Turquoise

Energy Ltd. News #96

covering January 2016 (posted February 2nd 2016)

Victoria BC

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Month In Brief

(Project Summaries)

- Hands-On Democracy - Electric Hubcap motor, Chevy Sprint &

variable transmission (January's main focus) - NiNi Battery Chemistry:

salt bridge? - Bitcoin Miners/Mining

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Sea Levels Rising - Bank Problems Rising ($)

- In Depth

Project Reports -

Electric Transport - Electric Hubcap Motor Systems

* Electric Hubcap Motors: Rotor

Magnet Placement Jig, motor rebuilt with improved rotor.

* Variable Torque Converter Transmission/Chevy Sprint car

- installation progress: several essential parts made and

installed.

- Test shows centrifugal clutch doesn't engage well enough

at the low RPM.s involved: right idea but not good enough.

Other "Green"

Electric Equipment Projects (no reports)

Electricity Generation (no reports)

Electricity Storage - Turquoise Battery

Project (NiMn, NiNi), etc. (no reports)

No Project Reports on: Lambda ray

converter, CNC

gardening/farming machine, Electric Weel, unipolar motor controller,

reluctance motors, aquaponics.

January in Brief

I may be getting some money to help foster the

projects. The donation is to allow others to commit some of their time

to

assist. If it comes to pass, this will be an exciting development! I'll

have to

organize myself and the projects so as to put this blessing to best use.

I did nothing on the radiant energy receiver. It's surely

the most valuable energy project to get working, but I really wanted to

finish and test the variable speed transmission drive in the Sprint

car, which has sat mostly done for months if not a year.

Diverting again, I spent time in December and January at

last

getting my bitcoin miners running. This would have been better done

last spring, as the network difficulty was increasing so fast that by

January the bitcoin rewards from the mining pool didn't exceed the cost

of the electricity to run the miners, which, doing hundreds of billions

of complex calculations per second, use hundreds of watts. If

the big banks fail and their tens of thousands of bitcoin miners go

off-line, or if the price of bitcoin rises substantially, or if there

are free radiant energy converters, mining may

become profitable for the thousands of "little guys" again. On the

other hand, if the mining pools shut down, one will have to figure out

the added complexities of doing solo mining.

But it can still be still virtually free electric heat, if

one can put up with the fan noise. I've even hatched a plan to pre-heat

the hot water with them, blowing their warm-to-hot air through a box

with a

copper water tank in it. In the financial sense, it's "free energy" -

the same electricity but having a payback.

After months of working on new 'BLDC4-3' and reluctance

motor types and new 'unipolar' motor controllers, and figuring out how

to make a VHE lambda ray energy converter work, I decided it was really

high time to get back to the Electric Hubcap motor with the variable

transmission to make the 'ultra-efficient' Chevy Sprint car EV. Theoretically

there was nothing to stop it from working properly. Of course various

things could still go wrong. Especially, as half expected, the

centrifugal clutch proved to have insufficient grip at the RPM.s

involved.

The first step was to get an Electric Hubcap motor rotor

that would stand up to the Kelly controller. If it has no finesse at

low power and spins my motors madly at the slightest touch. It also

promises to be able to supply levels of torque and power that seem to

make my BLDC controllers burn out transistors - also meaning, levels

that could potentially put a car on the road.

Hands-On Democracy

Again diverting from energy projects, I decided to

write something to tie all my 'political structure' ideas together. I

started

thinking of a book, but later decided on a web site by the same name,

which may be: Hands-On Democracy - How to run a world. It

focuses especially on how decision making and voting can become much

more direct, by citizens, now that we have the internet. While we still

need chief executives and legislatures as well as judicial systems, we

certainly don't need to delegate so much power to them that they become

our rulers, looking for political spoils, instead of our

representatives and servants. Today we should be able to implement

various forms of direct decision making and citizen

ratification of governmental acts that retain control of the agenda and

really reserve final power to the people themselves - ourselves.

This may seem radical, but is it not a major tenet of

democracy that government should be of, for and by the people? That was

considered very radical in 1776 and there were surely plenty of people

who thought the experiment would be a speedy failure. It has only very

gradually been failing, and that because there was no realistic

provision for growth and change. It hasn't evolved along with the

advancing civilization it spawned, and unscrupulous people have figured

out how to twist and divert rigid political systems to do their bidding

instead of doing what's best for society. It's time now for that lack

of evolution to be remedied by changes that will restore final powers

of decision to the

people, who governments are supposed to serve.

I ended up writing a considerable introduction to the

subject. As I did so I became convinced that that may be the most

needed part considering that most people have given the whole subject

area little thought, and also to provide some broader perspective. We

habitually look at everything through the narrow, distorting lens of

our

enculturation. Meaningful change is hardly possible without being able

to view the subject from a broader, more objective viewpoint - to look

in from the outside.

As I was writing the intro, I started thinking of

narrating it as a video and uploading it to youtube. It will doubtless

reach far more people that way. But as for January, it was just one

more

unfinished project.

Electric Hubcap motor, Chevy Sprint & variable transmission

I really wanted to get this project, this unfinished

business, going again. I really do want the "ultra-efficient" car. I

had misgivings about the centrifugal clutch, but there was nothing to

be done with it until it was tested... after all, it just might work.

With

a new motor rotor I could reassemble the motor and get back to

the rest. But I decided I didn't want to just use the other similar

rotor, potentially subject to the same problems. Much of my trouble has

come from not building things robustly enough. In the last issue I

mentioned some ideas for improving the

rotors.

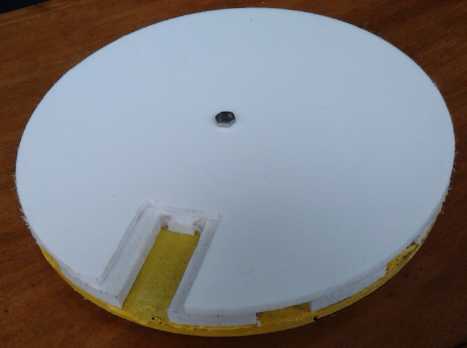

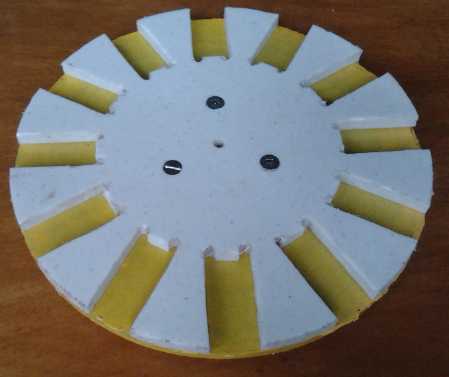

I

made the magnet placement jig I've been meaning to do

for so long, and a template to draw the strapping slot positions on the

rotor with felt pen.

I

made the magnet placement jig I've been meaning to do

for so long, and a template to draw the strapping slot positions on the

rotor with felt pen.

But when at last I went to rip the broken rotor apart

(14th) and recover the magnets from it, I found there was a good reason

it had come apart: the disk had been given a spray-on zinc anti-rust

coating. I had previously discovered on the first Electric Caik motor

that that spray-on zinc coating was feeble and would rip apart across

its whole surface as soon as the motor hit any decent RPM. This rotor

had been made just before the first Electric Caik. Somehow it had

lasted until I tried it with no load with the Kelly controller, which

had spun it up to high RPM.s almost instantly.

The other already made

rotor was the one with a zinc

coating done at Victoria Powder Coating. It had an entirely different

feel and it seems likely that it's much stronger. I decided to

"upgrade" it and use it, to mill the magnet strapping slots and add the

"round the magnet" strapping as a second layer. That (a) uses up the

'spare' rotor, (b) saves me from making another rotor in the

NNSSNNSSNNSS configuration that won't be wanted again, assuming I get

the unipolar controller working well.

Assuming the powder coated zinc is strong (unlike the

spray paint) and I can get it balanced, this rotor, and any future

rotors, should surely withstand 4000+ RPM and run fine rated up to

around

3000, instead of the 2000 RPM figure I've been working with.

