Turquoise

Energy Ltd. News #89

covering June 2015 (posted July 4th)

Victoria BC

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Highlights: New Configuration

Electric Caik BLDC Motor Runs great, with superior new "Single Ended"

or "Unipolar" Motor Controller! (see Month in Brief, Electric

Transport)

Month In Brief

(Project Summaries)

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Clean burning plastic - Chem spraying continues - Eating crow - TPP,

TPA or whatever it is - Greece: First Domino? - New Horizons Approaches

Pluto

- In Depth Project Reports -

Electric Transport - Electric

Hubcap Motor Systems

* "BLDC4:3" Electric Caik Motor & unipolar/single ended/half wave

motor controller: making, running, testing, reports & ideas.

* Axial Flux Switched Reluctance Motor? (AFSRM)

Other "Green"

Electric Equipment Projects

* Vertical axis lathe?

* Aquaponics & LED Plant Lighting update - Manual aquaponics?

Electricity Generation

(no reports)

Electricity Storage - Turquoise Battery

Project (NiMn, NiNi), etc.

* Making cylindrical Ni-Ni cell (but it didn't work well - what am I

doing wrong?)

No Project Reports on: Variable

torque converter transmission, Magnet

motor,

Lambda ray collector, evacuated tube heat radiators, CNC

gardening/farming machine, Electric Weel.

June in Brief

Development and testing of my new type of 'unipolar' (AKA 'single

ended', AKA 'half wave', AKA 'SRM') motor controller, along with the

new 4 rotor magnets per 3 stator coils configuration of "brushless DC"

motor ("BLDC"), was the main focus throughout the month, and there are

still a couple more things to try. It runs great! I'm sure it's

superior to the usual BLDC motor and controller configuration that's

out there now. Failure of BLDC controllers seems to be only too common

(almost inevitable with e-bikes?), and it looks like my controller in

addition to being inherently more reliable should have lower losses and

generate less heat. The motor is actually the same as all my previous

ones except the orientation of the rotor magnets, and there's a fourth

power wire, common to one end of all three coil sets.

It might be of interest to go over how my motor and

controller

development went. For the motor, at first (2008) I copied the Hugh

Piggott

axial flux

windplant magnet

arrangement, with 12 magnets on the rotor: 'NSNSNSNSNSNS', and with 9

phase coils on the stator, three sets of 3. Then I found the IR2130

3-phase coil driver chip and looked at the application notes for it. It

showed "standard" motor driver configurations. When I tried it, the

motor wouldn't turn - at every point of rotation the turning force was

(seemed to be) matched by a counter turning force. I concluded

(falsely, I think) that

in order to run with that driver

circuit, my motors had to be

'NNSSNNSSNNSS' - 2 magnetic poles per 3 coils instead of four. And

every BLDC motor diagram that I saw showed the 2 poles per 3 phases

arrangement.

I started by copying the Piggot rotor. If I hadn't

found the "standard" 3-phase H-bridge motor

controller configuration, I just might have used my imagination and

come up with the 'unipolar' configuration in 2008 to run with the

'NSNSNSNSNSNS' magnets as built. Instead I did what

we all do: I copied what was done before, and changed the

magnet rotor to copy the "standard" type... in spite of some

doubts that having transistors that could short out the power was a

reasonable approach. (...but if that's the way it's done...)

It took until 2015, some odd

experimentation with unipolar rotor and then SR motor designs, and the

unexpected

circumstance of the Weel being made as a 4 magnet poles per 3 coils

generator, and then realizing it would have to be run like a motor to

provide enough output, to put together the new and better "BLDC4"

configuration. Not just a copy! AFAIK nobody else anywhere had/has got

to that point

yet, simple tho it seems in retrospect! (Any such configuration is

certainly well hidden on the web. Wherever I look at BLDC motor

controllers, I see the usual 3-phase bipolar H-bridge drive transistor

configuration and coils connected "Y" (or occasionally "delta") with no

access to the "Y" center, and for the motors, always 2 magnet poles per

3 stator coils. I've found no suggestion anywhere that there might

be any alternative way to configure a 3-phase BLDC motor.)

Similarly, if I had known the controller for a

"unipolar" magnet motor controller would be the same as a "SRM"

controller, I would have simply looked it up and seen "how it's done",

and copied that,

and I probably wouldn't have come up with the new idea for saving half

the

transistors and diodes, with their need for floating high-side gate

drives, by using a coil instead. (While I had seen the name "reluctance

motor", they weren't discussed in my Electric Motors course at BCIT,

nor had I ever even taken a look at them since. To me the name sounded

like a

specialty or curiosity rather than a

serious power motor type.)

Similarly again (if somewhat digressing), I've seen many

lathes, but only huge

machine lathes will do larger diameter workpieces. I suddenly thought

up the idea of a vertical axis lathe for making larger diameter flat

disk rotors, pulleys and whatever. Again I had to break through what

all my past said was "normal" in order to conceive of something new.

And so it is: to create something new rather than a copy of some sort,

it must first be imagined, and

simply knowing the familiar way something is currently done actually

stifles that creative imagination.

It turns out there are vertical axis machine lathes, tho

they too are very costly, huge, and seem vastly overbuilt compared to

my 'compact', 'economical' vertical lathe idea - an idea I've written

up FWIW under "Other Green Projects".

To get to the

actual story, I put the additional magnets

on the formerly "N-N-N-N-" "unipolar" rotor, making it NSNSNSNS with

four magnet poles per

three phases instead of two. (It occurred to me that it should work

exactly the same, but it would have more torque since the coils would

attract a south magnet at the same time as they repelling the north

magnet. It would be better.) Then I made a hall sensor circuit

board and installed and troubleshooted(?) it, and assembled the motor.

To get to the

actual story, I put the additional magnets

on the formerly "N-N-N-N-" "unipolar" rotor, making it NSNSNSNS with

four magnet poles per

three phases instead of two. (It occurred to me that it should work

exactly the same, but it would have more torque since the coils would

attract a south magnet at the same time as they repelling the north

magnet. It would be better.) Then I made a hall sensor circuit

board and installed and troubleshooted(?) it, and assembled the motor.

Then I hooked

it to the semi-functional unipolar motor controller. I

bought a fancy new digital oscilloscope and started troubleshooting the

controller, and by the 20th I had everything running quite smoothly, on

straight PWM modulation. I don't think I'd have got there without the

scope. It least, it surely would have taken much longer with my crappy

old 1970s Heathkit scope. The next day I entered in some "version B"

stuff on

the motor controller schematic and circuit board with Eagle PCB CAD,

before I

would start to forget what the changes were.

Then I hooked

it to the semi-functional unipolar motor controller. I

bought a fancy new digital oscilloscope and started troubleshooting the

controller, and by the 20th I had everything running quite smoothly, on

straight PWM modulation. I don't think I'd have got there without the

scope. It least, it surely would have taken much longer with my crappy

old 1970s Heathkit scope. The next day I entered in some "version B"

stuff on

the motor controller schematic and circuit board with Eagle PCB CAD,

before I

would start to forget what the changes were.

Then I also gave thought again to doing an axial flux

switched reluctance motor. After all, it's the same motor controller

for it! I started thinking of doing one more along my original lines

than the ones in the AFSRM research papers. It'll probably work better

than I was thinking, and it can be "tweaked" in several ways. I hadn't

got the iron powder,

but I had many parts for my version including the ready-made iron

powder toroid cores. I could make a limited amount more powder by

grinding iron. I fiddled with some bearings and parts to determine what

might be workable mechanical configurations, which will be perhaps the

aspect most critical to initial success and performance. It can be

tweaked and other materials and parts tried out from there.

On the 21st, I gave thought to the perennial problem of

trying to mount a rotor over 'the gap' on my present lathe, which is

the only

spot where larger diameter objects can be turned. The diameter is half

the problem - mounting the piece is the other. The regular 3-jaw chuck

is so fat it extends past the gap, so it's useless. Backing plates

don't hold things exactly centered. All very frustrating! But most of

the rotors I do fit on a 1" shaft. Now I thought

of turning a 1" axle so that one end of it would fit inside the lathe

axle, which is #2 morse taper. I found a short piece of 1" shaft and

spent a couple of hours milling it down. I figured it would work its

way out, so I center drilled the inside end, then I drilled and tapped

it for 1/4" threaded rod, to stick out the far end of the lathe axle

(about a foot long) and put a nut on. This is how the milling machine

holds its tools securely, except it's a 6" hex head bolt.

Turning AFSRM

Rotor thrust bearing flat

Turning AFSRM

Rotor thrust bearing flat

Thrust bearing on rotor

Somewhere in

there, while I waited for the new

oscilloscope to

arrive, I made the new nickel 'negode' for the cylindrical

nickel-nickel battery. It should be a great electrode! I did a couple

of versions of a cylindrical battery by the end of the month. The first

one had a problem (bad graphite in the mix) and the second one,

finished July 1st, [also] has poor current capacity and likewise

doesn't seem to hold charge properly. What am I doing wrong?

Somewhere in

there, while I waited for the new

oscilloscope to

arrive, I made the new nickel 'negode' for the cylindrical

nickel-nickel battery. It should be a great electrode! I did a couple

of versions of a cylindrical battery by the end of the month. The first

one had a problem (bad graphite in the mix) and the second one,

finished July 1st, [also] has poor current capacity and likewise

doesn't seem to hold charge properly. What am I doing wrong?

