Turquoise

Energy Ltd. News #98

covering March 2016 (posted April 2nd 2016)

Victoria BC

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Features:

* Planetary Gear Torque Converter with Flywheel Drives Chevy Sprint!

(see Month in

Brief, Electric Transport)

* Nickel-Nickel Battery in Potassium Sulfate Holds Charge! (see

Month in Brief, Electricity Storage)

Month In Brief

(Project Summaries)

- The 28th - Miles Electric Cargo Truck Repair - Hands-On

Democracy Updated - a small

tilapia/aquaponics

update - Electropermanent Magnet Motors: A Whole New Field... or is it

"new"? - THREE Variable Transmissions & Sprint Car: 1. Frictionless

Centrifugal Clutch; 2. Add-On Motor & Wheel Drive; 3. Planetary

Gear Torque Converter (PGTC) with Flywheel (Now Working) -

Nickel-Nickel Battery: the simple secret! - Canada Revenue Report

(What, late again?!?)

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Life on Pluto - preposterous?

- In Depth

Project Reports -

Electric Transport - Electric Hubcap Motor Systems

* Lower RPM, Frictionless

Centrifugal Clutch - Making progress and tests - finally... abandoned.

* New direct-to-wheel belt drive with clutch and flywheel idea -

exploratory work.

* Planetary Gear Torque Converter (PGTC) installation and tests: it

works... Sprint to hopefully be made roadworthy with it.

Other "Green"

Electric Equipment Projects (no reports)

Electricity Generation (no reports)

Electricity Storage - Turquoise Battery

Project (NiMn, NiNi), etc.

* Nickel Foam Arrives

* Filling a nickel-nickel cell with potassium sulfate

* Making and testing a new test cell and purer potassium sulfate... It

works!

No Project Reports on: Lambda ray

converter, CNC

gardening/farming machine, Electric Weel, unipolar motor controller,

reluctance motors (will need to modify the controllers and motors for

electropermanent magnets!).

March in Brief

The 28th, A Happy Easter Monday

The month went by like most, doing this and that on the

projects amidst other things. But the 28th turned out to be a very good

day, with two positive results for things I've been trying to get

working for years. That seems like a good place to start!

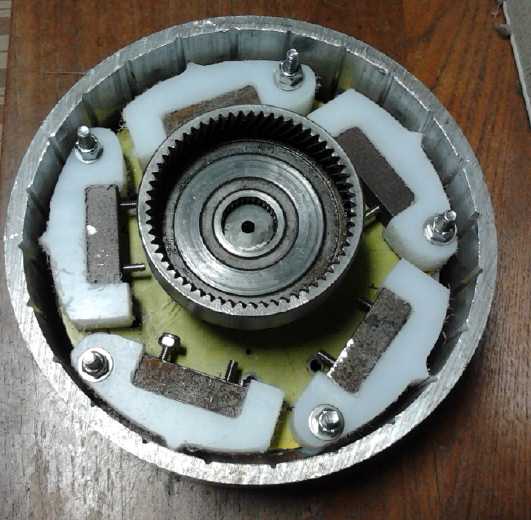

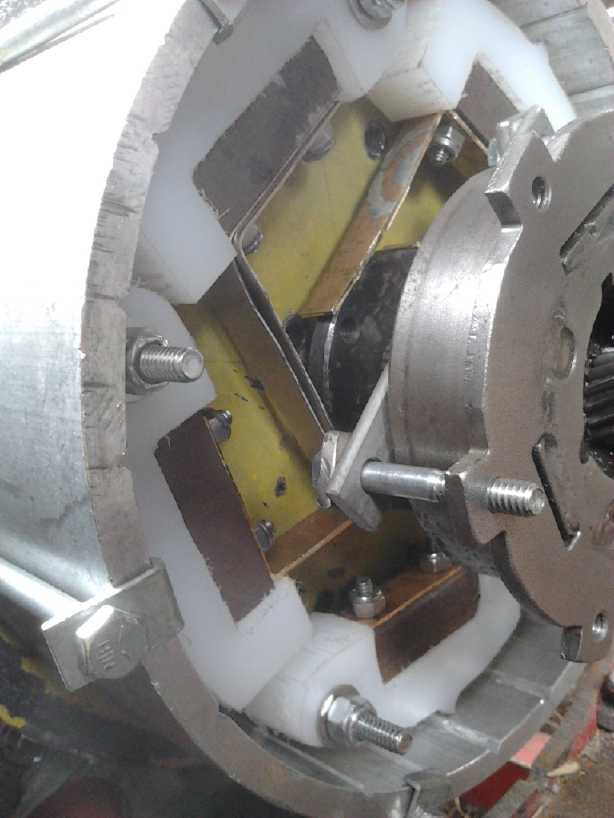

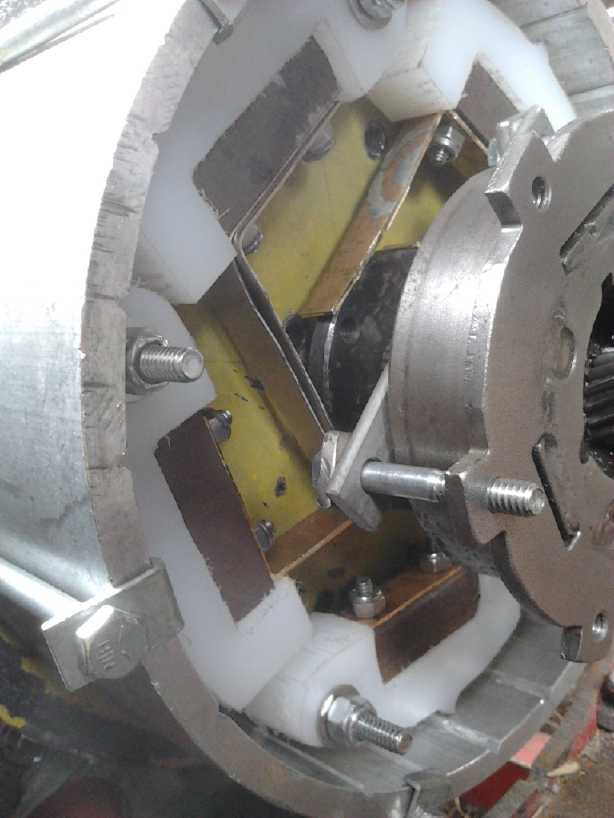

L to R -- Flywheel (heavy

cast 12" pulley); Yellow/Blue Electric Hubcap Motor;

Standoff with thrust bearing; Planet Assembly with 10" tensioning

pulley

& tensioning rope;

Ring gear (hidden) on shaft to sprocket (Chain Drive to Differential);

shaft

bearings in hub.

Upper thin pull rope is to operate tensioning system from outside car.

That day I at

last got the Sprint car to move

somewhat

nicely, with the planetary gear torque converter transmission (PGTC -

and no

centrifugal clutch). I shot some footage to show and describe it later.

With a flywheel on the motor to boost the car into motion (and after a

pile

of

incidental things to be done) I think it just might be able to hit the

streets and I plan to put it all together.

That day I at

last got the Sprint car to move

somewhat

nicely, with the planetary gear torque converter transmission (PGTC -

and no

centrifugal clutch). I shot some footage to show and describe it later.

With a flywheel on the motor to boost the car into motion (and after a

pile

of

incidental things to be done) I think it just might be able to hit the

streets and I plan to put it all together.

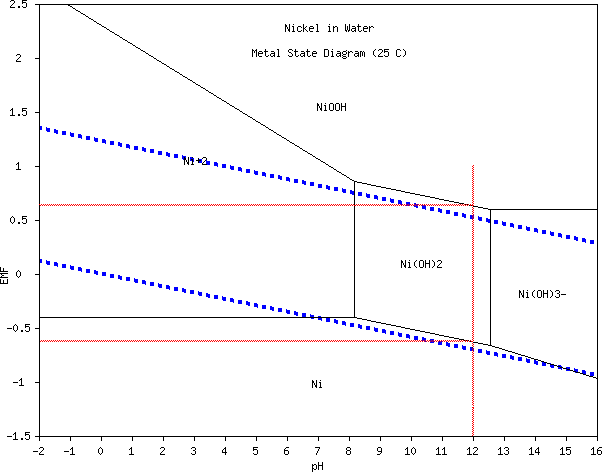

On the same

day I at last got a nickel-nickel

battery to hold its 1.25 volt charge, simply by using potassium sulfate

solution as electrolyte instead of potassium chloride. At last, with

this one little but apparently vital change, I think I just might have

a practical EV battery chemistry - one with good energy density and

exceptional current capacity!

On the same

day I at last got a nickel-nickel

battery to hold its 1.25 volt charge, simply by using potassium sulfate

solution as electrolyte instead of potassium chloride. At last, with

this one little but apparently vital change, I think I just might have

a practical EV battery chemistry - one with good energy density and

exceptional current capacity!

...and now back to a more chronological

order of events.

Miles Electric Cargo Truck Repairs

The culprit was the little brown

LED/Phototransistor assembly, here unplugged.

The culprit was the little brown

LED/Phototransistor assembly, here unplugged.

