Turquoise Energy Ltd. News #13

Victoria BC

Craig Carmichael - March 2nd 2009

http://www.TurquoiseEnergy.com

Contents / Highlights:

February in Brief (overview...

summary... the short version!)

INVITATION to Inventors

and Innovative Product Developers

* Owing to the absence of support for

innovative productdevelopment in Canada & BC, we hope

to create a professional innovators' association.

* Exploratory First Meeting Sunday March 15th, 1:30 PM

Electric Hubcap Car Drive Project,

Longwinded Detailed Report

* New motor spins wheel, tests look good.

* But lack of funds eventuates in further delay

of road testing.

Turquoise Battery Project, Longwinded

Detailed Report

* Several electrodes sent to U of Stockholm

for evaluation

Previous Issues Index/Highlights:

http://www.TurquoiseEnergy.com/TENewslettersIndex.html

February in Brief

It's as well I finally

sent the January report without waiting to see if the motor would run.

It didn't. There were assorted problems and it took until the 17th to get

the car wheel (jacked up) to turn. And it still wasn't ready to roll.

Then on the 19th, just as I was satisfied all was in order and it was about

ready for a road test, a corroded battery connection arced, shooting out

bits of molten lead that melted into the battery case, and fried the motor

controller, during a spin-up test with the wheel jacked up.

So I decided to lay out and build a new controller with more room on it

for additional protective components. I'm still waiting for two items to

arrive.

But failure can be the key to progress. The whole experience, of once again

having serious problems partly on account of using old garbage (scrounged

batteries and battery cables) instead of having a bit of money to go out

and buy decent new materials (as any car owner installing one for himself

would), got me thinking.

Just why is it no funding is available

to inventors and innovative product developers? I had been getting together

with two other innovators for Sunday coffees, and I thought, "Why don't

we broaden our circle once a month? We had a monthly product developers'

group in the 1980's. I could run an event notice at VIATeC."

Then the ideas avalanched. Government funding programs seem to operate

in an information and feedback vacuum. What is desperately needed is an

organized professional association of innovative product developers, able

to tell government what is really needed to support real innovation, oversee

the whole process of supporting inventions and innovations that shape a

better future, and perhaps even evaluate and monitor progress of individual

ideas and projects.

This is worth putting some energy into in spite of any additional delays

it may cause to the motor improvement and battery development projects,

and I have other things that need doing that will cause further delay,

such as income tax/SR & ED app, housework and yardwork long put off,

and a long, long overdue update of the Turquoise Energy website. (This

newsletter isn't written in an hour, either, but I think it's worth doing.)

I've hardly been able to look at the projects for a few days now, and it

may be the middle of March before those road tests!

INVITATION to Inventors

and

Innovative Product Developers:

Do we wish to form an Association?

Exploratory Coffee Meeting:

Sunday, March 15th 2009

1:30 PM

at my house, 820 Dunsmuir Road, Victoria

BC,

(inside of 'corner', tall house with hedges,

misc. parking Dunsmuir, Wollaston,

foot of Sea Terrace at Barnard Park.)

RSVP please

Events and conversations

over the last year and more have shown that it's not just me that can't

find funding for developing innovative products. Talking with others who

have made innovative new things, or who would like to have made them, disclosed

that almost none of them could find a penny besides their own resources.

(SR & ED tax credits can help leverage your money and are thus a valuable

tool, but they are not a source, per se, of funds.) Two of those who had

developed new things had their own relatively prosperous companies they

drew funds from, even though the projects weren't closely related to their

businesses.

I have now e-mailed or talked with just a few other

innovators, and we seem to be in substantial agreement about the problems.

I've proposed an organized professional association as a solution and found

they like it, and have some ideas similar to mine. A guide or possible

agenda to focus the meeting is below. All suggestions from attendees will

of course be considered.

If such an association can be organized by inventors from the grassroots,

then perhaps as an organized group we can make recommendations for the

future to the federal and provincial governments of effective means by

which the beginning steps of real innovation ought to be funded.

