Turquoise

Energy Ltd. News #73

(February 2014)

Victoria BC

by Craig Carmichael - posted March 5th, 2014

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Spotlight:

Graphite Foam & Graphite

Foil Yields Good NiMn Battery Performance (see Month in Brief,

Turquoise Battery Project Report)

Month In Brief

(Project Summaries)

In

Passing

(Miscellaneous

topics, editorial comments & opinionated rants)

* Economic Collapse Nearing? Ready?

Electric Transport - Electric

Hubcap Motor Systems

* Centrifugal Clutch for Planetary Gear Torque Converter?

Other "Green" Electric Equipment Projects

* LED Lighting: New 12V driver boards; Emitters performance update:

degrading - higher voltage over time

* Peltier Modules Heat Pump

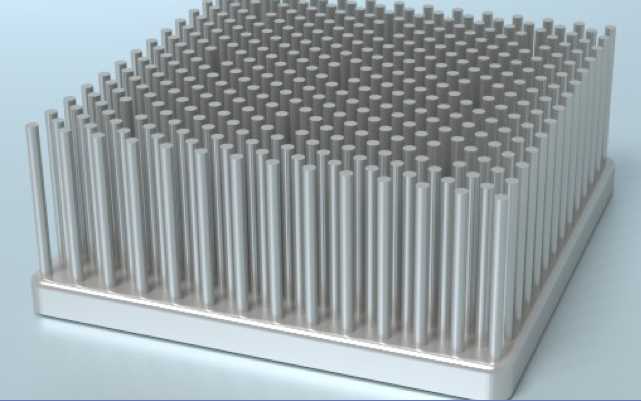

* New design "pins" heatsink

* Graphite as heatsink material

Electricity Generating

* Magnet Motor - magnet twisting idea

Electricity Storage - Turquoise

(NiMn) Battery Project etc.

* Graphite felt, graphite foil

* New Electrode Flat Compactor

* New cell "OJC1" with graphite felt & foil PERFORMS - 100 mA/sq.cm

current density!

* Performance deterioration

* Zinc current collectors gradually corrode

* Graphite foil negode current collector: Doesn't bubble hydrogen and

cause self discharge!

* Tentative conclusions: this cell is workable, should last a long

time,

next cell should be

better.

No Project Reports on:

Lambda Ray Collector, Pulsejet steel

plate cutter, CNC Gardening/Farming Machine (sigh, maybe summer 2014...

2015?),

Woodstove/Thermal Electricity Generator (will probably abandon),

evacuated tube heat radiators, individual EV

battery monitor (will probably cancel... well, maybe).

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers -

Ersatz 'powder coating' home process for

protecting/painting metal

- Preliminary Ni-Mn Battery Making book

Products Catalog:

- Electric Hubcap 4.6KW BLDC Pancake Motor Kit

- Electric

Caik

3KW BLDC Pancake Motor Kit

- NiMH Handy Battery Sticks, 12v battery trays & Dry

Cells (cheapest NiMH

prices in Victoria BC)

- LED Light Fixtures

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

February in Brief

I determined that I wasn't going to work on just

one project in February. My first thought was to pick four and spend a

week on each one. Then again, it was already the 5th so the first week

was largely gone.

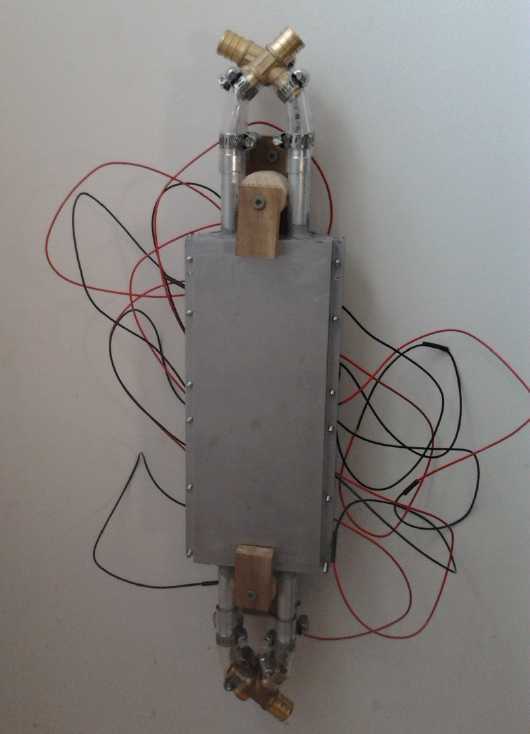

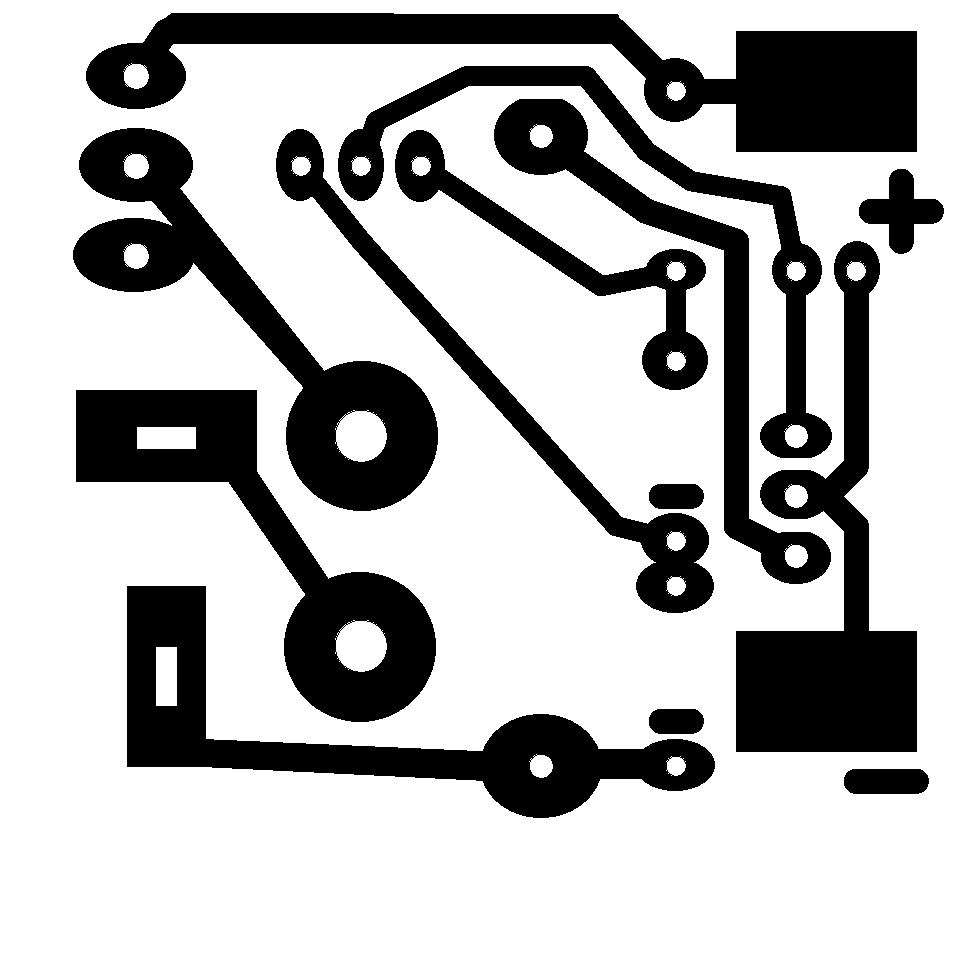

I spent that day mounting and connecting a peltier modules

heat pump that would

use water circulation and, having done most of the work previously

before being sidetracked by trying to make evacuated pipes, got as far

as a test. The water didn't circulate fast enough by convection, and

the warm side radiator didn't cool enough without a fan - or even with

one unless the air was to be ducted across the radiator fins. I thought

maybe regular heatsinks with fans - like on the fridge - might after

all be the best way to go. I ordered three heatsinks of a new design,

pure aluminum with round posts instead of fins. I tried one on the

fridge and it wasn't as good as the first one with closely spaced fins,

and they cost more. I can compensate with faster fans for testing, but

it was disappointing and rather costly.

Heat Pump initial experiments

Heat Pump initial experiments

complete with filler funnel and drip tray

The next day I

started in on a centrifugal clutch for the

Chevy Sprint. The planetary gear torque converter had essentially been

working in September 2012 except for the flat belt and clutch drive

component. This time I thought would try a chain again, and the

centrifugal

clutch. It sounded simple enough, but soon I found it wasn't going to

be done without some challenges. The centrifugal clutch units available

had sprockets for the wrong size chain. I did some turning on the one I

bought so I could weld a #50 chain sprocket onto it. Then, they

were too wide to fit on the shaft

without modifying the mounting box and making a longer shaft, and I set

it aside. That's probably what stopped me the last time I thought of

this, but I had forgotten about it.

On cars, last month I saw another in-wheel motor and

mentioned the problem that the unsprung weight of motor mounted wheels

is bad

for vehicle handling, and that a better arrangement for a new car was

"wheel motors" mounted inboard and connected to the wheels by CV

shafts. The shafts would hardly affect the efficiency. Now I've found

another car design doing it that way:

[citroen-ds3-electrum.gif]

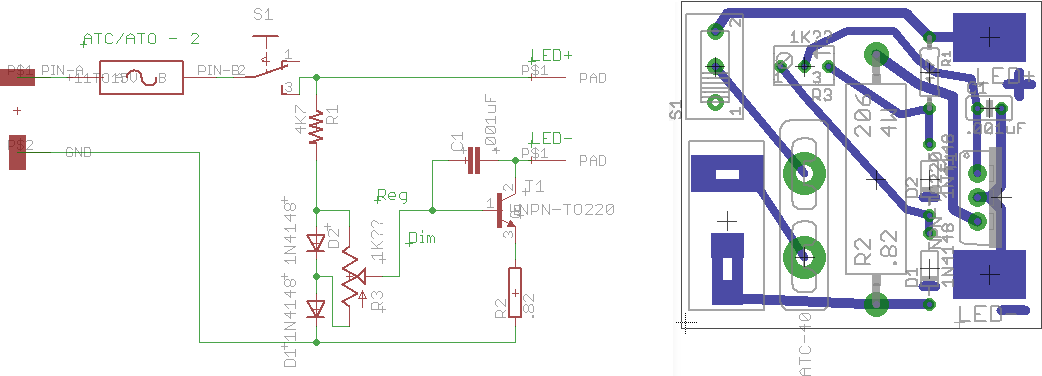

Next I did a

constant current power supply circuit design and

board for LED lights. I liked the flat panel lights I bought last month

and thought they would be great to produce, but an updated constant

current supply was the next thing I needed to make any LED light if it

was to run on 12-15 volts rather than strictly on 12.0 volts, LED s

being

quite particular about their current and voltage. Given an output

voltage not very far below the input, a linear regulator can be as

efficient as a switching regulator - ideally even better.