On the

afternoon of the 15th I drilled holes in a dogwood

2x2" for a rotor clamp, clamped the rotor onto the milling machine, and

(not without some hiccups, and not very evenly) milled the slots to run

the strapping through, 3/16" wide by 3/4" long. Of course if these

motors are to be produced, the magnets will be aligned using the new

jig, and the slots will be cut by CNC abrasive waterjet along with the

other rotor disk edges. It was tedious getting the steel shavings off

the rotor magnets. (detailed report)

On the

afternoon of the 15th I drilled holes in a dogwood

2x2" for a rotor clamp, clamped the rotor onto the milling machine, and

(not without some hiccups, and not very evenly) milled the slots to run

the strapping through, 3/16" wide by 3/4" long. Of course if these

motors are to be produced, the magnets will be aligned using the new

jig, and the slots will be cut by CNC abrasive waterjet along with the

other rotor disk edges. It was tedious getting the steel shavings off

the rotor magnets. (detailed report)

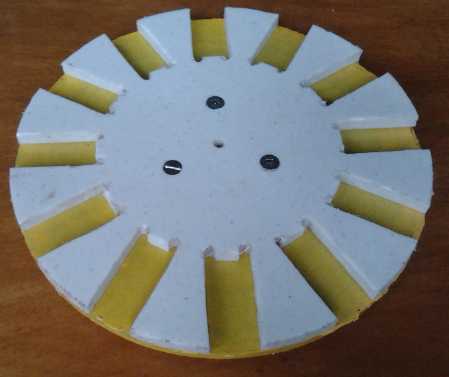

Next day (19th) I cut 12 straps of 1.5" wide by 9"

white polypropylene (PP) strapping, folded the ends, and fed them

through the

12 slots. Then I painted the tops of the magnets, the rotor surface

where the strapping would go, and the strapping. I pressed the

strapping into place and used a flat sheet of UHMW and some small steel

weights to hold it while the epoxy set.

Somehow the whole pace of the project had been less than

stellar - it was taking up the whole month! On the 21st I put the motor

back together. I added a couple of

spacer washers so the extra strapping thickness on the magnets wouldn't

rub on the stator-rotor separator wall. The flux gap ended up at just

over 1/2", which is probably about where it should be anyway. On the

second attempt the shaft still wasn't quite where I wanted it. I ended

up cutting the shaft holding the transmission ring gear 3/4" shorter to

adjust for the motor shaft. Shorter would probably be better anyway.

But another 1/4" would have been too short - it would have run into the

centrifugal clutch drum.

When I hooked it up and tried a test it wouldn't run.

Uh-oh, now what? Later I remembered it needed a jumper across the

ignition switch relay. With that connection the contactor clacked on,

and the motor ran. I'm confident it won't fly apart. The motor

going up to 3000 RPM or more would be more likely to activate the

centrifugal clutch than 2000 RPM. The next day (23rd) I reduced the

batteries to 24 volts. The

control seemed much finer and the motor didn't spin madly as soon as it

came on. That'll be better for testing.

That left one tricky mechanical part to build before an

initial test: the slipping pulley tension rope and tensioner,

controlled with the "gearshift" lever. On the 23rd I figured out a way

that looked like it should work with the rope pull at the top, and set

to making it. That day I made a midway clamp at the bottom, a flat bar

of metal between two bolts, clamping the rope under the bar to the

bottom motor mounting.

On the 25th I suddenly realized that with its helical gear

teeth, the planetary gear would push strongly to one side when there

was pressure on it. In forward all would be fine, but in reverse it

would slide out of the ring gear. It would need to be solidly held, not

just nudged into place by the tensioning rope. I spent that day

mounting a thrust bearing

on the motor shaft to hold it in place.

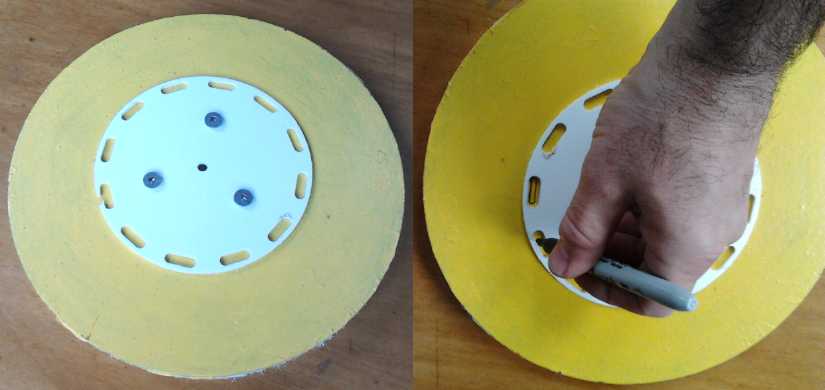

Pulley/Planetary Gear Assembly Side.

Pulley/Planetary Gear Assembly Side.

A washer with its inside trimmed to fit holds the bearing ring and

bearing.

On the motor side is a pipe with the motor

end notched to fit the protruding bolts,

and the other end hollowed out

to hold the other bearing ring.

Put together on the motor.

On the 28th I got back to the pulley tensioning mechanism.

I had found a piece of steel that might work as a lever. I cut it and

bent it to the shape I wanted, but

it didn't really look like it would work well and I set it aside.

Instead I beefed up the mounting with a new strut, as the whole

assembly had always been twisting to one side when it tried to drive

the car.

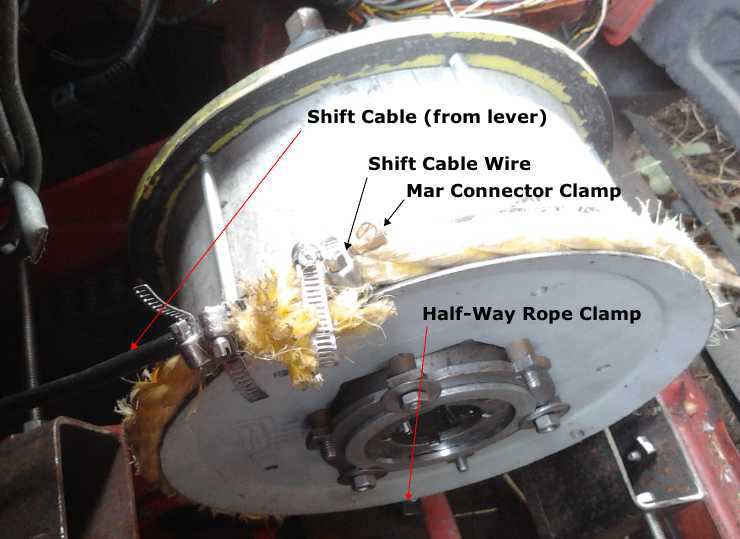

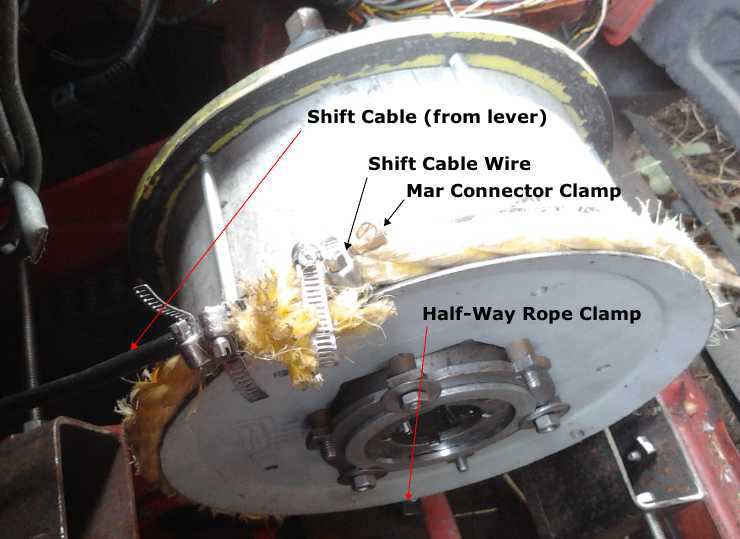

The evening of the next day I came up with what seemed

like a simple, effective new tensioner plan: simply strap the cable

sheath to one end of the rope and the cable to the other with pipe

clamps. When the shift lever was pulled backward and the cable pulled

into the sheath, the two rope ends would be pulled toward each other,

tightening the rope around the pulley as desired. I got some pipe

clamps and put it together the following day [30th], also using a 'mar'

connector's internal clamp piece to make a lump near the end of the

thin cable, to prevent it from slipping through the pipe clamps when

pulled. It seemed to work well, and the car drive was about ready to

test.

Under the Hood, Left to Right:

Under the Hood, Left to Right:

Hand-held test control box - Motor controller on heastsink &

aluminum plate -

Connection Wires - Electric Hubcap Motor - Thrust bearing (pipe)

and unseen sun gear on motor shaft -

Tensioner [planets] gear, pulley, rope - centrifugal clutch drum -

unseen planetary ring gear and clutch inner disk on floating shaft -

unseen chain drive to differential - cut-down trailer wheel hub with

its bearings holding the shaft.

I installed the motor and tested it on February 1st. Most

things seemed to work as planned. But, foreseen as a possibility, the

centrifugal clutch didn't engage strongly enough to start the car

moving. It will need some new ideas.

