Turquoise

Energy Ltd. News #27

Victoria BC

Copyright 2010 Craig Carmichael - May 4th 2010

http://www.TurquoiseEnergy.com

Highlights/Contents:

April in Brief

(summary)

* Another month of gradual progress in all

directions on each project:

Electric Hubcaptm

Car Drive System Project

* Motor Controller Modification: Ditch the 7uF coil filter capacitors

(works better without - coil spikes are no larger).

* MC33033 obsolescence. New chip?: probably Allegro

A3938.

Mechanical or Magnetic Torque

Converter

Project

* Vibration and poor thrust plague latest design.

* Very promising new design worked out:

- shifting and consequent vibrations are

radial instead of

axial, and should all cancel.

- thrust is repeated 'tugs' at the wheel instead

of 'hits'.

- May be made as either mechanical or

magnetic type. (guess which one would be quietest)

- Still quite simple, no "stator" piece

needed.

Nanocrystalline

Ceramic Motor Coil Cores Project

* Ceramic glaze compositions examined: the

commercial mixes of metallic elements.

* Fired some porcelain strips to apply the glaze to.

* Batch of rough, dark glaze made, fired, annealed,

fired hotter, annealed - no results.

* Rough, dark glaze?: more clear "amorphous glassy

substrate" needed (borosilicate glass), with less of the metals?

* Tried "glaze

mix 3" variant of previous - looks close to the desired overall form.

Ocean Wave

Power Project (no report)

Turquoise

Battery Project

* Salvaged Ni & Cd electrodes from a dry cell

work as a test/reference

battery

* KCl Salt electrolyte works: same chemistry,

different voltages

* My Ni(OH)2 'positrode' (~+1v, with MnO2 for higher

oxygen overvoltage)... it works!

* Mn 'negatrode' (~-1.3v): bubbles (hydrogen?)

* Ni 'negatrode' (~-.4v): Surprise! it bubbles, even

with such a low voltage.

(hydrogen?)

* Mixed Ni/Mn: less bubbles than either alone! Could

have

high voltage, high effective energy density.

* To raise hydrogen overvoltage: transition metals,

borohydride, and a secret weapon: egg white.

The Lead-Acid/Sodium Sulfate Battery

Longevity/Renewal

Project

* Sodium Sulfate For

Sale

* Convenient packages with instructions and 6

paper cups.

* Key to renewing old batteries: Dump out the crud?

Newsletters Index/Highlights:

http://www.TurquoiseEnergy.com/TENewslettersIndex.html

Construction Manuals for making your own:

* Electric Hubcap Motor

(latest rev. 2010/02/xx)

* Turquoise Motor Controller (latest rev.

2009/12/30)

* 36 Volt Electric Fan-Heater

are at http://www.TurquoiseEnergy.com/

April

in Brief

A pile of battery electrochemical experiments running

through much of the month showed that

(a) my nickel-manganese positive electrode works, (b) a similar mixture

of

nickel and manganese can possibly make a great negative

electrode if a

couple of tricks are used - but It's not there yet, and (c)

that it seems feasible to switch from potassium hydroxide alkali

electrolyte to

potassium chloride salt. These findings mean that

it may be possible to make a nickel-manganese /

manganese-nickel /

salt battery with all the most desirable characteristics: 2 volt cells,

highest energy density, high power density, economical, green, safe,

'indefinite' cycle life, maintenance free. It would be a distinct

advance on the

state of the art in a battery with economical ingredients.

The potential seems to be there, however, even if

I do

get a good negative electrode working, a lot of "tweaking" and testing

will still need to be done before there are

good, working batteries.

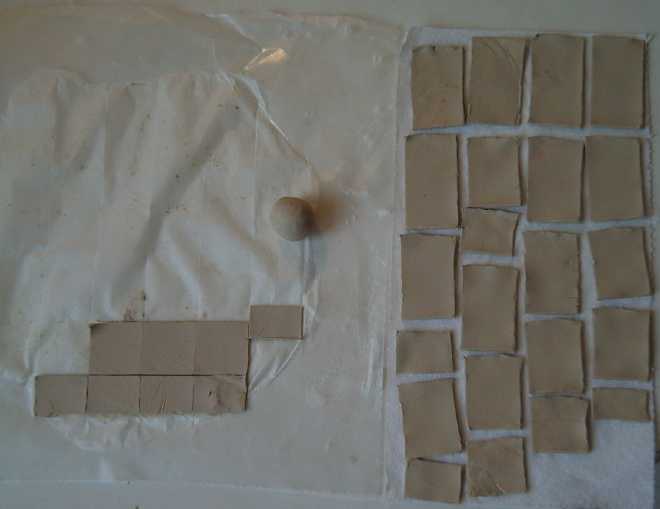

Some battery test electrodes, mine and some commercial ones taken

from dead Ni-Cd dry

cells.

