Turquoise

Energy Ltd. News #99

covering April 2016 (posted May 6th 2016)

Victoria BC

by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

= www.ElectricWeel.com

Features:

* A New Battery Chemistry: Air-Nickel in Potassium Sulfate -

High

Energy & probably Easiest DIY Battery Ever! (see Electricity

Storage)

* Chevy Sprint/Variable Torque Converter Transmission: Basic

Driveability at Last! (see Electric Transport)

* Another New, Super-High Performance Motor Type: Permanent Magnet

Assisted Motor (see Electric Transport)

Month In Brief

(Project Summaries)

- Chevy Sprint with Variable Planetary Gear Torque Converter: it rolls!

- Nickel-Air Battery - Electropermanent Magnet Motors - Permanent

Magnet Assisted Motors

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Geo-engineering, Climate Disasters, Social Evolution

- In Depth

Project Reports -

Electric Transport - Electric Hubcap Motor Systems

* Electric Hubcap motor, Chevy Sprint & Variable Transmission

* "Permanent Magnet Assisted" Unipolar Motor?

* Unipolar Motor "Breakthrough"? Oops.

Other "Green"

Electric Equipment Projects (no reports)

Electricity Generation (no reports)

Electricity Storage - Turquoise Battery

Project (NiMn, NiNi), etc.

* Self Discharge: Probably Caused by Graphite in the Positrode.

(Graphite surface needs to be

oxidized)

* News Report Confirms that Jelled Electrodes make for Virtually

Indefinite Cycle Life

* Conductive Carbon/Graphite Rods

* Notes on the Nickel Negative Electrode

* Self Discharge: Attempting to eliminate it. ... It must come from the

positive electrode.

* Nickel-Air (Air-Nickel) Battery

- Graphene or Graphene Oxide Layer on Plastic Film

- Rethinking It!

- Nickel Advantage?

- Cell Design & Humidity: moisture level maintenance

- 2 Test Cells

No Project Reports on: Lambda ray

converter, CNC

gardening/farming machine, Electric Weel, unipolar motor controller,

reluctance motors (will need to modify the controllers and motors for

electropermanent magnets - or just the motors for "permanent magnet

assisted" motors!).

April in Brief

April seemed to march by pretty quickly, but not without an

exceptional

share of good ideas and good project progress. First I was tipped off

(by Leonardo Janus again) to "Permanent Magnet Assisted" Motors. This

is a

variation on the electropermanent magnet motor, but it seems much

easier to

apply to my motors because it can use the same ARM reluctance motor

with some neo magnets added, and the same unipolar motor controller

I've been developing.

Then I had

considerable success with the variable transmission, as

installed in the Chevy Sprint car. With flywheel inertia to initially

start it into motion - and a little practice by the driver - the car

can be driven on the lawn, and, given enough room to roll (which I

don't have where it is) would surely pick up speed. At this point I'm

not confident

about starting up hills and sufficient acceleration for the street, but

it goes substantially better in forward than in reverse, so it may be

that adjustments can markedly improve performance in both directions. A

heavier flywheel first tried on May 1st seems to help the car start up

better on upward slopes, and readily got it into motion where it needed

20 foot-pounds at the shaft to do so (80 ft-lbs at the wheels), instead

of the 10(/40) that had been the max for a while. On May 3rd it rose

over a board placed in front of a wheel, that required 30 foot-pounds

(/120) - but only for a short distance, and on the third try. If

it's not enough for the street, it's in the ballpark.

Then I had

considerable success with the variable transmission, as

installed in the Chevy Sprint car. With flywheel inertia to initially

start it into motion - and a little practice by the driver - the car

can be driven on the lawn, and, given enough room to roll (which I

don't have where it is) would surely pick up speed. At this point I'm

not confident

about starting up hills and sufficient acceleration for the street, but

it goes substantially better in forward than in reverse, so it may be

that adjustments can markedly improve performance in both directions. A

heavier flywheel first tried on May 1st seems to help the car start up

better on upward slopes, and readily got it into motion where it needed

20 foot-pounds at the shaft to do so (80 ft-lbs at the wheels), instead

of the 10(/40) that had been the max for a while. On May 3rd it rose

over a board placed in front of a wheel, that required 30 foot-pounds

(/120) - but only for a short distance, and on the third try. If

it's not enough for the street, it's in the ballpark.

Finally, with yet another

battery cell with high self-discharge problems, I changed tack... and

stumbled onto what may be a better

EV battery in almost every respect - better than I was trying

for. In keeping with the usual tradition of putting the positive

electrode first, it should probably be called "Air-Nickel", in K2SO4

electrolyte. But air-zinc and others have come to be known as

"zinc-air" instead. Which

convention to follow? "Nickel-Air", then?

With the heavier, bulkier positive electrode substance

eliminated,

nickel-air cells could be half the weight of Ni-MH, and lighter than a

lot of lithium cells. In order to allow free air access to each

exposed, flat, air electrode surface, a stack of them would be bulky:

half the weight but twice the bulk. Another problem with air cells is

maintaining a

workable moisture level in the cell, but I accidently found there may

be chemical ways of solving this. Or perhaps a DES electrolyte could be

used, and would evaporate so slowly the issue would be trivial? With a

gelled nickel electrode, the cell should last virtually forever.

After one hastily slapped together cell that shorted from

invisibly tiny carbon/graphite fibers, I put together a more proper

cell, 3" x 4" and only about 1/8" thick. It went together easily. In

fact, it could be by far the easiest DIY battery to make, ever!

Flat Nickel-Air Cell.

Flat Nickel-Air Cell.

The layers from the top are:

* Permeable Transparent Plastic Adhesive Label (in fact, almost

invisible), stuck onto...

* Conductive Carbon (Graphite) Fiber Cloth Electrode (with "graphite

foil" positive terminal strip)

* Separator Paper (Arches white 90# watercolor paper)

* Nickel Foam impregnated with Nickel Micro Flake Powder gelled

in Glycerin

* Cupro-Nickel 70-30% sheet metal negative electrode, support sheet

& terminal.

* Later the paper was wetted with Potassium Sulfate electrolyte

* and the edges were sealed with beeswax.

Then I discovered that the

high self discharge that has plagued all my battery making efforts is

probably due to the graphite in the positive electrode and hence is

similar in every cell I've made regardless of chemistry. The solution

is probably to oxidize the surface of the graphite: with weeks of

charging current, or by pre-oxidizing it with strong hydrogen peroxide

or perhaps bleach.

In other battery news, I've retired the Toyota Tercel,

still with the 30 NiMH D cell battery installed in 2011. It is

doubtless somewhat weaker than when it was new, but it was still

starting the car - as long as it wasn't left sitting for days with a

door ajar. In the Mazda RX7, pretty much sitting since April 16th when

the insurance expired, one of the five sets of 12v, 100AH NiMH cells

ran down to 10.9v while the others were still 12+v. I figured there was

some bad cell dragging it down. But when recharged for a day or so, all

of them stayed up fine. They seemed to appreciate the rest rather than

continual float charging.

I also spent time every day in the garden, which was dug

and

prepped in March, planting vegetables

including potatoes and corn as well as greens. It has been an amazingly

warm

spring and on some days I feel like I must have moved to California. I

may get two crops of many things. It's not so long ago I remember

starting a garden near the end of June because the spring had been so

cold, wet and miserable. If food deliveries do

indeed run into problems this year as some are predicting, it may

alleviate personal shortages. But of course, the more you plant, the

more there is to water and weed. And it's looking to be really dry.

Since the winter deluges, my hilltop tank has already run out of water

from garden watering, when it should still be refilling now and then.

Toward the end of the month and into May I did some work

for AGO

Environmental Electronics, soldering and assembling water resistant

slip ring assemblies for ship winches, and this also ate into my time

(hence the late newsletter).

Notwithstanding that I need the money, I hardly got

anything done on my 2015 annual "Scientific Research and Experimental

Development" report to Canada Revenue. It seems like such a

distraction. Ideally I should have done it in March. I certainly

wouldn't have got as far on the fine April developments if I had spent

my time on that.

