Turquoise

Energy Ltd. News #34

Victoria BC

Copyright 2010 Craig Carmichael - December 1st 2010

http://www.TurquoiseEnergy.com

= http://www.ElectricHubcap.com

Contents/Highlights:

November in

Brief

(summary)

* A month of further development and refinement of the EH motor

Electric Hubcap System & Motor Building

Workshops

* Electric Hubcap Motors get Better and Better!

* EH Motor Testing: proving the efficiency and power; the motor

with adjustable performance specs!

* Magnet Rotors: Epoxy-polypropylene composite skin strengthens

magnet bond to rotor

* Welding bearing race hubs: preheating parts with torch

improves

hub-to-rotor welds

* Jigs, CNC drilling improve motors & speed making them

* Motor controller: Designing for serviceability is paying off!

* New Motor Controller printed circuit board designed - smaller

PCB uses improved A3938 chip.

* First motor workshop student completes his motor!

* Small business opportunity? for Victoria BC residents:

make

& sell Electric Hubcap motor coils, magnet rotors (sales

opportunities

per market demands).

* Making & marketing motor

components online to simplify making more marvelous motors

* Lower price

parts sources found: estimated parts cost to make an EH motor down

from almost $400

to under $300. (That's still buying parts at retail prices.)

* Lower cost for

workshops: $700 or less.

Better Blades for Windplants (just

some cool ideas... not a project)

* Residents object to nearby windplant noise.

* Here are ideas for quieter, also durable and

reproducible, windplant blades.

Torque Converter

Project

* Plan for modifying existing escapement converter -- 5-at-once

torque hits instead of one at a time should substantially boost

performance.

Pulsejet Steel Plate Cutter Project

* One-way air intake made, main parts cut out, welded... a

couple of parts left to make.

Electric Outboard Motor Project

* Steeper Pitch Propeller installed.

* On the water: Runs great, quiet!

* Movie Clips are on YouTube

(Search there for "Electric Hubcap Outboard" or "Turquoise Energy".)

* not 'speedboat' as prop is 'stuck in first gear' with motor

using only 1/4 power at its max RPM.

* but it should move a considerably larger boat just about as

fast as

the small one, drawing more on its available power.

Turquoise

Battery Project

* Latest carbon electrode backing experiment: hexadecane &

graphite.

* Some Behind the Scenes Battery News... and of course an

accompanying editorial.

- new developments in lithium and nickel-iron

- what the slippery big oil people try to get us to

believe, and to not realize, about bateries.

Newsletters

Index/Highlights:

http://www.TurquoiseEnergy.com/TENewslettersIndex.html

Construction Manuals for making your own:

* Electric Hubcap Motor

(latest rev. 2010/09/xx)

- the only 5+ HP motor that can easily be made at home?

* Turquoise Motor Controller (latest rev.

2010/05/31)

- for the Electric Hubcap. (Probably there are commercial

controllers that would work, too.)

* 36 Volt Electric

Fan-Heater

- if you're running your car on electricity, you'll want a

way to defog the windshield and keep warm.

* Lead-acid batteries: Sodium Sulfate 4x

longevity additive - "worn

out" battery renewal.

* Simple Spot Welder for battery tabs, connections (in TE News #30)

all at: http://www.TurquoiseEnergy.com/

November

in Brief

This month was devoted in large part to further

development and testing of various things related to working Electric

Hubcap motors and motor system components, rather than to experiments

with

partly working or new inventions that aren't ready to use.

Tristan Money finished his motor, the first "motor making

workshop" made

Electric Hubcap motor and (AFAIK) the first one not made by me, on the

18th.

With designs and techniques being continually improved and refined over

the last 2 or 3 months, it's also

the best EH motor to date and likely to be pretty much the final

design. He plans to use it for an electric motorbike and the project is

underway. I made a shop stand to hold the motors and I'm running some

tests on his motor.

On the last Sunday, a second workshop student came to help

make the next motor for the experience.

I got a steeper pitch propeller on the electric hubcap

outboard, dragged out the boat, and got things ready to sail. The

steeper propeller would push somewhat harder at lower RPM: the gas

engine was

probably around 5000 RPM, whereas the EH was 1750. On the first

outing (Saturday the 6th) with Tristan, the boat had decent speed, but

it wasn't

going

to make a big wake or get up on a plane. The motor loafed along near

its

maximum RPM drawing only 1150 watts of power (33 amps at 35 volts),

perhaps 1.4 HP. We

did a

couple of blurry (tricky camcorder) video clips - total 4 now

on www.youtube.com;

just search there for "Electric Hubcap Outboard" or "Turquoise Energy".

Still, the boat made several short trips with no hitches

and the motor performed reliably. It didn't even get warm, and the

controller stayed cold. If the

propeller wasn't geared down 2.75 to 1 in the leg I think it would

have given a

nice

fast ride. "Stuck in first gear" as it is, presumably it would work as

hard as necessary to push

a considerably heavier boat almost as fast as it ran the light 14'

aluminum one.

The

test against the induction motor outboard in a heavier boat was delayed

and finally scrubbed for the month

by preoccupations of the owner, by his boat having heavy marine growth

all

over it, which I scrubbed off in 3 or 4 sessions, and by

cold weather.

I used Bill Metcalfe's

homemade CNC drill/router machine to drill the 29 holes in three EH

motor

stators and the 9 in each of a couple of heatsink bars. Then I

purchased it from him. He had

been getting little use out of it in

recent years and it was rusting and dusting in his unheated shed. I

could see various possible uses for it. It will be valuable for making

the new motors and controllers, and for prototyping new designs with

more precision and accuracy.

We disassembled it, loaded

all the parts into his

van and my station wagon, and brought it here. Making floor space for,

reassembling and setting up the CNC machine was a small project in

itself. (oh

boy... another project!) It occupies 1/4 of my whole machine shop and

is

larger than I need, and the investment was all I could afford. But it

works! Making my own CNC machine would have been "problematic", as they

say.

Having the CNC machine now makes it practical to offer

pre-drilled

stators as "parts for

making Electric Hubcap motors", now listed on the web site. I hope

these will be the first of a growing list of DIY EH motor making parts.

It will take a lot of sales to recoup the cost... classes of electrical

students making motors, perhaps?

Of course, all the activity to do with the outboard and

with setting up a CNC machine ate seriously into

my R & D time. Running the motor making workshop didn't take a

whole lot of

time per se, but with the attention and thought to them, the motor

design and

construction techniques became more

refined as things progressed. I designed some small circuit boards to

hold the magnet sensors and a temperature sensor on the motors.

I didn't think I'd get much done on the

batteries or torque converter, but I did a small experiment in carbon

electrode making and came up with a good design for the next torque

converter prototype (only slightly modified from the current one but

should work much better!), and

I snuck in an hour

here and there to work on the pulsejet steel plate cutter and got it

pretty much together except the propane connection.

By the end of the month, the need for more motor

controllers, and for circuit boards for the magnet sensors in the

motor, were getting pressing, and I spent some late nights laying out

boards - the new motor controller board using the A3938 motor

controller and three little boards for the hall effect (magnet)

sensors, one also with a temperature sensor - not that any of the coils

have gotten more than slightly warm so far.

