Turquoise

Energy Ltd. News #86

March 2015 (posted April 3rd)

Victoria BC

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Highlights:

* A

new design concept for an add-on wheel motor system (see Month in

Brief)

* Porous nickel sheet and powder for nickel battery electrode

(see Month in Brief, Electricity Storage)

Month In Brief

(Project Summaries)

- Aquaponics & LED Lighting Progress - 'Ultra efficient'

Electric Chevy Sprint project to be resumed - Axial Flux Switched

Reluctance Motor (AFSRM, replacing unipolar motor) - Add On Wheel

Motor: a New System Design - AFSRM Generator for Windplants et al -

Electric Weel Generator - My/R & D finances? - The Usual Mazda

Batteries Update - Turquoise

Battery Project: Ni-Ni battery production ideas, great new nickel

negode idea!

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Ceres, Vesta and Vegetation - Unsustainable World Population

Electric Transport - Electric

Hubcap Motor Systems

* 'On hold' Chevy Sprint Electric Hubcap/Planetary gear torque

converter & Centrifugal clutch is to be completed.

* Electric Caik Axial Flux Switched Reluctance Motor - AFSRM (was

unipolar motor)

* Active Reluctance Generators: no cogging and output voltage

regulation!

* A Switched Reluctance EV Motor by Ricardo.com (85KW!), AFSRM design

papers

* Electric Weel - Huge low RPM generator [at last] nears completion

Other "Green"

Electric Equipment Projects

* Aquaponics & LED Grow Lighting - tilapia pool - Beans?!?

* Cordless Lawnmower with NiMH dry cells: User Review

Electricity Generation (No reports)

Electricity Storage - Turquoise Battery

Project (NiMn, NiNi), etc.

* Cylindrical cells with carbon rods?

* Ni-Zn or Ni-Ni acid battery with oxalic acid?

* Ni-Ni cell with nickel-brass sheet for negode?

* To make porous nickel sheets and porous nickel powder! (from

nickel-brass sheet and monel powder)

* Packing peanuts for carbon film, carbon nano-particles?

No Project Reports on: Variable

Torque Converter Transmission, Magnet motor,

Lambda ray collector, evacuated tube heat radiators, CNC

gardening/farming machine.

March in Brief

Aquaponics & LED Lighting Progress

I spent the early days of the month digging and working on a 'trench'

pond in the garden for the tilapia. it looked like it would be in the

way of access wherever I dug it, then I got the idea to put a bridge

across it. So far that's just a fat plank. There wasn't much extra pond

liner, and I sandwiched the edges between boards to keep it from

drooping down. The building supply ran out of 8x16" paving blocks, and

I bought some cement and sand and made some larger, thicker ones of my

own. I may

get around to a second batch some time.

I spent the early days of the month digging and working on a 'trench'

pond in the garden for the tilapia. it looked like it would be in the

way of access wherever I dug it, then I got the idea to put a bridge

across it. So far that's just a fat plank. There wasn't much extra pond

liner, and I sandwiched the edges between boards to keep it from

drooping down. The building supply ran out of 8x16" paving blocks, and

I bought some cement and sand and made some larger, thicker ones of my

own. I may

get around to a second batch some time.

The water was too cold for tilapia,

and I went to a pet shop and got a dozen goldfish to keep any mosquito

wrigglers out of

the water. (But it's probably too cold for them too.) I got some

duckweed and put it on top, and when there's surplus I can take it in

and

feed it to the tilapia - goldfish don't eat it.

Inside, the

beans in the aquaponics drain-down bed continued to grow, hitting the

ceiling and

blocking most of the light from the window. One flower appeared for a

couple of days and then wilted, with no more appearing. The beans

were just one of a number of things I planted in there last fall, but

they overgrew everything else and prevented any other crop. I certainly

won't try growing beans in indoor aquaponics again unless I find out

why they're not producing beans.

Inside, the

beans in the aquaponics drain-down bed continued to grow, hitting the

ceiling and

blocking most of the light from the window. One flower appeared for a

couple of days and then wilted, with no more appearing. The beans

were just one of a number of things I planted in there last fall, but

they overgrew everything else and prevented any other crop. I certainly

won't try growing beans in indoor aquaponics again unless I find out

why they're not producing beans.

The tilapia fish also continued to grow. The large female

was almost 12" long in a 12x12x12" space. They will certainly want that

(~400 liter) trench pond once it warms up and I get the beds connected

and a pump running. The little one was 2-1/2" long by month end.

I didn't do anything with LED lighting except decide that

a switching regulator would give a lot more flexibility and perform

better than the linear one, except with certain combinations of

voltages

and emitters which weren't nearly as much "the norm" as I expected them

to be before making and using a few lights with the varying solar

panel/battery system voltages. (And I was so proud of my minimal

components constant current linear regulator circuit!)

Axial Flux Switched Reluctance Motor (AFSRM)

Out of sequence, I'll mention that it now looks like the

AFSRM project now looks like it will stretch out a few months. The

motor, while very doable, is also very different from the BLDC magnet

motor, so there'll be a lot of new design. That suggests it might be a

good idea to complete the current version car drive first. It's all

been sitting nearly assembled and ready to install and try out in the

car. It's worth completing it and seeing if I've finally found a

workable path to a high-efficiency vehicle drive.

The "switched

reluctance" or "SR" type of motor seemed to

have all the advantages of the bipolar (or unipolar) BLDC types, would

use the same motor controller as I had just made for the unipolar, and

had reduced weight, cost and rotor thickness, plus greatly increased

RPM

capability compared with my rotors with magnets.

The "switched

reluctance" or "SR" type of motor seemed to

have all the advantages of the bipolar (or unipolar) BLDC types, would

use the same motor controller as I had just made for the unipolar, and

had reduced weight, cost and rotor thickness, plus greatly increased

RPM

capability compared with my rotors with magnets.

By about the end of February I made up my mind to convert

the new Electric Caik motor from unipolar to the SR type. The only

differences seemed to be the rotor and perhaps a few stator wiring

changes. The apparent similarity proved to be deceptive.

After thinking about it while working on the tilapia pond,

on the 12th

and 13th I designed a rotor that I hoped would have a relatively low

level of torque ripple, that being said to be the worst feature of the

reluctance type of motor. Later a correspondent pointed out that the

main

reason for the high torque ripple compared to BLDC magnet motors is

that the SR coils can only pull steel, not repel it, so more poles are

needed to get equivalent evenness of forces.

The rotor had the aspect of an "iron cross" with a

circular outside edge, and I made it by cutting out the four sections

between the four "lobes" from a ready-made "brake rotor disk", cast

from "soft magnetic" metal - that wouldn't magnetize when rubbed with a

supermagnet. The

cross section "sort of" followed the curves of the round coil cores.

It felt quite different installing a thin, magnetless

rotor that didn't try to grab tools off the bench and suck itself into

the motor unbidden while your fingers were still under it. And once it

was on, it didn't try to cog to different positions. Only the friction

of the grease-stuffed bearings kept it from freely spinning.

It also didn't turn, with 10 amps of current. The magnetic

forces were too weak. The sort of huge flux gaps and plenty of flux for

a relaxed BLDC design is replaced in the SR type by tiny gaps and a

struggle to find enough flux for decent torque. It needed a wholely

different design and layout.

So I took two

coils, the rotor and the lab power supply to deliver a constant 10 amps

to the coils, and started doing some electromagnetic experiments on the

bench to maximize the forces. These pointed to better ways to go, and I

made modifications that should get things working. A steel plate behind

the coils works to complete the flux circuit. Then someone suggested

using two rotors, one on each side of the stator, to double the flux.

This seemed like a

good plan. I also thought of putting a ring of metal around the outside

rim

of each 'donut' coil to concentrate the flux like in a cup magnet,

where a weak ceramic magnet has "supermagnet" levels of flux in the

small space between the round magnet and the rim surrounding it.

So I took two

coils, the rotor and the lab power supply to deliver a constant 10 amps

to the coils, and started doing some electromagnetic experiments on the

bench to maximize the forces. These pointed to better ways to go, and I

made modifications that should get things working. A steel plate behind

the coils works to complete the flux circuit. Then someone suggested

using two rotors, one on each side of the stator, to double the flux.

This seemed like a

good plan. I also thought of putting a ring of metal around the outside

rim

of each 'donut' coil to concentrate the flux like in a cup magnet,

where a weak ceramic magnet has "supermagnet" levels of flux in the

small space between the round magnet and the rim surrounding it.

A cup magnet

A cup magnet

Although I got the metal, I hadn't found a heavy sheet metal shear to

cut it into 1" strips by month's end. (Tin snips do an ugly job.)

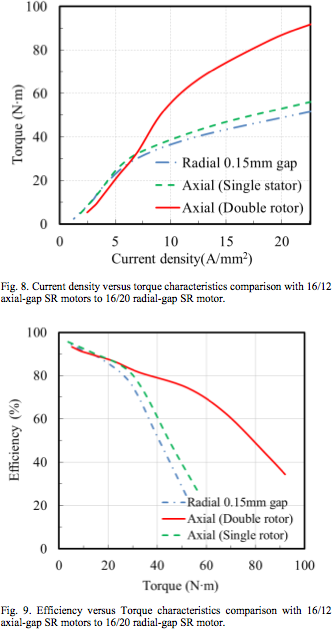

Then in the latter part of the month it occurred to me to

do a web search, and I found two technical papers (PDF.s) describing

axial flux switched reluctance motors (AFSRM.s).

