Turquoise

Energy Ltd. News #97

covering February 2016 (posted March 3rd 2016)

Victoria BC

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Feature: "Electro-Permanent"

Magnets Could Revolutionize Motors & Electric Vehicles -- 500 mile

range? (see Month in Brief & longer article below it... also

"Detailed Report" - actually my first thoughts on the idea.)

Month In Brief

(Project Summaries)

- Hands-On Democracy - Electro-permanent magnet motors - LED Plant

Growth Lighting Idea - Chevy Sprint: Electric Hubcap motor,

frictionless centrifugal clutch - An E-Bike with Motor Components

Around Wheel - Miles Electric Cargo Truck Repairs

Electropermanent Magnets & Motors

- seems "COP" may be over 5x(?) input power!

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Rising Financial Woes - USA Election Rigging - a funny or two

Electric Transport - Electric Hubcap Motor Systems

* Electro-permanent Magnets and

Motors (yet another little write-up - my early thoughts when I first

found out about the idea.)

* Lower RPM, Frictionless

Centrifugal Clutch Making progress

Other "Green"

Electric Equipment Projects (no reports)

Electricity Generation (no reports)

Electricity Storage - Turquoise Battery

Project (NiMn, NiNi), etc. (no reports)

No Project Reports on: Lambda ray

converter, CNC

gardening/farming machine, Electric Weel, unipolar motor controller,

reluctance motors (will need to modify the controllers and motors for

electropermanent magnets!), aquaponics.

February in Brief

Hands-On Democracy - Proposals for How to Run a World

On the 5th I registered "HandsOnDemocracy.org"

as

an

umbrella

page

for

my

various political structure ideas. I pointed it to my home

page at [ www.saers.com/recorder/craig/democracy

]. Then I uploaded a first draft of the text, and I put a link to it on

that page. It's got the basics. I put in all the keywords I could think

of so search engines will hopefully find it when people are looking up

topics along those lines. Over the rest of the month I did 4 editings

and made additions and improvements to the

text, with even another new - if less well defined - proposal. I'll do

more if I come up with any new ideas for the text or new

proposals. Personally, I

think what's there already would revolutionize the way societies work,

and go far towards making them sustainable into the indefinite future.

Electropermanent Magnets & Motors

On the 13th I watched a video about a

game-changing new idea for motors: "electropermanent magnets". [https://www.youtube.com/watch?v=n4YD8Nvyfa4]

The following description is modified to how I plan to use

the idea for BLDC motors, which seems to me to be simpler and better

than the original:

Instead of using magnetically soft iron for the motor coil

cores, use AlNiCo5 alloy. This alloy makes a powerful permanent magnet,

but it is much easier to magnetize and demagnetize than rare earth

magnet types.

Instead of powering the coil for the entire portion of motor

rotation during which it is to be turned on, a very brief pulse of

current magnetizes the AlNoCo magnet core, which then remains "on",

magnetized, without using any further electricity. At the endpoint

of the rotation where the electromagnetic core would be turned off, a

weaker brief reverse pulse demagnetizes the core. The cores can be

magnetized in either direction just like the soft iron cores, and to

different strengths to vary the power level of the motor.

From various accounts and rumors, this could probably give

(for example) typical electric cars

sufficient range for anybody's all day highway drive, even 500 miles.

On March 1st I found and enquired about some AlNiCo5 magnets 2" O.D. by

1" long, which I can use in the same Electric Hubcap and Electric Caik

motors, and simply replace the coils, using all the same motor making

molds. They seem to be pricey (18$US each) and will drive up the cost

of the motors, but the savings in batteries or increased range will

make it more than worthwhile.

The motor controllers will be quite tricky to develop,

being considerably different from any other motor controllers.

I've written this idea up in much more detail in the

article following this February in Brief section.

An LED Plant Growth Lighting Idea

Quite a while ago, Jim Harrington had given me a 5 meter

flexible RGB LED light strip he had bought, to try out for aquaponics

plant growth. The light can be changed or programmed to emit hopefully

optimum plant growth colors. But the long thin strip seemed to me to be

too dim in any given area unless it was within a couple of inches above

seedlings planted in a long strip, and I was reluctant to cut it into

short lengths and try to wire them side by side.

This month he said he was planting vegetable seedlings and

I gave it back to him. He came up with a novel, practical way to use it

and concentrate the light. He made a circle of sheet aluminum and

wrapped the light strip around the inside in a helix. The whole unit

went right around a plant pot with his seedlings. The light thus comes

at the plants from every direction, so they won't start leaning over

towards a point light source. Much of each light will reflect off the

far wall aluminum and go down, too. An aluminum or aluminized plastic

top piece of some sort will ensure that most of the light is going to

the pot. The solar panel he is using, planning "off grid" gardening

including for the arctic, will thus need a to provide an absolute

minimum of power to obtain maximum lighting effect.

There is also a relatively bright blue LED light hanging

directly over the pot.

Above, Magenta lighting.

Above, Magenta lighting.

Below, Blue.

Variable Transmission & Sprint Car: Frictionless Centrifugal Clutch

Making

I continued the Sprint variable transmission

work of

January, at an equally leisurely pace. It was almost the only project I

did physical work on, but there just seemed - and seem - to be

many other things to do including other research. With a 'dremmel'

cutter

tool, a 90° adapter and a wood/soft metal cutting bit, I cut the

slots in the

centrifugal clutch drum from a narrow "U" shape as sawed on the bandsaw

many moons ago to a broader "V"

shape

with 45° sides. I filed them smooth and then (more or less)

polished the whole inside of the drum on a polishing wheel.

On the 9th I installed the motor in the car without the

transmission and ran it. The phase wires, carefully marked with colored

tape, had been wrong. Switching them got the motor running nicely in

both directions - with smoother control from the Kelly BLDC controller.

One problem down!

Then I designed new shoes for the centrifugal clutch. First I cut a

sample

shoe on the bandsaw.

Then I designed new shoes for the centrifugal clutch. First I cut a

sample

shoe on the bandsaw.

Part of the slow progress was being unsure about strike

angles

with a hinge pin point that had to be itself at an undesired angle in

order to be within the drum and on the rotor disk. The strike and

rebound angles actually get complicated when one considers that the

disk is spinning faster than the drum. The 45° strikes are supposed

to be relative to the drum; the angles on the input disk matter less.

At one point I

thought I might use a sliding type of shoe that would go straight in

and out and I made a sample of that, but then I figured it would wear

out fast, and it might jam. I finally decided the first design was

about right after all and better (or at least more practical), and went

about manually writing

G-code to produce

10 of them until it looked about right on the screen. I then routed out

a sample of thin plastic. Several samples later it looked about right.

On the 25th I got 3 of the 5 pairs of plastic shoes

made, using 7/8" thick UHMW. (More ideally they should have been about

1.25" thick - the drum is 3" wide. I had lots of 7/8 and no 1.25".)

Making the last 2 pairs, four shoes in one shot, the router bit snapped

in

the middle of the work. (was it dull?) By not panicking and letting it

finish as if it was still cutting, I preserved the "home" position and

commanded the router

to return to it, so I could rout out the exact same path the next time

on

the same piece of plastic. (I was doing it in two passes anyway in the

thick plastic.) By the next afternoon I had 10 identical shoes.

On March 1st I obtained some 5/8" square steel rod and cut

the first weight to go on the shoes. The 2" length said exactly 100

grams on a scale: my target weight. I look forward, somewhat nervously,

to finishing it, installing it and trying it out.

An E-Bike with Motor Components

Around Wheel

In 2012 (see especially TE News #59) I proposed to place 6

"Electric Hubcap" type motor

coils along a bike frame by the wheel rim, and put magnets all around

the rim of the

wheel, to turn a bicycle into an efficient E-bicycle with no more

moving parts than it already had. Amongst all the other projects, I

didn't get around to making it. Now a friend has sent me a link to a

company that has done it, except they designed a whole new bike

around the idea. They seem to have used radial or transverse

flux.

