Turquoise

Energy Ltd. News #92

covering September 2015 (posted October 4th)

Victoria BC

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Highlights: Free Energy from Thin Air?

- Lambda Rays, or Atmospheric Electrical Charge? (see Month in

Brief, Electricity Generation)

Month In Brief

(Project Summaries)

- Further peltier module 12 V fridge experiments - ARM Reluctance Motor

Runs! - New (used) Batteries NiMH & Lithium iron phosphate - Free

energy... where's it from again? - Timing of inventions, a perspective.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

-

Syrian Girl's video: an 'on the

spot' perspective on what's happening in Syria - Loose Change -

Perpetual War - Arguably somewhat humorous things & "Political

Spin".

- In Depth Project Reports -

Electric Transport - Electric Hubcap Motor Systems

* ARM reluctance motor project

* "Transverse flux" SR motor rotor idea

Other "Green"

Electric Equipment Projects

* Peltier Module/Thermoelectric Cooler ('TEC') Experiments:

supply

voltage versus attained cooling - 15 amp Peltier module - better ice

tray - internal fan - evacuated tube heat radiator - DC to DC converter

* Water Conservation: Best Shower Nozzle and Video

Electricity Generation

* Electrostatic Perpetual Motion Motor?

* Thomas Henry Moray: not only free energy collector -- he invented

semiconductor electronics, in the 1920s... and lots more!

* Free energy from the electrical charge of thin air?

Electricity Storage - Turquoise Battery

Project (NiMn, NiNi), etc.

* Honda Insight NiMH Battery - converted to 14.4 volts, 65AH.

No Project Reports on: Variable

Torque Converter Transmission, CNC

gardening/farming machine, Electric Weel, battery making, aquaponics,

Magnet motor project.

September in Brief

My motors have evolved from "gosh it turns" in 2008 to

BLDC motors with excellent specs but not very well built, to

much improved constructions, then in recent months to a new BLDC plan

with double the magnet poles, and now to the first of two latest

switched reluctance

designs of great promise, the "ARM" which first ran on the 29th. My

several designs of "regular" BLDC motor controllers over the years

all kept blowing up at high currents. The new 'unipolar' controller

type should be much more reliable and will run either of the new types

of motor, but running the ARM has disclosed a couple of things that

need looking at in the controller.

My mom suggested I should finish the things I've started

rather than start more new things. In principle I fully agree. But not

for lack of trying I have yet to put an "ultra efficient" add-on

electric wheel or even a converted car

on the road, and somehow the projects seem to all evolve into improving

forms rather than to end.

A video shows that where once I got the Sprint car to move

forward in September 2012, I got it to continue, even upslope, until it

hit its 'parked' position end stops, driven by about 1 HP. This one is

perhaps the best demonstration that the slipping planetary gear torque

converter worked once the car started moving, and that it probably just

needs a clutch inline (or a big flywheel on the motor) to be practical.

I didn't know I had this, or even remember that one of the trials had

been that successful, until I found it on my old camera a while back,

and I've now finally posted the video. The actual move is near the end

of the video, which I didn't have an easy way to edit. (The

format/editing problem is why I don't use that camera any more.)

https://youtu.be/hZ_auUjW17M

--

Slipping

Planetary Gear Transmission

On the second (band

having not yet started up for the season) I went to the VEVA Islands

electric car club. One member had purchased a 1981 Bradley electric.

I'm sure I saw the Bradley in Popular Mechanics magazine way

back then. The "gull wing" doors were supposed to be great in crowded

parking lots. Another had brought his lightweight velomobile - which

has pedals but zips along the street at 50 Km/Hr under electric power.

We posed them along

with

my RX7 and a Mitsubishi iMiEV owned by a retired electrician.

The 1981 Bradley Electric (the only one ever

made in Canada) with its

proud owner.

The 1981 Bradley Electric (the only one ever

made in Canada) with its

proud owner.

The body is in great shape. Is it because it's fiberglass, or because

it spent 20 of its 34 years sitting in a garage?

(Of course if I was doing this now, I'd use polypropylene ("landscaping

fabric") with resin - It's tough; stronger &

lighter than fiberglass, and nice to work with. A good paint should

prevent degradation of the plastic by sunlight.

In fact, that could be a fabulous way to reduce vehicle weight, and

thus of course increase driving range!

...Make a whole car body?!? Yikes! Don't get ideas, Craig!)

In practice the Bradley's interesting gull wing door

design made it hard to get in and out of the car, and it's easy to see

why it never caught on. The unadjustable semi-reclined bucket seats

didn't help either.

On the third I decided to make the planned solar water

heater into a pumped system after all. Other than pump and controls,

the logistics are simpler. The pre-heat water tank and a system that

drains down when the pump shuts off can't freeze and burst. I ended up

buying more pipe for this, but didn't get any actual work done on it.

An 18.5V "power adapter" lithium battery charger in the

Mazda RX7 EV quit. On

the trip where I noticed it, the voltage of the whole pack was already

down to 12 volts - at my destination point, where I noticed it as I got

in

the car - and to nothing by the time I got home. They should never be

allowed to drop below 14.0 volts, 2.8 volts per (3.2V nominal) cell.

The drop was very rapid and luckily it was only short trip, about a

mile. It didn't seem to hurt them.

I soldered a plug back on the 17 volt transformer type

adapter I had first bought for them. It had worked well enough, but it

eventually brings the voltage up to 22 volts, when the cells should

never be allowed to rise above 20. A 15 volt adapter might stay under

20 volts, but then it might charge to 16.5 volts very slowly. This

shows the problems with unregulated supplies. OTOH the "17 volts" can

be down under 15 when charging a low battery without a series resistor

yet without overloading the transformer - a bit of 'constant current'

operation, or

say a sliding scale of current versus voltage. At one point I had tried

to put in a 19 volt zener diode to stop it from going higher, but it

got hot very fast. I guess I should buy a new 18.5 V regulated adapter

- ug! Or maybe I'll try a "15" or "16" volt transformer type. Or add

some diodes to drop the voltage a bit.

Later the

Bradley owner was given, and then gave to me, a Honda

Insight hybrid (or hybrid Civic) battery: 120 high rate D cells

providing 144 volts in series. I converted its strings of 12 cells to

parallel, 14.4 volts, thinking to use it in the Mazda RX7 EV. But my

enthusiasm waned: I found out on line that the cells were only 6.5

amp-hours for a total of 65 amp-hours. And it weighed 55 pounds - as

heavy as lead-acid. (extra metal and less chemicals, to get the very

high rate performance.) It should perform well and last for ages, but

with only 65% of

the capacity of the other batteries it would likely further limit the

already short driving range. Perhaps it could be a 28.8 volt, 33

amp-hour, 'spare' battery for the electric outboard? Then I found

another 6 tubes of 14.4 volts on ebay for (by the time I get them)

probably around 325$C. That makes over 100 amp-hours.

Later the

Bradley owner was given, and then gave to me, a Honda

Insight hybrid (or hybrid Civic) battery: 120 high rate D cells

providing 144 volts in series. I converted its strings of 12 cells to

parallel, 14.4 volts, thinking to use it in the Mazda RX7 EV. But my

enthusiasm waned: I found out on line that the cells were only 6.5

amp-hours for a total of 65 amp-hours. And it weighed 55 pounds - as

heavy as lead-acid. (extra metal and less chemicals, to get the very

high rate performance.) It should perform well and last for ages, but

with only 65% of

the capacity of the other batteries it would likely further limit the

already short driving range. Perhaps it could be a 28.8 volt, 33

amp-hour, 'spare' battery for the electric outboard? Then I found

another 6 tubes of 14.4 volts on ebay for (by the time I get them)

probably around 325$C. That makes over 100 amp-hours.