Next I did a

constant current power supply circuit design and

board for LED lights. I liked the flat panel lights I bought last month

and thought they would be great to produce, but an updated constant

current supply was the next thing I needed to make any LED light if it

was to run on 12-15 volts rather than strictly on 12.0 volts, LED s

being

quite particular about their current and voltage. Given an output

voltage not very far below the input, a linear regulator can be as

efficient as a switching regulator - ideally even better.

At the same time,

when I tested it using the 3 Cree XM-L-H emitters in series I had

removed from the kitchen, I discovered that the original voltage of

about 2.9 volts per emitter had risen - had degraded - over 2-1/2

years,

and they now took a 3.5v + 4.0v + 3.5v = 11.0 volt supply to obtain 1

amp and their 'normal' brightness, instead of 2.9 + 2.9 + 2.9 = 8.7

volts. This was somewhat disconcerting. They may have been running

rather warm to hot in the kitchen ceiling, and I've switched to

different emitters in more recent lights, but the

idea of 4 such emitter in series (11.6v when new) to attain 100 lumens

per watt efficiency at 12 volts now seems unattainable over time, even

tho

they'd do it fine at first. I'd better measure the other '11-12 V'

emitter lights I've been using and see how they're fareing over time.

I have some smaller emitters suitable to spread a number

of over a larger area to make flat panel LED lights. The heat in that

design is well spread out and hence the emitters can run at their

coolest.

I also found the first magnet motor rotor I made in

January

would try to twist and turn after all... if the axle was anywhere but

in the center, which is of course exactly where it was. That gave me

something that seemed better to go on, and

then I figured out how I could use the spiral stators I'd made with new

axial flux rotors. On the 13th, after trying again to fix my 3D printer

without success (but with some progress this time), I started in with a

spreadsheet to calculate the G-Code co-ordinates to make said rotors

with the CNC router.

However, mid month I felt I had to start on the long

overdue project

of removing an old brick chimney from my house. Many of the 1100

remaining bricks

in the 22 foot stack, weighing around 3 tons, could be loosened and

removed by hand, and it

would have made mincemeat of the the whole north side of the house and

buried

anyone in the vicinity in any sizable earthquake. With all the reports

of earthquakes and volcanoes in recent times and the ever-present

threat of "the big one" on the BC coast, it seemed only prudent to

dismantle this time bomb. Unfortunately that left the machine shop and

the

electronics

lab, where the chimney ran through, in a dusty shambles until the end

of the month and beyond.

NiMn Battery Advance: Practical Cells!

The month's big news is: Better performing NiMn batteries.

Having received from "SGL Group - The Carbon Company" samples

of porous graphite felt ("Sigracell") and graphite foil ("Sigracet")

especially made for batteries (albeit for liquid electrolyte "redox

flow batteries"), I went to work on using them in a NiMn cell on the

20th.

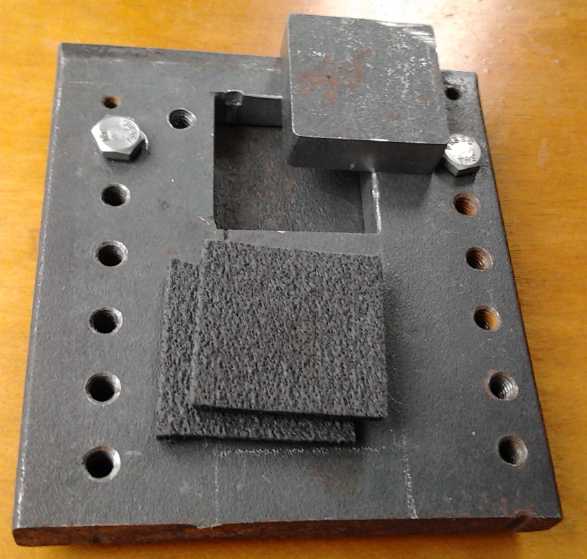

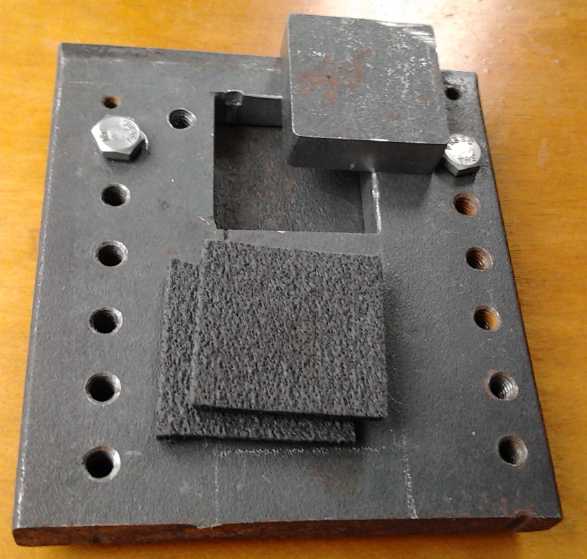

First I had to make an electrode compactor that compacted

on the flat, since edge compacting was out when any sort of

"dimensional" material was to be incorporated instead of just powder. I

made the box 40x40mm, requiring (according to only marginally

applicable calculations) about 10 tons of optimum pressure. The 64x64mm

electrode size would have required 26 tons - more than my press. 10

tons seemed like lots to aim for, and allowed headroom for trying 15 or

more to

see if that worked any better. I used a piece of steel big enough to

hold two electrode boxes in case I wanted to speed "production" up

later.

First I had to make an electrode compactor that compacted

on the flat, since edge compacting was out when any sort of

"dimensional" material was to be incorporated instead of just powder. I

made the box 40x40mm, requiring (according to only marginally

applicable calculations) about 10 tons of optimum pressure. The 64x64mm

electrode size would have required 26 tons - more than my press. 10

tons seemed like lots to aim for, and allowed headroom for trying 15 or

more to

see if that worked any better. I used a piece of steel big enough to

hold two electrode boxes in case I wanted to speed "production" up

later.

For the posode I infused mixed

Monel:Ni(OH)2:KMnO4:graphite:Sm2O3

powder into 3 layers of graphite felt by vibration and tapping in a

plastic jar. I wetted the surfaces and put

them in the box. The felts, initially over half an inch tall, squashed

down to an electrode about 2+ mm thick. The felt added about 15% to the

electrode weight, but since it also made the cell work better than

any previous cell, this was well worth it.

The negode was the same as previous ones, in fact using

some left over powder mix. The 2.6mm or so thick

electrode would have had somewhere between 5 and 10 amp hours - perhaps

5 to 10 times as much as the plus side, and it took such a long time to

charge up I thought for some hours the manganese wasn't holding a

charge

at all.

This small cell sourced at least as much current as the

previous larger ones, providing up to 100 mA/sq.cm of electrode

interface area instead of maybe 20-30. That's well up into acceptable

commercial range. There was then a performance drop, but I think it was

associated with electrode expansion (and hence loss of conductivity)

from taking everything apart 2 or 3 times and replacing the negative's

current collector. I have plans for improving construction of the next

one, and now I know that graphite current collectors work fine in

both electrodes, so I won't be unclamping the electrode stack to try

zinc

again, so I'm expecting good performance without deterioration. And in

the first days of March, further load tests showed improving

performance of OJC1 with charging and cycling, which will hopefully

continue.

NiMn Ointment Jar test Cell "OJC1"

Another

improvement of the new cell was the 'graphite

foil'

current collectors. They contain a polymer (making them actually some

sort of highly conductive composite material) and seem impervious to

anything in the battery, and while still brittle, the terminal tabs

don't break off with the slightest provocation and are still attached.

Regardless I coated

them with osmium doped acetaldehyde

to protect them from oxidation and improve conductivity.

Another

improvement of the new cell was the 'graphite

foil'

current collectors. They contain a polymer (making them actually some

sort of highly conductive composite material) and seem impervious to

anything in the battery, and while still brittle, the terminal tabs

don't break off with the slightest provocation and are still attached.

Regardless I coated

them with osmium doped acetaldehyde

to protect them from oxidation and improve conductivity.

In addition, I found that they didn't cause hydrogen

bubbling and consequent self-discharge of the negode. This let me use

them in both electrodes and ditch

the zinc current collectors, which seem to corrode away to nothing

where they're not near manganese, especially near the top of

the liquid, so they usually end up leaving

the negative terminal post detached from the rest of the electrode.

(I'm still not sure why this should happen, but it does. Maybe they

form ZnH2 rather than an oxide?)

Next I'll make a new cell and add graphite felt to the negode as well

as to the posode, and see how much that helps. These new graphite

materials are changing the picture, and in whatever time I find

to pursue the project, I don't expect to stop now at least until the

small "ointment jar" Ni-Mn test cells are driving respectable loads in

the 2.4 - 2.2 volt range and holding respectable energy and amp-hours.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Economic Collapse Nearing?

If one is watching, one senses the deteriorating world

situation in many areas and on many levels. It seems to me food prices

are rising more rapidly month over month, while the majority everywhere

is in debt or is having increasing trouble making ends meet. Sales at

most other stores (even Wallmart) are increasingly dismal, production

sits unsold and inventories build up, and shipping volumes continue

dropping. How much longer can this go on? a month? (probably) a year?

(hmm...) two years? (I doubt it.)

World

population is the highest ever and the crop year of 2012 was disastrous

virtually worldwide. I didn't notice the topic in the news in 2013

except for someone's account of seeing dirt instead of corn as he flew

over the US midwest in July, California droughts leading to crop

failures in that major food exporting state, and citrus trees getting

snowed on in the south. The last couple of winters have been bitterly

cold in much of North America and harsh in various ways in various

other places. The world's food supply must be getting rather thinly

stretched.

Protests, riots and insurrections are occurring

in more and more cities and countries as conditions worsen. 100 million

Americans aren't working - 1/3 of the population. Europe is surely no

better. And yet, the majority

don't seem aware that anything is badly enough out of kilter to worry

about it unless disorder strikes their own area.

Do you have some bags of rice and other non-perishable

food and garden seeds - the various things that you'll need -

stashed away for a lengthy hiatus in the distribution system? And fuel

to get where you need to go? Supply shortages might last 2 or 3 or 4

years rather than weeks or months, and will start with grocery stores

being emptied in a very few hours. Famines and epidemics are likely.

And the world "pyramid scheme" financial system is

teetering on the brink of the abyss. Do you have assets under your

personal control that won't vanish if all the so-called "zombie banks*"

suddenly

close one fine day (your safety deposit box will then become

inaccessible), impose low daily withdrawal limits, or if they do the

everywhere threatened "bail-ins" - stealing money from everyones'

accounts attempting to stave off collapse? Dr. Paul Craig Roberts,

father of "Reaganomics" in the 1980 s says that if you find your

dollars becoming worthless (even if accessible) and you go to buy gold,

there won't be any. Gold, silver coins and bitcoins (or other digital

currency?) are "monetary" assets to

trade with to acquire now.

