhaps a 555 timer as a pulse generator would be simpler than

wiring and programming a microcontroller.

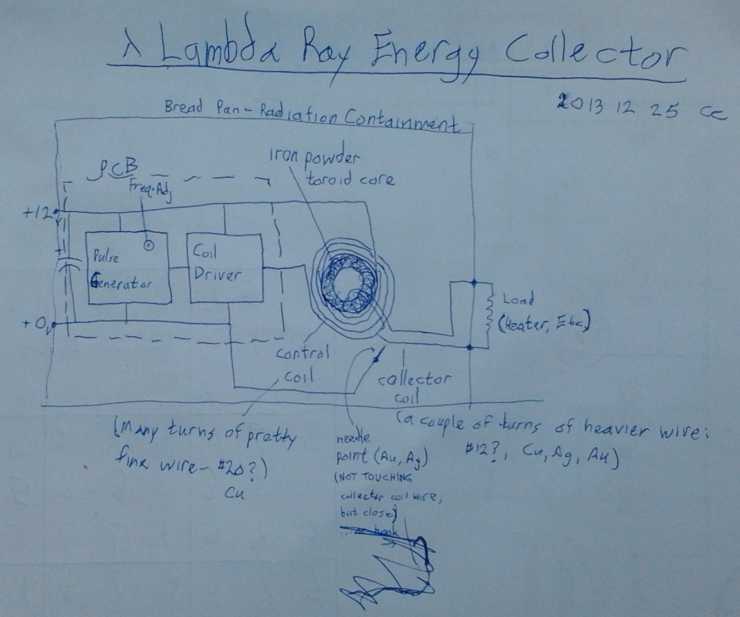

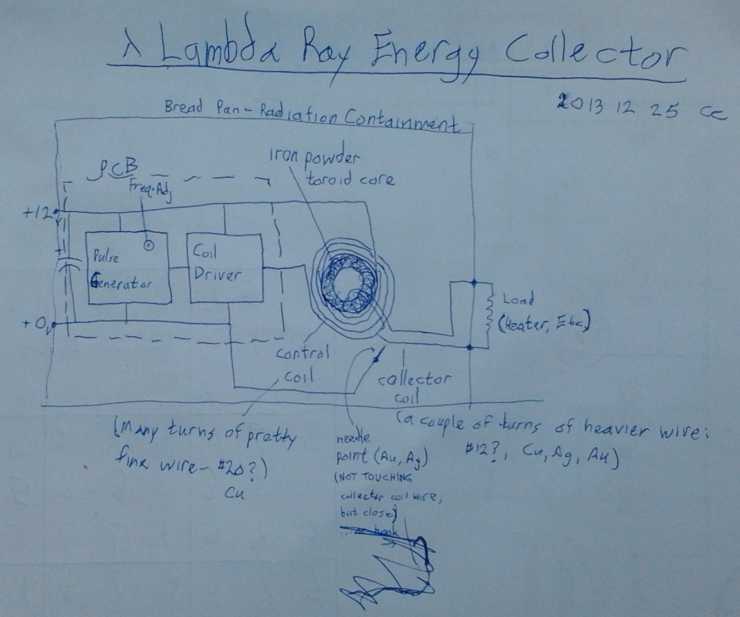

On Christmas day I drew by hand an overall circuit diagram

of the

lambda collector for version 3:

I think the scribbled out 'hook' ground wire

with sharp point, wrapped

I think the scribbled out 'hook' ground wire

with sharp point, wrapped

around the collector coil wire at one end of the coil, is probably best.

Winding the collector coil as a turn or two around the outside of the

donut,

and the control coil through the center of the toroid, opposite to the

arrangement shown, would probably be better.

