Turquoise

Energy Ltd. News #93

covering October 2015 (posted November 8th)

Victoria BC

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Month In Brief

(Project Summaries)

- Pulse Width Modulation for motor controllers - Atmospheric Energy -

High vacuum pump for evacuated tube radiators for thermoelectric

cooling? - NiMH Battery connection problems.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Legislation must be Ratified by the People - Energy Density:

Gasoline vs

batteries? - Importance of Location for Industrial Activities -

Negative interest rates - Another High Frequency Trading Scam - Itchy

chocolate - Book Barn Mini Library - Supercorder at Band & more

interest in it

- In Depth Project Reports -

Electric Transport - Electric Hubcap Motor Systems

* Unipolar Motor Controller: pulse speed control input to improve

performance.

Other "Green"

Electric Equipment Projects

* Peltier Module/Thermoelectric Cooler ('TEC') Experiments:

supply

voltage versus attained cooling - 15 amp Peltier module - better ice

tray - internal fan - evacuated tube heat radiator - DC to DC converter

Electricity Generation

* Atmospheric Ions - free energy from the electrical charge of thin air?

* Sigh, month ends with far more questions than answers.

Electricity Storage - Turquoise Battery

Project (NiMn, NiNi), etc.

* Lead? Lead? The acid battery element has potential uses for alkaline

or salt batteries, where it just might have 'forever' cycle life.

* Lead-acid battery charging & cycle life extension: pulse charging.

No Project Reports on: Variable

Torque Converter Transmission, CNC

gardening/farming machine, Electric Weel, battery making, aquaponics,

Magnet motor project.

October in Brief

A lot of October just seemed to slide by without getting a

whole lot, or even anything, done on sustainable energy projects. There

were many things needing doing around the house. I went to Comox on the

last

weekend

for my mother's 90th birthday party, and then my brother who had come

from Toronto stayed

with me for a couple of days, leaving on Halloween morning. I caught

his cold, with

headache most days. That

delayed this newsletter as well as projects. Somehow, however, I have

touched on quite a number of diverse topics in "In Passing".

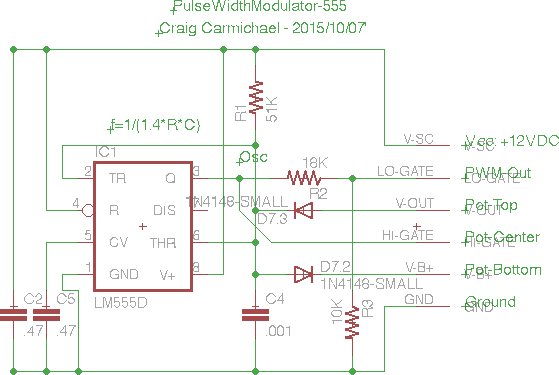

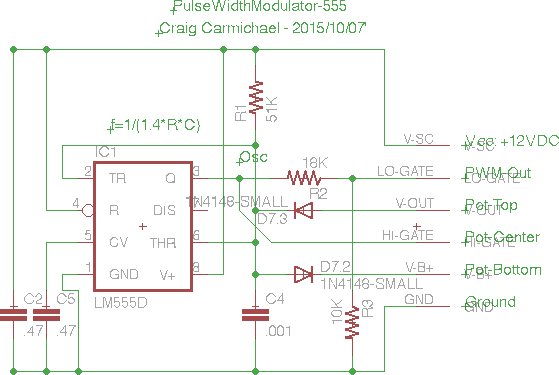

Early in the month I designed a circuit and PC board for a

pulse width modulator (PWM) for the motor controller. It would be an

external input to

the motor controller board, the PWM at 7Hz replacing the usual analog

speed control

potentiometer.

According to things I've heard, at least with a unipolar

motor controller, one gets better

energy usage with low rate pulses to get the desired power level than

with analog modulation, with the reason evidently being to saturate the

magnetic cores of the coils (or at least to run always at full power),

then letting the force drop to zero, repeating

in succession. This may not entirely make sense in a traditional design

sense, but according to many it works. But after completing my design

and layout there was a

long pause.

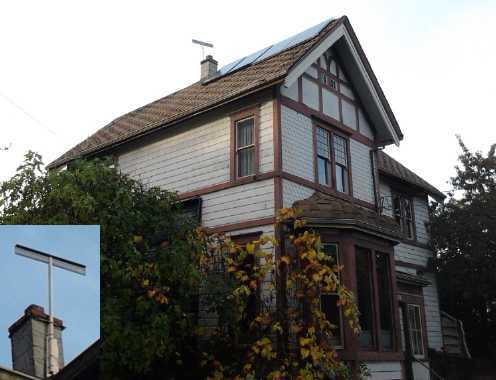

I wanted at

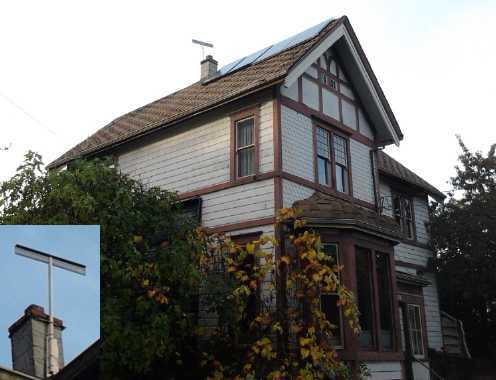

least to start in on atmospheric energy

experiments. I made an antenna for it and installed it at the peak of

the roof by the 16th. I ran a

shielded cable down the same route as the solar panel cables into the

solar equipment closet.

I wanted at

least to start in on atmospheric energy

experiments. I made an antenna for it and installed it at the peak of

the roof by the 16th. I ran a

shielded cable down the same route as the solar panel cables into the

solar equipment closet.

In all the searching through youtube for atmospheric

energy

info, inevitably some enticing videos about other forms of 'free

energy' including magnet motors were in the 'suggestions'. One person,

"(Something) Stators", had a bicycle wheel rotor test setup with a well

shielded

magnet on his stator, which he said offered the rotor magnets little

resistance as they approached but gave them a big push as they passed

by. It was similar to an idea of mine but he had done a working

construction with the bicycle wheel. I too think the shielding and

concentration of flux is

the

key - or at least one key. I started coming up with new designs in my

head again.

However, only once did he seem to have a design that

actually kept

turning. Even then, after a bit his cat, tentatively pawing at it a few

times,

dragged it to a stop, showing (along with the pretty low running speed)

how little actual torque there was. As a generator it

wouldn't put much out. Yildiz, with his 2000 magnet motor, seemed to

get a measured maximum of 200 watts AFAIK (tho I remember hearing 400

somewhere). Given the time quite a few people have put into getting

meager

results or failures, I think I'll stick with the atmospheric energy

as the better bet!

Moray got up to 50 kilowatts. Five kilowatts would of

course be fantastic.

(If I ever get my bitcoin miners running properly, I could then run

them and they'd also heat the house for free!) One KW would

still be great. A hundred watts would require installing a goodly

number of

antennae and units to make a real dent in the hydro bill. Ten watts

might be practical for limited off-grid applications. Of course, a unit

generating 24/7 would have

far more impact than solar panels of the same rating that run a few

hours a day and only

when it's sunny and there are no chemtrails. But reading more on Moray

at the start of November, I discovered that his later units actually

needed no antenna or ground, and worked for example inside a submarine.

That would indicate he was surely harvesting "lambda rays" rather than

atmospheric ions - at least with his later units... but weren't they

just derived from the earlier ones? Hmm, hmm!

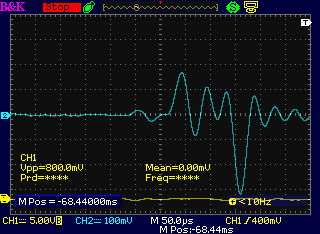

Again I got sidetracked into other things. It was the end of the month

before I tried the oscillator(?) circuit of 'Tesla Cult's youtube

videos of 2012. It didn't seem to work for me. Furthermore, the

oscilloscope disclosed only a 60 cycle hum at about .4v peak to peak

and virtually no DC component. There was none of the high frequency

noise components noted by Moray and seen on Tesla Cult's oscilloscope.

Perhaps insulating the antenna with high dielectric constant material

as suggested by someone else is a mistake. Maybe good, clean metal is

better. Gold plating?

