Turquoise

Energy Ltd. News #75

April 2014 (posted May 3rd)

Victoria BC

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Feature: Flat Panel LED Light:

simple, low parts cost, looks nice (see Month in Brief, Other Green

Projects)

Month In Brief

(Project Summaries)

In Passing

(Miscellaneous

topics, editorial comments & opinionated rants)

* Prep Brochures, finances, gardening, aquaponics, the Spark of God

Within

Electric Transport - Electric

Hubcap Motor Systems

* Centrifugal torque converter - new version 1/2 made

* Bedini style bicycle motor-generator?

* Lithium cells are heavy?

Other "Green"

Electric Equipment Projects

* Power Adapter Battery charging components printed circuit board

* Prototype flat panel LED light: promising design, simple, low parts

cost.

* Thermoelectric Fridge & heat pumping experiments continued.

* Bane of Peltier modules: nearly all are rated 15 V max: 22-28 V gives

much higher COP at 12 V.

Electricity Generating

* Flux concentration for magnet motors?

Electricity Storage - Turquoise

(NiMn) Battery Project etc.

* Need pure graphite powder

No Project Reports on:

Lambda Ray Collector, Magnet motor, Pulsejet steel

plate cutter, CNC Gardening/Farming Machine (sigh, maybe summer...

2014...

2015?),

Woodstove/Thermal Electricity Generator (may abandon),

evacuated tube heat radiators, individual EV

battery monitor (almost started on circuit board).

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers -

Ersatz 'powder coating' home process for

protecting/painting metal

- Preliminary Ni-Mn Battery Making book

Products Catalog:

- Electric Hubcap 4.6KW BLDC Pancake Motor Kit

- Electric

Caik

3KW BLDC Pancake Motor Kit

- NiMH Handy Battery Sticks, 12v battery trays & Dry

Cells (cheapest NiMH

prices in Victoria BC)

- LED Light Fixtures

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

April in Brief

I decided that April would

be well spent if I made a 2.4v Ni-Mn battery cell that worked half

decently without any notable self discharge, and made or at least

progressed well towards making a new version of the centrifugal torque

converter with a flywheel to give the "torque hits" the punch needed to

turn the drive drum instead of slow the driving motor.

I didn't get to the battery cell beyond thinking

about it. The first idea was to use no graphite or carbon powder at all

in the positive electrode, since impure powder (from an art supply

store) is now the suspect in the self discharge, and accept a high

impedance electrode. (The graphite felt and graphite foil, being made

for battery use, are probably pretty pure.)

Later I decided I should

look up some supply and see if I could order some graphite powder of

known purity, or else make some from the sugar technique. The big

trouble with that last was, where does one get nitric acid? No doubt

that

too would be a special order from somewhere, not a local pickup. Later

someone told me that you can make it from sulfuric acid (battery store)

or hydrochloric acid (hardware store), so I'll look that up when I get

there. Another potential for trouble is... the product is said to be

'pure', but might nitric acid not leave some nitrates behind? That's

the very thing that causes self discharge. Perhaps there's some other

way to make graphite. But it's all academic until I find time to dig

into it.

I started with the torque converter on the 4th, but didn't

get far except for a theory and a 10" x 5" aluminum ring purchase. The

theory went that many small slots would slow the motor less with each

hit and reduce or even eliminate the need for a flywheel. The other

part of this was that instead of having springs to hold the shoes back

until the speed was high enough to want to engage, springs would push

the shoes outwards against the drum at all times,

in order to shove the toes farther into the

slots than inertia would take them at any speed, and give torque hits

with enough force to move a car. It would have to be low enough spring

force

that the motor wouldn't jam with the toes in the slots when everything

was stopped.

Then the fridge started cooling poorly (a peltier module

had cracked - they're not well supported in my unit) and I diverted

into re-examining peltier modules and how to use them to best effect. I

re-examined using two stage cooling, but to cool by about 30° the

highest COP still seemed to be a single stage run at much lower than

its

maximum voltage.

Ironically the common 15 volt rated modules have

needlessly poor COP at their typical voltage of 12 volts and a typical

30°c spread from the warm side to the cold side. People seem stuck

on 'maximum pumped watts' and ignore the fact that they can do

approximately as much cooling by driving them at lower power, owing to

less internal heat being generated. It is especially surprising that

camping coolers, hungrily eating battery power, shouldn't be made to be

as efficient as possible. Modules rated for around 22 to 28 volts max,

which are hard to come by, work much better at 12 volts.

But I finally found some affordable "24 volt" peltiers,

along with some "4 volt" ones, (from China with no datasheets, sigh!)

and I placed an order. This was well. The cracked unit when reinstalled

seemed to be working nicely... for a few days, then it quit completely.

I put in a 6 amp module for the time being.

In the middle of the month, I started thinking about the

long overdue website that Jim Lawrence had created for me in 2011, but

which was never quite usable. When it was started I felt it was best to

let him do the rather complex coding, and anyway I didn't want to spend

my time on it. But owing to the fact that the new site was

theoretically being done, I stopped trying to update the old site, and

everything got more and more out of date. Now everything was a snapshot

of early 2011. After a last try to get him to do some updates which

didn't appeared on the site after a couple of weeks, I finally decided

I'd have to tackle it myself if it was ever to be made usable.

It was a beautiful page format, but the coding was so

complex that as I tried to change things, I soon had borders in the

wrong places, missing pictures, and all sorts of headaches. After a

second frustrating session of 3 hours, at 1 AM I put it up and linked

to it anyway. At least I reorganized the menus, edited some text, wrote

a little history of the development of the Electric Hubcap motor

system, and put in a couple of newer pictures... one of which refused

to show. The next day I got to the right hand column of the two column

page. The content is still woefully far from updated and presenting

things well, but at least it's on the move.

I'll be taking Jim up on his offer of "any help I need".

Getting back to the

torque converter, cutting the small, thin slots - easily done with a

bandsaw

- into the inside wall of the ring/drum looked like a challenge.

Centrifugal Torque Converter drum with narrow slots,

Centrifugal Torque Converter drum with narrow slots,

mounted in the Chev Sprint transmission box.

On the 17th I finally took an old, broken bandsaw blade

(the sharpest one to be found in the bushes where they get thrown) and

silver soldered it together looped through the 8" I.D. torque converter

'drum' ring, installed it on the saw, and cut 24 slots into the inside

wall. For once, it all went more smoothly and easily.

At first I thought I would try this smaller drum converter

on the

motorcycle and save the big one for the Sprint car. Since previously

the motorcycle would only just start moving at 60 or 70 amps with a 4:1

chain reduction, getting a decent ride from a torque converter, at much

lower amps, should at least prove the converter's efficacy.

Then I started thinking about the walls: round plates,

with pressed bearings in the middles, for both walls. The drum would

turn independently of the shaft that would go right through it and turn

the shoes rotor inside. A gear or pulley would attach somehow on one

side. On the other hand... it would be simpler to try it on the car

using

the same configuration as before. If it wasn't quite there with the

small drum, I could reconfigure it all and put it on the bike. If it

did really well, I could put in another gear and drop the final ratio

from 4 to 1 to 2 to 1, which should put it on the street RPM-wise, if

not on the highway.

I had to cut a big arc out of the side wall of the housing

since this drum was too wide to go inside, and I ended up taking the

motor apart to put a new and longer shaft in it. That was as far as I

got for April - but it's good progress.

Then, after a friend needed a battery charger adapted for

NiMH cells, I did 'generic' printed circuit boards to put between AC

power adapters or lead-acid battery chargers and NiMH (or other?)

batteries to adjust the voltage and limit the current to what the

adapter could handle. The component values will vary with the

application, but at least they can all be mounted on a decent board

instead of strung haphazardly on a wire. Not offering chargers has been

a sticky point for those interested in buying NiMH batteries. This

should simplify things.

After that PCB and toward the end of the month, I decided

to do the PCB for a flat panel LED light I'd been considering. Instead

of one or two large LED emitters, it has a dozen or more smaller ones

spaced around the board. Curiously, all of them together cost much less

than single large emitters, and there are no especially costly parts

except the 12 volt power adapter to allow 120 VAC operation. I made a

nice 13 watt prototype light to test. I hooked it to the 12 VDC solar

wiring. There are some things to change and improve such as to find a

diffuser that absorbs less light, but with its practical simplicity,

low parts cost and IMHO simple visual appeal, I see great product

potential - especially as electricity costs rise.

