Turquoise

Energy Ltd. News #91

covering August 2015 (posted September 2nd)

Victoria BC

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Highlights: TWO Improved Axial flux

Switched Reluctance Motors: "AFSRM" or "ARM" and "Transverse Flux" Motor

(Building ARM is in

progress - see Month in Brief, Electric Transport topic)

Month In Brief

(Project Summaries)

- Plan that got changed - ARM Motor - An even better(?) SR motor

layout! - Mounting a Motor for a Car Wheel Drive - Solar Water Heater -

Peltier Cooler Voltage Tests - Battery DES Chemicals arrive

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

* Solar PV Power coming of age - Comet

67"P"

for

"Perspective"

-

Putin/leadership/spread

of power - More Collapse Warnings and Signs

Add to the Chorus - chem trails seriously interfere

with solar collection - Fuchsia Berry Pie - Funnies(?)

- In Depth Project Reports -

Electric Transport - Electric Hubcap Motor Systems

* ARM motor project

* "Transverse flux" SR motor idea & project

* Making an offset motor with belt drive "Electric Hubcap" Plug-in

Hybrid EV Installation: wheel end parts.

* Sprint: work stopped again owing to competing attractions. (ie, by

very promising looking new motors, again!)

Other "Green"

Electric Equipment Projects

* Solar Hot Water Heater

* Peltier Module/Thermoelectric Cooler Experiment: supply

voltage versus attained cooling.

Electricity Generation (no reports

[but see Solar Water Heater in Other Green Projects,

and Solar PV coming of Age in In Passing])

Electricity Storage - Turquoise Battery

Project (NiMn, NiNi), etc. (No reports)

No Project Reports on: Magnet

motor,

Lambda ray collector, evacuated tube heat radiators, CNC

gardening/farming machine, Electric Weel, battery making, aquaponics.

August in Brief

The First Plan...

On the 2nd I prioritized what I thought were my main project objectives:

1. Make a 12 magnet placement jig for Electric Hubcap rotors, similar

to the one I did for the 8 magnet Electric Caik rotors.

2. Mill the rotor (same one) slots for the new style magnet strapping.

3. Attach the magnets. While the epoxy is wet, patch up the gouged

rotor wall in the motor.

4. Reassemble the motor and reinstall it in the Sprint.

5. Try it out with the Kelly controller to see if it works. (I'm really

still not quite sure whether it will or whether all the propulsive

forces cancel

out.)

PATH A: Kelly controller works

6. Connect the torque converter control pulley linkage to the shift

stick.

7. Try to get Sprint moving.

PATH B: It doesn't work, or after path A is done

6.(8.) Edit the unipolar controller circuit board and finish it up.

7.(9.) Print the artwork and Etch the board.

8.(10.) solder on the components.

9.(11.) put together the controller.

10.(13.) Test the controller on the Caik and Hubcap 4:3 motors.

11. Go to path A if it wasn't done before.

There was more of course, but I figured that would be at least a full

plate for August. I did have a little holiday coming up!

But the seemingly straightforward plan immediately got off

track. I started (ignoring

the task numbers) by trying to get the LED

headlights working in the Sprint, since I already had half the dash

apart. Something weird was happening and I soon wished I had left the

headlights alone. Then I pulled the shifter cable out to see how I

might set it up. Later I

thought to cut one end off the cable so it fit the same inside at the

shift stick but had a fresh cut end to work with under the hood. And it

let me slip off the offending pipe that diverted the cable in the wrong

direction at the firewall.

On the 7th I wired the headlight switch and the right

headlight back to the original wiring, and put a

halogen headlight back

in the right side. The only way it would come on was with "momentary

flash" - not with regular low or high beam settings. Apparently they

hadn't been working in the first place. (Didn't the dealer drive it to

my place with the headlights on? Who can remember so far back.) There

had to be a break between the light switch and the high-low beam switch

- but there should be nothing but a wire and maybe a connector between

them. Would I have had to deal with that somehow regardless? I decided

to give that a rest and bought some copper pipe for a hot water solar

collector.

Then the motor plans started to morf.

The ARM Motor

I rather suddenly determined on a good axial

flux switched reluctance motor ("AFSRM") design on the 9th. It should

be easier to make than my supermagnet motors, and if it's really

better, how much farther do I want to go developing the BLDC type I'll

probably never make any more of? Especially if the high RPM capability

of SRM.s eliminates the whole need for a variable torque converter

transmission for EV.s?

The new design still uses my same

toroidal coils, as "cup electromagnets" with a steel outer ring, to

attract

matching "overlapping ring" rotor poles. If the very tight tolerances

and narrow flux gap can be reliably accommodated, it promises to be a

winner, with much more torque than what I was thinking of previously

and (I expect) less torque ripple than other 3-phase SR motors. With a

'solid' steel rotor having no magnets or wires, very high RPM.s can be

easily and safely attained, and since power = torque * speed, small

higher power motors become more feasible. Outboard motor conversions

will work better with high RPM motors, and the external wheel drive to

"hybridize" cars, with just a fixed gear ratio,

gets much easier.

With no supermagnets and minimal copper they'd be

intrinsically the cheapest

of motors, and with waterjet cut steel parts they'll be easy to make

and to assemble. I can see motor kits being much more practical to put

together, more 'professional' in form and parts, and easier to assemble

than the BLDC/supermagnet type.

The inherently more reliable unipolar motor controller

I've been doing for some

months now is (somewhat fortuitously) the right type for both the

"BLDC4:3" motors and for the reluctance type.

The new concept had been

vaguely brewing in my mind. It was loosely based on an odd

feature of a 'theoretical' design AFSRM in one of the research

papers, a four phase motor with 16 coils and 20 rotor poles. So what

made that seemingly "written in stone" 3 to 2 configuration

necessary in three-phase motors? I had just successfully run the BLDC

magnet motor

having 4 magnet poles per 3 coils instead of two. For SRM.s were there

not multiple possibilities? On the 9th I decided to try out some

layouts for visualization.

Since I had "donut" coils with a metal ring around them,

forming something like "cup magnets" (here, "cup electromagnets"), then

instead of straight lines, I could have rings on the rotor that matched

the narrow flux gap rings of the coils. As the steel ring came near

alignment

with the coil flux ring, they would be strongly attracted to line up.

The reluctance would change rapidly over a short angle of turning which

creates strong torque, but it would be less abrupt than with straight

lines. Good torque but with less torque ripple would doubtless also

produce less noise, which is listed as a complaint against switched

reluctance motors. If after a

rotor ring(s) lined up with the phase A coil(s) another ring was in

position to start lining up with coils B (or C), the process could be

repeated, and then repeated again with coils C (or B). After that, the

second rotor coil would be in position for phase A again.

What was needed was not two rings per three coils, because

each time, the next ring would be too far from the next coil for good

torque. Instead a number of rings had to be found such that the next

ring for each phase was positioned just about right for high torque

just as the

previous phase shut off.

Four rings per three phases

When ring 1 reached coil A as shown, A would shut off and C would turn

on,

but ring 4 is too far from coil C for strong torque at first.

The same situation will apply for each change of phase.

(Coil A is shown with the outer steel ring. The rest are just

the cores.)

2, 4 or 5 rings per three coils weren't enough to get the

next ring

very close to the next coil. 3, 6 and 9 are even multiples of three so

the

rings all align with the coils at once instead of in a 3-phase

sequence. 7, while it might have been close to a good distance, had

two rings almost equi-distant on each side of the coil at turn-on time,

which

would cause nearly as much reverse torque as forward. 10 filled

in too much space to make a rather solid rotor instead of distinct

rings. But 8 seemed

to work out. As seemed intuitive afterward, the ratio at the ring

centers was about 1/3 metal ring to 2/3 air gap between... seemingly

just

right for

three phase operation.

The

energization sequence (clockwise rotation of the rings/rotor) pulls

ring 1 to coil A as shown,

then 4 to B, then 7 to C. Then 2 pulls to A, 5 to B and 8 to C. Then 3,

6, 1

etc. By the time

ring 1 is back at coil A, there have been 8 electrical cycles for one

electrical rotation. And since there are six coils, two for each phase,

there are 16

cycles for each physical rotation. So instead of 6 changes of active

phase through broad, mostly low torque areas, it's 48 total coil

activations in the sequence, each for a short distance through the

highest

torque zones.

The

energization sequence (clockwise rotation of the rings/rotor) pulls

ring 1 to coil A as shown,

then 4 to B, then 7 to C. Then 2 pulls to A, 5 to B and 8 to C. Then 3,

6, 1

etc. By the time

ring 1 is back at coil A, there have been 8 electrical cycles for one

electrical rotation. And since there are six coils, two for each phase,

there are 16

cycles for each physical rotation. So instead of 6 changes of active

phase through broad, mostly low torque areas, it's 48 total coil

activations in the sequence, each for a short distance through the

highest

torque zones.

ARM motor with overlapping rings rotor.

Bearings including thrust bearing are installed.

ARM motor with overlapping rings rotor.

Bearings including thrust bearing are installed.

Coils await outer rings and attachment to the plate, and then it needs

optical interrupter

rotor position sensors mounted. Then wiring, assembly and testing. oh,

and painting!

The outer flats are optical interrupters for sensing.

Test assembly of ARM motor case.

Test assembly of ARM motor case.

Far from my original design of AFSRM motor that would

probably run okay but with low torque and power, here was something to

challenge the state of the art - and drive a car with! If it could

provide start-up torque with a drive ratio for a single pair of toothed

pulleys, like 3, 4 or 5 to 1 (making it 3000-5000 RPM at 100 Km/Hr for

typical 13" wheels), that would be ideal. (If the ratio gets much

higher, there'd probably have to be a double reduction configuration

with two belts and extra pulleys.)

