Turquoise

Energy Ltd. News #79

August 2014 (posted September 2nd)

Victoria BC

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Month In Brief

(Project Summaries)

- Electric Hubcap Motors are more powerful than previously thought!

-

Electric Weel - Turquoise Battery Project - Write-ups

& Website - Shopping & supplies - Aquaponics Greenhouse &

LED Lighting - VA Wind Turbine?

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Research and development tax credit programs - New video on financial

system - Overpopulation & Epidemics

Electric Transport - Electric

Hubcap Motor Systems

* Major magnet rotor improvement!

* "Bedini" unipolar motors?

* Huge Torque, Low RPM Electric Weel Motor-Generator Project

* Lightest magnet rotors

* J1772 car charging plug

Other "Green"

Electric Equipment Projects (see month in brief: LED grow

lights)

Electricity Generating (see month

in brief: VAWT.s)

Electricity Storage - Turquoise Battery

Project (NiMn, NiNi), etc.

* Improved plastic electrode pockets: two-piece 'boxes' with 'lids'

* Nickel-Nickel cell tests

* Lead-acid battery renewal update

No Project Reports on:

Variable torque converter transmission, Peltier heat pumping, Lambda

Ray Collector, Magnet motor, CNC

Gardening/Farming Machine (sigh, maybe summer...

2015?),

Woodstove/Thermal Electricity Generator,

evacuated tube heat radiators.

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers

- Preliminary Ni-Mn, Ni-Ni Battery Making book

Products Catalog:

- Electric Hubcap 4.5KW BLDC Pancake Motor Kit

- Electric

Caik

3KW BLDC Pancake Motor Kit

- NiMH Handy Battery Sticks, 12v battery trays & Dry

Cells (cheapest NiMH

prices in Victoria BC)

- LED Light Fixtures

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

August in Brief

Electric Hubcap family motors are more powerful than suggested

previously

The main concern with motor continuous power rating is

whether the motor gets

too hot at a given power. They're usually rated for the power they'll

handle without gradually exceeding their maximum temperature. The

materials of my motors (in particular the epoxy) are only rated for up

to about 65°c which is much lower than steel body motors, but being

highly efficient and having good cooling they

make little heat.

The concern for intermittent power rating above the

continuous power rating is how much power they're wasting, since

efficiency drops more and more as power is increased. Typically peak

efficiency is at 10-20% of full rating. Usually the high end testing is

ended when the power loss reaches 50%.

Judging from the almost trivial

motor temperature rises in the Electric Caik outboard at

1200-1500

watts in actual operation on the water, it appears that's a low

percentage of potential power and so I've been rating my motors

extremely conservatively. They could probably do

four

times the power I've been saying for short periods without overheating

(and without exceeding 50% loss), and maybe as much as double for

longer if

not

indefinite periods. At the risk of

maybe going overboard the other way, that would be: 12/6 KW

(Caik), 18/9 KW (Hubcap) and 48/24 KW (Weel). Very roughly assuming efficiency losses of 50% and 25% at

such high levels, output power would be 8/6 HP, 12/9 HP, and 32/24 HP.

Such figures might put a new complexion on what people decide they can

use Electric Hubcap type motors for.

Proper testing for which I have had neither the proper

equipment nor time to do so far would obviously be valuable. I've been wanting to buy a commercial BLDC

motor controller that won't blow up if I drive them to the levels

indicated above,

in lieu of beefing up my own controllers to 500+ amps capacity without

failing, which

they've hardly managed 1/5 of so far. So far, I've been putting it off

until I

(presumably) get my annual SR & ED tax credit from Canada Revenue

Agency.

Electric Weel

Motor/Generator

Large and Small:

Large and Small:

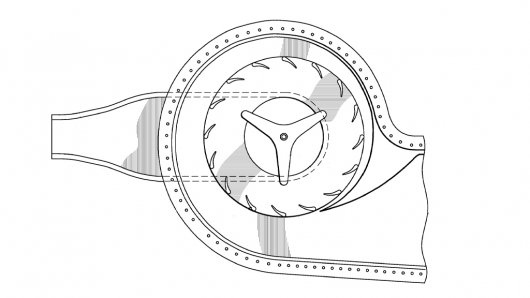

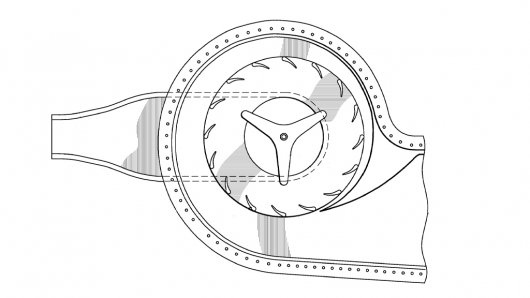

The newly made stator end piece for the huge torque, 28", 24(?) Kw Electric

Weel motor,

compared to the size of the outboard's 9", 6(?) Kw Electric Caik

motor.

In the early part of the month, I was molding a piece per

day, occasionally two, for the giant Electric Weel motor, and fastening

the pieces made in July together with polypropylene strapping and

the left over epoxy. Towards the end of the month I had two of the

three body pieces completed, the stator end piece, and the center piece

with a thick rotor side rim to safely enclose the rotor and stop any

magnets that might potentially come loose from flying out with

potentially deadly

force.

In spite of good intentions, the one additional mold piece

needed for the rotor end cover isn't made yet. (Two pieces from the 3

piece mold for the stator end cover can be used for both ends.)

This huge motor is certainly a lot more work than the

small units, with 24 moldings of body pieces instead of 3, then they

have to be epoxied together, plus a much larger rim that needed three

epoxy mixings instead of one. It's taking over 200 dollars of epoxy.

In a discussion, I also came up with a great way to

improve attachment of the magnets to the rotors: cut slots through the

rotor plate just inside from each magnet, and wrap the epoxied

polypropylene strapping right around the magnet and rotor plate from

inside via the slot to ouside around the rim. If I also balance the

rotors carefully, I think the Caik motor should be safe at at least

3000 RPM this way, whereas I've been reluctant to take it above around

2000 so far. This will be a major improvement to the whole family of

motors.

For the Electric Weel specifically, I got the idea

to use lexan plastic for the huge (26" OD) rotor instead of steel to

lighten it. Only outside where the magnets need steel backing will have

a steel ring. Even with the rotor lightened by having a 1/8" main body

with a 3/16" outer ring instead of being thicker throughout, the motor

with a steel rotor will weigh about 100 pounds (...that's the exact

figure I came up with in estimating it), and the plastic one can drop 8

or 10 pounds off that. Pounds count for handling and installation, and

in an EV it improves range that little bit.

Electric Weel body parts so far, in

assembled position - now it

Electric Weel body parts so far, in

assembled position - now it

just needs the top (rotor) end cover... and all the other parts.

The first Weel is already spoken for for

use as a large, low RPM generator for a novel floating river

hydroelectric project by Rick Linden of Coastal Geosciece Research

Corp. (http://www.coastalgeoscience.ca/

- a website even more in need of update than mine!)

Being made specifically as a generator for lowest RPM, each rotor

magnet will

alternate polarity and it can't be used as a motor.

As

I

think

about this project, I wonder if it has the

potential to replace river dams with more environmentally benign

floating structures. One thing working against this idea regardless of

the efficacy of the generators themselves, is that dams usually are

used to store winter rain water or snow melt for the dry summer season.

But it

could probably harness river and stream water that wouldn't otherwise

be harnessed at all. A hydro dam magnifies and harvests nearly all the

energy at one point in the stream, or perhaps it should be said, of the

section of the stream that the reservoir backs up to. Each floating

unit won't harvest a major portion of the flow, but they can be

placed up and down a river to harvest it at as many points as are

desired or seem useful. The aggregate just might rival a

showpiece dam project. Or it might complement it because if a dam

holds back water for summer, floating units downstream will also have

water flow to work well in summer.