Some see more sales potential in getting specific colors

of LED emitters and making them as grow-lights. It's not what I had in

mind, but it might be pretty simple to offer both. Maybe I'll make a

few and try them in the aquaponics setup. Year round lettuce would be

great!

Flat-panel LED light, 1" x 6.5" x 7.5", 12 watts

Flat-panel LED light, 1" x 6.5" x 7.5", 12 watts

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Collapse warning pamphlets - finances - gardening and aquaponics

I spent one of the first days of April writing a single

page

'pamphlet', Are You Prepared

for the Coming Collapse?, warning of the apparently inevitable

financial collapse,

which will surely lead to a period

of global chaos and devastating supply disruptions. The media have kept

silent about this biggest story of our time, perhaps hoping to delay it

or avert panic. Who wants to hear it anyway? Few are old enough to

remember the disastrous disruptions of the first half of the 20th

century, and few will listen to an individual 'alarmist' or prepare,

but they'll all remember who warned them and many may come knocking on

the door when

there is no food supply and none to spare. So those who are prepared or

preparing are

afraid to try to warn others.

But the more who are prepared, the better for all.

Thinking on this problem, I got the idea to

distribute pamphlets anonymously, quietly dropping one or two here and

there around the neighborhood, and hoping some would reach people who

are listening. But somehow so far I've just put a few on park benches,

on one evening.

I've been burning through money with disquieting speed in

the last year. (Why haven't I finished filling out my SR & ED

investment tax credit forms yet?) Partly it's energy projects and some

overdue home maintenance, and partly it's inflation. Fuel, various

items of food, and even various materials and parts are up

substantially.

On the other hand, Turquoise Energy made a bit of money in

2013 - a pittance, but I trust the trend will continue and expand.

Someone is buying an Electric Weel 'kit' as a large, low RPM generator.

Another person (or two) is interested in an Electric Hubcap or Caik

motor and

controller for a boat. And since I think I have the answer to the last

NiMn battery chemie problem - self discharge - there's the possibility

of battery manufacturing agreements.

One of the other projects is expanding the vegetable

garden. I keep thinking of the CNC gardening/farming machine to make

gardening easier, but without finding a moment to work on it.

Then I saw some info about aquaponics and looked it up on

youtube. Basically the fish waste is pumped around and fertilizes the

plants, and the clean water goes back to the fish. It uses a few

plastic containers piped together for the fish (tilapia are popular but

need warm water) and vegetables, a water pump, and an aerator pump. It

can be done on any scale and seems like a very good way to get both

fish (protein!) and vegetables from a small area, with the inputs

apparently consisting of fish food, vegetable seeds, and much less

water than for a regular garden.

Spark of God Within

Sometime around 200,000 years ago, a brilliant spirit

being, administrator of several hundred evolving worlds, Lucifer, and

his assistant Satan, decided to run things their way and to heck with

the rest of the universe, preaching a doctrine of unbridled personal

liberty. This caught the imagination of the spiritual overseers of

about 3 dozen inhabited worlds - especially very primitive worlds like

Earth was back then. After a very, very long while as we humans would

view it and every opportunity to make their case to all, the rebels

were incarcerated and replaced, but the 3 dozen planets have pursued

stormy courses. 37,000 years ago Earth's rebel overseer, Calagastia,

tricked the new physical representatives of higher order into trying a

proscribed act - to speed up the painfully slow planetary progress by

trying to produce a great leader for one of the more advanced tribes.

(You guessed it: Eve had sex with an Earth native. Cain wasn't Adam's

son.)

Since then, we've been virtually disconnected at the

humanly conscious level from all association with higher beings except

for two brief periods. This planet has become so materialistic the very

idea of there being some sort of spiritual oversight guiding our paths

and planetary progress is thought by many to be silly, and the entire

vital issue is little discussed and perhaps little considered.

But the Lucifer Rebellion was, at long last, evidently

adjudicated in or about 1986 Earth time. Only the rebels' way of

thinking has been left behind. I wrote quite a while back how our

civilization appears to have hit an evolutionary dead end, how the

entrenched have seized power, and have politically and economically

disenfranchised the inventive and those who would bring progress; how

society thus can't make the self corrections and changes that need to

happen to continue evolving towards a bright future.

The turmoil now starting to make itself felt in many lands

is the beginning of a wrenching and rather rapid evolutionary

adjustment back towards the normal paths of love, life and light. This

program planned on high will gradually result in the changes in

attitudes and perspective of most individuals that will make humanity

receptive to major changes in social systems and structures. Future

generations will be contemptuous of 20th century civilization, and the

social order won't settle down for a long age of moral quickening and

progress.

The program will culminate, perhaps long after all now

living have moved on, in the adult physical appearance of a magisterial

son, Serara, a spiritual relative of Michael of Nebadon (AKA Christ

Michael). He may perhaps stay for some human generations, suggesting

ideals of social and political organization - as leaven in the bread to

foster human progress.

It would seem that one of the key things if not the one

key thing, that the celestials presently in communication via various

volunteer contact persons and associated e-mail lists would have us

understand, and which far too many are unaware of, is that every person

of normal mind has within his or her mind a spirit fragment derived

from the first source and center of all things, the uncaused cause, God

the Father. By faith one can come to know and experience

that this is true - through prayer and meditation, seeking, receiving

and following the guidance of the still, small voice that ever says

"This is the way!" This is the doing of the Father's will, which leads

us to do better and to gradually become more divine, even to be all we

can be.

Electric

Hubcap Motor Systems - Electric Transport

Centrifugal Torque Converter

In considering the previous torque converter attempt,

with 5 very large

torque hits per rotation, the motor was greatly slowed with each hit.

This meant transference of much of the impact force to the motor, the

transmission housing, and the body of the car instead of to the output

drum. Again, it was like driving a spike with a tack hammer. The remedy

to smooth out the force would be a fairly substantial flywheel on the

motor shaft. With that, the shaft would probably have started turning

instead of

just the car shaking. I considered buying a new identical steel brake

drum and

making 10 smaller slots in the wall for somewhat smaller hits twice as

often, and adding a flywheel, just to prove the point. This seemed like

a lot of effort and again there was just nowhere a heavy flywheel could

be conveniently added, just for a test.

I then considered the clutch - centrifugal or otherwise -

where the torque of the motor is evenly applied, turning the output

shaft... and making heat. No flywheel is needed owing to the steady,

even forces.

If there were enough very small slots in the drum, there

would be many small torque hits, and the weight of the motor rotor and

the shoe rotor driving the drum could be sufficient flywheel weight for

them.

Even if no single hit was sufficient to move the vehicle, the rapid

succession of lighter hits might do it, just like the 'infinitely'

rapid succession of very minute hits in a clutch.

A 'new' thought for the torque converter was that the 10"

I.D.

x 4.5" aluminum pan drum could mount on a car wheel, making the

originally planned Electric Hubcap configuration, perhaps more easily

than the

Sprint transmission mounting could be modified. But that would mean

that the converter would have to move the car with no following down

gearing. But I hadn't been successful yet even with a 4 to 1

reduction following - why build in an extra challenge?

Another idea that occurred to me was that with the smaller

8" I.D. x 3" pipe, I could try making a converter for the motorbike

first, and then

apply any lessons learned before hacking up the larger one. Since

previously the motorcycle barely started moving at 60 or 70 amps with a

4:1 chain reduction, getting a decent ride from a torque converter, at

much lower amps, would surely at least show the converter's efficacy.

The E-Hog, a locally (Victoria BC

Canada) converted motorcycle, has a considerable

The E-Hog, a locally (Victoria BC

Canada) converted motorcycle, has a considerable

motor and a 4.125:1 reduction with a huge rear sprocket gear. The fixed

ratio works

well once the bike is moving at street speeds, but in common with my

attempts it has

rather low torque from

a stop, making for slower take-offs. It's a fine bike as built,

yet it's another illustration of the desirability of creating a really

effective variable

torque converter to handle all speeds optimally.

I marked off the inside of the drum with 24 even lines

about an inch apart. This convenient number would mean 24 torque hits

per rotation, and the strength of the hits could be varied not only by

the size and shape of the slots and shoes, but by the number of shoes,

which could be evenly distributed if there were 2, 3, 4,

6, or 8. (There wouldn't be room for 12 or 24.)