Then, Another New Motor Design

While I was on holiday, someone sent me a link to a new

"transverse flux" BLDC motor layout. It made some strong claims, and it

looked like it could be turned into a potentially superior reluctance

motor layout. The most interesting feature is that each phase has just

one coil, with the wire

wrapped all the way around the entire stator. Without having to wrap

a wire around each separate magnetic "tooth", the number and density of

the teeth can be greatly increased. More points of magnetic force could

greatly increase the potential

torque per area and per volume.

I would make a radial flux type of layout with the stator

ouside the rotor, and with narrow

"horseshoe magnet" teeth. With no coils overhanging the sides, even

with the three phases having to be

separate and side by side they are thin, and the motor

can

be thinner than my axial flux BLDC "pancake" motors. If the

"horseshoes" were a left and a right leg each from a mild steel plate

3/16" thick, with another piece of 3/16" thick plate between for the

'center' of the horseshoe (and a space to run the wire), that's

9/16", times 3 phases is 27/16", for a motor that could be as little as

2" thick. If the torque per area is effectively increased and a smaller

diameter rotor can have similar torque, a whole motor of a given torque

and power becomes substantially more compact. Cheaper. Lighter. Simpler

to make.

When this splendid info came the waterjet parts were

already cut. It seemed too late to simply cancel the "ARM" design, so

I've continued building it. I'll have two distinct models to compare.

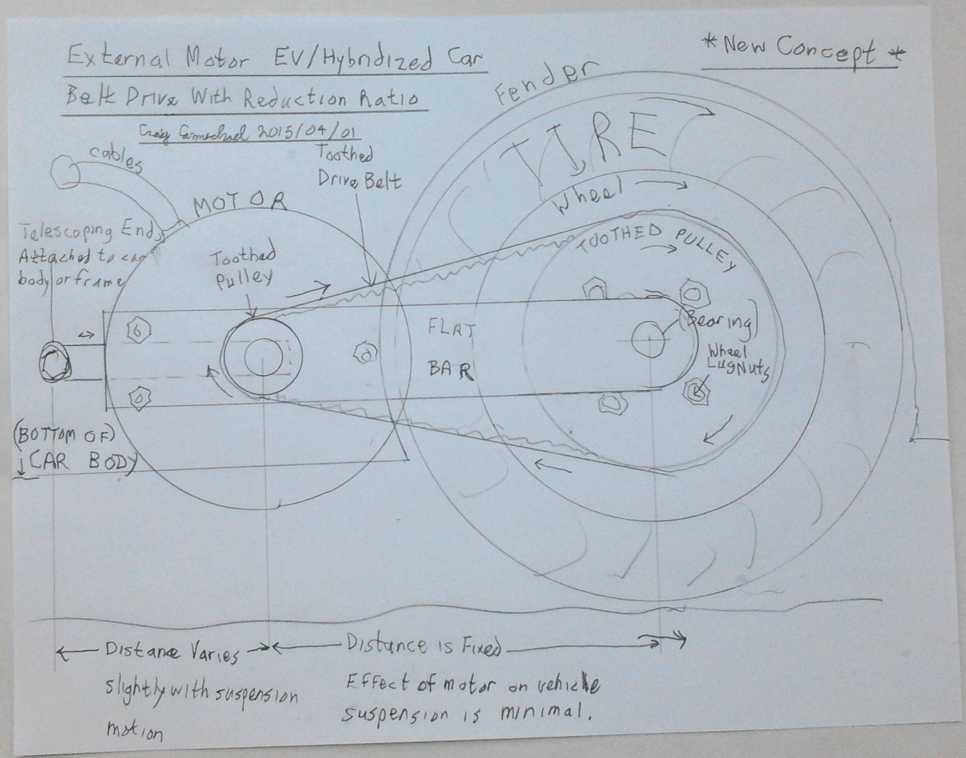

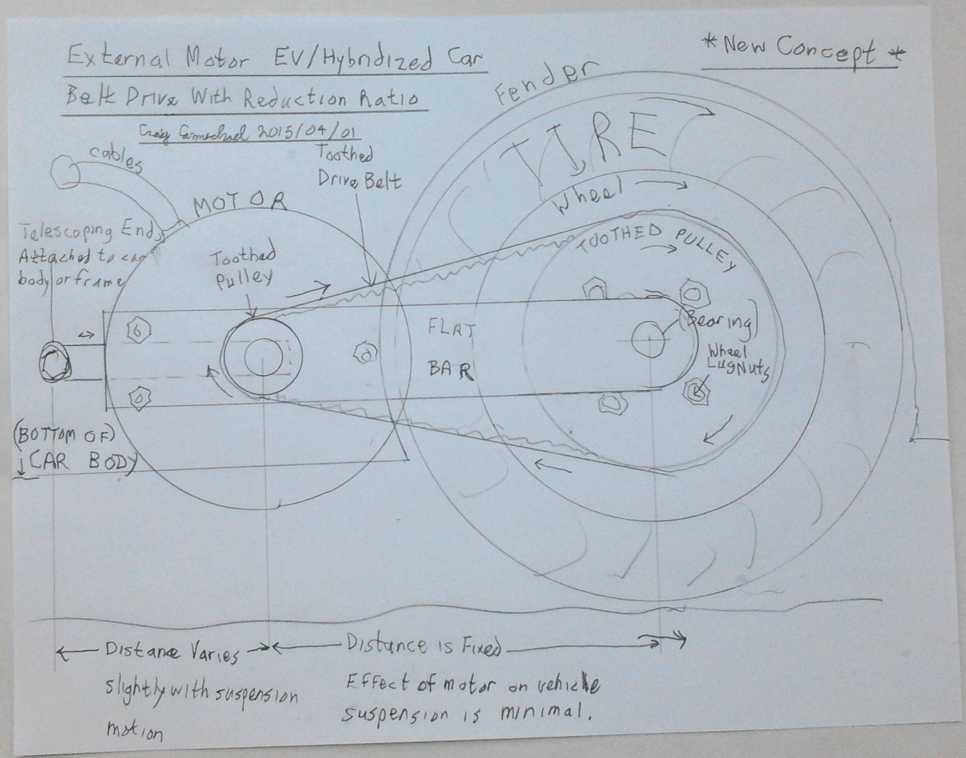

Mounting a Motor for a Car Wheel Drive

The troubles with mounting a motor directly on or in a car wheel are

(a) with no transmission it needs excessively high torque and (b) the

unsprung weight of this heavier motor interferes with 'handling', the

ability of the wheels to bounce up and down to drive over bumps and

dips smoothly. A few months ago I thought up an idea for mounting a

motor beside a rear wheel (behind it or ahead) with a belt drive, which

solves both problems without adding much friction. (Flat belt drives

are 99% efficient and toothed ones must be pretty close.) This month it

dawned on me what actual pieces to use to implement such a system, and

as I had them all I put them on the car to illustrate.

The troubles with mounting a motor directly on or in a car wheel are

(a) with no transmission it needs excessively high torque and (b) the

unsprung weight of this heavier motor interferes with 'handling', the

ability of the wheels to bounce up and down to drive over bumps and

dips smoothly. A few months ago I thought up an idea for mounting a

motor beside a rear wheel (behind it or ahead) with a belt drive, which

solves both problems without adding much friction. (Flat belt drives

are 99% efficient and toothed ones must be pretty close.) This month it

dawned on me what actual pieces to use to implement such a system, and

as I had them all I put them on the car to illustrate.

From the picture, visualize a sturdy bar with "belt guard"

edges, going straight back from the red hub to a pancake motor mounted

on the bar behind the wheel, with its axle sticking through to a

smaller toothed belt pulley. Since the bar is attached to the wheel

(hub) and the motor to the bar, the belt will maintain its normal

tension as the wheel bounces around with road bumps. The rear end of

the bar is attached to the car body/frame to hold it horizontal, but

with enough play to accomodate small movements as the wheel bounces.

Now it needs a high RPM 'pancake' reluctance motor having

the torque to turn the wheel with some fixed 'gear ratio' and the power

to run the car on the road.

See the detailed project writeup for more details.

Solar Hot Water Heater

On the 8th I thought again about the solar hot water (TE

News #88). In a house where people are living, solar hot water is the

best way to

reduce the electricity bill, heating much more water than solar PV

electric for a given panel size. A 4' x 8' (32 sq.ft.) panel is typical

for a minimal system. With all the plumbing involved it's not really

practical to bother with anything much smaller. Two panels is better

for a

family.

I had a copper tank (saved for many years now) for the

preheated

water. I decided to put a 'proper' copper collector

panel together, similar to the one I made in 1979.

Since copper pipe is rather costly I went to Ellice Recycling to see

what they had. I wanted 2-1/2' pipes, but at 5$/pound, it really wasn't

much cheaper than new pipes, and because they were odd lengths that had

to be cut with various leftover waste, they were actually more. I

spent a fair bit of money there before I realized this. I had a few

thin aluminum fins that clipped

onto 1/2" copper pipe and will buy more at Emco, to paint black and

form the

collection surface. They're 2' long by 4.75" wide. Since they're for

1/2" copper pipes, I'll still have to make something to extend the

collection surface of the 1" top and bottom pipes.

The pipes weren't cheap. I bought them in dribs and drabs, but

it was probably over 200$ for the collector alone.

Now I remember why alternatives to copper are ardently sought. But it's

the best for a collector (and perhaps woodstove connected) system that

might get quite hot.

