Turquoise

Energy Ltd. News #83

December 2014 (posted January 4th)

Victoria BC

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Features: Home-done Dental "fillers"

(see "Month in Brief")

Month In Brief

(Project Summaries)

Seven Years(!) in Review

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Keep the Corrupt from Power

Electric Transport - Electric

Hubcap Motor Systems

* Unipolar BLDC Motor & Motor Controller Project

Other "Green"

Electric Equipment Projects

* CAT Standard 12VDC Connector products line extended:

- 4-plex receptacle faceplates

- cigarette lighter socket adapters.

* Aquaponics & LED Grow Lighting Project - Water pH, Aquarium.

Electricity Generation

(No reports)

Electricity Storage - Turquoise Battery

Project (NiMn, NiNi), etc.

* Battery-Supercapacitor Hybrid Car Starter Battery

* New Soldered "D" cells, 100AH 12V NiMH batteries for RX7 EV etc.

No Project Reports on: Turquoise

Battery Project (rats, no time!), Lambda

Ray Collector, Magnet motor,

evacuated tube heat radiators, CNC gardening/farming machine.

December in Brief

I started the month

by getting the Mazda back on the road, by making a second 12V 50AH NiMH

battery on the 5th. I doubled it up with the other and installed the

100AH battery in the car on the 6th. I did the next one on the 8th, and

finally the 4th one on the 13th. After I installed them I checked the

lead-acid batteries in the back and found one of them had low voltage

and was probably ruined. So it was immediately back to 10 batteries

(128 volts) after all that work! Furthermore, the new battery from the

3rd and 4th 50AH units wasn't so hot. It held higher voltage under load

than the poorer of the two 90AH pipe batteries, until they both started

dropping to 10 volts at about the same time. I had made it from 10 new

cells and 90

that were 2 or 3 years old and subjected to varying uses and charging

or lack thereof. The lithiums also seem to be running more down toward

the

bottom of their allowable voltage range as well... aren't they supposed

to last thousands of cycles?

I started the month

by getting the Mazda back on the road, by making a second 12V 50AH NiMH

battery on the 5th. I doubled it up with the other and installed the

100AH battery in the car on the 6th. I did the next one on the 8th, and

finally the 4th one on the 13th. After I installed them I checked the

lead-acid batteries in the back and found one of them had low voltage

and was probably ruined. So it was immediately back to 10 batteries

(128 volts) after all that work! Furthermore, the new battery from the

3rd and 4th 50AH units wasn't so hot. It held higher voltage under load

than the poorer of the two 90AH pipe batteries, until they both started

dropping to 10 volts at about the same time. I had made it from 10 new

cells and 90

that were 2 or 3 years old and subjected to varying uses and charging

or lack thereof. The lithiums also seem to be running more down toward

the

bottom of their allowable voltage range as well... aren't they supposed

to last thousands of cycles?

To allow for 'non-new' performance, it would seem that the

batteries should optimally be 130 to 150 amp-hours or larger... like

the 8 volt golf cart batteries the original owner had selected for the

conversion.

It all reminded me why I'm trying to make batteries

that won't deteriorate over time and cycling, for which both the NiMn

and NiNi hold excellent promise. If only I could make batteries that

perform well and don't leak!

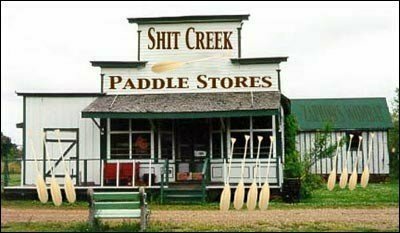

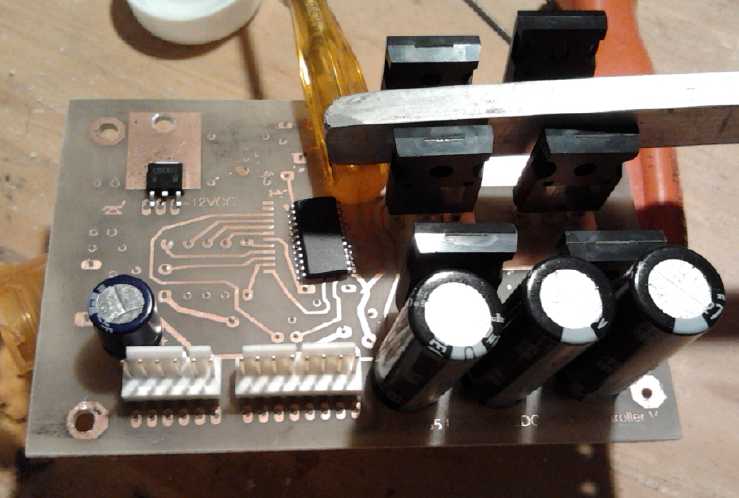

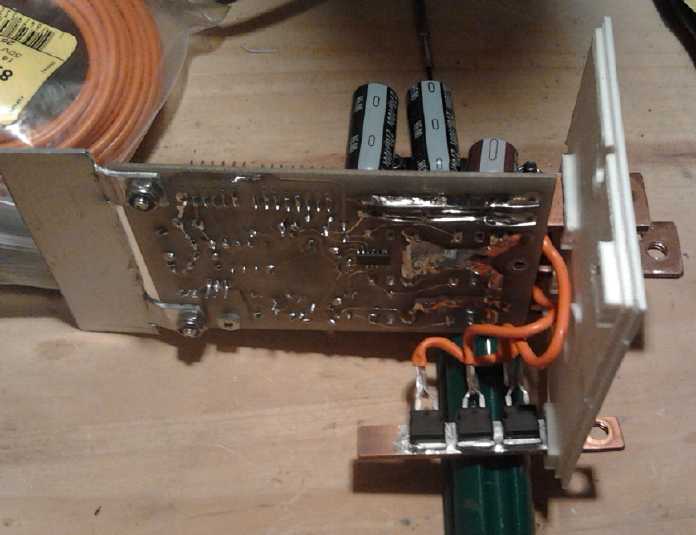

In the second

week, I continued with the unipolar motor

controller. I did the circuit board on the 10th and had it populated

within a few days, and by the 19th I designed and 3D printed a

plastic end cover for the case. Then I cut a piece of aluminum to hold

the back end of the circuit board in place, since the board

was just a little too narrow to be held by the slots in the extruded

box. There

it sat until after Christmas. Then I improved the 3D printed end and

figured out pretty much how the energy recovery diodes and in-box

wiring would go.

In the second

week, I continued with the unipolar motor

controller. I did the circuit board on the 10th and had it populated

within a few days, and by the 19th I designed and 3D printed a

plastic end cover for the case. Then I cut a piece of aluminum to hold

the back end of the circuit board in place, since the board

was just a little too narrow to be held by the slots in the extruded

box. There

it sat until after Christmas. Then I improved the 3D printed end and

figured out pretty much how the energy recovery diodes and in-box

wiring would go.

Just before Christmas I got

sick - a nasty cold with

fever, which held on into January. Perhaps ironically, I sat at the

computer and did four little "health tips" write-ups on things I've

happened across, one of which I had been meaning to do for some time.

These are a little outside the scope of energy projects, but inasmuch

as I've happened across them in my travels, I think I should spread the

ideas around.

They were about improving or curing shortsightedness,

improving near vision while we age, home-done dental 'fillers' (a bit

soft to call 'fillings'), and preventing or maybe even reversing

thinning hair and baldness. After occasional bits of editing, I

uploaded them to my web site: http://www.saers.com/recorder/craig/

on the 30th, and refined the main page a bit.

The "home dental fillers" seem like an especially exciting

technique. It's simple and painless. Essentially, white ABS plastic is

softened into a blob with methylene chloride solvent, and is pressed

into the target (chip, groove, cavity?), to which cyanoacrylate glue

("Krazy Glue") has been applied. Pressing it in molds the ABS to fit

before the solvent evaporates and the plastic hardens again. If good

dental care (and the supplies and anesthetics usually used by dentists)

become hard to get for a while, it could even be a lifesaver.

As I worked on

the 3D printed plastic end plate design for the motor controller, I

also did up two new CAT Standard 12 volt plugs & sockets ideas

which I've had in mind for some time. One was a 4-plex receptacle plate

instead of a duplex plate. I already needed this to plug 3 LED lights

in for the aquaponics system. I figure one could make a cover

plate that would fit up to 9 sockets, eliminating most uses for 'power

bars'... but then they all have to be

wired.

