Turquoise

Energy Ltd. News #81

October 2014 (posted November 3rd)

Victoria BC

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Features: Aquaponics! (see October

in Brief, Other Projects)

Month In Brief

(Project Summaries)

- Aquaponics - Solar Panels, CAT wall socket & LED "clear

cracked ice" diffuser - Variable Transmission - Unipolar Motor -

Coursera: free university education! - Wind Wave and Tides course.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Another "History of Money" video - Let's BE the Government -

Population

Control - Spiritual Teachers and Students

Electric Transport - Electric

Hubcap Motor Systems

* Variable Torque Converter Transmission

* Unipolar Motor & Controller

Other "Green"

Electric Equipment Projects

* Aquaponics & LED Grow Lighting Project

Electricity Storage - Turquoise Battery

Project (NiMn, NiNi), etc.

* Reason for self-discharge: Oxygen entering cells?

* Next Cell - not very good (so far)

No Project Reports on:

Electric Weel Motor-generator, Lambda

Ray Collector, Magnet motor,

Woodstove/Thermal Electricity Generator,

evacuated tube heat radiators, CNC gardening/farming machine.

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers

- Preliminary Ni-Mn, Ni-Ni Battery Making book

Products Catalog:

- Electric Hubcap 7.2 KW BLDC Pancake Motor Kit

- Electric

Caik 4.8 KW BLDC Pancake Motor Kit

- NiMH Handy Battery Sticks, 12v battery trays & Dry

Cells (cheapest NiMH

prices in Victoria BC)

- LED Light Fixtures

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

October in Brief

Aquaponics

Sometime near

the start of the month when I was spray

painting the Weel generator, I thought to also paint the inside of the

iron circpump for the aquaponics with polyurethane spray. That seemed

to completely stop the plenteous rust it had been emitting - a night

and day difference. On the 4th I set up the aquaponics tank and filled

it,

then spent more time draining it and fixing leaks.

Sometime near

the start of the month when I was spray

painting the Weel generator, I thought to also paint the inside of the

iron circpump for the aquaponics with polyurethane spray. That seemed

to completely stop the plenteous rust it had been emitting - a night

and day difference. On the 4th I set up the aquaponics tank and filled

it,

then spent more time draining it and fixing leaks.

Studying some aquaponics videos reminded me that one needs

a sump basin to take up the sudden outpouring of water from the

drain-down bin. It has to be the lowest point of the system, and the

pump pumps water to the rest of the system from it. The

fish tank has to drain into it from its surface level.

On the 10th I drained the tank and installed another

bulkhead pipe connector at the surface level for this. I purchased a

"13 gallon" rectangular plastic 'bucket' for the sump. It was just the

right height - the same height as the fish tank. Later I realized all I

had to do was run the pipe from the one at the bottom upward to surface

level outside the tank, and also that all lower bulkheads could be

"shut off" if

necessary without a valve, simply by screwing a plug into the threaded

inside end. Water exiting from the bottom is better because it should

suck out fish poop, so I changed it. (It does, but only with extra flow

- a 'cleanout cycle'.)

Over Thanksgiving weekend between my brothers Ian (a

one-time salmon farmer with a degree in aquaculture) and Stuart (a

biochemist, visiting from Toronto) and me, we determined that brook

trout might be an excellent choice of fish for my locale. They're

actually a species of char, and evidently tolerant of warmer water than

other trout. I had previously rejected trout, thinking they'd need

water too cold for good plant growth. But there's videos of people

doing

aquaponics with rainbow trout, so I was probably wrong. OTOH, the trout

videos didn't give much info and they didn't seem to show off their

vegetables that I recall. But it seems likely there are brook trout in

a lake near here.

I decided to stick with the tilapia indoors with LED

lighting plan for this winter, and see if I can find some brook trout

minnows in the spring. If so I'll make an aquaponics setup probably

with an outdoor "trough" pond in a shady place, and flow the water

through plant beds either outdoors or in the greenhouse. The summer

tilapia setup would be entirely in the greenhouse. Having two

aquaponics systems I'll be able to see which works better after a year

or two, or if it's worth maintaining both. or neither.

On the 13th I

'mounted' a 200W aquarium heater in the

fridge/tank and heated up the water from 20°c to tilapia

temperature, about 25. I didn't get the half dozen fish until the 19th,

after doing more of the plumbing. Contrary to advertising, they were

from a tank of 16° water full of algae, and already 6 to 8" long...

but they were the smallest fish available from two aquaponic peoples'

selections.

Many of the rest

looked like very good meals already. The next evening, considering that

I had no plants growing yet, I went to my brother's and got some

duckweed from his pond. He warned me that it was very hard to get rid

of. His pond water was also teeming with some tiny 'bugs' that on close

inspection looked

like very tiny freshwater shrimp. I put them in the tank but all was

gone in a few hours. I added some more, and this time saw the fish

gobbling up the duckweed - and no doubt they were eating the shrimp. No

wonder they didn't seem very interested in the fish food! The only

place I could try to keep the remaining duckweed was at one end of the

drain-down tank, which I didn't fill completely with lava rock. The

shrimp,

however, gradually disappeared. I think maybe the water was too warm

for them - or else the duckweed wasn't what they ate and they had no

food.

On the 13th I

'mounted' a 200W aquarium heater in the

fridge/tank and heated up the water from 20°c to tilapia

temperature, about 25. I didn't get the half dozen fish until the 19th,

after doing more of the plumbing. Contrary to advertising, they were

from a tank of 16° water full of algae, and already 6 to 8" long...

but they were the smallest fish available from two aquaponic peoples'

selections.

Many of the rest

looked like very good meals already. The next evening, considering that

I had no plants growing yet, I went to my brother's and got some

duckweed from his pond. He warned me that it was very hard to get rid

of. His pond water was also teeming with some tiny 'bugs' that on close

inspection looked

like very tiny freshwater shrimp. I put them in the tank but all was

gone in a few hours. I added some more, and this time saw the fish

gobbling up the duckweed - and no doubt they were eating the shrimp. No

wonder they didn't seem very interested in the fish food! The only

place I could try to keep the remaining duckweed was at one end of the

drain-down tank, which I didn't fill completely with lava rock. The

shrimp,

however, gradually disappeared. I think maybe the water was too warm

for them - or else the duckweed wasn't what they ate and they had no

food.

The drain-down bed with some duckweed at one

end and red lava rock grow media.

The drain-down bed with some duckweed at one

end and red lava rock grow media.

The top of the bell syphon is seen as is the hose from the water circ

pump,

and aluminum foil to help reflect whatever sun is to be had.

With sprouts now coming up, this bed definitely needs some LED grow

lights.

Later I planted some lettuce in

the flooded bed directly in the "freezer compartment" of the fridge

fishtank. There was so little light it started growing tall and

spindly. I finally got an LED light over it, which was no more than

adequate from a few inches away.

Later I planted some lettuce in

the flooded bed directly in the "freezer compartment" of the fridge

fishtank. There was so little light it started growing tall and

spindly. I finally got an LED light over it, which was no more than

adequate from a few inches away.

The disadvantages of growing the plants directly over the

fish tank started to show: First, the fish could get in and will

doubtless eat the roots as the plants grow. Second, I won't be able to

close the lid at night when they get taller. Third, I can't have the

light on and close the lid. Finally, they're not in the daylight from

the window. I'll probably make a separate floating plant bed, on a

shelf at the windowsill or even higher up in the window, and move them.

And I think I'll attach a couple of foot square mirrors on

swivel mountings to the window frame, that can aim whatever daylight

there is onto the plants - and from above. But as for

light, the 1 watt per square foot range of insolation implied by the

solar panels' performance

in the usual heavy overcast might be fine for vegetation on Ganymede or

Titan, but Earth summer garden vegetables will turn yellow and die.

(Full

sunlight square on is about 100 watts/sq.ft.)

Solar PV

On the 7th I

installed one of the two solar PV panels on

the 45° slope west facing house roof to extend the solar power into

the evening. To catch maximum sun all day, my ideal would be an arc of

panels tilted north-south by the angle of the latitude, ie flat at the

equator, 35° (facing towards the sun) at 35°, etc. In the

east-west direction, the east end panel might be also tilted, eg, for 5

panels: 60° towards the east, the next one 30°, then level,

then 30° and 60° west. Practicalities supervene. I have the

south and west slopes covered. One panel on the east slope could help

cover early morning, but it'd be a bigger project to get one up there

safely.

