Turquoise

Energy Ltd. News #29

Victoria BC

Copyright 2010 Craig Carmichael - July 1st 2010

*** Happy Canada Day! ***

http://www.TurquoiseEnergy.com

Contents/Highlights:

June in Brief

(summary)

* This month: Torque converter, solar cells, Ni-Mn

batteries

* Democracy for Canada: On-line referendums

Editorial/Review: Documentary Movie The

Corporation - the pathological pursuit of profit and power

* The dark side of society, the economy and politics

today.

* ...and even with all its fine insights, it doesn't

touch on what

goes on to deliberately keep us using as much oil as possible!

* Attainder looks more and more appealing.

Electric Hubcaptm

("EH") Car Drive System Project

* 3rd party extols the virtues of axial PM (eg, EH) motor format

* Motor fixed. Motor & controller working fine.

* Supermagnets: protect the neodymium... even from

dry air!

* Coffee can jig for getting metal hub past magnets

to assemble rotor

* "Bare-bones" EH motor weight: 37 pounds (17 Kg)

Mechanical or Magnetic Torque

Converter

Project

* The new magnetic radial design.

* Magnets edge-on are much better than face-to-face!

* Swiveling magnets permit one-way force.

* 2" magnet edges (over 30 pounds(?)) are much

better than 1" (15 pounds)

* Arms meet & magnets stick - arm swing limit

stops needed... made.

* Tests reveal all the desired properties except

one... the

force is much too light.

* Installing enough supermagnets to provide enough

torque would seem to be impractical.

* Clock escapements again: this idea, which I keep

harking back to, is probably what'll

work best, but making one that'll take and transfer the forces without

busting...

* Next design figured out: Lots of small nylon

escapement 'anchors' (however many are required!) each with small force

should add up to large force.

* Recap: the several designs since this project

commenced.

Nanocrystalline Solar Cell

Project

* Metal grid rear electrode: no more loss of light

than 'transparent' tin oxide?

* Glaze mix 9 is probably fortuitously close to an

'ideal' clear nanocrystalline borosilicate glaze mix.

* Tartrazine (common yellow food dye) seems like a great dye to use.

Turquoise

Battery Project

* MnO2 discharge with H2O2(?)

* Sealed Ni-Mn test battery

* Measured very low electrode conductivities by

voltmeter (large voltage gradients through electrode thickness during

charge): this, not chemistry,

explains many of the problems I've been having all along.

* Seemingly electrode compaction is insufficient for

good particle contact; even more is required.

* 12 ton hydraulic press purchased for electrode compaction.

The Lead-Acid/Sodium Sulfate Battery

Longevity/Renewal

Project

* Sodium Sulfate

'battery treatment kits' For

Sale

* (Fairly) comprehensive info is now on

the web at:

http://www.TurquoiseEnergy.com/Na2SO4.html

* According to local battery pro, the best way to access batteries with

glued-on lids: drill 1/4" holes in the 'solid' side of the lid, plug

them with heat gun glue. ("Rubber stoppers always leak

sooner or later.")

Newsletters Index/Highlights:

http://www.TurquoiseEnergy.com/TENewslettersIndex.html

Construction Manuals for making your own:

* Electric Hubcap Motor

(latest rev. 2010/02/xx)

- the only 5+ HP motor that can easily be made at home?

* Turquoise Motor Controller (latest rev.

2010/05/31)

- for the Electric Hubcap. (Probably there are commercial

controllers that would work, too.)

* 36 Volt Electric

Fan-Heater

- if you're running your car on electricity, you'll want a

way to defog the windshield and keep warm.

* Lead-acid battery longevity treatment - "worn

out" battery renewal procedure.

all at: http://www.TurquoiseEnergy.com/

June

in Brief

This spring Turquoise Energy Ltd. has received several

thousand dollars from Canada Revenue Agency's Scientific Research

and Experimental Development Tax Credit (SR & ED) program. 35%

of what the clean energy projects have actually cost me in the last two

years has been reimbursed. It's not the kind of salary most experienced

professionals would expect or that I ever received for software

developing or just working as an electronics tech, but it's most

welcome to an independent inventor. Most

major inventions, the ones that really change the world, are "pre

business stage", and no one wants to invest in them or fund them. SR

& ED is also the only government funding program that really seems

to fund the "D" in "R & D" as far as I can discern. And now

being 55 I deferred my homeowner taxes, a major relief. I'm out of

debt, I have money to spend on supplies and tools this year, and I even

got a real TV and have signed onto cable for a while! (As for replacing

the 1984 car...)

Torque converter side of motor rotor,

with 5 pivoting arms.

The arms match 5 supermagnets on the

inside of the drum driving the

car wheel.

Torque converter side of motor rotor,

with 5 pivoting arms.

The arms match 5 supermagnets on the

inside of the drum driving the

car wheel.

Having again conceived what appeared to be a promising

design, I went to work on the torque converter, with a pause to fix and

test the motor itself after two nickel plated magnets came unglued at

high speed and flew off in May. The rim magnet and even more the

swiveling

drive arm pieces were somewhat intricate, and with

five of everything, consumed many hours in the making and adjusting. By

the 18th, it was ready to test. The test showed it seemed to be doing

all the right things, but the forces created were surprisingly weak. I

decided

that rather than multiply the mass of supermagnets by an amount that

would be hard physically to fit in, it

would be preferable - again - to try something else.

That something else will be something along the lines of

the "anchor" clock escapement mechanism, but using multiple small nylon

"anchors", spaced in 12 divisions around the rim of the rotor. This

time, weak forces will be expected, but they can be multiplied until

they are

strong in total. If 3 or

4 or 6 anchors don't provide enough force (likely), I'll try 9 or 12.

If that's

still insufficient (less likely), there's 18 or 24 in two columns. If

that's still not

enough (hopefully unlikely), I'll make heavier ones. For the motor to

turn vis a vis the drum, all the anchors must swivel back and forth,

rattling in and out of "slots" and "teeth"

in an aluminum ring around

the inner rim of the drum.

As with most or all mechanical torque converters,

the operating principle is that these pieces will swivel effortlessly

at low speed, but put up more and more resistance to changing their

direction of motion as the speed increases, in accordance with the

square of their speed, which is dependent on the speed difference

between motor and wheel.

I managed to put in just a bit of time on the DSSC solar

cell

reflectors, painting underglaze and glaze and firing a few tiles and

melt-quenching

them. Results looked very good in effect, though my ingredient mixing

and technique could be improved to provide a more uniform result. It

may be possible to make a yet

better

nanocrystalline, clear borosilicate glass glaze, but the

characteristics seem great and currently I think beating the "glaze mix

9" I did last month would take considerable doing for

perhaps marginal

improvement. I picked out toluene as a potential electrolyte solvent,

and tartrazine

(yellow food dye) as looking like a good photosensitive dye. Its

maximum absorption centers on 427nm, the blue wavelength of maximum

solar energy.

Two tiles with zirconium silicate white underglaze and two thin

layers of glaze, melt quenched both times.

Third one is without underglaze. The glaze has pulled microcrystals out

of the

porcelain near its base.

One (with underglaze) and only one glaze layer, showing many

microcrystals. The leftmost piece looked akin to it before the second

layer was done. Some paintbrush strokes are still visible.

And I spent a few days on

nickel-manganese/salt batteries. I learned a few things and I think

working

batteries of exceptional energy density are close. A better

electrode compactor seemed to be needed, and I spent the last couple of

days of June looking at hydraulic presses, which were much cheaper than

I'd imagined. I bought a used 12 ton one - a common 12 ton hydraulic

jack in a

heavy steel frame - at Barclay's exchange for just $135 (with a couple

of easily replaced loose pieces missing). This would

seem to be the

way to go!

L: Manganese 'negatrode' with copper mesh electron collector after

(apparently insufficient) compaction.

R: Ultimate goal - to give something not so much bigger than the front

case the stuff

to make it roughly the useful energy equivalent of the lead-acid

battery behind.