An opposite problem is cold - freezing of pipes. Copper is

prone to splitting or joints pushing apart as the water freezes. I'll

circulate house water

through the collector and into the tank to keep the plumbing simple.

There will of course be valves but it's a pain to drain the collector,

high up on the roof with valves in the unfinished attic, for the

winter. I keep thinking a small water heating element in the

collector's

lower header

pipe, with a thermostat set just above freezing, would cause the water

to circulate to the tank and prevent everything from freezing. But

where does one find such a heater?

On the 28th I drilled thirty 5/8" holes in one of the

twelve foot

long 1"

pipes to silver solder three foot long 1/2" riser pipes to, then I cut

it at 8'. The fins above and below will bring it out to fill the almost

4' x 8' frame. A 4' x 8' piece of clear plastic (lexan?) would

cover the top with a bit of overhang. I tried to fit the pipes and they

didn't go in the holes easily. But if they weren't a close fit, they

couldn't be sliver soldered. I wished I had had something other than a

twist drill, which doesn't make very exact holes in thinner material

like pipe walls. Then I tried to solder in a pipe. While the silver

solder melted off the wire and beaded up near the joint, I couldn't

seem to get the

copper hot enough for it to flow with the propane swirljet torch. Of

course, there's a big copper pipe carrying off the heat, and the slower

the heat, the more it spreads out without getting the heated point up

to the required temperature. Next try will be with the scary old

naphtha gas torch someone gave me. It really puts out heat.

Peltier Module Cooler Voltage Tests

The Peltier cooler hadn't performed well when I went

camping. When I bought it to "reverse engineer" I had never intended to

use it. I had lost the aluminum heat transfer block and hadn't

reassembled it so well. After all this time, I thought to hook it up to

the the lab power supply and test out my ideas of better

performance at lower voltages. (I'd rather have Peltiers with 160-210

thermocouples to run at 12 volts, but except at very high price they

unbiquitously have 127 themocouples, which puts them in an operating

area that cools but has poor efficiency.)

Also, my complaints about their short life expectancy

(fine for occasional camping use, but not for continual home operation)

might be alleviated if they weren't being run so hard. That would make

a big difference in their practicality for appliances - heat pumps and

refrigerators.

I found it worked best at 9 or 10 volts. The temperatures got coolest,

and using much less power than at 12 to 14 volts. 9 volts got it

coldest, with half the power of 12 volts. Just as I suspected! (See

detailed project report for figures.) But I should try it all on the

Superinsulated Thermoelectric 12 volt Fridge, which is working well to

start with, and maybe try the large 14 amp Peltier module, run at lower

voltage and power. It might just cool the whole fridge better with the

same or less power.

Battery Making - DES ingredients arrive

When I returned from camping trip, my order for choline

chloride and ethylene glycol had been delivered, theoretically allowing

me to try making some "Ethaline" DES electrolyte. Then again, I need to

find time to check out the directions and do it. One can only tackle so

many things at a time, and I definitely have less energy than when I

was younger.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Solar Photovoltaic (Solar PV) Power Coming of Age

The price for smaller solar panels is over 2$/watt, but

the price for "full size" (about 1m x 1.6m) panels of 200-300 watts has

dropped to an

amazing 1$/watt even in shrinking Canadian dollars. If I went into a

glass shop and asked for a piece of tempered glass that size with an

aluminum frame, I'm sure it would cost more - without a solar

collector and wiring glued to the glass!

And the capacity of the panels (and so presumably the

conversion efficiency) has been creeping up, from a typical 200 watts

to 250 or better. This month I bought a 260 watt panel for 263$

(admittedly that's the wholesale price), to put

on the east sloping roof for more morning power. I'll then have

coverage pretty much from sunup until sundown.

But I seem to have missed making a contribution with my

nanocrystalline titanium dioxide borosilicate glaze frit, which was to

be sprinkled on solar panel cover glass and melted in like little

sidewalk pebbles. That would reduce reflections, difract the light

inward, and panels would pick up more ambient and low angle light when

full sun isn't coming straight on, for a higher daily total output.

In 2010 new solar installations became cheaper than new

nuclear plants. Solar has continued to cheapen and nuclear to rise in

cost even without considering serious environmental costs such as the

Chernobyl exclusion zone, and as the Fukushima nuclear plants continue

to disgorge dangerously radioactive waste into the Pacific ocean. After

this disaster in 2011,

Germany decided to phase out its nuclear power plants, and offered a

serious incentive program to homeowners to install panels on

their roofs, and (as best I recall) as of maybe a year ago had an

installed base equivalent to three nuclear plants. Power plant

operators were complaining of falling demand for their output. I heard

Ontario did the same thing briefly, but soon stopped. I had calculated

in 2012 DIY solar PV paybacks (well, just for the wholesale panels, and

on

kilowatt hours produced or consumed at the then current prices) of 10

years where there's lots of sun (2000+ hours/year), and 20 on the

cloudy-all-winter Pacific northwest coast (1000 hours sunlight per

year) at about 2$/watt for panels. These should now have dropped to

about 5 and 10 years

on this account, and the cost of electricity in BC has risen from about

9¢/KWH to 12, which makes it

well under 5 and 10 years. And there is no indication that electricity

price

increases are going to stop any time soon.

Solar power isn't a 100%

continuous power solution like river hydro, lambda ray collectors or

perhaps

magnet motors would be, or near to continuous like wave power on the

west coast

of Vancouver Island, but it's becoming a viable way to cut energy bills

and reduce dependence on the power grid - power in an emergency. But if

its use continues to grow, it may be practical at some point to

consider an electric grid ringing the globe: the sun is always shining

somewhere.

My payback assessment based just on wholesale panels is

doubtless

overstated for most homeowners. I tend to make my own electronic

parts and I do my own installing. The prices for the other needed

equipment - charge controllers and batteries, or grid tie inverters -

haven't come down as much, and installation costs are probably about

the same.

Then my 12V CAT standard plugs and sockets, which I should

be doing much more to promote and to market, can make 12V DC house

wiring far more practical than it is.

I discount the drop in insolation and loss of solar power

from the perpetual chem spraying, which I note in a brief clip below,

simply because I don't believe they can keep doing it for many more

years. Hasn't it caused enough ocean life die-offs and climate chaos

already? I hope by next summer this insanity has been ended.