The motor is underneath the truck. Two protective covers go over

this delicate

assembly including a big metal one over the whole end of the motor.

Notwithstanding,

there was some corrosion in the threaded bolt holes, and likely inside

the reader unit.

I received the part, the

"reader" for the motor rotation

sensing, from Canadian Electric Vehicles (canev.com) on the 4th. On the

5th I installed it, reassembled enough to

have it run, drove the truck up and down the street to test it, and put

the cab seats et al back together. It ran fine and I expect its

troubles

are

over. Perhaps it's just as well I didn't know the truck had an unknown,

intermittent problem when I bought it - I probably wouldn't have and

would have missed a bargain. It's a great in-town delivery vehicle, but

I don't think it's what I want to drive for most of my driving. So I'll

consider it an investment, perhaps to be sold hopefully for a

profit some time - unless I find I'm delivering green energy products

to customers!

Hands-On Democracy - Proposals for How to Run a World

I made several improvements and extensions to my Hands

On Democracy (HandsOnDemocracy.org)

write-up

for

having

people-controlled

governments

and

voting

via

the

internet,

including

new (if vague) proposals for how a future legislature just might be

constituted and for democracy in the workplace. That makes 10 unique

proposals for improving on the way things are run today. I put in lots

of

keywords for search engines and I now leave these seeds in the lap of

the gods for interested people to find, and to plant those they may

find useful. From

experience so far I don't expect much interest before things finish

falling apart. After that people will be searching for fresh solutions

and be willing, even eager, to try them out.

A Small Tilapia/Aquaponics Update

Well, I haven't done much on this this winter. The tilapia

have been languishing in an aquarium on the floor since the old one

started leaking. This month I found a used aquarium and stand and moved

them. Hopefully sometime they'll breed again. I consider that a main

problem I had with tilapia attacking each other earlier was that all

but one seem to have been males. Now there are just three: the large

female, a smaller male, and the one male offspring that I saved when

all the rest were eaten as tiny fry, which is now almost as big as the

other male. They seem to get along fine.

I have also acquired some hydroponic/aquaponic grow beds

and I plan to place

them in the greenhouse and connect them to the goldfish pond in the

garden. All the fish waste in the pond is just growing algae, and I

can't change the water fast enough. What to plant? Let's see:

lettuce, spinach, the ubiquitous basil... what else? Greens. No beans!

A nice 'new' 30 US gallon tank for the tilapia

"breeding colony"

A nice 'new' 30 US gallon tank for the tilapia

"breeding colony"

Electropermanent Magnet Motors: A Whole New Field - or is it

"new"?

I searched youtube, and then the web, for

"Electropermanent Magnet Motor" and "Electropermanent Motor". All I

came up with besides "Electropermanent Magnets" (not motors) was

several hits on a patent for a tiny servo motor from DARPA, developed

at MIT for microrobotics. Other than that, the only relevant hit seemed

to be something titled Turquoise Energy News #97(!), my own

last newsletter, about 40

hits down. Apparently the whole field is brand new with almost nothing

written on the web about it.

But I found one interesting development on Youtube just

before that search - I forget how I ran across it... Someone had

translated

to English a 1966 video, perhaps from a TV news show, from a German

inventor who in 1962 made a large magnet motor that turned itself. The

inventor said that the magnets were demagnetized just before they

reached the "sticky spot" (where most attempted magnet motors halt

their rotation), and remagnetized after it, and hence the motor kept

turning. How this was accomplished wasn't said, but in essence it's the

operating principle of the electropermanent magnet motor. And he did it

before there were 'supermagnets', too! (He also mentioned being

undermined and thwarted in his attempts to patent or commercialize his

machine, which he hoped would replace polluting gasoline engines.

...what a surprise!)

On the topic of

electropermanent motors, I thought that the way to get the magnet

magnetized fastest, and hence using the least power,

would be to have the lowest inductance, so the current would rise

fastest to the critical level where it magnetizes the AlNiCo core, and

then be turned off. That would mean

the fewest turns of the heaviest wire. But at high frequencies, or in

this

case the desired very short pulse widths, there's the 'skin effect'

where most of

the current flows around the outside of the wire, and fatter wire isn't

as useful as might be expected. Finally, small gauge copper pipe came

to

mind. Lots of copper, fat, and all "skin". And (perish the thought) if

it should run too hot, one could flow water/coolant right through the

conductor coil! But presumably it will use little enough electricity

that it won't get hot. On the contrary I might squash the ends and

mount some of the transistors right on the pipe - it would make a good

copper heatsink!

On the topic of

electropermanent motors, I thought that the way to get the magnet

magnetized fastest, and hence using the least power,

would be to have the lowest inductance, so the current would rise

fastest to the critical level where it magnetizes the AlNiCo core, and

then be turned off. That would mean

the fewest turns of the heaviest wire. But at high frequencies, or in

this

case the desired very short pulse widths, there's the 'skin effect'

where most of

the current flows around the outside of the wire, and fatter wire isn't

as useful as might be expected. Finally, small gauge copper pipe came

to

mind. Lots of copper, fat, and all "skin". And (perish the thought) if

it should run too hot, one could flow water/coolant right through the

conductor coil! But presumably it will use little enough electricity

that it won't get hot. On the contrary I might squash the ends and

mount some of the transistors right on the pipe - it would make a good

copper heatsink!

THREE Variable Transmissions

&

Sprint Car

1. Frictionless Centrifugal Clutch

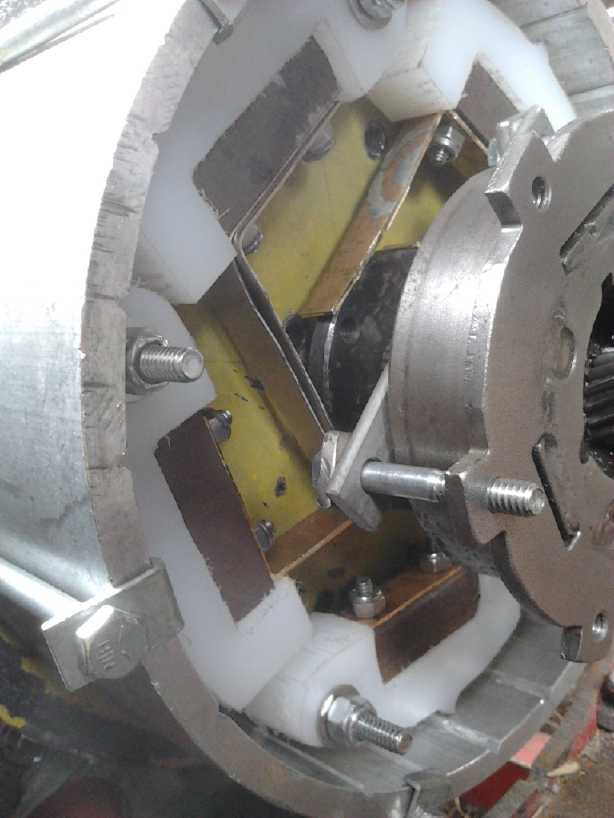

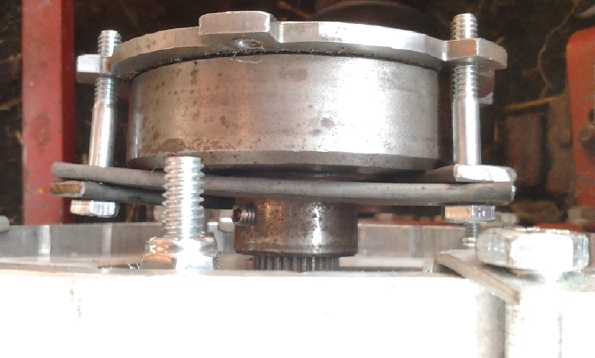

Centrifugal clutch with weighted shoes having

"V" points to click into the "V" slots

in the drum. The brass springs were much stronger than the first

thinner nickel-

brass springs. (With only enough brass for four springs, the fifth was

three of the

old ones put together.)

I continued

working on the frictionless centrifugal clutch. I bypassed the

planetary gear assembly (Clamped two of the gears together) so it was

just the clutch in effect on the motor shaft. I put in

the weights on the shoes and ran it. The car moved once, but the torque

was really pretty feeble. And it was noisy. I put in some springs to

push the shoes outward into the "V" slots in the drum and ran a test,

but the springs bent. Then I

made stronger springs and did another test, but I still wasn't getting

much torque out of it.

I continued

working on the frictionless centrifugal clutch. I bypassed the

planetary gear assembly (Clamped two of the gears together) so it was

just the clutch in effect on the motor shaft. I put in

the weights on the shoes and ran it. The car moved once, but the torque

was really pretty feeble. And it was noisy. I put in some springs to

push the shoes outward into the "V" slots in the drum and ran a test,

but the springs bent. Then I

made stronger springs and did another test, but I still wasn't getting

much torque out of it.

By this time however the partial hits had flattened out

the "V" points in the plastic shoes, which probably contributed

considerably to poor performance,

especially on the last tries with stronger springs, when everything

finally seemed to

"clack" solidly into place as it turned.

At this point I really should have sharpened up the "V"

points and put springs on the other 5 shoes on the other side as well

and tested it again.

