Turquoise

Energy Ltd. News #82

November 2014 (posted December 4th)

Victoria BC

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Features: Unipolar BLDC Motor &

Controller Progress (see "Month in Brief" and or detailed report)

Month In Brief

(Project Summaries)

- Unipolar motor controller circuit & circuit board -

aquaponics & LED lighting - variable torque converter transmission

- Coursera.org's "Wind, Waves and Tides" renewable energy course -

Electric Mazda & EV Mixed Batteries update - a small peltier fridge

update: it works better in cold weather.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- The Need to Enable Citizen Initiated Binding Referendums - Need

and Reasons for the Coming Collapse?... Superficial People Elect

Superficial Leaders.

Electric Transport - Electric

Hubcap Motor Systems

* Unipolar BLDC Motor & Motor Controller Project

Other "Green"

Electric Equipment Projects

* Aquaponics & LED Grow Lighting Project - 7" x 7" plant growth

light

Electricity Generation

* Wind Power: some VAWT calculations and schemes

* Wind Powered Vehicle goes straight downwind 3 times faster than the

wind! (Honest!) ...EV applications?

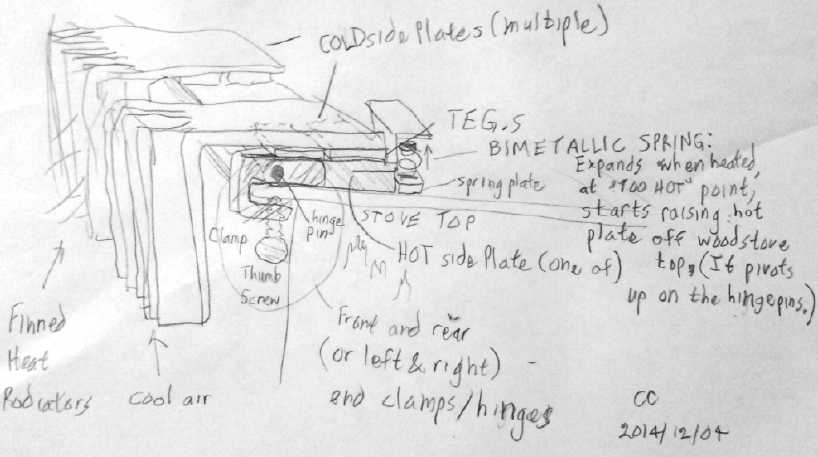

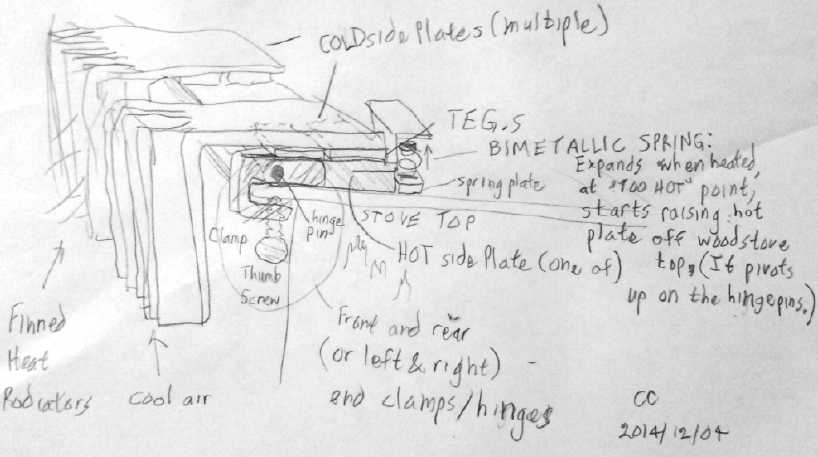

* Woodstove Thermoelectric Generator? - nah.

Electricity Storage - Turquoise Battery

Project (NiMn, NiNi), etc.

* New Soldered "D" cells, 100AH 12V NiMH batteries for RX7 EV etc.

* Real Lead-Acid - and NiMH - Capacities?

No Project Reports on: Turquoise

Battery Project (rats, no time!), Lambda

Ray Collector, Magnet motor,

evacuated tube heat radiators, CNC gardening/farming machine.

November in Brief

I thought I could get the unipolar BLDC Electric Caik

motor running in November and put considerable effort into it, and

towards the end of the month it became clear that it wouldn't be ready,

and I turned to some miscellaneous other things that weren't getting

done. I also did some aquaponics and LED lighting work trying to

prevent the plants from croaking and get some vegetable production

going.

Unipolar Electric Caik Motor

I did more work designing the circuit for the unipolar

motor controller and then the circuit board artwork. Some things being

quite critical, I carefully arranged

the

components and laid out the tracks by hand in the Eagle circuit

board CAD program. I thought I had it done on the 16th, but made a few

final changes in the next two mornings, and later had to change it

again when I found the 4000B CMOS NOR gates logic chip I chose is

unavailable. It's been superceded (probably long ago) by the 4025B.

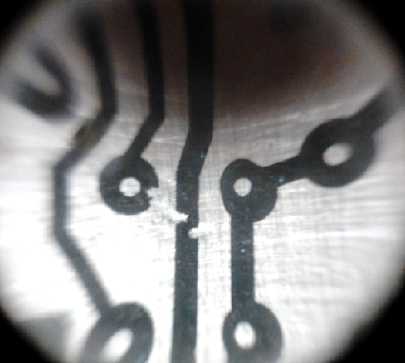

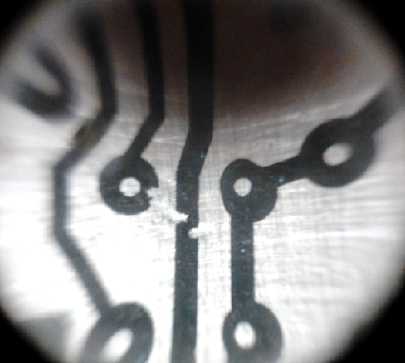

Unipolar BLDC Motor

Controller - printed circuit board artwork (bottom side)

with scattered voids from crappy printer

Meanwhile, on

the afternoon of the 16th I tried

printing

out the pattern for the bottom of the board (as it then was) on my

other printer. (The other one printed fine patterns instead of black,

explaining many of my PCB making problems.) I printed it on the "toner

transfer paper" and transferred it to a piece of circuit board. The

first one was abysmal. It looked bad, and some areas didn't stick to

the copper. They just floated off, even after running it through the

laminator a dozen times. I ran a drum cleaning cycle on the printer,

positioned the print in the middle of the page instead of on one side,

and tried again. It was much better, and I ran it through the laminator

in a different direction on each pass. This time there were no loose

toner patches, but there were little missing bits all over. It's the

printer. I need to find a better one to use or buy.

Meanwhile, on

the afternoon of the 16th I tried

printing

out the pattern for the bottom of the board (as it then was) on my

other printer. (The other one printed fine patterns instead of black,

explaining many of my PCB making problems.) I printed it on the "toner

transfer paper" and transferred it to a piece of circuit board. The

first one was abysmal. It looked bad, and some areas didn't stick to

the copper. They just floated off, even after running it through the

laminator a dozen times. I ran a drum cleaning cycle on the printer,

positioned the print in the middle of the page instead of on one side,

and tried again. It was much better, and I ran it through the laminator

in a different direction on each pass. This time there were no loose

toner patches, but there were little missing bits all over. It's the

printer. I need to find a better one to use or buy.

Caik Motor

assembled with 1/4" nylon bolts in the coil centers.

Sometime I

decided to use the second Electric Caik Motor body, which I had made as

an extra when I first developed that size motor, and make a completely

new unipolar one, rather than 'renovate' the old one for the first

unit. I was going to use a new pattern of bolts to clamp the body

pieces together, one which included nylon bolts ('machine screws')

through the coil centers to reduce magnetic heating of metal bolts. At

first I was going to use metal bolts in the outer ring... but even

there they would probably get a little warm, so plastic would doubtless

be ideal -- if it was strong enough so no threads would strip.

Sometime I

decided to use the second Electric Caik Motor body, which I had made as

an extra when I first developed that size motor, and make a completely

new unipolar one, rather than 'renovate' the old one for the first

unit. I was going to use a new pattern of bolts to clamp the body

pieces together, one which included nylon bolts ('machine screws')

through the coil centers to reduce magnetic heating of metal bolts. At

first I was going to use metal bolts in the outer ring... but even

there they would probably get a little warm, so plastic would doubtless

be ideal -- if it was strong enough so no threads would strip.