And there are more detailed ways in which we might as an organized group

become involved in the whole process of resource allocation for projects

that can redefine the future.

Points for debate/Agenda

1. Is the system

working as it is? Do people get a reasonable level of support from existing

programs?

2. Would a professional association of innovators have a reasonable

chance of making our collective voices heard by government? Is forming

an association a good idea?

3. If it is to be a professional organization,

what are the membership qualifications to be? Having invented a product

that became commercial? A technically successful project? Other ideas?

4. Constitution. It would seem inappropriate not to use the best advanced

democratic principles known for such an organization. Having made something

of a study of democratic mechanisms, I have some decided opinions which

we will not be ready to discuss immediately, but are nonetheless sketched

out below for consideration at the appropriate time.

5. It is my impression

that the small funding requirements for many prototyping projects - often

the equivalent of a salary plus expenses - fall beneath the radar screens

of government funding agencies, and also that those programs are much too

rigid to accommodate the beginning stages of inventive development. What

sort of general guidelines might we wish to submit to provincial and federal

government?

6. Would we want to be a body that looks at individual projects

and applicants and passes judgements or makes recommendations about supporting

that project? On what criteria? Possibilities include: * potential value

of the project in the long term* potential immediate benefits of the project*

past project performance record and credibility of the applicant* the applicant's

plans: does he wish to publish his results for all, patent and license,

set up a production line, ...?* prospects for success* valuable lessons

that might be learned (and posted on the web to help guide future developments)

in the event of failure. (In considering the prospects that an inventor

might "strike it rich" off his work, it should be borne in mind (a) that

less than 1% of inventors do, and that (b) unlike a permanent employee,

his funding is only for the duration of product development. If he does

"strike it rich" having developed it, society still paid little for a short

term, and gains much for a long term if not permanently.

7. Would we want

to try to get people with similar projects to work together? Funds might

be better spent and projects completed sooner. The whole is often greater

than the sum of the parts.

8. Would we want to discuss and target specific

areas that ought to be developed? Would we then try to find people with

ideas for developing them?

9. Would we want to help innovators with facilities

and skills they lack? For example, someone might have need of a machine

shop or a welder for a piece, and not have the equipment or skills. Or

someone might need help accessing government for regulatory or other specialized

approvals or support. Where, if anywhere, might we want to go with these?

10. The coffee may well be all gone by this time if not sooner.

Points For Constitution-----------------------

It is doubtless

premature to speak of a constitution, yet I fear if no mention is made

of these important but less familiar specific points of democracy, they

will be lost in the shuffle when the right time does come around.

a) All

votes should be by choice ranking (so-called "STV") as it is the only

voting system where one is completely free to rank the choices in the actual

desired order. If your first choice is eliminated on the first count,

your second choice moves up, and recounting continues until one choice

has over 50%. "Voting strategically", "vote splitting" or the need for

multiple ballots are eliminated. The single "X" voting system has never

worked properly nor served us well when there are more than two choices,

as all our political parties recognize when they select their leaders.

And it can improve debate procedures: There is no need to vote immediately

on each proposed amendment to an idea, as all contested options can be

saved for a single ballot and voted on at the end of the debate after all

has been said, without prejudicing the outcome. Thus: full debate without

interruption, proposal of every option anyone still cares to have on the

ballot, then one vote, and the version most liked by most people is chosen.

b) All positions carrying with them any power of decision within the organization,

including if there eventually come to be paid positions, should be elected

by the membership for specific terms. While day to day decisions may be

needed, we must be careful not to let a clique of permanent staff acquire

more power from the democratic membership than is warranted or necessary.

c) Power to amend the constitution should require no more than about a

55% vote. Over 11 to 9 or so is a credible majority provided all other

processes leading to the vote have been fair and above board.

Many organizations - and countries - hamstring themselves by requiring

up to 75% majorities, so changes are ultra-hard or impossible to make.

75% means that 26 people can hold 74 hostage and prevent action. It makes

revolution a more feasible option for change than democracy! Even 60% means

41 people can prevent 59 from making a change.

