Turquoise

Energy Ltd. News #78

July 2014 (posted August 3rd)

Victoria BC

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Features: Ni-Mn 2-1/2 volt

battery self discharge reduction (see month in brief, Turquoise

Battery project)

Month In Brief

(Project Summaries)

- Flat Panel LED Lighting - Electric Weel Motor/Generator -

Battery Renewal - Car Transmission - EV Individual Battery Monitor

- NiMn Battery Development - NiNi Battery Idea - Electric Caik

Outboard boat trip -

3D Printer repaired.

In Passing

(Miscellaneous

topics, editorial comments & opinionated rants)

- Illustration: "Price of electricity versus gasoline"

- A planeload of people killed to eliminate free energy?

- Slight of Hand: Repeated Insinuations Batter the Brain to

Manipulate Perception

Electric Transport - Electric

Hubcap Motor Systems

* Electric Weel Motor/Generator - Plastic for Molds: at long last, the

project proceeds

* Individual Battery Monitor - El Cheapo version (7-segment voltage

displays)

Other "Green"

Electric Equipment Projects

* Flat Panel LED lights: - assembly, circuit boards...

Electricity Generating (no reports)

Electricity Storage - Turquoise

(NiMn) Battery Project etc.

* Reducing or eliminating the NiMn self discharge

* Lead-acid battery renewal - Learning more chemistry - lower voltages

with higher pH.

No Project Reports on:

Variable torque converter transmission, Peltier heat pumping, Lambda

Ray Collector, Magnet motor, CNC

Gardening/Farming Machine (sigh, maybe summer...

2015?),

Woodstove/Thermal Electricity Generator,

evacuated tube heat radiators.

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers -

Ersatz 'powder coating' home process for

protecting/painting metal

- Preliminary Ni-Mn Battery Making book

Products Catalog:

- Electric Hubcap 4.6KW BLDC Pancake Motor Kit

- Electric

Caik

3KW BLDC Pancake Motor Kit

- NiMH Handy Battery Sticks, 12v battery trays & Dry

Cells (cheapest NiMH

prices in Victoria BC)

- LED Light Fixtures

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

July in Brief

I took things more or less

a work session at a time in the

first half of July, trying to do less "multitaskings" and more "in the

present moment" concentrated efforts, and to prioritize in advance

and not let the most important or timely projects lapse without

progressing. After that I was doing Weel motor pieces, monitoring

battery performance, and miscellaneous project work. It was quite a

productive month.

Flat Panel LED Light

Over several

mornings I put together an improved flat

panel LED light - the inner workings - with an improved circuit board,

higher light output from 12 watts with twenty 2.9 volt LED emitters

driven more

softly: less heat, and better heat dissipation. But it gave full output

above 13 volts. I hope I can bring that down some. OTOH, it's a good

battery saving voltage for off-grid use, dimming more and more as the

batteries get lower.

I found it was simple

to

punch vent holes in the copper strips with a center punch, a piece of

wood with a hole for the punch, and a hammer. This was better than

drilling the holes because jagged sides were left around the holes as

"cooling fins". Then I got onto other things.

At the end of the

month a couple of the 1200 lumen Chinese LED 'light bulbs' quit within

a day of each other (one for the third time), suggesting that replacing

them with my own lights instead of just repairing them might be

worthwhile. That'd also be good real-life testing before trying to

market them. On the morning of August 1st I mounted the aforementioned

light in

the bathroom above the mirror. It was nice to be able to reposition the

light

away from where the window hits the bulb when it's swung open.

It's okay with the 12 volt power

adapter, but it could have been brighter... about that 13 volts! (And

about that wire...)

It's okay with the 12 volt power

adapter, but it could have been brighter... about that 13 volts! (And

about that wire...)

Electric Weel Motor

Fortuitously

getting some very suitable UHMW-PE plastic from

Jim Harrington at AGO on the 5th, I made a mold for 1/8 circle pie

sections for

the giant

Electric Weel motor and generator, a long dormant project that I've

been wanting to get on with. Then I cast

a pie piece with it.

This was a 3-piece mold to get sufficient depth for some side wall

'ribs'.

The piece looked great, but the coil "buttons" turned out too large and

the toroid coil cores wouldn't quite fit over them. I went back over

the G-code for previous motors and found I had made them 10 thou

smaller than the stated 1.250" dimension (1.240") to ensure they'd fit.

Recalling they were a very tight fit even at that, I changed the Weel's

coil button program to make them 14 thou smaller (1.236") and routered

out a new mold piece. Over 10 days

or so ending about the 24th, I cast the remaining 7 sections and had

the full circle, and I also designed and routered a couple of sections

of the next mold. I

haven't epoxied it together into a single unit yet.

Fortuitously

getting some very suitable UHMW-PE plastic from

Jim Harrington at AGO on the 5th, I made a mold for 1/8 circle pie

sections for

the giant

Electric Weel motor and generator, a long dormant project that I've

been wanting to get on with. Then I cast

a pie piece with it.

This was a 3-piece mold to get sufficient depth for some side wall

'ribs'.

The piece looked great, but the coil "buttons" turned out too large and

the toroid coil cores wouldn't quite fit over them. I went back over

the G-code for previous motors and found I had made them 10 thou

smaller than the stated 1.250" dimension (1.240") to ensure they'd fit.

Recalling they were a very tight fit even at that, I changed the Weel's

coil button program to make them 14 thou smaller (1.236") and routered

out a new mold piece. Over 10 days

or so ending about the 24th, I cast the remaining 7 sections and had

the full circle, and I also designed and routered a couple of sections

of the next mold. I

haven't epoxied it together into a single unit yet.

Once this motor is done, I have an idea how to beef up my

motor controllers to get them working reliably even at very high

currents. (I had to admit that my

controller would

probably have blown up to a potential customer.) If that's successful

I'll have

really excellent sets of controllers with three sizes of fabulous

motors.

Electric Weel Motor - stator end, ready to epoxy together

Electric Weel Motor - stator end, ready to epoxy together

Some coils, coil cores, and a shaft bearing are shown.

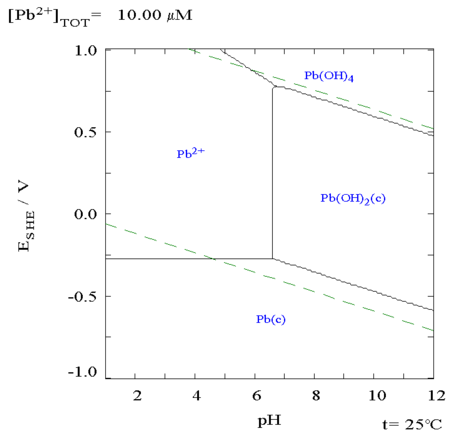

Battery Renewal

Finding another deteriorating

battery in the Mazda RX7-EV, I decided it was time to try again

to renew a lead-acid battery, of which I have a number sitting around -

mostly out of the Mazda. This time, I had learned that an important

number I had been using on a chart was in error - way off - and this

had led me astray for years in what I had assumed was happening inside

the cells.

Finding another deteriorating

battery in the Mazda RX7-EV, I decided it was time to try again

to renew a lead-acid battery, of which I have a number sitting around -

mostly out of the Mazda. This time, I had learned that an important

number I had been using on a chart was in error - way off - and this

had led me astray for years in what I had assumed was happening inside

the cells.

Now comprehension began to dawn that the lower voltages I

was so often getting were due not to "shorted cells" in the battery,

but rather to decreased acidity as more neutral sodium sulfate -

perhaps far too much - was added. My renewal "failures" were probably

just failure to understand.

I put the renewed battery into the Mazda. It reliably

provided 5-7 volts for extended periods of driving. It seemed to react

slowly to high loads, dropping in voltage and then rising over a few

seconds while the current stayed the same.

I should probably reduce the concentration of Na2SO4 in

all the batteries I've done and still have, and then maybe add some

acid to them if they still won't hold a good charge.

Car Transmission

I opened the manual transmission I bought for the Chevy

Sprint to see what went into it, but got no farther putting the Sprint

together. There were some very interesting gear arrangements, which are

probably pretty standard. One shaft turned a second shaft which

(depending on the gear selected) turned a third shaft which drove the

differential, and both the input and output shaft had gears turning

both directions at the same time, all churning up the heavy gear oil.

The reasons a typical manual transmission is said to lose 30% of the

input energy started adding up. Each individual meshing gear only had

to lose a few percent when there were so many of them engaged at once.