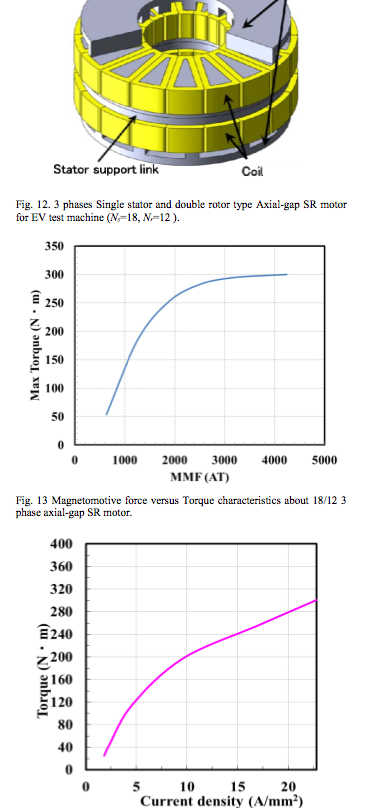

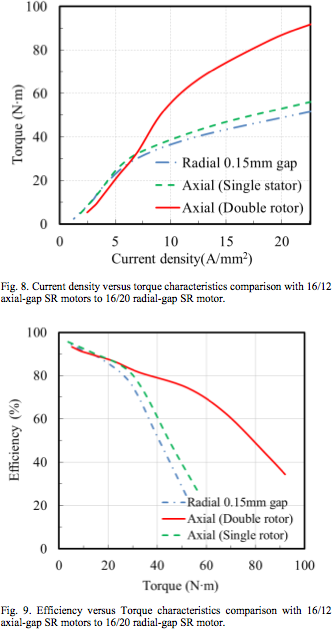

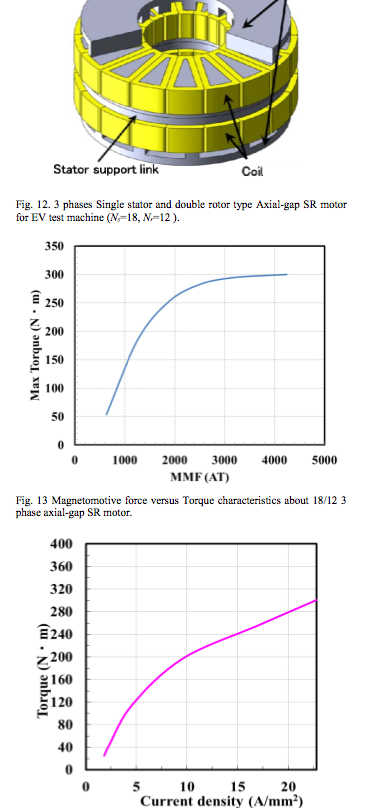

It turns out that the axial flux SRM layout is indeed much

superior to radial flux, but for different reasons than with BLDC

magnet motors. The flat rotors and coils with a flat profile can have

substantially larger adjacent surface areas for flux interaction. Also,

the usual two rotors with the stator between them virtually doubles the

forces available with the same current. With

the right designs, levels of torque can be attained that will move

vehicles by direct drive, for in-wheel motors as small as 12" diameter.

Such motors are however pretty heavy for good vehicle suspension

handling.

I plan to finish my small "AFSRM" as conceived and test

it out, along with the motor controller, which luckily is the same one

as for the unipolar magnet motor, that I designed and made earlier this

year. But the next and larger design for a car motor should probably be

more

along

the lines of the test motor built and tested in the Japanese AFSRM

design paper.

Along the way I made a balanced "arm" to measure static

"locked rotor" torque, in conjunction with a weigh scale. (After

shaping the pointer, I cut and ground metal off an "L" piece at the far

end until it

balanced.) It'll be far

more sensitive than a torque wrench. The "pointer" that presses on the

scale is exactly 6.0" from the center of the shaft, so it's easy to

convert the "weight" measured into foot-pounds.

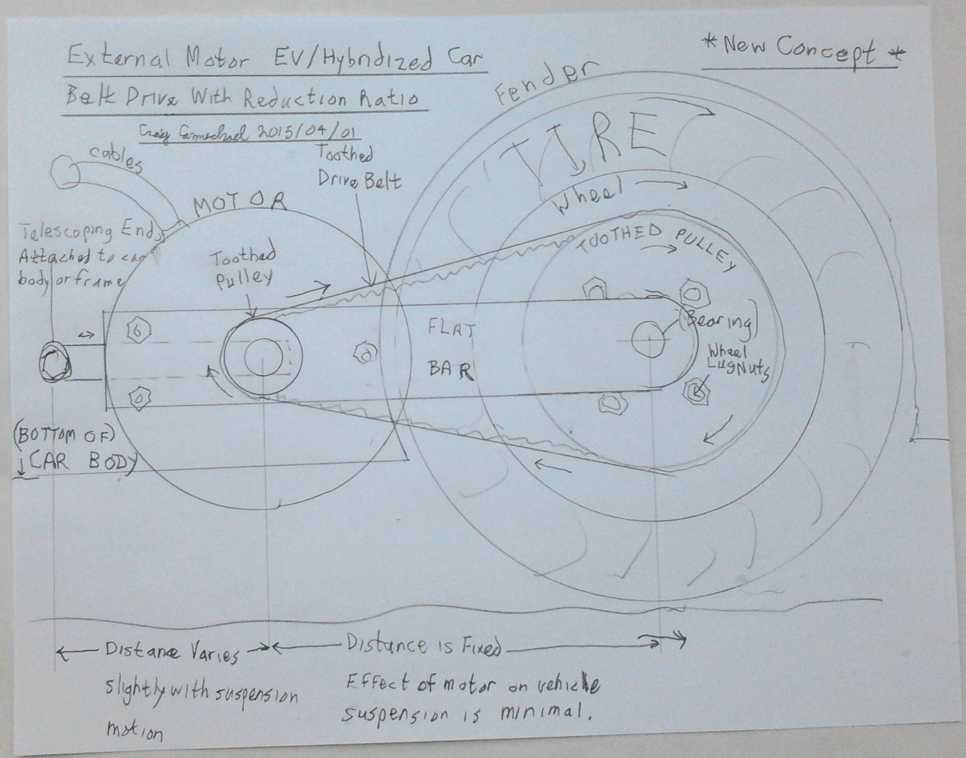

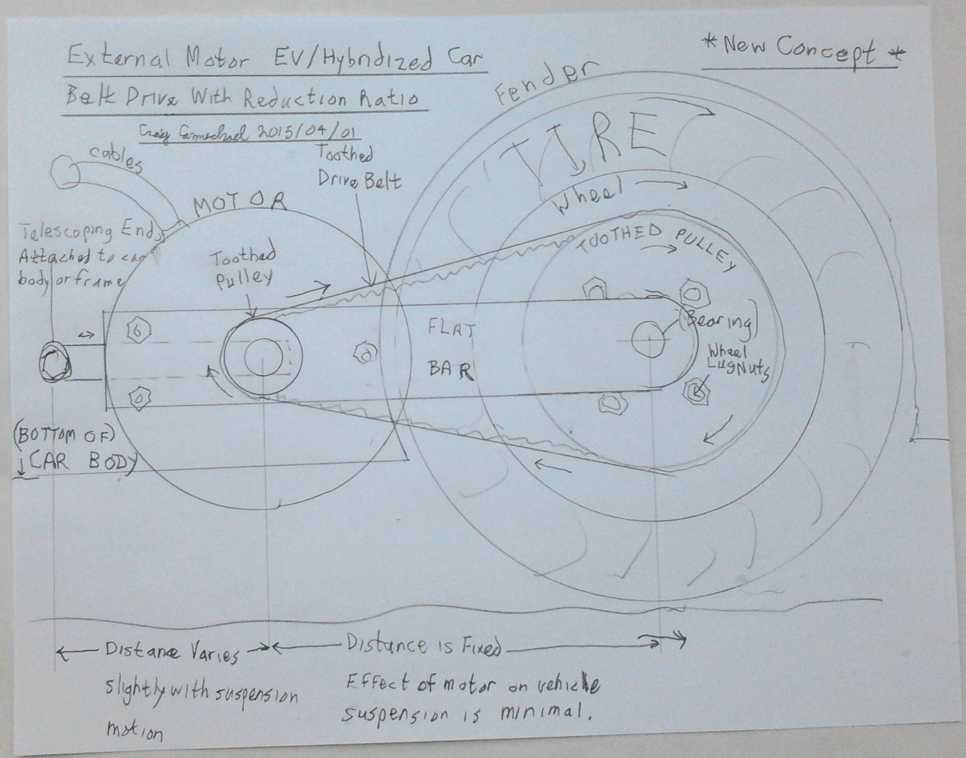

Add On Wheel Motor: a New System Design

Also along the way, I've conceived what I think should be

a good

solution to large and heavy in-wheel motors, as proposed in the two

papers and many other places. Placing an SRM directly on a wheel's axle

where its RPM

is

limited to the low speed of the wheel, is a waste of one of its big

advantages - the ability to run well and safely at high RPM.s. A motor

running at 0-5000 RPM

will be much

smaller and lighter to get the same power as one running at 0-1000 RPM

connected directly to a car wheel. With 1/5 the torque it is geared

down with a fixed ratio, eg 7 to 1, to deliver sufficient

car-starting torque, and because over-revving for this motor probably

means (say) around 10000 RPM or higher, 7000 RPM on the highway is

fine. The

rotors spinning at such high speeds are (as I envision them) solid

pieces of steel that won't fly apart, and

fairly light as steel rotors go. That means no variable

torque

converter, clutch, or gear shifting is needed. And that leads to

major

simplifications.