On the 7th I

installed one of the two solar PV panels on

the 45° slope west facing house roof to extend the solar power into

the evening. To catch maximum sun all day, my ideal would be an arc of

panels tilted north-south by the angle of the latitude, ie flat at the

equator, 35° (facing towards the sun) at 35°, etc. In the

east-west direction, the east end panel might be also tilted, eg, for 5

panels: 60° towards the east, the next one 30°, then level,

then 30° and 60° west. Practicalities supervene. I have the

south and west slopes covered. One panel on the east slope could help

cover early morning, but it'd be a bigger project to get one up there

safely.

I intended to put up the other panel, but I couldn't find

the angle bracket pieces I'd cut to mount it. I kept thinking they'd

turn up somewhere, but finally on the 30th I cut another set of four,

drilled the holes, and screwed them onto the collectors. On the 31st

there was a sunny break and I put it up on the roof. Seeing where the

shadows were trending, I mounted it a little higher than the first one.

(Some cherry tree branches are going to get clipped.)

I had disconnected the panel from the lower roof and I

wasn't going up in the ucky attic (full of fiberglass dust etc) twice,

so I

hadn't connected the first panel and neither of them was doing anything

useful. In the typical west coast overcast weather the four south

facing panels weren't doing much either, and the auxiliary battery

charger was often taking much of the load of the peltier fridge and the

new

LED 'flat box' grow light for much of each day. The two new west facing

250 watt panels will rendered some assistance in the afternoons now

that they're hooked up as of November 1st & 2nd. (I

had to go up twice after all.)

Then there were a couple of little 12 VDC power projects,

both done in a day:

CAT Standard 12 VDC wall outlet in standard

electrical box,

CAT Standard 12 VDC wall outlet in standard

electrical box,

powered from solar PV system and installed for use with the aquaponics

setup.

(Later the remainder of the pre-existing hole in the wall was covered.)

LED light" Previous diffuser was replaced with

"Clear Cracked Ice" diffuser plastic for use as plant grow light.

LED light" Previous diffuser was replaced with

"Clear Cracked Ice" diffuser plastic for use as plant grow light.

(I think this type of diffuser might be good for space lighting if the

light is mounted on a fairly high ceiling.

It breaks up the worst of the intense point source LED light, but less

effectively than the translucent version.)

I'll be making more of these with the 450nm blue and 660nm red LED

emitters especially suited for plant growth.

I'll mention in passing that I put together another cell,

with the more conductive carbon black, on the 23rd. It hasn't performed

well, probably largely because the posode was too thin to be held

properly compressed in its space. I wasn't able to put much time into

it. I'll have to get back to it next month.

Variable Torque Converter Transmission

I eked out a

little time to work on this, and made the

mid-shaft section that couples the variable planetary gear output (ring

gear, with a spline socket center) to the input rotor of the large

centrifugal clutch. I first got one half made from regular 1" shaft,

then I realized that, the new shaft being short, I could use the

original splined shaft that came with the gear set. I had to cut it in

two places, turn the non-spline end to 7/8" O.D. and make the bushing

hole again, but

the result was pretty much ideal - much superior to milling one end of

a round shaft to a

pentagon shape to roughly "fit" the spline socket.

I eked out a

little time to work on this, and made the

mid-shaft section that couples the variable planetary gear output (ring

gear, with a spline socket center) to the input rotor of the large

centrifugal clutch. I first got one half made from regular 1" shaft,

then I realized that, the new shaft being short, I could use the

original splined shaft that came with the gear set. I had to cut it in

two places, turn the non-spline end to 7/8" O.D. and make the bushing

hole again, but

the result was pretty much ideal - much superior to milling one end of

a round shaft to a

pentagon shape to roughly "fit" the spline socket.

After I got that cut to length, I set the motor on its 3

inch "stand-offs", marked out the holes, drilled, and then threaded

them. Shaft alignment seems pretty good - cetainly better than with my

previous configurations.

The view shows the assembly without the centrifugal clutch

disk & drum, which mount on the black bushing and on the shaft next

to

the chain, respectively. The large pulley is the slipping gear of the

torque converter, to have the tensioning rope from the 'gear shift'

lever wrapped around it.

Unipolar Motor

With the

promise of at least a better motor and controller, and even better, the

probability of it doing more with less energy, I set to work on the

unipolar Electric Caik motor and the controller, to be tested as an

outboard motor. Changes to the 'regular' bipolar BLDC motor are a

unipolar magnet rotor and an optical interrupter rotor position sensor

system. The more common hall effect magnet sensor system would be tough

to position and adjust properly without clear and obvious north-south

magnetic field transition points. I made the rotor and created a small

interrupter drum (slots

yet to be cut) for the optical system from a suitable PVC plumbing pipe

fitting.

With the

promise of at least a better motor and controller, and even better, the

probability of it doing more with less energy, I set to work on the

unipolar Electric Caik motor and the controller, to be tested as an

outboard motor. Changes to the 'regular' bipolar BLDC motor are a

unipolar magnet rotor and an optical interrupter rotor position sensor

system. The more common hall effect magnet sensor system would be tough

to position and adjust properly without clear and obvious north-south

magnetic field transition points. I made the rotor and created a small

interrupter drum (slots

yet to be cut) for the optical system from a suitable PVC plumbing pipe

fitting.

I balanced the rotor as best I could anticipating that I

would run it at higher RPM's than previous rotors - and attain higher

boat speeds.

Above: Unipolar Magnet Rotor - four magnets...

with

the new thru-slot radial epoxied strapping wrapping

that should be safe for higher RPM.s (3000 instead of 2000?)... and

four large spaces between.

Drum fitting (to be slotted) on shaft for

optical rotor/magnet

position sensor system.

Drum fitting (to be slotted) on shaft for

optical rotor/magnet

position sensor system.

I also did considerable design work in the last week on an

MC33035 based unipolar BLDC motor controller and the PC board for it.

The motor won't run without the controller! Of course some creative

design (and a CMOS 4000B logic NOR gate chip) was needed to allow CRM

instead of or in addition to PWM, but at newsletter time the schematic

is mostly complete and the board layout is largely figured out, but

much trace routing and some layout logistics remain.

Coursera.org and "Wind Wave and Tide" renewable energy course

I started

taking a course from University of Toronto via www.coursera.org , "Wind, Wave

and Tide", about generating electricity from those sources.

Coursera.org allows anyone to take courses or even get a university

education free, on-line, from their home computer. It features many

world renowned lecturers.

I started

taking a course from University of Toronto via www.coursera.org , "Wind, Wave

and Tide", about generating electricity from those sources.

Coursera.org allows anyone to take courses or even get a university

education free, on-line, from their home computer. It features many

world renowned lecturers.

While I have

my "Diploma of Electronics Engineering Technology" and a number of

sundry courses [far] behind me, this is the first course I've ever

taken from a university. And actually, I'm only doing the lectures and

'practice questions', not sitting for exams and labs to get the

certificate. But I now largely understand what drives the world's

winds! It seems that Savonius VAWT rotors that I've been

considering making don't make particularly efficient use of the wind -

only about 60% of a propeller type. But that's not bad, and they're

better at low wind speeds and in gusty or variable winds that keep

changing direction.

I

came up with the idea to make a darieus-segment sort of VAWT with

auto-pivoting blades, that would self-start. Then I found on youtube

that Alex Erauw (Belgium) already has a savonius-darieus hybrid VAWT

that turns 3 times

faster than other savoniuses, or in other words almost 3 times the wind

speed. Perhaps it extracts more of the available wind energy, and it

appears to have fixed blades - simpler than my idea. If so it achieves

what

I was after. But the video didn't show the airfoil details clearly, and

he says they're pretty critical. Then another video also from Erauw

shows a fixed position 'wind funnel' structure with four openings (Open

to "the four winds"?), that he claims doubles the wind speed going into

the turbine. Wind power is proportional to the cube of the wind speed,

so this would be extremely valuable in low average wind areas. It would

appear Erauw is at the forefront of vertical axis windplant design -

when I see an interesting design on youtube it usually turns out he

made it.