On the 17th I finally took an old, broken bandsaw blade

(the sharpest one to be found in the bushes where they were thrown) and

silver soldered it together looped through the 8" I.D. torque converter

'drum' ring. I installed it on the saw and cut the slots in the inside

wall. Then I unsoldered the band to free the drum. For once, all went

smoothly and easily and I wondered - except for having too many things

to do - why I hadn't done it 10 days before.

Cutting the slots/slits in the drum.

Cutting the slots/slits in the drum.

This was unusual not only for having to put the band together inside

the drum,

but for having to work from behind the saw to observe the cutting.

I had the idea to put a long shaft on the motor, long

enough to run through the converter, with the center disk with shoes

attached to it, and the grooved drum and output sprocket or pulley on

bearings to turn independently but perfectly centered on the shaft.

Then I started thinking about the drum walls: round plates, with

pressed bearings in the middles? The gear or pulley would attach on one

side. It would have to have side clearance and shaft clearance and yet

be perfectly centered. It would almost need a bearing on the outer

end...

As I thought about

disassembling the motor and the considerable reworkings and remountings

to make this, I decided to try this smaller drum in the

Sprint car after all, with the same basic configurations as before.

Faster to do. If it

didn't quite 'have it' in the Sprint, I could try the other route and

redo it for the bike.

On the 24th I

had my plans, but I decided to run them by

the people at AGO. Well, nix on welding steel to aluminum! (I should

have known - the two metals have completely different melting

temperatures.) But for an drum end, I had

happened to pick a used 10" rotor disk with six threaded mounting holes

(from the first centrifugal converter). These turned out to be exactly

outside of the drum diameter (wow, what luck!), and so could be used

with long bolts and hooks to clamp the cylinder to the disk. (I used

some small angle brackets, with one leg partly cut off, as hooks.) The

machinist from AGO came over after work and we figured out a simple way

to mount

the rotor - any rotor with an SDS taper lock shaft bushing center - for

turning on the lathe, where I dug a groove into one face to hold the

cylinder

centered. I didn't however turn it down to the size of the drum per the

original plan. That would have turned off the mounting bolt holes. (The

10" rotor had about 1/16" clearance over the lathe bed - whew!)

On the 24th I

had my plans, but I decided to run them by

the people at AGO. Well, nix on welding steel to aluminum! (I should

have known - the two metals have completely different melting

temperatures.) But for an drum end, I had

happened to pick a used 10" rotor disk with six threaded mounting holes

(from the first centrifugal converter). These turned out to be exactly

outside of the drum diameter (wow, what luck!), and so could be used

with long bolts and hooks to clamp the cylinder to the disk. (I used

some small angle brackets, with one leg partly cut off, as hooks.) The

machinist from AGO came over after work and we figured out a simple way

to mount

the rotor - any rotor with an SDS taper lock shaft bushing center - for

turning on the lathe, where I dug a groove into one face to hold the

cylinder

centered. I didn't however turn it down to the size of the drum per the

original plan. That would have turned off the mounting bolt holes. (The

10" rotor had about 1/16" clearance over the lathe bed - whew!)

Next, the motor and transmission mounting box was too

narrow to accommodate the 3" wide drum. I cut out a 10.2" diameter arc

from one side for the drum (or even a 10" drum) to protrude through. It

was well I cut it larger since I hadn't thought about the clamping

bolts sticking out beyond the 8.75" diameter.

To cut this

1/4" steel plate, I used a jigsaw with a metal

blade, at quite a slow speed and pausing frequently to add more oil to

keep the blade cool. It took a while, but I made a rather clean 10"

long cut, with one (new) blade. The angle grinder with zip disks would

surely have cut it faster, but I'd have spent more time afterward

cleaning up the ugly inside-curved edge with a grinder. And it would

have still been rough. Cutting a whole 7.5" Electric Caik motor rotor

would be a 23.6" cut - tedious but doable with the jigsaw in a pinch,

if you don't want

to wait for waterjet people to get around to it or it's not available.

The 10" Electric Hubcap rotors are 5/16" thick and a 31.4"

circumference cut -

probably doable too, but would probably try anyone's patience and might

consume several blades. But I digress.

To cut this

1/4" steel plate, I used a jigsaw with a metal

blade, at quite a slow speed and pausing frequently to add more oil to

keep the blade cool. It took a while, but I made a rather clean 10"

long cut, with one (new) blade. The angle grinder with zip disks would

surely have cut it faster, but I'd have spent more time afterward

cleaning up the ugly inside-curved edge with a grinder. And it would

have still been rough. Cutting a whole 7.5" Electric Caik motor rotor

would be a 23.6" cut - tedious but doable with the jigsaw in a pinch,

if you don't want

to wait for waterjet people to get around to it or it's not available.

The 10" Electric Hubcap rotors are 5/16" thick and a 31.4"

circumference cut -

probably doable too, but would probably try anyone's patience and might

consume several blades. But I digress.

I didn't find a 1-1/16" center "H" coupling, and I finally

gave up and took the motor apart to change the shaft to a 1.0" one. (I

did learn about "boring bars" for lathes, and found there's a taper

lock bushing size smaller and seemingly better than "H", labeled "JA".

I may employ this size in the cramped quarters of the next Electric

Caik motor.) I made it a very long motor shaft, not only to reach to

the drum shaft through a wider drum, but also so a flywheel could be

mounted on the other side of the motor if one should be required. Then

I got onto other things and that was as far as I got, with the inner

rotor and some chunks of plastic for the shoes lying on the bench.

I plan to drill holes in the end of the motor shaft and

the drum shaft, and insert a pin between them to force them into

alignment.

"Bedini" style

bicycle motor?

With most 3-phase permanent magnet motor systems, the

magnets are in a balanced configuration, two poles, north and south,

for every three coils. In the 1970s John Bedini made a motor with

unbalanced

magnets, and he actually extracted electric power from it, charging a

battery, even as it ran a mechanical load. It's said Bedini was beaten

and threatened ("You'll use oil for the rest of your life or else!")

and subsequently did little work, but with his coaching his system was

demonstrated in the 1990s by a girl at a school science fair (the

"Bedini

SG"), confounding everyone.

I haven't investigated this in detail, but as I understand

it, the process goes something like this: Two like magnet poles are

used at opposite sides of the motor, instead of one north and one south

pole, and two coils. The iron coils and magnets are naturally attracted

to each other, and being unbalanced, there is a half of the rotation

that powers itself as the magnets approach the coils and they pull

together. Furthermore, during this part of the cycle, the coils can be

connected to an electrical load and generate power into it.

When the coils pass the magnets, electricity is applied

for a short period to make the repulsion to push them apart and

continue the rotation. Sometime before the midpoint is reached, the

coils are switched back to 'generate'. The energy stored in the

magnetic field from the powered phase is released to the generator as

the field collapses. This is where energy used turning the motor is

returned. After that it's back in the regular attracting, 'generate'

part of the cycle. The mechanical work done is less than the electrical

input applied, and the electricity generated is also less, but

evidently

together they add up to more than the electrical input. It

probably depends how hard the motor is working, but even under heavy

load it's likely to consume less power than a typical motor system,

owing to there being at least some returned electricity.

I still have the bicycle wheel rim motor in my mind, and

it has a lot of freedom of potential design at this point. Furthermore,

since the bike can be started by peddling, having torque at all points

of rotation isn't a strict requirement. Of course, a bike motor that

uses less electricity or even keeps itself charged would be fantastic.

I'm also not entirely convinced that the results can't be

achieved with

a regular permanent magnet BLDC motor, using a special motor controller

and perhaps two

separate

wires to each phase - neither delta nor wye wired. The Electric Hubcap

and Caik certainly have positions they magnetically pull themselves

into - "cogging" as it's called. By hand it's hard to turn the shaft to

break it out of these positions.

I intend to study

this further and then play with motor and controller design ideas for a

while before actually building anything.

Lithium Ion

Batteries are Heavy?