The first type of gear reduction that came to mind was a

large planetary gear, perhaps with plastic 'planet' gears to eliminate

lubrication requirements. The motor

would be as originally conceived, in the "hubcap" position, bouncing up

and down with the wheel, probably with some flexible coupling making

for some level of "debounce".

Then a solution that seems superior came to me. The "on

wheel" or "in wheel" motor is conceptually elegant, but then one hits

bumps in the road, which are more easily dealt with without a

considerable extra weight on the wheel. One solution that's been used

is to mount the "wheel" motor within the vehicle. Drive shafts with CV

joints then connect it to the wheel.

My plan, for rear wheel drive only, is (AFAIK) new as

applied to cars: For an outside

"add-on" electric pancake motor mounting, a

telescoping 'arm' runs from the center of the wheel to somewhere on the

car body, either in front of or behind the wheel, about level with it.

(sketch below) The wheel end of the arm moves with the wheel as it

bounces up and down with

bumps. But the body end is almost stationary. The telescoping or flex

mounting piece attached to the car body to

allow the arm to move with the wheel is very short. (Probably with more

than one attachment point for

support against twisting.)

The smaller, lighter motor is mounted on

the arm, near the body end. It doesn't move around very much, thus

it will have little

effect on suspension handling. But being on the arm which is connected

with a bearing et al to the hub of the wheel, its position relative to

the hub of the wheel

is fixed. It is then necessary only to connect the motor to the wheel

with an efficient drive belt: toothed, flat or poly-V, with pulleys

sized to give

the desired reduction. And the pulleys can easily be changed to see

what reduction ratio works best on the road.

By putting the pulley on the axle inside from the wheel,

and

the motor in a "hump" (eg) behind the axle in the luggage space,

the same arrangement could even apply to a vehicle as manufactured,

with the

drive belt replacing the more costly, heavier drive shafts with CV

joints.

There are of course disadvantages. The belt is subject to

wear, and will need occasional replacement. And this drive train, short

as it is, should be more or less enclosed to protect it from road dirt.

...And it just doesn't seem as "cool", somehow, as a motor in line with

the wheel.

First sketch of the new idea wheel motor

mounting system.

First sketch of the new idea wheel motor

mounting system.

The motor (presumably) is mounted on the front of the bar with the

pulleys behind the bar.

The wheel pulley bolts to the wheel lug nuts, and has a center bearing

to attach the bar to.

Eg:

- Upper and lower body end bolts/pivots can give anti-twisting support,

which it would doubtless need.

- The motor can be mounted right over the pivot point at the back to

minimize effects on suspension/handling.

- Belt adjustments by motor mounting position, eg with slots for the

mounting bolts. (many potential variations)

- Safety cover over the belt & pulleys - to keep out dirt and

gravel as well as fingers.

Suddenly the potential for DIY creation of electric car

drives with small motors at home, including "hybridizing" a gas car

rather than "converting" it, comes back into focus as an attainable

objective!

AFSRM Generator

The absence of cogging also made me think of SRM

potentially as a generator. My

magnet BLDC motors wouldn't be, eg, good wind power generators because

the cogging would prevent them from starting to turn in a lighter

breeze. With no cogging, the reluctance motors should make great

windplant generators. A "problem" is that without a motor controller,

they would just spin without making electricity. On the other hand, with

an appropriate controller they could probably be coerced into putting

out a constant

voltage regardless of RPM. (Within attainable limits of course.) That

would be a tremendous advantage. Where one might have a typical

"passive" generator whose output voltage varies linearly with RPM,

followed by a very flexible DC to DC converter to output a constant

voltage, instead one could have an "active" reluctance generator

putting out a constant voltage at a maximum power point regardless of

wind speed. The DC to DC converter would be replaced by the motor's

controller so the controller would be an alternative electronic

component, not an additional one.

Electric Weel Generator

With a SR generator still being undesigned, work continued

on the original plan for the big generator for the floating hydro power

unit. We got the stator coils wired together and put the magnets on the

rotor. It's almost finished.

Magnet Rotor. (More lexan reinforcing pieces

are to be added to this main piece.)

Magnet Rotor. (More lexan reinforcing pieces

are to be added to this main piece.)

My/R & D finances?

I got my first monthly payment of 1000$ from CHIP bank -

owed with interest to be collected someday from my house or estate. I

also applied for Canada pension plan (CPP, 341$). My finances took

another

turn for the worse when I finally got my Turquoise Energy Ltd. income

tax refund for 2013. For every project they didn't like they knocked

off a percentage (just in case I wasn't worth 22000$ for any one or two

of them), and the government has apparently that decided rent

or equivalent for facility space to do R & D doesn't constitute a

legitimate R & D expense. It looked like that would knock it down

to 12000$. But I finally got my 2013 refund on March 20th 2015, nearly

a

year late, and it was even worse: somehow it was beaten down to just

under 8000$. I expect that pretty much covers all the time I spent

doing all the paperwork I have to do to qualify for the SR & ED

program - but not the actual inventive work. It certainly does little

to

compensate for what I've invested in the projects in time and money.

That has been financed with a considerable mortgage on my house. I

wonder how much the audit itself cost the taxpayer, complete with

scientific appraisal by a university academic who seemed to sneer at

the fact that I had no university degree and wasn't going out of my way

to try to get university collaboration. The salaries of the

two Canada Revenue employees are both doubtless far higher than what

I've been living and doing R & D on. Now I've started in on

all the

same paperwork for 2014, all seemingly no less exacting than if I was

claiming millions of dollars. And when will I receive some pittance for

having done that? Another product developer I know, and so probably

many others, have been similarly affected. It seems the

government is cutting everything that won't cause a public uproar (and

apparently

even some things that do),

while it involves Canada in shameful foreign wars and moves us

stealthily toward becoming a lawless police state, in step with the

USA. It doesn't look like

the next advances in human society will come from the west.

The Usual Mazda Batteries Update

The electric Mazda with 11 batteries and 144 volts has

become somewhat more practical

again, but still only for trips under 6 miles or so, or where I can

charge a while at the far end. I've been to a friend's at 5 miles

distance for a 10 mile round trip a couple of times, with a 2-1/2 hour

[slow, float] charge while I'm there, without getting too low

before getting home. OTOH, these were evening trips with light traffic

and I picked a route with few stops and just a couple of steep hills

(relatively short ones), and

used as little as 238 watt-hours per mile (1.7AH/mile @ 140V) rather

than the average of around 280 or more watt-hours. (Now I think I know

how the EV-1

used just 225 WH/mile or so, according to various reports. It's not

that the car was a whole lot better. It's that California is always

warm

(warm lowers consumption) and has fewer steep hills and generally

longer runs

between stops.)

The older NiMH batteries made from "D" cells don't work as well as the

newer ones - the voltages drop more when climbing hills or

accelerating.

Curiously, this doesn't seem to be a reduction in storage capacity,

only in current drive, as the voltages soon come right back up fairly

even

with the new ones after stopping, which means the state of charge is

the same. This suggests that the electrolyte gradually escapes. That

wouldn't hurt a flooded cell (especially as it can usually be

refilled), but the "dry" cell doesn't have much to start with.

I started thinking about the possibility of refilling the

dry cells, by immersing them in water for some period of time. It's an

experiment I'd like to try on some older cells, but I would want to run

a few load tests before and after, and ideally try varying lengths of

time and

depths of immersion, so it'd be a fairly involved set of tests in order

to come up with general guidelines for 'restoring' NiMH dry cells, if

indeed it can be done. And

different size cells - and even different brands - would probably have

different requirements.

I'll want more "identical" batteries, eg, 3 x 300AH of

NiMH.s, if I get the Chevy Sprint going with a 36 volt motor. I thought

about investing another 3000$ in "D" cells to get there. Ugh! What

about my own batteries? Surely there must be some way to make use of

the new chemistries I've found instead of just paying through the nose

for NiMH or lithium!

Turquoise Battery Project: Battery Production Ideas

I have two

fabulous new chemistries. But I don't seem to be able to make practical

batteries. I even started thinking about the nickel-zinc oxalic acid

cells again (might not care about air exposure?), and about sheet zinc

as an electrode. I thought about the way standard dry cells are made,

and the fact that they work well and their carbon rod is just what

would work with my salt electrolyte posodes. What about simply using

the rods from "D" or "F" dry cells and adopting the same construction?