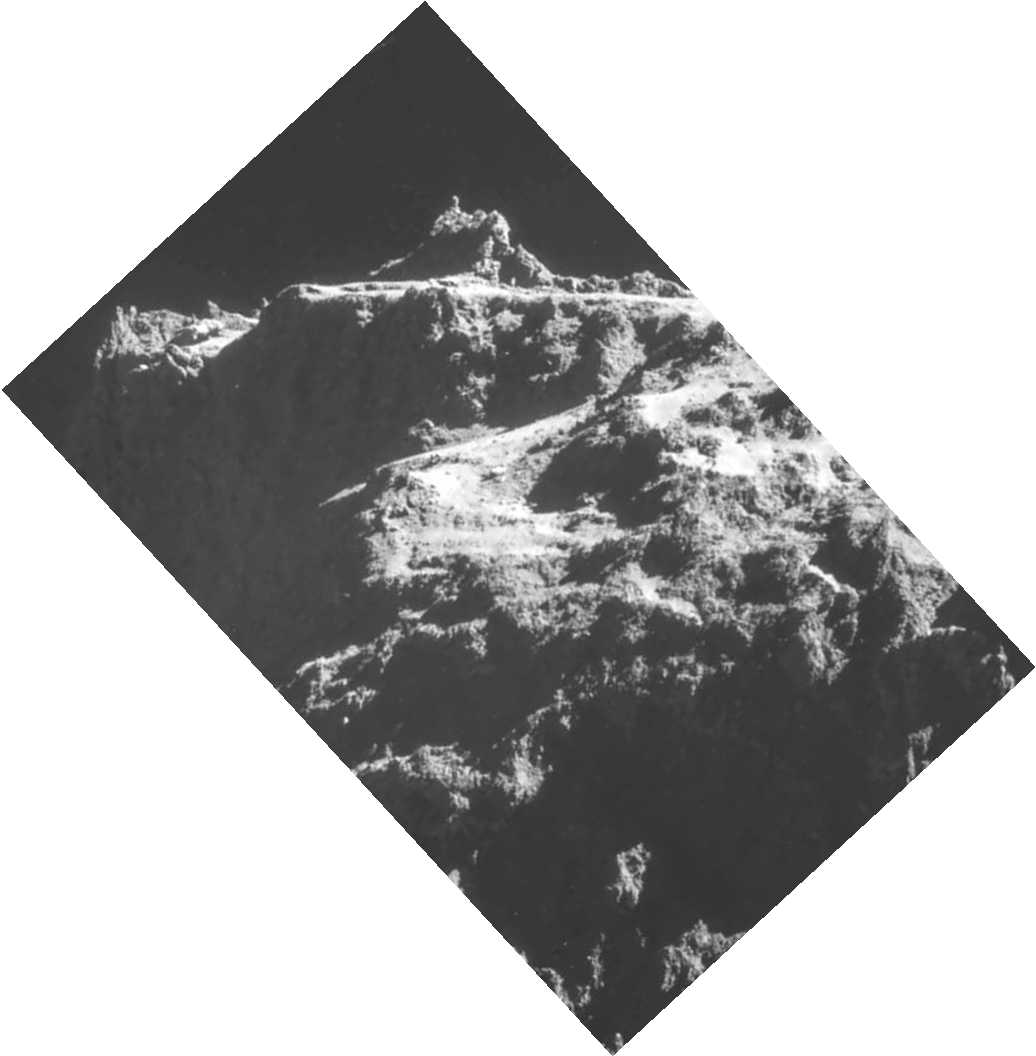

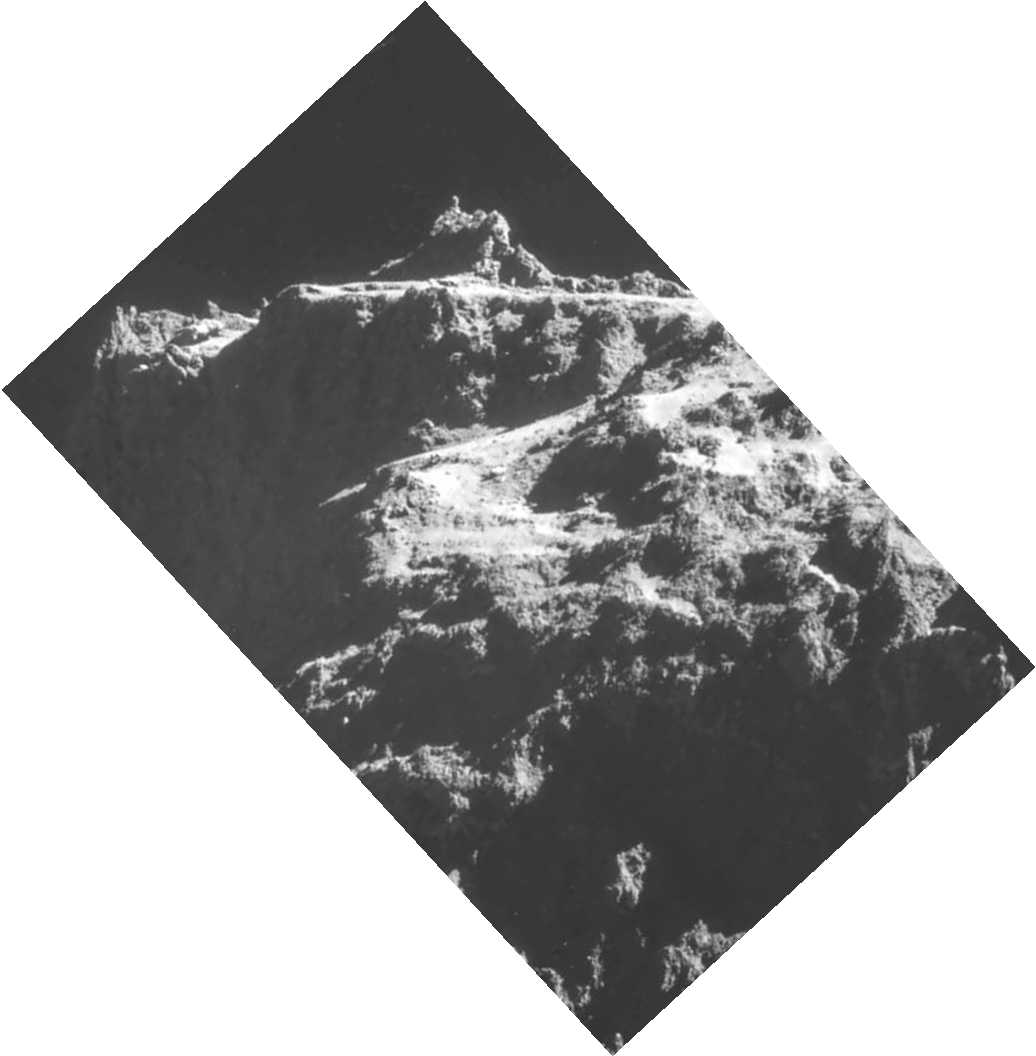

Comet 67"P" for "Perspective" (At the risk of excessively

belaboring this subject.)

Something that looks strange from one angle may look

familiar at another. For instance, people thought they were seeing

strange "glass tubes" sticking up on Mars in Mars orbiter images. I

myself was puzzled by these bizarre images. But when turned upside

down so the light is seen coming from the top instead of from the

bottom, they are seen to be sand dunes filling hollows in rocky areas.

In a

similar vein, if the picture of the comet shown last month is rotated

to apparently

"level" the surface (while acknowledging that the micro-gravity is

surely pointing different directions in different areas even within the

picture), the landscape

I thought looked like vegetation... looks even more like vegetation.

Right at the top is an apparently treed or bushy hilltop silhouetted

against the sky. Doubtless it must be very different from Earthly

vegetation. Further down, the appearance becomes more like aerial or

satellite images of scattered patches of trees as seen from above.

Perhaps one might decide it looks more like some form of

crystal growth. But dead crystals don't emit seeds - which are probably

what the organic particles being detected by the orbiting Rosetta

spacecraft are, which are probably similar to the 'seed from space'

collected in 2013 by a high altitude balloon above the Earth.

It's always dangerous to jump to conclusions about other

unfamiliar

worlds, especially based on a single image. The "glass domes" or the

"Face on Mars"

are but a couple of well known examples. But if a picture is worth a

thousand words, I'd guess that color photos of this comet from this

range would be worth a thousand black and whites. So would close-up

color images of any of those airless, icy worlds having fluffy,

polycyclic aromatic hydrocarbon surfaces.

Another interesting aspect

to this comet is its "dumbell" shape. Shoemaker-Levy 9 was pulled apart

at Jupiter by tidal disruption. Might 67P be two parts of a larger body

that was pulled apart - two parts that barely managed to stay together

in a similar event?

Here I'll update on Ceres: Dawn has lowered its orbit, but

it's still over 1000Km out. There are closer pictures, but without

spectral info there's nothing that leaps out and suggests the dark

material is aromatic hydrocarbons, and it doesn't even look much like

"fluffy", at least from the present distance.

Vladimir Putin - Leadership & the need to spread power more

widely

For those who believe the demonizing western media and think of

Russia's president Putin as

some sort of relic from the cold war, I say: go to youtube, type in his

name, and listen to

him speak - at most any function or time on any subject. His eloquence

and his

straight answers to any question show he's a deep, sincere and

philosophical thinker.

However, I point out again that the time of any leader in

the limelight is short, and that until real safeguards are put into

place and power is more spread out than today, with a good measure

reserved by the people directly, the chance of Russians finding another

Putin after he's gone is about the same as that of Americans finding

another Kennedy.

Furthermore, many things that should be done must be okayed if not

actively sponsored by the leader, but in the aggregate they are beyond

the compass of any one man,

and so they generally get left undone. Then when a less effective

leader is

elected, there is likely to be a disappointing era, and when one

ineffective leader follows another with no real input from an aware and

educated public, a collapse.

This link is to American Veterans Today. Is this

why the US government is afraid of their own veterans? Is it why

Russians are much better off today than when Putin first came into

office? Presented without further comment from me.

http://www.veteranstoday.com/2015/08/08/vladimir-putin-battles-satan-worshipers-and-new-world-order-agents-again/

“The continuing attacks on Vladimir

Putin and Russia by members of the western political, military and

journalistic elite tell us one thing – the Russian President is doing a

good job both for the people of his country and in the international

arena.”—Neil Clark

More Collapse Warnings and Signs Add to the Chorus (At the risk of excessively

belaboring this subject too.)

I recently got an e-mail saying a retired British

official, Damian McBride, adviser to former prime minister Gordon

Brown, is saying that the banks may close and people shouldn't trust

that their credit and debit cards will continue to work, and that

consequent supply chain interruptions will probably mean grocery store

shelves will be bare.

WHOA! British Official Warning Public: Stock up on food, water, canned

goods & cash - enough to survive 1 month - Banks may CLOSE (Stock

meltdown)

http://investmentwatchblog.com/whoa-british-official-warning-public-stock-up-on-food-water-canned-goods-cash-enough-to-survive-1-month-banks-may-closestock-meltdown/

This link points to a prior article link

in the British Newspaper The

Independent, which was based on a twitter 'tweet' by McBride.

http://www.independent.co.uk/news/uk/politics/stock-up-on-canned-food-for-stock-market-crash-warns-former-gordon-brown-advisor-10469509.html

There are of course many who think this is all ridiculous,

but many others would say his measures don't go far enough. They would

be an

excellent

start for those who've done no preparing at all so far. One spends

hundreds of dollars a year on house insurance against the remote chance

of a fire. Look at having some good supplies on hand as personal

insurance against various forms of wider disasters, natural or man-made.

The first hint was the dropping export of Chinese goods

to the west, where the bulk of the middle class is now essentially

broke. This led to the Chinese stock market plunge and the recent

devaluation of the Yuan. Related to but not really because of these

events, the first "shot across the bows" in the west was fired at the

US stock

market on Monday August 24th as the highly overvalued Dow Jones plunged

1000 points at the opening

bell, after a weird 'glitch' in the trading system in July and some

weeks of nervousness and small drops. By mid morning the president's

"plunge protection team" had brought

it back up substantially, and later in the week it was further

restored. But who else is buying? Will they simply print whatever money

it takes to buy all the stocks to prevent the bubble from bursting? Is

the New York Stock Exchange then a market, or just a pleasing

façade on some ugly economic realities? They may soon have to

give up and let it burst, as further drops on Monday, September first

would hint, or they may sustain it to the end with money

printing while everything crashes all around.

And this brings up the fact that "liquidity" is scarce

everywhere. China, also short of cash, has liquidated over 10% of its

US treasury holdings and isn't buying more. Added to this are all the

oil producing nations, now selling off accumulated wealth funds because

of low oil revenues. Who then but the US "Federal Reserve" will be

buying those back, and new US treasury bonds? Will they triple their

own balance sheet while continuing to force all American banks to also

buy bonds, to keep the US government afloat? How many trillions of

dollars can the economy absorb? If hyperinflation sets in, no one

trusts currency any more, and quickly its demise is all but ensured.