The Mazda RX7 EV update this month consists simply of

saying that after the NiMH battery swaps in May, I drove it 9.3 miles

on

June 21st with only a bit of a charge at one point. (only because I

forgot to plug it in after the second trip.) The batteries weren't

bottomed out yet, either, and I could have gone probably about another

3 miles if I had had somewhere to go. That'd be almost 20 Km - a big

improvement over 10 to 12! And by replacing just 2 bad cells, I have 7

tubes of left over cells (70 AH @ 12 volts) to use for something that

doesn't draw as much current as the car - and to run experiments on

re-hydrating the cells, which could possibly restore their current

capacity. The lithiums are still doing great. The four remaining

lead-acids are working well and have outlasted all the others by a wide

margin. If only I knew which ones were the ones to get when I go to buy

them!

All the while, while doing all these very exciting

projects, exciting

and successful as they were, it's been gnawing away at me that I still

haven't completed my SR & ED application, and that I still don't

have my bitcoin miners, which I got in February, running. I figure

that's "costing" me hundreds of dollars a month in income I could be

getting. That just might be the money I could be leveraging into funds

to commercialize some of my products.

Much to my amazement after so long with no sales except

the long-running Electric Weel kit/project, someone ordered two of the

stackable 12V, 10 D cell 3D printed battery cases by e-mail. He paid

and I sent them. Say, isn't this the way business is supposed to work?

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Plastic Debris Clogging Oceans - Burn your grocery bags?

Perhaps you've heard there are "islands" of plastic debris

"the size of Texas" floating in the oceans? This is becoming a critical issue to Earth's

ecology. It keeps getting worse, and no one is dealing with it. Whether

it's related to the "dead zones" isn't clear.

I met someone, a qualified ship captain, who had proposed

creating a clean-up ship operation that would profit from selling

the

recovered plastic. Of course that would require capital, and he said he

couldn't find any interest or support. (It seems to me this is another

illustration of how those who run our society have abrogated their

responsibilities in ways that seem to make no sense whatsoever except

that they must take some sort of satisfaction in doing harm - You can't

get good fruit from a corrupt tree, even when it seems to make sense by

their own "anything for profit" philosophy.)

Now, people keep saying "Don't burn plastic. It

creates toxic smoke." But there are many kinds of plastic, and this

isn't true of all of them. In particular, polyethylene such as is used

in grocery bags, soft transparent food bags, and many small plastic

containers, creates nothing but

carbon dioxide and water vapor. It burns as cleanly as gasoline or

cleaner. And a light plastic bag is probably

composed of less petroleum product than you burn to back your car into

your driveway. If you drive a gas car, but worry about burning

plastic bags, it's like worrying about an anthill and ignoring the

mountain. And if you can stick bits of paper, sawdust or whatever into

the bag

first, it's doing double duty in containing stuff that would otherwise

be messy to burn. And plastic as 'kindling' of a sort can help get a

fire going. (Even so, I often re-use my grocery bags. They're easy to

stuff into your pocket, and to keep a bunch in the back of your car.)

Likewise, polypropylene is polymerized cyclopropane, and

so has no more burning emission than propane, again just carbon dioxide

and

water - a cheery flame with very little smoke. In addition to many

small plastic containers, cloth grocery bags and landscaping fabric are

made of polypropylene.

Look for the recycling symbols identified as "PE", "LDPE",

"HDPE" (low & high density) and "PP" for these clean burning

plastics. Ideally all these can be recycled, but except for larger,

heavier pieces, the truck carrying all that fluff probably burns more

petroleum product than what it's carrying.

Thus it's my feeling that the best way to deal with them is to burn

them in a woodstove or fireplace. At least that way you can be sure

they're not adding to the mountains of floating debris in the oceans.

(Some plastics that DO make noxious smoke include: PS, ABS, PVC, PETE.)

Chem Spraying Continues

THIS is FRESH RAINWATER?

Many if not

most days, now that I know what I'm looking at, I see chem trails and

sometimes see or hear the aircraft making them. On the 15th extra-heavy

chem trails criss-crossed the sky all day.

Many if not

most days, now that I know what I'm looking at, I see chem trails and

sometimes see or hear the aircraft making them. On the 15th extra-heavy

chem trails criss-crossed the sky all day.

They are known to prevent precipitation, and rain clouds

have passed by overhead without any rain on several occasions this

spring. (Probably the clouds finally release a deluge to cause the many

flash floods seen this year in the interior of the continent.) A local

fire

chief says it's "very abnormal" for it to be so dry this early in the

summer.

One evening there was, finally, a light sprinkling that

continued into the night, which filled a 220 liter drum from the roof

downspout 2/3 full. I moved the hose to a second drum before I

went to bed, which filled about 1/3. Since it hadn't rained in quite a

while, one might expect a little dirty water off the roof at first. But

this picture is the second drum (which has an open top). It was

foamy at first. Later it was just this dark reddish brown color. Just

what

are they dumping on us? Yuk! (Later I found some water off the

galvanized garage roof in a garbage pail, that wasn't too bad. Still...)

Is it any wonder there's huge die-offs of

sea life? A video about "extreme weather" of last winter showed masses

of dead fish floating in lakes and washed up on ocean shores as

reported on the news in various places around the world. It's been

widely said that there is "a dark cabal" (as president Kennedy warned

decades ago) manipulating from "behind the scenes" who would like the

population reduced to that of the stone ages, and to enslave the

remainder. Destroying the major food sources of the world is certainly

a way to kill people. Can that be the motivation for all this?

On about the 23rd someone told me there has been a massive

algae bloom on the west coast of Vancouver Island that makes all

previous algae blooms look like peanuts. I was told the entire fishery

was shut down. I haven't heard any more about it. If it's true and

really all that bad, logically we may next hear about another vast fish

and sea bird die-off. Even non-toxic algae blooms, in sufficient

density, cause oxygen starvation in the water as the algae dies, which

kills the fish. Lack of food, or as seen recently the chem foam itself

on the water, can kill the sea birds and other creatures. It's

unsettling to look up and and realize that half the clouds hold not

moisture but unspecified and unidentified 'nefarious' chemicals. Many

can be identified as chem trails spreading across the sky and sometimes

the planes are seen, until one becomes suspicious of all clouds.

July 3rd: Last week the newspaper said Victoria had plenty

of water in the reservoir in spite of the lack of rain and heavier

usage recently - nearly 90% full. Hurrah! Today, just a week later,

severe water restrictions are being imposed. Huh? Who makes this stuff

up? My own rain water collected mostly from 36 hours last March

collected in the "swimming pool" is almost 3/4 used up. It shows the

value of storage capacity. I suppose it won't rain again here until mid

August - if then. On July 3rd also open fires have been banned, and

it's said things are tinder dry. This part is understandable. Water

rationing with a full reservoir isn't.

Why aren't there diplomatic protests, seeing the US air

force is now chem spraying in Canadian territory? Why aren't more

people protesting? And how anyone has the gall to perpetrate such

atrocities on the planet they live on I don't understand.

Please stop.

Eating Crow

On the 16th I went out to feed the goldfish about 10:30 AM

and found a drowned crow in the 'trench' pond, apparently a young one.

Making the pond with no

shallow place to stand and a drop-off from the rim was intended to keep

predators out. It wasn't there the previous evening, so it must have

just happened that morning. (Later I found a young crow in the garden

that

couldn't seem to fly over the fence and leave. Perhaps it was its

sibling that fell in?) Notwithstanding the derisive expression "eating

crow", or maybe just because of it, I plucked and cleaned it and boiled

it (about 10 minutes - 5 was too short) for

lunch, including the heart, liver and gizzard. It was a little tough,

but good meat.

This isn't a big livestock region, and the small island

deer that today wander around town eating peoples' gardens won't last

long

when and if the food

supply chain gets cut off. People may well need to do such things to

eat, so, strange as the idea seemed at first, I thought I'd get in a

little

practice. Somebody somewhere does it with all the chickens, pigs and

cows

we eat, and I saw in a National Geographic once that the Basques in

Spain would put up big nets to catch various small birds for food. Lo

and behold, Joy of Cooking even had a section on "small game

birds". And when I was little in Edmonton I helped pluck ducks,

partridge and

pheasants that my dad used to shoot, so it wasn't totally alien

territory. (Wild game birds are delicious. But I once

had a pretty tough partridge. Beef can be tough too, and after all,

crow is just cow with an 'r' in it.)

Joy of Cooking said blackbird and crow, if eaten

of

necessity, should be "parblanched" before cooking, which involved

putting it in cold water and bringing it slowly to a boil. That's when

I

figured I might as well just boil it. The part about "if eaten of

necessity" by German authors reminds us that food shortages do

sometimes occur in tough times, and not just way back in history or in

the "third

world".

But I want to get in some practice fishing this summer, in my

electric outboard boat, also trying out the new motor and controller in

real use. Most everybody likes fish! (I trust there still are some in

the strait.)

TPP, TPA or whatever it is...

How can a law or public agreement be a secret? The terms

are "classified". No one is allowed to see them, or having seen them,

is allowed to talk about them or make copies. Any US congressperson who

tells the public what the agreement is all about will be thrown in

jail. (I thought congress made the laws!?! How could they have decided

such a thing against themselves?) Evidently the public isn't even to be

told the terms for four years after it's been implemented! The

government says "Ignorance of the law is no excuse", but we're not even

to be permitted to know what the law is? But from leaks we know that

corporations can take governments - ie, the citizenry - to court to sue

for profits they they could have made if a decision they don't like had

been in their favor. The people can never reclaim any property that has

been 'privatized'. And legal actions aren't to be contested in real

courtrooms, but in private hearings behind closed doors. We may not

know what the rules are, or what was decided or done in the name of

this "deal", but we are expected to abide by whatever we are told, or

take whatever penalty is meted out for any transgression of the rules

we haven't been told, by a secret kangaroo court hearing with no appeal.