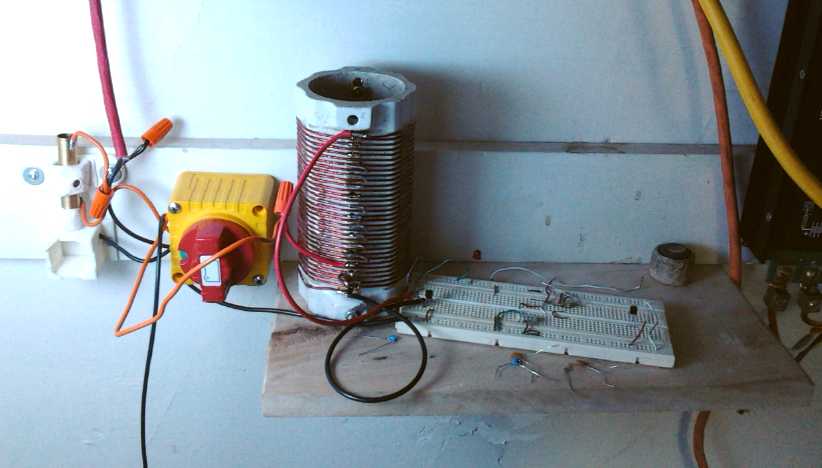

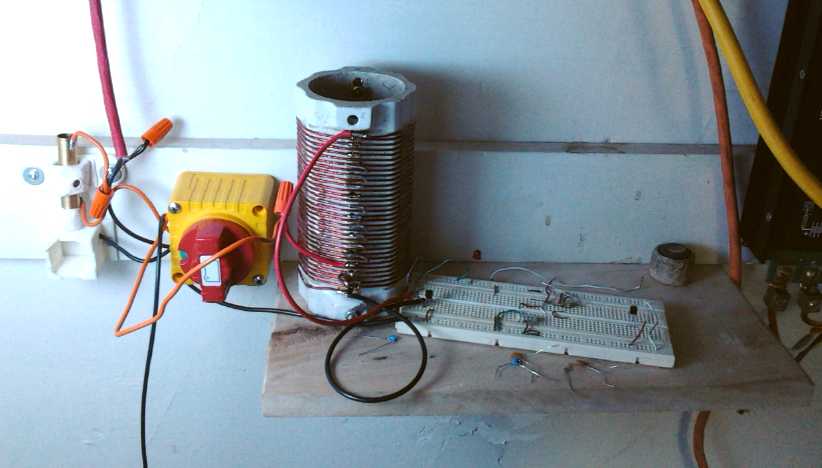

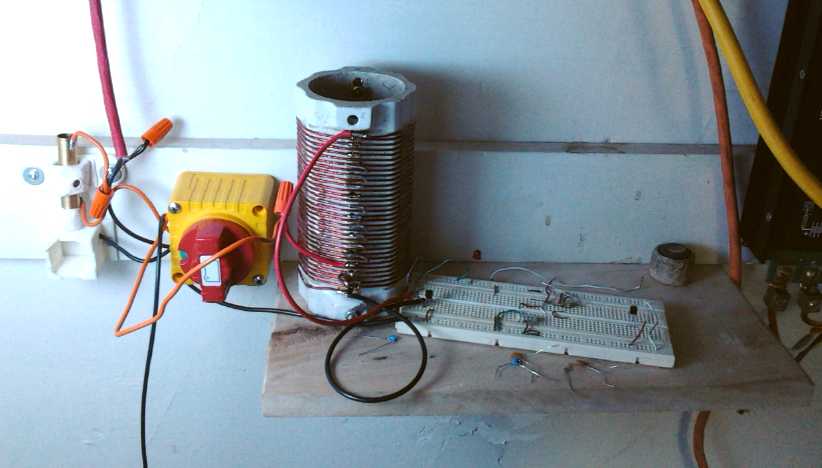

The bottom end of the atmospheric charge energy

experiments, in the solar equipment closet.

The bottom end of the atmospheric charge energy

experiments, in the solar equipment closet.

Cable from antenna with spark gap, antenna grounding switch, shelf with

the air core coil/transformer and circuit breadboard.

(At the far right is solar PV wires and equipment.)

Someone long involved with refrigeration came over (from

across town in an electric handicapped scooter) and we

talked on the subject. He mentioned having a high vacuum pump. I

thought it might be used to make the evacuated tube radiators I've been

wanting to make but have been unable to get a sufficient vacuum in by

the steaming method. He pointed out that the water in the pipe would

turn to steam and condense in his pump. Somehow I quickly

thought of freezing the water and pipe in the freezer and then

evacuating it. Then the water (ice) would stay in the pipe as desired.

He thought that could work.

Now I must talk with him again soon and get moving on it, as there's no

guarantee at his age and health he'll be around and mobile when it's

convenient for me to get

around to it. Maybe I can learn some more, and perhaps buy the pump?

In August and September I had been smelling a "burnt

plastic" smell at times when driving the Mazda RX7 EV - often when I

needed the most power, climbing hills. Finally in September the culprit

was located: a loose connection nut on the soldered nickel-metal

hydride battery in the back of the car. (this battery: see some TE News

issue of maybe 2013.) With the loose connection, the bolt with the wire

had been getting hot, and pressing against the side of the neighboring

lead-acid battery it was melting its way through the side. Luckily it

hadn't

got all the way through the wall yet, and just as luckily the car

hadn't let me down going up a hill. I tightened the nut and put a piece

of wood between the two batteries to keep them apart.

The smell stopped, but the problems weren't over with. I

connected the NiMH battery to one of the voltmeters on the dash and

found that it seemed to now be the weakest of all the NiMH batteries,

with the voltage dropping lower when power was needed and the charge

being depleted sooner than any of the others. Although it was the first

soldered NiMH battery I had installed, it had been with all new cells.

I wasn't driving more than about 4 miles, by which time it obviously

needed recharging.

Finally it occurred to me that it behaving was as if it was 50

amp-hours instead

of 100. And it was made in two 50 amp-hour boxes.

I pulled it out, brought it inside, and started to

disassemble it. On the bolt that

had the loose wire there was a nut with melted plastic on it facing a

washer with melted plastic on it, and the wire in between from the

lower box to the upper had some grit on it. Although the nuts had been

tightened, these things had conspired to cause the lower box to be

unconnected. I cleaned it up. While it was out I opened the lids, and

found that two of five wires in one box had come unsoldered and so two

sets of 10 amp-hours weren't making connection. At first I thought they

must have melted off, but close examination showed untinned copper

surface -

the original solder joint had been poor.

Also in October, the owner of the one NiMH D-cell car

battery I had made and sold (somewhat ironically for his Honda Insight

hybrid) brought it in because after 3-1/2 years it

wasn't working well. (battery covered in some TE News issue from 2012

or 2011.) I had

asked him a couple of years ago to bring it in as I had discovered the

safety concern with just the thin plastic sleeve casings on the cells,

and had had some packs burn up on me after being badly overcharged. And

I had used the stiff copper "buss bars" to connect the cells together,

which I gradually found out gradually come loose with vehicle road

vibrations. I wrapped the cells in masking tape for thermal protection,

and replaced the bars with AWG#16 flexible stranded wires, formed into

little arcs to allow for more flexing. There were 3 or 4 copper bar

connections that had come loose, definitely explaining the reduced

performance, and a couple more that might have gone soon. One of the

terminal posts was also quite loose, and I pointed out that the

clamping nut had to be on tight to ensure good connection. I tested all

30 cells with a voltmeter while I had them apart, and they were all

holding their voltage.

As I write about the loose bolt/post, a better system

comes to mind: instead of clamping the connection bar between the bolt

head and the case with a nut on the outside, clamp the internal

connections between the bolt head and a nut inside

the case. That (hopefully) can't be loosened from the outside. There

would still be a nut on the outside to hold the bolt in place, but it

wouldn't affect the connections and pehaps cause the case to get hot if

it came loose.

On the 26th I finally got back to the PWM for the motor

controller and

I got the board made, working (not without a couple of little problems

along the way), and installed in the test controller. Then it sat a

while again. On November 3rd I decided as it was made I'd better at

least try it out for this newsletter, so I hooked it all up and ran a

few tests. It seemed to run about the same except for the definite

pulsing action. As the power supply was balking at the currents, I

powered it off the handiest thing: the 14.4 volt, 65 amp-hour Honda

hybrid battery. So I was running it at half the voltage and the same

current, and getting similar results. That seemed agreeable. I bypassed

part of the shunt resistor (for a lower shunt resistance) and got

higher currents in both directions, which provided a higher but still

very low top RPM of about 225. The DC clamp-on ampmeter attached to the

oscilloscope seemed to indicate that the energy return current spikes

were higher voltage than the supply current spikes. Doubtless that must

mean they were a little narrower, but the battery voltage dropped

surprisingly little over the course of the testing, indicating pretty

low energy use. The peaks were about 14 amps used for the 225 RPM,

delivered as short spikes of 150 to 300 amps with return spikes of

around 250 to over 400 amps. The energy return coil still got hot, and

obviously the average supply current has to be a lot higher to get any

real power out of the motor.

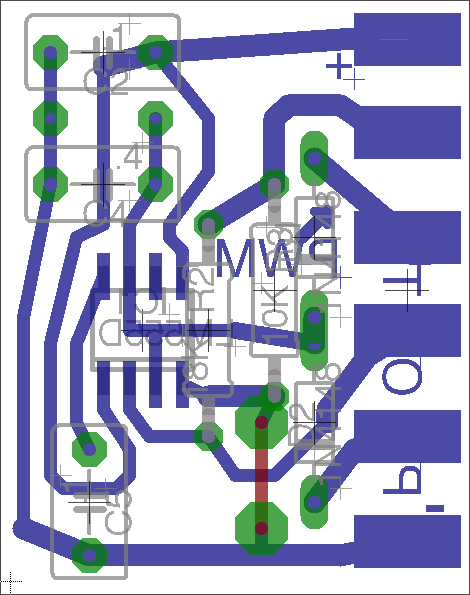

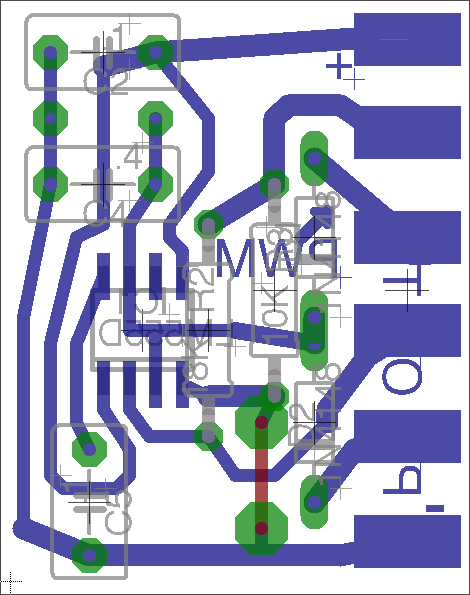

Pulse Width Modulator Board on pot, and

installed in hand-held control (SOIC 555 timer

chip on bottom)

Pulse Width Modulator Board on pot, and

installed in hand-held control (SOIC 555 timer

chip on bottom)

Aside from the direct-soldered potentiometer it has 3 leeds coming off

it, just like the analog pot alone:

Ground, Power (12V), and PWM out (0 or 4 volts with a resistive

divider).