When I got the eleven 'Thundersky' lithium-ion cells home

(36v, 100 AH, 3600 WH) I weighed them as they seemed quite heavy. The

bathroom scale said about 93 pounds. When I disassembled them, one cell

read 3684g. For all the hype about the high energy density of this

chemistry, that's just 89 watt-hours/Kg, not 140-170 per the usual

published Li-ion figures. And I would mount them in some kind of box,

so they'd work out to around 80. Probably the heavy plastic cases to

protect such large cells accounts for much of the 'extra' mass, but it

shows that the 60-66 WH/Kg I get for NiMH D cell assemblies is

certainly not "eclipsed" by fabulously lighter weight with lithiums.

There were 11

cells total. To get "18 volt" batteries I

could use 5 and be perhaps a little low in voltage (16-19 empty-full)

or 6 and be rather high. With 5, I'd get two sets with a cell left

over, so that was the obvious choice. For boating, one set running low

would indicate it's high time to turn around and head home using the

other set. I got two tote boxes to put them in for in the boat, which

measured slightly too small. Sure enough, slipping a battery into one

it cracked in one corner, so I ended up with a totes considerably

larger than required.

There were 11

cells total. To get "18 volt" batteries I

could use 5 and be perhaps a little low in voltage (16-19 empty-full)

or 6 and be rather high. With 5, I'd get two sets with a cell left

over, so that was the obvious choice. For boating, one set running low

would indicate it's high time to turn around and head home using the

other set. I got two tote boxes to put them in for in the boat, which

measured slightly too small. Sure enough, slipping a battery into one

it cracked in one corner, so I ended up with a totes considerably

larger than required.

The left over cell could go into the Mazda as a token

lithium cell to bring it up to a nominal 135 volts. The Mazda would

then have all three typical battery chemistries: PbPb, NiMH and Li-ion.

3-1/2

volts won't add much to the performance, but it should allow for some

comparison between types... and add a challenge to making and

programming the individual battery monitor.

With a voltmeter, I noted that the cells weren't at equal

voltage. Two were substantially lower than the other nine (2.4+v versus

2.7+ for the rest). When I connected a set directly to a 90w solar

panel

four were soon over 4 volts while the fifth was still down at 3.6.

Evidently a charge controller/Battery management

system is important even for a few Li-ion cells in series. Hmmf! I got

an 18.5 volt, 3.8 amp power adapter as a charger, and some 3.9 volt

zener diodes at the local electronics store to put across the cells to

prevent excess voltage. But they're only 2 watts and would probably

burn out with the solar panel and charged batteries.

Electric

Mazda/Lead-Acid Batteries/Mixed Batteries Update:

battery watering, constant voltage float charging, pulse charging

At the electric car show in February, Canadian Electric

Vehicles showed a Mite-E-Truck dump truck with a lead-acid battery

watering system installed. I've heard of these, but they seemed a bit

of a luxury

item to me. On the 13th it occurred to me that I hadn't checked the

water levels in the Mazda batteries in a long time.

Presently the Mazda has two 90 AH NiMh batteries composed

of 90 D cells in tubes, one 100 AH NiMH battery as a soldered pack of

100 D cells (two stacked wooden boxes of 50AH), 5 'regular' deep-cycle

lead-acid batteries with two

pop-off triple cell covers, two sealed lead-acids, and one lead-acid

with six screw-off cell caps.

Nothing could be done with the NiMH dry cells and the

sealed lead-acids even if it was desirable, leaving six.

I had never opened the one with screw-off covers. The

cells all looked as dry as a bone. Perhaps it's supposed to be that

way,

but I added 100mL of water to each cell to get the level just over the

plates, which bubbled air as I filled. (It worked well afterward.)

The five 'regulars' were still full to the max after all

these months. Obviously a battery watering system here would be a waste

of time. This seems like a vindication of sorts for my gentle 'constant

voltage' (13.8 to 14.0 volts) float charging system. After an initial

fill, watering is virtually a non issue.

However, the glowing reports of the retention of

performance and longer life span afforded by "pulse charging" (or

perhaps "supersonic charging"?) at last led me to buy a

pulse charger. It's a pretty slow charger that reduces the pulse

strength as the battery charges, and it seems to me it would do as well

(for lead-acids only) as my

float units, and keep them in optimal condition. The only trouble with

making them the regular PbPb chargers is that each one costs more than

100$ - substantially more than a "reconditioned" battery. I rotate it

around every couple of days to occasionally "pulse" each of the several

PbPb s in the car.

That didn't stop the one battery that was in the car since

the beginning, for a year, from losing mileage rapidly over a few days,

in spite of pulse charging it. (...bought in 2009 or 2010 and it had

sodium sulfate added when new. It sat around a lot until I got the

Mazda.) I removed it on the 24th and the car was down to 120 volts

again. I

caught on fairly soon and I don't think I ruined it with over-discharge

like I probably did to some others (must do that individual battery

monitor!), and I intend to try renewing it.

I found all the tire pressures were down a little, 25 to

32 pounds, and I filled them to "max", 35 PSI. Following this, and also

with warmer weather, the amp-hours needed to go a mile went from

2.2-2.5 down to as low as 2.0, in spite of being short a battery. Wow!

Other Green

Electric Equipment Projects

PC Boards to make AC Power Adapters

into Battery Chargers

When I speak of nickel metal hydride batteries, people ask

about charging. I usually say I just charge them with a constant

voltage float charge, but they seem to want more detail, like a

specific charger and a price.

The simplest way is to use a power adapter, generally

followed by a diode or two to isolate it if there's no power and or to

reduce the voltage to a desired figure, and a resistor to limit the

current when the battery is low, followed by the battery. If the driver

is a "real" battery charger being adapted for a slightly lower voltage,

usually from PbPb to charge NiMH instead, it may need a sense resistor

bypassing the diode in order that the charger senses the presence of

the battery. Various component values are necessary for different

setups. A fuse might be a useful addition.

Finally it

occurred to me to make "generic" circuit

boards that can accommodate the common arrangements. Most power

adapters have 'typical' jacks on them, so using the matching socket

means no modifications to the adapter; just plug it into the board. For

the battery end, I just used big solder pads to attach any cable. On

the board are spaces for a fuse, one or two 5 watt resistors or one 10

watter, one or two large diodes, and a sense resistor across the diodes.

Finally it

occurred to me to make "generic" circuit

boards that can accommodate the common arrangements. Most power

adapters have 'typical' jacks on them, so using the matching socket

means no modifications to the adapter; just plug it into the board. For

the battery end, I just used big solder pads to attach any cable. On

the board are spaces for a fuse, one or two 5 watt resistors or one 10

watter, one or two large diodes, and a sense resistor across the diodes.