But another design from Germany shows a wind shield aimed

by a vane, shading the 'lee' (counterproductive) side of the rotor -

just such as I proposed some months ago. The wind shield could probably

be combined with the wind funnel as a pivoting funnel-shield. On the

other hand... whatever the design it has to stand up to whatever wind

comes at it when there's a gale, and the simpler designs with the

shortest shafts are most likely to stand up without making overly heavy

constructions. And a larger but simple turbine, even if it doesn't make

optimal use of the wind, will provide as much power as the optimized

but smaller one and maybe for less cost. It's like the ideas to have

solar panels track the sun: it's now cheaper just to buy extra panels,

and fixed mountings are more robust, safe and trouble free.

Of course I'll have to leave VAWT construction to some

later date when I have more time. And I should look at

this week's segment of the course, which evidently covers practical

siting and design costs.

----

I had intended to get the body hole drilling templates

done on the Electric Weel motor/generator, but didn't. In November I'll

also be doing a revised one for the Electric Caik (unipolar edition),

so maybe I'll do them both then, since they both need similar

spreadsheets, G-code setup and CNC drill-router work.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

I looked at a number of movies on youtube about the state

of affairs on the planet. One I thought was especially interesting was The

Impending

Collapse

of

the

Global

Economy. It was more an in depth

history of money of the USA from the times leading up to the American

revolution on. It seems there were a lot more well organized, well

funded manipulations and political murders by greedy banksters over the

decades than one

would ever suspect.

As the movie repeatedly pointed out, it seems clear that

an agency of government, hence responsible to the people, should be the

issuers of a nation's money supply and that nations shouldn't incur

debts. Banks should never be allowed to lend out more money than they

have on deposit.

The quantity of the money supply, and its original issue

as credit rather than as debt, is the critical point, and if issued by

greedy private interests, they create easy credit, then dry it up to

create depression and crises and buy up peoples' assets at low cost.

However, when governments try to start printing money

presidents get shot, credit from banks suddenly dries up on orders

'from the top', and normal mortgage and loan renewals are denied, to

rapidly create mass foreclosures, business failures and deep

depressions in the economy - which the public is then led to attribute

to the printing of money by the government instead of by a private

central bank.

If people don't understand what's happening and support to

the hilt proper ways of doing things, if politicians are easily swayed

or too timid to act, will the parasitic plague of banksters continue

killing presidents, bribing elected and civil service officials,

stealing peoples' farms, houses and pension funds, and swindling

everyone double through inflation and sudden money supply or credit

contractions?

Electoral system changes and referendum calling ability by the populace

are some of the answers.

One sees time and again the public winning

some big fight, and the vested interest party coming back after it

seems to be all over, on some modified tack, and having worn the public

out, they eventually get their way. Here in Victoria a manipulative

lawyer wanted to make a "mega-yacht" terminal in Victoria Harbor, a

harbor that is really too small for current needs. Organized public

outcry stopped the project. Now, two years later, the instigator has

moved the project a couple of hundred yards down the shore and rapidly

started building it without anyone knowing it was coming. No doubt he

quietly got some sort of permit from someone without any publicity or

hearings, perhaps by misrepresentation, to sneak it by to be presented

as a fait accompli. The pile drivers can be heard working furiously.

The banksters fought several times to gain control

of the US money supply, from the days it was a colony onward, finally

losing it only to come back and try again a few years later. The

repeatedly bashed population and string of murdered presidents gave up

in 1913 and the "Federal Reserve" (privately owned bank - not federal

and with no reserves) has more or

less ruled the USA ever

since.

If any such projects affecting the public might have to

pass a referendum called whenever and wherever enough people demanded

it, before it was started or yet still after it was in operation, the

proponents would at least have to try to make a good case publicly, and

bad plans such as private control of the money supply would be stopped

dead in their tracks every time they raised their ugly heads, until the

greedy give up and accept their equality with others.

Then again, we could also change the whole money thing.

It's said that on some planets, there is no money. Instead what is

controlled is what people are allowed to own. The 'richest' are

permitted up to four times as many possessions as the 'poorest'. Excess

can be confiscated. This works because really everyone has plenty, and

the population is controlled to prevent development of scarcity. There

are "trusts" rather than private corporations. No way would these

societies put up with a few people controlling most of the wealth. Of

course, such developments may be premature here... or not. I'm not sure

how this would work on Earth in regards to, say, art collections or

manufacturing and farm land or collective properties, but it sounds

like a great idea worth exploring.

Listening to videos and drawing conclusions, unfortunately

usually negative, about how things are being run and how they're

working out, is one thing. But figuring out anything productive to do

about them is another matter. But at some point recently I had a

brainstorm: start an e-mail discussion group to talk about anything of

interest in my muicipality, Esquimalt BC Canada. On the 15th I started

the group "Esquimalt Online", Esquimalt@yahoogroups.com , and, an

election being on with candidate posters up everywhere, I made a poster

for the front boulevard: "Esquimalt Online" - Join the Discussion - and

instructions for joining. That didn't seem to get anyone joining and I

decided it needed more explanation. As I wrote on the 17th:

Our institutions of governance,

set up in simpler times and without provision for change and progress,

are today archaic. We have the internet for rapid communication, a more

educated population, and many conflicting ideas - some pushed by

special interest groups - of what it might be good for a municipality

or other government to do or not do. Yet we have almost no input and

increasingly we are being controlled by out of touch governments

instead of controlling them for our own collective benefit. We have the

right and increasingly the need to participate in decision making

processes, and to not have all governing power be concentrated into few

hands with little public input.

We need a vehicle whereby the peoples' representatives can be informed

by the people collectively what we want them to do, or to not do; what

bylaws, regulations, policies, and public works we want or do not want.

At a "meet the candidates" meeting, I gave out 1/2 page

pamphlets, on the above lines. A number of people said "Great idea!",

but still no one signed up. I think the idea and implications of

actually being able to run a government instead of being run by it is

too different for people to immediately grasp. I shall persevere. Next

sign was to be something along the lines of:

=============================================

Let's

BE THE GOVERNMENT

of Esquimalt!

In 1.s we are ignored.

In 10.s we have a voice.

In 100.s, if we have a consensus,

what we say we want, will be done.

Join Esquimalt Online today!

e-mail to:

esquimalt-subscribe@yahoogroups.com

=============================================

I thought this e-mail discussion group format had the

potential to be "version 1.0" of the governing vehicle.

But someone told me there are already discussions going on

on facebook. Not being a social media fan so far, I haven't done

facebook. I signed in once and now get daily spam from them. But I'll

join if facebook is at last unmuzzling Esquimalt's

"silent

majority". If it's working, great! If it doesn't seem to be what's

needed, I should at least be able to advertise the e-mail group there.

I sometimes wonder why no

one of authority has taken up the conversation about global

overpopulation since it was realized the "population explosion" was

approaching, in the 1960.s

and 1970.s. Then I think: if people were admonished to have fewer

children, the more socially responsible and intelligent would probably

realize that was right, and would have fewer children, while the

irresponsible and unthinking would carry right on having large families.

Thus, the most desirable genetic stocks would selectively

be reduced

and eliminated from the population while the least desirable would

proliferate. This would be a disaster for civilization. And this in

fact does appear to be happening. At least, the 'developed' nations

have

birth rates well below replacement levels, while other groups in

already overcrowded "third world" lands continue to proliferate, and

the

overflow is continuing the undesirable population expansion and

flooding into the 'developed' lands, changing the

character of their populations. The ancient Greeks seemed to be a more

capable people than the modern ones. What will the species as a whole

be like in a few thousand years if this should continue?

Yet, enforcing size limits on all families would gain

little

traction in today's world*. How then can responsible people even

attempt to address the question?

Under these conditions, the population growth continues,

putting increasing pressure on the world's land and resources until

pandemics and a

collapse are now inevitable. Ebola seems to be new, but hemorrhagic

fevers were probably part of the "black plagues" of some centuries ago,

and we still don't have 'antibiotics' for viruses.