(Circuit drawings/files in detailed project report.)

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Legislation must be Ratified by the People

As we enter the internet age, new forms of communication

and democracy, such as direct voting via the web are becoming feasible

for the first time, and at the same time there is a global awakening in

social consciousness.

Today's governments have mostly turned their backs

on the real needs of their citizens and social progress in favor of

special interest groups who broker their power for profit. When the

politico-economic power base is shattered as it doubtless will soon be,

from semi-chaos we will have

the chance to reorganize from the local level up in sustainable ways.

On the one hand, there is a need for elected government

made up of experienced, concerned citizens who have spent more time

than most studying the problems of society and devising solutions. On

the other hand, centralized power seems to increasingly attract

virtually the opposite type of people: the corrupt, the greedy, the

power hungry, the manipulators - insincere liars and sociopaths, devoid

of progressive ideas and ideals of social

sustainability. And these shut the honest and good-seeking citizens out

of the

fierce competition for political and economic power. We need leaders,

not rulers.

Some aspects of power need to be widespread, so that those

elected will have no opportunity to run roughshod over the rest, and

holding office won't attract those types. This has become possible.

People today know a lot more than those of previous generations, and

can learn more about what's going on more quickly. They will want to

know first why their social and political institutions, unexpectedly to

most, suddenly fell apart, and how it was that so many were so asleep

until it happened.

And they will want a more direct say in running the new ones to ensure

that autocratic decisions aren't imposed on them by those from whom the

police and the military take their orders.

Of course the citizens need the right to hold referendums

on any chosen issue. But it now seems to me that a possible solution, a

balance to the centralized power, is that any bill passed by a

legislature would have to be ratified directly by the citizens,

doubtless after time for due consideration and discussion. This seems

like the best way to eliminate odious and

perhaps deceitful legislation turning peoples' rights over to the state

or to special interest groups, and increasingly micro-managing

everyones' affairs with thousands of laws and bylaws. Such bills would

probably fail at the public scrutiny level, and the leaders

would realize it would, therefore they're unlikely to be pressed

forward,

and the types of people who would press them will be the ones who won't

bother running for office. Both of these polling

functions would be implemented via the internet in some form.

Gasoline: high energy density?

I happened to look up aluminum ion batteries on Wikipedia

to refresh my memory, and saw it said that even tho they were over a

kilowatt-hour per kilogram, petroleum was much higher energy density.

So I looked that up, converted joules to kilowatt-hours, and got 12.33

KWH/Kg for gasoline. At a glance, this is twelve times better. But one

must consider that the automotive gasoline engine is seldom over 20%

efficient, and add to that the inefficiencies of the drivetrain

components like the 30%-40% loss in a typical transmission

(standard-automatic). Call it 50% loss overall. The overall efficiency

of the typical car drive is then around 10%. So the 12.33 effectively

becomes 1.23 KWH/Kg. The rest of the energy is wasted as heat. An

electric drive can be made much closer to 100% efficient (up to the

rubber

tires and their road friction being similar), and of course a major

goal

of my

projects has been to improve efficiency, eliminating the wasteful

transmission one way or another and achieving the highest drive motor

and controller efficiency.

Of course no one is actually using aluminum ion batteries

at this point, and typical automotive lithium batteries are probably

under 200 WH/Kg at best. (Don't quote me on that!) Lead-acids are 40

WH/Kg or less. Furthermore, as the gasoline is burned its weight

vanishes, while the batteries remain as dead weight until recharged.

Still, there are promising new battery chemistries out

there such aluminum ion and several enabled by new DES electrolytes,

and as battery energy density increases over 100 or 200 watt-hours per

kilogram, the weight of the batteries as a percentage of total vehicle

weight starts to shrink and battery weight starts to matter less than

battery cost and cycle life. Add to that a reduction in required

battery capacity through higher efficiency, the ongoing cost of

gasoline and the likelihood that it won't always be available, Fast

charging and new public charging stations popping up everywhere, and

the electric car starts becoming the obvious

economic as well as ecological choice.

Importance of Location for Industrial Activities

I read an article in the Financial Times [http://www.ft.com/]

about industrialization creating less and less in the way

of jobs and wealth with each new industrializing country. I found one

of the comments someone posted below the article to be of particular

relevance to the work I've been doing. The writer says that industry

even in "industrialized" nations is concentrated in a small number of

"clusters". He went on:

"In a former life I have worked as an

industrial consultant and by observing it became clear companies inside

the industrial cluster have a competitive advantage in that they have

access to a dense local network of specialized suppliers and know-how

that often requires proximity to work well and is absent outside the

cluster. In other words, network effects are at play. Furthermore, the

presence of a sophisticated manufacturing base allows new types of

technologies and niche suppliers to develop, often requiring proximity

to customers - e.g. machine vision systems for automated quality

control. These then further strengthen the competitive advantage of

that cluster. The more technology advances, the stronger these

network effects become thereby further cementing the competitive

advantage of the cluster versus the world around it. 15 years ago, when

visiting competing companies in the same sector, it was obvious the

ones in Germany/Italy were way ahead of those in France, Spain as the

latter lacked plug-in into a strong local eco-system. I suspect since

then the divergence has only widened.

"This is also why Australia's doesn't manage to industrialize and

despite its highly educated population, one should always be short the

Australian dollar outside a commodity boom. This is also why Greece

will always run a deficit when in a currency union with Germany and the

EZ crisis is perpetual: if Greece were somehow geographically moved in

between Germany and Switzerland, its problems would quickly

disappear.

"This is also why everybody now wants to move to Germany as the

manufacturing base won't come their way. They have a point.."

I have struggled from the beginning of the "car

hybridization" projects with the fact that nobody around here seemed to

know anything or have any parts when one gets into the nitty-gritty of

various mechanical and technical areas. If I was located in a

"cluster" area where cars were manufactured, I'm sure I'd have had a

much easier time with a lot of things.

But I think as the internet has further developed, some of

the handicaps are being removed, and that this trend will continue into

the

future. More information is more accessible, and it's getting easier to

access parts and services. Progress in manufacturing automation has

also progressed. With various computer controlled devices, for example

abrasive waterjet cutting of steel and 3D printing, many things that

used to require expensive design and setup or painstaking fabrication

with lathes, welders and milling machines, can now be designed on a

computer at home and done either there or at a local facility by

automatic machines. Low cost

services are available for making printed circuit boards in China

simply by e-mailing the design, with the finished boards being thrown

in the mail - no need for proximity there! - and there are now

automated PCB

assembly facilities even in Victoria BC. And prototype boards can be

done

in a day at home as I've been doing, with laser printer toner transfer

techniques.

As communication and distribution improve, more and more

we can have self-sustaining local communities.

Negative interest rates

Today bank deposits earn almost no interest. With

inflation, it's effectively negative interest rates - the buying power

of your savings shrinks. For many currency is safer at home in cash. (IF

it

can

be very well hidden, preferably divided into small packets, and

that doesn't mean somewhere in your bedroom. A hidden safe, well bolted

down, might be invaluable - they start at under 100$.) Or maybe

some in a non-bank account such as paypal. In some European countries

actual negative interest rates, albeit

small ones so far such as -.1 percent, have been applied to bank

accounts.

It's

hardly a way to watch your savings compound! In recent weeks there have

been mutterings from the US "Federal Reserve" banking corporation about

instituting "NIRP" (negative interest rate policy) in the USA. Such a

"policy" hardly seems designed to attract deposits. Indeed, it has been

noted that people in affected countries have been gradually withdrawing

their money. In order to combat this, rather than making banking more

attractive, there are plans, or at least ideas, afoot to ban cash in

order to force people to keep their money in the banks - to force them

to lend the banks their money regardless of negative rewards and risk -

and by

the way

allow the government to spy on and review each and every financial

transaction of every person - rather than keep it more safely (less

dangerously?) themselves in cash.

I tend to dismiss this problem

because I think the whole ponzy scheme global financial system will

crash before such a system could ever be implemented. One can never say

what surprise tricks might be used to "kick the can down the road" a

little longer, but personally I expect the can to grow a handle well

within a year. Then it will be a bucket, and the financial system will

suddenly "kick the bucket" on its next kick. NIRP or "bail-ins" (the

everywhere-threatened direct theft from deposits by government and

banks) might do it, or the bond bubble implosion, or derivatives

dominos, or running out of gold or silver, or there might be some

unexpected cause. Expect chaos to spread quickly when that happens and

last for years (2 or 3?) until the survivors figure out how to get

vital trade and food supplies moving again.

In the meantime, as long as negative interest rates are

fairly and

consistently applied to all, I am for them! In fact, I look forward

eagerly to getting interest payments from the banks based on my

mortgage and

credit card debts instead of having to pay out on them!

Another High Frequency Trading Scam

Last February the CAVirtex.com bitcoin exchange in Calgary

Alberta announced it was shutting down, citing "a security problem". It

was a complete surprise to all. It asked all account holders to

withdraw their

bitcoins and Canadian dollars amounts within the next month and close

their accounts, and trading ceased in March. I withdrew "everything",

but

as it wasn't possible to get everything exact, I had left over one

penny and something like .00012 bitcoins - trivia.