Electropermanent Magnet Motor Field

Last month I mentioned a web search where I could hardly

find the term "electropermanent magnet motor". But it was an

exaggeration to say that that seemed to indicate it was a totally new

field. It's the term that's new. There was the 1962 machine. And

someone has done one in 2006 or earlier, albeit operating a little

differently than the prototypical "electropermanent magnet" of the

video linked in TE News #97, that seems to put out more elecricity than

it uses: http://www.peswiki.com/index.php/Directory:Hilden-Brand_Electromagnet_Motor

. And the (2012?) Zero Electric Motorcycle mentioned the motor was

"permanent magnet assisted". And

someone recently asked me if I could make "Electric Hubcap" motors as

generators for a self turning motor, one that is probably

electropermanent... or permanent magnet assisted... in some fashion or

other.

After a while I started realizing that 'electropermanent'

and 'permanent magnet assisted', while both gaining advantage from

supermagnet flux fields as a common feature, were really significantly

different types of motors. And my own idea for using only AlNiCo-5

magnet cores and no neo supermagnets is really markedly different again

from anything I've seen explained or have seen rumors of.

Permanent Magnet Assisted Motor

After thinking overnight about the motor in the above

video, which link was sent to me on the 3rd, I started to realize it

has some very specific advantages over the AlNiCo-5 designs. The

revolutionary potential may (or may not) be less, but it also has

practical developmental advantages. In the first place, since it uses

regular soft magnetic coil cores, it has the same driving requirements

as my other motors. A BLDC4-3 motor such as Electric Caik or Hubcap, or

a reluctance motor, could be made using the unipolar controller I've

already been designing, instead of a completely new controller with

some tough to meet driving specs.

The motor would have a cylindrical supermagnet, 1.25" O.D.

and 1" long, filling in the center of the iron powder toroid cores.

(Being unipolar, all would be oriented the same direction, which would

also be the direction of the activated coils.) Then they would no doubt

need some sort of magnetic 'shorting bars' or 'keepers' that would

short the field within themselves if the coil wasn't activated. (Or

maybe they wouldn't since the supermagnet and the coil core are in

contact along their length?) When the coil was activated, the

supermanget strength and the coil strength would be added together

externally, increasing the flux and hence motor torque over what the

coil power would do by itself.

If I could find the above size of magnet, it might turn

into

a pretty simple project. One problem likely requiring redesign of the

body part molds will be the "buttons" the coils are mounted on. Unless

supermagnets shorter than 1" can sit inside the toroid cores. That

might be worth an experiment in itself.

Later I located and ordered some 25mm O.D. by 20mm disk

magnets. These will be centered within the 1.25" I.D. space of the

regular toroid coil cores, and the extra 5.4mm to get to the 1" height

will be the thickness of the shorting bar, a 1.25" O.D. piece of soft

magnetic iron or steel. I noted that the Toronto company I got them

from also sold laboratory glassware and I got a bunch of that for the

battery lab.

About the end of the month, some friends wanted to see the

Miles

electric truck run. The driver's inside door handle broke off, but a

couple of good trips on the street appear to have

confirmed that the repair was good and it runs reliably. I still don't

like backing it up! Someone with a camper has suggested a back-up

camera. Perhaps that would would be good solution. That and a new door

handle, fix the window winder, fix the seat back adjuster, fix the

state of charge indicator, and add a voltmeter (or several, to show

individual batteries), and it should be quite nice.

The Miles Electric Delivery Truck out on a Road

Trip

The Miles Electric Delivery Truck out on a Road

Trip

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Geoengineering, Climate Disasters, and Social Evolution

At a media forum, Truth and Justice in St.

Petersburg, attended by many independent Russian and other journalists

and also some politicians, someone

asked

a

question

of

a

former German defense minister, Willy Wimmer, and he

had a few things to say. Russian president Vladimir Putin astonished

everyone by jumping

in with a microphone and translating Wimmer's fairly extensive German

reply into Russian for the

assembly.

Later Wimmer was interviewed by a news channel (in

English) and was asked if Putin's seemingly impulsive act might have

been rehearsed. Wimmer said the question wasn't known in advance much

less his answer, so that would have been impossible. (He also said

that after all his time in politics, he had just learned at this forum

about the workings of Swiss democracy.) The interviewer then asked

something about a "war on information". Wimmer said he objected to that

term. It was an American term, and the Americans always had a war on

something. Next year they would have a "war on sunshine." I laughed at

that.

But then I realized he's actually behind the times. They

already have an undeclared "war on sunshine" with all the chem

spraying. I think

there are those involved who take some sort of perverse satisfaction

when they hear

of solar panel installations being far less effective than expected

because

of the continual haze being spread over the sky. And maybe when they

hear of mass dieoffs of fish, birds and even pollinating insects, too.

Perhaps they started out sincerely believing, or at least

vainly hoping, that what they were embarking on was going to halt

global warming and help make things better. Such motives, up to that

point, are at least fairly benign. But they can hardly have failed to

notice

the devastation and the rapid acceleration of arctic warming, and to

realize the atmospheric blanketing effects of the sprays are the

obvious cause. To continue beyond that point is to live a

lie - dam the destruction, it's the chosen path and I'll hold to it

even knowing it's working evil. I get paid for it and jobs are scarce.

We can't

shut the whole vast operation down new!

On May 3rd, "Tar Sands capital" Fort McMurray, Alberta was

in the news for the whole town being on fire with all 60,000 people

being evacuated as fast as the meager highways permitted. The

government of BC said that they were presently busy fighting several

major forest fires in northern BC already and so were too busy to help.

(Did those even make the news?) This is only the start of May. The snow

should hardly have finished melting, but around Ft. McMurray it was

32°C - July weather! Last summer (as I wrote then), it seemed half

the world's boreal forests were on fire. This summer is already set to

surpass that - devastation on a planetary scale is underway.

"Chem Spraying" I saw while walking, over

Victoria BC Canada, April

2016.

"Chem Spraying" I saw while walking, over

Victoria BC Canada, April

2016.

Farthest (west) freshly released sprays are thin lines. As they drift

east toward Victoria,

instead of dissipating and

disappearing like regular contrails, they simply spread out wider and

wider,

until over town, the whole sky is

covered with silvery or (as others have said) "milky white" haze.

Some lower clouds look real - it gets hard to tell for certain.

The planes apparently come from Whidby Island Air Force Base in

Washington state,

and can be heard taking off from Eastern parts of town, often several

per hour, a roaring, rumbling sound.

It would seem they spray up and down the entire west coast of Vancouver

Island.

Normally very few jets fly over Victoria as it's not between any two

important population centers.

All those involved - not to mention

everyone everywhere - should remember that when their life on this

world is over, they will have to face what they've done on the worlds

on high. Ascending mortals are adjudged in mercy and with full

consideration for the confused, mall-administered planet they hail

from, but when each of us comes face to face with the universe

consequences and outworkings of his deeds, will he raise his head

proudly, saying "I contributed that"?

The world is improved as individuals improve it, and

degraded as individuals degrade it. We are its stewards and we have the

gift of freewill, but it is not in the divine plans nor to any universe

advantage that a beautiful

planet with a vast array of diverse climates and landscapes, patiently

created and evolved over billions of years, be rendered polluted

and lifeless, robbed of a glorious future by those in charge of one

misguided and senseless semi-civilized generation of its inhabitants.

But it is getting to be quite a disturbed and degraded environment that

is being left for coming generations to clean up.

And of course, all these things are symptoms of a grand

malaise that started with the Lucifer Rebellion of long ago. The root

causes are an evolving society with a lack of caring or lack of

examination and action on facts, with insufficient attention to what's

going on, enabling the creation and perpetuation of obsolete and

unsustainable societal systems, institutions and occupations that

aren't under citizen control. Ones' own self and ones' family exist in

a broader social context on a planet that can easily accommodate a

certain number of people (whether that's 1.5 billion or 3, or more -

partly depending how we live), but is deteriorating rapidly and heading

towards collapse just as was projected even by "Club of Rome" studies

in the 1960s if the population was permitted to continue to grow

unchecked.