Nickel-nickel with salt electrolyte should be doable as a dry cell.

(The high voltage of nickel-manganese, fantastic chemistry attainment

that it is, would make for too much gassing and pressure - they pretty

much would have to be flooded, vented or valve regulated cells.)

Then I figured that I could use the nickel-brass sheets as

the

outer layer, with the nickel in them as part of the nickel electrode. I

would assume the (18%) zinc would oxidize away leaving

the nickel (17%), active wherever it was exposed to the electrolyte,

and the copper (65%) as current collector. That would ensure some sort

of high-current active nickel electrode, but with quite low amp-hour

capacity.

Then I thought such an electrode might be improved by

dissolving away both the zinc and some or even all of the copper, to

leave a microscopically porous

nickel electrode. (17% nickel and 83% air space for electrolyte

penetration.) On April 1st and 2nd I extended this great idea. I have

the nickel-brass sheets, and

also monel powder (Ni:Cu 66:33%). If some or all of the copper was

leached

out of both these alloys (and all or most of the zinc) with HCl and

H2O2 (or

maybe ferric chloride), microscopically porous nickel should remain,

with mostly nickel on the surface, exposed to the electrolyte, and any

remaining copper inside as a highly conductive backing. That should

make a relatively solid electrode with very high current capacity and a

lot of microscopically rough, exposed nickel surface

and hence excellent amp-hours per amount of nickel. One might be able

to apply a flux [water soluble?] and sinter the powder and the sheet

together into a porous electrode with a torch, then dissolve

out the zinc and [some of?] the copper to also get the microscopic

porosity. It sounds like a real winner!

A nickel-brass (AKA "nickel-silver" or "German

silver") sheet to turn into a rolled-up electrode,

A nickel-brass (AKA "nickel-silver" or "German

silver") sheet to turn into a rolled-up electrode,

with an "F" cell carbon rod and its original plastic cap, and the

prospective PVC 3/4"

plumbing pipe as an outer casing. (Sigh - the '3/4" end cap' for the

bottom was the wrong size.)

On April 2nd I tried an

initial experiment, tossing the piece of nickel-brass into a solution

of HCl + H2O2 I had sitting in a jar for printed circuit board etching,

for about an hour. I taped over one side so as to etch only the other.

Sure enough, the exposed surface looked very different when it came

out. It had a 'matte' appearance instead of glossy, and a rough texture

with fine ridges instead of smooth under a 40 x magnifiying glass. It

looked very promising and I'll have more info next month. (I wish again

I had a microscope. Maybe I can get someone to put some samples under

the fab UVic electron microscope.) By evening I realized that that

solution doubtless dissolves nickel as well as the other

metals, so I'll have to look up something else. Edison used sulfuric

acid to dissolve copper from nickel, dissolving only a little nickel,

so it's known to be doable. I think I'll try ferric chloride. It might

dissolve no nickel at all.

Another interesting find

was that someone has discovered that parcel

packing "peanuts" can be turned into thin carbon film or carbon

nanoparticles (depending on formulation) useful for battery electrodes,

by heating in a kiln in an inert atmosphere, and sometimes with the

right salts added. (The salts used weren't listed). A friend sent me a

link

to the article. I may look for ways to try it out. The hard part will

be keeping the air out, and I've wanted to be able to do that in the

kiln for a number of things.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Ceres, Vesta & Vegetation

I searched youtube for any

more information about the Dawn

spacecraft mission to Ceres. Specifically I was hoping for information

about potential "polycyclic aromatic hydrocarbons" spectral findings or

"fluffy" surface textures that might (or might not)

support the visual appearance of Ceres as having the same strange

vegetation (assuming that's what it is) evident on several airless

worlds

of the Jupiter and Saturn systems. There was a 50 minute NASA/JPL press

briefing about Dawn entering Ceres orbit, but no one asked about those

topics. There was much interest in the two "mysterious" bright spots.

Since the bright spots appear to stick up above the

surrounding surface, they're almost surely ice extrusions formed by

expanding water, pushing up through holes or cracks and then freezing,

following meteor impacts that melt the ice into a pool that quickly

forms a crust. I have yet to hear this or any plausible explanation for

such features, which are ubiquitous on many worlds, from the space

science community. Unless that's what are being referred to as

"cryovolcanoes". But they'd be very short lived as active phenomena -

probably minutes to a very few hours, depending on the size and energy

of the impact.

In the search for info, I ran across several

quite "out there" videos: The

bright spots are alien lights. Jpeg images blown up into pixelated

squares show an alien city with square buildings. Ceres has air and

water. (!)

One starts to see why it's hardly possible to speak

rationally

of evidence for life on space forums without having people instantly

eject you from their membership without bothering to read what you have

to say. And Ceres is, after all, just an "oid" about 2% the size of

Earth's moon. (BTW: Evidently the equatorial diameter is substantially

greater than the polar diameter: 950Km versus 910Km, slightly different

than the figure of 915Km I used last month. Since the gravity is

so slight and the rotational period is just 9 hours, this oblateness

may perhaps be accounted for by centrifugal force. Hmm... Saturn, which

rotates every 10 hours, is similarly oblate.)

Dawn had already been to the second largest (but much

smaller) asteroid, Vesta, before it went to Ceres. What might be so

different that Ceres has a similar appearance to Jupiter/Saturn

"fluffy" icy moons, while Vesta looks more like a simple rock, like

Earth's moon?

Apparently, it's just enough of a temperature difference that all the

water ice has sublimated off Vesta (max. 253°K, -20°C), while

most of it has remained on Ceres (max 235°K, -38°C) so far.

Vesta is just a little closer to the sun. But both are much warmer than

Ganymede (~140°K) where the apparent vegetation doubtless

originated. So far the only real indication I've seen of vegetation is

the low albedo and the high contrast with the bright spots. This is

perhaps a rather superficial indication, and with such a temperature

difference, certainly more evidence is required one way or the other.

Hmm... I guess there's nothing stopping me from doing my

own video to explain what I think is, and might be, going on!... except

finding time to do it. I can see quickly wanting to make it into a

half-decent production, bringing in images and other findings from

other worlds to compare and illustrate the points. It would become yet

another project - AWG!

I was disappointed to hear in the press briefing that

Dawn's

orbit is only going down to something over 100 Km from the surface. (I

don't remember the exact figure.) It should surely be possible to get

down to 30 or even 10 Km above the tallest features to sample some of

the finer details... like "fluffy" vegetation. Perhaps it's not time

for humanity to indisputably see and recognize alien life.

Unsustainable World Population

It has been said that in primitive 'caveman' times the

world population was about 10 million. But this can hardly be true! It

was also estimated that before 1550 (before smallpox) there were about

50

million native

inhabitants of North America. This figure, for primitive

hunter-gatherer

societies often (if not usually) at war with each other, is quite at

odds with such an extraordinarily low global estimate. If North America

contains, say, around 10% of the world's productive land area (besides

desert or arctic), we may estimate that the world population for much

of our million year history was probably around 500 million primitive

people.

As herding and simple agriculture became common, the food

productivity and hence the population per area ratio perhaps

quadrupled. This would indicate that the world could, and probably did,

support around 2 billion people in more recent millennia. (IIRC, the

population before world war one was around 1.8 billion.)

When agriculture started to become mechanized, more people

moved to cities and the land was gradually converted to huge farms -

"agribusiness", and an enormous population expansion began. (I remember

in elementary school (~1964) my teacher mentioned to the class, and was

shocked,

that the population had reached 3 billion people!) It is now well over

7

billion, and there are numerous very serious food concerns. Not only

can bad crop years result in shortages, and not only is farming

presently dependent on fossil fuel*, but with the gradual loss of

various trace minerals from farmland soil without replacement it's been

said by a USDA

study to be

unsustainable (which is in fact obvious without a study). The rising

rate of arthritis, which evidently stems mainly from boron deficiency,

is

just one health affect just now being linked to this - to boron poor

soil. Besides food,

various resources including land are in

short supply and the quality of life is deteriorating rapidly. This is

exacerbated by the greed and hoarding of a few, and their fears of

"uprisings", and war. (There are

today over 50 million displaced refugees - more than at any time since

world war two.) As stock analyst Greg Mannarino puts it on youtube,

"The

population is in a bubble, and when that bubble bursts, there'll be

suffering on a biblical scale. People won't have the resources to

procure

the basic necessities they need to sustain their existence." (Not an

exact quote.)

According to various internet sources, some who rule our

world would like to see the population reduced to 500 million, and they

scheme means to accomplish it without bothering to inform people of

their

intent, educate them on the need for population reduction, determine

public opinion or explore peaceful, agreeable methods to accomplish it.

Obviously 500 million is almost absurdly small - a cave days

"hunter-gatherer" population and just 7% of the present population.

It might put an end to human progress. Certainly much would be run down

and abandoned.

They needn't fret now about the growing population because

in the

economic collapse looming in front of us, it's going to drop sharply.

