Turquoise

Energy Ltd. News #88

covering May 2015 (posted June 3rd)

Victoria BC

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Highlights:

* New configuration Bipolar BLDC Motor to use improved reliability

Unipolar Motor Controller (Month in Brief)

* Electric Weel: 'finished' at last, but... (Month in Brief,

Electric Hubcap Motor Systems)

* Geo-engineering: Playing Russian Roulette with Earth's Environment

(In Passing)

Month In Brief

(Project Summaries)

- NiNi cylindrical batteries - Electric Weel Hydro Generator -

Using a Unipolar Motor Controller for Bipolar BLDC motors! - Electric

Ooutboard from Scratch Revival? (with Caik motor & unipolar

controller, and double U-joint at foot) - Making a Flat Drive

Belt - Various NiMH Batteries & RX7 EV - Aquaponics... wheat field

- Thermoelectric: fridge update, heat pumping - Solar Hot Water? -

Paperwork for CRA -

Commercialization?.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Borax for Arthritis? - Geo-Engineering... potential human extinction:

Chem Trails!...

HAARP Too!... Unnatural Disasters? - The Three Core Values of

Social Sustainability.

- In Depth Project Reports -

Electric Transport - Electric

Hubcap Motor Systems

* Giant Electric Weel Generator

* Making Flat Drive Belts from Polypropylene (or other)

Webbing/Strapping

(Flat belts are 99% efficient!)

Other "Green"

Electric Equipment Projects

* Aquaponics & LED Plant Lighting update

* Thermoelectric (Peltier Module) Fridge & Space Heating Update

Electricity Generation

(no reports)

Electricity Storage - Turquoise Battery

Project (NiMn, NiNi), etc.

* The Battery Construction Puzzle

* Sheet metal Roll-bender; rolling up a negode sheet

* Making up NiMH "sub-C" power tool batteries, Electric Mazda RX7 NiMH

"D" cell pipe batteries

No Project Reports on: AFSRM,

Variable torque converter transmission, Magnet

motor,

Lambda ray collector, evacuated tube heat radiators, CNC

gardening/farming machine.

May in Brief

It appears I'm finding more time to come up with exciting

ideas,

and then to write about them while they're in mind, than I am to get

new development done. There are a bunch of topics here, each more than

a paragraph but

mostly too short to move to "detailed reports" and then to mention them

anyway

in a shorter form in "May in Brief", so the e-mail is rather long. The

main physical

accomplishment was (at last!) the complete assembly of the Electric

Weel

motor/generator.

Time, time, where is the time to get all these things

done? Months and then years are stretching toward a decade. Projects

and concepts have advanced to the point where I could certainly

delegate much of the work if I had help, and then things could proceed

pretty rapidly. I simply have to come up with means to get a few other

people

involved in some of the projects and developments.

I also wrote quite a piece on geo-engineering in "In

Passing". To all appearances, it has altered climate and grossly

increased and accelerated global warming, a most serious development.

There must be quite a few people who've taken leave of their senses for

this to be secretly going on. The climate disasters that appear to be

artificially caused may directly cause massive loss of human life. Why

is India now hotter than the Sahara desert?, and what happens if any

major portion of the 38 million people in California get nothing when

they turn on their faucets in about a year? As sea levels rapidly rise

in upcoming decades, what happens to the 160 million people of

Bangladesh, much of which is hardly above sea level now - not to

mention countless coastal areas?

Nickel-Nickel Cylindrical Battery

I had expected to get right onto the battery making

project and get one made, but time went elsewhere. I etched a couple of

pieces of

cupro-nickel. Under the 40x magnifying glass, the surface roughness

looked convoluted - very fractal. That was the desired result - lots of

nickel surface area to react.

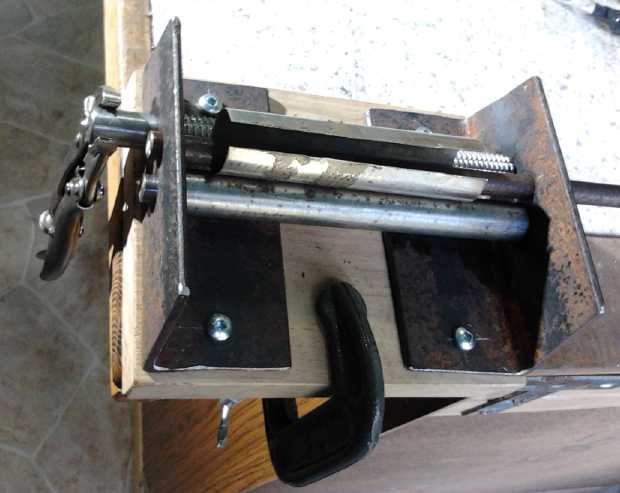

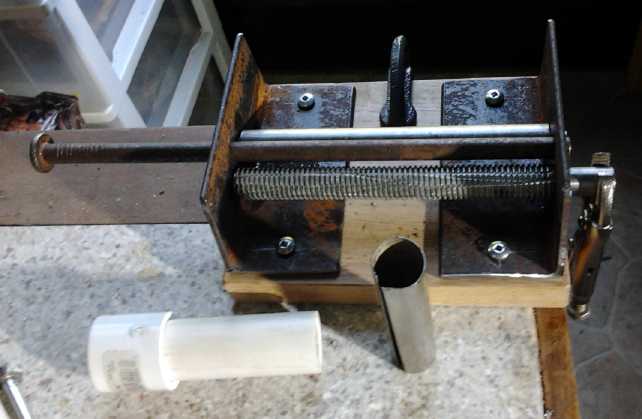

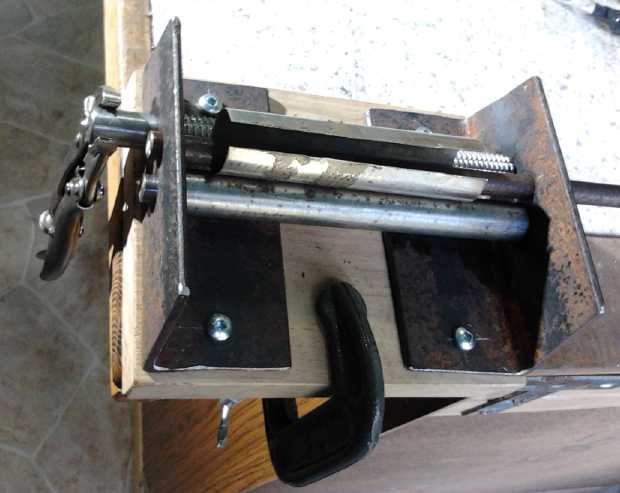

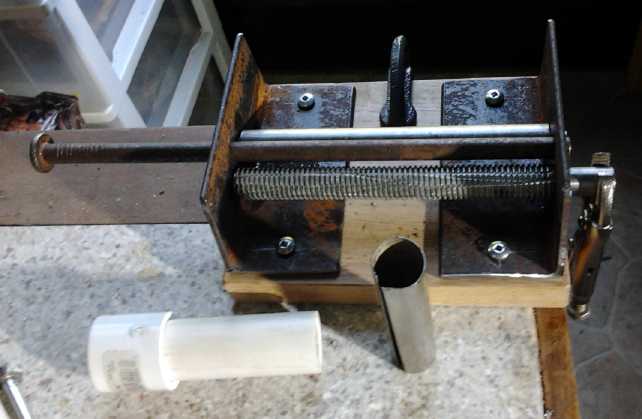

I made a "mini" sheet metal roller for the 'negodes' on

the 28th. It looked nice. I wasn't very happy with the result and I'll

doubtless change the roller setup, but I rolled up an electrode that I

decided was "good enough". That was as far as I got.

Giant Electric Weel Generator for Floating Hydro Power

The overriding

project of first half of the month was

assembling the Electric Weel generator, and partly mounting it in the

transmission assembly for the floating hydro power unit. But once it

was together, the electromagnetic coupling - the volts and potential

amps and watts at a given RPM - was beneath minimum expectations.