Tests of the mechanical torque converter looked quite

unpromising. I considered trying out some other more complex design of

several

I recently located on the web,

but they all needed a number of precision parts that weren't going to

be found in stores. A couple were amazingly complex. Then I came up

with a more promising idea, not so

different from a couple of my others, but with a valuable addition -

centrifugal swinging arms with shaped ends that would allow the motor

rotor, if it was turning fast

enough, to drag the wheel for a short distance before letting go,

with a torque advantage. I decided to try it out and did some paper

cut-out arms to check the fits. Then on May first, I drew up a magnetic

version that would probably work just about the same way, and of course

silently and with the least heat and wear.

Visualizing the concept: multiple arms "semi-hooking" themselves

onto

pins set around the rim of a drum on the car wheel, tugging the wheel

as

they pass. (drum behind) Magneticly "grabbing" and tugging might work

similarly - and silently.

Attempting to spread the word about sodium sulfate and

the tripling or better of lead-acid battery life, I bought a fair

quantity of it in

March, and in April I packaged some up in single battery doses with

instructions and little paper cups to pour it into each cell with.

The contents of a "battery longevity kit" package in front of a

battery. To the right is the new interface to allow a computer to turn

a battery load or charger on and off, made on an aluminum heat sink.

With triple or better cycle life and being more forgiving of rougher

use, lead-acid batteries are in fact a pretty decent type to use for

short range

electric transport. No one in industry seems to want to hear that, from

big oil to battery retailers - it would only be of interest to all

those drivers waiting for economical plug-in hybrid cars.

The nanocrystalline cores project crawled slowly along as

well. The new concept of obtaining that "amorphous glassy substrate"

with the suspended "FINEMET" composition nanocrystals moved from being

pottery to the glassy pottery glaze on a thin strip of

porcelain, a glaze being much more the right sort of composition. I'm

now trying to form and refine a fairly clear borosilicate glass glaze,

with the

active ingredients suspended in it.

The front loading mini-kiln has been indispensable. Last melt-quench

I used the two little tile "shelves" with the glazed strips on them.

The moment the

kiln was opened, they were yanked out and into the pan of water with

tongs, to quench (rapidly cool) the white-hot glazed porcelain "chips".

(I actually used a big cake pan, to make aiming simple.)

Apparently the desired form, provided by mix 3: an "amorphous glassy

substrate" with the

magnetic substances crystals suspended in it. However at just 10x

magnification, it's the unseen particles

making the clear glass yellow that may hopefully be "nano" size. (Where

did I put my SEM?) The big ones probably result from my grainy FeO.

Tune in next month to see how and if it worked.

The Electric HubcapTM

Vehicle Drive System

Motor controller changes

Somehow, I had got the idea that I should use some small

capacitors as filters in the motor leads, that they would damp the

spikes coming back from the coils. I put in 7uF motor "run" capacitors,

which took up considerable space in the motor controller box. In some

discussion on a motor controller design chat list (yes one exists!) I

mentioned this and the feedback was all negative. So I took them out.

Sure enough, it runs better without them and the voltage

spikes from the coils, as far as I can tell on the oscilloscope, are no

larger! Well, that clears up some mystery of why my controller didn't

like higher PWM frequencies... and clears a fair bit of space in the

chassis.

While I had the oscilloscope on, I noted that when the

motor is up to speed (~1600 RPM) and the drive is suddenly shut off,

the waveform from the coasting motor immediately drops by only about 6

volts: the back EMF generated by the motor at full RPM is 30 volts out

of 36 - the coils are effectively only getting 6 volts, and the rising

generated voltage sets the maximum RPM. To do regenerative braking, one

must amplify this generated voltage to a level above the battery

voltage.

I have also noted that the MC33033 motor controller chip I

used is (to be) discontinued. Another chip, the Allegro A3938 looks

like a better chip, and a very good fit for a 36 volt motor. It

eliminates the three half-bridge drivers by incorporating them

internally. But it has as many pins as all four chips on my present

design, and it has no PWM generator, so I have to add a small chip for

that.

So it looks like I'll need to do up a new circuit and

circuit board for this sometime. Amazing how the job list just keeps

growing after you think something is "good enough" and you're "done"!

But

one advantage of my layout with the hard-wired power components is that

the driving logic board is just a small piece. Indeed, one could

substitute any sort of driver logic board for different motor types,

microprocessor control, etc.