The most shocking estimates of "9 out of 10 Americans will soon be

dead" seem disproportionate, but "1 out of 2" would probably be

optimistic and "2 out of 3" to "3 out of 4" more likely. It seems

likely to come out around 2 to 2.5 billion people remaining by perhaps

mid century - about where it was when the 20th century began. Again

while spectacular events and disasters are inevitable, most of the

deaths will probably finally result from plagues**. At some point of

overcrowding and poverty, these become inevitable.

Hopefully the survivors, with the global awakening and

quickening of consciousness that is and will be taking place, and the

spread of knowledge via

the internet, will have the wherewithal to start a better civilization

- and to voluntarily regulate their numbers so everyone has enough for

prosperity.

- - - - -

* To get agriculture off oil, not only

is there the CNC gardening/farming machine idea (which would be powered

from the electrical grid), but there seem to be a number of

battery-electric tractor conversions out there. An electric tractor may

be more

practical at the present time than an electric car because it's never

far from home and from its charging station - or perhaps from a quick

battery swap.

** An interesting youtube news show that follows an amazing number of

major events

and "top importance" topics including food and disease concerns is "The

News in Two Minutes" (TheNITM") presented daily Monday to Friday by

"FullSpectrumSurvival" channel. It's hard to keep up with the dizzying

pace at which the news items (with relevant web pages pictured) are

presented!

It's quite an antidote for TV "nothing happening here" news where

usually one doesn't get the

impression that events of real import are happening daily often in

rapid

succession all around the globe.

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers

- Preliminary Ni-Mn, Ni-Ni Battery Making book

Products Catalog:

- Electric Hubcap 7.2 KW BLDC Pancake Motor Kit

- Electric

Caik 4.8 KW BLDC Pancake Motor Kit

- NiMH Handy Battery Sticks, 12v battery trays & Dry

Cells (cheapest NiMH

prices in Victoria BC)

- LED Light Fixtures

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

Daily

Log

(time accounting, mainly for CRA - SR & ED assessment purposes)

1-2nd: Finished February newsletter/report (#85)

3-12: Made insulated outdoor tilapia pond

12-13: Designed motor rotor to convert Electric caik motor from

"unipolar" to "switched reluctance" ("SR") type.

14: Made rotor. Made "torque bar" for measuring motor torque.

15: Installed rotor and ran a test. (which showed stator wiring needs

modification for SR operation.)

16: Worked on Electric Weel development - finished stator assembly,

wired stator coils together.

18: inverted 3 of 6 coils in Caik SR motor. Still no apparent torque.

19: Ran various magnetic experiments with two types of motor coils, the

SR rotor, a steel backing bar, and supermagnets and a supermagnet

rotor. Electric Weel: started installing magnets on rotor.

20: Ran a couple more SR motor experiment variations (repeated some to

verify impressions).

21, 22: Studied up on SR motor control "standard practices" &

advancing ideas & projects.

23: Glued remaining magnets to Weel rotor.

24: Searched for pipe suitable for making rings around coils for AFSRM.

(no luck.) E-mail conversation with a designer about AFSRM design.

25: Bought 2nd rotor for AFSRM.

26: Epoxied strapping to Weel magnet rotor.

27: Got sheet steel to make coil rings from.

28: Battery Production ideas. (I have two better chemistries... now,

how to make

batteries that work and are practical?)

31: Studied another theory paper of axial flux motors for EV.s,

describing a motor very similar to what I want to build.

Technical Papers Studied:

A Novel Approach to the Design of Axial-Flux Switched-Reluctance Motors

Tim Lambert *, Mohammad Biglarbegian and Shohel Mahmud

School of Engineering, University of Guelph, Guelph, ON N1G 2T6,

Canada;

A Design of Axial-gap Switched Reluctance Motor for In-Wheel

Direct-Drive EV

Tohru Shibamoto, Kenji Nakamura, Hiroki Goto and Osamu Ichinokura

Elec. and Comm. Eng. Dept., Tohoku University

Electric Hubcap Motor Systems - Electric Transport

Electric Caik

Switched

Reluctance Motor

The more I look at reluctance motors, the more I like

them! The more one looks, the more their unique physical and

operational features bring tremendous application advantages to the

imagination.

A Revolution for Car Hybridization?

The SR motor should prove compact and light, and if the rotor is

balanced, capable of running safely at very high RPM.s. Where my BLDC

magnet motors might be good for 2500-3000 RPM if the magnets are well

attached to the rotor (per the latest Electric Caik & Electric

Weel construction), the SR motor with a simple solid steel plate

rotor might be good for perhaps 8000-10000 RPM or more. If it has

enough torque, and if it's geared down enough, it might be mounted on a

car wheel simply with a fixed gear (or belt) providing sufficient speed

reduction/torque increase to reliably start the car moving rapidly or

uphill. The RPM on the highway can be very high without being dangerous

or wasting a lot of power. Thus the variable torque converter could be

dispensed with! That would revolutionize all my plans and bring the

wheel

mounted car hybridizing system back into immediate focus.

Furthermore, 5000-6000 RPM for the Electric Caik size

(doubtless quite attainable) is plenty high enough to get a small

motorboat up on a plane in outboard motor conversions, driving the main

shaft directly and without changing the typical manufacturer's gear

reduction down by the propeller, which is so frustrating for

conversions using typical higher torque, lower RPM BLDC motors.

Such potential benefits were completely unforeseen when I

started the unipolar motor project, which has turned into the switched

reluctance motor project!

I had been thinking the gearing down could be accomplished

by a planetary gear, with the motor directly in front of the wheel. But

near the end of the month, I thought of what seems like a very elegant

solution with a drive belt, as described in Month in Brief.

This simple installation plan brings mounting an external add-on motor

to "hybridize" a vehicle back into close-up focus, as an easy DIY

project.

Meanwhile Back at the Ranch...

Of course the layout of the motor, as per the usual BLDC

case, is 3-phase and in fact for the Electric Caik is like the

image below except for being axial flux instead of radial. The

Fleadh Electronics Ltd. web site has this to say [My boldings]:

<<

Switched Reluctance Motor Drives - http://www.fleadh.co.uk/srm.htm

Three-Phase Motor

Three-Phase Motor

Offers simplest solution to

starting and torque ripple without resorting to high numbers of

phases. Hence has been the most popular topology in its 6/4

form.

Alternative 3-phase machines with doubled-up pole numbers can offer a

better solution for lower speed applications. But again watch-out for

torque ripple especially in the voltage control single-pulse operating

mode.

>>

(Perhaps it's noteworthy

that this company includes major electrical equipment and motor

manufacturers such as Baldor in their client list.) Another document I

found said (among other things):

<<

SRM Summary (www.SRMDrives.com)

Due to the absence of rotor windings, SRM

is

very simple to construct, has a low inertia and allows an extremely

high-speed operation. <snip> Designing a motor with high

constant power range to base speed (e.g. at least 4:1), is not hard to

achieve with SRM, and has a great effect in designing a lower power

motor that can produce significant torque.

The SRM has many advantages, mostly resulting from its simple

structure: low cost, extremely safe and particularly suitable for

hazardous environments. The SRM drive produces zero or small open

circuit voltage and short circuit current.

Furthermore most SRM converters are simple because the current is

unipolar. The SRM drive is immune from shoot through faults,

unlike

the inverters of induction and brushless dc

motors.

<snip>

>>

SRM Drives speaks of high speed motors up to

100,000 RPM, and while that must describe quite a small diameter motor,

indeed a solid chunk of steel is highly resistant to centrifugal

forces. (But I still remember they guy in the 1970's(?) who was

promoting high speed flywheels for energy storage. His experiments and

grand ideas were featured in Popular Mechanics and Popular

Science magazines month after month (remember when there was no

internet?), until they just stopped appearing. It turned out he had

been killed, and his entire lab destroyed, by the "explosion" of a huge

flywheel at 50,000 RPM. Even the best steel has limits!)

The Electric Hubcap and Electric Weel

would be "Alternative 3-phase machines" with more poles and lobes.

(Come to think of it, the Hubcap version with 3 coils per phase

instead of 2 or 4 might not work out - instead of NS it would have to

be NNS or NSS. This concern was negated by later magnetic

configuration ideas, below.)

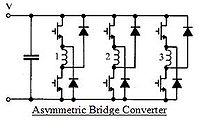

In further study of the switched reluctance motor, I

was surprised to see the seeming complexity of the control

circuitry to drive it as shown on Wikipedia.

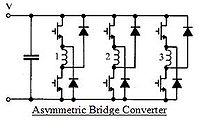

(In fact, I think the first time I saw the name "reluctance motor" was

in the description of an "Asymetric Bridge Converter", and the weird

circuit, with six wires to the motor coils instead of three, is

what made me reluctant to take any interest in reluctance

motors - plus the name just sounded weird. Unfortunately I didn't even

look them up.) But on closer

inspection, other

than needing 6 power

wires to the motor, it's the same six transistors and six diodes as in

a

'regular' 3-phase bridge driver. But again, as noted in the SRM

Drives summary above, the current is unipolar, and "glitches"

transiently

turning on transistors can't cause a catastrophic short ("shoot through

fault") from B+ to B-. In fact, both transistors of a phase are turned on

to energize the coil - the fault condition in a regular half bridge.