It might have worked a whole lot better. But it was still noisy. And by

then,

the 24th, I was thinking of other means for driving cars.

The clutch has to be workable somehow, but

apparently I don't have all the factors right. If the hits at the "V"

slots transfer more of the momentum of the motor to the drum, it pretty

much has to work.

On the 25th, having just removed the clutch assembly,

I started coming up vaguely with a new design of "V" tooth, with an

extra moving part, that would snap instantly into the slot without the

weight

having to move. But then the weight would have to bounce with it for it

to bounce out of the groove again. It seemed promising if a bit

complex, but with fresh thoughts about other types of drives, I tried

hard to shove the idea out of my mind.

2. Add-On Motor & Wheel Drive

This time, instead of either a wheel mounted motor or a

toothed belt or chain drive direct to a rear wheel, I started thinking

of a flat belt with a pivot and spring motor mounting that would allow

the belt to act as a clutch. The

clutch would be combined with a flywheel on the motor. To start the car

moving, the motor would be revved up, then the clutch pedal would be

released. As the belt engaged, the momentum of the slowing flywheel

would be transferred to getting the car wheel turning before the belt

was tight. That way, the reduction ratio

between motor and wheel could be much lower than that needed to start

the car moving with a stopped motor -- maybe 3, 4 or 5 to 1 instead of

the typical EV's 10 to 1. It could essentially start already "in second

gear", eliminating the need for "first gear". A 3 to 1 or lower ratio

would put a small car with a 3000 RPM Electric Hubcap motor up to

highway speeds. (For a rough comparison, the Nissan Leaf motor turns

over 9000 RPM on the highway, in order that it will have the high gear

ratio for starting torque.) A 5 or 6 to 1 ratio would at least allow

city

driving -- or highway driving with a high RPM reluctance motor. With

any motor and ratio, the clutch with flywheel reduces the necessary

single gear ratio and RPM at any given speed.

I started looking at pulleys for flat belts. Bandsaw

"wheels" looked flimsy. The most

promising seemed to be to make one, using a 13" O.D. PVC pipe for the

outer rim to run the belt on - and probably a double (1.5" thick)

plywood center reinforced with steel.

On the 22nd I went out and sized up the Sprint for such a

rear wheel flat belt drive motor, armed with the motor and a very short

piece of the Turquoise 13" O.D. PVC culvert pipe for which Turquoise

Energy was named. External drive would have advantages even for the

engineless Sprint: if the motor and a transmission weren't under the

hood, there was room there for most of the batteries and the spare

tire, leaving most of the car interior free for its regular uses.

I was a little disappointed with how far out the motor

would stick, 6 to 8" depending where one measured from. But it would be

down where the plastic fender was. I looked underneath the car. It

appeared that if a part of the fender was cut away, and just a small

piece of body sheet metal, there was room in this particular car to put

the motor underneath the car, with the bottom still above the wheel

rim. Only the drive belt, pulleys, and a belt guard would stick out.

That could hardly work out better!

On the 24th I did some exploratory surgery. I removed the

rear fender from the car. It looked like if I cut away some of the

plastic fender, the end of the metal bumper beneath it, and a small

area of the body below the floor, there was room to put the motor

directly behind the wheel instead of sticking out the side. I would add

a protective cover for the motor and a small

extended fender a little behind the the regular one at the right side.

By cutting away below the top of the square

hole, the motor could be swing- and spring-mounted under

By cutting away below the top of the square

hole, the motor could be swing- and spring-mounted under

the car directly behind the wheel with the flat

clutch-belt running between them. The "culvert pipe"

outer rim of the pulley (oops, not shown) fits just

inside the rim of the wheel, and a smaller pulley

would go on the motor. But the real drive power comes from the chicken.

3. Planetary Gear Torque Converter (PGTC) with Flywheel (Now

Working)

While thinking

of the belt drive, I considered that I had

never properly tried the PGTC with a flywheel on the motor. I wanted to

do that in 2013, but I got on to clutch designs that haven't worked out

just at

that time, and I had no way then to mount a flywheel on the motor

shaft. With

a sufficient flywheel, the PGTC should work. The slipping gear can act

as a clutch as with the flat belt drive and the flywheel inertia starts

the

car

moving. Once it's in motion the torque conversion comes into effect and

will keep it going. Now the motor would need a flywheel anyway for the

belt drive, and I had extended the shaft so one could be added on the

'back' side of the motor. Plus, the Kelly BLDC motor controller will

put about 4

times the current (= 4x torque) into the motor than my controller did.

If the system was sufficiently robust - and if I pursued it - the 4 to

1 drive chain reduction to the differential could be reduced to 3 or 2

to 1 to allow higher speed driving.

While thinking

of the belt drive, I considered that I had

never properly tried the PGTC with a flywheel on the motor. I wanted to

do that in 2013, but I got on to clutch designs that haven't worked out

just at

that time, and I had no way then to mount a flywheel on the motor

shaft. With

a sufficient flywheel, the PGTC should work. The slipping gear can act

as a clutch as with the flat belt drive and the flywheel inertia starts

the

car

moving. Once it's in motion the torque conversion comes into effect and

will keep it going. Now the motor would need a flywheel anyway for the

belt drive, and I had extended the shaft so one could be added on the

'back' side of the motor. Plus, the Kelly BLDC motor controller will

put about 4

times the current (= 4x torque) into the motor than my controller did.

If the system was sufficiently robust - and if I pursued it - the 4 to

1 drive chain reduction to the differential could be reduced to 3 or 2

to 1 to allow higher speed driving.

On the 25th I explored this idea by removing all the extra

stuff for the centrifugal clutch and reinstalling the PGTC and motor

more or less the way it was in 2012 when it had proved it could

keep the car moving if it could be coaxed into starting in the first

place. Most of it proved easy; I still had all the pieces. It just

needed 3

small new mounting brackets. I figured that the higher current Kelly

controller and the faster spinning Electric Hubcap motor would apply

more torque

even without adding the flywheel, to get the car to start moving for

tests.

I determined that I was

going to test out both approaches. The PGTC could theoretically have

the car crawl up a very steep hill or tow a very heavy load at low

speed. But now I just wanted to prove that it works, and then maybe run

a few more ambitious tests - ultimately to take it out on quiet streets.

In the Sprint a motor system under the hood is fine. And

if an electropermanent magnet motor gives the hoped for vehicle range,

the add-on hybrid idea may become superfluous. Regardless, the

wheel-belt drive gets back to the original Electric Hubcap add-on motor

idea, plus it looks far easier to do from scratch than any other system

so far. And it has no gears that would require lubrication. This

assumes it can start the car with sufficient torque without needing two

gears - one for startup and another for higher speed driving.

The next morning (26th) I thought of, and got, a

ready-made,

perfectly balanced flywheel: a large (12", 4Kg) cast iron spoked V-belt

pulley. (45$ surely well spent.) Later I did 2 of the 3 mounting

pieces. The next day I tackled the third one, the stay for the slipping

pulley

rope. (BTW the large pulley and tensioning rope replace the steel bands

used with planetary gears on some earlier(?) transmissions.) On the

morning of the 28th I turned down the 'stand-off' for the

thrust bearing, which was a little too long for the 'new' setup. Then I

tried the whole thing out, without the flywheel. It was a little

hesitant to start the car moving, but it worked. Once moving, the front

wheel even

jumped over a 2.5" x 2.5" block of wood that was supposed to keep it

from going too far. Adding the 4Kg, 12" flywheel to the motor

will help. If still more weight of flywheel is determined to be

desirable, the store has 12" double V-belt pulleys that are even

heavier.

It was a real pleasure running it all using the 300 amp

Kelly BLDC controller, which never blew up and which can deliver much

more current to the motor than my controllers do. I guess it was worth

all that

money after all.

The basic test having been run, the question now was

whether to pursue and complete in all

details what appeared to be a workable system on the Sprint, or to take

it out and try the belt drive. I want to try the belt drive, but except

for needing another motor and controller it could almost as easily be

on a different vehicle - like my "new" 2001 Toyota Echo (replacing the

rusty 1984 Toyota Tercel wagon).

I went out and looked under the Echo, and there was in

fact more room to mount a motor directly behind the wheel than on the

Sprint, both vertical space and sufficient horizontal space in front of

the rear bumper. Only the wrap-around side of the plastic fender would

need to be cut away where the motor and belt would sit. And the car had

quite a deep trunk where batteries might be installed. Pretty much

ideal! Perhaps there are lots of cars where the motor could be fitted

underneath the rear trunk space instead of sticking out the side. (The

Tercel isn't one of them - the gas tank is in the way.)

So that's it: it'll be the PGTC with flywheel on the

Sprint. A new motor with flywheel + clutch & belt to the rear wheel

on the Echo will have to be reserved to be a later project - preferably

after a new and improved motor is developed.

On April 1st I met a Mazda RX7 aficionado. He was just

getting out of his car as I passed by and I remarked that his was a lot

shinier than my electric one. We talked a bit and he was interested in

making one of his electric, and I would love to see the parts from mine

go into a car in better condition. Depending on his mechanical skills

and leanings, perhaps I can convince him to try out a flat

belt/clutch/flywheel drive system under the hood. That would give him

more range, with less power, than using the original transmission as

mine does.