And in any organization

where membership is voluntary, dissatisfied people tend to quit, leaving

the minority who like it the way it is behind, so it can be very difficult

to get even a 50% vote for changes that would bring the former members

back.

The Spark for an Association

I'd been gradually

recognizing the almost universal lack of support for innovative development

in Canada over the last three years, but there was a final spark for me

(literally, as it happens), working on the Electric Hubcap:

Just after I finally got the motor running properly on February 19th, a

spark at a bad battery terminal connection blew out the motor controller.

At that point, the unit had been at long last about ready for a road test.

Using new batteries and cables instead of old used, corroded stuff I'd

scrounged would have prevented the problem, and having some spare MOSFETs

on hand would have reduced the delay the failure occasioned. I hadn't ordered

them, hoping to avoid the $80 expense.

It seemed to me crazy that a project to redefine the future of transportation

and to a great extent get us all off of oil quickly, continues to be funded

by one highly skilled but very broke guy living on a few hundred dollars

a month, even after the October prototype drive test [CarMoveWave.AVI]

had proven the concept. The fundamentally better mousetrap is built and

works. It's an incredibly exciting development, full of promise for the

future, but there's still no point applying for funding - all the absurd,

rigid funding rules are the same as if nothing special has happened, and

Canada and BC remain indifferent and detached, unreachable through the

bureaucracies.

I remark again that for the almost trivial amounts of funding these sorts

of innovative prototyping projects can often be done for to be unavailable,

compared with the obvious and almost measureless potential benefits of

successful new designs that redefine the future, shows a warped and unbalanced

sense of proportion and priorities somewhere within our society's resource

allocation processes. Perhaps it would be better to say that the process

seems utterly confused, disordered and dysfunctional.

In my own case, as I have all the skills, tools, equipment and space necessary

to do practically all aspects of the projects myself at home, getting even

a couple of thousand dollars a month would make all the difference. I'm

sure most individuals would agree that would be a true bargain for Canada

or BC, to support the devotions of a skilled, experienced, multi-disciplinary

researcher, inventor and professional product developer with a long history

of successful groundbreaking inventive projects, now attempting - not without

visible and substantial progress - to create the very things most needed

by society in the vital field of energy!

Everyone who hasn't looked for funds for such purposes themselves will

surely be thinking "Surely there are government programs to fund this sort

of thing!"

For this reason, I'll run through them (or is it

"run them through"?):

Regardless of potential benefit to society or to the environment, potential

savings to the taxpayer, prospects of the applicant making any money himself

from a successful project, an applicant's track record of successful projects

or any other considerations, NRC/IRAP (National Research Council/Industrial

Research Assistance Program) and SDTC (Sustainable Development Technology

Canada) paradoxically both ask the applicant himself to put in as much

money as is being applied for or more when he is looking

to them for project funding. As if, in ostensibly helping

to permit him to try to improve the future for everyone, they

were doing him a Favour!

And they won't consider

time and money already spent by the applicant in the equation. (Gosh, thanks!)

Since no one knows in advance how much it will cost or how long it will

take to create something that's never been made before, they are likely

to hope they can do it on their own without going through all the hurdles

and delays these programs impose. Then if they find they need assistance

after all, they don't have the money remaining to qualify themselves for

it.

It is especially ironic for SDTC to ask the applicant for

money: the whole reason the program was set up by the Canadian government

was specifically to fund prototyping because no funds for that purpose

are available elsewhere.

(Perhaps the people allocating the

money should be required to incorporate a company, come up with a detailed

business plan and half their own salary to qualify for receiving the other

half, months later. How soon would there be no one left to submit an application

to?)

BC's "Innovative Clean Energy Fund" specifically prohibits funding

of prototypes, the first material step in innovation. WOW!

Also, none of these programs want to deal with the small (by government

standards) but vital amounts often required for prototyping, again especially

ironic for SDTC since prototyping support is what SDTC was created for.