And I'm thinking: here's July coming, the nicest month to

be down by the sea, and I haven't put together the wave power unit! Ah

well!

I also had another exciting idea in June, unrelated to

clean energy.

Democracy works by participation, but opportunities for the majority to

participate seem to be strictly limited to deciding who to have as your

legislative representative, which choice - "by the way" - will also

determine something else entirely: which partysan politician gets to

inflict his own personal agenda on the whole country or province.

These leaders like to claim that the silent majority "have

given us a mandate" for this, but there is no way to find out what

that silent majority actually wants. It is silent because it has no

voice. Instead, the most vocal and insistent, or the most powerful or

influential, are heard, and their clamouring voices are taken to be

public opinion.

I now plan to

set up a web site where anybody can start a petition about anything -

local, regional, provincial or national, and every applicable Canadian

who cares to can vote on line by ranking the available choices.

(The

choice ranking vote ("The 1, 2 vote", "STV", "automatic runoff") is the

only

single-ballot system where the

voter is completely free to vote exactly as he feels would be

the best outcome, second best, etc, from any number of choices. It wins

hands down over the primitive "X" vote system. The outcome is not

prejudiced by any number of

available choices having any number of variations on the themes -

there's no "vote splitting", and no "strategic voting": no "choosing

the

lesser

of two evils" in hopes of preventing a completely contrary result.)

Although the petitions would be 'unofficial' unless and

until the

system is some day endorsed and taken over by our governing

institutions, anyone who wants to know what the public really thinks

about an issue can simply go to the web site and look it up. It is also

likely that the number of voters will be a good indication of how

strongly people feel on the issue. The more who participate the more

respect the system will gain, and it'll be easy to participate - just

go to

the web site, read and decide. It will be much harder to push an

agenda if it's known that the great majority don't

support it. Those who agitate ceaselessly to get their own way will be

shown to be the small minority they are. When an unwelcome developer

threatens

to sue a city if it doesn't do as he

wishes, city council will have much more power to stand up to him if

they can say "Sorry, the citizens have rejected your proposal."

Conversely, it may be found that things they are reluctant to endorse

may be shown to be quite acceptable to the public.

There will be a lot involved in setting this up, and I

won't get it going this

year if I start it on my own. Then there will be a lot of publicity

needed so that people know

about it and how to use it. There are also serious issues of cheating

(ability to wrongly cast multiple votes) versus having a vast

collection of data on people so their voting eligibility status is

known, and maintaining the security of that data.

But I trust I won't be acting alone on this once people

start to grasp the tremendous potential of having such a system in

place.

Editorial/Review: The

Corporation

Documentary

I watched a documentary

video, The Corporation - the pathological pursuit of profit and

power. (Mongrel DVD. It looks from an insert like it's also a

Penguin book, by author Joel Bakan.) I

watched it in a few short

sittings: it was too much to absorb, and much of it was too disturbing,

to take in all at once. I think

it's a "must see" if you

want insight into the real workings of the economy and politics - into

a good part of

why things are the way they are and perhaps why we're gradually losing

our freedoms, inching for

many decades towards being police states. First

the various ways in which the actions of corporations accurately mimic

the

behavioral

profile of psychopaths are discussed, one at a time. Then there are

various specific subject areas and cases, some really shocking.

Did you

know that as well as being "Rah, rah!" for Mussolini and Hitler, big

business almost turned the USA into a fascist state in 1935? They

didn't like Roosevelt's "New Deal". Think of the world we'd live in

today if they had been successful! The rather surprising betrayal of

the plan to congress by the ruthless general they picked to be dictator

derailed execution the planned coup, for which half a million

soldiers or disgruntled veterans had been earmarked.

Things long considered to be basic human rights such as

drinking water

and saving crop seed have been privatized at the behest of

corporations to be sold for profit to the people that should already

own them. But even the psychologically

fine-tuned persuasions

of advertising to get children to nag parents to buy things they won't

want (not to mention adult targeting) don't escape the documentary's

purveyance.

Our society benefits greatly from trade and industry, but

the dark

side of the way it's run today is horrific. A corporation is a "person"

in the eyes of the law, yet it never grows old and dies, and if it

kills, steals, bribes, kidnaps or destroys the environment, the worst

it faces is a fine - a calculated business expense. So it rolls on and

on, an invincible, unaccountable, psychopathic juggernaut.

My one note is that for all its revelations, the video

doesn't seem to recognize what now seems plain to me: that big oil, the

automakers, and the battery companies are all owned not by random

profiteering stock market swingers, but by one group: a clique of

ruthless gangsters who work deliberately and unceasingly for a century

to kill all

alternatives to gasoline. They are rotting our society from the inside.

Identifying

the problems is the first step. Determining

good solutions is harder. The Russians revolted against the Czar only

to find they had raised a new and worse form of dictatorship,

Bolshevism.

What are good solutions to the many unaccountable, rogue

corporations and their owners who so control and manipulate our

economies and dominate our policies and politics, gradually destroying

the planet and working so much harm to human freedom, safety and

security? Near the end of the film, some cases

and solutions are discussed.

It turns out

government has indeed reserved to itself the power to dissolve

corporations - it just never

does it, regardless of the current provocation or the company's history

of continuing lawlessness or harm. And in California, even regardless

of a

citizens' group formed to demand that one particular state oil company

be

dissolved. The attorney general wouldn't do

it. There seem to be too many politicans who've gained power by

representing big business interests rather than the real national

interest.

People have taken legal action, sometimes successfully,

against the

most

flagrant abuses, and in one case shown it came down to actual

revolution and

bloodshed -

but it's all in the film.

The idea of attainder has grown on me. Why should it only

be people working for progress - inventors like Rudolf Diesel

(murdered for his engine), Churchill, Roosevelt, the three Kennedy

brothers - that

have to look over their shoulders, hit the dirt when a car backfires,

and wonder when their life might

suddenly be violently snuffed out? Why not also the most successful

criminals as well, who often perpetrate such violence, and who are so

rich and powerful that they seem to be above ordinary law? It would

seem

that only such a direct act by the peoples' chosen representatives can

terminate their ever growing domination of society and commerce, and

return their vast stashes of well-laundered but essentially ill-gotten

gains over to the public treasury.

Perhaps fittingly, though the film features many American

corporate insiders and critics (including corporation presidents and a

surprisingly humble Michael Moore), the end credits show it's a

Canadian production with

public financing from a number of Canada's leading sources.

The Electric HubcapTM

Vehicle Drive System

Commendation of EH type motors

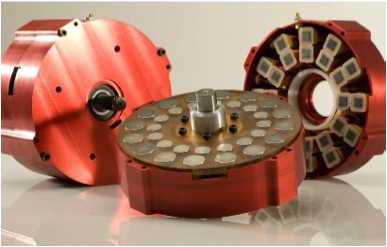

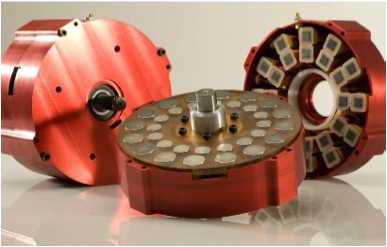

Here's a commendation of the Electric Hubcap (EH) type of

motor from a company (Apex Drive Labs) making one of rather similar

configuration. I downloaded this a year or two ago and just ran across

it again. Two points of interest are first that their gap from coils to

magnets is, like on the EH, unusually wide - about 1/2 inch, and second

that

they use two stators to drive one rotor, providing almost two motors in

one thicker package.

The

coils of this motor are "U" shaped, with the two ends

meeting

an

inner and an outer magnet on the central rotor.

(Unfortunately,

no motor weight was given, so there's no

basis

for power to weight ratio comparison with the EH.)

Most radial flux motors have hundredths of an inch flux

gap. The .5 inch gap (which any "regular" motor person would think

must be a typo) means the useless static pull from the magnets to the

stator is far less for the axial flux type, which leads to lower

bearing

wear, no gradual loss of magnetism in the supermagnets, and higher

efficiency.