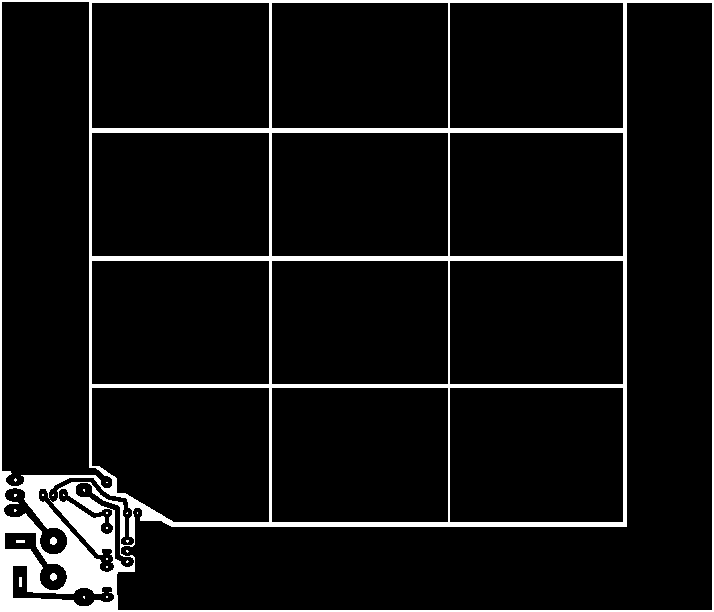

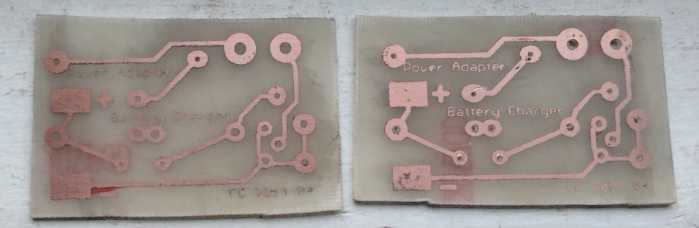

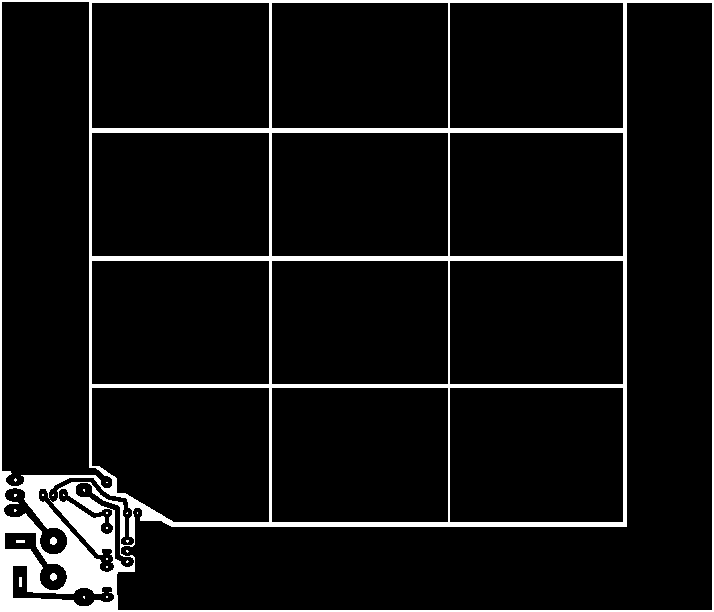

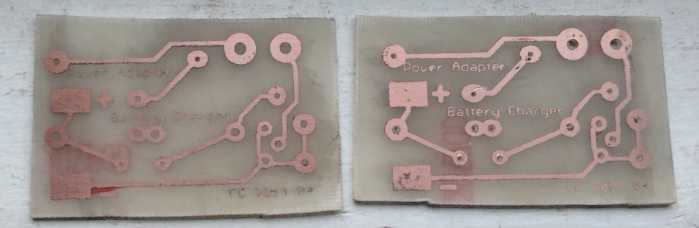

I designed boards on the 26th, printed a sheet with 12,

and etched 3. The patterns were large, but there was some pretty fine

text in the copper, which came out more legible on one board than on

the other two and showed the limits of resolution of the iron-on system.

I found a couple of layout problems and I did a second

board design on the 27th, but haven't made any so far.

Now, for example, to charge my 18v lithium batteries, I

have an 18.5 volt, 3.8 amp power adapter. If one plugged any such

typical adapter straight into any appropriate batteries when they were

low, it would be overloaded.

I'll omit the diode on this one since the voltage is just

right as it is. No sense resistor is needed. Since the cells may go

down to about 16 volts: 18.5v-16v=2.5v. A .66 ohm resistor would thus

limit the current to 3.8 amps when the cells are 'fully' drained. So

I'll append on this one's circuit board just the power adapter socket,

a .68 ohm*, 10 watt resistor or perhaps two of .33 ohm*, 5 watt, which

I may have on hand, and a fuse. The solder pads will connect a cable

with the battery's charging plug on the end.

* For the uninitiated, the reason seemingly odd

resistor values are commonplace is that each one is 20% higher

resistance than the last starting with one: 1.0, 1.2, 1.5, 1.8,

2.2, 2.7, 3.3, 3.9, 4.7, 5.6, 6.8, 8.2, 10, 12, 15, ... and as

electronics manufacturing got better there came to be 10%, 5% and even

1% values in between.

Making a

Prototype LED Flat Panel Light

After I had done the first

PCBs for battery charging on the 26th, I decided I should tackle my

conception of a flat panel LED light using a number of small emitters

apparently to be run at 1 watt: 2.9V, .3A, and 90 lumens. If it had 4

sets of 4 LED emitters in series (theoretically 11.6 volts), it should

work at 12-15 volts, draw a

little over an amp, and put out 1440 lumens. Using a bunch of small

emitters is actually substantially cheaper than using a couple of big

ones - they come in packages of 20 for about 5$, versus using two big

ones for around 10$ each. And they're more amenable to PC board

mounting, since the heat is spread out among the emitters and across

the board area.

Note: One 'failure mode'

drawback of my circuit is that the current is constant, so if one LED

in one of

the 4 legs fails, that leg will go dark, but the other 3 legs will

be driven too hard and will brighten - until they too burn out. Well,

best not to drive them hard enough that any will fail.

I simply divided the main area of the board into 16

rectangles, one per emitter, each forming a big slab of copper

insulated

from all the other slabs by a small gap. This would do the maximum of

heat sinking without adding components. Since my budget version of

Eagle PCB layout wouldn't do a big board, I copied my latest LED driver

board into one corner, and did the big blocks in a paint program.

Of course I

couldn't very well do a foot square board with

the laser printer. 7.5" x 10" would have been about the printer's

limit. I picked 6" x 7". When I printed it on the glossy paper, I could

see that interiors of big squares don't have much toner. (It wasn't too

noticable on regular paper.) This translated into blotchy or missing

areas in the artwork when ironed on to the PCB. This is the first board

on which the iron-on transfer method hasn't worked well since I

learned not to rub the iron back and forth but to lift and move it, and

to be really careful to press near the edge of the iron down on each

and every point of the surface... but then I did start rubbing it too,

owing to the large board size. I used packaging tape to cover the

rectangles up for etching. That was a lot of work to do an obviously

hand-made job. Production will probably need

another method. Or perhaps non-solid line pattern squares can made --

which may print out better?

Of course I

couldn't very well do a foot square board with

the laser printer. 7.5" x 10" would have been about the printer's

limit. I picked 6" x 7". When I printed it on the glossy paper, I could

see that interiors of big squares don't have much toner. (It wasn't too

noticable on regular paper.) This translated into blotchy or missing

areas in the artwork when ironed on to the PCB. This is the first board

on which the iron-on transfer method hasn't worked well since I

learned not to rub the iron back and forth but to lift and move it, and

to be really careful to press near the edge of the iron down on each

and every point of the surface... but then I did start rubbing it too,

owing to the large board size. I used packaging tape to cover the

rectangles up for etching. That was a lot of work to do an obviously

hand-made job. Production will probably need

another method. Or perhaps non-solid line pattern squares can made --

which may print out better?

Later it occurred to me I had another laser printer. It

might do better. And I hadn't even set my usual printer to "darkest" -

although its adjustment range is slight anyway. And then that it should

be a good board to do with a dremmel router on the CNC machine, because

most of the copper is retained and only strips need to be removed. I

must make a holder to mount the dremmel on the CNC machine!

I etched the

board on the 28th - and I left it in too long and over-etched an

already shoddy looking piece of work. I soldered on the 16 LED emitters

and tried it out with the lab power supply. The brightness seemed good,

but it took about 13.5 volts to get full brightness, instead of 11.6.

Once again, it looked like "2.9 volt" LED s aren't necessarily 2.9

volts, or even close to it. Full current would take at least 14 volts

with the driver voltage losses. Evidently I could only put 3 in series

instead of 4, making a board with 12 emitters and 1080 lumens - or just

accept that it wouldn't be entirely full brightness except when the sun

was shining on the solar panels.

I etched the

board on the 28th - and I left it in too long and over-etched an

already shoddy looking piece of work. I soldered on the 16 LED emitters

and tried it out with the lab power supply. The brightness seemed good,

but it took about 13.5 volts to get full brightness, instead of 11.6.

Once again, it looked like "2.9 volt" LED s aren't necessarily 2.9

volts, or even close to it. Full current would take at least 14 volts

with the driver voltage losses. Evidently I could only put 3 in series

instead of 4, making a board with 12 emitters and 1080 lumens - or just

accept that it wouldn't be entirely full brightness except when the sun

was shining on the solar panels.

Then again, I thought, the 16 emitters might total 1080

lumens or more even when it wasn't full brightness, and each emitter

would be driven more gently. 900mA (225mA per leg) * 16 emitters, gives

a value of 14.4. The full 1200mA (300mA per leg) * 12 emitters = 14.4.

But the light value of the 16 is greater because the majority of the

brightness comes from the first half of the current - the second half

gives somewhat less. And emitters driven with 225mA will run cooler

than with 300mA. But when I tried it, it still took over 13 volts to

get 800mA. So much for that idea!