On the 20th and 21st I did the drill template for the body

bolts/screws. On the first template the ring of outer holes didn't

look like a very good fit. I made a second one and then drilled

the holes using it. I test-fitted the stator side together and the

nylon coil center machine screws seemed satisfactory. I put in 10-24

metal screws around the outside, but later I decided to use entirely

nylon machine

screws for the stator body side. I couldn't get #10-24 nylons long

enough to do the outside ring - in fact, an inch was the longest. I

ordered 1/4"-20 x 2.5" instead, and will have to see how they fit.

They'll take up a good portion of the total thickness of the outside

wall, making weaker spots. Maybe I should look for some #10-24 or M5 on

the web.

Aquaponics & LED Grow Lighting

First I had a little disaster with pH.es not being what

they seemed, and lost half the tilapia fish in an hour, presumably to

high pH. Two jumped right out of the tank onto the floor. That saved

the others, because I wouldn't have noticed their distress in time if I

hadn't gone into the room and seen them lying there. I had added a

couple of teaspoons of calcium and potassium, after which the pH strips

said "7" instead of "6", and I thought I had finally neutralized it.

Afterward I checked and tap water also read pH 6. I thought the strip

colors were off. Afterward I got an aquarium pH indicator, but it said

about the same thing. So now I leave the pH reading well enough alone,

at "6" or "6.2". I thought that was acidic.

Two of the remaining three seemed to become lethargic, and

flighty if disturbed. (I replaced the other three on December 2nd when

the dealer got them in for me.) The fish make a lot of poop that

settles on the bottom, and I have to clean it out of the center-bottom

of the sump tank every couple of days, and what doesn't circulate out

of the fish tank once in a while. I can see having the tank on top and

draining into the plant beds is a better arrangement since the waste

automatically goes to the plants.

I planted

vegetables in the drain down bed. What started growing best was kidney

beans (scarlet runners?) and peas. But it was obvious there wasn't

anything like enough light through the window in the winter. I read in

Indoor Growing magazine that the biggest mistake beginners make is in

underestimating the amount of light required.

I planted

vegetables in the drain down bed. What started growing best was kidney

beans (scarlet runners?) and peas. But it was obvious there wasn't

anything like enough light through the window in the winter. I read in

Indoor Growing magazine that the biggest mistake beginners make is in

underestimating the amount of light required.

I got one blue-red emitters

flat panel LED light made, and I put it over the aquaponics drain-down

bed, now the only plant bed, to give the spindly plants some light. I'm

very pleased with it and I started thinking again about producing LED

lights, both white space lighting and blue-red plant growth lighting.

Human eyes are most sensitive to green, and so it seems non-intuitive

that these dull looking blue-red lights are actually brighter than

white at the blue and red light frequencies that plant leaves use. A

friend says I'll have the police here soon with a blue-red light

showing in the window, looking for marijuana. It hasn't happened yet.

(I'll say more on the subject of marijuana as an example of the need

for the right of all citizens to initiate binding referendums in "In

Passing".)

By varying my search terms

I located and ordered some 410-415nm

(nanometers wavelength) and 420nm LED emitters - more centered in

the 400-450nm photosynthetic range than the 445-455nm ones I found

before. The visible spectrum is about 390nm to 700nm. 400nm verges on

the near ultraviolet.

Of course the tilapia seller also had an aquaponics setup.

He had a fat disk shaped 50 watt LED grow light about 7" in diameter.

It ran on

120VAC and the top part enclosed a fan that cooled the emitters and

electronics. You could feel the heat on your hand under it. He

said it cost about 70$. That's some stiff competition if I have to

charge 50$ to make my 15 watters viable. OTOH if I add fan cooling to

mine I can up the power and light density quite substantially (double

or better?) in the same space for 15 or 20 extra dollars.

I also made a featherweight mirror of coroplastic and

aluminum foil.

So far I haven't found a ball joint thing so I can mount and deploy it

in front of the windows at any angle to beam any sunlight there may be

onto the plants. More lights will be needed, and more places to plug

them in.

On the 30th I designed a fourplex CAT sockets 12V wall

plate for a regular 1110 electrical switch/plug box, in OpenSCad. I

haven't yet printed it on the 3D printer. When I get up to over 4 LED

lights to plug in in one place, I'll do a 6-plex. 6 CAT receptacles

should still fit in the available 1110 box space. And maybe I'll try a

new style with the receptacles built into the plate instead of being

inserted later. It might look better. The wire sockets would slip in

from the back and then a rear cover would screw over each receptacle to

keep them from popping out.

Variable Torque Converter Transmission

In working on the Unipolar

Electric Caik motor project, I barely found time to mount the

centrifugal clutch, and that only because I wanted to put it all

together and

clear it off the workbench. The only remaining obstacle to completing

the assembly is that the planet gear is 1.064" I.D. and the shaft in

the motor is 1.0". I made a shaft with a 1.064" end previously, but

it's too short as now configured and I haven't found a shaft "blank" to

make another, longer one. So it'll need some sort of shim.

And if the unipolar motor and controller works anything

like as well

as I hope, I'll be wanting to make them for the car as well, before I

bother trying to put everything together, rather than set up the Kelly

controller and get everything configured and working only to very soon

want to change it. Thus the new priority of the unipolar motor

project over the transmission. (I guess I spent hundreds of dollars on

the 300A, 36V Kelly

bipolar BLDC controller just to see an important feature of the power

transistors layout to use in my own design.)

Coursera.org and "Wind, Waves and

Tides" renewable energy course

Correction: In the

last

issue I said that savonius rotors only made 60% of the power from the

same wind frontage as a propeller type. That didn't look right for 32%

over 47% per the diagram, so I calculated again later and the correct

figure - going just by the graph - is 68% - about 2/3.

Correction: In the

last

issue I said that savonius rotors only made 60% of the power from the

same wind frontage as a propeller type. That didn't look right for 32%

over 47% per the diagram, so I calculated again later and the correct

figure - going just by the graph - is 68% - about 2/3.

Perhaps with a wind funnel/shield it can be still better,

and for light winds or gusty shifting winds it's surely "the" choice.

If the vanes are only turning the speed of the wind, it should

be much quieter - a big asset in an urban or suburban area and thus

again "the" choice. I also note that the darieus, harder to build and

use and inherently less sturdy, is only 12% better, so the savonius

again looks like a better choice.

But I think a good blade design for a hybrid

"savonius-darieus" could turn at double the windspeed or better, which

ups the theoretical power available considerably.

The wind data for my area, from Environment Canada and

pointed to by the lecturer, seemed pretty discouraging - which I

already knew from living here. But there's more wind in the winter when

solar is pretty useless, and much of the month had at least some

breeze if not wind.

I did some more looking into and thinking up design

details for a VAWT for the house roof as the breezes blew and the

overcast sky prevented much of any solar power from happening. Near the

end of the month I got an e-mail titled "Last Week of Wind, Waves and

Tides". Alas, I've fallen way behind and I'll have even less time to

finish it in December.

Electric Mazda & EV Mixed Batteries update

As cooler weather arrived, I again found

the e-RX7 again using substantially more energy per mile. From under

1.9 amp-hours/mile (@140V) it rose to 2.0 and then 2.2 to 2.5 and

beyond, even 3 on short trips. I found the tires all down to

about 28 PSI and I inflated them to the max, which was 35 PSI except

for one that, to my surprise, said 44 PSI. It wasn't the whole

difference, but it seemed to bring it down some - maybe 10% better

range. Perhaps I should find 3 more of the higher pressure type.

Obviously tires make a big difference. I wonder what can

actually be done to reduce tire losses without them losing road

traction.

I've seen a number of ideas for better, mostly airless, tires published

over the years but none seem to be on

the market. Did they all have problems, or are better types of tires

being kept from us by the corrupt? For example, what about polyurethane

or a rubber/polyurethane blend surface to provide better traction per

square

inch, which would then require less road contact area? It could even be

a solid sponge rubber

needing no air.

As for the rest of the performance reduction, perhaps some

greases and oils that stay thinner or slipperier at cool temperatures

need to be created, found or spec.ed for winter driving. Better still,

get rid of the lossy

transmission.

