Turquoise

Energy Ltd. News #77

June 2014 (posted July 5th)

Victoria BC

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Features:

* Flat Panel LED Lights: production steps & a great 'cracked ice

texture' diffuser acrylic

* Turquoise Battery: Self discharge problem of positive electrode

eliminated!

Month In Brief

(Project Summaries)

- distractions - flat panel LED

lights - torque converter, manual transmission et al - Peltier woes -

NiMn

batteries: self discharge of postitve electrode solved - VEVA Electric

Vehicle

meetings.

In Passing

(Miscellaneous

topics, editorial comments & opinionated rants)

- Ooops: 'unsold cars sitting everywhere' was in 2009,

not 2014. - ISIS & Iraq

Electric Transport - Electric

Hubcap Motor Systems

* Suspension for Bicycles! - Loopwheel and Shockwheel -

game changers for cycling and e-cycling?

* Application of my rim motor design to new wheel types

Other "Green"

Electric Equipment Projects

* Flat Panel LED Lights

- some more printed circuit board making techniques

- case production

- 'pebble texture' acrylic diffuser material gives great 'ice

cube' look, passes more light!

Electricity Generating (no reports)

Electricity Storage - Turquoise

(NiMn) Battery Project etc.

* Positive electrode self discharge problem solved: it was the impure

graphite powder.

No Project Reports on:

Variable torque converter transmission, Peltier heat pumping, Lambda

Ray Collector, Magnet motor, CNC

Gardening/Farming Machine (sigh, maybe summer...

2015?),

Woodstove/Thermal Electricity Generator (may abandon),

evacuated tube heat radiators.

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers -

Ersatz 'powder coating' home process for

protecting/painting metal

- Preliminary Ni-Mn Battery Making book

Products Catalog:

- Electric Hubcap 4.6KW BLDC Pancake Motor Kit

- Electric

Caik

3KW BLDC Pancake Motor Kit

- NiMH Handy Battery Sticks, 12v battery trays & Dry

Cells (cheapest NiMH

prices in Victoria BC)

- LED Light Fixtures

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

June in Brief

Various things that needed

doing kept me from getting to green energy projects. One was the

reporting of last

year's project work. My T2 and SR & ED form and other things for

Revenue Canada (CRA) being now 3 months late, and containing a couple

of

things I didn't know how to deal with, I tried to get accountants to do

them. The first one looked it over and said it was too complicated for

him. The next one, after 2 short but

helpful sessions over about 3 weeks, looked everything over and said I

was closer than I thought, and that I should finish it myself to avoid

paying him a lot of money to redo it. A week of part time work finally

finished it

off and I put it in the CRA drop box (the only piece of CRA in town) on

the 24th. After that and an "overdue T4 Summary" I also got done and

posted, I

have only two more overdue things to file for CRA - for now.

Occupying another week's worth of effort (but spread out

over much

of the month) I assembled and wired ten 8-wire waterproof slip rings

for vessel winches under contract for AGO Electronics. Then there were

gardening (unfortunately not the CNC gardening machine), continued

setting up of the aquaponics greenhouse, and other home projects. And

weekly concert band rehearsals ending with a concert in the park and a

barbecue on the 28th. With my alto Supercorder I was of course

the only

one who has invented and was playing their own instrument. (I played

oboe parts, there being no oboe, and I doubled the flutes in places

because the conductor liked the fuller sound... "Flutes can sound so

thin!")

I sat down a few times trying to figure out a mold for the

big Electric Weel motor, and a new bicycle suspension-wheel

system led me to consider anew the best way to make a bicycle rim

motor. And I looked at the variable transmission and how to fit it all

together. However, little was done beyond playing with layout and

design concepts.

To finish this

subject, on July 1st I decided that even tho I finally have what I

think is a workable configuration for the variable torque converter,

there was still quite a bit of work to do to get it going, of which

virtually

none got done in June. To get the Chevy Sprint on the road I would --

hopefully only temporarily -- give up on it, and just go out and buy a

manual transmission. The Sprint would at least be bound to start moving

in first, second or reverse gear. And if I got a commercial motor

controller with more amps, say up to 300, 400 or 500, that just might

give it the power to put it on the street, and I would find out the

real limits of my Electric Hubcap motors. I've been saying they're

"4.5KW" or "5KW", but they might well handle 10KW or more for short

periods - or even for longer for all I know.

With the transmission out of the way, I could concentrate

on fixing up the bugs in my own motor controllers, and on designing and

making motors -- things I've been much more successful at so far than

the

torque converter transmission.

Since that was Canada Day and everything was closed, I did

the shopping the next day, the 2nd. As I bought the transmission and

looked at it, I

realized that I still didn't have the clutch, and the flywheel clutch

plate for the motor side (Duh!), and when I got home, that all the

mountings in the car

were different. I might have to do some welding to fit it on. More and

more I wish I'd found a manual transmission Sprint in the first place.

But if what's missing is a clutch... didn't I just create

a new sort of centrifugal clutch? Perhaps I could use that. Let's

see... how hard might this be? Am I still going to be experimenting

with mechanical transmission stuff after all?

The big 62x62mm, 14 amp

peltier modules arrived around

mid-month and I installed one. It didn't work very well and I took it

apart and redid it, checking for trapped bits that might push the face

away from the heatsink or cold bar. That still didn't do it. I also

attached the control unit I'd bought with it, but since it never got

cold enough to shut off, it didn't do much except make a loud, annoying

beep when the power came on, and show the temperature. It may still

have a setup problem, so I'm not ready to say the module is bad. But I

didn't have

time to keep frigging around with the fridge system, so I have nothing

definite to report.

But near the end of the month, I got a couple of

interesting things done. I made several cases for flat panel LED lights

to

get production going - at least for some samples (and 3 or 4 to install

myself), and I started on the workings for a second light. Then,

looking to see what Industrial Plastics had on hand that I might use

for motor molds, I found instead some "cracked ice" pattern translucent

-

almost transparent - thin acrylic sheets to use for light diffusers.

They look fantastic when the light is off, but almost a bit as if they

were dirty when the light is on. However, they let more light through

than anything else I've seen, and one doesn't normally stare at lights

that are on. I think they'll work out great!

"Cracked ice" plastic diffuser prototype

light

"Cracked ice" plastic diffuser prototype

light

Turned on: Sufficient diffusion with high light transmission

(Left row: old emitters (4500K?). Mid, Right: new brighter, bluer ones

(6000K?).)