Then I got three 12.8v, 40 AH lithium batteries for 600$

locally. It was just too good a deal to pass up. I initially got them

for someone else who was to pay me back, but then it looked like he

couldn't use them. If I put everything together right, I may not need

any golf cart batteries for a 300 AH, 36V vehicle drive system. Instead

I can probably use two 300 AH, 12 v (or 14.4 v) batteries of NiMH D

cells and one of 12 v worth of lithiums in parallel. That would

certainly lighten the car, allow regenerative braking, and of course

last longest.

And apparently I bid on an auction for another 5 tubes of

12 Honda batteries, because on October 2nd I got a notice from e-bay

that I had won the bid, for 99¢. At first I thought I must have

made some mistake and bid on empty plastic tubes or something. Nope,

they were batteries. No one else had bid! The shipping was also 99, but

with the decimal point on the other side. Still, it was 5 more tubes,

60 cells, for 1/2 the price of the first 6 and 1/4 the price of new

Tenergy cells. From the original 10 free sets I'll be up to 21 - total

252 high rate NiMH D cells and about 500$C.

I did more

peltier cooling experiments. I put a 14 or 15 amp peltier module

(62x62mm) into the shallow chest fridge and tried running it at some

lower voltages with the lab power supply. Obviously the cold from the

peltier wasn't being transferred well into the ice tray, so I soon

found and put in a new ice tray, a little shallow but much larger and

made of thick (cast?) aluminum instead of stamped from thin pressed

sheet metal. It worked much better, but the ice still formed from the

cooling bar end, and the inner end never froze over. Then I needed the

power supply for other things and I put the fridge back on the solar

panels, with the battery charger taking the load at night. It was

getting quite cold underneath and around the ice tray, as low as

2.5°c, but it was still over 15° at the far wall near the top.

I added a small 12V "computer" fan (with some resistors in-line to keep

it to a whisper and a light breeze). It took days for the stuffed-full

warm end to cool, but eventually it was all under about 8° or so at

the warm end and 5.5° under the ice tray - much better overall

cooling. But it was using 130 watts during the day. When I find the

time, I should make the microcontroller based control, with (along with

various features) a DC to DC converter in it to supply a lower voltage

to the peltier for a higher COP. It gets that at night when the battery

charger takes the load - and the voltage drops to 11 volts (with the

peltier still drawing almost 8 amps), and the fridge temperatures in

the morning are no higher than in the day (if not lower) when it's up

over 13 volts and 9.6 amps.

I did more

peltier cooling experiments. I put a 14 or 15 amp peltier module

(62x62mm) into the shallow chest fridge and tried running it at some

lower voltages with the lab power supply. Obviously the cold from the

peltier wasn't being transferred well into the ice tray, so I soon

found and put in a new ice tray, a little shallow but much larger and

made of thick (cast?) aluminum instead of stamped from thin pressed

sheet metal. It worked much better, but the ice still formed from the

cooling bar end, and the inner end never froze over. Then I needed the

power supply for other things and I put the fridge back on the solar

panels, with the battery charger taking the load at night. It was

getting quite cold underneath and around the ice tray, as low as

2.5°c, but it was still over 15° at the far wall near the top.

I added a small 12V "computer" fan (with some resistors in-line to keep

it to a whisper and a light breeze). It took days for the stuffed-full

warm end to cool, but eventually it was all under about 8° or so at

the warm end and 5.5° under the ice tray - much better overall

cooling. But it was using 130 watts during the day. When I find the

time, I should make the microcontroller based control, with (along with

various features) a DC to DC converter in it to supply a lower voltage

to the peltier for a higher COP. It gets that at night when the battery

charger takes the load - and the voltage drops to 11 volts (with the

peltier still drawing almost 8 amps), and the fridge temperatures in

the morning are no higher than in the day (if not lower) when it's up

over 13 volts and 9.6 amps.

I trimmed and

epoxied the steel rings onto the ARM motor coils to make them into "cup

electromagnets", and epoxied the coils onto the bottom plate. And I

welded the rotor to its hub. Then I designed and made a small circuit

board for the optical interrupters that tell the controller where the

rotor rotation is at. I had meant to check to make sure there were no

shorts of the coil windings to the case before the epoxy was hard - too

late! There was one. I didn't manage to break the coil loose with a

hammer and a wooden block, but finally I unwrapped a bit of the coil

wire and the short vanished. At least the episode showed the coils were

very solidly glued onto the bottom plate by the epoxy. Then I did the

heavy wiring, and found the fat wires simply wouldn't fit as intended

into the case. It was too cramped. I finally unscrewed the cable clamp

from the case and let the cable hang out. Every time there was a

problem I would set the project aside for a couple of days. I had

trouble concentrating on it. It wasn't until near the end of the month

I checked out the optics board. It had a problem too - wrong

connections from a mirror image defined optical interrupter part. I cut

traces and added wires to get it to work, then fixed the design on the

computer.

I trimmed and

epoxied the steel rings onto the ARM motor coils to make them into "cup

electromagnets", and epoxied the coils onto the bottom plate. And I

welded the rotor to its hub. Then I designed and made a small circuit

board for the optical interrupters that tell the controller where the

rotor rotation is at. I had meant to check to make sure there were no

shorts of the coil windings to the case before the epoxy was hard - too

late! There was one. I didn't manage to break the coil loose with a

hammer and a wooden block, but finally I unwrapped a bit of the coil

wire and the short vanished. At least the episode showed the coils were

very solidly glued onto the bottom plate by the epoxy. Then I did the

heavy wiring, and found the fat wires simply wouldn't fit as intended

into the case. It was too cramped. I finally unscrewed the cable clamp

from the case and let the cable hang out. Every time there was a

problem I would set the project aside for a couple of days. I had

trouble concentrating on it. It wasn't until near the end of the month

I checked out the optics board. It had a problem too - wrong

connections from a mirror image defined optical interrupter part. I cut

traces and added wires to get it to work, then fixed the design on the

computer.

A regular cup magnet. The flux is concentrated

in

A regular cup magnet. The flux is concentrated

in

the gap between the magnet and the outer ring,

providing supermagnet levels of strength in that small gap.

The rotor with overlapping rings that match the

stator's "cup electromagnet" rings.

The rotor with overlapping rings that match the

stator's "cup electromagnet" rings.

Besides the flowery shape, the other unique feature is in having many

rotor "poles", 8, per each 3 phase coils, instead of 2.

This places each ring quite close to the stator electromagnet rings as

each phase is activated, for highest torque.

Instead of switching once per electrical revolution, each coil switches

8 times - 16 times per physical revolution.

ARM Motor more or less Assembled

ARM Motor more or less Assembled

Short video: https://youtu.be/cifPWF1Snr0

--

ARM

Motor Running (top cover off)

On the 29th I hooked it up to the motor controller and ran

it with the top off. It started promptly and ran quite nicely in both

directions except for the rotor rubbing a bit in one spot (which was

worse with the top on), but I won't vouch for performance or

efficiency. The optics adjustment was more critical than it should have

been owing to the thin little light interrupter tabs on the outside of

the rotor. They really should have been wider, and rounded on the

outside. There seemed to be a lot of torque ripple, and not all phases

had the same strength - again perhaps an optics problem, because it

changed after adjustment from one stronger phase to two out of three.

If the motor was to be produced the torque ripple might be reduced by

adjusting the thickness of the rotor rings, probably by increasing the

outer diameters a little. But I'm more keen on trying out the highly

promising 'transverse flux' design than making more of this style.

Running it disclosed some issues with the unipolar motor

controller which need to be looked at. Nothing quit or went up in

smoke, but the energy return coil got smoking hot. Much of the energy

seemed to be going into heating it up! I started thinking that there

wasn't enough current flowing in the wires to explain it. Was my

simplified controller design wrong? But the pulses to it are very

sharp, and I remembered that iron cores are only good for low

frequencies, up to a few hundred hertz, not 20 or more kilohertz with a

high harmonic content. I may need to make a coil with a ferrite core.

And the motor would only go up to a couple of hundred RPM. It seemed to

go from zero to drawing 11 amps in a very short space on the rotary

control, but turning the control up further, even all the way to the

top, had little or no further effect on current and speed. Wasn't this

supposed to be a 200 amp controller?