This so-called "trade deal" effectively takes the power to

make laws out of the hands of elected lawmakers and gives it to global

corporations and banks. Is that who we want running the world?

Democracy is to be officially subservient to corporatocracy. Let the

implications of that sink in! Are these, especially the banks, not the

lampreys which have attached themselves to the unwitting shark, sucking

the economic blood of productive citizens and of society as a whole?

And now they are demanding total control and reserving all rights to

themselves? Will they not kill the society that gives them life?

Apparently the madness must continue until most every

surviving human says "Enough is enough! No more!" Then they will

reassert their God given individual sovereignty to create societies of

strong families that will have more moral sense and the courage to act

on it against threats and coercion, who will trust in humanity but

individually and together rein in all those who make outrageous demands

and perform outrageous acts trying to gain unfair advantage over

others, keeping in mind the cosmic core values (quality of life,

provision for growth, equality) in their acts and decisions.

"Someday love will rule this very world." - Jesus

I recently saw a great video on youtube titled All

Wars Are Bankers' Wars. While I don't agree with everything it

says, it gives insights as to how the insidious process of behind the

scenes control of societies, of their finances and economies, has

worked over the past several centuries. But with the internet, people

are gradually learning how these hidden things work, and soon and in

the future will no longer tolerate them. For the few most stubborn and

deluded individuals working insidiously and tirelessly behind the

scenes to enslave humanity, we have a celestial promise that they will

be "unceremoniously removed from the planet" when the time is ripe,

their remnant Luciferian philosophies no more to disturb planetary

progress.

Greece: First Domino?

The latest bank runs closing the banks in Greece are only

the tail end of around 35 billion Euros withdrawn this year, from a

total of around 160 billion Euros on deposit in Greece in January.

Since banks keep only a small fraction of the currency placed on

deposit available, European central banking has (if I have it right)

given emergency "liquidity" money to them five times to keep them

afloat. 4 billion dollars withdrawn in 5 days at the end of June has

brought things to a boil. The financial institutions don't like the new

Greek government, which outright stated the obvious: "Greece is

bankrupt.", shortly after being elected. They refuse to offer any terms

besides "Give us Greece's pensioners' money, right now.", which

wouldn't help Greece except to buy them another five months, ending

with them right where they are now. They wouldn't even grant a few days

to await a national referendum on whether the Greek people want to

accept this temporary "solution". The referendum is to be held on

Sunday July 5th and it's expected that the Greek people, in spite of

the banks being closed, all the fears, and apparently an organized

[read, paid for by the bankers] campaign to convince people to vote

"yes", will probably vote to reject this latest imposition of further

"austerity". (If they accept European terms, PM Alexis Tsipras and

finance

minister Yanis Varoufakis have said they will resign.)

The Syriza party had only a tiny fraction of the vote in

the previous election, but ran on the promise of ending European bank

imposed austerity - the cause of much very real suffering and dozens or

perhaps hundreds of protests in Athens. It's said the banks care little

for anything now beyond punishing the government unexpectedly elected

by the Greek people, and certainly they have no sympathy for the people

of Greece or Greece's plight.

Most of the immense "Greek bailout" money since 2010 went

to financial institutions in Greece. They were bailing themselves out.

The government received very little of it, yet is expected to pay the

huge debts. (Remember Thomas Jefferson said there are two ways to

conquer a nation: With armies and with debt.) The new Greek government

has

pointed out that several European nations are in little better shape

than Greece and proposed a conference for a general write-down of all

debts in Europe. The banks are apparently furious at that idea - that

someone is working against their financial

tyranny. (Will they dig out some patsy malcontent to

try to murder Tsipras and or Varoufakis? Blame it on "terrorism?" Asked

how it felt to be elected to power in Greece - and one might add, to go

from being a Texas university professor to the center of the world

stage - Varoufakis replied "Scary!") I found a good briefing video

by Varoufakis on youtube on July 2nd, explaining (in English) what was

- and wasn't - offered and why they were recommending people vote "no",

but

that that recommendation would change to "yes" if a Greek deal offering

a

ray of hope for the future was brought to the table - there were two

full days left for the bankers to make an offer.)

Missing the payment due June 30th is clearly a loan

default by Greece, and no realistic alternative or compromise has

been offered by the "Troika", the ECB, IMF and 'Eurozone Commision'.

The question now is whether this hard attitude

makes Greece knuckle under so they can steal the remaining wealth of

its citizens, or if it may somehow blow over for now, or if it may

prove to be the first domino in the collapse of the corrupt, insolvent,

unsustainable ponzy scheme that is the global financial system. If it

is the latter, events could move quickly. There are said to be 100

trillion dollars of outstanding Greek "interest rate derivatives" and

"credit default swap derivatives", which the major banks have

guaranteed.

On the other hand, economies are bad everywhere since so

many people are competing for the world's resources, and some like Greg

Hunter (USA Watchdog.com) feel the

decisions made at this point will make little difference to the final

outcome. Bix Weir (always with a different take on things!) thinks the

banks want Greece to default, and then they'll start printing the

truckloads of money Europe already needs to keep the system afloat, and

blame it on Greece.

As I said after Cypress, the next time a country uses

"bail-ins" - theft of depositors' accounts - to save their banks,

people world-wide will probably start withdrawing their accounts and

hiding their cash. It might take until "bail-in" #3, but #3 will

probably closely follow if #2 gets away with it. (...which has led to

the proposal to ban cash entirely to prevent bank runs - and to further

interfere in peoples' lives!)

---

My version of the "trickle down" theory of economics:

Wealth from the productive starts circulating through the economy, but

as it comes in range, it is sucked to the bottom into giant traps to

add to the immense fortunes of the bottom feeders, never to re-enter

circulation. Thus everyone else is sucked dry and economically

enslaved, working harder and harder stay in the same place.

New Horizons Approaches Pluto

The New Horizons space probe, after 9-1/2 years of flight,

will fly by the 2345 Km diameter sphere called Pluto, around which

orbit an even smaller 1250 Km diameter moon called Charon and several

"oids",

also titled "moons" per the prevailing misleading custom that gives

equal billing to worlds half the size of Mars and to little whirling

chunks of rock. Pluto is about 1/3 the size (by

volume) of Earth's moon. For more on the mission: http://www.nasa.gov/newhorizons

and http://pluto.jhuapl.edu .

For my take on how Pluto with its associated bodies as well as Triton

formed (think of the breakup of comet Shoemaker-Levy 9 near Jupiter): http://www.saers.com/recorder/craig/

(scroll down to find article link).

BTW, I've seen nothing definitive on Ceres. The views are

getting closer, and some ice extrusions are visible. Of course, I

should be searching for spectral findings.

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers

- Preliminary Ni-Mn, Ni-Ni Battery Making book

Products Catalog:

- Electric Hubcap 7.2 KW BLDC Pancake Motor Kit

- Electric

Caik 4.8 KW BLDC Pancake Motor Kit

- NiMH Handy Battery Sticks, 12v battery trays & Dry

Cells (cheapest NiMH

prices in Victoria BC)

- LED Light Fixtures

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

Daily

Log

(time accounting, mainly for CRA - SR & ED assessment purposes)

1-3: Finished May TE News (#88)

4: Added 4 magnets to rotor to make Electric Caik "Unipolar" motor into

"BLDC4" bipolar motor (so called because it has 4 rotor magnet poles

per 3 phases instead of 2 poles). Edited & Printed Electric Caik

Hall sensor PC board, and an LED flat panel light board.

5: Boards etched badly. Made a 2nd Caik board (satisfactory). Epoxied

in the PP strapping to hold the new magnets securely. Moved the 2

tilapia from the mini-fridge into a barrel and shut off the aquaponics

pump.

6:

7: Drilled PCB, soldered parts and cable on. 2 Tilapia died - aquarium

water bad. (High ammonium nitrate?) Transferred remaining large female

to a 10 gollon aquarium.

8: Installed Hall sensor PCB, Assembled motor (not without a few hicups

and adjustments)

9: Emptied and cleaned out 30 gallon aquarium.

10: Brought it back and refilled it.

11: Put the 2 tiplapia from the barrel into the aquarium. One didn't

look well and died within a few hours. The other seemed fine.

12: Put the last tilapia into the aquarium, the big female. She didn't

look well either, but was still alive the next day, with a bit more

color. Rewired the motor controller sensor wires with two 3-wire plugs

to match the motor. Then I changed both motor and controller to match

the PC board socket, ie, 123456 = Ground, +12Vsupply, SenseA, SenseB,

SenseC, Temperature.

13: Tested motor with unipolar controller. (Controller still gets hot.)

14: Ordered 'modern' oscilloscope to check waveforms in motor

controller, and a few other parts.

15: Made inside-fitting end caps for 3/4" PVC pipe batteries. Painted

battery negode with micro nickel flake powder in gum arabic.

16: Oscilloscope arrived. Learning how to use it... OSC signal on motor

controller not right.

17: Motor controller testing and troubleshooting. Got it running well!

(but not perfectly)

18: More motor controller testing and troubleshooting.