As more than one person has said, being ready years too

early is better than a day too late. An advantage of starting to get

ready early is people start to remember gradually all the items they

haven't initially thought of. Toilet paper? Salt? Coffee? Have you ever

grown a vegetable garden? - you need a whole spring and summer to

practice. I doubtless started early a couple of years ago, but I

suspect it's no longer early.

And there are nations whose "leaders", rather than lifting

a finger to mitigate the situation or even to warn the public, are bent

on starting a war - any war - to distract attention from these problems

and cast the blame on the war, when they have made things so much worse

themselves. How many people will die violently or as an indirect result

of violence, eg, starve in refugee camps, for nothing? How can we stand

up to those whose duty is supposed to be to us and insist squarely "NO

MORE WARS!" before the whole environment is brutalized for thousands of

years or even destroyed by nuclear weapons?

The seeds of CHANGE have been scattered and the spores are

blowing in the wind, but they must be nurtured, fostered, directed, by

living

people in the years and decades to come to direct the change towards

building the utopia that this planet should be and will become -

sooner, or later, according to what people do during this fermenting

and formative time.

* "Zombie banks" or insolvent

banks includes pretty much all of them worldwide - including Canadian,

which were quietly bailed out with 114 billion $ of taxpayer money in

2009-2010! China too is in serious financial trouble.

Electric

Hubcap Motor Systems - Electric Transport

Planetary Gear Torque Converter (what, again?)

After reviewing a 2012 video again, I realized that the

planetary gear torque converter had performed okay... once the car was

moving. Once moving, the car could be kept moving, with a kilowatt or

so

of power. The part I had failed to get working was a clutch to engage

the system without stalling it. How could something so common as a

clutch have prevented success and left me trying another torque

converter system? Perhaps it was because I was trying to fit too much

into the box, a pre-made space that wasn't quite big enough.

I determined to would try again, and consider expanding

the 'transmission' box to give the clutch portion space away from the

converter gears portion if that seemed to be what was needed. But it

might not even be needed. This time I would try a regular V-belt

instead of the flat belt. The flat belt was theoretically better, but

standard belts and pulleys simply weren't available as they were for

V-belts - it had been just too many experimental, homemade things in

one go.

Then I thought of the other options: a flywheel on the

motor so it could start the car moving as the motor slowed... or the

centrifugal clutch idea again. The flywheel would need a longer motor

shaft with the flywheel on the other side of the motor, since there was

no room for one inside the box.

What had stopped me from trying the centrifugal clutch the

last time? Princess Auto had them. It turned out it was several things.

I had purchased one for #35 chain. On the 6th I tried to exchange it,

but there weren't any for #50 chain, only for lighter chains. Switching

the car to a lighter chain was probably unwise. The clerk thought the

clutch might be too light for a car whatever chain it had. I bought a

#50 "weld on" 15 tooth gear whose fairly large hollow center was

intended to be welded to a standard O.D. center piece having the

desired axle hole size. On the machine lathe I turned the center hole a

little larger so it fit onto the outer clutch piece right next to the

existing gear. Then I turned the teeth off the original gear since they

would hit the chain. The new gear would have to be welded on.

The next problem was that the clutch itself was a little

too wide to fit in. I would have to lengthen the shaft and move the

motor and the torque converter planetary gears over. Or I could

reposition the bearing assembly and turn the clutch around so it stuck

out the other way. That would still need a longer shaft, but it would

be easier to move the bearing assembly than the whole torque converter

and motor.

Finally, the clutches were designed to engage when the

motor hit about 2200 RPM. That wasn't going to happen with a 0-2000 RPM

motor driving the system and a torque converter gear reduction after

that. The retention springs would have to be removed and replaced with

much lighter ones to allow it to engage at maybe 50-150 RPM instead.

Herein lies my hope that the clutch isn't too light: there'll be much

less heat generated as it engages than at the higher speed.

(Is all this really easier than getting the flat belt

clutch system to work?)

When I looked over the unit carefully to figure out the

easiest way to do it, there didn't seem to be any simple way. I think

that must be what stopped me last time. Thus it

went by default into the "too hard" bin for now as the Sprint sits out

in the yard over its third winter.

Other Green Electricity Projects

LED Lighting: New 12V Nominal Driver

Boards; Emitter Performance Update

I have been wanting some new LED lights for some time, if

only for my own use. I'm short of them

after giving 3 or 4 of the LED lamps I'd made to relatives for

Christmas in 2012. Last month I bought two flat panel LED lights:

30x60cm, 30 watts, and 30x30cm, 17 watts, from Jim Harrington who had

purchased them from two different Chinese companies. The larger 30 watt

light (70$, at Jim's cost) is amazing - it's considerably brighter than

any of my

previous kitchen lights, including dual 4', 40W fluorescent tubes.

The

smaller unit (50$) seems much less than 1/2 as bright and was

disappointing after the first one. It was said to be 17 watts, but I

measured 13, explaining part of it, and it was "warm white" which

doesn't usually perform quite as well as fuller spectrum.

However where the large

one was 40V, the smaller was 12V and hence useful with the 12V solar PV

system as well as automotive, marine and RV systems in general.

From these I got the idea of trying my hand at making flat

panel LED lights myself. I purchased some smaller 2.9V, 300mA, 120

lumen(?) LED emitters to mount spread out for making more diffused

lights 3 or 4 months ago.

At

the same time, I didn't want to make more 12.0 V

lights with just a resistor for current control, which either would

draw

excess current and blow their fuse if fed, eg, 13 volts from a NiMH

battery or up to 14 volts from a running car or solar PV system,

or else would be rather dim at 12 volts.

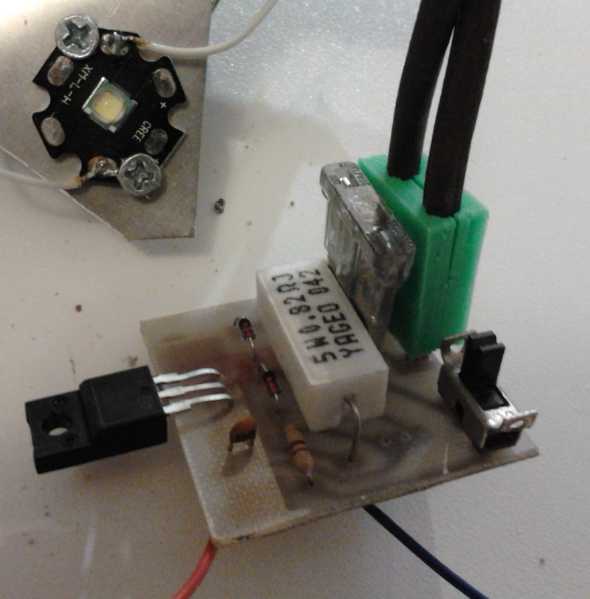

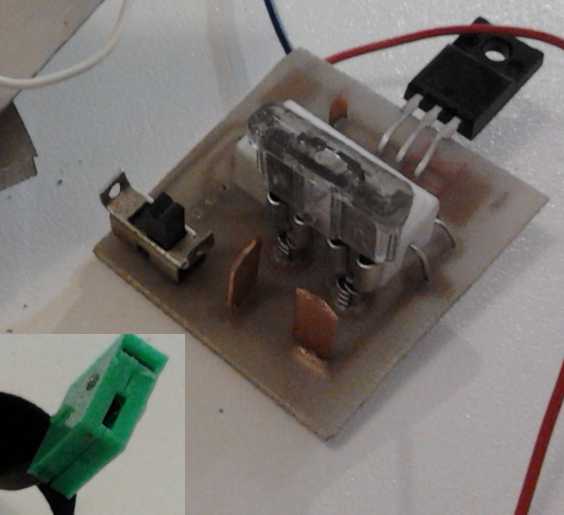

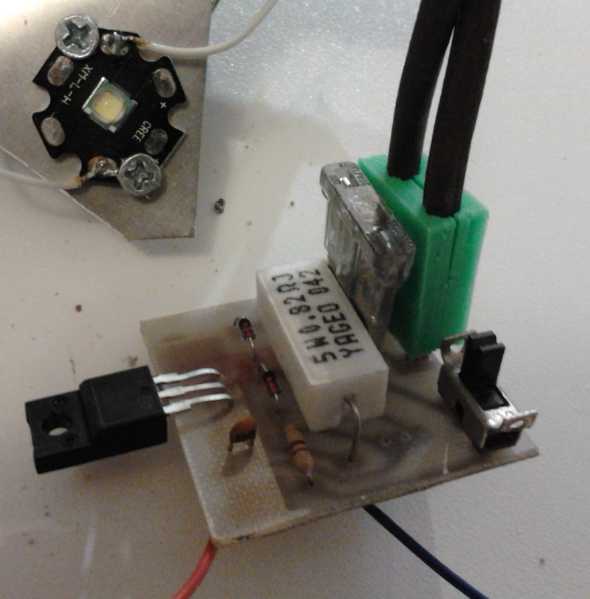

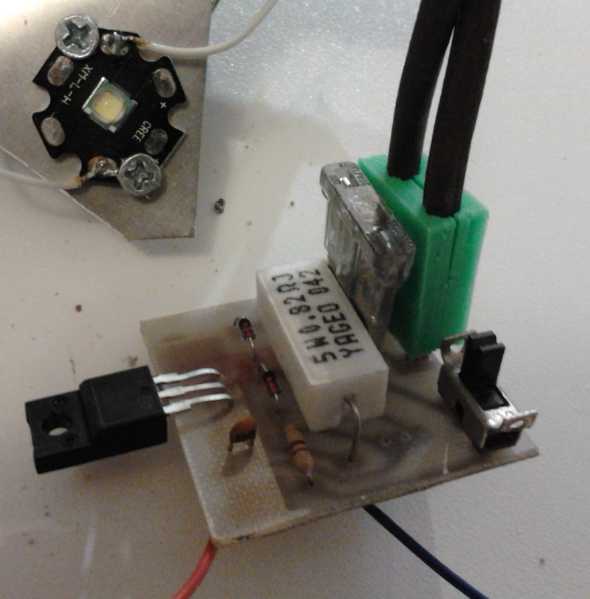

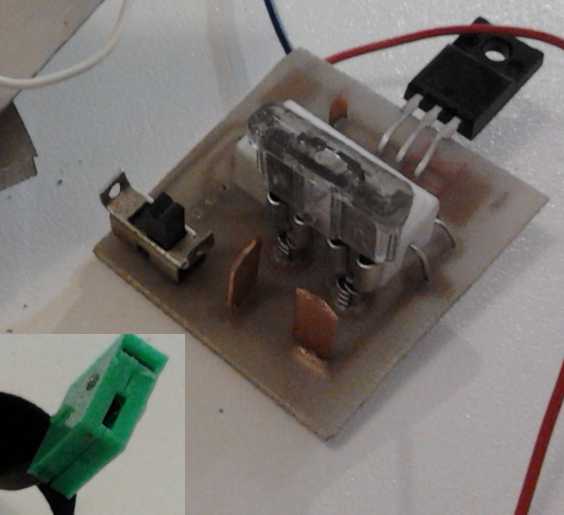

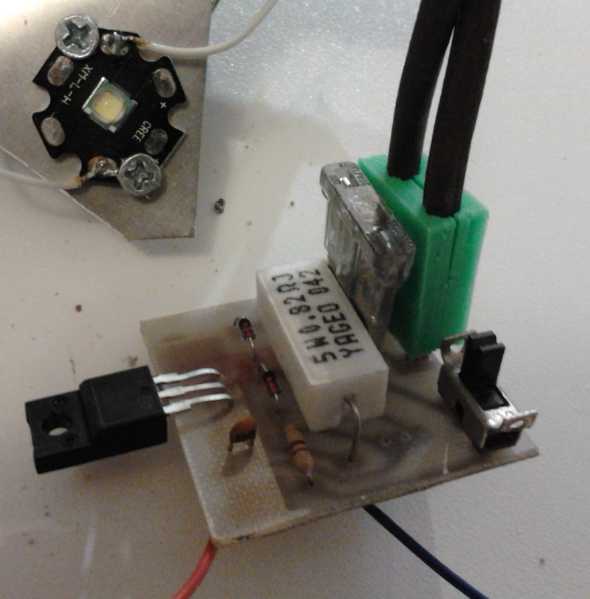

The board, showing the CAT

standard plug pins.

