Turquoise

Energy Ltd. News #85

February 2015 (posted March 2nd)

Victoria BC

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Month In Brief

(Project Summaries)

- unipolar motor & controller - variable reluctance motor -

magnetic shielding material? - aquaponics & LED lighting

- Giant Electric Weel motor/generator & floating hydro power

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Improving Systems of Governance: Election CampaynCentral.com

web

page - Airless World Life in the Solar System: alien plant seed

found...

vegetation on Ceres too!?! - Offensive Cartoon - Precious metals:

Silver investing video

series; the

investor fleecing

game; Operation Chokepoint - Feedback on Patent Suppression of energy

inventions - NO MORE WARS!

Electric Transport - Electric

Hubcap Motor Systems

* Unipolar Motor & Controller

* Turquoise Bipolar BLDC Motor Controller Problem Identified?

* RX7 New Battery Notes

* Electric Weel Generator/Motor

Other "Green"

Electric Equipment Projects

* Aquaponics & LED Grow Lighting

Electricity Generation (No reports)

Electricity Storage - Turquoise Battery

Project (NiMn, NiNi), etc.

* Leonardo Elionix's Manganese-air cell

No Project Reports on: Variable

Torque Converter Transmission, Turquoise

Battery Project, Magnet motor,

Lambda ray collector, evacuated tube heat radiators, CNC

gardening/farming machine.

February in Brief

After more time setting up finances and then finishing the January

newsletter on the 5th, on the 6th I installed the new 11th battery in

the

Mazda RX7 EV, bringing it up to 140 nominal volts. On the 9th, quite a

warm day, I drove 3.4 miles using just 252 WH per mile (1.8 AH/mile

@140v) instead of about 300 WH or more (2.3+ AH/mile @128v). That's

over 15% less energy per distance. Theoretically it should be the same.

Does the 144 volt motor become less efficient at

lower voltages, or was it "luck" with traffic, traffic lights and the

route? I drove it quite a bit towards the end of the month,

knowing that if I had to go two or three extra miles it now wouldn't

poop

out on me. Mostly with traffic and shopping stops and starts it used

around 280 WH/mile, but occasionally on smooth trips, catching most of

the traffic lights green, it would do notably better. I can see that on

level

ground at low constant speeds (under 50Km/hr) in warm weather it would

do much better, but that's not the driving conditions around here.

On adding another 10 amp-hour set of dry cells to the

weakest NiMH battery (in PVC pipes) to make it 110AH, I found it still

loses the most voltage under load, but after stopping its voltage would

now recover to above its "twin". It seems as they age the NiMH dry

cells lose current drive more than storage capacity. This is probably

from gradual escape of the tiny amount of liquid in the electrolyte -

the dry cells actually drying out. The big flooded NiMH cells that

Chevron won't let anyone make wouldn't have that problem.

I

got back to the unipolar motor on the 6th. I fixed the

too-large bolt holes by using waxed threaded rods to shape the holes

and keep them

open,

and using them to push in some PP cloth and epoxy filler. It's great to

be able to add material

back into the motor body as well as remove it! When the epoxy was set I

unscrewed the

rods and screwed in the nylon bolts to fasten the rotor end cover on.

The next day I added 5 bolts to the stator side. (The 6th one couldn't

be placed because the heavy wires inside were in the way.) That

finished the

motor!

I

got back to the unipolar motor on the 6th. I fixed the

too-large bolt holes by using waxed threaded rods to shape the holes

and keep them

open,

and using them to push in some PP cloth and epoxy filler. It's great to

be able to add material

back into the motor body as well as remove it! When the epoxy was set I

unscrewed the

rods and screwed in the nylon bolts to fasten the rotor end cover on.

The next day I added 5 bolts to the stator side. (The 6th one couldn't

be placed because the heavy wires inside were in the way.) That

finished the

motor!

But tests on the optical rotor position sensors indicated

they

might cause trouble. Everything fit well and it turned freely, but with

the wide gap for the thick plastic slotted drum, the phototransistors

were too far from the LED.s and so weren't driven anything like as hard

as they should be.

I asked on the

motor controller e-mail group (osmc@yahoogroups.com) if there was any

other type of motor that

could run unipolar, with no H-bridges in the controller - fully

expecting the

answer would be "no". But some smartass came up with one: the "switched

reluctance" motor. The name just sounded so weird I'd never looked it

up before. The rotor

has no magnets, just iron.

I asked on the

motor controller e-mail group (osmc@yahoogroups.com) if there was any

other type of motor that

could run unipolar, with no H-bridges in the controller - fully

expecting the

answer would be "no". But some smartass came up with one: the "switched

reluctance" motor. The name just sounded so weird I'd never looked it

up before. The rotor

has no magnets, just iron.

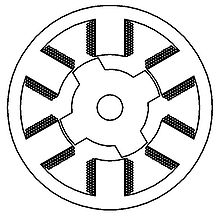

Because of the shape of the rotor, if any

coil is on, a long axis ("salient pole") will try to align with that

coil, and running

the motor can be done exactly like my own unipolar system, with the

very same controller I've just made. The inductance of the coils varies

with the rotor position, and this is said to be a control challenge.

But the CRM type modulation I use in place of PWM adjusts cycle by

cycle anyway: the value of the inductance is accommodated by the

variable frequency cycle. The

only

difference in the motor from my unipolar is the rotor, which for axial

flux might simply

be a silicon steel

plate with cut-outs. (It should apparently be soft magnetic material:

Silicon steel, Mu-metal, the same iron powder toroids I use for the

coil cores,

or...?) Surely it wouldn't

take much to convert any of my motors to switched reluctance type. The main questions will be about torque and

efficiency, but I suspect they wouldn't be much different.

As the month wore on, I

became more and more enamored with the

idea: a rotor without magnets to fly off could tolerate much higher

RPM.s safely, and the labor and cost for the rotor would drop - the

labor to

nothing if a simple steel plate (with a correctly patterned outer edge)

was waterjet cut. It sounds like a

better, cheaper motor!

With the motor together I wanted next to start on the

motor controller, but I

became busy with other things.

On the 13th

the customer for the big Electric Weel called,

at last wanting to finish the Weel. We must be headed for the 2 year

point. His floating hydroelectricity project seems to be running on and

on

like many of

my projects. That's just as well for me since I've had so little time

to spare for the Weel. But it sounds like the vessel and mechanism is

nearing completion.

On the 13th

the customer for the big Electric Weel called,

at last wanting to finish the Weel. We must be headed for the 2 year

point. His floating hydroelectricity project seems to be running on and

on

like many of

my projects. That's just as well for me since I've had so little time

to spare for the Weel. But it sounds like the vessel and mechanism is

nearing completion.

He came over and drilled the holes and we assembled the

stator side. We decided to use #10-24 stainless steel bolts (AKA

'machine screws') on the inside area (which is farther from the

magnets) and the rim area, using 1/4" nylon bolts only for the coil

centers where metal would be magnetically heated the most.

The unit

except the rotor weighed only 58 pounds! With the

lexan rotor (and 32 magnets), hopefully it'll be around 80 pounds

complete. I think a

low

RPM unit probably good for almost 20KW continuous would

usually want a hoist to lift it.

When I wrote the G-Code for routing out the lexan rotor I

came up with a new idea. The 26" O.D. steel ring around the outside

holds the magnets, and I sized the lexan the exact inside diameter of

that ring. Thus it would fit flush with the metal. The slots for the

magnet strapping would be CNC router cut through the lexan (much easier

than through steel!), and the epoxied straps would wrap around both

lexan and steel (and the magnets - plus maybe some extra straps) to

bond everything together. The strong outer steel ring should guarantee

a strong rotor good for higher RPM.s. (Which means only maybe 750

RPM for such a huge diameter machine.)

A couple of days later I wrote G-Code for, and made, 3

lexan reinforcing rings, to be glued to the main ring. With two keys on

opposite sides of the shaft, running across an inch of lexan, I hope

for the sort of strength that a thinner piece of metal with one key

would provide.

It occurs to me that I myself have two skinny 12',

lightweight, foam sandwich 'catamaran' floats that I made long ago as

part of a trimaran boat idea. (The center hull is long gone.)

Unfortunately they're rather small to use as a catamaran (tho my

brother and I once put a sail on it and took it out on a lake). With

these I could probably make a small version of a floating hydro power

plant myself. But I don't have river or stream front any more than I

have ocean front for doing wave power, so I wouldn't know where to

install it and would have a hard time deriving any benefit myself.