(Automatics and 4-wheel drives are worse - 40%. Hence my lengthy quest

for something better. Couldn't they at least make them with 99%

efficient flat belts instead of metal gears in heavy oil? But cars are

designed from start to finish to consume fuel - the car companies work

with the oil companies, all under the gangsters who've been running our

society so far.)

Electric Car Individual Battery Monitor

On the 12th I

made a sort of plastic case and put in 6 of

the little 4-LED-digit voltmeters - the "el-cheapo" version of the

individual battery monitor for EV s. The next day I finished getting it

into the Mazda showing the five batteries under the hood and just one

(any one) of the six rear under-trunk batteries.

On the 12th I

made a sort of plastic case and put in 6 of

the little 4-LED-digit voltmeters - the "el-cheapo" version of the

individual battery monitor for EV s. The next day I finished getting it

into the Mazda showing the five batteries under the hood and just one

(any one) of the six rear under-trunk batteries.

The process got exciting when I accidentally touched a

wrench to Ni-MH terminals with 24 volts between them to attach a

connector. It welded itself on for a few seconds, but I managed

to knock it off. The wrench "fingers" that grip the nut were gone, and

a hole was burned into the center of the wrench. Not to mention that

those two nuts will never be turned again. The batteries still seemed

to be pretty fully charged.

The displays showed that some batteries were being charged

to slightly higher voltages than others: 13.7, 13.8 or 13.9. (The

lithium-ion battery was at 18.7.) Optimum for the Ni-MH s should be

14.0

but no more, and they weren't reaching it.

The first drive showed that the lower 90 AH Ni-MH battery

wasn't performing as well as the upper one, dropping substantially more

voltage under heavy loads. I'd suspected that but wasn't sure. This was

an immediate vindication of doing individual battery monitoring. It

also showed that the lead-acid batteries had lower load voltages than

the Ni-MH s, from the start dipping under 12 volts with load when the

Ni-MH s were dipping under 13 volts. So the PbPb s were yielding maybe

5-9% less energy with the same nominal ratings.

Either the lower Ni-MH battery needed looking at or it

just wasn't being charged as high. I may re-make them both as soldered

battery

"packs", as I'm becoming increasingly mistrustful of the bulky "giant

flashlight tube" or "battery stick" batteries where there are more than

maybe 2 or 3 or 4 tubes. It's hard to tell in a permanent installation

if there's a

malfunctioning tube and then hard to pin down which one it is.

In addition the weakest 'size 27' lead-acid battery in the

back was shown to be weaker than the two 'size 24's in the front (both

pretty fair despite being rather small for an EV), dropping more

voltage with load and as the trip progressed. It soon needed

replacing -- but I could see its voltage drop and removed it before I

started running it into the ground. It should be good to renew.

With the monitor showing the weak links, I can work on

improving them and hopefully getting more range out of the car. Of

course, it could use a second monitor to show all the rear batteries at

once. (Ugh!) Since getting a look at all those numbers on the first

monitor is distracting while driving, perhaps this should be an

incentive to do the "real" monitor with programmable green bar graphs

for each battery that turn yellow as it gets low, red when it's really

time to stop, and flashing red if they're probably sustaining damage

under load.

NiMn Batteries

The main focus of the month's Turquoise Battery Project

was to try to eliminate, or reduce to practical levels, the self

discharge that has been plaguing the cells. Such a project involves a

little wok and then oodles of charging, cycling and testing. There was

some success, but it's not clear yet whether the steps taken will be

sufficient, as the cells evidently need a lot more cycling to prove or

disprove the efficacy of the effects.

On the 14th I made a new 'negode' without graphite felt,

after the one last month with felt wouldn't charge. Sure enough, the

felt mustn't have had enough hydrogen overvoltage and was gassing,

because this negode worked.

I thought eliminating "contaminated graphite powder" from

the positive electrode would finally end the nagging high

self-discharge problem. But nothing changed from earlier cells. A zinc

strip test electrode revealed that it was the negative electrode that

was 'leaking'. Somewhere months back I had determined it was the

positive, but obviously that was wrong. It was already fine and nothing

I did to it would help.

Charging a cell for a week or more with sufficiently high

charging current to keep the charge voltage around 2.9 volts, gradually

brought the self discharge down, but acceptable levels weren't attained.

So I made another 'negode', this time with about 11%

zirconium silicate additive instead of the 3% I'd been using. After

just one night's charge, its self discharge was just 1/2 as fast as the

best figure with the previous electrode - 26 seconds per millivolt drop

instead of 13. But it didn't improve with time.

I decided to try something organic. I took the cell apart

again and painted both electrodes with "Diesel Kleen", which contains

tri-methyl benzene (among other things) and doesn't evaporate rapidly

like straight methyl benzene (toluene). This time the cell started

improving with charging and after a couple of days it became

impractical to stand there ticking off seconds - 45 to 70 - waiting for

the meter to drop by one millivolt. Success? But it still didn't

progress to an acceptable level, and then it seemed to regress a bit.

After a load test August 1st it improved a little again. Looks like it

needs cycling, not just charging. I'll be running more tests in August,

and I might add more "methyl-something" if it seems necessary.

AFAIK for the first time ever, a manganese negative has

been induced to charge and to hold manganese's high voltage metallic

charge... at least for a while. I thought I had an earlier cell headed

for success of some weeks, but its zinc current collector corroded away

before proving it. This time I think I have a better idea of what's

helping. If the high self discharge can be adequately solved, it'll be

the highest theoretical energy density ever likely to be attained in a

water based electrode and battery, by a good margin.

NiNi Batteries

At the end of the month I decided to include some of these

in my next 'batch' of batteries. They would be under 1/2 the voltage of

the NiMn cells, about 1.1 volts nominal, actually charging to 1.25 or

so. There are two or three reasons for making them.

First of course is that I haven't necessarily solved the

self discharge problem of NiMn. It looks promising, but in spite of the

major advances already obtained it's possible that I never will, or

even that it's impossible entirely. The lower voltage NiNi cells should

have little or no self discharge. Second is that the lower voltage of

NiNi should allow it to be made as a sealed dry cell - I doubt NiMn dry

cells would be practical. Third is that except for being .1 volt lower

(and hence needing 11 cells for 12 volts instead of 10), they should

actually be better in some ways (with 'everlasting' cycle life) than

nickel-metal hydride, of which larger size production has so far been

suppressed by the corrupt, and also should be the most readily makeable

at home or in small production of any battery.

Boat Trip with Electric Caik Outboard

On the 30th, after preparations (some going back some

weeks), I finally took my 14' aluminum boat with the Electric Caik

outboard out on a fishing trip. There was a breeze and some distant

whitecaps

could be seen, but it wasn't that bad where I was. The waves still made

me

seasick, but

weren't splashing over the sides. After 20 minutes or so I reeled in

the

line and went back in (no fish). My Chinese voltage and current

meter with 50 amp shunt did fine on voltage, but the current readings

bounced around

wildly. Evidently it can't handle pulsed circuits. The Electric Caik

motor RPM with a 16 volt lithium battery

never got over about

1700, so there was no chance of accidentally over-revving (unless it

ran out of charge and I had to switch to the 24 volt NiMH.)

I didn't measure the motor temperature, but I took the

hood off as soon as I got back. After this considerable run, the motor

still felt cool... except that the heads of the coil holding bolts

were hot (not finger burning, but getting up there). They are of course

heated by magnetic induction from the magnet rotor... oh yah, and from

the magnetic switching of the coils. I had reduced the

bolts from 1/4" to #10 to pick up less magnetism, but it seems they

still get hot. I think I want to find a way to make motors with even

less - ideally no - 'extra' metal bits in the path of the rotor.

Plastic clips?

I started thinking of putting the coil clamping bolts

for the Electric Weel inside and outside where the magnets

pass, but having none in line with them. (And definitely outside the

coil cores!) Originally the bolts held the

coils in place as well as clamping them, but with the coil holding

buttons molded in, the bolts

don't have to be inside there any more, just somewhere to clamp the

body

pieces together. I can probably change the bolt configuration template

on the Hubcap and Caik motors too, tho there's little room in the Caik

to really get them clear of the magnet fields.