If I made the connections via a connector plug or header

strip instead of solder-on wire pads, changing or upgrading the

controller logic could be a simple plug-in job. (On the other hand,

solder makes the most reliable connection.)

Mechanical Torque

Converter Project:

Torque Leverage Without Gears

I got excited by at last

making good progress with battery

designs, so the torque converter project continued to proceed in very

low gear. But the work done in recent months, however gradually,

was finally finished up. I

switched to the idea of spring return, conceived at the end of March,

when I realized I could simply slip four smaller springs onto the link

pins and unbolt the upper ramps, making the change trivial. And Capital

Iron even had suitable springs ready made. I still had a feeling it

wasn't

going to work very well (which did much to limit my enthusiasm for

working on it).

I tried it on the car on the 13th. There was again a lot

of vibration. The car did grudgingly

back up - down a slight slope - if I put my foot against the motor to

hold

it against the wheel - bumping back a tiny bit at a time with each

torque hit. (I even managed to get a bit of video of this, but I

decline to post it as things have moved on.)

The springs weren't solving all the problems. But in this

test, seeing the motor bouncing outwards and

yet the car starting to move, I realized that if I turned

the axis of the strike 90º, the sideways vibrating force

would generate pulses

outwards instead of sideways. If four pins strike four ramps each

90º spaced around the rim, all the forces causing vibration should

cancel each other out, leaving only the rotary force. This brought me

back to the clock escapement type of mechanisms.

However, when I had disassembled the key pieces and I

started to consider actually implementing this sort of design, it

started to look more complex. Finally I put it all together again and

tried it out again. This time I noticed that although the car wasn't

moving, the metal part of the car wheel seemed to be vibrating back and

forth - it

would seem perhaps the rubber tire was absorbing the torque hits,

bouncing back and forth without the car starting to move. When I took

the motor off, I also found that all four link pins had come loose

(tightly though I'd done them up) - more play in the mechanism! Like

the wave power design, this mechanism only works if the small back and

forth

motions aren't taken up by slack in the system.

I started to consider how to get stronger individual

torque hits as well as tighten things up. The strength of the hits

depended on (a) the mass of the inertia piece (b) the ramp angles and

(c) the speed. The speed seemed high enough. Changing the ramp angles

had some effect, but evidently the mass hitting the ramps had to go up

considerably. How could I increase the mass of the torque plate?

Probably not by replacing the plate with smaller

"escapement" pieces! That pretty much scotched the idea of doing it

that way.

Well... How about if the entire motor was the inertia

plate? 45 pound hits instead of 5. That's about what was happening when

I pressed the motor in with my foot and it finally moved the car

(however little). And, once thought of, it seems more like the sort of

weight for a hammer that might move a car!

But it struck me that if the rubber tire let the

rim move forward a jog and then bounced it right back again, perhaps

the whole idea of using "torque hits" wasn't going to work, at least

not very well here, because of play in the system that couldn't be

eliminated. Even the whole motor is very little mass to strike with

compared to the mass of the car - like driving a spike with a tack

hammer. For the lightweight motor, we evidently need another approach.

Unfortunately it seemed likely to be more complex.

An internet search using Altavista brought up more designs

than when I tried it quite a while back with Google. Where

were these back then? I studied some of them to see if there were

any

that could be metamorphosed into the sort of physical shape required

for

the Electric Hubcap. But they looked complicated and needed precision

made parts that

certainly wouldn't be "off the shelf".

What about more powerful hits? If the diameter of the drum was larger,

they'd have more leverage. What if, instead of a drum, say about five

"things" were sticking out from the wheel rim for five weighted

flailing "arms" from the motor rotor to hit, all at once? That could

have considerable striking force, and

the vibrations would all cancel. The motor would have the fewest parts:

indeed, any old axle system and construction of the motor would work.

No more need to turn down trailer hubs on a lathe! When the motor and

wheel were spinning fast enough, the weight of the arms would "lock"

them into 1 to 1 drive. The motor would be flexibly connected to the

wheel.

All the previous principles remain in play. The

force of each impact will be regulated by the angles, the weight

of the inertia pieces, and the speed. The leverage provided by the

force would be greatest out at the wheel rim. And it would be simple -

very, very simple.

But then I considered that there could be other torque

developed by this layout

besides an initial hit: By adjusting the length and shape of the outer

ends of the arms, they can be made to twist to an appropriate angle

before letting go, to drag the pin around for a short distance with a

"gear ratio", as the motor turns to a given relative angle, to pull the

wheel around and give advantageous torque leverage. In fact, let's

forget the 'hit': strike at a shallow angle, and let the 'inertia

hook' drag the wheel around a bit as each arm goes by each pin. I think

this

version of the "torque hits" mechanism sounds like the most promising

one yet!