The best that could be coaxed out of it by careful adjustment at 60 RPM

(we could get this speed turning it by hand) was about 5 volts open

circuit and maybe 6 or 7 amps short circuit. (I couldn't get it up past

about 30 RPM shorted.) A "maximum power point" for 60 RPM might be

between 4V * 5A = 20 watts and 5V * 6A = 30W. At a top speed of 600

RPM, that would come out to maybe 2000-3000 watts.

The overriding

project of first half of the month was

assembling the Electric Weel generator, and partly mounting it in the

transmission assembly for the floating hydro power unit. But once it

was together, the electromagnetic coupling - the volts and potential

amps and watts at a given RPM - was beneath minimum expectations.

The best that could be coaxed out of it by careful adjustment at 60 RPM

(we could get this speed turning it by hand) was about 5 volts open

circuit and maybe 6 or 7 amps short circuit. (I couldn't get it up past

about 30 RPM shorted.) A "maximum power point" for 60 RPM might be

between 4V * 5A = 20 watts and 5V * 6A = 30W. At a top speed of 600

RPM, that would come out to maybe 2000-3000 watts.

This was disappointing from something so large and capable

of handling far more power. Apparently my design is a better motor

than a "passive" generator.

There is still one way to pull a rabbit out of the hat.

With a motor controller connected, it could be set into what's

described as "regenerative braking" mode, which can increase the output

a lot. And as an "active" generator, the output can be matched to the

force available - torque and speed - and to the load. It's

"programmable".

Until now, this would have meant ripping half the magnets

off the rotor and flipping them over, since the "generator max" magnet

pole configuration of NSNSNSNS.... would need to be replaced by the

standard NNSSNNSS.... motor configuration. (2 rotor magnet poles per 3

phase coils instead

of 4 per 3.) But read on!

New Concept: "Unipolar" Motor

Controller for Bipolar BLDC Motors!

An exciting new possibility drifted into my consciousness

toward the end of the month. As I found in 2008 when I first started

making motors, if there are four rotor magnet poles for each three

stator coils, as there are with the Electric Weel generator as made,

the magnetic forces cancel out and the motor won't rotate. Thus... with

the standard type of BLDC motor controller... this magnet configuration

can only be used as a passive generator.

But if I use the new unipolar/SR motor controller, only

one phase is on at

a time instead of two, so the thrust forces don't cancel and the

present magnet configuration could be made to work.

Traditionally for a 3-phase BLDC motor there are two rotor

magnet poles for each three stator coils. One phase is driven "north"

while another is driven "south", with two phases active at any given

time, all switching around as the rotor turns. To send the power to the

coils, the controller employs a 3-leg H-bridge of power transistors.

As mentioned before, the H-bridge has inherent reliability

issues owing to the fact that most any "glitch" or failure can cause

the

transistors to short circuit right from the power to ground, a

catastrophic failure mode which usually destroys multiple electronic

components, ruining the controller.

It would be desirable to eliminate the H-bridge as in the

unipolar or SRM motor controller. And the 4 magnet poles per 3 coils

configuration is actually better than 2. Finally I thought of these two

things together

instead of separately. They make a matched configuration that

will work. With the unipolar controller, only one phase is active at a

time, so the balancing of magnetic forces resulting when two phases are

active

doesn't happen. There can be forward (or reverse) thrust in all

positions of

rotation. And in spite of only one phase being on at a time instead of

two, it's probably no weaker because the ON coil is always both pushing

on one magnet and pulling on another, working in the strongest magnetic

flux where the poles transition, and there are twice as many

transitions per rotation of the motor.

Therein appears to be potential for making superior, more

reliable BLDC

permanent magnet motors, using the same motor controller that can run

an axial flux switched reluctance motor (AFSRM). They

will have lower torque ripple than the 3-phase AFSRM because the coils

are both pulling and pushing on magnets, and during rotation, as the

push

on one magnet weakens the pull on the other strengthens. And the

simpler hall sensor magnet

position sensors can be used where the AFSRM needs optical sensors.

A third and not inconsequential advantage is I can already

make BLDC motors and (except for the control change) I know they work

really well, whereas I haven't yet built and tested an AFSRM motor, and

the exacting physical requirements of AFSRM.s with their

sub-millimetric flux gaps potentially pose

production problems. With one having smoother torque and the other

being capable of very high RPM.s, it may be that both types will prove

useful in different applications.

Electric Outboard 'from scratch' Project: almost revived? ... to be

revived?

I was apprised by Jim Harrington on the 10th that the

University of Victoria mechanical department was looking for a student

project, which would be picked on the 12th. There was very short

notice, and he had just submitted a project.

We talked about how outboard motors for boats always have

a gearing down

down by the propeller (between ~ 2.5:1 and 3:1) because gas engines are

lower torque, higher speed. So when the engine is doing 5000-6000 RPM,

the prop is only turning 2000. This is always frustrating to anyone

converting an outboard to electric because electric motors are higher

torque, lower speed - often 2000 RPM range. So the prop is only turning

650-800 RPM instead of 2000. It really needs about 1:1; no reduction at

all.

I wrote, explaining the idea for using two U-joints, each

one changing the direction by 45° to effect the direction change

from the vertical shaft down the leg to the horizontal prop with low

losses and low noise, naturally having a 1:1 ratio, so a project would

be to make a bottom end for an electric outboard with this mechanism

and all the required characteristics.

Briefly I was looking forward to the idea of having

someone else do some of the development work that I haven't had time

for. I was told the idea came in second. Oh well!

Near the end of the month, after considering this along

with the more reliable motor controller to be used with the BLDC motors

I can already make, I

thought I'd think again about actually manufacturing electric

outboards. It should be a clearly superior product, with 6 horsepower

from the Electric Caik motor or 9 from the Electric Hubcap (considered

equivalent to about 2.5 times that in gas in marine circles), high

efficiency and improved motor

reliability. And that presumably better propeller I tried to cast an

aluminum copy of. I think they should sell. I'm not going to do it all

by myself, so it will depend what

arrangements can be made. But proving the new BLDC motor and controller

system works well comes first.

Making a Flat Drive Belt

One experiment

I did try in May was to make a sample flat drive belt from a piece of

2" polypropylene strapping. To form a loop I melted the ends together,

using an iron isolated from the plastic with two pieces of cellophane,

above and below. Cellophane [unplasticized] won't melt. (My dad and

friends long ago made ice fishing tents this way with polyethylene!)

The belt is so strong yet limp one can see why they'd be almost 99%

efficient at transferring power.

One experiment

I did try in May was to make a sample flat drive belt from a piece of

2" polypropylene strapping. To form a loop I melted the ends together,

using an iron isolated from the plastic with two pieces of cellophane,

above and below. Cellophane [unplasticized] won't melt. (My dad and

friends long ago made ice fishing tents this way with polyethylene!)

The belt is so strong yet limp one can see why they'd be almost 99%

efficient at transferring power.

Being able to simply make any desired belt from common

material should be a big advantage. (Maybe I'll try a flat belt on my

bandsaw first, replacing the V-belt!)

Pulleys for flat belts should be slightly convex profile,

with or without retaining sides. They'd be easy to make on a lathe.

(Some readers may recall I 3D printed a couple of 7" flat belt pulleys

from ABS a couple of years ago.)

Various NiMH batteries, Electric

Mazda RX7 et al (short version - more detailed version is under

"Electricity Storage")

I have been

using NiMH AA batteries to replace dead NiCd

batteries in cordless drills. After all this time, I checked at

all-battery.com, and found the "weird" power tool size is a standard

called "Sub-C" (for underwater use?). I ordered 52. They arrived on the

26th. I spent a couple of hours, first wrapping up a set of 15 with

masking tape because they just had cheap easily melted plastic

insulation (hazardous in a battery pack!) and

then soldering them for one 18 volt drill. It worked great! According

to Tenergy the 30 amp, 3.0 amp-hour cells should

also have 40% longer running time than NiCd. And of course far longer

life span. On the 29th I soldered together another 8 for the 9.6 volt

drill, replacing the weakening regular AA cells I originally installed

maybe 7-8 years ago.