Turquoise Battery Project

With the 3D printer repaired, on the 4th I printed a bunch

of electrode containers... each pair improved a bit over the previous

as I saw flaws. But leaking electrodes from July's batteries, which I

finally abandoned for that reason, got me thinking about an idea for

improved

plastic battery electrode 'pockets'... something like little boxes...

where the sides

of the box slide over each other, so that no matter the exact thickness

of the electrode materials, there'd be no gaps around the edges. If it

seemed helpful, I could even glue the edges together. (Fearing the

usual paper deterioration I'd rather not glue prototypes and then be

unable to open it to replace the paper, but it's doubtless the way to

go for production.) But somehow I hadn't had time to get it done.

On

the evening of the 11th after dinner, I finally decided I just had to

get this together. Working around some frustrating idiosyncrasies of

the 3D printer - actually mainly of the printing program - I had a

workable pair done by about 1:30 AM. (It occurs to me I should download

a new version of "Pronterface" in case there have been any improvements

that would help.)

On

the evening of the 11th after dinner, I finally decided I just had to

get this together. Working around some frustrating idiosyncrasies of

the 3D printer - actually mainly of the printing program - I had a

workable pair done by about 1:30 AM. (It occurs to me I should download

a new version of "Pronterface" in case there have been any improvements

that would help.)

I made a nickel negative electrode that crumbled, then

another one, and put it in one of the new boxes. By then the end of

the month was approaching and I decided to leave it until my conductive

carbon black arrived to make a better positive side from. Supposedly

that should have been shipped on the 24th, but it hadn't arrived by

September 1st.

Electrode boxes that I hope should serve to

prevent leakage

of electrode substance into body of battery cell

Write-ups & Website

From the 12th to 17th I was busy writing up info Canada

Revenue Agency ("CRA") wanted to have preliminary to a technology

review and inspection of

Turquoise Energy's facilities, the first since their initial visit over

four years ago. There was a deadline for submitting it. I finally

mailed off about 40 pages of info on the 17th, a little about finances

but mostly about the projects claimed last year.

Having done a sort of an 'overview' writeup on each

project, I plan to use the material to update the Turquoise Energy

website. I've put more about the tax credit funding subject, and its

stormy history, in "In Passing".

And I finally started a rewrite of the Turquoise Energy

web site on the 31st. A couple of weeks previously, Jim Lawrence came

over and went into web page CSS coding with me. CSS 5 has new features,

created

since he had done up the website for me in 2011 in CSS 3, which make it

far simpler to do what he did then. In several frustrating hours I had

the commands worked out to create similar article frame borders in two

columns

to what he had done then, but which were then so complex they got

messed up

every time a change

was needed. I kept the upper part of the page with the menus and links,

and the footer part with icons and links to twitter, facebook, etc, and

the appearance of the main section but with the new CSS 5 coding. Of

course, after three years most all the projects are much

farther along and needed or still need major revisions. It'll take a

couple more sessions before I can upload the new main page, and then

the other pages can follow one at a time.

Shopping - Supplies

I spent the whole day of the 21st shopping for various supplies, in

particular for the Elecric Weel motor, and a cheap flux core wire feed

welder to help with building a new 'box' for the variable torque

converter transmission. I find the considerable time I have to spend

either visiting stores or sitting on the computer looking for and

ordering things this somewhat

frustrating, as well as seeing the money go out, when I want to get

building. But one can't build without parts and materials. I got a

great deal at a tent and awning store on

1.5" PP strapping for the rim of the rotor compartment (the immediate

concern) - a 60 or 70 yard roll of white that the clerk said had been

'kicking around a long time' and had become a bit discolored, for about

1/3 of the regular by-the-yard price.

Aquaponics Greenhouse - LED Grow Lighting

Access to the greenhouse is

through the garage wall for security.

Making the

greenhouse dragged out through the whole

summer, since I didn't put much time into it. Finally I put on the last

outside "coroplast" panel on the 29th. There's still work to do on it,

but I now have an enclosure.

Making the

greenhouse dragged out through the whole

summer, since I didn't put much time into it. Finally I put on the last

outside "coroplast" panel on the 29th. There's still work to do on it,

but I now have an enclosure.

It seems the federal government would love to see

food being grown in the arctic in greenhouses, since it costs a fortune

to have it flown in for workers and residents in the far north. I got a

5 meter RGB - LED strip light from Jim Harrington on the 23rd, and it

seems I've

sort of been volunteered to work on ways and means for the lighting. It

can be cut into sections or bent around, and it even has a remote

control. I also have the

blue and red plant-grow wavelength LED.s I purchased myself for flat

panel grow lights.

Victoria isn't the frozen north, but it's certainly a

challenge to try and keep a greenhouse warm and lit and grow food here

in the winter, so maybe things worked out here could be applicable. If

I'm to keep tilapia fish for aquaponics, the water certainly needs to

be kept warm, and so does the greenhouse to grow plants. The tilapia

tank (to

be) is an apartment size fridge (insulated!) that holds water nicely if

it's lying on its back, as I found when I first saw it that way lying

on an

old pickup truck. The idea for an insulated fridge or freezer I got

from "cold weather aquaponics" on

youtube, where others are also working out the challenges of growing

food in cold climate greenhouses. If I'm able to contribute anything

new or special to that work, it'll probably be in the LED grow lighting

area and maybe renewable energy supply. (Perhaps I should contact

them...?)

The adhesive backed lights could simply be stuck to the

underside of a metal strip -- eg, aluminum angle irons. These would let

all the light shine down from above the plants, while the vertical part

placed at the front would shield the LED emitters from peoples' eyes.

This much sounds simple enough.

Aquaponics is apparently an excellent way to provide food

for people from small spaces with very minimal inputs in supplies:

fish food, water (but it's mostly recycled), energy and labor.

Vertical Axis Wind Turbine

I have again been thinking some about the VAWT idea. It has occurred to

me to make a very miniature version on the 3D printer. Or I'd make a

larger "real" version with the top and bottom pieces (and maybe a

center piece?) to hold the blades cut precisely on the CNC router.

I have again been thinking some about the VAWT idea. It has occurred to

me to make a very miniature version on the 3D printer. Or I'd make a

larger "real" version with the top and bottom pieces (and maybe a

center piece?) to hold the blades cut precisely on the CNC router.

And I ran across an interesting so-called "bladeless"

turbine. Of course it isn't bladeless, but the blades are inside a

housing something like the one I envisioned a while back to "aim" the

wind at the blades better, but still more elaborate and allowing more

efficient wing-like blade shapes.

Of note, where I would orient this unit with a vertical

axis and a vane so the housing would pivot about the shaft axis to face

into the wind, the authors had it horizontal. In that case the entire

unit would pivot including the generator at one side.

It should work about the same either way, but with a

vertical axis the generator can be in a fixed position underneath with

no need for slip rings to wire it.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

R & D Tax Credit Programs (Canada, history)

In July I got some notice from CRA of several pages,

saying that they wanted to do a finance and technology audit on

Turquoise Energy's work. Being in the middle of projects I ignored it

for 3 weeks, then read it and discovered there was a 30 day response

time limit. From about the 10th to the 17th I was busy writing up the

info they wanted preliminary to an inspection of my facilities and got

little done on the actual work beyond molding 2 or 3 more sections of

the big Electric Weel generator. I finally mailed off about 40 pages of

info, a little about money but mostly about the seven projects TE

claimed

for last year. When I first submitted SR & ED investment tax credit

forms in 2010, someone from CRA came to make sure I was doing what I

claimed, and this is the first time since then they've wanted to do an

inspection. I think that the Turquoise Energy News monthly reports

being on line has been considered sufficient proof for quite some time.

Notwithstanding the time it took me to get this together,

seemingly the same as if my 20000$ tax credit claim for 2013 was for a

million$, Canadian taxpayers

should be pleased

that the SR & ED tax credit program, based on a percentage refund

of resources

already invested by companies in R & D, is doubtless a pretty tough

program to scam. And it's about the only government program open to

those doing quite speculative inventive work. Most funding sources

forget there's "D", development, in R & D, and it's much harder to

get funding for creating new products than for "R", research.