Looking it over, it appears the rim of the wheel could be

accessed best by a plate bolted to the wheel. But that diameter isn't

so much greater than the 10" drum, so using the drum - and having all

those flailing arms safely enclosed - might still be the best idea.

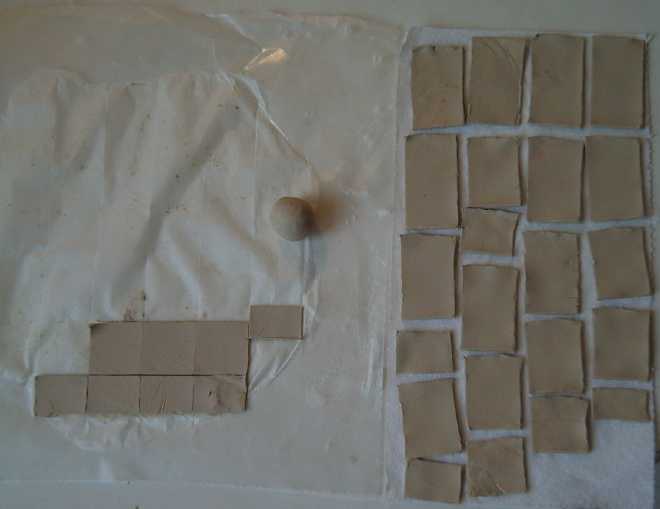

The arms of black styrofoam (shape 1) and green cardboard (shape 2).

One arm is seen in concept of "dragging" past a pin, which would be

attached to the drum (behind) on the wheel. Probably these arms will

have to be about as heavy as I can make them - goodly chunks of 1/2" or

3/4" steel, with semi-hook shapes that _almost_ won't let go of the pin

as the motor spins it by.

The length and shape of the arms being

evidently important if not

critical to this design, I did some concept visualizing with a

styrofoam package and then green paper, which are both easier to cut

than slabs of steel. The idea is that the ends of the arms almost hook

onto the

pins on the wheel, but not quite. As the motor turns they'll pull the

wheel for a short distance as they're slipping off each pin. If the

motor is

turning fast enough and the torque required isn't great enough to slow

it down, the arms will stayed "hooked on" by centrifugal force for a 1

to 1 direct drive. In this layout, the

arm

pivots are at 2" while the wheel pins are at about 4". The 'gear ratio'

achieved will depend on the

speeds of both motor and wheel, the weight and shape of the arms, and

on the torque being transmitted.

Then on the first of May, as I sat listening to someone speak, I

started doodling on a piece of paper and drew up a very similar design

with magnets replacing the pins in the rim of the drum. Each steel arm

will jump forward by attraction as it approaches a magnet, then it'll

swing backwards more and more, trying to stay at the magnet. As it

passes, the motor will be trying to pull the arm away from the magnet,

creating a similar tugging force on the outer drum to turn the wheel.

I've just realized that the best test will be if you can

stomp on the gas pedal when stopped, and the wheel spins out. If the

torque converter can achieve that, it's really working!

What is a mechanical or magnetic torque

converter? What does it look

like? What are its main features? How does it work? For me the entire

idea

began completely undefined and as clear as mud, as a need for a

specific function that isn't performed well by existing designs (gears)

that most of us are aware of. How many wildly

different versions have I gone through so far, including ideas,

designs, construction

and tests of various magnetic and mechanical converters? And how many

wildly different (and convoluted) designs are out there on the web?

That's what

inventing something new is all about.

Now if after a year of puzzling over the problem and

trying

various things out I create a simple working model of torque converter,

in its simplicity

anyone will easily grasp how it

works,

copy it, and improve upon it. If it gets a good start, it'll spread

until it's the automotive standard and heavy, crappy transmissions have

gone the way of the dinosaurs. The suddenly "obvious" principles on

which a 'simple' new invention works, and which

no one sees any reason to pay some weird guy for afterwards just

because he

made the first one, are often

hard won. Until now, none of my designs have worked very well, and

nobody else has come up with anything that's been adopted, so everyone

continues to expend their efforts and money on, and contend with, those

dinosaur transmissions.

If I had found a design on the web that I could use or

modify, I would of course have simply appropriated it myself for the

Electric Hubcap system.

And all this is why

sensible people don't get involved with inventing -- it'll remain a

wretched, impoverished career as long as society offers only lip

service encouragement and pie-in-the-sky promises of "you'll be rich!"

but no real, working mechanisms for paying inventors either for time

spent, for working inventions once

eventually completed, or even after their profitable adoption by

society.