19: More motor controller testing and troubleshooting. (Main problem:

high pulse current

was overdriving apparently inadequate 'flyback' diodes!)

20: Redoing motor controller schematic & PCB layout in Eagle PCB.

21: Made morse taper shaft for mounting rotors on lathe; turned AFSRM

rotor to hold thrust bearing.

22:

23:

24: Made new bar & mounted heavier 'flyback' diodes. (They are

STILL inadequate, but not quite as badly.)

25: Consult with AGO about wobbling motor shaft. (Got new piece of

shaft owing to slightly tapered end on old one.) Made NiNi battery

'posode' & assembled battery (wrong mix - contained art store

graphite! Self discharge.)

26:

27: Talking with prospective partners.

28: (Played a concert with a concert band, on my own invented

instrument, the Supercorder - playing flute and oboe parts.)

29: A few more motor controller tests, with diodes, and a writeup about

that for the OSMC motor controller e-mail group.

30: Made 2nd nickel manganate battery posode.

July 1: motor test: bypass coil. Sure enough, watts to run motor goes

WAY up. More converse with OSMC: someone told me about "FERD" diodes,

which may have lower Vf for the recirc diodes (if I use enough of them

in parallel).

Electric Hubcap Motor Systems - Electric Transport

"BLDC4:3"

Electric Caik Motor and Unipolar Controller

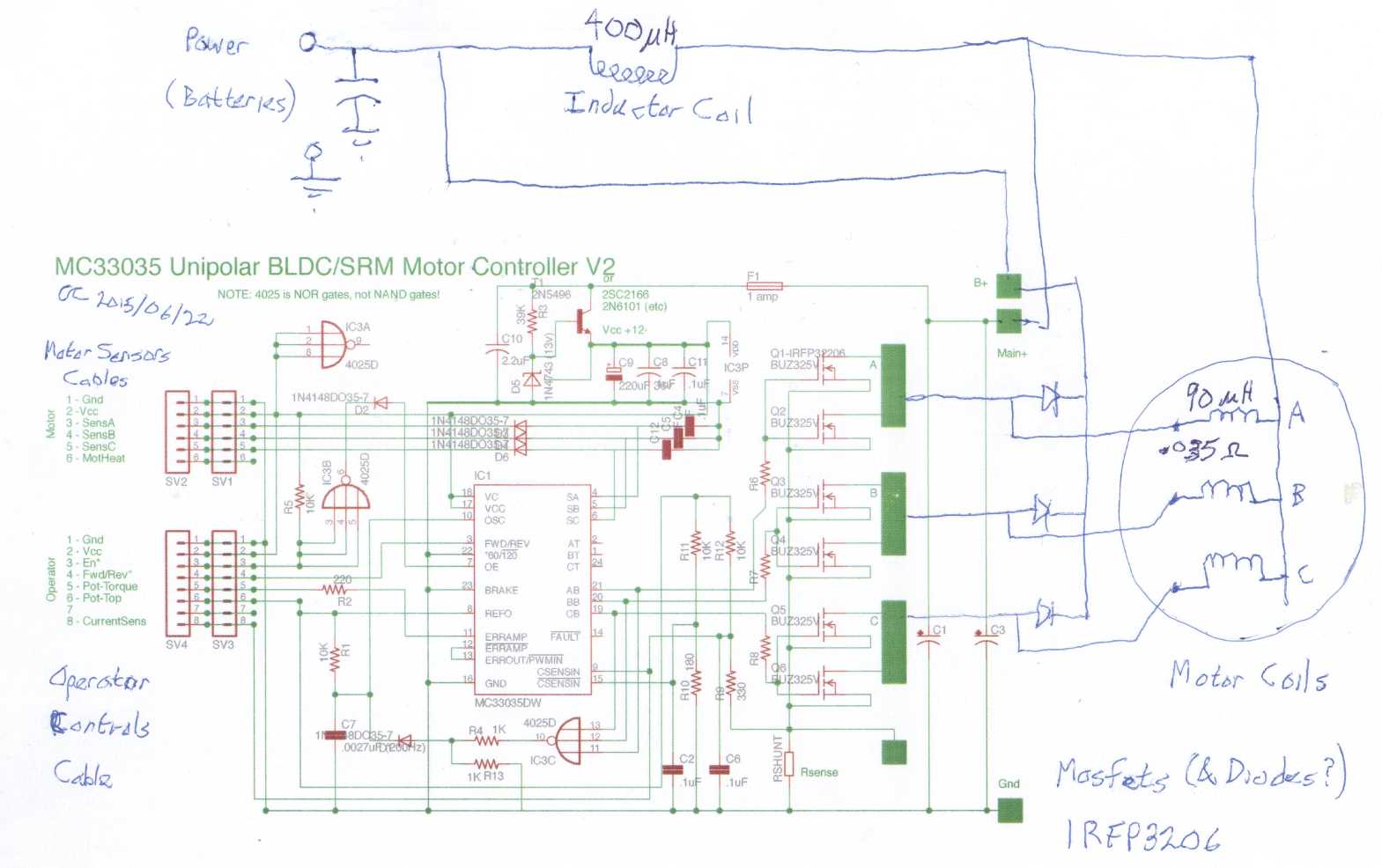

Having decided the unipolar BLDC motor wasn't the way to

go seemed

to leave me with options of:

a) buying BLDC motor controllers to go with my motors.

b) trying to improve my controllers so they wouldn't blow up at high

currents, so they'd be a product along with the motors.

c) making axial flux switched reluctance motors (AF-SRM.s) that would

use an inherently more reliable type of controller.

Option B wouldn't give me anything better than anybody

else has and I'd probably have to charge more. In option C was the

possibility of making regular SRM controllers or, if I could make it

work well, my new type with half as many power transistors and half as

many diodes, the

remainder being replaced by a coil (to allow return energy from the

motor

coils).

d) Then along came the Electric Weel generator, needing a motor

controller... but it had been made with 4 magnet poles per three phases

instead of 2, and (I thought) a regular BLDC motor controller won't

work with that.

But it sometime dawned on me that the more reliable "unipolar" or "SRM"

controller that I designed and made last winter would work instead, and

better still, that it looked like it

would be superior to today's standard BLDC configuration. With 4 rotor

magnet poles going by where there were two, the electrical frequency is

doubled and each coil is ON right between a north and a south magnet,

where the motive force is highest attracting one and repelling the

other. The torque per amp should be high and the torque ripple lower

than a SRM.

To me, given my many motor controller failures and seeing

so many elsewhere as well, the reliability of the motor controller is

the most

important aspect. Of course I would do my best work, but even if it was

"cheap" and "glitchy" the controller wouldn't suddenly fry at high

currents, so here was my best chance to make highly reliable

controllers in-house to go along with the motors.

On the morning of the 4th I prepped the existing unipolar

rotor by scraping off the paint and epoxy where four more, opposite

polarity magnets were to go. Milling four more slots would have been

awkward and

left countless filings stuck to the existing magnets. So instead, I

decided to slit the straps and fit each half through the existing four

magnet slots, which were fat enough to pass another strap through once

excess epoxy and strapping were cut or filed away. Not ideal but

hopefully good

enough for at least 3000 RPM without magnets working loose and flying

off.

On the morning of the 4th I prepped the existing unipolar

rotor by scraping off the paint and epoxy where four more, opposite

polarity magnets were to go. Milling four more slots would have been

awkward and

left countless filings stuck to the existing magnets. So instead, I

decided to slit the straps and fit each half through the existing four

magnet slots, which were fat enough to pass another strap through once

excess epoxy and strapping were cut or filed away. Not ideal but

hopefully good

enough for at least 3000 RPM without magnets working loose and flying

off.

Although the magnet placement jig couldn't fit around the

magnet strapping, I bolted it over top and used it as a visual guide

for placing the new magnets to what I hope is within a couple of hair

breadths of

where they should be. I was afraid it would be hard to get the 2" x 1"

x 3/8" magnets to stay in place without the jig, and not jump over

and glom onto the other magnets, but they stuck down to the rotor steel

well enough to prevent that, even with wet epoxy under them.

I forgot to sand the slick epoxy coating on the new

magnets. This is where the original Electric Caik had failed on its

first run, the magnets simply sliding right out of their (admittedly

bottomless) pockets at no great RPM. But these didn't jump off when

hammered... but then the epoxy wasn't fully set yet. I decided to wait

and

see how they fared once it was. (Then I forgot all about it. I've run

it up to 1200 RPM so far with no trouble.)

The next step was to make a regular hall sensor circuit

board as used in the other Electric Caik motor, because the optical

sensors were crowded enough to bother me. So if I didn't need them for

this motor, I'd change it. I started that on the 4th too, and etched it

(along with another LED light board) on the morning of the 5th. I

thought I finally had the toner transfer method circuit board making

down pat. But these boards seemed to take ages to etch. After well over

an hour, I thought it must be really weak etchant. I looked again, and

suddenly wondered if the unusual yellow board material looked the same

as the

copper in the yellowy ferric chloride. I pulled one out and rinsed it,

and found it was not only done but badly overetched, with the traces

being

undercut and thinned. There were some breaks in the runs.

I didn't quite have to start over since I'd printed two

copies of the sensor board, but it was afternoon before I had a board,

with just 15 minutes of etching in the same etchant. (Again it didn't look

done until the etchant was rinsed off, but I was wise to it this time!)