I remember the early 1980s... 1984 or so (the fermenting,

enthusiastic early days of

computing) when "Scientific Research Tax Credits" ("SRTC"s) were frist

introduced and Frank Hertel scammed 70 million dollars

of taxpayer money with vague, then unworkable promises of remote power

meter

reading, and Fitsch(sp?) of 'Fitsch Research' got 35 million. (Both

fled to Venezuela with their 'winnings'.) Any number of smaller players

also scammed millions, while those actually doing R & D couldn't

get funding except through these high profile companies in trying to

make themselves look legitimate.

Hertel had a history of bankrupt companies behind him in

Germany, as anyone who bothered to read his resumé and check out

his references would have

discovered. An astute prospective employee came back laughing after his

interview and said the whole thing was an SRTC funding scam.

Where was the government's "due dilligence"?

Fitsch research tried to hire me in late 1984... not when

I

applied, but some months later. I got an interview when, as it turned

out, they were about to be audited to justify the lavish amounts

bestowed upon them. They wanted me to start immediately

and go to California and design IC memory chips. I had good experience

designing products using IC chips, not actually designing the chips.

And it all seemed too rushed. Where were they when I was free and had

offered my talents 3 or 4 months before -- and why hadn't they

interviewed people in good time? A month or so later Fitsch was in the

newspaper as the sheriffs were removing the furniture from their

offices. I expect I'd have never got a paycheque and would have been

left to hitchhike home from silicon valley.

Another Documentary on the crooked money system: Century of

Slavery: History of the Federal Reserve

In a similar vein to Mike Maloney's educational Hidden

Secrets

of

Money

Episode

4 now comes James Corbett's Century

of

Slavery: History of the Federal Reserve, 'an intense 7 months of

work' according to Corbett. It's been released free at

CorbettReport.com and on YouTube.com, and there's a full 90 minute

version or a condensed 55 minute version (which is the one I watched).

Corbett goes into more detail about the specific history of banking and

money in the USA than Maloney in this very watchable and informative

documentary. Both producers stress that the best way to help yourself

prosper and keep from being inexorably bled by the deliberately

complex and

confusing ponzi game financial system, is to educate yourself

about how it works.

Financial and Economic Collapse and Epidemics

As economic conditions worsen and the financial system

implodes, and with worldwide travel, it becomes more and more likely

that some of the various serious diseases in the news - such as MERS,

Ebola (evidently it's airborne, BTW), Dengue fever, and various

virulent forms of

flu - are likely to start sweeping across populations weakened by

overcrowding, poverty and shortages of nutritious food. With a still

growing global population (even tho that growth has at last slowed

considerably except in a few countries), and grossly inequitable

distribution of wealth, a crash of global systems and

with it the "population bubble" has in fact become inevitable.

In the middle ages black plague, coming "out of nowhere"

via rats brought from Asia in ships, gradually killed over half the

population of Europe in the only recorded century so far of global

population decrease. (It was said that while no one was immune, the

"lower and meaner" sorts of people were disproportionately affected. We

might suspect that many of these were less "cultured" groups with

poorer nutrition and lower

standards of hygiene... such as it was back then.)

In 1919 and 1920, at least Germany and parts of Europe

were starving, and an influenza epidemic killed more people (tho

worldwide)

than the devastating first world war (fought mostly in Europe) that it

followed. Antibiotics now available can mitigate bacterial diseases,

but viral ones like flu still can still sweep through populations, as

we all well know. Flu vaccines are apparently not very effective, and

also

vaccines have been implicated as a major cause if not the major cause

of autism. (An interesting study showed the great flu epidemics were

also

statistically linked to schizophrenia: it was noted at a British

psychiatric institution that schizophrenia was commonly grouped into

very specific age groups, which correlated to mothers being apparently

4-5 months pregnant at the time of a flu epidemic. Since the

correlation wasn't noticed until decades after, when the patients were

adults, it wasn't determined whether the pregnant women had to contract

the flu, or merely be exposed to it at the wrong time.)

Vast tracts of the interior of my large province of

British Columbia were planted with nothing but pine trees. A usually

minor pest, the pine beetle, started multiplying and spreading until it

infested the whole province, killing vast pine "forests" (plantations?)

provincewide. (I expect most farmers can tell us the hazards of crop

monoculture.)

Starfish have been in the news a couple of times in recent

years now. First

it was because they had been multiplying in numbers to the point where

it was feared they would utterly destroy all the world's coral reefs.

But this

overpopulation bloom has now brought a plague on the plague of

starfish, and they have been lately in the news again, this time for

dying off en masse of some

disease that rots them away.

When any species has grown in numbers too large for the

available resources to sustain (in the human case,

farming and land for all purposes), epidemics strike. Instead of a

leveling off of population with barely enough for everyone, there is

disease and a

population collapse. With seven and a half billion people in the world

today many vast areas are overpopulated compared with what current

societal and technological conditions can support. Diseases will soon

have a golden opportunity to wipe out maybe 2/3 of this mass of

people to produce a second century of global population drop, and a

very substantial one. I won't say the planet can't support this

population. If seawater were desalinated and the deserts turned into

gardens, if resource distribution and population distribution were

equitable, it might. But would the population then cease to grow,

or would it continue increasing until it was unsustainable at an even

higher level?

As it is, the three cosmic core values (quality of life,

growth and equality) are out of reach for too many people. The

reduction of pressure from our species

will be a welcome relief to the Earth. The lesson taught by the global

devastation will probably not be lost on the remaining populations

everywhere. They will probably decide that having children in

uncontrolled numbers isn't a right, and maybe that improving all the

human races by selective breeding to reduce the proportions of

"challenged" children

and increase those of the more intelligent and physically fit, only

makes sense. The Universal Father loves every person equally, but he

doesn't need for large percentages of them to continue being born with

various

built-in

genetic problems that detract from their personal growth potential and

from building the utopia that every

inhabited world should become.

Electric

Hubcap

Motor

Systems

-

Electric

Transport

Magnet Rotor Mechanical

Improvement!

My magnet attachment setup for the magnet rotors was the

best I could come up with at the time. But all along, I've been

somewhat

uneasy about it. The polypropylene strapping is strong stuff, but

keeping it attached to the rotors and the magnets glued to it, all

withstanding high centrifugal forces at higher RPM.s without something

delaminating, has been

something of a challenge. It was worst with the first attempts at the

Electric Caik rotor, where the slick coatings on the new magnets let

them

slip right out of the 'sleeves' at a very low RPM, and even after

sanding them to give the epoxy a better grip and re-doing the rotor, I

decided I didn't want to run it above 2000 RPM when I had originally

intended 3000.

I've thought of a new pattern or two for the strapping

that would cover the outer end so the magnets couldn't slip out. I

haven't made a new rotor since, so this never got put to the test. But

the whole thing, epoxy, strapping, magnet and all, could still

delaminate and pull away from the rotor with enough centrifugal

force. Some way to definitely attach the inner end of the strapping so

it absolutely couldn't pull off with any force less than required to

rip the very strong strapping itself would be much better.

In considering the magnets for the Electric Weel motor

with its two-piece rotor on the 11th, I finally thought up a truly

better answer: make a slot through the rotor just above the inner end

of each magnet. The strapping can be pushed through the slot and

wrapped right around the magnet on the rotor vertically (from inner

slot to outer rim), overlapping itself on the back side, and of course

all

epoxied into place. Even a loose magnet couldn't slide out, and the

strapping would have to tear to pull away from the rotor at the inner

end.

With this arrangement, which I will adopt for

all, the

rotors will be much more robust and able to withstand considerably

higher RPM s without flying apart. Maybe I'll have the Electric Caik

motor doing 3000 RPM or more after all... and maybe even get the 14'

aluminum

motorboat up planing!

After over 6 years of motor development, here was a place

to fix a remaining real design weakness that's been nagging my

thoughts! Counting moving the bolts farther from magnetic fields so

they don't get hot,

that'll be two new improvements, and of course the motors will be

better

than ever!