CAT Socket - inset.

The current

control circuit was essentially similar

to my last one except I gave it a CAT plug instead of a crappy power

adapter socket, and put an on-off switch and an optional dimmer

potentiometer on the board. On the 14th I designed the circuit and

board, etched, populated (soldered the parts on) and tested it. I

didn't have the exact value of 5 watt resistor I wanted (.68Ω) for 1

amp, so I used a .82Ω and got .8 amps. (Actually, a 2 watt resistor

should be plenty big enough and I bought some .68Ω, 2W later.) I picked

a switch profile almost

at random for the parts library, and after I had made the boards, I

found a box of switches I've had almost since high school that fit

right

in!

The current

control circuit was essentially similar

to my last one except I gave it a CAT plug instead of a crappy power

adapter socket, and put an on-off switch and an optional dimmer

potentiometer on the board. On the 14th I designed the circuit and

board, etched, populated (soldered the parts on) and tested it. I

didn't have the exact value of 5 watt resistor I wanted (.68Ω) for 1

amp, so I used a .82Ω and got .8 amps. (Actually, a 2 watt resistor

should be plenty big enough and I bought some .68Ω, 2W later.) I picked

a switch profile almost

at random for the parts library, and after I had made the boards, I

found a box of switches I've had almost since high school that fit

right

in!

It seemed to work well with three Cree XM-L-H emitters in

series, a convenient assembly left over from the kitchen light:

9.0 V - .1 A

11.0 V - .5 A

12.0 V - .8 A

13.5 V - .8 A

15.0 V - .9 A

16.0 V - 1.0 A

Another view with CAT

socket 'extension cord' plugged in.

The transistor needs a heatsink,

the switch needs to be taller,

and a dimmer potentiometer isn't installed (the 3 holes).

But other than that...

This was more

or less the desired range, where

if the

voltage gets low the current drops to spare the power source, ie, the

battery, but if it's higher than necessary, the current is (nearly)

constant and excess voltage is dissipated in the power transistor. I

used a rather thin cable and the voltage had to be measured right at

the board, as the cable lost 1/2 a volt at rated current. Voltage drop

is of course the objection to using low voltage - but 12V is

generally a convenient voltage for LED s.

This was more

or less the desired range, where

if the

voltage gets low the current drops to spare the power source, ie, the

battery, but if it's higher than necessary, the current is (nearly)

constant and excess voltage is dissipated in the power transistor. I

used a rather thin cable and the voltage had to be measured right at

the board, as the cable lost 1/2 a volt at rated current. Voltage drop

is of course the objection to using low voltage - but 12V is

generally a convenient voltage for LED s.

People comment on my use of "low efficiency" linear

regulators instead of "high efficiency" switching regulators. The

efficiency of the linear circuit depends on the voltage

supplied to the LED emitters and the power supply voltage. If the LED s

need 11.0 volts and the power is 12.0, it's 92%. That's better than

most switching regulators, which are typically 80-90%. If the power is

13V, it's 85% - still as

good as most and there's no electrical switching noise. Feeding 9V LED

s

from 14 volts, however, it's down to 64% and the transistor definitely

needs a heatsink. Most ideally for four 2.9 volt LED emitters in series

(needing 11.6 volts to get an amp), the supply has to be about 12.4V to

get

full brightness, at which levels 94% efficiency is attained.

Cree XM-LAWT or XM-L-H LED emitters appeared from

the specs to be "top of the line", providing over 100 lumens per watt.

But I had been thinking lately that the three Cree emitter assembly in

the kitchen didn't seem as bright any more as it was when I installed

it in

summer 2011. Per specs, they're about 2.9 volts per emitter when

drawing one amp. Now, two of them redd 3.5 volts and the other was 4

volts, total about 11 volts. Instead of 4 emitters in series for 12

volts and 1 amp, I could only have 3. (And that was at .8 amps instead

of 1.)

Whether they deteriorate(?) like this normally, or if

perhaps the cooling was insufficient and they were running too hot -

likely they were pretty warm - I'm not sure. But it may be just as well

I never sold

any of the 12.0 volt, Cree emitter globe lights, and that I went with

other emitters for later

lights.

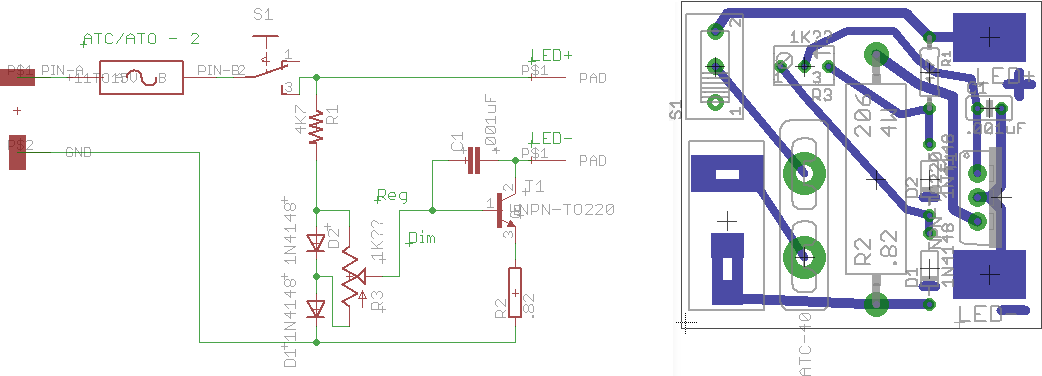

The LED driver circuit and board - single

sided, no jumpers. (EAGLE files on request)

The LED driver circuit and board - single

sided, no jumpers. (EAGLE files on request)

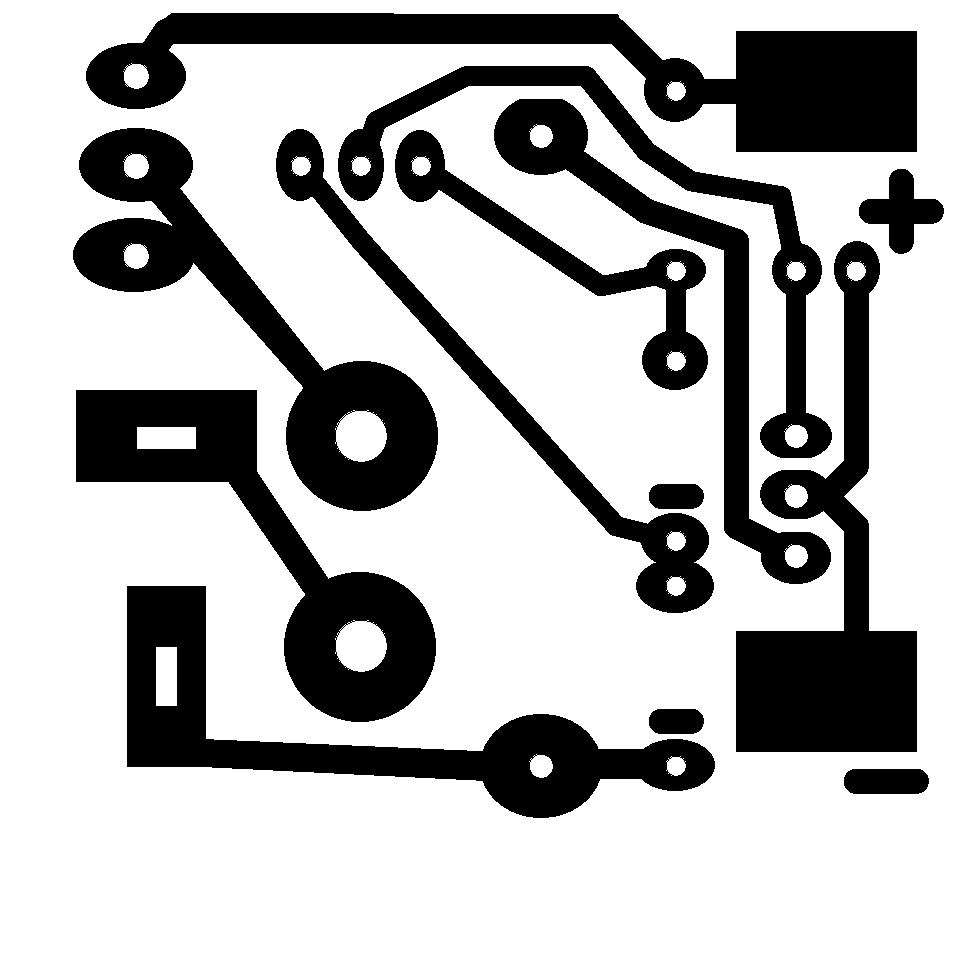

The board (correct size at 600 DPI).

The board (correct size at 600 DPI).

I upped the pad sizes (better for single sided boards) in a paint

program.

This was printed on a laser printer on glossy magazine paper

(12 copies on a page) and transferred to the PC board with a hot iron.

With 12v 'constant current' boards ready to go, I'm now

ready to make LED lights - flat panel, globe, or any sort of portable

lamp. The control could also be placed in a separate box and be a

separate product, wired to the light with a two wire cord. This would

also allow placing

them where convenient for the user while the light is in an awkward

place to reach like

on the ceiling.