I also, finally, made a Ni-Mn battery on the 29th and 30th

to see if avoiding the art store graphite powder would solve the

self-discharge problem of the positive electrode. It did.

Unless

there is still deterioration of the posode over time, which I believe I

solved by increasing the ratio of nickel oxides to manganese oxides (to

form nickel manganates rather than potassium permanganate as the cell

charges and discharges),

the "nickel-manganese moderately alkaline" battery chemistry is now

known

to work with nothing to say it might be impractical for commercial use

for any reason.

But I still don't have a proper battery cell. For some

reason the

negative electrode unexpectedly didn't work right in this particular

cell - not even

in the fridge. Even its zinc powder wouldn't hold its charge. I must

have done something wrong somewhere -- the manganese negatives with

trace additives zirconium silicate and antimony sulfide have been

working well until this one. I'll make

a new one soon and demonstrate for certain everything working together

properly in the same cell.

Finally, in June just after the May newsletter, and on

July 2nd, I went

to meetings of the VEVA electric vehicle - Islands chapter. At the June

meeting was a really well done Honda Del Sol conversion. The July

meeting had a big turnout with quite a lot of electric bicycles.

Is there some irony here? The 240 volt

J-1772 electric car plug-in stations look nice, but

Is there some irony here? The 240 volt

J-1772 electric car plug-in stations look nice, but

I had to go park the Mazda, the only EV on the premises, on the lawn

where my 70 foot

extension cord could reach a regular 120 volt outlet, potentially

risking a ticket or tow-away.

Honda Del Sol EV conversion, very professionally done by an auto

mechanic.

The July 2nd VEVA-Islands meeting. I gave some rides in the electric

Mazda, and

I got to drive the Nissan Leaf,

and leave all the other cars far behind when I took off from a traffic

light.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

"Where Unsold Cars Go To Die"? (mistake from last issue)

My apollogies... I should have checked more carefully. The article on

unsold cars was evidently incorrect. The 'countless acres of cars'

pictures were real enough, but

they were from 2009 after the 2008 'crash'. And car makers did stop

production as inventories piled up.

http://www.snopes.com/photos/automobiles/unsoldcars.asp

I must be more careful not to believe everything I read.

This may well be the type of storm drain that

was

under

the grassy knoll

This may well be the type of storm drain that

was

under

the grassy knoll

where people heard the shots coming from when John F. Kennedy was shot,

and where (I now hear) a puff of smoke was seen in the air after

the

shooting.

It certainly does appear to be a mafia hangout!

When this was made, these prices were probably intended to shock.

They're now the actual ballpark prices for a small car,

and in a year or two they may look like a real bargain.

While the real background story behind the news reports

seems unclear so far, one hears rumors - or is it fact? - that as

ISIS/ISIL (however it formed and whoever provided their military

training and weapons) penetrates Iraq, it's perpetrating murders and

atrocities. So still more inhabitants are fleeing their homes --

joining

Iraqis who fled previously and the one half of the Syrian population

driven from their homes.

How then is this group better than those who invaded

before them in 2003, and the government they set up? Now we have suni

Muslims persecuting shi'ite Muslims instead of the other way around.

(And all of them persecuting Christians.) Sadam Hussein was the last

ruler of Iraq who kept internal peace between the various interests and

religious groups (ditto for Moammar Kadafi in Libya).

Tolerance, forgiveness, patience, benevolence... love...

these are the leadership qualities that would rally citizens to the

cause, or at least permit peace and stability to develop. Instead it

would appear the

populace only has one more prejudiced, dictatorial, manipulative and

well armed group rampaging through their towns and cities, to hate and

fear.

But perhaps one should look beyond the specific case,

broaden the

perspective and ask oneself, "What are the conditions that favor the

formation of such extreme groups?" Is it an isolated event unique

to Iraq, or is there some common thread? How does it relate to the US

led invasion of 2003, US and international relations and events today,

and to the continual American drive to get middle eastern oil and to

prop

up the "petrodollar"? And what drives the aspirations of various

groups around the world to want to separate and form their own

administrative regions (countries) in the midst of growing global

connectedness and political amalgamations such as the European Union?

I think that implicit in

all of it is unfairness, on many levels with many indistinct

boundaries,

and the hope that by becoming independent, more localized control might

somehow

address the unfairness. But (as Kennedy said) "We all drink the same

water; we all

breathe the same air." Mostly today the real divide is between those

with wealth, power and influence - "the 1% of the 1%" - and the rest of

us, who have lost or are losing it all to them. It's a system that

increasingly people simply want out of, and which is starting to be

sidestepped at the individual level by those who are starting to

recognize that they are being manipulated and

fleeced by the greedy.

One suspects that as economic conditions worsen globally,

hardships in various forms are likely to spread. Certainly there are

governments,

including nominally democratic ones, that are out of control

oligopolies/corporatocracies/cleptocracies that badly need to be

replaced. Our

institutions of

governance have structural weaknesses that have allowed corrupt

gangsters to

seize control over them. The ever increasing number of laws and rules

for the populace

don't apply

to the rich and powerful. Not only the gross unpunished fraud robbing

the middle class of its wealth, but the 25 or 30 banking executives

murdered in the last few months (added to the regular persecution of

journalists, politicians and inventors who would "buck the system"),

with no investigations or charges

laid, attest to that. Democratic power by the citizenry has been

essentially lost*.

Can we avoid the temptation to blame each other and split into factions

ruthlessly vying for power or create smaller geographic groupings, and

instead attempt to solve the structural

problems

of our unsustainable social institutions?

It's said there are three core values that socially

sustainable institutions must foster: Quality of Life, Growth, and

Equality. I've mentioned before how our present institutions are unable

to grow

and change to meet the needs of the day, putting our civilization at an

evolutionary dead end. And the other two values, quality of life and

equality, have been under ongoing

serious attack for generations. As individuals we don't have the

continuity to look back 100 or 150 years to realize the many ways we've

been socially regimented, economically controlled and otherwise... is

this the right word?... enslaved. We believe the conditions we're

born into are just and right, "that's the way it is", and as we see

petty measures taken that

restrict freedoms and liberties bit by bit, and adverse conditions

gradually develop, things that we don't really

agree with or like, in the news and around us week after week, we are

like the frog who doesn't notice that the temperature of the water

he's in is slowly, slowly, rising and rising. It all seems normal and

the frog doesn't jump out, and finally the water is too hot and he

dies.