Nanocrystalline

Ceramic Motor Coil Cores Project

The whole field of nanotechnology is pretty new, and

evidently the magnetic ceramics area isn't very well explored. I

thought there were probably people around somewhere who knew how to do

this if I could find and ask them, and doubtless I'll find many more

pointers on the web, but perhaps I may be breaking some new

ground.

The difficulty of applying such materials to traditional

motor designs is perhaps illustrated by omission in one paper (Soft

Magnetic Nanocrystalline Alloys, Journal of Optoelectronics and

Advanced Materials Vol. 5 No. 1, March 2003) that suggests applications

such as "choke coils, transformer cores and power transformers".

Implicit in leaving out motors is the idea that they would be too

difficult to fit, large sheets of material being required to die-cut

their cores rather than the simple "tape strips" being produced by

current techniques. The Electric Hubcap's

individual component, bolt-on "fat

hockey puck" coils can use whatever's available.

Three nanomagnetic alloy formulations are the first one

determined in 1988, Finemet,

along with Nanoperm and Hitperm.

FINEMET: Fe 73.5(%), Si 13.5, B 9, "M" 3, Cu 1. Metal "M" can be Nb,

Zr, V, Mo...

NANOPERM is similar but without the silicon, eg: Fe 84%, B 8, Zr 3.5,

Nb 3.5, Cu 1.

HITPERM adds a lot of cobalt to NANOPERM: Fe 44%, Co 44, Zr 7, B 4, Cu

1.

Traditional high permeability transformer core alloys

saturate at 1.6

to 2.2 Teslas. A table shows HITPERM with the highest saturation

magnetism (1.6 to 2.1 Teslas) and FINEMET with the least (1.0 to 1.2

Teslas). Amorphous FINEMET cores (rather than nanocrystalline) saturate

down at 0.125 Teslas, so getting the nanostructure correct is

important. But the text says FINEMET has the most promising

combination of permeability (10^5 at 1 kHz) and saturation

at room temperature. At higher temperatures, it craps out, but it

doesn't say what temperatures. I'm going to assume the motors don't

reach those temperatures.

Actual work during April started with annealing glazed

strips

made in March and finding no positive results, then preparation of a

new

batch of porcelain strips to paint the "finemet" glaze materials onto.

This time, care was taken to keep them pressed flat while drying, the

first batch having had many annoyingly warped and curved shapes. Still,

the pieces didn't end up as flat as might be hoped. In principle, the

clay strips should be as thin as possible - they're only there to hold

the glaze until it dries and the firing is done. But they break easily.

Porcelain clay cookie cutting. I need to get the thickness more

uniform and keep them pressed flat (while somehow allowing the moisture

to escape) as the clay dries.

Next step was to estimate what combination of minerals

would

give something like a "FINEMET" composition. For "Glaze Mix 2" I used

titanium for metal "M" -- it's next to Zr, Nb and V on the periodic

table, has some similar magnetic characteristics, and

it's cheap. And some zirconium, also pretty cheap. So I mixed: FeO

60% (60 grams), laguna borate (for the boron) 20%, Ilmenite (Ti:Fe:O)

10%, zircon

(Zr:Si:O) 5%, and copper sulfate crystals 5% (total 100 grams/100%),

all watered down to a

pottery glaze in lots of sodium silicate "water glass" (~60 grams?).

It made a dark brown, somewhat greyish, chocolate syrup.

As suspected, the copper sulfate crystals remained as big lumps.

Hopefully enough would disperse when melted during the firing.

I tried firing for 75 minutes (then quenched, each

firing), annealed for 15, refired for 85 minutes, annealed again, then

fired for 95 minutes, then annealed again. Each time, the magnetic

field was no stronger than for air. The glaze was slightly attracted to

supermagnets.

I am of course handicapped by not

having access to the sorts of test equipment for techniques usually

used in this field: Mossbauer spectroscopy, SEM, TEM and a couple of

even more unfamiliar names... and by not knowing how to use them if I

had them. It would be nice to link up with someone who could give me

some

sort of idea of what general stuctures I'm creating at the nano

level. About the only things I know of that I can check are the field

strength by putting it in the center of a coil, whether it's

attracted to a magnet or not (of "incidental" significance), and the

visual appearance at x100 micro and larger scales.

One thing that bothered me was that the glaze was lumpy

and dark

instead of more smooth and clear. The metallic ingredients are supposed

to be dispersed in an amorphous glassy structure. I fear this glaze had

far too little glass in it.