Even after such a collapse, putting limits

on family sizes will be a hard sell -- but such a hard experience as

the

world will have passed through will make the vital need for limiting

population

understood much more clearly than it is today, and I trust people will

then bite the bullet and enforce such a measure to prevent a similar

future calamity. At the same time, hopefully the obvious desirability

of having

more people who are more capable and spiritual will be worked into the

equation.

* China's one child policy is an

important exception, the one

such plan in effect. Problems notwithstanding, it has doubtless had a

big impact in reducing family sizes and slowing

China's population growth. China had 1/4 of the world's population in

the 1960.s, and today (notwithstanding China's rise from "3rd world" to

economic stardom, and further population growth) it's closer to 1/6th.

I usually take pieces of what I find and put it into my

own words. I don't think I could do this quote justice:

"A true

spiritual teacher knows that there really aren’t teachers and students.

All are involved in the same learning process, sharing the lessons and

the understandings, to together achieve the goal of perfection. Every

soul you meet on your path is your teacher and your student because the

goal of the ages – perfection and the likeness of the Father – is a

goal that can only be achieved in collaboration, since all are part of

God and all are one. The actions of one human being may be outstanding.

The actions of humanity working in harmony under the guidance of God

can achieve the impossible, even turning a backward material world into

a kingdom of true perfection and beauty." www.1111angels.net

Daily

Log

(time accounting, partly for CRA - SR & ED purposes)

1st to 4th: Worked on TE News #80. Spray painted Weel

generator & inside of the iron circpump for the aquaponics with

polyurethane spray. Then I set up the aquaponics tank and filled it.

5th: The compression fitting leaked so I replaced it with a bulkhead

pipe

connector.

6th: That leaked a little so on the 6th I drained the

tank with the pump and tightened the nut a little more. That seemed to

cure it.

7th: I installed one of the two solar PV panels on

the 45° slope west facing house roof to extend the solar power into

the evening.

8th or 9th: except studied some

aquaponics videos.

10th: I drained the tank and installed another

bulkhead connector, this one at the surface level. Purchased a "13

gallon" (US or Canadian gallons?) rectangular plastic

'bucket' for the sump. It was just the

right height - the same height as the fish tank - except that it was

1/8" too tall to fit under the table where I wanted to put it. I

unscrewed and broke the glue on two side supports of the table and

ripped 1/4" off them, then screwed them back on. The bucket now fits

under those two sides: It can be pulled out the front or the table can

be pulled away to the right. I then went to look at aquaponics

plumbing diagrams.

(Thanksgiving weekend: discussion about aquapoincs)

13th: I 'mounted' a 200W aquarium heater in the

fridge/tank.

14th: I tidied up some construction/finishing

details around the greenhouse door, then spent the afternoon shopping

for supplies, including a centering drill bit for the lathe. In the

evening I drilled a centered end hole for the bushing in the 'in

between' shaft for the variable torque converter transmission, which

I'd cut to length and faced square the previous day.

15th: made splined shaft for the variable

torque converter transmission (see report). I didn't get the keyway

done for the rotor's "H" taper lock bushing, and I left the hole

slightly undersize. The next morning (16th) I attempted to mill the

keyway, but found the end mill to be dull. I bought a new one and while

I was there I looked for a boring bar to ream the hole to precise size,

but the store didn't have one. On the way home I picked up a couple

more pipe fittings for the aquaponics. I phoned another store. It had

boring bars, in sets, and I bought one.

The new end mill didn't work any better than the first

one, immediately starting to get dull. The shaft steel was too hard for

them!

16th: I put together some of the pipes in the aquaponics system.

I came up with the idea to aerate the tank using a pipe with the end

closed off and some tiny holes drilled in it for the water to spray out

of, instead of the garden hose sprayer. I made this and it seemed to

work well, but the top pipe hole in the tank was a little low down, so

some fittings - or a bend in the pipe - would have to be used to raise

the holey pipe up above the water level. Surprisingly, the #56 drilled

holes seemed a bit on the large size. I had thought they'd probably be

too small.

17th: I visited AGO and asked the machinist about

the key slot milling. He said I needed a carbide toothed end mill. I

hadn't looked for those at the store the previous day since I didn't

know there was such a thing. I wasn't sure I could get one, so he

loaned me one. I was also given some coolant to keep squirting on the

tool as it slowly cut, at "under 900 RPM". Then people kept visiting me

all afternoon, one after the other, and I had to go out in the evening,

so I

still didn't get at milling the slot or the hole.

Also 15th to 18th: I worked on starting a new

e-mail group, "Esquimalt Online", to discuss municipal issues. Since

this isn't directly related to energy issues, I've put it in the "In

Passing" section.

18th: got the aerator spraying properly.

19th: Business breakfast; had to buy parts; finished most of the

plumbing; In the evening I went

out of town to where the tilapia were for sale and bought six.

20th: I got the shaft finished and tried fitting it onto the

transmission. It didn't quite fit and I cut 1/4" off the end. In the

evening I went to a pond and got some duckweed with tiny 'shrimp' and

tiny

snails.

21st: Fitted gear and taper-lock ("H") bushing to the center shaft, and

the Electric Hubcap motor to the transmission housing with the shaft in

place; measured up where the shift (tension) cable might go.

2nd, 23rd: Put together a Ni-Ni battery cell. Made bell syphon for

aquaponics and got it working.

24th: Fixed some broken links on the web site and re-uploaded the motor

controller making manual, which had somewhere got deleted. Finished

bell syphon housing and added some lava rock to plant bed. Battery

isn't working well or holding charge (see report).

25th: Put lava rock in aquaponics drain-down bed, made new housing for

bell syphon and adjusted, cut slots in rotor for making improved &

unipolar Electric Caik motor.

26th: Made venturi in lower pipe to improve bell syphon (successful).

Prepared Caik rotor and mounted magnets on it. Went to a 'suppressed

propulsion systems' meeting.

27th: Balanced Caik rotor. Read about a new monopolar motor being made

in Brazil. Did much e-mail about projects.

28th: Worked on Unipolar motor controller schematic & PCB layout.

Tried 5m LED RBG strip light for growing plants. It wasn't very bright.

29th: Wired 12v house circuit from solar panel. Reconstituted 2nd LED

light with new diffuser. Trace in light's PCB burned out - repaired.

Found PVC plumbing part that can work for drum style optical slots for

Unipolar Caik motor, drilled and hacked it to fit on shaft. Worked on

controller schematic and PCB.

30th: Installed mounting brackets in second solar panel.

31st: Put up 2nd west facing solar panel.

Nov. 1, 2: Wired in the solar panels.

Nov. 3: Worked on unipolar motor controller circuit design, finished

this newsletter.

Electric Hubcap Motor Systems - Electric Transport

Planetary Gear

with Clutch Torque Converter Transmission Project

Full as the days were, I really wanted to move ahead on

this and get the Sprint car going. I made some progress but didn't get

it finished before deciding the unipolar motor was probably even more

revolutionary and should be built ASAP.

I was putting

together the case width extension with the

motor "standoffs", and I thought to line the motor up I should next

make the

mid-shaft, a 3" extension coupling the variable planetary gear output

and the large centrifugal clutch input rotor. I cut a piece of 1" to

length (3.25") and did a center hole in one end for the bronze bushing,

but I've never liked having to cut a pentagon cross section shape - the

one thing I can make that will fit (if "fit" is the word) in the

planetary's 25-segment spline socket. The previous pentagon was a

little crooked, tho done as carefully as I could with the angle

grinder. This time I had the milling machine and could ensure flat,

square faces, but I still didn't like the arrangement. It seemed too

likely to wear out and start slipping.

I was putting

together the case width extension with the

motor "standoffs", and I thought to line the motor up I should next

make the

mid-shaft, a 3" extension coupling the variable planetary gear output

and the large centrifugal clutch input rotor. I cut a piece of 1" to

length (3.25") and did a center hole in one end for the bronze bushing,

but I've never liked having to cut a pentagon cross section shape - the

one thing I can make that will fit (if "fit" is the word) in the

planetary's 25-segment spline socket. The previous pentagon was a

little crooked, tho done as carefully as I could with the angle

grinder. This time I had the milling machine and could ensure flat,

square faces, but I still didn't like the arrangement. It seemed too

likely to wear out and start slipping.