* See of course my booklet Fundamental Principles

of Democratic

Government - Towards Utopian Systems of Governance

at www.saers.com/recorder/craig/FundamentalDemocracy.html

for some ideas.

Electric

Hubcap Motor Systems - Electric Transport

Suspension for

Bicycles

Various means for

giving bicycles some shock absorption have been around for a long time.

There have been "typical" motorcycle type springs and shock absorbers.

Then there's a spring and shock that allows the seat to go up and down,

springing the rider's body without springing the bike itself. But

except for the inflated tire and padding in seats, these haven't caught

on much with riders.

Various means for

giving bicycles some shock absorption have been around for a long time.

There have been "typical" motorcycle type springs and shock absorbers.

Then there's a spring and shock that allows the seat to go up and down,

springing the rider's body without springing the bike itself. But

except for the inflated tire and padding in seats, these haven't caught

on much with riders.

Now "re-inventing the wheel" is an old saying meaning

wasting effort to create something that's already been created. But

maybe it was already a saying when wheels were round chunks of wood

with a primitive wooden axle and rubbing bearings. We may think of

wheels as "already done to death", but at various points they got steel

rims, spokes, rubber and then air filled tires, and roller bearings:

wheels have in fact been progressively "re-invented" many times.

Here is another substantial new idea, seemingly invented

independently first in the UK then in the US: bicycle wheels with the

rim connected to the hub by curved leaf springs instead of by spokes.

This gives the bicycle a springy suspension within each wheel, and

makes the 'normal' bumpety-bump bicycle ride, jarring the rider at

every lump, crack and pothole, apparently even smoother than that of a

motorcycle. Suddenly bicycles -- and e-bicycles -- can be far more

comfortable to ride. Maybe such e-bikes will start replacing

"e-scooters" and "e-motorcycles"... and some riders may even decide

they can replace their cars, or use the bike and drive less.

The earlier invention would appear to be the "loopwheel"

from the UK. And it's not only invented, one can buy a bicycle made

with them. A BBC news report had the reporter riding pretty comfortably

on a rough cobblestone road. The inventor said he worked 4 years on the

composite material for the loop-springs. They're probably lighter than

spring steel.

Link: Loopwheels - For a

smoother, more comfortable bicycle

ride...

At 20" the Loopwheel is smaller than a typical

bicycle wheel, so simply replacing your crate's wheels isn't an option.

The second similar invention, the Shockwheel by

Chet Baigh, appeared on youtube in February 2013.

The ShockWheel

invention by Chet Baigh - YouTube

First concept-prototype Shockwheel

wasn't rideable

First concept-prototype Shockwheel

wasn't rideable

Footage of the second one in use, including on

very large bumps, was the meat of the video

Footage of the second one in use, including on

very large bumps, was the meat of the video

The inventor had only done

a prototype on the front wheel, and doesn't seem to have posted

anything about it since except 'looking for someone to take it

commercial'. Nevertheless it looked like it was doing a very good job

in the video. And he said everywhere people stopped him to ask about

it, and even crowds gathered around. An observation is that the wheel

rim might need to be heavier steel or otherwise beefed up. On the other

hand, maybe not: the Shockweel has four support points while the

Loopwheel has only three, and on both, shocks to the wheels are in

effect cushioned by the springs.

A big advantage to Shockwheel is that it's made to fit a

regular bicycle. I'm sure there'd be a gigantic market for retrofit

wheels.

Assuming it looked sufficiently robust and with any sort of economical

price, I myself wouldn't hesitate. And I might even ride more!

There have been other ideas for shock absorbing wheels.

But they mostly use flexing rubber or plastic parts, and I doubt if any

of them would last very well, or replace a suspension system as well as

the ones above. The one below at bottom may have metal springs, but as

shown it would only be good for small bumps - about like an inflated

tire. (But now I'm starting to think of the many possibilities!)

I got these from some web site discussing

Shockwheel... somewhere

I got these from some web site discussing

Shockwheel... somewhere

Application to the Rim Motor?

Assuming these types of spring-suspension wheels are the

future of bicycling, the next question for me is: what about that rim

motor with the arc of coils attached to the frame, that I've been

planning to make? The magnet rotor ring was to mount on the spokes of

the wheel. Now there are no spokes, and also the rim bounces around

with bumps and dips on the road. The magnet rotor ring would bounce

along with it. This wouldn't improve alignments to the coils, and 1/2"

of sideways motion of the rim would have the magnets scraping the coil

housing.

This is doubtless going to call for some revisions to the

plan. Perhaps the magnet rotor can be attached to the hub. That would

make a single design, more applicable to a wider range of bicycles

anyway. But looking at a couple of bikes, I'm wondering if a whole

special wheel might have to be made to accommodate both the suspension

springs and the motor. But such a wheel would have double the

attraction to buyers: a smooth ride and power!

As occasionally happens, I may be ahead by not having

built this project yet.

Other Green

Electric Equipment Projects

Flat Panel LED Lights

My flat panel lights, being uneven in brightness across

the face, may have a bit of a hard time competing with the fairly even

glow of the Chinese flat panel lights. At first I thought they might

not really be competitive. But they'll probably be brighter

per watt, and it's a design I can make relatively easily and offer at a

competitive price. Some "cracked ice" diffuser plastic I found near the

end of the month looks nicer when the light is off than flat plastic,

and transmits more light than anything else I've found.

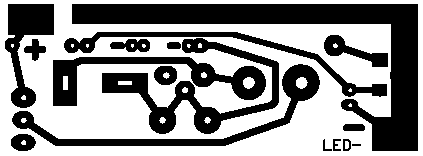

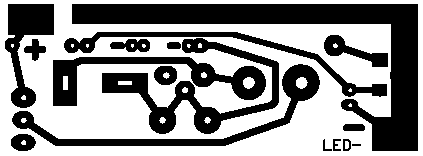

On the 8th I

designed a PCB for the other components. It was mostly a modification

of the previous board as to component placement, dimensions and

connections, but I added a receptacle for typical power adapters ('fat'

pin, center '+', 12v) in addition to the CAT standard plug pins, and

simply in parallel to them.