Nickel-Nickel Battery Chemistry Battery Development

Someone pointed me to open cell "nickel foam" available on

alibaba.com . Heretofore I could hardly find a pure nickel product for

sale anywhere, and when I did, the prices were preposterous. (An

exception was finding nickel powder, at MicronMetals.com) I never

thought of looking at the Chinese umbrella vendor group, "alibaba" or

"Aliexpress". There there are a wide variety of manufacturers or

dealers with various pure nickel products at reasonable prices. I found

some that was made for making battery electrodes. It seems the Chinese

want to do business, even if North Americans don't.

Open cell nickel foam should have a large surface area

wetted by the electrolyte, with all the particles well connected to

each other. Nickel powder could be sprinkled into it to further improve

everything, and it could still all be backed with the etched

cupro-nickel sheet metal, for an enormously conductive electrode with a

lot of amp-hours. (This would be the negative electrode, not the

positive that nickel would usually be used for in NiFe or NiMH. In the

alkaline but lower pH environment for NiNi, the positive has to use

graphite materials.)

And it occurred to me that perhaps I could be using that

gum arabic not only as a 'glue' for the powder, but as a barrier to

create a salt bridge between the electrodes, more or less in a dry cell

configuration rather than a flooded cell. That just might solve the

self-discharge problem. (Although, I'm still not sure of the reactions

causing that problem.)

I took the last 'pipe' cell I made apart and painted the

gum onto both sides of a new separator paper. It didn't seem to help.

OTOH, the positrode did a lot of crumbling, it was hard putting it back

together, and I wouldn't swear there was separation with the painted

paper everywhere. Nor would I swear gum arabic is a good substance to

make a salt bridge with to start with. It's soluble. It was just an

idea that could

be tried quickly.

Perhaps agar would be a better thing to try. I fact, agar is

specifically mentioned in the Wikipedia article on salt bridges. And

from that same article, I also got the idea to try another electrolyte.

Perhaps a sulfate salt like potassium sulfate wouldn't give the same

self-discharging effect as potassium chloride? I'm grasping at straws

because I don't know why it's doing it in the first place.

I painted up a separator paper with agar dissolved in hot

water. It jells as it's cooled, well above room temperature. I set that

aside to dry... and apparently set the whole project aside for the

entire rest of the month. I didn't even get the nickel foam ordered.

Bitcoin Miners

Another project I did some work on was the bitcoin miners.

"Mining bitcoins" means getting a reward in bitcoin for using special

computers to improve the operation and security of the bitcoin

blockchain.

I had ordered one in fall 2013, a "Butterfly Labs"

"Monarch". Instead of "installing" it in a computer, it simply

connected by USB. I had a "Raspberry Pi" single board computer that I

heard one could run them on.

(I had also ordered another "Babyjet" miner weeks

previously, but "Hashfast" went out of business without delivering it.

Vindictive customers sued it out of existence because of late delivery

-- even after they had at last delivered the first batch and were at

last ready to ship the rest. Only the lawyers will get anything. It was

a good thing I decided to order the Monarch as well.)

Because of the delays, Butterfly Labs sent 3 miners

instead(!), finally delivered in February 2015. It all comes of

ordering things that are still being designed. The price was greatly

reduced and I ordered two more. The only trouble then was, I couldn't

get them to work.

Finally in the summer I got a linux programming and

bitcoin guru to get them going. He found all the right parts and got it

to work for him. Things still didn't go well for me. I had to replace

the "RasPi" with a "RasPi B+". Twice I bought 5 power supplies that

weren't right and had to take or send them back, the "quality" powered

USB hub I bought to connect it all was crap, and the "pre-April 2015"

miners apparently had problems and would crash occasionally. I could

only hook one up to the Pi and have it run at all, and it would quit

working any time after 3 seconds to 3 hours and sit there until the

BFGMiner program was restarted. So by October I could mine with only

one miner, and

only when I was in the room to watch it like a hawk and keep restarting

it. Nearly useless without going 24/7. Butterfly labs tech support

wasn't much help. Messages went back and forth for 2 weeks with

questions and misunderstandings from him about things I had carefully

stated in my very first message.

By this time it was mid October. When too many bitcoins

are created in a two week period, the "mining" difficulty increases to

compensate. The mining difficulty was "60.9G". (whatever that figure

means.)

Finally in mid December I went into the "BFG Miner"

program code

myself. The usual error message was "Received unexpected queue result

response." I eventually located this phrase in one of the many files,

and since it never recovered from it, I changed it from printing that

to simply restarting the miner program. Then in all but fairly rare

cases with other errors (less than once a day), no matter how often it

boinked, it simply started over and continued 'mining'.

Near the end of December I ordered a new "Raspberry Pi 2

B". I thought I might need one for each miner and an ethernet router to

handle them all, but the new one had a quad core ARM processor running

over double the clock speed of the originals. To my amazement, I simply

unplugged the micro-SD card with all the hard-won software from the old

one and plugged it into the new one, and it worked. It booted much

faster, and with two miners attached, it all ran much longer without

stopping. Then I hooked up 4 (at two electric separate outlets on

different circuit breakers - 1820 watts). (With 4 it rarely runs half

an hour before stopping and restarting. So what?)

But by this time the mining difficulty had gone to 104G,

and before the end of January it hit 120G - double the October figure,

and hence 1/2 the rewards. Each 2 weeks I watched the "income" reading

from the

miner or miners drop. If I had got all five running last spring, I'd

have made hundreds of dollars a month. As it is, these power-hungry

beasts consume most or all of the income in hydro bills.

As

a mere handful of the biggest banks move in with tens of thousands of

bitcoin miner machines, probably set up wherever power is cheapest,

they have reduced the rewards more and more for the thousands of common

'private

miners' like me. (...and the many more former or would-be private

miners with now outdated mining equipment - or who perhaps never got

theirs running? The 4 biggest outfits - financial institutions of

some sort I presume - account for about 1/2 the total mining of the

pool with 20 quadrillion hashes per second out of 40.)

And so much time went by before I got it all running

because I always had other things to do -- especially, renewable energy

projects. And none of this is really long-term since all bitcoin mining

ends in 2022 IIRC, or sometime around then.

But if I use the miners in place of electric heaters that

would be running anyway, the bitcoin rewards pay (or almost pay) for

the power, and hence I can get "free" (tho rather noisy with the strong

fans) electric heat. (And you thought there was no "green energy'

connection!) Of course it doesn't generate or save any energy overall,

but with the bitcoin income applied against the electric bill, they'll

still eventually pay for the miners and equipment. On the 13th I found

some 15' long USB

cables so I could start spreading the miners around the house. (The guy

at London Drugs said 15' was about the limit for USB 2. Maybe another

USB hub can extend the range to reach the far rooms?) Then I can work

out

some mufflers for the noise. The other saving grace will be to get the

lambda ray converter making the electricity if I can manage that.

Needing 2420 watts continuously (if all 5 miners are running) is good

incentive! Then however slowly the income is generated, it's all income.

Otherwise, if I'm lucky, either the big banks will go out

of business

(seemingly inevitable) and their tens of thousands of miners will be

turned off or destroyed (hmm) and the mining difficulty will drop in

half, or the price of bitcoins will keep rising (pretty likely) and

they'll remain at least somewhat profitable as one gets less and less

coin. Or both.

Using the miners as hot water preheaters,

maybe isn't too far fetched either. The miners run at around

60°C according to their own internal temperature sensors. This is

inaccessible, but I measured the temperature of the air coming out of

the fans: about 37°C, from all 4 miners. (The following days, with

the house a little cooler because with the bitcoin miners running I

didn't bother to light the woodstove, they were all about 35°.) If

water could be raised to near that temperature, raised say from 10°

to 33°, it would be half way to the 55° I usually have my hot

water set at. If one put a copper water tank inside a fairly close

fitting box or tube with the warm air blowing in one end, it would

gradually get up to that temperature. That tank would then feed the

regular water tank - the usual arrangement for solar hot water, but

with no outdoor plumbing potentially subject to freezing. The warm air,

cooled as it flows through the box to the far end if the water is cold,

then comes out into the room to heat the room. If the air is often

coming out markedly cool, two or three miners could be used to provide

more heat. The water heater elements as well as electric space heaters

"waste electricity" by not producing any bitcoin, and this would cut

their 'on' time way down.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Rising Sea Levels

People talk of global warming. For quite a while I wasn't

convinced, and plenty of people still think it's a myth. Recently there

have been alarming documentaries on melting glaciers and melting

permafrost. It looks to me like the warming timeline has been

drastically speeded up by geoengineering.