The next surprise was two or three weeks later, when

CAVirtex.com re-opened under new management. It didn't look like

anything had changed a whit. My account was still there with the small

change.

But I had already noticed in the weeks leading up to the

closing that suddenly most of the trades were being front-run by some

high-speed computing algorithm. This has become common on Wall Street

in the stock markets (and as usual there's no investigation, and no one

is ever charged or goes to

jail), but is a huge cash cow in the bitcoin market on

CAVirtex.

The price of bitcoin having risen recently, I decided to

sell some to pay expenses. Normally, when you go to buy bitcoin on an

exchange you

can look at the

trading page and either offer the amount of the lowest sell offer and

buy immediately, or you can make a lower offer and wait for someone who

will sell at your price.

Now (buying) if the lowest offer to sell bitcoin was for

500 $/BTC,

you can offer that price to buy immediately. But when you do, your

purchase instead goes through for 499.99 $/BTC. Afterward, the bitcoins

for sale at 500$ are still all there: the seller has sold nothing.

Instead, when you hit the last key or mouse click to buy, somehow

before your offer hits the exchange, it's intercepted, and instantly

someone else

puts in a sales offer for your exact amount of bitcoins at 499.99$.

That

499.99$ offer takes precedence over the 500$ and immediately goes

through, so fast that it never appears on anyones' computer

displays in the 'bitcoins offered', only in the 'completed

transactions'

section. Unless he looks down there, the only thing the offerer for

500$ sees is that none of his bitcoin has sold yet.

The same thing happens with selling bitcoin: if the

highest offer to buy is 470 $/BTC and you offer to sell for that much,

your

trade goes through instead for 470.01$, and the would-be buyer is left

high and dry. Instead, the front-runner, who just sold bitcoin at

499.99$ moments ago, now buys it back for 470.01$ and pockets the

29.98$ (less the exchange's transaction fee of .75 or .5%). If the

exchange trades 200 BTC a day and the spread is 30$, and

if 90% of the trades are front-run, the scammers are making 5400 $/day.

This money comes off the backs of everyone trying to buy and sell

bitcoins on the CAVirtex exchange, who can't make their trades go

through except by buying and selling at the asked and offered prices,

always getting the least "bang for the buck" with most of the trades

going through the hands of the scammers who pocket the difference.

This is just now appearing also on the Quadriga.com

bitcoin exchange in Vancouver: I just lost a sale for .75 BTC, with a

"sell" offer

for 1.00 bitcoins being posted as I watched and asking a dollar lower

than me, which proved to be exactly the amount of an offer to buy 1.00

bitcoins just before it appeared. It was visible on the listing for

just a few seconds before the trade went through. Then I looked at

'recent trades' and saw that they all had been for a dollar less than

my price. I don't remember that happening before.

It may be that

the scammers have acquired physical intercepts into the exchanges'

internet

lines, so that all the communication goes through their

equipment

first and their computers can pick and choose with every transaction.

This would be a variant of what's been done to the New York stock

exchanges for high frequency trading. It may even be that it was the

scammers who re-opened the CAVirtex exchange

after it was shut down. They could certainly afford to buy it with

their illicit profits, and they certainly have every incentive to keep

their

rigged game running! And then they even keep the transaction fees.

Perhaps more needs to be done through "local bitcoins" -

private buying and selling of bitcoins not through on-line exchanges.

Itchy Chocolate

I used to get unbearably itchy in my 20s, and I scratched

so much I now have various nasty moles and things on my back and chest.

When I was 29 I finally discovered it was from eating chocolate, which

I was eating a lot of. I quit eating chocolate and gained much relief.

A lot

of things give me migraines, including most processed or non-fresh milk

products including milk chocolate. But after over 30 years, I forgot

the other reason I don't eat chocolate, and I bought a big dark

chocolate bar

at a grocery - maybe dark chocolate wouldn't didn't give headaches like

milk chocolate? After having too much for 2 or 3 days, I was unbearably

itchy the next night. I thought maybe pollen, which I'm allergic to,

had somehow got on my bedsheets. As I washed them the next morning I

remembered about itching from chocolate. I related this to a friend and

gave him the rest of the chocolate bar. The next day he said he had had

several itchy sessions at night for no apparent reason. I thought it

was just my own allergy. Is this a common reaction? After a few days of

itchy chest, I also got a zit there, also doubtless from the chocolate

(not from the itching per se).

Book Barn Mini Library

In the middle of the month I finally finished a project

inspired by a "resilient streets" meeting in the spring and made from a

boulevard giveaway cabinet I put a cor.o.plast "roof" on: a very local

place for people to exchange books. A number of books have come and

gone. I think more 'duds' have come or remain, and more interesting

ones have gone. The books mostly seem to have come in three batches:

the ones I initially set out, a batch someone else brought, and a batch

of cookbooks from another person. At one point, some 'librarian' set

them all up nicely. Someone kicked in one door. I feared it might soon

be completely vandalized and wondered if it was silly even attempting

it, but it hasn't happened yet. Lately there's been a big plastic bag

over it to keep the heavy rain out.

I found a video of the original "Resilient Streets" book

boxes, and they were nicer, mounting on posts and with glass (lexan?)

doors that open, to keep the rain out.

Supercorder at Band & more interest in it

Having been asked to leave the "Intermediate" band because

my Supercorder "doesn't sound the same as a flute", in the last week of

October I re-joined the "Junior" band, where the conductor, and a few

players who said something had seemed to be missing without my sound,

seemed more than happy to have me back. As there were no oboes I'll

mostly

play oboe parts - and sometimes flute where the oboe part has nothing,

tho there are six flutes this year.

There was further interest in my instruments in an e-mail. Some

else wanting to experiment with improving recorders asked where I had

got my information. That was here and there, and I realized that if I

wrote up some "tips and principles" of recorder and supercorder design,

it might save people a lot of time and grief. Doing so further

contributed to delay in writing this newsletter. And I think expanding

on the subject, showing some of my jigs and techniques, might also be

more than helpful to potential makers, so I may take some more time out

to do so. There are lots of guitar and violin makers and doubtless lots

of books and plans for them, but there's

really not much info for an aspiring woodwind maker to go on.

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers

- Preliminary Ni-Mn, Ni-Ni Battery Making book

Products Catalog

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

Daily

Log

(time accounting, mainly for CRA - SR & ED assessment purposes)

Oct 1-4: More research on aerial energy

devices - Read Tesla's famous patent on the subject. (Also watched a

technical video about Bedini motor.) But mostly editing newsletter.

5: Picked up NiMH Honda Insight battery sticks & cleared through

customs.

6: Researching on aerial energy (a couple of good technical videos -

Ion Power Group, more).

7: Started laying out a PCB for a 555 timer based PWM control to

attempt some additional pulse strategies with the unipolar motor

controller.

8: Finished PCB layout

9: More video 'atmospheric

energy' studies.> (Inevitably some stuff on magnet motors too.)

10: Still more video 'atmospheric energy' studies.

11: -

12: ditto to 9th and 10th. I also spent quite a while writing an e-mail

to MicroMetals[.com] looking for advice on coil core types for the

motor controller.

13:

Bought heavy "battery" switch for grounding atmospheric energy receiver

antenna. (safety for electronic circuits and for people, esp. me.)

14: Bought a "gutter guard" aluminum plate to use for plate antenna.

15: Constructed atmospheric energy receiver antenna assembly and

mounted it up on peak of roof. (~40' elevation above ground)

16: Ran cable from antenna to solar panel/12 VDC equipment closet.

17: Major cleanup of the closet.

18: Formed a ceramic insulator set for the spark gap pieces.

19: Fired insulator set in kiln, mounted it in wiring closet.

20: Finished up wiring spark gap and grounding switch, added a small

shelf to place circuit breadboard on for trying things out.

21: Wired up coil, connected it to antenna, and tried a couple of

things. (No notable results)

24-25: family

26: Made PCB of PWM control

27: Drilled holes in PCB

28: Mounted components & tested & troubleshooted(?) PWM

control, mounted in controls box.

29-30: family

Nov 1: Atmospheric energy experiments.

2: (bad cold)

3: Testing motor with PWM controller.

4: cold

5: cold

6: cold

7: newsletter

Electric Hubcap Motor Systems - Electric Transport

Unipolar Motor

Controller

I decided to try pulsing the drive at a low frequency,

just a few pulses per second, like maybe 6 to 8. This idea goes back to

my earliest motor controllers... like the one that actually moved the

car, however feebly, with direct drive on the wheel in October 2008.

This feat was never repeated in spite of improving the motors. A

couple of times I had heard Toyota hybrids make the same sort of

pulsing sound

as they started moving on electric power.

By

repeatedly giving the transistors a brief rest the current, and hence

torque, can be permitted to go higher when they're on without

overheating them. I also suspect it's the way to get the best

performance out of an "active generator", where the motor controller

acts like a "regenerative braking" circuit and dumps power 'back' into

the 'supply'.

For the PWM generator I made a simple 555 timer based

pulse width modulation circuit to feed 7.8Hz PWM to the controller in

place of the simple analog potentiometer. That's the Schumann resonance

frequency, for want of any particular reason for any particular

frequency. (Any RF emitted would travel around the world in all

directions and back to the motor in that length of time, FWIW.)

I remembered doing such a PWM generator when I had first

started in on doing motor controllers, and I looked for it in my EAGLE

PCB files. I couldn't find it. But I knew I had it somewhere! Where was

the circuit and the board design? At length I remembered I had wired up

the first controller on a breadboard, so there was no PCB layout. I

found the circuit diagram (originally off the web somewhere) in the

last undamaged copy of the "early motor controllers" manual - an image

of the circuit drawn on paper with pencil and pencil crayons. I had

forgotten how primitively I started out on all this!