The article points out a potential mechanical problem:

"One current disadvantage of this “Maglev Transrapid technology” is

that the wheel rim magnets and inductive coils must be relatively close

together for it to be an efficient system. That could be a problem if

the wheel rim is not very straight or if debris gets between the rim

and inductive coils in the frame. It will be interesting to see if this

issue can be overcome in the near future."

While my plan wouldn't be immune to this problem (and

magnets may pick up debris), the axial flux motor has a 1/2" flux gap

between the coils (to be mounted to one side of the wheel) and the

rotor supermagnets on the wheel. That is at least a lot of elbow room.

(Here is a place a reluctance motor with its tiny flux gaps might be

problematic to fit reliably.)

Now, let's make that an axial flux BLDC type motor with AlNiCo 5

coil cores. (see Electropermanent Magnets and Motors, below.)

That might well ride along under motor power for hours with only a few

batteries to power it. (eg, 20 NiMH D cells for 24V)

Miles Electric Cargo Truck Repairs

On March 1st I took someone up on his offer to help out

with the Miles electric cargo truck, which has done nothing but sit in

the yard since I found it was intermittent and thus unreliable to

drive. Of all problems, intermittent ones are generally the hardest to

solve, when something unknown quits 'randomly' while in use. He came

over and in accord with his idea of disassembling a few things we

managed to extract the motor shaft encoder "reader" (which I am

virtually certain is the problem) from the front end of the motor,

reaching down from above in the cab instead of crawling under the

truck. We couldn't see it under a metal plate, but we could feel it and

reach the screws from in front. He had the valuable idea to insert his

cell phone, which had a light, and take excellent very close-up

pictures, from which we could see where the screws were and what to do

next, by feel. (Where did my 3rd new inspection mirror go?) The

pictures were also vital in that we e-mailed them to Canadian Electric

Vehicles so they could identify what part was required. They had them!

for 81$. I ordered one.

In fact, the slotted interrupter wheel on the end of the

motor shaft looked immaculate and clean, so it was just the LED and

phototransistor assembly (the "reader" according to CEV) that were

probably quitting randomly. I had ruled out most other possibilities

when I discovered that unplugging the plug at the motor controller and

plugging it back in (hence cycling the power to the reader) seemingly

always brought the truck back to life. And some of the screw sockets

holding the encoder together had a bit of corrosion (visible in the

pictures), which itself made the delicate miniature circuit board

suspect. All it takes is one tiny bad corroded solder joint. Far less

likely, it could be something in the controller itself, or in the

wiring.

I'll only be sure once I install the new part and have

driven at least a few trips with no further problem.

Electropermanent

Magnets

and

Motors

On the 13th Leonardo Janus of "Elionix" (see his new DES

battery electrolyte in an earlier TE News) sent me a video link to a

game-changing new idea for motors: "electro-permanent magnets". [https://www.youtube.com/watch?v=n4YD8Nvyfa4]

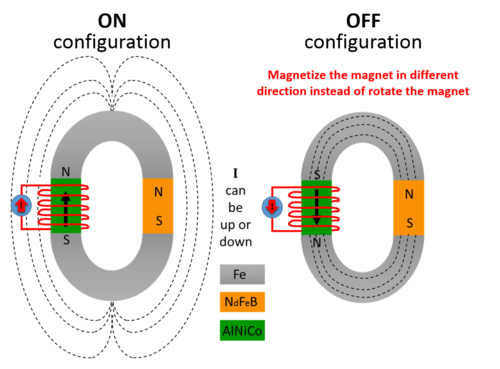

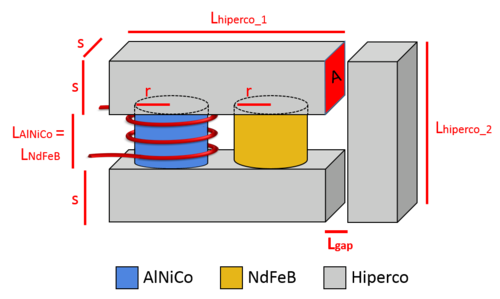

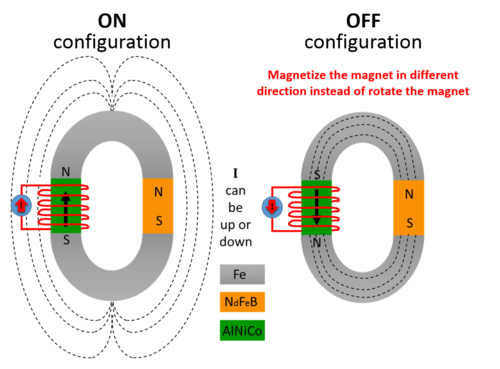

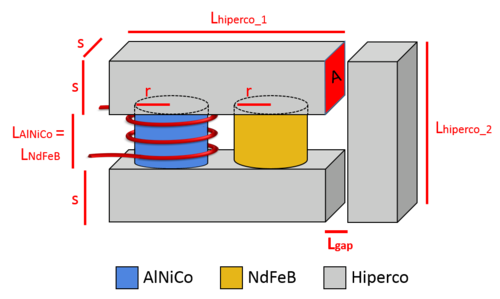

As shown, dual magnet combinations (one FeNdB and one

AlNiCo tied together with "keepers") were used which could be turned

either "on" or "off" by pulsing a coil around the AlNiCo magnet in one

direction or the other.

The Principle: In the original version, the

AlNiCo magnet is

always fully magnetized, but in

The Principle: In the original version, the

AlNiCo magnet is

always fully magnetized, but in

one direction or the other depending on the polarity of the current

pulse that

magnetized it.

In one direction the combo, with the magnetically soft iron magnetic

circuit

connections,

makes a strong external field, in the other it doesn't - the magnetic

circuit is internal.

In a more practical configuration the straight

top and bottom (soft magnetic)

In a more practical configuration the straight

top and bottom (soft magnetic)

bars deliver high flux to objects near the bars. The bar at

the right is attracted

only if both magnets are magnetized in the same direction. A magnet

above (or

below) would also be repelled then, if the pole faced that magnet's

like pole.

AlNiCo, actually FeAlNiCo

and sometimes with a few minor elements, is the strongest

permanent magnet material discovered before rare earth magnets. It has

been widely used in speaker magnets, guitar pickups, and other places

where strong magnets are needed. Rare

earth magnets take a whopping jolt of current or magnetic field to

change their magnetization, but AlNiCo 5 takes only a fraction as much,

say 5%.

I keep

hearing rumors about motors that give very much longer range to

vehicles, for example the "Zero" Electric Motorcycle, and Troy Reed's

2011 Geo Metro video on youtube. ("You can drive it around all day.")

Details have been

sketchy, but these magnets would surely be how it's done. It sounds too

good to be true, but I don't see any flaws in the theory (so far,

anyway).

Certainly motors can be, and apparently are now being,

made using the above magnet configuration. But I can't help think it

could be

done more simply.

Instead of just having full-strength "on" or "off", modulation of the

strength of the

pulses should allow low to high magnetization (in either direction) of

a single AlNiCo5 magnet core for

low to high power motor

operation, with weaker pulses more or less demagnetizing the magnets

when

they're not wanted. And it should run more smoothly at lower power.

Ideally it would work like this:

- In BLDC motors, the stator

electromagnets attract and repel permanent magnets on the rotor to

cause it to rotate. FeNdB 'supermagnets' are usually used on the rotor.

It is very hard to change the powerful magnetization of this alloy -

they are

very "permanent" magnets. Someone once told me that a million amp pulse

for a microsecond is used to generate enough magnetic field magnetize

them. An interesting feature is that although it's a truly impressive

current, it's only one coulomb, one amp-second, of total charge.

- Usually very "soft magnetic"

material (plain iron or alloy) is used for electromagnet coil cores.

This won't hold a magnetic charge - can't be magnetized to be a

permanent magnet - in order that as it is electrically magnetized from

'north' to

'south' and back as the motor rotates, no extra energy is wasted to

demagnetize it when reversing polarity. The coils are using power for

their entire "on" time over the appropriate part of the rotation in

order to continue to attract or repel the rotor magnets for that time.