Then it occurred to me that I could use the original

splined shaft that came with the gear set. It couldn't have been used

(as the longer output shaft) in the previous configurations, but now it

was a

short mid shaft. I spent the 15th and 16th cutting, turning and milling

it to be what I needed. It wasn't an inch diameter, but the requisite

uneven sections turned down smoothly on the lathe for a 7/8" I.D. "H"

taper lock shaft bushing for the clutch rotor.

In spite of the progress, the intriguing potentials of the

unipolar motor diverted me from the transmission towards the end of the

month.

Transmission Assembly,

without centrifugal clutch rotor disk and drum.

(The disk mounts on the black taper-lock bushing on center shaft and the

drum on the output shaft beside the chain sprocket, fitting over the

input disk.

Big slip pulley for controlled slipping of planetary gear torque

converter is seen at center; yellow Electric Hubcap motor at left.)

Unipolar

('monopolar') Motor

& Controller

Revolutionary potential

The point about simpler, cheaper, inherently more

reliable motor controllers wasting half the energy (and so getting half

as warm) compared to typical bipolar BLDC motor controllers decided me

that unipolar is a better configuration - at least, well worth trying

out.

But then there's the other point: John Bedini's

'monopolar' (unipolar)

motors seemed to get more energy out than expected; seemingly even more

than went in. They amazed a good number of educated people, which tends

to suggest the unexpectedly high performance is more or less proven.

Then there's Troy Reed, who said in a 2011 youtube video

he "can drive around all day" in a converted car with his new motor,

which seemed to draw considerably less current on the road than most...

but he didn't explain what the motor was. (It's said he was

assassinated in

2012. I was unable to verify this in a brief search.) Then there's the

rumored new Japanese e-bicycles from about 2012 that get a couple of

hundred

kilometers range instead of tens of kilometers, apparently with

unipolar motors.

Such monopolar motors should certainly be good at

reclaiming

remaining coil 'flyback' energy as the coils are switched off, and

obviously unenergized coils can generate electricity as the magnet

approaches them, perhaps reclaiming other energy. Plus there's the

lower iron losses, and lower motor controller losses.

If none of this proves to make any major difference,

unipolar still looks like the way to go. If it does, the potential is

revolutionary. We might start

seeing cars having ranges of 500 kilometers on a charge,

with no more battery watt-hours than cars getting 100-150 Km or less

today.

It would make a number of things much more practical than today, such

as electric commuter trains without overhead wires, solar electric

boats, and electric ferries.

This was my thinking until on the 27th an e-mail arrived

about a new motor, that appeared to provide still more evidence that

it's all true

and works better than regular motors.

The new Keppe motor is described at

keppemotor.com/about/faq.html

. They feel their motor is so good they're calling it "new physics"

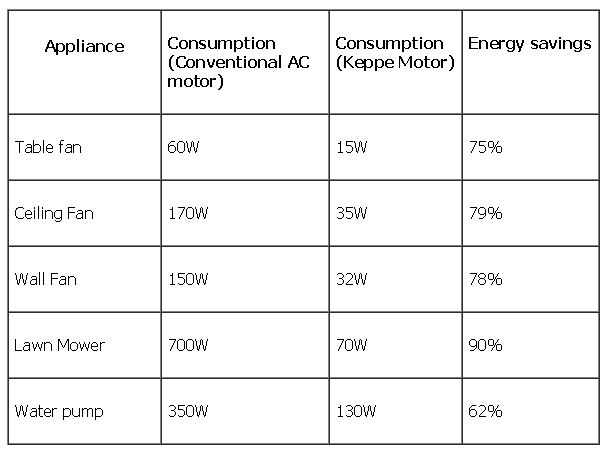

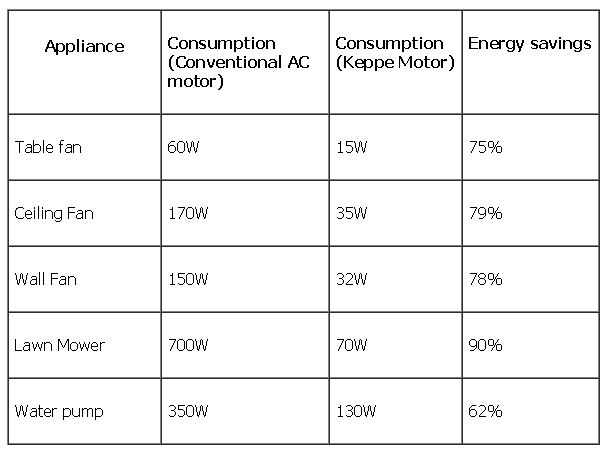

principles. It gives the following performance chart:

The performance

improvements appeared to be broadly in keeping with the previous

claims and rumors. Again the motor controller - and in particular,

power pulsed on and off in resonance with the coil resonant

frequencies - plays a key part.

On reading further, I discovered a major error in their

claims. They noted that while an AC motor might be efficient at rated

load, it still drew a lot of current even with no load. This is

observable with an ampmeter, and it confuses a lot of people. But the

AC current with no load is almost 90° out of phase with the AC

voltage, and simply

multiplying volts times amps doesn't give watts. The volt-amps may be

high, but the actual watts of power works out to a low figure for an

idling motor. (Multiply the volt-amps by the cosine of the phase

difference to get watts, IIRC.) So it would appear they are

overestimating the power consumed by other motors. This doesn't

necessarily negate all the savings or say their product isn't good, but

it does bring the amazing claims more into line with "normal physics"

reality.

But

I had already decided I would simply have

to do a unipolar rotor for the Caik Outboard and get the project

moving, this month, even before finishing the variable

transmission, and I had started work on it.

So far the Keppe motor is only made in small sizes -

fractions of a horsepower, and I know of no other unipolar motors in

production at present. Unless someone else jumps in before I finish, I

may have the only multi-horsepower sized units. It seems like an

excellent track to be on!

Unipolar Motor Construction

On the 25th I

milled slots in the last remaining waterjet cut Electric

Caik rotor blank for the radial magnet strapping (or 'webbing'). (I

forgot about the "ready made" '7.8" brake rotor' from Princess Auto. I

could have equally used that.)

Since

it's to be unipolar, there'd only be 4 magnets so I did 4 slots just

over an inch wide. I had planned to drill a starting hole and make the

slots with a jigsaw, but having just milled the key slot for the

transmission, I thought of milling and of how much cleaner a job it

would do. Since I used a 3/16" end mill bit (my smallest), that's the

width of the

slots. Anyway it leaves lots of thickness for two layers of strapping.

(When I did it, the strapping only overlapped on the back side - I

didn't double it through the slot. But I used 1.5" wide strapping

instead of 1".)

On the 25th I

milled slots in the last remaining waterjet cut Electric

Caik rotor blank for the radial magnet strapping (or 'webbing'). (I

forgot about the "ready made" '7.8" brake rotor' from Princess Auto. I

could have equally used that.)

Since

it's to be unipolar, there'd only be 4 magnets so I did 4 slots just

over an inch wide. I had planned to drill a starting hole and make the

slots with a jigsaw, but having just milled the key slot for the

transmission, I thought of milling and of how much cleaner a job it

would do. Since I used a 3/16" end mill bit (my smallest), that's the

width of the

slots. Anyway it leaves lots of thickness for two layers of strapping.

(When I did it, the strapping only overlapped on the back side - I

didn't double it through the slot. But I used 1.5" wide strapping

instead of 1".)

I considered using 2" x 2" magnets, but I have just 7 of

them, and if I save them for a larger motor needing 6, that motor will

probably have more torque, whereas the problem with the Caik outboard

is getting enough RPM, not torque. And the Caik's rotor being so small

(7.5"), curved arc magnets would be a lot better if a larger size is to

be

used. Putting two magnets side by side is almost impossible because

they repel each other so strongly. So I sized them for very strong

single 1" x 2" x 3/8" magnets... which I have lots of.