Circuit Board Making Techniques (the continuing search for

better processes)

I made a board

the next morning. Instead of printing the

artwork on thin, glossy magazine paper, I printed it on "toner transfer

paper" from "Fab in a Box" (www.pcbfx.com). The first image transferred

poorly,

but I turned down the temperature of the iron and the next one looked

good. It transferred well and the backing paper virtually fell right

off

after a brief soak. All the toner and no paper fiber was deposited on

the board, which seemed to be an improvement over the magazine paper.

It was again a bit light with missing spots... at least partly because

I

forgot again to print "darkest", which in turn is because the print

darkness adjustment isn't shown in the multitude of print setup

options. It's well hidden and doesn't have a big range. The on-line

instructions said they preferred a laminator to an iron, and the

instructions mention some other 'foil' product of theirs that I didn't

buy, to laminate on after the toner transfer.

I made a board

the next morning. Instead of printing the

artwork on thin, glossy magazine paper, I printed it on "toner transfer

paper" from "Fab in a Box" (www.pcbfx.com). The first image transferred

poorly,

but I turned down the temperature of the iron and the next one looked

good. It transferred well and the backing paper virtually fell right

off

after a brief soak. All the toner and no paper fiber was deposited on

the board, which seemed to be an improvement over the magazine paper.

It was again a bit light with missing spots... at least partly because

I

forgot again to print "darkest", which in turn is because the print

darkness adjustment isn't shown in the multitude of print setup

options. It's well hidden and doesn't have a big range. The on-line

instructions said they preferred a laminator to an iron, and the

instructions mention some other 'foil' product of theirs that I didn't

buy, to laminate on after the toner transfer.

When I etched the board I wasn't very happy with the final

result. The general outlines seemed sharp and well defined, but the

copper wasn't shiny and buffing it didn't help. Under a magnifying

glass, many areas that were supposed to be solid copper were etched

partly or completely through in a fine "woven" or "checkerboard"

pattern. The iron

may have been too hot or cold, and the print too light, and I didn't

have the 'foil' stuff. So I thought I probably hadn't given it a fair

trial.

On the 12th or 13th I was driving by Microsec R & D,

where I heard Ed had switched to "a better way of doing boards" a few

months ago, and I stopped in. It turned out he was using the same toner

transfer paper I was trying out, but using a laminator

instead of an iron. He had some very nice looking boards he'd recently

done and said it was as good as the old photo process. And he had the

'foil' as well, but said it just seemed to be a nuisance and he wasn't

using it. "Run it through the laminator 10 or 12 times." It also turned

out that laminators are no longer large machines doubtless costing many

hundreds of dollars as they were in the 1980s when I used to deal with

them, but could be had as a little on-off plastic device for 50$.

50$?!? Why was I bothering with an iron?

On the 15th I printed 9 copies of the artwork in a

vertical column. The print on regular paper was fine, but on the toner

transfer paper it got worse and worse from top to bottom. I did the top

3 "V2" boards - the rest were unusable. The transfer via 12 laminator

passes was good except in a few spots that inexplicably stuck to the

paper instead of the board. I used a felt marker pen to touch these up.

The boards came out no better than the previous ones, with the same

crosshatch patterns in the copper.

Surely the printer was the main problem then. After a

search, I found where to adjust the darkness, under the heading

"Printer Setting" -> "Graphic" -> "Color" -> "Manual color

adjustment". I moved the "black" bar all the way to the right... but

did that mean 'darkest', or 'lightest'? There was no indication. So I

did a test print there, then moved the bar all the way to the left and

did another.

The first one was slightly darker, so I set it back. But

under a magnifying glass, the same crosshatch pattern that was plaguing

the circuit boards was visible on the paper in both copies. Humpf! I

suppose that with the glossy magazine paper and the iron, there was

just enough smear, or enough stuck paper fibers, to smooth out the

pattern and fill the voids. The special toner transfer paper gave

higher resolution that showed the printer's flaws. Evidently with my

printer I should stick with the glossy magazine paper.

Judging by the results, with even the fine crosshatch

pattern showing up clearly, I did better with the iron, carefully

pressing each and every spot right near the edge of the iron, and

lifting the iron to move it, than I did with the laminator. That was a

bit of a surprise. And the paper runs through the laminator so slowly

I'm not sure, after 12 passes through it, it was any faster. But I'll

try the laminator again... after all I now have 50$ invested in it!

I do have one other laser printer, an "all in one"

monochrome unit I had bought to use as a photocopier, and have never

connected to the computer. For the next try I'll use that. In the

meantime I have four poor but essentially usable boards to make

prototype lights with.

Meanwhile, back at the ranch...

In the

afternoon (of the 10th) I put the workings of the

first light together.

I found a couple of mistakes on the board - I still didn't have the

power adapter socket right and it came out mirror image, and the

transistor pins were backwards. I didn't and don't see why, but I

simply turned it around. I cut a couple of traces and ran a couple of

wires

to make the board work, and corrected them in the layout editor

("Eagle")

for next time.

In the

afternoon (of the 10th) I put the workings of the

first light together.

I found a couple of mistakes on the board - I still didn't have the

power adapter socket right and it came out mirror image, and the

transistor pins were backwards. I didn't and don't see why, but I

simply turned it around. I cut a couple of traces and ran a couple of

wires

to make the board work, and corrected them in the layout editor

("Eagle")

for next time.

I had spread out the LED s on the copper strips and the

transistor was soldered to a piece of copper as well, but with just

1.15 amps flowing in at 12 or 13 volts - 12 or 13 watts in 15 emitters

(much of which surely comes out as light),

a transistor and a resistor - the whole 4" x 7" works got surprisingly

hot. I think I'll have to use wider copper strips and space the LED s

farther apart. And maybe punch holes in the copper to improve the

airflow. A larger area panel will make shadows more diffuse but it'll

be the same amount of light. This 4" x 7" panel size might be better

with 9 LED s, 675mA, 8-9W. Concerns about simply upping the size are:

(a) While the surface area is the length times the width, the edge

length for

airflow is only the length plus the width (x 2), so airflow doesn't

increase proportionately as the size increases. (One can of course go

for long and thin shape, or thicken the ceiling-to-light gap.) (b) The

copper heatsink sheets are the most expensive component. Larger area

means higher price. But you can't solder the emitters (or anything

else) to aluminum, the cheaper heatsink material.