Only CRA (Revenue Canada) has any useful program: the SR & ED (Scientific

Research and Experimental Development) program will refund a portion of

money already spent on R & D materials (and salaries) at tax time.

This is good leverage for your own money and without the hurdles of the

other programs, but again not a source of funds to live on and work from.

If there are any other available funding programs or sources, they are

certainly well hidden from potential recipients

One begins to see why, in spite of scientific and technical progress, nothing

ever changes in areas too big for one individual to manage, and we still

drive gasoline cars, and there's no economical decent batteries, just the

old lead-acid crap, in Canadian Tire or Wall Mart. Why we head into a new

millennium with energy all around us as wind, waves, tides and sun but

the only proposals that are taken seriously are to flood another valley

of the Peace River and to import more gasoline and natural gas.

Flat little Denmark exports wind powered electricity to Europe when it's

windy. Why has rich, mountainous BC on the ever turbulent Pacific coast

been allowed to become a net electricity importer?

It seems to me there's a hidden organizational vacuum that needs to be

filled, and that organizing it well could pay huge social dividends.

The Electric HubcapTM

Vehicle Drive Motor

February Gory Details

The Production Prototype motor on the car in February.

It seemed to take

an amazing length of time to get the motor running when I thought all was

in readiness.

There were a mistake, more than one omission,

and a bad solder joint that looked fine on the new motor controller interface

board, located one at a time. These things would have been solved faster

if I'd tested everything on the bench before mounting it on the car.

Plus, the mountings of a coil broke and the coil jumped out and stuck to

the magnet rotor. Luckily, the wheel was still jacked up and I happened

to try to turn it by hand and discovered it without further damage. (Driving

the car would have shredded things nicely before I was out of the driveway!)

I spent a couple of days figuring out a better mounting system. Now the

coils would have to almost crumble to come off.

Then I spent a session belatedly sitting down and figuring out where the

slots and optics actually ought to align, instead of just expecting to

adjust them later by rotating something as I had been doing on the first

prototype. It turns out that if the slots and solids are lined up with

the magnet poles, the optical elements should (conveniently) aim directly

from the axle center to the centers of three adjacent coils. So I adjusted

everything to attain this alignment. But that's if the coil

low drives are connected one way at the MOSFET driver chip:

Optics A => A hi &C low

Optics B => B hi & A low

Optics C => C

hi & B low

If they're the other way, A hi & B low, B hi & C low and C hi &

A low, the optics should point directly between the coils, 20 degrees off.

I don't know how, but I managed to wire and rewire this the same way -

wrong - three or four times! The motor ran lazily at 150 or 200 RPM drawing

around 50 amps continuously regardless of speed.

I tried reversing

the motor while it was still turning and 'instantly' blew the phase "A"

MOSFETs. I replaced them, and replaced the socketed IR2130 driver chip

to be on the safe side. The motor ran. So I put the old 2130 back, thinking

it was probably okay and a $10 chip shouldn't be thrown out needlessly.

The instant I touched the power, BANG!, another set of phase "A" MOSFETs

went up in smoke. Now I've burned up 8 MOSFETs instead of four, and the

driver chip. New rule: any MOSFETs go, replace IR2130 regardless of anything.

On the 19th, I rewired the optics to the phase inputs for about the fifth

time and finally got it right.

This time, there was some other

weird problem. Checking things with the oscilloscope revealed that daylight

was activating the phototransistors in the motor! I dismounted the motor,

put the protective cover on it, and put it back on. Problem solved!

The motor ran well. I took it from 12 volts to 24 to 36 and

everything seemed fine, but then there was an arc and some smoke from a

battery terminal. I tightened the connections. It ran fine once more, then

there was another spark from a battery terminal (it shot out some molten

lead, which melted itself into the battery casing) and the motor controller

blew up and caught fire!

It would appear that the cause of

the problem was the bad battery connection and the large transient spikes

inherent in having the main power flash on and off with the motor running,

rather than any fault of the motor controller circuit, which had been (finally!)

working perfectly up to that point.