This is typical motor theory and operation. Conventional logic until

now has said

this is how it has to be.

- Permanent magnets made of alloys

of aluminum, nickel and cobalt, "AlNiCo", and particularly "AlNiCo 5",

can have fields as strong as "supermagnets". However, they

require a much smaller current pulse to magnetize and demagnetize, much

less than a coulomb. They are

harder to induce a field into than "soft" magnetic material, but once

pulsed they will hold the magnetic charge. (FeNdB: ~1,000,000 A/m;

AlNiCo5: ~50,000 A/m; Soft Fe: 160 A/m)

- Thus, if an AlNiCo 5 magnet was to

replace the soft magnetic coil core material, one would have a

"permanent" magnet that would be magnetized by a single short pulse of

current to the coil.

- Once it was magnetized, a rotor

magnet would continue to be attracted to or repelled from that stator

magnet without using any more electricity, until the magnetization

strength and polarity was deliberately changed by another short pulse,

of reverse current.

- So again: where a "regular" motor

coil has to stay energized and draw current over an entire segment of

motor rotation, the AlNiCo 5 core coil only needs to be pulsed "on" at

the rotation start point and pulsed "off" again at the end point, with

a

weaker reverse pulse. Through the whole desired arc, it's a "permanent"

magnet driving the rotor magnet. The amazing electricity saving

potential becomes

apparent.

- Current in a coil increases over

time with

pulse length. Thus the maximum current can be set for magnetizing or

demagnetizing simply by timing the length of the pulse - no current

sense shunt resistor is required. To obtain the required very high

current in the minimum possible pulse width, very few turns of very

heavy wire would be used. (Perhaps my usual 21 turns of #11 wire, but

with the phase coils wired in parallel instead of in series? Or maybe 2

sets of 10 turns, in parallel?) The magnet magnetizes

to the maximum current that hits

it, even if it's only on for a microsecond. A microcontroller based

motor controller could "learn" (or be programmed with) the pulse

lengths required to obtain

smooth control of the motor from low to full power. (Since single

phases

would need to be individually controlled, a full bridge is probably

required for each

phase, doubling the number of driver transistors. Must think about

this!) But the transistors will be on for such short lengths of time

they can probably be downsized without risk of overheating.

Possible cautions?: One

thing that might militate against this simpler electropermanent magnet

model is that AlNiCo magnets, being said to be easily demagnetized by

an external magnetic field, might become demagnetized by the rotor

magnets during a single pass as they go by, strongly enough to greatly

decrease their intended attraction or repulsion of those magnets.

However, there is a large flux gap in axial flux motors, and the stator

magnets are supposed to be off anyway at the nearest points, as rotor

and stator magnets pass by each other. So I expect it would take many

passes to gradually demagnetize an AlNiCo5 stator magnet -- which is

being repeatedly magnetized and demagnetized in both directions by

electrical

pulses anyway.

The other possible caution is that the short magnetization

and

demagnetization pulses might just possibly take as much or more energy

than

powering a regular coil ON for the entire duration. Given that the

pulse if heavy wire is used will be so short, that

this also seems improbable. And of course lower

RPM motors such as the Electric Hubcap axial flux types will also have

fewer pulses per second than very high RPM ones, and the pulses require

the same current

regardless of motor speed to obtain the same magnetization.

Given these factors plus given that electropermanent

magnet motors made so far are claimed to be so good, I'm going to

dismiss both concerns as being highly unlikely. And the factors are

adjustable.

A reluctance motor could also be run by the same system.

Since the rotor iron doesn't care about magnetic direction and is

attracted to either north or south magnet poles, the cores must be

demagnetized pretty fully when they aren't wanted as well as magnetized

when they are. Again, carefully tuned weaker reverse pulses could be

used to

demagnetize the AlNiCo, rather than going to the more physically

complex two-magnet system shown in the video.

For either, the single magnet also

delivers maximum flux, to the steel rotor or rotor magnets. And reverse

pulses are required to demagnetize so the unipolar motor controller is

"out". A whole new type of controller with different operation is

required.

The most mind boggling thing is that this electro-permanent magnet

motor idea is so simple, yet no one

seems to have thought of it before. (If Bedini's motors use it, it was

never explained so I understood it.) Rather than in motors, its chief

use so far seems to be in heavy lifting of magnetic materials such as

steel plates, where the magnet can be pulsed on to lift them and then

pulsed off to let go of them. It seems likely that's what it first was

invented

for. Certainly nothing like it ever crossed my

own mind. But I was unaware of the magnetic properties of AlNiCo.

This would add a whole new dimension to the idea of

"ultra-efficient" drives. It could probably give typical electric cars

sufficient range for all day highway driving (recharge at night on long

trips), and the power taken from the power grid (or other source) for

typical/regular driving will be quite minimal. On March 1st I found

AlNiCo 5 magnets of similar size and shape to my usual coil cores

so I can make a motor easily when the time comes. With a small shim (as

they're not identical inside diameter) I can use the same

motors and simply replace the coils, and I can use all the same motor

making

molds to make more BLDC motors.

The BLDC motors being pretty much identical, the

controllers will be the part needing effort to develop. The reluctance

motors will need some redesign. Something much like the type I made one

of is probably more practical in this case than my proposed "transverse

flux" type, unless AlNiCo can be had in the form of metal plates that

can be cut by CNC abrasive waterjet.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Rising Financial Woes

The long predicted financial events, strongly foreshadowed

since the 2016 new year, seem to be starting to unfold. Major banks

withdrew much of their remaining gold from the COMEX

inventory, leaving 500 "owners" for each piece of gold remaining.

Demand for the actual physical metals keeps breaking records around the

world as people start to lose trust in paper assets. Gold

and silver rose about 10% over a week, and on the night of February

10th started to explode, rising a further 5%. The stock markets looked

dismal. Then the manipulators moved in and patched things up again -

don't look at that man behind the curtain, everything is rosy!

But one hears that shipping, rail and trucking indices

were at multi-decade lows, more major chains were closing more stores

with layoffs probably totaling 100s of thousands in the USA, and

manufacturing continued to drop - all continuing trends over several

years. Teamsters union pensions in the midwest (or was it just

Michigan?) were all cut, by as much as 50%, the funds having been

"borrowed" (AKA looted) by government and with almost no possibility of

reasonably safe interest bearing investments on the rest in the present

environment. (You worked your 35 or 40 years and were told from the

start your pension terms. Sorry, we spent your money!) Farmers strikes

and riots in Athens speak of the dreadful pension cuts and tax demands

being made on people there, and it's probably happening in various

cities around the globe, so common that it's mostly unreported even in

the alternative media. Many banks will need bailouts, one or two

Italian one being said to be on the brink. Deusche Bank, Germany's

largest (and with 70 trillion dollars of derivatives exposure), was

said to be struggling day to day for funds to keep its doors open. With

the low oil prices, virtually all the shale oil frackers will soon be

declaring bankruptcy. With over 19 trillion dollars of debt (and far

more off the books) the USA has over 3 trillion dollars in assets...

but 1/3 of those "assets" are student loan debts, which are mostly in

default -- non-performing loans are everywhere! Yet the US government,

having lit the middle east, Ukraine and north Africa on fire, continues

to spend over 1/2 their budget on the military, to threaten and posture

aggressively.

Aging populations with (thank goodness!) fewer young

people illustrate Harry Dent's The Demographic Cliff - aging

people don't buy larger homes, fancy new cars and the latest gadgets,

and so the economy is bound to slow. But now migrants from areas still

having high population growth threaten the tranquility of the

established West, especially in Europe. And it is said the USA will be

over 1/2 Hispanic by 2030.

"Alta Web Bott" Reports make quite detailed incredible

predictions of things to come, and not without some successful

predictions although the timing for the events is often off. The guy,

Cliff High, says he sends out "spiders" all over the web to search for

out of place words (like "battleship" on a gardening site?) and then

sorts them and finally reads the sorted data. Where he really comes up

with this stuff I don't know, but much of it sounds all too plausible.