Hoping to assist with guidance in the social evolution

that is already starting to take place, just for starters, are my own

new www.HandsOnDemocracy.org

writings, and a recent book by Daniel Raphael, PhD: Social

Sustainability Handbook For Community Builders.

Newsletters Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

- Electric Hubcap Family Motors - Turquoise Motor Controllers

- Preliminary Ni-Mn, Ni-Ni Battery Making book

Products Catalog

(Will accept BITCOIN digital currency)

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

Electric

Hubcap

Motor

Systems

-

Electric

Transport

Electric

Hubcap motor, Chevy Sprint & Variable Transmission

I've been having a hard

time pulling the tensioning rope hard enough to bring the pulley to a

stop, or even to near a stop, under full torque. On the 2nd I went to

Castle (ex Rona) building supply to get a thicker polypropylene rope to

try out. They didn't even have the same 3/4" thickness, just thinner.

Well, maybe a thinner rope would fit the pulley more solidly? I brought

home pieces of 1/2" and 5/8". The 1/2" one slipped worse than the

original 3/4" one. Maybe I'll have to rough up the smooth pulley

surface with a grinder or sandpaper?

On the 3rd I connected up the driver controls -

forward-off-reverse switch and electron pedal - to the Kelly BLDC motor

controller. Loathe to cut the plug off the connector for my own motor

controller, I removed the whole cable and made up a new one. But the

light on the controller flashed '... ...'. That error code turned

out to be "hall speed control open or shorted". When I made it I used a

10K ohm potentiometer ("pot" for short). Nothing in the diagram said

what the resistance should be, or said that it was critical. Since it

simply panned from 0 volts to 5 volts, which it could do with virtually

any reasonable resistance value, it didn't seem like something that

should be critical. I opened up the Kelly test control box. Its pot was

2.5 K ohms. It's okay to ask for a specific resistance value, but the

least they could have done was to tell the customers that there was

one, and what that value was! I could have ordered a 2.5 K pot at any

time in the last 2 years, but now that I need it I don't have it. I

could try bridging the pot (ie, across the 5 volts) with a smaller

resistor. That might or might not work.

But I did (at considerable expense) get Kelly's own

("Qiang" brand) 'electron pedal', a nice, rugged unit which appears to

have a hall sensor in it rather than a pot. I decided the best thing to

do was to replace the Sprint pedal that had my pot attachment, with the

Kelly one. That got into doing new mechanical mounting along with the

wiring.

The mountings were in totally different places. I decided

to try the resistor on the old pedal. Let's see... as best I recall...

Rparallel = R1*R2

-------

(R1+R2)

So

2500 = 10000*R2

-----------

(10000+R2)

So R2 = ...I've never been any good at this... Let's just try R2 = 3300

ohms in the formula.

Then Rparallel = 2481 ohms. Close enough. (Apparently R2 should be

3333.3333 ohms)

I put the pedal back in and wired in the resistor. It

didn't help. Then I put a brick on the pedal to hold it part way down,

then turned on the power again. I got a new error, '.. ....' which

turned out to be "throttle above dead zone at startup". Hmm... If I got

the brick just right, the green light came on. I measured the pot in

the Kelly control box. It only went down to 70 ohms when off, not right

to zero. 70 with a 2.5K pot is 280 with a 10K pot. I put a 330 ohm

resistor in series with the pot ground connection. Now the pot in the

pedal couldn't go below 330 ohms to ground. This time, the green light

came on and the motor ran! Now I removed the 3300 ohm resistor I had

put across the pot. It still worked fine. With the fwd-off-reverse

switch down the motor changed direction. All good!

I had also sometimes got the 'open or shorted' error with

the Kelly control box at full throttle. Sure enough, the throttle

control in the box measured 0 ohms to the "+5" when at full throttle.

Doubtless that end can be cured with a small resistor, too. Since

nothing is said about it, apparently they are counting on crappy pots

that don't quite go all the way to each end!

The manual does say: "Standard

Throttle Input: 0-5 Volts(3-wire resistive pot), 1-4 Volts(hall active

throttle)." Apparently it's

operating on the assumption that it's 1 to 4 volts, and it's flagging

an error if it's more or less. No doubt that can be reconfigured if you

have a way to program it. I'll just put resistors in series with the

throttle pot, top and bottom, to reduce the range!

That took up all the time I had, but at least I figured it

out and got the motor to run from driver's seat. If there'd been a note

in the user manual trouble shooting section explaining the conditions

under which the '... ...' lights would blink, it could have been a

whole lot easier. The next day (5th) I soldered in the two resistors. I

made them 470 ohms in case 330 was just on the edge of working. The

green light came on and it worked fine.

The next morning I had an idea, to try letting the

slipping pulley slip until the rope and pulley started to heat up. I

pulled the rope to "moderately tight" with the shift lever. As usual

everything just turned and the rope slipped. But after just a few

seconds - just after I normally would have given up and stopped - the

rope started jerking on the pulley and the car shuddered like it was

about to start moving. It didn't, but it seemed to be almost there, and

with much less tension on the rope than I had been using. I also had

the thought that the tension rope seemed to need a spring on it to

maintain a more even tension. Also that I should adjust the motor

mounting for a better fit on the thrust bearing, which holds the pulley

in place. It wasn't quite straight and had too much room to wobble.

After a few

tries the motor had got hot even faster than

the rope and started to steam or smoke, so I quit. It was definitely

time to drill out those air circulation holes! I hoped that would be

enough, but given the speed of heating my confidence was low. And if I

had to derate the motor to half what it was, to 3.6 KW to prevent

overheating, it certainly wasn't going to put cars on the road.

After a few

tries the motor had got hot even faster than

the rope and started to steam or smoke, so I quit. It was definitely

time to drill out those air circulation holes! I hoped that would be

enough, but given the speed of heating my confidence was low. And if I

had to derate the motor to half what it was, to 3.6 KW to prevent

overheating, it certainly wasn't going to put cars on the road.

When I took the motor off for adjustments, I drilled the

air exhaust holes out from the 9/64" holes of the CNC drill-router

template to 1/2". That should move a whole lot more air.

But I soon realized that

the shuddering was due to a rope

clamp (plumbing hose clamp) hitting the pulley and grabbing. With the

old fatter rope, the clamps had sucked in inside the diameter of the

rope when I tightened them. With this one they stuck out. In fact, the

motor jammed and wouldn't always run in reverse. And having adjusted

the motor, after some more tries the thrust bearing was loose again.

The shuddering had put so much force on the shaft that it had pushed

the set screw in the chain sprocket sideways and the shaft was again

loose side to side. (I had only done up one of the two for the moment.)

On the 9th I put on the 5/8" rope I had also purchased.

This time I put in a spring for the tension. It fared better for going

forward, but the pipe clamps touched the pulley and kept the rope from

tightening for going backward, so it just slipped freely. In forward, I

could rev up the motor, pull back the stick, and as long as it didn't

need more than about 10 foot-pounds to the chain (40 ft-lbs at the

wheels), the car started moving. A couple of times, if I just let the

pulley slip without very much tension, the car started moving after a

few seconds. Either way it didn't accelerate well, and it didn't seem

to take much to stop it. More than 10 foot-pounds was a no go. Why was

it having such a hard time delivering such a small amount of torque?

And the motor still got hot fast. I started wondering if

even a special fan blowing air straight onto the coils would be

sufficient. I started to think that before I went much farther, I

wanted to be able to see the voltage, current and temperature on the

dash. Preferably with a temperature alarm, a beeper.

150 amps times 36 volts is 4800 watts (a little over 6

HP), but if the

overloaded batteries are dropping to, say, below 7 volts (extreme

case), 150 amps

times 20 volts is only 3000 watts. It would be good to see if that's

happening, or how badly that's happening. (It really should have 300+

amp-hours of batteries to provide sufficient current without straining

them. At the

moment for testing it's

just around 100 amp-hours - three size 'frame 27' deep cycle lead

acids.) Which leads to the thought that in 2012, when I only had maybe

about 1 KW, I must have had around 25 foot-pounds or 100 at the wheels

- once the car was moving, and if only at about the best point for 4 or

5 feet of distance it went. I wasn't getting that now.