On the 29th I removed one LED from each string and put

wires across the gaps. As might be suspected, it now took about 10.5

volts to reach 1200mA (300mA per string). When the internal constant

current power supply was wired and tested, 12 volts was exactly the

lowest voltage that made full power. Power supply efficiency would be

10.5/12=87% at 12 volts and 75% at 14 volts. A good switching regulator

could do better than the linear for 14 volts, but at 13 or less there'd

be little point to it. If there's 14 volts it's because the system is

being charged (ie, for solar the sun is out), and a few extra percent

power to lights will hardly be noticed. I went back to the supplier

website (dx.com) and found more exact specs for the emitters, which I

hadn't discovered before. They still appear to underestimate the 3.5V

forward voltage drop, but even the "3.2V" figure says four won't work

well at 12 volts.

- Material: Plastic + copper

- With LED white light

- Power: 1W

- Voltage: DC 3.0V~3.2V

- Current: 300~350mA

- Brightness: 80~90LM

- Color temperature: 6300~6700K

- Contains 20 pieces a pack

I still thought maybe a

lower current in the emitters would be preferable. 5 strings of 3 LED s

instead of 4 strings, run at 250mA each instead of 300, would mean a

1250mA total supply instead of 1200, and 15 emitters emitting at this

somewhat lower current would probably be brighter than 12 at 'max'.

Also on the 29th I got a piece of 3/16" 'frosted' plexiglass. It was

actually pretty clear and probably let nearly all the light through,

but one could see the outline of each emitter as a bright spot. If it

was moved a couple of inches away, it was somewhat more acceptable.

Somehow that didn't quite fit my vision of a flat panel. But maybe a

"light box" would be a good adaptation.

And herein

came an idea with a new advantage: The commercial flat panel lights all

had aluminum edges, and that had been my plan all along. But I could

glue acrylic edge pieces, any height, to the acrylic front, and skip

the metal entirely. These sides could be slotted to slide the circuit

board into, and I could glue acrylic tabs to the edges for screwing the

unit onto a ceiling or wall - a feature lacking in the aluminum edged

lights. Most of the whole unit would glow: light would come out the

sides as well as the face. The whole unit would be substantially

simplified, the materials costs would be low, and it would look nicer

and give a bit more light.

And herein

came an idea with a new advantage: The commercial flat panel lights all

had aluminum edges, and that had been my plan all along. But I could

glue acrylic edge pieces, any height, to the acrylic front, and skip

the metal entirely. These sides could be slotted to slide the circuit

board into, and I could glue acrylic tabs to the edges for screwing the

unit onto a ceiling or wall - a feature lacking in the aluminum edged

lights. Most of the whole unit would glow: light would come out the

sides as well as the face. The whole unit would be substantially

simplified, the materials costs would be low, and it would look nicer

and give a bit more light.

I cut the sides of the box in white on the radial arm saw,

but discovered the white scrap plastic I used wasn't acrylic - it

wouldn't bond to the frosted face with methylene chloride. or probably

with anything else. Rats!

I visited the

plastic shop the next morning, the 30th. A translucent milky white

acrylic for all faces would be great. They only had 1/8" thickness of

that unless I had it specially cut, so I got that for the bottom and

some 1/4" thick "bronze" acrylic for the sides. I asked about the light

properties of the translucent acrylic, and found one more and a serious

inefficiency: the 1/8" was said to absorb 50% of the light, and the

1/4", 70%. (They didn't have 1/16".)

I visited the

plastic shop the next morning, the 30th. A translucent milky white

acrylic for all faces would be great. They only had 1/8" thickness of

that unless I had it specially cut, so I got that for the bottom and

some 1/4" thick "bronze" acrylic for the sides. I asked about the light

properties of the translucent acrylic, and found one more and a serious

inefficiency: the 1/8" was said to absorb 50% of the light, and the

1/4", 70%. (They didn't have 1/16".)

The flat panel LED light, mounted with a couple

of screws

The flat panel LED light, mounted with a couple

of screws

The "bronze"

turned out to look unexpectedly like "clear" with the bright LED s

inside, and they glare out from the sides. Then there's the ugly

circuit board with the missing LED emitters making for an uneven light

pattern. However, it's a prototype for a potentially excellent product,

which I will improve on for the next rendition... and a nice light

regardless, which I will use. I anticipate these will be both less

costly and more desirable than the LED globe lights have proven to be

so far - they're another new form interior lighting can take. But

rising electricity prices will make all LED lights more popular.

The "bronze"

turned out to look unexpectedly like "clear" with the bright LED s

inside, and they glare out from the sides. Then there's the ugly

circuit board with the missing LED emitters making for an uneven light

pattern. However, it's a prototype for a potentially excellent product,

which I will improve on for the next rendition... and a nice light

regardless, which I will use. I anticipate these will be both less

costly and more desirable than the LED globe lights have proven to be

so far - they're another new form interior lighting can take. But

rising electricity prices will make all LED lights more popular.

For testing and temperature readings I mounted it in the

solar PV system wiring closet where there was already a 12V CAT plug-in

and it was within easy reach. I'll be looking for a bottom cover

that'll

transmit more light without allowing the glare of each emitter to show

through.

The prototype flat-panel LED light printed

circuit board layout

Thermoelectric Equipment - Experiments

The prototype flat-panel LED light printed

circuit board layout

Thermoelectric Equipment - Experiments

First, the Conclusions...

There's a mishmash of stuff below, essentially my 'lab

notes' written at the times I was doing the paper research and the

experiments. So here are the main findings, which most may not care to

read beyond.

1. I couldn't find 'nanomaterials' Peltier modules with improved COP s

for sale so far. There are a number of patents for them.

2. Laird has some 'improved'(?) peltiers rated for higher voltages for

sale at electronic suppliers (Digikey, Mouser) that may be a little

better than most - but they are costly. DX has some small (15x30mm), '4

volt', 5 amp Peltiers that can add their voltage to a 15 volt (5 amp)

unit to raise its voltage rating, as well as a '24 volt' 6 amp unit and

several '12 volt' units, for affordable prices. Since DX provides no

datasheets with any of these, use is somewhat speculative. Undoubtedly

the '12 volt' units are rated for 15 volts max. like all the others. Is

the

'24 volt' one really 30 volts? I ordered some anyway. They haven't

arrived yet.

3. Owing to heat rise on the module warm side and the need for the cold

side to be below freezing to freeze an ice tray, the temperature spread

is likely to be around at least 30°c with a 20° ambient room --

and higher if the Peltier module generates much extra heat owing to

excessive input power, or in warm summer weather.

4. To get a good coefficient of performance , Peltier modules should be

run at around 50-65% of their maximum rated voltage. For a 12-14 volt

system, modules rated for maybe 20-28 volts, or combinations of modules

to

attain these voltage ratings, use much less power (than typical 15v

max. units) to provide almost as many watts of cooling.

5. Most Peltier modules, and nearly all the lower cost ones, are rated

about 15 volts maximum, intended to pump maximum watts of heat with

12-14 volt systems. But this is an unfortunate choice for typical 12

volt

cooling and heat pumping. The extra power used by the lower COP shows

up as extra heat in the warm side, so except with noisy high rate fans

the temperature differential is

greater and it actually consumes those extra watts to pump the same

amount of cooling to the cold side. Typically it appears there's no

cooling gain at all over using a higher voltage module(s) at 12 volts

with lower

current (and hence consuming less power) to attain higher COP.

In my fridge, power used with a single 15V, 8.5A module

was about 85 watts, and the warm side temperatures were exceeding

40°c.

For a 15V, 6A module, using 60 watts, the warm side was about 35°

and the tray would only partly freeze over.

It has a quiet fan, but a very good heatsink. With two 8.5A modules

(15v+8v) making a 23V rating, power was 45 watts, the warm side was

just 30°, and the ice tray froze as fast or faster as with the 85

watts.

6. Thus 15 volt units - almost the only ones available - don't take

into account the need to conserve power in battery operated systems,

energy conservation and efficiency in general, nor the extra heat that

will raise the temperature of the warm side. Of course, they could be

run at 7-9 volts quite effectively, but for 12 volt power that

introduces power supply issues. At 6 volts of 15, the cooling capacity

gets rather low with a typical temperature spread, so using two

peltiers in

series doesn't appear to work out very well at 12 volts either.