(See HalfPastHuman.org or listen to summaries by 'jsnip4' on youtube

for more details.)

The January and

February reports predicted for

2016 and 2017: a mid-level bank failure that would spread to engulf the

global financial system, shortages, rationing of many things,

riots, break-ins to sensitive government documents and arrests by US

marshals of highly

prominent figures whose activities have at last been fully exposed.

Much infighting in all that.

The bank failures are supposed to leave people celebrating

briefly that at least they don't have to pay

back their credit cards and other bank debts. Incredibly hot weather is

supposed to strike the west coast this summer, killing people and

filling hospitals and "cooling centers", and paralyzing ground and air

traffic. Incredible property tax

hikes will lead to abandonment of condos and tax revolts. All for

2016 and 2017.

Another person on youtube, Mike Boutwell, reading from the

same report, remarks "This will hit a lot of people like a brick in the

face."

What really happens we'll have to wait and see, but don't

expect it'll be "business as usual" for many more months. More and more

it looks like any of a number of dominos could fall at any time and set

off a chain reaction where everything will suddenly slip out of

control. I'll continue to sing my old song: get your storable foods

stashed away, fuel to 'get out of dodge' or whatever if required

(better still a nice electric vehicle!), and some silver to trade with.

Even if you're not convinced, how much do you spend per year on house

insurance, just in case? You'll probably never use that insurance. How

about investing in these other potential lifesavers - just in case?

Besides, with rising prices, food bought now is cheaper than food

bought in a few months from now - it's actually a money saver.

USA Election Rigging

Hold the presses! We heard earlier about Hillary Clinton

"winning" a state (Iowa?) because of democrat "establishment super

delegates", in spite of Bernie Sanders clearly beating her in votes and

bona-fide elected delegates. Today, March 3rd, it came out that in

several states, votes for Donald Trump were coming out of the machines

as votes for other republican primary candidates. There were thousands

of calls from incensed voters to an 'electoral fairness' agency whose

name escapes me. We can surmise that Clinton will be the democrat

faction candidate, and that Trump will not be the republican faction's

rep, regardless of the wishes of the people.

Can we expect any better when the actual election is

underway? Even if everyone picks any other candidate, it seems that the

votes will switch themselves to the oligopoly's choices. It is also

probable that a number of other candidates will split the vote even

without rigging, so even if a majority of Americans choose "anything

but republicrat", that's what they'll get anyway. It is becoming

abundantly clear is that there is and will be no even nominally fair

election in the USA in 2016. Until and unless the sort of events

foreshadowed above unfold, we already in fact have an

oligopoly-dictatorship.

For more on "vote splitting" on single "illiterate's X"

ballots, see TE

News

#74 and for various possible solutions, my new site Hands-On Democracy.

Humorous or not...

A word is worth one millipicture.

or

A word is worth 2 pixels.

More and more rat traps were all set up with aromatic bait. Then it was

announced that all the rats were gone. After much debate about all the

dangerous set traps, it was decided to set up a debaiting society.

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers

- Preliminary Ni-Mn, Ni-Ni Battery Making book

Products Catalog

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

Daily

Log

(time accounting, mainly for CRA - SR & ED assessment purposes)

Feb 1: Installed motor in Sprint and

tested operation.

Feb 1-2: Working on this newsletter.

3:

4: Disassembled much and removed clutch rotor & drum from Sprint to

work on them. Ordered "nickel foam" for battery electrodes.

5: Edited "Hands-On Democracy" text - uploaded to web page.

6: Found 'right angle cutter' attachment and cutter for 'dremmel' tool,

bought a new file, and ground and filed centrifugal clutch drum slots

from narrow "U" to broader "V" shape with 45° sides. (90° angle

at bottom.)

7:

8: (yet another migraine.) Inspected "V" points on centrifugal clutch

shoes. I thought they were badly worn, they were okay for another test.

9: Tested motor and changed connections.

10: Worked on new centrifugal clutch design ideas. (Added "Choice

Ranking Vote" (CRV) section to Hands-On Democracy)

11: Still on clutch design - another improvement (rotor slots) or two.

12: Cut sample UHMW clutch shoe to check fit.

13: Didn't like it. Decided hinge pins was better system.

14: Cut out sample shoe for that system.

15: (Worked on personal income tax)

16: Hands-On Democracy additions.

17:

18: Hands-On Democracy additions.

18 & 19: Figuring out centrifugal clutch strike angles

20: Put together G-code to produce the plastic shoes (initial version)

21: Tried again. Versions 2,3,4 and 5. Hands-On Democracy additions.

25: Cut 3 pairs of final version shoes. (Router bit broke.)

26: Cut remaining 2 pairs.

27: (Finished, sent personal income tax)

28: Hands-On Democracy additions. Tried again to buy Dremmel right

angle attachment.

29: Bought a 'new' aquarium for the tilapia breeding tank for

aquaponics.

March 1: Took shaft encoder "reader" off Miles electric truck for

repair. Ordered a new one. Bought steel and cut the first of 10 weights

for the clutch 10 shoes. Found a web site offering the right size and

shape of AlNiCo5 magnets.

2: Worked on this newsletter. Cut 5 more weights. Conversed with magnet

company by e-mail.

3: Newsletter.

Electric

Hubcap

Motor

Systems

-

Electric

Transport

Electro-Permanent Magnets &

Motors

Well, I wrote this here when I first heard of

electropermanent magnets.

Then I decided to do a "feature article" on the subject. There seem to

be enough different material in here to be worth reading if one is

"into" the subject, so I'll leave it in.

Checking my e-mail

on the 13th, I found a link to a video

about magnets that could be turned on or off, and would remain in

either state once power was removed. [https://www.youtube.com/watch?v=n4YD8Nvyfa4]

This

device

looks

like

a

real game-changer!

Essentially they were two magnets: a supermagnet that

couldn't be modified, coupled with steel "keepers" at both ends to an

AlNiCo "regular" permanent magnet that be switched in polarity with a

DC electromagnetic coil, energized one way or the other. The pulse to

magnetize the AlNiCo magnet could be as short as a microsecond. Thus

very little energy is used to switch it. If both magnets were

magnetized in the same direction, the "regular" AlNiCo magnet

reinforced the FeNiB magnet beside it and they would attract metal

objects. If it were magnetized in the other direction, the two opposite

magnet poles would be "shorted" through iron pieces connecting the

ends, and it wouldn't pick up anything. The AlNiCo was described in the

article as "soft magnetic material". But surely if it was really

"soft", it wouldn't hold a magnetic charge at all. So either it's

simply soft"er" than the FeNdB, or I don't have the theory straight.

I had heard about motorbikes, and Troy Reed's car, getting

fantastic driving range, but details on the motors were to say the

least sketchy. This video seems to clear up the mystery.

Every time I think I've got "the ultimate" in electric

propulsion motors, somebody sends me some link to something better! Now

here is another worthy motor project, a game changer as I say, to make

obsolete the way I'm doing it now.

I can now think of a couple of possible ways this idea can

be used in motors. Perhaps easiest, why not have a single "permanent"

magnet that can be energized either direction, used in a BLDC motor

with a regular supermagnet rotor? Each coil need only be turned on for

a microsecond, to attract or repel the nearest rotor magnet, for

milliseconds or tens of milliseconds (thousands of times as long as the

pulses), depending on the RPM and

configuration.

The first version could be a modified Electric Caik motor,

which could be tested in the outboard. In the motor, the modification

would consist simply of replacing the iron powder donut coil cores with

a more "hard" magnetic material that would hold its magnetic charge.

(Usually that's just what you want to avoid!)

The motor controller would have to be set up to put out

just the short pulses, just one pulse per step. Then, some pulses would

have to be be missed if full power wasn't needed. Unless there were to

be still shorter, or weaker, pulses to demagnetize without magnetizing

in the other direction, allowing the rotor magnet to "drift" by an idle

coil wouldn't be an option.

But why couldn't shorter and hence weaker pulses be

tailored to partly magnetize, or to demagnetize, the magnets? The motor

doesn't need full power all the time, and that would be a good way to

modulate them.