Now the effects are becoming

definitely evident. Not only are trees budding here in January instead

of

February or March, but ocean levels definitely appear to be rising.

Once about 15 years ago, an El Niño plus torrential rain on the

mainland causing the Fraser river to flow a deluge into the strait,

plus a high tide but with no large waves, caused the harbor to reach

the

lowest areas of the concrete sea walk level and deposit ocean debris on

it. This was a unique event until this winter.

This winter the water has seemed surprisingly close to the

lowest walk levels on a number of occasions when I was there, and

several times has reached it - I saw ocean debris deposited on it. Once

I had to wait for a low ebb between small waves and run across a

certain spot. I have never seen the water way up there before, and it

was only 6" lower the next time I went to that location.

By itself this could indicate the land around Victoria BC

is sinking. But we now frequently hear in the news (at least on

Youtube) of record flooding during storms in coastal areas in various

places, indicating it's a global phenomenon -- the rising sea levels

that are only to be expected from melting of glaciers in Greenland,

Iceland, the Rockies, Andes and Alps mountains, not to mention at the

poles. What havoc

will a ten foot rise wreak around the world? What will happen in

crowded Bangladesh where I hear 100 miles inland the elevation is still

just 10' above sea level? Where will all those people go?

Rising Bank Dangers

People have been warning that the global banking system

must fail for some years now, and that the banks as whole are all

linked together and overall, insolvent. Few cracks are visible on the

surface. Precious metal prices have been suppressed, and stock markets

have been propped up, probably with a trillion dollars of artificial

stock buying by government agencies. But now commodity prices are also

falling as monetary liquidity dries up through the whole economy. Some

predicted this "deflationary debt collapse" (to be followed by

hyperinflation), for example Mike Maloney ("Hidden Secrets of Money"

video series) and Harry Dent, who points out how demographics of aging

populations aren't going to consume like young families.

Now we're starting to see how this might play out with the

banks: "non-performing loans". There are trillions and trillions of

dollars worth of foreclosed mortgages (with falling house prices and no

buyers), defaulted car loans, defaulting credit card debt, unpayable

student loans (no jobs for grads), and defaulting corporate debt as

companies downsize and go out of business, as they are doing across the

board - their ex-employees swelling the ranks of the unemployed. Even

Wallmart is closing around 260 stores, 150 in the USA. Global shipping

(the "Baltic Dry Index") is hitting record lows of cargo tonnage, which

is being matched by rail and truck freight traffic on land. A large

shipping company spokesman said in January they didn't have one ship at

sea in the Atlantic. They were all sitting in ports waiting for enough

cargo to bother sailing.

Notably, upcoming bankruptcies will include most all the

"fracking" companies, to whom the banks loaned a trillion dollars when

oil prices were far higher. These were never viable overall to start

with, and now even the best producing "established wells" operate at

huge losses, and cheap Iranian oil is just coming on line to drive the

price down further. The Alberta tarsands is in the same position.

If the governments print money to bail out the banks,

hyperinflation will come. Otherwise a "bank holiday" one fine weekend

(they may blame "a technical glitch") followed by the "bail-ins"

(exchange of depositors' money for worthless bank stock) and "capital

controls" (can only take out your money a bit at a time) surely has to

be in the works.

There is now a chorus of voices rising from the swamp like

frogs croaking, saying "Get your money out of the banks!" There are

many good suggestions for converting it into real goods and precious

metals and for keeping a good chunk of cash well hidden.

You could also transfer money to your PayPal account (or

perhaps even to an account on a bitcoin exchange - with or without

buying bitcoin?), institutions which hold your funds electronically but

which aren't banks -- they don't lend out or invest your money and so

have no "non-performing loans" or "derivatives" where your savings are

being lost. So they should survive a banking system collapse.

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers

- Preliminary Ni-Mn, Ni-Ni Battery Making book

Products Catalog

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

Daily

Log

(time accounting, mainly for CRA - SR & ED assessment purposes)

January 1-3: Writing previous newsletter

4: Enquired about "nickel foam" for battery electrodes to

Chinese/Alibaba.com supplier.

5: Tried "gum arabic" as a salt bridge in Ni-Ni battery. It didn't seem

to help.

8: Make Hubcap Motor Magnet Jig: Tried to transfer G-Code spreadsheet

data from Netbook to new Tablet - had to buy cable.

9: Couldn't find a spreadsheet program that would run on the Tablet!

10: Did spreadsheet on the netbook. Made up G-Code program on CNC

machine computer. A number was a bit off and the magnets didn't quite

fit.

11: Bought more plastic and made 2nd one.

12: Made top piece for it.

13: Made template piece to help place milled slots.

14: Ripped failed Hubcap Motor rotor apart. (Found rotor failure was

due to zinc anti-rust spray paint on rotor.)

15: Milled slots in "spare" motor rotor (motor to be used in Variable

Transmission/Sprint car tests).

19: Epoxied the strapping to the rotor magnets.

21: Assembled the motor

22: Adjusted (cut) transmission shaft length to match motor shaft, and

mounted motor in Sprint. Tested motor - ran great!

23: Figured out plan for tension rope attachment and operation. Made

center clamp for rope at bottom of control/tension pulley.

24:

25: Made thrust bearing mounting system to prevent tension

pulley/planet gear assembly from pressing sideways.

26: Worked on "Hands-On Democracy - How to run a world" text.

27:

28: Made support strut for motor/transmission housing to prevent it

from twisting under load.

29: Figured out that pipe clamps and the wire clamp from inside a mar

connector could be used to hold the activation cable to the tensioning

rope and pull it tight from the gear shift lever.

30: Bought pipe clamps and made/installed the linkage. It seemed to

work well but I had paperwork to do for Canada Revenue before they

fined me another 100$ for late submission, so I at last set about that

instead of installing the motor and testing the completed car drive.

31:

Feb 1: Installed motor in Sprint and tested operation.

Feb 2: Working on this newsletter.

Electric Hubcap Motor Systems - Electric Transport

Electric Hubcap motor, Chevy

Sprint & Variable Transmission

I really wanted to get this project, this unfinished

business, going

again. I really do want the "ultra-efficient" car. Development of the

new motors and controllers is dragging on, and theoretically I already

had the required components for this. With a new motor rotor I could

reassemble

the motor and get back to

the rest. But I decided I didn't want to just use the other similar

rotor, potentially subject to the same problems. Much of my trouble has

come from not building things robustly enough. In the last issue I

mentioned some ideas for improving the

rotors.

I thought maybe this was something I could get someone at

AGO to do

if I had cash. I had the CNC drill-router to make a plastic piece with

magnet holes in it, but rather than do it all manually on a spreadsheet

again, perhaps someone could pick out a proper CAD program like the

"Rhino Express" that Victoria Waterjet uses, and figure out how to

apply it to my machine. Then it would be almost trivial, like at

Victoria Waterjet. Then a "DXF to G-Code" converter that made

compatible G-Code would still be needed... or a G-Code program that

would work with my router, bypassing my present software entirely.

It has occurred to me more than once that a solid lip on

the outside

of the rotor that the magnets would butt solidly against would be a

great asset. To my mind, the biggest advantage of the outer drum rotor

motor type, with the coils inside, is that the magnets are pressed

against the inside of the drum when spinning. The RPM could be very

high before the magnets would start coming loose, and even if loose,

they could hardly fly off. But to put a lip on a disk rotor seemed

pretty tricky. A fatter disk could be milled on a lathe, but that would

be an awful lot of milling. And the steel, "shorting" the outside of

the

magnetic circuit, would interfere (if only a little) with the magnetic

field. Welding a non-magnetic stainless steel ring around the outside

might be the most practical. At least 3/16" thick? and as wide as the

magnet thickness - but then it would need slots or holes

between the magnets for centrifugal air fan flow. Better still... no

holes

in the rim ring: drill them through the rotor disk itself, between

magnets out near the rim. (Yes, I think I like this. But it would be

quite a project with my meager welding skills and no curve bender. Hmm!

I could probably find 3/16" x 3/4" S/S bar... and use the steel roller

at Makerspace to bend it into a ring. So I should actually be able to

make a good ring. Then use lots of weld and grind it smooth later. Hmm!

More robust! How bad do I want to build that?)

As usual, having given the project thought and with no one

else

around, I started in on it myself. I decided to do it with the PP

strapping wrapped through slots in the rotor after all. My mind spaced

out on the fact that by gluing the magnets on I was committing to doing

one layout, NNSSNNSSNNSS or NSNSNSNSNSNS. I couldn't easily change it

later. I decided on the former since the Kelly BLCD motor controller

still looks

like the best bet for now.