3D Printer: Repaired

To end up a rather successful and progressive month, I

ordered and received a new "Melzi" circuit board from RepRapPro, and in

the evening

after the fishing trip I installed it in the 3D printer, adjusted

things,

and successfully

printed out a trinket. Yay! The printer had been offline for almost 14

months and I really need it to make some things - more CAT plugs and

sockets, and I want to try making frames for electrodes for the NiMn

2.5 volt (and NiNi 1.1 volt) salty electrolyte cells, to keep the paper

edges from bursting

open and leaking briquette substance.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

The price of electricity to run a car

Someone made this picture up to illustrate how much less

it costs to run an electric car than a gas one. I think it was at

11¢/KWH. Sure beats a dollar and a half per litre!

A planeload of people killed to eliminate free energy?

Someone has told me that the Malaysian passenger jet that

famously disappeared over the ocean 3 or 4 months ago had a team of

people on board

that had created a "free energy" device -- likely a

'lambda ray

collector' (TE News #69,70,71). Perhaps they were in southeast Asia

looking for

manufacturing arrangements.

This is just a rumor as far as I know, but it certainly

would be a convenient way to dispose of a whole team, the inventor

and all involved, if they were all on the same flight, without raising

immediate suspicion that getting rid of yet another free energy

invention was the motive. And it's a very good explanation for why the

plane would have crashed without even a distress call or a signal from

the 'black box'. It was probably blown up with a bomb or otherwise

booby-trapped so that no one would get off a distress call. The crew

and the rest of the passengers were then just 'incidental' casualties

-- and cover to obscure the motive. Who would suspect?... but I've

heard before of airliners apparently being downed to kill just one key

person on board.

The perpetrators of this crime against humanity - if

indeed that's what it was - may be "rich" and "powerful" and able to

elude human

justice, and laugh it off or even brag about it in their inner circles,

but they will still have to answer for it on high when their mortal

days have ended. When they come face to face with the universe

outworkings of what they have done, they may well condemn themselves

for the lives they have lived and their evil deeds.

They are cunning and ruthless, but even in the material

sense they are blind fools.

They want to prevent progress, seemingly taking some sort of

satisfaction in ruining

the beautiful planet they live on, and without stopping to think that

the reason they aren't running around barefoot and hunting

deer with sticks and rocks is because of the sort of inventive people

they work so desperately to put out of action.

As for the newer Malaysian jet disaster, the one shot down

over the Ukraine... the airline and the crew were certainly playing the

odds, flying through a war zone in an airspace where multiple aircraft,

albeit military, had been shot down on previous days. The issue had

come up, and some airlines were re-routing their flights. Others didn't

want to pay for extra fuel and time.

As for who fired the fatal missile: Western Ukraine,

Eastern Ukraine, and Russia all have the same missiles. Russia

has been trying its best to stay out of the conflict - except to accept

the stream of refugees coming across the border. Considering Western

Ukraine has been raining destruction on Eastern with aircraft and that

Easterners have naturally been shooting back at the aircraft, the Kiev

government is by no means blameless, regardless of who fired the

actual shot.

Slight of Hand: Repeated Insinuations Batter the Brain to Manipulate

Perception

One of those

lead-acid batteries I was renewing has a

large sticker with the head of a sharp-eyed eagle and the word

"Greens". Another

nearby had a green sticker saying "Econo Power". What's not to like

about "green", "econo" and "power"? And what could be

closer to nature, be more powerful, and see things more clearly, than

an eagle? But the labels make no actual claims to

denounce. They are tools in a subtle form of

decept also carried out via other means such as mainstream media.

One of those

lead-acid batteries I was renewing has a

large sticker with the head of a sharp-eyed eagle and the word

"Greens". Another

nearby had a green sticker saying "Econo Power". What's not to like

about "green", "econo" and "power"? And what could be

closer to nature, be more powerful, and see things more clearly, than

an eagle? But the labels make no actual claims to

denounce. They are tools in a subtle form of

decept also carried out via other means such as mainstream media.

With the repeated misleading association of such positive

terms and

icons with perhaps the most negative common battery type - the least

green, least economical [over time,

and without battery renewal], and with almost the lowest power

for its weight - a perhaps subconscious association is formed in the

mind between these opposites, and one gains by osmosis the impression

that lead-acid is "seen clearly" as a

green, economical and powerful battery type. At the same time,

derogatory remarks about other battery technologies by those making a

good living off short-life lead-acids, and probably by paid shills and

spokesmen, blow up molehills

of near trivial weaknesses into mountains of seemingly expert

criticisms of other chemistries. And

still further, the corrupt have shut down nickel-iron and large cell

nickel-metal hydride production entirely in the west, with the

molehills and other misleading propaganda as excuses for why, to soothe

the public and deflect popular outrage. The fact that these types are

unavailable and it appears no one uses them seems again to support such

assertions by osmosis, since the obvious logical conclusion, especially

by the young and innocent who naturally assume that fair play rules in

our world,

is that if other types were better they'd be produced and in common

use. The news

repeatedly has stories about exciting new battery developments... which

never seem to get onto store shelves. Lithiums are tolerated because

the demand

for better batteries is too high to quell, yet their high cost chills

the mass market while at the same time diverting attention and

inventive and economic

energy from other better types.

Whenever someone makes a decision regarding batteries, all

the misleading associations and misrepresentations, presented

repeatedly whenever and wherever

the subject arises, are in the subconscious, working to cloud impartial

judgment. Yah, green, economical and powerful lead-acid is the only way

to go!

And this same technique is used in many areas. The USA is

trying to pick a fight with Russia. It's managed to get Poland to

accept placements of its ludicrous "anti missile shield" installations.

It's spent billions of dollars to destabilize the Ukraine, in order

dominate it economically, and to move in and up to Russia's border.

Everything that's happening there is being repeatedly blamed by US

politicians and their spokesmen

on "Russian aggression" with no evidence (even when asked to present

it) that Russia has done anything aggressive. Indeed, Putin has been

most restrained in his responses, to the point where author and former

assistant treasury secretary Dr. Paul Craig Roberts

[PaulCraigRoberts.org] thinks leaving Russians in the Eastern Ukraine

(historically part of Russia) to the mercy of the attacks by the Kiev

government is going to backfire on him. And yet, surveys show that the

majority of people in the USA believe Russia is to blame for what's

happening - Surely those ongoing claims, repeated and repeated in the

news with

apparent conviction, must be backed by facts, not just hot air? Some

haven't learned from Iraq and Saddam Hussein's non-existent "weapons of

mass destruction" that the aggression is coming from their side, that

it's all lies and the USA has become the USSR, or as some put it, the

"USSA". (Joke losing funniness... Q: How do you know a politician is

lying? A: His mouth is open.)

Shortly after writing this, I ran across an hour long

youtube video lecture, Propaganda and Manipulation: How Mass Media

Engineers and Distorts Our Perceptions. It goes into the insidious

techniques mentioned and others, and examines the often

devastating results.

Perhaps I should repeat my own bit of 'propaganda' to set

the message into the subconscious of anyone with any influence who may

chance to read these words:

No More Wars!

Don't start them, don't provoke them, don't join in them. No foreign

military power is going to invade North America and we have no

legitimate reasons to be trying to dominate and control nations abroad

- much less to be invading and killing people and turning whole

societies and

peoples into chaotic messes with many millions of refugees who have

nothing to eat and nowhere to go. Violence begets violence. And I must

include Canada in this, since our government of late has been showing

all the signs of being led by the same bankster-gangster methods and

motives as the US government.

We've known

for decades that if wars continue, they'll sooner or later escalate

beyond one-sided massacres, and probably destroy all life on our

planet. As it is, they're definitely contributing to and speeding up

the coming global financial, economic and population collapse.

No More Wars!

No More Wars!

No More Wars!

Electric

Hubcap Motor Systems - Electric Transport

Huge Torque, Low

RPM Electric Weel Motor-Generator Project

Resumed at last!

On the 5th I showed the LED

light to friends. I happened to mention I had found the "cracked ice"

diffuser plastic while looking for some big "offcut" chunks of UHMW-PE ("ultra-high molecular weight polyethylene")

to make motor molds with. I was told there were some big scrap pieces

of UHMW under the stairs at AGO, and we went there. I picked up just

what I needed, and there's more if I need it. This was great since it

would have cost me hundreds of dollars for just enough UHMW at

Industrial Plastics. (One problem is that I needed about 14"x14" and

IP will only sell in multiples of 12", ie, a 24"x24" piece, to get it.)