I did the schematic in EAGLE and the PCB layout on the 7th

and 8th. There was one aggravation: I had selected the DIP package of

the 555 timer and designed the board. Then I checked my stock and found

I had the SO08 surface mount package instead. To change it on the

single sided board meant it would mount on the bottom and so all the

pins were not just smaller but mirror imaged. So it all had to be

rerouted, taking 2 more hours, and it ended up needing a jumper, which

it hadn't originally. But at least I shrank the board to 1" x 1.2". I

would just solder it onto the back of a rotary potentiometer control to

'mount' it. External connections are +12 volts, Ground, and PwmOut

(7.8Hz, 5 volts).

I finally got around to printing the 555 timer based pulse

width modulator circuit board on the 22nd. Here are the files.

EAGLE PCB CAD

files:

555-PWM.sch - 555-PWM.brd

Ready to print artwork (2 copies) at 600 DPI, with the pads expanded in

a 'paint'

program (Graphic Converter) to make solid solder points

on a single sided PCB:

555-PWM-x2.png

Schematic:

R1 should be omitted entirely. C2 and C5 are just filters

- .1µF or whatever is fine for both. R3/(R2+R3) sets the output

voltage. The potentiometer and C4 set the frequency. As it says in the

schematic, f = 1/(1.4 * R * C). If my 500,000 ohm potentiometer is 1/2

way, that's 250,000 ohms in each direction. That's muddied a bit by the

diode drops, but we'll use it. Let's see...

7.8 Hz = 1/(1.4 * 250000 Ω * C4 [in Farads])

1.4 * 250000 * C = 1/7.8 Hz or

C = 1/(7.8 * 1.4 * 250000) or

C = 1/2730000 or

C = .3663 µF.

.4 µF gives 7.1 Hz. So how about four .1 µF capacitors in

parallel? (Perhaps I should have allowed for multiple capacitors on the

circuit board layout?) We still have the diode drops to consider,

and the frequency might skew as the pulse width is changed.

Image of (untested) V2 board

Image of (untested) V2 board

Artwork, first printed on paper (right),

Artwork, first printed on paper (right),

then on toner transfer paper taped to the original piece of paper and

run through the printer again (mid),

then laminated onto a copper faced circuit board (lower) with 10+

passes through the laminator,

then the board is etched to leave the desired patterns (top).

I only got around to the project again on the 26th, when I

printed and etched the PCB. The next day's puny accomplishment was to

drill the holes. On the 28th I finally soldered on the parts and tried

it out.

Testing disclosed a mistake in the design, a hangover from

copying the schematic from something a little different. "R1" (51K

ohms) should simply be omitted. After a couple of hours debugging and

changing the design and layout, measurements confirmed that the pulse

width varied the frequency somewhat, from 125mSec to 170mSec, frequency

range 5.9Hz to 8Hz. Target was 6 to 8 Hz, so that's great. Pulse width

can vary from under 1% to over 99% by

adjusting the potentiometer. The potentiometer with the PWM board

simply replaces the regular control pot and outputs a duty cycle at

about 7Hz at 100% amplitude (or adjusted lower via R2/R3) instead of an

analog voltage. It worked for me, and it seems it works for Toyota.

Then my brother from Toronto came to visit for a couple of

days and give me his cold. I figured having built the thing that I

could at least try it out, and on November 3rd I ran the motor with it.

It didn't seem too different from the analog operation except that the

on-off pulsing was quite distinct. I put the current meter on it and it

said up to 11 amps, same as before. I shortened the shunt by putting

the connection in the middle, and it went up to about 15 amps, and a

little higher RPM (225). Then I attached the oscilloscope to the

current

meter so I could really see what was happening. I got the following

waveform, shown at 3 time scales. (Upper white figure is time per

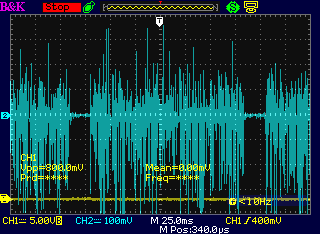

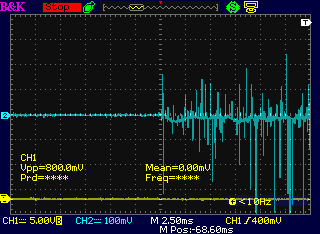

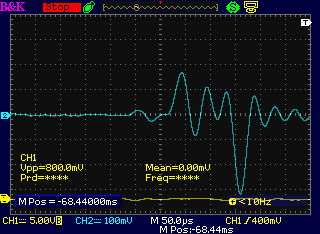

division.)

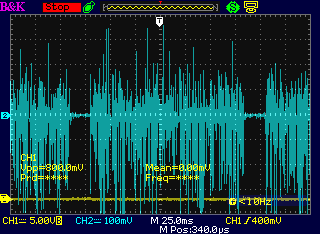

Power Supply/Battery Current via DC current clamp: Vertical scale is

100 amps per division.

Power Supply/Battery Current via DC current clamp: Vertical scale is

100 amps per division.

The 200 amp cutoff is

apparently a more approximate spec as made than expected, but it works.

Most 'on' pulses seem to stop at 100 amps, but a few go up

to 350 amps, and energy return pulses go down even beyond 400 amps.

Left: the overall 7Hz pattern, with a pulse duty

cycle of about 85%(?)

Middle: Beginning of the "on" section expanded 10x

Right: expanded another 50x.

An interesting feature is the high return currents as the

coils are switched off, apparently higher current than the input

current (but probably of shorter duration). Someone mentioned that the

return spikes would be about (or exactly?) twice as large as the

original current spikes. Apparently true for current as well as for

voltage... but wouldn't that make more power returning than entering?

The energy return coil

still gets hot rapidly. Now if I had only examined these waveforms with

the original analog speed control differences might be evident. Maybe

I'll try looking at that later.

Other

"Green" Electric Equipment Projects

Peltier Module / Thermoelectric Cooling

With the old 8.5 amp peltier module, it didn't seem to

make a big difference how fast the fan was running to carry off the

heat. With the new 15 amp one, it definitely cools better with the fan

on higher speed. With the internal fan and the larger peltier, the

whole fridge is now cooler, mostly 7 or 8 degrees C instead of 10 or

higher toward the far end, with the area near the ice tray being around

5 or 6, which it still is. (Lower winter room temperatures sometimes

lower that to about 4°.)

That brings us back to my desire for a quiet large

evacuated tube radiator, which would have sufficient cooling surfaces

to operate without a fan. I talked with someone I knew involved with

refrigeration. He said he had a double vacuum pump that would create

very high levels of vacuum. But if I had water in the tube, it would

evaporate and come out as water inside the pump, doing the pump no good

and leaving no water to boil in the pipe. I hadn't been able to make

the steam-out of the air work, and now I was disillusioned about my

alternative idea of simply sucking out the air.

But I soon had another thought. If one put the pipe with

the

water in the freezer, the water would freeze. Then the air could be

sucked out without sucking out the water. Now all I need is time to put

together a pipe with some sort of pinch-off end or other means of

sealing it, and go to my friend's shop and see how to best do it. (Does

he have a freezer?)

Electricity Generation

Atmospheric Charge Energy

Recap - What and from Where is Atmospheric Charge Energy?

The Earth is a giant dynamo with 200 million amps flowing

continuously around it. It might seem only natural that such current

provides the known electrical charges in the air, which voltage levels

may rise on a clear day by almost +100 volts per meter of altitude. So,

if the Earth is neutral in charge, there are more and more electron

deficient ions in the air as one ascends. This is what can electrocute

linemen touching unconnected power lines from tall, grounded towers,

and cause big sparks from cables hung from helicopters. Furthermore,

that voltage is an average. There is also a large AC component to it,

ebbing and flowing, according to Tesla, and to Moray it sounded through

headphones on an unconnected telegraph line like static, pulsating

rather like crashing waves, with big peaks followed by decreasing ones

until the next big one comes along. On a stormy day, moisture in the

air multiplies the effects by orders of magnitude, and the DC charge is

often reversed, with negatives at or above the clouds. Lightning is the

sudden discharge of the turbulent, highly charged air either to ground

or to a "nearby" air space with a different charge. But some of the

atmospheric electricity that causes lightning is always present, and

can be harvested in controlled, useful ways.

It is well known that a simple circuit of diodes and

capacitors can capture the ions that happen across its antenna,

producing a small current that can gradually charge a cellphone. (It

can also harvest from nearby power lines and radio signals.) A huge

antenna such as Ion Energy Group's is required to harvest much

power.

But it appears that an oscillating circuit such as those

made by TH Moray from 1926 to 1929, probably resonating with natural

frequencies of the energies, can multiply the energy, bringing the ions

to the antenna and generating vastly greater quantities of useful

electricity, apparently at ultrasonic or RF frequencies - LF, MF and

maybe HF. The difference is between milliwatts and kilowatts. A good

number of testimonials written at the time demonstrates that it did

indeed work as stated, leaving no credible possibility of a hoax. [A

compilation of them are here: http://svpvril.com/Moray.html

-- "Of the great number of learned men who have seen or heard of

Moray's work, not one of them has ever been able to disprove his

theories, claims and discoveries."]