I thought I'd

just make a magnet placement jig using the

usual

spreadsheet for the G-Code, but I'd try doing it on my new RCA Android

tablet - No annoying fan or drive whirring away as you work! First

finding an adapter to hook up a USB memory stick having a template

spreadsheet on it took a day. Then another couple of days passed before

I found that I couldn't find a spreadsheet program that worked.

I thought I'd

just make a magnet placement jig using the

usual

spreadsheet for the G-Code, but I'd try doing it on my new RCA Android

tablet - No annoying fan or drive whirring away as you work! First

finding an adapter to hook up a USB memory stick having a template

spreadsheet on it took a day. Then another couple of days passed before

I found that I couldn't find a spreadsheet program that worked.

So! Another couple of hours on the old netbook (sines and

cosines on

the spreadsheet) and on the drill-router's computer (final G-Code file)

got the program done. But I had a mistake, one number I got wrong in

the spreadsheet but close enough that I didn't notice it on the screen

image. The magnets didn't quite fit in some of the slots. The next day

I looked for more plastic. I had been 'lucky' enough to find one piece

stashed away, and had now ruined it. Instead of getting UHMW at

Industrial Plastics, I found some kitchen cutting boards that were the

same stuff but doubtless cheaper. (Retail plastic is cheaper than

"industrial supply" in Victoria!?!) I cut the main piece that day and

the cover piece the next. Let's see... Friday, Saturday, Sunday,

Monday, Tuesday. For one lousy magnet jig! Somehow, I just had to pick

up the pace!

The next step was to

mill slots in the rotor for the magnet holding straps. Then I realized

I could have also cut slots in the jig to mark off in crayon or felt

pen where to mill the slots in the rotor where the straps go through

it. Rats! I decided to make another jig/template for that purpose. The

more uniform everything is, the better balanced the rotor will be. If

it's well balanced and the magnets strongly attached, perhaps it can

withstand 4000 RPM or more and be "rated" for 3000 in regular operation

instead of

the 2000 RPM max figure I've been working with. That would give the

motors more

flexibility.

Anyway I made it in 1/8" plastic instead of 1/2", which is

easier to

get a felt pen into to trace out the slots. I'd have liked to have the

slots 1.5" wide for 1.5" wide strapping, but that would cut a complete

circle around the rotor, breaking it into two pieces. I made them about

3/4". The strapping would just have to fold through them. (That worked

out well - better.) I designed and made the template on the morning of

the 13th, so at least the pace was improving.

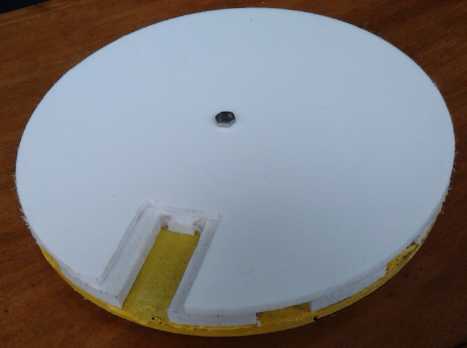

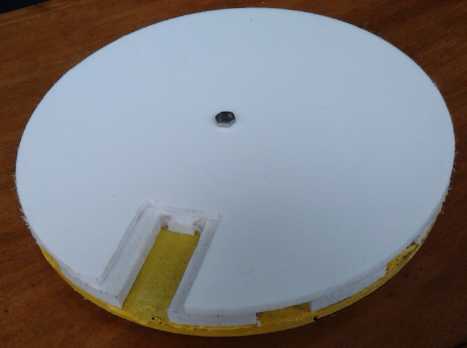

The slot template

The slot template

But when at

last I went to rip the broken rotor apart (14th) and

recover the magnets from it, I found there was a good reason it had

come apart. I thought the epoxy was pasted on the plain steel disk, but

I discovered the disk had been given a spray-on zinc anti-rust coating.

I had previously discovered on the first Electric Caik motor that that

spray-on zinc coating was feeble and would rip apart across its whole

surface as soon as the motor hit any decent RPM. This rotor had been

made just before the first Electric Caik. Somehow it had lasted until I

tried it with no load with the Kelly controller, which had spun it up

to high RPM.s almost instantly.

But when at

last I went to rip the broken rotor apart (14th) and

recover the magnets from it, I found there was a good reason it had

come apart. I thought the epoxy was pasted on the plain steel disk, but

I discovered the disk had been given a spray-on zinc anti-rust coating.

I had previously discovered on the first Electric Caik motor that that

spray-on zinc coating was feeble and would rip apart across its whole

surface as soon as the motor hit any decent RPM. This rotor had been

made just before the first Electric Caik. Somehow it had lasted until I

tried it with no load with the Kelly controller, which had spun it up

to high RPM.s almost instantly.

Without meaning to take away from the force of everything

above

about improving the rotors, this put a different complexion on things.

Without the spray-on zinc coating, the rotors were doubtless much more

robust than I had been giving them credit for. The other rotor was the

one with a zinc coating done at Victoria Powder Coating. I couldn't

think of a way to test it except the same way as the previous rotor,

but it had an entirely different feel and it seemed likely that it was

much stronger. I decided to "upgrade" it and use it. Forget the outer

rim. I would sand the existing strapping to thin and even it, and to

roughen the surface. Then I'd mill the magnet strapping slots

(notwithstanding that the magnets would make everything harder to do),

and add the "round the magnet" strapping as a second layer. That will

(a) use up the 'spare' rotor, and (b) save me from making another rotor

in

the NNSSNNSSNNSS configuration that I expect won't be wanted again -

assuming I get the unipolar controller working well.

I looked somewhat dubiously at the rotor with its slightly

crooked,

unevenly spaced magnets. Now it looks amateurish. The new jig would

have fit them on perfectly. But it would do. Assuming the powder coated

zinc is strong (unlike the spray paint) and I can get it balanced, this

rotor should surely do the 4000+ RPM and run fine at 3000. If it

isn't, magnets will break off and I'll end up ripping it all apart,

sanding the remaining coating off, and redoing it all. (So far all is

fine, after some run-ups and other trials with the Kelly controller.)

But how to do the milling? If the magnets faced down, the

rotor

would clamp onto the carriage really hard. It would be hard to move and

remove not to mention dangerous, yet couldn't be trusted not to shift

while milling. If they were up, it had better be well clamped when the

bit and chuck came near, yet the magnets would grab everything that

came near including the clamping piece. I finally hit on the idea of

using a stiff board just a little longer than the rotor diameter, with

a hole at each end to bolt it down with stainless steel screws. Ideally

I'd want the rotor to turn on its center to get each slot exactly

aligned. The board and eyeballing it will do. By this time it was late

afternoon and I had an evening engagement. Well, mañana!

Next, would I

just have to put up with painstakingly

pulling the

shards from the magnets afterward, or could I fit something into the

narrow spaces that I could pull off later, along with the shards? Tape?

How about duct seal or modeling clay?

Next, would I

just have to put up with painstakingly

pulling the

shards from the magnets afterward, or could I fit something into the

narrow spaces that I could pull off later, along with the shards? Tape?

How about duct seal or modeling clay?

On the afternoon of the 15th I drilled holes in a dogwood

2x2" for a

clamp, clamped the rotor onto the milling machine, and started. My 1/8"

milling bit soon snapped (oops!), and I went to shop for another one.

It was too late in the afternoon and the road to KMS Tools was blocked

with daily traffic. I tried a couple of nearby 'hardware' stores to no

avail,

and Western Equipment didn't have any 1/8". Finally I hit AGO on my way

home. "Why so tiny?" asked the machinist. Okay, if he considered that

tiny, maybe I should go bigger? "How about 3/16"?" He gave me one. I

went home and got 3 slots milled before dinner. The other 9 took up the

rest of the evening. I sharpened it a couple of times. There's nothing

fast about milling steel, even mild steel. And in spite of the

template, the slot placements and lengths weren't even. This was

probably inevitable since the placement of the magnets they were

supposed to line up with weren't the best to start with. Of course if

more of these motors are to be produced, the magnets will be aligned

with the new jig, and the slots will be cut by CNC abrasive waterjet

along with the other rotor disk features. Hopefully this is a one-off,

tho I have a couple more slotless rotors left if I do make more BLDC

type motors.

I used duct seal pasted against the magnets to try to

capture the

shavings,

but it was only partly effective and there were plenty left. I tried

blowing them off with compressed air, to no avail. Trying to pick them

off by hand led inevitably to tiny, sharp steel slivers.