And somewhere along the way, I had an inspiration for how

to

make improved windplant blades, written up below - ways to make them

quieter, strong, replicable - which I don't have time to pursue. If

anyone is interested though, I'd be glad to go over it, and photocopy

some blade dimensions and shapes from a book.

Electric Hubcap System & Motor Building Workshops

I read in a newspaper that a Canadian sponsored "Around the World

80-Day Zero-Emission Race" of electric cars is in progress. It crossed

Asia from the Geneva starting point on August 16th, and hit Vancouver

November 12th en route to Cancun Dec. 5th to hit the World Climate

Change Conference, and back to Geneva in January.

It's a pity there's

no

"World's Most Efficient Electric Car Motor" contest, because I think

the Electric Hubcap would win it. I've said it before, but perhaps it

bears restatement:

1. The brushless permanent supermagnet motor is inherently the most

efficient family of electric motors.

2. Axial flux layouts with wide magnetic flux gaps are the most

efficient of those, and the Electric Hubcap has a 1/2 inch gap.

3. The lower RPM range of the EH (0-2000) results in lower running

losses, and having no brushes also reduces friction losses.

4. The donut shaped coils filled with core material to form fat "hockey

pucks" magnetize the maximum ferromagnetic core

interface, nearest to the rotor magnets, with the minimum amount of

copper wire,

for the lowest possible copper resistive

losses.

5. As well as being insulated between strips, the soft-magnetic iron

alloy nail gun finishing nail strips typically have poor conduction

along their length, further minimizing iron stray conduction losses.

(Even lower iron losses are possible, and feasible with capitalized

production methods... The ideal core "traditional alloy" form is even

thinner, individually coated iron alloy wires packed tightly together,

all

aligned straight up-down in the coils. If they were nanocrystalline to

much reduce hysteresis losses as well as stray conduction losses, so

much the better. I think the ultimate core is nanocrystalline ceramics,

which would have virtually no losses at all.)

6. For electric transport, the motor itself needs to be

carried around. A lighter motor is effectively more efficient. The

latest EH design, bare bones, weighs only 32 pounds. In contrast, my

7.5 HP

sawmill motor is about double that weight for just 50% more power - and

that is in fact much the smallest 7.5 HP induction motor I've seen;

typically they are considerably larger. Many radial flux permanent

magnet motors are smaller for their power, but their high RPM ranges

would lower their efficiency.

Performance Testing EH: the motor with adjustable specs!

Better than just saying how good it is in theory will be

actual tests to prove it. I thought I'd need a pretty fancy setup to do

so, but someone on a motor controller chat list (!) says it can be done

with some fairly simple techniques and measurements, and then calculate

some of the specs like efficiency from there. I've done the first of

these: the coil resistance measures to be about .064 ohms between

phases - almost exactly as calculated for the length of wire in the

coils and the resistance of #14 AWG copper wire. Since most ohmmeters

including mine only go down to .1 ohms, this was measured by applying

power to the coils from a power adapter, and measuring the voltage

across and the current through the coils between any two phases. I =

E/R, and also R = E/I. The voltmeter is much more precise than the

ohmmeter: .0001 volts.

For the next step, I had to turn the motor with another

motor and measure the generated

voltage at several different RPMs. That entailed building a stand to

hold the motor securely and making some way to connect it to another

motor. I made a stand from angle iron (to be C-clamped to a

bench) that holds a EH motor vertically, and drilled holes in a 9"

V-belt pulley made of sheet metal, so it can be mounted on an EH rotor

disk.

Then I used my radial arm saw with 2 or 3 smaller pulleys to

spin it, and recorded the voltages. (farther down) Then there's some

calculations and

some results, including efficiency.

Testing EH motor on the new motor holding stand as a generator,

Testing EH motor on the new motor holding stand as a generator,

using radial arm saw and various V-belt pulleys to turn it at different

speeds.

A 6 diode bridge for the voltage, and a power supply for the magnet

sensors

to get the RPM, were required along with the meters.

To get the maximum current, I need to be able to put a

steady load on the motor and measure the current how hot the coils get

after a while, but someone good at math can derive the horsepower

(roughly) from the acceleration of the motorbike now being made, so I

won't need to know or measure just how strong that steady load is.

Some interesting specs are different currents and RPMs

measured on the same motor with the flux gap set to about .5, .65 and

.8 inches. The farther the rotor is from the stator, the lower the

current at a given RPM, and the higher the maximum free-spinning RPM

is. Naturally, the torque, and the horsepower at a given RPM are

reduced as the gap increases. Within limits, the motor has "adjustable

specs" with respect to torque and speed.

The "Adjustable

Specs Motor" table:

No-Load Current versus RPM with the flux gap set to three different

widths.

(@ 24 volt operation - I really must treat another

supposedly "worn out" old car battery

with sodium sulfate for use in the shop so there's 36 volts handy!)

RPM

|

Amps, Gap .5"

|

Amps, Gap.65"

|

Amps, Gap .8"

|

200

|

2.0

|

1.8

|

1.4

|

400

|

4.5

|

4.0

|

2.6

|

600

|

7.0

|

6.3

|

4.1

|

800

|

9.5

|

8.7

|

5.9

|

1000

|

(not measured, max RPM not measured)

|

11.6

|

7.7

|

1200

|

|

13.9 @ 1150 (max)

|

10.2

|

1400

|

|

|

11.9 (max 1440)

|

One interesting thing I

might try related to this is to

increase the gap in the EH outboard motor. This would up the RPM

somewhat, and so the boat would go faster - up to the limit where the

torque stops being adequate to get the motor up to the higher speed

under load. I doubt if going to an inch or beyond would leave a whole

lot of torque and power.

The present gap is roughly .57" and the maximum RPM is

about 1770 (at 36 volts). If I upped it to .75", it might well go up to

around 2500 RPM. On the other hand -- Ooh that's fast!

Note: More on performance testing is farther down... I seem to

have accidentally split the text into two areas, with considerable

duplication, and I don't have time to correct it.

Parts!

But low losses and high performance are only one part of

the equation. Motors

need to be affordable and practical. With the strengthened magnet

rotors - improved twice in

two months - and generally

improving parts and construction techniques in all areas, the Electric

Hubcap motor is getting simpler and faster to make, and I have

confidence that it is also

getting to be rugged and dependable to a degree probably unmatched by

other

axial flux supermagnet motors.

The improvements

lead to the tentative offering of parts to

help make the motors. Some of them (eg, the stator) can be CNC

drilled. I'll be offering stators complete with turned, welded bearing

hubs on a limited basis. Other labour intensive parts (coils,

magnet rotors) can

perhaps be made by people who might like to start their own little

business.

(Any volunteers living around Victoria?)

Hubs - Welding

My biggest remaining qualm was that the welded hubs hadn't

turned out to be as strong as I expected welds to be, owing to the

weakness of cast metal and especially after the heat of welding. If

pounded a bit, the welds would break where they met the rotor metal.

The

welds themselves also tended to crack during cooling, which appeared to

be

a separate heat stress problem - probably related to the cast hubs

shrinking when heated by welding.

I was thinking that perhaps there might be some better

part than the 1-1/2" pipe couplings to use for hubs. But on further

reflection, that's not where the welds had been breaking - changing

the hub wouldn't solve the

problem. Changing the rotor disks isn't practical, unless perhaps one

brand

proves to be notably better than others.