This apparently first and very successful resonant

circuit atmospheric energy harvester used some unique components in his

circuit, and also never fully explained how his device worked. For

these reasons, no one ever managed to copy his design. One key device

was the world's first semiconductor diodes, made from "Swedish rock"

germanium, which even Moray, a mineralogy and crystallography materials

expert, was never able to adequately synthesize once he ran short of

the original natural material. Another device was his specially made

vacuum tubes with unique sounding operation that I won't attempt to

describe here. (He made three models of the tubes, that all worked in

the energy devices.) Moray described

the energy being harvested as "radiant energy" as he was aware that it

was radiant energy that ionized the air, but it seems he thought it was

the atmospheric

ions he was harvesting.

Soon corrupt interests sabotaged Moray's efforts to patent

anything at all, and tried to have him killed, apparently on three

occasions. Moray had become

suspicious and carried

a small gun, and he evidently kept his wits about him and was a very

good shot, because he came out alive on all three occasions. Finally a

jealous

person smashed his machine, and the work came to a sudden inglorious

end. (Moray went on, among other fascinating projects, to invent/design

improved (vacuum tube) radio receivers and amplifiers for well known

companies such as General Electric and Sylvania, which units graced

many homes up until the early to mid 1960.s when the first small,

portable Japanese "transistor radios" came out, followed by more modern

solid state stereo equipment in the late 1960.s. But I digress.)

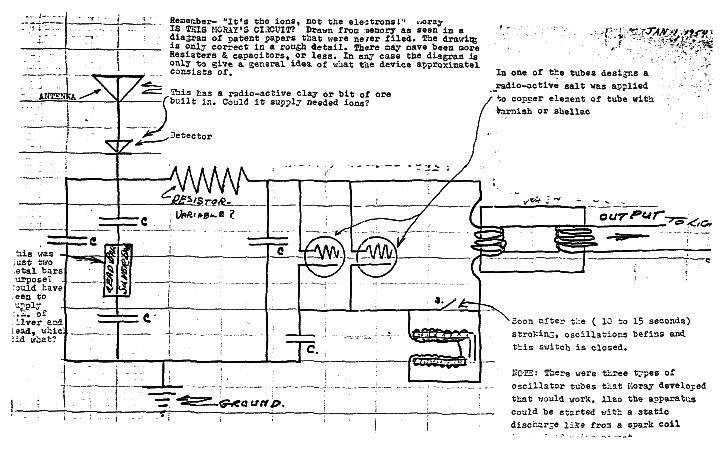

A researcher tried to draw Moray's energy harvesting

circuit schematic from memory from seeing it in the patent application.

(Moray's patent applications were denied on specious grounds, and the

contents of the application envelopes mysteriously disappeared from the

patent office.)

Of course the chances of it being mostly correct are

small. The person

didn't know what the bimetallic lead/silver piece was for, and its

placement between two capacitors (according to his memory) is even more

puzzling. (Doubtless all explained in the patent.) One recognizes

a potential L-C oscillator involving the two tubes with the lower coil

and switch, which (having no source of power until the unit was

working), had to be "stroked" with a magnet to get it started, at least

in the early units.

Today's problem is that while atmospheric charges are

better

known, the resonant oscillations technology for harvesting them

effectively has been little known or misunderstood and has never

spread. Only recently with the advent of the internet has it started to

become somewhat easier to separate facts from myths, and to find

nuggets of information about Moray's work and other more recent

apparently successful work. Still those with

nothing real to offer, perhaps some of them shills for the corrupt,

seem to shovel out all the disinformation they can, and by perpetrating

so many convincing and unconvincing hoaxes, make it seem like it must

all be hoaxes.

Yet we understand that the atmosphere is in fact full of

ionic energy. And that Moray's energy harvesting device worked to

the extent of at least several kilowatts, day or night. Today we have a

wide variety of electronic devices that were unavailable to Moray. One

person described the tubes as "oscillating tubes", and there are lots

of ways to make an oscillator. We have both germanium and silicon

diodes readily available, and active rectification if extra-low forward

voltage drop proves somehow instrumental to the harvesting. Surely in

the 21st century, Moray's pioneering work can be explored and expanded

upon. Even if there were no other, this well known - if not well

understood - form of plentiful free energy is all around us, seemingly

just waiting for appropriate circuits to be invented or reinvented in

order to harvest it!

Correction: The air-core coil I got last month (left) is about

25 microHenries, not 25 nanoHenries. (Small slip, BIG 1000x difference

when

designing a circuit!)

On the 6th I searched youtube for "Atmospheric

Electricity" and

found a channel called "LaserSaber", who had done some experiments in

that area, using a hexcopter to lift wire high up into the air. The

most interesting video was one where because of a high voltage

electrostatic motor (with considerable torque!) that he had built and

shown on youtube, he was invited

to visit Ion Power Group which has been working on harnessing

atmospheric energy for 10 years in Florida. I was impressed with

several things,

not the least of which was the many kilovolts coming down from the 4

antenna wires 130 feet up, strung between 4 poles in a very large

square. The danger of working with such high voltages was impressed on

me many times in the video, from heavy rubber gloves, to 6" long

ceramic

insulators, to a 1000 to 1 reduction voltage probe (reading ~9 = 9000

volts, or ~12 = 12000 another time),

to a continuous thick arc bridging a gap of nearly an inch on a

turbulent day, to 4' long

sticks used to hold and connect wires, to a giant shower of sparks

that lit the room from connecting something wrong. And they spoke of

250000

volts on a stormy day!

But they were using passive

collection. Their web site mentioned the collection of energy

"skyrockets by many orders of magnitude" when the atmosphere is

disturbed, but not that they had any

thought of electromagnetically disturbing it to get the same effect.

They had

big, high antenna lines and got energy, and used some streaming wires

with graphene that formed

micro-spikes that would multiply their charge collection by 10 via the

corona effect, but it

still wasn't the sort of high energy Moray was collecting with what

appeared to be resonant circuits -- except on stormy days, when they

got up to over a kilowatt. Moray got several kilowatts any day.

I plan to try out Moray's route...

with considerably more caution than I was thinking of and a much

smaller, lower antenna. (an

aluminum plate, tied to my chimney about 40' up?) Evidently it could

still make

potentially lethal voltages. But if I can make the resonance technique

work, it should still produce very useful power instead of milliwatts.

It occurred to me that a good place to start might be to

connect a diode or a diode bridge and a microampmeter (big needle, -50

to +50 µAmps) between an antenna and a ground wire and see what

DC current might flow. I could also hook the oscilloscope in there and

see the actual voltage waveforms instant to instant. With all the

nearly "mystical" talk about germanium, I got four 1N34 germanium

diodes for the bridge. From what I've been seeing the difference

between .3v (Ge) and .7v (Si) forward drop should be a drop in the

bucket. And

yet...

Then there's spark gaps. Apparently blue sparkles could be

seen running down Moray's "Swedish stone" germanium diodes. Did the

germanium crystals in his stones form tiny spark gaps? Is a spark gap a

diode? Maybe sort of. Depending how it's made, it

should be more prone to arcing in one direction of voltage than the

other,

again by the corona effect. There's no current at all until the arc

begins. (Then when current starts to flow, does the forward voltage

drop drop to zero?)

But I decided to make a spark gap as a safety device to

protect both my circuits and myself against overvoltage. On the 9th I

came

up with a tentative plan for a one: an outside surround of metal such

as a round or square pipe or tube, with a gold surface, perhaps simply

plated with gold, arcing to something like a stainless steel sewing

needle. The needle might be placed in-line, parallel, with the surround

metal, just an 8th, 16th or 32nd of an inch (or whatever seems to work

at a desirable voltage) from one edge. The surround metal (anode) goes

to the antenna at the top, and the needle (cathode) is grounded. Where

most metals will corrode and form an oxide

layer of some sort under positive voltage (anode) conditions that will

hinder arcing, gold, almost alone, is very difficult to oxidize. (I

wonder if my ~2004 Caswell Plating gold brush plating solution will

still work?) The metal tube could be inside an insulating plastic or

ceramic pipe, and the needle could be mounted in a big ceramic block...

after seeing all the arcs and sparks at Ion Energy's facility, I want

to try hard not to electrocute myself. Or get the radiation(?) burns

that Moray got on his hands, that were probably the same as those I

seemed to be being warned of in a dream. Maybe I should make some

ceramic parts first in my mini-kiln. And maybe the antenna will go next

after the spark gap to a big knife switch... enclosed in something...

that I operate from a distance with a plastic rod. It can also have a

shorting switch to ground to prevent high voltage from getting to the

circuits as the antenna is switched in - assuming I always

remember to turn the short on before activating the antenna. But

relying on memory for the switch-on sequence isn't a reliable

technique. Maybe if opening the knife switch automatically closes the

shorting switch. I think I like that idea. Well, doubtless I'd have to

make my own switches regardless to get that to happen!

And yet, from the passive designs I've seen, the voltage

builds quite gradually in the circuit when the antenna is connected.

Should it not be possible to make, eg, a 12 volt DC output unit, and

the oscillator shuts off momentarily or something shunts off the excess

if the voltage gets too high? Except at the spark gap and the knife

switch, with the circuit turned on there should be no high voltages. An

inverter can be used to change the 12 VDC to 120 VAC/60 Hz as required.