I have been

using NiMH AA batteries to replace dead NiCd

batteries in cordless drills. After all this time, I checked at

all-battery.com, and found the "weird" power tool size is a standard

called "Sub-C" (for underwater use?). I ordered 52. They arrived on the

26th. I spent a couple of hours, first wrapping up a set of 15 with

masking tape because they just had cheap easily melted plastic

insulation (hazardous in a battery pack!) and

then soldering them for one 18 volt drill. It worked great! According

to Tenergy the 30 amp, 3.0 amp-hour cells should

also have 40% longer running time than NiCd. And of course far longer

life span. On the 29th I soldered together another 8 for the 9.6 volt

drill, replacing the weakening regular AA cells I originally installed

maybe 7-8 years ago.

What's the difference between a cheap cordless drill and

an expensive one? I think it's mainly the batteries. These "cast away"

cheap drills now perform like the best ones and should last many years.

Soldering up the 9.6V

cordless drill battery

As to the Mazda EV batteries, "D" cells, it was always the

same oldest NiMH

battery (originally 90AH) that got low first. This was one of the

"giant flashlight tube" batteries

composed of nine PVC "1.25 inch irrigation pipes" tied together. I got

the idea to

exchange 1/2 the pipes for pipes with new cells to help take the load

better. That would increase the overall driving range. And I made both

pipe batteries ten pipes for 100 amp-hours, and I changed the copper

sheets on one side to flexible wires so they wouldn't tend to pull the

end caps off. This took up the day of the 30th. Now it stays slightly

higher than [what was] the next weakest battery, but I haven't put it

to any "ultimate" range test yet. I found two actual bad cells that

won't hold their charge and may have been adversely affecting

performance - not bad out of 210 that have been running the car for 2

years and many of which were bought in 2011 and variously used

previously. And melted plastic on one of them showed it had been

overheated some time prior to putting it into the pipe.

Next, besides seeing how much farther the car goes, I'll

take some of the old cells and test their

current and storage capacity. Then I'll submerge them in water to some

particular depth (pressure) for some particular time, and test them

again. If indeed loss of moisture inside is the problem, and if a

little more

water can be successfully introduced, they should perk up and perform -

ideally like new again.

BTW: Again as the weather warms up (and it's been really warm

this spring), the car again is using less amp-hours per mile, around

10% improvement. Again the only

thing I can attribute this to is the thinning of lubricants and

whatever else would reduce rolling friction in warmer weather - or

maybe the rubber in the tires becoming more pliable? Obviously tire

friction is a considerable load.

Aquaponics & LED Lighting

Progress - Lettuce - End

of the 'Swimming' Pool - New Aquaponics Fish Tank

The lettuce here seen at

mid-month

outgrew the light on all sides by the end.

For whatever reason, two plantings of spinach failed to

sprout. Come to think of it, the small round seeds probably washed away

with the water circulation in the loose lava rock. The leaf lettuce

started in seedling pots grew, but it seemed spindly, as if it thought

it was in the shade and was trying to

get taller to find sunlight.

For whatever reason, two plantings of spinach failed to

sprout. Come to think of it, the small round seeds probably washed away

with the water circulation in the loose lava rock. The leaf lettuce

started in seedling pots grew, but it seemed spindly, as if it thought

it was in the shade and was trying to

get taller to find sunlight.

I moved the LED grow light down from a stand couple of

feet above the bed to resting on a couple of sticks 6" above it. That

seemed to make a difference. The sunlight, now at a steep angle for the

summer, hardly came in the window, and the plants needed the LED light

perhaps even more than in the winter. Some of the leaves shot past it,

and by the end of the month it was in the midst of the lettuce insead

of above it. I move it around

a little occasionally to simulate the movement of the sun. ...And

occasionally I forget to turn it on in the morning and the plants go

with only indirect window light most of the day. Anyway the lettuce is

growing nice big leaves in its quest for light.

I have the impression that it would be best to have these

LED lights spaced fairly closely together, if not abutting, 14-18" or

so over the whole grow bed. Four would be a good start; six or even 8

would be better. That's around 60, 90 or 120 watts. It seems like a

lot, but growing vegetables isn't even possible under a 100 watt

incandescent bulb. So... I need to make more lights. Of course right

now there's lots of lettuce in the garden outdoors, but indoor lettuce

would be available all year.

The plastic swimming pool I

had bought was made of vinyl.

One day my brother in Toronto called, and in the conversation he said

vinyl is poisonous to fish. Malaspina College aquaculture department

had bought some vinyl pools once and they had to let them sit for 6

months

before they could put fish in them. The 9 goldfish I'd put in it were

still alive, but I started viewing the 1500 gallons of water as

"contaminated". I determined to eliminate the pool, and got some more

220L plastic food drums (surplus) and started pumping the water into

them, and into a somewhat larger tank I bought last summer, and into

some garbage cans. When the pump to the large tank

was started, I went back in to work on the Weel generator. When I came

out, I found that the 12V pump wires' insulation had melted, shorting

the wires and the battery, and the hot wires had melted through the

inflatable ring that rises up as the pool is filled to keep the water

in, and through the side of the pool proper. In addition, I was told

that the side of another plastic pool had split open and drained all

the

water while the owner was away. I decided that thin plastic pools

for fish - or even rainwater - are just a bad idea all around, prone to

trouble! I did manage to save most of the water.

And a large patch of bare earth was left where the pool

had been. I thought of planting potatos, but freeloading deer had been

coming into the yard and had eaten some unprotected potatos. (and my

lush strawberries: GRR!) I decided to plant wheat instead. Since I

still haven't made the CNC gardening machine, I got out the Ryobi

electric rototiller and tilled it by hand.

Rototilling the mini wheat field where the pool

had been.

Rototilling the mini wheat field where the pool

had been.

The hand-held tiller didn't want to stay in the ground and dig, so I

added

a concrete block to weigh it down. This makes it quite heavy to pick up.

I started

getting nervous about the battery lab aquaponics

setup after a couple of dreams about water flooding the floor, dripping

down through the kitchen ceiling below. Could that fridge on its back

spring a leak suddenly enough to do that? Or was there a weakness in

the pump or plumbing that would burst and the pump would rapidly pump

out all the water from the grow bed and sump tank? (It can't pump the

water from the fish 'fridge' below the regular surface level.)

I started

getting nervous about the battery lab aquaponics

setup after a couple of dreams about water flooding the floor, dripping

down through the kitchen ceiling below. Could that fridge on its back

spring a leak suddenly enough to do that? Or was there a weakness in

the pump or plumbing that would burst and the pump would rapidly pump

out all the water from the grow bed and sump tank? (It can't pump the

water from the fish 'fridge' below the regular surface level.)

It seemed imperative to change the setup. I had a 220

litre white plastic drum I had cut the top cut off of, which is what

the guy I bought the tilapia from used for tilapia tanks in his

aquaponics setup. I took it inside. Later I drilled a hole and threaded

it for a hose connector type shutoff, about 2/3 of the way to the

bottom. A filter will sit on the floor inside. I want to pump from the

bottom to get waste out, but I don't want the pump to be able to suck

it dry in case of any problem, since that would immediately kill the

fish.

I still haven't got it in operation. If I don't get a move

on, I may soon be mopping up a flooded floor.

DIY pipe socket threader: a convenient little

iron pipe,

DIY pipe socket threader: a convenient little

iron pipe,

with the threads notched with an angle grinder zip disk

to cut into the plastic.

Thermoelectric (Peltier Module) Fridge & Space Heating Update

(Short version - long report is under "Other" green projects)

I continue to be disappointed by what seems to be quite

a limited lifespan of Peltier modules. The one that had been in the

fridge for some time (a year?) performed worse and worse, and the

fridge

temperature rose gradually from a typical 6°c to almost

11°. And that's at the cool end. The only thing worse than a "Q" of

.8 to 1 is a "Q" that's dropped to .5 or .6. Doubtless for a camping

cooler used for a week or two a year it's fine, or maybe in an electric

vehicle, it's fine, but for full time use,

it's a problem.

Likewise, I wouldn't want to explore thermoelectric space

heating for houses much further as it stands, because the savings in

electricity

would be replaced by the headache and expense of replacing the modules

on a too regular basis. It might still be practical for

electric cars, where any saving in heating electricity reduces the loss

of driving range, and where the unit is probably only used an hour a

day instead of 24.