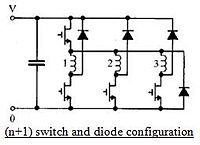

<<

Power Circuitry (Wikipedia)

The most

common approach to the powering of a switched reluctance motor is to

use an asymmetric bridge converter.

The most

common approach to the powering of a switched reluctance motor is to

use an asymmetric bridge converter.

There are 3 phases in an asymmetric bridge converter corresponding to

the phases of the switched reluctance motor. If both of the power

switches on either side of the phase are turned on, then that

corresponding phase shall be actuated. Once the current has risen

above the set value, the switch shall turn off. The energy now

stored within the motor winding shall now maintain the current in the

same direction until that energy is depleted.

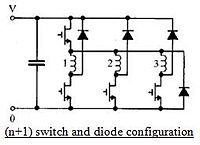

This basic

circuitry may be altered so that fewer components are required although

the circuit shall perform the same action. This efficient circuit is

known as the (n+1) switch and diode configuration.

A capacitor, in either configuration, is used to suppress electrical

and acoustic noise by limiting fluctuations in the supply voltage.

>>

The rising current shutting the coil power off is of

course what I call CRM - current ramp modulation. So my controllers,

ever since the A3938 version in 2011, already have it. (In the MC33035

based

controller so far, it's in an approximate form.) No complex DSP or

processor

control is required to achieve it.

The yellow lines are current to the active

phase coils. The red lines show inductance with rotation, maximum

The yellow lines are current to the active

phase coils. The red lines show inductance with rotation, maximum

inductance being attained when the rotor pole lines up with the coil.

(The coil should be 'off' by that point of rotation.)

Left: Current ramps up quickly at low speeds and attains destructive

values unless limited.

The rate depends on the

inductance of the coil, which increases as the rotor pole metal goes by.

When the current reaches a

maximum value, the coil is briefly shut off to allow it to drop back

down.

Right: Owing to back EMF, current ramps up slowly at higher speeds, and

either the current limit

isn't reached, or it's reached more slowly and less often and the CRM

is less active or inactive.

If the control current is set lower for less drive to the

motor, all the yellow lines are

reduced in amplitude.

The second "n+1 Switch and Diode" circuit seemed more intriguing at

first. Where I put

in a coil to dissociate the supply voltage from the actual supply to

the coil switches during voltage spikes, this circuit uses another

mosfet. This is probably

superior - more predictable and controllable.

But the high-side transistor is turned on

whenever any of the others is turned on. It'll get hot 3 times as fast.

It would seem then that at least for larger motors such as mine, the

asymetric bridge type is used so as to spread the load between three

sets of drivers.

On the other hand, my controller with the in-line coil has

only

three driver transistor points instead of six, with no troublesome

floating high-side gate drives. If the coil can adequately isolate the

supply from the battery for energy pulse switching purposes, it may be

the optimum solution. It was derived from not knowing what a "standard"

solution might be, since I was initially trying to drive a unipolar

magnet motor - a new type of motor for which I didn't expect to find an

existing type of controller. Occasionally not knowing "standard

practices" in advance can be an advantage!

A problem noted with switched reluctance motors is the

generation of acoustic noise owing to flexing of the stator with

ever-changing magnetic loading. (No doubt this is to an extent true

also of BLDC with magnets on the rotor, and especially it would be of

unipolar.) The

polypropylene-epoxy

composite bodies of my motors should damp the sound and make less

noise than 'ringing' metal bodies.

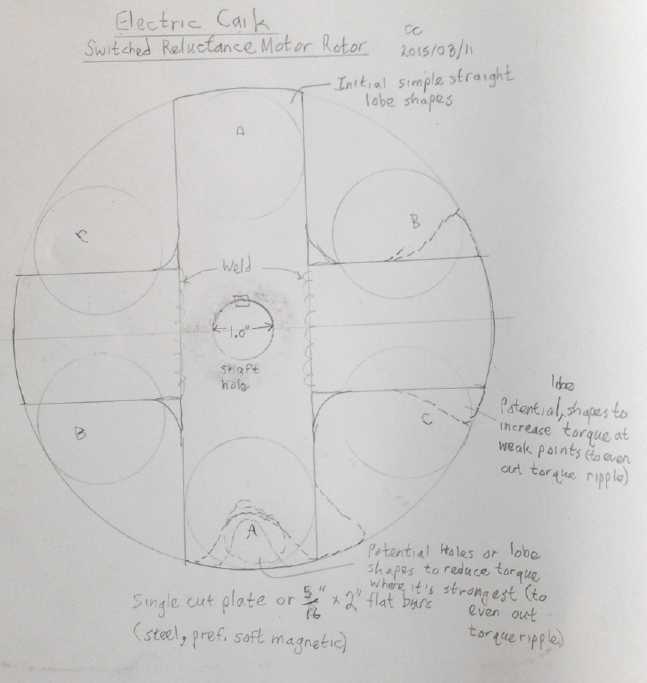

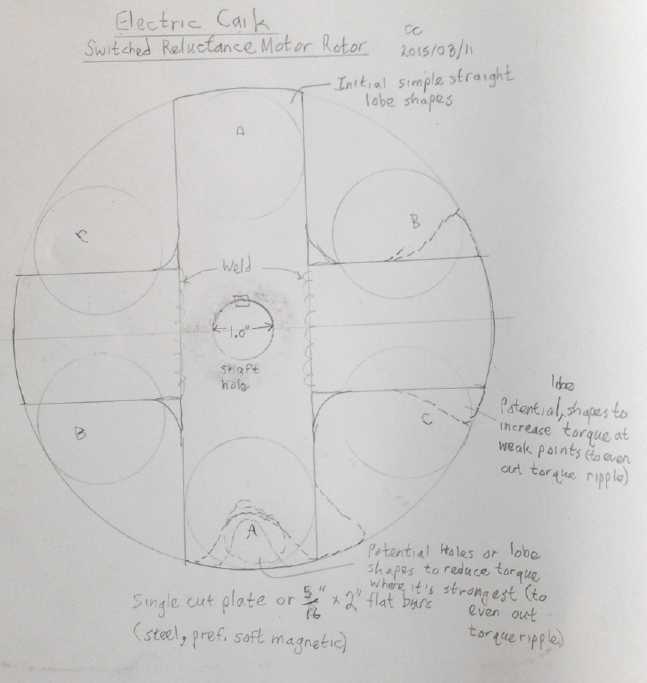

Concept Drawing to define rotor shape

Concept Drawing to define rotor shape

Another

consideration is electromagnetic inductance into

the rotor steel. Soft magnetic material (eg, high silicon steel) is

used, and some have used laminations or other induced current

restricting materials.

Another

consideration is electromagnetic inductance into

the rotor steel. Soft magnetic material (eg, high silicon steel) is

used, and some have used laminations or other induced current

restricting materials.

I considered using 1/4" x 2" bar stock and welding two

pieces together in an "X" (or something along those lines), drilling

out a 1" center hole for the axle. That would give a "disk" with four

good lobes, but not quite what I thought would be the best shape. I

finally decided that the most practical thing was to take a pre-made

7.8" "disk brake rotor" disk and cut out four shapes to leave the

desired four lobes in what I hoped might be a design with minimized

torque-ripple. My biggest concern was that this rotor was only 3/16"

thick. But at worst, the maximum torque would be lower. It would also

be easier to cut than thicker metal. I drew this up on the evening of

the 12th, drew it on the rotor with a felt pen on the 13th, and cut it

the day after that, using a jigsaw with a metal blade.

It came out looking somewhat like an "iron cross" medal

with the outside edges being the original circular rim segments. The

extra metal around the outside edges should give the coil more to

attract when it first comes on as the lobe approaches it, while having

sufficient clearance between the coil core and the lobe behind, plus it

would spread the center of the lobe and reduce the higher torque as the

lobe approached the center of the coil. Or so went my reasoning. I

thought I cut it pretty well and I didn't try to balance it. First get

it to run! Then the details.

On the 15th I installed

this four-lobed rotor into the

motor. I seemed very strange having no annoying magnetic forces at work

trying to suck the rotor toward the stator. And when it was assembled,

there was no cogging - no force except bearing friction. (...which was

considerable. Oh well, some grease will ooze out of them as it runs.)

And I had

started to consider that a very useful device

would be a torque wrench or other torque measuring device that measured

in "inch-ounces" or some such units instead of "tens of foot-pounds",

that I could put on the motor shaft. That could give an idea not just

of torque, but of torque ripple, by measuring the static torque at

various angles of rotation. A Texas Instruments document suggested that

torque ripple in SR motors can be minimized by careful mechanical

design, which mirrored my own thoughts.

And I had

started to consider that a very useful device

would be a torque wrench or other torque measuring device that measured

in "inch-ounces" or some such units instead of "tens of foot-pounds",

that I could put on the motor shaft. That could give an idea not just

of torque, but of torque ripple, by measuring the static torque at

various angles of rotation. A Texas Instruments document suggested that

torque ripple in SR motors can be minimized by careful mechanical

design, which mirrored my own thoughts.