No doubt a microcontroller - controlling three full bridges to

drive the mosfets - would be the way to handle the unique aspects of

the operation. No available motor controller chip is designed for this!

On looking things up, it seemed that "AlNiCo 5" looked

like a good alloy. It has similar strong pull to FeNdB supermagnets,

but is easily magnetized and demagnetized. That seemed to say they

should work well in BLDC magnet-rotor motors per above. So I looked for

some the same size as my Electric Hubcap type coil cores. I did find

some that looked like they might be somewhat suitable, or 6" long 2"

diameter rods that might be cut to length, 5 magnet cores per rod.

On the other hand, I haven't looked into this very far yet

and I'm not certain I understand all the details. I shall be checking

into it in more detail before trying anything.

And then there's Bedini... His motors are supposed to use

single pulses to run. And then they collect electricity off the coils

as in a generator! Now I can see how this might produce extra energy -

if the pulse magnetizes a magnet, input energy is only required to

magnetize it and demagnetize it again at the right times. Maybe it's an

"undocumented feature" of his motors that's really how they work? Maybe

that he didn't realize himself but he picked steel for his coils that

holds magnetism, or holds it until it's used as a generator later in

the rotation? But that's all just speculation.

Electric

Hubcap motor, Chevy

Sprint & Variable Transmission

The Theory of The Frictionless Centrifugal Clutch

Insufficient traction of the centrifugal clutch seemed to

be the big problem with the drive. How is it supposed to work?

This clutch, designed for effective operation at lower and

marginal RPM.s, has a slightly different

operating principle than other centrifugal clutches: instead of the

shoes flying out with centrifugal force and engaging the outer drum by

friction, these shoes are made of slippery UHMW plastic, and have

45° "V" shaped lower points. (UHMW - ultra-high molecular weight

polyethylene - long polymer molecular chains. The two 45° angles,

for forward and for reverse, form a single 90° "V" angle.) When

they fly out, these

points slide easily along the polished aluminum drum until they reach

slots in the drum wall. When they hit the far wall of

the slot, they are forced to bounce inward for the input rotor to

continue rotating. The momentum of the weighted shoes bouncing off the

slot wall

is what produces thrust to the output drum. With the low friction

of the plastic on the aluminum, this should allow partly engaged

operation at "marginal" lower RPM.s with low losses and little heat,

with the input drum turning

faster than the output.

The angle of bounce that produces the most force in the

output drum is 90° - a straight-on hit with reflection straight

back. A hammer works that way. That angle of course stops the hammer.

We don't want to stop the motor. The best angle of impact and

reflection to impart the most force with lowest loss of motor speed is

45°, with the shoe bouncing 'directly' inward (90°) while the

input rotor/motor continues to turn.

Once the drum is turning at sufficient speed and the input

torque isn't too high, the points (or at least one point) will

centrifugally "lock" into the grooves and the clutch would be locked,

the output turning with the input.

In keeping with the large mass to be moved - the car - the

drum is 3" wide instead of a typical 3/4" for small rotary clutches. In

keeping with the low RPM.s, it's 9" diameter instead of a typical 4".

The car wheels will only be doing perhaps 1200 RPM on the highway and

600 in town. The drum speed depends on the final drive ratio. If it's 3

to 1, that's still only around 1800 RPM of the drum in town at 50 Km/Hr.

Slots and Points/Dogs

I had

impression that the 45° "V" shaped "dogs" on the

plastic shoes had

been partly worn off of it by the edges of the aluminum slots in the

drum. The slots were cut with a bandsaw. I had scraped them with a tool

that smoothed off and beveled the corners, but essentially the flat

plastic faces were still hitting against a 90° corner - a "V" point

hitting a "U" hollow - and that was wrecking them. What was needed

surely was two flat faces hitting each other. That would mean filing or

cutting out all 24 slots in the drum so they were 45° "V" shaped

slots instead of "U" shaped.

I had

impression that the 45° "V" shaped "dogs" on the

plastic shoes had

been partly worn off of it by the edges of the aluminum slots in the

drum. The slots were cut with a bandsaw. I had scraped them with a tool

that smoothed off and beveled the corners, but essentially the flat

plastic faces were still hitting against a 90° corner - a "V" point

hitting a "U" hollow - and that was wrecking them. What was needed

surely was two flat faces hitting each other. That would mean filing or

cutting out all 24 slots in the drum so they were 45° "V" shaped

slots instead of "U" shaped.

I discussed this with Jim Harrington at breakfast on the

6th. I thought maybe a 'dremmel' motor tool with some cutter might

work, but perhaps there was some sort of 'right angle' dremmel tool -

shaped like an angle grinder - that would fit inside the drum. Perhaps

a visit to a tool store? We stopped by his shop. He had a right angle

attachment for his demmel tool. I borrowed that, and found a suitable

rotary cutter in my own attachments.

I spent the afternoon changing the vertical

slots to

45° "V"s. I was guessing the angles at first, then I reasoned that

while one may be in considerable doubt about most 'eyeballed' angles,

vertical and horizontal can be judged pretty accurately by eye. If I

clamped the rotor so the slot was at 45°, those would be the

angles. Logic said that if there were 24 slots, a slot 3 up from the

bottom one would be 45°. It looked to me more like the fourth slot

was 45°. I got out a plastic 45° drawing triangle and it was

indeed the third slot, not the fourth. That shows how far off my

freehand angle estimates might have been, but now the walls of the

slots I was cutting were to be either vertical or horizontal.

I spent the afternoon changing the vertical

slots to

45° "V"s. I was guessing the angles at first, then I reasoned that

while one may be in considerable doubt about most 'eyeballed' angles,

vertical and horizontal can be judged pretty accurately by eye. If I

clamped the rotor so the slot was at 45°, those would be the

angles. Logic said that if there were 24 slots, a slot 3 up from the

bottom one would be 45°. It looked to me more like the fourth slot

was 45°. I got out a plastic 45° drawing triangle and it was

indeed the third slot, not the fourth. That shows how far off my

freehand angle estimates might have been, but now the walls of the

slots I was cutting were to be either vertical or horizontal.

Although the cutter wasn't symetrical it was cutting into

both sides of the slot. But I thought I should flip it up so both sides

were cut with both faces of the cutter to be the most symetrical. After

grinding the cutter through a few times horizontal, I tried to turn it

vertical, but it bounced and stuttered. So instead, I turned the drum

around so the current slot was 3 up on the right instead of the left,

and turned the cutter to vertical. This worked. (Hmm, I could have just

flipped and rotated the drum so I could have done all the cuts

horizontal.)

After cutting a few I started filing them smooth. The

whole process went smoothly, but it was time consuming to do all 24

slots. The most brilliant thing I did that afternoon was to stop after

doing a few and go out and buy a new file. Not surprisingly, it filed

faster than any of my old ones.

I had, for my original

experimental purposes, taken the

path of least resistance in making the clutch. It was really only 'one

way' and would jam going the other way. The dual 45° "V" is of

course a right angle, 90°, which I got by using a corner of the

rectangles. To get true symmetry, the pivot hinge of the shoes would

have to be straight in line with the "V", which would put it outside

the drum. That would be theoretically possible with a drum open on one

side, a larger input disk outside that open side, and shoes with a

"stem" attached to pins outside the drum radius through the open side.

But that would be inherently weak. Otherwise, the 45° bounce from

an interior hinge point has to use different angles for one direction

than for the other. My "V" points and slots should be quite

slanted, "in italics" to say the least, to have symmetrical forces

forward and backward.

In fact, that's probably a reason for the low force. The

active side should be steeper. Now I think of that, after doing

the "V" slot cutting and filing, symmetrically! It was only as I was

half way through that it gradually started to dawn on me that the other

sides would have to be shallower so as not to jam, and still later that

the one-way active side should be steeper to match the pivot points. If

it doesn't work well I could make pivot pin points closer to the outer

edge of the input disk - where I had them originally - and shape the

shoes' "V" points on the bandsaw - as I also did them originally. I had

changed it for the last version only because they were hard to cut.