It turned out to be only partly module degradation. The

other factor was the heatsink had become quite dusty.

Once I had checked out the difference just the

cleaning made - 2 or 3 degrees - I put in a new module. It's now

down to 5 or 6° and the ice tray is

half ice - back to usual performance.

I may try putting in a very large peltier module (I have a

couple of 14

amp ones) and use a DC to DC converter to supply it a lower voltage.

Hopefully being run more gently will considerably extend the life span

as well as increase the coefficient of performance. 8 or 9 volts with

such a high current module should provide more cooling than at present,

probably with no more current. This will of course need a

programmable control. But I don't seem to be finding much time to

take on more projects, even when they're extensions of existing work -

things that 'should' have already been done. Of course, the plan gets

better as I go, so it'll be better if it does ever get done.

So far I haven't seen any sign of higher performance

peltier modules entering the market. A Q-max of 2 to 3 would make a big

difference over .8 to 1... and dropping from there. But I haven't

looked for them for a while.

Solar Hot Water Heating

I gave thought to how to do a solar hot water heater.

Heating water directly with the sun is more effective than making

electricity with solar panels and then heating water with the

electricity. I've thought about various arrangements for the last

couple of years, with pumps and controls and "rubber mat" black

"swimming pool" solar water collectors, and finally concluded that the

best way was exactly the same way I did it in 1979.

The steep 45° roof of my house is pretty much an ideal

average angle for catching the sun. Furthermore, it makes for a

considerable vertical height in the centerline of the attic. A typical

hot water solar collector is 4' x 8', 32 square feet. By making a

collector 2.67' x 12', again 32 square feet, it can be mounted low on

the roof, partly over the eaves. Then, the water tank is mounted on a

stand in the attic, and the entire tank is above the level of the

collector. With a pipe from the top of the collector to the top of the

tank, and another from the bottom to the bottom, the warmed water

circulates by convection, but if the water in the collector is cooler

than the tank, there's no flow. No controls or pump are required,

greatly simplifying the whole thing. With a shallower sloped roof, it

could still work with the tank on its side under the peak. (It can also

be hooked with a similar loop to the woodstove for winter hot water.)

The water circulated freely through the collector and tank.

Two shut off water pipes still run to the attic, in line

to the electric water tank. Copper was used except for the cold water

inlet because of heat concerns. I drained the collector for the winter,

but two problems with the original installation were from water

freezing:

(a) The collector wasn't quite straight and a pipe through it

would freeze in winter and burst even tho it was drained.

(b) the pipes between collector and tank did a short dip down

where they went through the roof, and one of them too froze and burst

one winter.

I finally got fed up with doing plumbing every spring and

took the collector down. It still ran off the woodstove. I had a 12'

loop of soft copper pipe coiled through the stove, and it would

actually boil the water if not enough hot water was being used.

The third and finally fatal for the whole thing problem

was that in about 1984 the galvanized water tank sprung a leak. It had

so much plumbing soldered to its specific four openings that I blanched

at the thought of trying to replace and replumb it. I acquired a copper

water tank not long after that, but the collector was gone and I never

got around to rebuilding the system. So far!

This time I hope to do most of the soldering on the

ground, use plenty of pipe unions, and just bolt it together once the

collector and tank are in place. I think I'll make the collector the

same way as in 1979: enclosed in wood, insulated at the back, copper

pipes with black painted aluminum fins for backing and "glazing"

(hmm... single or double?) of light plastic. A small electric heater in

the bottom pipe of the collector would use minimal power and avoid

having to drain it in the winter.

CRA Paperwork

I worked fitfully on the 2014 paperwork for CRA.

Admittedly I haven't been applying myself very well to this task, but

I'm wondering how it can take longer and longer each year, now for less

and less refund of my considerable investments in R & D. Since they

had complained about my supporting documentation, I put together all

the monthly TE News articles for the four projects I'm claiming into

separate files, along with a daily log and some other material. I was

shocked to discover the projects will take over 100 pages to print out.

June Priorities

* Finish CRA paperwork and submit it ("should" have been done in March)

* Make a NiNi cylindrical battery. (should have been done in May)

* Add 4 magnets to the new Electric Caik motor's rotor (configuration

NSNSNSNS) and reassemble it.

* Get the unipolar motor controller reliably and effectively running it.

* Once those are done, make a magnet sensor for the Electric Weel and

apply the unipolar controller to it.

I'll try to dig into that list, but there are little

diversions like the NiMH batteries for the RX7 EV and trying to renew

(rehydrate?) older NiMH dry cells, LED lights ...and just plain living.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Borax for Arthritis?

This is an idea that may be of interest to the many who

are affected by arthritis. Some recent research has identified the

chief cause of arthritis, as well as of calcium deposits, as boron

deficiency. Many farm soils are becoming deficient in boron and other

trace minerals since only the major fertilizer chemicals are being

replaced. I had heard a couple of people raving before about how borax

has cured their arthritis. That seemed iffy since borax is sold as a

cleaner, surely not for ingestion! After I heard about the studies I

found a couple of types of 3mg boron pills at a health food store. One

was boron citrate, the other, cheaper, brand was boron glycinate. But

it seems sodium borate - borax - is actually the prefered form. And

I've heard from a couple of people that regular grocery store "20 Mule

Team" brand borax is quite pure. On the web I found the recipe of one

teaspoon of borax to a liter of water, with the dose being to drink two

teaspoons a day giving 7mg of borax. Probably just one teaspoon is

better once arthritis symptoms have cleared up. If you just don't trust

that the borax is pure (who could be blamed for that?), the 3mg boron

citrate pill is doubtless the one to use. (An available 700 microgram

boron citrate pill is a pretty low dose, tho the pill also has some

calcium. 3 milligrams seems to be usual, and up to 10mg is often used

for 2-3 months while curing the arthritis.)

Three months of 3mg boron citrate pills seemed to have

have taken away my mostly minor arthritic aches and pains, but a couple

have returned since I ran out 3 weeks or a month ago. So I've just

started with the borax in water.

Apparently boron is best taken with vitamin D and calcium.

(I take 1000 IU/ 25mcg vitamin D every second day anyway, since most of

us on the cloudy west coast are vitamin D deficient, leaving us highly

prone to cancers. Surely there's enough calcium in regular foods?)

Geo-Engineering: Chem Trails!

Last winter mysterious rumbling sounds started up, perhaps

every 20 minutes or less. They sounded like very heavy aircraft taking

off, apparently from somewhere in Washington state (Widby Island?) just

across the strait from Victoria BC. Others across America have been

noticing strange rumbling sounds as well for at least a couple of years

too, to

the point where they were posting about them on youtube. A friend

staying on the west coast of Vancouver Island reported hearing heavy

military jet aircraft flying north, and coming back south sounding much

lighter, week after week. (He thought they must be taking troops and

materiel to Alaskan bases. He was in the forest and couldn't see much

of the sky. He said it was unusually dry, and that the trees weren't

healthy

- the whole vast forest.)

Early in May the same friend, back in Victoria, pointed

out to me aircraft "vapor" trails to the west, drifting eastward over

us. They criss-crossed the sky, and didn't seem to fade but instead

they spread out, until the whole sky had a light overcast. We don't seem to be on any regular

commercial flight routes and jets are only occasionally seen in

Victoria skies. But the trails were everywhere. More aircraft were seen

occasionally trailing another batch. I had seen some similar suspicious

looking cloud formations before but wasn't sure. By month's end there

it happened a few more times. These one could

point to and say "That's just not natural!" It's not random aircraft,

nor just regular vapor trails, and there were lots of them. What could

it be but the chem trails people have been talking about since at least

2010, sprayed by

the heavy planes from Washington state, flying out over the Pacific off

the west coast?

In the next few days, heavy clouds came over but didn't

drop more than a few drops of rain one night. And it's been hot - July

weather in May, when single digit (celsius) nightly lows are the norm!