Everyone rushes out to cash out and buy things while they can, the

stores empty and close, and the distribution network also goes into

turmoil when the truck drivers (etc) won't accept payments in devaluing

cash.

As exclamation points on the end, HSBC bank seemed to be

having trouble meeting payroll near the end of the month. They claimed

it was a technical glitch, but employees complained they weren't

getting paid. And the state of Illinois isn't even paying out lottery

winnings over 25000$! A family "won" 250000$ but evidently will get

nothing. If your dream, or your last ditch financial plan, was to win

the lottery, it looks like you can forget it!

Remember: currency and credit are only claim checks on

wealth, not wealth itself. If the claim checks, now mostly just blips

on a computer screen, disappear, are dishonored or are made virtually

inaccessible, if the insolvent global banking system holding most of

them collapses, if rules are changed through government or financial

institution dictate, or through rapid inflation, life savings can

disappear overnight. When in such times of sudden crisis the claim

checks vanish or lose their value and people with too many of them and

too little actual property are impoverished, actual wealth doesn't

disappear, but it gets transferred from those trusting the claim checks

- most people - to those more knowledgeable, prescient or just well

placed, who hold their wealth more "outside the system". While most

were impoverished, more people became millionaires during the great

depression of the 1930s than at any previous time.

Real property is wealth. Precious metals, silver and gold,

are only one

form, but the most tradeable one, of real property. So formed as coins

or bars of specific weights they have been considered "money" for

thousands of years. They can't be hyperinflated to worthlessness, and

if held physically by the owner they can't be transferred away or

locked in by the stroke of a computer key or government decree. They

can only be taken by physical robbery -- which is of course never a

danger to be neglected. But in turbulent times and with good

precautions, it's less risky than trusting in claim checks or having

others hold your valuables. Actual cash is likewise much safer

possessed than held as accounts in the custody of untrustworthy

trustees.

(Interestingly, money in a Paypal account may be safer than in a

bank(?) - while they transact with banks continually, they aren't

leveraged and the funds held

seem to be pretty much held outside the banking system. Bitcoin in your

own encrypted, password protected wallet, seems pretty safe, and is

hyperinflationproof.)

A means of producing something or providing a service

people want is a means to 'generate' wealth. But new things made

usually equal old things recycled, and land is pretty constant, so

there's only a certain, somewhat constant

amount of real wealth on the planet. The 'cosmic values of social

sustainability' again apply: Quality of life, from which must follow

Provision for Growth and Equality of opportunity and laws. The land-man

ratio dictates how much wealth is available per person. All else being

equal (technology, farming, social development), if there are half as

many people, everyone will (or should) be notably better off, and

quality of life will continue to deteriorate with an ever growing

population. (I'm just now reading Social Sustainability HANDBOOK

for Community Builders by Daniel Raphael, PhD, which goes into

these recently recognized principles and their applications in more

detail.)

Chem Spraying Ruining Solar Electric

Car Charging!

I've had the RX7 EV running for 3 summers now, and the solar panels on

the roof

for 4. Now charging the RX7 with solar power has become difficult

because even the lightest of chem trails blocks the sun and spoils

the effectiveness of the solar PV panels. The 12V fridge and the indoor

plant light, together using around 80 watts, are okay, but if I've

driven the car and it needs another, eg, 200 or 300 watts (from the 892

rated watts from the south facing panels plus 500 from the west facing

ones), then whenever a chem trail, however light, drifts past the sun,

the inverter goes into low voltage alarm and the power, which there

should be plenty of, goes on and off because it's insufficient. It's

not practical to charge the car batteries in banks, so I have

to plug the car into grid powr, on an otherwise sunny day.

Solar charging is unreliable to impossible in other seasons when

overcast or frequent clouds come by, and of course towards evening (now

almost at sunset with the west facing panels), but it has never

happened in the summer repeatedly, day after day, until this summer.

I'm also getting tired of collecting brown rainwater that foams when

it's poured, on the rare occasions it has rained.

I note that this month (about the 23rd) brings news of a

big die-off of whales in Alaska. Their bodies are washing up on

beaches. The suspected culprit: algal blooms

(again), which would of course be caused in the open ocean mainly by

the unusual level of nutrients for plants/algae in the water from the

chem spraying.

Fuchsia Berry Pie!

Someone told me fuchsia flower berries are edible. I kind

of rolled my eyes inwardly. Like there would ever be enough to use! But

I have a large fuchsia bush, and this

summer I noticed there were really quite a lot of berries hanging down.

Enough for a

pie? I picked them. Well, they made a thin pie with no top crust.

(And there were more later!) It was quite tasty, with mild flavor and

much less gritty than pies from the prolific blackberries people insist

on picking.

The fuchsia bush

The fuchsia bush

The berries look rather like beans, but the soft texture and mild taste

is of course entirely different

Purportedly Funnies (Originals unless someone else already

thought of the same ones)

Veteran: A veteranarian in training.

----

"Dan, I know the transmogrifier has radically altered my appearance,

but you know me, I AM Franz Jeckyl. To prove it, ask me anything that

you know only I would know."

"Let me get a pen. Now, what is the online password to your

Royal Life Savings bank account?"

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers

- Preliminary Ni-Mn, Ni-Ni Battery Making book

Products Catalog:

- Electric Hubcap 7.2 KW BLDC Pancake Motor Kit

- Electric

Caik 4.8 KW BLDC Pancake Motor Kit

- NiMH Handy Battery Sticks, 12v battery trays & Dry

Cells (cheapest NiMH

prices in Victoria BC)

- LED Light Fixtures

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

Daily

Log

(time accounting, mainly for CRA - SR & ED assessment purposes)

August1: Disassembled Sprint dash to fix headlight wiring (no worked

with LED lights!) Worked on July report.

2: Finished & posted July TE News (#90). Changed headlight wiring

in Sprint because polarity was backward for LED lights - Ugh! And

they're still not working.

3: Cut shift cable.

4: Started in on the design for the 12 magnet jig.

5:

6:

7: Worked on Sprint headlight problem. (Turning into a big waste of

time!)

8: Started on a solar hot water collector. Bought some copper pipe (but

not enough)

9: Started newly inspired design of AFSRM rotor

10: Continued design of AFSR motor.

11: Figured out how to export to .DXF - Victoria Waterjet said the

AFSRM motor rotor and plate files weren't suitable... needed defined

curves instead of curves broken into short line segments.

12: Checking out other CAD programs that might put out .DXF files with

suitable curve definitions.

13: Learned more or less how to coerce LibreCad into producing a .DXF

file for the rotor. Took it to Victoria Waterjet (where he modified it

since it still wasn't right, but had the essential curves and lines.)

Did up bottom plate.

14: Fixed a problem with the plate, then did up the top plate as well.

E-mailed them to Victoria Waterjet.

15-21: Holiday!

22: Read about new "transverse flux" BLDC motor - has advantages.

Bought more copper pipe for DHW solar collector.

23: Worked out many of the design concepts for "transverse flux" SR

motor. Started Peltier module voltage versus cooling experiment.

24: Went shopping, found/bought possible 6 inch "drum rotor" for said

motor.

25: Picked up AFSRM (ARM) motor parts at Victoria Waterjet, got a hub

at Princess Auto. Picked up a 6" disk with 1" hub there as well, for

'transverse' flux... "Horseshoe?"... Motor.

26: Turned hub lower end OD to diameter of thrust bearing ID. Started

fitting motor together.

27: Carefully fitted motor rotor to lower plate. Finished first Peltier

versus voltage experiment.

28: Wound 4 coils for "ARM" motor. Drilled holes in copper pipe for DHW

(domestic hot water) solar collector.

29: Wound last 2 coils (needs 6), did some adjusting and fitting on the

motor.

30: Touched up wires/epoxy on coils - and figured out how to get them

to work despite slight overhangs on at least half of them.

31: Worked on newsletter

Electric Hubcap Motor Systems - Electric Transport

AFSR Motors for Hybridizing Cars

For some reason, I seemed to be having a hard time getting

started on the motor and controller work. Somewhere in the back of my

mind

was the nagging thought that the axial flux switched reluctance motor

(AFSRM or AFSR motor) might be the best of all motors once developed

(and

probably cheapest to produce) and would supplant all my other types,

and

also that I now had a superb design for

putting one on a car wheel. (TE News #87 & below) Furthermore,

there was a good

chance that if I drew out the design nicely, the mechanic at AGO might

have

time to put together the critical mechanical parts set.

This came back to the fore in my consciousness on the 9th,

as I thought about potential rotor designs with more "lobes", that

might work better than what I had made so far. The overall value of

converting

a car from gas to electric at this time, however superior the expected

performance, seems to me to be less than that of making a regular gas

car into a plug-in hybrid (with similar great performance except for

hauling the gas propulsion system's 'extra' weight around), using an

add-on external motor.

But having looked at the other designs, I was convinced

that my AFSRM design, while it would run, would be rather low torque.

It wouldn't be a really effective design. The six donut coils with

rings could work. The rotor was the problem. Unless the steel torque

elements on the rotor matched the curved lines of flux from the coils,

the torque would be low.