But the start-ups with the rather loose tension started me

wondering if I had made a mistake in 2012. Could it be the torque

conversion actually works from 0 RPM? But why does it take several

seconds before the car starts moving? I started to think that maybe it

might all be a matter of fine adjustments to the tensioning system, and

I decided to concentrate on that.

On the 14th I bought a stronger spring, and an eye hook

screw. I shortened the rope a couple of inches to accommodate it (I

"cut" it with a propane torch) and screwed the eye screw into the end.

Then I tightened a hose clamp around it. that seemed to make a good

assembly for that end, the 'move forward' end. With the tension on

light, the car started moving almost immediately, but it still had to

need under 10 foot-pounds or so, or it wouldn't move.

I went out to the car on the 19th and revised the rear end

of the pulley rope connection. I found a good reason it wouldn't back

up: the cable from the tension (ex 'shift') lever tightened up before

the rear end of the rope, and actually held it away from tightening

around the pulley. I improved it, but I probably should have pulled

through another 1/4" to 1/2" or so. (It was hard pulling through the

cinch point, in spite of really loosening the bolts there.)

If I revved up up the motor, and then put some

tension on the lever/rope/pulley, according to the new plan, the car

did seem to pull forward under somewhat more load (but not measured)

and start moving fairly well, as the motor slowed. It seemed that the

torque conversion with the car stopped still wasn't happening, but that

the flywheel/clutch start-up idea was working. Backward it still only

moved if it

was about to roll that way anyway, but that was still an improvement

over "doesn't move"! Apparently both sides of the rope were now

contributing at least to some extent.

So! Adjustments and driving technique did seem to be

helping. Would they help to the point that the car could drive across

the lawn without risk of getting trapped in some low spot? Would they

help to the point where the car could be tried out on the street? I

wished I had some nice, level, paved area to try things out in. I could

definitely at least drive it across a space like that, which would be

perhaps more heartening as well as giving a better idea how well it's

doing. There's nowhere in my hilly yard like that. The most level

potential test area now has my RX7 (insurance expired on 16th and I

didn't renew it) and Tercel (insurance expires on 29th and I'm not

renewing it) parked on it. And if I could get the Sprint to it, it

would only be because it could climb hills and doesn't need a level

test area any more!

The extra 1/2"

of rope shift adjustment had to wait until

the 24th as I just had too many other things to do. It didn't seem to

help. I found the set screws of the ring gear had come loose and I

tightened them. I tried a few more things. It seemed quite

disappointing. Then I looked more closely at the transmission, which

had made some odd noise. Things had come loose and the output shaft had

shifted over. When I went to adjust it, I found another loose bolt.

Darn it, was it my mechanical build again at fault? I just don't seem

to build car drive things as robust as they need to be.

The extra 1/2"

of rope shift adjustment had to wait until

the 24th as I just had too many other things to do. It didn't seem to

help. I found the set screws of the ring gear had come loose and I

tightened them. I tried a few more things. It seemed quite

disappointing. Then I looked more closely at the transmission, which

had made some odd noise. Things had come loose and the output shaft had

shifted over. When I went to adjust it, I found another loose bolt.

Darn it, was it my mechanical build again at fault? I just don't seem

to build car drive things as robust as they need to be.

I adjusted and tightened everything, squirted a little oil

into the planetary gear and onto the chain, and tried again. There was

less vibration, but the car still just wouldn't move where it took more

than

about 15 foot-pounds (60 at the wheels), nor in reverse. I think the

pathetic reverse was better before the last rope adjustment. I gave up

in some frustration. I just don't understand why it won't go.

But then I went out on the 29th, pushed the car backward a

few feet on the lawn, and tried driving it forward again. I was

refining my driving technique, spinning up the motor and then pulling

the lever back to where there was moderate tension on the rope. This

generally got the car to start moving as the motor/flywheel slowed, and

I could generally keep it moving - even speeding up a bit - until it

hit a fairly steep up slope about where I usually parked it. If the

motor slowed down too much, I went one notch looser. Then it even

backed up a couple of feet under its own power.

I thought a

heavier flywheel would help, and I

got a

double 12" cast iron V-belt pulley to replace the single on April 30th.

The old one weighed 9 pounds. I neglected to weigh the new one, which

would be about 13-16 pounds, with most of the additional weight

around the rim for the extra belt slot - right where it's most helpful.

I thought a

heavier flywheel would help, and I

got a

double 12" cast iron V-belt pulley to replace the single on April 30th.

The old one weighed 9 pounds. I neglected to weigh the new one, which

would be about 13-16 pounds, with most of the additional weight

around the rim for the extra belt slot - right where it's most helpful.

Not to keep those interested in suspense another month, I

put it in and tried it out on May 1st. I set the car in a position

where it would take about 20 foot-pounds at the output shaft (80 at the

wheels) to rise out of a slight dip and start moving. The first try

didn't quite get it going, but on the second I revved the motor up a

bit more and the car started moving and drove ahead. That's much better

than the 10 foot-pounds or so maximum I had before.

On the old shift stick, it seemed to start and go ahead

best at low speed somewhere between "N" and "D". (That leaves "2" and

"L" in reserve.) I'll adjust it so a good point seems to be right on

something. Or better, I should find a tension lever that will lock in

place pretty much exactly wherever the driver lets go of the button. Or

modify the original stick for that.

Then on May 4th I put a 1" board in front of a wheel so it would take

about 30 foot-pounds to start the car moving. It climbed over it on the

second try. However, starting on a slope where it needed 30-40

foot-pounds (120-160 ft-lbs at the wheels) for some distance, it could

only creep ahead a couple of inches at a time as pulley tension was

applied, before the motor came to a stop.

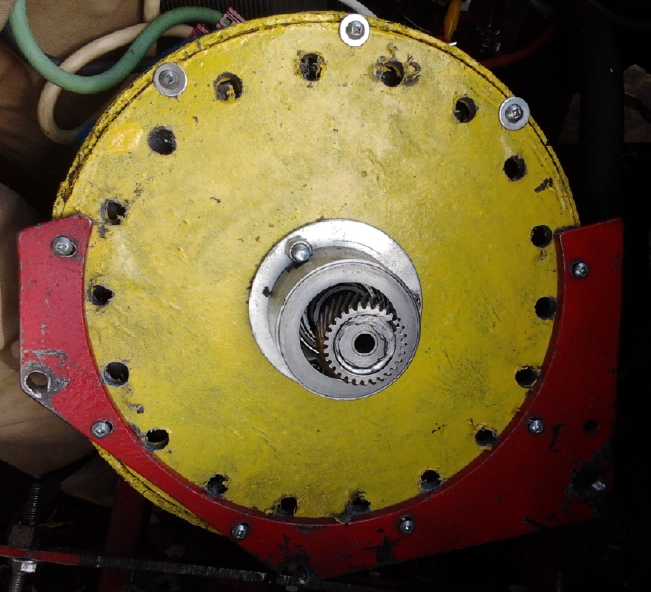

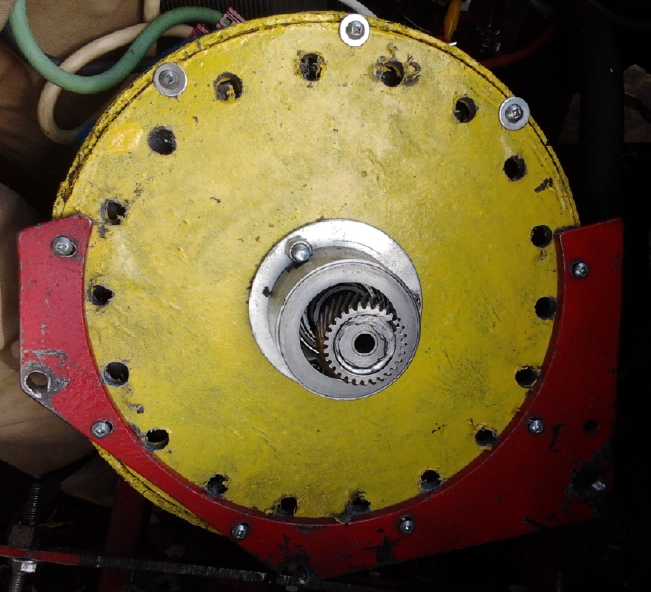

The double pulley flywheel.