While waiting for the first "slow" etching, I managed to

work the PP strapping for the new magnets through the slots, after

widening them by filing with very thin files to get some of the old

epoxy (and maybe some of the PP) out. In the afternoon I epoxied the

straps on. It looked a little messy, but I trust it'll be good for 3000

RPM or so once it's balanced. I didn't bother with balancing for now.

Motor open,

showing Magnet Rotor from the back

Motor open,

showing Magnet Rotor from the back

On the 7th I

drilled holes in the magnet sensor PCB and

put the

components on. I had a lot of trouble with mirror images because

this board has the copper on the top instead of the bottom, so whatever

I thought was right was wrong.

On the 7th I

drilled holes in the magnet sensor PCB and

put the

components on. I had a lot of trouble with mirror images because

this board has the copper on the top instead of the bottom, so whatever

I thought was right was wrong.

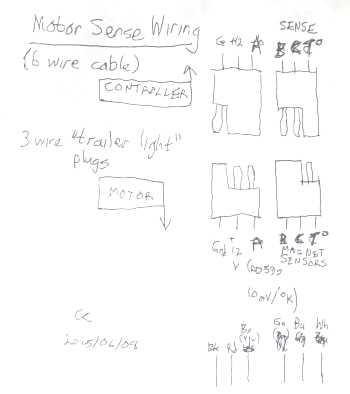

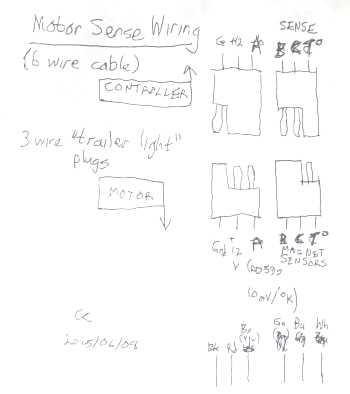

On the 8th I turned the (oops, mirror image) hall sensors

over and then

soldered the cable to the board. The fact that 6 connections are needed

is annoying for using "trailer lights" connectors, but I can't think of

any other connectors I'd rather use. Instead of using a 5 pin "trailer

lights"

connector as I had been doing, and then needing one more pin for the

temperature sensor, I

used two 3-pin connectors as follows, with "F" and "M" applying to the

controller side, the motor being opposite. (There is a 6-pin "trailer

lights" connector, but it's two rows of 3 pins and rare - special

order. And they might be hard to plug in and unplug.) I

didn't use two identical plugs because they would be bound to get

connected to the wrong wires, so I did one the other way around. I

pinned it one way, then later I realized it would be confusing that it

wasn't the same as the motor controller's header pin pinout, and I

changed it

to match: 1--6 = ground,+12V,SenseA,B,C,Temperature.

The first plug has one male

pin on the controller side...

The first plug has one male

pin on the controller side...

1. M Ground

2. F Power - +12 Volts

3. F Magnet Sense A

(The motor side is of course opposite: FMM)

The second plug has the two male pins on the controller side...

1. (4.) M Magnet Sense B

2. (5.) M Magnet Sense C

3. (6.) F Temperature (AD590, 10mV/°K)

(The motor side is FFM)

(Now I just hope people don't get these confused with identical 3-pin

plugs for speed control and a forward-off-reverse switch when they're

installing a system. Anyway, it reduces the variety of the inventory!)

Then I assembled the motor with various trials and

tribulations. (It sure could have used another 1/4" of height... and

1/8"

greater radius... for clearance in the rotor compartment!)

Piles of Testing, Troubleshooting and Correcting - New Oscilloscope

I tested the sensors board with the lab power supply,

a prototyping board (for connections and pull-up resistors), and a

voltmeter,

turning the motor to see the signals change with the rotor magnets. I

was out of hall sensors and I used one labelled "?" for the third one.

It didn't work. Neither did the temperature sensor. Had I got it mirror

image after all that?

Then I thought to use a hall sensor from a left over

circuit board. I rooted through the drawer and there were some. I

disassembled the motor stator compartment to access the board. The

temperature sensor

was squashed under a coil. That was fixed by straightening it. When it

was all back together it all worked.

Next was to hook up the 'unipolar' motor controller and

try running it. Since it ran (barely) as a unipolar motor with only

N-N-N-N- magnets on March first, I anticipated no problems at least

getting it to turn

with NSNSNSNS magnets. The question was how much energy would go into

heating the transistors in the controller instead of turning the motor.

For this, I had the other coil, with twice the inductance

(400µH), to put

in series with the power. The trick should be that the series coil

should have

much higher impedance to the coil turn-off spikes than the motor coils

(90µH), so

that the return energy would all be back to the supply by the time the

" B+' " coil voltage started to rise much.

It seemed to me it shouldn't matter what frequency the

PWM/CRM was at since the reverse spike comes after the pulse turns off,

regardless of how long it was. But that's probably not exactly true.

The longer the pulse is on, the more energy may be in the coil.

I got tied up with various things, and it was the 12th

before I got the sensor cable wired. I ran the motor on the morning of

the

13th. (@17 volts) I connected the coil phases per TE News #85 - I

*thought* the magnet sensors were the same way around as back then, and

it proved to

be right. It seemed a little stronger with double the magnets, but

still pretty feeble, and the driver transistors still got hot fast with

just a few amps of drive. Just when I thought to try it backwards and

see if it ran the same that way too (to verify that the phases were

connected right), a transistor burned out.

The energy return coil idea didn't look good so far! Then

I checked over my wiring. The energy return 'flyback' diodes, on a

copper bar hidden underneath the controller PC board, hadn't been

connected to the common supply side! Well, that would explain a lot!

(In fact, that may have been the problem last winter, too, seeing the

symptoms were the same.)

In the afternoon I replaced the blown mosfet (phase C),

connected the diodes, and tried again at 18 volts - the voltage that

had caused a quick blowout in March. The transistors still got hot

pretty fast, but this time I could turn the motor up a little higher,

and didn't get an immediate blowout. Phase C seemed to get hotter than

the other two. The flyback diodes got a little warm. It was

still only 5 amps and not much power, but more than "barely turning". I

turned the current limiting up a little higher to about 7 amps and the

voltage to 20, and it was still okay and the motor turned faster. But I

wouldn't give the hot transistors a ghost of a chance of surviving 2

seconds at 200 amps!

The coil had only about twice the inductance of the first

one. Maybe it needed a still much larger coil to keep the energy from

going back into the transistors? I didn't have any bigger ones, but I

had more the same... would putting two inductors in series improve

things?

But when I thought about that... even if the energy was

being shorted, it should short through the diodes across the coils, not

through the transistors. So why were the transistors heating up? Ah...

maybe the power supply needed more capacitors to absorb the flyback

voltage? If the voltage was going above the transistors' zenor point,

they would absorb the excess energy themselves and heat up. I thought

it had two 4700µF capacitors, but on inspection they were were

270µF... at 100V rating because of the high currents and hence in

rather large cans. Probably

not enough. I added two more for a total of 1080µF. The

transistors still got hot pretty quickly, and again phase C faster than

the other two. Well, on the other side of that coil was the motor

supply, with only 640µF. I soldered another capacitor on the

bottom side of the circuit board, making it 860µF. That didn't

seem to help either.

Time to get

out the oscilloscope and look at the

waveforms. ...Or maybe buy a new oscilloscope that would be reliable,

correctly calibrated, nicer, better, and easier to use than the old

10MHz, 1970.s Heathkit? I opted

for the latter and ordered a BK2530B digital LCD storage oscilloscope

the next day.

I also ordered 50

more A1203LUA hall/magnet sensors, and while I was at it, a few 555

timers and LM339 quad voltage comparators. (After chancing to see the

US$ prices before I saw the CAD$ prices at Digikey, I thought the

exchange rate seemed off. I looked elsewhere and ordered them from

Mouser instead, for about 650$ instead of 750$. The chips were cheap,

but I could probably have done much better on the hall sensors if I'd

ordered them from China. Evidently sometimes it still pays to shop

around!)

Time to get

out the oscilloscope and look at the

waveforms. ...Or maybe buy a new oscilloscope that would be reliable,

correctly calibrated, nicer, better, and easier to use than the old

10MHz, 1970.s Heathkit? I opted

for the latter and ordered a BK2530B digital LCD storage oscilloscope

the next day.

I also ordered 50

more A1203LUA hall/magnet sensors, and while I was at it, a few 555

timers and LM339 quad voltage comparators. (After chancing to see the

US$ prices before I saw the CAD$ prices at Digikey, I thought the

exchange rate seemed off. I looked elsewhere and ordered them from

Mouser instead, for about 650$ instead of 750$. The chips were cheap,

but I could probably have done much better on the hall sensors if I'd

ordered them from China. Evidently sometimes it still pays to shop

around!)

It arrived on Tuesday the 16th. Aside from the typical

functions of old types of storage scopes, it has some great features

including storage, "playback", printing on-screen the volts/division,

time/division,

offset voltage and trigger frequency, and saving the screen to a

USB memory

stick. The

range controls are optical(?) dials instead of rotary switches with a

zillion

contacts to get dirty and wear out, and there were several menus to set

things up with a minimum number of pushbuttons, which matched the menu

placements beside the display. And with no CRT tube, it's compact

and lightweight: 6" high x 12" wide x 4.5" deep. Even the probes are

easier to use, and clip onto wires better than the old ones.