The next day I scraped the paint off the rotor where the

magnets and strapping were going (see the magnet loosening problems of

the first Caik motor rotor in issues... about maybe January 2013),

sanded the rotor and the magnets so the epoxy would stick well, and

mounted the magnets with the new configuration, presumably safe for

another 1000 RPM (Caik to be rated 3000+ RPM instead of 2000+) or

better. I used

1.5" wide strapping and had only milled 1" slots, so I cut 1/4" notches

in the strapping. When things were half set and flatness on top of the

magnets was assured, I slipped aluminum brackets over the magnets to

push the strapping down over the sides of the magnets.

The next day I scraped the paint off the rotor where the

magnets and strapping were going (see the magnet loosening problems of

the first Caik motor rotor in issues... about maybe January 2013),

sanded the rotor and the magnets so the epoxy would stick well, and

mounted the magnets with the new configuration, presumably safe for

another 1000 RPM (Caik to be rated 3000+ RPM instead of 2000+) or

better. I used

1.5" wide strapping and had only milled 1" slots, so I cut 1/4" notches

in the strapping. When things were half set and flatness on top of the

magnets was assured, I slipped aluminum brackets over the magnets to

push the strapping down over the sides of the magnets.

To balance the rotor for

the anticipated higher RPM.s

(27th), I mounted it on an axle and put the axle between two parallel,

level straightedges. In theory it would naturally roll until the

heavier side was down, and a little of the leftover epoxy (kept in the

freezer

overnight and not quite set yet) could be brushed on the

top side for weight until it showed no preference of orientation.

In practice, the shaft wasn't quite round and the rotor

would sit one way up or the opposite. I found a better shaft, which

wasn't perfect either, but by rotating the shaft inside the rotor

center and trying 2 or 3 times gave a fair consensus that one

particular side was lighter, which I marked with a felt pen. I put on

the epoxy without gaining too much. Then I stuck a couple of short

pieces of PP strap in the epoxy between magnets, one on the back and

one on the magnet side, still without getting a balance. It was better

than it was initially. Then I sanded a bit off the double-layer of

strapping on the back side of the two 'heavier side' magnets. I don't

think it's perfect, but it seems pretty close now. It may change a bit

when matched with a shaft that has key slots and a key.

The second

challenge to making the motor is the optical

sensor system for the magnet positions. A slotted disk or a slotted

drum has to mount on the motor shaft and spin with it, and three LED

and phototransistor pairs have to be positioned on opposite sides of

those slots. The drum type is superior for this application because the

shaft can be inserted from the rotor end and won't hit the optical

components, which have to be installed first, on its way past.

The second

challenge to making the motor is the optical

sensor system for the magnet positions. A slotted disk or a slotted

drum has to mount on the motor shaft and spin with it, and three LED

and phototransistor pairs have to be positioned on opposite sides of

those slots. The drum type is superior for this application because the

shaft can be inserted from the rotor end and won't hit the optical

components, which have to be installed first, on its way past.

Having been working with plastic plumbing fittings, I

thought that there might be one that would work as a drum. I went to

Rona and found one: a PVC pipe coupling with 1.5" pipe glue-on on one

end, and .75" inside threaded at the other. The .75" threaded pipe

fitting is in fact just under 1", and I drilled it out with a 1" drill

to fit over the 1" motor shaft. The 1.5" end has a rim about the right

diameter to cut the slots into, and have the phototransistors inside

the rim

(still clear of the shaft) and the LED.s outside, on a flat circuit

board on the inside of the stator end cover. The threaded end was too

long and I cut it shorter with a hacksaw. Then I drilled in through one

side and tapped it for a long 1/4" set screw to clamp it onto the

shaft. This same fitting should work for all Caik and Hubcap motors

with 1" shafts.

The next job will be the optics circuit board. And after

all this time but having switched to hall sensors until now, I still

haven't identified proper part numbers for optical couplers to use with

interrupter slots - I've used ones from old computer mice, but I threw

the rest of the old computer stuff out a while ago since I hadn't

touched it in years and needed the space.

Unipolar Motor Controller

I hadn't worked on this since September. On the 26th I

showed the ideas to a couple of people, one of whom mentioned part of

Bedini's key was to pulse the motor on. The next day on reading

the Keppe motor material, it appears it also pulses the motor,

at a resonant frequency. I had my circuit in mind, with an in-line

coil to transiently store motor coil energy, but I hadn't considered

this resonance idea, which could attain the maximum magnetic field

with the least electrical energy. Now I began to realize that the PWM

frequency might be a key to this, so I decided to incorporate a

variable PWM frequency control in the design. (I hope the optimum will

prove to be a relatively low frequency to minimize switching losses.)

The CRM could be separate from that (PWM-on AND CMR-on =

CoilsEnable-on), to ensure maximum currents didn't exceed ratings. But

the controller is so much simpler and more fault tolerant that I expect

good results from the first design.

I got back to the circuit design and PC board layout on

the 28th and did some work on it every day after that. After trying out

a couple of layouts, I started to realize that the way the Kelly

Controller laid out the coil drive transistors was very good. It seemed

counter-intuitive that they weren't bonded to the heatsinks, but only

to aluminum bars that stuck out the ends as terminal posts, to which

the power wires were attached. But the heavy copper power wires should

themselves be good heat sinks, carrying heat away from the transistors

and even from the whole controller.

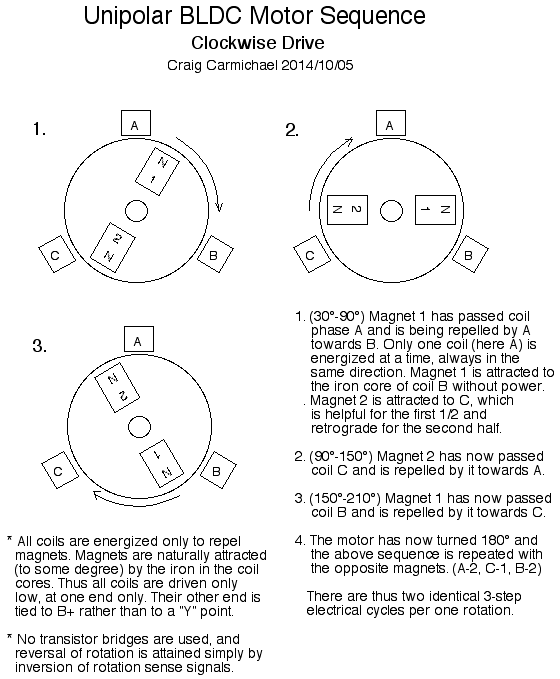

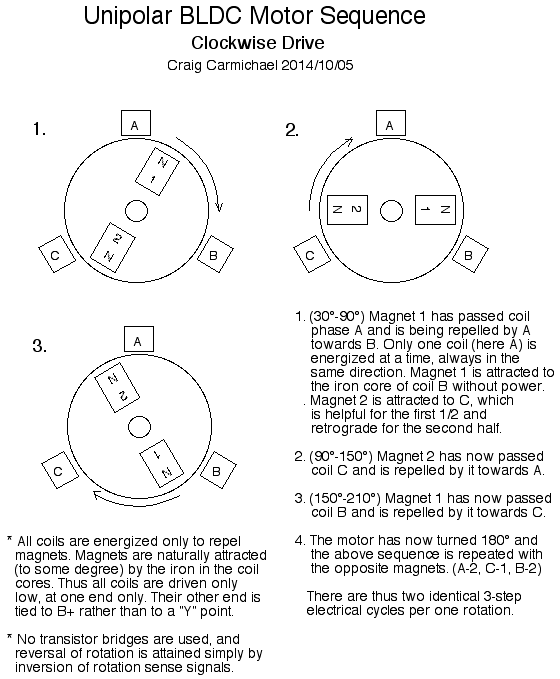

I'm not sure I explained the commutation sequence very

well last month, and a picture can be worth many words. So here's the

sequence, in a diagram.

"Green" Electric Equipment Projects

Aquaponics

& LED Grow Lighting Project

I worked away

on

this project up until mid month, gradually getting the plumbing set up

for the tilapia and plant bed in the upstairs battery lab. I got the

aquaponics part done, but didn't get to the LED lighting.