Towards the end of the month I started looking up 'free

energy' devices again. I'm not sure anything else in the sustainable

energy field would be quite so valuable. There was an interesting

electrostatic "Perpetual Motion Motor" video. I don't think I've seen

anything using that sort of motive force before. https://www.youtube.com/watch?v=dGPnxLSgnUI

It turned, but the motive force was so slight I couldn't imagine trying

to scale it up to get useful power from it.

Somewhere I found someone who actually seemed to know

quite a bit about magnet propulsion, youtube channel "MotionMagnetics".

He went into three types of magnet motive force machines in three

videos. He mentioned that things were very exacting, and that magnets

weren't identical. Small variations in the magnetization of each magnet

would make a machine work or not work, probably explaining why no one

has successfully produced them for sale after making a working

prototype. I heard of an attempt where this happened. He didn't get

into the easier to make hybrid types where the machines self-propel

around the loop with permanent magnets except at the one inevitable

"sticky spot", where an electromagnet or mechanical device assists it

past. The electromagnet is said to use less energy than is generated in

the rest of the loop.

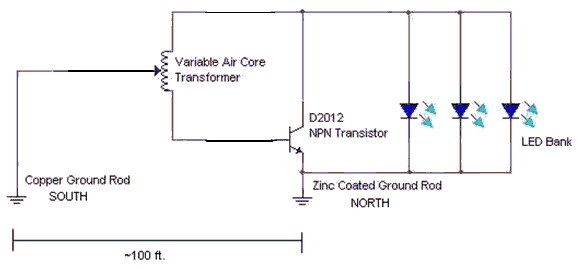

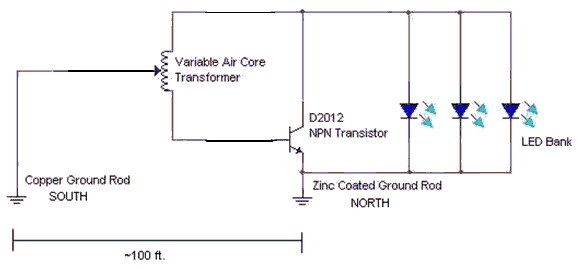

But my main target was "lambda ray collectors", which I

searched on as "radiant energy receivers". After a week of this puzzle,

I finally figured that Tesla, Moray and others probably hadn't captured

lambda rays, radiant energy, at all - at least not directly. Most

likely they had captured the static electrical charge of the

atmosphere. Air has an electric charge that increases rapidly with

altitude, amazingly up to 100 volts more positive per meter on a clear

day. Lightning discharges clearly demonstrate the existence of airborne

ionic energy. But some lesser amount of electrical potential energy

must be present in the air when there is no lightning. In fact, people

have been electrocuted by the static charge on unconnected power lines,

and a long steel cable strung from a helicopter makes a huge spark when

it touches ground. Is this what was being harvested, and can it be done

again effectively with today's technologies? Moray made special

germanium semiconductors (the world's first semiconductor devices) and

special vacuum tubes that would be hard to duplicate, but other things

might work in their place.

A passive circuit with antenna, ground, capacitors and

diodes will gradually build up a few volts and supply a few milliwatts,

but it isn't very effective. You want kilowatts (or at least watts);

you want to run your house, but it will only gradually charge a

cellphone. (I made one in 2013 - TE News #68. With the antennas I tried

it only got up to a volt or so and imperceptible power.)

It appears that the successful people, in particular

Moray, made tuned circuits with a driver - oscillators - and actively

pulled the energy, literally, out of thin air with resonant circuits.

Instead of getting a few charged ions that randomly drift by the

antenna, they are actively pulled and pushed in tune with the

oscillations, vastly increasing the interaction of the antenna with the

air. There probably are some lambda ray energy receiver types of energy

devices, but famous(?) powerful 'free energy' devices like Moray's

might well instead be atmospheric charge harvesters. Some puzzling

things about these various energy devices started to make more sense to

me.

For the past

year and a half I had been playing in the Greater Victoria Concert Band

"junior band" with my Supercorder. The conductor liked the sound and it

had been well received. It was a small band when I first joined and I

was well heard. But this season I tried the "intermediate band" to play

some more challenging music. It seemed to me to be going well but on

the 30th out of the blue I was asked to leave. Apparently the conductor

and one or more of the flute players didn't appreciate the fine tonal

and expressive qualities of my instrument (which have earned me many

compliments) because it didn't sound the same as a flute. It wasn't

quite what their ears were familiar with. Well - their loss!

For the past

year and a half I had been playing in the Greater Victoria Concert Band

"junior band" with my Supercorder. The conductor liked the sound and it

had been well received. It was a small band when I first joined and I

was well heard. But this season I tried the "intermediate band" to play

some more challenging music. It seemed to me to be going well but on

the 30th out of the blue I was asked to leave. Apparently the conductor

and one or more of the flute players didn't appreciate the fine tonal

and expressive qualities of my instrument (which have earned me many

compliments) because it didn't sound the same as a flute. It wasn't

quite what their ears were familiar with. Well - their loss!

I know some like it. One flautist had seemed glad to hear

I would be there, and one who was elderly sitting beside me (and

perhaps having a hard time sightreading some tricky rhythms) had just

the previous week told me "You're a treasure! You're right on and the

sound is clear and easy to follow."

Even in music it seems successful adoption of inventions

has a lot to do with timing. Sax was too late to have his creations

adopted into orchestras, whose instrumentation had by then become more

or less "standardized", but new types of bands were springing into

existence, and the saxophone came to be standard fare in some of those,

including in the large concert band - pretty much an orchestra

of wind and brass instruments with considerable percussion. (...itself

perhaps a timely invention of JP Sousa?) I suppose if Sax had invented

them today they'd be quite unwelcome there. There would be no parts

written for them and the unfamiliar sound would probably be considered

crass. If on the other hand he had made them 50 or 100 years earlier

than he did, they might well have become mainstay orchestra

instruments. (and perhaps clarinets would have been dropped?)

Likewise, if the recorder had had my improvements by

perhaps by 1850 instead of 2006, it just might have been the transverse

flute that would be considered "airy" sounding and "parochial", and

might have been left "unmodernized".

The earlier part of the day

had gone better. Having borrowed a surplus tunable air core coil and a

tuning capacitor the day before, I picked up books on LC oscillator and

HF transmitter design for the atmospheric charge energy harvester and

(bonus!) an evacuated tube heatsink module that I can try out with the

peltier camping cooler. And my vacuum jar for one of the steps in

making the ethylene glycol/choline chloride DES battery electrolyte

arrived by post.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

A Perspective on the Syrian Crisis

It's hard to form an informed opinion on what's been

happening in Syria from the occasional disconnected reports with no

background context in the western media, which give no overall view.

Until refugees started flooding into Europe recently, virtually no

mention was made that over 1/2 the entire population had been driven

from their homes by war and bombing, with towns, utilities and

industries reduced to rubble over the past 4 or 5 years.

Listening to Syrian Girl, who has been occasionally reporting

from Syria

on the events and politics for some time now, may broaden your

perspective, if not change your views considerably.

https://www.youtube.com/watch?v=pHFnvFbThDE

- Syrian girl

NO MORE WARS!

Loose Change

I asked in a coin shop how much old (Canadian) silver

quarters were worth. These were made from 80% silver and 20% copper

from 1920 to 1967. (The alloy was harder than pure silver and

so the coins lasted longer.) I found out that a dollar as coins had .6

troy ounces of silver, regardless of denomination. Thus a silver dollar

had .6 ozt, a 50¢ piece .3, a quarter .15, and a dime .06 ozt. (A

troy ounce, or Trojan ounce as I like to call it, because somehow it

seems

sneaky, contrived), is about 31.1 grams, where the "real" Avoirdupois

ounce is 28.something grams.)