One further

good thing I noticed on the plus side for the

design as a

whole: Whereas I had been concerned about the unevenness of the light,

with the emitters showing through the diffuser as bright blobs, that

was looking directly at the face. But for a ceiling light,

that

would be standing right underneath it and looking up. Viewed from more typical angles, the bright

spots disappear and a fainter pattern replaces them. At further angles,

a

uniform glow is seen. So for

typical lighting situations, the desired even glow is sufficiently

attained by this layout. I even made the 7x7 box with transparent

sides, since the bulk of the light is aimed downward. That way too, the

light within and its construction can be viewed by potential partners,

supporters and customers - a demo unit.

One further

good thing I noticed on the plus side for the

design as a

whole: Whereas I had been concerned about the unevenness of the light,

with the emitters showing through the diffuser as bright blobs, that

was looking directly at the face. But for a ceiling light,

that

would be standing right underneath it and looking up. Viewed from more typical angles, the bright

spots disappear and a fainter pattern replaces them. At further angles,

a

uniform glow is seen. So for

typical lighting situations, the desired even glow is sufficiently

attained by this layout. I even made the 7x7 box with transparent

sides, since the bulk of the light is aimed downward. That way too, the

light within and its construction can be viewed by potential partners,

supporters and customers - a demo unit.

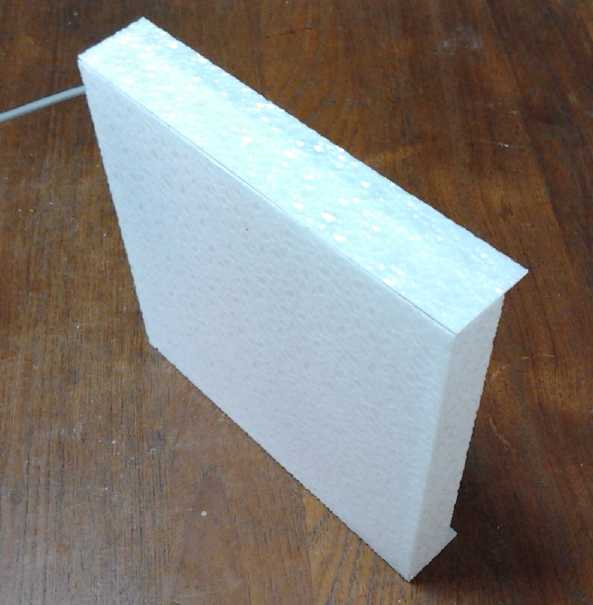

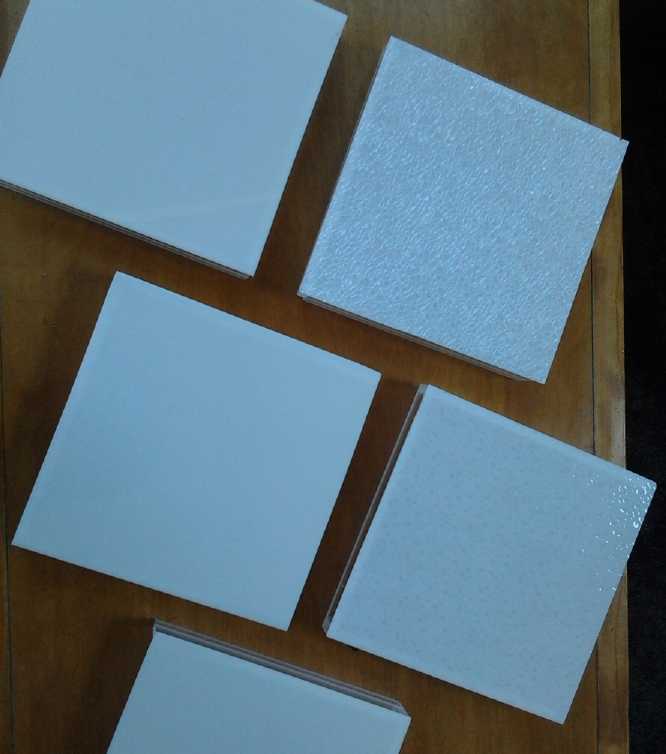

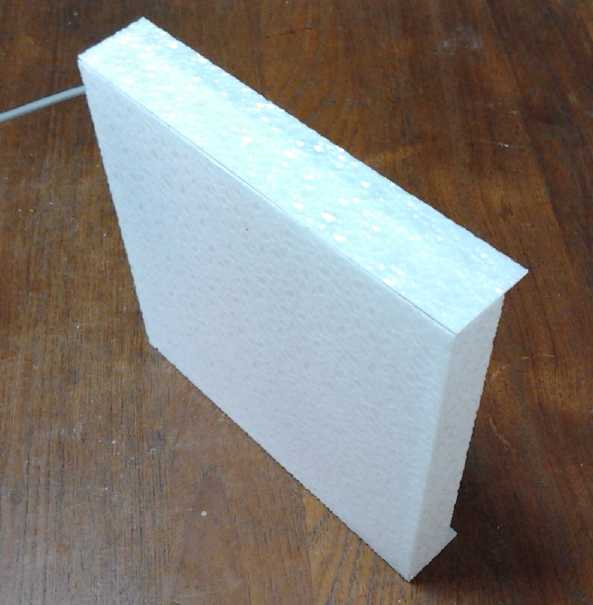

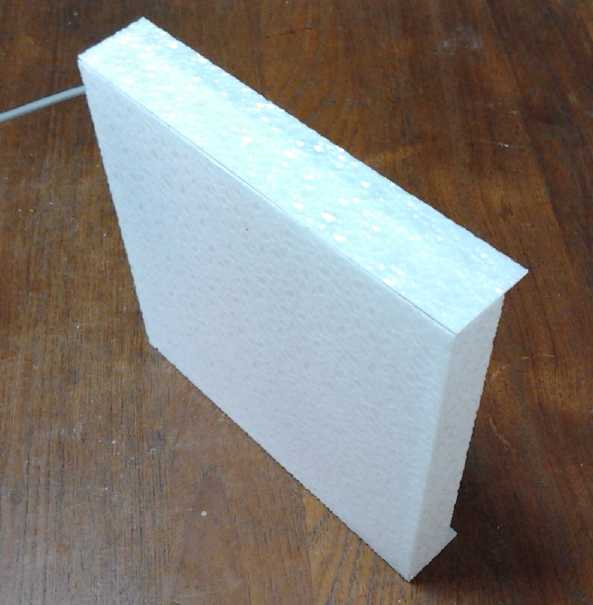

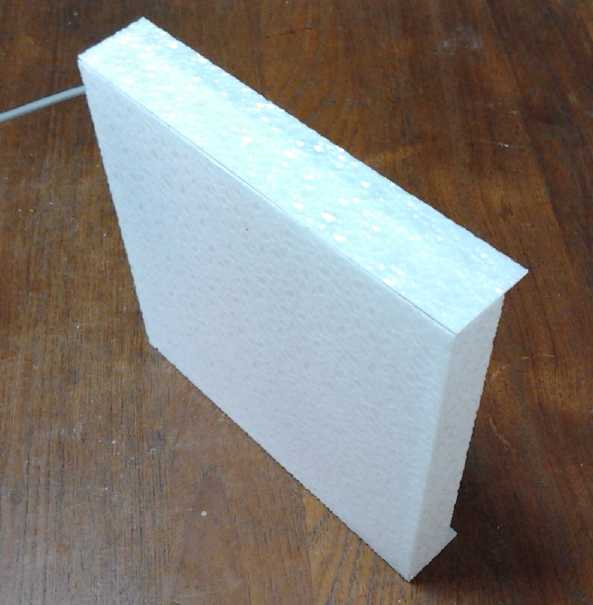

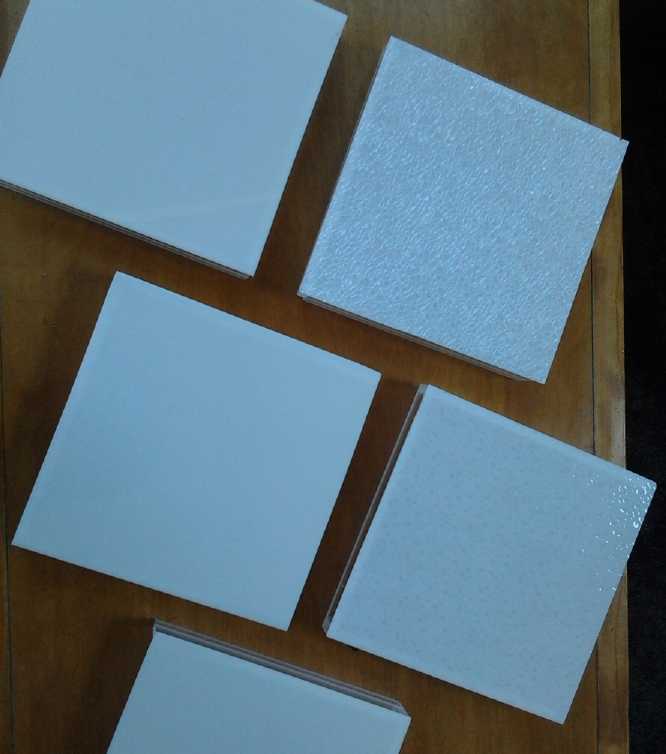

Three of the translucent light cases and the

"cracked ice pattern" ones discussed below.

On about the 28th I cut enough

plastic pieces to make 5

flat panel LED light cases and assembled them minus the last wall that

holds the light works in place and minus the mounting tabs. It took

about 3 hours. I got better at sawing, finding that one key to

smooth(er) cuts is to not quite cut it through, then snap it off and