I suspect the efficiency improves especially in larger

power sizes - I've heard it said that around 10 HP up the PM motor

becomes less

efficient than the induction motor. Inefficiency in the larger sizes

must surely stem from the tremendous static forces between the magnets

and the stator -- in radial flux designs. It seems likely Apex derived

the wide flux gap from mathematical modeling. I got there by

experiments that showed it worked best, without at the time knowing

others were using a similar gap.

Apex's having two stators - one set of coils on each side

of the rotor - helps to compensate for the low magnetic flux of

electromagnets compared to supermagnets. It might almost be said to

be two motors in one. At the time of the article, they planned two

direct drive

motors, on left

and right wheels, for a small Neighborhood Electric Vehicle (NEV).

Evidently by the watt specs they have almost four times the power of

the EH, so almost 8

times the power with two motors - 40 HP. This is far more power than is

required for a NEV, but without a torque converter or gears the

huge size would be needed to attain sufficient torque to get the car

going up

a hill.

"It is widely recognized that axial

flux permanent magnet (AFPM) machines usually have higher torque

densities and efficiencies than their radial flux (RFPM) counterparts.

Its pancake shape geometry and high torque capability make AFPM motors

a preferred choice for direct-drive systems. In recent years, many

different topologies of AFPM machines have been developed and reported

[1]."

My comments on this: Yes, higher torque, but for direct

drive of the wheels, it's still not commensurate with what's needed

except with very oversize motors. Hence

gears, or better, an efficient torque converter, allows a much smaller

motor. (Since there's no ultra-high permeability soft magnetic

materials or superconducting coils to raise the electromagnet flux and

hence the torque.) Yes, there can be "many different" axial flux

topologies, but

I'll bet the Electric Hubcap is by far the easiest one to make, having

standard auto and trailer axle parts for its main structure and common

boxed strip nails for coil cores! The parts

are all readily available (...no "by prescription only" or otherwise

banned or controlled items) and any motor repair shop could easily

make them.

Repairs to Magnet Rotor

The rotor, motor side: - new flat head screws help to "clip in"

the magnets so none fly off again.

Note also how solidly the lug bolts for the torque converter arms are

pounded in: at least one of the heads is visibly flattened and dented.

One of the four lug bolts for the axle hub had to be removed to fit all

five for the torque converter.

Drilling holes in a magnet worked, but was difficult, and

each hole broke out a clump as the drill neared the bottom. I

turned the magnet over and used the divots as

the recesses for the flat head machine screws. (This was the magnet

that the nickel plating came off of.)

I soon spray painted this assembly

well with rust paint to prevent corrosion of the rotor and the magnet

iron and the vulnerable

neodymium. Someone tipped me off that the neodymium degrades

from oxygen even in dry air, turning into non-magnetic oxide powder, so

I

spray painted all my supermagnets, which are mostly scratched

up from use on various rotors one time or other. (So that's why the

older ones always seem to look worse and to be weaker than I remember!)

I glued the magnet on, then drilled and threaded the holes

in the

rotor. The threading tap broke off in the last hole - impossible to do

anything with, so I put one screw on the outside of the magnet.

It's also worth noting that I use a big tin can with the

ends removed (and a slit cut in the edge so it'll fit in) when I put

the axle hub on or take it off. (I've been doing this for some time but

have previously neglected to mention it.) Otherwise, the hub always

ends up latching itself onto a magnet with considerable force, making

the job very difficult and rather hazardous. Even at that, the hub has

to be worked into place onto the lug bolts. (The tin can, though it's

also attracted, is thin metal and much easier to manipulate around the

magnets.)

Motor Weight

I worked out the weight of the bare EH motor if it was

made now with

the rather light 6129 disk brake rotor disks, which seem (without

having tried them yet) as close to ideal as will be found using

ready-made parts. It would weigh about 37-1/2 pounds, 17 Kg. (Parts

cost

might be around $300 to $350. "Bare motor" means: no mounting

straps, no cover, no torque converter specific pieces... except two

trailer hubs and the 6" flanged trailer axle... it

would only need one hub and perhaps a short axle if made for use

without a torque converter.)

Axle (6" long, 1-1/16" diam, with flange) - 1.6 (all weights in Kg)

4 bearings, axle nut - .37

2 hubs (length turned down to both fit on axle, diameter turned down to

fit in 6129 rotors) - 2.6 (est)

2 6129 Disk Brake Disks @ 3.0 - 6.0

9 coils @ .46 - 4.14

12 magnets @ .125 - 1.5

4 lug bolts for rotor - .15

other nuts and bolts - .14

Wires, plugs, Hall sensors - .5

Total 17 Kg, 37.5 pounds

This weight means little to the car overall. And with the

link

pins,

it will pivot when the car wheel hits a bump so it's largely not

"unsprung weight". Still... lighter is

better.

Potential places where weight could be further reduced:

* Replace the stator hub and its brake rotor disk with a single flat

steel disk, with a short pipe coupling welded to its center to mount

the

bearings. That might save about 1.25 Kg (2-3/4 pounds).

* Replace the 1-1/16" axle with 1". This would save only a bit, and

since the flange is needed on the end, it seems impractical to replace

the trailer axle with a 6" long, 1" diameter bolt.

* Drill holes in the rotor disks and cut out some unneeded metal in the

spaces between coils. The holes would also act as ventilation holes,

but otherwise, I'm guessing it would be a fair bit of work for minimal

reduction. (You don't want the rotor metal much thinner, and be careful

where you cut - the metal completes magnetic circuits between

coils/magnets.)

* IF nanocrystalline ceramic cores can be produced, they would be

lighter than metal by around 3.5 pounds. This is the biggest potential

reduction: 9% - IF.

If there's going to be a torque converter, replacing the

magnet rotor assembly - disk and hub - might make it harder to

build with

only a marginal weight reduction, so I haven't mentioned that idea. On

the

other hand, the trailer hub has to be turned down on a lathe anyway.

Mechanical or Magnetic Torque

Converter Project:

Torque Leverage Without Gears

When I first screwed magnets into the aluminum drum, I

didn't concern myself with north-south polarity. Either polarity would

attract the steel

arms, right? Then I realized that the steel arms as the rotor spun

would be magnetizing themselves first in one direction, then the other,

and it takes energy for that to happen - a needless inefficiency! When

I remounted them on the outside, I set them all the same way.

First I mounted the magnets on the inside of the rim.

Then I realized that the 12" aluminum pan was practically non-magnetic,

and that an extra 1/2 inch of radius could be gained by putting them on

the outside.

It's now about as big as the 13" car wheel allows -

any larger and a flat tire would cause damage, with the magnets hitting

the

road.

On the evening of the 4th I finished making the new

pivoting arms to match the diameter of the large aluminum drum. I did

them by bolting new pieces onto the original (2nd set) arms. Two piece

arms were necessary anyway because they were

now longer (2 & 9/16" from pivot point to tip) than the distance

between adjacent pivot bolts, so full length straight arms couldn't

have been

threaded on.

Motor rotor/torque converter input rotor with pivoting torque

converter arms June 4th,

"upside down" in torque converter output drum.

The arrangement has a side

effect: the inner end of the

outer arm pieces hits the center hub edge and limits the amount of

swing of

the arm (2 or 3" from one side to the other - can be increased by

grinding the inner end of the piece). Whether this is detrimental,

valuable or neutral remains to be determined.

With the limited pivoting, the arms won't swing back far

enough to fit in the blocks intended to hold them back until the center

of the next magnet is reached. I'll try without them first. The arms

are longer now and with more inertia should take longer to swing out,

which could solve the problem 'automatically'.

On the 5th I mounted the rotor and the drum on the axle

and tried turning the rotor, holding the drum steady with a stick. The

arms were about the right length, and the the force impulses to the

drum seemed to be pretty much unidirectional, but they seemed much too

light to move a car. As before, the greatest impulses were with the

rotor going a very low speed. The rotor was easily turned; obviously

the motor could take a lot more without being in danger of being

stalled - this would be a benefit of the increased outer diameter.