I had heard of "chem trails" before, but I didn't know

what to make of it. Surely at least this strange idea was the product

of an overactive imagination, not some twisted evil plot? It seemed

absurd to think that those running

our society would permit - or that anyone would want to pay for -

widespread, reckless experiments with the atmosphere that gives us

oxygen, rain and life. Yet... I'm not sure how much central control

there really is. Government has sold out to corporatocracy, and there

seems to be less and less co-ordination of or control over various

mixed agendas. People with power are doing some crazy things, and the

evidence (seen with my own eyes) says there's ongoing aerial spraying

on a massive scale.

The jet stream

that normally flows west to east now typically does a big climb north

over the Pacific, then goes south in the middle of the continent, below

much of the eastern USA, and back up at the Atlantic coast. The last

few winters have been bitterly cold out east ("colder than the north

pole!"), while in the west things have been balmy - and very dry.

California has been having the worst drought "in 12000 years" for four

years, and off the coast of California is where the heaviest spraying

has been done. It looks like this altered jetstream is also sucking the

cold from the arctic, where the arctic ocean polar cap is gone in

summer or nearly so, and the glaciers of Greenland are melting and

flushing out into the Atlantic as fast as the water can flow.

[According to a recent TV documentary by climate scientists in situ in

Greenland] The melting ice and melting permafrost are releasing vast

quantities of trapped methane hydrate into the atmosphere from both

land and sea, and this greenhouse gas is 50 times more potent at

raising temperatures than carbon dioxide. [According to another recent

TV documentary by climate scientists in Alaska] The polar ice cap

reflected away most of the sunlight. The open water absorbs most of it,

so the melting is at this point irreversible. They spoke of a potential

ten degree celsius (!) average rise in arctic temperatures. This is

Earthshattering stuff - much worse than previous "alarmist" predictions

of six degrees by mid century. (Those were for 6° rise in the

arctic, 4° in temperate zones, and 2° in the tropics.)

One rumored rationale for chem trails, if there is one,

has been to 'reflect

away sunlight to cool the Pacific ocean' which keeps producing frequent

warm "el-niño" weather. This has predictably failed as much of

the additional warmth in the Pacific is evidently due to magma

circulating closer to the the crust than usual (also bringing

volcanos), not to sunlight. And

the blanketing effect of the particles may trap more heat than is

reflected away, again making a net warming effect rather than cooling.

The particles high in the atmosphere also inhibit rain. (One military

explanation told to pilots - something about stopping surprise "enemy"

attack flights - is so bizarre as to not just stretch but break

credulity.)

There's a saying "April showers bring May flowers", which

for Victoria BC I sardonically convert to "May showers bring

June flowers" because there's often so much rain through April and May.

This year (and last year) there's been little rain since March. When I

set up the 'reservoir' (inflatable swimming pool) in early March, it

filled with 11" of water in one 36 hour deluge (fed from two sets of

eaves-troughs). Only another 9" was added throughout the rest of March,

all of April, and all of May - most of it in March.

Now, who would go to the expense of buying all these

chemicals - countless thousands of tons, no doubt - for no better

purpose than to play Russian Roulette with the whole planet's

ecosystem? According to at least one internet source, the chemicals are

made from fly ash from coal burning. Apparently it's cheaper for the

coal plants to spray it out of aircraft than to have it hauled to a

landfill and pay to dump it there! So (in twisted corporate minds), why

not see if it can be used that way to improve the climate, perhaps

reduce global warming? With no actual studies, initial or follow-up, as

to consequences. But after all... it's cheaper!

In California the huge agriculture business that helps

feed so much of North America is turning to dust, and 38 million people

could turn on their faucets and have nothing come out in about a year.

(L.A. area tap water may be crappy, but at least it's water - so far!)

And it gets worse. The materials in the fly ash/chemtrails

aren't innocuous. It's apparently causing individual heath problems.

Various metals like strontium and barium have been identified in rain

water and lakes, and more especially aluminum compounds - the major

component. Aluminum is linked to Alzheimer's disease, and probably to

Autism, both of which are skyrocketing. It may be causing skin rashes

and, apparently containing "polymeric"(?) nano fibers (perhaps similar

in size and shape to asbestos fibers?), cancers.

This may - or may not - explain why I myself have been

mysteriously getting itchy as if I had been working under the house in

the fiberglass dust, without changing clothes or showering after, with

little slivers poking through my skin here and there. Like fiberglass,

asbestos, and sometimes fir stickers, they're so fine I can't see them

to remove them. I can only take a razor blade and shave the area. That

way the part sticking out with luck is cut off (or the whole thing is

pulled out?) and the irritation stops or is much reduced. (Hopefully

the remaining bits eventually work their way out.) For a while I was

changing my clothes sometimes almost daily as they so often seem to

have become contaminated. People around here with no prior lung

problems, including me occasionally, seem to have developed a cough.

That part

seems to have stopped for now.

As I first wrote of this on the afternoon of May 21st,

there were

more odd clouds in odd patterns instead of what seemed like it should

be blue sky. I went for a walk and found an unusual afternoon fog over

the strait, somewhat under a single dark cloud jutting from the Olympic

mountains, that seemed fixed in position. I suspected but wouldn't have

sworn the lighter, somewhat linear clouds were chem trails. But my

observant friend, having been where there was a good view to the west,

said they

were spraying all day out over the ocean. It drifts over the

land on the wind. That night there was lightning - usually a once a

year phenomenon in Victoria in July or August (if even once) -- and

yes, lightning has also been said to be an effect of chemtrails, the

aluminum particles increasing the conductivity of the atmosphere. And

again there was no rain.

After adding some rainwater from the 'reservoir' pool to

my tilapia aquaponics tank in early May, a scummy foam covered part of

the surface, frothed up by the aeration spray and general water

circulation. This was quite puzzling, as there had never been foam

before, and I always used rainwater. I didn't know what to do about it.

Apparently the rainwater in

the pond was less than pure! It lasted a few days then dissipated.

Later there was a lesser amount of foam in the large aquarium after I

added just a little pond water to it. If I remember right, there was a

bit of foam on the pool, but not much, perhaps because the calm water

wasn't being stirred up. Luckily it didn't seem to hurt the fish. Am I

digressing here? I'm afraid not!

Late on the 21st, I looked on "Dahboo7's" youtube channel.

Dahboo7 covers unusual news almost daily, or more than daily, with a

separate short video on each

subject. There was one about massive seabird dieoffs along the Pacific

Northwest coast. That led me to another longer news report video about

the same phenomenon, which explained there were [probably tens of]

thousands of seabirds of various species washing up on beaches from

Washington to California, dead or dying. No doubt on BC's west coast as

well. The culprit: scummy foam from "a mystery spill", clearly seen at

the shoreline and on the beaches, was soaking their waterproof downy

feathers and they were getting wet and chilled. The foam immediately

reminded me of that in my tank.

Apparently this "mystery spill" had reached my outdoor pond as well as

the ocean.

Connecting the dots, the source material causing the foam

has

to be airborne. What but countless tons of chem spraying? Is aerial

chem spraying related to other Pacific mass die-offs, such as that of

the salmon(?) that is causing mass starvation and die-off of California

sea lions, or the mass starfish die-off a year or two ago? There I have

less to go on. (I'm sure there were other Pacific die-offs recently

too... what were they?)

You can find out more on the web about chemtrails and

"geoengineering". Especially look on youtube for Dane Wiggington, who

has been trying for some years to alert everyone to chemtrails and

their potential for

ruining the whole ecosystem and even making Earth uninhabitable. He

thinks that if enough people know what's happening, it will stop. The

pilots will refuse to dump toxins on their friends and relatives,

others may refuse to deliver the ash to the airports, etc... and just

maybe those who think they are in charge, whoever they are, will stop

ordering it done. But there are "gag orders" for "national security"

(!?!) on everyone involved, and the pilots are carefully selected for

callousness and are frequently rotated. Of course the "mainstream

media"

will never air anything about it, so it's an uphill struggle.

(Reporting on vast die-offs of seabirds and other creatures is okay, as

long as the root cause isn't identified!)

HAARP Too!

The High Frequency Active Auroral Research Program (HAARP)

in

Alaska uses extremely high powered radio waves from an upward aimed

antenna array to heat the ozone layer, creating artificial high

pressure areas and consequent rising winds that blow the ozone away,

and other

effects from heating the ionosphere. HAARP is apparently responsible

for many extreme weather anomolies, and according to some can even

trigger earthquakes. (This last seems far-fetched to me.) Pictures have

been shown of clouds with big holes punched right through them, and of

various other bizarre aerial phenomena.