Peltier Modules

Heat Pump

I

still had the water circulation peltier heat pump unit

I made but didn't connect and install last spring. I got diverted

by the evacuated pipe radiator

idea at that time. At long last I made a mounting and hung it on

the wall on

the 5th,

connected the warm

side loop, and tried it out. At 20 volts and 4 amps - 80 watts or 10

watts per peltier - the warm side got overly warm after 20 minutes or

so. The flow probably wasn't very high: the bottom wasn't as warm as

the top. But it was too warm overall everywhere. A pump might be better

than convection flow, but a fan

across the radiator fins would probably make more improvement overall.

The cold side with no radiator loop must have picked up a lot of heat

from the warm side, because it didn't feel very cold.

I

still had the water circulation peltier heat pump unit

I made but didn't connect and install last spring. I got diverted

by the evacuated pipe radiator

idea at that time. At long last I made a mounting and hung it on

the wall on

the 5th,

connected the warm

side loop, and tried it out. At 20 volts and 4 amps - 80 watts or 10

watts per peltier - the warm side got overly warm after 20 minutes or

so. The flow probably wasn't very high: the bottom wasn't as warm as

the top. But it was too warm overall everywhere. A pump might be better

than convection flow, but a fan

across the radiator fins would probably make more improvement overall.

The cold side with no radiator loop must have picked up a lot of heat

from the warm side, because it didn't feel very cold.

The next morning I hung a 48 volt

'computer' fan on the side, and turned the supply to 23 volts, the

lowest at

which the fan would run, and gave it some time to reach a steady state.

It drew about 5 amps, so 115 watts, or 15 per peltier. (The hottest

thing in the room was the lab power supply driving all this.) I dumped

a bit of powder into the filler pipe, from which the flow rate of the

water could be more or less seen - maybe an inch a second. It wasn't

fast enough, because the water, cooled by the fan and the radiator,

came in at the bottom at 31° (centigrade) and exited the top at 42.

That needs to be brought down to a 3 or 4° difference. A circ pump

would obviously be required to attain that with this setup. Another one

on the cold side is probably implied. The units from TEC-TEG were

obviously intended for pumped applications, having dual inlet and

outlet pipes of just 1/4" I.D., and considerable internal convolutions

increasing flow resistance. Nor was the one fan sufficient as set up,

since it would have been better to cool the water to 25° or less,

the room being 20° by the same temperature sensor. With a proper

casing around the the radiator to steer air flow across all the fins,

one fan would probably be sufficient.

Closeup of the main unit with 8 peltier modules.

Closeup of the main unit with 8 peltier modules.

Warm side is 'in', cold side against the wall.

My thoughts last year were that a 6° outside design

temperature versus 20° inside is only 14° difference, so one

might aim to keep the total difference across the peltier modules

within about 20° and get up towards 2 to 1 coefficient of

performance

(COP). But more carefully taking everything into account, it'll be

deceptively tricky to keep the differential even under 30°, which

might also be

considered the maximum workable range for any sort of non-trivial COP,

around perhaps 1.5.

One might at best - and at least - attempt to stay within the

following ranges:

6° - outdoor air temperature (OAT)

5° - cold water return (BTW, that'll be water with ammonia to

prevent freezing)

3° - cold water out from heatsink, entering cold outdoor radiator

2° - cold side heatsink

0° - cold side of peltiers

---

20° - indoor air temperature (IAT)

23° - warm water return

27° - warm water out from heatsink, entering warm side radiator

28° - warm side heatsink

30° - warm side of peltiers

So the objective can only be to get some worthwhile

gain, to create units that put say 1.5 times as much heat per watt into

the

heated space as an electric resistive heater, and then wait for

better peltier modules to come on the market and improve that figure to

at least 2, or maybe 2.5, 3 or 4 times. Then one is ahead of the market

with optimum components, tested unit designs, and control software

already

written - ready to start production when others are just thinking about

the possibilities and

starting to design theirs.

I figured that the alternative to pumps of course would be

the elusive

evacuated tube radiators. I'm not sure they'd replace the fans - inside

and outside - with so much heat to be dispersed into the air at such a

low temperature differential. But these fans would be small and

relatively quiet

'computer' type fans, not the compressor based heat pumps or Telus

equipment boxes with loud fans that are an affront to household quiet

and

to neighborhood peace.

On the cold side with liquid circulation, having a water

pump might be unnecessary if

larger piping is used. Using the flattened 1.5" pipe, oriented

vertically, to mount the peltiers, one could drill holes in the back

near top and bottom for 3/4" or even larger pipes, to go straight

through the house wall for outdoor radiator connections. If circulation

through a 1/2" pipe finned radiator was insufficient, it could be

increased to 3/4" pipe.

If fans are necessary, perhaps

it would be better to eliminate the indoor piping entirely and have the

fan blowing across a heatsink directly connected to the peltier warm

side plate - about like the fridge except using a substantially bigger

heatsink. Seems to me I've been here before... and after making one

I found out that most "aluminum" isn't really aluminum but various

alloys

that don't conduct heat anywhere near as well as the pure metal.

Copper, better than even pure aluminum and usually sold pure, is

getting to be very expensive. (Ultimate is of course silver, 10% better

than copper... but the price!)

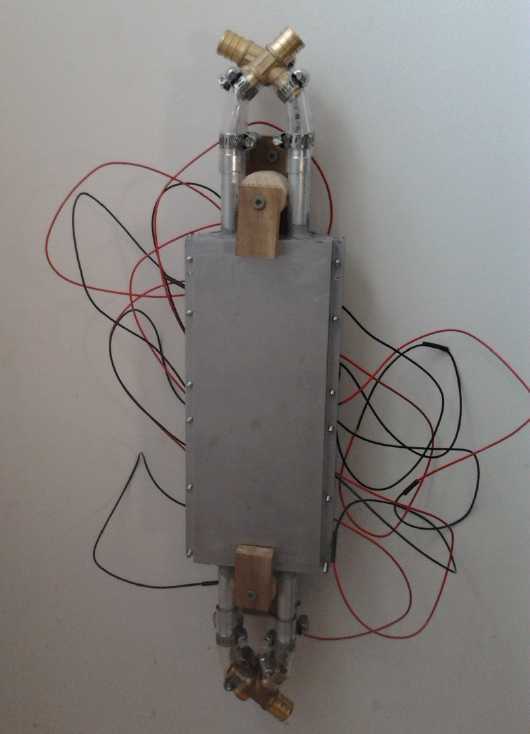

I searched on

"pure aluminum heatsink". The best looking

ones I found were ones with dense 'pins' or 'rods' at:

I searched on

"pure aluminum heatsink". The best looking

ones I found were ones with dense 'pins' or 'rods' at:

http://www.coolinnovations.com/products/heatsinks/datasheets/power-devices

These were rated as low as .06°/watt of temperature

rise with 600 LFM of airflow, for units of sizes that would hold 9

or 10 peltier modules. But with a noisy fan and for just 100 watts of

heat, that would be 6°C. Add 2° between the peltier surface and

the heatsink. One could also use more, smaller heatsinks.

I figured any of these lovely heatsinks were going to be

more than a

little pricey. It was starting to look like the cost of heat radiators

might make the whole project uneconomical. On the other hand, paying

for

more electricity every month in the winter is getting costly too.

I started to realize just how close a parallel to the heat

pump the peltier fridge really is. It uses 45-50 watts of

electricity with 'one and a half' peltiers (the 'main' 15 volt one plus

a smaller 8 volt, both rated 8.5 amps), has same same 30° spread

between warm and cold, and (according to the manufacturer's graphs) is

probably pumping around 25-30 watts of heat. Rounding that to 50 and 30

would mean it's putting 80 watts of heat into the room. (and 30

watts of cold into the fridge.) Of course, that's with '1.5' peltier

modules. The 15 volt peltier (running on about 9 volts) would account

for about 33 watts electricity and 53 watts of heat.

These are almost exactly the figures I've planned for the

heat pump per peltier unit. It just needs more units. I could probably

put 2 peltiers (better placed) under each heatsink instead of '1.5' and

still get similar results.

So a modest - or perhaps "minimal" - test unit could be 6

peltiers with 3 heatsinks using 200 watts and making 330. The cold

sides would mount on the 15 inch long flattened 1.5 inch copper pipe,

all mounted vertical against an outside wall with the large copper

pipes sticking straight out the back to the outdoors. The outdoor

radiator would still be liquid with fins (ammonia-water so it won't

freeze), hopefully with convection circulation (fat pipes) but

otherwise with some small circ pump.

I thought perhaps I'd just get 3 more of the same TEC-TEG

50 $Cdn ones as I used in the fridge, just for simplicity, rather than

importing. They seem more effective than most with a 5" computer fan

screwed on top - and I'm not even using it to best effect.

Then I

checked at CoolInnovations.com -- it's Canadian! E-mail and

a phone call disclosed that unless people would put up with a lot of

fan

noise, the medium density dissipated heat as well as the high density

at lower airflows. The 5x10" size was simply two 5x5" units bonded

together,

so the 5x5" was the best size for use with a 'computer' fan of similar

dimension. (I'm starting to suspect that these heatsinks are made of

aluminum cast in a mold. Most are extruded. Once I have the pattern, I

*could* probably cast my own... but it's probably not worth doing.)

I ordered 3 heatsinks for 50$ each, and was told that in

quantity they'd get down to around 25$. The last e-mail from them

included some cooling test specs the two 5x5" heatsinks with different

fans. I include a few useful results.

| Heatsink |

Fan |

Power (Heat, watts) |

Fan Rated CFM |

Blowing - Sucking - Best

(°c/watt) [best result format] |

| 3-505017R |

DELTA PFR1212DHE |

200 |

254 |

.064 -.053 - .053 [suck] |

|

SUNON MEC0251V3 |

200 |

75 |

.122 - .130 - .120 [.188" gap, blow] |

| 3-505025M |

DELTA PFR1212DHE |

200 |

254 |

.069 - .063 - .063 [1" blocked, suck] |

|

SUNON MEC0251V1 |

200 |

108 |

.104 - .100 - .089 [1" blocked, suck] |

On looking these over, it becomes apparent that even for

just 100 watts per heatsink, temperature rises approaching 10° are

pretty much inevitable except with considerable fan noise. Oh well, at

least the air coming off the heater should feel slightly warm and not

cool!

Heatsink Test

After the new heatsinks arrived, I tried one out on the

fridge. (Feb.21st) It was disappointing, as the temperature rise was a

little higher than with the original one with closely spaced

rippley cooling fins from TEC-TEG (www.tecteg.com), perhaps 1.5 degrees

or so. I

suspected - and still suspect -

the biggest reason was because the base was thinner, 3/8" instead of

1/2". Since the peltier modules have to be mounted over to one side,

the heat has to

spread across the base to make use of the radiating elements at the

other side, and the thicker base is better. But another factor was that

when I calculated out the total

surface area for heat radiation, it had only somewhat over half that of

the TEC-TEG unit with its closely spaced fins. And the TEC-TEG unit

works well with minimal air flow.