So! A month working out

the bugs, it ran great for a few wheel spins, and then poof!, it's dead

again. I didn't even get a video!

At that point, the work was stalled because I had to order more MOSFETs.

I had wanted to have some more on hand just in case and to try out a new

layout, but I was reluctant to spend the $80 if I didn't have to.

Oh well, on the bright side the motor runs, setting the timing is figured

out, and the forward/reverse by inverting the photo signals is now tested

and proven to work well. And this time, I left the motor mounted on the

car. Theoretically it should sit there harmlessly, and that has proven

to be the case so far. The magnets induce a slight vibration at very low

speed.

I gave some thought to ways and means to protect the motor controller better

and to limit damage if there's a problem. As it is, if one phase blows

MOSFETs, it seems to damage the motor controller chip, which then manages

to burn out all of them in all three phases. About the only thing that

has never yet blown is the circuit breaker, which should be protecting

all these components at a considerably lower current than their ratings!

I could replace the IR2130 three phase MOS driver with three single phase

IR2110's. Then if one blew, it wouldn't directly affect the other phases.

In addition, I could have a current sensor/limiter circuit shut off the

motor for one or more seconds if an excessive current is seen.

These things add complexity to what seems remarkably simple so far, and

they aren't foolproof. (The IR2110's seem to have no protection against

turning on the high and low sides at the same time, which will require

more chips.)

I made a new controller with the new layout when the MOSFET transistors

arrived.

New spread-out "production version"

motor controller layout. (but still with the prototype logic boards.) It's

on the inside of the front cover of the wiring box. The 12 transistors

are mounted on two 1/4" x 1" aluminum bars for immediate heat removal (with

tarpaper electrical insulation). The heat sink "fan" of aluminum roofing

flashing (very top) is a sample of those that will be clamped opposite

the transistors on the outside.

Six fuse legs are soldered to

a solid copper bus bar (+36 volts), with the other leg directly on the

transistor pin. The low side transistors are soldered directly to a heavy

ground bus wire under their legs (rather hidden here). Directly across

each transistor pair are a 100uF & .1uF filter capacitor on the DC

power. The leads that go to the coils are joined by bare #10 copper wires,

each forming an "N" with the #8 output leads soldered at the middle.

What I did do for

better protection was:

1.

Spread out the transistors (as seen) for better heat dissipation and room

to mount more protective components. This layout is what I've been envisioning

for the production model, so I'm just trying it out sooner. For production,

viz: the layout above but with only one long, thin, clean circuit board,

its top edge clamped directly onto the lower aluminum bar directly below

the lower transistors, and the small transistor control wires all connected

at the top edge.

2. I put

individual smaller value automotive fuses in the power line to each transistor.

These should blow long before the breaker would.

3.

I've ordered some 17 volt, 5 watt zenor diodes. The maximum voltage the

MOSFET transistor gates can have WRT the source is +/- 20v, then they fry.

A fried motor controller might send them the whole 36 volts. This may be

why all twelve often burn up instead of just one phase. The zenors from

gate to source should limit the voltage to the range -0.6v to +17v. Normal

operation is 0 v to one battery v, about +14 volts max.

4.

I've also ordered some "MOV's", metal oxide varistors. These interesting

devices do nothing until a certain voltage is reached, their breakdown

voltage. Then the metal oxide conducts until the voltage is reduced, shorting

out the overvoltage. As the voltage selected is above the battery voltage,

the only time they should be active is when there are voltage spikes, eg

when coils switch... or perhaps when there is some bad battery connection.

I've just finished this controller except

for the heatsink fins and the protective parts I don't have yet (at the

time of this newsletter). Other than that, everything is about ready for

further tests when I find the time.

A noteworthy sideline is that in testing the stator coils, I noticed that

energizing a coil with a battery wasn't enough to push a supermagnet away.

It seems that the small-space attraction between the magnet surface and

the coil iron surface overpowers the strong but more diffuse field of the

electromagnet. When I set the supermagnet on a piece of plastic 1/2 inch

above the coil, it jumped away by repulsion when the coil was activated.