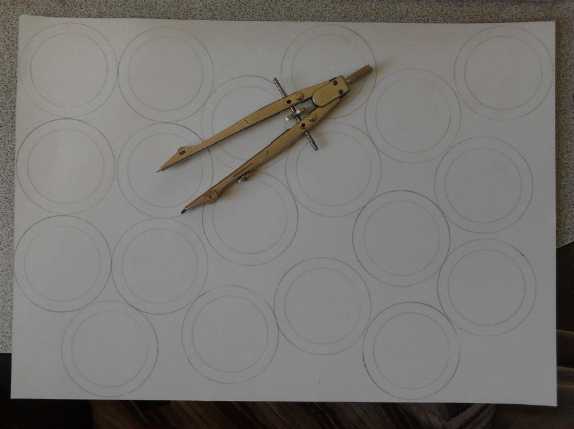

Let's see... I

have the 2" O.D. donut coils, with the wire coils and then sheet metal

rings around them, making a ring of very high magnetic flux with about

2" I.D. and 2.5" O.D. What if I welded overlapping steel rings of that

size, maybe 3/16" tall, to a solid steel rotor, in a pattern such that

just as one is pulled into alignment with coil A, another ring is set

to pull onto coil B with high torque, and then the same for C, then A

again? One might

thus attain a large number of very high-force pulls per rotation. And

with just .25" wide walls that don't align with anything except right

where they're being pulled, the rings wouldn't exert much magnetic

drag. It sounds ideal. Now... how far apart and how many rings? I

figured

that would be best drawn on paper to get a sense of the geometric

proportions.

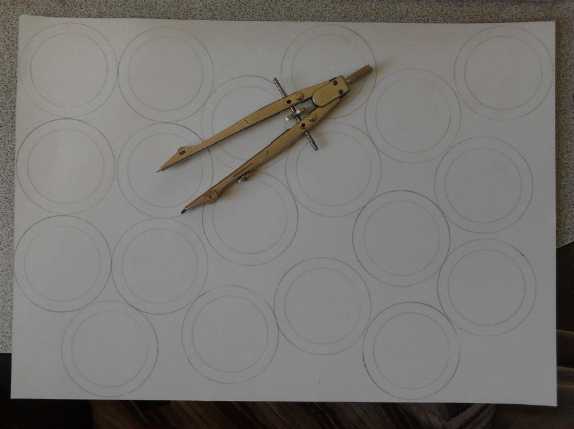

Even better, how about cutting rings out of paper and arranging them in

different patterns? First the 'ring draw' on a piece of cardboard. The

cutting was much slower than the drawing. I eventually cut 11, just the

number really required for the last layout.

Let's see... I

have the 2" O.D. donut coils, with the wire coils and then sheet metal

rings around them, making a ring of very high magnetic flux with about

2" I.D. and 2.5" O.D. What if I welded overlapping steel rings of that

size, maybe 3/16" tall, to a solid steel rotor, in a pattern such that

just as one is pulled into alignment with coil A, another ring is set

to pull onto coil B with high torque, and then the same for C, then A

again? One might

thus attain a large number of very high-force pulls per rotation. And

with just .25" wide walls that don't align with anything except right

where they're being pulled, the rings wouldn't exert much magnetic

drag. It sounds ideal. Now... how far apart and how many rings? I

figured

that would be best drawn on paper to get a sense of the geometric

proportions.

Even better, how about cutting rings out of paper and arranging them in

different patterns? First the 'ring draw' on a piece of cardboard. The

cutting was much slower than the drawing. I eventually cut 11, just the

number really required for the last layout.

I used six real coil cores roughly layed out

on a real rotor plate per the Electric Caik motor. (The thrust

bearing for visual effect would have been better if I'd straightened it

out.)

I used six real coil cores roughly layed out

on a real rotor plate per the Electric Caik motor. (The thrust

bearing for visual effect would have been better if I'd straightened it

out.)

First arrangement is the unipolar motor controller's "normal"(?) 4

rotor elements per 3 coils. The fifth (dark) ring starts the second set

of three coils (A), (B) and (C), which is merely a duplicate of the

first set. This is 'theoretically' good, but (for

clockwise rotation) as rotor ring 1 lines up with coil A as shown,

having produced its thrust, rotor ring 4 would be too far from coil C

to have good torque at first. Each ring in sequence would be the same,

making

poor and lumpy torque.

Next I increased it by one ring to 5. This

time, ring 3

would next align with coil B. It's getting better, but the metal of the

ring is still pretty

distant from the flux ring at first, which would make for bad torque

ripple with low torque areas.

Next I increased it by one ring to 5. This

time, ring 3

would next align with coil B. It's getting better, but the metal of the

ring is still pretty

distant from the flux ring at first, which would make for bad torque

ripple with low torque areas.

As with 3 rings, six rings per three coils would have all three phases

line up at the

same time, then there'd be no torque at all. No coil could be turned on

without producing reverse torque

as the motor went further. Depending on the starting rotation, the

motor wouldn't be

able to start, negating the whole point to having 3 phases 120

[electrical] degrees apart!

So the next choice would be 7 rings per

3 coils. At this point, there's a lot of metal, and we need to ensure

there's no undesired backward force seriously counteracting the forward

force.

So the next choice would be 7 rings per

3 coils. At this point, there's a lot of metal, and we need to ensure

there's no undesired backward force seriously counteracting the forward

force.

In this case, ring 6 is quite close to coil C, and should jump into

alignment with it when C is turned on. Since only coil C is on (one

coil ON at a time), alignments of other rings with other coils won't

cause backward forces. But looking more closely, I would hardly

trust ring 5 not to jump

backward to C instead of 6 to jump forward. They're too equidistant for

my liking, and the torque will be reduced until 6 gets

closer and 5 gets farther from the coil.

[Ignoring that...] Once 6 and C were aligned, 4 would be ready to

attract to B, and so on, and the energization sequence would be

CBACBA... Note that this is opposite to the 5 ring arrangement and the

same as the 4 rings. But that merely reverses the sense of the

forward-reverse switch.

If counterclockwise motion was desired instead, coil B would go on next

and attract ring 3 equally but opposite to C and 6, then ring 5 to coil

C for the sequence ABCABC...

Finally(?) I tried laying out 8 rings per 3

coils. At this point

there's more metal in the rings than space in between. But is that bad,

or good?

Finally(?) I tried laying out 8 rings per 3

coils. At this point

there's more metal in the rings than space in between. But is that bad,

or good?

Ring 4 [note: should be placed a little farther to the outside] is

almost aligned

with coil B, and it should have strong torque to pull into alignment

with it. Close together as the rings are, ring 3 is farther away so it

won't do much backwards force. Ring 5 will be minutely helpful, almost

canceling 3.

Then 7 will be equally close to C (as 4 was to B), and following that 2

will be ready for coil A to turn on. then 5 at B, 8 at C, and then 3 at

A. Two rings are skipped in each sequence, but they are different ones

in each successive sequence. This may be the highest torque arrangement

because the rings are each energized in turn just approaching their

highest torque area, in rather rapid succession, and nowhere else. As

it happens, the geometry just works out much better than with 7 rings

per 3 coils -- for these rings and these coils, at the spacings shown.

9 rings per 3 coils would again have rings aligned at all three coils

at

once and wouldn't have any torque to start at some points.

I was pretty sure 10 rings

would have so much ring with so little space

between them it would start losing the torque by the coil attracting

more than one ring. Later I tried it anyway. Not only did that look

like a problem, but like the 7 ring setup, it looked like two rings

would be almost equidistant, pulling in opposite directions.

I was pretty sure 10 rings

would have so much ring with so little space

between them it would start losing the torque by the coil attracting

more than one ring. Later I tried it anyway. Not only did that look

like a problem, but like the 7 ring setup, it looked like two rings

would be almost equidistant, pulling in opposite directions.

Having so casually placed the coils, I later checked to see that they

were 7.75" at the outside diameter. [Electric Caik rotor size]. They

were about 8", so I adjusted them and tried again. The results were the

same. 3, 6 and 9 rings are out because they line up with all three

coils at once. 2, 4 and 5 left some large gaps - very low torque areas.

7 and 10 made for rings trying to pull almost equally in both

directions.

8 rings - doubling up the

'typical' 4 - looks like the

arrangement for good torque. This could make for some tricky

fabrication - cutting and welding or machining. Even the optical rotor

position sensing device will need 16 slots!

I was hoping it would want fewer rings. But that's why I cut all those

cardboard rings and layed them out; to find out. And now that I have,

it makes sense that if the ring width is .25" and each coil is on 1/3

of the time, the spaces between rings should be 1/2", which is about

what it is (widest part). But I only realized that after having done

the layout and perhaps because of it.

There will be 8 activations of each coil

per electrical rotation (one per ring), or 16 cycles per physical

rotation since there are 6 coils, two per phase, and so 16 rings.

That compares with just 4 for the BLDC4:3 motors and two for regular

2:3 BLDC.

The next morning (10th) I was casting around for materials

and ran

into a washer about the right outer diameter but with a little smaller

inside and so thicker walls. It occurred to me then that instead of

having so many rings,

one might simply make them like that - inside smaller or outside

larger. That way,

with the 5 ring system the edges of the rings would be closer to the

flux areas when they activated and there'd be more torque. In fact,

adjusting the ring size would be a way of fine tuning the torque ripple

versus peak torque. And the 1/3 metal to 2/3 space ratio could be

attained with the 5 or even 4 ring layouts. But fewer rings would

surely be lower torque. Or the rings could be

thinned a bit for the 8 ring layout if that seemed desirable.

One can of course try out new rotor designs for real in

one motor, by creating and mounting the desired rotor and an optical

sensor ring with the matching number of slots. The one that seemed most

advantageous would be kept.