sand off the thin bits remaining. I also put masking tape along the

line to be cut, top and bottom. Sharpening the saw blade probably

helped too. But even for home production, I need a way to make it take

less time to cut plastic, not more. The band saw also makes better cuts

than the radial arm saw , even with a coarse toothed band. However, it

doesn't really cut straight lines very well.

On about the 28th I cut enough

plastic pieces to make 5

flat panel LED light cases and assembled them minus the last wall that

holds the light works in place and minus the mounting tabs. It took

about 3 hours. I got better at sawing, finding that one key to

smooth(er) cuts is to not quite cut it through, then snap it off and

sand off the thin bits remaining. I also put masking tape along the

line to be cut, top and bottom. Sharpening the saw blade probably

helped too. But even for home production, I need a way to make it take

less time to cut plastic, not more. The band saw also makes better cuts

than the radial arm saw , even with a coarse toothed band. However, it

doesn't really cut straight lines very well.

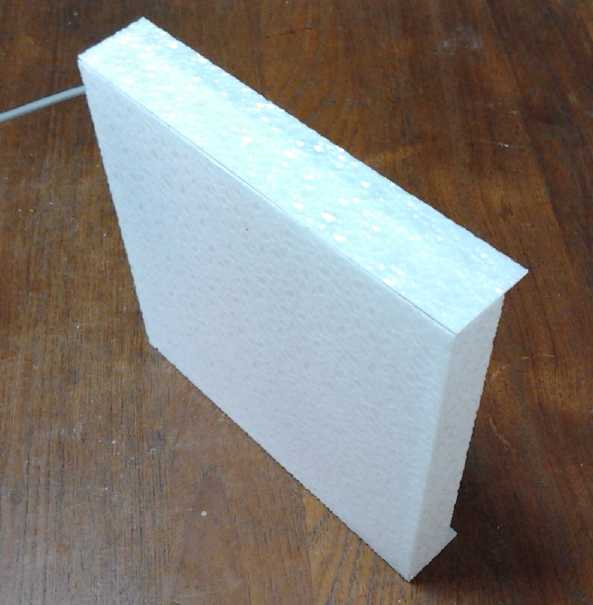

On the 30th I did a little shopping looking for a fat

piece of UHMW to make motor molds for the Electric Weel motor and the

Bike Rim motor, but at the plastic shop I found instead some thin,

textured acrylic plastic with a sort of inverse pebbly surface.

(Duralens Cracked Ice Acrylic "22969") It let through more light than

the thin sheet I had bought for the purpose - in fact, I think more

light than anything else 'transulcent' I've seen - and rather than

allowing the sun to show though as a small spot, it broke it into

dozens of tiny points, each of which let through most of the sun's

light.

So I put

together two more 7x7" lights to see how they'd

compare with the others. One had the texture on the outside face and

the other on the inside. I had the impression it

didn't make much difference. Either way it seemed like a good look and

it seemed to let light through really well. I could see using this on

all sides -- the light would look like a cube of frosty ice! So I cut

edge pieces and glued them over the transparent edges to see the effect.