The conclusion

from all this is that I have more respect

for the TEC-TEG heatsink (left) than I had, and that I see little

chance of

improving on them very much, except maybe a bit by using pure aluminum

instead of alloy. Visiting the site again, I see the claim "Extruded

multi-fin heat sinks with the largest Thermal Conductivity ratings in

the market today."

The conclusion

from all this is that I have more respect

for the TEC-TEG heatsink (left) than I had, and that I see little

chance of

improving on them very much, except maybe a bit by using pure aluminum

instead of alloy. Visiting the site again, I see the claim "Extruded

multi-fin heat sinks with the largest Thermal Conductivity ratings in

the market today."

Possibilities include buying more of them, casting

my own similar units (using it as a template for the mold)... and maybe

seeing

if CoolInnovations can come up with something better.

Graphite Gasket

as a Heatsink?

Perhaps the way to go would be to find something cheap

and really spread out the peltiers. Make it big. What's cheap and

conducts heat well? Perhaps graphite

gasket had a role in here somewhere. It seemed to conduct heat well -

especially along the grain, it was said. I had been going across the

grain to use it as a gasket, and yet it worked quite well. And it's

cheap.

That suggested a plan: Cut pieces of graphite gasket, maybe a

dozen, to stack over the peltier(s) warm side and stick out as heatsink

fins. Cut a piece of stiff metal - cheap steel? - to 42mm wide and

whatever length, to clamp the graphite against the peltiers. As the

graphite is compressed, it'll conduct heat better across the grain, and

the 'surplus' graphite will fan out to form heat dissipation fins. If

it worked

well enough, it could replace costly heatsinks of copper or aluminum

and eliminate the main use of an evacuated tube.

I tried it out on the peltier refrigerator. I cut 10

pieces 4" x 5.25". There was only room to have fins sticking out one

direction instead of both sides, about 3.5" long. The 10 layers didn't

automatically spread into a fan shape when one area was pressed

together and needed a wire threaded

threaded between each piece to spread them out. The temperature drops

seemed a little higher than with aluminum, but not bad. Plus, having no

effective fan and horizontal orientation, the whole thing got very

warm, so evaluation or comparison was suspect. With the fan placed on a

stool and wafting some air across the vanes, typical temperatures (warm

side) read: peltiers 44°; where the vanes come out from them (mid

stack) 41°; middle of the vanes 32°; outside end at the top

25°. This was in a nasty (for Victoria BC) cold snap and the air

temperature was just 13°, so the 25° doesn't represent almost

complete cooling. (I was working with my coat on, in the

house.)

My general impression was that it would probably work well

enough if it was carefully made, placed inside an enclosure with

"cheese cutter" wires carefully strung to gently spread the vanes

without breaking the fragile graphite, forming (with the enclosure) air

channels with good flow from a fan. One thing: I can't see using it in

a car or other moving object subject to vibration. The graphite

would probably fall apart eventually. Even cleaning the dust out

occasionally without destroying it may be a challenge. (On the 12th I

got some "graphite foil" in connection with battery experiments. It's

considerably stiffer and might be used like flat sheets of aluminum.)

A composite design might have a fat bar of aluminum (or

copper) backing the peltiers, and graphite fins clamped at a right

angle under metal along the sides of the bar. This would provide 2 sets

of fins instead of 1.

(Another use of graphite might be for lining that loosely

fitting hole in the aluminum

block

for

connecting to the evacuated pipe - one expects it'd work much better.

Now... do we still want an evacuated pipe for anything? Steam still

carries heat fastest.)

Electricity (Energy) Production

Magnet

Motor

About the first of February I discovered that the first

magnet rotor I made in January, which didn't turn at all after the

promising

experiments with a wooden arc of magnets, would try to twist around,

centered on the magnetic action, if it wasn't mounted on an axle. In

fact, it became apparent there would be a motive force with a center

placed any distance but at the

axle radius, which is of course exactly where it was. I verified this

by drilling a hole half way between the magnets and the center, and

putting a bolt through it there for an "axle". With a "stator magnet"

on the

short side, the rotor would turn one way, and with it on the long side

and the same magnetic direction, it would turn the other way. If the

stator magnet was reversed, so was the direction. There were two points

part way between on each side where the rotor wouldn't turn either

way.

A basic principle can start to be glimpsed. If magnets in

an arc shaped path are magnetically connected to a magnetic field that

wants to twist their orientation, and are prevented from twisting on

their own center by physical connection to an axle, there will be a

motive force in the direction that will move the arc of magnets towards

a less twisted position - if such a direction exists. Motive force by

magnets wanting to twist is somewhat different in concept than when

they want to move toward or away from each other by attraction or

repulsion, although these same forces are of course still the ones at

work. Of course, it has to be done with axial flux

How could the magnets be positioned on the rotor so they

made a smaller arc everywhere than the axle distance? Or a larger one?

Or did it only have to be an apparent difference, based on the

angles of the magnets as well as actual distances?

Again a spiral magnet path might work.

With the spiral, the center of the arc is always offset from the

turning

center. But only by a little bit for a gradual spiral. So this time, it

seemed that a double or triple spiral,

something like the Yildiz stator but on a flat platter, might be the

ticket. And it couldn't be where I had made the spiral of the last

attempt, on a stator outside the turning rotor. It had to be on the

rotor or on a stator parallel to the rotor with axial flux. But the new

idea, once again, seemed promising enough to try building.

Other patterns also might work. One would be a series

of arcs of smaller circles than the actual rotor diameter, with spaces

between them. Another might be a series of straight lines - an

"infinite

radius" vis a vis the actual circle. Or maybe a bunch of short spirals

like a pinwheel.

How would I test all these out? Instead of making a new

rotor for each, I decided to drill 1/2" holes through existing rotors

on the drill press, and not to make complete rotors until I found

the most promising patterns. The .5x.5x.125" magnets could be jammed

into the holes with any orientation. But the results were inconclusive

and the magnets kept jumping out of the holes.

So it looked like I'll have to make another proper set of

rotor/stator parts to get a good test. I really must get my 3D printer

working again. It would be much easier to make rotors that way! If they

spin up and the plastic won't take the forces, that'll prove it's worth

doing solid plastic parts on the CNC router.

I didn't get to it, then on the 12th I figured that I

could make larger rotors about 6.6" diameter (& 2.648" magnet

center radius) that would interface with

the spiral magnets on the existing stators from an axial direction,

without hitting the support rods in the corners. If that didn't work

(or even if it did), I

could try stators with other patterns, but the single spiral seemed

like a

good start.

Unfortunately, I had to take down an old brick chimney for

earthquake safety and my machine shop and electronics lab above it

became dust encrusted disaster areas for a couple of weeks. I turned to

another project... the battery lab was unaffected and I had new

materials to attempt to make improved cells.

Electricity Storage

Turquoise Battery Project

Graphite Felt, Graphite Foil

I had thought

probably to set this project aside now that

I

had created a great working chemistry, and hope others would work on

production aspects, since I hadn't made a lot of headway at improving

performance to get really practical cells.

I had thought

probably to set this project aside now that

I

had created a great working chemistry, and hope others would work on

production aspects, since I hadn't made a lot of headway at improving

performance to get really practical cells.

But people e-mail me with battery making questions and

ideas, and

someone mentioned "graphite felt". I hadn't heard of

that before, notwithstanding having gone to various graphite selling

websites and looked around. And I had looked for "graphite foil"

before, but the closest thing I came up with was expanded graphite

gasket

material. I don't understand how, for all the web searches and

explorations I've done, I haven't been finding - or even finding out

about - the more appropriate materials, but there seem to be an amazing

number of forms and types of graphite and carbon materials, and just

because any given supplier has a few of them doesn't mean their web

site will disclose the existence or names of other types. You would

think there must be a comprehensive overview of conductive carbon

materials somewhere, but I haven't seen it yet. (Hmm, a search on

"conductive carbon materials" is giving some interesting results.)

I looked into graphite felt. It sounded very promising for

increasing electrode conductivity. I

e-mailed

4

companies

and

only

one

responded,

"SGL

Group

- The Carbon Company". I seemed to

be having trouble

getting a price out of them to place an order, but a goodly sample box

of their "SIGRACELL"

graphite felt and "SIGRACET TF6" graphite electrode plate material

magically arrived via FedEx one day. The plate is .6mm thick and said

to be made from expanded graphite, but also to contains a "fluor

polymer". From the specs it appears to be almost impermeable, which is

much better than regular expanded graphite.

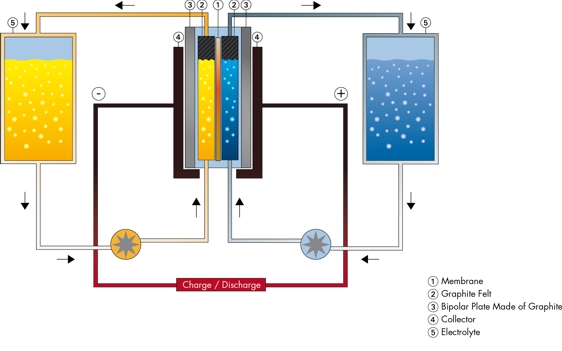

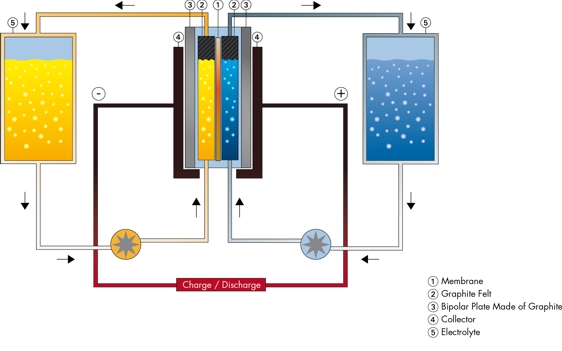

These

materials were specifically intended

for "redox flow" batteries (left). The intent was that the liquid

electrode

substance would flow through the felt, making very good electrical

contact via a zillion points in a 3D space. The felt was then backed by

the foil, which would transfer electrons from the felt to the external

terminal.

These

materials were specifically intended

for "redox flow" batteries (left). The intent was that the liquid

electrode

substance would flow through the felt, making very good electrical

contact via a zillion points in a 3D space. The felt was then backed by

the foil, which would transfer electrons from the felt to the external

terminal.

In order to use them for solid electrolyte batteries, the

electrode material powder or paste would have to be impregnated into

the

felt somehow, and then be compacted on the flat -

edge compacting is pretty much out if there's a 'dimensional' material

enclosed

instead of

just powders.

There is also "carbon felt". What the difference is

between "graphite felt" and "carbon felt" I don't know. Since the

graphite felt I got was specifically intended for batteries and (IIRC)

has slightly lower electrical resistance, I'll assume it's the right -

or the better -

stuff.