I wasn't seeing what I needed at local auto and tool

stores. Then I thought of making a balanced bar to put on the motor

shaft, with a 'pointer' on one end. This would press on a small

mechanical weigh scale when the motor was energized, to give a reading

in grams or ounces. Knowing the length of the bar, foot-pounds or

newton-meters could be derived, to a fine scale. To find the torque at

different angles of rotation, the whole motor would be rotated to keep

the bar level. Since the first objective would be to measure

differences in torque at different angles, only a small force where the

motor could be held by hand would be applied. (Maybe even just from the

DC lab power supply to one pair of coils at a time, to get exactly the

same current each time.) I made this also on the 15th. I found a nice

bar on which it was simple to shape a 'pointer' to press on the scale,

at exactly 6.0" from the center of the shaft.

Static torque per amp - including maximum and minimum if

there's

much ripple - can be derived by knowing the current which gave the

figures. (That's another reason for using the power supply, in

"constant current" mode.) To measure torque with the motor rotating

will still need something like a dynamometer.

I foresee a problem with determination of back EMF per RPM

("Kv"): With no magnets to induce electricity into the coils, the rotor

can spin freely all it wants and essentially no voltage will be

produced.

Apparently if it's being pulsed by the controller this changes, but it

sounds like it'll start to get complex -- couldn't any desired back EMF

be generated at any RPM?

On the 16th I

hooked up the lab power supply to one set of

coils and turned it on to 10 amps. I turned the rotor to find where the

torque would occur and how strong it would be. (Funny I never thought

of doing this with any previous motor!) To my surprise there was no

apparent force or torque at any point. My best guess was that with a

north electromagnet pole at both ends of the engaged rotor lobes, the

repulsion of the two norths canceled the attraction to the metal.

I'd have to rewire half the coils - or flip them over - to create

north-south magnetic circuits.

On the 16th I

hooked up the lab power supply to one set of

coils and turned it on to 10 amps. I turned the rotor to find where the

torque would occur and how strong it would be. (Funny I never thought

of doing this with any previous motor!) To my surprise there was no

apparent force or torque at any point. My best guess was that with a

north electromagnet pole at both ends of the engaged rotor lobes, the

repulsion of the two norths canceled the attraction to the metal.

I'd have to rewire half the coils - or flip them over - to create

north-south magnetic circuits.

I manged to flip 3 coils over on the 18th. But the slotted

optical interrupter

drum seemed to rub on the wires, which I had done my best to get out of

the way. I might need to start banging on them with a hammer to get

them aside! Not my idea of a simple adjustment. For the moment I

removed the drum. I again hooked up the power supply to one pair of

coils, and again there was no perceptible force. If I put a supermagnet

by the coil, I could feel a small amount of repulsion or attraction,

but not with the rotor. And not with a fat chunk of steel that would

stick fast to the supermagnet. My motors with the supermagnet rotors

work great with these coils. Plain steel doesn't seem to work at all.

Apparently with the reluctance motor I was moving into unexpectedly

unfamiliar territory.

Of course, usually motor coils have metal behind them,

connecting them all together magnetically. The coil cores are usually

integral to the die-cut laminates that comprise the stator. Connecting

metal didn't seem to be necessary with the supermagnet motors. Going

from steel backing disks to plastic composites had improved performance

a

lot. The magnets, which were connected together by the steel rotor

plate, seemed to make for a complete enough magnetic circuit. Here the

steel in the rotor just doesn't seem to help. Perhaps I needed to go

back to a metal coil backing plate in the stator? Since there are no

supermagnets to generate current into it, it shouldn't cause the losses

that it did with the supermagnet rotor.

Configuration Experiments

The next

morning (19th) I took two older coils with 63

turns of #14 AWG wire (instead of 21 turns of #11 - normally 3 were

wired in parallel instead of 3 in series to get to 63 turns total for

Electric Hubcap motors) and set them on a steel bar, about the same

distance apart as in the motor, opposite magnetic polarities up. These

would of course give 3 times the force with the same current. I put the

rotor over them and applied the same 10 amps. This time the lobes

pulled fairly strongly down onto the coils. Pulling up on the rotor, it

could just lift the heavy coils and bar. With the coils on the bench

instead

of on the steel bar, the force was much weaker and it would by no means

pick up the coils, or either one alone.

The next

morning (19th) I took two older coils with 63

turns of #14 AWG wire (instead of 21 turns of #11 - normally 3 were

wired in parallel instead of 3 in series to get to 63 turns total for

Electric Hubcap motors) and set them on a steel bar, about the same

distance apart as in the motor, opposite magnetic polarities up. These

would of course give 3 times the force with the same current. I put the

rotor over them and applied the same 10 amps. This time the lobes

pulled fairly strongly down onto the coils. Pulling up on the rotor, it

could just lift the heavy coils and bar. With the coils on the bench

instead

of on the steel bar, the force was much weaker and it would by no means

pick up the coils, or either one alone.

I tried the same thing to repel a single small

supermagnet. It was stronger with the steel backing the coils, but less

notably, and the forces were stronger overall.

Next I tried again with a spare Electric Hubcap magnet

rotor. It

was again somewhat stronger with the plate than without, but even with

an inch flux gap, it had good force either way.

Finally I tried putting both coils the same magnetic

polarity and tried the reluctance rotor again. This still worked, and

worked much better with the steel bar than without, but the force was

somewhat weaker than with opposite polarities.

I didn't actually measure the forces with a scale. That

would have taken much longer to set up. When I speak of "somewhat"

stronger or weaker I mean somewhere around double or half. "Much"

weaker might be 1/4 to 1/8 as much force. The flux gap with the

reluctance rotor was much smaller than for the magnet and magnet rotor,

eg 1/8" to 1/4" versus 3/4" to 1".

Evidently the lack of steel backing for the coils with the

supermagnet rotors simply means using a smaller flux gap to get the

same force. The With the lobed steel rotor, it appears to make

the difference between "works" and "doesn't work". The small flux gap

might preclude having the "wall" making separate stator and rotor

compartments.

As the day wore on I thought of more things to try. The

toroidal iron powder coil cores worked fine in the supermagnet motors,

but their magnetic permeability is much lower than solid iron. How

would iron laminate coil cores work, like the ones I was originally

making with nail gun nail strips? Always wanting

to keep a few "artifacts" of earlier work (and packrat that I am), I

went out to the garage

and found two sets of the old original Electric Hubcap coils. I took

one in, snipped a wire so I

could activate two coils alone, and put those on the steel bar. That

had more

somewhat more strength than the toroidal core coils - not earth

shattering but it was a notable improvement. With the powder cores I

could just pick up the coils and bar with attraction to the

rotor lobes. With the nail strip cores it was a fairly solid pick-up

that took a little shaking to break loose. I repeated the test a few

days later with similar results. Then I remembered that the 2" (O.D.) x

1" laminate type actually has more iron. The 2" x 1" toroid cores with

the 1.25" hole in the center have only 60% as much. Doubtless that

explains the strength difference, rather than any qualitative

difference between materials.

I put the shaft through the rotor so it sat just above the

coils on the end of the shaft. With either set, the rotor would turn

until two lobes were in

line with the coils. That didn't necessarily mean there'd be a lot of

torque, but a motor made this way would definitely run.

But I thought

of yet another trick. I had purchased a

couple of years ago some ceramic "cup magnets" that I saw on line when

ordering supermagnets. Although ceramic magnets aren't very strong,

these boasted an impressive pulling force. The magnetic metal "cup"

surrounding the magnet concentrates the flux into a narrow gap between

the magnet and the rim, and just in front of that gap is its powerful

pull. Why couldn't

this

technique be used with an electromagnet to greatly increase its

strength

in a narrow flux gap between coil and rotor lobe?

But I thought

of yet another trick. I had purchased a

couple of years ago some ceramic "cup magnets" that I saw on line when

ordering supermagnets. Although ceramic magnets aren't very strong,

these boasted an impressive pulling force. The magnetic metal "cup"

surrounding the magnet concentrates the flux into a narrow gap between

the magnet and the rim, and just in front of that gap is its powerful

pull. Why couldn't

this

technique be used with an electromagnet to greatly increase its

strength

in a narrow flux gap between coil and rotor lobe?

The cup magnet technique should also make the steel

backing redundant, since it completes the magnetic circuit locally at

each coil. Plus, since that's the case, it wouldn't matter which

polarity the coils of each phase were: the three coils per phase

in the "Electric Hubcap" motor size should be fine.

But testing the "cup electromagnet" idea out was going to

take more than a quick setup: parts would have to be made. (and from

what?) And cups, if used, would have to fit in the cramped Caik motor

stator area.

I found a pipe (chain link fence type) that seemed to be

about the right size for the outer rim of the 'cups'. It barely fit

over the coil wires - and might need a few protruding "next layer"

turns removed. But it was rather thick walled. Not only might it be

hard to fit, it was going to take some cutting to get even-length 1"

cup sections. (at least, if I cut them with an angle grinder.) I

decided to wait until Monday and see if there was an electrical conduit

pipe size that was better. (And if it could be cut - evenly - with a

pipe cutter, so much the better!) Those were about the only types of

pipe I could think of that just might be suitable. The place I went to

then (24th) didn't have any large enough.