With the

cooler, wetter weather also, I recalled that the

switch I had to turn off the plug the car was plugged into, was a

regular single pole switch. But the inverter from the solar collector

puts voltage on both the line and the 'neutral' wires. One day a while

back I had seen the neon light at the end of the extension cord at the

car glowing with the switch OFF. This was an evident electrocution

hazard, so I bought a double pole switch. However, I had placed the

switch under the shelter of a firewood shed and in the meantime had

filled that with firewood. I had left a place to reach in, but I

couldn't replace the switch. Now that cooler weather has arrived, I

started using the firewood and I pulled some more out to access it. I

replaced the entire thing with a new box, the switch and a duplex

receptacle.

Then I thought to mount it on the outside of the wall instead of

inside, and make a box to keep rain off it.

With the

cooler, wetter weather also, I recalled that the

switch I had to turn off the plug the car was plugged into, was a

regular single pole switch. But the inverter from the solar collector

puts voltage on both the line and the 'neutral' wires. One day a while

back I had seen the neon light at the end of the extension cord at the

car glowing with the switch OFF. This was an evident electrocution

hazard, so I bought a double pole switch. However, I had placed the

switch under the shelter of a firewood shed and in the meantime had

filled that with firewood. I had left a place to reach in, but I

couldn't replace the switch. Now that cooler weather has arrived, I

started using the firewood and I pulled some more out to access it. I

replaced the entire thing with a new box, the switch and a duplex

receptacle.

Then I thought to mount it on the outside of the wall instead of

inside, and make a box to keep rain off it.

Finally, the two 'size 24' PbPb batteries started getting less and less

range, seemingly with each passing trip, and I took them out. They

lasted only about 18 months in spite of having sodium sulfate added to

them when new. They can probably be renewed... if done carefully... but

when all was working fine

they were always the range limiting batteries. Maybe I'll use them to

increase the solar storage instead of putting them back in the car.

I decided to replace them with soldered-up NiMH D cell

batteries. I figured out that if I soldered them together one

particular way, I could fit two 100AH, 12V NiMH batteries where the two

smaller size 24.s (about 85 rated AH and lower current capacity) were

previously the only ones that would fit. I had enough D cells here and

there to scrounge up for one battery and half of the other (using the

ones for the boat and most everything else). The other one has cost

500$

for 50 new D cells. But this was part of the mixed battery idea: to be

able to replace poorer batteries - or poorer types of batteries - with

better ones individually rather than incurring a huge bill to do them

all at once.

I also plan to redo the 90 AH pipe batteries by

soldering those cells into new 100 AH batteries for better reliability

and smaller footprint. I'll then have five 100 AH, 12V NiMH dry cell

batteries. Or to be more exact, I'll have ten 50 AH, 12V batteries,

which I'll double up.

These will of course be transferable to the Chevy Sprint

with a longer-range unipolar Electric Hubcap motor & controller,

the ultra efficient

variable torque converter transmission, perhaps with solar panels or

VAWT on

the roof, when - and presuming - the time comes. For 36 volts they'll

be be configured as three 150 AH, 12V batteries with one spare 50 AH.

(Those will probably be augmented for more range by PbPb.s (with diode

isolation), perhaps six 6V golf cart batteries of over 200 AH each.)

And presumably someday the batteries will all be replaced with

nickel-manganese or nickel-nickel "everlasting" batteries. If the

unipolar motor is as good as hoped, giving a potential range of 300

miles or more without driving around in a giant tank of batteries, the

question arises as to whether it's still worth trying to hybridize a

gas car.

I've made one, but obviously I have a lot of soldering and

battery assembly ahead of me. Soldered packs are dangerous if they

don't have paper wrapping the cells: the thin plastic covers can melt

or wear off, then the cell cases short circuit together and really

start heating up, destroying the pack... and at worst might potentially

cause injury or burn down the building they're in. "Cordless" power

tool batteries all have paper/cardboard wrapping around each cell. And

yet, companies will sell you individual cells with welded tabs intended

for soldering into packs: with no paper wrapping. I made several

unprotected packs out of ignorance - and all of them I either took

apart again or they burned up. (3 burned IIRC.) Companies in the

battery business surely know better, so selling them that way seems

irresponsible. And I'd probably have avoided the mistake myself if I'd

seen "with tabs and cardboard wrapped for making battery packs" on the

batteries for sale.

One new

100AH battery would get the RX7 EV on the road again at least for short

trips. I started the ball rolling on the night of the 24th by cutting

150 tarpaper wrappings for the first 150 cells, then wrapping the first

50 of them - one battery's worth - by 1AM. The next day I made a vented

wooden box to hold 50 D cells - one battery, a little jig to cut all

the wires to the same length, cut and stripped them, and soldered up

the 5 strings of 10 cells for the first 50AH 12V battery with #16

stranded wire. At noon I stopped for breakfast. I finished the battery

about supper time. I can improve on the build time somewhat (since I've

got the nuts and bolts now), but not a whole lot.

One new

100AH battery would get the RX7 EV on the road again at least for short

trips. I started the ball rolling on the night of the 24th by cutting

150 tarpaper wrappings for the first 150 cells, then wrapping the first

50 of them - one battery's worth - by 1AM. The next day I made a vented

wooden box to hold 50 D cells - one battery, a little jig to cut all

the wires to the same length, cut and stripped them, and soldered up

the 5 strings of 10 cells for the first 50AH 12V battery with #16

stranded wire. At noon I stopped for breakfast. I finished the battery

about supper time. I can improve on the build time somewhat (since I've

got the nuts and bolts now), but not a whole lot.

Finally, here's a small update on the peltier module

fridge: With winter here, in the now quite cool kitchen the same

peltier

module that couldn't keep the fridge

below 6 to 8°C in the summer and made only a little ice is freezing

the whole ice tray solid and lowering the fridge temperature near the

ice tray to 3, 4, or 5°. It can now be turned off for several hours

without melting all the ice. In attempting to evaluate the

effectiveness of

different peltier modules and combinations of modules, I'm sure I

haven't

been taking the room temperature sufficiently into account.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

The Need for the Right to hold Citizen Initiated Binding Referendums

On the whole Pacific northwest coast, BC now stands out as

being the only jurisdiction in which marijuana is still illegal, with

Alaska, Washington and Oregon having dropped prohibitions against it.

This example shows the difference between where citizens can

create a binding referendum relatively easily and where we can't,

because there's little doubt the laws against marijuana would also have

been rescinded in BC if we should have a vote on it. In fact, if people

had the

right to create referendums before the time such laws had been enacted,

they

probably would never have been, or they would have been quickly

canceled by

the populace.

While I'm here... marijuana laws have some interesting

history. Many people are unaware that the push to ban marijuana was by

the cotton growing lobby. It had nothing to do with impartial reasons

or studies of a medical or law enforcement nature. The cotton lobbyists

reasoned that if they could get the government to ban marijuana, for

which its properties and effects on its users were merely a pretext,

when marijuana and hemp are virtually the same plant and can't be

easily distinguished, the government would have to ban growing of hemp

as well. Hemp was a big industry. It is in many ways a better fabric

fiber than cotton and the seeds are nutritious. (They contain no THC.)

The American Constitution is written on hemp paper. Thus at a stroke,

they eliminated the main competitor to cotton. And they created a

monster. Money and monopoly is the reason for more problems than one

realizes - "Follow the Money!" "Greed is the root of all evil."

Before world war two, marijuana was purportedly illegal

(I'm paraphrasing) 'because its users become aggressive and violent'.

During the war it was legalized again because the government wanted

aggressive, violent soldiers. After the war it was made illegal again

'because its users become passive and have no initiative'. That this is

the opposite of the original reason shows how casually laws may be

enacted that deprive people of rights and freedoms, that emotion and

sentiment rather than facts often rule. And they rule with an iron

fist. How much tax money is spent attempting to enforce marijuana laws?

How has it distorted the justice system? How many innocent people,

having not robbed, cheated, assaulted or otherwise victimized anyone,

are in jail for simply possessing of a bit of this sought after and

medicinal plant that grows naturally in warm climates? Do the cotton

growers care about that? What fine organic hemp products do we not have

available to us today?

But marijuana is just one of countless instances of

government meddling in peoples' private affairs that infringe on

peoples' rights and freedoms to no good cause, on behalf of

profiteering monopolies or would-be monopolies.