And to skip ahead a bit, when I set the pieces together

after the rotor was made, the rings seemed a little more distant from

the coil flux rings for the starting rotation of each phase than I

expected, which will reduce the torque until they get closer. Thus the

torque may have a fair amount of ripple. Maybe I'll do a second rotor

with bigger outsides on the rings, which should solve that. Or maybe

check out 10 or 11 thinner rings, which just might make higher torque

than 8

after all (with of course higher coil sequencing speeds).

The motors in the research papers had two rotors, one on

each side of the stator. But absolutely flat, rigid and level

construction on all

points is

vital. I decided to try out a single rotor design - it would be way

simpler and more robust. It might be good to aim for about a .025"

(.6mm) flux gap. The

needle bearings hold more precisely than the automotive ("trailer

wheel") bearings, so they're the pick. The center holes will be

perfectly sized for them to hold them in alignment. The thrust bearing

will help

with precision leveling between rotor and stator. A flat plate of mild

steel would seem to be vital as the base for the stator both to hold

the coils exactly and to complete the magnetic circuits at the bottom.

As I thought about doing a drawing for the mechanic, I

started thinking more about having a circular bottom plate with a

center hole sized for the bearing cut by waterjet. And then, why not

waterjet cut the bolt holes for the coil holding bolts?... and then,

for everything else? And then, why not do a top plate, too? And why not

have the whole rotor, with optical interrupter holes and all those

overlapping rings cut out of a plate by waterjet, too? That would take

all the precision grunt work out of it. Any number of rings becomes as

simple as any other (except to the waterjet machine), and it makes it

easy to try out

the most promising ring layouts and variations of them!

Suddenly making an AFSR motor started looking, if not

trivial, at least simple enough. I called Victoria Waterjet and they

said they can use .DXF files. OpenSCad, the program I design 3D objects

in for the 3D printer, can export to .DXF. So I could create the

designs in software I already knew, and have them precision made:

BINGO! (And there I was, about to go down to Western Equipment to buy a

bunch of those washers, to cut them up and weld the pieces onto the

bottom of a steel disk!)

Next feature: Princess auto sells hubs that fit on a keyed

shaft to weld chain sprockets onto. I could make the rotor center to

fit one of those, and weld it. And I could machine out a bit of the

bottom end of the hub to fit it to the thrust bearing. Finally, a 3/8"

aluminum plate could be rolled into an outer shell (only about 3" tall)

with the metal roller at Victoria Makerspace, and then perhaps be

welded into a "perfect" tube. Or, given that SRM.s are said to tend to

be noisy, perhaps a PP-epoxy outer shell would be appropriate as a

sound dampener -- if the top bearing position could be centered

accurately.

Knowing how cramped it was inside the Electric Caik

motors with 7.5" diameter, I decided to use the 8" diameter to the

outside of the coil cores; 3" radius to the centers of the coils and

rings. That would leave more space for the optics and wiring in the

middle - and enough room for running wires between coils. By evening of

the same day, the 10th, I had the bottom plate and the rotor with 16

overlapping rings designed in the CAD program. Suddenly, the design was

coming together with blazing speed, with most of the nebulous loose

ends pegged!

I went through some SRM literature on the web late in the

evening. Before I went to bed, I had the thought to use the outer

curves of the rotor rings as the optical interrupter slots and solids.

The optics could be mounted on the outside wall - and probably would be

wired from the outside. This too seemed like a simplification, and I

had just the right opto-interrupter units for it. It looked like it

would be

faster and easier to make this motor - including the prototype - than

my BLDC motors.

What a long way this project came in two days! However, on

the 11th came a check. After figuring out how to export the files to

.DXF format, which to my surprise took the computer a couple of hours,

I drove out to Victoria Waterjet. As with the .STL files for 3D

printing, the .DXF curves were broken down into a series of short

straight

line segments. I was told those were very hard on the waterjet machine,

which would repeatedly stop at the end of each line and then restart in

the next direction, 'jittering'. The 3D printer doesn't stop, but I

know my

drill-router also breaks down G-code curves into line segments, and it

too stops at the end of each segment, so I was familiar with that, and

if it's a problem for the waterjet machine, I have to accommodate that.

That meant I'd have to find and learn to use another CAD

program that would put out .DXF files suitable for the waterjet

machine,

and redo the designs in it. This would take it from "done in a day" to

days or

even weeks, considering the learning curve for new software. I had

downloaded the 2D CAD program LibreCAD a couple of years ago, hoping to

use it

with the CNC drill-router, but it hadn't worked out. It was pretty

unintuitive. I had to ask the author how to do some pretty basic

things. It did them well if you knew how. But by now I had essentially

forgotten how to use it.

I went into AGO on the 12th and found they had an

assortment of CAD programs that did .DXF. I was given a CD with an old

MS Windows version of Autocad. But when I got home I thought an old

version of software might not be the best, and I decided to try

LbreCAD again ("better the devil you know" - tho I never really got the

hang of it before). The program was again unintuitive and the on-line

manual was sketchy at best. It was enough to get you to hurl

your computer out a window, but eventually I got the hang of some basic

things and suddenly most of the rotor layout magically appeared.

When I took that out to Victoria Waterjet the next day, it

was just lines and circles on his screen with all the solid and area

"fills" missing, but he managed to cut, paste and manipulate it (using

a CAD program called Rhino3D, 700 or 800$), which he

manipulated with great ease and familiarity)

until it was how I wanted it. I did up the bottom and top plates on the

morning of the 14th, and

simply e-mailed them. Then it was just a matter of waiting for them

getting around to

it. I didn't ask how many weeks that might be. I was leaving for a week

holiday anyway.

Here are the .DXF ("Drawing eXchange Format") files as

done in LibreCad, which as I found may need some tweaking when applied:

AFSRM-Top-Plate-LCad.dxf

AFSRM-Rotor-LCad.dxf

AFSRM-Bottom-Plate-LCad.dxf

Note: I moved the three bearing holder holes outward a bit on the

bottom plate to miss the thrust bearing. I threaded the plate holes,

filed the square bearing holder holes outward a bit, and used regular

5/16" hex head bolts. This was unnecessary on the top plate. They

should be moved in to (IIRC) 1.5" radius from the axle and cut to 5/16"

diameter. The center bearing holes are sized to form one side of the

bearing holder, so only one pressed needle bearing holder is used

instead of two.

Aside from the top and bottom plates, the other body

component is the outer rim. As long as it's stiff and the right

diameter (10"), I think it could be anything from aluminum to PVC. A

plastic shell might help dampen vibration and noise. The coils are

1.0"... the rotor is .025" above the coils and is .25" thick, and the

hub sticks out maybe .125" above that... clearance from hub to upper

plate .05"... The thrust bearing might add .1" or less. That's a

whopping 1.55" height needed on the inside, for a total of just over

2". (That doesn't count how far the bearings and shaft stick out.)

Remembering having to raise the Weel's sides later I'll give it some

extra height, but even at 2.5" x 10" it looks like this is going

to be one very skinny pancake motor! It will however weigh about 25

pounds, 10 pounds heavier than the present Electric Caik. I could

change the top to aluminum and save a couple. The bottom needs to be

very stiff, and also to carry the magnetic circuit. But perhaps that

too could be replaced by a thicker slab of aluminum and some steel

rings under the coils to lighten it a bit more, and at least get it

under 20 pounds or so.

When I returned from vacation, I found that someone had

e-mailed me a link to a "Transverse Flux" BLDC motor. After thinking

about this for a day or two, making a reluctance motor with a similar

layout seemed so promising that I e-mailed Victoria Waterjet and asked

them to cancel cutting the axial flux design. But it was too late. So I

decided I would make this design first while I thought about the new

one. At least I'd be able to compare two quite different designs, one

done with iron powder in the coils and the other with mild steel, and

see what happens as the RPM goes up.

On the 25th I picked up the cut parts. I had to file out the center

hole of the "lacy" rotor a bit to fit the center hub. (Better that than

too loose!) Then I turned down the center hub on the bottom to fit

inside of the thrust bearing. The bottom ring of the bearing was to go

in an indent on the bottom plate, which at 10" diameter with an odd

size center was too big to turn on my lathe. I took it down the street

to AGO Environmental Electronics for the machinist there to do, and it

was done the next morning.

On the 25th I picked up the cut parts. I had to file out the center

hole of the "lacy" rotor a bit to fit the center hub. (Better that than

too loose!) Then I turned down the center hub on the bottom to fit

inside of the thrust bearing. The bottom ring of the bearing was to go

in an indent on the bottom plate, which at 10" diameter with an odd

size center was too big to turn on my lathe. I took it down the street

to AGO Environmental Electronics for the machinist there to do, and it

was done the next morning.

After getting the waterjet cut steel parts I

made an aluminum body ring, threaded the case bolt holes,

After getting the waterjet cut steel parts I

made an aluminum body ring, threaded the case bolt holes,

and put together the case to see what it looked like. Everything seemed

to fit together nicely.

Inside: bearing with rounded edges only goes part way through.

Outside: regular pressed bearing holder holds bearing centered in hole.

With these thick steel plates for stiffness, it'll weigh almost 25

pounds. One might try, say, 3/8" aluminum for the top plate, 1/4" steel

for the bottom, and 3/16" for the rotor, to lighten it up. ...if the

bottom plate and rotor don't flex too much and close the flux gap

during operation.

The next question mark was details about making and

mounting the coils.

I may "fill in" the centers with epoxy, or PP epoxy, somewhat recessed.