As it was, the

pieces were the oversize outside corners

left over from cutting very large rotors - about 16x16" with a huge

quarter circle bite out of one corner leaving only 4" sides on each

side of the bite. The plan was to make a 1/8 of a circle (or octagon)

mold, and mold 8 identical "pie" pieces that would form the complete

octagon or circle for each motor. I thought these plastic pieces would

be too small for the largest mold sets, but after a couple of hours of

drawing on one with a felt pen (and erasing with alcohol), attempting

to design a good pattern for the outer stator end ring, as well as to

hopefully fit it on the plastic, I found I could lay out a very good

one, with ample outside margins, by skewing it at 22.5° so the

"pie" slice lined up with one edge. In fact the size and shape of the

plastic pieces was almost ideal for the mold. This got the long-stalled

Electric Weel motor project back in motion at last.

As it was, the

pieces were the oversize outside corners

left over from cutting very large rotors - about 16x16" with a huge

quarter circle bite out of one corner leaving only 4" sides on each

side of the bite. The plan was to make a 1/8 of a circle (or octagon)

mold, and mold 8 identical "pie" pieces that would form the complete

octagon or circle for each motor. I thought these plastic pieces would

be too small for the largest mold sets, but after a couple of hours of

drawing on one with a felt pen (and erasing with alcohol), attempting

to design a good pattern for the outer stator end ring, as well as to

hopefully fit it on the plastic, I found I could lay out a very good

one, with ample outside margins, by skewing it at 22.5° so the

"pie" slice lined up with one edge. In fact the size and shape of the

plastic pieces was almost ideal for the mold. This got the long-stalled

Electric Weel motor project back in motion at last.

Whereas all my previous molds have a one piece "dish" on

the bottom to make a flat ring, this motor is so big I wanted to put

some fairly tall radial ribs ("spokes") in it to stiffen it up - even

5/8" or 3/4" tall. My biggest concern about this motor is the stiffness

required to hold the axle and hence the magnet rotor, when the bearing

is at the center and the magnets are so far away at the outer rim. Just

a little flexing of the outer cover and the magnets will start rubbing

on the inner stator wall - which they pull toward magnetically. The

UHMW plastic is just under 7/8" thick, so to have such ribs sticking up

above the rest, meant bolting two pieces together to get a deep enough

mold. And if I put the ribs at the edge of each octagonal slice,

they'd provide the maximum thickness of edges to epoxy (and perhaps

screw or bolt) the 8 pieces together into a complete circle with.

I figured bolting two thicknesses of UHMW together for the

deep dish - and then prying them apart when the casting has set - would

make removing the castings much easier than with a very thick single

piece mold. (It was still surprisingly hard to pry the pieces apart,

and I finally started waxing the mold before casting.)

The next step was to set up a G-code program for the CNC

drill router to cut it. I did this, and then cut the two 'dish' pieces,

on the 6th, finishing rather late in the evening. The top cover piece

followed on the 8th. Offsetting the radial lines and circumferential

curves by the radius of the router bit made for some tricky

trigonometry for all this, since it slightly changed all the angles and

cut lengths, and made inner angles different from outer.

Fortunately, even slight errors made the cut lines look

noticeably "off" on the CNC program display, and all errors got

corrected (or got approximated closely enough), except that the inner

diameter edge didn't seem quite right. Luckily it's a short segment,

and it overlapped the top cover rather than leaving a gap. I filed and

scraped it out a little to get it to fit. (Later I found I had entered

co-ordinate "1.354", as "1.345".)

On the 9th I looked over back issues of TE News (like

maybe #38 to #42) to decide how much epoxy resin and polypropylene

cloth to use. It's been so long since I made a motor I didn't remember.

It seems I eventually picked about a 4 to 1 ratio of epoxy to cloth by

weight, and maybe 500g of epoxy and 125g of cloth would be a good

amount to use. 8 pieces will then be 5 Kg for the stator end cover.

That's very light for such a huge motor. If it's stiff enough. The

whole motor, with so many heavy coils and magnets, a huge metal rotor

plate and a fat axle and bearings, will of course be heavy, but this is

about the lightest possible composite body material, and it'll probably

be very easy to manage compared to other motors of such power. And one

suspects, 'amazingly' light compared with other motors of similar

torque.

First 3 pieces of 28"

diameter Electric Weel ! Ruler is 16" long.

On the 10th I put nine threaded

bolt holes around the

edges to hold the two bottom "dish" pieces of the mold together, and

cut strips of polypropylene cloth to make four 125 gram bags of strips.

On the 11th I tore a bag of the polypropylene strips into 6" x 6"

squares,

mixed 500 grams

of epoxy, and stuffed the mold, using the "kneading" technique with

vinyl gloves on to mix the fabric and epoxy. It turned out well enough

- slightly bulged in the center, and with a little missing cloth and

epoxy in spots in the tight corners. The first one came out easily

enough by

unbolting the lower mold pieces and prying them apart, with some more

prying on the part itself. (Subsequent ones got harder to remove, until

started I waxing the mold.) The 625 grams of composite material seemed

about right.

On the 10th I put nine threaded

bolt holes around the

edges to hold the two bottom "dish" pieces of the mold together, and

cut strips of polypropylene cloth to make four 125 gram bags of strips.

On the 11th I tore a bag of the polypropylene strips into 6" x 6"

squares,

mixed 500 grams

of epoxy, and stuffed the mold, using the "kneading" technique with

vinyl gloves on to mix the fabric and epoxy. It turned out well enough

- slightly bulged in the center, and with a little missing cloth and

epoxy in spots in the tight corners. The first one came out easily

enough by

unbolting the lower mold pieces and prying them apart, with some more

prying on the part itself. (Subsequent ones got harder to remove, until

started I waxing the mold.) The 625 grams of composite material seemed

about right.

But the next day I tried fitting a coil core over the

buttons. It just wouldn't go. Either I had made the previous motor coil

buttons a few thou undersized to fit well, I had a number slightly

large on this one... or the radius of the router bit was actually

slightly over .125". The diameter measured .252" with a micrometer, or

.126" radius. That didn't seem like enough to account for the problem -

it might even be measurement error.

That put a slight monkey wrench in the works. Instead

of casting more pieces of the motor and moving on to the next mold, a

revised section was needed for this mold. I did that on the 15th or

16th, and had a half circle on the 18th.

On the 18th I also designed and routered the first piece

for the mid-ring mold, the separator between the coils and the rotor,

and the 2nd piece on the 19th. This would again be in 8 segments.

I trimmed the button edges on the first piece with a

'dremmel' tool with a steel cutting bit with straight sides and a

square end that also cuts. This technique worked very well and I must

remember it for whatever future PP-epoxy trimmings are required.

Talking with a friend on about the 17th, the idea came up

to build up the outside face of the motor, noting that the pieces that

weren't uniform thickness, with more epoxy and PP cloth in the thinner

spots. Then, even better, to epoxy some PP strapping along the joins to

attach the pieces together, along with simply gluing the seams with

epoxy. That should make very strong joins and my confidence in the

robustness of the design has risen. In fact, I changed 500g epoxy +

125g shredded PP cloth per piece to 400g and 100, which makes thinner

pieces, but is easier to stuff into the mold.

I finished the last of the 8 pieces on the evening of the

25th. But I didn't get them glued together.

Electric Weel Stator End Pieces

Electric Weel Stator End Pieces

Eight 45° "pie" pieces with toroid coil mounting 'buttons'

showing 3 finished coils and 21 unwound coil cores,

1.75" 'trailer' tapered roller bearing, and one

of the washers to clamp the bearings with.

With 24 flat molded pieces plus a huge rim to make, this

isn't

going to be a cheap motor/generator to produce. On top of all the

mechanical and electromagnetic parts, the molded body is a huge amount

of

work, and I can see 300 or 400$ of epoxy and PP cloth going into each

one. It'll weigh quite a lot, but the design and composite body will

surely make it much lighter than any similar sort of motor, and the

efficiency should be excellent.

EV Individual Battery Monitor - El Cheapo version (7-segment

voltage displays)

(Batteries top to bottom:

a size 27 lead-acid (rear), 5 cell lithium-ion, two NiMh

90 AH D cell tubes, and two size 24 lead-acid, that

seem here to be more charged than the rest.)

On the 12th I opened the

drawer with the little 7-segment display

voltmeters (a very few dollars each from China, found somewhere on

aliexpress.com), and decided it was high time to make at least the "El

Cheapo" individual battery monitor. I got out some ABS plastic and

methylene chloride solvent to 'glue' it with, and made a case of

sorts that I could screw in 6 little displays in a vertical column.