As I worked on

the 3D printed plastic end plate design for the motor controller, I

also did up two new CAT Standard 12 volt plugs & sockets ideas

which I've had in mind for some time. One was a 4-plex receptacle plate

instead of a duplex plate. I already needed this to plug 3 LED lights

in for the aquaponics system. I figure one could make a cover

plate that would fit up to 9 sockets, eliminating most uses for 'power

bars'... but then they all have to be

wired.

4-plex CAT socket plate holding 3 LED light

plugs.

(Now about that drywall filler, tape and paint...)

CAT Socket adapter in electric Mazda RX7 cigarette lighter socket.

The other design was an adapter socket

that would put a CAT socket where a car cigarette lighter socket was.

The other design was an adapter socket

that would put a CAT socket where a car cigarette lighter socket was.

The point here is to provide a

migration path. 12 volt equipment makers can supply CAT plugs on their

equipment instead of ugly cigarette lighter type plugs. If the first

few products come with such adapters, soon enough everyone will have

them and it will no

longer be necessary to supply them - they'll be a dollar store type of

item.

I think one could actually fit two CAT sockets on the face, potentially

eliminating a 'splitter'. A click-lock socket might be another useful

idea... but I'm not sure how the whole adapter would lock into the

cigarette lighter.

At the end of the month I uploaded these designs (the

OpenSCAD files) to Thingiverse.com where there are now hundreds of

thousands of public domain 3D printer designs, along with the

click-lock plugs and sockets (belatedly) and the 12 volt NiMH D cell

battery case.

All great! But if I get nothing else done in January, I'd

like the unipolar motor and controller to be running. And maybe I'll

have some time to look into how lithium & fuel cells using

carbon/graphite are sealed, since it seems silly to have great new

battery chemistries but no practical batteries.

Seven Years in

Review

When I suddenly realized it was time for the annual "Years

in Review" column, I thought it could be kept to

a few paragraphs to briefly describe each project. But in seven years

I've ground away at or at least touched on so many interesting projects

that "brief

descriptions", even without hitting all the projects and sub-projects,

have become a considerable write-up. Of course I'd like to be able to

say that the early projects have been completed and wrapped up, but

instead they're either still in progress even after all this time (but

seemingly getting closer), or

they've evolved and moved into new phases of development beyond the

original plans - such as multiple sizes of Electric Hubcap type

motors, now made ultra-efficient with molded composite bodies, and soon

perhaps to be unipolar to use even less electricity and with simpler,

more robust motor controllers.

The first 'green energy' project, ocean wave power, which

I actually started in 2006, foundered on rocks of official

dysfunctionality combined with the hardware required being too big for

one person without waterfront property. That was just as well because I

later found and expanded on a

much better design, a sketch of which can be found in TE News #80. I

sense that it's the winner design for wave power the way the

three-blade propeller has been the winner for wind power. But it's

still too

big a project for me to champion if I'm to do anything else as well. By

2008 I had decided there were other 'green energy' things worth doing

too.

Since 2008

I've created two battery chemistries that hold the promise of lasting

forever: nickel-nickel (~1.2 volts) and high voltage (~2.3v)

nickel-manganese. I'm the first person ever to get

manganese to hold its enticing high voltage metallic charge of about

-1.5 volts, using

lower alkalinity (pH < 14 with KCl salt) and the two trace additives

described in previous

issues. So far, no one has mentioned duplicating my results. However,

being "moderately alkaline" instead of pH 14 extreme alkaline,

the cells require carbon/graphite current collectors. The usual metal

used

as an alkaline cell current collector, nickel, will oxidize, and no

other metal works. (How

could one have nickel-nickel chemistry if the nickel won't oxidize?)

Since 2008

I've created two battery chemistries that hold the promise of lasting

forever: nickel-nickel (~1.2 volts) and high voltage (~2.3v)

nickel-manganese. I'm the first person ever to get

manganese to hold its enticing high voltage metallic charge of about

-1.5 volts, using

lower alkalinity (pH < 14 with KCl salt) and the two trace additives

described in previous

issues. So far, no one has mentioned duplicating my results. However,

being "moderately alkaline" instead of pH 14 extreme alkaline,

the cells require carbon/graphite current collectors. The usual metal

used

as an alkaline cell current collector, nickel, will oxidize, and no

other metal works. (How

could one have nickel-nickel chemistry if the nickel won't oxidize?)

But for all the chemistry, most of my cells don't perform

well and at no time have I

successfully made a cell that doesn't leak. The salty solution seeps

through the graphite at a surprising speed, and since any metal inside

the cell deteriorates rapidly, I can't use metal to make a leak-proof

connection. These are similar constraints to those of lithium cell and

fuel cell makers, but I'm at loose ends and don't know what to do next.

I don't know what to try besides things I've already tried.

Salt crystal buildup on the positive terminal

notwithstanding

all attempts to seal the cell. Over a month or so all the liquid

in this cell made in October (which does have a lot of foam

filler and hence less liquid in it) was lost. And look at that salt-

corroded aligator clip!

Since 2008 also I have of course created a novel new

design of

excellent, highly efficient and lightweight powerful motors for

electric transport, with two

models implemented: the Electric Hubcap and the smaller Electric

Caik.

And this sort of motor is much more doable as home projects since they

don't

require custom die-cut laminates.

This fabulous success story would be more exciting if I had also

created motor controllers that could deliver those high powers without

going up in smoke, and mechanical devices that could

deliver this high power efficiently to vehicle wheels. So far in spite

of much experimentation, experimental development and intermittent

effort over the years neither

of these have been forthcoming. It may however be said they've come a

long way towards workable ideas and products. And in spite of much time

and effort -

again intermittently applied - the third model of the motor, the 28"

diameter Electric Weel motor that should have huge torque, isn't

finished yet. It's a bigger project than I thought. It makes the

smaller motors seem quick and simple to do. And even then the first one

is earmarked as a low RPM generator, which won't be testable as a

motor. Once I've made one I'll have the molds and jigs, and duplicating

it will be much simpler than making the first one... but not trivial.

At the same time applying the Electric Hubcap motor ideas to a

direct-drive bicycle or motorcycle motor with the magnets mounted on

the spokes of the wheel has had to be set aside again and again.

The main actual transport success has been the converted

Electric Caik Honda Outboard. It's quiet - nearly silent - and seems

reliable. The motor hardly gets warm with 1.5KW going in, suggesting

it's

good for at least 3 times as much power - perhaps 5KW, from a 15 pound

pancake motor, equivalent to 7.5KW for the 30 pound Electric Hubcap!

However, the

propeller is geared down in the foot (of most every outboard) so that

the motor RPM is maxed out without getting the boat up on a plane. So

it doesn't look very exciting and the motor's power limits

can't be

tested.

And if I got that much power going in, my motor controller would likely

blow anyway.

And then in spring 2013, I was offered the 'derelect'

electric Mazda RX7. Since this would actually work once it had

batteries, I thought it could give me some good electric car

experience. But it's been a project that's taken up quite a lot of time

in itself, without giving results beyond what anyone would get from

converting a car to electric except in experiments with mixed battery

types.

Last fall I bought a Kelly 36 volt, 400 amp BLDC motor

controller intending

to use it on the Sprint Car project, which was just about ready to try

out again, now outfitted with a variable torque converter transmission

with a large-drum centrifugal clutch. With enough amps, the motor will

move the car even without good performance from the torque converter.

But at just that same time, the concept of the unipolar

motor presented itself and I thought of applying it to the BLDC type of

motor. According to the design and records, and my implementation of

the controller, the unipolar motor returns magnetic field energy to the

battery via flyback diodes and an "isolation coil" as the motor coils

are switched off, hence apparently making much better use of the

electricity than

was previously thought possible. Not only was this aspect exciting, but

it appears the unipolar BLDC motor controller is much simpler than a

typical bipolar BLDC controller, with half as many power transistors

and no H-bridges - only low-side 'pull-down' transistors. This

also means only half as much heat is generated within the controller.

Since glitches in the H-bridges and heat are the primary cause of

failures of BLDC motor controllers, this means the controllers should

be much more reliable.

With all this going for it, I decided to put the

Sprint car on hold and make a unipolar Electric Caik motor and

controller, and try it out in the outboard. I thought maybe I could do

them in a month, but it's been

two now. There's been progress and the end is in sight, but neither the

controller nor the motor are finished yet. If it proves as good as its

promise, that bicycle motor might finally get done as unipolar.

Meanwhile the Sprint sits out its third winter with no motive power

under the hood.