A typical borosilicate ('pyrex') glass composition is

about 70% silica, 10% boron

oxide, 8% sodium oxide, 8% potassium oxide, and 1% calcium

oxide (lime) [per Wikipedia]. We get silica and sodium from the

sodium silicate 'water glass', the boron from the borate (...maybe

borax?). We seem to need more silicon in proportion to sodium (and all

the FINEMET stuff), and more boron. We've missed the

potassium and the calcium

entirely in "glaze mix 2", though potassium isn't so different from

sodium, which we seem to have too much of.

There'd be no need to find calcium oxide - calcium carbonate will break

down

into that as it heats up (CaCO3 => CaO + CO2 above around

800ºc). I might also try barium

carbonate in addition or instead. It would be pretty similar (but I

must look up the breakdown temperature -- hmm, doesn't look right on

Wikipedia...), and we're

already adding the titanium - to form some barium titanate, a substance

of value as mentioned in a couple of places for magnetic nanomaterials.

On the morning of May 3rd after a weekend away, I added 3g

of barium carbonate, 8g of potassium hydroxide, and 20g of Laguna

borate to the 150g or so of glaze mix 2, to make "glaze mix 3". I

noticed the copper sulfate crystals had turned into blueish blobs.

Effectively dissolved, there's about 4x too much copper - oh well.

Also, the whole thing had hardened in it's margarine container in a

week even with the lid on, and I had to add water and sodium sulfate,

break it into lumps, break up the lumps, and mix it all up again. On

mixing with the new materials, it lost much of its ilmenite brown

colour and became more greyish. But when painted on and dried, the

brown reappeared and stayed after firing.

If a mix and process can create working nanomagnetic

glaze, it remains to be seen how to use it. If it's just a glaze on

clay strips, there'll be much of the core filled with inert clay. If

the glaze is attracted to magnets, however little, the glazed strips

can be ground to powder and a magnet can fish out the magnetic material

while leaving the clay behind. Then the nanocrystalline powder can be

cast in epoxy or other material. Polyester resin, plastic or even wax

might work, though high temperature epoxy would have the best specs.

Motor varnish is possible, but it would probably do too much bubbling

and mess things up. (My brother, a biochemist, thinks sodium silicate

plus calcium (carbonate?) might harden into a permanent silicate, and

I'll probably experiment with this -- if it doesn't need a high

temperature to make it work.)

Ocean Wave Power Project

(No report.)

Turquoise Battery Project

The

Ni-Ni Cell and Ni-Mn Cell: April Experiments

Battery experiments were almost contiuous throughout

April. Per the plan determined about the end of March, I took

apart an old dead (shorted) Ni-Cd cell and used the electrodes as a new

battery with a new separator sheet. Though the connections weren't very

good and I couldn't get a seal ('0 PSI'), it held a charge. A working

battery meant further experiments could start with one untried element

at a time, a luxury I didn't have when trying to test the all-new

perchlorate chemie.

A bunch of experiments of early April:

Top: new curled up 1/2 electrode from Ni-Cd cell, a used one with rust

and (?)zircon.

Lower row: Zinc electrode (it worked, but zinc gradually migrates (so

does cadmium), and it seems Ni-Zn at best are only good for a couple of

hundred recharges), um.. one with brownish permanganate, 3 with

manganese, one having remains of a layer of zircon painted onto it (all

5 made compacted onto fine stainless steel conductive mesh.), jar with

commercial electrodes (mostly cadmium), the flattened acryllic plastic

test battery tube with pressure gauge.

Bottom (horizontal): Flattened nickel electrode from Ni-Cd cell. They

buckle in places when flattened. These ones are sintered or paste

compacted around perforated steel foil. The positrode foils are

doubtless nickel plated.

Main Features and Findings

Here are the main features and findings in brief. I wrote

great gobs of

great gory

details which I finally decided were best saved as a file of scattered

notes and left out of this newsletter.

* The salvaged Ni-Cd battery electrodes worked in alkali, providing a

starting point

for experiments.

* Switching the electrolyte from alkali (KOH) to salt (KCl) also

worked.

There were side effects (rust), that would be eliminated by choosing

other

materials. I now see virtually no chance I'll want to use alkaline

electrolyte. KCl is evidently a

faster electrolyte (allowing higher current flow) as well as being much

safer

to work with, and it doesn't degrade with atmospheric contact. Perhaps

surprisingly, many reactions remain the same

(oxides and hydroxides are produced, not chlorides). But the voltages

shift. Many positives like nickel and manganese increase in potential,

while negatives decrease. But the cells mostly seem to be a little

higher voltage overall. (Eg, Ni-Cd looks like it should be around 1.65

open circuit volts instead of 1.35.) Compatible electrode materials

must be chosen.