At the hexagonal far end of the drive shaft, a torque wrench is used to

determine how much torque is required to move the car ahead or back

from the position it's presently in. When it can climb slopes that

require

40-50 foot-pounds, it'll be strong enough for the street. 10 foot-pounds

has been doubled to 20, but it needs to be at least doubled again.

That's

probably attainable with adjustments.

I shot some good video footage of some of the tests, but I haven't had

time to put it together into a movie.

The main problem with reverse seems to be that even in

"P",

there's still some tension on the pulley that isn't there in forward.

That load prevents the motor and flywheel from spinning up sufficiently

for a good starting boost.

I'll see if it can graduate to still higher start-out

torques with adjustments and more practice. (One can't

drive a regular gas car with a clutch and manual transmission without a

bit of practice, either.) If it's good enough, I'll change the chain

sprocket to the differential from 4 to 1 reduction to 3 to 1, at

which point the motor won't over-rev (over 3000 RPM) anywhere on city

streets.

Adjustments, adjustments!

Conclusion

Even if the Sprint with PGTC probably isn't yet

streetworthy, April's progress was at least a qualified - and

heartening - success. In fact, other than trying various adjustments to

get better and smoother operation, the next jobs will be rather mundane:

* beef up

some of the mechanical parts so they won't come loose after some small

amount of driving.

* put meters in the dash to show battery voltage,

amps, and motor temperature.

Later and still before going on the street, it'll still need some more

battery

capacity (300+ amp-hours) and more "mundane" things:

* reconnection of the speedometer cable to the differential in the PGTC

housing

* reinstallation of various car parts removed (rear fender, etc)

* repair of the

headlight circuits and reassembly of the dash (Why did I get into that?)

* adding an amp-hour meter to the dash (the "Link 10" from the Mazda?)

* adding an oil dripper or something to keep the

planetary gear and the chain lubricated while driving. (I guess canola

oil would work, and be environmetally benign? Maybe a cup to catch

dripped oil? Maybe later switch to a toothed belt? And to some nylon or

UHMW-PE planet gears?)

"Permanent

Magnet Assisted" Unipolar Motor?

One vital question I have

about

the electro-permanent magnet motor idea is, how much energy does it

require to magnetize the AlNiCo-5 magnets? Obviously, if it took more

energy in the fast pulse to magnetize at turn-on time, then demagnetize

it at turn-off time, than to keep a regular electromagnet energized

throughout, it wouldn't save energy. And this is dependent on how

often it has to be switched on and off, which depends on the RPM and

the number of stator poles.

There is the possibility of making some form of BLDC4-3

motors like or almost like the Electric Hubcap and running them with

the unipolar motor controller. As long as the RPM.s are relatively low,

an electropermanent magnet solution might save substantial energy.

But I wanted to make reluctance motors, partly for their

potential for very high RPM running, and my ARM motor gets its torque

by

having many overlapping rotor poles. Both of together these mean far

higher magnet on-off switching speeds, the worst case for the

electro-permanent magnet idea. The ARM motor is thus about the least

likely candidate for saving energy as an electro-permanent magnet

machine.

Admittedly I have no figures for any of this, but below is

yet another new option for getting higher performance out of a motor.

My feeling is that it would be just as good or better for the ARM

motor, tho maybe not for the lower RPM BLDC4-3 with fewer rotor poles.

On the 3rd Leonardo, always a great sender of the most

interesting info, sent me a link to a motor made before 2006 in which a

cylindrical supermagnet was placed inside a toroidal soft magnetic core

-- much like my toroidal motor coil cores. With 'keepers', the

supermagnet field is said to be shorted through the soft magnetic core

and have no external effect. (That seems odd when there's no opposing

magnet like with the electropermanent configuration, but that's what is

being said for both types. Maybe it's "less perfect" than the other?)

But if the coil

is actuated, the supermagnet and coil electromagnet fields are

additive, so the field is stronger than with the electromagnet alone.

Again, we seem to be getting "something for nothing", or at least

getting more flux with lower current and losses than normal.

Another video had a home-made test motor. Assisting

supermagnets could be placed on the coils by hand with the motor

running to see what difference there was, if any. It seemed to show

that it worked much the same with no load with or without the magnets.

I thought he was about to debunk the whole idea and show it didn't

accomplish anything. But with the motor running under heavy load, when

the magnets were set in place, the current meter dropped from 4 amps to

2 amps with the same load, while staying at about the same RPM.

Wow! That would be a great energy savings in an EV! In it we start to

see potential for a 500 mile daily cruising range. (I don't think I've

ever driven that far in a single day myself.)

What's really appealing to me is that this system would

mean using the same unipolar motor controller I've been developing. And

since I could do the magnets the same way in my motors, it would seem I

could just add 6 magnets to my unipolar motor and get the better

performance out of the same motor.

I ordered some, 25mm O.D. by 20mm long, and they arrived

on the 18th. That size leaves 5.4mm height/thickness for inserting

1.25" O.D. "keeper" circles without raising the height of the coils,

with the steel base of the motor being the other end's "keeper". Now,

people have been mentioning "mu-metal" as being a better magnetic

conductor than steel for those keepers. And I was given 3 old hard

drives, said to contain it. I'm dubious about finding a 1.25" piece 5mm

thick, let alone 6 of them. When I looked up mu-metal, I found

permalloy should be even better, while supermalloy was probably tops.

But were they really necessary? It didn't really sound

like it, and I didn't fancy my chances of finding any of them at Metal

Supermarket. Maybe I could just find some 1.25" O.D. washers, in any

kind of soft magnetic material? I found a 1/4" (I.D.) "fender washer"

in my collection, but it was much too thin, and then I figured, it

really needs to be one piece. Multiple layers interrupts the magnetic

flux.

Then it occurred to me that instead of trying to cut

"perfect" disks out of steel plate, I might cut them off the end of a

1.25" O.D. steel rod to the desired thickness. Ya, that was it!...

using somebody else's power hacksaw. But if I cut them roughly from

plate, say with the jigsaw, I would cut them slightly oversize and then

I could turn them down to circles on the lathe, and at the same time

put in an upper lip that would follow the rounded top edge of the

toroid

coil for a better fit. Sigh, that's probably the way to go. Now we have

not only finicky plate cutting with a slow jigsaw, but finicky lathe

work following that!

Unipolar

Motors "Breakthrough"? Oops.

In thinking about the flux, on the 4th a possible reason

the 'unipolar' Electric Caik motor doesn't seem to have as much "oomf"

as I expected occurred to me. The coils themselves don't care about

magnetic polarity. They carry their own field through the ilmenite, and

behind them is plastic laminate. the supermagnets have their own

polarity. But the rotor disk backing the supermagnets is steel. Both

coils put "north" towards the rotor, which is bound to weaken the flux.

If one coil was north and the other south, things might work out

better. The field would flow across the rotor from one side to the

other as well as through the rings.

The trouble was, if one coil was changed to the opposite

polarity, it would try to turn the motor the opposite direction to the

other and nothing would happen. First I thought of having an odd number

of magnets on the rotor so the polarities would be opposite. Duh... one

side would be between magnets while the other was dead on one! That

wouldn't work. Besides, with an odd number, two consecutive magnets

somewhere would have to have the same polarity.

The other possibility was that the stator coils be offset

so that when one is between a NS pair on the stator, the other is

between a SN pair, on almost the opposite side of the rotor.

Then they could have opposite polarities and yet both add to the

rotational force in the same direction. That would be a considerable

modification to the stator layout, and might cause a fair bit of

vibration when running. If there were 4 coils per phase instead of two,

the offsets could cancel out. That's a somewhat bigger motor than I've

been building. But three coils per phase with only one phase on at a

time, the Electric Hubcap size,

would be magnetically unbalanced.

Perhaps the easiest way to test the theory would be to

disconnect half the coils and try just one coil per phase. If it has

more than 1/2 as much torque as two coils (with the same current), it

probably means opposite polarities should be put to the rotor. If not

there'd be no point building a special motor.