Virtually unrelated: It has been found that an alloy of silver and

germanium makes a "sterling silver" that doesn't tarnish. (The patent

has probably expired.) This might have made better coins for

circulation!

The price for any and all of this change was thus

denominated as the price per face value dollar, ie per .6 ozt of actual

silver content. At that store it was 13.50$. This is a good indication

of how far inflation has gone. In 1920 the silver content of the coins

would have been pretty much a token amount. Coins were probably also

the main form of exchange, since prices of most small items were in

pennies. Paper bills were for large purchases. (Even in 1960 kid's bus

tickets in Edmonton were 6 for a quarter - 4-1/6¢ each.) By 1967,

Canada's 100th

birthday, the face value of each coin had become worth less than this

"token amount" of silver. Oodles of US and Canadian silver coins were

melted down for their silver value. An old quarter or dime in change

has been a very rare sight for decades now.

Today four "nothing special" silver quarters or ten dimes

- change for a looney - will cost you 13.50$ or more to buy. So

the dollar is now worth only 7% of what it was worth in 1967. And since

2011 the price of silver has been manipulated down with "high frequency

trading" of huge,

uncoverable "naked shorts" (banks selling silver they don't have on the

futures market) to make the dollar look better, dropping from

over 40 US$/ozt to under 12. The 2011 high price would indicate today's

dollar is under 2.5% of what it was in 1967. In 2011 silver may have

been

overvalued. It is certainly undervalued today. The best guess is

somewhere in the middle, that the dollar is worth 3 or 4% of what it

was in 1967.

Backed by nothing and printed as notes or simply conjured

into existence on banks' computer screens ad infinitum, the whole

world's fiat currency is headed for zero. It is not necessarily that

fiat

currency can't work, but that those in control of the supply have

always

opted to print more, gradually transferring the value of peoples'

savings to themselves as new tho decreasingly valuable money, rather

than face budgetary restrictions. Every fiat currency in history has

ended up being worth zero.

Silver on the contrary is a tangible asset, whose value

may fluctuate in accordance with supply, demand and sometimes market

manipulation, but which owing to limited (and presently declining)

mining supply and electronic device market demand on top of investment

demand, can never fall too much...

unless some fantastic

new silver deposits are discovered or "cold fusion" can be used to

create far more. (That would be fabulous, since it's about 12% more

conductive than copper for making motor coils - the most conductive of

all elements by size. But the chances seem remote.) It will therefore

tend over time to at least stay even with inflation, rising in dollar

price as the value

of paper money falls. Silver and gold have thus long been viewed as

"safe havens" for storage of wealth, especially in volatile times, and

this is better understood over much of the world than it is in the west

after our long period of relative stability and prosperity.

As I write, the supplies of silver and gold seem

to be running short. Month after month there is new record demand from

Asia

and from a million small investors who wish to cash in their claim

checks on wealth (dollars) for things outside the banking system that

won't inflate away and can't be confiscated with "bail-ins" and

"capital controls" (where you can only withdraw a very limited amount

of your dollars each day), as is starting to happen here and there. The

CEO of Sunshine Mint, a main coin blank supplier to the US

Mint, said in an interview

that shortages so far are owing to production time to stamp out the

record demand for coins and bars (they're running 24/7 and have tripled

their production capacity since 2007), but he also said that they are

now pulling

old silver ingots out from the backs of their vaults, and that it takes

weeks

to get more in instead of a day.

At some point everybody will catch on

and there'll be a run. If you don't go to a coin shop or go online and

get some 'soon', when that run starts there won't be any at any

affordable price. (with no known date on 'soon' - maybe within weeks

but

quite possibly months, or even a year or two.)

Some day there will be no more money. World population

will be controlled by common consent (2 to 3 billion?), and everyone

will have what they need for a good quality of life with free time to

learn and grow. Instead of being

permitted to earn a certain amount, people - everyone - will be

permitted to have a certain amount of possessions and supplies

for their

personal use. No one will be permitted to hoard unreasonable amounts of

goods which would result in scarcities for others. There won't be a

small clique commanding most of the resources, and natural resources

will be considered common property. The whole mentality will be more

social - less "me first!", more "consideration for all but without

neglecting me, too." Since everyone will be permitted to

own reasonably similar amounts, and since those amounts are sufficient

for all to live a good life, all will agree to this system. Those whose

talent and enterprise provide large social benefit will be permitted

somewhat more than the average - perhaps 3 or 4 or more times as much

as the "poorest" or basic allotment: the

'profit motive' or reward is not to be discarded. But no one will have

a hundred, thousands or a million times as much as most others.

Everyone will do

perhaps 3 or 4 hours work per day to maintain this sustainable social

system, and then fill their days with more creative or spiritual

pursuits or pastimes. It will probably take a thousand years to get

there, but in the

million year march of human history... that's 'soon'.

Perpetual War

Someone made this list of countries the USA government and

or its "corporatocracy" and or it's military-industrial-financial

complex has struggled with, covertly or overtly interfering in its

affairs through the military or various government or "private"

agencies, since world war two. I don't vouch for its accuracy - some of

the dates given seem arguable. And I don't know what the asterisks are

for. (Probably this is just a copy of a list that originally gave some

context.) Ten years of peace might transform the face of the USA if it

allows that to happen - and perhaps the face of some beleaguered

countries where "regime change" keeps getting instituted!

China 1949 to early 1960s

Albania 1949-53

East Germany 1950s

Iran 1953 *

Guatemala 1954 *

Costa Rica mid-1950s

Syria 1956-7

Egypt 1957

Indonesia1957-8

British Guiana 1953-64 *

Iraq 1963 *

North Vietnam 1945-73

Cambodia 1955-70 *

Laos 1958 *, 1959 *, 1960 *

Ecuador 1960-63 *

Congo 1960 *

France 1965

Brazil 1962-64 *

Dominican Republic 1963 *

Cuba 1959 to present

Bolivia 1964 *

Indonesia 1965 *

Ghana 1966 *

Chile 1964-73 *

Greece 1967 *

Costa Rica 1970-71

Bolivia 1971 *

Australia 1973-75 *

Angola 1975, 1980s

Zaire 1975

Portugal 1974-76 *

Jamaica 1976-80 *

Chad 1981-82 *

Grenada 1983 *

South Yemen 1982-84

Fiji 1987 *

Libya 1980s

Nicaragua 1981-90 *

Panama 1989 *

Bulgaria 1990 *

Albania 1991 *

Iraq 1991

Afghanistan 1980s *

Somalia 1993

Yugoslavia 1999-2000 *

Ecuador 2000 *

Afghanistan 2001 *

Venezuela 2002 *

Iraq 2003 *

Haiti 2004 *

Somalia 2007 to present

Honduras 2009

Libya 2011 *

Syria 2012

Ukraine 2014

NO MORE WARS!

Advantages of hard assets for

wealth retention when things crash - from 2002 after the 'dot com

bubble' collapse (Author unknown)

: If you had bought $1000.00 worth of Nortel stock one year ago, it

would

: now be worth $49.00.

:

: With Enron, you would have $16.50 of the original $1,000.00.

:

: With Worldcom, you would have less than $5.00 left.

:

: If you had bought $1,000.00 worth of Lone Star Beer (the beer, not the

: stock) one year ago, drank all the beer, then turned in the cans for

the

: 10 cent deposit, you would have $214.00.

:

: Based on the above, my current investment advice is to drink heavily

and

: recycle.

Caught Red Handed!

Since the US government has withdrawn the border guards and left the

Mexican border wide open, citizen militia have started patrolling the

border. One group chased down and stopped an SUV with two men that had

come across. It was full of cocaine. The men pulled out CIA employee ID

cards. But officials at the Cocaine Importing Agency, the world's

largest and oldest drug running group, denied any association with the

vehicle and men.

Prime Minister's "Famous" Great-Great Uncle (and black is white and

white is black! Received in an e-mail.)