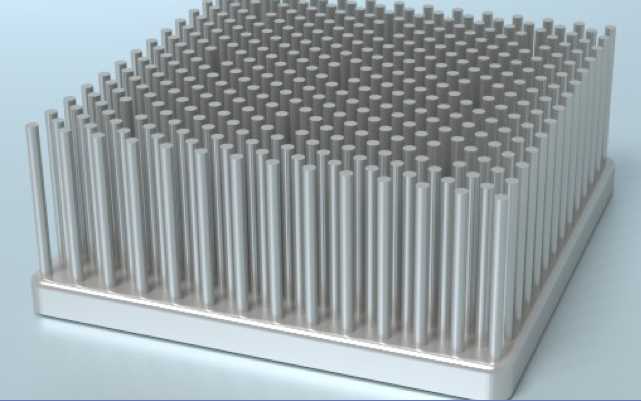

Closeup of the porous, fiberous "Graphite Felt".

Closeup of the porous, fiberous "Graphite Felt".

The space between fibers is more open than is apparent here,

and if they're filled with electrode mix and compacted, the

resulting electrode is much more conductive than without the felt.

I also started thinking about "carbon black", 'partly

oxidized carbon' which was

said to be used in standard dry cells as an alternative to graphite

powder. The fact that anyone bothers with an alternative probably means

that either graphite has some problem (oxidation?) or that carbon black

is more

conductive, or both. (...or could it be cheaper?) I found a company

dealing with it that seemed to

indicate that carbon black itself is divided into many types for

various purposes, only one of which was batteries.

http://www.cabot-corp.com/New-Product-Development/Advanced-Batteries

I didn't try to place an order. If "carbon black" was

partly

oxidized carbon, what was

"charcoal"? I found charcoal powder at the art supply store, but it

seemed to be an insulator. Could that change inside a battery? - or is

there some simple way to make it conductive or turn it into carbon

black? Maybe there's simple way to use such commonly available

materials.

Better Battery, "OJC1"... & Production?

Having obtained the new graphite felt material, and now

looking into the "carbon black", the prospect of making batteries with

vastly improved substance utilization and current capacity came into

view. My cells need an order of magnitude improvement and more, and

these seem like the sort of things that might provide such gains. Thus

it now

seemed worth trying to make an actually practical cell, with an eye to

potential production. If they could be made with a reasonable amount of

automation to the process, they should be cheaper than lithiums as well

as better. Intrinsically they're far cheaper.

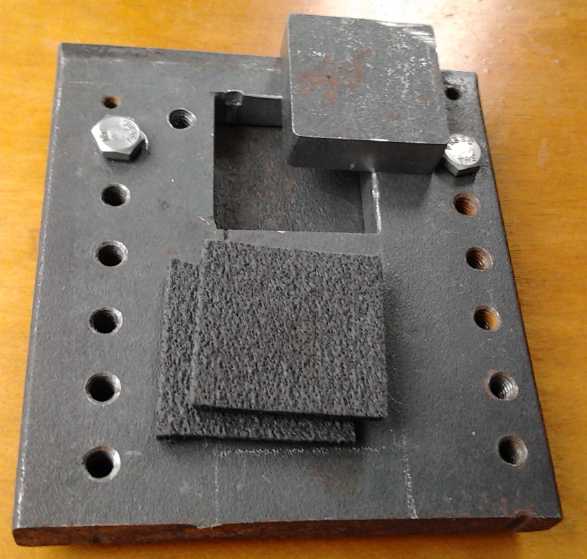

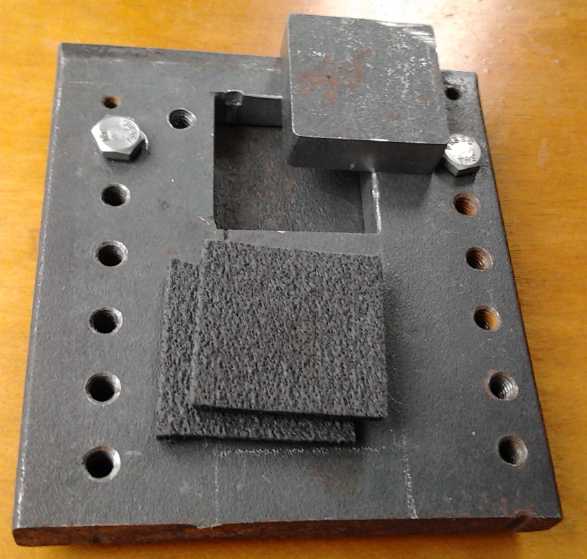

New Flat Compactor for 40x40mm electrodes

With the graphite felt necessitating compacting on the

flat, I had to make a new electrode compactor. In order that good

compaction wouldn't take 25 or 30 tons of pressure, I had to shrink the

electrode size from 64x54mm to 40x40mm, which would only require around

10 tons.

With the graphite felt necessitating compacting on the

flat, I had to make a new electrode compactor. In order that good

compaction wouldn't take 25 or 30 tons of pressure, I had to shrink the

electrode size from 64x54mm to 40x40mm, which would only require around

10 tons.

I made the steel box on the 20th and 21st, amid other

pressing work unrelated to energy projects. First I tried some 3/8"

stainless steel plate, but in order to cut the inside square a jigsaw

was required, and the stainless made short work of the metal cutting

blades. I switched to a 1/2" thick piece of mild steel (a better

thickness anyway) and drilled holes all the way around the edges so the

jigsaw only had to cut from hole to hole until the center fell out.

Then came some hours of filing to get the hole to size and everything

straight and even. This part, tho made from a previously used piece of

steel with a bunch of holes that I had on hand, is big enough to cut a

second "window" into. (It was intended that the stainless steel piece

would have four, to do four electrodes at a time. I think if I really

want a compactor with multiple "frames", I'll have it cut by CNC

waterjet

since each one is so much work to do by hand.)

The square "punch" piece for the middle, again 1/2" mild

steel, was easier as it could be cut with the angle grinder and mostly

ground to shape, with just the final shaping and squaring done by file.

Finally I found a piece of 1/4" plate for a bottom and did

a couple of threaded holes for bolts to attach it to the "frame" piece.

First Graphite Felt Electrode

The first electrode would of course be the posode with

graphite felt, made with the Ni:Mn 60:40 ratio. I showed this in TE

News #69, but

apparently I showed it with additives for the negode instead of the

plus

side. The corrected mix with the right additives would be:

Substance % % Ni or

Mn Total Ni or Mn Ratio Ni:Mn (%)

Monel 16

69.65 11.14

30.74

Ni(OH)2 17 63

10.71

29.54

KMnO4 40

36 14.4

39.72

Grafit Pwdr 20

Sm2O3 7

----

100

Considering that the monel powder was coarser and some of

the nickel would doubtless be unavailable, I decided to use a little

less KMnO4. I bought some "charcoal powder" at an art store, but it

seemed to have infinite resistance, so I stuck with the graphite

powder. This should also indicate the difference between without and

with graphite felt better, without throwing in other variables at the

same

time. The actual mix became:

Monel - 19

Ni(OH)2 - 18

KMnO4 - 32.6 (subtotal 69.8)

Graphite - 20

Sm2O3 - 7

----

96.8

The optimum proportions to use, especially of graphite

powder and samarium oxide, are only guesses.

In the absence of

any sort of special shaker machine to

get the powders to work their way into the spaces in the felt, the

first plan I came up with was to strap a plastic jar with the felt

pieces and fairly full of powder to my ankle and go for a walk. On the

23rd I cut some felt pieces to 40x40mm and mixed the powder, dry. I did

the jar, full of powder and felt pieces, but I just tapped and shook it

in my hands while I watched some youtube videos. Since it wasn't full

afterward, some of the powder must have gone into the spaces between

the fibers in the felt. I added more powder and stopped tapping

eventually after no more seemed

inclined to go into the felts.

I put two pieces of this "saturated" felt into the

compactor box, adding a little Sunlight dishsoap and Dieselkleen liquid

between

them, and pressed to about 8 metric tons (8 megagrams - Mg). That made

a pretty thin electrode, so I added a bit more of the liquids and a

third piece of the felt on top, which I then pressed to 10 Mg. I would

seem I should have used still thicker steel, since 3 thicknesses of

uncompressed felt will stick out the top a bit.

The electrode looked about the same as previous ones

except smaller

and thinner (2.5mm? - I forgot to measure it), and a little fuzzy

around the edges from the felt

fibers. It seemed pretty conductive, under 10 ohms if I dug the

ohmmeter probes in a bit, 20-30 if they were laid on it flat. The

electrode weighed 7.8 grams, of which about 1.8 would have been the

felt, so the rest was 6 or so, so under 5 of active chemicals. If one

attained 100 mAH/g that would be around 1/2 an amp-hour. If it got

anything like that with good voltage, it would be far ahead of previous

cells. I painted it with ferric chloride. (...There's something about

those recent iron electrode experiments suggesting it might be a good

additive.)

I then cut a couple of 40x40mm (plus terminal tails)

pieces of the

graphite foil to face electrodes with. I hope it's more durable than

the graphite gasket material, but it cut pretty easily with scissors,

as did the felt. I then painted one with osmium doped acetaldehyde as a

surface conductivity layer - and I suppose antioxidant layer - for the

graphite. It didn't soak into the shiny foil much so very little liquid

was required.

Next on the list of non-durables, I took apart the recent

unsuccessful cell and noted that the tail of the zinc current collector

on the negode had entirely corroded away from the electrode. I decided

to try the graphite foil on that side too. I've been meaning for

some time to see if graphite in that electrode would bubble hydrogen

and discharge it. If it does, perhaps I should look at lead (Pb)

current collectors. That would be nothing like lead in a lead-acid

battery since (in theory) the current collector will never deteriorate,

it's only a small portion of the battery, and the battery should last

indefinitely. Or it could be any metal with a lead coating.

The other electrode briquette, done rather casually on the

24th from a previous mix, again with 10 Mg pressure, weighed 13.9 grams

and

was about 2.6mm thick. Since Mn as a negative is almost an amp-hour per

gram, it'll have far more capacity than the plus side. I used the other

graphite foil current collector but didn't coat it. The graphite shouldn't

oxidize with a negative voltage on it. (Then again, I don't see why the

zinc should either. Perhaps it's forming zinc hydride, ZnH2?)

I torched the surfaces of both electrodes for a few

seconds and then assembled the cell, this time with watercolor paper

surrounding both electrodes and 3 layers of PP cloth between the

papers. I cut 2 pieces of 3/16" ABS for ends then clamped it all

together. Then I cut slits in the lid of a small plastic "ointment jar"

for the terminals

and assembled the cell, "OJC1".

Charging, testing and Performance

It started with a reading of 1.37 volts. I hooked up a

charge and it jumped to around 2.4 volts at about 25mA, then proceeded

gradually (a few minutes) downward to about 1.7 with current rising to

33mA - hopefully as electrode conductivity picked up and not as thing

went bad and shorts formed.