Rotor balance didn't matter much under 2000 RPM, but it

does anywhere much

above that. One can figure out where the imbalance is by putting the

rotor on an

axle and setting it on the axle between two perfectly level

rails. It'll roll until the heavy side is down. Weight would then be

added to the top side or removed from the bottom.

Unipolar

"Bedini"

Motor-Generators

There's "efficiency" from 0 to 100%, but with some systems

such as heat pumping, there's also "coefficient of performance" which

yields energy performance substantially in excess of the input energy.

Could there be such a thing with motors as well? Could my 95% efficient

motors be radically improved? John Bedini seemed to have demonstrated

it in the 1970s with his unipolar motors.

The more I considered it, the more I liked the idea. With

a regular motor, when a permanent magnet is between two coils, the coil

behind pushes with an energization the same polarity as the magnet (eg,

both south), while the coil ahead is magnetized to attract the magnet

(ie, north). But the iron in the coil itself also attracts the magnet

regardless of polarity, even if the coil isn't energized. If only the

coil behind is energized to push, the coil core ahead still pulls on

the rotor magnet, and regardless of polarity. The motor has magnetic

"cogging" and wants to jump to certain points of rotation where magnets

line up with coils.

Furthermore if the coil isn't energized, it can be used to

generate electricity just where the magnetic attraction pulls the

rotor, and

also the collapsing field from when it was energized can be recaptured.

With light mechanical load, Bedini seemingly had it generating as much

electricity as it used, charging a second battery even while

being driven from the first. The rumored Japanese e-bikes I heard of

last month, evidently using unipolar motors, apparently have far

greater travel range than others.

One could make a motor controller to do the Bedini 'trick'

with

bipolar magnet rotors - but with double the MOSFET drivers in order to

activate each phase independently north or south. With unipolar rotors,

they only need to repel one polarity so they only need to be activated

in one direction, making the controller much simpler instead - with

half the

MOSFET legs (3) instead of double (12) of the common BLDC controller.

The "Y

point" of the coils is tied to the battery plus voltage ("B+") instead

of left floating. The

three phases of coils are then actuated independently just by pulling

the other side to

ground. So the 3-phase bridge changes to 3 pull downs, eliminating

the high-side mosfets - half the heat-making power transistors and the

complexity they add.

Tying the "Y point" to B+ has another benefit: when the

magnetic field collapses after powering the coil, the voltage reverses.

With the Y point floating at 1/2 the supply voltage, this voltage

doesn't get higher than the battery voltage unless it's greater than

1/2 that voltage already (and even then perhaps it just pushes the Y

point around a little), so some of the resupply of power back to the

battery is lost. With one side of the coil at B+, all unused energy

(above the .5v reverse diode drop) is returned.

Furthermore, a 'regularly' configured motor has to go fast enough to

generate more voltage than the battery in order to passively recharge

it. But with one end of the coil at B+, the coil's back EMF would

generate electricity above the battery voltage whenever it's off and

the polarity is right. (Do I have that right? There seems to be

no ground reference for the coil voltage at this point. This may be

where Bedini charged a second battery - because the circuits didn't

work out for charging the same one supplying the motor. To charge the

same battery might need some sort of charge pump or an isolated output

DC to DC converter. This needs more thought.)

A complication with the control arises with the magnet

sensors. With alternating north-south magnets, the hall sensors can be

pretty much relied on to switch back and forth at the center points

where the field crosses zero. There are unipolar hall sensors, and even

with

unipolar magnets, south and north fields alternate if the sensors are

strategically placed, but the fields are unlikely to be even lengths. I

can see having to go back to the optical sensors I was using before I

found out about Hall sensors. Those of course will have to be mounted

in the rotor compartment rather than more conveniently in the stator

compartment. If I adopt lexan plastic rotors, a new idea mentioned in

"Electric Weel Project" below, they could perhaps be painted with the

appropriate stripes, and the LED.s and sensors be placed on opposite

sides of the rotor.

Huge Torque,

Low

RPM Electric Weel Motor-Generator Project

On the 8th I got

back to this and I wrote the G-Code (mostly by cutting and pasting from

the lower piece) and made the 3rd piece of the stator-rotor division

mold with the CNC router. Again the parts would be in eight 45°

pieces to be fastened together into a complete ring. On the 9th I

finished tidying it up and drilled and threaded holes for bolts to

clamp it together. I let the first piece harden up well before removing

it, thinking it might just pop out easily, but I almost wrecked the

mold getting it out. After that I waxed

the mold.

On the 10th & 11th I made a piece each day and 2 on

the

12th. I finished on the 19th, skipping the odd day because of the time

spent to write the CRA info. At the same

time, I used the epoxy that squeezed out of the mold to start gluing

the outer end (8 pieces molded in July) together, strengthening the

seams with PP strapping on the outside. It's hard to do more

than one in a work session because the epoxy in the mold has to set.

Also it takes a while to clean out the mold and get everything ready

for each one. It's far more work to do this large motor than the small

ones!

When I do a second unit, I can use the different molds and

maybe do 2

(or even 3?) pieces at a time. (if I buy a bunch more 4" C-clamps.) But

I took this one slow to see how

the molds worked

out - I might (and did) want to change something.

Also probably worthy of note is that owing to some of the

parts turning out a bit dry of epoxy, I'm changing the ratio of 4

epoxy to 1 polypropylene cloth, to 5 to 1. That's by weight - the light

cloth is still over half of the bulk.

On the 21st I needed supplies in order to proceed, and

spent the day shopping. But I got a great deal on

1.5" PP strapping for the rim of the rotor compartment - a 60 or 70

yard roll of white that the clerk said had been

'kicking around a long time' and had become a bit discolored on one

edge, for about

1/3 of the regular by-the-yard price.

The next day (22nd) I decided I'd do the outer part with

2"

strapping instead of 3", and alter the form for the top. Now the entire

rim would be even height, and the cover piece would be the full motor

diameter and made with a lip just inside of the rim to 'lock' it into

position. This was in

fact the reason I hadn't made the top mold piece(s) yet - just in case

the design changed before I got there!

I

didn't have enough 2" strap and bought 15 yards at

regular price. Then I made a big wooden ring to fit inside on top of

the center body ring, to wrap the epoxied strapping around to make the

outer part of the rim. (The wooden form was also modified - lower -

because of the rim change.) I made it out of 2" boards screwed

together.

These would be waxed

and a liner strip of 1/16" thick polyethylene plastic would be wrapped

around the wood, to keep the epoxy from sticking to the wood. In the

worst case, unscrewing some of the boards from each other should free

up the wood from the rim after the epoxy hardened. (Wasn't necessary.)

I

didn't have enough 2" strap and bought 15 yards at

regular price. Then I made a big wooden ring to fit inside on top of

the center body ring, to wrap the epoxied strapping around to make the

outer part of the rim. (The wooden form was also modified - lower -

because of the rim change.) I made it out of 2" boards screwed

together.

These would be waxed

and a liner strip of 1/16" thick polyethylene plastic would be wrapped

around the wood, to keep the epoxy from sticking to the wood. In the

worst case, unscrewing some of the boards from each other should free

up the wood from the rim after the epoxy hardened. (Wasn't necessary.)

On the 23rd I epoxied the center body ring pieces

together. The main trick to this was to make sure the 24 sets of coil

buttons matched and the coils fit on both sides. With the stator end

ring already made, later adjustments would be difficult. Luckily

PP-epoxy has just a bit of flex. The other

trick was to get them even so nothing stuck up to where the magnets

rotate. I bought some plastic clothes pegs. I ended up just using the

angled pieces as shims to adjust heights to evenness, but they were

probably the best thing I could have used.

On the 25th I

waxed and then set up the wooden ring on the

motor body center ring piece (I had to wait for Monday to buy some PE

plastic to line the outside edge). I painted epoxy onto the outside of

the body center ring and onto the 2" wide webbing, and wrapped two

layers around the outside. Since the center ring's outside edge is 1/2"

thick, the webbing stuck 1-1/2" up above, forming the outside edge of

the rotor compartment. After a few hours I pulled the wooden ring out

of the middle.