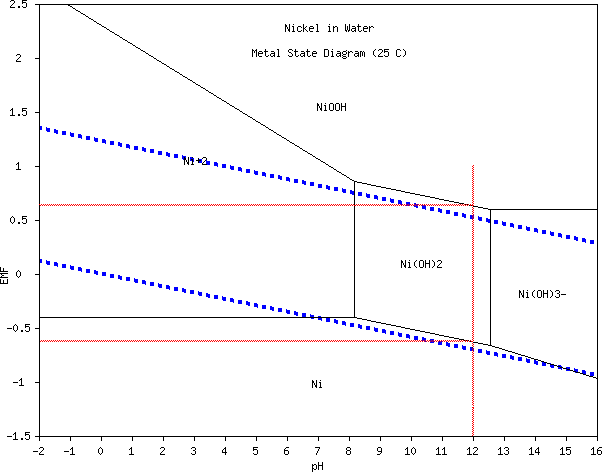

Nickel-Nickel Battery: the simple secret

On the 27th I finally got back to new chemistry batteries.

1.1 volt nickel-nickel cells seemed to be more promising in some ways

than the nickel-manganese 2.4 volt cells, but whenever I tried to make

one, there was unexpected relentless self-discharge. Perhaps 3 months

ago I thought of trying a different electrolyte instead of potassium

chloride, and I finally got around to the next choice, potassium

sulfate. It worked! The self discharge was reduced from immediate to

taking overnight. The remainder, which was pretty much similar to the

NiMn cells, is probably owing to oxygen entering the water in the open

top test cell, or because the positive side hasn't got much substance

and isn't well made, or because of contamination from the carbon rod,

which came from a chloride electrolyte dry cell.

And I thought

that the old "pocket electrode" from about

1900 would be a great form for the negative electrode. But I didn't

manage to punch perforations through the cupro-nickel sheet metal

(Cu:Ni 70%:30%), which was much harder than just copper. Instead I

destroyed the pin frog I was trying to punch them with.

And I thought

that the old "pocket electrode" from about

1900 would be a great form for the negative electrode. But I didn't

manage to punch perforations through the cupro-nickel sheet metal

(Cu:Ni 70%:30%), which was much harder than just copper. Instead I

destroyed the pin frog I was trying to punch them with.

I may just end

up making them much like standard manganese-zinc dry cells. It

would be ideal if I could find cupro-nickel cans.

Canada Revenue Report (What, late

again?!?)

All well and good... Much as I prefer working on real

projects, I'd better get

started on the annual report for Canada Revenue Agency. I seem to have

been dragging this out longer and longer each year, finishing in May or

June the last couple of last years instead of in March. Considering

this brings my annual compensation, such as it is, for doing

experimental development, you'd think I'd be more enterprising about

getting it done.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

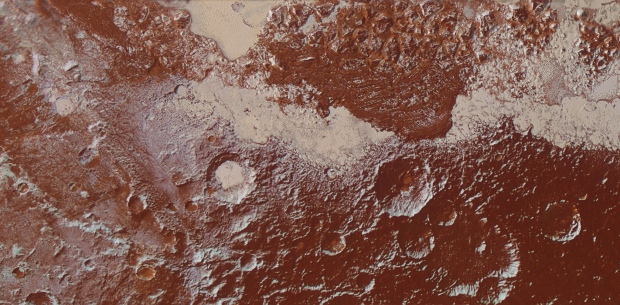

Life on Pluto?!?

Is it even conceivable? The temperature must be

hardly 50 or 60°K even when Pluto is closest to the sun. Yet here

from

the scientists is that typical mention, stated uninterestingly and

vaguely as "dark reddish 'tholins'" -- which probably means

the same telltale spectral signature of polycyclic aromatic

hydrocarbons as has been found on several airless icy worlds of the

Jupiter and Saturn systems, on asteroid Ceres and even on an icy comet,

which seem to have organic, perhaps a sort of "crystalline",

vegetation.

Temperature regulation on airless worlds would be vastly different than

those with an atmosphere, but if such vegetation can actually grow in

such a deep freeze as Pluto, so far from the energy of the Sun, it must

live in

really slow motion.

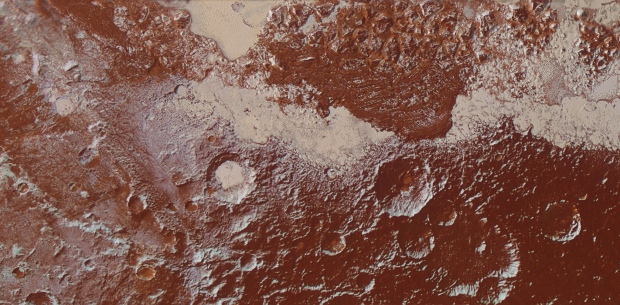

"Pluto's surface is still geologically active and changing. At lower

right, ancient, heavily

cratered terrain on Pluto is coated with dark,

reddish tholins. At upper right, volatile ices

filling the informally

named Sputnik Planum have modified the surface, creating a chaos-

like

array of blocky mountains." (NASA/JHUAPL/SwRI)

Currency Crunch?

Around the turn of the millennium, the ever growing US

debt hit around a trillion dollars. By 2008 that grew to 8 trillion,

and it is now approaching 20 trillion. If things are to continue, in

another 8 years - even if attempts at prudence were finally to kick in

at this point - it would doubtless be at least 40 trillion. The economy

continues to decline with record bankruptcies, ever shrinking consumer

spending and real estate markets that continue to decline,

notwithstanding a few local areas of good industrial activity and real

estate investment prosperity. The middle class has lost its wealth, and

anyway an aging population doesn't need so many new things. Pensions

are being slashed and even so pension plan funds are dwindling. 30% of

Americans are having trouble paying ever increasing rents and putting

food on the table. The young and even the middle aged are moving back

in with their parents.

Where it counts the mainstream news is lies, and more lies

by selective omission of what's covered. A long time respected

journalist in Germany says the CIA has been telling everyone in Europe

what to report on and what to say for decades. Fail to comply and

you'll lose your job and never find another in the business. Think it's

better in the USA? They get people to believe the lies not by evidence

but simply by repeating them and repeating them until everyone thinks

"It must be true."

The stock markets look rosy and the price of precious

metals is low. These indicators are carefully manipulated at all costs

because they are what people usually look at to judge the health of the

economy - in a sense they are more lies. But "QE 4" - trillions and

even tens of trillions of dollars of more money printing - is probably

just around the corner, as are bank "bail-ins" and bank failures owing

to all the outstanding bad loans. Fraud is now the admitted source of

virtually all the profits of the big banks on Wall Street and in the

city of London. Other countries are starting to balk at accepting US

dollars as major payments, and are quietly trying to unload their US

treasuries holdings.

Think about it - this has gone on for a long, long time.

The numbers grow ever more ludicrous. Can they just keep growing

forever, and financial crimes be ever more egregious, as the global

economy declines and populations suffer, or is trust slowly being lost,

and finally some pivotal event will take place, after which the world

will never be the same again?

Humorous or not...

Q:

Can sheep fly? ----- A: Obviously. They travel

in flocks. (Duh!)

Why is the word "small" bigger than the word "big"? Why is "slim" wider

than "fat"?

Q: What are the three types of mammals that lay eggs?

A: The Duck-Billed Platypus, the Echidna (obviously related to each

other), and the Easter Bunny.

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers

- Preliminary Ni-Mn, Ni-Ni Battery Making book

Products Catalog

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

Daily

Log

(time accounting, mainly for CRA - SR & ED assessment purposes)

March 1: Took shaft encoder "reader" off

Miles electric truck for

repair. Ordered a new one. Bought steel and cut the first of 10 weights

for the clutch 10 shoes. Found a web site offering the right size and

shape of AlNiCo5 magnets.

2: Worked on February newsletter. Cut 5 more weights. Conversed with

magnet

company by e-mail.

3: Newsletter.

4: Cut remaining clutch shoe weights.

5: Finished Miles Electric Cargo Truck repair. Centrifugal Clutch

(CClutch) - Slotted the shaft

alignment pin.

6-7-8: CClutch - Drilled and coutersunk and threaded 20 holes (#10-24)

and bolted the weights to the shoes.

9-10 -

11: Installed CClutch in Sprint car & tested: Car moves! (Further

tests prove the torque is dissapointing.)

12: More CClutch stuff.

14: same.

15: Removed/bypassed PGTC section for higher RPM at clutch

16: Tested with above.

18: New design for direct wheel drive add-on for 'any' car. CClutch:

Made and attached springs on the 5 outward facing shoes.

19: Tested CClutch again. Springs didn't stay taut. Looked around for

bandsaw wheels (for wheel drive idea). Found 14" one - it looked too

flimsy for a car wheel.

20: (Sick.) Thought of better ways - better materials - for making the

car wheel pulley. 1: A solid disc of 1.5" UHMW plastic. 2: 12" PVC pipe

ring, glued to a disk of compatible plastic - or plywood.

22: Sized up Sprint car for an external wheel-belt drive system. It

looked better than expected - very feasible.