Then I found an 8-wire cable, poked another hole in the rubber gland

with the main hood-to-dash wiring, and pushed it through.

On the 12th I opened the

drawer with the little 7-segment display

voltmeters (a very few dollars each from China, found somewhere on

aliexpress.com), and decided it was high time to make at least the "El

Cheapo" individual battery monitor. I got out some ABS plastic and

methylene chloride solvent to 'glue' it with, and made a case of

sorts that I could screw in 6 little displays in a vertical column.

Then I found an 8-wire cable, poked another hole in the rubber gland

with the main hood-to-dash wiring, and pushed it through.

I didn't like hard-soldering the wire to the displays in

the case, but it was a lot easier than finding plugs and sockets to do

it, especially on the weekend with the electronics store closed and

with the 3D printer still off-line, so I could neither buy nor make

them. (I finally ordered a new "Melzi" control circuit board from

ReprapPro for the 3D printer. Their techs said from the sound of it,

the cheap Chinese board I got was a "version 1" and it looked like it

had a common version 1 hardware problem - that the temperatures would

never read

right. They apparently came out with a beefier "version 2" board a

while back.)

And I soldered CAT click-lock plugs (still have a few!)

onto the other end of the wire to match the sockets placed on every

second battery when I put them in the car. Unfortunately they were on

the wrong every second battery in the front of the car (#2 & #4),

and instead of being able to see all 5 batteries, I just hooked up 3

(#2, #3, #4) via two plugs: one of the smaller "size 24" lead-acids,

and the two 90 AH D cell Ni-MH long tube batteries.

The first thing notable was that there's no way to turn

the displays off except to unplug them all. I don't suppose they'd

discharge the batteries in any length of time that might be a concern.

Also of note is that the red LED displays can't be read in sunlight,

but are overly bright at night. An LCD display would be better.

I put the display up pretty high on the left side of the

dash where I thought it would be easily visible. Instead from driving

position it was perfectly covered by my left hand on the steering

wheel. I had to shift to the right to see any of the displays. Awkward

to see equals easy to be unduly distracted and have an accident.

(I totalled a nice car and injured myself badly that way once, with a

poorly functioning add-on intermittent windshield wiper control,

mounted too low down.) Nevertheless I went for a 4.2 mile round trip

drive, with Tillicum mall

at the

far end. I then moved it to the far left. That was better, but really

the

only place easy to see is where the factory instruments are, behind the

middle of the steering wheel.

Even displaying 3 batteries was rather revealing. When I

started out, the size 24 lead-acid quickly dropped below 12 volts. The

Ni-MH s dropped below 13 but stayed about a volt higher than the PbPb.

They also soon began to differ from each other. By the time I neared

home, one was dropping well below 12 volts under high loads, but the

other was going down below 11. When there was no load, they both

innocently read about 12.9.

So I can already see that one of the Ni-MH s isn't

performing as well as the other. It may have

a disconnected tube or a couple of poorly connecting tubes, or there

may be a problem with one or some of the cells. Alternatively, it may

be that it just isn't being charged to quite as high a voltage as the

other - when still on charge before I started they read 13.8 and 13.7

volts. And 14.0 is optimum float charge voltage, so they may be both

undercharging a little.

I'm less and less enamored with the bulky "battery stick"

tubes for high capacity batteries with many tubes. (Still great for 10,

20 or 30 AH, and for single AA cell tubes!) And probably ditto for the

3D printed cases. Now that I can make soldered together batteries that

seem to be safe and reliable (see some back issues(s) of TE News for

the techniques), I think I prefer them.

Also perhaps noteworthy was that the Ni-MH s were giving

a little more for their rating than the lead-acid simply by their

somewhat

higher voltage. 13/12 or 12/11 volts = 8-9% more energy. But what about

the

larger "size 27" lead-acids in the back of the car?

The next day I changed the wiring around a little and had

5 of the 6 displays showing the 5 batteries in the front of the car,

with 3 plugs, on every second battery #1, #3 & #5 as planned. The

front is the most interesting to monitor because it has lead-acid,

Ni-MH and Li-ion batteries and mostly they're also the smallest

amp-hour rated and so are the range limiters if there are no weak

batteries in the back. The 6th display I wired independently and put it

on the known weakest battery in the back, then for a trip on the 100 AH

Ni-MH to compare it to the two 90 AH ones. Once I knew how low it was

going, I soon replaced the weakening battery before it started being

damaged. Previously, I would have attributed the voltage loss while

driving to general drop by all the batteries.

I replaced that with a "renewed" battery with very low

voltages (very last article in this issue). I've recently heard that it

takes a long time, many cycles, for the voltage to rise up towards

'normal', and with a continual display of the voltage I should be able

to see this. The voltage held after charging but before use has risen

from 10.1 to 11. Perhaps the load voltages - under 5 to 7.5 volts

depending

on load - are rising too, but it seems imperceptible so far.

On the 27th I noticed from its voltage display that one

NiMH battery was getting low and didn't seem to be charging. It took a

fair amount of sleuthing (after changing chargers a couple of times) to

track down a nut with one of the charging wires that hadn't been

re-tightened after installing the monitor. (Probably forgotten after

the wrench welding incident.) The loose wire had made connection up

until that day.

The monitor is showing its value for revealing unsuspected

trouble.

Other Green

Electric Equipment Projects

Flat Panel LED Lights

Early in the month I put together a light with a set of

twenty 2.9 volt LED

emitters - 5 wide (in parallel) by 4 deep (in series). This should give

much the most light with about 12-14 watts input. With the total

current of 1 amps, each emitter will see only 200mA, well below its

rating, providing best lighting efficiency with least heat, and the

total voltage will be about 11.6 volts. I'm counting on these emitters

lasting and maintaining their 2.9 volt forward drop with full

brightness for a very long time at this relatively low power level.

Brightness is attained by the many emitters rather than by forcing each

emitter to output as much light as possible.

Current regulation isn't perfect, and the 'dropout'

voltage is a little higher than might be desired. On the other hand,

one might consider the operation to be ideal for lead-acid battery

powered systems. It gives target brightness (1 amp) at about 13 volts,

in fact hitting about 1.2 amps at 14 and up. Below that it starts

dimming to save battery power, dropping to half current (55%

brightness?) at 12 volts, very dim by 11 volts, and shutting off

entirely around 10.

I'll try different resistors to try to get full brightness

at 12.5 volts and up (and no extra for going higher), with a steeper

slope to still hit the same targets at 12, 11 and 10 volts. Power

supply efficiency at 12.5 volts would then be 11.6v/12.5v=92.8%, which,

in this case, is better than switching regulators.

But I got onto the motor and battery projects and let this

one slide. I shouldn't as it's probably the simplest project that has

good commercial potential.

According to

theory, high power supply efficiency plus

high emitter efficiency plus high light transmission through the

'cracked ice' diffuser should yield about the most light per watt

attainable anywhere. It seemed to run cooler than the previous 12

emitter light, and was certainly bright for 12 watts.

According to

theory, high power supply efficiency plus

high emitter efficiency plus high light transmission through the

'cracked ice' diffuser should yield about the most light per watt

attainable anywhere. It seemed to run cooler than the previous 12

emitter light, and was certainly bright for 12 watts.

Some may consider the 6000K emitter light to be rather

cold (bluish), so I'll see what emitters I can find that are 2.9 volts

at 4500-5500K. Personally I now dislike the orange or yellowish light

(3000 K) of typical tungsten lights and "warm white" LED emitters, but

I suppose I should offer them - everyone has their own tastes, and a

mix of emitters in one light shouldn't be ruled out.

When a Chinese LED light 'bulb' quit for the third time I installed the

light in the bathroom above the mirror. The 13 volts requirement with a

12 volt power adapter didn't help the brightness any, but it's

adequate, and with the low heat and vertical air flow it should last a

lot longer than I will.

Electricity Storage

Turquoise Battery Project

The immediate question for this month was of course why last month's negative

electrode wouldn't charge. I was pretty sure the very same jar of

chemical powders had worked in previous electrodes. I had made this one

with graphite felt in it. Didn't that work before? On the other hand,

the previous cell with the contaminated charcoal in the posode hadn't

worked well enough to know if anything else was wrong. But hadn't I

used graphite felt in the negode before that?