I didn't get at it on the weekend. On Monday (18th) I

got out

another supermagnet and held it with vise-grips, and stuck a thin round

file to that magnet, also holding the file with my hand, with the

smooth and pointed grip end sticking out. (A very long nail might have

worked just as well.) I put a leather glove on my other hand. Whereas

two supermagnets clamped strongly together, it was pretty easy to pull

the long, thin file away from the rotor magnets. But some of the

filings on each rotor magnet stuck to the file as I touched it then

pulled it away, because it was being supplied with magnetism by the

supermagnet in the vise-grips. And charge tends to collect at a point,

like the end of the file and even the round side. Then I ran my gloved

fingers down the file,

pushing the shavings off the end and dropping them into the garbage

bucket. After quite a while of this rather tedious procedure the rotor

looked much cleaner. I sanded the tops of the magnets (wooden sanding

block) to remove any projections and roughen the surface, and called it

"good enough".

Next day

(19th) I cut 12 straps of 1.5" wide by 9"

white polypropylene

(PP) strapping, folded the ends, and fed them through the 12 slots. The

ends overlap behind, making them a double thickness over most of their

length on the back of the rotor.

Then I prepared a flat surface and put a sheet of polyethylene (PE) on

it so the epoxy wouldn't stick. I mixed about 70g of epoxy and used a

1" brush to paint the tops of the magnets and the strapping from the

inside. (It was barely enough epoxy.) Then the outside over the

magnets. After it was all on I turned the

rotor over so the magnets were down and pressed against the PE on the

flat surface - so nothing extra would stick out from the flat tops of

the magnets. Then I painted the rotor disk back and the rest of the

straps and pulled both ends tight and stuck them down. Then a small

piece of PE and a small steel weight went over each one to hold it

while the epoxy set. That wouldn't hold the PP stretched, but will

avoid

protruding ends and I trust hold well enough to ensure the magnets

never come loose. When it was mostly set, I turned over the rotor and

found there were "bubbles", disconnects, between the magnets and the

strapping in many places. I pulled the weights and PE bits off the back

and put them on the magnets. It wasn't easy to get them to stay in

place on top of each magnet, as they wanted to slide magnetically

across the still slightly gooey epoxy to join adjacent magnets of

opposite polarity. I ended up breaking up some styrene foam pieces to

hold them apart. If it wasn't for the strong magnetic press on the

steel weights, I'd have worried that the epoxy was too much set to join

up. As it was I was sure they would be well bonded. Actually the

picture shows from the lack of solid black shadows that there were

still air bubbles. But it seemed good enough.

Next day

(19th) I cut 12 straps of 1.5" wide by 9"

white polypropylene

(PP) strapping, folded the ends, and fed them through the 12 slots. The

ends overlap behind, making them a double thickness over most of their

length on the back of the rotor.

Then I prepared a flat surface and put a sheet of polyethylene (PE) on

it so the epoxy wouldn't stick. I mixed about 70g of epoxy and used a

1" brush to paint the tops of the magnets and the strapping from the

inside. (It was barely enough epoxy.) Then the outside over the

magnets. After it was all on I turned the

rotor over so the magnets were down and pressed against the PE on the

flat surface - so nothing extra would stick out from the flat tops of

the magnets. Then I painted the rotor disk back and the rest of the

straps and pulled both ends tight and stuck them down. Then a small

piece of PE and a small steel weight went over each one to hold it

while the epoxy set. That wouldn't hold the PP stretched, but will

avoid

protruding ends and I trust hold well enough to ensure the magnets

never come loose. When it was mostly set, I turned over the rotor and

found there were "bubbles", disconnects, between the magnets and the

strapping in many places. I pulled the weights and PE bits off the back

and put them on the magnets. It wasn't easy to get them to stay in

place on top of each magnet, as they wanted to slide magnetically

across the still slightly gooey epoxy to join adjacent magnets of

opposite polarity. I ended up breaking up some styrene foam pieces to

hold them apart. If it wasn't for the strong magnetic press on the

steel weights, I'd have worried that the epoxy was too much set to join

up. As it was I was sure they would be well bonded. Actually the

picture shows from the lack of solid black shadows that there were

still air bubbles. But it seemed good enough.

Somehow after making the mostly unneeded jig and template,

just

doing the rotor milling and strapping took another whole week. So much

for "picking up the pace!"

On the 21st I put the motor back together. While it was

still apart I

noticed that the gear on the end wasn't straight, in spite of having

been pressed on endwise with the hydraulic press. There were other

problems: the gear meant the rotor end bearing (needle bearing with

pressed mounting) had to be put on from the far end. That also meant

putting on the rotor end cover first instead of last, and it was in the

way of seeing and adjusting the placement of the rotor onto the shaft.

Instead of a nut driver, an open end wrench had to be snuck in from

the side and the SDS taper-lock bushing bolts tightened a bit at a

time. I added a couple of spacer washers so the extra strapping

thickness on the magnets wouldn't rub on the stator-rotor separator

wall. The flux gap ended up at about 17/32", which is probably about

where it should be anyway. On the second attempt the shaft still wasn't

quite where I wanted it, but I decided it was close enough and some

spacer washers could be added when mounting the motor onto the

transmission. I didn't work continually all day, having other things to

do as usual, but it was late when I finally had the motor together. The

extra rotor diameter of the wrap-around strapping lightly rubbed on the

body, making some noise, but not hard enough to affect operation.

On the 22nd I checked the motor fit, and decided that

spacers would

be too much. There were already nuts making 3/8" extra space. Another

set would be 3/4". The bolts just might bend. But there seemed to be a

simple answer. It looked like I could just cut the shaft holding the

ring gear 3/4" shorter. Shorter would probably be better anyway. The

ring gear was well pressed onto the splined shaft, but I eventually

wedged it off, cut the

shaft down, and pounded the gear back on. It was almost too much: the

pulley for the tension rope rubbed slightly on the clutch drum. Another

1/4" would definitely have been too much. But the motor now fit on with

no 'extra'

spacers, just a couple of washers to help align the shafts.

On the 22nd I checked the motor fit, and decided that

spacers would

be too much. There were already nuts making 3/8" extra space. Another

set would be 3/4". The bolts just might bend. But there seemed to be a

simple answer. It looked like I could just cut the shaft holding the

ring gear 3/4" shorter. Shorter would probably be better anyway. The

ring gear was well pressed onto the splined shaft, but I eventually

wedged it off, cut the

shaft down, and pounded the gear back on. It was almost too much: the

pulley for the tension rope rubbed slightly on the clutch drum. Another

1/4" would definitely have been too much. But the motor now fit on with

no 'extra'

spacers, just a couple of washers to help align the shafts.

Then I hooked it up and tried a test run. It wouldn't run.

It didn't

try to turn and seemed dead. I was frustrated for the zillionth time

that I couldn't see if the rotor position sensors were working, and I

decided to at last make a "break-out board" to insert in the cable,

with 3 LED.s that would tell the state of the 3 sensors. I closed up

the car for the day.

But hmm... the Kelly controller came on and the steady

green light

meant "all okay". It would have been blinking if the sensor state was

wrong (all sensors off or all on). Then, come to think of it, I hadn't

heard

the contactor click on, so of course there was no power to the

controller power circuits or the motor. I opened the car and removed

the hood again. I put a jumper across the ignition switch relay and the

contactor clacked on. I tried again and the motor ran. I'm pretty

confident it won't fly apart. Hopefully the whole mechanism would turn

fast enough to activate the centrifugal clutch. I can (I'm sure) now

run the motor up to 3000 RPM or higher in order to make that happen.

The next day (23rd) I reduced the batteries to 24 volts. The control

seemed much better and the motor didn't spin madly as soon as it came

on. That'd be better for testing.

That left one tricky mechanical part to build before an

initial

test: the slipping pulley tension rope and tensioner, controlled with

the "gearshift" lever. I recall from 2012 that it was best to fasten

the rope on one side of the pulley and have the lever pull on both ends

of the rope on the opposite side of the pulley, making a relatively

balanced pull, instead of yanking the pulley and planet gear assembly

towards one side by having the rope loop around the whole pulley,

anchored and pulled from almost the same place. (Balanced should also

make forward and reverse tensioning even, and half loops should have

much less tendency to grip the pulley by friction even without tension

on the rope.)

On the 23rd I looked it over and came up with a better

plan than I'd

had. If the midway point was near the bottom instead of the front, the

tension cable attachment would be near the top - which was already

where the cable would sit if lifted a bit. The only tricky part then

would be attaching a stationary anchor/mounting point. It would be a

bit distant from potential anchor points on the frame. Oh well, one can

always bend up some piece of metal to fit somehow.