On consideration, I decided to try pre-heating the cast

parts, as suggested at one welding store with agreement by another that

it should be helpful. Perhaps that might pre-shrink them, or at least

be an advantage. I used a "swirljet" propane torch to preheat, and

though I couldn't get all that metal glowing red, it would have been

much more than warm. It was the best I could do at that moment. Then I

welded, using lots of stainless steel weld, all the way around the

circle.

That seemed to do the trick. I did two rotors, and

considerable hard pounding with a hammer didn't break the hub away from

the rotor or otherwise seem to have any effect on either of them. I

stopped short of probably breaking the rotor or hub themselves, or

seriously mushrooming the edge of the tenon, with the hammer. (One of

the rotors already had a minor crack, that probably

developed during the welding. It seemed unaffected by the hammering.)

Unless there are future problems, I'm calling the problem solved,

providing the preheating is used and the hub is welded all around with

the stainless (or special cast metal) welding rod.

Hubs - Turning - CNC Lathe?

Another small concern is getting the hubs lined up true

with the rotors so the rotors sit absolutely straight. With a clamp and

careful welding they're 'good enough', but ideally they would be welded

on and then the races would be turned, but I can't fit the finished

rotors onto the lathe. The answer to this must be either a special

plate that would allow finished rotors to fit onto the current lathe,

or a bigger lathe. (...and just where would I put that?)

Later I figured out a way to mount the rotor so the outer

face (only) could be turned after assembly. This has proved to be vital

as the hub, at the outer tenon end, so carefully turned to exact size,

seems to distort and

shrink a bit during welding, and the bearing races won't fit in. It

would

seem that the outer tenon can and should be turned after the rotor is

assembled. That should improve alignment. (Hub shrinkage also explains

why the welds are prone to cracking as they cool, and shifting

alignment during welding despite the hub being securely clamped to the

rotor.)

My latest thought for a solution to getting the rotors

onto the

lathe facing the other way, since I'll probably be doing a lot of

rotors, is to cut 1/4" off the lathe bed, thus making the 5" radius gap

zone just that vital little bit wider. Then nothing else is needed.

Now I'm thinking... A CNC lathe to turn the hubs

automatically

would be ideal. But isn't it just a matter of the tool moving against

the spinning part? That would mean a minimal CNC lathe could just be a

CNC

lathe tool turret mounted on any old lathe... even mine. In fact, it

would seem it may be just a matter of replacing two hand cranks with

stepper motors. The hard parts would be (a) getting the cutting point

set to

some "home" so it's moving from a known reference point relative to the

hub and (b) in my

lathe, there's some play in the threads: the position doesn't start

going backwards to the previous direction until this play is taken up.

That would make for uncertain positioning by the computer, which can't

account for that.

Rotor: Magnet Attachment Improvements

After having another magnet fly off a rotor in October I

realized

first that the epoxy glue I'd been using loses its grip after a couple

of years, and then further that something more than just gluing would

be best regardless. The problem was slight when the motors originally

were

supposed to turn with the car wheel, where they would never go more

than about 1200 RPM (at 120 Km/H on the highway with 13" wheels), but

it increases with the square of the speed. It would seem they want to

go up to somewhere around 2000 RPM when spinning freely. This time I

used a liquid epoxy resin as glue. Then I coated the whole

rotor and the magnets

with a thin layer of epoxy, which gave 'glue' around and going up the

sides of the magnets, rather than just a layer

underneath.

Still, I wrote last month that I wouldn't want to be

around if my 2000 RPM motors were turning at over 3000 RPM. At 3200 RPM

the centrifugal force would be 10 times stronger than at 1000; at

5000 RPM, 25 times stronger. But

these are being billed as "DIY" motors, and what people might do with

them in experimentation is unpredictable. Someone with no tachometer,

or unaware of the danger or not even knowing the motor specs, might,

eg,

boost the voltage to 48 volts or more and actually get it turning at

3000

RPM or higher.

Owing to this, and on general principles of strength and

durability, I decided the magnets needed to be attached even better. I

decided to do polypropylene-epoxy composite, and tried it out on the

outboard motor's rotor. "PP" cloth is lighter and

stronger than fibreglass cloth, and non-itchy. (Its great tensile

strength is why polypropylene is used for that rather coarse common

yellow rope.) Drawback

as a composite cloth is that it likes to hold its form and any creases

- it

won't lie

flat like fibreglass - it "floats up in the resin and so is harder to

work with". (It would also be

degraded by UV light, but what I found only comes in opaque black

anyway.) Although this information is on the web, nobody in town seems

to have ever heard of polypropylene cloth, much less has it in stock.

Unexpectedly, I seem to find myself at... well, near... the leading

edge yet again, even in such a 'mundane' area as 'fibreglassing'!

But at Capital Iron I found heavy PP strapping ("web") up

to 2" wide,

such as

might be used in

backpack straps, cargo straps, etc. Can't get more solid than that!

They had

it in both the marine department and the fabric department - same stuff

at somewhat different prices. (Aha!, it's true... boat owners

pay extra!)

I first planned to wrap a long strip around the outside of

the

rotor and cut slits in it, and fold the pieces over the magnets from

the outside edge. Then I would paste some around on the inside, slit

it, and fold it over the magnets from the inside. That would cover each

entire magnet and hold across much of the rotor surface.

But the PP strapping was too stiff to work with so easily.

I

ended up cutting a separate trapezoid piece for each magnet, and then

making an

aluminum form (x 12, with non-glueable polyethylene sheet liners) to

press the cloth flat against the magnets while

the

epoxy set. I put small pieces of steel on top of these, and the

magnetism pushed the aluminum pieces down firmly.

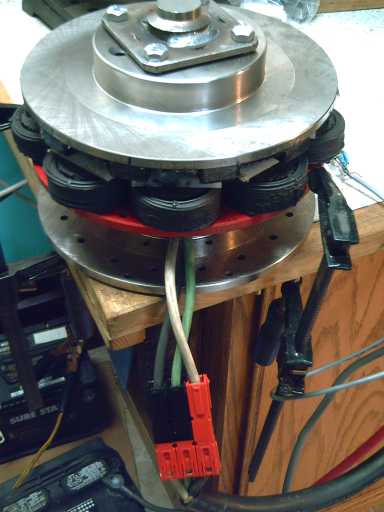

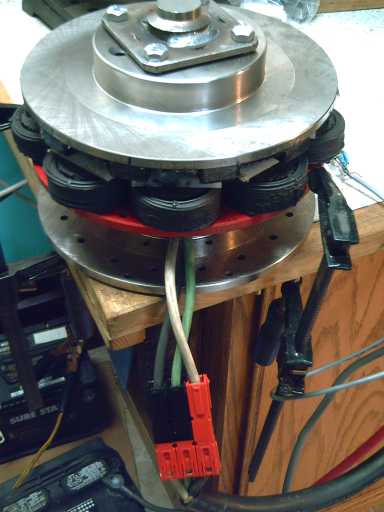

Covering the rotor with epoxy/polypropylene (re-enactment):

Covering the rotor with epoxy/polypropylene (re-enactment):

12 aluminum clamps (with polyethylene under to keep them from sticking)

held the stiff cloth pressed against the magnets

Finished Magnet Rotor (with another coat of epoxy).