(Eg, the iron in

Ni-Fe and Ni-Cd - actually an Fe:Cd mixture - doesn't like salt,

whereas alkali is a rust inhibitor.)

If the positive voltage had been above +1.36 volts,

chlorine gas would be generated, but it's not. Electrode substances and

structural materials that will probably work well in salt water

include:

monel,

nickel-silver, stainless steel, maybe copper. That seemingly

"unobtainium", pure nickel metal and powder, needed in alkali

'positrodes', isn't needed in salt.

* The voltage of the nickel [oxy]hydroxide

positive shifts from +0.5v to about +1v, which is a good energy density

improvement if a

matching good voltage negative can be found. (The reaction voltages for

neutral solutions aren't shown on the charts, hence my estimates of

"about" midway between acid and alkali voltages.)

With manganese added, increased oxygen overvoltage

should allow the nickel to go from valence of about 2.25 (discharged)

to valence 3.8 instead of just to 3.0 (charged), yielding the high

energies of recent Ni-MH batteries such as the 2.6 AH "AA" cell, which

has 100 WH/Kg. (Another possibility is that it won't even need the Mn

to effect this desirable change. That could happen if the oxygen

overvoltage goes up faster with acidity than the NiOOH reaction

voltage, which is very possible -- it's evidently over +1.69 volts in

sulfuric acid, allowing lead-acid batteries to work.)

* A nickel-manganese positive worked pretty well using cadmium

electrodes from the Ni-Cd's for negatives, but lost its charge

overnight. This is the first powder/paste electrode I've made that has

been shown to work. Doubtless it can be improved, or it may improve by

itself. The loss of charge

may be related to the rusting of the cadmium electrodes, which were

made to work in alkali. Once these materials are changed the problem

may disappear. If not, it will be addressed then. Or, the electrode may

simply need time to "form" - it may hold charge for a longer period

each time until it's fine.

* The manganese negative turned out to bubble hydrogen audibly - the

hydrogen overvoltage is a bit too low. Likewise, a nickel negative,

even though under 1/2 a volt or so, also bubbled hydrogen audibly. This

was a surprise and

a disappointment -- I thought Ni-Ni 1.1 volt cells were a "sure-fire"

fallback plan! It turns out

nickel is a great thing to use if you want to generate hydrogen because

of its especially low hydrogen overvoltage. However, a

combined electrode of nickel and manganese (made as a "+" and tested as

a "-" on a whim!) didn't bubble much as far as I could hear. But it

also didn't hold charge. Transition metal additives such as tin,

bismuth, gallium, indium or antimony (or oxides thereof) can be used to

increase the hydrogen overvoltage. Experiments continued along these

lines.

* Albumin, the stuff of egg whites, turns out to be a major increaser

of hydrogen overvoltage. Even minute amounts might raise it by up to

1/2 a volt. This discovery (made in 1964 but not mentioned in any

battery literature I've found) makes

the experiments more promising. It may prove to be a key ingredient.

* I am currently charging an electrode with 60% Ni(OH)2,

40% Mn, 1% Sb4O6, and a smear of egg white. And I added a

bit of Sodium Borate (borax) to the electrolyte. It's taking its own

sweet time 'forming' - weeks - but it's gradually holding more voltage

longer and may eventually (sometime next month) prove to be the working

negatrode for that elusive 2 volt cell.

Lead-Acid/Sodium

Sulfate Battery

Renewal Project

April Details

In looking for anything authoritative on the life

expectancy of lead-acid batteries treated with sodium sulfate (or

alum), I found an interesting story: In about 1998 someone with Hot-Rod

Magazine designed an 'ultimate' lead-acid battery.

[http://www.theautochannel.com/news/press/date/19981215/press001556.html]

It had spiral plates (Planté's original 1860

format), calcium and silver in the plate grid for durability and

conductivity, "paste expander" in the negative plates for greater

conductivity... and

sodium sulfate. According to the article, the

sodium sulfate was supposed to "help them accept a charge more quickly

and hold it longer". It was expected the batteries should last "22%

longer".

The magazine approached Interstate batteries, who agreed

to manufacture them. Seems they dropped the "Hot-Rod" name called it

the "Optima" line of batteries. (...and we thought a battery company

came up with

these (known techniques) innovations on their own? Hah!)