This lesson had its effect when the motor was tested on the car. With twelve

volts power, the wheel wouldn't start to turn unless I gave it a start

by hand, and there was a lot of vibration while it was running. I backed

off the stator and rotor from about 0.1" gap to perhaps 0.25" (That's a

guess -- to check the gap was one reason I had wanted to run it with the

cover off!) and then it worked by itself and ran much more smoothly.

Probably accidentally having a large (1/4") gap when I tested the previous

prototype was the reason it worked and drove the car, while a later test

with the gap reduced to 1/8" unexpectedly didn't! Who'd have thought? What

a piece of luck to have made a "mistake" that made the October test successful!

I could well have given up the whole project if it hadn't moved at that

time, none the wiser!

No doubt there's an optimum gap, and

it's a lot wider than I thought it should be. and far wider than for any

other motor type. That's good for efficiency, low vibration, construction

tolerances, and for much reduced stress on the motor shaft inner bearing

and on the coils. (I had noticed the car had a lot of vibration from about

5 to 15 Km/Hr driving with the motor mounted and the small gap. It's vanishingly

less with the larger gap.)

Passenger Heat and Windshield

Defog

I searched on the

web for 36 volt electric fan-heaters. Without heat it'll be pretty cool

in winter and the windshield won't defog if the gas engine is turned off

while driving. I found that they are made: for golf carts, 500 watts. They

appear to be just what I was after, for a couple of hundred dollars.

One morning last week I tried getting ice off the car windshield by putting

an electric fan heater (120 VAC) on the dash, set to 600 watts and low

fan. The ice was thick and really stuck on, and it would have been a tough

scrape (a stiff broom did little). In a couple of minutes or so some had

run down and the rest was melted enough to clear with the windshield wipers.

No doubt if the windshield had been fogged it would have gone about as

fast.

I want to mount the heater so it can pivot in all directions to aim at

any part of the windshield or backwards towards the driver and passenger.

Two heaters might be good for starting up, but if left on they'll certainly

shorten the driving range. (Good batteries with very long cycle life...

must get those going!)

Battery Voltages: 36 Volts

Rocks!

Also for 36 volt golf

carts were battery state-of-charge meters for lead-acid batteries, which

may or may not be useful once I get some new chem batteries going, but

are inexpensive and will be valuable until then.

In the search, I ran across a golf cart maker's interview. It's from 2002

but it has some interesting material.

http://www.golfcarcatalog.com/index.cfm?fuseaction=archive&step=3&archive_id=16

"Craig Journey was the lead electrical engineer with E-Z-GO, starting in

the early 1990Õs, and a pioneer in the development of Electronic

Speed Controllers for Separately Excited Field DC Motors."

Among many things, Journey said:

"Anything over 36 volts, you have to be warned and marked. In a 48 volt

system there are additional issues, but there is no doubt in my mind that

72 volts is a hazard. The National Electric Code now has two numbers, 30

volts wet and 60 volts dry."

I'm so glad I switched the Electric Hubcap from 120 volts to 36! Functionally,

the only differences besides safety are the increased diameter of a few

short heavy wires and the specific specs of a few power components, and

you can't plug in house lightbulbs. (I wonder what he thinks of 144 volt

and 300 volt cars? I hear police and rescue workers aren't permitted to

touch badly damaged hybrid cars even if someone inside needs help.)

"As a matter of fact the hazard above 48 volts is not an electrocution

phenomena. The phenomena that kills you is called 'let go'. In other words

you'll touch one of these high potential sources and you'll lose control

of your voluntary muscles and can't let go. So it doesn't electrocute you.

You can't breathe so you suffocate. It takes 7 or 8 minutes to die."

DC is worse than AC because AC goes on and off giving some chance (though

sometimes not), while DC is continuous.

And finally, in case I thought I was having a rough time with the motor

controller, which has a much more demanding job than the golf cart field

winding controllers, he notes: "There

are some failure modes associated with all these electronic systems and

it took us a couple of years to figure them out."