What with all the other projects and despite their exiting

prospects, I've been working on these cells so slowly I can forget what

I've done. My newsletters are also my own logs. I went back to TE News

73, the last cell that worked half decently. (The next month was the

charcoal experiment.) Sure enough, I had mentioned perhaps trying out

the graphite felt in the negode to improve conductivity - but hadn't

done it. The felt was probably the trouble, so I would make this

negode with the same chemicals and no felt and see if it worked. It did.

But what would be the difference between the graphite foil

current collector that worked, and graphite felt that doesn't? For one

thing, this graphite foil is actually a composite material. But isn't

graphite, graphite? Could its hydrogen overvoltage change depending on

form?

The other difference is that the current collector is

painted with osmium doped acetaldehyde and the felt isn't. Osmium,

being a very heavy element in the 6th row of the periodic table,

probably has a high hydrogen overvoltage. (Good luck finding it in an

overvoltage table!) This is most likely the key.

I took apart the old cell and electrode assembly, and

painted a previously cut graphite foil current collector with the

osmium doping. On the morning of the 14th I made the negode briquette

using 25g of the same powder. (plus Sunlight dishsoap & water.)

Pressed to 10 Mg it made a 5mm fat briquette, much more than a match

for the "+" side. Since that was probably fat enough to limit the

current substantially, I then did a thinner one with 12.6g (~2.7mm).

Finally with 8.65g left over, I did a third even thinner one (~1.8mm).

This was doubtless still plenty of substance and I used it. I singed

all three with a propane torch (so I'd have a couple to use for the

next

cells), wrapped the thinnest one in watercolor paper, and assembled it

with the previous posode, paper, macramé cloth between, plastic

end cover plates, and a new cable tie. Worthy of note was that there

was no purple permanganate color in the electrolyte of the previous

cell, nor black crap (MnO2) coating everything. It probably wasn't

optimum percentages, but at least it wasn't too much Mn. But I put

fresh KCl solution into the same jar and put it all together.

Starting at 1.237 volts at 11:11 AM, 70mA of charging

current soon brought the voltage up to about 2 volts, where it would as

usual have to charge some zinc back from oxides to metal before going

on to the higher manganese metal voltage levels. Before attaining this

desirable state without wild fluctuations, I had to scrape the rust off

a couple of the alligator clips off with a knife - the salty

electrolyte always manages to wick up the terminals to the clips and

corrode them. By 12:12 it was

2.085v. By 2 PM it was 2.3v and would supply about 1.5v/1.5A for a few

seconds into a 1 ohm load. In another day it was just at about 2.65

volts, and it had self discharge over a few hours when the charge was

removed. What was wrong?

I started to think, that nitrates and nitrites are

soluble. To run a self-discharge "shuttle" as

they're said to do, the ions must drift back and forth between the

electrodes. I took the cell apart. The

water looked cloudy, and there was some whitish sludge on the bottom,

which seemed to indicate impurities of some sort from somewhere. (Again

there was no purple permanganate color.) So I started thinking, that I

should be able to dilute dissolved nitrates out by changing the water.

Never mind mixing electrolyte: just fill the battery with water and let

it sit a while. Then change the water, and do it a few times to dilute

out all solubles.

On the third or fourth water change, the bottom paper of

the posode broke open along its length, spilling Ni(OH)2. Nickel

hydroxide electrodes are infamous for swelling in the cell after

they're made.

Evidently there was a lot of uncharged turquoise electrode substance

[Ni(OH)2]. I opened the

electrode assembly and stuck in some more pieces of paper to cover the

gaps.

All those dilutions didn't seem to help. But, whereas I

had somehow been thinking the self discharge was in the posode, in the

previous cell the posode had shown no self discharge against a zinc

strip, the same voltage reading being attained whenever the zinc strip

was inserted, over a day or two. I attributed this to elimination of

impure graphite, yet the new cell, with the same posode, had the same

self discharge as usual.

Perhaps the graphite had nothing to do with it. I tried the zinc strip

against both electrodes, and to my surprise it was the negode that had

the self discharge. I thought I had checked this long ago and found it

was the posode, which after all has almost twice the reaction voltage

it had in pure alkali. How had I come to that conclusion? Evidently

I've been worrying about the wrong electrode!

What else? I recalled that the self discharge seemed to

diminish over time. But the zinc current collectors of previous cells

had eventually corroded away, so the cells didn't last long enough for

longer testing. Now I had the graphite foil collectors.

Could it be that changes were taking place, perhaps in the

trace additives, with charging and or discharging? For example, I read

somewhere that Sb2S3 would readily convert to Sb2S2O, the "least

oxidized form" of antimony, in reducing conditions. On the 18th I

decided to try relatively strong charging, taking the cell up to about

2.9 volts overnight. By morning the self discharge wasn't stopped, but

it was indeed much slower. Was sufficient charging all it needed to get

it working?

The next day I kept using smaller series resistors, hence

more charging current, to keep the voltage near 2.9. In a few hours 10Ω

became 1.5Ω. But the power adapter was unregulated, and when I checked,

80mV over 1.5Ω was still only 54mA. Hopefully the dropping resistances

meant more and more of the Mn was becoming metallic and hence had

increasing conductivity. I tried a 10Ω load test (200+mA), which

previously had dropped below 2.0 volts immediately or within a few

seconds. It ran 40 seconds.

The time on charge to reduce the self discharge toward

acceptable levels was measured in days and longer. From dropping by a

millivolt every 2 seconds it went to one per 5, 7, 8 and 10 seconds on

successive days, gradually holding higher voltages longer and longer.

As the last part of a manufacturing process, that's acceptable. this

seemed great for a bit, but it stopped rising above about 13, although

the time it would deliver 2+ volts to a 10 ohm load rose to 2'40" and

finally to 3'35".

What else could I try? So, it was the negode that was

discharging. I had found that 1% stibnite (antimony sulfide) and 3%

zircon (zirconium silicate) had allowed the manganese negode to charge

and hold charge, and at room temperatures - something apparently no one

had accomplished before. But in my triumph, I had only done fairly

short term tests to see the voltage attained, not looking for a gradual

loss of charge. I hadn't tried varying the proportions, and I hadn't

tried any more substances that might help.

On the 24th I decided first to try more zircon. I crunched

up the 25g electrode with mortar and pestle, and added 2g of "Ultrox"

(pure zircon). That's 8%. It had 3%, so it now had about 11%. If zircon

would make a difference, that should be enough change to see, if not to

solve the problem. I made a new negode with half of this powder. I took

the cell apart to re-use the posode and entire assembly again with the

new negode.

Things are never simple... the old negode was fine, but

the electrolyte was a greenish color and full of guck. (It appeared to

be floating insolubles - the liquid gradually cleared some.) The edges

of the posode, all the paper, had corroded or been pushed away and

stuff was leaking out. I peeled the remaining paper away.

I wrapped the '+' briquette and current collector in some

white polypropylene non-woven, with several layers around the edges and

a couple across the front. Then I put new paper on over that. (Perhaps

there's something I could paint on the paper that would preserve it.

Maybe lime, titanium dioxide, or zirconium oxide?)

I reassembled everything with the 11% negode, added fresh

solution, and put it back on charge overnight. The next morning, the

rate of self discharge was half what the previous electrode had been at

its best - a millivolt drop every 25 seconds or so. I smelled chlorine,

so I reduced the charge voltage to about 2.8 (from 2.9). But instead of

improving with time, it got worse. (and the air still smelled of

chlorine.)

What else? My thoughts drifted to... maybe something

organic? But what? I had experimented with methyl benzene - toluene,

and had used it to improve the graphite powder's conductivity. It was

something I could try on the existing electrodes. In the posode, it

should oxidize to form a benzoate. The negode was the 'loser', but

benzoate is soluble and it should migrate there. What would it do

there? But toluene evaporates quickly. It might vanish before I even

got the cell together again. On the 26th I got out the "Diesel Kleen",

which contains tri-methyl benzene but evaporates very slowly, and I

painted some onto both electrodes.

After a while there didn't seem to be much improvement...

but maybe a little. But it still worked. The next morning tho, the

27th, the time to lose a millivolt was up to 45 seconds or so, so the

voltages were staying higher considerably longer. I started to think

the chloriney smell had something to do with the reactions causing the

gradual improvements.

On the morning of the 28th it didn't seem much better, but

by late afternoon was dropping a mV in 50-60 seconds. It was getting

impractical to stand there watching the meter and counting seconds.

But it held at 2.57 volts or so after 5 minutes, up from 2.52 and then

2.55 in previous days.