Finished Magnet Rotor (with another coat of epoxy).

Lots of epoxy and the polypropylene strap/cloth pieces overlap --

I don't think there's any chance now that any magnets will come loose

at

any sane RPM.

On December first I inadvertently got an EH motor turning

slightly overspeed (2300 RPM) myself, during testing of its specs as a

generator. I was glad for the solid assurance no magnets would fly off.

I think next time I'll try to leave more of the strapping's rougher

surface rather than have so much of it 'flooded' with smooth epoxy -

after all, golf balls have little pits all over because it actually

cuts air friction. (See the 'better windplant blades' article for my

idea of the 'ideal' texture.)

Magnet Sensors

The only other thing that's been bothering me is finding a

better holder for the magnet sensors, one that can be 'mass produced'.

...But never mind, as I write I've just thought of a nice circuit board

arrangement to bolt to the angle bracket mountings!

Later in the month I designed these boards in Eagle PCB

layout program, ready to send off the Alberta Printed Circuits along

with both types of motor controller boards when the A3938 board design

was ready to try, which it was on November 29th.

Coil Clamp Bar Drilling Jig

When Tristan got to the nylon coil clamp bars, I cut a

heap of them from a nylon sheet on the radial arm saw in a few minutes,

and I had

him make a jig for drilling the holes in the clamps exactly 1.5" apart.

Two thumbscrews clamp the work in place, and they just need to be

loosened slightly to slide it out by pushing the next one in. It worked

perfectly, and made it a snap to drill 9 clamp bars for the 9 coils of

a motor.

Drilling the nylon coil clamp bars with 1.5" apart holes jig

Later I found it was much faster to use a variable speed

(cordless) drill to turn the tap to thread holes, and I did it also

with the six #6-32 MOSFET mounting

holes in some heatsink bars. The cordless drill has adjustable "slip"

settings so it won't snap the threading tap if it's accidentally turned

too hard. This is a great production speed-up!

I used 3/16" nylon for the bars, but with a 1/2" flux gap

leaving

plenty of room, I may increase that on the next purchase to 1/4" for a

longer threaded thickness.

The reasons for using nylon bars to clamp the coils down

are:

1) Bars instead of just nuts prevent laminate pieces of the coil under

the nuts from breaking off, which allows the rest of the coil to slide

forward and hit the spinning supermagnets. (Experience! But the coils

that

did that also had a weakness around the bolt holes, now eliminated.)

The bars hold across the whole coil including the wire, so it would

have to break into little pieces before it would come unclamped - and

even

then the coil of wire would be held back.

2) Metal bars would interfere with the motor's electromagnetism and

decrease efficiency.

3) The nylon makes for a friction fit, providing "nyloc"

lock nut function so the bolts won't work their way out.

The bolts are placed left and right on the coils because that's the

direction of

magnetic thrust, so it holds the coils stiffest. Otherwise a

vertical bolts and a vertical bar (that is, pointing inside to outside

of the rotor) would be preferred for cooling air flow. (...a

single mounting bolt might let the coil twist and work loose.) Also to

aid

cooling it's just a bar, rather than a big round piece covering the

whole coil.

With the CNC drilled stator holes and the jig drilled

clamp holes both exactly 1.50" apart, everything lines up perfectly and

tightly with no custom fitting, hole edge filing, or need to drill

oversize holes, which multiply the hours of assembly time, as often

happens

with hand-drilled holes.

First EH Motor Workshop Student Completes His Motor

Tristan Money got his motor running on Thursday the 18th,

after

about 38 hours of actual working time during October and November. (Yes

I was keeping track.) He did everything including the welding and

the lathe work (which jobs I had pretty much expected to do myself),

except for a couple of painting

jobs that I did between sessions just so the paint would be dry and not

hold things up. The magnet rotor has the polypropylene/epoxy composite

shown above.

But now

there's the CNC drilled stators, preheating and defined better

procedures for

welding and turning the hubs (...or complete, ready to use stator

plates for those who don't want to weld), the strip lengths chart

and simplified assembly techniques for the coil cores, and the jig for

drilling the coil clamp bars. Sometime soon there will also be little

printed

circuit boards for the magnet sensors to simplify their wiring and

assembly.

I anticipate all the improvements together will likely cut

around 14

hours off

the building time for future motors, making it somewhere around 24.

If ready-made coils could be made available, they would

cut off another 7 or 8 hours, altogether cutting building time to less

than half. In lieu of some success at making nanocrystalline ceramic

coil cores (so far elusive) that are also economically practical, this

would be dependent on someone wanting to make coils to sell.

Tristan's motor on bench. 32 pounds; It ran great!

Turquoise Motor Controller: Designing for serviceability pays off!

I ran Tristan's motor the next morning to take a few

sample

readings, and suddenly it quit working. The problem appeared to be with

the motor controller. I opened the case and wiggled the control wiring

sockets, and the sound changed. Having made it integrated into a wiring

box chassis and easy to dismount the motor

controller side piece, I did so. There are just a few chassis screws, 5

heavy wires and two small plugs to disconnect,

and out comes the whole controller to troubleshoot and repair (or send

for repair), without disturbing the 'junction box' wiring to the

outside.

I unscrewed the small circuit board, and found two pins of

the controls socket had been left unsoldered when I made it. Of course

I thought that was the problem and looked no further. On reassembly and

reconnection, it still didn't work right,

but wiggling the plug now had no effect. The unsoldered socket pins on

the

circuit board could have caused intermittent problems, but in fact none

had

previously been evident.

Next I tried measuring voltages

and found that a pin in the motor power connector wasn't pushed home

in its socket properly and had come disconnected. When I fixed that the

motor did violent

things.

Then I measured some resistances and found there was a

short-circuited power mosfet. I took the controller apart again and

replaced

it. Since it was mounted to the heatsink and was connected with wire

and not to a circuit board, replacement was pretty simple. Everything

worked fine after that. The original problem was doubtless the

improperly inserted

power plug pin - it probably made a spark that 'took out' the mosfet,

as

it came disconnected while the motor was running.

Problems including blown components are more likely in

high power circuits than in other electronics, and the units are

usually more costly. At Canadian Electric

Vehicles I heard blowing controllers was common in new installations

owing to incorrect

connections. And in my experience, with poor connections in any of the

high power wiring. Once things are properly installed, trouble

is rare.

With most

motor controllers I suspect opening, troubleshooting, disassembly and

repair would have

been a much bigger job, and I had to do it 2 or

3 times, so it saved me some grief. With a construction that's hard to

disassemble, test

components, and access for repair, it gets to the point where you order

a whole new $500 (or whatever) unit -

and possibly more than once before the problem is debugged - instead of

taking a few readings and replacing a $4 transistor.

Motor Controller

Tristan did up an initial schematic for the A3938 motor

controller PCB. I fixed up or changed a couple of things and layed out

the circuit board for it, "Rev 1", finished on the night of the 29th.

In looking a bit further into regenerative braking, I

realized it's not done the way I thought, and it probably would be

complicated with a permanent magnet motor. With an electrical field

creating magnetism, the field voltage is increased to raise the

generated voltage ("back EMF") above the battery voltage, hence

charging them with the rotating energy of the motor.