In one year I've done the whole Electric Hubcap motor design and prototyping

all by myself from the ground up: mechanical, electrical and electronics,

including the motor controller as one of its components. (There have been

at least three versions of most everything.) Of course, there will always

be more electronic "failure modes" waiting to be discovered!

Electric Hubcap Motor Factoids: [Deleting-- see "About Electric Hubcap" page]

Turquoise Battery Project

February Gory Details

Electrodes Sent for Evaluation

I made contact with

an alkaline battery researcher in Sweden. He offered to test a few of my

electrodes, so I sent him two variations of nickel, two of zinc, and titanium,

calcium and antimony ones, 7 in all. All of them have a couple of percent

cobalt added to ensure conductivity, and all have a layer of zirconium

silicate dielectric "shield" sprinkled on top (and around the edges) to

hold metal ions in place and prevent dendrite growth at the separator sheet.

Seven electrodes that took a surprising amount of time to make

The electrodes carefully boxed.

The nickel hydroxide

with 15% potassium permanganate electrode looks almost black, which colour

holds great promise for being highly conductive - very high amps for a

given size. The other nickel one (below) has a thin layer of calcium at

the collector plate, promising to prevent or reduce outgassing during charging,

which builds up pressure inside the battery until (in my experience) the

case wants to burst.

The true green battery chemical: nickel hydroxide.

Collector plates (with tabs) are "nickel-silver" (copper, zinc &

nickel alloy 65%,18%,17%) with a 60 mesh stainless steel screen on top

to help connect the chemicals to the plate. Some of the zircon is sprinkled

on top.

The calcined zinc

oxide ones are one plain and one with 1% antimony oxide, hoping again to

stop or reduce outgassing.

The other three electrodes are more

speculative. The antimony oxyhydroxide one (+ 0.8v?) may not be solid on

both sides of its (uncertain) redox reaction in alkali solution. (I have

better hopes for it in neutral electrolyte.) The titanium oxide

one (- 1.38v) will have less amp-hours per weight than zinc, but may (or

may not) be more conductive. (Again, it may do better for amp-hours in

a neutral electrolyte.)

The calcium one (+ 1.55v) looks promising,

but one never knows for sure what will actually happen. Also the density

is low... similar to nickel hydroxide. Though

having little time to spare, I did put together one sealed cell of nickel

and zinc, in mildly acidic electrolyte of mainly KCl with CH2Cl2, and HClO4

(AKA potassium chloride, methylene chloride and perchloric acid). This

is the first one since discovering the need to compress the powders. The

nickel has potassium permanganate, but I diluted it to 7.5% instead of

15%. It still looks virtually black.

It charged but very very

slowly. Somehow, I'm still not getting those ions going easily through

the cellophane. This appears to be the main stumbling block right now.

How is it others are using it and similar semi-permiable products and getting

good results? Evidently I need to do more reading and maybe experimenting.

While admittedly trying to stress the nickel with potassium permanganate

electrode as little as possible, in removing and reinserting it from the

battery my impression was that it seems like a little rubber hockey puck,

and it didn't break or crumble. This surely bodes well for a long lasting

electrode that will take many cycles.

I decided to try magnesium perchlorate as an electrolyte. So I looked out

on the web for how to make it and found that the chief reason to want to

make it at all is that it's considered to be a good neutral PH battery

electrolyte, both aqueous and non-aqueous for lithium! This

was also my first clue that I was on the right track with perchlorate.

I had I bought some potassium perchlorate, along with perchloric acid.

But it turns out that although KCl is quite soluble, KClO4

isn't. Sodium, for NaClO4, is more soluble but would

probably have less conductance, so the magnesium (MgClO4)

appears to be a good choice.

I'll make some MgClO4

(mix MgCO3 with the right amount of perchloric acid.)

Then I'll open the battery and put some in, and try some other separator

sheet.