On the 25th I

waxed and then set up the wooden ring on the

motor body center ring piece (I had to wait for Monday to buy some PE

plastic to line the outside edge). I painted epoxy onto the outside of

the body center ring and onto the 2" wide webbing, and wrapped two

layers around the outside. Since the center ring's outside edge is 1/2"

thick, the webbing stuck 1-1/2" up above, forming the outside edge of

the rotor compartment. After a few hours I pulled the wooden ring out

of the middle.

For wrapping the inside of the rim I "spooled"

the strapping within, then started painting it with

For wrapping the inside of the rim I "spooled"

the strapping within, then started painting it with

epoxy and pressing it against the now solid outer rim to form a thick

solid wall.

Electric Weel

axial flux Motor or Generator composite body, 28" diameter:

Stator end is under midsection with thick rotor compartment rim (white).

(The pieces are held at finished spacing by unwound coil cores, not

visible.)

Material: "Advanced" molded composite of epoxy, and polypropylene cloth

ripped

into 6" square pieces or 2" & 1.5" polypropylene strapping or

"webbing" (rim).

On the 26th I used 390 grams of

epoxy in three mixings and

7 layers of white 1.5" strapping wrapped around the inside to thicken

the rim

to 1/2". (it was a bit more - I'll do 6 layers next time.) I tried to

paint fast, but the day being

unusually hot and sunny for Victoria BC, first little tub of epoxy

started to smoke and set up before I had finished. I salvaged the brush

by putting it in the freezer. For the second two, I moved out of the

sun, and I kept the plastic tub of epoxy in a slightly larger plastic

tub of ice water. I tried to make a little video of Electric Weel

Motor Construction as I went, but without a camera person I

couldn't show doing the actual work - I'd have gummed up the camera

with epoxy.

On the 26th I used 390 grams of

epoxy in three mixings and

7 layers of white 1.5" strapping wrapped around the inside to thicken

the rim

to 1/2". (it was a bit more - I'll do 6 layers next time.) I tried to

paint fast, but the day being

unusually hot and sunny for Victoria BC, first little tub of epoxy

started to smoke and set up before I had finished. I salvaged the brush

by putting it in the freezer. For the second two, I moved out of the

sun, and I kept the plastic tub of epoxy in a slightly larger plastic

tub of ice water. I tried to make a little video of Electric Weel

Motor Construction as I went, but without a camera person I

couldn't show doing the actual work - I'd have gummed up the camera

with epoxy.

When I was done I set the piece in the sun to set. With

the black plastic outside and white inside, the sun facing side got

quite hot and was soon set, so I turned it around. A while later it was

solid, and I sanded off some sharp edges with the belt sander. It had

been an all day project, with breaks for breakfast, coffee, and later

to lop off some blackberry canes that were threatening access to my

carport.

Despite good intentions, I didn't get to laying out and

making the mold piece for the rotor end cover pieces in August. The way

I did the rim, two of the three pieces for the stator end can also be

used for the rotor end, and only one new piece needs making.

Lightest Magnet Rotors? - Electric

Weel Total Weight Estimate

With a 26" diameter rotor, a 5/16" thick steel rotor would be horribly

heavy. I've thought of various ideas for making it lighter. The way

I've done the first one is with a 1/8" steel disk, with a 3/16" ring at

the outside where the magnets are, welded together and making 5/16"

thickness to carry the magnetic fields. I then had pieces of 3/16" disk

left over: an 18" disk that I had planned to use for the center of one

end of the plywood body, and a ring about the right size for a bicycle

wheel magnet rotor but only about 1.5" wide when I have all the 2"

magnets and coil cores.

Before that, as an earlier TE newsletter or two show, it

first occurred to me to make the whole thing as a

frame, welded together. 'Spokes' with transverse cross section would

give it more structural strength against warping and bending. That was

actually my first plan, but as I put it together, I was losing

confidence in

the strength of my structure at higher RPM.s, and at the same time, I

found the CNC waterjet steel cutting companies and did the above

mentioned design.

Now it occurs to me that a lexan plastic rotor, perhaps

bolted to a steel center disk to connect it to the shaft, would

probably be lightest. This would then have a steel ring on the outside

where the magnets go. I may even cut off the welds on the present rotor

and

keep the 3/16" ring but replace the center disk with lexan.

Weighing the parts (# = pounds), I find:

Coil end of body - 8 #

Ring part of body - 3 #

Coils - 23 #

Shaft (short), SDS bushing, bearings, bearing holders, seals - 12 #?

Magnet rotor (metal) - 27 #

Attempting to estimate the total weight, I get:

Total body - 25 #?

Total Wiring - 26 #?

Rotor (metal) with magnets - 37 # ?

Shaft etc. - 12 # ?

Total: 100 # even.

That's no doubt quite light for such a motor, at the

bottom

end of what I thought might be expected, and it'll certainly be easier

to handle than 150 or 200 pounds. But the plastic rotor would shave a

few

more pounds off it.

(Let's see: area of circle = pi * radius^2

= pi * 13"^2=530.9 sq". Area * .125" thick = 66.4

cubic".

The outer 3/16" ring is about 10-7/8 I.D. so 371.5 sq". inside

has no metal.

530.9 - 371.5 = 159.4 sq". * 3/16" thick = 29.9 cubic"

66.4 + 29.9 = 96.3 total cubic".

rotor 27# / 96.3 cub" = .28 #/cub".

ring 29.9 cub" * .28 #/cub" = 8.38 # weight of ring

8.38 # - 27 # = 18.6 # weight, of main rotor piece, removed.

)

Add the weight of the lexan and center hub for it, about 8

pounds, and the total weight reduction of the motor is about 12 pounds

for a total of about 88 pounds. That's probably worth it, although it's

still winch territory rather than "by hand" to install. And it's a

little less steel to rust. OTOH there's now only 3/16" thickness of

steel to carry the magnetic fields instead of 5/16". Since I don't know

the optimum thickness anyway... I'll just ignore that!

It would be nice to eliminate the steel altogether. I

could then make the rotors by layering lexan type plastic (for the

inner hub), glued with methylene chloride, and having the CNC router

precision cut everything including rectangular holes for the magnets.

But that's probably not feasible magnetically.

When I went to Industrial Plastics they had some pretty

imposing prices for the lexan. It looked like it might be a couple of

hundred dollars. I wandered around to their off-cuts bins and shelves,

where, as I remembered, they had quite a lot of scraps of something

called "impact modified acrylic plastic" - probably as good as lexan -

in pieces cut at odd angles for some job that was never completed: all

7.50$ each or two for 10$. They weren't big enough for this large

rotor... but from the larger sizes two of them glued together with

methylene chloride would be, with half the rotor from each piece. I got

about 14 sheets (70$), all the ones that would work, adding to 4 I had

bought earlier for flat panel LED lighting. The seam between the pieces

will have another piece a few inches wide backing it, also melted to

the main pieces with methylene chloride, eliminating possible weakness

at the seam. In addition, the 'lexan' will be thickened around the hub

to several thicknesses with a key slot on each side to secure it to its

axle, and without an SDS bushing, thus almost eliminating the weight of

that hub. (Hmm... under a pound, it seems.)

I plan to cut the 'lexan' rotors with the CNC router

machine. This cutting includes the center hole with the key slots, the

outer rim, rectangles that the magnets will fit into (thinnest rotor

and most secure magnets!), and slots for the PP strapping. With the CNC

router and all cut in one G-code program and one operation, everything

will line up "perfectly" with itself. The seam cover and other hub

pieces will be done separately and all melted together (with methylene

chloride as always) while mounted on the axle to prevent any possible

misalignment.

J1772 Car

Charging Plug - other safer charging plugs?

With the 3D printer finally working again, on the morning

of the 12th I printed out a plastic shell for a J1772 plug, the plug

all those

EV charging stations use, for the Mazda. I don't know whether the

charging stations will kick out at the slightest imbalance between the

two

lines, or whether there's enough slack that it will work if I put half

the chargers on one line and half on the other, using the ground as a

neutral. But I intend to try.