I could easily double or even triple the amount of steel

attracted to the magnets, but I suspected that would still be

insufficient. The way to get a much greater field and force would be to

put supermagnets on the ends of the arms and have supermagnets

attracting supermagnets.

This brings the design back to being similar to one of my

early ones (that I didn't finish putting together owing to lack of

confidence in it) with a sliding aluminum "flat donut" plate that could

pivot back and forth about 2-1/2" (from which the five slots in the

drum rim remain), but with three key differences:

1. the mechanical foundation - pivoting arms, is both simpler and

more robust than the sliding plate. It should be much less subject to

heat and to wearing out.

2. there are no axial forces acting on the magnets: the arms pull

towards the rim rather than to one side.

3. The hinge of the pivot pins is only about 2/5 of the way out

to the drum, giving the motor a leverage that allows it to start

turning more easily in the presence of heavy magnetic cogging forces.

The amount of the leverage depends on a number of factors and can't

simply be ascribed as being 5:2.

On the 6th, an idea about something someone said some

months ago, which had been in the back of my mind, came forward. He

said something along the lines of "It's really hard to pull magnets

straight apart, but they can be slid apart sideways much more easily.

Your design is sliding them apart; it needs to be pulling them apart to

get the main force."

I decided if I was going to put magnets on the arms,

perhaps they should be edge-on instead of face-on to the drum rim

magnets. Turning the magnetic lines of force would have a modified

effect. Experimenting with a 1"x1"x.5" magnet held with pliers seemed

promising, then I thought, what if the drum magnets were also edge on?

I put another 1x1x.5 magnet in the side of a vice and put them both

edge on.

Sure enough! There was a slight repulsive force as the

magnets approached each other from the left or right, then a very

powerful attractive force once they were in line. They could easily be

slid apart up and down, but to the left or right was very difficult:

although they were "sliding past" each other, it was closer to the

level of force of "pulling apart" rather than "sliding apart".

Note: Using a piece of unmagnetized steel with

the magnet edge on showed very low levels of force. If a magnet is to

act on

steel, a pole facing the steel is better. Forces between two edge-on

magnets seemed to be a magnitude greater than any configuration of

magnet on steel, so magnet to magnet was the obvious choice.

I expected that this force could be multiplied to any

desired extent by stacking magnets. If I stacked two rim magnets to get

a 1"x1"x1" cube, oriented edge facing in, it should almost double it.

Even better would be magnets that were magnetized "sideways" compared

with the usual. With a similar double magnet on the arm a huge force

would be needed to pull them past each other.

Instead when I ran the experiment it didn't feel any

stronger with the doubled magnets - perhaps not even as strong. To

verify this I got a fish scale (no fish were harmed) and measured the

amount of force needed. With single magnets, it took 12 pounds of force

to slide them apart with a .08" sheet aluminum spacer between them

(similar

to the minimum gap they might actually have installed), and 16 pounds

with the

magnets touching. With double magnets making cubes it took only 9 and

12 pounds! It

seems the "sharp edge" of magnetism was the vital factor. Obviously,

with 2" tall magnets instead of 1" and with the same .5" edge, the

force should be around double, but there wasn't enough height for them.

(1.5" might fit, but I'd have to buy them that size - the heat from

cutting the magnets - at least with the zip disk in the angle grinder,

which seems the practical way - loses so much magnetism that the 1.5"

would be little or no better than 1".) Later I realized that while a 2"

magnet wouldn't fit inside on the arms, the ones on the outside could

overhang a bit. I tested a 1" against a 2" in the vice and found the

forces were about 15 and 20 pounds, a modest but worthwhile increase.

Also noted in passing in the experiment was that unless

the magnets were sticking well out from the vice and the pliers, the

tools' steel shorted out much of the magnetic field.

Later (10th) I tried a 1x2x.5" magnet with the 1" edge

against the 2" edge. If the space could be found this was a modest

improvement, giving about 17-18 pounds with the spacer. Finally (11th)

I tried the obvious optimum: two 2x1x.5" magnets with their 2" faces

together. The force, with spacer, went off the end of the 25 pound fish

scale, probably 30-35 pounds. Here is the obvious

configuration if there's room. With such forces, one might even be able

to use fairly wide air gaps for loose fitting tolerances. That would

make them easiest to make. For me at this point, it would also mean

switching to a new motor rotor (ironically one with a taller center hub

is ideal, to accommodate the magnet lengths) and a new torque converter

drum - a lot of rebuilding.

I can visualize the 'optimum' embodiment of the design

more easily than I

can take apart and re-assemble everything (and more easily than I can

find the ideal drum): an ideal 12" diameter drum of aluminum with 2.1"

straight rim walls (no curve to the base), .5 x 1" steel arms with 3/8"

pivot bolts, .5 x 1 x 2" outer arms, sideways, next to the magnets

outside of them, and 1/8" stainless steel plates to attach the magnets

to these.

The present question is: do I have to build the optimum to

get the car

moving properly, or is the design with lighter parts and lesser

magnetisms that I can throw together fairly easily now good enough? Or,

the other nagging question, is it possible that even the optimum isn't

good enough?

If the arms swung freely, the slight repulsive force would

hold back a slow moving arm until its inner end was past center. But as

the motor sped up, the centrifugal force flinging the arms outwards

would overcome the weak magnetism and put the magnets directly across

from each other hopefully just after the pin passed the center point,

so the force should mainly or all be one way and should increase with

motor speed.

I found there was actually a considerable backwards force

as the magnets latched onto each other: the arms jumping forward

pulled the drum backwards. It occurred to me that if

the arm magnet was able to twist sideways, or to move inwards away from

the drum rim magnet, the arm perhaps wouldn't have to pivot, and the

arm magnet would simply twist or retract as it entered the zone of

light repulsion approaching the rim magnet, then straighten or spring

forward again as it entered the strong attraction zone, to give the

drum rim the sharp tug that should turn the wheel.

The one "sticking point" would be if the motor came to

rest with all the magnets lined up, would it have the force to break

loose and start spinning? The swinging arms get around the problem,

giving the motor a lot of leverage to pull the magnets apart.

Well, there's still a lot of "hopefullys" in here and it's

shy on descriptive math weighing the balance of the forces. But

formulae characterize the various parameters of a given design, and a

given

design is exactly what we didn't have yet.

On the 7th, I mounted a 1x2x.5" magnet edge-on outside of

the drum rim, held by aluminum angle pieces, having of course removed

the flat

mounted magnets. The setup at this point allowed experimentation by

hand turning the rotors on the axle along with easy removal of the drum

with no other disassembly. Ideas could now be tested at a far greater

rate than was possible at any earlier time with any other design.

Approaching the (vertical)

drum magnet with a magnet held

horizontal disclosed that the forces attracting them were virtually

annulled. (In fact, twisting the loose 'arm' magnet horizontal proved

to be the easy way to separate the two supermagnets.) However, when

they were lined up, there was a very strong force wishing to twist the

arm magnet back to vertical orientation. The forces on the approach and

exit tended to want to spin it the other way up.

If the arm magnet could be mounted "hinged" so it could

twist 90º, from horizontal to vertical with one face (eg, north)

up or to the right only, it would turn horizontal on the approach to

the drum magnet - from either direction - then would suddenly go

vertical just about as the magnets passed each other. Thus there would

be little or no "backwards" force on the approach but the most powerful

forward tug just as they passed. The tug comes from the sudden slowing

of the outer end of the five arms, which kinetic energy is imparted to

the rim via the magnets. The faster the motor is spinning, the greater

the velocity or the arms and the greater the centrifugal forces holding

them straight out, and the greater the impetus as they pass the rim

magnets - provided the magnetic forces are sufficient.

(It would seem necessary to stop the twist a few degrees

short of vertical to ensure that it twists back, since at exactly

vertical, it would equally want to flip both ways and might stay

upright.)