Judy Harper, an amateur genealogy researcher in Northern Ontario, was

doing some personal work on her own family tree. She discovered that

Prime Minister Stephen Harper's great-great uncle, Remus Rudd, was

hanged for horse stealing and train robbery in Winnipeg in 1889. Both

Judy and Stephen Harper share this common ancestor.

The only known photograph

of Remus shows him

The only known photograph

of Remus shows him

standing on the gallows at the Manitoba Provincial Jail.

On the back of the picture Judy obtained during her research

is this inscription:

'Remus Rudd horse thief, sent to Stony Mountain Jail 1885,

escaped 1887, robbed the CP AND CN trains six times.

Caught by Mounted Police Force, convicted and hanged in 1889.'

So Judy recently e-mailed Prime Minister

Harper for information about their great-great uncle, Remus Rudd.

Believe it or not, Harper's staff sent back the following biographical

sketch for her genealogy research:

"Remus Rudd was famous in Ontario during the mid to late 1800s. His

business empire grew to include acquisition of valuable equestrian

assets and intimate dealings with the CP and CN Railways..

Beginning in 1883, he devoted several years of his life to government

service, finally taking leave to resume his dealings with the railroads.

In 1887, he was a key player in a vital investigation run by the Mounted

Police Force. In 1889, Remus passed away during an important civic

function held in his honour when the platform upon which he was standing

collapsed."

NOW That's how it's done, Folks! That's a real POLITICAL SPIN!

(Author unknown. Hmm, I'm sure I've seen that before somewhere... where

some "notable"(?) died tragically in some apparently freak accident

"when the platform he was standing on collapsed" at some public

function.)

I only caught the last half of the reportedly

excellent total eclipse of the moon,

I only caught the last half of the reportedly

excellent total eclipse of the moon,

but the next night there were some really interesting clouds lit up by

the moon.

The photo does them little justice. Below are lights across the bay

reflected in the water.

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers

- Preliminary Ni-Mn, Ni-Ni Battery Making book

Products Catalog:

- Electric Hubcap 7.2 KW BLDC Pancake Motor Kit

- Electric

Caik 4.8 KW BLDC Pancake Motor Kit

- NiMH Handy Battery Sticks, 12v battery trays & Dry

Cells (cheapest NiMH

prices in Victoria BC)

- LED Light Fixtures

- CAT 12 volt DC plugs, sockets, wall receptacle plates...

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

Daily

Log

(time accounting, mainly for CRA - SR & ED assessment purposes)

September 1: Worked on August newsletter

2: Finished and posted it.

3: -

4: Started voltage versus cooling experiment in 12V thermoelectric

fridge. ARM motor - Epoxied steel rings around coils. (Got 2 chickens.

1 egg first day, 2 the next, 0 for a day then 2 more... Hmm, chickens

eat a lot more than fish. Then no more at all after the first dozen.

Laying shut off like a switch, both birds! ...Roast chicken next

perhaps?)

5: ARM - Trimmed sheet metal rings and sanded coils to a semblance of

flat

and even. Epoxied them to motor base plate.

6: Touched up epoxy job. Designed circuit board for rotor position

sensor optics.

7: Printed out, laminated, etched, drilled and populated circuit board

for motor. Made an "L" bracket mount for it. Wire brushed top and base

and painted them with urethane spray paint.

8: Mounted and tried to adjust board so optical sensors didn't hit

rotor. Rotor wasn't quite flush -- it hit both top and bottom during a

rotation. Welded rotor to hub. Two tries. (That didn't help the

flushness.)

9: Tried to adjust rotor alignment with minimal success. Made cable for

rotor position sensor (triple optical interrupter) board.

10: Populated PCB for LED light and restored first LED grow light to

operation. (It still runs too hot!)

11: Made a video about (world's most?) water conserving shower nozzle,

the Waltec 10C, which uses less than 1/2 the water of any other "water

conserving" shower nozzle. (How about a good shower with 5 or 4 or 3

liters per minute?) It appears to be long out of production. It should

be brought back! Or re-invented.

12: Wired the pairs of coils together. Tested and found a coil was

shorted to the case. Ouch! (Rats! -- I meant to check for that while

the epoxy was still soft!) Installed 14 amp peltier module in

thermoelectric fridge. (Also see 15th, 17th, 23rd. Voltage trials went

on a few days.)

13: Tested to find which coil of two. Attempted to remove coil. I might

have to smash it to pieces. Changed Peltier Module on solar fridge to

large size 15 amp unit and started cooling tests.

14: A few Peltier fridge temperature measurements. (Heat transfer to

ice tray is poor.)

15: Bought rectangular aluminum pan with thick bottom & sides,

hoping it would make a better ice tray for the thermoelectric fridge.

Repaired shorted motor coil.

16: -

17: Installed the tray.

18: Did the heavy wiring in the motor - it doesn't fit - can't close

the case.

19: Pulled the connector off the case and pulled the wires out a bit.

Just fits! With the case closed, the rotor rubs at least a bit

somewhere, but I'll try it out as is.

20-26th: Studying "free energy receiver" circuits and writings.

23 (& on): Placed small fan to blow air in Peltier 12 V fridge.

Trials continued into October. Major improvement in overall cooling.

27: Tested motor optics. Optical interrupter part had mirror image

LED.s. Sigh! Cut and soldered wires to get board working, redesigned

part & PCB. At last discerned that the "free energy" as collected

by Tesla, Moray and others actually does come out of thin air. Air has

increasing charge with altitude, and their oscillating devices could

apparently collect that energy far more effectively than the passive

"cell phone charger" system with only diodes and capacitors.

28: Designed a tentative schematic for capturing air energy charge.

29: Got reluctance motor running. (YAY!) Filed off a coil ring where

the rotor was rubbing. (It would work better if the rotor was dead flat

and straight!) Did a revised air energy charge harvester schematic and

picked up a tunable coil and tuning capacitor for air charge energy

device.

30: Tried a few more things with reluctance motor. Obtained some books

on oscillators and radio transmitter design, and (bonus!) a vacuum pipe

heat dissipator intended for computer CPU.s, but just the right size

for a typical 40x40mm peltier module. (I'll try that with the camping

cooler some time, seeing the new peltier in the thermoelectric fridge

is 62x62mm.)

Electric Hubcap Motor Systems - Electric Transport

ARM Motor

The ARM (Axial flux switched Reluctance Motor)

The ARM (Axial flux switched Reluctance Motor)

On the 4th I did my best to

adjust the steel rings I made and rolled up (now months ago) for the

ARM motor coils to turn them into "cup electromagnets", and I epoxied

them onto the coils. There was lots of trimming to do before the coils

were anything like flat and the right height. Much as I feared,

attaining the exacting dimensions for .025" flux gaps is virtually

beyond my ability for largely hand-made assembly with epoxied wires and

curved sheet metal parts. So the gaps will be larger and hence the

specs not as good as might otherwise be expected. There will have to be

some major assembly simplifications and quality improvements to the

process if this motor is to be produced. (The transverse flux design

seems more promising.)

On the 5th I trimmed the rings with tinsnips and then

carefully sanded them, then painted on some more epoxy (a couple of the

rings were loose at the end) and let it set. In the evening I numbered

the coils and positions and ground out dips in the base plate in places

on 3 coils where where flattening them had sand them down to bare wires

in spots. That should keep them from shorting to the plate.

I had decided

simply to epoxy the coils onto the steel bottom

plate, and then build up the epoxy a layer or two, and maybe a little

polypropylene cloth, for strength. This is safer than simply epoxying

magnets to a rotor, since the stator doesn't spin - there's no

centrifugal forces and it doesn't have to be balanced. The

day-and-a-half old epoxy (kept in the freezer to prevent rapid setting)

seemed rather thick, so I just painted one more layer on when the first

coat had set.

I had decided

simply to epoxy the coils onto the steel bottom

plate, and then build up the epoxy a layer or two, and maybe a little

polypropylene cloth, for strength. This is safer than simply epoxying

magnets to a rotor, since the stator doesn't spin - there's no

centrifugal forces and it doesn't have to be balanced. The

day-and-a-half old epoxy (kept in the freezer to prevent rapid setting)

seemed rather thick, so I just painted one more layer on when the first

coat had set.