A safe outdoor charging plug that doesn't turn the power

on until it has a secure connection is a good thing, but it seems to me

dysfunctional to make the "standard" for it so that it's apparently

unusable by the majority who have 120 VAC chargers, simply owing to it

being missing a neutral pin. (I don't think you'll find a 240 VAC

battery charger in a "box store" at a good price in North America

unless it's a dual voltage one, will handle any voltage from 120 to

240, or is a special order... much less a model specific charger for

your particular e-bike or whatever.)

I had a hard time finding out the pin lengths and

diameters.

One site implied that the large pins were 3.6mm diameter. I gathered

the small one just might be about 2.5mm. It didn't seem like much to go

on. I didn't get it done.

In the absence of any agreed practical 120VAC EV standard, I

keep trying

to think of a way to make a safer 120V EV plug-in. The best I've come

up with so far is a regular socket (with a ground fault

detector-breaker of course), but one where the last couple of

millimeters of insertion of the plug pushes a button in the socket that

activates a relay that turns the power on. The main problem I foresee

with this is that people can plug the plug end in first, and then their

extension cord is live before plugging in the vehicle end. Also the

extension cord can easily be stolen while the vehicle is charging

unattended. If on the other hand this switched socket is itself on the

end of a (four wire) cord of sufficient length, that would greatly

reduce the likelihood that people would use an extension cord.

Perhaps the simplest arrangement of this sort would be a

cord with a shortened blade for the live line connector. Then the

ground and the neutral would make connection first, and the line only

in the last couple of millimeters. I could see a grounded plate over

the end of the cord as well - or on the socket - surrounding but

(definitely!) not touching the live line. If there were any arcs in

dampness, they should go to the metal plate rather than the fingers.

Electricity Storage

Turquoise Battery Project

Electrode Frames - Better 'Pocket Electrode' Design

Near the

start of the month I made some plastic electrode holding frames. I kept

coming up with minor changes while printing them, and over some hours

came up with quite a

few (image to left).

Near the

start of the month I made some plastic electrode holding frames. I kept

coming up with minor changes while printing them, and over some hours

came up with quite a

few (image to left).

Then on the 6th or so I got an idea to make two part electrode frames

that fit together like a two piece

cardboard box, one's edges fitting just inside the other. The rear side

would be solid plastic (replacing separately cut ABS pieces), with the

terminal supporting tab as a piece of that. If the sides were a little

shorter than the thickness of the electrode, pressure on the faces

would clamp it together 'perfectly', and there would be little chance

anything could leak out except through the porous face - with the thick

watercolor paper covering it. A thinner briquette wouldn't have a

hollow space to expand into, and a thicker one wouldn't create gaps at

the sides. If experience shows any stuff still manages to get out the

edges, they can be glued together.

Then on the 6th or so I got an idea to make two part electrode frames

that fit together like a two piece

cardboard box, one's edges fitting just inside the other. The rear side

would be solid plastic (replacing separately cut ABS pieces), with the

terminal supporting tab as a piece of that. If the sides were a little

shorter than the thickness of the electrode, pressure on the faces

would clamp it together 'perfectly', and there would be little chance

anything could leak out except through the porous face - with the thick

watercolor paper covering it. A thinner briquette wouldn't have a

hollow space to expand into, and a thicker one wouldn't create gaps at

the sides. If experience shows any stuff still manages to get out the

edges, they can be glued together.

This hearkens back to nickel-iron 'pocket electrodes', but

in plastic - something I've wanted to attain for quite a while, but

only now at last found this good design for. One difference is that the

porous front face won't be strong enough to retain expanding electrode

material without bulging, so pairs of electrodes will still have to be

clamped securely together. (Even Edison made pockets of round

perforated "pencil" metal tubes so they couldn't bulge.)

On the night of the 12th I worked through some frustrations with 3D

printer quirks in designing the 'boxes', and printed 2 of each part

before 1:30 AM.

Nickel Manganese Tests

I put in a zinc strip during a load test to check

electrode voltages against. I had assumed that the manganese had been

discharging most of its energy over a few hours. Thus the rapid voltage

drops in a load test would be due to lowering Mn negode voltages, and

the drop slowed somewhere under 2 volts because the zinc conductivity

additive would start to discharge, turning the cell to Ni-Zn.

That wasn't what I was seeing with the zinc strip, so I

continued the test down to lower voltages. Now it appeared that it was

the posode that was rapidly dropping voltage during the test, until the

voltage was under about 1.6 volts. The Mn stayed about .4 volts more

negative than the zinc strip. Below about 1.6 volts, the negode started

losing voltage - much more slowly than the previous voltage drops -

while the posode steadied. I think it went from the nickel-manganate

and nickel hydroxide voltage down to the manganese dioxide reaction

voltage, and then down to the Mn2O3 voltage. When it was down to a

volt, the

negative was almost down (up?) to the zinc voltage. (But I also suspect

the zinc strip was also changing voltage over time.)

I have some ideas about this, but basically I'm not sure

what will happen. So far I'm not seeing any further improvement in the

self discharge, but I'll continue the deep discharge tests to low

voltages. They may well be making some beneficial changes, especially

in the posode.

The next test (5th. 15:00 PM) showed little improvement in

the self discharge (30': 2.518v), but my thoughts turned back to the

borax which would probably form some borohydride in the negode. I

dumped in about 1/4 teaspoon - twice what I'd put in before. Now

something came back to me: the first electrode had been slowly

improving. With more zircon (11%), the second one had started out

better, but didn't improve. I would have changed the electrolyte unless

it looked clean, which is unlikely. I don't remember adding borax the

second time. No borax, no gradual improvement!

I note that

the little bits of white (KCl?) and green

(CuO?) stuff that were exuding from the electrode terminals grew into

fluffy crystal forests after the addition of the borax. (I've always

seen polyethylene, and glass, as hydrophobic, but somehow even the

glass marble on the lid becomes salt encrusted.) By the 8th, the cell

was definitely holding higher voltages longer at first. But over an

hour and more, it was losing considerably faster. It was as if there

were two causes of self discharge. One was decreasing, but the other

was increasing. I opened the cell.

I note that

the little bits of white (KCl?) and green

(CuO?) stuff that were exuding from the electrode terminals grew into

fluffy crystal forests after the addition of the borax. (I've always

seen polyethylene, and glass, as hydrophobic, but somehow even the

glass marble on the lid becomes salt encrusted.) By the 8th, the cell

was definitely holding higher voltages longer at first. But over an

hour and more, it was losing considerably faster. It was as if there

were two causes of self discharge. One was decreasing, but the other

was increasing. I opened the cell.

The electrolyte was black! Perhaps the same chemical

reactions that were reducing the self discharge of the negode were

contaminating the electrolyte and causing the second type of self

discharge? But this could presumably be solved by changing the

electrolyte. I put the electrode assembly in water for a while to help

dilute the electrolyte held in the electrodes, and did so. The crystal

forest on the lid quickly disintegrated in the water.

Then I realized that there was only one cable tie holding

the electrodes together instead of two. It was nearer the top, and the

bottom had swelled up and was releasing black electrode powders. This

was the last battery made before I got the 3D printer working again, so

the electrodes were merely wrapped with watercolor paper, which had

broken open again, and some PP nonwoven cloth that didn't have enough

fibers to prevent leakage. The electrode pockets are looking more and

more attractive!

I used a little more paper and 3 layers of fat

macramé cloth between them and stuffed it all together again.

But I'm starting to think more definite results might need to wait for

a new cell made with the glued 'box' pockets described above. (I only

wanted to run a test here not get into more battery making work but the

morning has gone - I was trying to work on the Electric Weel motor!)

Nickel-Nickel Cells

The nickel-manganate positive has almost double the

voltage in salty electrolyte that it would

have in

strong alkali. Choices for a really good negative side are more

difficult: iron, cadmium, zinc and metal hydride all eventually succumb

to gradual chemical changes and deteriorate, or even short out the

cell. Some other metals with good reaction voltages, eg vanadium and

chromium, have various soluble states and will rapidly dissolve.

Two especially promising metals that look like they should last

'forever' are

manganese and nickel.