When I tested the finished assembly on the car wheel, the

forces seemed to be all in the right direction, there was no vibration,

and the turning force increased with motor RPM. Unfortunately, that

turning force was much too light by at least an order of magnitude - I

could rather easily stop the jacked-up car wheel by hand.

If it had seemed like even 1/4 as much force as needed, I'd have

started working out ways to add enough arms and magnets to make it

work. But to add ten times as many supermagnets or get them ten times

bigger seems problematic. At some point, it's easier to just do a

greatly overpowered motor with ten times the needed horsepower in order

to get the needed torque without gears. But then it wouldn't fit on the

outside of a car wheel, so the main purpose is defeated.

What's Next?

The best idea now looks like the clock escapement type

of mechanism. The hard part is to figure out one that looks robust

enough to transfer the torque forces from the motor rotor to the slower

wheel rotor without the serious vibrations of the shifting plate

design, and without quickly falling apart.

I now have the glimmerings of a design that might

work.

It's going to take at least another month to put it together.

The idea is little "many" short two-point nylon "clock

escapement anchors"

sized so that at

least a dozen will fit around the outside of the motor rotor, with the

points sticking into slots (rectangular holes) in a strip (aluminum?)

around the inside of the rim of the drum. Each one will provide only a

small force (like all my other designs have done so far anyway), but

they'll all add up. (Ack! It has to be made so it

can be assembled without dismounting the anchors! The slots will have

to be open to the open edge so motor and drum can be fitted together.

But I digress.)

The pivot holes for the anchors will be drilled through

the

motor rotor between magnets, and threaded. (Tentatively, 1/4" bolts for

axles.) 2, 3, 4, 6, 8, 9, 10 or 12 anchors can be installed with

balanced forces, as seems appropriate when the forces are measured. I

can start with just two, or even one, and check the results without

making the whole works, in case changes are needed to the design.

(...why do I have the feeling it'll need more like 24, 36 or 48, and

how will I fit them all? At least 24 and possibly 36 could be doable by

stacking them

two or three per axle, if the slots in the rim are wide enough.)

These anchors will swivel back and forth very fast. Since

E = .5 M V^2, faster gives more energy than heavier. But I

can add steel weights to nylon anchors too, if it looks like

that'll help, or make them of steel entirely.

In principle I think I'll also keep the magnets

mechanism in

some similar form, with the external drum magnets, as a means to

lock up the converter to 1 to 1 when the torque required is light.

RECAP

Perhaps it would be interesting to run through the several

designs of torque converter since the start of the project a over year

ago.

My first idea was that one could use a typical induction

motor design adapted to axial flux, but instead of electric coils

creating a rotating magnetic field, have supermagnets on the motor

rotor. That way, the output rotor would be driven by a supermagnet

strength rotating field. The fundamental problem with that was that the

motor itself was still driven by electromagnets, and the unit still

couldn't have more torque than they would provide. The motor wouldn't

run fast enough to provide any more torque than without the new

mechanism. And all the slip was

just losses: there was no way to convert or transform

the torque, only to couple the original, insufficient torque to

the output.

The second idea seemed good in principle: magnets would

flip up and down on hinges. They'd flip down next to a magnet on the

output rotor just as it was going by, giving it a tug forward without a

preceding tug backwards. The third design was a variation on the same

theme. A plate on the output rotor holding all its magnets was to slide

backwards an inch or more as the motor rotor magnets reached them, move

forward to the end stops, and then the inertia and the attraction

between magnets would give the output rotor a 'hit' of torque as the

motor moved on. There were two main problems: the first was that if the

magnets lined up with the motor stopped, the motor probably wouldn't be

able to break free and start spinning. The second was that the

mechanical construction didn't seem up to the level of the forces

involved. I built some of the parts of these two designs and tried

turning them by hand, then gave up

without completing them.

A couple of times I studied clock escapement mechanisms.

They seemed to have the basic idea: when you try to run it too fast, it

gets very hard to push. If you turned it around, running the motor fast

should create a lot of torque. But it looked like the 'escapement'

pieces would be getting bashed around at very high speed and would

probably break or wear out quickly. But perhaps something that had

those beveled hits, with a higher mass and hence lower speed...

The fourth design was purely mechanical: a plate would

spin with the motor, and would hit ramps on the output rotor at

intervals that would cause it to shift sideways, in and out. The hits

on the ramps would be 'torque hits' to the car wheel. I went through

about 3 variations but found they all had serious vibration and not

enough turning force, or that the turning forces were so short the tire

absorbed them. In retrospect, the main cause of the vibration was that

since

it wasn't one solidly fixed assembly, it was actually much easier for

the whole motor to bounce in and out than for it to cause the car

to move - so it did.

In between a couple of these variations, I thought (again)

about Constantinesco's 1920's designs, and looked up some more recent

patents as well. The big trouble was that his design took linear space

between the driving motor and the driven output. Then I thought, what

if the motor was mounted on the car body above the wheel? It all

started to look quite straightforward when I found a ratchet wrench

that was strong enough to move the car without a problem. (I put it on

the car wheel and stepped on it - the car rolled.) But early in

construction, I suddenly realized that since the car and wheel moved

separately at bumps, the torque applying rod would simply make the car

bounce up and down instead of turning the wheel. I was also having

serious doubts about the efficiency of forcing a heavy wrench and steel

bar to shift back and forth at high speeds.

So I finished the last version of the shifting plate and

tried it out. The vibration was still terrible, for the reason given.

Somehow, I had to shift the axis of action from axial to transverse

with a workable design. Transverse forces would be in the wheel turning

plane, and furthermore a number of them spaced around the rim would

cancel out their vibrations.

The first idea for this was swinging arms on the motor

that almost hooked, sort of clung, to pins around the inside of the rim

of an output drum, yanking them along before they let go. It might have

worked, but I didn't get it made.

On April 30th I doodled out a diagram of a

mechanism with the same swinging arms but with magnets on them, going

past more magnets inside the rim of the output rotor drum. I figured

the arms would freely swing forward magnetically when they reached the

magnets, then un-freely pull away from them. Then I also figured that

since

only attracting forces were involved, the arm magnets could simply be

replaced by steel. But when briefly tested (in May) the forces seemed

too light, and also somewhat 'balanced', pulling both directions: as

the arms swung forward magnetically, they also pulled the drum

backwards.

The unique feature was that the motor would pry the arms

and rim magnets away from each other with leverage, so the motor would

need far less torque to start up with the magnets 'latched' in the

attracting position, the frustrating problem of all the other magnetic

designs.

To get more radius of action and more prying leverage, I

went back to the larger 12" (aluminum frying pan) drum of the earlier

magnetic trials, and then to putting the magnets on the outside of the

non-magnetic rim. This had the benefit of allowing me to see what the

arms were doing and run more experiments faster.

Finally some experiments disclosed that two magnets

edge-on to each other have much more 'ideal' characteristics for the

job, especially if they could pivot as well as the arms swing. This led

to this month's design, which had the right rotational forces, but they

were much lighter than I expected, and the amount of supermagnet mass

needed to up them sufficiently would seem impractical.

Now I'm thinking again about clock escapements. This time,

with the forces radial and balancing, and as many small "anchors"

or whatever as possible or as needed, spaced all around the outer rim,

to transfer motor

forces to wheel, increasingly with motor speed.

Nanocrystalline Ceramic Motor Coil

Cores Project

I seem to be out of inspiration for this at the moment. (I

may try using FeO again, this time well mashed with the mortar and

pestle, or maybe steel grindings. Finding fine metal powders or lower

oxides instead of fully oxidized metal oxide powders might be of

considerable assistance. and costly.)

Ultra-high permeability soft magnetic materials may or may

not exist, and may or may not be found if they do, but good "FINEMET"

nanocrystalline alloy cores are made, and good results have been

obtained with composite materials. This much (my original goal) is

known to be possible.