I've stuck with all these electric transport projects for

all this time, but

of course more ideas come along from time to time that look too good to

ignore, and one sometimes needs to try a change from projects where

frustration has set in. I put up the solar panels and did some 12 volt

DC house wiring,

creating the CAT Standard 12 volt plugs, sockets, wall plates,

click-lock plugs and sockets, and now a "cigarette lighter" to CAT

socket adapter described herein. I uploaded the new designs to the 3D

printing site (Thingiverse.com) on New Years Eve, where they've already

aroused interest. On the 2nd I uploaded the click-lock plugs and

sockets which I hadn't previously got around to, and the 3D printable

10 D cell, 12 volt NiMH battery case (version 4).

I've made LED lighting, LED plant lighting, and a

thermoelectric refrigerator, all 12 volt units. It appears the fridge

is only marginally practical until improved COP peltier modules become

available. I delved into magnetic refrigeration for a while, then I

realized people do in fact seem to be working on improved peltier

modules, and that when (assuming) they become available, no one will be

interested in refrigeration units with moving parts.

Then there are promises of other means for generating

electricity. There's wind of course, and I occasionally do a bit of

work on the idea of a vertical axis wind turbine, as being a better

type for the gusty, variable direction winds encountered around my home.

But I'm more particularly thinking of

magnet motors, and people who seem to get energy out of thin air,

starting with Nicola Tesla a century ago. I haven't successfully made a

magnet motor, but it looks potentially doable. Certainly Muammar Yildiz

has demonstrated his widely. But surely it must be possible to do it

with far fewer magnets than he uses - over 1000! I feel the magnetic

forces are some large

scale extension of atomic thermal or nuclear forces and energy, and

that looked at at the nuclear scale it'll be recognized that they don't

violate any laws of thermodynamics or physics.

On looking into how energy might be "pulled out of thin

air", I checked out the electromagnetic spectrum. It appears the

spectrum was extended to 10,000 times the frequency and energy of gamma

rays by satellite observations in 2007, and of course to 1/10000 of the

wavelength. Little work seemed to have been done or excitement roused

outside the astronomical community, but visible light has an energy of

2 or 3 electron volts per photon, while such high frequency, short

wavelength rays would have somewhere around 1 to 100 trillion electron

volts per photon. In addition, the "X-ray observatory" satellites

showed that short wavelength rays, while concentrated in the plane of

the galaxy, come from all directions: "If you had gamma ray eyes, no

part of the sky would look dark."

These unnamed "very high energy gamma rays", surely, are

the source of the invisible energy that surrounds us in all directions.

They are much farther from gamma rays than ultra-violet is from

infra-red, so I felt they deserved their own name. I called them

"lambda rays". It seemed appropriate on several counts. (These and

other rays are not to be confused with "cosmic rays", which are not

electromagnetic "rays" at all but energetic charged particles

accelerated to near light speeds.) The devices that have claimed to

capture free energy vary widely if not wildly, but they all have

certain features in common. They all switch electromagnetic fields

rapidly on and off, using coils to generate voltages in the range of

hundreds of volts. They all have insignificant looking "collection

coils" wherein the lambda rays release "a whole stream of electrons and

anti-electrons" when they are coerced into reacting with ordinary

matter by the switched voltages and fields.

I've had very limited success with making a "lambda ray

collector" myself and I set it aside pending some new inspiration. But

just before Christmas someone phoned about NiMH battery packs, and said

he had been delving into this area with some success. I'm skeptical,

but some of the features sound right, so he just might have something.

He's in a nearby town with no car. When I feel up to it I'll drive out

there and have a look.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Keep the Corrupt from Power

"It's not that power corrupts, it's that power attracts corrupt

people." - Someone said it on youtube, I can't remember who. But

it seems right. Really moral, trustworthy people don't become corrupt

just because they land a powerful position. The corrupt will use

subterfuge and secret deals and pervert everything to gain and to hold

that same

position, until it becomes impossible for well intentioned, moral

people to gain it - or regain it. Open democracy and representative

government degenerate into a façade of lies, deception and

crimes.

"We're having a hard time winning the offices of power. But once we

have them the only way we'll give them up is when they cart out our

dead bodies." - Hermann Goering, before the Nazis attained power. (As

best I

recall it.)

Society must develop effective safeguards - conventions,

traditions and

means to prevent corrupt people from attaining positions of political

and economic power in

the first place, or we will continue the cycles of initial freedom,

prosperity and the rise of culture, followed by ever more overbearing

governments removing freedom after freedom until finally they steal

everyones' wealth, start a war or wars, and it all ends in a huge

collapse.

Again I commend the choice ranking vote. With a fair

voting system it becomes much harder for those with their own agenda to

control the agenda and prevent even relatively unknown but sincere

candidates from attaining the coveted offices when people recognize

"the usual" choices aren't doing any good and want to vote for real

change. I'm not saying it could

necessarily reverse the extremely corrupt, dysfunctional situations

that now

exist without a crash, but it would definitely have helped prevent them

from arising in

the first place.

When it seems all is lost and there's no way

out...

When it seems all is lost and there's no way

out...

Sometimes there is!

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers

- Preliminary Ni-Mn, Ni-Ni Battery Making book

Products Catalog:

- Electric Hubcap 7.2 KW BLDC Pancake Motor Kit

- Electric

Caik 4.8 KW BLDC Pancake Motor Kit

- NiMH Handy Battery Sticks, 12v battery trays & Dry

Cells (cheapest NiMH

prices in Victoria BC)

- LED Light Fixtures

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

Daily

Log

(time accounting, mainly for CRA - SR & ED assessment purposes)

4th: Finished November newsletter/report (#82)

5th: Made 2nd 12V 50AH NiMH D cell soldered-together battery

6th: Installed the pair, 12V 100AH, in the Mazda, short test drive,

then left it to charge overnight.

7th:

8th: Made 3rd battery.

9th: 5.7 mile electric RX7 test drive... bought laser printer for doing

PCB.s and acrylic plastic for LED lights. Dismounted and tarpaper

wrapped 50 more cells for 4th EV battery.

10: Installed printer, printed unipolar motor controller PCB artwork on

toner transfer paper, laminated it to board, and etched the board

(bottom side, then top side). Drilled holes & started test-fitting

components. (Some layout adjustments will be required.)

13: Finished 4th 50AH 12V NiMH EV battery.

14: Assembled new batteries & installed in car. Removed another

bad lead-acid battery. Test drive; good.

15: Set up CNC and program and drilled bolt-hole template for Electric

Weel motor/generator. Started populating unipolar motor controller

board, soldering surface mount chips and inserting all smaller

components.

16: Soldered components to PC board. Test drive RX7 5.3 miles (to buy

prism to check LED emitter wavelengths.)

17: Soldered large components to board, cut copper bus bars for the 3

phase outputs. Started fitting board into extruded case & designing

end cover for the case. Corrected problem with CAT Standard 12VDC

4-plex outlet cover.

18: Finished motor controller box end cover plate design in OpenSCAD.

3D-printed test sample CAT 4-plex cover, then another one to use. (3D

printer was somehow out of square - so I adjusted it.) 3D-printed

Motor Controller box end plate. 3D-printed 9 CAT sockets for plate etc.

20: Wound main energy recapture coil for the unipolar motor controller.

Found a better light diffusing plastic for LED lighting.

22: Started Car Cigarette Lighter Socket to CAT Standard Socket Adapter

design for 3D printing.

23: Finished it. It worked fine on 2nd try, but still needs some

tweaking. (Now the CAT 12VDC connector product line includes sockets,

plugs, duplex & 4plex wall plates for regular 1110 electrical

boxes,

"deco" (rectangular hole) 1110 box wall plates, click-lock plugs and

sockets, and the cigarette lighter adapter.

24-31: sick.

27: Outfitted & attached bus bars in unipolar motor controller,

worked out energy recovery diodes wiring.

28: Revised end plate & 3D printed it. Also printed 4plex cover

plate with minor corrections.

30: Installed 4plex CAT receptacle plate on wall, for aquaponics

lighting.

31: Uploaded 4plex plate and cigarette lighter designs to

thingiverse.com for anyone to use. (A user commented favorably on the

previous CAT designs. Still to upload: click-lock plugs & sockets.)