24: Tried stronger springs on centrifugal clutch. Result was

disappointing but not conclusive. Removed rear bumper to look at

possibilities of mounting motor behind rear wheel for belt drive.

25: Removed centrifugal clutch and re-installed PGTC without clutch -

some things remain to be done.

26: Continued installation.

27: Continued installation. Tried getting a nickel-nickel battery cell

working with K2SO4 electrolyte instead of KCl. That seems to be the key!

28: Finished installation and tested it. Car moved well enough going

forward but poorly going backward. (Still needs flywheel, etc.) Made

nickel negative electrode and nickel hydroxide positive, immersed in

small jar of K2SO4. Worked well with low self discharge (compared to

most of my experiments). Probably just needs a 'sealed' cell with

properly made electrodes to have a practical, economical and

'everlasting' battery.

29: Clamped down wires and fitted flywheel. Shaft needs a keyway slot.

Did some charging and discharging of the NiNi battery.

30: Tested PGTC variable transmission with flywheel. It moved the car.

31: Worked on this newsletter.

Electric

Hubcap

Motor

Systems

-

Electric

Transport

Electric

Hubcap motor, Chevy Sprint & Variable Transmission

The Frictionless Centrifugal Clutch

Here is a theoretical thought to start with: It has always

seemed to me that the frictionless centrifugal clutch should act as a

torque converter by itself. If it did it could be ideal because no

manual clutch or gear shifting would be required.

Power = torque * speed.

The speed of the motor may be 1000 RPM, and its torque may

be 10 foot-pounds. If the speed of the car is such that the clutch

output drum is turning 250 RPM, and if frictional losses are small,

where is the motor's power going if not to the clutch drum? If the full

power is being output, the torque on the drum must then be 40

foot-pounds. (And with the 4 to 1 chain reduction, 160 foot-pounds at

the wheels.)

OTOH, the impacts of the shoe points bounce the shoes

inward. The angle of bounce to the drum is around 45°, not straight

on. That would indicate that the moment of the pulse transfers the sine

of 45° times the input energy, or .707, or 28.28 foot pounds. Is

the rest of the energy wasted in flailing the weighted shoes around? Or

is it just energy the motor doesn't supply? It seems likely it's the

latter. In that case, the motor is still speeding up - it isn't at

equilibrium yet. Anyway, even 28 foot-pounds is still more torque than

the motor has by itself, and it's still a torque converter.

Work

On the 5th I thought of how the 3/8" shaft alignment pin had unscrewed

itself and fallen out. (It was eventually found on the lawn.) After

making a new one including turning the hex head off the bolt with a

lathe to leave the exact diameter at the outer end, I cut a slot in the

end with the angle grinder so it could be more forcefully screwed into

the drum end with a slot screwdriver, to hopefully prevent repetition

of the problem.

On the 4th I

finished cutting the 100g steel weights for the UHMW shoes. On the 5th,

7th and 8th I drilled and threaded all the holes for #10-24 machine

screws, and bolted the weights to the shoes. I countersank the (pan)

heads to make sure they wouldn't hit the aluminum rim.

After making the first four went fine on the 6th, I

drilled

holes in the rest on the 7th, and on the 8th trying to finish up they

started being troublesome for no apparent reason. The machine screws

went in effortlessly to a certain point, to where they just started to

protrude out the other side. Then they would suddenly jam and neither

go in farther not come out easily again, including not screwing out

easily where they had easily screwed in - it was a fight nearly all the

way back out, holding and turning the bolt head with vicegrips. The

threads were damaged when they came out. One snapped off in the hole

with nothing to grab on either end. I had to drill it out, the whole

bolt. I managed to re-thread the hole and save the weight. But I'm not

sure it was worth it. One starts to think "I should be done by now.

Instead every piece is fighting back." It turned out the #10-24 tap was

to blame. I had bought a new one on the 7th for a spare. I tracked it

down (still in the car) and looked at both of them under a strong

magnifying glass. The old one was dull. The sharp triangular thread

ridges on the new one, on the old one near the end were worn down to

semicircles. Since the metal was 5/8" thick, not enough good tap came

out the far side even when I screwed it all the way in. In the most

dull area near the end, it didn't thread the piece to a workable

thickness - just to enough so that the screw jammed at the last turn or

two. Running the tap through again didn't help. (If I had put the tap

in from the other side, it would have reamed it out enough.) Why did

the first four go fine? Anyway I used the new tap and the rest of the

job went

smoothly and quickly.

I bolted the weighted shoes onto the disk rotor,

and it was all ready to reassemble and try out in the car. I finally

got it installed on the 11th and turned on the power. I tried having

the car go forward... and it went! I pulled out my cell fone and set it

on

camcorder and tried again. It went even better. In fact, it seemed

pretty good. When I tried to go backward, the planets assembly pushed

out - I had forgotten to install the thrust bearing piece to prevent

that. I got a video of that, but one press on the wrong button on the

cell fone exits the camcorder mode without saving the video. DON'T HIT

THE BIG BUTTON IN THE MIDDLE! ...or accidentally touch any of the three

buttons below the screen!

...hit only that little button with the square, off in the corner of

the

display! In total I've

only successfully made 3 or 4 videos on the cell fone, but I've lost

several when I went to stop recording. So as a

camcorder, it's a very frustrating device.

I digress... Later I installed the thrust bearing, but I

couldn't get the car to back up... and barely to go forward. I had the

car on planks so it wouldn't take much to move it. According to the

torque wrench, about 40 foot pounds at the wheel to back up, and 30-40

to go

forward. Assuming it didn't have a lot to spare the first couple of

times, and since it hardly moved later, it was probably doing under 40

foot-pounds - With the 4 to 1 chain drive, just 10 at the clutch. And

after a couple of minutes of hardly

moving, the motor

coils were quite hot.

In the moves, sometimes the slipping pulley of the

planetary gear torque converter turned slowly, sometimes it stayed put.

If I let it slip more, there was less torque to the clutch and the car

didn't move - only the slipping pulley and gear spun.

So the success seemed pretty minimal. But I know that to

move the car by

turning the clutch drum by hand, takes a lot of force on the drum. If

it doesn't get around 200 foot-pounds to the wheels, or 50 at the

clutch drum, it won't be hitting the street. Was there something I just

wasn't getting right in all this, or was there something I could adjust

or change to get more torque?

Just as it was getting dark, I remembered I could put the

torque wrench on the clutch output shaft instead of on the wheel. I

went out again and tried it. This time I noticed that the slipping

pulley tensioning rope was out of place underneath, off the pulley. It

had caught a bolt head on the clutch drum. Small wonder the drum

wouldn't turn and the car wouldn't move! I was glad to discover that

perhaps my whole approach wasn't faulty after all. Perhaps the wheels

were getting at least 60 to 80 foot-pounds after all?, as it had seemed

to be on the first tries.

The next day (12th) I got the rope straightened out and

tried again. Results were still pretty dismal - the car only moved if

it was about ready to roll in the proper direction by itself. I decided

it was time to charge the batteries. After a number of tests, they were

probably getting down, limiting power to the motor. And then I could

jack up one front wheel and see how much torque it was really getting

by putting the torque wrench onto it. Or maybe just put it on the drum

shaft - test it there and multiply by 4.

Another thing was that the planetary gear had a built-in

reduction of about (as I recall) 1.8 to 1. So if the motor was turning

2000 RPM, the input to the clutch would only be doing 1111 RPM. And if

the planetary gear torque converter was slipping, increasing the torque

coming from the converter, that would merely further reduce the RPM to

the clutch and hence its driving force.

It was a concern I'd had from the start, that the clutch

would be turning too slowly to provide sufficient torque to drive the

drum and the car. Perhaps now that it was close to working, providing

at least some torque, it would be advantageous to try out the

centrifugal clutch as the torque converter, and eliminate the planetary

gear assembly altogether? The RPM would be higher and so the clutch

would engage more strongly.

This could be done _relatively_ easily, by removing the

motor's extension mountings and changing the motor shaft to one without

the sun gear pressed onto the end, and cut to the right length to put

the clutch input disk directly on it. Then the RPM would be the motor

RPM, and there'd be no complications in between. *IF* I was right about

the clutch acting as a torque converter.

Soon I thought of a much easier way to test the idea: take

off the slipping pulley and jam something in the planetary gears so

they would all turn together on the motor shaft. Meanwhile, the day was

done, and only one battery was almost charged. They must have been

getting rather low. I decided to keep the video on hold for now.

On the 14th I

did as above - I put some washers into the

planetary gear to jam it. When I started the motor, they immediately

fell out and the planets

assembly shifted over toward the motor. (Again I had left out the

thrust bearing, this time thinking it would be unneeded.) Maybe if I'd

tried it in

reverse? On the 15th I cut and drilled three pieces of light steel bar

and bolted them to form a triangle so as to press the planets and ring

gear tightly together. On

the 16th (much nicer weather) I put it together and tried it in the

car. The motor (directly turning the clutch input disk with the shoes)

spun mightily at a pretty high speed, but there still wasn't much

torque. The car would only move if carefully placed so it was almost

ready to start rolling by itself. My feeling is still that the

potential is there, but that it still didn't have sufficient coupling

between the input disk and output drum of the clutch. If it had loaded

down the motor better, and that load had transferred the force to the

wheels, it would have worked. To put the car on the road, it'll need

something like 10 times as much output torque. It seems a tall order,

but I think it's there. Somewhere!