So I put

together two more 7x7" lights to see how they'd

compare with the others. One had the texture on the outside face and

the other on the inside. I had the impression it

didn't make much difference. Either way it seemed like a good look and

it seemed to let light through really well. I could see using this on

all sides -- the light would look like a cube of frosty ice! So I cut

edge pieces and glued them over the transparent edges to see the effect.

Then, having used the same light workings for all the

tests, I started in on another one on July first. I took the copper

'beams' and punched holes through them for air flow by settings them

over a hole in a piece of wood and then punching them through with a

center punch. This made holes the size of whatever drill bit I used.

This proved quite easy, and contrary to drilling holes, it left them

with jagged copper sides sticking up - extra surface area ideally

placed by the airflow for cooling.

The bright but broken-up pattern of light

through the 'cracked ice' diffuser

The bright but broken-up pattern of light

through the 'cracked ice' diffuser

Electricity Storage

Turquoise Battery Project

For almost 3 months competing attractions kept me from the

simple test of making a new electrode and battery cell to verify that

the

high levels of self discharge, the last nagging chemical problem of the

whole

Ni-Mn battery chemistry, was

simply due to graphite contaminated with nitrates/nitrites, purchased

at an art supply store. As I hadn't found carbon black so far to buy, I

settled for using the MnO2/carbon black mix from a dry cell. That

leaves the cell with both less carbon black than desired and less KMnO4

than desired, but since it's battery quality ingredients (unless

perchance the KMnO4 isn't pure... egads, another one to check out!), it

should at least work.

On the 29th I finally got to it - I just wasn't going to

let it slip another month! I had worked out a mix in May, the first two

ingredients being the approximate contents of a standard dry cell. But

(without bothering with calculations) there didn't seem to be enough

nickel compared to manganese. Extra nickel doesn't hurt whereas extra

manganese does, so I added 10 grams each more monel and Ni(OH)2, and a

bit more

samarium to account for it, making well over the intended 100g:

28g - MnO2 (or Mn2O3 or MnOOH or Mn3O4 or Mn(OH)2 in various

proportions depending on discharge state)

12g - carbon black (substantially less than I'd like)

18g - KMnO4

28g - Monel

28g - Ni(OH)2

8g - Sm2O3

===

122g

I put in the now usual 40x120mm piece of graphite felt and

shook it all up to impregnate the felt with powder. Then I folded it

into 3 in the 40x40mm compactor box, adding a few drops of Diesel Kleen

and Sunlight dishsoap. I pressed it to 3Mg (mega-grams) AKA 3 metric

tons, in the 20 ton press with gauge, and left it pressing in the press

for a while. Then I torched the surface for a 3-4 seconds, then painted

in a bit of ferric chloride, then matched it with a composite graphite

current collector and wrapped it in watercolor paper.

I looked around for an existing negatrode, but I wasn't

positive which was which now that both 'trodes have graphite composite

current collectors... and anyway it might have become contaminated. I

made a new one, then assembled the cell on the 30th. I used the old

current collectors - not in bad shape - and tossed the electrodes and

their papers and cloths. I put in a little modeling clay around the

slot gaps in the jar so the negode wouldn't discharge from oxygen in

the air getting in.

After a couple of hours charging, I thought that this was

perhaps a bit more like a flooded lead-acid cell than the usual

alkaline dry cell, and wondered if it might benefit from pulse

charging. In mid afternoon I happened across the narrow-pulse pulse

charger I had made some months ago, and (after a little confusion with

the unlabeled connections) hooked it up, with about 6 volts for power

and for charge voltage. I put in a 10 ohm resistor to limit charge

current.

Testing

Voltage came up slowly from under 1/2 a volt as it usually

does, stopping for quite a while at 1.6 to 1.8 volts ("Ni-Zn") while

the zinc powder turned or returned from oxide to metallic form. When

the pulse charger was put on, the reading jumped up to 2.4 volts, but

that must have been peak voltages, or at least above the average DC

level... I think.

Later I found it hadn't charged above 1.9 volts - not an

auspicious sign! In fact, it just didn't want to charge higher. That

sounded like a negative electrode problem, not the plus side. Kind of

like 2012 before the zirconium silicate, when it worked in winter but

not in summer. I put some water in a container and put the battery in

it, then I put in some ice cubes. Gradually the voltage started to

rise. But the ice melted and it was bedtime. The container had

indicated the mix had the right things, but obviously there was some

problem with it.

The next morning, July first, I put in a slice of zinc as

a test electrode. This verified that the voltage from the negode was

about the same as the zinc, the cell voltage being a little over 1.8

volts with either. The manganese wasn't charging. I disconnected the

pulse charger, oscilloscope et al and put the cell in the fridge.

Self Discharge Appears to be Solved!

After the charge had been turned off for a couple of hours

it also looked like there was less self discharge from the posode. I

used the zinc strip to check it against, and I pulled the strip out of

the cell after each test, to prevent cumulative effects emanating from

the minus side. I decided to leave it sitting a day or more and get a

clearer picture. Voltage was 1.76 and it would supply 150mA into the

meter shorted on the 0-300mA scale. After 12 hours voltage was 1.707

and it supplied 145mA, and these figures stayed steady another 3 hours

until I went to bed. The next morning (24 hours) it had about the same

voltage - even up a bit (<= 1.712v) after I wiped the zinc with a

nylon pad. The current drive had dropped to 134-139mA depending on

placement of the zinc. (Using two zinc strips didn't raise it much.

Say, wasn't the electrode compaction supposed to be much stronger?

Where did I get the low values I used this time?) 36 hours: 1.698v,

129mA. 48 hours: 1.690v, 128mA.

Like most if not all rechargeable cells, Ni-whatever

cells do have some self discharge. Especially over the first day they

may lose 10%. The drop with time here is within that sort of range and

quite workable for EV use. The

essential high self discharge problem, which had been leaving the cells

with dropping voltage and little usable energy after a day or so,

seems to be solved.

It would seem the art store graphite powder, probably

impure with nitrates, was indeed the

problem all along. I *think* all problems with Ni-Mn flooded cell

battery chemistry are now solved. Remaining problems are production

problems, especially getting things to stay sealed.

But now, I still

don't have a properly working cell because of the unexpected problem

with the negode! The manganese won't charge even in the fridge, and

even the zinc discharges itself over some hours.