On the 23rd I looked it over and came up with a better

plan than I'd

had. If the midway point was near the bottom instead of the front, the

tension cable attachment would be near the top - which was already

where the cable would sit if lifted a bit. The only tricky part then

would be attaching a stationary anchor/mounting point. It would be a

bit distant from potential anchor points on the frame. Oh well, one can

always bend up some piece of metal to fit somehow.

I concentrated that day on the midway clamp at the bottom.

Access

was okay once I took the motor off again. The only thing there seemed

to be enough room all around for was a flat bar of metal between two

bolts, clamping the bar to the bottom motor mounting. After making the

bar with two bolt holes, I drilled and threaded one bolt hole on the

motor mount, then used the bar with a bolt into that hole to locate the

second hole. (Then as I expected, the tension pulley hit the bolt heads

until

the rope was tightened down.)

Now, just how was all this going to connect and

work?

Now, just how was all this going to connect and

work?

The tensioning pulley and planetary assembly were free to

pull out,

to move sideways toward the motor. In 2012 I had had a needle bearing

between

the motor and the pulley to prevent that, but it couldn't be slid onto

the motor shaft now that the sun gear was pressed onto it. I had

thought that, forces being balanced, the tensioning rope on the pulley

would keep it from sliding out.

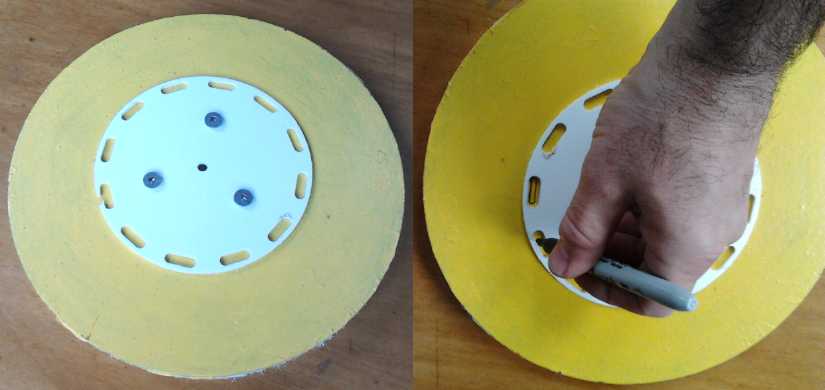

On the morning of the 25th I woke up

with the realization that because the gears were helical, the forces

weren't balanced. There would be a strong push to the side when the car

was being pushed. In forward the push simply forces the planetary gear

assembly against the ring gear, but in reverse it would push it out

toward the motor. It definitely would need something to prevent that,

preferably a thrust bearing, and the thrust bearing would need some

sort of mounting.

I tackled the problem that day. I removed the green

plastic piece that had centered the pulley on the motor shaft with the

needle bearing. I had large thrust

bearings I'd purchased

for the reluctance motors. I couldn't quite think how to do the pipe,

and I went to the mechanic at AGO. He made a suggestion. I left

thinking I pretty much knew what to do. After I

started lathe-milling a stand-off pipe, it occurred to me that the pipe

should

only hold one side ring. That was a little different than the

suggestion, but it would allow play in case the shafts weren't

perfectly aligned. I had just started

cutting deeper but stopped when it dawned on me that it was already

just how

it should be. The thrust bearing and the other side ring should be in a

recess

on the side of the planet assembly. The one thing that would be needed

for this arrangement would be for the

motor to stay in constant good contact. Otherwise the bearing pieces

would fall out

and hang on the motor shaft, as there was nothing else to hold them in.

I assumed I could get it.

Pulley/Planetary Gear Assembly Side.

Pulley/Planetary Gear Assembly Side.

A big washer with its inside trimmed to fit the bearing and its

side ring, is held in centered position by small washers and nuts.

(Small washers with one side filed to exact fit are under the larger

washers and nuts.)

On the motor side is a pipe with the motor end notched to fit around

the protruding bolts,

and the outer end is grooved out to hold the other bearing side ring.

Put together on the motor.

On the 28th I got back to the pulley tensioning mechanism.

I had found a piece of steel that might work as a lever. (but it was a

bit on the light side.) I cut it and bent it to the shape I wanted, but

it didn't really look like it would work. The way it would pull would

tighten one rope and loosen the other. It seemed to need a stationary

piece to pivot from, and there wasn't anything stationary up near the

top of the mechanism. I thought of a few ideas, but wasn't satisfied

I had a winner.

On the 28th I got back to the pulley tensioning mechanism.

I had found a piece of steel that might work as a lever. (but it was a

bit on the light side.) I cut it and bent it to the shape I wanted, but

it didn't really look like it would work. The way it would pull would

tighten one rope and loosen the other. It seemed to need a stationary

piece to pivot from, and there wasn't anything stationary up near the

top of the mechanism. I thought of a few ideas, but wasn't satisfied

I had a winner.

Occasionally I

remembered that the whole transmission

mechanism would twist badly when it tried to move the car. Lacking

inspiration on the other, I decided to tackle this and put in a

diagonal brace piece. I found a 10" piece of steel for it. As usual

everything is harder than expected. The

cordless drill wouldn't fit inside the hood to drill the bolt holes,

and I ended

up removing both mounting pieces and taking them into the shop to do on

the

drill press. As soon as I finished, there was a torrential deluge and I

put the hood on and went inside. Considering it could have been cold

and snowing much of the month, I'll count my blessings that this year's

mostly warm January

weather has only occasionally delayed the work.

Occasionally I

remembered that the whole transmission

mechanism would twist badly when it tried to move the car. Lacking

inspiration on the other, I decided to tackle this and put in a

diagonal brace piece. I found a 10" piece of steel for it. As usual

everything is harder than expected. The

cordless drill wouldn't fit inside the hood to drill the bolt holes,

and I ended

up removing both mounting pieces and taking them into the shop to do on

the

drill press. As soon as I finished, there was a torrential deluge and I

put the hood on and went inside. Considering it could have been cold

and snowing much of the month, I'll count my blessings that this year's

mostly warm January

weather has only occasionally delayed the work.

The following

evening (29th) I had the idea

that the

shift/tensioning cable could simply be clamped to the rope with pipe

clamps, and that if their heads faced up, outwards, the tightened

clamps

wouldn't even protrude beyond the ouside of the rope. That would be way

simpler than anything else I had thought of!

The following

evening (29th) I had the idea

that the

shift/tensioning cable could simply be clamped to the rope with pipe

clamps, and that if their heads faced up, outwards, the tightened

clamps

wouldn't even protrude beyond the ouside of the rope. That would be way

simpler than anything else I had thought of!

In the morning I bought some small pipe clamps. There

wasn't much cable sticking out of the end of the sheath - almost none

when the shift lever was pulled back to "Low". I removed it, slid the

wire part way out, and cut the sheath so there was about 3-1/2" when

it was forward in "Park". But what would stop the thin steel

cable from slipping through the pipe clamps and the rope loosen? I had

thought of silver soldering some blob on the end. But the cable had no

rust... was it stainless steel? I've had no luck trying to silver

solder to that. Then I thought of screwing the clamping piece of a mar

wire connector on near the end of the cable. Much easier, and it could

be slid up and down and retightened to adjust, or removed to let the

cable slide out of the sheathing entirely if needed! I had some, so I

got one and screwed it on. I installed the shift lever end of the cable

so the other end would be in the right place, and slid on the pipe

clamps and tightened them in about the right positions.

When the lever was pulled back from "Park" to "Low", the

pulley went from "too loose" to "can't turn by hand". With the rope

backed off to "Reverse" on the lever, pulling up on the link area

seemed to tighten the pulley quite well. A short rope there to pull on

should allow control from under the hood for testing. With that and the

motor in place, the car would at long last be ready for a test. It was

just early afternoon and there should have been enough time, but

somewhere over the years I've lost not the

enthusiasm but much of the excitement for doing the project. There was

an evening

music jam to think of, and I went off to start working on some

paperwork for Revenue Canada that was soon due and I was getting

increasingly anxious about.

Under the Hood, Left to Right:

Under the Hood, Left to Right:

Hand-held test control box - Motor controller on heastsink &

aluminum plate -

Connection Wires - Electric Hubcap Motor - Thrust bearing (pipe)

and unseen sun gear on motor shaft -

Tensioner [planets] gear, pulley, rope - centrifugal clutch drum -

unseen planetary ring gear and clutch inner disk on floating shaft -

unseen chain drive to differential - cut-down trailer wheel hub with

its bearings holding the shaft.

I got back to it on Monday February 1st. I put in the

motor and connected it. For some reason it would only run in one

direction, to push the car backward. Usually this would signify crossed

phase wires, but they were marked with colored tape and I connected

them the same as before. The Kelly BLDC motor controller started

blinking its red LED twice. I decided backward was good enough for the

initial test, and shrugged it off.