Motor Base with "Cup Electromagnet" Coils

Next came the optical rotor position sensing system. I

thought the 3 optical interrupter sensors had to be placed at 60 or

120° intervals around the outside edge. That's how I did it with

the magnet sensors. That precluded putting them on a single circuit

board. In fact, the available space was a little cramped and they would

have to be mounted at an angle instead of straight on. That would keep

them inside the outer case ring so I didn't have to cut holes at 3

exact spots and then line it up accurately, and also let them miss the

case assembly bolts using existing holes.

Then it occurred to me that with 8 overlapping rings per 3

coils, the interrupters could be much closer together -- in any three

positions where they lined up in a proper 3-phase spacing to the rings,

which were about 42mm spacing, so at 0, 14 and 28mm. Perhaps I could

drill one or two new

holes and mount an assembly with the three interrupters? When I

checked, it looked like that would work.

I measured about 1.65" from one ring to the next at the

outside, so 2/3 of that would be 1.1", with the 1/3 position at .55".

(which is, sure enough, 14mm)

It looked like the board should be about 1.75" tall to mount with a

small "L" bracket from the bottom plate and hold the 3 interrupters.

(LED + Phototransistor pairs facing each other in a housing with a

5/16" gap between them - ordered from somewhere on aliexpress.com).

Make it 1.4" wide to cover the 1.1" plus connection wires plus margins.

There was the basis for a PCB design. Making a PCB seemed the best way

to go. I've developed an aversion to "cludged-in" component

constructions.

I designed it on the 6th, then printed, 'laminated' it,

etched it, drilled it, and populated it on the 7th. And made an "L"

bracket mounting to hold it u to the rotor. I managed to forget to

print it mirror image on the first try, but I decided to do a couple of

flat panel LED light boards at the same time, and the reversed

lettering on them prompted my memory before I etched it. I then

proceeded to print it out the right way around... on the back side of

the

toner transfer paper. I didn't notice until the paper wouldn't release.

I patiently soaked it off, worked it up and used it anyway. The board

came out with a

few paper fibers (which I had tried to rub off) shorting close

gaps at the optical interrupter modules, seen (by 60 year old me) only

under a magnifying glass. I scraped them away with an exacto knife.

There were "micro-pits" in the copper everywhere, but all the

connections seemed good.

Mirror image board - Motor optics and LED light

boards ready to etch

Mirror image board - Motor optics and LED light

boards ready to etch

Finished (except for wires/cable) Board

Finished (except for wires/cable) Board

Optics in Motor (Light from behind shows copper

traces through PC board)

Optics in Motor (Light from behind shows copper

traces through PC board)

( EAGLE PCB Files: Schematic , Board , Optical Interrupter "lbr" -

corrected but untested as drawn )

(The 5/16" optical interrupters were from somewhere on aliexpress.com )

On the 8th I got out the little MIG welder and welded the

rotor to its hub. I'm definitely no pro welder. Someone feared it might

break off at high RPM. I hadn't yet put the welder away, so I went out

again and added lots more equally ugly

weld. The poor carpenter blames his tools, but I suspect the cheap, 120

volt welder is too light for these heavy pieces. But then personally

I'm not sure I'd do any better with the old 230V stick welder either.

Then I ground off the ugliest bumps with the angle grinder and it

didn't look so bad.

First and Second so-called Weldings.

First and Second so-called Weldings.

The second one looked somewhat better after some grinding to smooth it.

Is that the trick?

Then I went to try and true up the run, to eliminate the

wobble, by bending the rotor plate just a fraction. It grazed the

bottom of the optical interrupters at one point of rotation, and the

top 1/2 way around from there. I spent a lot of time without

accomplishing much. It would be off at different points each time I

tried bending it. The next day I checked again. I found I had bent up

an actual bump, a raised area, to add to the problem. I went out to the

big vise and pushed - one more time after so many - hoping to bend out

the bump. Miraculously I did, and the whole alignment was virtually

perfect all the way around. Wow! Quit while ahead!

Then I went to try and true up the run, to eliminate the

wobble, by bending the rotor plate just a fraction. It grazed the

bottom of the optical interrupters at one point of rotation, and the

top 1/2 way around from there. I spent a lot of time without

accomplishing much. It would be off at different points each time I

tried bending it. The next day I checked again. I found I had bent up

an actual bump, a raised area, to add to the problem. I went out to the

big vise and pushed - one more time after so many - hoping to bend out

the bump. Miraculously I did, and the whole alignment was virtually

perfect all the way around. Wow! Quit while ahead!

On thinking about it, it's possible there was some speck

of grit between the two upper rings of the thrust bearing (I added the

second ring to increase the clearance), and that that rather than the

rotor caused the wobble, with the 'random' bad alignment rotations. (I

did casually wipe them off once, but without apparent effect.)

After a lot of work drilling and filing holes in the "L"

bracket and much adjusting, I found that the optics assembly

had to be removed to install or remove the rotor, and then needed

realignment. And the head of the bottom bolt was inaccessible until the

upper one was removed, and the upper one had a nut, hard to reach, that

made it hard to loosen and tighten for adjustments. It occurred to me

that if the

bracket was threaded so the bolts were put in in the other direction it

would all be much simpler. Easier to do it now than after further

frustrations and possibly breaking something. I replaced the hardware

store "L" bracket with a new one made out of 16 gauge nickel-brass --

with holes that were where I wanted them, and threaded. (As I gave it a

final sanding, I lost my grip and it shot out the back of the bench

belt sander and fell behind the bench, never to be seen again. I

finally

gave up looking and made another one.)

With the rotor straight and a bracket that would stay

where it was positioned to, the rotor spun true in the gap between the

optical elements. But some imp must have come along and bent it again

while I wasn't looking, as it ran crooked again later. (Or was it just

a fleck dust somewhere... or more likely, a fleck dust the time it ran

straight?)

On the 12th I wired the pairs of coils in series. Then,

belatedly, it occurred to me to make sure no coil wires were short

circuited to the bottom plate. I had intended to do this while the

epoxy wasn't set yet, but had forgotten. Now there was a penalty for

that omission: there was indeed a short, and the coils were solidly

epoxied to the bottom plate and the pairs were wired together. In order

to identify the coil, I ran a 1.0

amp current through the offending pair, and checked the voltages to the

plate to see which end was closest to the plate. One end definitely was

closest, the

coil I'd marked "5". I pried off the outer ring of the coil, and

scraped away as much epoxy from around the base as I could. But

hammering it via a block of wood wouldn't budge it. It looked like I'd

have to smash it to get it off. I set it aside for a couple of days.

Perhaps an inspiration might come?

It did. I thought to unwrap just the outer bottom winding.

Maybe that would make take away enough epoxy grip that I could knock it

loose? But when I started, I only unwound a couple of inches, then

thought to check again. The short was gone! It must have been right

there at the start of the coil... or else it had been shorted to the

outer ring. (Maybe I hadn't needed to do anything but remove that?) I

scraped the stuck epoxy off the ring, mixed a very tiny new batch, and

epoxied it back on. I put a heavy weight on it hoping to

keep it down below the rotor while it set. By night the epoxy was hard

- and there was no short. The rotor spun freely again after I filed off

the epoxy and metal ring inevitably sticking up a bit. Well, that was

certainly easier than breaking off the coil and making and installing a

whole new one! The three days lost were of course fully occupied by

other things.'

At least the episode demonstrated that simply epoxying the

coils on held them quite well. And the current test for the short

incidentally disclosed that the DC resistance of each phase was about

30 milliohms. That's 1/2 the resistance it would be if the phases were

used in "Y" configuration, going across two phases instead of having

each phase tied to B+. As I recall, the Electric Hubcap motors of the

"standard" BLDC configuration with #11 wire coils were about 67

milliohms. This should result in overall copper losses being quite

similar, notwithstanding that only one phase is energized at a time

instead of two, and so (all else being equal, which it surely won't be

anyway) more current will probably be required to attain the same

magnetic force.