Electric Hubcap Motor Systems - Electric Transport

Unipolar

('monopolar', 'homopolar') Motor

& Controller

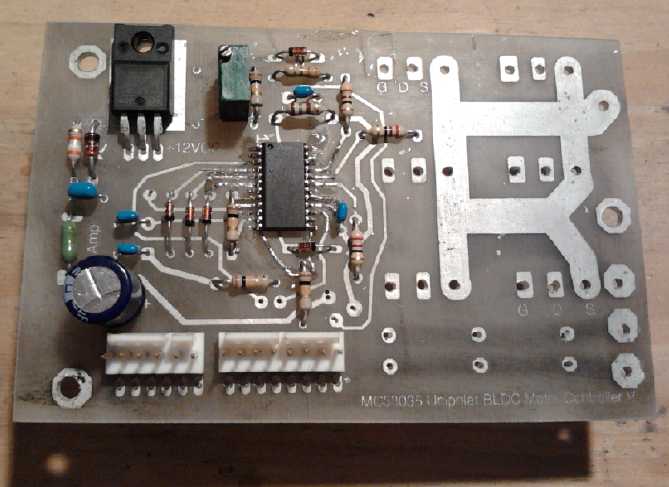

Unipolar Motor Controller

I bought a new laser

printer on the 8th, got it hooked up and running on the old i-Mac on

the 9th with the install CD, and printed the circuit artwork on toner

transfer paper on the

10th. (I thought it was pretty amazing something new actually installs

and works on it - most new programs and upgrades of older programs say

"Not Compatible" after installation and you're [hopefully] left with

the old version. Kudos to Samsung!)

I then did the bottom and then the top layers of the board

-

toner transfer and etching. I taped up the side not being etched with

packing tape, carefully applied. That seemed to work well.

For cleaning PC board copper, I'd been using the technique

from

"How to Electroplate a Penny": a toothbrush and toothpaste. However, I

couldn't seem to brush coffee stain off my front teeth, and I had

recently rubbed baking soda (NaHCO3) on them. That got rid of the

stain. It

seemed only

natural that it would clean the copper better too, and the results were

very good. Nylon scouring pads ("Scotchbrite" pads) still have their

place, but the toothbrush and baking soda did all but the most ugly

spots.

I had been using methylene chloride to clean the toner off

the finished PCB, but I tried acetone recently and it seemed just as

good. This time I tried simply scrubbing it with the toothbrush and

baking soda. That seemed just as good too, and with a pretty benign

chemical. (In fact, I've seen it touted recently (on youtube) as

an anti-cancer food or cancer treatment.)

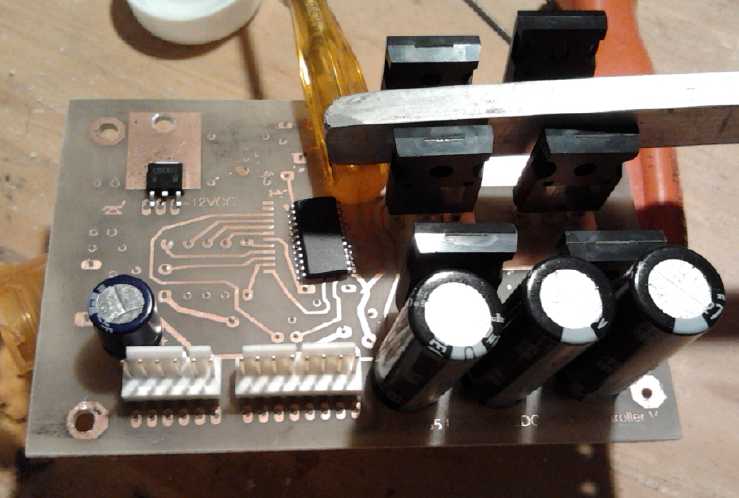

Then I drilled

holes in the board and test fitted some of

the larger components. There were

some non-obvious fitting problems with some of them. The most annoying

was that while there was clearance between the capacitors and the power

transistors, there would be nowhere to get an allen wrench past the

capacitors to screw the transistors to the conductor bars. I ended up

putting in one smaller capacitor.

Then I drilled

holes in the board and test fitted some of

the larger components. There were

some non-obvious fitting problems with some of them. The most annoying

was that while there was clearance between the capacitors and the power

transistors, there would be nowhere to get an allen wrench past the

capacitors to screw the transistors to the conductor bars. I ended up

putting in one smaller capacitor.

A problem that had been bothering me about those phase

power conduction bars (to the motor coils) suddenly seemed to solve

itself. On the outside of the case, the obvious thing to do to connect

the wire was to put a bolt through the wire lug and through the bar and

tighten it. But it would be hard for the installer to get a nut driver,

screwdriver or allen wrench through the front bars onto the back two

bars. (This is also a nuisance inside when connecting the

transistors.) I had thought of twisting the bars so the bolts would go

up-down or at least diagonally, but in addition to other problems, that

seemed to have considerable potential for shorting phases together if a

wire was loose or got shifted over.

The sudden realization was that if the back bars were

simply made longer than the front ones, their bolts could be beyond the

end of the one(s) in front. And then, since the rear bar can be

bolted from the rear, only the middle bar need be longer. Having the 3

bars protrude about .875", 1.5" and .875" would probably be about

right. (If the fat wires are in-line, they'll be in the way, but that's

solved by attaching the center one first.)

I have 5 nice aluminum extrusion piece "boxes" about 4" x

4",

6" long that I found at a scrap place, just about ideal for making into

cases for the first few units. If the circuit board is extended to 3.0"

wide, it'll fit into a slot inside, with room above for the board

components and room below for the off-board components - in particular

the large coil in-line with the power, that allows the batteries to

charge from transient reverse motor coil currents. And the plastic ends

of

the box including the end that the bars stick out through? I figured I

could make those to optimum "molded" shapes on the 3D printer.

On the night

of the 15th I soldered on the two SOIC

surface mount chips and inserted the component leeds of the other

smaller components. The next morning I soldered them on, and then

inspected the board with a magnifying glass (my eyes not being what

they used to be) looking for bad or missing solder joins (I found a

few), or broken traces owing to the toner transfer voids. As

I passed over the 14 pin NOR gate, I noticed it said "ALS86". Wait a

minute, didn't I use 4000 series CMOS? Then I realized it was the chip

for the previous IR2133 controller. It was an easy mistake to

make

when they look the same and the writing is too small to see. I blew a

heat gun straight on it while pushing on the end with a tool until the

solder melted on all 14 leeds and it moved away. That seems to be the

way to unsolder surface mount chips. I found the tube of

CA4025B.s and soldered one on. (It wasn't easy since the board now had

a lump of solder at each pin, so the chip leeds wanted to sit in the

valleys between, half way between pins. I got it straight enough to

work.) On the 17th I soldered on the power mosfets and large

capacitors, and found and cut a big piece of copper for bus bars.

On the night

of the 15th I soldered on the two SOIC

surface mount chips and inserted the component leeds of the other

smaller components. The next morning I soldered them on, and then

inspected the board with a magnifying glass (my eyes not being what

they used to be) looking for bad or missing solder joins (I found a

few), or broken traces owing to the toner transfer voids. As

I passed over the 14 pin NOR gate, I noticed it said "ALS86". Wait a

minute, didn't I use 4000 series CMOS? Then I realized it was the chip

for the previous IR2133 controller. It was an easy mistake to

make

when they look the same and the writing is too small to see. I blew a

heat gun straight on it while pushing on the end with a tool until the

solder melted on all 14 leeds and it moved away. That seems to be the

way to unsolder surface mount chips. I found the tube of

CA4025B.s and soldered one on. (It wasn't easy since the board now had

a lump of solder at each pin, so the chip leeds wanted to sit in the

valleys between, half way between pins. I got it straight enough to

work.) On the 17th I soldered on the power mosfets and large

capacitors, and found and cut a big piece of copper for bus bars.

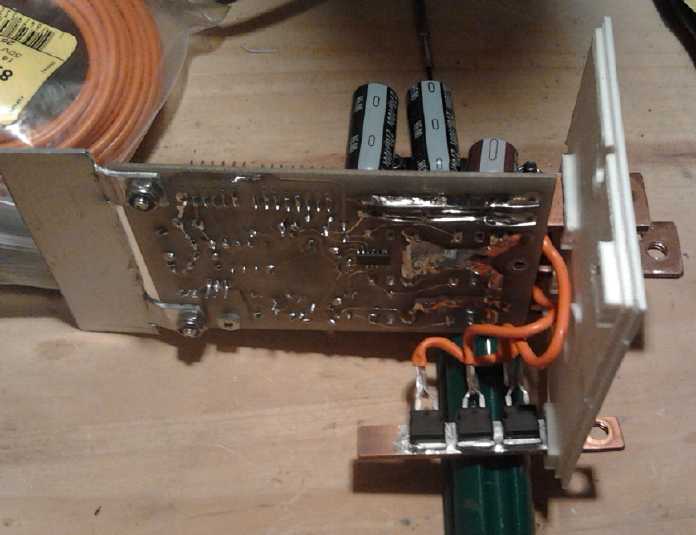

Then I started

trying to see how to fit everything into

the extruded aluminum case, and designed an end cover plate with slots

for the phase bus bars. The next day I 3D-printed a couple. They both

had problems, and, trying to get it to exactly fit the square

extrusion, for the first time ever I noticed the printer didn't quite

print

right angles - X and Y weren't quite perpendicular. (I also

printed the first 4-plex 12VDC CAT outlet covers and a set of 9 CAT

sockets.) On the 19th I modified the design, adjusted the printer, and

did another one. It was very close to fitting. I did a 4th one with

adjustments, and made it thicker. At last it looked like a keeper - and

"manufactured" like a molded plastic part.