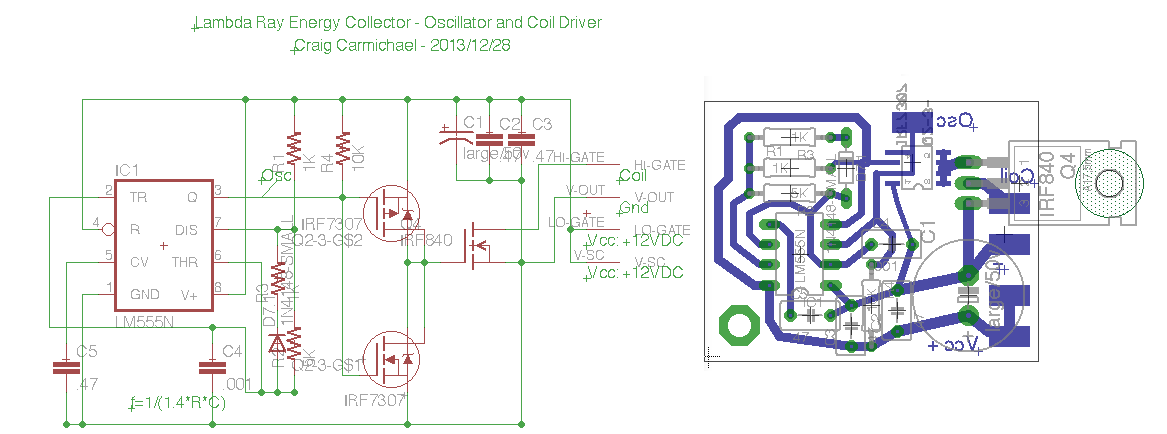

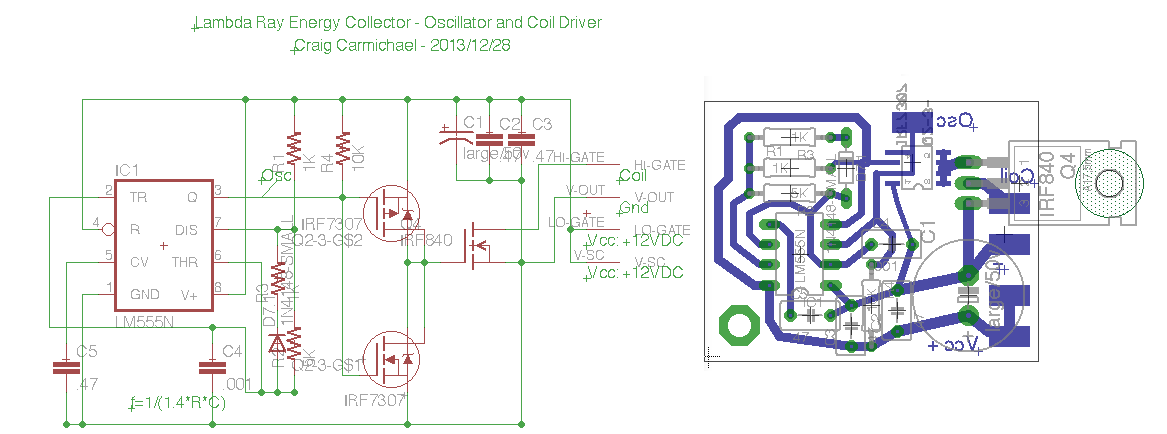

On the 26th I looked up 555 timer circuits and found the

one I'd used for motor controller PWM. I modified that to generate

narrow pulses that wouldn't use so much current and designed a circuit

board complete with all the electronics in Eagle PCB. (what a great PCB

CAD program!) On the 27th I tidied up the layout and made the board. On

the 28th I put the components on the board and started wiring it all

together, but it was a considerable job and I didn't finish before

having to do other things.

Version 3 with built-in pulse generator

Version 3 with built-in pulse generator

One important assembly job was to make a top cover for the

bread pan I had elected to use as an enclosure. I strongly suspect that

dangerous radiations are released in all this process, and that there

should be a metal shield between the collector unit and any human being

in the vicinity. (In the 'version 2' tests I had set it up high and

ducked below it.) After all, the process starts with rays

shorter than

dangerous gamma rays and x-rays, and descending down the spectrum, even

infra-red or "microwaves" (centimetric rays) can cook flesh. I used a

6" x 12" piece of #28 nickel-brass and folded the edges to fit it over

the

top of the bread pan. At the back end I cut a piece to fold up as a gap

for wires to enter.

I made it positive ground for the 12 volt supply in order

to connect the mosfet drain electrically to the bread pan. After

sorting out a few wiring problems, it still didn't seem to collect any

energy. But I didn't have time to continue, and there's still coil

driving oddities to figure out and then more things to try.

Magnet

Machines

In attempting to look up designs for radiant energy

collectors, I found a site, www.magnetmotorhojo.com

, where they offered a book with detailed instructions for making

Howard Johnson's patented magnet machine for about 50$. Since this has

been said to work, I decided to order the book. I might have eventually

reinvented this wheel, but if others already knew how to make one,

probably better than what I'd have come up with, why not use it?

Once I had paid, the book

was in PDF for immediate download, and there were four instructional

videos on turning a regular motor into a magnet machine.

If the book convinced me of one thing, it was that

Johnson's design probably worked with no arms or cams, just magnets

fixed on a rotor and fixed on a stator. The main trouble was, probably

for

everyone that wanted to make one, that the rotor magnets were a weird

shape, something like a cylinder having a "crescent moon" cross

section. I've never seen such a shape for sale, so unless you can make

your own magnets, the otherwise simple design seemed rather unmakable.

Could such a simple design actually work? Johnson did

get a patent on it. As I hear the story (second hand), the patent

office said they would give him one only if his machine was still

running in their office after a prolonged period - at least weeks if

not months. It was. It ran for a decade in the patent office until the

magnets weakened too much. There has been talk that the machine was

powered by the weakening of the magnets. But a supermagnet (again

according to what I hear) is magnetized by a pulse of current through a

coil, to whit, a million amps for a microsecond: one amp-second of

energy. That that energy could, by its 'dissipation', run a mechanical

unit for weeks, months and years before expiring is harder to believe

than the explanation in the patent. And there are magnet machines and

rumours of magnet machines that seem to have no moving parts besides

their rotor.

I decided to order some small, thin magnets to experiment

with. The big, thick ones I've been using (Electric Hubcap Motor

magnets) have such a great depth of field it's hard to move them

mechanically in and out of magnetic interaction. I'm still not entirely

convinced it can be done without that. Johnson's machine might have

attained some mechanical resonance, "slop" or "play" in the mechanism,

that moved his magnets fractionally up and down, or twisted them, at

just the right moments.

Troy Reed's first giant motor on youtube had some sort of

"crank rods", but his second, much more compact one, didn't appear to.

I

now intend to find out, one way or another!

A first stop was to check out chapter one of The Free

Energy Book again (http://www.free-energy-info.tuks.nl/,

where

many

designs

are

shown. The author says it's very hard to get a magnet

machine to run without moving parts but that it can be done. Evidently

it's much easier to get one with moving parts going. Could I be right

about the "play" and "resonance"? Perhaps the author was right that

ones with a coil to push the magnet through sticky spots is a simpler

choice, and that the coils can be energized with electricity generated

by the unit itself. Or perhaps it really is true that no energy can be

gained -- but there are an awful lot of stories of successful units.

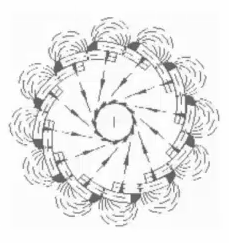

On the other hand, a diagonal arrangement of magnets seems

somewhat promising to create a 360° imbalance in one direction. I