On the 14th I

did as above - I put some washers into the

planetary gear to jam it. When I started the motor, they immediately

fell out and the planets

assembly shifted over toward the motor. (Again I had left out the

thrust bearing, this time thinking it would be unneeded.) Maybe if I'd

tried it in

reverse? On the 15th I cut and drilled three pieces of light steel bar

and bolted them to form a triangle so as to press the planets and ring

gear tightly together. On

the 16th (much nicer weather) I put it together and tried it in the

car. The motor (directly turning the clutch input disk with the shoes)

spun mightily at a pretty high speed, but there still wasn't much

torque. The car would only move if carefully placed so it was almost

ready to start rolling by itself. My feeling is still that the

potential is there, but that it still didn't have sufficient coupling

between the input disk and output drum of the clutch. If it had loaded

down the motor better, and that load had transferred the force to the

wheels, it would have worked. To put the car on the road, it'll need

something like 10 times as much output torque. It seems a tall order,

but I think it's there. Somewhere!

One good thing noticed in

the testing (with a new

single-unit DC

clamp-on ampmeter making it easy to measure): The 300 amp Kelly BLDC

motor controller was

delivering up to 150 or 160 battery amps to the motor when I turned

everything right up, and everything worked fine. That's double the best

I was able to squeeze out of my own controllers without them going up

in smoke - and mostly they fried with less so call it 4 times.

Everything worked fine.

That made all the testing I did much

simpler - and probably made the expense and time of buying and setting

up the controller worthwhile. Delivering all that current, the

batteries would have dropped to well below 12 volts - we'll say 11.1

for the math. 150 amps * 33.3 volts is about 5000 watts. Judging by the

rapid heat buildup in the coils, my estimated nominal rating of 7200

watts for Electric Hubcap motors might be overoptimistic. OTOH, this

motor has pretty small exit vent holes in the rotor side face, which

could (and apparently should) be enlarged to improve air flow. And

certainly the Electric Caik motor hardly even got warm at 1200-1500

watts on the water, translating to 1800-2250 W for "hardly warm" for

the larger Hubcap

size.

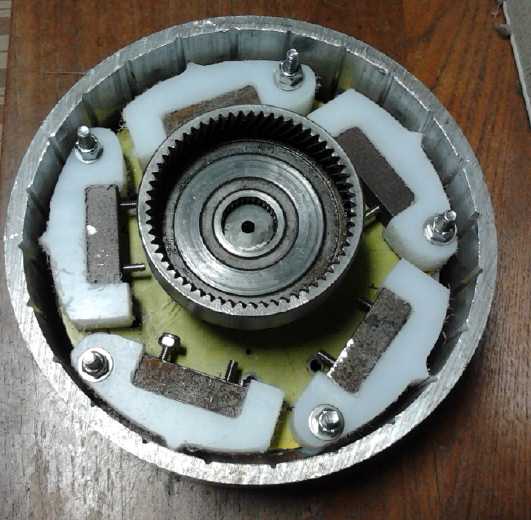

Inner/Drum side

Inner/Drum side

Outer/Gear side

Outer/Gear side

Something else to be addressed if and once

it's working is that it's rather noisy. Gluing some chunks of rubbery

stuff onto the outside of the drum like they do to keep car body sheet

metal parts from vibrating would probably dampen the noise to

acceptable

levels.

Meanwhile... there's getting it working. There

were

at least a couple more things I could think of to try. One was to put

springs on the shoes, to force the "V" toes to spring outward into the

"V" slots in the drum instead of just using centrifugal force to have

them go in at a tangent. With the tangent, such a small bit of the

'toe' goes into the slot that the tip of the plastic "V" point is

rapidly getting worn off. With springs pushing them in, a much broader

face area would hit (greatly reducing wear), and the bounce angle would

be better. The weights would go from springing outward to reflecting

inward, a

much more substantial bounce with more 'hammer' energy to push the

drum. I think the wear on the plastic will prove to be something of a

'switch'. If the force per unit area is below a critical point, wear

should be very slow. If it's above that stress, the points will quickly

wear off, as is presently being seen. It's like, depending on a small

critical temperature

difference, water is either frozen solid or is thin liquid. There is no

range where it's like

molasses or like pliable putty.

Another way to achieve some of that would be to widen the

"V" slots. Then the 'toes' would enter deeper into the slots just from

the tangent centrifugal entry. But I'm not sure that would be enough of

a difference, and the weights still wouldn't be pushed out rapidly like

with springs.

Still another way to change things would be to change the

size or configuration of the shoes or the position of the 'toe' in the

shoe. For example, if the toe is 1/2 way between the hinge pin and the

weight, the weight has to bounce twice as far, and hence at twice the

speed. This should mean 4 times as much force involved. (e = 1/2 m * V^2.)

But these are all just ideas. What to actually try...? Or

is there something that is obviously intrinsically superior

in theory, something that I can say "Aha! This would surely do it!"?

Nothing came to mind.

That evening I

came up with a pretty simple way to attach

leaf springs to the shoes on one side, springing them against the SDS

bushing in the center. With a small modification it could work on the

other side too, but 5 springs should be enough to tell if there's any

major improvement. The following evening (18th) I made them and bolted

them on.

That evening I

came up with a pretty simple way to attach

leaf springs to the shoes on one side, springing them against the SDS

bushing in the center. With a small modification it could work on the

other side too, but 5 springs should be enough to tell if there's any

major improvement. The following evening (18th) I made them and bolted

them on.

On inserting the disk the next day, I found that the

springs were loose. I took it out, bent them over a little farther to

about 90°, and put it back in. Now they had some tension, but it

didn't seem like very much. I tried running it, but there still wasn't

much torque. Seemingly it loaded down the motor a little more, because

instead of 150-160 amps, the motor drew up to 170-180 amps from the

battery. (I even saw "190" and "200" flash by at one point.)

As another side note 200 amps is my nominal maximum

current for the Electric Hubcap motors -- nominally, 200A @ 36V or

7200W. But the coils got hot pretty fast. And for all that power - no

real torque.

I started thinking I was doing far better with the

slipping planetary gear in 2012 (TE News #56) -- except for the fact

that the car had to be already moving before it would work. I thought

more and more that the most practical way to get that system to work

would be to have a big flywheel on the motor shaft, the inertia

of which could be used to initially get the car moving.

When I took it apart again, I discovered the springs were

bent back to almost the same angle as the first time. So they weren't

doing much good. (Maybe about 180 over 150 amps or 20% improvement?)

Evidently my nickel-brass metal, tho squashed through the jewelers

rolling mill a few times to "temper" the pieces, wasn't very tempered

and preferred to deform rather than spring back very far. They weren't

good enough - rats! Here is a place that regular brass seems superior -

I know I've had better results than this using it for springs.

I was about ready to make

some brass springs, but right at

this point, I started thinking other thoughts about how to push the

car. The flywheel idea I should have tried in 2013, but I thought a

clutch would

be better. The other sprang from newer ideas that have

been brewing in my mind about how to mount a wheel motor using a belt

drive. I started to think that both would work, and that (at least) the

wheel drive should be better than the centrifugal clutch.

Within a week I made up my mind to quit the noisy and so

far frustrating centrifugal clutch project. But since it was all set

up, it seemed silly not to do one more work session and try stronger

springs. On the 24th I made 4 of them from a thick piece of brass. The

brass

springs were much harder (after squashing the sheet metal to temper it,

it was very hard cutting it with the tinsnips), and it was thicker

metal too. When I put it all together and tried it, it seemed to work a

little better at first. It seemed more robust. But by now, _presumably_

mainly because of the earlier abuses with no springs or weak springs in

the shoes, the points were about worn off the shoes, so there still

weren't two flat surfaces hitting each other. The "V" point snapping

into the "V" groove was only a flat bottomed bump. I suspect that was

now a major part of the problem. I could probably have resharpened them

with a dremmel tool, but even so the action seemed pretty

disappointing, and if I wasn't going to use it anyway, why bother? I am

by no means convinced that it won't work, and I probably should have

tried sharpening the points and putting good springs on both sides.

Within a week I made up my mind to quit the noisy and so

far frustrating centrifugal clutch project. But since it was all set

up, it seemed silly not to do one more work session and try stronger

springs. On the 24th I made 4 of them from a thick piece of brass. The

brass

springs were much harder (after squashing the sheet metal to temper it,

it was very hard cutting it with the tinsnips), and it was thicker

metal too. When I put it all together and tried it, it seemed to work a

little better at first. It seemed more robust. But by now, _presumably_

mainly because of the earlier abuses with no springs or weak springs in

the shoes, the points were about worn off the shoes, so there still

weren't two flat surfaces hitting each other. The "V" point snapping

into the "V" groove was only a flat bottomed bump. I suspect that was

now a major part of the problem. I could probably have resharpened them

with a dremmel tool, but even so the action seemed pretty

disappointing, and if I wasn't going to use it anyway, why bother? I am

by no means convinced that it won't work, and I probably should have

tried sharpening the points and putting good springs on both sides.