Then I started

trying to see how to fit everything into

the extruded aluminum case, and designed an end cover plate with slots

for the phase bus bars. The next day I 3D-printed a couple. They both

had problems, and, trying to get it to exactly fit the square

extrusion, for the first time ever I noticed the printer didn't quite

print

right angles - X and Y weren't quite perpendicular. (I also

printed the first 4-plex 12VDC CAT outlet covers and a set of 9 CAT

sockets.) On the 19th I modified the design, adjusted the printer, and

did another one. It was very close to fitting. I did a 4th one with

adjustments, and made it thicker. At last it looked like a keeper - and

"manufactured" like a molded plastic part.

On the 27th I made the threaded holes in the bus bars for

the heavy wires, cut the middle one to length (the outer ones were

almost too short already), attached them to the transistors and

assembled it all. Then I checked some high current schottky diodes I

had to see how they'd work the energy recovery diodes. The case, which

could be soldered to a copper bus bar for heat sinking, was connected

to the cathode side. That was the wrong side to solder to the three

phase bus bars. But it was the right side to solder all three of them

to a single B+ battery voltage bus bar. Then the cable to the battery

would carry off the heat from all three, without adding more heat to

the phase transistors. Short wires would connect the phases to the

anode pins.

So this suggested a wiring layout, which clarified my

previously murky thoughts on just how everything might go together

within the case:

* The battery

wire to the clamp at the end of a rather short

B+ bus bar sticking out of the case below the phase bus bars, with the

3 diodes soldered to it, and the energy recovery coil soldered to the

inside end.'

* The battery

wire to the clamp at the end of a rather short

B+ bus bar sticking out of the case below the phase bus bars, with the

3 diodes soldered to it, and the energy recovery coil soldered to the

inside end.'

* The other end of the coil is the main power to the circuit

board and to the motor coils "common".

On the B- ("ground") side, a short bus bar with a similar external bolt

connection would have the board ground wire and the current sense shunt

soldered (or clamped) to it. The other end of the current sense shunt

would supply the sources of the mosfets.

All the off-board components would be thus accommodated.

It was

a

pity I had made three round holes in the end plate to run heavy wires

through instead of slots for two bus bars. I can cut slots between the

holes... or 3D print yet another end plate. Since I hope to make 4 more

the same, I decided it was worth revising the end plate now instead of

later. I designed and printed the revised one the next evening (28th).

Then I realized I still didn't quite have it. There's "B+"

from the battery, then there's the "B+" to the motor coils, after the

in-line energy recapture coil. First I decided to change the design but

use this one for the first unit.

The copper bus bar I chose for the phases was 1/8" x 3/4",

which is the length of the heatsinks on the TO-247 MOSFETs. It's far

more than enough copper cross section. For the power connections, I had

a piece of 1/8" x 3/8" - about the equivalent of 2 or 3 gauge AWG.

That's still plenty, but when I put in the hole for a 1/4" bolt to

connect the wire to, there's not much left on each side. I don't want

to shrink the bolts, so I reluctantly concluded that 1/2" wide should

be the minimum for production. But maybe just 3/32" thick.

When I checked the fit, I decided the lower bus bars were

too near the edges of the case and might short to it, so I'll be making

the new

3-power-bus-bar version soon after all. And the bottom slot extrusion

in the

extruded box needs to be cut off in order to fit the energy recapture

coil - otherwise it's just a little too tall.

Electric Weel

Motor/Generator

On the 15th I finally got

back to this project and did the "lexan-ish" drill template for the

body screws. When I lined it up, it seemed the 96 outside holes were

just a bit close to the outside edge, but by only a slight amount.

Unfortunately the target rim edge isn't very wide, so the aim needs to

be good. Holes meeting the outside or inside edge of the rim wouldn't

be good. Part of the problem was that the units were slightly out of

round - a product of making them from eight separate pieces each, with

the adjoining edges sanded and then glued together. It would be hard to

get them absolutely perfect while dealing with gooey epoxy resin with a

very limited working time. (Maybe some sort of polyethylene

template/form?) So while they seemed about right where the body was

widest, they were definitely close to the outer edge where it was

narrowest. For the 24 stator inside edge and the 24 coil center holes

there's more room and the aim is less critical.

But I used the router with a 1/8" bit to drill the

template, and the holes were to be expanded to 9/64" with a drill. I

decided instead to expand the outer edge holes with a file and file

toward the inside, slightly moving their centers inward. Then I would

change the spreadsheet and the G-Code to move the outer holes inward by

about .04" for making the next template, should there ever be one. But

the holes seemed to be about 9/64" diameter already. Looking it over

again, I decided that it was probably about right after all.

I e-mailed the hydro power maker and said it was ready,

but he didn't reply. The last major item is the lexan rotor plate. This

is much lighter than steel, but it'll have a steel ring around the

outside to carry the magnetic fields. I'll have to tackle that some

time in January. It'll be good to see this project finally come

together!

"Green" Electric Equipment Projects

CAT Standard 12VDC Connector

Project: CAT products line

extended

I had realized

that I would soon need more 12 V plug-ins

for lights around the aquaponics system. On the 17th and 18th, while 3D

printing the end for the motor controller box, I also made a CAT 4-plex

receptacle faceplate for standard 1110 electrical boxes. This was only

a modification of the duplex faceplate. It was considerably easier than

starting from scratch, but not trivial. A slightly off hole position on

the original became two mistakes on the new one. I remember having that

problem. It's best to fix designs as soon as the error is seen, before

it multiplies.

I had realized

that I would soon need more 12 V plug-ins

for lights around the aquaponics system. On the 17th and 18th, while 3D

printing the end for the motor controller box, I also made a CAT 4-plex

receptacle faceplate for standard 1110 electrical boxes. This was only

a modification of the duplex faceplate. It was considerably easier than

starting from scratch, but not trivial. A slightly off hole position on

the original became two mistakes on the new one. I remember having that

problem. It's best to fix designs as soon as the error is seen, before

it multiplies.

I have since

near the beginning of the CAT

connectors project

in 2012 wanted a car cigarette lighter adapter. This

provides a path of migration from that rather ridiculous design that

was never intended to be used for general purpose plugs and sockets, to

the CAT system. On the 22nd and 23rd I designed and 3D printed one. It

worked fine on the 2nd try, but still needed some tweaking. I adjusted

the numbers in the design but didn't print another one.

I have since

near the beginning of the CAT

connectors project

in 2012 wanted a car cigarette lighter adapter. This

provides a path of migration from that rather ridiculous design that

was never intended to be used for general purpose plugs and sockets, to

the CAT system. On the 22nd and 23rd I designed and 3D printed one. It

worked fine on the 2nd try, but still needed some tweaking. I adjusted

the numbers in the design but didn't print another one.

'Cigarette lighter' adapter socket in electric

RX7.

'Cigarette lighter' adapter socket in electric

RX7.

(Now, if only the cigarette lighter socket

actually worked in either of my cars...)

Now the CAT 12VDC standard connector product line includes:

* regular sockets (for in-line or wall mounted connections)

* regular plugs

* Click-lock sockets (in-line or wall mounted)

* Click-lock plugs (hooded to reduce risk of short circuits, for

battery charger, etc.)

* duplex wall plates (2 CAT sockets [regular or click-lock]) for

regular 1110 electrical boxes

* 4plex (4 CAT sockets) 1110 box wall plates

* "deco" (rectangular hole) 1110 box wall plates

* Cigarette lighter adapter socket.

I already needed 3 of the 4-plex sockets for grow

lighting,

so it may not be long before I do a 6-plex cover plate. 9-plex - 3

sockets wide by 3 tall - is probably doable, and should pretty much

eliminate any need for power bars. Beyond that they'd probably get hard

to fit onto one faceplate and to wire into one box.