I met someone who was connected with someone reputed to

have created some special magnetic shielding material, supposedly

useful for

making a magnet motor. This was interesting because the keys to making

a magnet motor work are getting intense flux at the right point, and

(presumably) creating an asymmetry of strength interaction as seen by

the rotor between the forward propulsion and the reverse propulsion

magnetic fields. Both of these would seem to be strongly influenced by

magnetic shielding factors.

There was a video clip with a stator and a rotor magnet,

showing that the rotor would turn strongly in one direction as it

passed the stator magnet, with seemingly very little reverse force at

any point in the rotation. But it didn't do a full circle. The

construction was amateur and the magnets were only held down with cable

ties, so they shifted around as they crossed paths. The originator

doesn't want to disclose the material without a non-disclosure

agreement... and he's also in hospital. (Hmm... He had a heart attack

returning from a trip to promote a material for free energy. Something

untoward happens to yet another free energy inventor... is that

suspicious, or just a coincidence?) I asked if they knew what the

material was, thinking of one elderly person who had made something

unusual and maybe useful which

he demonstrated in a video, and then died without revealing his

secret. "More or less." Perhaps if it turns out to be anything more

special than Mu-metal, I'll be told some day. Certainly there are also

interesting materials like bismuth that are diamagnetic and might

deflect a magnetic field. Bismuth will in fact float over top of

supermagnets.

The Weel rotor, with

outer steel

ring, lexan center with slots for the magnet

straps, and reinforcing pieces for the center area and shaft connection.

It seemed I

was diverted every day by something or other

more pressing than the major energy projects, aside from the sudden

productive day working on the Weel - which was itself that day's

diversion from the unipolar motor. By the 16th, I felt like I was just

treading water. After spending the day with my two brothers (one of

whom had just arrived from Toronto for a visit and the other who was in

hospital), and desperate to get something underway, I started

shortly before 10PM to cut the lexan rotor for the big Weel motor and

worked into the wee hours. I got it done. The next day I cut off the

welds holding the metal outer ring for the

magnets from the previous heavy steel rotor piece, ground off the weld

crap, and sanded down the lexan to fit inside that ring by some

millimeters. (It was somehow a bit too big by in spite of careful

measurements and

calculations.) On the 18th or so I cut some smaller diameter pieces to

reinforce the center axle area, to be glued to the main rotor piece.

It seemed I

was diverted every day by something or other

more pressing than the major energy projects, aside from the sudden

productive day working on the Weel - which was itself that day's

diversion from the unipolar motor. By the 16th, I felt like I was just

treading water. After spending the day with my two brothers (one of

whom had just arrived from Toronto for a visit and the other who was in

hospital), and desperate to get something underway, I started

shortly before 10PM to cut the lexan rotor for the big Weel motor and

worked into the wee hours. I got it done. The next day I cut off the

welds holding the metal outer ring for the

magnets from the previous heavy steel rotor piece, ground off the weld

crap, and sanded down the lexan to fit inside that ring by some

millimeters. (It was somehow a bit too big by in spite of careful

measurements and

calculations.) On the 18th or so I cut some smaller diameter pieces to

reinforce the center axle area, to be glued to the main rotor piece.

After that, it needs some sort of jig for placing the 32

magnets in exact positions on the rotor ring. Then the rotor can be

made and installed, and the first Electric Weel will (at last!) be

complete.

With the big cutback and year late refund for 2013 from

Canada Revenue (still not received), I spent a lot of time in February

on "financial affairs" of one description or another. I traded last

summer's high rate house mortgage for a CHIP reverse mortgage, for

those over 55, where they assume you'll die or sell the house in a

foreseeable future, and that the dollar value of the home will rise

over time. In this mortgage, a value up to somewhat less than 1/2 the

home's value may be borrowed (depending on age), and the interest each

month is added to the amount owed instead of being paid off monthly.

Indeed, one can even get money monthly until the limit is reached, and

I'm taking a modest amount to help stay afloat. CHIP never forecloses,

foreseeing getting all their money plus the interest due 99% of the

time, perhaps taking a small loss of interest very occasionally if an

owner should live for a very long time and values fail to rise.

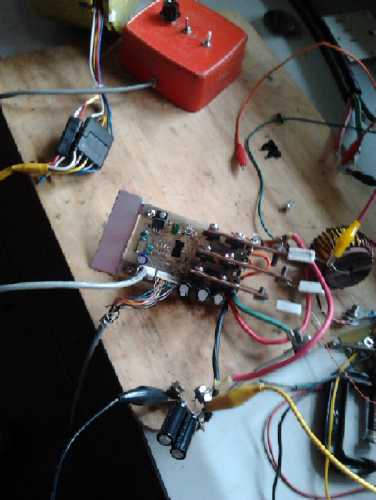

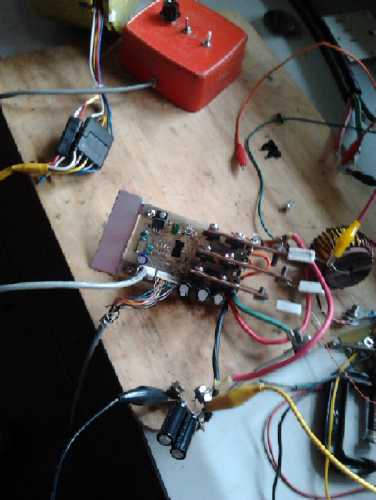

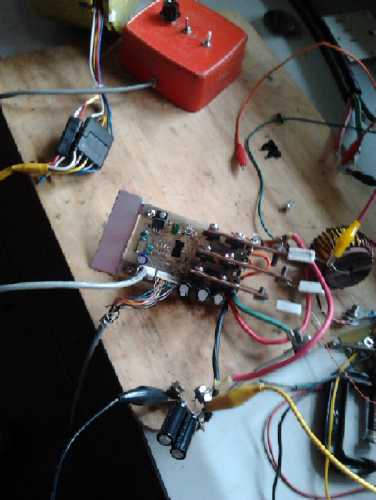

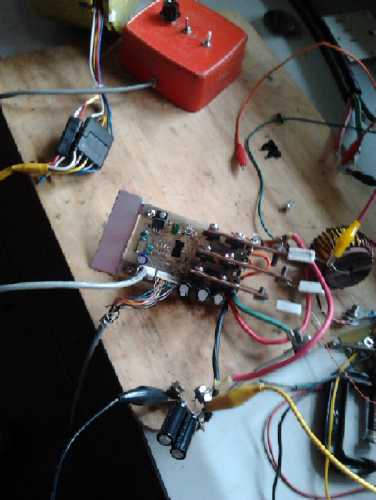

Unipolar Motor & Controller testing.

(Bottom of

motor, on table within reach, is just visible at top)

From the 20th on in bits of time I found, I put the unipolar motor and

controller together and began to troubleshoot and test it. I wired the

controller out of its box so I could measure voltages and make any

needed changes.

From the 20th on in bits of time I found, I put the unipolar motor and

controller together and began to troubleshoot and test it. I wired the

controller out of its box so I could measure voltages and make any

needed changes.

There was a problem with the optical interrupter system.

One phototransistor wasn't matched to its LED and (as I had feared) I

had to take the motor apart and replace the pair, with new

optical parts received since the original assembly.

There were problems with the modulation system, which had

to combine CRM and PWM owing to the overcurrent signal not being

available on the MC33035 motor controller chip. I made

some changes, but I'm still not satisfied.

On March 1st (call it February 29th!) it finally ran. But

most of the 80 or so

watts seemed to be going into heating up the power transistors. I had

blown 3 before it was going, and they were still getting hot. This

behavior might (perhaps) be explained if the coils are attracting the

magnets

instead of repelling them, so the polarity needs to be verified.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Improving Systems of Governance: CampaynCentral.com

web

page

I wrote a draft letter for the newspapers about the civic

e-mail group list which I hope will become the main vehicle of

communication for civic governance discussions. In it I gave a URL to

go to "for more information". I couldn't think of much that I hadn't

already put in the letter, but I thought I'd better at least write up a

web page and put it at the URL given so people wouldn't get an error

trying to look it up. I copied the letter to the page.

Then I started to write up the web page, just a couple of

sentences saying there was no additional info so far beyond what was

said in the letter... and what I

think is a brilliant idea came to me as I wrote: "Election

Campaign Central". (That seemed too long and I made the actual

title "CampaynCentral.com".

CampaignCentral.com and most anything with the word "campaign" was

taken. Some appeared to be being held for ransom.)

Please note that the page/site doesn't exist yet at

this writing. I've only had time so far to reserve the domain name, so

you'll get an error if you try to go there.

CampaynCentral.com would be a

web site where most of the promotion for any election would be

done -

all at no cost. At first I was only thinking of civic elections, but it

should work just as well for state/province and national elections...

anywhere! It

would soon become known as the place to find information about

all

elections. As a starting point, I would divide the page into three

sections.