That's surely just some glitch - nickel-zinc is known to work, and

manganese certainly was holding charge previously. (Maybe even from not

compacting it enough?) I'll mix new chemicals and make another one in

the coming days.

http://www.TurquoiseEnergy.com

Victoria BC

Various means for

giving bicycles some shock absorption have been around for a long time.

There have been "typical" motorcycle type springs and shock absorbers.

Then there's a spring and shock that allows the seat to go up and down,

springing the rider's body without springing the bike itself. But

except for the inflated tire and padding in seats, these haven't caught

on much with riders.

Various means for

giving bicycles some shock absorption have been around for a long time.

There have been "typical" motorcycle type springs and shock absorbers.

Then there's a spring and shock that allows the seat to go up and down,

springing the rider's body without springing the bike itself. But

except for the inflated tire and padding in seats, these haven't caught

on much with riders.

I made a board

the next morning. Instead of printing the

artwork on thin, glossy magazine paper, I printed it on "toner transfer

paper" from "Fab in a Box" (www.pcbfx.com). The first image transferred

poorly,

but I turned down the temperature of the iron and the next one looked

good. It transferred well and the backing paper virtually fell right

off

after a brief soak. All the toner and no paper fiber was deposited on

the board, which seemed to be an improvement over the magazine paper.

It was again a bit light with missing spots... at least partly because

I

forgot again to print "darkest", which in turn is because the print

darkness adjustment isn't shown in the multitude of print setup

options. It's well hidden and doesn't have a big range. The on-line

instructions said they preferred a laminator to an iron, and the

instructions mention some other 'foil' product of theirs that I didn't

buy, to laminate on after the toner transfer.

I made a board

the next morning. Instead of printing the

artwork on thin, glossy magazine paper, I printed it on "toner transfer

paper" from "Fab in a Box" (www.pcbfx.com). The first image transferred

poorly,

but I turned down the temperature of the iron and the next one looked

good. It transferred well and the backing paper virtually fell right

off

after a brief soak. All the toner and no paper fiber was deposited on

the board, which seemed to be an improvement over the magazine paper.

It was again a bit light with missing spots... at least partly because

I

forgot again to print "darkest", which in turn is because the print

darkness adjustment isn't shown in the multitude of print setup

options. It's well hidden and doesn't have a big range. The on-line

instructions said they preferred a laminator to an iron, and the

instructions mention some other 'foil' product of theirs that I didn't

buy, to laminate on after the toner transfer. In the

afternoon (of the 10th) I put the workings of the

first light together.

I found a couple of mistakes on the board - I still didn't have the

power adapter socket right and it came out mirror image, and the

transistor pins were backwards. I didn't and don't see why, but I

simply turned it around. I cut a couple of traces and ran a couple of

wires

to make the board work, and corrected them in the layout editor

("Eagle")

for next time.

In the

afternoon (of the 10th) I put the workings of the

first light together.

I found a couple of mistakes on the board - I still didn't have the

power adapter socket right and it came out mirror image, and the

transistor pins were backwards. I didn't and don't see why, but I

simply turned it around. I cut a couple of traces and ran a couple of

wires

to make the board work, and corrected them in the layout editor

("Eagle")

for next time.

One further

good thing I noticed on the plus side for the

design as a

whole: Whereas I had been concerned about the unevenness of the light,

with the emitters showing through the diffuser as bright blobs, that

was looking directly at the face. But for a ceiling light,

that

would be standing right underneath it and looking up. Viewed from more typical angles, the bright

spots disappear and a fainter pattern replaces them. At further angles,

a

uniform glow is seen. So for

typical lighting situations, the desired even glow is sufficiently

attained by this layout. I even made the 7x7 box with transparent

sides, since the bulk of the light is aimed downward. That way too, the

light within and its construction can be viewed by potential partners,

supporters and customers - a demo unit.

One further

good thing I noticed on the plus side for the

design as a

whole: Whereas I had been concerned about the unevenness of the light,

with the emitters showing through the diffuser as bright blobs, that

was looking directly at the face. But for a ceiling light,

that

would be standing right underneath it and looking up. Viewed from more typical angles, the bright

spots disappear and a fainter pattern replaces them. At further angles,

a

uniform glow is seen. So for

typical lighting situations, the desired even glow is sufficiently

attained by this layout. I even made the 7x7 box with transparent

sides, since the bulk of the light is aimed downward. That way too, the

light within and its construction can be viewed by potential partners,

supporters and customers - a demo unit. On about the 28th I cut enough

plastic pieces to make 5

flat panel LED light cases and assembled them minus the last wall that

holds the light works in place and minus the mounting tabs. It took

about 3 hours. I got better at sawing, finding that one key to

smooth(er) cuts is to not quite cut it through, then snap it off and

sand off the thin bits remaining. I also put masking tape along the

line to be cut, top and bottom. Sharpening the saw blade probably

helped too. But even for home production, I need a way to make it take

less time to cut plastic, not more. The band saw also makes better cuts

than the radial arm saw , even with a coarse toothed band. However, it

doesn't really cut straight lines very well.

On about the 28th I cut enough

plastic pieces to make 5

flat panel LED light cases and assembled them minus the last wall that

holds the light works in place and minus the mounting tabs. It took

about 3 hours. I got better at sawing, finding that one key to

smooth(er) cuts is to not quite cut it through, then snap it off and

sand off the thin bits remaining. I also put masking tape along the

line to be cut, top and bottom. Sharpening the saw blade probably

helped too. But even for home production, I need a way to make it take

less time to cut plastic, not more. The band saw also makes better cuts

than the radial arm saw , even with a coarse toothed band. However, it

doesn't really cut straight lines very well.

So I put

together two more 7x7" lights to see how they'd

compare with the others. One had the texture on the outside face and

the other on the inside. I had the impression it

didn't make much difference. Either way it seemed like a good look and

it seemed to let light through really well. I could see using this on

all sides -- the light would look like a cube of frosty ice! So I cut

edge pieces and glued them over the transparent edges to see the effect.

So I put

together two more 7x7" lights to see how they'd

compare with the others. One had the texture on the outside face and

the other on the inside. I had the impression it

didn't make much difference. Either way it seemed like a good look and

it seemed to let light through really well. I could see using this on

all sides -- the light would look like a cube of frosty ice! So I cut

edge pieces and glued them over the transparent edges to see the effect.