Another thing I might try is faceplates with sockets

'molded' into them, with a separate piece that screws to the back of

each socket front to hold it together once it's wired. This would

eliminate the cracks around each socket for a cleaner faceplate

appearance.

Aquaponics

& LED Grow Lighting Project

Water pH Problems

None of this is innovative or will come as any surprise to

an experienced aquarium owner...

On the 15th I tried out the pH test from a multi-parameter

aquarium test kit I bought. The gauge in the system still said it was

low, and the test kit now said it was around 5.5. That's definitely

acidic. Perhaps the tap water really is just 6... I'm now remembering

it does seem it's acidic on this island. (In fact pH even went below 5

at Bull Harbour near Port Hardy in the 1970.s when the Utah Mines

copper mine was causing acid rain all over the north end of Vancouver

Island. The water was always brown, acidic and dead and there wasn't an

earthworm to be found anywhere. Gardens wouldn't grow. Many or even

most people thought it was "natural" acid rain! Finally the mine closed

and it ended. But I digress.)

Reading the microscopic print in the booklet further under a good light

(they make it smaller every year!), it said - contrary to the

aquaponics info I've seen - that pH in an aquarium decreases over time,

owing to bacterial action. Photosynthesis should increase it, not

decrease it. Maybe it depends on the concentration of fish, and 6 fish

aren't enough to cause a lot of ammonia build-up and raise the pH.

The test kit also said not to raise the pH by more than

1/2 a unit

per day or the fish would be stressed. A web site also said a rapid

rise in pH could kill the fish. So it looks like what I did last month

that

caused the pH disaster was actually the right idea, and I went too fast

rather

than too far. Baking soda was the most recommended alkalizer. That

would certainly be more gentle and gradual than hydroxides... but don't

plants need potassium and calcium anyway? I decided to try a small

amount

of each, like 1/4 of a teaspoon of calcium one day and a teaspoon of

baking soda the next. Or maybe 1/8 and 1/2... once bitten twice shy.

After a few days I had to get somewhat more aggressive, because the pH

stayed acidic and refused to rise. I started using a teaspoon of baking

powder or 1/2 a teaspoon of lime each day. Then even more. The little

indicator continued to show a greenish color that apparently meant "pH

below 6". But I checked with the test strips and the test droplets and

they said more like 6.5. Finally on the 30th both agreed it was about

pH 7, and I stopped adding things for a while. So it looks like the

test papers are pretty much right on after all.

The beans were growing well and their poles had to be

extended. I should have done this mid-month, but I didn't get to it

until the 30th, by which time the tips were growing up and down looking

for a way up. Other plants are growing, but the pole/kidney beans are

definitely the star performers and their profuse foliage is now hogging

much of the light. Unless the lava rock has fertilizer properties,

they're way too big to be subsisting off anything but fresh nutrients

coming from the fish tank. A cucumber has small leaves with spots on

the corners,

probably indicating some deficiency. A pea plant is doing okay and a

tomato seems to be growing. And there's something that may be basil,

evidently a favorite for a quick aquaponics plant. It might also be

from a seedless mandarin orange seed I stuck in. I really wanted leaf

lettuce for sandwiches

and

burgers, but it doesn't look promising at the moment.

The beans were growing well and their poles had to be

extended. I should have done this mid-month, but I didn't get to it

until the 30th, by which time the tips were growing up and down looking

for a way up. Other plants are growing, but the pole/kidney beans are

definitely the star performers and their profuse foliage is now hogging

much of the light. Unless the lava rock has fertilizer properties,

they're way too big to be subsisting off anything but fresh nutrients

coming from the fish tank. A cucumber has small leaves with spots on

the corners,

probably indicating some deficiency. A pea plant is doing okay and a

tomato seems to be growing. And there's something that may be basil,

evidently a favorite for a quick aquaponics plant. It might also be

from a seedless mandarin orange seed I stuck in. I really wanted leaf

lettuce for sandwiches

and

burgers, but it doesn't look promising at the moment.

Below the LED lights the leaves are

'level-ish'. Above them,

the leaves all point toward the window.

A few other plants are trying to grow.

Aquarium

I finally got a ruler on the biggest tilapia. It had

definitely gained some meat. I was sure it was 9" long now and looking

potentially tasty, but in fact it was about 8" long. No doubt then I

was

overestimating the size of the tilapia when I bought them. Rather than

6"-8" they were maybe 5" to 7" - closer to the seller's estimate of 4".

But this one was near 9" by January.

He said that to breed them a male should be placed in with

3 or 4 females, in uncrowded conditions and warm water with gravel for

the male(s) to dig a nest(s) in.

I bought some aquarium gravel and put it in a shallow

plastic tray

which I placed in the tank - neat and tidy. The fish carried it all

around, almost emptying the tray, and seemed especially intent on

blocking the water exit pipe with it, raising the tank level

substantially and keeping the guck from flowing out into the sump tank.

My biggest fish, now 8" long, was chasing and biting at

the other fish. In all the videos I've seen on tilapia breeding, an

aquarium was used. I finally broke down and got an aquarium, another

water heater and a filter/aerator. I put it in my electronics lab on a

previously surplus 'coffee table' size laminate top thing with drawers.

On

the 20th I filled it with rain water from a 200 litre barrel outside

and waited a day for the heater to warm the water up, then I put the

big fish in it. It's definitely easier to see in there. That's when I

got the ruler up close. It appeared to be a female. They have either

one (M) or two (F) holes near the anus, but they drop to the bottom

whenever you look at them, and it's not so easy to get a really good

view without netting the fish, stressing them and maybe getting jabbed

by a few dorsal spines. (The thing I noticed was that the poop seemed

to come out from a point 10mm behind where it seemed like it should.

That seemed to indicate an extra hole ahead of the anus.) A couple of

days later I put in the next biggest fish - a male, I believe. And then

some of the gravel. So far

nothing has happened.

My biggest fish, now 8" long, was chasing and biting at

the other fish. In all the videos I've seen on tilapia breeding, an

aquarium was used. I finally broke down and got an aquarium, another

water heater and a filter/aerator. I put it in my electronics lab on a

previously surplus 'coffee table' size laminate top thing with drawers.

On

the 20th I filled it with rain water from a 200 litre barrel outside

and waited a day for the heater to warm the water up, then I put the

big fish in it. It's definitely easier to see in there. That's when I

got the ruler up close. It appeared to be a female. They have either

one (M) or two (F) holes near the anus, but they drop to the bottom

whenever you look at them, and it's not so easy to get a really good

view without netting the fish, stressing them and maybe getting jabbed

by a few dorsal spines. (The thing I noticed was that the poop seemed

to come out from a point 10mm behind where it seemed like it should.

That seemed to indicate an extra hole ahead of the anus.) A couple of

days later I put in the next biggest fish - a male, I believe. And then

some of the gravel. So far

nothing has happened.

A pH test at the start of January showed 6.5. That seemed

pretty good. Some aquarium plants would be nice to have. Duckweed is so

simple. Too bad they eat duckweed!

Electricity Storage

(Sorry, No Report on Turquoise Battery Project)

Battery-Supercapacitor Hybrid Car Starter Battery

Someone phoned me with some questions about batteries. But

he also mentioned a video on youtube about a hybrid car starter battery

using a small 12 volt battery plus supercapacitors, or technically, a

supercapacitor composed of several low-voltage rated supercapacitors in

series. This idea is intriguing.

It seems that supercapacitors will put out tremendous

current and start a car (I've seen it in several youtube videos by

different people), but they don't hold a lot of charge. The 350 farad

size employed (divided by 6 in series = 58 farads) is only 58

amp-seconds of current or maybe 1/3 of a second of cranking before it's

down a volt. Since the car usually starts almost instantly, it works.

But if the car is left for a few days, it's likely to be dead since

most cars these days use a little current for clocks and computers even

when they're "turned off".

But any small battery will rapidly charge the capacitors,

which can then start the car. The video itself is a good advertisement

against using finicky lithium battery types. Nickel metal hydride would

seem to be the choice. How big should they be? Since it would only

take a few seconds to charge up the capacitors, probably even ten AAA

cells (one amp-hour or less) would work fine. Since there's no reason

to go so small, AA cells (two or more amp-hours) might be a good

choice. On the other hand, leaving the lights on might overpower their

current supply capacity as well as quickly drain them. D cells (8 to 10

amp-hours) can power the whole car except for starting it - and even

run the lights an hour or two if they're left on. I think that would

be my choice. C cells or two or three sets of AA cells might also power

the car, but would have much less reserve than the D cells. The D cells

could lose 1/2 their capacity - over thousands of charge-discharge

cycles and many years - and still work fine.