I started studying free energy devices rather intensively

(along with getting more batteries and doing various things that needed

doing) and it wasn't until the 27th that I hooked up the motor optics

to the controller and tested it. It turned out that the LED.s were

defined backwards in the part "library", so it didn't work. I cut

traces and put in wires to make the connections, then fixed up the part

and board designs. Once corrected, the unit seemed to operate just

right. (The little tabs I put on the outside of the rotor were quite

thin, and I had been afraid one or two of the outputs would be blocked

too much or too little and wouldn't change state at the right times.

Once the motor was running this did prove to be the case and

adjustments were required.)

On the 29th I bought some connectors to put on the ends of

the heavy wires, hooked it up, and (after 5 tries out of 6 possible

ways to connect the 3 wires) the motor ran. It seemed to use too much

current to spin with no load, but it got up to about 195 RPM with 10

amps at 30 volts. Soon I disconnected the lab supply which only goes to

10 amps and hooked up 24V of NiMH D cells in two 12V tubes.

But turning the control up higher seemed to have no effect

- only about 12 amps of current was drawn, and the speed didn't rise.

There was only a small area on the rotary control where the motor went

from zero to this maximum. This is probably mainly a controller issue.

I hadn't turned up the BLDC 4:3 motor above about 10 amps because I

just ran it on the 10 amp lab supply (and it got up to good RPMs with

that), probably explaining why I hadn't run into it before. After a

time the coil got smoking hot, and the energy return diodes were also

pretty hot. The switching mosfets were only slightly warm, and the

motor was hardly warm. Before, I thought that it just needed to be a

bigger coil with heavier wire. Now it occurred to me (again, as with

the free energy device coil and frequency) that the frequency of the

switching, and especially the sharp switch-off pulse spikes, was

probably too high for an iron [iron powder] core. Surely it needed to

be ferrite or something. Definitely much of the power was going into

heating up the coil, not running the motor.

I found there was a lot of torque ripple by holding the

rotor back, allowing it to slowly rotate. In some spots it could be

easily held, but it would jump through some others with far higher

force. I could see as I was putting things together it wasn't going to

achieve even torque, the "phase ON" start position being farther from

coil alignment than I expected from the cardboard trials. I still think

this can be evened out by adjusting dimensions, even if the weaker

areas are only increased at the expense of the maximum torque.

When I went to check the actual levels of torque, I

discovered the shaft I had used had no keyslot to attach the device. So

I've left it for now.

One phase seemed to have substantially more torque than

the other two. This was a puzzle since the coils were all the same.

Then I loosened a screw on the optics board so I could move it around a

bit. Side to side made little difference, but moving it in and out

changed things markedly. Moved out, the motor stopped entirely. Moved

in, the RPM appeared to about double, still with the same 11 amps

current. Of course the middle phase interrupter was slightly closer in

than the other two, with the flat circuit board not quite matching the

curved rotor. Presumably it was full strength while the other two were

getting light prematurely and switching at the wrong times. But I

adjusted the optics to a new position and was still getting higher

currents and torques for two phases than for the third. The whole thing

still has some puzzling features, including that the interrupter

frequency shown as a number on the oscilloscope sometimes seemed

different at the same RPM (perhaps was a harmonic) - and didn't match

the actual waveform seen. Later all three phases seemed to have the

same strength.

Since I've already found a better design I don't plan to

make any more of this motors. On the other hand, by running this one I

might learn some more about reluctance motors and about my own

implementations of them in particular before making the next one. And

the motor controller, which I hope to use for any and all of my future

transport-size motors, definitely needs at least some "tuning up" in

the coil - and the synchronous rectifier drivers, and it definitely

doesn't run this motor as well as the BLDC4:3 type, so the interactions

need study.

"Transverse

Flux" Motor

A probably better

way of using the "hole saw" drum came to me watching a video of a

commercial reluctance motor. The outer rim of the drum is only 1/16"

thick or so.

Instead of attaching the "horseshoe magnet shorting bars" across the

outside face, they could be attached on the inside. With the thin metal

elsewhere, that would provide enough of a difference that it should

work pretty well. Anyway that seemed to be how the commercial one was

done.

That would be a big relief from a design standpoint,

because if the 'bars' are on the outside, the diameter for designing

the stator would depend on the thickness of the bars. The bar thickness

would be critical and at the same time might easily vary owing to

welding or soldering variances, and any change in thickness would mean

redesigning and rebuilding the stator. On the inside, slight variances

won't affect the dimensions and the flux gaps. I can now start

designing the stator for the drum's exact outer diameter, without

fearing

that diameter will need changing at a whim.

With each bar resting at the drum's bottom, they should be

easy to silver solder on - they won't try and shift or fall off. Or

maybe I can just epoxy them on?

Other

"Green"

Electric

Equipment Projects

Water

Conservation: Best Shower Nozzles and Video

I have what appears to be a "well kept secret", or rather

a piece of useful knowledge that just never spread: shower nozzles

capable of delivering a fair spray with under 3 liters of water per

minute, and a good stiff spray with 4 or 5. Well, maybe 6. A so-called

"water

conserving" shower nozzle is considered to be one that uses 9 liters

per minute, so this is 1/2 the water usage.

It happened that I bought a "Waltec" bathtub faucet set in

about 1980 or 81 (or even earlier?) in bathroom renovations. The

faucets and spout were

nothing special, but the shower nozzle I would call "clearly

superior". Instead of having the water come out around the edge

and through "watering can" holes here and there, it all comes out

sideways behind the adjustment knob from a central point, spraying into

curved triangular grooves that spread it out and aim it down, and not

all the same (which would form a single ring of water) but with varied

ejection angles.

I soon went out to the same plumbing store and bought

another one for the other shower, specifically asking for that same

part number, a "Waltec 10C shower nozzle" (IIRC the number), and one

was produced from the back of the store. The clerk even seemed familiar

with that specific number without looking it up - something someone

else had asked for? I've never seen anything like it before or since,

in spite of looking at shower nozzles in stores on several occasions.

"Better mouse traps" seem to often be invented and then go out

of production and are forgotten, for reasons that seemingly have

nothing

to do with performance. Whenever I shower away from home, such as at a

public shower (pool or campground), I'm aghast at how much water gushes

out, yet often with a rather feeble spray - such a waste of energy and

water! Surely they could do better in showers that are in use all day

every day!

But no. As far as I can find, they haven't been available

for decades, and there's nothing else like them. I think the original

mold and design needs to be found and returned to use, or it needs to

be be reinvented.

The

nozzle

originally made a soft spray with a minimum of

about 4 liters of water per minute. I added a final touch: a small

rubber washer around the adjustment knob, the same diameter as the

knob. By closing the adjustment down just a bit more, the start of the

already small grooves is closed a bit more by the rubber and the most

water conserving operation mentioned above is possible, still with good

spray.

The

nozzle

originally made a soft spray with a minimum of

about 4 liters of water per minute. I added a final touch: a small

rubber washer around the adjustment knob, the same diameter as the

knob. By closing the adjustment down just a bit more, the start of the

already small grooves is closed a bit more by the rubber and the most

water conserving operation mentioned above is possible, still with good

spray.

I must add here that some people don't like it and open

the adjustment wide to get "typical" higher water usage. That too can

be accommodated. But I can hear that they just open the taps wide open

to start, and then of course the spray is much too hard when they pull

the shower knob. They haven't figured out that a good but water

conserving shower requires setting the water initially to a pretty low

level. (These same people also don't pay my water or power bills.) It

would no doubt help if faucets were made that make it easy to make

small adjustments to the flow. (I think those single knob bathtub

faucets that don't adjust at all - full blast or nothing - are the acme

of a bad idea!) Or perhaps reducing the water supply would make the

adjustment range of the taps finer. As it is, when I budge the cold tap

just a smidgen (...did I actually turn it, or not?), the temperature

goes between too cool and too hot. The hot tap has somewhat better

range, if only because my hot water isn't turned up too high.