7. Peltier modules pump heat more efficiently across a low temperature

differential, so I thought a two-stage unit with one Peltier on top of

another, each pumping across 15° instead of 30°, might give a

better COP.

The problem is that the warm side module has to dissipate

the heat made internally by the cold side one as well as the heat

pumped by it. So far, for a 30° spread, it looks like things work

out pretty much the same with either single or two stage cooling.

However, this is not the last word. I've ordered more

modules to get more balanced pumping between the stages and try more

actual experiments. Sometimes there are things that don't show up in

the datasheets - for example, when the unit is shut off, less cold will

be transferred from the fridge to the warm side heatsink through two

layers than through one and so it'll stay cold longer.

8. A technique recommended to maximize thermal conductivity is to

metalize the warm side of the peltier module and solder it to the

heatsink. Since graphite seems to conduct heat very well, an experiment

I'm trying is to mix silicone heatsink grease and graphite

powder, to get a much better thermal grease. Ideal contact with the

heatsinks could lower the temperature differential at the peltier

surfaces by a couple of degrees - and maybe double that for two stage

coolers. It seems to be working well, but spreading it thinly and

evenly is still vital - the difference is probably small.

Thermoelectric Fridge Update: another

cracked peltier module

I got on the web to see if perhaps anyone had started making

higher performance peltier modules, and I read that they have a life

span of some sort, with deteriorating performance over time. This was

the first inkling I'd had of that, which

would mean occasional module replacements would have to be figured into

the cost of peltier driven appliances. At the same time seemingly just

to emphasize the point, the fridge started working worse and worse, and

after a couple of days, it would no longer even make ice, just cold

water. (The copper bar right under the modules remained iced over.)

I had been thinking I might change it from 15+8 volt

peltier modules to 15+4 volt ones to get faster freezing of the tray,

but I had only 15v and one more 8v matching modules. I thought of

trying 8+8 (was that really better than 15?), and I took it apart on

the 8th. But a corner of the 8v peltier was cracked. That was of

course the reason it wasn't working well. I thought I had again clamped

them too tightly, but on

further reflection, they don't seem to deteriorate immediately, and

pressing on a corner of the heatsink would stress out the edges and

corners of the peltiers even if they were clamped loosely, potentially

breaking them. It would seem I need to ensure that external stresses

don't couple through to the modules, or they'll continue to get

'randomly' broken.

The choices were to use 15v+8v [the other 8v], 15v+15v, or

a single 15v.

IIRC 15+15 didn't make enough cooling, and the large surfaces caused

excessive transfer of cold to the heat sink when the unit was

off. I put it together as it was, 15+8 with the spare 8, and considered

getting more

options (8v, 4v, 2v) next time I ordered electronic parts. It turned

out after some perplexing experimental results, when I finally read the

numbers on the part, that the "spare 8V" unit was in fact a 12v unit

with the same smaller dimensions as the 8v one. I didn't have a spare 8

volter.

I haven't found any nano layered materials, higher COP

modules - so far. No doubt the lifespan of uncracked peltier modules is

at least several years -- and surely much longer if used at around

1/2 the maximum ratings instead of up near the limit.

The Two-Stage Peltier Cooling Module Revisited

In reading I was reminded that efficiency of Peltier

modules increases rapidly with decreasing temperature differences. (The

piece suggested that they might be used in conjunction with compressor

and gas heat pumping to increase the efficiency.) I had early on

concluded that using two stages instead of one didn't make much

difference... but had I discovered the 'deceit' of the graphs when I

estimated that? And might the result also be improved by the efficiency

increase gained by running the modules at well under maximum

voltage? It seemed to deserve another look.

(The document said:

http://www.thefreelibrary.com/Thermoelectric+technology+assessment%3a+application+to+air+conditioning...-a0186399835

CONCLUSION

Some observations on thermoelectric technology, especially those

relevant to large scale air conditioning and refrigeration.

* Thermoelectric modules are solid-state electronic devices that

directly convert electricity to temperature difference. Thermoelectric

devices have no moving parts and therefore are inherently reliable and

require little maintenance. Furthermore, the lack of refrigerants used

in the systems provides many benefits to the environment as well as for

packaging and safety.

* The use of thermoelectric devices and systems has been limited by

their relatively low energy conversion efficiency. Present commercially

available thermoelectric devices operate at about 10% of Carnot

efficiency if used as home refrigerators, whereas compressor-based

refrigerators usually operate at about 30% of Carnot efficiency.

* A broad search for thermoelectric materials with high efficiency has

been conducted. Currently, there is no known theoretical impediment to

significant increases in thermoelectric energy conversion efficiency. A

breakthrough in thermoelectric materials could spark many applications

that use thermoelectric technology as a safe, efficient, and reliable

alternative.

* Thermoelectric technology is suitable for applications where its

compact size, reliability, absence of moving parts, and silent

operation outweigh its relatively low efficiency. Thermoelectric

devices have been used in situations where the heat load is small

(e.g., <25 W), the required temperature lift is small (e.g.,

<10°C [18°F]), or the variation of the heat load is large

(e.g., train passenger cabin). It is important to note that the COP of

thermoelectric modules increases significantly with decreasing

temperature lift, as shown in Figure 4. [figure wasn't there]

* Instead of utilizing a fully designed thermoelectric cooling system,

it is also possible to use a small thermoelectric system as a subcooler

to improve the performance of a traditional system. This is a "hybrid

system" since it combines a solid-state cooling device together with a

conventional vapor-compression-type air conditioning and refrigeration.)

Now, if one took the 30° spread for the fridge or a

heat pump, and divided it into two 15° stages, being run

(especially the second stage) in the peak efficiency area per voltage

and current, could a higher COP be obtained even with today's 'low

performance' modules? If a COP of 2 could be obtained, a warm side

peltier delivering twice the cooling could sit directly on top of the

cold side one running 1/2 the power (assuming they were the same size

or separated by a block of copper to fully contact both surfaces),

and the temperature drops should be about equal.

I dug into the CUI module datasheet graphs. Again the

graphs were deceptive and difficult to evaluate, since they chart watts

of heat transfer versus temperature for different supply currents

instead of for different supply watts. 1/2 current (all else

being equal) also means 1/2 voltage and hence 1/4 power, not 1/2 power.

I finally printed out a couple of the graphs and started scribbling

numbers on them.

My estimate, which can only be a rough one, was that four

15V modules could be used to attain better COP. Two "8.5A" modules

(40mm square), electrically in series and hence being run by 6 volts

each, would sit on top of two "4A" or "5A" modules (same dimensions,

same wiring) and at 12 volts deliver around 40W of cooling power. Total

supply current would be 5.8 amps, for a 70 watts supply draw. (At 13 or

14 volts, all the figures would rise a little. I didn't work it out.) A

single 8.5A peltier would use about 80 watts to make about 35 watts of

cooling. So the improvement seems to be there: more cooling with less

power. And

there might be somewhat less heat leakage from the cold to the warm

side when the unit is off.

The fridge at present probably has only about 25 to 35

watts of cooling, but it would be nice to up that so it can cool faster

while the sun is out, so 40 watts would be better. Otherwise, the

peltiers could be reduced to say 6A and 4A devices, or 5A and 3A.

Is it worth it? Maybe. Certainly for a heat pump in a

battery powered electric car, all savings in power are valuable.

Logically the next thing to try figuring out was how two

sets of three stacked peltiers, each dropping 10° to make the 30,

would fare. A quick look showed that with the small change in

temperature drop, the 6 modules would use more electricity than 4 and

pump less heat. If the temperature drop was, say 45°, three stages

might become worthwhile.

Being lazy, I stuck an 8.5A and a 6A peltier together,

connected them in series, and tried them out. The voltage balance

looked

reasonable and I installed them in the fridge. I got the following

rough readings:

Supply: 12.25 v

8.5A peltier: 5.20 v

6.0A peltier: 7.05 v

Current: 2.7A (33W in)

Or (unplugging the electric car so the voltage came back up):

Supply: 13.7v

8.5A (warm side) peltier 5.9v

6.0A (cold side) peltier 7.8

Current: 3.0A (41W in)

Next question was how much cooling would that provide? If

it made 20 watts of cooling it would be doing well, and that probably

wouldn't be enough. After a few hours the copper bar had frost, but it

took ages to make ice in the tray, and the coolest area in the fridge

was about 7°.