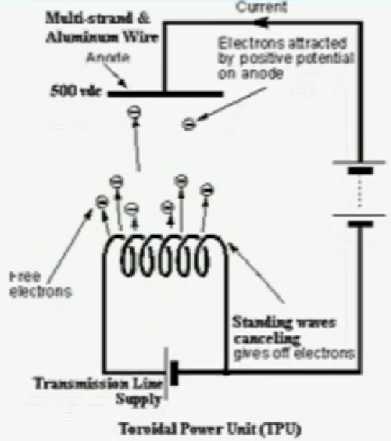

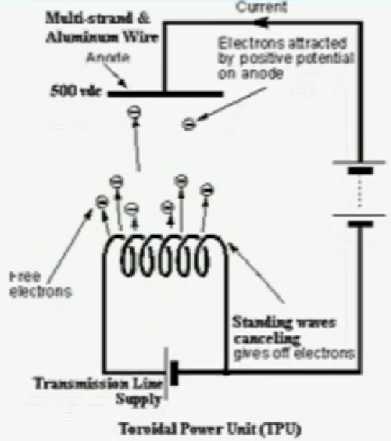

On youtube I found an explanation of sorts for active use

of a "spark gap" of sorts... a "Toroidal Power Unit" ("TPU") was shown

as being kind of like a vacuum tube effect with no vacuum, the

electrons flying toward a high voltage 'plus' plate.

I decided to use an "extension cord", a cable having an

outer sheath, for the antenna leed wire. I could drill a hole in the

roof near the chimney and feed it through. First I selected an aluminum

plate from my collection for the antenna. Next question was, what to

use for an insulated "mast" to hold up the antenna. I would tie this to

the chimney. (Say, how come I've never heard of people getting shocks

putting up or hooking up, eg, a TV antenna?)

Then on the 9th I thought that if the Ion Power Group was

using spikey bits of graphene not only to make lots of little spikes

but also to increase surface collection area in general, maybe an

aluminum window screen - lots of fine wires - would be better than a

plate. Or even such a screen with some graphite fiber wrapped around it?

On the 10th a considerable search with some clean-up found

the ±50µAmp meter, and a cable for the antenna connection,

but not the big knife switch. Further searching over the next couple of

days was to no avail. Who would ever dream I'd ever actually want to

use that antique?

Soon I decided I'd have to make my own special double

safety switch: Opening the antenna knife switch would automatically

close the safety ground-short switch to protect the electronics and

perhaps myself. Only once the antenna switch was reclosed could the

ground short switch be opened, allowing the antenna voltage to rise to

power up the circuit. The electronics itself would have some means of

preventing the antenna voltage from rising too high. So the electronics

need not be designed for high voltages, except perhaps for the

oscillator to 'stir' the air.

Then I realized that the antenna never needed to be

disconnected. If it was grounded everything was safe. It just needed a

simple knife switch, but to ground, not to the electronics, which could

always remain connected. I still couldn't find it. Perhaps I actually

threw out something that looked sort of interesting, just because I

couldn't think of a use for it? On the 12th I gave up and bought a new

large size switch, a battery switch from an automotive place. It's

probably better because the wires (in particular the antenna wire) are

enclosed.

On the 14th I

went to buy an aluminum screen. But I got a

thin, solid aluminum "gutter guard" instead. It was bigger in area than

my aluminum plate but it had holes to increase the surface area and to

let some wind go through. I thought about the idea of insulating it (it

was already painted), more particularly with a high dielectric constant

insulation. On the 15th I thought of the static cling of transparent

tape. Since I couldn't see wrapping it with countless skinny pieces of

that, I used packaging tape, which also has a lot of static cling. If

it makes all that static as it's unwound, surely it has the right

characteristics? (So much for the holes in the aluminum!) Then I

mounted this plate on a 5 foot PVC pole, clamped that to a piece of

wood, connected the cable, and tied it to the chimney at the peak of

the roof with a few wraps of rope, about 40' up from the ground. I

drilled a 3/8" hole through the roof, next to the peak and next to the

chimney, and pushed the cable through, into the attic space. The next

day I donned gear and ventured into the attic (full of

blown-in-fiberglass dust, cellulose fiber dust, rat droppings et al)

and ran the wire through to the solar equipment closet below.

On the 14th I

went to buy an aluminum screen. But I got a

thin, solid aluminum "gutter guard" instead. It was bigger in area than

my aluminum plate but it had holes to increase the surface area and to

let some wind go through. I thought about the idea of insulating it (it

was already painted), more particularly with a high dielectric constant

insulation. On the 15th I thought of the static cling of transparent

tape. Since I couldn't see wrapping it with countless skinny pieces of

that, I used packaging tape, which also has a lot of static cling. If

it makes all that static as it's unwound, surely it has the right

characteristics? (So much for the holes in the aluminum!) Then I

mounted this plate on a 5 foot PVC pole, clamped that to a piece of

wood, connected the cable, and tied it to the chimney at the peak of

the roof with a few wraps of rope, about 40' up from the ground. I

drilled a 3/8" hole through the roof, next to the peak and next to the

chimney, and pushed the cable through, into the attic space. The next

day I donned gear and ventured into the attic (full of

blown-in-fiberglass dust, cellulose fiber dust, rat droppings et al)

and ran the wire through to the solar equipment closet below.

Cleaning the closet occupied the next day's work session.

It was full of plaster and drywall compound from fixing the wall when I

first did the solar stuff along with crap from the holes for wires into

the attic, some firebricks and other bricks I had set dry cell

batteries on for fire safety, batteries lying around, and various bits

of electrical stuff, both on the floor and the shelves. I did a lot of

vacuuming. None of it my favorite work. But I think I'm digressing from

the story here. Comes of writing late at night.

On the 18th I

formed a couple of ceramic clay pieces for

an insulator to hold the spark gap. I left them to dry overnight, then

fired them in the mini kiln.

On the 18th I

formed a couple of ceramic clay pieces for

an insulator to hold the spark gap. I left them to dry overnight, then

fired them in the mini kiln.

On

the 19th I voted, marking my ballot 3 - 4 - 1 - 2 in my order of

preference for the candidates. No 'illiterate's X' ballots for me!

Hopefully it'll at least give the vote counters something to think

about!

Then I contrived to mount the spark gap and the antenna

grounding switch on the wall in the closet, and connected the antenna.

Then next day I added a couple of wires to connect to a nearby circuit

and put in a small shelf to hold a circuit 'breadboard' to try things

out. I measured the voltages from the antenna: .34 VAC, and -.012 to

-.02 VDC. Not only were the voltages trivial, the DC component was

backward compared to expectations. Quick attempts to hook up diodes and

2.2µF capacitors seemed to kill it. It turned out to be the

2.2µF ceramic capacitors, which *should* have virtually no

leakage. A .1µF capacitor charged up so slowly to over 1/2 a volt

(still backward polarity, with the diode either way around!), that

simply connecting the voltmeter - doubtless quite a high impedance unit

- caused the voltage to rapidly start dropping instead of rising.

Variations on the circuit seemed just as futile. Had I made a mistake

by insulating the antenna? It certainly appeared, as many have found,

that a simple diode-capacitor circuit doesn't bring in much power.

Others have had better (less trivial?) success on youtube. The

possibility remained that a resonant oscillator would revolutionize the

picture.

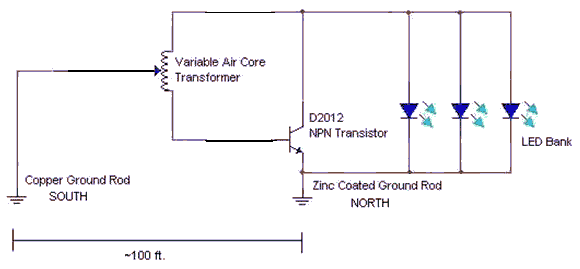

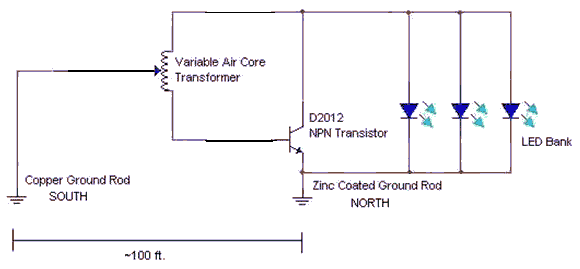

The next morning (21st) I looked again at the "Tesla Cult" circuit.

(but remember "ground rod south" was replaced by "antenna".) My antenna

voltage of only .34 VAC was hardly enough to overcome the forward

voltage drops of semiconductors. It didn't even seem to matter which

way around the 1N34 germanium diode was. But the coil with the tap, the

"variable air core transformer", would magnify the voltage by the ratio

of:

The next morning (21st) I looked again at the "Tesla Cult" circuit.

(but remember "ground rod south" was replaced by "antenna".) My antenna

voltage of only .34 VAC was hardly enough to overcome the forward

voltage drops of semiconductors. It didn't even seem to matter which

way around the 1N34 germanium diode was. But the coil with the tap, the

"variable air core transformer", would magnify the voltage by the ratio

of:

the whole coil

---------------------

the tapped portion.

If that was (say) 6 to 1, the tap 5/6 of the way to the bottom, it

would be .34v * 6 = 2.04v making the voltage high enough to work with.

The already feeble current would be similarly decreased by 6x, but it

seemed the voltage was too low to make good use of whatever current

there was anyway, so it's probably all gain. Here was the first key:

the coil makes for not just a resonant circuit, but an AC/RF voltage

multiplier. Here we get the impression that it may be more the AC

component of the atmospheric ions that is important than the DC one,

which can't be amplified by a transformer. But maybe it's the combo.

But when I connected the coil, the AC voltage dropped to zero. That

suggested a low frequency rather than RF.

Being busy with other things, it wasn't until the 31st I

brought over the

oscilloscope to better see what was coming in. With no other connection

to the antenna, the DC component was pretty much imperceptible and the

AC component was just mostly 60 Hz hum, .4V peak to peak - no surprise

in a wired house. There was another sinusoidal waveform on top of it at

about 1MHz, but only about 20mV peak to peak. This could have been a

nearby AM radio station - in fact the signal's amplitude modulated

probably about like music playing. Something else briefly appeared at

regular short intervals that seemed to be about 10 MHz, but it seemed

to be synced to the radio station. Nothing seemed anything like a

random sort of atmospheric noise, but it had an 'artificial' look to

it. I saw no lightning from distant thunderstorms but then it was

October, and we get less lightning on the west coast than anywhere else

on Earth. Where then was this atmospheric energy?