Then I came to the ARM reluctance motor... In theory the

ARM motor wouldn't care about coil polarities because the rings around

the coils conduct the field. But I had a suspicion it would work a

whole lot work better if one coil was magnetized in each direction.

Unlike the BLDC's rotor supermagnets, the steel rotor doesn't care

about coil polarity; it's attracted to both north and south - nothing

repels. So reverse polarities with each pair of coils would be easy

enough to try simply by reversing the wires on half the coils. (In the

cramped space - easier said than done. Oh well!)

I have a hunch using opposite coil-pair polarities will

make a big difference on both unipolar motors, but especially the ARM

motor. My first reluctance experiments had no rings around the coils,

and it certainly performed night and day better with opposite polarity

coils. But the rings probably don't carry all the flux, so some would

still go across the rotor. On the 6th I disassembled the motor and took

it to the garage where I could use the propane torch for soldering. I

un-wired half the coils and connected up their wires the other way

around.

The results surprised me. It seemed to work no better. The

torque was certianly no higher, and indeed the RPM only went half as

high. Then I belatedly checked with a magnet. All six coils were now

the same polarity. Apparently I had originally wired them oppositely...

and then forgotten that I had done so... and now, probably thinking of

the Caik motor which had to have like polarities, so completely assumed

they were that I hadn't that I didn't even

check before rewiring them.

So I proved that it does work better with opposite

polarity coils, by changing them to like polarity and observing that it

works worse. Next I have to spend more hours on it, putting all the

wiring back the way it was! To make matters worse, the high currents

had managed to damage my lab power supply, so that it too needed

repair. One step forward and two backward. Curses! (The power

supply turned out to be merely a bent relay contact arm. The voltage

selection relay had been flicking on and off rapidly with each current

pulse, and finally had had enough.)

When the motor was rewired I could throw in the neo

magnets and have it "permanent magnet assisted" quite easily. The one

thing was

I would need to make six 1.25" "keeper bar" circles from 3/16" steel

plate, and probably some plastic spacers to center the magnets in the

coils. Then everything would have to be epoxied in place.

Slipping

Clutch Belt Vehicle Drive Idea - an improvement?

I thought of a potential improvement for the slipping belt

drive, perhaps thinking of how the rope in the Sprint car was behaving.

If the flat belt itself was "stickier" in one section and "slipperier"

in the rest, it would tend to slip more easily over most of its

circuit, then somewhat "grab" as the stickier part went by the small

pulley. This would give the motor a chance to speed up, then apply its

energy to the car wheel, via its flywheel, in the stickier section. I'm

not sure how this would work out in practice. For one thing, the belt

might just stop when the 'stickier' section is on the large pulley.

Then the motor would just spin. (Two sticky sections at opposite

points? Instead, a section of the drive pulley "stickier" than

the rest?) Anyway, it seemed like an interesting theory that might

warrant an experiment at some point.

But some of these things seem to just cause vibration. The

impetus during the push phase doesn't get things going. A much longer

period more push/less push cycle, like the flywheel in the torque

converter, seems to work well.

Turquoise

Battery

Project

-

New

Chemistry

Battery

Making

Self Discharge: Probably Caused by Graphite in the Positrode

It is perhaps so taken for granted among battery makers

that it is virtually unmentioned in the literature: It took me 3 years

to learn that at lower than pH 14, all metals including nickel will

oxidize in a positive electrode. This has been the raison d'etre of

alkaline battery chemistries, where nickel or nickel plating can be

used for positrode current collectors. The only material that will

stand up at lower pH.es is graphite, carbon. This is again implicitly

assumed, seemingly without ever being stated, in literature on lithium

batteries and fuel cells.

But ever since I got cells that worked, they have been

plagued

by high self discharge from an unknown cause. In the 2.6 volt

nickel-manganese cells I attributed it to the high cell voltage,

although at one point I figured I had traced the discharge to the

nickel hydroxide positive side rather than the high voltage manganese

negative.

So I thought I would make 1.2 volt nickel-nickel cells,

but once I got them working (in potassium sulfate electrolyte), they

seemed to also have the same self discharge. Thus it was virtually

certain it was the plus side, since it was the one thing still the same.

This month I decided to try something else again, and

replace the nickel hydroxide electrode with air, oxygen. Oh no, it

STILL has the self discharge!!! What's left? Just the graphite

conductors!

But I also learned in looking at graphene based conductors

that one evidently wants graphene oxide ("GO") based conductors

in the

positive electrodes. There's the key. With enough charging current for

a long enough time, the surface of the graphite starts to oxidize and

the self discharge eventually slows. I think I got this result 2 or 3

years ago. In cells that lasted long enough, the self discharge

continually reduced itself over weeks of testing. But I haven't tried

any cells for long enough to

see the effect recently, and the significance was forgotten over time

until now.

A better way to oxidize the surface of the graphite is

probably to douse it with hydrogen peroxide before using it in the

cell, and I plan to order some strong H2O2 in the near future for this

purpose. (May 6th: My brother has suggested bleach, and a youtube video

last night gave me the idea of using potassium chlorite or chlorate

(stronger than bleach).

Probably there has been all along nothing wrong with any

of my battery chemistries - nickel-manganese 2.6v, nickel-nickel 1.2v,

or air-nickel ~1v ... except for the failure to properly or adequately

oxidize the surfaces of the graphite in the positive electrodes.

I am writing this note on April 30th, having come to this

realization (or at least my conclusion at the moment) only in the last

days of the month. Much of the report below deals with the headaches of

attempting to eliminate the self discharge without having a grip on its

real cause.

News Report Confirms that Jelled Electrodes make for Virtually

Indefinite Cycle Life

Readers especially of earlier issues of TE News will

recall that I have been trying to gel electrodes in one way or another

since I started trying to develop batteries, even to the present cells

with glycerin, in order that they may last 'forever', or at least far

longer than present day cells. Here is a recent news article that

supports the

idea:

http://www.theweathernetwork.com/news/articles/scientists-accidentally-make-batteries-that-last-a-lifetime/66934/

Cheryl Santa Maria

Digital Reporter

Monday, April 25, 2016, 4:37 PM

-

California-based researchers have developed a nanowire-based battery

material that can be charged hundreds of thousands of times. This could

eventually lead to commercial batteries for computers, smartphones,

appliances, cars and spacecraft that may never need replacing.

A typical lithium-ion battery has a lifespan between 300

and

500

discharge/charge cycles for commercial products, according to

manufacturers.

After that, the filaments eventually grow brittle and crack.

But

by coating gold nanowires in a manganese dioxide shell and encasing it

in a gel, researchers at the University of California, Irvine (UCI)

have managed to make batteries last far longer.

A coated

electrode was tested up to 200,000 times over three months without

losing any of its capacity or power. For perspective, charging a

battery once a day, 200,000 times, equates to about 547 years of use.

Another interesting revelation of the article is something probably

most people have been experiencing: that lithium batteries typically

don't last anything like the many thousands of charge cycles often

touted, or even 10% that long, and are in fact no better than

nickel-metal hydride or even lead acid 'golf cart' batteries with

sodium sulfate added.

I write this note too on April 30th, having just been sent

the link by Jim Harrington.

Conductive Carbon/Graphite Rods

I sometimes amaze myself, as I suppose we all do, in

suddenly seeing that the answer to a problem has been right in front of

my face all along. I've looked in vain for local sources of carbon

rods. Finding nothing suitable, I take carbon/graphite rods out of old

dry cells, and think "Okay for a prototype or two, but what about

production?"

On the 10th, after all these years, it suddenly occurred

to me to look on line. Even "Graphite Store" where I ordered "flexible

graphite" sheets from before has conductive graphite rods! (did I

not see them?) A graphite company in Chicago had some too, at better

prices.

I ordered a bunch, in 3 different diameters, and they

arrived shortly after I had decided to try something completely

different - air-nickel cells - that would use no graphite rods.

Notes on the Nickel Negative Electrode

(Note: the following 2 sections are pre the Nickel-Air idea and pre

finding that the graphite surfaces have to be oxidized.)