The reaction voltage of manganese is so high it's hard to

make it

work, as the ongoing thread of these newsletters shows. No one else has

even got it to charge and hold a charge. I've accomplished that, but a

gradual self discharge has prevented practical cells so far.

Nickel metal has the unique attribute that it won't

oxidize

in pH 14

alkali even at a positive voltage, so it's never been considered for an

alkaline battery negative. Instead it's been used for non-corroding

current collectors -- which is the reason alkaline batteries became

popular. But (as I finally understood) it will

oxidize at any lower pH, so it can

be used as a negode in salt solution, at least with a graphite based

current

collector even if no metal works. Like Mn, Ni should last approximately

forever in a negative

electrode to make 'perpetual' cycling batteries. The chief drawbacks of

NiNi

over NiMn are higher cost and over a volt lower reaction voltage,

making cells only

around 1.1 volts nominal. On the

other hand, this voltage is so low self discharge should be no issue,

and sealed dry cells should be practical.

There's another factor: The current drives of my Ni-Mn

cells seem rather low. Whether this is just my constructions or

inherent in the chemistry is unknown at this point. It might be that

Ni-Ni would have a higher current capacity, perhaps even a much higher

drive, than Ni-Mn. This might mean that Ni-Mn would be great for low

current devices, but not for high loads such as electric transport.

Ni-Ni might turn out to

be as good as or better than nickel-metal hydride for either dry or wet

cells, and would be far easier and safer to make at home or in small

production.

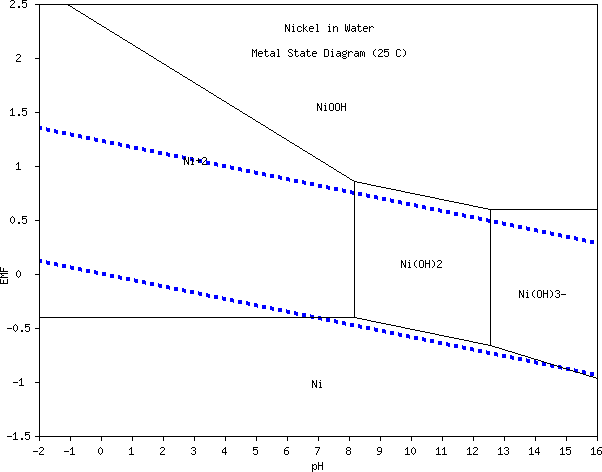

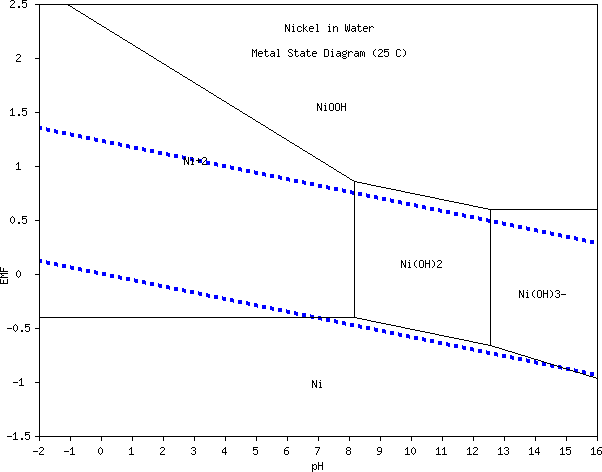

At any pH from about 8 to 12-1/2, a cell with nickel in both electrodes

should charge to about 1.25 volts and last an indefinite number of

charge-discharge cycles. (I'm not sure where the Ni(OH)3- shown at pH

13

and 14 comes from - it doesn't seem to apply in today's alkaline cells.

I also don't know how pH.es below zero and above 14 are obtained.)

At any pH from about 8 to 12-1/2, a cell with nickel in both electrodes

should charge to about 1.25 volts and last an indefinite number of

charge-discharge cycles. (I'm not sure where the Ni(OH)3- shown at pH

13

and 14 comes from - it doesn't seem to apply in today's alkaline cells.

I also don't know how pH.es below zero and above 14 are obtained.)

The first thing I did, on the night of the 3rd and the morning of the

4th, was to make the electrode frames. Hopefully these could

drastically

cut or eliminate the oozings of electrode materials into the

electrolyte.

The next question was just what form the nickel electrode

should take. With such a low reaction voltage - about .1 volts less

than hydrogen - there should be no need for overvoltage raising

ingredients.

Should there be a metal to improve conductivity, and if

so,

what? Did nickel need one, or would pure charged nickel metal itself be

plenty conductive? Zinc electrodes generally have no conductivity

additive and have very low internal resistance. I couldn't think of a

metal I'd want to use except maybe copper. If I used that, perhaps

monel would be a good form. But copper has a lot of soluble reactions.

Then again, with such a low reaction voltage, would carbon

black or graphite be suitable? And if so, what about using graphite

felt? And would a graphite foil current collector need doping?

I decided to go for nickel oxide (nano particles) for the

nickel substance, and graphite felt with a graphite foil current

conductor for the first try.

The usual battery reaction to NiOOH valence 3

isn't shown in this chart,

The usual battery reaction to NiOOH valence 3

isn't shown in this chart,

Instead its voltage of .49 is shown as going to NiO2, nor is a valence

6 shown anywhere else.

This may be more errors in the charts I was using all this time until I

discovered Pourbaix diagrams.

Nickel Negode

Working out amp-hours, pure nickel (discharging to nickel

hydroxide) would have 914 amp-hours per kilogram. This high figure

surprised me, given that nickel hydroxide as a positive is just 289

theoretically... and realistically maybe 1/3 of that. But why should

it have? Zinc is 820

and manganese is 976. Nickel is between them in atomic weight and all

of them move 2 electrons per reaction. Nickel discharged to

hydroxide in the negative side, counting the "(OH)2" mass, would be

579, or nickel oxide (NiO), my planned starting form, would be 718. If

the voltage seems low, at least that's good amp-hours! The NiO should

charge to Ni metallic nano particles and then

discharge to nickel hydroxide and never be NiO again.

It seemed there was nothing else to add unless it was a

percent or two of "vee-gum" - a bentonite clay to "glue" the briquette

together a little better. But better than what? Zinc electrodes were

flimsy, but nickel ones might be fine with nothing, and it would have

the felt anyway.

On the evening of the 4th, I put the felt in a small jar,

filled it with powder, tapped and refilled until the felt seemed

saturated. The triple felt layer was about 1.75g, and the nickel powder

in it was about 10.5g - so about 7 theoretical amp-hours. Then I

dripped in some Diesel-Kleen, Sunlight dishsoap and water and pressed

it to 10 Mg (mega-grams - tons), 625 Kg/sq.cm and left it in the press

for a while. When I took it out, unlike most electrodes it was somewhat

flexible instead of brittle. This may be from using too much liquid.

Some

oozed out in the press.

My [pottery supply store] nickel oxide was black,

indicating that it was non-stoichiometric, which means that some nickel

atoms might be at valence 3 (or 1 or 0?) rather than 2 and the crystal

structure isn't entirely regular. This is probably an advantage in

conductivity over green (stoichiometric) nickel oxide... unless it has

deleterious impurities. I chose it over my turquoise colored nickel

hydroxide also because it was more dense. I thought the fluffy

hydroxide might charge to rather loosely packed metallic particles,

reducing conductivity.

However, whatever form it starts as, it will all discharge to

hydroxide. Maybe I should go back to adding thiamine for a better size

balance between charged and discharged?

Posode (with graphite powder)

Next I pressed the posode. Since the graphite didn't

seem to be the cause of the self discharge, I used some powder with

graphite that I still had in a jar. (When I get the fine conductive

carbon black in a month or so, I think it should at least double the

current capacity over graphite powder. For now I just want an electrode

that works.) I pressed it to 8 Mg. It was only 5g of the lighter powder

in the felt, and it compressed to a thinner electrode. This is

backwards, since it needs at least 1.5 times the active material to

match the negode's amp-hours, even in theory. If it gives 1/2 an

amp-hour I'll be thrilled. Oh well. "Works" is the main point here.