Old laws, good or bad, are rarely retracted because

politicians don't want to spend time reviewing past decisions from

before (or even during) their time, which would require looking into

all the possible reasons the legislation might have been enacted and

might still have a purpose, versus the reasons it might now be

irrelevant, harmful or should never have been enacted in the first

place. That would require study of the subject to a depth deeper than

in the original often casual passing of the legislation. Since new

regulations are made at the drop of a hat, often to solve some small

real - or perceived potential - specific problem in one situation

without regard to the fact that they will be applied everywhere to

everyone in every situation, until one can hardly turn around without

breaking a law.

As an example, a municipality near here which shall remain

nameless didn't want trees on a new subdivision to be cut down. They

passed a law requiring a permit to cut down any tree in the

municipality. I thought "That's outrageous! I'm sure glad I don't live

there!" I've probably cut down about 20 trees on my property over the

many years I've lived here. And some new ones have grown, planted by me

or volunteers. They grow, and eventually they need to go. I don't need

somebody from the city to tell me when it needs to go, or worse, have

them deny my "request" to be allowed to remove it.

But soon every local municipality, like robots, passed the

same law! There was no discussion and no public hearings or other

input. Now homeowners live in fear of a municipality - that was created

in the first place to serve them - and which their ever increasing

property taxes funds. The penalty for cutting down a tree on your own

property without a permit is $10000! That's much greater than for

cutting down a tree on public property, which is only considered a

"misdemeanor". Congratulations, the government has usurped control of

YOUR land and garden, and has hired more civil servants at your expense

to do so! And, showing how insidious laws become once enacted, a young

arborist said to me "We need that law, or else everyone would cut down

all the trees." I pointed out to him that there were no fewer trees

before the law than after, and that except for the youngest, the

present trees had been there since long before the law was made. In

addition, people would now be leery of planting trees or letting them

grow because they wouldn't want to lose control of their property to

the municipality. That's after less than 10 years. After 20 or 30,

everyone might

think the arborist was right, or at least had a good point, and it will

be almost impossible to get politicians to delete this absurd law.

However, I doubt the law would stand in a vote by house

and land owners. Just maybe I could be wrong... I can't see it. Either

way everyone would know it's the peoples' decision and not just a few

flakey politicos doing it because somebody else did it. There's why

citizens need to be able to initiate referendums - at every level of

government.

Publicly initiated referendums are a means to start

redressing the imbalance between what's needed and what elected

officials are inclined to do.

"If there were ten thousand laws, it would destroy respect for law." -

Winston Churchill.

Need and Reasons for the Coming Collapse?

Individuals make the world. There seem to be a

lot of people on this one who seem to be superficial and shallow.

They'll believe and think what they're told without any effort at

rational examination or logical consistency. In 12 or more years

of education, they haven't been taught to think critically,

analytically, and independently. They're "politically correct" and

asleep. Perhaps they're more interested

in the latest episode of some TV show, a computer game,

or they fly from one form of entertainment or distraction to another.

They seem to live somewhat removed from

real life and give it little attention. Or they're in economic hardship

and considering how to improve their world isn't on their radar screen.

Recently I heard that public opinion polls

show that the great majority, after a few 'beheadings', much contrary

to pre-ISIS polls, now support the US military going back in -- to help

eliminate ISIS. But there seems to be considerable evidence that the US

bombings are dropping supplies

to

ISIS ("Oops it was an accident") and bombing Syria's infrastructure.

This would appear to still be following the same worn

agenda Washington has consistently pursued for almost the whole of this

century, and Washington is still saying, now

incongruously to the purported reason for invasion: "Assad must go!"

Like Sadam Hussein and Moammar Qaddafy(sp?), Assad isn't knuckling

under to Washington's demands. 1/2 the population of Syria

was already refugees before ISIS. That majority of Americans who've

changed their minds over a few beheadings and murders

don't seem to mind that the US military has killed

a million people in the middle east over a decade, and many thousands

in "impersonal" drone strikes in various places.

"Negotiating with

Washington

is

like playing chess with a pigeon - the pigeon knocks over the pieces,

sh*ts on

the board, and then struts around like it won the game." - Vladimir

Putin

And even in municipal elections here a few days ago, the

poll topping

alderperson was one who went to "campaign school" and was taught that

you should never say anything of substance, take a stand on

anything, or make any promises. (I heard this from her aunt, who I

know.) When you speak, something you say or believe in

is bound to offend someone. Your opponents will then hype that up

(often out of context) and use it against you, and the shallow public

will then vote against you on that

basis regardless of anything and everything else you've said and done

and stand for -

which will be given no publicity whatsoever. So the superficial voters

elect a

bunch of superficial wishy-washy non-entities who stand for nothing,

have no idea how to help their society, and

just like the idea of money, power and prestige. Real leaders don't

have a prayer of being elected, because there aren't enough people

paying real attention!

Add to this the seemingly gradually deteriorating human genetic base of

which I wrote last month, and one might start wondering how things can

possibly be fixed.

POST TURTLES

While stitching a cut on the hand of a 75 year old farmer,

whose

hand was caught in the squeeze gate while working cattle, the

doctor struck up a conversation with the old man.

Eventually the topic got around to politicians and their

role as our leaders.

The old farmer said, "Well, as I see it, most politicians

are 'Post Turtles'.''

Not being familiar with the term, the doctor asked him

what a 'post turtle' was.

The old farmer said, "When you're driving down a country

road and

you come across a fence post with a turtle balanced on top, that's a

post turtle."

The old farmer saw the puzzled look on the

doctor's face so he

continued to explain. "You know he didn't get up there by himself, he

doesn't belong up there, he doesn't know what to do while he's up

there, he's elevated beyond his ability to function, and you just

wonder what kind of dumb arse put him up there to begin with."

- Author unknown

All those sleeping,

superficial people will have to either wake up

sometime

soon, or risk going down with the ship. I know I keep saying the

financial system will implode et al and it hasn't happened yet. It

could start tomorrow or it could perhaps still be two or three years

off. If the Swiss had voted to back their currency 20% with gold on

November 30th, which would have required Swiss banks to buy over 1000

tons of gold [evidently non-existent in the west], it might have been

triggered. But the

"bankers get rich" ponzi scheme that is the global financial system is

unsustainable and there's no political will or plan to make the major

and fundamental changes that might prevent collapse. And the

ever-growing population puts a great strain on resources. Some

economists

are saying (eg, on youtube) it's starting to look like almost

everything

everywhere is reaching its limit.

All those sleeping,

superficial people will have to either wake up

sometime

soon, or risk going down with the ship. I know I keep saying the

financial system will implode et al and it hasn't happened yet. It

could start tomorrow or it could perhaps still be two or three years

off. If the Swiss had voted to back their currency 20% with gold on

November 30th, which would have required Swiss banks to buy over 1000

tons of gold [evidently non-existent in the west], it might have been

triggered. But the

"bankers get rich" ponzi scheme that is the global financial system is

unsustainable and there's no political will or plan to make the major

and fundamental changes that might prevent collapse. And the

ever-growing population puts a great strain on resources. Some

economists

are saying (eg, on youtube) it's starting to look like almost

everything

everywhere is reaching its limit.

Things that are being put onto people seem to me to be

ever more desperate and lawless, with the big banks and governments in

collusion and protected by the police who should be arresting the

ringleaders. Look around at negative interest rates

on

savings accounts in Europe, 'random' thefts of individuals' larger

value

bank accounts by the IRS in the USA, "capital controls" (can't withdraw

your own money except in small amounts) in some European countries,

"bail-ins" (bank account theft) in Cypress and and

then legislation for doing the same thing in many countries "if

necessary" (including in

Canada), investment and retirement funds pillaged, and the

incomprehensible sums of currency being printed or

just

conjured up on computer screens in countries everywhere. Look at

governments actually admitting they want inflation - to reduce

the impact of their staggering debts... which BTW also robs your

savings of their value. Who would have dreamed of such things, and not

risen up in indignant revolt over them, 15 or 20 years ago?

Look at government statistics, calculated in more and more

"creative" ways to produce satisfactory numbers for public consumption

through the propaganda networks, and the manipulations in every

market, setting values arbitrarily to try to convince the sleeping

public that everything is fine, when each year higher and higher

percentages of whole populations have more marginal or no employment as

economies contract.