And chem spraying, making the atmosphere more conductive,

magnifies the effects of the HAARP signals.

The holes in the ozone layer are killing trees globally by

allowing short wave UV radiation to reach the Earth's surface. (That

was being blamed for mass bee die-offs... but apparently the cause for

these has now been pinpointed as being Monsanto's genetically modified

crops that generate their own insecticides, not HAARP. Monsanto is

playing Russian Roulette with the whole world's food supply, not the

environment!)

The US government says HAARP has been shut down. Hurrah!

What they don't say or comment on is what people are saying:

that as many 18 new HAARP sites, some of them on ships for mobility,

have now been created and are actively interfering with natural

weather. And that's just the US operated ones - they say they're not

the only ones. Again there's more info on HAARP on the web and on

youtube.

Someone showed microscope images of the fibers reputed to

have come out of the sky after chem spraying. There were pictures of

someone with a nasty rash on his shoulders and back, attributed to

them. Someone showed weather

satellite time-lapse images of the western seaboard and pointed out 5

unnatural

weather conditions that he attributed to HAARP and chemtrails, saying

the drought in California was being deliberately created. Many other

videos each paint a tiny portion of a sinister and disturbing picture.

Unnatural Disasters?

Well, the missing rain here on the west coast had to go

somewhere! After the Colorado "1000 year" flood of September 2013 and

now the preliminary flash flooding of San Diego area on the 19th,

seemingly it all came down at once on the 24th-25th (and continuing on)

over the whole

south central USA, washing out roads and bridges and creating disaster

zones here, there and everywhere. Texas is prone to flash floods, but

no one had ever seen water rise so

far so fast as it did in some areas. Oklahoma got 27" of rain in May

(to the 25th) when its annual average is 4-5".

But the USA wasn't the only place hit, and according to

some, it isn't the only place where geo-engineering is going on. It

seems like half the world, in places as diverse as Australia, Europe

and Moscow, has suddenly been inundated. The other half is being dried

and roasted, with Alberta forests burning up and killer heat waves in

India.

The rebalancing of the ocean and the atmosphere to some

new equilibrium could

easily take decades after the "geo-engineering" ends, and in the

meantime extreme weather and climate events will be commonplace.

Globally, powerful earthquakes and volcanos have also become

'abnormally' active in the last few years and may well continue

increasing. Whether this is weather related I don't know. I have a

feeling that the present focus on war and international affairs will

gradually start to give way to internal disasters and damage control

and repair within nations in the coming years and decades.

Sustainability

To outward appearances we are headed for extinction, at

the hands of spiritually and morally blind or defective people with a

lust for power, control over others (to what end?!?)... and

destruction. Some of them seem to actually despise anything having

pristine and natural beauty, impudently not subject to their whims, and

probably take satisfaction when they hear of seabird die-offs and

horrific environmental disasters. A complacent public is allowing it to

happen. Who'd have thought extinction could

be accomplished by hateful people without a nuclear war? What will

become of them

when they have to give an accounting for the mortal lives they lived?

Doubtless many will choose oblivion over eternal life. The coming

collapse of the global financial system, economy, and probably of the

effective operation of governments everywhere, accompanied by unnatural

natural disasters, deprivations, wars and plagues, devastating as

it will be, will be a welcome fresh start for the planet and for

humanity.

The celestials, the spirit beings who manage the universe

and

the planet, and offer us guidance but never interfere with human free

will, are here and ready to assist whenever a human turns his spiritual

side 'on' and follows his indwelling spirit of God's leadings. They say

there are three core values of social sustainability which have never

been applied on this planet and which need to be applied

to every endeavor if stability is to be attained:

1. Quality of Life

2. provision for Growth

3. Equality.

Everything should be judged with

these in mind, and the more people who are aware of them, the better.

For example, war leads to unsustainability just for

starters

because there is no equality between invader and invaded. Uncontrolled

population growth and genetic degradation lead to unsustainability

because they lower the quality of life for everyone, while a reasonably

sized and genetically improving population will have a higher and

rising quality of living, over their increasingly lengthy lives.

Uncontrolled population growth is always followed by periodic disasters

with huge die-offs not only of wildlife but of the human population,

and it has been seen many times throughout human history - but never

before on a global scale.

One can easily see that most of our present institutions

don't take these three core things into consideration, and need to be

modified or replaced. But they say that the Earth's peoples can all

agree on these three things even if various groups will disagree on

most everything else.

To accompany those, there are three core value-emotions:

empathy, compassion and love.

One sees that our governing institutions were solidified in form

a hundred years ago and more, and that they are little changed in since

then spite of the whole of society and life changing around them. They

were created without provision for growth, so they are stuck in the

past and increasingly unable to cope with modern realities. That there

should be mass protests and riots in democratic nations shows that the

will of the people isn't being reflected in the operation of their

governments.

In my own ideas for a government Department of Progress,

for citizen initiated referendums and for an "Election Central" forum,

one can see that the aims are for provision to allow political

institutions to grow and adapt, and for improved equality, on many

levels, to the end of a better quality of political and social life.

Tolerance, respect, peace, enlightened social progress

and other attributes and blessings - eventually utopia on this

beautiful and "exceptionally diverse" world - will gradually

accrue from wide observance of these three core values.

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers

- Preliminary Ni-Mn, Ni-Ni Battery Making book

Products Catalog:

- Electric Hubcap 7.2 KW BLDC Pancake Motor Kit

- Electric

Caik 4.8 KW BLDC Pancake Motor Kit

- NiMH Handy Battery Sticks, 12v battery trays & Dry

Cells (cheapest NiMH

prices in Victoria BC)

- LED Light Fixtures

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

Daily

Log

(time accounting, mainly for CRA - SR & ED assessment purposes)

1: Worked on Electric Weel - improved rotor mounting

2:

3:

4: Finished April newsletter (TE News #87)

5: Worked on Electric Weel - revised & finished rotor mounting

6:

7:

8: Weel - assembly and adjustments

9: 10: weekend

11: Weel - assembly, adjustments

12: Etched a piece of cupro-nickel for a battery electrode/test.

13: Weel: added ribs to strengthen body side of stator and to mount

unit in hydro power assembly.

14: CRA paperwork for 2014.

15: Weel: Inspected and adjusted. Improved power per RPM readings but

they're well below the expected range. (Unsatisfactory. Now what?)

16:

17:

18: Etched a second piece of cupro-nickel, this time with agitation

attempting to prevent discolorations (contaminations?). Had idea to

turn generator into an "active" generator using the unipolar/switched

reluctance motor controller. This should save the project!

19: Turned a piece on lathe to make a tiny sheet metal roller for

cylindrical (outer, negative) battery electrodes.

20: Inspected, cleaned and re-installed thermoelectric fridge's cooling

unit, which was gradually losing its cooling power.

21: Inspected thermoelectric fridge and cleaned cooling unit.

22: Replaced peltier module in fridge. Made flat drive belts from

polypropylene strapping to test the idea. (hold at least 200 pounds.)

23:

24:

25: CRA Paperwork

26: Soldered together a battery pack with "Sub-C" batteries.

27: Re-adjusted Weel generator (plastic bends!); turned shaft for

(battery electrode) sheet metal bender; Installed "hose faucet" onto

new tilapia tank drum.

28: finished sheet metal roller and rolled a piece of cupro-nickel for

a NiNi battery electrode. CRA Paperwork.

29: Made another battery pack with sub-C cells, and 6 tube batteries of

12V, 10AH D cells.

30: Removed two tube batteries fron RX7 EV, swapped 5 tubes from one

tube battery and added one to the other - now both 100AH, 12V and

stronger. Re-installed in car. Hopefully driving range will be extended

a couple of miles.

31: Test drive. Battery stayed higher - better than previously 2nd

weakest.

Electric Hubcap Motor Systems - Electric Transport

Electric

Weel Motor (Generator)

Stator with coils wired up and with alternator

diodes thrown in.

Stator with coils wired up and with alternator

diodes thrown in.