After taking a while to look at the manual and familiarize

myself with the controls, I put the probe on the OSC signal on the

motor controller chip. It was wrong - staying high instead of

oscillating. Amazing how a very foggy picture of what's assumed to be

happening starts to clear up with proper test equipment! The old scope

could have told me this too, but as testing went on, the new storage

scope quickly proved its worth, showing things clearly by getting a

snapshot at the critical time, for later viewing including

expanding very short period pulses across the whole display in

sub-microsecond intervals.

I could have cleared the picture by looking more closely

at my schematic, too. I had somehow reversed the connections between

OSC and ERRAMP pins. No wonder I've been having problems. OTOH I found

had already corrected part of it last February. And I saw a better way

to rapidly end the modulation cycle if it shuts off on overcurrent.

But the next day (17th) I decided for testing to reduce

the number of variables by eliminating the overcurrent variable

modulation completely, and going with simple fixed high frequency PWM.

This all started messing up the circuit board, with

components upended and vias that had to be cut, all rerouted by messy

wires. It starts to get pointless to go into all the details. I'll want

a new PC board for the "real" controller.

There seemed to be a lot of very glitchy signals, with an

annoying thread of 3MHz oscillations at an amplitude of up to several

volts.

Even the magnet sense inputs had it, to the point where the scope

couldn't trigger properly off them. (indicating I should be using

shielded cable, and filtering them on the board!) I was amazed it

worked. But when I looked again later (after having added some

capacitors) it seemed not bad. It depended on where I connected the

probe's ground clip.

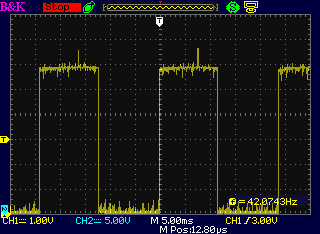

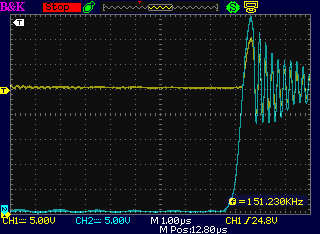

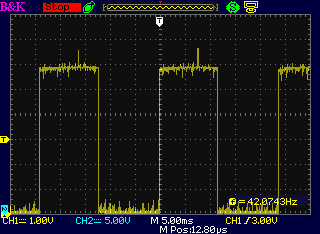

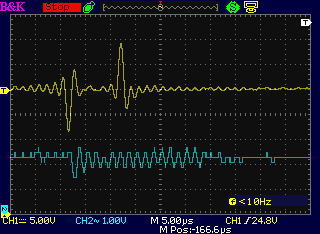

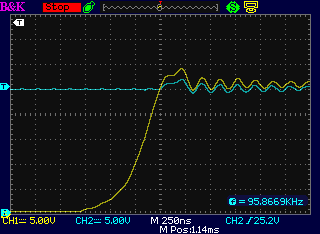

A Hall Sensor Signal - the second time with

A Hall Sensor Signal - the second time with

the ground clip near the signal.

42Hz * 15 = 630 RPM

At the current sense

input, the signal was supposed to

be filtered with an RC filter (330Ω, .01µF), which seemed to do

nothing - it had the same RF noise at the same amplitude as the direct

connection. In case it needed a larger capacitor, or in case there was

a bad through-hole connection on the capacitor, I soldered on a

.1µF on the back of the board.

When I did that, the motor magically ran properly and

smoothly with the control, and the transistors didn't get hot: it was

working! Instead,

the flyback diodes got warm. Roughly, the motor seemed to use about 150

watts to idle at 1000 RPM. This didn't compare favorably to the

original Electric Caik measured at 101 watts. (TENews #60) I thought it

might

indicate inefficient energy return - especially with the diodes heating

up. However, if there was no energy return, currents could be

expected to be at least 5 times higher than the other motor, if not 10

or more. So the basic system was essentially working. (In fact, later

some of the load was shown to be the bearings, which were stuffed full

of thick grease, and the shaft, which wasn't square to the lower

bearing.)

I thought that was good accomplishment for one day and it

was 4:30PM, but a while later I remembered, then went back and dug out,

the device I made a few months ago for measuring static "locked rotor"

torque with a scale. Of course the rotor wanted to cog to certain

positions. From the center of where it naturally sat, I got the

approximate readings below. I could only get it up to about 3 amps if

it wasn't turning, partly no doubt because of the disabled current

modulation leaving only PWM, which I had set at 12KHz.

0Amps: 0g

2.0A: 140g

3A: 190g

If I set it to a rotation where it had the maximum forward turning

force with no power applied,

0A: 115g

2.0A: 230g

3A: 280g

The scale arm is 6" long, so divide by 2 for feet. 454 grams in a

pound, so

divide by 454 to get pounds. The highest relative reading was the

first, 70g/A (below), and the lowest ones, after subtracting the

cogging force, were just over 55g/A. (In review it was probably a

little lower than 140g, maybe 130-135, but the readings weren't at all

steady.)

140g * .5ft / 454 g/pd / 2A = .077 foot-pounds/Amp

As current is raised, the cogging force should become a

smaller and smaller component, since it doesn't increase, which would

seem to indicate torque ripple will prove to be relatively low. But

until I can drive it to some higher static amps, which should attain to

greater accuracy and precision of measurement, these figures seem to

indicate somewhere around .6 to .7 of a foot pound per 10 amps, as

opposed to the original Electric Caik which seemed - as measured very

vaguely since I didn't then have a good system - to be around 1

foot-pound/10Amps. This reduction seemed in keeping with the 50%

extra no-load watts.

To end the day I ran it up to 1200 RPM with about 8 amps,

in both directions. That was about all the lab power supply wanted to

put out. The diodes rapidly got hot but the transistors stayed cool.

Then 600 RPM in both directions took only about 2.75 amps, and the

diodes heated slowly. Apparently it's wasting more power to run it

higher power and speed. 'Why?'

Anyway it finally was running well, and a lot of things could be tried

or adjusted.

The next morning I turned up the PWM frequency to 22KHz. I

thought that would raise the 'locked rotor' amps and torque, but it

didn't seem to change anything. The diodes still got hot. As I began to

investigate with the scope many unexpected things were seen. On one end

of a wire things weren't always the same as at the other end. (I

probably wouldn't have noticed with the old scope.)

The gate drive signals, short tho the traces were, instead

of sitting peacefully at ground, had big glitches up to 4 or even 7

volts when a different coil was being turned on or off. These are just

the thing that blows up a typical BLDC motor controller, causing

"shoot-through" currents from the supply to ground. All they do here is

start to activate the wrong coil. That doesn't of course mean they

shouldn't be cleaned up - only that the controller is still working,

which

makes figuring out the problem much simpler.

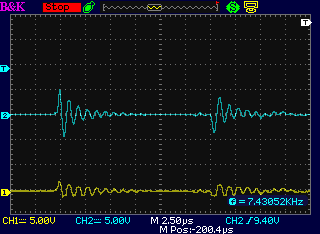

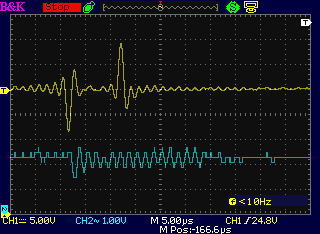

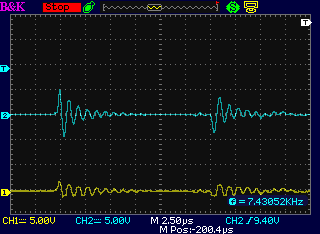

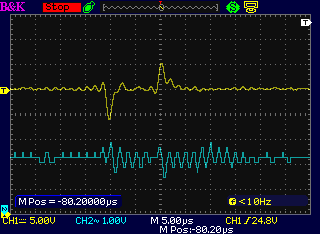

An "off" gate drive as another phase is being

switched ON then OFF.

An "off" gate drive as another phase is being

switched ON then OFF.

Both traces center on 0 volts. The lower trace is straight at the

controller chip,

the upper one is at at the mosfet gates, past the gate resistor.

The scope screen shows the problem: At 5 volts per

division (when about 8 volts turns most mosfets fully ON) these are

serious spikes, and could well be the cause of the extra power that

seems to be needed to run the motor. Why are they there, and why are

they worse at the gates than at the driver chip?

But checking the mosfet common showed almost the same

waveform, so it wasn't really turning the gates on. This gets even more

perplexing, because if mosfet common goes

above the 100mV reference on the driver chip, it should shut off the

cycle. How can it be going up several volts? But wait... what about

that .1µF capacitor I put on the current sense pin, replacing the

.01µF, and which made the controller start to work? I put the

probes on the current sense and reference pins, but the simple presence

of the scope probe on the reference pin caused the controller to

malfunction.

The next morning I increased the flux gap in the motor

itself, and the current to idle at 1000 RPM dropped to about 4.75 amps,

or 118 watts at 25 volts. Now it didn't seem so different from the

first motor. Perhaps the controller was just fine... but then why were

the diodes heating up? I also added a 270µF capacitor from the

mosfet sources to the supply to try to dampen down transients on the

current sense line and the gate drives. This seemed to be somewhat

successful.

To digress from the sequence but complete a topic, the

motor

wobbled at higher RPM.s. I thought the rotor wasn't on quite straight.