Presuming that will stick to the cores, it'll give something solid for

the coil bolts to go

through without anything sticking up above the 1.00" tall cores. The

cores will only take 9 wires (11 AWG) when they can't stick out the

slightest bit top or bottom, so 18 wires in 2 layers instead of 21. (It

can't extend to 3 layers because the steel ring has to fit to the

outside.) Unless

I put the wires into the rolling mill and flatten them just a little

bit. But then, could they be kept straight "on edge" while winding

anyway? I had my doubts, and decided to just use 18 turns. At worst, a

little lower torque, power, and voltage than it ought to have. Since

it's so hard to estimate what it'll have to start with, I can just add

15% to the figures if I figure out a way to wind them better. Maybe

micrometals.com has some slightly taller toroids?

On the 27th I

fiddled with the rotor/bottom plate assembly and 6 toroidal cores with

no wires. First the rotor plate wouldn't quite fit down onto the hub. I

figured the inner lip of the hub must be slightly rounded, and I filed

out the lower edge of the hole in the rotor at a 45° angle to

match. This time it went on with no gap showing anywhere between rotor

and

hub.

On the 27th I

fiddled with the rotor/bottom plate assembly and 6 toroidal cores with

no wires. First the rotor plate wouldn't quite fit down onto the hub. I

figured the inner lip of the hub must be slightly rounded, and I filed

out the lower edge of the hole in the rotor at a 45° angle to

match. This time it went on with no gap showing anywhere between rotor

and

hub.

The fronts of the rings seemed a little far from the

highest torque areas at the point where each coil would turn on, which

may make for weaker torque points - torque ripple. If measurements

indicate, I may want to try a rotor with rings of slightly larger

outside diameter later.

I wanted the rotor to sit and turn about .025" above the

coils. To get this, the rotor hub and bottom plate had to be carefully

turned on the lathe to set the hub the right height on the thrust

bearing. After measuring things with a feeler gauge for a while, I

decided to take the hub down a few thousandths of an inch. After that

it seemed about right. It didn't turn with zero wobble, and different

coils had different clearances, meaning the base wasn't totally level,

flat and even. The lower ring didn't sit flat, but on further

examination, it was the thrust bearing's race ring that was slightly

bent, not the bottom plate. But it was close enough, and I couldn't

flex the rotor enough to make it hit the coil cores.

It became a

slightly different story when I wound the coils on the 28th and 29th.

It was easier to say "absolutely no protrusions above or below the

cores" than to achieve that when confronted with wires that

weren't perfectly straight, gooey, slick wet epoxy, side guards of

plastic that

annoyingly insisted on curling in under the windings, and a winding

setup that wasn't made to prevent said protrusions. Some made it, a

couple didn't.

It became a

slightly different story when I wound the coils on the 28th and 29th.

It was easier to say "absolutely no protrusions above or below the

cores" than to achieve that when confronted with wires that

weren't perfectly straight, gooey, slick wet epoxy, side guards of

plastic that

annoyingly insisted on curling in under the windings, and a winding

setup that wasn't made to prevent said protrusions. Some made it, a

couple didn't.

I finally decided that instead of winding more coils and

trying to achieve ultimate perfection in the prototype I would match

each coil to a specific position and grind a dip into

the plate where the offending wires would touch it. (I had got used to

there being no chance of coils causing shorts with the PP-epoxy plastic

cases in the BLDC motors!) And if necessary I'd add enough of a shim

under

the thrust bearing lower ring so that

everything had clearance, even if it would result in more than .025"

gap most places. IF I

stick with this model I can improve the winder pieces, and make 6 or 9

winders

so all the coils of a motor can be done at once instead of two at a

time, to make it considerably easier and faster. (The epoxy

must set in the oven for an hour after winding.)

I finally decided to epoxy the outer rings onto the coils

first, then

sand them to exact 1.00" evenness. Then I'd epoxy the finished coils

onto the plate, making a thicker patch of

polypropylene-epoxy in the center of each coil. The patch, covering the

mounting holes, could be drilled out and nylon(?) bolts threaded in to

better secure everything. ...or maybe just use lots of epoxy all over

to glue them down, maybe in 2 or 3 coats? Being on the stator, they

wouldn't have to endure centrifugal force.

Rotor and coils on bottom

plate. (Rim and top plate behind.)

I found a "hidden" item 'invisibly' increasing

the top and bottom gaps:

the paint on the coil cores is at least several thou thick.

I found a "hidden" item 'invisibly' increasing

the top and bottom gaps:

the paint on the coil cores is at least several thou thick.

Ideally it should be sanded off. (Note the sanded spot on the wire

insulation - it

protrudes past the end where it shouldn't.)

Also note the apparent solidity of the "iron powder" core. An ohmmeter

shows that the iron particles are in fact not

insulated from each other, although the resistance is high enough to

prevent significant iron conduction losses.

I conclude that they are probably sintered iron powder cores,

or at least that the particles are pressed together with many tons

of force. I didn't see that on the manufacturer's web site.

(micrometals.com) This is merely an observation.

But also the sanding reduces the grainy appearance of the iron.

If I was making iron powder components myself I expect I would simply

use epoxy saturated with iron powder

and pour it into a plastic mold because it would be easiest for me to

do. But it might not work as well.

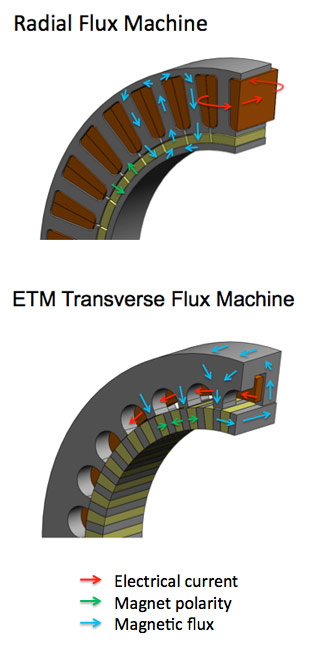

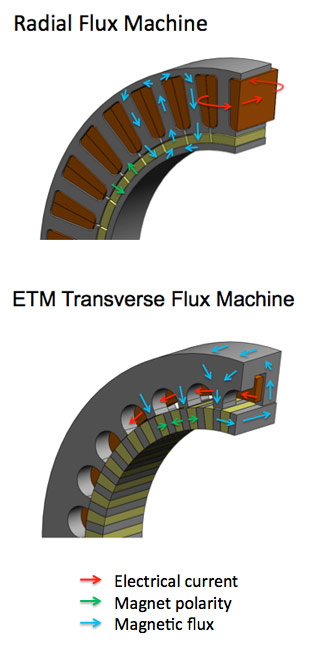

Another Layout: "Transverse Flux"

Motor

Just when you think your design

must be pretty much the best thing going, somebody comes up with

some great new idea. After my exciting new "ARM" motor was all in train

and

the designs for the steel parts were at the

waterjet company awaiting cutting, someone sent me a link to

a website with an interesting new "transverse flux" BLDC motor layout,

which looks like it should adapt well to the SR motor type. [ http://etmpower.com/

] It took me a while to figure out from the diagram just what was

happening. The on-edge magnets with the "offset horseshoe"

electromagnets should make impressive torque. It seems to show only one

phase, presumably of a 3-phase

motor if one wants torque at all points of rotation. I don't see any

way the phases

could be interleaved in one stator, so I guess they must go side by

side, making the rotor also 3 times as wide, which seems

like a waste of magnets and rotor material. But perhaps it isn't once

it's

all calculated out -- and the SR motor won't be using any magnets.

Just when you think your design

must be pretty much the best thing going, somebody comes up with

some great new idea. After my exciting new "ARM" motor was all in train

and

the designs for the steel parts were at the

waterjet company awaiting cutting, someone sent me a link to

a website with an interesting new "transverse flux" BLDC motor layout,

which looks like it should adapt well to the SR motor type. [ http://etmpower.com/

] It took me a while to figure out from the diagram just what was

happening. The on-edge magnets with the "offset horseshoe"

electromagnets should make impressive torque. It seems to show only one

phase, presumably of a 3-phase

motor if one wants torque at all points of rotation. I don't see any

way the phases

could be interleaved in one stator, so I guess they must go side by

side, making the rotor also 3 times as wide, which seems

like a waste of magnets and rotor material. But perhaps it isn't once

it's

all calculated out -- and the SR motor won't be using any magnets.

The coil winding should be very simple since each phase is

just a

single large coil wrapped right around the entire stator. (Probably the

stator should be made of iron powder, but I'll do a prototype from

waterjet cut steel pieces to make a lower RPM version just

to try it out and check the construction layout, and test the torque et

al. With really good luck, I just might find solid mild steel is fine

for

the

desired RPM range anyway.)

The flux goes around the coil wire, transverse to the

stator in any

direction, so it could equally have the rotor inside the stator,

outside, or axially, by aiming the stator "teeth" and rotor poles/lobes

in the appropriate directions.

For axial flux and flat rotor for a "pancake" shape, one

could put

one phase on each side of the rotor, but I don't see where the third

phase could fit without adding a second rotor. On the other hand

there's nothing intrinsically evil about a radial design. Since the

coil wires aren't run around the teeth, one

could make the parts with quite thin stator 'teeth' and rotor lobes. It

could be stacked with lots of them like gear teeth, making lots of

magnetic interaction points. Where my layout has two fairly large rings

active at any one time, this could have maybe a couple of dozen finer

lines. So the issues mentioned for radial designs in

the AFSRM research papers could disappear - perhaps plenty of torque,

even very high torque,

can be developed. And the radial direction (with magnetic points all

around the circumference) also

puts no axial bending stress on the rotor - a distinct advantage with

the tiny flux gaps. The thrust bearing,