(Later it seemed more complicated... read on.)

I thought I would turn the present clutch shoes around so

they would use the un-worn corners of the rectangles. Then the car

would go only forward instead of only backward. To prove a point of

working or not, it makes little difference. Once the point was proven,

the angles would have to be adjusted... or would the active edge angles

have to be optimized in order to get it to work and prove the point?

But when I went to do it (8th), I found that only the

outer bits of the shoes were badly worn - the parts that are seen from

outside. Here they were hitting the support clips that hold the drum

onto its backing disk. I had realized this was inevitable, but I didn't

see any better way to attach it when I was making it. The corner-edge

hitting along the slots was only slightly dulled. That means that

changing the slots to "V"s would make little difference... except that

they were now substantially wider at their tops and in total effect.

Changing to the italic "V" shape might make more difference.

Anyway I decided that it was worth trying again with the wider slots to

see what improvement there might be.

Next something jogged my memory: some centrifugal clutches

didn't have pivot hinges. Instead, the shoe piece slides straight out

to contact the drum. Two I bought quite a while ago from Princess Auto

were examples of that. If I could arrange mine somehow like that, the

straight "V"s would be right, and the forces maximum. Also the slippery

plastic would allow them to slide in and out with little friction. Fat

aluminum blocks on the input rotor disk, holding slippery UHMW shoes

(with weights) that bounce in and out - Ya, ya, I thought, that's the

ticket!

Commercial centrifugal clutches with sliding

shoes for snowmobiles, motorbikes, etc.

Commercial centrifugal clutches with sliding

shoes for snowmobiles, motorbikes, etc.

Clutches from a washing machine transmission

with pivoting shoes.

Clutches from a washing machine transmission

with pivoting shoes.

The one on the left would doubtless grab - jam - in one direction, slip

in the other.

The one on the right will press against an outer drum and an inner drum

with strategically placed weight and springs.

On the 10th I considered that I should make this - redo

the input rotor and shoe arrangement. But to get sufficient weight in

the shoes for good forces at low RPM.s, they should probably be heavy

steel, with a plastic "V" face screwed onto the outer end to contact

the drum. Then instead of aluminum, the side walls should be UHMW. Best

might be a single piece of UHMW with four cutouts for four sliding

shoes, almost as large as the inside diameter of the drum to make

maximum length slots to hold the shoes. (The clearance on the small

commercial clutch is about 2mm.) Let's see... The present weight of

each of the 6 shoes is 90 grams. If the new shoes were 1.25" wide by

.75" long by 2.5" high (depending which way you look at it) solid

steel, they'd be 280 grams. (about 120g/inch^3) So 3 times the weight

per shoe, bouncing in a more effective direction (and so imparting,

say, triple the force?), then 8 shoes instead of 6, would likely make

around 12 times the turning force at the same RPM. That seemed likely

to produce results.

A shoe to slide in and out, a lead weight for a

shoe (too heavy!), and a steel rectangle

to slide along a slot in the disk, with a shoe bolted to each side.

In the evening I came up with a somewhat different plan

than the commercial units: Leave the disk rotor centered in the drum,

so that it will still have 1/2 the shoes on each side, about 1-1/4" on

each side. Instead of a metal "X" for the shoes to slide against, mill

short slots in the rotor, 2 for each pair of shoes. Bolts will clamp

the left and right half shoes together through the slots.

In the evening I came up with a somewhat different plan

than the commercial units: Leave the disk rotor centered in the drum,

so that it will still have 1/2 the shoes on each side, about 1-1/4" on

each side. Instead of a metal "X" for the shoes to slide against, mill

short slots in the rotor, 2 for each pair of shoes. Bolts will clamp

the left and right half shoes together through the slots.

I worked out more details on the 11th. The slots will

contact only the slippery UHMW plastic of the shoes, hold the shoes at

right angles to the drum as the "X" pieces, and allow them to move in

and out by about 5mm - from 2mm clearance like the commercial units to

where the "V" points would bottom out in the "V" slots in the drum.

Bolted to the UHMW shoes and fitting into the profile would be lead

bars for weight. The same bolts that clamp the shoe halves together

will clamp the bars onto the outside.

All great, but by the 13th I started to think of the high

transient forces knocking the shoes to the side. I started to realize

that the commercial shoes wouldn't tend to twist because their feet

were so wide, taking up almost 1/4 of the drum each. And they were

intended to rapidly "latch" by friction against the drum, not to

operate for long

in a slipping mode. My shoes had to

bounce in and out of the "V" grooves - they hit at specific points

along the

rim. The operation just wasn't the same. Could the plastic at the slot

edges take repeatedly rubbing up and down against strong sideways force

on the outer end? Maybe the sliding part should be inserted steel bars?

Then it would need lubrication. If the sliding slot parts got too worn,

or if the lube ran dry, might it tend to jam?

I started to think hinge pins were the better form after

all, and went back to that idea. Since the pivot point had to be inside

the drum on the rotor disk, the best way to keep the forces relatively

even between forward and reverse would be the distance between hinge

pin and "V" slot in the drum where the force would be tangental to the

disk. (Ie, parallel to the edge at the hinge pin. I *think* I have the

right word.) That appeared to be about 2.0". The lead weight would also

center over the "V" point at the 2" mark, and the shoe lengthened

beyond 2" to attach the weight.

Also on the 13th I got some lead fishing weights and a 3Kg

chunk of galena from Jim Harrington to use for the weights. The galena,

natural lead mineral or ore, looked to be reasonably pure lead. I

figured I could melt some of these down in the mini-kiln and cast them

into bars easily enough, rather than trying to source lead bar of just

the size I needed. People warned me to beware of lead fumes. This is

why I would use the kiln. With a torch, the temperature on the outside

can start the lead boiling and giving off fumes before it's melting on

the inside. In the kiln, I won't let it get hot enough to give off

fumes. If I use the galena, I will still be cautious because of the

unknown impurities in it.

On the 14th I

cut a sample shoe out for size and tried it

for fit. A 1"x~1"x2" lead weight would go in the hollow space, perhaps

100 grams. I carefully cut out the shape on my scary big bandsaw, and

drilled the hole for the pin, without incident up to the point where

the drill was stopped, all operations completed. The thick UHMW plastic

(as usual) had wound itself up the drill bit as it drilled. As I

twisted the chuck backward to wind it off while holding the piece with

my left hand, my middle fingernail caught and cut a gash in the knuckle

on my left index finger. Ugh, where's the bandages? Accidents are so

often when no danger is suspected! The piece seemed

just about right, except for tending to jam if the middle piece was

turned clockwise. Making the one edge just a little shallower angle for

'reverse' should take care of that. And of course a steeper angle would

be better for 'forward' - the italic "V" slots and points. Well,

I could still do them, digging all the slots a little deeper

and wider. I decided it should be done.

On the 14th I

cut a sample shoe out for size and tried it

for fit. A 1"x~1"x2" lead weight would go in the hollow space, perhaps

100 grams. I carefully cut out the shape on my scary big bandsaw, and

drilled the hole for the pin, without incident up to the point where

the drill was stopped, all operations completed. The thick UHMW plastic

(as usual) had wound itself up the drill bit as it drilled. As I

twisted the chuck backward to wind it off while holding the piece with

my left hand, my middle fingernail caught and cut a gash in the knuckle

on my left index finger. Ugh, where's the bandages? Accidents are so

often when no danger is suspected! The piece seemed

just about right, except for tending to jam if the middle piece was

turned clockwise. Making the one edge just a little shallower angle for

'reverse' should take care of that. And of course a steeper angle would

be better for 'forward' - the italic "V" slots and points. Well,

I could still do them, digging all the slots a little deeper

and wider. I decided it should be done.