Nanocrystalline Reflective Rear Electrode for Dye

Sensitized Solar Cells

Some Design Considerations - Rationale for using certain materials

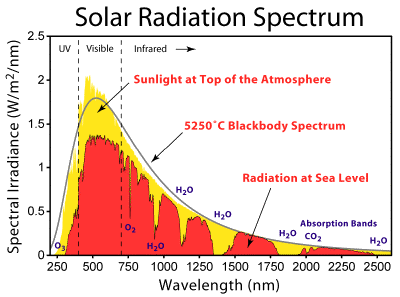

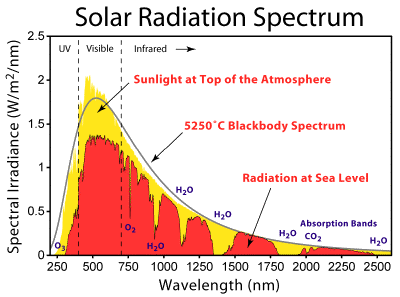

I chose tartrazine (yellow food dye from the

grocery store) as a good looking photosensitive organic dye. Its

wavelength of

maximum absorption, 427 nanometers, is at about the wavelength of the

strongest levels of solar irradiation (below, the peak of the yellow

area, also the peak of the red on some charts, is at around 400nm).

Totally off topic,

this particular chart was especially interesting to me as it notes the

absorption of specific wavelengths by ozone, oxygen, CO2 and water

vapor in the

atmosphere. That's interesting in itself, but also I thought from

previous limited information I'd found that the 'cyclic' absorption

lines on Titan from

methane vapor were quite unlike from the spectrum of water vapor. This

graph reveals instead a

similar sort of spectral pattern.

Titan is an atmospheric planet, between Mercury

and Mars in size, that orbits Saturn. It's the only other world in the

solar system with an air pressure similar to Earth's, and composed

mainly of the same gas, nitrogen. It is also the only other world with

land and rivers, lakes and seas - albeit of liquid methane.

I see from a release June 4th, along with an earlier title

announcing a lecture about it at a conference, that space scientists

are finally starting to talk about the possibility there's life on

Titan

-- not because of the aquatic leaves and stems ("rocks"!?!?) in the

Huygens lander images and evidenced in the Cassini T14 RSS pass, and

not because of the forests of gigantic trees visually revealed and

otherwise evidenced by the Cassini SAR radar (Cassini SAR image swaths

of Titan's temperate and polar regions are similar in nature only to

satellite/Google Earth images of forested areas.) Instead they're

saying it for the equally evident chemical/spectral reasons: covering

over of expected inorganics such as water ice by complex and unknown

organic spectra with abundant benzene, and a seemingly unexpected

absorption of

expected energetic gasses (in particular H2 and HC2H, acetylene) at the

surface. (The shortage of hydrogen at the surface seems to be what's

finally caused the awakening, perhaps because it fit with a prior

theory that hypothetical Titan life might use it for energy as a

breathing gas.) So far

they are still looking for "microbes" on a world evidently verdant with

huge

forests and aquatic vegetation of a scale unknown on Earth.

On January 15th, 2005, the Huygens probe parachuted down

and as far as I can tell splatted down on Titan's swampy tropical tidal

methane seas right on top of a dune, just a couple of inches below sea

level. The images obtained were immediately released to the public on

the Huygens DISR website, in a form which was said (most

unprofessionally) to be the original raw images: but which were

actually grotesquely contrast magnified, and by completely inconsistent

amounts. Luckily, René Pascal pointed me to two archives of the

actual raw images. It took me until mid July in uncounted hours of

study to figure out the true nature of the scenes: submerged wetlands

(formed into dunes by Titan's powerful tides), covered in aquatic

vegetation of stupendous dimensions. After that everything started to

fit into place. Apparently scientists haven't got that far yet. Perhaps

they were misled by their own unmentioned and bizarre image processing.

My studies of Titan from 2005 to 2007 are on the web in my

'book', Living Titan.

Some later thoughts (mainly 2008) on a number of worlds and the strange

things and activities on them are at Space

Update Notes Web Page. The main index to my pages on that site is: www.saers.com/~craig .

But I seriously digress!

The choice of borosilicate glass ("pyrex") for the glaze

layer and for the front glass is because it is the most transparent

glass at the strongest wavelengths. In fact its transparency is

exceeded

only by pure silica - quartz, which can't readily be purchased nor made

in a typical kiln.

"Pyrex glass

(borosilicate type) is opaque to radiation in the UV-B band and

attains a maximum transmission level at 340 nm and beyond (Acra et

al. 1984). The coefficient of transparency for borosilicate glass, 1.0

cm in thickness, is 0.08 at 310 nm, rises sharply to 0.65 at 330 nm,

and attains a peak level of 0.95-0.99 from 360 to 500 nm. (Weast

1972)"

Although I purchased a piece of

borosilicate ("wood stove door") glass to divide into solar cell test

pieces, and stannous chloride and tin dioxide, having now tried to put

the conductive tin oxide layer on some test pieces I must conclude that

unless its horribly expensive I'd be better off to order some ready

made.

(Oh, wait, I forgot... it's become almost impossible to find goods on

the web any more, with all the "parasite sites" that each appear a

dozen times in the same search and claim they link to

thousands of companies selling just what you want, dominating the

results of any search for anything and knocking out the bona-fide

sellers. Maybe local glass companies might know something...) The

resistances I've heard of for commercially made pieces are ohms or tens

of ohms, whereas the best I've got - on porcelain which process I can't

duplicate on glass or glaze - is hundreds of ohms, with thousands and a

cloudy appearance being my best on glass.

Perhaps I can do better on glaze at high temperature, but

it would mean a lot of manipulating glowing hot ceramics straight out

of

the kiln, and then putting them back in. It will certainly complicate

the melt-quench. Unless I can think of a better technique than what I'm

envisioning now.

As an alternative, perhaps it would be easier to use an

"open" metal grill that lets most of the light pass by as the rear

electrode collector, and forget about making the glaze conductive. Of

course, its thickness would greatly thicken the electrolyte layer, even

with quite fine mesh.

The 'glaze mix 9' seems, by some fluke of luck given that

up to about mix 6 it was supposed to be for another purpose entirely,

to be pretty much ideal for the reflective rear reflectors, or

certainly 'close enough' for working purposes.

I painted on a thin white zircon (zirconium silicate)

underglaze and then a very thin glaze layer on two pieces of porcelain,

and one with no zircon for comparison, and fired and quenched them. One

with zircon was clearer than the other two, but all had colour, and

showed clumps of coloured microcrystals under strong magnification. I

painted on a second thin glaze layer and

fired and quenched again. This time, the glaze looked uniform and clear

except for a couple of streaks on one piece, the microcrystals

evidently having given way to transparently thin nanocrystals in both

layers.

With thick underglazes (or two layers), the glaze wouldn't

stick on the porcelain, and with thick glazes, there were a lot of

dark, coloured microcrystals rather than transparent nanocrystals. It

would seem that two or more thin layers is the way to go rather than

trying to do everything with one coat of glaze.

The zircon white underglaze seems a little brighter than

the titania (titanium oxide) white underglaze - at least to my eyes.

(Must try tin oxide, too! ...would that be called "tinia"? Of the three

common glaze whiteners, Ti and Zr are adjacent in the same column of

the periodic table.) In the comparison piece with no underglaze, the

whole tone was less bright, and the glaze seemed 'rougher' at the

microlevel, especially with only one layer. I expect the glaze was

pulling 'impurities' out of the grainy porcelain, and conforming to its

grain, instead of having fine white zircon smoothing its base.

The reason for the titanium oxide nanocrystals in the

glaze is because it has a very high refractive index (highest of any

substance) and a very high dispersion - the prismatic separation of

colours. It is likely to most modify and disperse the light to give

good

prospects of making it more susceptible to being absorbed by the dye on

the way back out.

Zircon underglaze and one thin coat of glaze (no underglaze on

rightmost piece).

Zircon underglaze and one thin coat of glaze (no underglaze on

rightmost piece).