But it was the latter and the voltage continued to drop. I took the

electrode assembly apart and didn't see much. I added another sheet of

watercolor paper around the posode, stuffed in a fold that was

sticking out on the negode, and put it together again. This time it

was evidently okay as it started charging, painfully slowly. I upped

the current to 90mA. It took hours to get from 1.8v to 2.0. There were

bubbles and the water level appeared to be down a bit. I added more

water and increased the charge (it was down to 65mA) to about 100mA

with a smaller series resistor. It would hopefully be charging up the

oxidized zinc to metallic particles, and the plus side oxides to nickel

manganate. Would it then charge the manganese and proceed up to 2.6

volts, or would the graphite foil bubble hydrogen?

Since the active surface area of the electrodes is 16

sq.cm instead of 41, 100mA is similar to 250 mA with the larger size

electrodes, a rate at which the charge voltage would have been much too

high. Hopefully this meant the new cell had substantially better

substance utilization and current capacity, which would be due mostly

to the graphite felt, plus a little due to the electrodes being more

uniformly compacted with the flat compation. But I reduced the charge

to the 65 mA figure before retiring.

The next morning the voltage was still only 2.09 and tiny

bubbles were everywhere. I figured the graphite foil current

collector on the minus side was bubbling away the charge of the

manganese. pH was about 13 and the electrolyte was clear of purple

MnO4- ion. On the good side, a 1 ohm resistor load only

dropped the voltage to 1.3, ie, this small cell was sourcing 1.3 amps.

That's about 80 mA/sq.cm, which is a good figure and about four

times better than my previous cells. Doubtless that will be matched by

at least a similar rise in active substance utilization. It also shows

that the posode was definitely limiting the current. The negode,

charging to metallic state, should be highly conductive in theory, and

evidently in practice. Zinc is a known high current electrode, and the

manganese with the 20% zinc powder additive is probably similar.

I took the cell apart and replaced the graphite foil

negode current collector with a zinc one. It didn't seem to help.

Perhaps I had been premature and the cell really was taking that long

to charge. The plus side would have finished charging and would bubble

as the negative shed hydroxide. If that was what was happening, it

would mean it had good amp-hours in the negode. Theoretically it has

over 10 amp-hours of substance, and it might have maybe 5 to 10 in

actuality, so actually it should take many hours to charge at .065 amps

current.

Then I found one of the aligator clip leeds with a rusty

clip had a bad connection. (The clips corrode easily and frequently

doing salty battery tests. Salty moisture creeps up the electrode

terminals unless well sealed, and you can't seal them if you might want

to take the cell apart again. I do buy new clip leeds occasionally, but

I don't

seem to be keeping up.) With the clip flexed around a bit, the voltage

started to rise rapidly (a few minutes) over 2.3 volts. Now... was the

original problem the graphite collector, or the rusty aligator clip?

The voltage

wouldn't go up to the now expected 2.6 volts. Nor did putting the cell

in the fridge seem to help. About 12 hours of patience however revealed

that it was in fact slowly rising and it neared 2.4 V on charge, and

the next morning (26th) it was over 2.5. It also put out around 1.6

volts/1.6 amps into one ohm for a few seconds, for 100 mA/sq.cm of

electrode interface - yay! The previous top was at best about 20-30

mA/sq.cm.

I had put the cell in the fridge, and I now took it out to

verify that the Mn would hold its metallic state charge at a higher

temperature. (I should put it in warm water to try higher

temperatures and find the limit.) It worked, but the self discharge

went up. I was

concerned by the self discharge, until I finally remembered it drops by

itself over a few weeks.

Graphite Foil Negative Current Collector Works!

When the voltage was finally up, the performance in a

discharge test seemed to be way down. I had to do 50 ohm load tests

because 10 ohms was now an overload - the voltage dropped rapidly with

10 ohms. Once again, promising initial results seemed to deteriorate -

but when size was accounted for it still seemed better than previous

cells. Later I suspected that in taking the stack apart after it was

wetted, twice, I had permitted the electrodes to expand somewhat,

losing internal conductivity and hence performance. Assuming I didn't

allow that to happen again, future cells should live up to the initial

performance of "OJC1".

I took out the zinc current collector and put the

"Sigracet"

graphite foil one back in. I have been meaning to test and see if

graphite materials in the negode would could self discharge for quite

some time now. It worked. This was good news as I have lost all

confidence now in zinc current collectors.

Performance was even poorer. So I took the graphite sheet

out, cleaned it, and painted the contact surface with osmium doped

acetaldehyde. The main problem turned out to be that I hadn't recharged

the cell very long after taking it apart, but it still wasn't as good

as before I'd replaced the current collector the first time. I probably

got better contact to the first current collector. (And the electrodes

had probably swelled while apart.)

The next test, after several hours charging, went better.

And with no zinc in the current collector (albeit zinc powder as a

conductivity additive), it shouldn't matter much to the cell how far it

ran down. I decided to run the test longer and see if the voltage would

level off somewhere. I was about to quit at 1.7 volts when it started

leveling out, soon dropping by only about 3 to 6 mV/minute in the 1.69

- 1.55 volts range, and the cell ran for an hour. Below 1.55 volts the

rate of drop increased again and I stopped at 1.48.

I figure in the higher voltages the posode went from

NiMn2O4 (nickel manganate) to nickel hydroxide and manganese dioxide

(~+.9v?), and in the lower range the manganese went to Mn2O3 or MnOOH

(+.2v). Further still lower voltage ranges should occur as the Mn goes

to Mn3O4 (-.1v) and then to Mn(OH)2 (-.3v). The other electrode should

contribute a fairly steady voltage (~-1.4) to the total, since it has

substantially more substance.

With a 50 ohm load and current dropping with voltage, the

cell still only delivered about 35 mA-H, far below the moderate

expectation of 500. And why had the current capacity dropped so

markedly? Could the graphite felt be deteriorating? Should I have

dipped it in osmium doped acetaldehyde? Or, would carbon black help?

I noted that a fair amount of Ni(OH)2 had come out of the

electrode. Perhaps next time I should try a simple "book" fold with the

watercolor paper, and then seal the other three edges with wax. The

'origami' paper folding often doesn't seem to work out very well.

Or could the negode be the problem? That was the part I

had disassembled and replaced the current collector of several times.

It was in several broken pieces with bits at the bottom by the time I

had finished. It may be that it now had few contact points with the

current collector in spite of clamping the electrode assembly together

fairly strongly.

But, now that it was determined that graphite doesn't

prevent it from holding its charge, perhaps graphite felt in that

electrode as well would raise performance? It should certainly improve

things a lot if there was spotty contact between electrode and current

collector.

Again, the later thought that the electrodes had swelled

seemed the most likely explanation.

On the 28th I

ran another discharge test. Initially it

went about like the previous one. But when the voltage dropped below

about 2.1 volts, the rate of dropping continued to increase more and

more without slowing at any intermediate levels. Thus it only ran 1/2

as long, 29 minutes, "full voltage or nothing". It only ran 4 minutes

below 1.7 volts, falling from 1.443 to 1.160 volts in the last minute.

On the 28th I

ran another discharge test. Initially it

went about like the previous one. But when the voltage dropped below

about 2.1 volts, the rate of dropping continued to increase more and

more without slowing at any intermediate levels. Thus it only ran 1/2

as long, 29 minutes, "full voltage or nothing". It only ran 4 minutes

below 1.7 volts, falling from 1.443 to 1.160 volts in the last minute.

Overnight the charge voltage went up from the previous 2.8

volts to 2.9 volts, and on the morning of March 1st there was a smell

of chlorine in the lab. That would be the Cl from the KCl charging to

gas. The negative side was wicking up white salt (& hydroxide)

forming large white crystals

through the unsealed terminal slit, while the positive side had

creamier looking yellow stuff. (salt + sulfates?) Evidently 2.8 V

should be the charge

voltage limit to avoid loss of chloride from the electrolyte.

In the next test (again 50 ohm load) the voltages were up

a little, the bulk of the discharge curve being in the 2.2x volt range

instead of 2.1x. There was something of a voltage drop slowdown through

the 1.8x volt range, but nothing like the 'steady state' near 1.6x of

the earlier test. The cell ran 39 minutes instead of 29. The

overcharging doubtless contributed, but hopefully as self discharge

decreases the amp-hours will also continue to improve. Another test on

March 3rd yielded almost identical results, and two on March 5th & 6th

drove slightly higher voltages yet for a 30% longer

run time - from almost 2.4V (after 1 minute) down to 2.0V (@36'). And

this cell won't die after a few weeks from a zinc current

collector corroding away until it falls off.

My theory for the change in discharge behavior is that

once the nickel manganate has formed during charge cycles, the

manganese doesn't detach from the nickel again during discharge to act

as an independent oxide. Nickel manganate evidently consists of a

variety of related compounds, generically stated as NixMn(3-x)Oy

, or presumably NiMn2O4 and Ni2MnO4,

and

some

with

fewer

oxygens,

perhaps

NiMn2O3 and

Ni2MnO3. It's probably the oxygens that come and

go as the electrode charges and discharges:

NiMn2O4 + H2O + 2 e- <--> NiMn2O3 + 2 OH- [~ +1

V]

It may be

noted that experimenters at Sanyo, using the

nickel hydroxide and manganese combo, used equipment that determined

there was nickel charging to "average valence up to 3.8". They

attributed this to "oxygen overvoltage raising" by the manganese to

allow the nickel to form "alpha nickel oxyhydroxide". There was no

mention of what the manganese was doing, despite the fact that

manganese oxidizes at a lower voltage than nickel, and that formation

of slightly soluble KMnO4 during charging is undesirable (as has been

gradually beat into my head through experiments, notwithstanding

chelation and notwithstanding that using KMnO4 is a good way to

initially make the electrode). NiMn2O4 could perhaps have nickel at

valence 4. Such observations and measurements are a whole field I don't

want to get into myself and requiring electron microscopy equipment and

knowledge, but I think probably they

weren't looking for the right things to find the right explanations of

the chemistry. (Especially given that they were trying unrelated metals

as well and only picked Mn because it "worked best".)

It may be

noted that experimenters at Sanyo, using the

nickel hydroxide and manganese combo, used equipment that determined

there was nickel charging to "average valence up to 3.8". They

attributed this to "oxygen overvoltage raising" by the manganese to

allow the nickel to form "alpha nickel oxyhydroxide". There was no

mention of what the manganese was doing, despite the fact that

manganese oxidizes at a lower voltage than nickel, and that formation

of slightly soluble KMnO4 during charging is undesirable (as has been

gradually beat into my head through experiments, notwithstanding

chelation and notwithstanding that using KMnO4 is a good way to

initially make the electrode). NiMn2O4 could perhaps have nickel at

valence 4. Such observations and measurements are a whole field I don't

want to get into myself and requiring electron microscopy equipment and

knowledge, but I think probably they

weren't looking for the right things to find the right explanations of

the chemistry. (Especially given that they were trying unrelated metals