My next questions were about price and impedance. I went

to the Digikey website and at first it looked like the price would be

prohibitive, but soon I found more economical choices. I thought some

310 farad, 2.7 volt, 2.2 milliohm capacitors for about 15 $C looked

very good. The 2.7 volts appears typical. The only ones I saw rated for

higher voltages looked like they were composed of several low voltage

cells put into one

package. I was surprised to see supercapacitors have a "Lifespan"

rating, measured in hours - mostly 1000 or 1500 hours at 65°c.

Well, the one time they would probably get warm was when starting the

car. That would be short but intense heating. As with using NiMH dry

cells for car starting, I figure they'll probably last a long time, but

it's a question mark. None of the youtube videos so far seem to have

reported any failures. (BTW the 30 D cells NiMH starter battery in my

Toyota

Tercel has now been in it 4-1/2 years and still works great.)

The voltage drop when cranking depends on the "Equivalent

Series Resistance". In typical cranking (good lead-acid or 'enough'

NiMH batteries) the voltage may briefly dip down to around 9 or 10 or

even 8 volts. If the capacitors were at 13 volts and starting current

was 220 amps as the key was turned (small car), that would be .0022

ohms * 220 A = .484 volts, bringing it down just a bit to 12.5 volts.

This

gets the starter motor up to speed, and to a notably higher speed, in a

hurry. It's why supercapacitors start the car so fast, which is also a

key to their success since they can't crank very long. (What that

'extra' power does

to starter motor and starter mechanism life I don't care to speculate.)

Where the battery starts to recover up to 10 or 11 volts as it cranks,

the capacitors mostly just keep dropping. In the hybrid system with

batteries to charge them back up in a few seconds, at least a few tries

at starting should be possible.

The Video: www.youtube.com/watch?v=8miq6sDy0wA

New Soldered Together NiMH EV Batteries

Since I had 7 more soldered together, 50 NiMH D cells

batteries to make, I thought I'd do all I could to make them better and

faster.

On the morning of the 5th, I cut about 100 more tarpaper

covers for the cells. Since the tarpaper came off a roll, I noticed it

curled up

in one direction, and this time I cut them all to wrap that way. On a

few the tape had come loose

and the tarpaper unwrapped. Once in the battery that's not serious

since it has nowhere it can go. But this time I cut the 'invisible'

transparent tape I'm using longer than the paper. Once it's together, I

slide the battery out a little one way then the other and fold the tape

inside, for a better seal. None came loose.

Then I

improved the little block of wood that I'm using to

cut the bridge wires to the same length with a "V" on the input side so

I didn't have to hit dead on to get the wire to slide into the hole.

Then I mounted it in a vise instead of holding it, and had both hands

free: one for the wire and the other for the cutters. I cut the 45

wires in just a few minutes once I had it set up. I pushed each wire

through the hole in the block of wood until it just showed coing out

the other side.

Then I

improved the little block of wood that I'm using to

cut the bridge wires to the same length with a "V" on the input side so

I didn't have to hit dead on to get the wire to slide into the hole.

Then I mounted it in a vise instead of holding it, and had both hands

free: one for the wire and the other for the cutters. I cut the 45

wires in just a few minutes once I had it set up. I pushed each wire

through the hole in the block of wood until it just showed coing out

the other side.

Stripping the wires didn't seem to get any easier. I tried

to put one in the vise but it pulled loose when I pried with the

strippers. I went back to holding it with pliers and pivoting the wire

strippers against those to strip the end off.

Next, since I'm using the final boxes to hold the cells

while soldering them, the box had to be assembled. And the terminal

posts had to be mounted with copper plates, each with 5 wires to

connect

the 5 sets of cells. I didn't time these fabrications. They took up the

afternoon.

In the evening I soldered the bridge wires to the cells.

When I turned them over and did the bottom sides, I put them in with

the honeycomb angles backward, and had cells instead of voids where the

terminal posts were. Choices were to move the terminal posts or to

rewire 20 bridge wires. Since I'm making 8 batteries that are supposed

to be identical and which are used in pairs, I chose the latter,

spending the extra time.

I finished it by soldering the terminal post wires to each

of the 5 sets of 10 cells to make it one 50 amp-hour, 12 volt unit. I

finished a little before midnight.

Get cells out of PETE wrapping plastic: 15'

cut tarpaper: 40'

wrap 50 cells: 40'

cut bridge wires: 15'

Make Box and terminal post assemblies: um, at least a couple of hours,

probably 3. 180'(?)

Strip both ends: 25'

Solder bridge wires: 60'

Resolder rong-angled bridge wires: 20'

Solder cells to terminal posts: 25'

Total: 7.0 hours

I only approximately timed things, but considering I spent

entire the day on this from maybe 9:30 AM to 11:40 PM, except for an

hour's music rehearsal and meals, I'm not sure how I come out with such

short "billable hours".

The next day I screwed the two batteries together and

installed them in the RX7. This didn't go smoothly and took about three

hours, with having to replace a cable that was too short from the

hard-to-access tube batteries in the big wooden box, cutting to shape

and inserting a piece of wood to ensure the battery didn't slide over

and the lower terminal posts short against a piece of the angle iron

battery mounting frame, and other little nuisances. Finally it was in

and I took a little test drive around the block. The battery started at

12.5 volts and was down to 12.2 afterward, having dropped under 11

going up a hill. I left it overnight to charge. The next day by noon,

it was just reaching 13.7 volts. I drove it 2.2 miles to a parking lot

with plug-ins near where I was playing in an orchestra concert and

plugged it in again. It held voltage better than either of the two 90AH

NiMH.s, one of which has also been stronger than the other, one typical

reading being 12.4, 12.2 and 11.8 volts, or, going uphill 12.1, 11.5

and 10.4 volts. I'll only know if one or even two of the tubes of the

lowest one aren't working right (as seems likely) when I take it apart.

The voltage does however spring back considerably once rested a while,

showing that more somewhat current than it can handle nicely is being

asked of it, rather than that it's being overdischarged.

The next day (8th) I spent a good part of the day on the

next one. I disassembled the six 3D-printed battery holders battery to

get the cells from it, and made two wooden boxes, so the next one

should take less time. I ran out of the "correctly curled" tarpaper

after 94 cells, and did the last 6 with ones curling the other way.

With folding the ends of the tape inside, they seemed fine. In the

evening the Hampton Orchestra had a wine & cheese party and I

played my supercorder with piano accompaniment. (I meant to record it,

but in the event it completely slipped my mind.) Then I soldered until

well after midnight and finished the battery.

On the 9th I did some driving - to buy a new laser printer

for PCB making and some acrylic plastic for LED lights. The weaker

90AH NiMH tube battery was getting down to the 10 volt limit during

acceleration on the return trip. I found I had driven 5.7 miles using

12.7AH (@ 128 nominal volts= 1625 watt-hours, /5.7 = 285 WH/mile) with

a short 1/2 hour recharge in a mall parking lot. That's not a long way,

but it's the longest for quite a while (and farther than I thought I'd

be going). Another new battery and bring the two 90AH.s up to 100 with

any required new cells, and things should be looking up!

In the evening I took apart the remaining 3D printed tray

batteries and two single tube batteries to get 50 more cells. At this

point, seeing I was using various used cells, I started testing them

and I

discarded a couple whose voltages were lower than the rest. I found a

couple of other cells to use. They were among a suspect bunch that had

been

badly overcharged, but these were holding voltage well. Ideally I'd

have charged them all, waited a couple of days to see how they were

holding voltage, and then load tested them to ferret out any weak ones

or any not holding charge well.

That would have been a prohibitive amount of work. I should have

checked the first 50 with the meter just in case, but 10 were new and

the other 40 were from the 60 cell battery. It hasn't been used a lot,

and I don't think I ever overdischarged or overcharged it. I wrapped

the chosen ones with tarpaper.

The fourth battery left me with just 40 remaining cells,

being used in the solar power system. ...and 5 more in my 6 volt

bedroom LED

lamp (the very first one I made) powered by a 10 watt solar panel. If I

took apart the two 90AH tube

batteries in the Mazda, they should be about enough to bring them up to

100AH and replace any weak cells. I might just have one 10AH tube

battery left. The solar power could use lead-acids for a while. At that

point the car would have five 100AH NiMH batteries, 4 lead-acid size

'frame 27',

and two 16 volt lithium-ions, all (supposedly) rated at 100AH or more.

If I'm lucky, the lead-acids will last until the Chevy Sprint is

running.