The melt-quenched glazes were clouded with microcrystals.

After a second thin coat of glaze, fired and melt-quenched, the

microcrytals were evidently

refined down to transparent nanocrystals except in the piece with no

underglaze. A new piece with only one glaze layer was fired and

quenched in the same batch.

After a second thin coat of glaze, fired and melt-quenched, the

microcrytals were evidently

refined down to transparent nanocrystals except in the piece with no

underglaze. A new piece with only one glaze layer was fired and

quenched in the same batch.

I'd like to try expanding on the glaze layers idea a bit

by

painting 'tinia' on the last glaze layer, and then doing another layer

of tinia on top of that. At some point, it should become conductive.

(though it may lose transparency - all in trying it out and seeing if

some way works.)

An alternative configuration for the solar cells, if

making the glaze conductive works, and IF the electrolyte is quite

transparent, might be to have the nanocrystalline titania sintered onto

the rear electrode instead of the front one. The rear electrode would

then be the negative and the electrolyte ions would flow the other way

around.

Now if that titania could be formed into vertical

nanotubes or nanorods impregnated with the dye, that "light guide"

could possibly be

still another improvement.

Turquoise Battery Project

June Experiments

When the new version

torque converter didn't seem to have enough 'kick' on the 23rd, I

decided it was high time to get back to the battery project, sitting

since April in promising condition. Perhaps the best thing to do next

was to make a sealed Ni-Mn/KCl battery that wouldn't need watering all

the time, and wondering what other things might be getting in or

escaping though the open top.

This time I considered thoughts that had come to me about

the manganese while I was making the previous electrodes in April.

For manganese, I had purchased MnO2 (local pottery supply)

and Mn metal powder (Micron Metals). The

form in which these are added to the battery probably deserves

consideration, since starting with one electrode charged and the other

discharged is bad. It seemed easy to add some of each to get the

desired starting charge state, but each form has its own small issue:

The MnO2 (Mn valence IV) seems to be the common 'pottery

glaze' form of manganese, but if put into a battery it makes a

pre-charged 'positrode' (MnO2 being the usual positive chemical of

non-rechargeable dry cells). For a negative, it's 'overdischarged'.

Expected discharged form in salt solution would be Mn(OH)2 (II) or MnO

(II). Starting from a higher 'overdischarged' oxide, less conductive

and probably bulkier, seems counterproductive. One solution is to add a

higher percentage of metallic Mn. But MnO2 is a cheap oxide and Mn

powder (typical of pure metal powders) is expensive. To reduce the

valence of the Mn oxide from four to two (or even to three) would be

quite helpful by itself, and would reduce the metallic Mn required.

NiOOH (III) can be discharged to Ni(OH)2 (II) with

hydrogen peroxide, H2O2. Oddly enough, this oxidizer seems in effect to

steal even more oxygen, probably from the water in the presence of the

nickel compound, which bubbles off as (presumably) O2.

The first experiment was to see if it would do the same

for MnO2. It did seem to work the same way. (The gas didn't

smell, so

it wasn't H2, and that's pretty much the only other choice besides O2.)

A week later, I realized the bubbling had stopped because the hydrogen

peroxide was exhausted, not because the MnO2 was all converted. I added

some more H2O2 and it went back to frothing away. I converted all my

MnO2.

I bought some

more to weigh the product before

and after next time. I should be able to tell by the weight change if

it's MnO, MnOOH, or

Mn(OH)2... and also make sure it's not actually oxidizing to some even

higher valence form!

The pure metal, Mn (0), is the negatively charged form in

the battery. Yet I started to think: when the Mn powder was mixed with

liquid, it might well discharge spontaneously before the hydrogen

overvoltage ingredients were added. It all looks pretty black - I can't

really tell MnO2 from Mn powder in the damp mix, let alone discern

MnO or Mn(OH)2. If it was discharging, I wouldn't know.

The obvious thing to do here is to mix the hydrogen

overvoltage and all other dry ingredients first, then add the Mn

powder last.

Another consideration that may have been a factor in the

difficult charging of the previous Ni/Mn mix is that I don't have (and

can't seem to get) nickel powder. I added the nickel as discharged

Ni(OH)2 (II) as well. Now that I think about it, this presumably has to

charge up to Ni (0) before the manganese can start to charge, since

it's a lower voltage.

So perhaps I should be using monel powder instead? (It's

around 2/3 Ni & 1/3 Cu).

I looked at both of them at 40x magnification. The

"blackish" monel looks like shiny little rounded chunks of silvery

metal - which of course it is. The nickel hydroxide looks like green

laundry soap

flakes. While the fluffy Ni(OH)2 'snowflakes' tend to be of similar

size to monel grains, some are much smaller, and when compacted they'll

break down much finer.

It seems to take some doing to charge the Ni(OH)2 to Ni

metal one-time, whereas the monel is already "charged". Depending how

intimately the Ni needs to be in contact with the Mn to effectively

raise the hydrogen overvoltage (or whatever it does that seems to

help), the fine Ni(OH)2 may do a much better job. The best way to find

out

is probably to try them both, and to try a mix with half of each. (At

the rate I've been running battery experiments, that could take months!)

If the compaction is good, the electrode should certainly

be highly conductive with all the monel or nickel, and the manganese

metal and lower oxide being quite conductive as well. If the "+" can be

made half as good, a pretty small battery might start a car engine.

Another thought is to buy NiO at the pottery supply if

monel powder proves too coarse. Why run down my Ni(OH)2 supply when

it's what's needed for the positive electrodes and is harder to get?

While I was at it, I took a magnified look at MnO2 and Mn

powder.

The metal chunks in the "grayish" powder had a bronzy sheen and were

much more irregular than the monel particles. The particle size was

similar (well, I did order them both as -320 mesh! Perhaps I should be

ordering micron sizes.)

The MnO2, quite black at any scale, was clumped into quite

large particles, but these easily broke down with compaction. They

didn't seem to get as fine as the Ni(OH)2.

When some was dry, I inspected the Mn(OH)2 (or is it

MnO?). (That's the trouble with pouring 3% H2O2 into some powder... it

got soaked into a wet slurry. Oh well, pretty much dried overnight when

spread around a bit. But I doubt I added enough H2O2 to

reduce all the MnO2 powder. I really should calculate it out and

then measure the ingredients - that would be easier if I knew exactly

what the reduction reaction was.)

I decided to use a previous nickel "+" electrode that was

already in the battery test case. (A slightly dangerous thing to do

since it hasn't proved itself and I don't remember exactly what's in it

- but easiest.) The final mixture for the first "-" was:

Expanded copper mesh collector sheet/backing, approx. 1.3" x 3" - 1.75g

Monel alloy powder - 10g (conductivity, ??)

Mn(OH)2 (?) - 7g (active ingredient - discharged state)

Mn metal powder - 5g (active ingredient - charged state)

Sb4O6 - .2g (increases hydrogen overvoltage)

CMC gum - .2g (glue)

Albumin (egg white) - a smear (significantly increases hydrogen

overvoltage even in PPM quantities)

HOH distilled - 2cc

In the electrolyte is Na2B4O7:10H2O (borax) and KCl

(potassium chloride), not to mention

water.

The KCl is of course the neutral pH salt electrolyte. The

idea of the borax is that if hydrogen is created by overcharging the

negatrode, instead of making H2 gas, it'll change it to a borohydride,

which, being like the borax, soluble, will diffuse over to the positive

electrode to give up its 'H's and discharge some NiOOH to Ni(OH)2. This

will create heat but eliminate buildup of hydrogen gas pressure.

On the first attempt to charge the battery, the voltage

went up to only ~~ 1.6 volts while charging and rapidly dropped off to

under a volt with the charge removed. The pressure went up to 12 PSI in

a few hours without the battery being charged. Overnight I reduced the

charge. In the morning the voltage was only marginally higher, but the

pressure was up to 18 PSI.