(I doubt if those plates will be sufficient heatsinking for continual

use.)

The Weel came together, but not without some

teething problems. The huge diameter, with the body held together at the outside rim, greatly

exaggerated dimensional issues that were only of minor concern with the

smaller motors. 2

or 3 millimeters of flex at the bearing holders in the center top and

bottom became 6 or 8 in spite of some reinforcement. The "impact

modified acrylic" ("like lexan") rotor too

seemed adequately strong but it wasn't 100% stiff even with the glued

reinforcing/thickening pieces.

When it was assembled, either it would seem there was

excessive flux gap or the rotor magnets would rub on the center wall.

Or both.

The center

hole on the rotor side, and its 6 bolt holes,

were all enlarged with a file so the bearing could be moved around, its

position adjusted. Later, 4 threaded holes were put through from the

stator side to allow

long bolts (actually threaded rods with a wing nut tightened against

another nut) to press against and hence adjust the position of the

rotor. Then the top could be put on and the bearing assembly tightened

with the rotor presumably already in position.

The center

hole on the rotor side, and its 6 bolt holes,

were all enlarged with a file so the bearing could be moved around, its

position adjusted. Later, 4 threaded holes were put through from the

stator side to allow

long bolts (actually threaded rods with a wing nut tightened against

another nut) to press against and hence adjust the position of the

rotor. Then the top could be put on and the bearing assembly tightened

with the rotor presumably already in position.

When all this was worked out on a Friday, the rotor could

be adjusted and the machine turned freely. But the next morning, the

rotor was rubbing somewhere, and by Monday it was stuck solid. The body

not only bent under the pressure of the rotor's magnetic attraction to

the stator, but gradually deformed. I had noted that before, but I had

been hoping it only happened for a week or so after molding. This had

been molded months ago. Again, the small effect was magnified with the

large diameter.

On the 11th and 12th we cut and attached two heavy

aluminum channel bars, with 6 bolts through each to the stator end of

the body, forming two ribs to give the body more rigidity, and to mount

it into the hydro power transmission. This - pretty much - solved the

problem of flexing and deformation. It would turn freely with a spacing

washer inserted, but the alignment wouldn't stay without one. One

problem for testing was that the top cover didn't have enough bolts

(four short test bolts instead of 24 longer ones) and it shifted around

a bit, which of course changes the shaft alignment.

I gave it another try on the 14th. I lowered the rotor to

the lowest and adjusted it carefully. I drilled a small inspection hole

in the lid. As I observed the rotor go by, it seemed even enough. But

it would rub at one point in the rotation, so there was definitely a

lower spot, if only by a bit. I marked it with a felt pen to put in a

piece of cardboard or paper as a shim. The open circuit voltage was up

to 4.5 volts at 60 RPM, and it looked like the current would have gone

to 6 or 7 amps at 60 RPM if I had been able to turn the shaft that

fast. As it was it was about 3 amps at under 30 RPM. Well, at least the

maximum power point would be up to 2500 watts or so at 600 RPM. At

least 4 times as much would be a lot better! And later, it had deformed

enough that it was rubbing again.

On the 27th I drilled a hole in the side and found the

rotor dipped down on one side during rotation - about 1/8 to 3/16 of an

inch wobble was much easier to see from the side. I tried a couple of

shims to even it out. One (electrical tape) seemed to do nothing, the

other (thin plastic strapping) pushed it much too far the other way.

Somewhere I'll get it to the middle and then it should run freely at

the smallest flux gap easily attainable. (That's where the rotor

assembly on the shaft rests on the lower bearing with no spacer washers

between.)

Major Problem: Insufficient Output!

Unfortunately, I had never worked out just what voltage it

would generate at what speed. There just seemed to be too many

variables, and of course nothing is set up for this type of machine

construction. (If anyone can find "toroidal iron powder donut coils",

"ilmenite" and "paramagnetic materials" used in

a motor design book, I'll eat my hat!) But with 8 coils in each phase I

anticipated it would be somewhere in a good range. If it was too high,

the coils could be broken up into parallel sections to get higher

amperage instead of higher voltage.

One could spin it up to 60 RPM by hand, and with the heavy

rotor, the speed could be kept steady enough to get meter readings. The

cogging was surprisingly low - hardly evident. To our surprise it put

out less than 3 volts DC. Later, with better adjustment of the rotor

position, it was still only 3.5 to 3.75 VDC. With such low voltages,

even the 1 volt or so losses through the rectifier diodes were

significant. I checked over the wiring, then put in some extra wires

temporarily to measure at different points. From each phase end to the

"Y" point was around 1.7 VAC, all very close to identical, ditto for

3.0 VAC between any two phases. If I shorted the DC output I measured

about 3.3 amps at 50 RPM, which was as fast as I could turn it when

shorted. Of course, even with the huge diameter 60 RPM is awfully slow,

equivalent to only 160 RPM for the Electric Hubcap size. The Electric

Hubcap doesn't put out much voltage at that speed either.

To get even a basic 12 volt battery charging system it

would have to put out 15 volts. Allowing for constant diode voltage

losses, and trying to estimate a maximum power point below the open

circuit voltage, I estimated that it would need to spin at somewhere

around 250-300 RPM, at which point it might put out 15 amps, for a mere

225 watts. At 600 RPM (probably a reasonable maximum), it might be

around 33V @ 33 A or 1000 watts. This is hardly 12+ KW territory! If

the coils were rewound with more turns of finer wire, they'd produce

more voltage, but presumably with correspondingly decreased current

capacity. A smaller flux gap would produce higher voltage and power

per RPM, but the minimum flux gap is enforced by the need to clear the

center wall, which the rotor rubs on as it is unless carefully

adjusted. The flexibilities in the construction, and the design itself,

work against it. And

the cogging gets bad at smaller gaps anyway.

Apparently my "Electric Hubcap" construction makes much

better motors than it does simple generators! One could make a more

complex generator by using a motor controller with it in "regenerative

braking" mode. A range of output voltage and power would then be

available, "maximum power point" adjustment for the conditions. But we

put in 32 magnet poles instead of

16, and it couldn't be run as a regular BLDC motor that way - as I

found out in 2008,

the magneto-motive forces in each direction cancel out in this

"generator only" configuration.

But this seemingly unfortunate circumstance led to the

realization that the "unipolar" type of motor controller would work.

With this very 3 to 4 coil to magnet ratio that seemed all wrong, an improved

type of BLDC motor can be created with the improved motor controller.

That seemed like a great concept, so I've written it up in "Month in

Brief".

Making Flat Drive

Belts from Polypropylene Webbing/Strapping

Welding the seam to form a flat belt:

Welding the seam to form a flat belt:

strap ends together - hot iron - cellophane

I've thought now and then of flat transmission belts on

slightly convex pulleys. Wikipedia says that with modern materials

they're nearly 99% efficient and that a 1" wide belt may transmit up to

100 horsepower. And they can be de-tensioned and slipped for a clutch

action, unlike chains and toothed belts. But when I tried to find flat

drive belts on line, they hardly seemed

to exist.

It occurred to me that one might make flat belts using

flat polypropylene or other strapping, which comes in various widths.

But how to make a length of it into a loop that wouldn't break at the

seam? On the 22nd I was uncrateing a "portable heat pump / air

conditioner" I bought for the house, on "sale" at Costco for 400$. The

straps around the box were completely unyielding and had to be cut with

scissors. The ends were melted together for a couple of inches.

This was a means I had vaguely considered. Now I made it

an

experiment. I got a length of 2" wide PP strapping and cut a couple of

pieces of cellophane. My dad used to make ice fishing enclosures, clear

"tents", by

putting cellophane sheets over and under polyethylene plastic and

melting two pieces of

plastic together with an iron to join them. I put down a piece of

cellophane, then

the ends of the strapping on top of it with only about 3/8" of overlap,

then another piece of cellophane. When the iron was hot I applied it

and after a couple of tries and then flipping the belt over to heat

from both sides, I melted

the seam. It made a bit of a lump that wasn't very flexible, but it

wasn't bad.

When it was

cool it tried to pull it apart. It didn't

break. I put a weigh scale on the corner of a table and looped the belt

over it, so I could push down with my foot. (The picture is worth many

words.) I put my full weight on it, then jumped up and down a bit.