I worked away

on

this project up until mid month, gradually getting the plumbing set up

for the tilapia and plant bed in the upstairs battery lab. I got the

aquaponics part done, but didn't get to the LED lighting.

On the 14th I also realized that I could have used the

lower opening in the fish tank after all and not made an upper one,

just by bringing the pipe up vertically outside of the tank to its

surface height, before turning it horizontal to drain into the sump

tank. In fact, that's probably a better arrangement because it'll suck

up fish poop from the bottom of the tank. Furthermore, since the

bulkhead connectors are threaded on both sides, instead of having a

valve for the (hopefully) rare occasion of shutting off the water in

the fish tank or sump tank, I can just screw in a pipe endcap on the

inside. The only disadvantage is you have to get your hand and arm wet

to do it.

On the 16th I filled the

sump by pouring water into the tank and watching it pour out through

the overflow from the bottom. It poured more slowly than I expected,

the level in the tank rising an inch before there was a lot of flow. I

think I'd use 1" pipe instead of 3/4" next time.

On the 16th I filled the

sump by pouring water into the tank and watching it pour out through

the overflow from the bottom. It poured more slowly than I expected,

the level in the tank rising an inch before there was a lot of flow. I

think I'd use 1" pipe instead of 3/4" next time.

I didn't want to have to add a separate air pump, and

while putting together

some piping from the pump, I came up with the idea to aerate the tank

using

a pipe with the end closed off and some tiny holes drilled in it for

the water to spray out of, instead of the garden hose sprayer. I made

this and it seemed to work well, but the top pipe bulkhead hole in the

tank was

a little low down, so some fittings - or a bend in the pipe - would

have to be used to raise the holey pipe up above the higher water

level.

Surprisingly, the #56 drilled holes seemed a bit on the large size and

the spray a bit coarse. I had thought they'd probably be too small.

(18th) I tried heating up the aerator pipe and bending it so it would

be higher up, but it wasn't enough. So after a couple more trips to

Rona for fittings that somehow still weren't in the growing pile of

them, I put in a threaded elbow that I sanded down the corners of so it

would turn past the wall of the tank, aimed it up a bit, and screwed

the aerator into that. At last everything seemed to be working except

the bell syphon for the drain-down plant bed. I did a couple of little

experiments with that, and found that with the sump bucket being only

50 liters and the fish tank filling fuller than expected, there wasn't

a lot of water left in the sump to fill the drain-down bed, which was

around 100 liters. Yet if I filled it fuller, it might flood if the

pump shut off and everything drained down. Estimating that the bed

could fill twice as full once the lava rock was in it, that still made

for only a 6" bell syphon height and maybe 7.5" bed depth in the 12"

tall container. I'll put a compression fitting at the sump's entry from

the fish tank water. That way I can add a few more liters of water and

allow the sump to fill a little above the hole if it's completely

drained down - which won't be the case in normal operation. Next time

I'll use a sump tank with more capacity - at least the same as the

drain-down beds or in this case 100 liters (~25 gallons).

Then I cut a piece of 2" polystyrene foam to 17" by 5" and

with three holes for 4" pots, for three lettuce or other plants to sit

in the fish tank covering the freezer compartment. I filled three

hydropnics pots with the porous lava rock obtained early in the summer.

Having flooded roots in the water limits what might be grown, but the

compartment will keep the fish and light away from the roots.

With the pump running there were after a while patches of

tiny bubbles covering large portions of the water's surface, promising

that the fish would be well aerated. The lava rocks in the flooded bed

were moist right to the top, well above the water line.

The next day (19th) I picked up the tilapia (and 3 pounds

of fish food). I went went to the appointed house, and found that the

"6

inch" tilapia were more like 10 to 12 inches. This struck me as being a

bit much fish to start out with, notwithstanding his own crowded tank.

The seller said

not to worry, a friend had some smaller ones. On the phone I heard "3

inches". We drove there and out of a big circular tank full of algae

and covered with wood in

a dark greenhouse, he started netting fish. They were 6 to 10 inches by

my estimate. How are they measuring these things - the height? After

throwing back

several larger ones and trying again, we finally got a half dozen of 6

to 8 inches. Sex was pot luck - but luckily with 6 at random there's

only 1 chance in 32 they're all the same sex. I forgot to ask how to

tell them

apart... but there's always youtube. The water in the tank was only 16

or 17°c, and he said blue tilapia could take down to 10° before

they'd expire -

cooler than nile tilapia (12°). So much for "25 to 30°"! They

would eat

and do less in colder water. The range now seemed much more tolerant.

Since the pail water was cold and I'd heated the system to the

recommended temperatures, it took an hour to equalize temperatures

before I dared release the fish into their new home, adding and

removing a

little water from time to time. I kept the algae water for the bacteria

and as I had no other plants growing yet. I lowered the thermostat a

couple of degrees. They seemed to get on well, and seemed to become

more active at the higher temperatures even before release from the

pail.

While at the second house, I asked about making bell

syphons for drain-down tanks. His system was pretty close to what I'd

planned, but he showed me a flare on the top of the inner 1/2" PVC pipe

that he said helped get the suction going, and he had an 8 to 10" x

1/2" PVC

pipe sticking out under the bottom that also helped the suction action.

As with my plan, he used a bulkhead connector through the floor of the

plant bed, a 2" closed end cover pipe with cutouts around the bottom,

and a 3" pipe around that to keep the grow media away. And he said that

the water flow had to be adjusted so that it worked. Too slow (or too

fast?) and the bed wouldn't empty.

In the morning (20th) when I opened the (almost) closed

lid/fridge door, the fish darted around and then all turned sideways

and dove through the crack into the freezer area with the floating

plant pots 'lid', where I'd thought they'd have trouble getting into.

Within a day there was a lot of fish poop drifting around. I reduced

the flow to the plant bed, which increased the water flow to the fish

tank but didn't seem to raise the level much this time, and the poop

gradually started drifting out the outflow pipe and (at least some of

it) settling on the bottom of the sump tank.

The next evening, considering that I had no plants growing

yet, I went to my brother's and got some duckweed from his pond. He

warned me that it was very hard to get rid of. His pond water with the

duckweed was also teeming with some tiny critters that looked like very

small freshwater shrimp, and some tiny snails. I put some in the tank

but all was gone in a few hours. I added some more, and this time saw

the fish immediately gobbling up the duckweed salad with shrimp and

escargot. No wonder they didn't seem very interested in the fish food!

On the 22nd I planted leaf lettuce, counter lettuce and

spinach in the 3 pots in the fishtank.

Within a couple of days, the aerator pipe was repeatedly

getting clogged. It was definitely time to get the bell siphon going

and put the lava rocks in the plant bin, which could then do some sort

of job as a solids filter. So far, the pH of the water was reading 6 or

so on my broad pH range 'litmus' paper.

After expanding the bottom

slots on the bell pipe a couple of times and sanding away part of the

'hex nut' fitting in the bulkhead adapter, to let more water get by

more easily, the bell syphon essentially seemed to work (23rd), but

until I put in the lava rock I couldn't extend the pipe to the desired

height, as the required water volume would empty out the sump tank

first.

After expanding the bottom

slots on the bell pipe a couple of times and sanding away part of the

'hex nut' fitting in the bulkhead adapter, to let more water get by

more easily, the bell syphon essentially seemed to work (23rd), but

until I put in the lava rock I couldn't extend the pipe to the desired

height, as the required water volume would empty out the sump tank

first.

Later, (26th) I put the lower pipe in the oven and

tightened a pipe clamp around it to squeeze a section near the bottom

into a venturi. This seemed to help get the suction started without

preventing it from stopping once the bed was drained, which a long

horizontal pipe had done. It was still something of an adjustment to

have it work right, and I ended up with a short horizontal pipe on the

bottom after all. I ended up with the water cycling about every 12

minutes. The water certainly pours out when it's syphoning. It created

a definite swirling in the sump bucket. If I had bought a cylindrical

sump bucket instead of a rectangular one, it would have been a great

swirl filter, which is cleaned occasionally by scooping accumulated

crap off the bottom at the center.

View with plumbing essentially completed.

View with plumbing essentially completed.

The circulation pump, set to "Low" flow.