But I started to think the belt drive

should be better, and at least reasonably easy to make.

New Design for

Direct-to-Wheel Belt Drive

Rick Linden got an elevator motor to use for a

generator for his floating hydro power project. The Electric Weel just

didn't have enough electromagnetic coupling unless it was made into an

'active'

generator by using a motor controller in a 'regenerative braking' mode.

The voltage and current output were both lower than I expected. The

elevator motor, also a permanent magnet "BLDC" motor, seems like the

ideal

unit, providing one volt per RPM, and if an output is shorted, it's

amazingly difficult to turn at all.

My thoughts returned to flat belt

drives for this. Then they wandered back to belt drives for a car

wheel. On the on the morning of the 18th I thought of another new

design, which seems even better than the one I proposed in TE News #86

and #91. Again a pulley is attached directly to the center of

the wheel, bolted on with the extended lug nuts.

But this time it's a flat belt pulley, or poly-V. This has

an advantage over toothed belts in that it can be slipped to act as a

clutch. Then a smaller motor with a flywheel, with a smaller pulley

reduction ratio, can be revved up to some

RPM before trying to start the car moving. The energy stored in the

flywheel will budge the car and start it moving as the clutch is

engaged. Once the car is moving, even a few kilometers per hour, it

needs a much lesser 'gear' reduction ratio than it would starting from

a stop with a

stopped motor. (The motor rotor could be made of thicker steel for a

flywheel. If that is insufficient, an external flywheel may be needed

or may be more practical.)

Again the motor is mounted in line, somewhere horizontally

behind the wheel. But it is "hung" from a fat hinge pin attached to the

car

body or frame, which holds it rigidly from twisting in any direction,

but which allows the motor to pivot back and forth, toward or away from

the wheel. A stiff spring pushing the motor backward tensions the belt

between the motor and the wheel. (The pin might go through the body

panel into the car at the cargo space floor, and could extend any

length for strength and rigidity, even across the whole width of the

car if desired, to be clamped at both ends.)

Mounted on the pulley on the wheel is a bearing with a

short shaft holding a

small stationary (non-turning) plate that allows attachment of the

clutch cable sheath and a light safety cover over the belt and pulleys.

The pulley with its light attachments are the only extra unsprung

weight on the wheel - it's ideal.

With the clutch cable body attached at the wheel, pulling

the cable pulls the motor toward the wheel to loosen the belt.

This time, there is no rigid bar holding the motor at a

specific distance from the wheel to tension the toothed belt. Between

the motor and the wheel are just the belt, the clutch cable, and the

light safety cover.

Let's say having the clutch and flywheel allows us to use

a 5 to 1 pulley speed reduction, eg, a 2.4" pulley on the motor and a

12" pulley on the car wheel. This is half of a typical 10 to 1

reduction for an electric vehicle motor. For the average 13" small car

wheel doing 10 RPM per each kilometer per hour, and the improved

Electric Hubcap motor now rated for 3000 RPM instead of 2000, we then

have (3000/5)/10=60 Km/Hr maximum speed. Above that speed one would

have to run on gas and have some mechanism to definitely disengage the

belt, preferably at the wheel. If the ratio could be reduced to 3 to 1,

the limit would be 100 Km/Hr (62 Miles/Hr), and one might just accept

this as top speed for all driving. The motor would need 2/3 more torque.

Theoretically I should be able to put 200 amps into

Electric Hubcap motors, but my controllers don't seem to have 1/2 of

that. In tests on the Sprint with the Kelly controller so far I've seen

up to around 150 amps, and it seemed to me from earlier tests that the

motor produced about 1.5 foot-pounds per 10 amps, so 22.5 foot-pounds

with 150 amps. 6 to 1 ratio (135 foot-pounds at the wheel, 50 Km/Hr

max) or 5 to 1 (111 FP, 60 KPH) seems more likely to be practical than

3 to 1 (67 FP, 100 KPH).

Of course two motors, one on each rear wheel, would

improve the equation considerably. So would a reluctance motor that

could do 2 or 3 times the RPM with similar torque, since higher ratios

then wouldn't mean limiting the top speed. The electro-permanent magnet

motor is a wild card, since I don't know how much maximum torque is

attainable. It depends on the strength of the fully magnetized AlNiCo 5

magnets compared to "fully energized" (say 150 to 200 amps from the

battery)

electromagnets. As shipped they certainly don't seem as strong as

supermagnets.

Thinking of where one might get a flat belt pulley for the

wheel, at first I thought of an old machine sitting outside a brewery.

I wrote an e-mail to the owner to see if he would sell it, but just as

I finished writing it, thinking of how to give the pulley traction, I

thought of how bandsaw pulleys give traction with a polyurethane

"tire", which also gives the pulley the right profile for a flat

band/belt and... wait a minute, why not a bandsaw pulley? They're

probably available in various diameters and widths. How about one

something like 12" diameter and 1.5" wide or wider, perhaps made for a

bandsaw resaw or sawmill? There were some "bandsaw wheels" on e-bay if

I can't find one closer to home. I didn't send the e-mail.

Considering that the installation plan looks like the

simplest one ever, and how easy it would be to change ratios to find

the most

practical, or to change motors as different motors and controllers were

developed or became available, this seems like a fabulous way to do it.

If I wasn't in the middle of trying to do the Spint car with the

centrifugal clutch, I would unhesitatingly start on this plan, with the

Electric Hubcap motor and the Kelly BLDC controller, which are working

well together now. Even on the Sprint, it would be great to

have the drive external and the most of the space under the hood left

vacant for batteries. Then, weight balance permitting, the whole rest

of the car could be kept "as is" for its regular passenger and cargo

uses. (Maybe the spare tire and 2 of the 3 batteries up front, and one

battery at the back in the spare tire space.)

On the 19th I asked at a tool store. They had a 14"

Delta(?) bandsaw wheel. Like the ones in my own bandsaw, it was

aluminum and looked too flimsy to put on a car wheel. But seen without

the tire, there was a 1" wide indented area between the outside ridges,

and it was bulged - slightly barrel shaped. I had thought it was the

polyurethane "tire" that had the bulge, now I realize that it's the

pulley itself that's bulged and the "tire" is flat urethane, simply

stretched over it. I could make a pulley the correct shape, something

like the brewery's but custom made, and order available "tires" to fit

it.

Here's one idea: draw up a circular steel plate for a

center (3/16" thick?) and have it cut out at an abrasive waterjet

place. Get some 1.5" wide by 1/4" thick bar stock and use a roller to

bend it to the outer curve to fit around the disk. Weld it on all

around. Using a large metal lathe trim it to true and round while also

shaping the surface: the 'barrel' shape with an edge on each side to

hold the non-skid urethane 'tire'. As a refinement, one could use

fairly thin plate for the disk (1/8"? 3/32"?), and weld a thicker but

smaller diameter disk having the same patterns to it to reinforce the

center area. That should minimize weight.

Or one might use thicker pieces of aluminum to make the

same thing. It would be lighter, faster (cheaper) to waterjet cut, and

surely easier on the lathe. I've recently heard about "aluminum

brazing" which might work well, or I might just give the job to a

welder who's familiar with aluminum welding and has the equipment.

Hmm... another option could be to have the disk and two outside rings

cut on the waterjet, totaling 1.5" width. Make them so they just bolt

together, then trim the rim on the lathe. No welding required. Darn,

soon I thought of more and more ways it might be done. (Not even to

mention making it out of wood or plywood on a wood lathe!)

On the 20th I thought of a couple more ways yet to make

the pulley. The first would be to take a 1.5" thick piece of UHMW

polyethylene and make a whole one piece wheel. A 12" pulley would

weight ~2.9Kg, but some could be milled out for "spokes" or other

pattern cutouts or thinnings to lighten it.

The second would be to use a piece of glueable PVC (or

???) plastic pipe, juat 1.5" long, and make an inner disk of the same

material. After gluing the pieces together, this would of course be

shaped and trued on the lathe. (By gosh, I even still have the

turquoisy colored 12" PVC culvert pipe section for which Turquoise

Energy was named!) That might not even need a "tire" on it for

traction. (The UHMW definitely would.) It might even be just about the

right texture for the clutch action.

On the 22nd I

sized up the Sprint for this potential idea.

The only really tricky part would be the mounting of the motor. It

looked like it would stick out farther than I expected. It could

probably be

made acceptable with appropriate cowlings, but you wouldn't want it to

hit any chickens while driving along the road.

On the 22nd I

sized up the Sprint for this potential idea.

The only really tricky part would be the mounting of the motor. It

looked like it would stick out farther than I expected. It could

probably be

made acceptable with appropriate cowlings, but you wouldn't want it to

hit any chickens while driving along the road.

But it looked like on this

particular car, one might reverse the motor and put it under the car

body, straight behind the wheel and clearing it by a couple of inches.

That would take it to the rear fender, some of which might have to be

cut away, but only a small piece of body sheet metal would have to be

removed so that the bottom of the motor would be above the wheel rims.

Aside from being a legal requirement, you don't want your car skidding

along on the motor if you get a flat tire!