A few days later (21st) I took the top off the motor to fix it. The

lower bearing still held the shaft on solidly. So I ran it up to 1000

RPM with the top off and only the one bearing. Instead of drawing 4.75

amps it drew only about 3.5, or 87 watts instead of 118. In other

words, substantial power was being used to overcome friction. The whole

shaft wobbled, so it

wasn't the rotor, and this (more than the thick grease coning out the

gills of the bearings) was probably the major friction cause. This was

doubtless the case in the previous motor

too, and I noted in TE News #60 that it seemed to take less current and

power as the motor warmed up - and perhaps as it expelled some of the

excessive grease, or the set screws relaxed a bit. (I could see in both

cases it wasn't getting the 95%

range of peak efficiency of the larger Electric Hubcap motors, where I

used lightly greased trailer wheel bearings that didn't care if the

shafts weren't 'perfect' and IIRC was using around

70 watts for 1000 RPM. And I did attribute it to the bearings, which I

discounted as being a problem because they'll 'wear in' and improve.

But running with one bearing showed the effect starkly. I got a new

shaft to try and turn more exactly, but that's another job to get

around to.)

Diode Issues

If you want to shorten your reading, skip this down to

"Diode Report" below, where I summarized the findings.

Next I checked on a coil (at the anode of one diode) and

the supply power (at the cathode of all three diodes) and found that

for the first 1/2 a microsecond, the forward voltage across the diodes

was about 5 volts instead of .5 volts, even at the low currents I was

using. (I might never have figured this out with the old oscilloscope!)

They were power schottky diodes, but apparently they weren't the least

bit fast diodes. The amps being conducted as each diode switches on,

with the high voltage 10000 times per second would probably heat the

diodes up and cause extra watts to be needed to turn the motor - the

observed symptoms. It seems it needs fast switching diodes

(short Trr) that can also handle very high current.

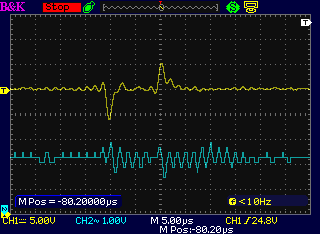

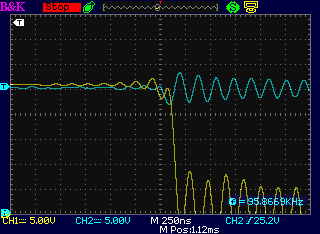

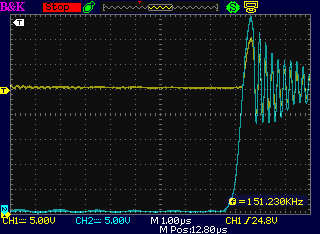

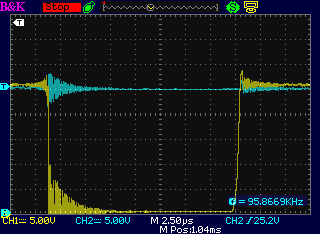

The coil voltage (cyan) as it switches off

exceeds the power supply voltage (yellow) by as much as 5 volts.

The coil voltage (cyan) as it switches off

exceeds the power supply voltage (yellow) by as much as 5 volts.

The two probes are directly on the anode and cathode of one of the 40

amp schottky rectifiers, which should clamp it at ~.5 volts.

Conclusion: fast reverse recovery time diodes are needed.

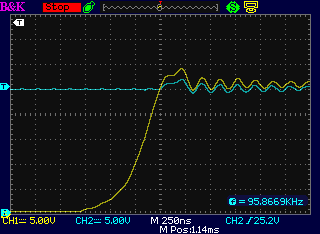

Yellow: ON-OFF switching spikes on the

power buss,

Yellow: ON-OFF switching spikes on the

power buss,

TOP: supply side of the coil (almost 10 volts peak)

BOTTOM: at the supply filter capacitors (about 5 volts).

These are the two ends of the same 9" piece of fairly heavy wire:

with higher frequencies and currents wires aren't just wires!

Cyan: the motor side of the supply bus coil, damped by multiple

capacitors. (under a volt)

In the previous controllers, the diodes were the built-in

body diodes of the power mosfets. Here the configuration is wrong for

that, and I used the heaviest diodes I had, dual 20 amp schottky

rectifier diodes. I checked and compared the specs:

IRFP3206 MOSFET body diodes: Trr = 33nSec (typ), Vf = 1.3v (max, @75A)

If(max) = 200A, Ifm(max) = 840A

TRPS40M120 dual schottky rectifier diodes: Trr = not specified!,

Vf

=

.79

(@20A), If(max) = 2 * 20A), Ifm(max) = 2 * 220A

The datasheet claims that the diodes are good for "high

frequency switching power supplies", but doesn't even specify Trr!?!?

But the reverse capacitance graph up to (2 * ~.001µF) seems very

high to my uneducated eye, so it looks like it's an awfully slow

recovering diode. Not what's needed for capturing the energy from a

short pulse!

I didn't think much of the 1.3 Vf for the MOSFET body

diodes, either. That seemed like a notable energy waste and heat

source, that I was unaware of until now. (What happened to "typical" .5

Vf for schottkys?) I thought they might work better for now than the

schottkys until I figured out what to order. Then I went to Digikey.com

and found that simple diodes with the specs I wanted were in fact far

more costly than the IRFP3206 with the built in body diodes - they

started at over twice the price and went up from there! And the only

spec that was better for most of them was Vf, mostly about .95 to 1.1

volt. But that was "typical" and the 1.3v was "maximum", so they

probably weren't much different. The body diodes in the mosfets I

already have are superior in every other way. Anything with faster Trr

than 500nS was considered "fast". Only one was faster than the mosfet's

diode.

Then I checked the body diode specs for the other power

mosfets I have, IRFS7437.s, and they looked even better, and cheaper.

Again Vf(max) was 1.3 volts, but Vf(typ) was 1.0 volts. 1000 amps

momentary pulse. 30nS Trr. The one minus was that they were only 40

volts reverse voltage. That's okay for the 24 volt controllers. I'll

have to find something else for 36 or more volts. I started this motor

controller thinking to cut the number of mosfets in half from 12 to 6,

but now it looks like I'm going to add three just to use them as

diodes! (But other than tying the gate to the source so they never turn

on as mosfets, what's the difference? Lots of the diodes are in the

same or similar package styles.)

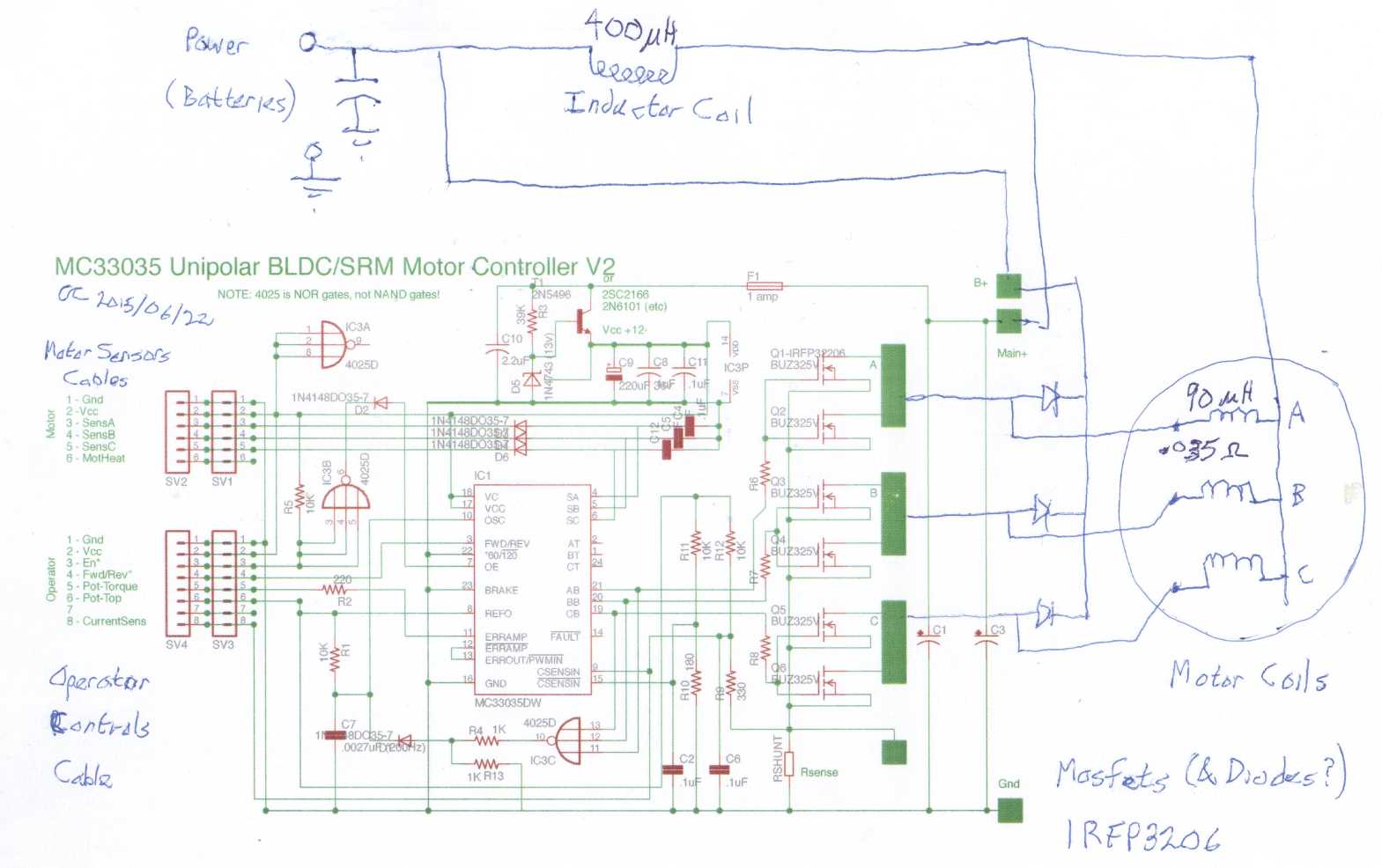

On the 24th I changed the flyback diodes to IRFP3206

mosfets (gate shorted to source). On the scope they still appeared to

be rising substantially above the supply voltage, but not as much,

maybe 3 or 4 volts instead of 5, and for a shorter time like 300nSec

instead of 500. The current to idle at 1000 RPM, with the motor still

open (unchanged), dropped again to about 3.25 amps from 3.5; 81 watts

instead of 87. The transistors stayed cool. The diodes still got hot -

probably not as fast. Wow, how much of the heat in a regular controller

is from the flyback diode action of the mosfets, rather than from the

actual mosfet conduction of power?