The next morning, the 9th, I tried wiring the two stacked

modules in parallel instead of in series. With 12.4v in it drew 9.5

amps - 120 watts, and probably making about 30 to 40 watts of cooling

to the fridge. That's a pretty poor coefficient of performance and at

best no more cooling than the theoretical two pairs at half voltage

using 70 watts. Furthermore, it's probably an overestimate, because

with so much power going in, the heatsink temperature rose from the

usual 27-33° to a high measure of 46°, negating the

intended lower temperature difference effect. In fact, it made so

little cooling the ice melted off the copper bar.

It's frustrating that nearly all common (cheap) peltier

modules are rated

~15 volts maximum. This would be of course to get maximum cooling from

a 12 to 14 volt battery supply. However, a much better COP from those

voltages is attained from peltiers rated about 20 to 24 volts.

These seem to be considered specialty products and cost far more. A DC

to DC converter might take the voltage down to 7, 8 or 9, but that

introduces its own inefficiencies and complexity. That

leaves putting two modules in series, which at 12 volts leaves them

running at just 2/5 of their rated voltage, where performance is

marginal for a 30° temperature spread. 1/2 to 3/5 is probably ideal.

In the afternoon I put in the "full deal", two stacks of 2

peltier modules, 8.5A and 6A. (I'd have gone for 8.5A and 4A or 5A, but

I only had one, 5A size.) Current was 5.1 amps, about 67 watts. After

temperatures stabilized, they read 37° - 25° - 0° (warm

side, between peltiers, cold side). It seemed the extra watts had

mainly just raised the high side temperature, and the 6 amp units were

somewhat too large to go under the 8.5 amp ones. Owing to the unequal

temperature distribution it appeared there would be only around 26

watts of heat pumped from the fridge instead of 35-40. In mid afternoon

the water temperature in the ice tray was 5° at the top and 3 or

4° near the bottom. I left it to see how fast it would cool. In an

hour those were only down one degree. It did eventually make some ice,

but most of the tray stayed water and the fridge didn't get under

6°.

But again, really the main reason for low heat pumping,

regardless of COP, was probably using the modules at 43% of their rated

voltage with the 15 volt peltiers in series (6.5v each), with no

intermediate voltage modules available. Where were all the other

possibilities like 10v or 24v?

I also went to DigiKey to look at peltier modules. Here

(and then elsewhwere), I found Laird Technologies peltier

modules, which had more thermocouples for higher voltage ratings.

"The UltraTEC Series is a high

heat pumping density thermoelectric

module (TEM). The module is assembled with a large number of

semiconductor couples to achieve a higher heat pumping capacity

than standard single stage TEMs. This product line is available

in multiple configurations and is ideal for applications that

require higher cooling capacities with limited surface area.

Assembled with Bismuth Telluride semiconductor material and thermally

conductive Aluminum Oxide ceramics, the UltraTEC Series is designed

for higher current and larger heat-pumping applications."

"The ZT Series is a high performance thermoelectric module

(TEM). The module is assembled with premium Bismuth Telluride

semiconductor material that achieves a higher temperature

differential than standard single stage TEMs."

It seems to be vaguely implied in the bolded phrases that

these

are somehow more than single stage peltier devices, but there is no

such indication in the datasheets. Three higher voltage modules looked

appropriate, which

would according to my readings of the graphs provide the following

results with 13

volts and 30° temperature spread (presumably with hot side

temperature 25°c) :

UltraTEC Series UT6,24,F1,5555 ("30V"): Supply 2.4A (31W), 28W pumped

[84-89$]

UltraTEC Series UT8,24,F1,5555

("30V"): Supply 3.4A (44W), 37W pumped

[108-$]

UltraTEC Series UT6,19,F1,4040 ("24V"):

Supply 3.0A (39W), 31W pumped

[66-71$]

ZT Series ZT5,16,F1,4040 ("20V"): Supply 3.2A (42W), 28W pumped [57-$]

ZT Series ZT7,16,F1,4040 ("20V"): Supply 4.1A (53W), 35W pumped [79-$]

[Prices Canadian$ @ Mouser-Digikey, April 2014]

The first three provide almost as much

cooling watts as input watts, and the 24V unit is also very good. This

is excellent for a 30° temperature spread - compare it to the 8.5A

Cui "regular" peltier type:

Cui CP85440 ("15V"): Supply 6.8A (88W), 37W pumped [24$]

But a comparison between 30v and 24v units at lower

voltage and a 15v unit isn't fair.

With a small 15° temperature spread, the specs were even more

impressive:

UltraTEC Series UT6,24,F1,5555 ("30V"): Supply 2.6A (34W), 51W pumped

UltraTEC Series UT8,24,F1,5555

("30V"): Supply 3.6A (47W), 70W pumped

UltraTEC Series UT6,19,F1,4040

("24V"): Supply 3.2A (42W), 52W pumped

ZT Series ZT5,16,F1,4040 ("20V"): Supply 3.3A (43W), 40W pumped

ZT Series ZT7,16,F1,4040 ("20V"):

Supply 4.4A (57W), 54W pumped

A worrisome feature of the

30 volt units, as with putting two 15 volt units in series, was that

they would be operating at the very bottom of their voltage range for

the temperature spread. If in the summer the 30° spread increased

to 40°, the heat pumping would be cut in half, and also by 1/3 if

the supply dropped just a volt to 12. The 24 volt unit wouldn't change

so drastically, going from around 30 to 20 watts at the 40° spread,

or to 25 at 12 volts.

The prices were steep, even as much as putting together

the four 'ordinary'

peltier modules, but the design appeared to do exactly what I was

trying to do, and better, in a single module. And the prices for all

the modules

were up sharply from the last time I ordered, a year or two ago.

Then I went to figuring out how my 'original' two side by

side peltier setup stacked up. The 15v and 8v modules in series

(electrically) made effectively a 23v one, about 50x50mm. According to

the graphs, it should do around 35 watts of heat pumping, with a supply

of around 45 to 50 watts. At a glance it looks as good as the fancy

setups except for one thing: it doubtless transfers substantially more

cold from the fridge to the outside heatsink when it's turned off.

Although two-stage pairs pumping across smaller temperatures pump more

heat, some of the heat pumped by the warm side unit simply goes into

counteracting the heat produced by the cool side unit. (Maybe if the

warm side dropped 20° and the cool side only 10? ...Then the cool

side would make less heat. But then the warm side would have to pump

that across the 20° instead of 15°. Maybe it all comes out

equal regardless of how it's configured?)

In order to keep the fridge cool I put in a 6 amp module

and awaited the arrival of the new choices. I'm still waiting.

This isn't the final word. I plan to try out more configurations and

two stage arrangements. There may be other details that

affect performance that, like the off-state heat transfer, don't show

up in the datasheets.

Electricity (Energy) Production

Magnet Motors:

Magnetic Shielding and flux concentration

It occurs to me that

in considering magnetic shielding, one should examine ceramic "cup

magnets". The rather thick-ish steel cups concentrate the flux around

the edge of the front face of the magnet, and in that limited area, the

field attains the force range usually associated with supermagnets. If

such cups were applied to supermagnets, the flux should be powerful

indeed.

If a magnet motor is going to work, this would be the

means of making it powerful enough to produce a decent amount of power

for its size, rather than feeble power that merely keeps it turning

itself with a small load or none at all. The way the cups are formed

for ceramic cup magnets is thus probably the ideal way to make them for

supermagnets and magnet motors. (Short lengths of steel tube with an

end soldered or welded on might be a simple way to go?)

Electricity Storage

Turquoise Battery Project

Ferric Chloride

I've mentioned painting ferric chloride onto/into the

positive electrode a couple of times. What's it for? It converts to

ferric oxide/hydroxide, and people have mentioned using this as a

positive electrode active substance. I thought I'd add it on spec.

But as someone on a list mentioned, it has another action.

In becoming oxide, it turns

copper into copper chloride - it's usual use is as copper etchant for

making printed circuit boards. This means it eats away at the copper

content of the monel, creating pits and rough surface area and exposing

more nickel on the surface where it can convert to chemically active

NiOOH and nickel manganates, both increasing the electrode capacity

derived

from the monel.