On the 24th I did an exploratory surgery, removing the

rear fender - 2 pieces of plastic with a solid foam core. Aside from a

couple of rusted, very recessed bolts that I had to drill out, it all

came apart readily in a couple of hours. There was both more body metal

in the way of the motor than expected and less. Less because much of it

was rusted out anyway. It was rustier than I had expected. There was a

metal bumper under the plastic, which would need about 3" cut off the

end to fit the motor. But all the bolts were farther toward center so

it wouldn't hurt anything. The motor would be at the very back of the

car. I would want to put an additional bumper of some sort behind it.

Just a few inches. And a very good guard to keep out dirt flung up by

the wheel.

The other chicken inspecting the behind-wheel

motor

& belt drive arrangement.

The other chicken inspecting the behind-wheel

motor

& belt drive arrangement.

The corner of the body would be cut away at the top of the rectangular

hole - just under the cargo floor.

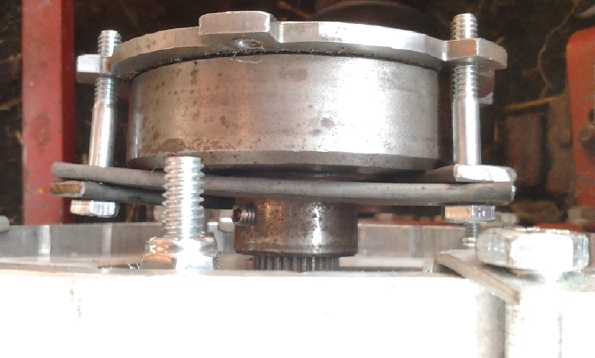

The Planetary

Gear Torque Converter (PGTC)... again? --- Now Working!

Another thought arose from

consideration of the slipping belt clutch with flywheel... The reason

the PGTC wasn't a go in 2012 was because it wouldn't start the car

moving - it seemed to have no conversion effect until it was. I made a

serious mistake after that (TE News #69) in putting a flywheel on the

slipping gear instead of on the motor (that being much easier to

accomplish the way it was set up), thinking that a flywheel would start

everything moving and that it didn't matter which of the two moving

gears it was on. (A manual clutch I tried to install around the same

time also might have worked, but with trying to fit it into a limited

space it was poorly made, flimsy, and not surprisingly the belt just

slipped off it.)

As with the slipping belt clutch, flywheel momentum - on

the motor shaft - could initially boost the car into motion. Once it

was in motion, the torque converter variable reduction could easily

keep it moving.

Now if I wanted to try this plan again I had (a) the

realization that the flywheel has to be on the motor shaft (duh!), (b)

the idea of adding a second steel rotor inside the motor as a flywheel,

(c) a motor shaft that I put in later with extra length sticking out

the 'back' side of the motor - just for possibly mounting a flywheel,

(d) a motor that can now spin up safely to a substantially higher RPM,

and (e) the Kelly 300 amp motor controller that can put much more

torque to the motor. In fact, at least on smooth level ground the car

would surely start moving with its current gearing even without the

torque converter action.

With it, it should be able to get going anywhere, although

I fear the PGTC slipping gear as a clutch will probably have muddy

action compared to the slipping belt on the wheel. On the plus side, it

drives both front wheels through the original differential and CV drive

shafts. The belt-to-wheel will only drive one rear wheel, making it

best a "pavement only" vehicle, the antithesis of a four wheel drive.

I hadn't thrown out the old PGTC shaft to potentially

reconnect it all the way it was. Given that I needed to add a flywheel

anyway to try the slipping belt idea, the rest should now be very easy

to try out, except perhaps for changing the tensioning rope position

back to where it was then, fitting the thrust bearing, and a couple of

altered mounting issues. If those didn't look too bad, it might be

worth doing at this point just to say "it works". If I was going to try

it, it should be done first, while the motor controller was still under

the hood and the transmission body was still installed and connecting

the front wheel drive shafts.

At first, on the 24th, I decided not to bother. The flat

belt on the wheel seemed promising, and it would be quite simple to do

from scratch, and it

doesn't have gears that need lubrication. Plus, it allows essentially

the original Electric Hubcap "add-on motor" plan to "hybridize" a

regular gas car without removing the engine et al. For these reasons,

it's probably worth building and testing the belt-to-wheel system even

if the PGTC under the hood did provide a working car.

But on the 25th I removed all the extra stuff for the

centrifugal clutch and reinstalled it more or less the way it was in

2012 when the PGTC had proved it could keep the car moving if it could

be coaxed into starting in the first place. It proved quite easy

because I still had all the pieces, and it looked like it would all

work again. The slipping gear tensioning rope looked like it could be

persuaded to move over the required couple of inches, tho a new center

stay would need to be mounted. I needed to make that and 2 small

mounting brackets before I could try it out. I figured that the higher

current Kelly controller could get the motor spinning faster and apply

more torque even without adding a flywheel, to get the car to start

moving.

But on the 25th I removed all the extra stuff for the

centrifugal clutch and reinstalled it more or less the way it was in

2012 when the PGTC had proved it could keep the car moving if it could

be coaxed into starting in the first place. It proved quite easy

because I still had all the pieces, and it looked like it would all

work again. The slipping gear tensioning rope looked like it could be

persuaded to move over the required couple of inches, tho a new center

stay would need to be mounted. I needed to make that and 2 small

mounting brackets before I could try it out. I figured that the higher

current Kelly controller could get the motor spinning faster and apply

more torque even without adding a flywheel, to get the car to start

moving.

Then the next morning (26th) I realized there was a

simple, balanced flywheel readily available: Princess Auto had small

and large cast iron V-belt pulleys, single and double, with an "H"

bushing center, which bushing could be had for my 1" motor shaft. If

one 10" or 12" pulley wasn't enough, I could put two on, or a double

one. I went out there and found mostly empty shelves. The only choices

above 6" were a spoked 12" and a double spoked 12". I took the single,

which proved to be 4Kg. It was 45$. With this large, heavy piece

spinning at high speed, I could wish the motor had a thicker shaft. At

least it doesn't have a V-belt attached, stressing it to one side!

That afternoon I made 2 little mounting pieces, and on the

27th the rope stay. When I tried to put the motor on, I found the

thrust bearing stand-off was about 3/8" too long. No run test today! I

started to think it would be better if the stand-off was made from 2

pieces of 'telescoping' pipe. Then it could be fitted to length during

installation and set screws tightened. Was it possible I could find

such a piece of pipe to fit the one the stand-off was made from, which

in turn fit the bearing plate 'washer' piece?

But the easy way was just to trim off 3/8". I trimmed off

1/4" or so on the morning of the 28th. It still didn't quite fit, but I

saw that I could just adjust the shaft over 1/8 or 1/4" at this point,

and I did so. It was now ready to try out. The car went forward nicely

until it hit a 2.5" x 2.5" block of wood. I didn't realize it had and

was momentarily disappointed that it seemed to have stopped for

nothing. It didn't work very well backward, but on the next forward try

it jumped over the block and bumped into my tool stand before I got it

stopped.

There are still issues

before the car hits the streets.

The revved up motor lost much of its speed before the car would get

going fast enough for the torque converter to take over. Installing the

flywheel should solve that. The motor's wires will all have to

be tied or clamped out of the way so they don't hit it. (now done.)

The slipping pulley got rather warm. I'm starting to see

the slipping pulley PGTC as a low speed device just to get the car

moving, with the slip to be ended as the vehicle crosses maybe 10

Km/hr. Unlike in the cool-running Electric Caik outboard, the motor

also got more than warm. I need to drill out the vent holes in the end

cover to a larger size and probably add some more of them to get more

air flowing through it. Heat may become a major issue in running actual

travel trips on the street. I'll leave it at larger vent holes for now.

The chain drive reduction ratio will have to be reduced from 4 to 1 to

3 to 1 or less even for city driving to keep the RPM.s down - I trust

the car can still get going.

The decision now had to be taken whether to finish the car

with the PGTC, which now with the flywheel at least looks like it will

work in town, or to dismantle everything and try the belt drive.

I really like the belt drive plan. OTOH, it hasn't been

tested or proven yet. What if there are unforeseen difficulties? What

if the required reduction ratios prove disappointing? Perhaps better to

go with something that already seems to be working. And doing the PGTC

on the Sprint isn't necessarily incompatible with trying out the belt

drive on some other vehicle - even on a gas car to turn it into a

hybrid per the original plan. As it happens my 'new' 2001 Echo has lots

of room for the motor behind the right rear wheel - much more than the

Sprint. And perhaps it could be in conjunction with a new

electropermanent magnet motor, either of the Electric Hubcap BLDC4-3

type or the ARM reluctance motor type.

So PGTC it is. The next step will be to connect the gas pedal

and inside Fwd-Off-Rev switch so the car can be run from inside instead

of from the test control outside.

I clamped the wires to the motor so they

wouldn't hit the flywheel.

I clamped the wires to the motor so they

wouldn't hit the flywheel.

Then I mounted the flywheel. But I'm not happy

with just a taper lock shaft bushing friction fit.

Then I mounted the flywheel. But I'm not happy

with just a taper lock shaft bushing friction fit.