First, candidates for office would put up a main

introductory

video and or write-up. They would be free as to content and length. For

example they could introduce themself and state their qualifications,

and their goals and ideas of what they would like to do if elected.

The next section would be a place for public questions and

comments. In the third section the candidates (or in larger

jurisdictions perhaps their campaign representatives) would be able to

respond

by video or in text to any of the topics raised by the public that they

care to address.

The mainstream media is almost 100% delinquent in putting this sort of

essential information across to the public, so candidates become known

only in proportion to how much money they have behind them, and

elections have become corrupt, with the whole agenda controlled by the

ultra-rich. This web site should go a long way to removing the dollar

sign from election success prospects. Having the ultra-rich buy

candidates and buy elections should become impractical. Voter apathy

has become inevitable as people see how they vote usually makes no

difference to anything.

Once one candidate for office puts up a promotional video,

then, given a certain minimum amount of publicity for the site, the

other candidates wouldn't dare ignore it. Anyone not bothering to do

their video or other introduction would stand out as being an

"absentee" candidate, someone not really serious

about winning votes and the office. This will ensure universal,

'permanent' adoption of the site once it's been used in an election or

two and people are familiar with it. Promotions elsewhere and by

monetary means should become much less effective.

A follow-up idea is to get the world's open source

programming community behind these projects instead of trying to do

everything myself. As readers of this newsletter know, I already have

projects to from here to yin-yang. Someone suggested I could do it all

with "JOOMLA" web page environment, which I haven't had a chance to

look at yet. But that doesn't fit in very well with "offloading" the

project!

The descriptive page for more information is here:

www.saers.com/recorder/craig/cities.html

Airless World Life in the Solar System

The airless worlds orbiting Jupiter and Saturn seem so

cold and distant and well... airless... to us on this planet that the

mind simply rebels at any thought that anything could possibly live on

them. And when one does think of life on other worlds, one thinks of

animals, or maybe microbes. But plant life, the "forest canopy", is

what will

be observed from space.

Spectral readings in specific locations on various of

these

worlds are described as showing

mainly 'polycyclic aromatic hydrocarbons', with carbon dioxide in a

'stretched' or 'energized' state. And descriptions such as

"fluffy" and "very fluffy" have been derived from analysis of diurnal

temperatures.

It has for some years now been apparent to me that these

things, however impossible it seems, can hardly mean anything but that

there's some sort of strange alien

vegetation growing on the

surface. (Another scientist's skeptical writing about the 'fluffy'

layer actually reinforced the picture. He said (not an exact quote):

'Sunlight would have penetrate the proposed fluffy layer in order to

produce the

results as described.' Thus it sounds more and more like vegetation.)

But how did it spread from world to world?

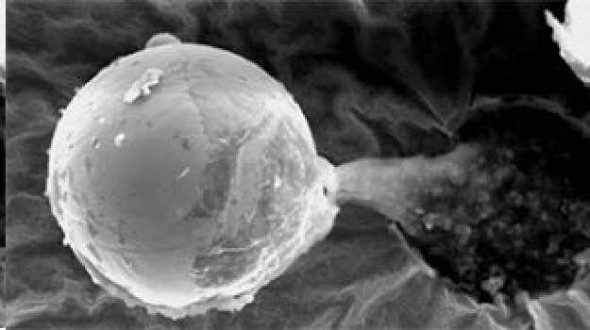

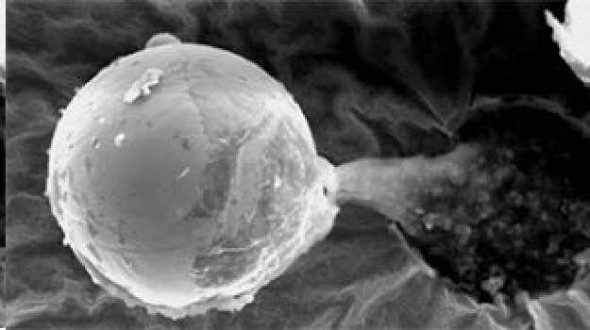

This month two

new findings have hit my eye. The first is

the collection of a what was described as an alien "seed" by a

balloon sent 27 miles above the Earth's surface. It left a crater

in the sample collector, indicating it must have come in from space at

a high rate of speed rather than having a terrestrial origin. (One of

several links:

This month two

new findings have hit my eye. The first is

the collection of a what was described as an alien "seed" by a

balloon sent 27 miles above the Earth's surface. It left a crater

in the sample collector, indicating it must have come in from space at

a high rate of speed rather than having a terrestrial origin. (One of

several links:

http://www.buckingham.ac.uk/research/bcab/news)

The object was "the width of a human hair" and with a hard

"metallic" shell (but organic looking), and what might be a root or

stem coming out of a hole in one side.

My theory

of one technique for spreading of spores or seeds on airless worlds is

that the

plants would shoot them out at high speeds to fall and start to grow

elsewhere. Once such plants got transplanted from Ganymede

(...the likely guess since it's half the size of Mars and has a

magnetic field) to any tiny world, in debris kicked up by meteors,

their ejected seeds would escape the tiny gravities and start flying

all over the solar system. This seed sheds light on the specifics,

entirely in accord

with and reinforcing this theory. That anyone might find it without

going to another world was a

surprise, but the balloon experiment by believers in "panspermia"

was

searching

for

exactly

this

sort

of

thing. What a stunning success!

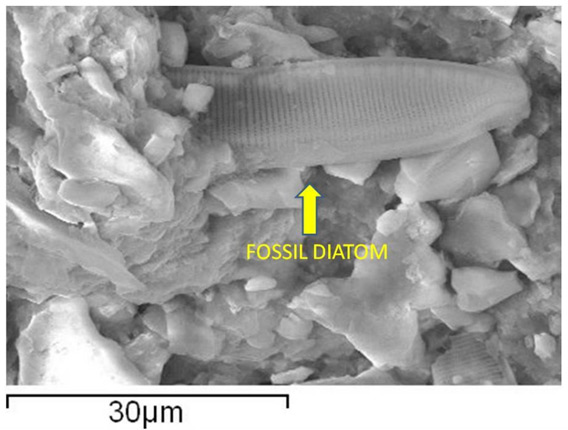

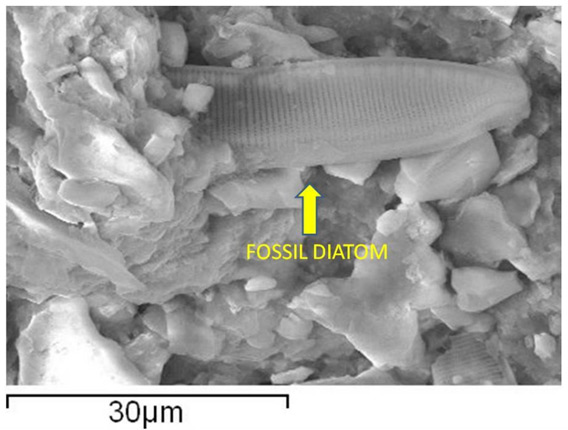

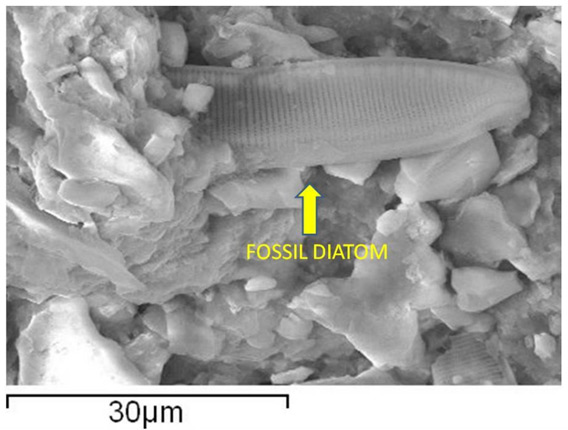

This follows intriguing findings by others in

recent years of

what appear to be microbes or diatoms, in carbonaceous chondrite

meteors,

which I

believe are composed of soil debris kicked up by larger meteors from

airless worlds that

have this same strange life, somewhat fused into a solid by passage

through Earth's atmosphere as well as heat and pressure from the

original meteor impact that kicked it into space. This same may be what

"fossilizes" the organisms. (Links: http://www.panspermia.org

/hoover.htm and http://www.usaukonline.com/latest-news/8091-second-study-finds-extra-terrestrial-fossils-in-meteor-fragment.html.

One

person, widely quoted, "debunked" the first findings, but a second

thorough university study

concluded the diatoms weren't of terrestrial origin. This too found its

detractors.