The posode is regular nickel hydroxide charging to

nickel oxyhydroxide. (If potassium permanganate (better) or else

manganese dioxide is added, it will charge and discharge to various

nickel manganate forms that will gain and lose oxygen or hydroxides.

That's more conductive and holds more charge than NiOOH.) Anyway, these

are both no different to many others except for using current

collectors and conductivity additives of graphite/carbon/carbon black

instead of nickel metal, which would oxidize away in salt solutions.

The negode starts as nickel metal particles, discharging

to nickel hydroxide. This reaction wouldn't work at pH 14 where nickel

simply will not oxidize, but it will work in salt solution, at any

lower pH. For some reason I have finally found out that for nickel it

has to be sulfate

salt rather than chloride salt. The salt solution gravitates to about

pH 12 or 13 and so the reactions are essentially the same as alkaline,

with slight voltage shifts but in the same direction in both electrodes.

It *could* start as nickel hydroxide and be charged to

nickel particles, but I think it's better, or at least easier, to start

with nickel, the charged state.

So one can use a cupro-nickel, monel or (less preferred)

nickel-silver sheet current collector, nickel wool to make the whole

electrode very conductive, and press in fine micro nickel (or monel)

powder to give the most possible exposed nickel surface area. Of

course, one

might profitably add a sprinkling of nickel hydroxide powder to the

nickel powder. It

might improve the capacity.

Only the surface layer exposed to the

electrolyte reacts, leaving metal underneath untouched. Etching in

ferric

chloride roughens the surfaces at the nano or micro scale to increase

the surface area. The copper in the Cupro-nickel, monel or

nickel-silver etches away faster than the nickel (and the zinc in the

"nickel-silver" (better name: nickel-brass) etches even faster),

further increasing the exposed nickel content of the surface area of

the sheet metal.

The reaction voltage of copper is lower than nickel, so

the copper in the alloy always stays in its metallic form unless the

cell is drained down to nothing.

Self Discharge - Grrrrrr!

When I was making Ni-Mn cells that charged to 2.6 volts, I

assumed it was hard to prevent gradual (hours to a day or two) self

discharge because of the high voltages within the cell. It's one reason

I quit working with that chemistry. When I tried Ni-Ni, the other

highly promising chemistry I identified long ago, I got an unknown (to

me, anyway) rapid and continuous self discharge reaction, apparently

between the KCl electrolyte and (presumably) the nickel negative. It

didn't work worth a darn! That took me aback and I left batteries to

work on other things. After a long time, an inspiration finally came

along: try another electrolyte. Ni-Ni in K2SO4 works fine, but I find

even the low voltage (1.25v or so) cell having similar gradual self

discharge to Ni-Mn.

On the 7th I

got around to putting the electrodes, with

the impurities presumably diluted out, back into the test jar/cell and

added some fresh potassium sulfate. I noticed the jar with that

electrode and a couple of other carbon terminals had fluffy orange

precipitate filling the water. I'm not sure what that is, but I've seen

it in test cells before. Really, another dilution should have been in

order. But surely most of whatever it was was gone from the electrode.

(When it was refilled with fresh

water, the remaining carbon electrodes produced no more of it. Must

check the cell to see if it produces more.)

On the 7th I

got around to putting the electrodes, with

the impurities presumably diluted out, back into the test jar/cell and

added some fresh potassium sulfate. I noticed the jar with that

electrode and a couple of other carbon terminals had fluffy orange

precipitate filling the water. I'm not sure what that is, but I've seen

it in test cells before. Really, another dilution should have been in

order. But surely most of whatever it was was gone from the electrode.

(When it was refilled with fresh

water, the remaining carbon electrodes produced no more of it. Must

check the cell to see if it produces more.)

When even a small charge was connected, the voltage jumped

from .2 to .9 in a couple of seconds. It hit 1.25v in a couple of

minutes of ever slowing rise. Now that sort of immediate jump up from

nothing to somewhere near the expected voltage is more like a real

battery! It continued charging at 2.5mA and in 15 minutes hit 1.44

volts. Well, it's not much of an electrode. In an hour: 1.56v. 2 hours

brought it to just 1.57 and 3 to 1.58, so I guess it was still

charging. I took it off charge. When I came back an hour or more later

it was way down below a volt.

I put it back on for about 4 hours, then off at 22:30PM.

It had reached 1.6 volts. An hour later it was at 1.37 and losing a

little faster than a millivolt per minute. It really wasn't much

different than before the cleaning.

By the 10th I decided to

work exclusively to tackle the

self discharge. It was really the key problem, and unless I could get

rid of it or at least reduce it to insignificance, I was never going to

have practical batteries. But what was its cause? It seemed to be more

or less the same both for NiMn (in KCl) and for NiNi (in K2SO4).

For the negatives I had fairly pure nickel and

cupro-nickel. The cupro-nickel apparently had a bit of iron and

manganese in it, about 1% total. Any exposed manganese would

self-discharge to insoluble Mn(OH)2 and thereafter be inert. The same

could be said for iron, permanently discharging to Fe2O3 (or Fe2(OH)6

or something) since the pH is less than 14. .05% zinc might charge and

discharge, and cause the voltage to be somewhat higher with a very

fully charged cell, but not for long once any current was drawn. Other

impurities listed were in vanishingly small quantities.

Surely the electrolyte, KCl for the NiMn chemistry and

K2SO4 for the NiNi, couldn't be the culprit. Not when they were both

seemingly pure, and yet both cells had the same sort of self discharge.

That seemed to leave the positrode. It's the part that's

the same for both chemistries. One might blame one of the additives

like the Sunlight dishsoap or the samarium oxide... except this time I

hadn't used any additives at all. All that was in this electrode was

the carbon rod, active pure Ni(OH)2, and conductive carbon black. And

the carbon black was something different than the graphite powder I was

using earlier, yet the self discharge still seems similar. I've also

used various forms of carbon rods, sheets, and "graphite foil"

seemingly without curing the self discharge. I will of course buy and

try out some of the graphite rods mentioned above. Of course in the

lower pH, the NiOOH has a higher reaction voltage than at pH 14. Maybe

it *has* to have some oxygen gas suppression additive or additives,

like the samarium oxide. If so, maybe without it, it would work better

at fridge temperature? There's an easy experiment to try!

And of course, watercolor paper wraps it all up, with

plastic cable ties. Yikes... the paper?!? there is another common

ingredient to all or nearly all my cells. Hmm... Didn't my first Ni-Mn

test cells in February 2012, using perforated plastic "pockets" - and

no paper - have virtually no self discharge? Or was I just so thrilled

they worked with little self discharge that I paid it no

attention? I'll have to try PP fabric(?) with no paper.

Whatever was causing the self discharge didn't seem to be

diluted out by putting the electrodes in pure water. Perhaps I should

try diluting it in solvent - toluene (methyl benzene) of course comes

to mind. I looked this substance up again on Wikipedia. Unless my

memory is wrong (easily possible of course), it used to say toluene

dissolved graphite to make carbon nanotubes. Now it says it 'dissolves

carbon nanotubes'. A '.edu' source says graphite (among other things)

won't dissolve in anything it doesn't chemically react with - the

molecular bonds are too strong. I did find that a treatment with

toluene (or "Diesel Kleen") made the electrodes about 40% more

conductive, whether because of dissolving the graphite powder, chemical

alteration, or simply by the graphite particles floating around and

re-aligning themselves in lamilae and other favorable patterns, I don't

know. (Diesel Kleen is good for wiping up spilled carbony/graphity

messes that nothing else seems to touch, even once dried. I guess

the graphite must react with it.)

A small quantity of toluene wetting the electrode, while

improving the conductivity, never seemed to do anything for the self

discharge. This time I immersed the whole electrode in a jar of it. At

the risk of possibly dissolving out all the carbon black and eating

away the carbon electrode?

I let it dry out, put it in toluene for a while, let it

dry out, and put it back in the cell on the 12th. By the next day it

was apparent that it was somewhat better, still 1.38v after 2 hours,

and losing about 2/3 mV/minute - a third slower. After 4h15m it was

down to 1.20v.