It's said that nearly 100 million Americans, practically 1/3 of the

population, are collecting some form of government assistance. The

entire world economy is shrinking. Shipping tonnage is way down. Only

the top few percent are prospering,

and of those, mostly it's the 1% of the 1% of

the 1%. It was recently said that 85 individuals have as much wealth as

the entire lower half of the world - 3.6 billion people. In feudal

times the inequality of wealth distribution was probably never so

great. Then look at all the

debts, immensely larger than all the money in the world. How can they

ever be paid back, when all new money is borrowed into existence,

adding more debt due back with interest? Debt, increasing debt,

economic slavery, for everyone, forever?

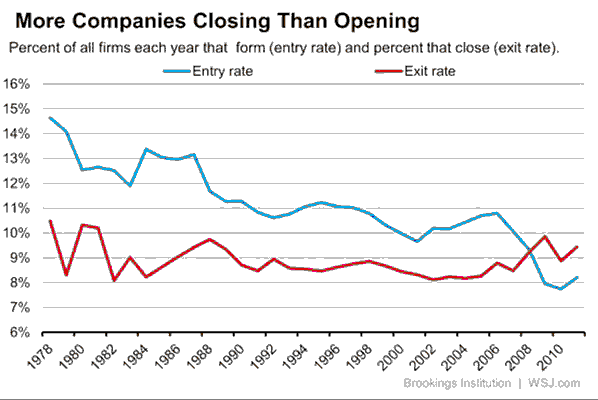

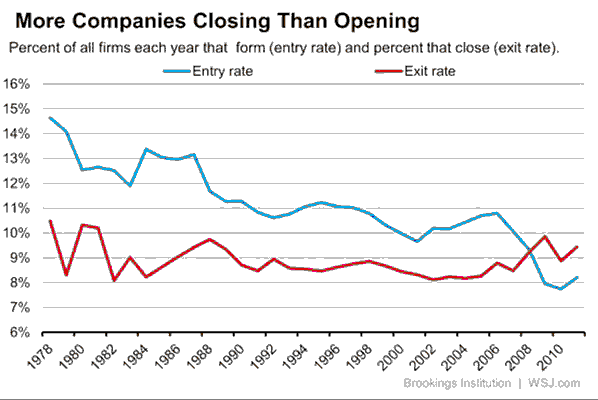

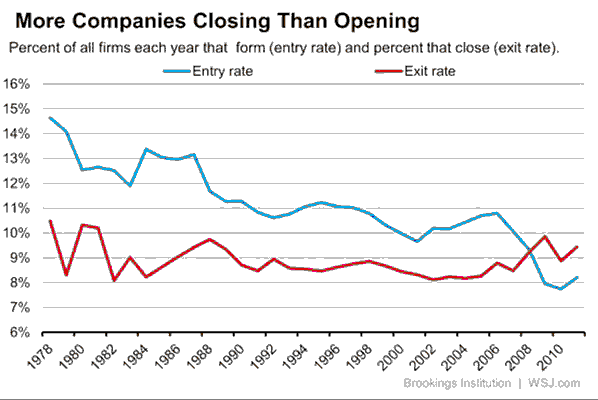

What's all this doing to the economy? An independent

company can't prosper in a corrupt and increasingly impoverished

society, because any who still manage to prosper without being part of

the corrupt establishment oligopoly become targets for wealth

confiscation. This itself ensures eventual collapse of the economy and

the society. Here's a graph of businesses starting and ending. It's

American and a bit dated but by all accounts things are generally

getting worse,

not better, pretty much everywhere. One sees that the new businesses,

the ones that bring innovation, new industries and new employment, have

mostly stopped happening. Some of the businesses closing in the last

few years have been big store chains and established manufacturers,

representing massive layoffs and decrease in economic activity. (I

don't know if individual stores of a chain are counted - many chains

apparently have closed some but not all of their stores.) And there's

probably lots of "for lease" and "for sale" vacant commercial spaces in

your town, too - the signs are there, literally. And the "money

velocity", the rate at which money is changing hands in sales and

purchases, is at record lows.

Of course, the usual

alternative for storing wealth if one

doesn't trust fiat currency or the markets that operate through fiat

currency is precious metals. Mike Maloney ("Hidden Secrets of Money"

video series) says that as trust in a fiat currency dies, gold always

"does an

accounting" of it. That is, the price of gold rises until it takes all

the available fiat currency to buy all the available gold, and the

price rises sharply. In 1971(?) when the US$ was taken off the gold

standard, gold went from a heavily undervalued artificial price of 35

$/ozt, to 800 $/ozt. (ozt = troy ounce - or as prefer to call it, a

trojan ounce, at 31.1 grams somewhat more than a regular ounce,

28.34g.) After that, with the dollar surviving the transition, it had

become overpriced and dropped to 400$ - till over 11 times what it was

before. (Bitcoin is

a new wild card. It probably won't collapse with every other fiat

currency because it can't be printed to death. With little physical

gold to be had, it may do some of the "accounting" and fly up in price.)

Of all people, Allan Greenspan is going around advising

everyone to buy physical gold. But people were taking his advice before

he said it, as sales of gold and silver (just as good) bullion are at

record levels

and more countries are trying to get their hands on all the gold they

can find. According to big dealers like Rob Kirby (KirbyAnalytics.com),

the COMEX and LBMA spot price of gold - what you pay for an ounce of

gold at a coin shop - is now subsidized, as part of the manipulation to

make the US$ look good. But if you want a large quantity such as a ton

of actual gold, and if you can find it (somewhere in Asia?), be

prepared to pay not 1200 US$/ozt but 1800-2000 and up. And you may not

find it unless you offer a lot more. Kirby said he and his brother,

about 10 years ago when gold

was 300 $/ozt, happened to get matched up with a retired chairman of a

Swiss banking institution in Canada while playing golf in Toronto. As

they played the

conversation turned to the markets and the banker asked them what they

thought was a good place to put money for the future, and they said

they'd like to be in the gold market. The banker said "If you knew how

much effort and how much resources have been put out by the

central bankers around the world into discrediting gold, you wouldn't

be

nearly as bullish as you are now!" ...The banksters don't want people

"opting

out" by choosing a form of wealth outside their control!

Even before money comes food and living supplies. Once

organizational structures and supply chains are disrupted and

governments are unable to respond well and quickly, this overpopulated

planet will almost inevitably face hunger, which will herald a pandemic

or even multiple pandemics until the number of living people is much

reduced. Most likely such disease(s) will start in the crowded parts of

Asia and Africa. Fast travel will carry them around the world. The

"black death", which probably included a hemorrhagic fever like ebola

as well as bubonic plague, killed over 1/2 the population of Europe in

a few decades, and while we have come a long way in treatments and

cures since then, we know that fast 'mutating' viruses like influenza

are very hard to control, much less stop, while vaccines for it are

often of dubious value. (I remember reading long ago that two distinct

forms of the "black death" were recognized, 'contact' and 'airborne'

forms, which behaved differently with different rates of progress and

different survival rates, the 'airborne' (if you were coughed on by a

sick person) being far more deadly. I infer it was probably ebola or

something like it.)

After all this trouble, when the problems that were

unleashed by low moral standards, by allowing unscrupulous hidden and

uncontrolled power to arise, and the folly of allowing unlimited

population growth on a finite planet, become exposed and generally

understood, a glorious new world awaits -- if the remaining individuals

heed these lessons, and cause education and the new global society to

conform to principles of

higher morality, philosophic ideals and spiritual values than

presently. Humble as it may seem, it still comes down to each

individual. And some of what each individual is and does depends on

their upbringing, and on their real education.

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers

- Preliminary Ni-Mn, Ni-Ni Battery Making book

Products Catalog:

- Electric Hubcap 7.2 KW BLDC Pancake Motor Kit

- Electric

Caik 4.8 KW BLDC Pancake Motor Kit

- NiMH Handy Battery Sticks, 12v battery trays & Dry

Cells (cheapest NiMH

prices in Victoria BC)

- LED Light Fixtures

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

Daily

Log

(time accounting, mainly for CRA - SR & ED assessment purposes)

4th: Worked on Unipolar Motor Controller PCB

5th: Tried alkalizing fish tank water a bit. Cleaned up aquaponics

disaster, saved remaining 4 fish. Worked on Unipolar Motor PCB.

6th: Worked on Unipolar Motor Controller PCB

13th: Replaced box, switch & socket for EV charging for safety

reasons. (live neutral from solar inverter)

14-15th: Investigating VAWT parameters, transport applications for

VAWT.s: (EV.s could partly or fully power themselves from an enclosed

VAWT on the roof on windy days, regardless of wind direction!)