Unless my memory

is bad, there have been other meteorites (one or two) previously said

to contain "primitive (non-eukariotic) microbes" from space, but the

Sri Lankan meteor is the only one I seem to be able to find reference

to at the moment.)

SEM Electron microscopic image of a bit of the

meteor, seemingly a sample of

SEM Electron microscopic image of a bit of the

meteor, seemingly a sample of

"diatomatious earth" with a diatom (algae cell) that looks a lot like

Earthly ones.

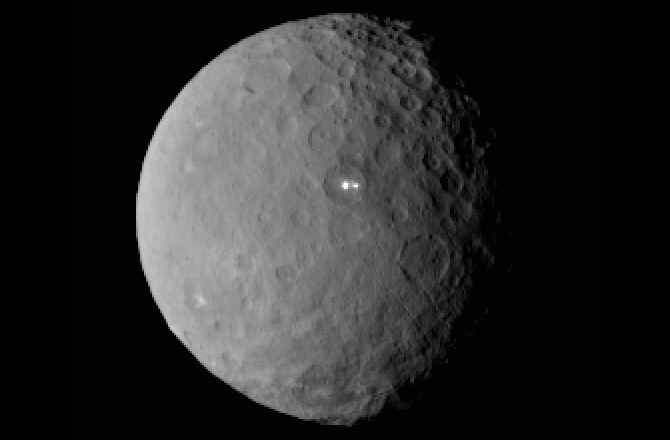

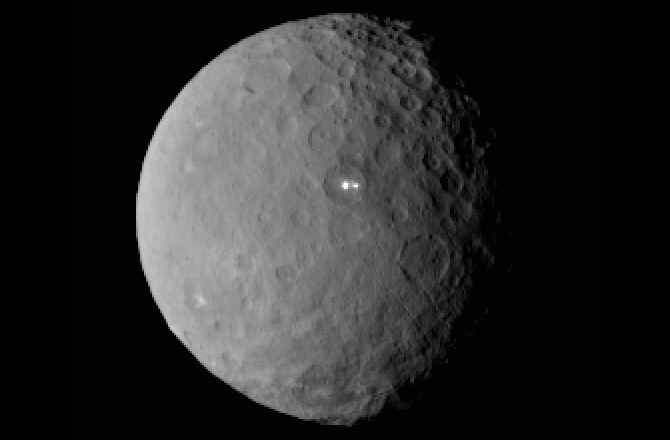

The second item is new "highest rez so far" images of Ceres

from the Dawn

spacecraft. In March 2015 Dawn is to enter orbit around Ceres, the

largest

asteroid orbiting the Sun in resonance with Jupiter. At 915Km

diameter

Ceres is about 2% of the size of Earth's moon (3476Km).

The second item is new "highest rez so far" images of Ceres

from the Dawn

spacecraft. In March 2015 Dawn is to enter orbit around Ceres, the

largest

asteroid orbiting the Sun in resonance with Jupiter. At 915Km

diameter

Ceres is about 2% of the size of Earth's moon (3476Km).

(Note: It's an

almost ubiquitous mistake to compare diameters of worlds as "sizes".

Volume - size - of

a sphere is 1/6 pi D^3, and (3476/915)^3 is a 48

to 1 volume ratio. A baseball may be, say, twice the diameter of a golf

ball, but that's 8 times as large.)

Expecting that Ceres consists primarily of water ice,

scientists anticipated a high albedo with a lot of reflected

light -

like the trailing hemisphere of Saturn's moon Iapetus. Instead,

Ceres is quite dark - like the front

hemisphere

of Iapetus.

Any plants on the trailing hemisphere of Iapetus would be

irradiated by Saturn's deadly ionizing radiation, swept around at high

speed by its magnetic field, so mainly the leading hemisphere can grow

vegetation. Ceres is far from Saturn's or Jupiter's

radiation, but evidently isn't too close to the sun for this type of

life and probably it would have decent soil. Two bright

(ice) craters similar to some bright craters on the front face of

Iapetus visually indicate

compositional similarities. On Iapetus, space

scientists estimated that for there to be so few bright craters, the

world is being resurfaced with the dark fluffy organic material in, at

most,

100,000 years, and more probably in much less time than that.

(Apparently that didn't lead to any thoughts that the fluffy organic

surface might be

composed of living

vegetation.)

Another reason for bright areas is glare ice rather than

good soil. Inner worlds of Saturn and Jupiter (Europa, Rhea, ...) are

tidally churned so that the heavier elements sink to the middle leaving

ice on the whole surface, and various bright ice extrusions are found

around many craters on the outer worlds - since water expands as it

freezes.

I have been idly wondering for some time if some of the

asteroids might be covered

with the same vegetation as Ganymede, Callisto, Iapetus and other

airless worlds of the Jupiter and Saturn systems. I couldn't think of

any good reason why not unless they were too warm. After these images I

am waiting to hear that

the

surface of Iapetus is "fluffy" and that spectral readings are of

polycyclic aromatic hydrocarbons. And that small scale surface features

such as small craters are obscured by the dark material. And I'm

wondering if the Dawn might

actually give us a tantalizing glimpse, or even a good view, of the

plant life canopy as it approaches Ceres in the coming weeks.

(One link is here: http://www.sciencedaily.com/releases/2015/02/150217111111.htm)

My most recent write-ups of these various phenomena are in

my

space "updates" web page on my site at:

http://www.saers.com/recorder/craig/

. There are also links here to my older writings, which should be read

after

the "updates" page, which illuminates and corrects some errors I made

in the

older material. (scroll down near the bottom to find the

planetary explorations links.)

Offensive Cartoon

When India put its brilliantly successful (and cheap!)

space probe "MOM" (Mars Orbiter Mission) into

Mars orbit in January, the New York Times published an article, with a

cartoon. Evidently some found the cartoon offensive, and they

apologized. Indeed, the depiction of bright western and Russian

engineers and space scientists as balding, bespectacled old slobs

lounging about some posh, decadent clubhouse is sickening. Even more

offended should be the Chinese, with manned space flights to their

credit and the only

remotely operated rover ever landed on the moon.

Leaving them them out of the picture was a real "thumb your nose" at

China, for which the Times should apologize 'till the cows come home!

Feedback on Patent Suppression

After writing about suppression of inventions by patent in

the USA "for reasons of national security" last month, one reader said

the patent

office had no mechanism or authority to suppress patents. Certain

sensitive patents in already classified areas could be withheld for a

period of time and the inventors compensated. Certainly his description

of how it worked was how it ought to work, supposedly works, and

probably would work in a rational and sane world. He thought peoples'

ideas

that energy patents

were being suppressed were paranoid.

Then another reader wrote what he had found about patent

suppression on The Orion Project, a site promoting breakthrough

energy

inventions. (http://www.theorionproject.org/en/suppressed.html)

IIRC,

The

Orion

Project

originally

was

started a few years ago to try

to fund work on such inventions. Now the web site seems to focus more

on how such technologies are being suppressed. (In fact, I seem to be

using up quite a lot of virtual paper on such subjects myself of late.)

The Orion site states:

"The U.S. Patent Office has a nine-member committee that screens

patents in order to protect “national security”.

"A hidden purpose of this committee is to also find and remove from

public access energy-related patents which could threaten the fossil

fuel and power monopolies."

There's more. Then it shows

the gag order sent to affected inventors, and penalties

which will be applied should the inventor or anyone he knows (even

including his heirs) ever talk. "SECRECY ORDER (Title 35, United States

Code (1952), sections 181-188)..." I looked this up and indeed found it

on a US patent office web site. http://www.uspto.gov/web/offices/pac/mpep/consolidated_laws.pdf

This says in officious language pretty much what I wrote of last month.

It's couched in what a friend of mine would call "weasel words".

Notably, where

the invention needs to jeopardize "national security" to be kept secret

at the top, farther down it says anything violating "national

interest". And while the duration of suppression is "for a maximum of

one year", it can be arbitrarily renewed each year. Then, compensation

is to be given to the inventor... That sounds reasonable, but

compensation starts from the time the government starts making use of

the invention. Since they won't use the energy inventions, no

compensation is ever due or paid.

The agencies which may order the invention to be kept

secret are stated as "the Atomic Energy Commission, the Secretary of

Defense, and the chief officer of any other department or agency

[as designated by the president]...)

The maximum penalty for talking is stated to be a 10,000$

fine or two

years in prison, but there was more to read than I have time for and I

wouldn't doubt it says something much harsher somewhere farther down.

The patent secrecy law is clearly intended to be wide open to whatever

interpretation

the government agents decide to put on it, without any recourse by the

inventor or anyone else involved.