It occurs to me that with the "adjustable specs" EH motor,

one could have in the brake mechanism a means to reduce the flux gap.

This would raise the generated voltage and induce regenerative braking

at higher RPMs (which is where the bulk of the energy is anyway).

But that would certainly complicate construction of the

motors!

The CNC Machine!

The CNC drill/router machine maker/owner asked when I was

coming

to do the rest of the stators on the evening of the 3rd, and we

arranged for the next morning, so I got ready to go over there and do

the two I had on hand, and since I was going, I wrote a CNC drill

sequence for the heatsink bars of the motor controllers and a jig to

hold them in place for drilling.

I did the rotors and bars, then we had lunch, and he said

(again)

that he didn't want to go to too much trouble adjusting it for smoother

operation since he had to move it somewhere - it was collecting dust

and

rust, little used in the unheated garage. And, again not for the first

time, he suggested an option was to move it to my place. This time, I

had uses for it and readily agreed. We took it apart and brought it

over in my station wagon and his van.

A couple of days later I decided where to put it - a

corner of the machine shop - and removed the prior furniture and drill

presses, and started setting it up. It takes up 1/4 of the whole floor

space of my shop (ugh!). I did a considerable amount of work

on it and spent some money on air line, plugs and switches.

Then I thought that having someone else's machine set up

in my shop was eventually

almost bound to prove unfair or troublesome to one or both of us --

either he would

gradually start to feel he

was intruding to come over and use his machine and I would essentially

'acquire it by osmosis' as time went on,

or he would find a major use for it himself and the frequent use

actually would have become intrusive,

or he would take it back after I'd invested my time and energy and was

using it regularly and was counting on it. So I bought the complete

machine

off him. The

investment was more than I've put out at once for any single item

besides property taxes in many years, and it pretty much wiped out my

meager bank accounts, yet it was doubtless a great deal for an

"industrial

strength" CNC unit that I already knew does what I need it to do.

I can now do a better job making prototypes where

precision is important, make motors faster and more accurately for

testing and evaluation, and also "mass

produce" certain parts for the motors and controllers - initially

pre-drilled stators and heatsink chassis parts - and put them

up for sale on the web site, to make building EH motors and controllers

easier for others.

Torque & Magnets (how many is optimum?)

Last month I wrote that with 6 supermagnets (2" x 1" x

.5") on the EH outboard's rotor I could prevent it from starting to

turn

even at full power with my hand. I tried it again with all 12 magnets

and I couldn't hold it back. (These tries were just with my hand on top

of the smooth rotor with nothing to grab.) I still think 18 magnets

would be

overkill, though, and have no plans to try so many again.

Unexpected Motor Current Measurements

Before I had the DC clamp-on ampmeter, I had no way to

measure higher DC currents. Measuring up to 30 amps earlier had

apparently "done in" my good multimeter's test leeds, causing

measurement problems later on, especially with some battery resistance

tests. I was taking the AC current flowing in one phase, as measured

with my AC clamp-on ampmeter, and multiplying by the square root of

two, per my BCIT 1975 Electric Power course notes.

This month, I tried measuring both the DC and the AC

currents, and I found the situation was wholly different than I had

imagined. I ran a motor spinning with 3 amps DC coming from the battery

per the DC ampmeter clamp attachment and checked the three phase

currents. Much to my surprise, the AC current readings averaged about

4.3 amps! According to formulas, there should either have been 2.1 amps

AC (with 3.0 amps DC), or 6.1 amps DC (with 4.3 amps AC in each phase).

What is the answer? Either the AC meter doesn't like

pulse width modulated square waves and its readings are out to lunch,

or else the AC current

isn't in phase with the voltage, and so the volts * amps, volt-amps or

"VA", doesn't translate directly into watts, where the DC current times

the battery voltage does. The latter idea would seem reasonable on a

motor with inductive coils, but the former seems indicated by the fact

that by changing the range on the AC meter, the reading changes: on the

0-20 amp scale, it says (eg - they fluctuate) 5.67 amps; on the 0-200

scale, 4.6 amps, and on the 0-600 amp scale, it just reads 1 amp!

Assuming then that the DC current draw figures are to be

trusted over the AC, I have some recalculating to do! Further specs

testing is regardless coming up.

Motor Testing and Performance Categorization

So far, I've built the Electric Hubcap motors and measured a few

things, but they haven't been properly measured as to efficiency, total

power, etc, except in vague terms or in certain aspects. Now someone on

a chat list has said I can calculate some of the specs such as

efficiency with a few readings and without much special equipment. And

Tristan pointed out that horsepower can be derived from knowing the

weight of his motorbike plus load, and timing the acceleration from 0

to whatever. Only maximum steady-state currents and power levels really

need some

sort of mechanical load in the shop, and a temperature probe to check

the maximum temperature of the coils over time.

But minimal equipment isn't no equipment! Last month I

made the second motor controller, for testing motors in the shop.

On Nov. 26th I made a motor holding stand from pieces of

angle iron so that the motors would sit still and securely while

running. It can be attached to a bench with my favourite bolt-down

devices: C-clamps.

Finally I drilled holes in a large V-belt pulley (a

'solid' sheet metal body pulley) so it could

be attached to a trailer (motor) axle flange or to a rotor, and on

December 1st I fitted it out and got it attached. This is to

allow an EH motor to be turned by another motor in order to measure the

generated voltage, which when a motor is running is called the "Back

EMF".

Later I plan to make another stand to allow two EH

motors to connect, and then one can be used as a test load, eg,

powering car headlight bulbs, to test the other's motor characteristics

under load.

To digress a bit into motor theory, the generated voltage

increases linearly with RPM, and is subtracted from the supplied

voltage. This

is why motors accelerate quickly to a certain speed and then run

steadily at that speed. If the motor runs at 36 volts and really only

needs 2 volts to keep it running at top speed, it will draw lots of

current and accelerate rapidly until the back EMF approaches 34 volts.

The motor won't go any faster unless it's pushed mechanically (as

below), in which

case, if the voltage rises above the 36 volts of the batteries, the

push starts generating

power that goes backwards, into the batteries, recharging them.

Below is a table of the generated voltages for Tristan's

motor, which should be typical, with about a .65" flux gap, at

different RPMs

obtained with the V-belt pulleys I happened to have on hand that had

the right bore size to mount the radial arm saw. The two low RPMs were

turned by hand to a ticking clock and readings are approximate. (One

could wish for a couple more in-between figures, eg 400 & 1500

RPM.) The voltage measured was the 3-phase rectified DC voltage. Since

the diode drop across the rectifiers read .765 volts on the meter, this

figure

was added to the measured readings.

The 2300 RPM reading is interesting because it's the

fastest any one of these motors has ever spun, and because the voltage

is

over 36 volts, so this speed wouldn't be attained with a 36 volt supply

- it would put charge into the batteries instead of drawing it out.

With a wider flux gap, the generated voltage would be lower and the

2300 RPM might be attained. A 42 volt supply would probably do it, too.

At 2300 RPM with the motor mounted on a stand and clamped

to the saw table, everything seemed quite solid and there was no

serious vibration or other problem. In addition to voltage, it

generated a feeling of confidence that all was as it should be.