15: Worked on Unipolar Motor Controller circuit (power supply) design,

PCB artwork

16: Worked on Unipolar motor Controller PCB. Test printout of artwork -

poor results; may need new laser printer.

17, 18: Touch-ups of Unipolar Motor Controller PCB artwork; started

G-Code for Unipolar Electric Caik Motor; started Caik optical rotor

position board layout.

19: Finished rotor position PCB design. Continued G-code.

20: Continued G-Code and started it for Electric Weel as well.

21: Finished G-Code, made Caik drill template with CNC router (after

two tries), and drilled some body bolt holes and test fitted them.

Glued two pieces of 'lexan' together for Electric Weel drill template.

22: Set up pea, bean and LED light supports (wood, rod, wire...);

Cleaned printer and printed PCB pattern for optics board. It still had

random white spots, voids, in the black areas. Decided to liason with

Microsec R & D on Monday, where Ed makes very good boards with the

same techniques... maybe print it out on their printer.

23: Made Optics PCB - artwork via laminator, etched, drilled and

shaped. Finished main parts of G-Code for Weel motor drill template.

24: Populated & tested motor optics board. Found a few minor

problems and revised board design, but will use the one made. Cut 150

pieces of tarpaper and wrapped the first 50 "D" cells for a NiMH

soldered together EV/car battery.

25: Made wooden battery box and soldered 5 strings of 10 "D" cells for

50AH NiMH battery.

26: Made LED grow light. Ordered various parts for LED lights and motor

controller.

27: Misc.jobs for next NiMH battery, LED lights. Found 4000 chip isn't

available - revised motor controller design to use 4025 and ordered

some, along with a few other parts.

28: Assembled modified construction flat-panel LED light housing.

Couldn't access a better laser printer to do the PCB artwork for toner

transfer to the PCB.

29: Studied Peltier Module info (Where are the improved nano-layered

modules with higher COP?) and

30: Reporting & Sharing info: writing & editing this

newsletter; made modified LED light body; worked on design of a

woodstove TEG.

Electric Hubcap Motor Systems - Electric Transport

Unipolar

('monopolar', 'homopolar') Motor

& Controller

Unipolar Motor Controller

I did more work designing the circuit for the unipolar

motor controller and then the circuit board artwork. With the MOSFETs

standing on the board it was a large board compared to my simpler ones

where the MOSFETs and their bypass capacitors were hard-wired

separately, off the board. And

even more so compared to (eg) my simple, single sided LED light driver

and other boards. Being quite painstaking about designing circuit

boards, I

carefully arranged the components and laid out the tracks by hand in

the Eagle circuit board CAD program. In particular, the power MOSFET

gate

runs

have to be as short as possible, and since I was going to make the

prototype board myself with no through-hole plating facility and also

wanted others to be able to do so if they copied it, consideration had

to be given to the minimization of the number of vias and their

2-sides accessible placement (not under components), and some traces

had to

specifically be

run on the bottom or the top side of the board so the connected side

was accessible for soldering. And careful spacings can accommodate

imperfections in the printing and etching... and it's good to do the

board

well just in case it might

be the final version! I thought I had it finished on the 16th, but

looked it over and made a few final changes in the next two mornings as

well.

Meanwhile, on the afternoon of the 16th I tried printing

out the pattern for the bottom of the board as it then was on my other

laser printer. (The first printer prints fine "basketweave" patterns

instead of

black,

visible under a magnifying glass, which finally explained many of my

mediocre PCB making results, and why it worked better on glossy

magazine paper heated with an iron that usually smeared it just a bit,

than with the laminator and real toner transfer paper.)

Gaps in the printer's printing. They might be

unnoticeable

on paper, but they can make a mess of a circuit board.

It

looked okay on paper, so I printed it

on the "toner transfer paper" and transferred it to a piece of circuit

board. It was abysmal. It looked bad, and moreover, some

areas didn't stick to the copper. They just floated off when the

backing was soaked and removed, even tho it had been run through the

laminator a

dozen times. I ran a drum cleaning cycle on the printer, positioned the

print in the middle of the page instead of on one side, and tried

again. It was much better, and I ran it through the laminator in a

different orientation on each pass. That seemed to work - there were no

loose toner

patches. But there were little missing bits all over, as if dust

particles were preventing adhesion. It was the printer. I took it apart

and tried to clean the drum and the fuser roller, but there was no

evidence of anything not clean and nothing helped. I left actually

making the board for another time, using somebody else's printer.

It

looked okay on paper, so I printed it

on the "toner transfer paper" and transferred it to a piece of circuit

board. It was abysmal. It looked bad, and moreover, some

areas didn't stick to the copper. They just floated off when the

backing was soaked and removed, even tho it had been run through the

laminator a

dozen times. I ran a drum cleaning cycle on the printer, positioned the

print in the middle of the page instead of on one side, and tried

again. It was much better, and I ran it through the laminator in a

different orientation on each pass. That seemed to work - there were no

loose toner

patches. But there were little missing bits all over, as if dust

particles were preventing adhesion. It was the printer. I took it apart

and tried to clean the drum and the fuser roller, but there was no

evidence of anything not clean and nothing helped. I left actually

making the board for another time, using somebody else's printer.

After I

finished the motor controller PCB design I started in on

the other one that would be needed: the magnet rotor position sensors

(optical since magnetic field transition points would be hard to

predict). I started with an old optical design of the desired 'drum'

slots form, from 2008 or 2009 before I discovered Hall sensors. That

made a good template to follow. I just adjusted dimensions, positions

and angles. I got the design onto a single sided PCB that just fit, and

the optical components just missed the moving parts, in

the cramped space inside the Electric Caik. I also noticed that if I

just trimmed a bit off one corner it could be fit through the center

hole and inserted or removed without disassembling the whole stator

compartment to get at it. With a couple of soldered-on nuts, or perhaps

captive standoffs, on the board, that should greatly simplify any

required repair. I finally made, populated and tested the optics board

the afternoon of the 24th.

After I

finished the motor controller PCB design I started in on

the other one that would be needed: the magnet rotor position sensors

(optical since magnetic field transition points would be hard to

predict). I started with an old optical design of the desired 'drum'

slots form, from 2008 or 2009 before I discovered Hall sensors. That

made a good template to follow. I just adjusted dimensions, positions

and angles. I got the design onto a single sided PCB that just fit, and

the optical components just missed the moving parts, in

the cramped space inside the Electric Caik. I also noticed that if I

just trimmed a bit off one corner it could be fit through the center

hole and inserted or removed without disassembling the whole stator

compartment to get at it. With a couple of soldered-on nuts, or perhaps

captive standoffs, on the board, that should greatly simplify any

required repair. I finally made, populated and tested the optics board

the afternoon of the 24th.

Now I have to wind coils for the new motor, and to make

and

populate the controller circuit board. Then paint, wire and assemble

the motor, and

build a case for the controller and wire it all up. Originally I hoped

to do it

all by the end of November - a tall order, as usual. But when printing

the board artwork, which had to be 'perfect', went badly, it made

delays. It turned out the printer at Microsec R & D, where Ed gets

very good circuit boards using the same process, was out of toner.

(The simple, single-sided optics board I made on the 22nd, and in spite

of making the traces rather wide, yes, I had to bridge a couple of

broken ones.)

I started thinking again about "remodeling" the original

Electric Caik Motor and doing the second one later. then I spent 2 days

on other projects, and it was clear that the motor wouldn't be running

this month.

On the 27th I went to order the 4000B logic NOR gates chip

in a SOIC package... and found it wasn't available, at least, not at

Digikey. It seemed to have been supplanted, probably long ago, by the

similar 4025B. I changed the circuit and board layout to that chip and

ordered some, along with a few other parts like some 2SC5101

transistors that seemed to be better ones for the LED lights. Amazing

how the simple act of ordering a few parts takes hours by the time

you've uncovered the various things you need from a list that must

contain hundreds of thousands of parts. If you don't have exact numbers

and exactly what you want down pat, I think buying in person is

actually faster... if you live fairly near a store and if it has what

you need.

Caik Motor with nylon machine screws through

the coil centers.

Caik Motor with nylon machine screws through

the coil centers.

(These must be trimmed flush and can't have protruding nuts, since the

magnets spin right next to the dividing wall, centered on that radius.)