Another factor is simply what people are used to and what

they expect. If one is expecting a huge gush of water, a strong, finer

spray probably seems weird, and people may start adjusting to get

something more familiar, more in line with expectations, without

critical examination of what might actually be better.

I started out by deciding to do a video about water

conservation quite a while ago, and then to cover the shower nozzles

specifically. I still haven't posted the first one, but here is the URL

for the shower nozzle one: https://www.youtube.com/watch?v=Qs6iKSch2sI

.

Peltier Module / Thermoelectric Cooling Experiments

As voltage on a Peltier module is increased, so is the

current, so the power consumption is related more to the voltage

squared than to the

linear increase. The fridge has been using a 15V, 8.5 amp rated

module, which values yield 128 watts. But the calculations aren't so

simple because the current drops as the temperature difference rises

between the hot and cold side. The

experiment with changing voltages on the 12V solar fridge showed that

there was considerably more cooling at 9 volts than at 8, and at 10

volts than 9, slight gain going

from 10 volts to 11, just a little from raising that to 12, and

apparently none

going up from 12 to 13 volts. 14 volts seemed, if anything,

slightly worse than 13.

And it turned out that the voltages at the peltier itself

were notably lower than at the power plug, with some resistance in the

wires and connections. I had been content to use the volt meter on the

power

supply, while realizing that there would be a little more drop across

the wires and the control relay before the peltier modules. When I

returned the supply to the solar panels I belatedly measured the solar

voltage at the socket (13.4 volts), and then at the leeds of the

peltier module/TEC ('thermo-electric cooler') itself. It was only 11.6

volts - a 1.8 volt drop! That meant that my results were skewed -

that the voltages I was comparing were actually 10-15% lower than

what the meter said. (Also that I should be using heavier wires... or

long, light wires to get to a desired lower voltage!)

Another unreliable figure is the interior temperature: the fridge is in

use, mostly for canned milk for coffee and mixed nuts and things (plus

cool storage for many items that are rarely used). Every time the lid

is opened, the temperature rises perhaps 1/2 a degree, and it takes

some time to return to the pre-opening figure. Plus if a warm item is

placed near the sensor it warms up the vicinity. I present the

table below derived from 2 pages of measured figures over 6 days from

Sept. 3rd to 9th, and later (9th, 10th) measured

real voltages at the TEC's input leeds for the given supply

voltages, and otherwise cleaned up and estimated,

with various similar readings averaged out.

When (2015/09/--)

|

Volts (at actual Peltier

module connections)

|

Amps

|

Power

(TEC actual)

|

Room°

|

Fridge°

(Cold end)

|

Notes

|

/03 - 9:00 AM

|

11.8 v (solar, at plug)

(~10.3 v at peltier)

|

-

|

-

|

-

|

6.0

|

Initial reading. Then set to 8.0

volts (at power supply!) at 9:30

|

- 11:20

|

7.3 v

|

3.0 a

|

22 w

|

20.0°

|

8.1°

|

warming. Ice in ice tray melting.

Set to 9.0 volts after readings.

|

- 15:00

|

8.0 v

|

3.7 a

|

30 w

|

20.0°

|

6.6°

|

Ice still melting.

Set to 10.0 volts after readings.

|

- 24:00

|

8.8 v

|

4.1 a

|

36 w

|

21°

|

6.5°

|

Melting of ice much slowed.

Set to 11.0v after readings.

|

/04 - 9:00

|

9.7 v

|

4.5 a

|

44 w

|

20.5°

|

6.1°

|

More ice (still < 1/2 tray)

Set to 12.0v at 18:40 PM

|

- 21:30

|

10.6 v

|

5.0 a

|

53 w

|

21°

|

6.0°

|

More ice - headed for 1/2 tray.

Set to 13.0v next day at 15:30.

|

/05 - 15:30 to

/06 - 9:00

|

11.6 v

|

5.4 a

|

63 w

|

21.5°

|

6.3°

|

A bit more ice. (note > room°)

Set to 14.0v, /08 at 8:45 AM.

|

/08 - 12:15

|

12.5 v (est)

|

5.9 a

|

74 w

|

23°

|

6.5

|

Temperature not dropping

(but room temp higher)

|

Referring to the table, the 8 volt setting (delivering

just

7.3v to the TEC, <50% of its rating) was obviously not

doing enough cooling and I raised it a volt to 9 after about 2-1/2

hours.

That, delivering 8.0 volts to the module, still had the ice tray

gradually

melting, and I raised it another volt to 10 (8.8v at peltier) after

3-1/2 hours. That reduced the melting speed to a crawl and I left it

there 9 hours, but it was still a warming trend. At 11 volts (9.7 at

peltier) more ice started to form. 12 volts was a small improvement,

but going to 13 (still only 11.6 at the TEC) seemed to make minimal

difference. I did some more readings at 11 volts on the 6th to 8th. The

room temperature had risen with warm weather, as high as 24°. The

fridge warmed up by a somewhat lesser amount, mostly under about

7.0°.

On the 8th I tried 14 volts (~12.5v at the module) just

for completeness. As expected, it seemed to be little better, if at

all. The heatsink and fan work too hard to dissipate 74 watts of input

heat energy plus about 40-45 watts of heat transferred from the cold

side, so the warm side temperature gets much warmer than room

temperature, raising the temperature differential the heat has to be

pumped across. Going to the higher levels was just wasting energy and

worse, probably was a major contributor - if not the main contributor -

to shortening the lifetimes of the modules.

The next thing to try was to install the big 14 amp

peltier module, 62x62mm, that I got from somewhere on AliExpress.com

(TEC12715...

maybe it's 15 amps?). That could

certainly be run at lower voltages (8 to 9v?) and hence in a more

efficient

range, to presumably deliver the same cooling using lower power. Or

(9 to 11v?) substantially more cooling at the same power.

Perhaps it could even get

the whole fridge nice and cold. Then I could put in a fan to blow the

air

around for even all-round cooling. It might even allow the intended

operation mode of turning the fridge mostly off at night (or whenever

the 12 volt supply voltage was lower) and doing extra cooling during

the day (whenever the supply voltage is higher indicating the batteries

are charging), ideally freezing the whole ice tray while the energy was

coming straight from the solar panels (or other periodic power source

[wind?]).

I installed it on the 12th. When I started to disassemble

the old setup I found it had made lots of ice overnight and the fridge

was surprisingly (after the temperatures in the above table) under

5°c. Power would have been at about 11v

overnight and then 13.5v during the morning. The only thing that seemed

to account for it was less opening of the lid.

I also found that the switch was hot and also some of the

connectors. I got rid of it all - switch, Chinese control unit with

relay, and some skinny wires - and left just the plug, cord, fan and

connectors for the peltier. If it's plugged in, it's on. (One skinny

wire remained.) And I discovered that it was a little harder to change

the Peltier module than expected: the copper bar didn't stick out far

enough to hold the 62x62mm square. However, I had at one point

previously fitted it, and there were threaded holes in the right places

to do it. I had to thaw out and remove the ice tray to change it, so I

put fresh water in it. And the lid was open a long time. Obviously it

would take a day or so to settle in before ice extent and temperature

readings would mean much.

When everything was together I set the power supply to 9.0

volts (at 15:00 PM), and it was using 6.4 amps. At the Peltier leeds it

was 8.4v. That made 54 watts actually reaching the TEC, about

equivalent in input power to the 12 volt setting on the old unit. I

also got out an actual ampmeter and compared it to the power supply's

meter. It seems that in this middle range at least, the power supply's

meter is pretty close. In the lower ranges (eg, under 3 amps) it reads

low by about 10%, and I applied this factor, evidently in error, to the

amp readings. I adjusted those and the resulting watt figures in the

table - or should I say I un-adjusted the erroneously adjusted readings?