Following these tests, I ran the motor with no load at the

same RPMs (except 2300) to find the idle currents. Perhaps only the 840

and 1040 RPM readings are reliably precise.

RPM

|

Generated VDC (diode drop corrected: +.765V)

|

Running, No Load: DC Amps @ same RPM

|

60

|

roughly 1.5

|

.5

|

120

|

roughly 2.8

|

1.0

|

840

|

15.1

|

9.4

|

1040

|

18.8

|

12.4

|

2300

|

39.6

|

Mechanical Torque Converter (MTC) Project

I had little time to work on this in November, but some

time to consider it. In the first rendition of the 'escapement' torque

converter, the original light escapements had provided little thrust,

but when just 100g was added to each one, their force was strengthened

by a

surprising amount. I had made the 25 'fan fold' drum rim, and

spots for

six escapements, but tried out just three. However, these ratios, 25 to

3 or 6, meant

each escapement provided its pulse

of force at a different time, and (obviously) non-symmetrically around

the wheel. But part of the idea is to provide enough force at one

moment to overcome any slack, inertia and static friction and start the

wheel turning and the car moving. It is then assumed that the next

force pulse will come

before it has a chance to stop moving again, so it will accelerate. So

having

one

escapement at a time provide a push probably wasn't a very good idea.

My next idea was to change the ring of teeth to a

different shape that would increase the inner diameter and allow 27

teeth that would fit the same escapements. That way, three teeth at

120º intervals would 'strike' at the same time. Although the

average force would be the same, the force at that moment would be

triple. I didn't get around to making this new ring. Then I realized

that it would put the teeth farther from the

center, which would mean drilling yet another six

escapement mounting holes, probably almost overlapping the previous set

and maybe at or beyond the outer rim of the rotor. And theoretically

the escapements

would be just a slightly different shape for the new radius, though

they were probably close enough.

While considering these complications,

it dawned on me that another way achieve the same thing - even

better - would be to change from six

escapements to

five, evenly spaced (72º) around the rim, and the spacing of those

would match the current tooth spacing

and all five would act in unison for a quintuple pulse of torque. For a

while I didn't want to drill the escapement

mounting holes, as some of them would have to be behind magnets, and

the drill

and threading tap would surely poke through and damage the magnets. But

on further consideration... too bad for the magnets - it's a prototype!

I'll spray some paint in the holes to seal the magnet alloy from the

air

again. As it happens, I even made just five of the previously intended

six escapements.

Hopefully I can complete this and try it out in

December. There would seem to be reasonable hopes that this version

will move the

car well beyond the "just barely" of the last couple of tests (I can

push it harder by hand)...

which are now at least a couple of months ago.

Quieter, Reproducible Blades for Windplants

Denmark gets 20% of

its electricity from wind and exports power surplus to its needs to

Europe on windy days. Even here in BC several windplant sites have been

or are being set up.

I've heard

that a

prime objection of residents to

nearby windplants is noise, and a small one deployed near here by the

city certainly makes enough air/propeller noise. The shape

of windplant blades is 'optimized' in cross section for lift, and

smooth, which

one would think would provide the least noise and the most efficient

operation... but does it?

There are indications of at least two ways to improve

the seemingly "no brainer" optimum designs. First, research on the

notched flukes of humpback whales has

pointed

the way to quieter, more efficient cooling fan blades incorporating

notches and

ripples. (This was on TV a while back.) Second, textured surfaces (eg,

the holes in golf balls) can have less air

resistance than smooth ones and may be quieter.

These ideas could both be tried and likely used to

advantage. A windplant blade akin to designs of fan blades with notches

or

ripples might be quieter, and I think a blade surface texture,

especially such as "pebbly" (I visualize sand

size and somewhat larger rounded surface bumps - varying random sizes)

would

also help air slip past and quiet them. Any such measures that made a

blade quieter would probably also decrease wind resistance and make it

more efficient as well.

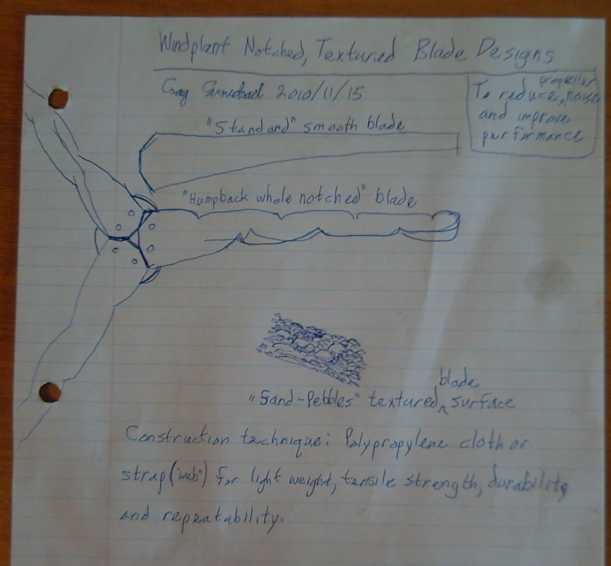

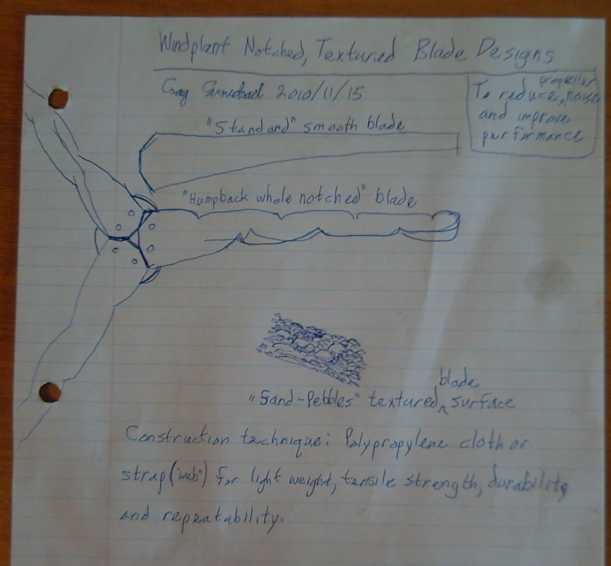

As a production idea, tough polypropylene cloth or strap +

polyester or epoxy (resin)

could make lighter, stronger blades than fibreglass + polyester or

epoxy, would

be easy to

reproduce in a mold or jig (even with odd notched shapes), and would be

more durable than

wood. An opaque "sand pebbles" surface layer might be applied

afterwards (to also provide UV protection), or the surface texture

might be incorporated into the mold.

Perhaps a single blade could be hand made, and a mold cast

from it for duplication.

First drawing of the design ideas.

First drawing of the design ideas.

(Date of conception is approximate - I added the text to the pictures

later, on the 20th.)

In spite of the intriguing possibilities I don't propose

to add this to my already extensive project list any time soon.

However, if anyone in Victoria would like to pursue it I would be

pleased to help give direction and support to the effort,

including typical blade profiles and overall windplant designs,

web

links and perhaps a lawnmower motor. There currently seem to be very

few sources for windplant blades

on the web (I only found one), and none for smaller, eg lawn mower

motor, sizes.