The Orion site suggested patenting in Canada where there

is no [known] security committee screening applications [so far], and

only

later applying for a US patent when it's too late for USA to invoke

secrecy.

But

that's playing their game against the pros, and I expect it

would turn out badly one way or another. The person who sent me the

link and I both agreed that open

source publishing is better than patenting if knowledge is to be spread.

Precious Metals & Investing

I recently found a set of highly interesting, quite

condensed and perhaps

entertaining presentations about investing in silver, done as a

computer animation & voice series of short (~5m) "conversation"

videos on youtube by "Brother John F", called The Office Series.

I

also

thought

the

program

used

to

turn

typed

scripts

into

videos,

Text

to Movie, was very interesting.

Brother John F youtube channel: https://www.youtube.com/user/BrotherJohnF

First video in the series (of 19): https://www.youtube.com/watch?v=iX8GHFiCbaA

It's probably the most interesting "money" information

video set I've seen since Mike Maloney's Hidden Secrets of Money,

packed

with

good

information.

On a somewhat related note, on the 17th I looked at the

Kitco.com silver and gold prices. Silver had dropped overnight from

about 17.20$US/ozt to 16.20 and gold from 1235$US/ozt to 1205, after

rising

substantially in January, from 14.xx and 11xx in early December.

All over youtube one hears that gold and silver prices are

being suppressed to keep fiat paper currency from looking bad and

demonstrating how much inflation there's been in recent times. No doubt

this is true, but I suddenly realized there's a second reason - the

reason why the prices puzzlingly seem to go up and down markedly with

no evident cause. It's

a game played by big investors and banks in the stock markets... and

now with

gold and silver and bitcoin. It's said that with SLV and GLD, there's

actually only one ounce of physical bullion in stock for every 100

ounces traded "on paper" by investors and banks. And the terms for

actually

taking physical delivery of the bullion one supposedly has a claim

check

on are

impossible for small investors. So the actual metal plays only a minor

role in another big ripoff.

We've all heard the basic investment advise: "Buy low,

sell

high." But these manipulators have the money behind them to actually

cause prices to rise and fall substantially through high volumes of

strategic buying

and selling. This includes (eg) selling a huge amount (on paper) below

the

current value to an allied bank one day and buying it back at an

equally

low price the next. As prices drop, people who bought a little higher

and

planned on it going up further often start to panic and sell. A

rapid

drop may even trigger automatic "sell" orders in trading computers.

People who bought on margin (borrowed money) may be forced to sell by

the lender (which may be the same banks that do the manipulating). A

few may have

bought too much (again, expecting it to go up) and now need cash. (In

the case of stocks, many investors are tricked into thinking somebody

with inside information knows something bad about the company, that the

stock may be about to become worthless, and they panic and sell. Some

bitcoin holders might panic as well, but obviously gold and

silver are real property with an intrinsic physical value.)

Paper

futures contracts, and little bits of real gold and silver, are sold,

all at a loss. Except to the manipulators, who now do the buying at the

low price they've created. Once the purchases drop off - no more

sellers, they then raise the price again at some unpredictable time and

rate of

speed to some unpredictable level, getting peoples' hopes up, and do a

major sell-off at the

higher prices, reaping huge profits at the expense of the investors who

sold low. No one, however experienced at analyzing

"trends", can figure out or guess when the where

the prices will go next. Then they lower the prices again and start all

over

to fleece a new crowd, or perhaps many of the same crowd over again.

So the price fluctuations have almost nothing to do with

the actual metals, or with supply and demand. However, as recent record

sales of one troy ounce silver eagle (US) and silver maple leaf

(Canada) coins show, those who invest in and hold the actual metals as

a hedge against the stealthy theft of value from paper money (ie, as an

inflation fighter) or as insurance against the seemingly inevitable

coming demise of fiat currency, are only a little concerned whether

it's a little lower or higher, and they simply use the low "subsidized"

prices as

opportunity to stock up more if they can afford it. This is adversely

affecting the fleecing... er, metals trading... business. See next.

Operation Chokepoint

The US executive has bypassed congress, the legal system

and they hope the public eye with Operation Chokepoint (new:

"Operation Choke Point"), a devious and non-legal move intended

to shut down targeted types of businesses.

There is a considerable list of types. Many of them such as "escort

services", "drug paraphernalia" and scams that should already be

culpable by law and hence shouldn't exist anyway, seem designed to

deflect attention from the obvious real targets: gun and ammunition

dealers, and bullion dealers ("coin shops").

It's hardly a secret that the administration has been

trying hard to pry the guns out of the US public's hands for some

years. A little sticky point is that the US constitution guarantees

"The right to bear arms". This was specifically included, for one

thing, to allow the public to defend themselves should their government

become tyrannical.

Operation chokepoint, instead of going after the public or

gun dealers directly, puts pressure on the banks where these businesses

have their accounts, and makes life rough for them until they will

decide to close the business's account. And there are threats to the

banks against talking about the operation or explaining it to those

affected. There's no legal recourse against a decision by a bank to

close your account, but a business can't operate without a bank

account. Cash that can't be deposited would become a grand

target for thievery, and how does one order supplies without credit

cards or ability to write a cheque? Again, large sums of cash in motion

would be targeted - not only by ordinary thieves but by agents of the

same government that would start an "operation chokepoint" in the first

place.

As far as bullion dealers (see "precious metals" topics

above), if one can shut them down, one can keep the prices of gold and

silver set to any arbitrary low level, once people can't actually buy

any to finish exhausting the dwindling reserves.

Apparently after being exposed by Mike Maloney on youtube,

the Wikipedia article about it was changed to say that Operation

Chokepoint

has been terminated, but as Maloney says, when the light is shone on

them, the cockroaches crawl under a log, only to reappear once the

light has passed. As of the 27th it appears the article has been

changed again and renamed from Operation Chokepoint to Operation

Choke

Point, perhaps in order that the links given to it won't work.

No More Wars!

As politicians and corporate leaders push an agenda of hegemony over

the world, and nations and peoples of far-off lands increasingly resist

the ever increasing, disruptive and deadly interference in their

affairs, let us remember how they convince us by ongoing repetition of

baseless accusations (remember "Iraq has weapons of mass destruction"?)

that their "fears" must be real and somehow justify militarizing and

invading

foreign lands. (A Pakistani lady on youtube said "America is afraid of

its own shadow!")

"A lie, repeated often enough, will be believed." - Joseph

Goebbels(sp?), propaganda minister for Nazi Germany.

Would "Iraq is selling oil for Euros instead of

Dollars!" have rallied the American public to support an invasion?

We too can all state our demands for an end to militarism

ad

nauseum, to remind those in charge that we can see via the internet and

alternative media what's happening, and that no one wins in wars.

Certainly not the peoples of either the aggressor or the invaded, who

are impoverished, displaced or killed, and stripped of their rights and

liberties. Bankers and arms dealers get rich, but only in a shallow

material sense to the detriment and peril of their

own souls. The horrific possibility of destroying all mankind can't be

overlooked, but alarmingly likely is long-lasting environmental

devastation making vast portions of the planet uninhabitable for

decades, or hundreds or even thousands of years, and destroying much

quality of life most everywhere for many generations.

With viewership of mainstream "entertainment" or

"propaganda" news programs dropping and dropping as more and more

people either get the real news on line or simply find nothing of value

in the "distraction" news stories, recently US officials have

authorized actual state

"propaganda", and are calling for a 700 million dollar budget "to

counter RT" (RT.com). The total budget for RT, according to RT, is

about 230 million US dollars. Several news shows on youtube subsist on

donations or specific sponsors (eg, bullion dealers). Apparently it

costs far more to lie than to just tell about things the way you see

them.

The impetus for war needs to be replaced by global trade

and industrial competition, and fair play. We are all one people, and

we all want mostly the same things. "We all drink the same water. We

all breathe the same air." - John F. Kennedy

What more can be said about some of the above topics? Only that

governments that continually put corrupt vested interests ahead of the

public interest kill social and technical progress, and are bound to

bring the civilizations they lead to grief

eventually.

That "eventually" draws near. When it arrives, the next

generation of idealists must be so practical as to find means to defend

and protect the new, more idealistic civilization they create, from the

many

weak and unscrupulous elements who seek out holes in the defenses in

order to take unfair advantage of the productive and the provident

without contributing themselves.