As I went to put it in the fridge it tipped over and I had

to refill it and put the modelling clay top back on. I put it back on

charge in the fridge to see what would happen. Later I removed the

charge, but the self discharge seemed about double, ie taking half as

long. Not what I was expecting! I took it out and noticed there was

quite a gap in the cover, between an electrode and the rim. And the

discharge was even faster than in the fridge, even with the gap

somewhat covered. There seem to be some unknown factors - or change

over time or cycling. But what? I opened the cell and found the paper

had unraveled at the bottom and spilled out some of the positrode

substance, which lay on the bottom and may have been touching both

electrodes. That solved that mystery! I decided I'd flogged about all I

could out of the little test cell.

Air-Nickel Battery?

The Ni-Mn (2-1/2v) cells had the high self discharge. I

originally attributed it to the high reaction voltage of Mn metal, ~

-1.5v. Then the Ni-Ni cells, half the voltage, didn't work at all until

I changed from potassium chloride electrolyte to potassium sulfate. (I

still don't understand why KCl doesn't work.) But these lower voltage

cells had seemingly identical high self discharge to the others. That

meant it had to be coming from the plus electrode common to both of

them. What else but nickel hydroxide or nickel manganate might one use?

Silver oxide is another alkaline positive, but it's less than

economical and it too might have problems in my cells.

From time to time I've

heard of air - meaning the oxygen in the air - as a type of electrode.

Somehow the thought of an air electrode crept into my thinking.

In most cells, the main metal of the posode is given

first, then that of the negode. For some reason, when the positive is

an air electrode, this gets reversed. Instead of air-zinc, it's usually

called zinc-air. Being stubborn, I'm presently calling the new idea

with the older convention, air-nickel. Also, calling it nickel-air

might confuse people into thinking it's a nickel oxyhydroxide posode

rather than a metallic state nickel negode. And then what is in the

"air" as a negode instead of an oxygen posode?

The half reaction, at the interface between gaseous oxygen

and liquid water, is:

O2 + 2 H2O + 4 e- <==> 4 OH- [at about +.40v in

alkali - I think.]

That voltage is lower than the nickel oxyhydroxide

reaction in sodium sulfate. The four OH- ions behave in the usual way

to react with the negatrode:

2 Ni + 4 OH- <==> 2 Ni(OH)2 + 4 e- [at -.72v at pH 14]

Those voltages both head in the "+" direction with

decreasing alkalinity, so the voltage at slightly lower pH is likely to

remain at about 1.1 volts. That may seem a little low, but 2/3 to 3/4

of the cell weight and considerable bulk is eliminated by the absence

of posode active substance. So even adding a few extra cells to get a

particular voltage is going to cut weight and internal size for a given

voltage

and storage capacity.

People have seemed to have various issues with air-metal

cells and I haven't yet heard of what sounds like a really practical

rechargeable one so far - certainly nothing that I've heard of has come

onto the

market.

But what are the issues? One keeps hearing of air-zinc.

Zinc is always a problematic metal for rechargeable batteries since it

gradually dissolves, and usually forms dendrites that grow through the

separator and short out the cell. Cadmium has the same problem to a

lesser degree. Iron has been or is being tried, but has low

conductivity and tends to clump up with cycling, losing surface area

and capacity.

Metal hydride might work well, but I haven't heard of anyone trying to

make air-metal hydride. (Perhaps it has to do with all the patents

Chevron has acquired on metal hydrides to stop people from making Ni-MH

batteries big enough for transport?)

Other than finding a good choice of metal, mainly it seems

it's hard to control the humidity of the cell when one of the

electrodes is exposed to the air, and to prevent infiltration of carbon

dioxide. But it may be that we can get around those problems. First,

nickel seems like a great choice of metal. No one else has tried it

because metallic nickel, uniquely, doesn't work in potassium hydroxide

electrolyte, which is almost universally the chosen one.

Then, carbon dioxide gradually turns potassium hydroxide

electrolyte into potassium carbonate. With potassium sulfate as the

electrolyte instead, perhaps CO2 will be much less of a problem? OTOH,

the reactions are still alkaline, and the nickel may be

susceptible to

being turned into nickel carbonate, which is probably an insulator that

won't recharge.

Low density polyethylene film blocks liquid water while

allowing

oxygen gas to penetrate. What if one simply had an LDPE film encasing

the

entire cell? And then what if there was a water reservoir that could be

filled if the cells should gradually dry out?

Graphene or Graphene Oxide Layer on Plastic Film

What about a positrode conductor sheet? It has to let the

oxygen molecules pass through from the air into the liquid, as well as

conduct the electrons from the reactions. I recalled that someone I'd

seen on Youtube had found a great mechanical way to make graphene

sheets. This turned out to be Robert Murray-Smith, who has a fantastic

assortment of technical videos with a lot of great new ideas. His

method involved graphene powder, very fine sandpaper, rubber blocks,

and polycarbonate (lexan) plastic. His very first one read just 1 ohm

between

random points on his meter! A couple of updates to the technique,

forming the graphene on glass with an orbital sander and soft cloth

instead of sandpaper looked even better. If I could make it on LDPE

instead, it should allow oxygen through, and also repel water to keep

it inside. Maybe that's a magical front surface for an air electrode?

And maybe finding the right density could even allow O2 through freely,

but block CO2 (which I would hope is a larger molecule?) if it even

matters.

I decided to

try making a graphene layer on a piece of

LDPE film. If that worked okay, I might try doing an air-nickel cell.

First I made a comment on his video explaining what I was going to try,

to see if he might have any suggestions.Then I went ahead and tried it,

using a thin piece of PE window film from a pie package/box and

conductive carbon black. The carbon wouldn't rub into the plastic.

Either PE doesn't work or carbon black just isn't the same thing as

graphene. I added a few drops of toluene, but it didn't help. The

plastic stayed clear and was above 2 megohms resistance. Only the

napkin I was rubbing with gained something of a black sheen. Well, I

had a feeling it wasn't going to be that simple! At least the plastic

didn't rip, or even stretch much. On the 21st I bought a 1/16" 'rigid'

sheet of the plastic used in the video, polycarbonate (which turns out

to be the 'real' name for "lexan", although polycarbonates can have

various formulas), and tried on that... with about the same results.

But it seems from Wikipedia that polycarbonates are also somewhat

permeable to oxygen. Specs are given for it, but there are none for

polyethylene, so I can't compare them.

I decided to

try making a graphene layer on a piece of

LDPE film. If that worked okay, I might try doing an air-nickel cell.

First I made a comment on his video explaining what I was going to try,

to see if he might have any suggestions.Then I went ahead and tried it,

using a thin piece of PE window film from a pie package/box and

conductive carbon black. The carbon wouldn't rub into the plastic.

Either PE doesn't work or carbon black just isn't the same thing as

graphene. I added a few drops of toluene, but it didn't help. The

plastic stayed clear and was above 2 megohms resistance. Only the

napkin I was rubbing with gained something of a black sheen. Well, I

had a feeling it wasn't going to be that simple! At least the plastic

didn't rip, or even stretch much. On the 21st I bought a 1/16" 'rigid'

sheet of the plastic used in the video, polycarbonate (which turns out

to be the 'real' name for "lexan", although polycarbonates can have

various formulas), and tried on that... with about the same results.

But it seems from Wikipedia that polycarbonates are also somewhat

permeable to oxygen. Specs are given for it, but there are none for

polyethylene, so I can't compare them.

Only on the 'magic transparent' tape that I held the

pieces down on the glass backing with did the carbon black 'stick',

yielding resistances in the lower 100s of kilohms between any two

points. I rubbed one piece specifically and it dropped into the mid 10s

of kilohms. Those values were too high to consider using, so that

simple technique wasn't going to do the trick with the tape, either.

Next I tried adding a few drops of sulfuric acid (SG 1.25

battery acid strength), on both surfaces. The friction when rubbing

went way up, and a smear of carbon could be left behind. But it didn't

build up with successive passes. I added a few drops of hydrogen

peroxide, but aside from a tendency to bead up at first, that didn't

help either. Where I left smears, the resistance went down a little