I unscrewed the pressure gauge and sniffed the air coming

out as I did. I didn't smell much, and it didn't seem to be hydrogen.

That seemed to say the negative wasn't bubbling hydrogen gas. So I

concluded that the positive electrode was already charged and giving

off oxygen on further charge, thus the negative wasn't reacting with it

to charge properly.

I took the battery apart and put the positrode in 3% H2O2.

There were lots of tiny bubbles for over two hours, and even after

four, a little shake would start it mildly fizzing again. This

evidently means it was charged to NiOOH and was now being discharged to

Ni(OH)2. After that I put it in water to rinse it out.

As I left it in a considerable puddle of H2O2 and the

bubbling continued for such a long time (even at that I can't say it

had really ended), I think my previous attempts to discharge nickel

positrodes used much too little H2O2 for much too short a period of

time to discharge them more than a fraction of their full charge. This

may well account for a few disappointing experiment results.

(FWIW The reaction might be: 4 NiOOH [III] + 4 H2O2 => 4 NiOHOH [II]

+ 2 H2O + 3 O2.)

On further testing the cell, the positive connection

(nickel-brass)

corroded away, and in the restoration I put the meter probe at various

points in the electrode briquette itself. This disclosed that while

charging there was a great voltage gradient through the thickness of

both electrodes. The closer the probe to the interface between the

electrodes, the

greater the voltage drop from the collector screen. Evidently both

electrodes have very high internal resistances.

This could explain many poor experiment results!

And I've started to realize that if a battery has 10 AH of material and

it'll only charge at (eg) 20 mA, it'll take over 500 hours to charge

it! A few hours, or even days, may not bring it up to the expected

voltage, explaining that many "failures" weren't due to the

electrochemistry at all. When the area of best conductivity to the

collector becomes fully charged, the voltage goes up to some ridiculous

level, and I finally conclude it isn't working right at all. But much

of the rest of the electrode has yet to be charged, so as soon as the

charge is removed, the voltage drops below the expected voltage. And if

the current that can be stuffed into the poorly conductive battery

isn't above the level of self discharge, it'll never get charged.

Perhaps my electrode compactor, though forming the powders

into a seemingly solid 'briquette', isn't pressing hard enough? My

briquettes crumble more easily than the ones from the Ni-Cd dry cell,

though none are immune to losing material when mechanically stressed.

It would seem I probably need to find a still better compacting

technique. Maybe double the screws? -- screws going in from both sides

of the compactor to

increase the available pressure? Maybe pound the compactor with a big

hammer when it's already fully tightened, and then see if the bolts

will turn in a bit farther?

I decided on the 29th to

look into hydraulic presses. A big 45 ton press is

$2000, but a 6 ton one is just $100, and a 12 ton press is $270:

nothing

like the high capital costs I'd expected. I even got a used 12-ton at

Barclay's Exchange for $150. (KMS Tools had just sold their last 6 ton

one: I saw

it - it waved at me on its way out the door. But I'm guessing that 6

tons would be a bit underpowered anyway.) And I had found doing up a

bunch

of

bolts to compact an electrode would have been a serious production

bottleneck even for enough homemade batteries for a car. The press is

just a common 12

ton hydraulic jack in a big heavy steel frame.

BTW I wish I had some much finer copper mesh. I got a

coarse mesh roll at an art store (Opus) and I was probably lucky to

find that. It doesn't help conductivity when much of the active

material is somewhat distant from the collector. Also BTW this was the

first time I had the mortar and pestle to give the mixture a good

grinding and mixing before compacting it.

Higher Voltage, Cheaper, Higher Energy Density Batteries: the easy

way?

In considering making higher voltage batteries with

multiple cells, I had thought of putting a "+" and a "-" electrode on

opposite sides of one collector sheet, when I was using nickel-brass

brass

collector sheets. Then when I started using metal grilles, it occurred

to me one could more simply use a

metal grill wrapped around a thin piece of hard plastic.

Now I'm thinking: why even use the plastic? The voltage of

both electrodes is necessarily the same, so why does the electrolyte

need to be blocked, especially if it's a dry cell with no extraneous

liquid that might bypass the electrodes? Why not just compact the two

electrodes together into one bipolar briquette? And then, with all the

current

simply flowing across the thickness, why use any grill or collector

sheet at

all? Why not have nothing but the active electrode briquettes?

This would be the simplest and cheapest, with the highest possible

energy density.

Here we hark back to Volta's original 1798 "electric

pile" in a modern form. Except for a collector grille or plate in each

end electrode, the whole

battery is full of nothing but active electrodes, with the requisite

separators

between them.

It's getting tempting to try making a "full size" 12 volt

Ni-Mn battery

with 6 cells of 3" x 6" electrodes, maybe 50 or more amp-hours. But I'd

better work on improving the conductivity first - it would be

of little use for transport if it only supplies (eg) a half amp for 100

hours instead

of 50 amps for 45 minutes.

A Battery Comparisons Thought

* Left: "D" cell size battery. (Ni-MH

"D" cells are up to 10 AH, 1.2 V,

"1000

charges", 100 WH/Kg.)

* Left: "D" cell size battery. (Ni-MH

"D" cells are up to 10 AH, 1.2 V,

"1000

charges", 100 WH/Kg.)

* Center, Right: Ni-Fe 10 AH, 1.2 V

pocket cell battery, 20 WH/Kg.

(Larger ones are said to be up to 50 WH/Kg.)

These last for decades. The active chemicals are inside rectangular

"pockets"

which are combined into flat plates. Changhong uses battery production

line equipment purchased from Varta in Sweden, so their batteries are

about the same as Varta's.

* The "hacked" electrodes at the

back-left was a Ni-Ni experiment in

the spring.

* I imagine the same batteries as

Ni-Mn and think: 2V cells and

almost double the energy, for all types!

Knowing a few more details

now about batteries, I have an observation for comparing various

chemistries with a

little more savvy, especially alkaline types versus lead-acid. The most

important

ratings for EV batteries are

WH/Kg and WH/$.

Lead-acid battery ratings are deceptively high. They're

rated at a 20 hour discharge rate, and the amp-hours are much reduced

at high rates. And even with

sodium sulfate keeping them from decaying, they can only be discharged

to about 60% depth of discharge for electric drive because the

voltage seems to start seriously dropping off when much current is

asked

for

beyond around 50%. With Ni-Cd or Ni-MH, one can tap around 90%

of the

charge out before the voltage plummets, and the amp-hour ratings are

for a shorter discharge time and they degrade less at high rates.

Therefore,

most other batteries

store perhaps 60% more usable energy than a lead-acid battery

with

the

same rating. A 100 AH lead-acid battery should therefore be compared

with a 60-65 AH battery of most other types. The same derating scale

could be used in reverse for the cost, ie, multiply the lead-acid cost

by 1.6 to compare it to other chemistries. And the weight, already

heavy, must also be multiplied by 1.6 to compare it fairly with other

types.

Thus if I can make a 60 AH 12 V Ni-Mn battery (a rough

estimate, perhaps a little on the high side) by incorporating

everything I've found) in a 4" x

4"

x 8" case (128 cubic inches) it would compare with a 100 AH size 27

deep cycle lead-acid battery of 12" x 7" x 8" size (672 in^3)

- five times the size.

The Ultimate?

The Ultimate?

for the front battery

to be usable energy equivalent to the rear one,

cheap, safe, and superior in every

other way.

Lead-Acid/Sodium

Sulfate Battery

Renewal

Project

Sodium

Sulfate for Battery Renewal (Click for Prices, Info.)

I finished restoring the batteries I got last month and a

couple of others. There was tremendous variation in initial performance

after draining the acid and adding water and sodium sulfate, one

battery seeming to be pretty fair after one or two charges. Two others

maintained only 8 volts at 10 amps for just a minute or so on the first

try, but one rapidly improved. The other seemed to get just marginally

better each cycle, slightly perking up in voltage and time, but never

really seeming to work properly.

Shorting out Shorts?

I tried for a while to burn out "shorts"(?) in some cells