At the risk of frequently missing the mark and

inconvenience (as the varied reading times below show), I decided to

check the voltage after 30 minutes off charge. (I should put all these

readings into a chart or table. I don't have time.)

First recorded reading

on the 28th was 2.512 volts. Morning of 29th: 2.532 (and 2.487 after an

hour - Probably I used a higher charge current overnight), and in the

evening 2.515 volts. 30th AM: 2.517 (80': 2.475; 2 hours: 2.411). I

slightly upped the charge current. 5PM: 2.522 (70' 2.486v; 80' 2.476v;

3 hours 2.312v). 31st AM: 2.515 after 35' and 2.499v after 60'. 5PM:

(2.467 in 80') August 1st AM: (2.500 in 41') PM: 2.506. For a few days,

there seemed to be gradual improvement, and acceptable levels of self

discharge seemed to be

approaching. Then things started sliding back again.

There may be

'incidental' adverse factors. On the 31st I found the water level was

down some. When I topped up the water, the charge voltage dropped and I

had to

increase current a bit to stay around 2.85 volts. The next day, it

looked like the alligator clips weren't making good contact and moving

them around changed the readings some.

Also, I've been charging and charging, rather than

cycling. Running a load for a while might help perk things up. I

ran a 50 ohm load for 20 minutes after the self discharge test on the

night of August 1st, then put it back on charge. The next morning it

held 2.513 volts for 30 minutes, a 7mV improvement over the previous,

and 2.485 after an hour, also up considerably. In the afternoon it got

better even without another discharge: 5' - 2.561v; 30' 2.517v. I did

another discharge. (Perhaps the

higher

readings of the 29th were also after a load test.) On August 3rd AM it

was slightly better again, 2.523v (30') and 2.492 after an hour. So it

looks like

cycling and not just charging are what make the improvements. Whether

cycling eventually truly solves the problem will have to be for next

month's

report.

I don't have any clear idea what's happening. Doubtless

the tri-methyl benzene forms something along the lines of potassium

benzoate in the posode. Potassium benzoate is soluble, so some should

work its way around to the negode. Also I painted the Diesel Kleen

directly onto the negode. What happens there? My best guess is that

every time a manganese atom absorbs OH- from H2O to become Mn(OH)2, if

the active chemical is present, the reaction that prevents further self

discharge takes place then with the free "H+", and gives off the

chloriney smell. That reaction obviously affects the negode and maybe

the KCl electrolyte, and may have anything to do with any or all the

various organic compounds employed: ingredient(s) in Sunlight dishsoap,

the borax dumped into the electrolyte, or even the osmium doped

acetaldehyde. It's seems definitely related to the Diesel Kleen

(probably to the tri-methyl benzene in it) because it wasn't working

very well until I painted it onto the electrodes. In fact, I suspect

that a number of things with a "methyl" or "methylene" in them would

work, such as toluene, methyl-ethyl ketone, methylene chloride or

acetone. It's not related to calcium hydroxide because I didn't use any

in this cell. But something is working!

Source of Conductive Carbon Black

I finally got on line for a search again, and wrote to a

company that said they have

conductive carbon black, BariteWorld.com. Yes, they would sell a small

quantity - 125 $US for a one pound can ("but huge reductions

for larger quantities"). I'm ordering it.

Making Large Battery Plates, Batteries

Making three negodes at once was perhaps the first time

I'd done

more than one electrode

of the same type (all negodes) in a row. It was certainly much easier

without having to wash the compactor, containers and all, and cut

new pieces of plastic liner, for every electrode. If I was making 10

cells at a time, I can see it would go much faster than making 10 cells

serially.

It also occurred to me that a good way to make larger

batteries might be to make multiple 40x40x3mm electrode briquettes and

simply mount, say, 4 butted together on an 80x80mm current collector.

As long as the backing was stiff enough not to flex in the middle, any

size 'plates' could be done. I might try 2 or 3 wide by 1 tall for

starters.

For higher voltages, multiple single plate thin cells

could be sandwiched, and only the outer end walls would need the

stiffness. I might try 2 or 3 wide by 1 tall for starters. (Note: But

if chlorine is being consumed in the process of eliminating the self

discharge, one might want a fair quantity of electrolyte and hence a

larger case than otherwise required - just as the plastic jars I'm

using hold a lot of liquid for the size of the electrodes.)

As they seem to be working now, but take time to "work

up", perhaps it's time to make a small batch. In two I'll try Diesel

Kleen on just one electrode (one +, one -) and see which one doesn't

stop self discharging after a while.

My main misgivings now are the structural strength of the

electrode terminals, leaks, and the fact that just about everything I

use to wrap the posode disintegrates. The positive charge is so high it

seems to oxidize nearly everything away, and the swelling which nickel

electrodes are well known for seems to rip open the weakened edges. Wax

(applied melted around the edges) soaks surprisingly well into the

briquette and passivates (waterproofs) too much of it. But the

non-woven polypropylene cloth ("landscaping fabric") seemed to be

holding out so far.

External Leaks:

External Leaks:

Water and salt wicks up the terminals,

and somehow even the

marble over the filling hole becomes encrusted with KCl salt.

The plus side shows green stuff, which may be nickel hydroxide,

or perhaps copper chloride (which would be soluble) formed

when ferric chloride is painted onto the briquette.

(Orange modelling clay was used to attempt to seal the terminals.)

Internally, it's hard to keep the posode from oozing out substance.

Plastic Posode Frames

Now that the 3D printer is working again, I think I'll

make little plastic frames with bars along one face again, for the

posodes. The frames should stop them from oozing substance out the

edges.

Nickel-Nickel 1.1 volt Batteries

In pH 14 alkaline solution, nickel metal just won't

oxidize, as Jungner found in his survey in 1899 or 1900. This is in

fact the raison d'être for alkaline

batteries: nickel can be used to plate metal current collectors in the

posodes, and they won't dissolve. No other metal works, and nickel

doesn't work below pH 14. In salt electrolyte, every metal oxidizes

away, and so carbon or graphite current collector structures seem to be

the only ones that work.

This same characteristic prevents nickel from being used

as a pH 14 alkaline negode. Once the nickel compound is charged to

metallic state, it won't discharge (oxidize). But in a salt solution,

this no

longer applies.

Substances used so far for commercial alkaline battery

negodes all eventually deteriorate for one reason or another. I

identified two elements that can make negodes for 'everlasting'

cycling batteries: manganese and nickel. Neither of them has either a

soluble nor an electrically insulating chemical state anywhere in the

negative to zero voltage range, in the alkaline range but below pH 14.

Manganese's high reaction voltage makes it very enticing, yielding

cells of well over 2 volts. After some years, I have got it to

charge readily, but I've been unable - so far - to reduce the self

discharge to practical levels. Nickel has a rather low potential which

will yield cells that only charge to about 1.25 volts, but that low

voltage should also make it virtually self-discharge free. They should

make good dry cells as well as wet cells.

I believe Ni-Mn can be made to work. But in order to

ensure a practical 'everlasting' battery from the Turquoise Battery

project, and one that should work readily now, I've decided to make

some Ni-Ni cells along with the Ni-Mn ones. They'll be simpler to get

working, and they might well make a great replacement for NiMH, and be

easiest to make at home.

Lead-Acid Battery

Renewal

Old Misconception Corrected

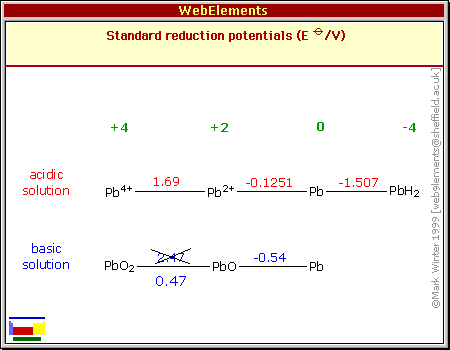

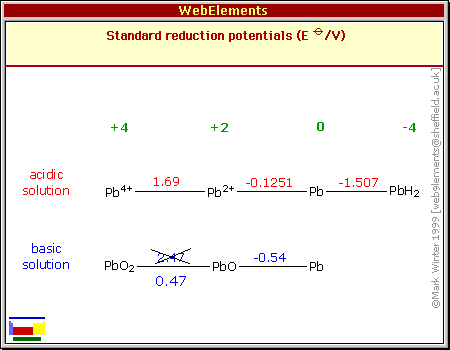

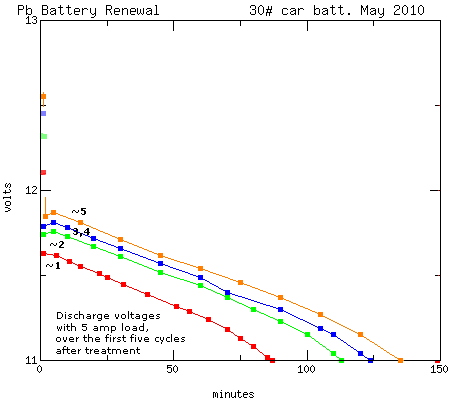

Back when I

started renewing lead-acid batteries, I was under a considerable

misconception. I thought they couldn't go alkaline, or even less

acidic, because of a graph I downloaded, supposedly based on the CRC

handbook, that had a major error: it showed the alkaline reaction

voltage from Pb valence 4 to Pb valence 2 (In this case PbO4 to PbSO4)

as being +2.47 volts when it's actually only +0.47 volts.