Nothing ventured nothing gained, it was time to breadboard

the oscillator. I thought I'd start with Tesla Cult's circuit since it

was simple. I plunked in the components and connection wires. Nothing

seemed to happen. That was as far as I got. Next will be a real

oscillator with a tuning capacitor to vary the frequency and a battery

to provide initial power to make sure it's working.

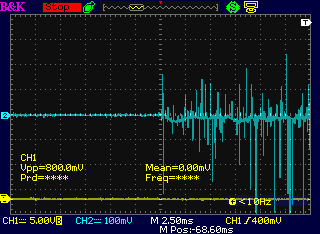

The test setup.

The test setup.

The red shielded wire comes from the antenna. The black wire

is grounded at an electrical outlet. The spark gap to ground is

to help protect circuits and ensure safety should high voltages

actually become present if it works. Likewise, the red switch

shorts the antenna to ground. I screwed a piece of wood into

a board in the closet wall to make a small shelf for trying out

circuits.

(The wires on the far right are from the solar PV panels and the

black box is the Zahn DC to DC converter that converts the solar

panels' output to 14.0 volts to charge NiMH and PbPb batteries and

for the 12V receptacles around the house, so far used for LED lights

and the Peltier fridge.)

Frankly as I write, I realize that I still have virtually

no success and far more questions than answers. Is atmospheric energy

worth pursuing or just a curiosity? Or is the seemingly elusive lambda

ray energy the only practical pursuit along these lines?

I think that a spark gap, like Moray's sparking mineral

diodes and like the "TPU" circuit diagram above, has some valuable if

not fundamental purpose in capturing lambda ray energy. But if so, just

how and where should it be employed? Perhaps the "TPU" illustration is

a clue - maybe it just makes a high frequency, high voltage diode?

Well, perhaps I'll try a bare metal antenna next, as the

dielectric coated one doesn't seem to do much of anything. One thing

sure: if anything I try yields success measured in tens of watts or

better, I'll document every aspect well so hopefully everyone can

achieve similar results.

Electricity Storage

-

Turquoise Battery Project Etc.

Lead? Lead?

On the 30th I was thinking about

the nickel-nickel cells that keep having more self discharge than

nickel-manganese, which are double the voltage. Something I don't

understand is going on there. Then I thought of zinc,

that elusive metal that works so well... except for gradually

dissolving during discharge (and sometimes shorting the cell) and so

giving short cycle life.

On the 30th I was thinking about

the nickel-nickel cells that keep having more self discharge than

nickel-manganese, which are double the voltage. Something I don't

understand is going on there. Then I thought of zinc,

that elusive metal that works so well... except for gradually

dissolving during discharge (and sometimes shorting the cell) and so

giving short cycle life.

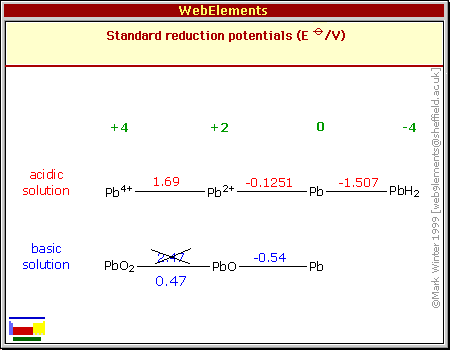

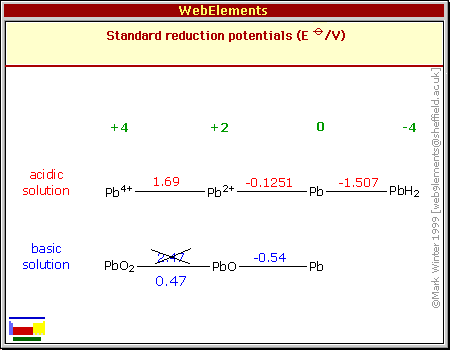

Then I thought of lead, similar to zinc in some ways, but

it doesn't dissolve even in sulfuric acid. I looked again at the

reduction potentials diagram. (the one that had steered me so wrong in

the past by having a wrong value printed on it.) In sulfuric acid,

metallic lead discharges to lead sulfate, PbSO4. This substance

gradually forms larger, non-conductive crystals that can't be

recharged, helping to give lead-acid batteries their well known limited

cycle life.

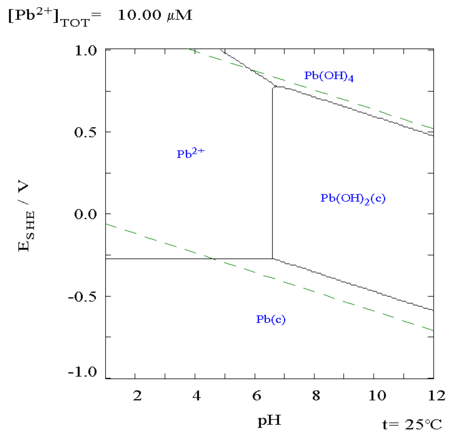

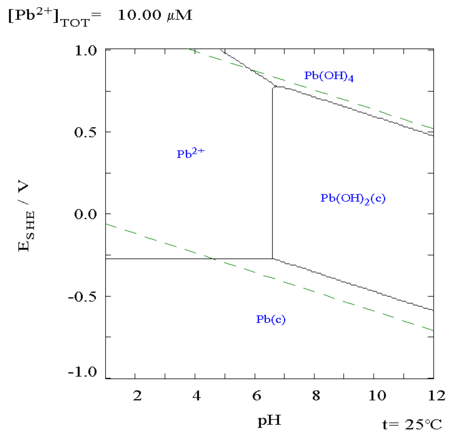

But in alkali the chart shows it discharging to lead

oxide, PbO. (or more likely to lead hydroxide Pb(OH)2 per the Pourbaix

diagram

below. It make little difference which it is.) This (surely?) won't

have such a problem. And the reaction

chart is dead simple - no branching tree or dissolved ion or

non-conductive states. (We know from lead-acid that batteries that PbO2

(or, surely, Pb(OH)4) is a conductor.) So unlike nickel-iron, I would

think it

shouldn't have to be used at pH 14 to prevent irreversible corrosion to

a non-conductive oxide form. It should thus have a very long cycle

life. As we all know lead has a high molecular weight (207.2), which

does little good for energy density (theoretically 259 WH/Kg for the

metal)... but might it work for me better than things I've tried? Might

nickel-lead provide a simple chemistry for small scale production which

has eluded me so far?

The reaction voltage of metallic lead to valence 2 is very

low in acid. But in alkali it's over 1/2 a volt. A nickel-lead cell in

KCl solution at pH 12-13 should work with a voltage of about +.85 -

-.54 = 1.39 volts, or maybe somewhat less. If it worked well, I'd be

farther ahead than I have been so far!

I decided the thing to do would be to take apart a

lead-acid battery and disassemble some of the plates. I have a simple

candidate in a small one about the size of a 'D' cell that has been

sitting around for years and has just turned up from a dusty cupboard.

Or maybe just find a chunk of lead for a quick experiment.

One is tempted to look above lead on the periodic table

for a lighter element in the same column. But the next one up is tin,

which has many soluble reactions. Above that are germanium, then

silicon, then carbon. Carbon, and probably silicon, wouldn't oxidize.

My mind balks at the idea that germanium might work even without

checking it out. Lead seems to be unique.

A separate possibly

useful lead reaction is Pb(OH)4 to Pb(OH)2 for

the positive electrode. It moves 2 electrons where simple NiOOH to

NiOHOH only moves 1. In alkali the theoretical reaction voltage is a

little lower than NiOOH. The high atomic weight gives it a

theoretical energy density of just 200 WH/Kg (at pH 12, counting the

atomic

weight of three 'OH's), versus 289 for the NiOOH (at pH 14).

A separate possibly

useful lead reaction is Pb(OH)4 to Pb(OH)2 for

the positive electrode. It moves 2 electrons where simple NiOOH to

NiOHOH only moves 1. In alkali the theoretical reaction voltage is a

little lower than NiOOH. The high atomic weight gives it a

theoretical energy density of just 200 WH/Kg (at pH 12, counting the

atomic

weight of three 'OH's), versus 289 for the NiOOH (at pH 14).

There are two ways this might be useful in place

of NiOOH.

The first is if it has significantly better percent utilization

of the

atoms. Then it might outperform the nickel, which I've heard somewhere

gets around 90 WH/Kg in actual use. The second is if a solid

piece of

lead reacts on the surface without the reaction penetrating deeper, ie

if the oxide layer that forms is solid and doesn't dissolve. In

that case, a lead

(Pb) wire in the positrode wouldn't dissolve, and the current collector

and connection wires can be lead (as they are in lead-acid batteries)

instead of graphite. That's not lighter but it's simpler to make and

promises better internal and external connections. (Potentially lead

leeds

would work for nickel hydroxide electrode current collectors in KCl,

too. IF

it works that way.)

But with decreasing pH, while still on the alkaline side,

the lead voltage rises more gradually than that of the nickel types, so

the cell voltage will be somewhat lower. Since that probably means both

lower voltage and lower amp-hours for lead, and as it seems to be

finding a good negative electrode I'm really having trouble with, I'll

probably leave the lead positrode idea well enough alone. Except maybe

I'll try out a lead terminal wire and see if it stands or dissolves. It