There were already 5 holes

equally spaced around the rim

of the rotor from some previous attempt. There were 24 slots in the

drum. 5 pairs of shoes would mean that one pair of points would hit one

slot at a time in quick succession, rather than all the points striking

at once. Would that have the desired effect? I decided to try it. If it

worked, it would be the smoothest. If it worked. I still didn't have

any proper software to draft the shapes. The curves would be

complicated to work out directly in G-code. I decided to approximate

them as a series of short lines. Each shoe would be cut out with a

series of relative moves, and between those, 10 absolute moves to

position the router for the start of each shoe to make all 10. The

italic "V" dog/point angles could be seen and adjusted to

45° relative to the hinge pin angle for optimum bounce.

Ideally I'd use 1.25" thick UHMW, but I had 13/16", 1" or

1.5". Or

there was thinner stock which could perhaps be doubled. Simplest would

be to use 1" and accept that the points would only be using 2" width

within the 3" drum slots. If it worked well - and if there were no

other desired changes anyway - I could worry about optimizing the

widths better when the first set wore out - if they did wear out over

too short a span of time. (I used the 13/16" for

the first experiment, since it was the one thickness I had plenty of.)

On the 18th, I still wasn't sure about angles. I didn't

want to grind new angles in the drum and then have to undo them again!

And they would get wider and deeper with each cut. I had to have a

clear concept. How did the forward and reverse angles of the hinge pin

figure in? Wasn't it the weights, to be positioned directly over the

points, that would push the shoes out centrifugally? If the rotor was

spinning a constant speed, wouldn't they go out tangent to the start of

the slot until they hit the far side, rather than at the hinge pin

angle? Weren't the angles of the points hitting the drum then

independent of the hinge pin angles? Then again, the angle of

relection/bounce would be different for the input disk than for the

output drum because they would be rotating at different speeds. The

whole thing was more complicated than I'd realized. It seemed likely

that the hinge pin point would make the action somewhat different in

one direction than in the other, but it probably wasn't as much

difference as the hinge pin angle by itself would indicate. If one

direction worked better than the other, one would of course pick the

better one as forward and the other as reverse. And the test shoes

would be symmetrical and could be reversed. Or, the shoes on one

side could be reversed and it would be symmetrical. But the uneven

forces would stress the pins. The angles of points and

slots on production prototypes and production units could be adjusted

optimally for both directions.

Perhaps the only critical point was that the "V" dog must

not actually jam if one fell into one of the "V" slots while the

mechanism was stopped. I checked this out with my sample shoe on the

19th and pinned at the pivot point and with disk holes correctly

positioned, it didn't seem it could jam anywhere. I started in on the

G-code to rout out 10 identical shoes but was soon interrupted. I got

an initial version designed on the 20th, but didn't find time to get

everything set up and make a sample. On the 21st I made 5 versions of

sample shoes before getting the dimensions close enough to use, and a

couple more later. On the 25th I figured I had them nicely figured and

made a pair. It seemed to fit well and I made two more pairs. I now

needed more bolts, nuts and washers and went off to do some shopping. I

told the router to do all the remaining 4 at once. Part way through the

first pass, the router bit snapped off. (I suspect it was getting dull

- it didn't seem as smooth as usual.) Since the router now wasn't doing

anything, I let it finish its course not cutting instead of shutting

the machine off. That way when I told the router to move to "home", the

starting point, it "knew" where "home" was to find it. From "home" it

could cut exactly the same path again next time and redo the job. It

was too late to go out and buy a new router bit, so that was it for the

day. I finished the next.

Perhaps the only critical point was that the "V" dog must

not actually jam if one fell into one of the "V" slots while the

mechanism was stopped. I checked this out with my sample shoe on the

19th and pinned at the pivot point and with disk holes correctly

positioned, it didn't seem it could jam anywhere. I started in on the

G-code to rout out 10 identical shoes but was soon interrupted. I got

an initial version designed on the 20th, but didn't find time to get

everything set up and make a sample. On the 21st I made 5 versions of

sample shoes before getting the dimensions close enough to use, and a

couple more later. On the 25th I figured I had them nicely figured and

made a pair. It seemed to fit well and I made two more pairs. I now

needed more bolts, nuts and washers and went off to do some shopping. I

told the router to do all the remaining 4 at once. Part way through the

first pass, the router bit snapped off. (I suspect it was getting dull

- it didn't seem as smooth as usual.) Since the router now wasn't doing

anything, I let it finish its course not cutting instead of shutting

the machine off. That way when I told the router to move to "home", the

starting point, it "knew" where "home" was to find it. From "home" it

could cut exactly the same path again next time and redo the job. It

was too late to go out and buy a new router bit, so that was it for the

day. I finished the next.

It seemed lead isn't as dense as I thought, 11 g/cc where

I had been thinking upper teens. Then, it didn't look like it would

need a very big piece to gt 100 grams. Why not use steel instead? On

March 1st I got some 5/8" x 5/8" steel rod. I cut one 2" length to fit

in a shoe (does that make it a foot?) and it weighed exactly 100 grams.

On the second I cut and shaped 5 more.

The output drum with the input disk rotor

holding the 10 shoes,

The output drum with the input disk rotor

holding the 10 shoes,

one with the first weight in it.

A side thought was how the angles might change if there

was a very short spring on each side of the hinge pin. The pin with the

weight would then be free to bounce straight inward, at 90°,

45° from the face of the slot. Compared to the input disk, it could

even bounce backward to an extent as it bounced out of the slot. The

force to the output would be a sudden impact, but the force on the

motor would be more spread out, over the compressing and decompressing

of the spring. But I decided to think about that rather

complicated-to-build idea later.

Motor & Kelly Controller

Meanwhile (9th), I looked up the Kelly BLDC motor

controller error codes to see why the motor would only run one

direction and the red LED would start repeatedly doing 2 blinks for the

other, and why it was stopping with 3 blinks at times with high load.

But the blinks didn't match what the manual said, which was that 1

initial blink, or 2, or 3, or 4, would be followed shortly by a second

set of 1 to 4 blinks. Unless it was 2-2 and 3-3 I was getting and I

hadn't noticed a different gap length between pairs. 3-3 might make

sense for "shorted throttle" for when I turned it right up... in which

case the potentiometer should be "shorted", 0 ohms. Why wouldn't that

be a normal condition? 2-2, "internal fault or +5v supply overload",

didn't seem to make sense to happen only for one direction.

I mounted the motor without the transmission in

place and tried running it again. Momentarily not thinking I turned

the control up to maximum. Sure enough, the blink had been 3-3

("throttle shorted"), then a longer gap, from turning the throttle

right up.

I wasn't thinking when I did this. Of course going to full

power also spun the unloaded motor up to a scary RPM, well over 3000 I

think and maybe over 4000. But nothing happened. At least it showed the

motor was substantially more robust than before! What I still didn't

have was the "break-out box" for the position sensors so I could easily

connect a frequency meter as a tachometer to read the actual RPM.

It still only ran one direction. The phases were indeed

wrong. The pieces of colored tape were, somehow, on the wrong wires. On

the 5th try out of 6 possibilities, it ran smoothly - more smoothly

than before - in both directions. Probably I didn't have it right to

start with. The motor originally had only done a few spins before the

magnets flew off the rotor, so the testing didn't get very far. I got

some new pieces of colored tape and put them on the appropriate wires.

I could clip all three pin sockets together on each side so it can't be

plugged in wrong, but I've found that three big "70 amp" APP connectors

in one are very hard to push together and pull apart. One at a time is

much easier, and I'm doing a lot of mounting and dismounting of the

motor in this.

But there was something very concerning: I smelled

something. It was the motor coils getting hot. With no load! With my

controllers, the motors seem to pretty much run cold. Why should they

be different with the Kelly controller? One phase seemed to be hottest,

one midway and one definitely cooler than the other two. Could it have

been heating up when the phases were hooked up wrong, and was still

hot? That would probably result in different currents between phases...

but some time had gone by since then. Or was it simply the higher

switching frequency... and, should that make a difference to the coils?

At least it meant that the controller must be delivering some very

substantial currents to the motor! It would be something to check next

time I ran it.

I took off the motor and put the clutch input plate in,

without the planets gears and pulley. That way I could see inside. I

wasn't sure the sun gear on the motor wasn't rubbing against the side

of the ring gear, but to my surprise, in fact there was about 1/4" gap.