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers

- Preliminary Ni-Mn, Ni-Ni Battery Making book

Products Catalog:

- Electric Hubcap 7.2 KW BLDC Pancake Motor Kit

- Electric

Caik 4.8 KW BLDC Pancake Motor Kit

- NiMH Handy Battery Sticks, 12v battery trays & Dry

Cells (cheapest NiMH

prices in Victoria BC)

- LED Light Fixtures

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

Daily

Log

(time accounting, mainly for CRA - SR & ED assessment purposes)

1-5th: Finished January newsletter/report (#84)

6th: Installed new lead-acid battery in RX7. "Shrank" unipolar motor

rotor cover bolt holes to "threaded" size by filling in with epoxy

resin and

PP cloth.

7th: Added 5 nylon bolts to stator side.

8th: Crimped lugs onto motor heavy wires, checked fit of connections to

controller, checked installed optics.

9th-12th: Mostly busy with other things (especially CRA

demands/paperwork)

13: Worked on Electric Weel generator with customer who wants it for

hydro power. Wrote G-Code for making rotor.

16: Revised G-Code and cut lightweight lexan rotor for Weel

motor/generator with CNC router.

17: Cut out metal ring & fit it to lexan rotor piece for Weel.

18:

19: Cut lexan reinforcement pieces for the Weel rotor.

20: Hooked up unipolar motor to the controller and did some testing.

Disassembled motor owing to problem with an optical rotor position

sensor.

21: Replaced optical components & rewired temperature sensor (wrong

pin of plug). Reassembled motor.

22: Sunday!

23: Tried to run motor. Found problems - troubleshooting.

24: (working on my finances)

25: "

26: Purchased pond liner and cleared ground for pool for aquaponics.

Repaired motor controller (blown transistors)

27: Ran tests on unipolar motor and controller. Possibly figured out

long-time

problem with my regular bipolar BLDC motor controllers.

28: Redesign & rewiring of PWM/CRM control circuits.

March 1: Finished changes. Ran motor. (Some problems remain.)

March 1 to 2: Editing this newsletter of February's work.

Electric Hubcap Motor Systems - Electric Transport

Electric Caik

Unipolar BLDC Motor

Unipolar Electric Caik motor from stator side.

Unipolar Electric Caik motor from stator side.

Nylon bolts to clamp it together won't get warm electromagnetically.

(Hopefully the bearing flange is too far from the rotor magnets to be

much affected.)

As explained last

issue, the bolt holes for the rotor side were somehow too large. The

bolts slid in instead of threading in. On the 6th I folded

a cut strip of PP cloth over the end of each #10-24 waxed threaded rod,

painted it with epoxy, dripped a bit more epoxy into the hole, and

stuffed the rod with cloth into each of the 6 holes, going down at

least 2" and in fact right through to the stator compartment with most

of them. This seems to be another advantage to the molded PP-epoxy body

- to be

able to modify it later by either subtraction or addition of material,

which would also apply to stripped threads.

It was quite tedious turning out the threaded rods with

visegrips, and almost as bad putting in the nylon machine

screws with a slot screwdriver. It's a good reminder why square,

hexagonal and "X" screw heads were invented and are almost universally

used. With nylon, you take what you can get, and that's slot heads

because they're the least likely to strip. But I finally tried a slot

bit in the drill and found that with care it worked well enough and

saved a lot of wrist twisting.

Then I crimped (and soldered) connection lugs on the ends

of the 4 heavy wires. The motor was at last complete. As with the LED

lights, I must remark that unless I can greatly speed up the

manufacturing, the motors would have to command an exceptionally high

price if I made them for sale. However, a do-it yourself kit might work

out.

On the 9th I checked the installed optics again. With 47K

ohm resistors pulling up the phototransistor outputs (to 12v) it worked

great. With 22K two outputs were okay but one wouldn't pull down to

full 'on'. Looking at the MC33035 it seemed quite marginal - the specs

were vague with wide margins from 'min' to 'max', but the typical load

was somewhere between my 22K.s and 47K.s. I might or might not have

trouble

with the prototype's sensor system. (I did.)

With the motor

magnetically cogging at 12 positions per

rotation, each sensor was low (light) at one cogging spot then high (no

light) for two cogging spots. Somehow this seemed inexplicable to my

brain when the slot sections are the same width as the wall sections

and the cogging is (surely!) at even points in the rotation. But there

are 8 slot and wall pairs and 12 cog points, so the cogging obviously

occurs in

the middle of each slot and near both ends of each wall.

With the motor

magnetically cogging at 12 positions per

rotation, each sensor was low (light) at one cogging spot then high (no

light) for two cogging spots. Somehow this seemed inexplicable to my

brain when the slot sections are the same width as the wall sections

and the cogging is (surely!) at even points in the rotation. But there

are 8 slot and wall pairs and 12 cog points, so the cogging obviously

occurs in

the middle of each slot and near both ends of each wall.

Since the cogging was pretty strong as usual, and since

part of the idea of the unipolar motor was that the natural attraction

of the magnets to the coil core iron [iron powder] was used, I

contrived a way to put the torque wrench onto the motor shaft. It's

hard to read low torques when the smallest divisions on the wrench are

5 foot-pounds, but it looked like somewhere between 1 and 2 foot-pounds

of purely magnetic attractive force. Pretty small compared to the

electrical part with 50 or 100 amps going in.

Back to the controller!

Unipolar

('monopolar',

'homopolar') BLDC Motor Controller

Owing to many

competing attractions and problems taking up

my time, I didn't get the motor and controller hooked together until

the

20th. I decided to run the controller board out of its box, where I

could access it for voltage readings and any needed changes. My first

check after ensuring nothing was smoking was the optics.

As I had earlier feared, two of the optical pairs worked fine, but the

third phase couldn't drive the signal low, only down to 2.5V. Already

the motor had to come apart!

Owing to many

competing attractions and problems taking up

my time, I didn't get the motor and controller hooked together until

the

20th. I decided to run the controller board out of its box, where I

could access it for voltage readings and any needed changes. My first

check after ensuring nothing was smoking was the optics.

As I had earlier feared, two of the optical pairs worked fine, but the

third phase couldn't drive the signal low, only down to 2.5V. Already

the motor had to come apart!

I had hoped one would be able to remove the circuit board

without disassembling the stator compartment, but I hadn't reckoned on

the rubber connection plugs coming out from the board to the side of

the motor.

There was no way to pull them through to the middle area, and even less

way to put them back in if they did come out. Sigh! I took out all the

screws and pulled it apart. It occurred to me

that the new optical interrupters, tho identical in spacing to my

board's layout, were too tall to fit (a dimension I hadn't concerned

myself with when I ordered them), but that I could probably cut them

down or use the inner components. I hacked one apart, and sure enough,

the LED and phototransistor were much the same as the ones I had taken

from old computer mice. And of course, they would be a matched pair. By

the next afternoon I had them installed, tested with the controller

outside the motor, and then the motor together again. Another item that

came up was that the 12 volt supply was way below 12 volts unless the

main motor voltage supply was around double that. Most of them

previously have worked with the supply down at 15 volts. Apparently the

base resistor of the pass transistor needed to be much lower than 39K

ohms with the low Vce-sat 2SC5101 pass transistor.

On the 23rd I tried some live tests on the motor, hooking

up one coil. Altho the power supply registered several amps when the

control was turned on, no thrust or rotation was evident. Then a power

MOSFET burned out. It seemed strange that this should happen at under

10 amps with paralleled transistors each rated for 120 amps and even

more peak amps. I tried a different phase and got the same result. The

main thing I could think of was the the sense resistor was quite large,

since I was limiting current so much, and that the mosfets' source

voltages were rising to, say over 5 volts and with the gates at 12

volts, they only had 7 or less, and the transistors were operating in a

linear region instead of on-off switching. Having this effect blow them

still seemed out of proportion to the currents and watts involved, and

contrary to the sense resistor circuit. And

why were all the transistors equally a little warm?

A couple of days later (25th) I came up with another

theory: It was intended that the power spikes when the coils were shut

off would discharge their power back into the battery. But I was

running it

from a lab power supply. If its voltage was raised above the selected

output voltage, it wouldn't absorb it, it would just let it rise. Thus,

the turn-off spikes could exceed the (60 volt) voltage rating of the

MOSFET.s and potentially blow them. I looked up the 'avalanche' specs

of the MOSFET.s and found currents of less than ten amps being above

the limit depending on pulse width. The fix would be a capacitor across

the 'battery' supply from the lab power supply to absorb the spike

current and prevent serious voltage rise. Luckily I hadn't had a chance

to try again in the meantime, since I'd probably have just blown more

transistors.