The cast iron pump emitted a lot of rust until it

was spray painted inside with polyurethane spray.

The intake hose is a special one that won't suck closed,

collapse, from negative water pressure.

Closing the fridge door at night to retain

warmth seemed like

Closing the fridge door at night to retain

warmth seemed like

a good idea at first... until I realized the fish would need air!

Light: Mirrors (but no smoke) and LED

lights (with smoke)

When the lettuce started sprouting, the leaves pointed

toward the window and they were spindly. There really wasn't enough

light. Lighting became a

focus because they'd die or at least grow poorly unless something was

done. (Several leaf lettuce plants sprouted, and just one counter

lettuce [similar to romaine]. The spinach didn't come up.)

On the afternoon

of the 27th, I set a mirror behind the plants. There was really no

sunlight, but it brightened things up. In a couple of hours I

noticed the leaves were pointed more toward the mirror. Making use of

whatever daylight is available may not be very high-tech, but it might

change things considerably. Instead of a mirror I can use aluminum

foil, and shape it to reflect light toward the plants - preferably from

above - during a good part of the day, or make a mechanism to have it

follow the sun. I put some foil around the inside of the drain-down bed

container and that pretty much used up what I had.

The lettuce sprouts were growing tall and spindly. They

definitely weren't getting enough light. On the 28th I tried a 5 meter

strip of LED RGB lights with remote control. I just draped it above the

plants, back and forth. But it wasn't very bright. On the 29th the sun

came out, and I aimed it via the mirror at the plants, which then

pointed towards the mirror. The strip light, which was still on, merely

cast a shadow in the sunlight. I finally removed it. But the mirror had

to be moved every few minutes to keep the bit of sun on the plants.

Also on the 29th I planted a few vegetables in the

drain-down bed. I'm not holding my breath, but I trust a few things

will come up. Usually I understand seedlings are planted in dirt and

transplanted to hydroponic beds later. Putting them right in the

beds I didn't have to water them.

I broke up the

second flat panel LED light I had made some

time ago and replaced the mediocre diffuser with a clear "cracked ice"

style diffuser I had bought. My impression is that the

diffuser is just adequate to make the pinpoint LED light sources

tolerable as building lighting for higher ceilings. I'd prefer the

translucent for wall mounting or lower ceilings.

But for grow lighting, clear transmits the most light, which the

plants crave. I'll also probably get better results with blue and red

emitters than white, and I expect to try them soon. Someone tells me

that with stationary LED lights, spots can get burned on the leaves, so

any diffuser would appear to be useful even with plants. (So would a

light that moves from east to west over the day!) He bought a one foot

square, 40 watt, blue and red LED grow light that he said was effective

at short range - a foot or two. Let's see... a 7" x 7" square light is

1/3 the area, and is about 12 watts, just under 1/3 the watts. Well!

With red and blue emitters, my prospective grow lights should be about

on par with these commercial units on an area basis, and at 30$,

cheaper for

the moment. The fact that mine are 12 volts DC should put them in a

slightly different market, tho of course a 12V power adapter is all

that's needed to make them 120VAC.

I broke up the

second flat panel LED light I had made some

time ago and replaced the mediocre diffuser with a clear "cracked ice"

style diffuser I had bought. My impression is that the

diffuser is just adequate to make the pinpoint LED light sources

tolerable as building lighting for higher ceilings. I'd prefer the

translucent for wall mounting or lower ceilings.

But for grow lighting, clear transmits the most light, which the

plants crave. I'll also probably get better results with blue and red

emitters than white, and I expect to try them soon. Someone tells me

that with stationary LED lights, spots can get burned on the leaves, so

any diffuser would appear to be useful even with plants. (So would a

light that moves from east to west over the day!) He bought a one foot

square, 40 watt, blue and red LED grow light that he said was effective

at short range - a foot or two. Let's see... a 7" x 7" square light is

1/3 the area, and is about 12 watts, just under 1/3 the watts. Well!

With red and blue emitters, my prospective grow lights should be about

on par with these commercial units on an area basis, and at 30$,

cheaper for

the moment. The fact that mine are 12 volts DC should put them in a

slightly different market, tho of course a 12V power adapter is all

that's needed to make them 120VAC.

Then I wired a

12 volt dual CAT socket from the solar

panel system in the wall behind the fish tank, in an existing hole that

I made slightly taller for the electrical box. (I used one click-lock

socket just to see the effect. The flush ones of course look better.) I

put the light a couple

of inches over the lettuce plants. It still wasn't as bright as the

sun. It was the one made with 3.5 volt LED.s instead of 2.9 volters, so

it only had 15 emitters instead of 20, and the transistor gets quite

hot at 14 volts since it's dropping it to about 10.5, and so has 3.5

volts

across it. I returned after a while to find the light out: a trace on

the circuit board had burned out. I bridged it with a piece of copper.

It wasn't the hot transistor's fault: it was another result of the

Samsung CLP-315 color laser printer printing a hatched pattern where

it's told to print solid black. I won't use it for circuit boards

again! On the 30th, another dull day, the plants at last started to

turn up toward the lights just a couple of inches above. The area was

certainly the bright spot of the room.

Then I wired a

12 volt dual CAT socket from the solar

panel system in the wall behind the fish tank, in an existing hole that

I made slightly taller for the electrical box. (I used one click-lock

socket just to see the effect. The flush ones of course look better.) I

put the light a couple

of inches over the lettuce plants. It still wasn't as bright as the

sun. It was the one made with 3.5 volt LED.s instead of 2.9 volters, so

it only had 15 emitters instead of 20, and the transistor gets quite

hot at 14 volts since it's dropping it to about 10.5, and so has 3.5

volts

across it. I returned after a while to find the light out: a trace on

the circuit board had burned out. I bridged it with a piece of copper.

It wasn't the hot transistor's fault: it was another result of the

Samsung CLP-315 color laser printer printing a hatched pattern where

it's told to print solid black. I won't use it for circuit boards

again! On the 30th, another dull day, the plants at last started to

turn up toward the lights just a couple of inches above. The area was

certainly the bright spot of the room.

On November 2nd the light fell into the fish tank. The

light kept working and no fish were harmed - a definite advantage of

LED.s and 12 volt power! (Of course, if it had been 120 V I'd have been

less nonchalant with it!)

Electricity Storage

Turquoise Battery Project

On the 6th someone in an e-mail said he was getting

self-discharge of his batteries similar to mine until he put them in

vacuum pack bags. It seems oxygen from the air was the cause of the

self discharge, and it's probably the cause in mine, too. I've made

some efforts to seal some cells, but they were half-hearted because I

didn't think air would filter in and absorb into the electrolyte water

fast enough to cause the problem. It also never occurred to me to take

note of the relationship between how good the sealing seemed to be and

the rate of self discharge. So I'm probably wrong and I'll try much

harder to get a good seal. I was of course disappointed to find the

lower voltage NiNi cells seemed to have at least as much self discharge

as the higher voltage NiMn, but if air is the cause the voltage

probably doesn't matter, so it seems likely that it is.

At any rate, assuming this is correct, the problems

with both NiMn and NiNi are simply construction problems, not

chemical problems. Making well sealed cells with sheet graphite current

collectors has been a headache - they can't be threaded like a bolt and

sealed with round grommets. But it's a "pre-production" detail, not a

basic research problem any more.

Perhaps another problem with using round jars for cells is

the amount of air already inside the cell, including that dissolved in

the considerable volume of water. Maybe I should go back to the thin

3D-printed cells? When I was doing those, I was getting deterioration

from using too much manganese oxides in the posode (with little or no

nickel oxides) and corrosion of the zinc current collectors, so the

cells didn't last. I may have better results if I try that format again

with nickel manganate posides and graphite foil current collectors on

both electrodes.

Next Posode

I decided to go with just Ni(OH)2 for the nickel. It's 63%

nickel atoms by weight. Using KMnO4 for the manganese (37wt% Mn), and

Mn being a bit lighter than Ni (54.9, 58.7), a 50-50 wt% mix should

give about 60-40 Ni to Mn, the desired ratio. The desired product is

nickel manganates, an insoluble, more highly conductive, and somewhat

variable product of Ni, Mn and O or OH. Since excess Mn will form