(Much less doing what are probably improved designs!) I'm not

sure if anyone has thought

of polypropylene-polyester composite construction either - perhaps not

a surprise

when the main fibreglass/plastic store in town hadn't even heard of it!

Pulsejet Steel Plate Cutter Project

I drilled out the telescoping holes, finished the floating

ball bearing one-way valve, and cut out most of the parts.

Pulsejet 'exploded' view.

Pulsejet 'exploded' view.

L to R: inverse conical exhaust tube, main combustion chamber, nut

& sparkplug.

Lower, inset, from bottom, the one-way air intake: ball chamber &

outer (air sealing) stop,

'floating' ball, notched (air passing) inner stop.

Assembled. Threaded exhaust (left end) allows for trying different

size nozzles.

Assembled. Threaded exhaust (left end) allows for trying different

size nozzles.

Then I welded them. I

burned a hole through the stainless tube by the spark plug nut, and

pretty much burned the "spark plug seat" surface off the nut itself, so

I cut the end off, got a new, thicker, nut, and re-did that. That

almost finished the main body.

Then I got busy with other things.

Remaining items were:

* a means to make the spark plug spark. There are a couple of ways that

this might be done. Tristan's motorbike engine yielded a spark plug

transformer, which itself now needs a means to activate it... but a low

voltage means.

* the propane connection. I picked up a .28mm nozzle with 6mm threads

for attaching it... to something. (I lost it somewhere and had to get

another

one.) I also got two 20 pound propane tanks someone had tossed in the

bushes on the boulevard, and a hose to connect the tank to the nozzle.

The outer end was a fitting with an outside thread that was

fortuitously the right size inside to thread for the 6mm nozzle.

* Some handle or way to hold it - pulsejets get red hot and more in

operation. One idea is to make a long handle that was also the propane

intake duct. Another is to put a long tube over the air intake - but as

that's threaded on, it might turn loose.

Electric Outboard Motor Project

The original guzzleine engine had worked with the prop

speed reduced about

2.75 to 1, because it ran at a high RPM (eg, 5000?) to get its 7.5 HP.

The Electric

Hubcap is a low RPM motor and at its maximum RPM

(1750) the

prop was spinning too slowly, because of the now counterproductive gear

reduction.

It's like having your car stuck in first gear - there's power to spare

for a truck, yet you can't get going very fast.

So the first task

was to fit a new propeller with a steeper

pitch. The steeper pitch prop

moves more water at a lower RPM. I

found an "11

pitch" Johnson propeller of the same diameter that looked like I could

make it fit,

propellers for the Honda evidently being out of production. I was told

the standard Honda one was "10 pitch", but the new one appears

considerably steeper - so I suspect my original was actually shallower,

perhaps 8 or 9.

It took a couple of days, but with some drilling, turning down and

sawing slots in a

shaft collar, turning a nylon "diameter matching fairing" (the prop's

diameter was

smaller than the outboard's) and other cludjing, it fit on.

Next was another water barrel test on Saturday the 6th.

With the first

propeller, the outboard had drawn 29 amps at 36 volts and churned up

the water "about so much" (for which the movie must be the record).

With the new one, the current rose only to 30 amps - but it did seem to

move noticeably more water. A little even slopped out of the bucket.

After the water barrel my motor making workshop student

Tristan

Money and I took it down to Esquimalt Anglers boat launch and took it

out in the sheltered harbor. On the 14' aluminum boat with two

passengers and

140 pounds of batteries (3 "size 27"), it drew 33 amps at about 34-1/2

volts (gradually dropping to 32 amps at 33 volts over the course of

several short

outings) at the motor's maximum RPM, 1740. That's 1100 watts, under 1.5

HP, and naturally with the motor loafing along like that the boat

didn't get up on a plane or even make much wake. The prop would have

been turning only about

630 RPM. But it did run well

and certainly moved

well above trolling speed. The heat sink bars

on the motor controller stayed completely cold to the touch. Once

I stopped on the water, opened the hood and felt the motor coils. They

were perhaps body temperature.

Tristan shot some videos with my camera, but not being

familiar with its idiosyncrasies, he didn't realize it was set to

"close-ups" and all the footage was quite blurry. (A couple of short

clips are nevertheless on

www.YouTube.com

- search for "Electric Hubcap Outboard"

there.)

Images from the movie clips.

Images from the movie clips.

The motor controller (I'm turning the speed control) was clamped to the

seat.

Another movie details the insides of the motor.

The owner of the induction

motor outboard said they also

had had problems getting enough RPM out of the propeller. It

seems they doubled the speed of the motor in the

induction motor frequency drive controller - from 0 to 60 Hz (normal)

to 0 to 120 Hz (well above the motor's rated RPM specs, I'm sure). They

also placed the motor behind the drive

shaft, turning the shaft with a chain drive. The chain sprocket gear

sizes

also pretty much doubled the RPM again, so they had 4 x RPM increase to

counteract the built-in decrease (Yamaha 9.9 HP). Neither of these is

an option with

the PM EH motor, driving the shaft directly.

I looked at the gears of the outboard and saw nothing that looked like

it could increase the prop speed short of making different gears to

fit. Later I thought: perhaps I could, with more or less difficulty

(probably more - the two shafts were quite dissimilar), reverse the

gears. Then the ratio would be 1 to 2.75

instead of 2.75 to 1. At only 1000 RPM on the motor, the prop would be

turning 2750 RPM... assuming the motor could get it going that fast!

That would be like being stuck in fourth gear instead of first gear...

or maybe fifth, sixth or seventh? If it isn't geared too far in the

other direction, perhaps the

speedboat is in there yet. But it would be a difficult job.

I guess I should just look at the silver

lining: it's

solid, quiet, and will get you out to... well, I'm going to say it

(hey, it's my newsletter... you can skim over it!)

...to

where I've been hearing

the RCMP now lie in wait to levy big fines against those who haven't

kept abreast of the

latest regulations, bought the latest required gear, acquired a

"certificate of competency" to run anything over 0.0 HP, and paid

admittance fees to trespass on private BC public waters. This should

chase most

casual boaters off the water, which may gradually kill pleasure

boating entirely the same way provincial park use has dropped off

with pricey "day use parking fees". I think our governments want

everybody to just sit at home and watch TV.

I probably don't have the details entirely

right, but just the thought of probably being pulled over by the RCMP

almost as soon as I get out on

the water would have

dissuaded me from doing an outboard if I hadn't already invested a lot

of time

in the project.

That I am not alone in disliking such "big brother" overregulation

is attested to by the fact that, when only boats

with outboards over 10 HP had to be registered - just the boat

registered - by

far the most popular

outboard size for use on lakes was 9.9 HP. The government could have

inculcated safety consciousness and safer boating practices as well,

and

more easily and cheaply, with educational pamphlets placed in marine

and

water sport related stores, without creating a whole new odious system

of regulation and enforcement. It seems our governments try to protect

people from themselves by attempting to control them, passing

restrictive laws

that impact on everyone in unforeseen - and sometimes unseen - negative

ways, to control some minor problem caused by a few, instead of simply

pointing out better ways.