Rather than a pull rope, I reached into the car and simply

set the tension (ex 'shift') lever to a moderate tension. When the

motor started, the clutch slipped. As it sped up, the clutch started to

engage, and the slipping gear with the big tensioning pulley started

turning. I increased the tension setting. It worked about the same

except the pulley started slipping at a higher RPM. I increased tension

to max. Now the pulley didn't slip, but the car still wouldn't move.

The clutch simply wasn't engaging strongly enough at the RPM.s

available. I went back from 24 to 36 volts to get higher RPM but it

still didn't move. I put boards under the wheels. It moved much more

easily when pushed by hand than on the dirt. But it still didn't move

much, with the clutch slipping away.

At the higher powers, the motor stopped and the red LED

started blinking 3 times. I need to check out the meaning of the blink

codes. It was reset by turning the controller off and on again.

A 'minor' problem noted was that the tensioner gear and

pulley pushed hard against the motor and thrust bearing. The planetary

gear assembly actually forced itself part way out from the sun gear.

This may have added to the friction, but it was still engaged and I

don't think it was a main concern - at this point.

So: As I suspected was likely, the car didn't move, with

the clutch being the main problem. It needs heavier weights or some

springs to help push the shoes against the drum much more strongly at

lower RPM.s. Or maybe there's some other solution? I'll have to give

some thought about how to improve it. The main objective of the test,

aside from seeing if there were any weak points, was really to see

whether the clutch needed changes. I figured it probably would, but

there was little point worrying about it until I tried it as it was.

The idea of little pointed ridges of plastic going into

slots in the drum to make sudden points of push seemed (and still

seems) good, but in practice the points on the shoes wore off quickly

when the clutch was originally tested. Maybe some of the aluminum slots

aren't smooth enough and cut the plastic? Perhaps I should clean and

polish it all up, fix the shoes, and try again?

http://www.TurquoiseEnergy.com

Victoria BC Canada

I

made the magnet placement jig I've been meaning to do

for so long, and a template to draw the strapping slot positions on the

rotor with felt pen.

I

made the magnet placement jig I've been meaning to do

for so long, and a template to draw the strapping slot positions on the

rotor with felt pen. On the

afternoon of the 15th I drilled holes in a dogwood

2x2" for a rotor clamp, clamped the rotor onto the milling machine, and

(not without some hiccups, and not very evenly) milled the slots to run

the strapping through, 3/16" wide by 3/4" long. Of course if these

motors are to be produced, the magnets will be aligned using the new

jig, and the slots will be cut by CNC abrasive waterjet along with the

other rotor disk edges. It was tedious getting the steel shavings off

the rotor magnets. (detailed report)

On the

afternoon of the 15th I drilled holes in a dogwood

2x2" for a rotor clamp, clamped the rotor onto the milling machine, and

(not without some hiccups, and not very evenly) milled the slots to run

the strapping through, 3/16" wide by 3/4" long. Of course if these

motors are to be produced, the magnets will be aligned using the new

jig, and the slots will be cut by CNC abrasive waterjet along with the

other rotor disk edges. It was tedious getting the steel shavings off

the rotor magnets. (detailed report)

I thought I'd

just make a magnet placement jig using the

usual

spreadsheet for the G-Code, but I'd try doing it on my new RCA Android

tablet - No annoying fan or drive whirring away as you work! First

finding an adapter to hook up a USB memory stick having a template

spreadsheet on it took a day. Then another couple of days passed before

I found that I couldn't find a spreadsheet program that worked.

I thought I'd

just make a magnet placement jig using the

usual

spreadsheet for the G-Code, but I'd try doing it on my new RCA Android

tablet - No annoying fan or drive whirring away as you work! First

finding an adapter to hook up a USB memory stick having a template

spreadsheet on it took a day. Then another couple of days passed before

I found that I couldn't find a spreadsheet program that worked.

But when at

last I went to rip the broken rotor apart (14th) and

recover the magnets from it, I found there was a good reason it had

come apart. I thought the epoxy was pasted on the plain steel disk, but

I discovered the disk had been given a spray-on zinc anti-rust coating.

I had previously discovered on the first Electric Caik motor that that

spray-on zinc coating was feeble and would rip apart across its whole

surface as soon as the motor hit any decent RPM. This rotor had been

made just before the first Electric Caik. Somehow it had lasted until I

tried it with no load with the Kelly controller, which had spun it up

to high RPM.s almost instantly.

But when at

last I went to rip the broken rotor apart (14th) and

recover the magnets from it, I found there was a good reason it had

come apart. I thought the epoxy was pasted on the plain steel disk, but

I discovered the disk had been given a spray-on zinc anti-rust coating.

I had previously discovered on the first Electric Caik motor that that

spray-on zinc coating was feeble and would rip apart across its whole

surface as soon as the motor hit any decent RPM. This rotor had been

made just before the first Electric Caik. Somehow it had lasted until I

tried it with no load with the Kelly controller, which had spun it up

to high RPM.s almost instantly. Next, would I

just have to put up with painstakingly

pulling the

shards from the magnets afterward, or could I fit something into the

narrow spaces that I could pull off later, along with the shards? Tape?

How about duct seal or modeling clay?

Next, would I

just have to put up with painstakingly

pulling the

shards from the magnets afterward, or could I fit something into the

narrow spaces that I could pull off later, along with the shards? Tape?

How about duct seal or modeling clay? Next day

(19th) I cut 12 straps of 1.5" wide by 9"

white polypropylene

(PP) strapping, folded the ends, and fed them through the 12 slots. The

ends overlap behind, making them a double thickness over most of their

length on the back of the rotor.

Then I prepared a flat surface and put a sheet of polyethylene (PE) on

it so the epoxy wouldn't stick. I mixed about 70g of epoxy and used a

1" brush to paint the tops of the magnets and the strapping from the

inside. (It was barely enough epoxy.) Then the outside over the

magnets. After it was all on I turned the

rotor over so the magnets were down and pressed against the PE on the

flat surface - so nothing extra would stick out from the flat tops of

the magnets. Then I painted the rotor disk back and the rest of the

straps and pulled both ends tight and stuck them down. Then a small

piece of PE and a small steel weight went over each one to hold it

while the epoxy set. That wouldn't hold the PP stretched, but will

avoid

protruding ends and I trust hold well enough to ensure the magnets

never come loose. When it was mostly set, I turned over the rotor and

found there were "bubbles", disconnects, between the magnets and the

strapping in many places. I pulled the weights and PE bits off the back

and put them on the magnets. It wasn't easy to get them to stay in

place on top of each magnet, as they wanted to slide magnetically

across the still slightly gooey epoxy to join adjacent magnets of

opposite polarity. I ended up breaking up some styrene foam pieces to

hold them apart. If it wasn't for the strong magnetic press on the

steel weights, I'd have worried that the epoxy was too much set to join

up. As it was I was sure they would be well bonded. Actually the

picture shows from the lack of solid black shadows that there were

still air bubbles. But it seemed good enough.

Next day

(19th) I cut 12 straps of 1.5" wide by 9"

white polypropylene

(PP) strapping, folded the ends, and fed them through the 12 slots. The

ends overlap behind, making them a double thickness over most of their

length on the back of the rotor.

Then I prepared a flat surface and put a sheet of polyethylene (PE) on

it so the epoxy wouldn't stick. I mixed about 70g of epoxy and used a

1" brush to paint the tops of the magnets and the strapping from the

inside. (It was barely enough epoxy.) Then the outside over the

magnets. After it was all on I turned the

rotor over so the magnets were down and pressed against the PE on the

flat surface - so nothing extra would stick out from the flat tops of

the magnets. Then I painted the rotor disk back and the rest of the

straps and pulled both ends tight and stuck them down. Then a small

piece of PE and a small steel weight went over each one to hold it

while the epoxy set. That wouldn't hold the PP stretched, but will

avoid

protruding ends and I trust hold well enough to ensure the magnets

never come loose. When it was mostly set, I turned over the rotor and

found there were "bubbles", disconnects, between the magnets and the

strapping in many places. I pulled the weights and PE bits off the back

and put them on the magnets. It wasn't easy to get them to stay in

place on top of each magnet, as they wanted to slide magnetically

across the still slightly gooey epoxy to join adjacent magnets of

opposite polarity. I ended up breaking up some styrene foam pieces to

hold them apart. If it wasn't for the strong magnetic press on the

steel weights, I'd have worried that the epoxy was too much set to join

up. As it was I was sure they would be well bonded. Actually the

picture shows from the lack of solid black shadows that there were