I finished the battery on the night of the 13th, and

installed the new 100AH pair the next day, when the weather was luckily

sunny. I neglected to unplug a plug from the other new 100AH NiMH to

the 7-voltages display. There was a small spark when a wire from the

loose socket touched the motor, and I had to replace one of the little

voltmeters and also one of the battery chargers. Yep, those are

'random' high voltages between batteries when they aren't all wired up

together.

On checking the rear batteries after installing - only one

of which was being monitored on the dash - the first lead-acid I looked

at was only at 11.1 volts instead of nicely charged to 12.7v+. It was

one that hadn't been renewed, and it had a glued on top. This explained

why the voltages had seemed to drop so far so soon when I was driving!

I

had doubtless repeatedly overdischarged it pretty much into the ground

without realizing it. It shows the need to be able to see ALL the

battery voltages. I removed it and bridged the two neighboring

batteries. (The other three lead-acids were fine.) So despite all my

efforts building two new batteries, three were gone and there were

still just ten. After a year and a half and not one of the original or

I think even the second PbPb.s left in the car, I'm really starting to

hate

lead-acids, of which the car is down now to just three (all fine), plus

5 NiMH and 2 lithium-ion (@16v). I'd like to spring for another NiMH

for the 11th battery, but considering I still need to re-do the 90AH

tube ones to 100AH soldered, and the high cost, it'll have to be

another lead-acid.

On driving the car some, I discovered that the new 100 AH

battery didn't seem to be a lot better than the weaker 90 AH one. Of

course, except for 10 new cells, I had used batteries that had been

lying around for a couple of years or more, used for whatever and

subject to who-knew-what states and rates of charge and discharge.

The better NiMH batteries hold their voltage well, and the

others 'bounce back' once the load is off for a while. That means that

they still have good charge, but as they get lower their drive capacity

starts being overtaxed, the voltages dragged down by the heavy loads.

This has probably been the case for some time if not since the

beginning, but it wasn't readily apparent until I started monitoring

the individual battery voltages.

Lower currents would help. An 11th battery would drop the

currents by about 10%. And it appears that all the drooping voltages

would hold much better if the batteries were just somewhat bigger, like

maybe 130 to 150 amp-hours or so instead of 100. Thus the plan of the

original converter of the car was evidently quite sound: He used

eighteen 8-volt golf cart batteries which (looking at a Trojan

brochure) are available in 150, 170 & 190 AH capacities (20 hour

rate), or 125, 145 & 155 amp-hours at a 5 hour rate, weighing 56,

63 & 69 pounds each. These would seem to be the optimum sort of

size, and smaller and lighter than the more common twentyfour 6-volt

golf cart battery configuration.

This

rather disappointing result brings me right back to one of the main

points for trying to make a new battery chemistry: of very much wanting

everlasting batteries that don't deteriorate. I now have the

chemistries - two of them that should work great - nickel-nickel and

nickel manganese. What I haven't been able to do is make practical

cells that

perform well and don't discharge from air leaks and ooze their

electrolyte out the terminal posts.

In the meantime: I could obviously fit one 8V golf cart

battery in (they're shorter) instead of another 12 volt. I wonder if I

could squeeze two in and have 16 volts, total 144? Otherwise, when the

next 12 volt one gets weak, I could fit 24 volts with three 8 volters

where two 12 volters were.

But this all seems so unsatisfactory! I must finish the

unipolar motor and controller and try them out, then finish the Sprint

'ultra-efficient' EV conversion that will hopefully use less current

and even less power in the first place. Then the range should rise

substantially and the import of all these battery issues will shrink to

much smaller proportions.

http://www.TurquoiseEnergy.com

Victoria BC Canada

I started the month

by getting the Mazda back on the road, by making a second 12V 50AH NiMH

battery on the 5th. I doubled it up with the other and installed the

100AH battery in the car on the 6th. I did the next one on the 8th, and

finally the 4th one on the 13th. After I installed them I checked the

lead-acid batteries in the back and found one of them had low voltage

and was probably ruined. So it was immediately back to 10 batteries

(128 volts) after all that work! Furthermore, the new battery from the

3rd and 4th 50AH units wasn't so hot. It held higher voltage under load

than the poorer of the two 90AH pipe batteries, until they both started

dropping to 10 volts at about the same time. I had made it from 10 new

cells and 90

that were 2 or 3 years old and subjected to varying uses and charging

or lack thereof. The lithiums also seem to be running more down toward

the

bottom of their allowable voltage range as well... aren't they supposed

to last thousands of cycles?

I started the month

by getting the Mazda back on the road, by making a second 12V 50AH NiMH

battery on the 5th. I doubled it up with the other and installed the

100AH battery in the car on the 6th. I did the next one on the 8th, and

finally the 4th one on the 13th. After I installed them I checked the

lead-acid batteries in the back and found one of them had low voltage

and was probably ruined. So it was immediately back to 10 batteries

(128 volts) after all that work! Furthermore, the new battery from the

3rd and 4th 50AH units wasn't so hot. It held higher voltage under load

than the poorer of the two 90AH pipe batteries, until they both started

dropping to 10 volts at about the same time. I had made it from 10 new

cells and 90

that were 2 or 3 years old and subjected to varying uses and charging

or lack thereof. The lithiums also seem to be running more down toward

the

bottom of their allowable voltage range as well... aren't they supposed

to last thousands of cycles? In the second

week, I continued with the unipolar motor

controller. I did the circuit board on the 10th and had it populated

within a few days, and by the 19th I designed and 3D printed a

plastic end cover for the case. Then I cut a piece of aluminum to hold

the back end of the circuit board in place, since the board

was just a little too narrow to be held by the slots in the extruded

box. There

it sat until after Christmas. Then I improved the 3D printed end and

figured out pretty much how the energy recovery diodes and in-box

wiring would go.

In the second

week, I continued with the unipolar motor

controller. I did the circuit board on the 10th and had it populated

within a few days, and by the 19th I designed and 3D printed a

plastic end cover for the case. Then I cut a piece of aluminum to hold

the back end of the circuit board in place, since the board

was just a little too narrow to be held by the slots in the extruded

box. There

it sat until after Christmas. Then I improved the 3D printed end and

figured out pretty much how the energy recovery diodes and in-box

wiring would go. As I worked on

the 3D printed plastic end plate design for the motor controller, I

also did up two new CAT Standard 12 volt plugs & sockets ideas

which I've had in mind for some time. One was a 4-plex receptacle plate

instead of a duplex plate. I already needed this to plug 3 LED lights

in for the aquaponics system. I figure one could make a cover

plate that would fit up to 9 sockets, eliminating most uses for 'power

bars'... but then they all have to be

wired.

As I worked on

the 3D printed plastic end plate design for the motor controller, I

also did up two new CAT Standard 12 volt plugs & sockets ideas

which I've had in mind for some time. One was a 4-plex receptacle plate

instead of a duplex plate. I already needed this to plug 3 LED lights

in for the aquaponics system. I figure one could make a cover

plate that would fit up to 9 sockets, eliminating most uses for 'power

bars'... but then they all have to be

wired. The other design was an adapter socket

that would put a CAT socket where a car cigarette lighter socket was.

The other design was an adapter socket

that would put a CAT socket where a car cigarette lighter socket was. Since 2008

I've created two battery chemistries that hold the promise of lasting

forever: nickel-nickel (~1.2 volts) and high voltage (~2.3v)

nickel-manganese. I'm the first person ever to get

manganese to hold its enticing high voltage metallic charge of about

-1.5 volts, using

lower alkalinity (pH < 14 with KCl salt) and the two trace additives

described in previous

issues. So far, no one has mentioned duplicating my results. However,

being "moderately alkaline" instead of pH 14 extreme alkaline,

the cells require carbon/graphite current collectors. The usual metal

used

as an alkaline cell current collector, nickel, will oxidize, and no

other metal works. (How

could one have nickel-nickel chemistry if the nickel won't oxidize?)

Since 2008

I've created two battery chemistries that hold the promise of lasting

forever: nickel-nickel (~1.2 volts) and high voltage (~2.3v)

nickel-manganese. I'm the first person ever to get

manganese to hold its enticing high voltage metallic charge of about

-1.5 volts, using

lower alkalinity (pH < 14 with KCl salt) and the two trace additives

described in previous

issues. So far, no one has mentioned duplicating my results. However,

being "moderately alkaline" instead of pH 14 extreme alkaline,

the cells require carbon/graphite current collectors. The usual metal

used

as an alkaline cell current collector, nickel, will oxidize, and no

other metal works. (How