Apparently it will hold at least 200 pounds or thereabouts. I had

thought it would break at some point and a longer overlap

would be required. I managed to break it by putting it around my knee

and pulling it with my fingers at one edge instead of uniformly

centered. But it wasn't easy. It broke along one edge of the seam where

the single layer had been weakened at the edge of the melt, so the

length of the overlap was irrelevant. The next two seams failed. I

didn't apply enough heat for long enough to melt through to the middle

nicely. The

fourth one, heated longer, held and I was unable to break it by hand,

period. The 3/4"

fairly stiff seam would have been rough going around a small pulley,

but again it seemed it didn't need to be so long. 1/4" would probably

be fine. I'm calling it a success. The rest of it is so limp compared

to most any other drive belt, I can see why it might be 99% efficient.

When it was

cool it tried to pull it apart. It didn't

break. I put a weigh scale on the corner of a table and looped the belt

over it, so I could push down with my foot. (The picture is worth many

words.) I put my full weight on it, then jumped up and down a bit.

Apparently it will hold at least 200 pounds or thereabouts. I had

thought it would break at some point and a longer overlap

would be required. I managed to break it by putting it around my knee

and pulling it with my fingers at one edge instead of uniformly

centered. But it wasn't easy. It broke along one edge of the seam where

the single layer had been weakened at the edge of the melt, so the

length of the overlap was irrelevant. The next two seams failed. I

didn't apply enough heat for long enough to melt through to the middle

nicely. The

fourth one, heated longer, held and I was unable to break it by hand,

period. The 3/4"

fairly stiff seam would have been rough going around a small pulley,

but again it seemed it didn't need to be so long. 1/4" would probably

be fine. I'm calling it a success. The rest of it is so limp compared

to most any other drive belt, I can see why it might be 99% efficient.

One thing left to try would

be to spray it with polyurethane. That should give the surface more

grip. Note also that slippery-smooth pulleys wouldn't be the thing to

use either. Something rough sanded or textured, or a surface material

with grip to it, would be the thing to use. In a bandsaw, where the

band/blade has this sort of flat belt arrangement, the (slightly

convex) wheels have polyurethane "tires" (a relatively fat flat belt of

polyurethane that fits tightly around the pulley) to give the pulleys

more grip.

This nagging point about flat belts and their availability

is now reversed: a flat belt is easy to make and cheap. No worries

about where to get one of the size needed. (Any advantage or purpose to

a mobius strip?) The slightly convex pulleys can be

made perhaps even on a wood lathe. (not to mention 3D printed.)

Furthermore, instead of having to disassemble something complex or

awkward to get a belt on or off, it could be pulled through as a piece

of strapping and then the seam could be sealed in situ. I could

see creating some sort of special handheld "belt seam welder".

A flat belt is the plan for connecting the generator to a

vertical axis wind turbine, with a speed-up ratio to turn it faster

than the turbine. No noise, hardly any losses, and the generator can

turn at a higher RPM than the turbine. But I think for a first real

test I'll change the V-belt on my bandsaw to a flat belt and see how

that works.

"Green" Electric Equipment Projects

Thermoelectric (Peltier Module)

Fridge & Space Heating Update

I'm disappointed by what seems to be quite

a limited lifespan of Peltier modules. The one that had now been in the

fridge for some time (a year?) performed worse and worse, and the

fridge

temperature had risen gradually from a typical 6°c to almost

11°. And that's at the cool end. The only thing worse than a "Q" of

.8 to 1 is a "Q" that's dropped to .5 or .6. Doubtless for a camping

cooler used for a week or two a year it's fine, but for full time use,

it's a problem.

Likewise, I wouldn't want to explore thermoelectric space

heating much further as it stands, because the savings in electricity

would be replaced by the headache and expense of replacing the modules

on a too regular basis. But again, it might still be practical for

electric cars, where any saving in heating electricity reduces the loss

of driving range, and where the unit is probably only used an hour a

day instead of 24.

On the 21st I went to replace the peltier module. When I

took the unit apart, I found the fan and heatsink were rather

clogged with dust. So I cleaned them off and

replaced the same module. The temperature dropped a couple of degrees

to about 9. If I increased the fan speed - which gave it an annoying

buzz - it went down to 8.

Apparently it was partly module degradation and partly

just being dusty, and obviously higher fan speed helps. A filter over

the fan intake might help with the dust; maybe a piece of furnace type

air filter - if it's cleaned regularly.

The next day, having checked out the difference just the

cleaning made, I put in a new module. Soon I could feel frost on the

copper coldness transfer bar instead of just condensation. The

temperature didn't seem to go much below 8 after a couple of hours, but

ice was forming on the bottom of the ice tray for the first time in

ages. By the next morning it was down to 6° and the ice tray was

half ice - about the best I usually get with an 8.5A/15V peltier

module. On the morning of the 25th and beyond, even with the

fan on lower speed, the temperature was around 5° and the tray was

over 1/2 ice. Even the heatsink felt cold. During the day, this

rose to 7 and the ice melted. Upping the fan speed somehow only seemed

to make it worse, or at least no better.

For a while I thought the peltier module worked

considerably better at the lower nighttime voltage (~11.7) than when

the solar panels bring it up near 14 volts during the day. But it

turned out the Chinese control I had installed was actually turning it

off, owing to the temperature sensor having fallen into the cold

condensation water under the ice tray. I moved it.

Since it's hard to find peltier modules with a slightly

higher voltage spec that are more in their highest Q range around 11-14

volts, one thought that does occur to me (I may have already written

this) is to put in a very large peltier module (I have a couple of 14

amp ones) and use a DC to DC converter to supply it a lower voltage.

Hopefully being run more gently will considerably extend the life span

as well as increase the coefficient of performance. 8 or 9 volts with

such a high current module should provide more cooling than I'm getting

now, probably with no more current. The voltage should be on a

programmable control. But I don't seem to be finding much time to

take on more projects, even when they're extensions of existing work -

things that should have already been done. Of course, the plan gets

better as I go just in case it does ever get done.

Finally, also on the 21st I got a "portable heat pump /

air conditioner" at Costco, on "sale" for 400$. Instead of being a

window mounted unit, or a two-piece unit that has to be installed and

connected by a refrigeration professional, this one simply sits on the

floor and there's something like a dryer hose to stick out the window

to vent the outdoor air. At first this seemed like a much superior

arrangement, especially for "DIY", which is made trivial. The heating

mode is "11000 BTU". This worked out equivalent to a 3200 watt heater.

It says it draws "10.3A" in heating mode, which is 1236 watts. That's a

"Q" of 2.6, or 2.6 times as much heat as an electric resistance heater

using the same amount of electricity. For cooling, it's "14000 BTU" and

"11.9A", for cooling worth 14000BTU*.293W/BTU=4100W and hence a "Q" of

4100W/(11.9A*120V)=2.87.

Presumably the heat or cold made by the unit is expelled

outside.

But herein lies a design problem: the hose vents outside, but if air is

vented outside, it has to be replaced by air coming into the house from

somewhere else. It might be better to have two hoses, in and out, but

it has no provision for a second hose.

Otherwise, a heat exchanger for incoming air would be desirable.

Costco said this was the first time they had got a unit

that was a heat pump as well as an air conditioner, and it was the

first time I had ever seen a "portable" one. (I suppose one could

install a window mount air conditioner backwards.) There were two

purposes to buying it. First was the

actual electrical savings potential. If it was being fully utilized as

a primary

heat source, the electrical savings would reach its purchase price in

as little as 4 months of cold weather. (I mostly heat with wood,

relatively abundant around here, but it's a big house and a number of

electric heaters are required. Especially the machine shop is too cold

to work in on cold days in the winter, and it takes considerable heat

to

warm it up.) Second was to inspect the various heat exchange

components,

radiators and fans, and their design and implementation. If I do do a

thermoelectric heat pump, this unit seems to be really well set up...

depending how noisy it is - I haven't turned it on yet. But it has big

"squirrel cage" fans like small furnace air duct fans, that probably

aren't as bad as blade fans.

So far I haven't seen any sign of higher performance