I had cut the splined shaft a little too short last month. That

explained why the planets gear had worked itself part way off the ring

gear in spite of the thrust bearing - it wasn't pressing sideways with

unstoppable force, rather there was nothing to stop it from drifting

sideways that far. At least that now made sense and showed it wasn't a

real problem. I decided to pound the ring gear 3/16" off the end of the

shaft to effectively lengthen it. That puts the strongest part of the

sun gear center over the end gap, but it should withstand at least a

few tests.

I also discovered that the pin holding the splined shaft

centered in the transmission had unscrewed itself and fallen out. In

forward

it would try to screw itself farther in, and when I had made it I had

discounted the chance it would unscrew in the occasional bit of reverse

driving. Now all my tests were in reverse. It would have fallen out

when I took out the input rotor, as soon as I tipped it down. (Now,

where did it go? Into the lawn somewhere, most likely.) Well, it was

just a 3/8" stainless steel bolt with the head cut off. I didn't find

it so I made a

new one.

All was then ready and waiting for the next clutch

experiment.

http://www.TurquoiseEnergy.com

Victoria BC Canada

Then I designed new shoes for the centrifugal clutch. First I cut a

sample

shoe on the bandsaw.

Then I designed new shoes for the centrifugal clutch. First I cut a

sample

shoe on the bandsaw.

I had

impression that the 45° "V" shaped "dogs" on the

plastic shoes had

been partly worn off of it by the edges of the aluminum slots in the

drum. The slots were cut with a bandsaw. I had scraped them with a tool

that smoothed off and beveled the corners, but essentially the flat

plastic faces were still hitting against a 90° corner - a "V" point

hitting a "U" hollow - and that was wrecking them. What was needed

surely was two flat faces hitting each other. That would mean filing or

cutting out all 24 slots in the drum so they were 45° "V" shaped

slots instead of "U" shaped.

I had

impression that the 45° "V" shaped "dogs" on the

plastic shoes had

been partly worn off of it by the edges of the aluminum slots in the

drum. The slots were cut with a bandsaw. I had scraped them with a tool

that smoothed off and beveled the corners, but essentially the flat

plastic faces were still hitting against a 90° corner - a "V" point

hitting a "U" hollow - and that was wrecking them. What was needed

surely was two flat faces hitting each other. That would mean filing or

cutting out all 24 slots in the drum so they were 45° "V" shaped

slots instead of "U" shaped. I spent the afternoon changing the vertical

slots to

45° "V"s. I was guessing the angles at first, then I reasoned that

while one may be in considerable doubt about most 'eyeballed' angles,

vertical and horizontal can be judged pretty accurately by eye. If I

clamped the rotor so the slot was at 45°, those would be the

angles. Logic said that if there were 24 slots, a slot 3 up from the

bottom one would be 45°. It looked to me more like the fourth slot

was 45°. I got out a plastic 45° drawing triangle and it was

indeed the third slot, not the fourth. That shows how far off my

freehand angle estimates might have been, but now the walls of the

slots I was cutting were to be either vertical or horizontal.

I spent the afternoon changing the vertical

slots to

45° "V"s. I was guessing the angles at first, then I reasoned that

while one may be in considerable doubt about most 'eyeballed' angles,

vertical and horizontal can be judged pretty accurately by eye. If I

clamped the rotor so the slot was at 45°, those would be the

angles. Logic said that if there were 24 slots, a slot 3 up from the

bottom one would be 45°. It looked to me more like the fourth slot

was 45°. I got out a plastic 45° drawing triangle and it was

indeed the third slot, not the fourth. That shows how far off my

freehand angle estimates might have been, but now the walls of the

slots I was cutting were to be either vertical or horizontal.

In the evening I came up with a somewhat different plan

than the commercial units: Leave the disk rotor centered in the drum,

so that it will still have 1/2 the shoes on each side, about 1-1/4" on

each side. Instead of a metal "X" for the shoes to slide against, mill

short slots in the rotor, 2 for each pair of shoes. Bolts will clamp

the left and right half shoes together through the slots.

In the evening I came up with a somewhat different plan

than the commercial units: Leave the disk rotor centered in the drum,

so that it will still have 1/2 the shoes on each side, about 1-1/4" on

each side. Instead of a metal "X" for the shoes to slide against, mill

short slots in the rotor, 2 for each pair of shoes. Bolts will clamp

the left and right half shoes together through the slots. On the 14th I

cut a sample shoe out for size and tried it

for fit. A 1"x~1"x2" lead weight would go in the hollow space, perhaps

100 grams. I carefully cut out the shape on my scary big bandsaw, and

drilled the hole for the pin, without incident up to the point where

the drill was stopped, all operations completed. The thick UHMW plastic

(as usual) had wound itself up the drill bit as it drilled. As I

twisted the chuck backward to wind it off while holding the piece with

my left hand, my middle fingernail caught and cut a gash in the knuckle

on my left index finger. Ugh, where's the bandages? Accidents are so

often when no danger is suspected! The piece seemed

just about right, except for tending to jam if the middle piece was

turned clockwise. Making the one edge just a little shallower angle for

'reverse' should take care of that. And of course a steeper angle would

be better for 'forward' - the italic "V" slots and points. Well,

I could still do them, digging all the slots a little deeper

and wider. I decided it should be done.

On the 14th I

cut a sample shoe out for size and tried it

for fit. A 1"x~1"x2" lead weight would go in the hollow space, perhaps

100 grams. I carefully cut out the shape on my scary big bandsaw, and

drilled the hole for the pin, without incident up to the point where

the drill was stopped, all operations completed. The thick UHMW plastic

(as usual) had wound itself up the drill bit as it drilled. As I

twisted the chuck backward to wind it off while holding the piece with

my left hand, my middle fingernail caught and cut a gash in the knuckle

on my left index finger. Ugh, where's the bandages? Accidents are so

often when no danger is suspected! The piece seemed

just about right, except for tending to jam if the middle piece was

turned clockwise. Making the one edge just a little shallower angle for

'reverse' should take care of that. And of course a steeper angle would

be better for 'forward' - the italic "V" slots and points. Well,

I could still do them, digging all the slots a little deeper

and wider. I decided it should be done. Perhaps the only critical point was that the "V" dog must

not actually jam if one fell into one of the "V" slots while the

mechanism was stopped. I checked this out with my sample shoe on the

19th and pinned at the pivot point and with disk holes correctly

positioned, it didn't seem it could jam anywhere. I started in on the

G-code to rout out 10 identical shoes but was soon interrupted. I got

an initial version designed on the 20th, but didn't find time to get

everything set up and make a sample. On the 21st I made 5 versions of

sample shoes before getting the dimensions close enough to use, and a

couple more later. On the 25th I figured I had them nicely figured and

made a pair. It seemed to fit well and I made two more pairs. I now

needed more bolts, nuts and washers and went off to do some shopping. I

told the router to do all the remaining 4 at once. Part way through the

first pass, the router bit snapped off. (I suspect it was getting dull

- it didn't seem as smooth as usual.) Since the router now wasn't doing

anything, I let it finish its course not cutting instead of shutting

the machine off. That way when I told the router to move to "home", the

starting point, it "knew" where "home" was to find it. From "home" it

could cut exactly the same path again next time and redo the job. It

was too late to go out and buy a new router bit, so that was it for the

day. I finished the next.

Perhaps the only critical point was that the "V" dog must

not actually jam if one fell into one of the "V" slots while the

mechanism was stopped. I checked this out with my sample shoe on the

19th and pinned at the pivot point and with disk holes correctly

positioned, it didn't seem it could jam anywhere. I started in on the

G-code to rout out 10 identical shoes but was soon interrupted. I got

an initial version designed on the 20th, but didn't find time to get

everything set up and make a sample. On the 21st I made 5 versions of

sample shoes before getting the dimensions close enough to use, and a

couple more later. On the 25th I figured I had them nicely figured and

made a pair. It seemed to fit well and I made two more pairs. I now

needed more bolts, nuts and washers and went off to do some shopping. I