Back when I

started renewing lead-acid batteries, I was under a considerable

misconception. I thought they couldn't go alkaline, or even less

acidic, because of a graph I downloaded, supposedly based on the CRC

handbook, that had a major error: it showed the alkaline reaction

voltage from Pb valence 4 to Pb valence 2 (In this case PbO4 to PbSO4)

as being +2.47 volts when it's actually only +0.47 volts.

It's amazing how this one little number screwed up my

thinking on the whole subject for several years. 2.47 would have meant

spontaneous self discharge, and that lead couldn't work in alkaline

solutions - in fact, doubtless only in pH 1 acid. Thus, when people

talked about "converting lead-acid to alkaline" I thought they didn't

understand the chemistry, that it wasn't possible. But it was me

that was in error.

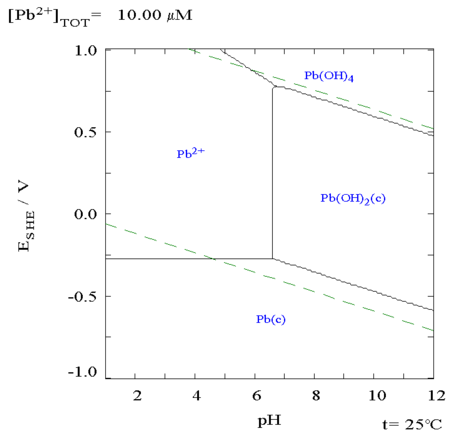

Instead, the less acidic the solution is, the lower the

voltage should be, down to .47 - -.54 = 1.01 volts with alkaline

electrolyte, or 6 volts for a normally 12 volt battery. This now (aha!)

fits with the lowered voltages I observed when I added an excess of

sodium sulfate.

This in turn may explain some of the "failures" where

everything seemed fine until the voltage suddenly started to drop

during charging and cells seemed to short or something: The voltage

wanted to be lower and the chargers kept trying to bring them up,

perhaps until

they started frying them, since they were really already fully charged.

Also, when I would see 11 volts instead of 13 or 10

instead of 12, I would assume a cell had shorted out. I was continually

perplexed by these supposed "failures" of cells in the batteries.

It seems possible that batteries with "too much" sodium

sulfate, or perhaps too little acid, probably work fine but might need

a custom charger for their specific voltage. I could also see this

might complicate the individual battery monitor, too. 10.5 volts is

alarm territory for a typical lead acid, but that might fall to say 9.0

or even lower for less acidic renewed ones, and an alarm at 10.5 would

be a nuisance.

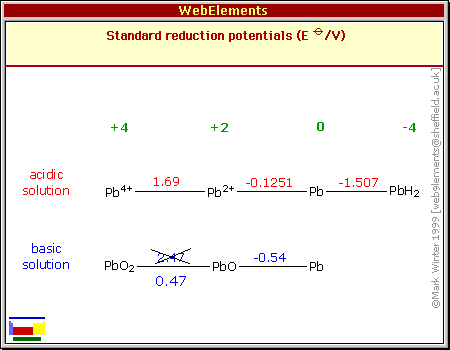

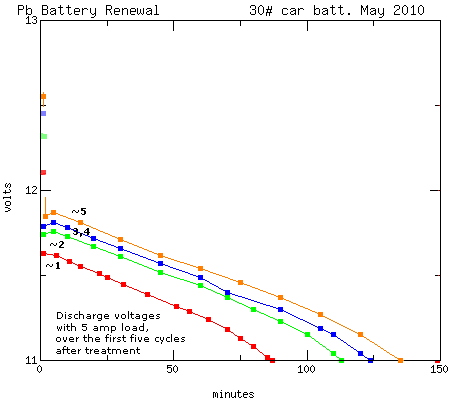

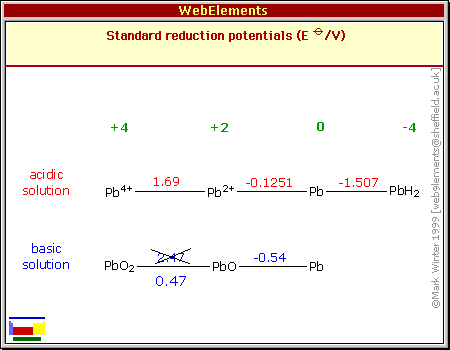

But this seems to be a moving target. On the second

discharge, voltages seemed to be even lower, but third charge ended a

bit higher. The third discharge seemed to hold voltages a little

higher. This is what others mentioned, and I'll revert to this graph

from TE News #28, which shows how voltages rose for me in one renewal

over 5 charge-discharge cycles:

Now seeing the chemistry a little more plainly, it would

appear that the reduced acidity accounts for the reduced voltage. But

the battery should become more acidic as it pulls sulfate off the

plates

during charging and discharging, as part of the renewal process, thus

raising the voltages. The half reactions forming acid are the regular

ones, with the voltages modified by the pH neutral Na2SO4 salt.

2 H2O + PbSO4 => 2 H+ + PbO2 + H2SO4 + 2 e- [+1.7v in acid]

PbSO4 + 2 H+ + 2 e- +> Pb + H2SO4 [-.35v in acid]

and of course if there's enough acid, the Na2SO4 + H2SO4 will no doubt

dilute to 2 NaHSO4 (sodium bisulfate), which is pH 1.

Will the battery always become fully acidic again? It

probably depends on the quantity of sulfate that comes off the plates,

and the quantity of sodium sulfate salt that was put in. Is "full"

voltage and strong acidity the aim, or will the renewed battery last

far longer if it's somewhat less acidic? It would take a lot of testing

over time to be sure of that, but it certainly seems batteries with

sodium sulfate (or, second best IMHO, AlNa(SO4)2 - alum) last far

longer

than plain acid ones.

An interesting aspect of this process is the rising

starting voltage (squares at left edge). I had back then a "cheap" old

charger with lower current that wouldn't try its best to fry batteries

that wouldn't quite come up to voltage, allowing the battery to survive

a few cycles without manually cutting off the charger. At first, the

battery wouldn't hold over about 12.1 volts, but by the fifth cycle it

was over 12.5.

Knowing now about the reduced voltages with rising pH, and

that the pH can in fact rise without without causing mayhem, it would

have been nice if I had graphed it down to 6, 8 or 10 volts instead of

cutting it at 11.

A Battery Renewal

Since I bought the Mazda and tried, seemingly

unsuccessfully, to renew some batteries to use with it, I've avoided trying to do any more. In early

July another battery in the Mazda was getting weak. I was driving it

quite a bit, and on the 9th I decided to try renewing a weak one one I

previously removed - as per my original plan for making them last well

- before I again had to run out and buy another one.

I took two seemingly identical batteries and drained the

acid. I couldn't remember which was the right one. One had relatively

clear liquid; the other was black. I turned them sideways and sprayed a

hose with a pressure nozzle into the cells. The one was clear. The

other continued to emit black liquid as long as I cared to spray it.

Then one of my renters said that one was one he had picked up to trade

in, and he had set it with my little collection (along with another

that didn't look familiar). No wonder I was confused!

Of course I renewed the one from the Mazda with the clear

water. I used Britta filtered water. For sodium sulfate I used some

from a big pail I had made last year by neutralizing battery acid with

sodium hydroxide. (It's a rather violent reaction that froths strongly

and may suddenly foam acid up in your face if you add a little too

much. I did it to get rid of some sodium hydroxide I didn't want. I