Canadian Electric Vehicles got some of the early

Optima prototypes, and according to the owner, the difference was

amazing: they lasted five years in an

electric car instead of "the usual 1 to 1-1/2 years". Then they

couldn't get more for some years - they weren't in production. Finally

Interstate supplied more, but the new ones only lasted 1-1/2

years.

I suspect what happened was this: Interstate management

made the decision to make the "Optima" batteries on their own in

conjunction with Rod-Rod magazine, and put them into production. When

the corporate shareholders - doubtless the same clique who control big

oil and the automakers, who think life is just a big game of Monopoly

where they get to make the rules - found out how long the batteries

were

actually lasting, they were as horrified as the customers were

overjoyed, and had production halted.

Then Interstate continued making them, either without the sodium

sulfate, or,

better yet, with a tiny quantity that won't

do much good. That way they can now say, "Yes, they contain sodium

sulfate." and leave people to draw the "obvious" conclusion that sodium

sulfate doesn't make a big difference.

So I'm pleased to have worked out by experimentation a

fairly optimum amount to put in and to spread the word about it. As I

feared, I'm hearing more and more in recent months about 'sealed'

batteries with glued-on lids that you can't easily get into, seemingly

a diabolical countermeasure to finding that people are discovering

how to access this piece of "suppressed technology" for themselves.

Sodium

Sulfate for Battery Renewal (Click for Prices, Info.)

Last month I obtained a 30Kg bag/keg of anhydrous sodium

sulfate to

treat/renew batteries.

This month I packaged them in small quantities to sell

from $7

(average car battery) up, for anyone who would like to treat

their own battery(s) to increase their life span somewhere from

probably double to five times. I spent considerable time writing up

instructions and making package labels.

I found a source for convenient little plastic jars for

the salt, paper dixie cups and (eventually) a good size of plastic

bags. The six dixie cups help to divide the salt into six equal

portions and make it easy to pour it into the battery holes. And, when

pouring the salt in the six cells with the six cups, one won't easily

lose track of which ones are already done and which remain.

Except for direct selling, I don't know who will want to

sell it. Places that sell batteries haven't latched onto it, though one

I gave samples to is going to test it.

It's in the Dump: Key to rejuvinating old batteries?

I was having a hard time understanding why the people

pouring out the acid and putting in alum claim good results renewing

batteries while I, adding in a theoretically better salt, was having a

bad time with shorted out cells and getting generally poor results.

I finally put together part of the automated battery

cycling system: an interface to turn the load on or off - or connect or

disconnect a charger. (That leaves out the other test component, a

connection to measure and record the voltage - for the moment.) The

immediate

intent of this piece was to pulse the charger on and off to attempt to

clear shorts in the cells, which was unsuccessful (as was pulse

charging from a commercial charger with pulse charge) - for the moment

- on the batteries I tried.

The interface was connected to the control computer I created in

1985-86 for the Victoria School District, which I also wrote the

"Control BASIC" language for. The computer program was:

NAME OUT6=BattOn : "Out6 Bit0 (I/O 6 pin3)

NAME VAR6=BattTimer

70 BattTimer=BattTimer+1%5

71 BattOn=(BattTimer=0)

This program runs about 8 times a second. BattTimer counts up to 4 then

resets to 0 on the next count ("%" being the symbol for "modulo", the

remainder of a division); BattOn is only on when that's 0, ie, one pass

out of 5, a brief pulse a little less than once every half second.

Then on the 30th I dropped off some samples of sodium

sulfate

product at Canadian Electric Vehicles and in that process got the

scoop: It seems that

as the plates gradually corrode, they give off dust. (lead and-or lead

sulfate

and-or lead oxides) The powder accumulates on the bottom until it's

touching

the bottoms of the plates, and at some point, it shorts one of the

cells. A battery with more bottom depth under the plates will last

longer before shorting.

This explanation was in accord with the crap I had dumped

out of batteries early in my experimenting.

The

renewal cycling might add a one-time emission of more corrosion dust

that would

have soon come off anyway. Or there might be a one-time emission of

powder from the plates where the salt is concentrated before it

dissolves. (This seems likely, now that I think about it.) Presto! In

older batteries, it might well be

enough to often cause a short. Of course, once the battery is up and

running properly, most of this gradual corrosion and accumulation is

arrested by the additive, and any battery should last much longer.

So the difference between the successful technique and

mine would be that they dump out the battery, and often specifically

clean it out,

whereas I've just been adding the salt and leaving the crap in the

bottom. (...and not even making much effort to mix the salt in and

disperse it.) In May I plan to test this

idea out by cleaning out some batteries with shorted cells and trying

again. (Dumping acid

and crap out of batteries: Ugh!)

http://www.turquoiseenergy.com

Victoria BC