Assembly

I left the electrodes to dry overnight and on the morning

of the 5th I singed them and then assembled the cell. This time I

remembered to paint the calcium hydroxide layer onto the posode current

collector sheet. I didn't however do the osmium doped acetaldehyde.

This was probably a mistake, as the initial current capacity seemed

very low and the cell had to be charged quite slowly - 30mA and it was

almost at 2 volts. This was also probably from using straight nickel

oxide with no metal in the initial negode. (Why don't I think more

often to put in zinc strip to help see which electrode is

doing what?)

Putting both

electrodes in the little frames made the work

easy. The frame edges took the place of wrapping the paper around the

briquettes, so just little squares of paper (~41x44mm) were needed for

the active faces. These were placed in the frames in advance with one

edge folded up a bit, then the briquette dropped in. Behind each one

goes the current collector, and then a heavy piece of plastic to hold

everything stiff. A cable tie wraps it all up into one layer cake

assembly. A bit of RTV silicone glues the graphite foil terminal tab to

the plastic tab piece.

Putting both

electrodes in the little frames made the work

easy. The frame edges took the place of wrapping the paper around the

briquettes, so just little squares of paper (~41x44mm) were needed for

the active faces. These were placed in the frames in advance with one

edge folded up a bit, then the briquette dropped in. Behind each one

goes the current collector, and then a heavy piece of plastic to hold

everything stiff. A cable tie wraps it all up into one layer cake

assembly. A bit of RTV silicone glues the graphite foil terminal tab to

the plastic tab piece.

Next holes, slots, are made in the lid of the jar for the

terminal tabs. When they are pushed through, They're glued with heat

glue or RTV. If desired, a round hole is put in the lid for a filler

and inspection hole. This is covered with a small glass marble (from

Michael's Crafts store floral arrangements section). But the hole isn't

vital. The jar can be filled first, and can be unscrewed and opened,

with the electrode assembly attached to the lid, not to the jar. (Good

for changing the initial electrolyte if it gets dirty, too.) A pinhole

for emergency venting might be nice - otherwise I'm sure something will

give to release any dangerous pressure buildup without a blow-up.

Next!

After a while and the usual internal leakages of materials

- and self discharge somehow just as bad as the manganese in spite of

the much lower voltage - I gave up testing the cell. I decided to

assemble a new one using the new plastic electrode 'boxes' that would

hopefully last. On the 19th I made a briquette with monel pressed to 10

Mg - no graphite felt. It was so crumbly that I dropped it back into

the mortar for remixing, and got out the Veegum (a bentonite clay),

intending to add a few percent. On the 23rd I finally got back to it. I

added around a gram of VeeGum. (somewhere in adding and subtracting and

forgetting I managed to confuse myself as to just how much it was - .75

or 1.75g.) Considering the crumbling briquette and thinking how hard

monel is, I pressed it this time to 15 Mg instead of 10.

Before making the posode, I decided to wait a few days for

the conductive carbon black I ordered, which was to arrive just about

the end of the month. But it still hadn't by September 2nd.

Lead-Acid Battery Renewal

The second battery I renewed (of three seemingly identical

size 27 batteries) behaved rather differently from the first in the

Mazda. Of course lower voltages are to be expected from higher pH, but

they both got about the same electrolyte. They would both eventually

charge up to full voltage, but the first one, as soon as it was used,

would drop down to about 7 volts. Under load it would drop to 6, 5 or

even 4 volts, but it stayed about the same while driving several miles.

The second one only went down to 10 volts. But over about 3 miles the

voltage dropped more and more, until the voltage display was winking

out at about 2.5 volts under moderate load and it may have been going

to zero or even lower. I tried not to stress it too hard, but to drive

anywhere I kept finding it failing on the return trip.

For a while, neither of them seemed to improve markedly

over time - the first to get to higher voltages, nor the second to

either go higher or to last longer. (If it's deteriorating further it

would be no surprise.)

Finally the second one started going to higher voltages,

and one day (25th?) it stayed high longer, but I drove too far that day

(owing to a rather long detour) and it rapidly went down to nothing

again after a certain point. I stopped and disconnected it on the way

home since I was doubtless damaging it. But now the voltage (with no

load) stayed up higher longer, and on the 28th I reconnected it to see

if it

was better, the same, worse, or essentially shot. It didn't seem to

last as long. On September first, with the car having been plugged in

and no

driving the previous day, the battery started out at just 10 volts,

notably

lower than it had been doing. It dropped fairly rapidly and I had to

disconnect it again. I can only assume the pulse charger hadn't kept it

up once it got it there. It may have decided the battery was bad and

quit or

something.

It will be interesting to try the third battery, which I

haven't refilled yet.

http://www.TurquoiseEnergy.com

Victoria BC

On

the evening of the 11th after dinner, I finally decided I just had to

get this together. Working around some frustrating idiosyncrasies of

the 3D printer - actually mainly of the printing program - I had a

workable pair done by about 1:30 AM. (It occurs to me I should download

a new version of "Pronterface" in case there have been any improvements

that would help.)

On

the evening of the 11th after dinner, I finally decided I just had to

get this together. Working around some frustrating idiosyncrasies of

the 3D printer - actually mainly of the printing program - I had a

workable pair done by about 1:30 AM. (It occurs to me I should download

a new version of "Pronterface" in case there have been any improvements

that would help.) Making the

greenhouse dragged out through the whole

summer, since I didn't put much time into it. Finally I put on the last

outside "coroplast" panel on the 29th. There's still work to do on it,

but I now have an enclosure.

Making the

greenhouse dragged out through the whole

summer, since I didn't put much time into it. Finally I put on the last

outside "coroplast" panel on the 29th. There's still work to do on it,

but I now have an enclosure. I have again been thinking some about the VAWT idea. It has occurred to

me to make a very miniature version on the 3D printer. Or I'd make a

larger "real" version with the top and bottom pieces (and maybe a

center piece?) to hold the blades cut precisely on the CNC router.

I have again been thinking some about the VAWT idea. It has occurred to

me to make a very miniature version on the 3D printer. Or I'd make a

larger "real" version with the top and bottom pieces (and maybe a

center piece?) to hold the blades cut precisely on the CNC router. I

didn't have enough 2" strap and bought 15 yards at

regular price. Then I made a big wooden ring to fit inside on top of

the center body ring, to wrap the epoxied strapping around to make the

outer part of the rim. (The wooden form was also modified - lower -

because of the rim change.) I made it out of 2" boards screwed

together.

These would be waxed

and a liner strip of 1/16" thick polyethylene plastic would be wrapped

around the wood, to keep the epoxy from sticking to the wood. In the

worst case, unscrewing some of the boards from each other should free

up the wood from the rim after the epoxy hardened. (Wasn't necessary.)

I

didn't have enough 2" strap and bought 15 yards at

regular price. Then I made a big wooden ring to fit inside on top of

the center body ring, to wrap the epoxied strapping around to make the

outer part of the rim. (The wooden form was also modified - lower -

because of the rim change.) I made it out of 2" boards screwed

together.

These would be waxed

and a liner strip of 1/16" thick polyethylene plastic would be wrapped

around the wood, to keep the epoxy from sticking to the wood. In the

worst case, unscrewing some of the boards from each other should free

up the wood from the rim after the epoxy hardened. (Wasn't necessary.) On the 25th I

waxed and then set up the wooden ring on the

motor body center ring piece (I had to wait for Monday to buy some PE

plastic to line the outside edge). I painted epoxy onto the outside of

the body center ring and onto the 2" wide webbing, and wrapped two

layers around the outside. Since the center ring's outside edge is 1/2"

thick, the webbing stuck 1-1/2" up above, forming the outside edge of

the rotor compartment. After a few hours I pulled the wooden ring out

of the middle.

On the 25th I

waxed and then set up the wooden ring on the

motor body center ring piece (I had to wait for Monday to buy some PE

plastic to line the outside edge). I painted epoxy onto the outside of

the body center ring and onto the 2" wide webbing, and wrapped two