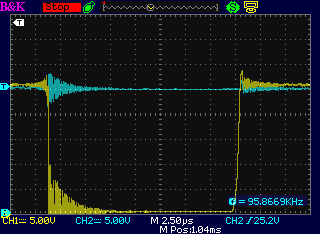

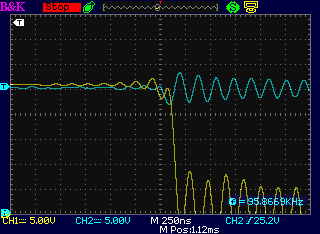

Coil pulses with single IRFP3206 'diodes'

Coil pulses with single IRFP3206 'diodes'

Yellow: the coil. Cyan: power line.

1: An entire coil ON pulse - a little under 20µSec.

2: Turn-on, 250nSec/div

3: Turn-off, 250nSec/div (Energy recirculation when coil > .8 volts

above supply voltage.)

This means a design change: the diodes will have to be

firmly heatsinked to the case. (But electrically insulated.) If they

get hot on a copper bar with 3 amps of motor current, the whole case

will get hot with 200 amps. And that's with 1/2 as many diodes as a

regular controller.

A possibility to eliminate much of the heat is to have

"active rectification", where mosfets turn on whenever the diode would

be on. The forward drop of a mosfet when fully on is much lower

than a diode, so its power dissipation is also lower. But it gets

complicated.

Silly as it seems, it should be useful to parallel two or

more diodes so they handle the spike of current, short as it is,

without such high forward drops. If two diodes lowered the drop to 2

volts instead of 4 volts, they would not only split the heat, there

would be half as much of it. I made the copper bar for this on the 28th

and ran tests then and the next day.

Torque Inconstant

I checked static torque per amp by turning the supply to

1,2,3 and 4 amps with the torque measurement arm attached. Kt (torque

per amp constant) is supposed to be linear, but (come to think of it),

that's the "AC" current, presumably as measured on any phase, not the

average DC

current from the supply.

1A: 100g

2A: 150g

3A: 180g

4A: 215g

Perhaps the thing to do would be to apply a DC current

straight to a coil from the lab power supply and leave the motor

controller right out of it.

Diode Lab Report

I found the diode stuff important enough that I explored

it fairly thoroughly. On the 29th I wrote a "lab report" on it and sent

it to OSMC@yahoogroups.com [Open Source Motor Controller], where I had

been conversing with knowledgeable people about the new motor and

controller. I noted the surprising amount of heat - energy losses - in

the diodes. Of course, the "half wave" controller has only one set of

forward diode drop losses instead of two, so that source of heat and

energy loss is actually halved.

Here is a copy of the report, where I summarized the main

points/findings.

For those interested...

I said I'd have more on the 'flyback' diodes that take the pulse of

energy stored in the motor coils and feed it back to the power supply.

So here's my "lab report". The whole issue seems more noteworthy than I

had expected.

In this sort of controller, often used for SR motors, the diodes are in

the wrong place to be the body diodes of the mosfets. That lets us view

the diode activity separately from the mosfet switching aspects.

In this particular "single ended", "half wave" or "unipolar" motor

controller, with no high side mosfets and only one direction of motor

coil activation, the complication is that the spike is up above the

supply voltage, but the other side of the coil is connected to that

same supply (instead of to high side mosfets) and not referenced to

ground in any way except when a coil is turned on. So a 'flyback' diode

to "+" would simply short out the motor coil, wasting the energy.

Rather than doubling the components by adding high side mosfets and low

side diodes as is typically done, I put in the supply line coil, to

dynamically decouple the motor coils from the battery for an instant

while the turn-off pulse dumps back the dynamically stored energy, into

capacitors or the battery.

The system seems to work. The supply current is much lower with the

diodes than without and the driving mosfets stay cold (at the lower

currents for an unloaded motor). But, unexpectedly to me, the diodes

heated up badly.

---

Being used to seeing and hearing ".6 or .7 volts" for diodes, I was

surprised to see forward drop ratings for really high current diodes to

be on the order of 1.0 to 1.3 volts. I was even more surprised to see

on the scope 5 volts across the ones in the motor controller.

Evidently the forward drop can be much higher in a short, high current

pulse. With 40A rated schottky diodes I was seeing 5 volts for 500nSec,

and they got hot pretty fast.

So I changed them for IRFP3206 mosfets, connected backwards and with

gate connected to source, just to use their body diodes as diodes.

(Rated at 200A, 840A pulse, Vf max 1.3V @ 75A) This brought it down to

around 3.5 volts for 300nSec, and they still got hot, but more slowly.

The no-load power to run the motor at 1000 RPM dropped from ~87 watts

to ~81, suggesting the reduced heat was less wasted watts.

Yesterday I doubled them, two parallel diodes per phase. This brought

it down to about 2 volts for 300nSec, and they heated more slowly

still, partly because of lower internal dissipation and partly because

the copper bar mounting was twice as long with twice as many diodes.

Current seemed to drop a little more to around 73 watts. (around 2.9A @

25V... I have to say say "around" because the analog current meter on

my power supply is something like 10% off, so when I see "2.6" onthe

needle I have to add ~.3. I did however get a new BK2530 digital

storage oscilloscope for this project. I don't think I'd have got it

all figured out with my old 1970s Heathkit scope with just one decent

probe!)

I'm satisfied with this, at least for now. (I suppose I could triple

the diodes and lower the losses a bit more.)

They surely need to be heatsinked to the outer case. (but electrically

insulated.) After it's in a case and not spread out on the bench.

---

I doubled the PWM frequency from 10.5KHz to 21KHz. The switch-off

waveform looked identical to the 10.5KHz, but since it was switching

twice as fast, the diodes got warm faster, and the power to maintain

1000 RPM went up a few watts. But there's more torque/current at 0 RPM

-

6A instead of 4A. This shows there are a few savings to be made with

variable frequency or "CRM" modulation, where the switching speed drops

with increasing RPM and or reduced load.

---

Throughout, the actual coil switching mosfets have remained virtually

cold. So the only significant heat in the controller is from the pulse

diodes.

---

BTW for the astute... the reason the power is still relatively high to

idle the 4.8KW(?) motor at 1000 RPM is that its needle bearings are

stuffed with pretty thick grease (you can feel the resistance when

turning them by hand), and the shaft isn't held straight, so it

wobbles. I have a new shaft to turn, but that's another job to get

around to. The grease will eventually thin out.

Regards,

Craig

The conversation continued with feedback on this message.

I got a couple of insights from it, and someone mentioned "FERD" -

"field effect rectifier diodes"

with low forward drop, which I had never heard of. This sort of

unexpected information is why it

often pays to run things by others. To demonstrate that the circuit

works (there was a "skeptic"), I bypassed the coil. And sure enough,

the current and power to run the motor went way up. I'll

order some FERD.s and try them out, but as the highest rated are only

so high,

I'll still have to parallel some. Maybe even 3 or 4 pairs per phase.

Any

more than that I'll stick with the IRFP3206es. Rather than rewrite

about the same topics, here's the message I sent.

Thanks everybody for the feedback!

The circuit does work. The watts to turn the motor drop with lower Vf

through bigger/more diodes. If the diodes were merely shorting the

motor coil spikes and not returning the energy, the watts would remain

constant.

But to see it better I've just tried bypassing the coil. I turned the

PWM up to 21KHz instead of 10.5, but I could still only get the motor

up to about 650 RPM, where it was drawing ~5.4 amps; 135W. (@25V)

That's where the PWM is limiting on overcurrent with the present sense

resistor. And the diodes get hot faster. (The driver mosfets still run

cold.) With the in-line coil, the same RPM takes about 1.5A; 38W.

I already know that if you try to run it without the diodes even at the

lowest power, the mosfets get hot fast, until one shorts out - also the

motor barely turns.

---

>I think using diodes to steer energy will

always be a lossy method.

At least with this controller there's only one diode drop instead of

two! And the coil voltage is drained to zero instead of just to the

power supply voltage.

>If you want to switch currents from here to

there it seems like you should use a switching device not a blocking

device.

I'm trying to keep it simple. This would re-introduce potential for

shoot-through currents, and require floating high-side gate drives,

both of which I wanted to get away from. Of course I never suspected

such high diode losses. But the FERD diodes Chris P. mentions might be

just as good, which is exciting.

>With large diodes you will always have a

significant turn-on time (and turn off). That is why you see the