I replaced the blown transistors on the 26th. I put in

some heatsink grease on all of them, just in case there wasn't a good

thermal connection between the transistors and the copper bars. (As

expected, the closely spaced nuts and bolts holding the bars to the

transistors were somewhat frustrating to disassemble and assemble.) On

the 27th I added two 270uF, 100V capacitors and I replaced the thin

wire "shunt resistor" with a 2 milliohm piece of #6 AWG nickel-brass

wire. I tried again to power up one of the motor coils. It went

smoothly up to about 2 amps, then "avalanched"(?) up to 10 amps, and

wouldn't come down again except to below 2. It was the same regardless

of which coil I tried, in turn. Only in one position did I feel a very

slight magnetic force. It was so faint I wouldn't even swear which

direction it was trying to turn. I had inserted a 1.2 ohm, 5 watt

resistor in each phase to limit currents to non-destructive levels, but

these soon started to smell hot and one burned out, so I bypassed

them with the test clip leeds.

With the supply at 14.5 volts, the current would

'avalanche' to 4 amps. A very slight turning force could be detected

and I tried all combos:

Switch

|

Controller

Phase

|

Motor

Wire

|

Force

|

Forward

|

A

|

Black

|

CW

|

|

|

Green

|

-

|

|

|

White

|

CCW

|

|

B

|

Bk

|

CCW

|

|

|

Gn

|

CW

|

|

|

Wh

|

-

|

|

C

|

Bk

|

-

|

|

|

Gn

|

CCW

|

|

|

Wh

|

CW

|

Reverse

|

A

|

Bk

|

-

|

|

|

Gn

|

CCW

|

|

|

Wh

|

CW

|

|

B

|

Bk

|

CW

|

|

|

Gn

|

-*

|

|

|

Wh

|

CCW*

|

|

C

|

Bk

|

CCW

|

|

|

Gn

|

CW

|

|

|

Wh

|

-

|

When testing phase B I tried turning the voltage up from

14.5 to 18 volts, expecting to feel stronger force. I had already

turned up the current limiting, as it wasn't reaching the limit anyway.

The current pinned the needle at 12 amps and phase B shorted - another

transistor blown! The phase B output copper bar was warm. (Here the 1.2

ohm resistors might have been valuable.) It would seem

a lot depends on the motor's supply voltage. (The two "*"s in the table

indicate the expected readings, since I couldn't do the last two tests.)

But at least, with no floating high-side voltages, and

perhaps since I was keeping the supply under 20 volts, the motor

controller chip wasn't being affected. Replacing a surface mount chip

is much more time consuming than just a transistor.

Note that only in one configuration (A-Wh, B-Bk, C-Gn)

will the motor run both directions properly, with "forward" being

counterclockwise and "reverse" being clockwise. If "forward" is chosen

as clockwise and the wires connected accordingly (Bk, Gn, Wh), it looks

like it'll run fine that way - but it won't run the other

way. This is similar to bipolar BLDC, where it runs more or less okay

in one direction but crappy and with high current drain in the other.

Except it appears the unipolar type won't run at all in the 'wrong'

direction, but will probably run just fine the 'right' way.

Before it'd run I wanted to figure out what's

blowing the transistors. I looked at the control circuits and I think I

made a mistake. I wanted to implement constant torque "current ramp

modulation" (CRM), but on the MC33035 the output of the current limit

comparator isn't available on a pin as it is on the IR2133. I set the

PWM to "on" and made the current sense variable... but the current

sense in the MC33035 shuts off the PWM, so there's two contradictory

things happening.

Instead of straight CRM, I changed the circuitry to do a

modified CRM/PWM where the cycle starts as a regular PWM cycle, but

when it's terminated by overcurrent (sensed when all three drive

outputs are

'off', since there's no access to the overcurrent signal), the

components then activated will finish charging the oscillator timing

capacitor

much faster, causing the cycle to terminate rapidly, instead of at its

own leisurely pace with commensurate loss of torque. This still allows

a far lower PWM frequency (eg, 1KHz or lower instead of 16KHz) with

reduced ultrasonic noise irritation and switching losses. Unfortunately

the current limit has to be fixed at the maximum value, eg 200 amps,

since it would be hard to adjust both the PWM and the CRM at the same

time. I can't say I like this much.

I finished wiring this up on the morning of March first.

After testing and finding a couple of bad connections, I hooked up one

phase to a coil. Currents rose only somewhat more smoothly, but I had

them limited to about 5 amps. Then I hooked all three coils to the

correct wires, turned it up to a couple of amps, and spun the motor by

hand. It slowed down much faster in one direction than the other. I

turned up the voltage to 18 and the control to four or five amps and

tried again, and it kept turning. Both directions worked. The unipolar

motor runs!

However the power transistors were strangely getting quite

warm even at this low power, and the motor didn't seem to have much

"oompf" for 70-90 watts of power in. Apparently most of the power is

somehow being used to heat the transistors.

I opened the rotor end of the motor and pulled out the

rotor to access the slotted drum. I reversed the magnet sensor shaft

rotation adjustment, exchanging the slots and solids. This changed the

sensor readings at the cogging points from two high and one low to one

high and two low, but except exchanging forward and reverse, it didn't

change the operation.

So there's more to do, and I'm probably missing something.

I'll probably want to be able to set the controller output by CRM

rather than by PWM (with CRM set to 200 amps) somehow. (Fix the PWM at

90%

- instead of 100% - and then adjust power by the current sensing?)

Later it occurred to me the behaviour might be explained

(maybe!)

if the coils are attracting the magnets instead of repelling them, so

that should be checked again. I did check coil polarity before wiring

the motor since getting it wrong would mean rewiring the stator, but a

lot of building went on after that.

Further trials will have to await the next newsletter. At

least

I got it to run!

Turquoise Bipolar BLDC Motor Controller Problem Identified?

Readers will know that I've had trouble with my

controllers blowing transistors at higher currents, which problem I

haven't managed to solve. In working out the

unipolar controller, I suddenly realized a mistake I was making. Bypass

capacitors are used on each transistor pair. I was soldering the

capacitors right to the source of one and the drain of the other

mosfet. That seemed the most direct and shortest path. But the sources

aren't connected directly to ground, they go through the shunt

resistance to ground. As the coil current rises,

the

voltage across the shunt resistor should rise to match the current, and

end the cycle at the cutoff current.

But the voltage across the shunt can only rise as it pulls

voltage off the bypass capacitors, since they are on the wrong side.

Thus, the indication of high current is delayed. Perhaps at higher

currents it's delayed long enough to burn out transistors before the

cycle shuts off? On the other hand, the capacitors will continue to

charge and draw current while the transistors are off, leading to

falsely high readings at other times, which may somewhat negate the

problem. But putting the capacitors direct to ground is certainly

something to

try out.

Mazda RX7 New

Battery/140 volts notes

On the 6th I installed the new 11th battery in the Mazda

RX7 EV, bringing it up to 140 nominal volts. Hopefully it'd be back to

at least 7 miles range again. On the 9th, quite a warm day, I drove 3.4

miles using just 252 WH per mile (1.8 AH/mile @140v) instead of about

300 WH or more (2.3+ AH/mile @128v).

That's over 15% less energy per distance, where

theoretically there'd be a 9% drop in amp-hours compensating for the 9%

rise in voltage and watts would be the same. One must conclude that

using a lower voltage reduces efficiency somewhere. Where might that be

but in the motor itself, which is made for 144 volts? That's on top of

reduced currents putting less strain on the batteries and giving them

effectively more amp-hours, a separate range increasing factor.

One might be tempted to want to add those last 4 volts to

bring it to 144 nominal volts. The NiMH batteries, of which there are

5, put out around 13 volts instead of 12 when well charged, so it

should already have it. But all the batteries drop in voltage under

load on hills or accelerating. One suspects that with 150 amp-hour or

higher batteries instead of 100, for better current drive as well as

the capacity, the range of the car would be much more useful, even

doubled. But I'd have to pretty much start over with new arrangements.

The next day a 4.6 mile drive had more stop-and-go and

used 280 WH/mile, but it probably still took ~15% less energy than a

similar drive with the 128 volts.

The next day a more "liberal" 6.1 mile drive with somewhat

higher speeds and some faster accelerations used 308 WH/mile and

brought that weaker NiMH battery down below 10.0 volts at one point

nearing home. I decided I should do something about it. I'd noticed

that there was room for a third "quintos" pack with the two put in a

month ago, and I decided to bring the weak battery up to 110 amp-hours

with an extra one. While I was putting it in I noticed an end had

popped off one of the main long tubes. I pushed it back (about 1/8")

with a screwdriver and applied some methylene chloride to 'glue' it

back on. So! At least one of the tubes surely had no connection,

bringing it down originally to 80 AH. That would explain why it was

weaker. Maybe now it'll be the strongest one?