While all the rest was in

progress, I had been on the

motor controller e-mail list. A couple of people, one in particular,

were very interested in the SR motor concept. When I explained I was

doing axial flux, he replied on the 24th and suggested having two

rotors, one on each side of the coils. This idea grew on me. I had

thought this impractical and seemingly unnecessary for magnet motors,

but here, struggling to find more flux and magnetic force - torque - it

seemed like a good idea. Later I continued reading the axial flux SRM

paper and found "everyone" is using two rotors.

While all the rest was in

progress, I had been on the

motor controller e-mail list. A couple of people, one in particular,

were very interested in the SR motor concept. When I explained I was

doing axial flux, he replied on the 24th and suggested having two

rotors, one on each side of the coils. This idea grew on me. I had

thought this impractical and seemingly unnecessary for magnet motors,

but here, struggling to find more flux and magnetic force - torque - it

seemed like a good idea. Later I continued reading the axial flux SRM

paper and found "everyone" is using two rotors.

I could still put a pipe/ring around the coil (or bend 1"

wide sheet steel into circles), but instead

of being like the cup magnet, both ends would have open gaps and would

interface with a steel rotor. It would even out axial forces, too, so

there'd be no pull towards one end of the motor at any time, quite

unlike the continuous pull of magnet rotors toward the stator side.

There should be, if perhaps not double, at least substantially more

torque than

with a single rotor.

Here I realized I'd hit a point of almost complete

redesign of the motors. They'd have to be re-done more or less from

scratch. My experience in designing and building molds and motors should

shorten the process substantially... but with something new, you never

know for sure. Somehow the coils will have to be held in the center,

inside metal rings, with very thin flux gaps to adjacent rotors on each

side, too

small to permit separator walls. God only knows how thick the outer

perimeter would have to be to protect against a steel rotor flying

apart at very high RPM. On the other hand, the chance of that happening

is pretty remote, and the mass of the rotor is relatively small.

Perhaps the

biggest bonus for SR is that the solid steel rotor is safe up to very

high RPM.s.

The optical position sensor unit could perhaps use the

petals/lobes of one of the rotors itself as the optical interrupters.

It might have to be installed last, inserted through the outside

perimeter wall. In fact, it might best be done as three separate

inserted sensors. Or there could be a slotted drum with the electronics

mounted in one end "bell".

How "fat" will the pancake be? (Stator coils 1.0") + (2

rotors 1/4" = .5") + (two flux gaps of 1/16" = .125") + (clearance,

rotors to end walls [with bearings] .375" = .75") + (two end walls 3/8"

=

.75") = 3.125". If the actual build pans out, that's over 3/4" thinner

than the single magnet rotor type. (Not counting the protrusion of

needle or "trailer wheel" bearing hubs. A single rotor unit would work

out to just 2.675" thick!)

On the 25th I bought the second rotor. These are (I

believe)

cast metal, with a built-in 1" machined and keyed center hub. The next

day I wrote

to the chief author of the AFSRM paper hoping for comments on my

design. Then I tried to magnetize a cut-off piece of the first rotor by

rubbing it with a supermagnet. It wouldn't hold magnetism! The soft

magnetic rotor material is the best, and I had it. A rotor that holds

magnetism would cause losses. It would be good for functional "gosh it

runs" motor tests, but not for a finished motor. I guess you wouldn't

want a disk brake that picks up metal particles, which would scratch it

and wear it out, and it was made soft magnetic to prevent that.

Evidently I lucked out.

Next I decided that the only way to get an outer ring just

the

right diameter would be to roll it from flat stock. On the 27th I went

to a sheet metal fabrication shop and got a piece of sheet steel, about

8" x 48" x .032" (20 gauge) ... from their scrap bin. That was a little

thinner than I thought best (.04-.05?) but beggars can't be choosers.

Would two winds of it around the coil work, or would that just diffuse

the magnetism? I decided one layer would be best. I wanted soft

magnetic material, but thought it might be hard to find, and I forgot

to bring a magnet to test with. Anyway, I wanted to get the motor

running before worrying too much about efficiency. To my surprise, the

sheet wouldn't magnetize. Had I just 'lucked out' again? Or was it made

that way (a) because it was cheaper, or (b) deliberately, because you

don't want your furnace ducts picking up shards and filings of steel

either?

At this point I tried several bits of steel, including a

mild steel bar, and found most of them wouldn't magnetize. A threaded

rod and a drill bit did and they would then pick up steel washers, so I

wasn't doing something wrong. Apparently "soft magnetic" steel is much

more common than I thought, and the annoying magnetization and pickup

of filings and bits of steel by drill bits, files and screwdrivers

isn't "the norm" with most steel stock types.

The design of the coils, it seemed, needed only a little

change. The

biggest constraint was that nothing could stick out either end, even a

little bit, since there would be rotors flying by in very close

proximity. (.5 to 1mm?) The second one was that each layer of wire

would make the gap between the inner toroid and the outer ring wider.

Where I had been using 21 turns of fat #11 wire per 12 volts, turn #21

started a third layer since just 10 turns fit on each layer. Then, in

order that the inner end of the wire could come out without protruding

past an end, the second layer couldn't overlap the first wire. At first

I thought that meant eliminating turn #20 as well as #21, leaving just

19 turns - a 10% reduction. Then I realized turn #20 could end just

before the protruding inner wire, putting the inner and outer wire

right next to each other - a lesser 5% drop. Okay! But if the outsides

of the coils were to hang over, past the outer edge of the coils, then

the protruding wire would be okay. At first glance, that would seem to

be just lost flux. OTOH, it's mainly the leading edge of the coil where

the flux is most needed. The loss is in the middle of the outside edge.

I took a coil, which had the old cotton insulation, and

unwrapped two turns to get it down to two layers of wire. (They unwind

disturbingly easily considering they're epoxied on.) Then I cut a piece

of the sheet metal ~1.05" x 9.5" with tinsnips. I wrapped it around and

found it only needed 8" length. The O.D. was just ~2.55", or less than

.3" radius of wire and outer ring around the 2.0" core. With modern

insulated magnet wire, it would be slightly thinner, with slightly less

than 8" of 1" strip sheet metal required.

If the core to ring gap was just, say, .25", but

considering the core itself had .375" thick walls, I estimate the best

flux for the rotor occurs within, say, .25" to .35" of the coil. With a

gap of (<)1/16" and a rotor 3/16" thick, the entire rotor is just

within .25". The actual rotor metal may expand that flux distance, too,

which would mean substantially thicker rotors could be accommodated.

The outer ring of soft metallic steel would replace the ilmenite

paramagnetic coating of my coils for magnet rotors.

IMHO I think the best form for a coil for axial flux SR

would be two parallel "slot" lines in the radial direction, at the

front of the coil and the back, rather than the toroid. That would also

modify the best shape of the rotor to pretty much straight radial

front-back edges. However, the toroid coils are what I have at the

moment. At least they enclose the most core per length of copper wire.

But if each coil is but little changed, the stator as a

whole needs to be radically different, first because of the narrow flux

gaps, and second because of the double rotor layout. I can't think of

any reasonable way to put it together except to epoxy it all into a

blob - a very flat, precision width blob. That certainly doesn't help

with heat dissipation. Oh well, that's the way the axial flux windplant

makers do

it.

Switched Reluctance "Active Generators"?

With a motor controller it's possible

to use the SR machine as a generator. As with the bipolar BLDC,

it's accomplished by attempting electrically to slow it down - to drive

the motor in reverse of the

direction it's turning. I am interested in this, as it must be possible

to change the generated voltage by varying the control, at any given

RPM.

Thus the large Electric Weel might be done as a SR machine that

could equally be a motor or a generator, and

as a generator (its intended use) the output could be programmed or set

to a desired voltage, or to the point where it presents the 'maximum

power

point' ("MPPT") output at whatever RPM it's turning, as opposed to

simply putting

out a fixed "volts per RPM" that may not be a convenient value.

As a magnet rotor, magnet-driven generator, the maximum

output occurs with alternating north-south magnets, four rotor magnet

poles per three phases. To run it as a motor it has to have two magnet

poles per three phases. So configured as an optimal 'passive'

generator, it won't run as a motor. For the SR version, which must have

'active' control, the motor and generator would be the same machine.

With magnets, there is usually cogging with the iron in

the coil cores. Hence, the best permanent magnet generators where low

or zero cogging is required have used two large diameter rotors with a

lot of supermagnets (a couple of dozen), and thin air core coils

between the rotors. The area needing this most is wind power, where

even slight cogging means no rotation of the propeller and hence no

power in light breezes. The active reluctance generator solves this

problem too as it has no cogging. And with appropriate control

(microcontroller?) it should be able to set an

output voltage and maintain it at any wind speed, instead of having the

voltage vary with wind speed. This

should eliminate any need for a separate DC to DC converter since it

can regulate its own voltage. So in many installations there may be no

more circuitry overall.

This situation might also apply to the Electric Weel being

used for hydro power. I have been somewhat concerned that the cogging

of the huge Weel, combined with the strong gearing up of the speed of