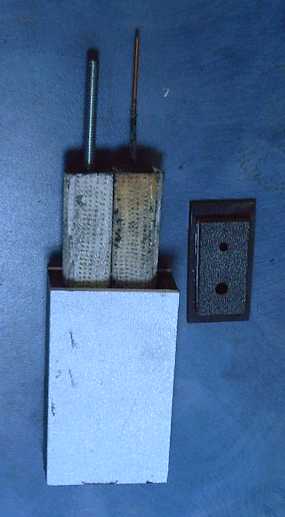

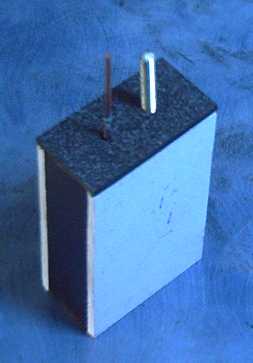

Handy Battery Sticks, 12 volt, 6 volt

30 D cells worth, 12 v, 30 AH, runs my car.

NiMH is a perfect drop-in

replacement for lead-acid in cars.

Later I made "quintos battery sticks", 12 volters to fit properly where

lead-acids used to go.

Still later I made 70 amp-hour, 12 volt "Super Battery Sticks" for

electric cars.