"Green" Electric Equipment Projects

Aquaponics

& LED Grow Lighting Project

Plant bed earlier in the month

Plant bed earlier in the month

I meant to buy a pH meter

at an aquarium store. When I was there, I forgot to gt one. The pH test

strips kept saying the water was about pH 6. I had seen someone add

calcium

hydroxide (lime) and potassium hydroxide to his aquaponics system to

raise the pH in a youtube video. I was puzzled why the water might be

acidic, but didn't think too much of it. I added 1/2 teaspoon of

each. It seemed to make a slight difference.

The next morning (5th) I added a whole teaspoon of each.

Then the pH strip at last said it was 7. I came back in an hour and two

fish had jumped out of the tank, and were lying on the floor, dead! I

looked in the tank. One fish was in a corner at the surface, gasping,

and the other three were drifting around at the bottom and not upright.

I went outside and grabbed a pail of rainwater from a

bucket, and added some hot tap water so it wasn't icy cold, and put the

fish in it. I started pushing the listless fish around with a net to

get some water going through their gills. Two of them finally revived.

The third one's gills occasionally flapped feebly. I kept coming back

and pushing it around. It seemed to revive and soon lapse again when I

stopped helping it. Finally it too started swimming around, after an

hour or more.

Meanwhile, I had moved them to a plastic garbage 'can'. I

put rainwater on the stove in pots to boil, and I gradually added more

and more not-too-cold water. Then I took apart and drained

the whole system and refilled it with rainwater, using all there was

from three garbage 'cans'. It was just enough. (It rained overnight and

in the morning (6th) there was

more than ever.)

The fish seemed lively again. The one piece not

reconnected was the drain-down bed. I had added water until it drained

down, so there was only a little water in the bottom. I refitted it and

turned on the tap. Everything seemed to be running fine, but the fish

seemed to have become inactive again. Could it be that just that little

bit of the old water was harmful? I took out two small pails (7 L?) and

replaced them

with fresh rainwater.

I gradually realized that only the one fish seemed

entirely "normal". Two just

seemed to do almost nothing and maybe lethargically ate some food. (One

seemed to become a coward that fled for cover whenever I came near, if

it came out at all.) They gradually improved. The fourth one had

serious problems and never properly

recovered. I finally put it out of its misery. Never having eaten

tilapia

(that I know of) I cleaned and cooked it. It only made a small,

bony snack, but the taste seemed good.

These were the same broad range pH test papers I've been

using for batteries. It never occurred to me they might be wrong. The

colors were clearly those of "6" and then "7" pH, but really it was

probably at least 8 to kill the fish. (which also explains a few odd

results from my battery tests.) I finally tried a piece in plain tap

water: sure enough, it said "6"! And I've decided the guy in the

youtube video probably didn't know what he was doing... Maybe he was

using the same test strips. Later I got a pH indicator and it too

seemed to read acidic, including in tap water: 6.2. Could the

indicators all be right, and tap water around here is actually pH 6.2?

But if so, why would the fish die at just neutral pH, 7 or so?

In their stressed exertions, the fish had knocked the LED

light into the water. It was still on. But when I took it out, it

almost instantly quit working. When I looked at the circuit board, the

negative voltage traces were okay, but the positive ones were quite

corroded -- just like in a battery. I removed the floating plant unit

and I put an acrylic cover over the tank so they won't 'escape' again.

I decided to go with just the drain-down bed for plants.

On the 6th I started in on the LED grow-lights. Once again

I broke the old and not so transparent acrylic plastic diffuser face

off one of the unfinished flat panel lights and replaced it with the

'clear cracked ice' acrylic type. Then i

started checking out the blue and red LED emitters I bought a while

back. Specs for the red were .35 A, 2.5 to 2.7 volts - under a watt. I

don't like to run them at anything like maximum because they'll get hot

and won't last as long. I decided I wanted about 15 total watts. Since

these would be running during the day, the collectors should put out 13

to 14 volts. Call it 13 and 1.15 amps would be 15 watts - call it 1.2

amps

for 15.6 watts. If I placed 8 in parallel, it would be 150mA amps each

- under 1/2 of maximum rating, giving 'extra' light per watt. At .15

amps, I read 1.95 volts. That's a lot lower than most others. The blue

emitters were rated for twice the current, .7 A. If there were 5 in

parallel they'd be about 250mA each, or 6 would be 200. At 250mA a blue

emitter read 3.13 volts. (If it were critical I'd try more than one.)

Two blue sections plus two red sections would be:

1.95+3.13+1.95+3.13 = 10.16 volts. That should give full power at

maybe 11.5 volts up.

Another possibility would be three blue and a red:

3.13+3.13+1.95+3.13= 11.34 V. This should be full on at about 12.75

volts up and would give 'extra' photosynthesis - leaf growth - and less

flower production, as I understand it. I'm not at this point attempting

to make units with any sort of adjustable color balance. That would

take a big, not to say total, design change. Note also that at full

rated current the rated voltage would be about: 3.5+3.5+2.6+3.5 = 13.1

volts -- too high to consider putting four in the string for 12 volt

operation. It would have had to be: 3.5+2.6+3.5 = 9.6 volts. That would

be, eg, 1.4 amps with just 8 emitters instead of 1.2 amps with 23, and

substantially lower efficiency.

Last it occurred to me that 9 reds instead of 8 would have

5 that line up with the blues and four in between, as well as dropping

the design current to 133mA per red emitter. I didn't get any

farther for a while - I got more heavily into developing the unipolar

motor and the

Electric Weel generator.

BTW I read that two inventors recently won a Nobel prize

for inventing

high intensity blue LED emitters. In addition to getting 400 to 450nm

(nanometers) wavelengths for grow

lights (and other nearby blue wavelengths like 470nm), putting

phosphors over them makes white LED.s, which are so rapidly changing

the face of electric lighting. (The phosphors are similar to those used

in mercury vapor fluorescent lights, but the LED.s are minus the

ultra-bright mercury spectral wavelength spike that makes fluorescents

so unpleasant and bad for the eyes.)

Red (660nm, @ .15A): 1.95 V

Blue (450nm, @ .25A): 3.13 V

Making a 7" x 7" Flat Panel LED Grow Light

The clear "cracked ice" diffusers don't reduce

the light like translucent types,

but they break up the intense LED emitter light to more bearable

levels. For plant

growth lights and for space lighting mounted higher up on a ceiling,

they're great!

The plants

kept growing... long and spindly from lack of

light. With this impetus, on the 26th I thought I'd finally throw

together the first red & blue grow light as a "morning project". It

went pretty smoothly until I came to the driver circuit board. There

was one I had made last summer and soldered most of the components

onto. I looked at it. It was terrible, made with the laser printer that

prints patterns instead of black... it had traces that were surely

broken. I decided I could bridge them, so I finished the board and

mounted it to the light. It was so bad I spent about an extra two hours

troubleshooting it before it finally worked. Even then it's the worst

board I've ever done, with about half a dozen wires bridging open

circuit runs, a diode on the back sticking up, and the whole board in

upside down and just hanging there because it just wouldn't solder and

hold to the copper bar. Not the least bit presentable! I'd have been

better off to unsolder the components, print and etch a whole new

circuit board, and redo it all. Ah, hindsight..!

The plants

kept growing... long and spindly from lack of

light. With this impetus, on the 26th I thought I'd finally throw

together the first red & blue grow light as a "morning project". It

went pretty smoothly until I came to the driver circuit board. There

was one I had made last summer and soldered most of the components

onto. I looked at it. It was terrible, made with the laser printer that

prints patterns instead of black... it had traces that were surely

broken. I decided I could bridge them, so I finished the board and

mounted it to the light. It was so bad I spent about an extra two hours

troubleshooting it before it finally worked. Even then it's the worst

board I've ever done, with about half a dozen wires bridging open

circuit runs, a diode on the back sticking up, and the whole board in

upside down and just hanging there because it just wouldn't solder and

hold to the copper bar. Not the least bit presentable! I'd have been

better off to unsolder the components, print and etch a whole new

circuit board, and redo it all. Ah, hindsight..!