I'm hoping for some interesting results. First, perchlorate and permanganate

are such strong oxidizers that the nickel, or a good portion of it, may

charge from Ni(OH)2 (valence II) to NiO2

(IV) instead of just NiOOH (III), thus moving up to twice as many electrons

for double the amp-hours. Second, the voltages will be different in neutral

solution. The nickel may be +0.75 to as much as +1 volts instead of +0.5

volts, while the zinc will be reduced from -1.28 volts reaction to perhaps

-1 volts.

Thus we may see the nickel providing two, three or

even four times the energy it does in alkali, the zinc losing almost 30%,

and a cell voltage not too far under two volts. The improvements to the

nickel make it look like a much more attractive cathode than it is as usually

used in alkali! Altogether it should make for a battery around half the

size for a given energy, and the permanganate in the nickel should increase

the available current per square centimeter of interface considerably.

At least, those are my expectations, without having tried it yet. IF I

manage to solve the separator sheet mystery.

I will of course try out other electrode elements as indicated last month,

but zinc is good if the zirconium keeps the dendrites under control, and

the nickel looks much better than it was. It will be ironic if after having

looked at so many possible electrode elements I end up using "the usual",

nickel and zinc! However, I think my supporting ingredients should make

them better.

NEW!

Liquid Battery

MIT Review shows a

new battery conceived by Donald Sadoway with

liquid metal electrodes and liquid salt electrolyte. It would have to be

heated substantially to melt the metals, but it looks very interesting!

It's intended to be huge and for storing tremendous amounts of electricity,

like solar power during the day for cities at night. WOW!

In

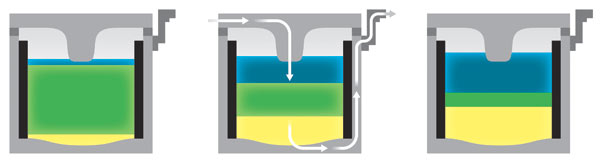

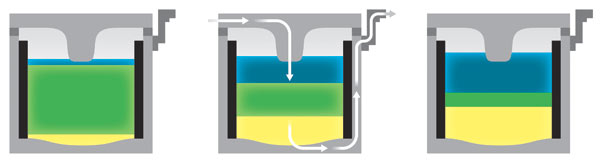

the article, the bottom of the three layers is said to be antimony (a dense

cathode element as I mentioned last month). The electrolyte, the middle

layer, is a liquid salt that's lighter than antimony, The top layer is

magnesium, lighter than the salt. The metal top and bottom of the can are

the electrode terminals.

Sadoway did however say he'd switched

materials and declined to say what metals he's now using. What salt(s)

were used weren't mentioned at all.

As the full battery (right)

discharges, the metals are oxidized or reduced and become magnesium antimonide

dissolved in the electrolyte (left). Recharging restores them to their

liquid metallic state, and they rise or fall to their place in the gravitational

scheme.

As the full battery (right)

discharges, the metals are oxidized or reduced and become magnesium antimonide

dissolved in the electrolyte (left). Recharging restores them to their

liquid metallic state, and they rise or fall to their place in the gravitational

scheme.

My guess is with Sb & Mg it might be around 3.5

to 4 volts (not mentioned), and the article says it has tremendous (but

unspecified) current capabilities.

I'm not sure if I could

make any use of this fine looking idea for car batteries or not. It certainly

looks like a major departure from what I'm doing now! (Let's see... what

metals and salts are liquid at about room temperatures? mercury (ugh!),

gallium for metals, hmm, what salts might be liquid?...) Say! the

bottom metal (heaviest) could be a solid, the other layers floating on

it! The top metal (lightest) could also be a solid if it was free to float

up and down. That could solve many problems for a moving car and greatly

expand the range of possible elements. Hmm!

How about a cylinder

with a metal bottom (+), metal cap (-), and flexible rubber or accordion

fold sides? Hmm, Hmm!

I can also see some potential problems

with using solids in this application, but it bears more thought.

http://www.TurquoiseEnergy.com

Victoria BC