Two lessons may be taken:

1. There's no way to tell if all the cells in the tubes are making

connection. I

don't trust multiple tubes of batteries as I've been making them, and

have wanted to disassemble them and solder them together.

2. Don't connect batteries with bars or heavy straps where there's

movement and vibration. Use stranded wire that will flex and not put a

strain on the connections.

But now I'm thinking that maybe with some sort of spring on one end

(instead of gluing both ends) they could be made more reliable. Maybe

an external spring? Or one around the inside portion of the terminal

bolt? (The usual flashlight tube internal coil springs have inductance,

most undesirable in high current, switching circuits.)

As it is, that battery still drops voltage most under

load, but now it often comes back to a slightly higher voltage than its

"twin" instead of the same or slightly lower. The problem indeed seems

to be current capacity (gradual loss of electrolyte?) rather than

energy storage capacity.

Towards the end of the month I used the RX7 for a number of trips, and

everything seemed pretty good... except the clutch cylinder started

sticking again, and the lack of clutch travel made shifting while in

motion quite difficult. I've already disassembled and repaired that

clutch cylinder once! Is everything going to start quitting again?

Electric

Weel

Motor

(Generator)

The last major items for this machine were the lexan rotor

plate and a magnet placement jig (CNC design & G-Code for

both). Lexan is much lighter than steel, but it would have a steel ring

around the outside to carry the magnetic fields.

But the person I bought the tilapia fish off of also was

doing some interesting electrical things. And he had two big surplus PM

elevator

motors of very low RPM and something like 12 and 20 HP, with no

cogging, which he showed

me in December or January. Those seemed ideal for the floating hydro

project, so I mentioned them to the developer. If that project used one

of those, he wouldn't need the Electric Weel. (If that was the case,

I'd

probably make it into a unipolar motor instead of a generator.)

Side view of motor without rotor, shaft and rotor end cover.

Coils remain to be wired and the ends of the nylon bolts were later cut

off.

Inner and outer (stainless steel) body clamping bolts remain to be

installed.

View from the stator end.

On the 13th the developer called. He had finally checked

out the elevator motors. They seemed

very suitable, but the present owner, who works for the elevator

company, didn't like the idea of them being used

"commercially" (whatever that means for an R & D prototype!), and

anyway new ones were too costly to consider if the hydro units were to

be commercialized. So he wanted to finish the

Weel.

He came over and drilled the holes and we assembled the

stator side.

As there's lots of room inside and excellent access, we just left the

wires sticking in

toward the middle for wiring later. The rim was a bit thin around the

outside and we decided to use #10-24 stainless steel bolts on the

inside area (which is farther from the magnets) and the rim area, using

1/4" nylon bolts only for the coil centers where metal would be

magnetically heated the most. Perhaps the hypothetical next one should

have 3 or 4 layers of strapping/webbing epoxied around the outside

instead of 2, to ensure sufficient substance for nylon 1/4" bolts.

With the rotor cover on and the bearings and (15" long,

1.75") shaft - everything

except the rotor - the unit weighed only 58 pounds! With the lexan

rotor, hopefully it'll be only about 80 pounds complete. For a low RPM

unit

probably good for almost 20KW continuous, one would usually expect to

need a hoist to lift it.

Lexan Rotor

The project

having become active again, I came up with a

new idea. The 26" O.D.

steel ring around the outside holds the magnets, and instead of making

the lexan piece 26" as well, I made it the exact inside

diameter of the

ring. Thus it would fit flush with the metal. The slots for the magnet

strapping would be [were] router cut through the lexan, and the epoxied

straps

would wrap around both lexan and steel (and the magnets) to bond

everything together. The strong outer steel ring should ensure no

catastrophic failure of the plastic owing to centrifugal forces

twisting the magnets.

The project

having become active again, I came up with a

new idea. The 26" O.D.

steel ring around the outside holds the magnets, and instead of making

the lexan piece 26" as well, I made it the exact inside

diameter of the

ring. Thus it would fit flush with the metal. The slots for the magnet

strapping would be [were] router cut through the lexan, and the epoxied

straps

would wrap around both lexan and steel (and the magnets) to bond

everything together. The strong outer steel ring should ensure no

catastrophic failure of the plastic owing to centrifugal forces

twisting the magnets.

I wrote some the G-Code for

routing out the lexan rotor and its slots in the afternoon, and more in

the evening. Not liking the closeness of the slots to each other and

the resulting thin bridges of lexan between them on the display, I

re-did it with

shorter slots, and then again, still shorter. The first slots would

easily accommodate 1.5" wide strapping. The final ones were only 1.1"

long... plus the 1/4" router bit diameter: 1.35". One just might still

squeeze 1.5" wide PP strapping through them

- I'll see when I try it. Aside from extra strength, if wider strapping

'droops' over the edges of the magnets, 1/4" on each side, then even if

a magnet actually came loose, it would theoretically have nowhere to go.

Late in the evening of the 16th I readied the lexan and

set up the CNC router. I adjusted the program to cut the outer diameter

last, so the screws at the outside corners holding the piece in place

wouldn't be cut away until the final cut. It cut well, tho it didn't

quite go through the plastic in some areas, so I had to lower the

router bit a bit and redo it.

On the 17th I dealt with the outer ring of 3/16" steel,

still spot welded to the original rotor plate of 1/8" steel. I used a

zip disk/angle grinder and cut away the 18 or so welds, and then ground

off the rough weld protrusions into the center of the ring. Somehow the

lexan was 3 or 4 millimeters too large in diameter, and I sanded off

all around the outside on the belt sander, twice, until it fit nicely

into the center of the ring.

On the 19th I cut three lexan reinforcing pieces for the

rotor. These are smaller diameter pieces (13", 8" & 6" O.D.) with

identical centers, which will glue to the main rotor piece and to each

other. The stack is almost an inch thick, and instead of one keyslot, I

planned keys and slots on opposite sides of the shaft, to give twice as

much again gripping surface. Lexan obviously isn't as strong as steel,

and by broad contact area I hope to compensate. BTW of course the

router

couldn't cut the sharp keyslot inside corners in the lexan, so they'd

be filed out by hand, and lastly all glued together, when the shaft is

ready.

Total Weight Estimate

I checked the weight of the various pieces. The original

steel main rotor piece was 19 pounds. The lexan replacement was 3

pounds. The outer steel ring, still needed to complete magnetic

circuits, was 6 pounds. Thus the rotor went from 25 pounds to 9. That's

before magnets, and before adding the lexan reinforcement

pieces to strengthen the center of the rotor. Those things may add

about 11 pounds or so.

So the total weight should be 58 + 20 = 78 pounds or so.

Call it 80. That's featherweight for a low RPM machine headed for 20KW

of capacity.

"Green" Electric Equipment Projects

Aquaponics

& LED Grow Lighting Project

On the 14th I got a

'new' 5 gallon aquarium, and I filled it and transferred the baby fish

from a small pail into it. Once I could see them from the side instead

of just the top, I discovered that all but one were guppies! They had

bred about a day later than the tilapia. Now I'm kicking myself for not

filling the bucket and transferring each one to it as it appeared.

Surely several baby tilapia must have been eaten by the adults.

That evening it occurred to

me that I needed a water tank

for summer garden watering owing to the rising price of city water (in

a land

where the yard is flooded half the winter!), and also I was going to

make some sort of expanded aquaponics fish pond. What about a plastic

swimming pool for both? I looked on UsedVictoria.com and found an

inflatable one for 50$ complete with filter, pump, patch kit (might be

vital!), ladder, and every accessory, even the original manual and box:

"best offer takes". There was nothing else like it in the ads. I

offered 70$ and

it was brought from the town where it was to my place the next day. The

extra 20$ probably saved me from 2 or 3 hours of driving. Meanwhile,

the

weather had turned from months of drizzle and flooded lawn to sunny and

drying, almost overnight. Now I hope I can get it set up

and then there's enough rain before summer to fill it!

Where to put it was a problem. My original idea was to put

it in the garden where (hopefully) the deer couldn't reach it to

possibly stab it with their hooves. But at 14' diameter - and around

11,000 litres - it was so big

it would take up half the garden. It was huge! I finally (with some

help) emptied and removed a 'temporary' shed and leveled a presently

muddy patch of dirt/lawn in the back yard for it.

I started thinking that it might not be a good idea to put

fish in

that huge inflatable pool. If deer should get to it they might puncture

it with their hoofs getting a drink. And raccoons with sharp claws and

teeth would surely try to go fishing in it. I would hate to come out

and find all the fish lying dead on the bottom of a deflated, empty

pool. Even if I was in time, where would I then put them all?

Furthermore, now it wouldn't be in the garden by the greenhouse with

the

other components of the aquaponics system. And on top of all that, if