Then I did some testing, and I made a CAT std 12V

extension cord to plug the light in with. I made a couple of small

changes to the board design, and threw out 3 other previously etched

boards that didn't look a lot better than the one I used. I definitely

need a better laser printer. Finally I made "mounting feet", that

hadn't been put on the case earlier. This was the second "morning

project" in a row that lasted all day. Later I was up until almost 2AM

at AliExpress.com ordering parts, some for LED lights. I got some PCB

mount push switches to turn the lights on and off. I re-read a

technical magazine article on LED plant lighting, and noticed the

410-450nm blue there was called "ultra-blue". Searching on "ultra blue"

found mostly "ultra violet" emitters. But now I found 415-420nm 3W LED

emitters (@ 56¢US), which I had missed before, by searching on

"violet" instead of "blue". That's closer to the center wavelength of

blue for plant lights than the 450nm ones. The next morning the browser

was still sitting at AliExpress. I thought to search on "LED emitter

violet -ultra". Having eliminated hundreds of "ultra violet" emitters

with the "-ultra" term, I found exactly one choice for suitable lower

cost (@ 72¢US) 1W violet 420-430nm emitters, right in the center

of the desired range of 410 to 450, and I ordered some of those, too.

Probably both wavelengths are better than 450nm. These are all a lot

more than the 10¢ white LED.s and, using 10 or more per light,

will have to be figured into my price for the grow lights.

I've found many times in the last few years that finding

something is half in finding the right place to buy it (eg, pottery

supply for many chemicals), and half in finding out the right name to

call it - or on the web, picking out the right search term(s)! (Q: "Do

you have hydrochloric acid?" Hardware store: "No!" ...wrong answer...

"How about 'muriatic acid'"? "Of course we do!" ...same thing.)

Tests: All 28 emitters shone brightly and

evenly. Currents, voltages: At 11 volts it drew 1.13 amps, at

12 volts 1.26 amps, and at 14 volts 1.33 amps. Voltage across the LED.s

was 10.0V, 1.9 for each red set and 3.1 for the blues, and only a few

tens of millivolts change with power from 11 to 14 volts. That seems

like quite good regulation. Below 11 volts, current and brightness

dropped rapidly. Power: 10.0V * 1.26A = 12.6 watts to the

actual emitters. The rest is consumed by the driver board to regulate

the current, eg, at 12 volts, 12 * 1.26 = 15.1W for an efficiency of

83%.

1.25 amps is .25 amps per blue emitter (rated for .7 max)

and .138 per red (rated .35 max). That's about where it should be. I

could add 2 more blues (6 per set instead of 5) to reduce them to .208A

while presumably upping the brightness just slightly. (lower current =

higher light output per watt.) One could almost add a third row

of

reds, but then it would start to dim with power supply voltage below 13.

The emitters have a small heatsink spot on the back. In

previous lights I positioned this on the copper heatsink bars. In this

light I placed them over the gap between bars to see how well the leads

carried off the heat. That makes easier assembly and saves a bit of

costly copper. I can feel that they get hotter than the bars, so I

won't repeat the experiment.

Conclusions: I very much like the new light. It's

very bright and pretty even. Vegetables will love it! It looks like a

smash hit to me!

My one small technical

concern is that they run rather warm. It's amazing how high temperature

will rise over a 7" x 7" area with just 15 watts of energy, and in

spite of the copper spreading the heat for air dispersion. Solutions

could be lower wattage, larger area lights, or heatsink fins above the

emitters and (especially) the pass transistor - which would make the

lights fatter. (At some point they're no longer "flat panel" lights.)

Or a fan.

I'll start in the next unit by extending the copper plate the pass

transistor is

soldered to. That's the hottest plate, especially when

the supply voltage is high (eg 14V).

If running a few lights for a while discloses no serious

problems, I'm probably about ready to produce flat panel grow lights as

well as space lighting. The thought of making some money from them is

appealing, assuming I can get to a reasonably short build time... or

get someone else to do much of the work. A nephew said he's too busy...

but he'd like to buy a room light and a grow light! The fact that they

run on 12 volts has also aroused interest from motor home owners. It

would seem there's probably a market - if the prices are low enough.

Well... I can contract out circuit boards, and perhaps the

component stuffing of them (evidently there's a good place in town with

automated equipment for it), and perhaps I could make a big steel punch

and die on the milling machine, and use it in an arbor press to stamp

out the shaped copper plates instead of doing each one by hand in a

number of steps. Then too, they'll be better and more easily done with

a little jig to hold the emitters in exact place while soldering them

onto the copper plates. The 12V CAT plugs, sockets, wall plates and

cords can be sold as adjuncts to the lights.

The next evening I was ordering other parts and looking

for transistors for the LED lights. Way back in BCIT in 1975 I remember

learning that a transistor typically has a 100mV Vce-sat. Thus I've

always assumed that a low dropping voltage power supply is simple -

that four (white) 2.9V LED emitters in series, totaling 11.6 volts,

could be run from a transistor controlled supply as low as 11.7 volts

without dimming. I paid the specs little attention, but apparently that

was just a generalization for small signal transistors. Now I've been

looking and seeing Vce-sat.s for higher power transistors like 1/2 a

volt to well over a volt - or even 3 or 4 volts. I also had neglected

the .6 or .7 volts loss through the current sense resistor.

This explains why my LED light power supply voltage has to

get up to about 13 volts instead of 12 to run the 11.6 volt white

emitter strings without dimming. I found and ordered some power

transistors (2SC5101) with a 'very low' .25 volt Vce-sat. These promise

four-string LED lights with full brightness at about half a volt lower,

12.5 volts. (with 11.6/12.5=93% linear power supply efficiency!) It

would be more convenient for running from a 12 volt supply if the

emitters were about 2.7 volts, but they aren't, and dropping series

strings from four emitters to three loses 25% of the light without

saving any power - four slightly dimmed are still brighter and

save a bit of power. And of course, if running on 12V batteries, it can

help save the batteries if the lights dim rapidly as the voltage gets

lower.

My mind started working on new power supply ideas (with an

opamp and the 2SC5101) that should give great regulation right down to

12.0 volts. But after giving it some thought, I realized the whole

thing is somewhat academic. Who really cares or notices if a light is

just slightly brighter or dimmer? The main thing is that the current

regulation circuit, instead of just a current resistor like I used with

my earlier LED lights, lets them work from 11 to 15 volts without

either being really dim at 12 or less, or else burning out at 13 or

more. And the plant growing lights have lower string voltages than

11.6V anyway - about 10 volts. They regulate fine down to 11 volts or

so. But I might

try a small modification: using a schottky (or a .9v zenor?) diode in

the base circuit to lower the sense resistor voltage from .7 volts to

.3 or .4. That should let it maintain full regulation (for the 11.6

volt white light strings) down to 12.1 or 12.2 volts supply - and over

95% supply efficiency at those voltages.

On the 29th or

30th I put together a new LED light body the same shape as the others

but constructed a

little differently. Instead of using 1/4" acrylic or lexan for side

pieces and sawing a

groove for the edges of the copper sheets, I used 1/8" and glued in

1/8" thick strips with a groove space between them. I thought it might

be easier and look better. I don't

think it was easier, and because of non-uniform wetting of the strips

with methylene chloride, the sides looked splotchy. Scratch that idea!

On the 29th or

30th I put together a new LED light body the same shape as the others

but constructed a

little differently. Instead of using 1/4" acrylic or lexan for side

pieces and sawing a

groove for the edges of the copper sheets, I used 1/8" and glued in

1/8" thick strips with a groove space between them. I thought it might

be easier and look better. I don't

think it was easier, and because of non-uniform wetting of the strips

with methylene chloride, the sides looked splotchy. Scratch that idea!

In the same light I put a 1/8" sheet of clear lexan on the

bottom, then the "cracked ice" diffuser sheet on that. If I'm doing

lights for

boats, motorhomes and greenhouses, they're almost bound to get hit

occasionally on low ceilings or with gardening tools, and the thin

diffuser will easily crack. The lexan is pretty indestructible and

should give a reputation for durability.

Plant bed later in the month with grow light.

Plant bed later in the month with grow light.

(The beans will soon hit the top of the 4' poles!)

Electricity Generation

Wind Power

After a calm summer and fall, the afternoon of the 6th

brought gusty November winds, the

waving treetops taunting me for not harvesting them while I pay rising

power bills. With the Coursera.org course on the subject and youtube

videos showing various and sundry VAWT windplant units, I thought of a

mounting that would be simpler than those I've been contemplating,

which

involved having the shaft go through the roof and putting the generator

in the attic.