Our "tolerant society" of the latter half of the 20th

century has become intolerant to the point where using one's "freedom

of speech" plus honestly holding "politically incorrect" beliefs can

land you in jail, "zero tolerance" is even a slogan, and official

advice "Just say no." even shuns common courtesy - what happened to "No

thank you."? It seems to me we are gradually losing rights and freedoms

in every direction and edging towards dictatorship.

Naturally I wanted to test the EH outboard against the

induction motor outboard, on the same boat drawing the same amount of

power from the batteries. The tests were delayed by preoccupations of

the owner

of said boat and outboard, the need to scrub heavy marine growth off

the unused boat, not to mention by very cold

(for the coast: -7ºc) November weather.

A single set

of three 'deep cycle' lead-acid batteries should last a couple of hours

at the low 30 amps current draw. Two sets (280 pounds) might last five

hours.

Again I reflect on how lack of - and indeed sabotage of -

commercialization of

economical batteries has been sabotaging economical electric

transport. For more on that, read the next section, Battery News Behind

the Scenes.

If I get batteries using the NiMn-Mn chemistry working,

you'd lift a cheap maybe

30-40 pound

battery into the boat for the trip instead of a 30-40 pound gas tank -

and on the ocean another

one for a spare for an extra 5

hours reserve.

Turquoise Battery Project

Carbon Sheets

The battery project seems to hinge now on creating

impervious, conductive carbon sheets that won't deteriorate, to connect

the entire outer surface of the positive electrode briquette to the

positive terminal.

The traditional carbon electrode uses "pitch", evidently a

mish-mash of higher numbered hydrocarbons. In a store one day, I saw

"Diesel Kleen Cetane Boost". This is mainly hexadecane, C16H34. (or

more

precisely, an alkane - a rather heavy, acyclic, saturated hydrocarbon

string:

CH3CH2CH2CH2CH2CH2CH2CH2CH2CH2CH2CH2CH2CH2CH2CH3.) It came as a black

liquid in a plastic

bottle. (It may, or

may not, be some additives that make it a liquid.) Although pitch is

quite thick and the "cetane boost" was a liquid, pitch is also a liquid

- simply a very, very

viscous one at room temperature. It needs to be heated in hot

water on the stove to become workable: hexadecane (evidently) doesn't.

But the lighter alkanes such as methane (CH4), ethane (C2H6) and

propane (C3H8) are gaseous at Earth's temperatures.

Perhaps it would do the same job - without the heating? I

mixed a small quantity with graphite powder until it was a thick paste

with quite a low electrical resistance - x 10s of ohms; upper x 1s with

the electrodes close together. Then I rolled it out into a sheet

between two pieces of polyethylene with a "mini rolling pin" - a yellow

pencil crayon that was handy. (Another color might work okay, too.)

Oddly, the polyethylene, inert to so many things, started

curling up. So I transferred it to an aluminum sheet, and left it to

see if it would dry and harden or otherwise change. The smell indicated

something was evaporating. It would have to be considerably

dryer before I could try to compact it.

The next morning, the sheet had evidently dried

considerably and was cracked in several places. It wasn't hard, but it

had become quite crumbly.

I waited a couple more days, then tried to compact it. It

remained very crumbly. Then I heated it to 450ºF in the oven for

75 minutes. No noticable change.

It was just strong enough to get some ohmmeter readings:

as low as 2.1 ohms with the leeds close together, and under 4 ohms

anywhere to anywhere. Interestingly, the same readings were attained

whether the sheet was on aluminum or plastic, which would tend to

indicate that much of the resistance is at the contact points rather

than within the sheet. But pushing on the meter leeds harder would only

have broken up the sheet.

I think the hexadecane may be a good ingredient to add to

the

pitch as part of a mix, but it doesn't have the right characteristics

by itself.

Battery News Behind the Scenes & Editorial

I continue to

hear things about the lamentable state of battery commercialization

today and to give them thought. In battery news:

* I heard Michael Moore tell Larry King that 1% of Americans "earned"

(my quotes) 25% of the nation's total income last year. I'll

tie that in with

that university researchers found a way to produce nanotubes that

magnified the power density of lithium batteries tenfold.

The potential

value of this work to electric transport is zero: It

was patented, and Chevron has bought the patent, another corpse to add

to their

graveyard of

murdered battery technologies. No one will be able to

manufacture

transport size batteries using the advantageous new technology - they'd

be sued into

the ground. The 1% control the economy through such means.

* In India, Ni-Fe dry cells, made possible by research in 2004 at

Bangalore University, are now being produced in research quantities and

tested in applications such as telephone exchanges. If they perform

well, more than one interest has ideas about producing them to sell.

(We may well see attempts to suppress the new aspects of this

technology as well.)

* Europe may adopt Ni-Fe batteries as a standard to replace Ni-Cd,

owing to the toxicity of cadmium (and lead) and Chevron's suppression

of the green Ni-MH technology.

The

Ni-Fe's will last much longer than Ni-Cd's, too.

* Ni-Fe battery standards are being reviewed and reinstated by IEEE.

Evidently Exide

lead-acid battery company long ago convinced IEEE to drop the

standards. With standards in place, Ni-Fe batteries may be purchased by

telephone companies and others who have large needs for reliable

storage, which could increase quantities manufactured and reduce

prices. Even the original Ni-Fe cells Edison developed were

substantially better than lead-acid for electric transportation, and

"the 1%" played a substantial role in getting them off the market.

And here's yours truly's inevitable accompanying editorial:

Regarding the first

item: if Chevron (more correctly, the unscrupulous owners

of big oil and transport in general via any of their subject companies)

can seize

enough lithium battery

technology patents they may be able to stop manufacture of EV size

lithiums altogether. (Then they'll tell us that lithium is too scarce

to squander on batteries.) How do these people sleep at night, knowing

full well they're working directly against what the world wants and

needs? What does it profit a man to gain fortunes of money and lose his

own soul?

It shows how patenting

new transportation technology only guarantees it can't be used. How

long

will these greasy reprobates continue to bleed us all white and

sabotage non-petroleum transport before people rise up and demand the

changes to the patent system needed to rein them in - and, oh by the

way, perchance to allow inventors to get paid in some way commensurate

to their

contribution to society rather than to starve - the supposed but

non-functional raison d'être of the whole patent system in the

first place?

Big oil's sabotage

of superior battery technologies includes not only buying up patents

and

companies that try to start producing better batteries, and leaving out

the sodium sulfate

from lead-acid batteries in order that they'll corrode too quickly to

consider as being truly viable for electric transport, but also

strategically

spreading propaganda that blows the weak points of the best

technologies out of all proportion while staying silent on the good

points and on the fact

that lead-acid has many worse features. As there is no major organized

group with an interest - or even the knowledge - to

counteract these gross distortions of the facts - in effect lies -

they

get accepted as being true in everyones' mind, steering research and

potential manufacture away.

I'll single out two much-distributed statements about

Ni-Fe for

scrutiny:

"Nickel-iron batteries have a very high level of self-discharge."

"Nickel-iron batteries have a low charging efficiency."

Without qualifying context these over-emphasized

statements effectively

give the impression that the speaker must be experienced in the matter

and know what he's talking about, and that after a few days, at best,

the charged battery

must surely have little useful energy left, and

that it is very wasteful of electricity to recharge it. Is that

why Ford and Edison wanted to use it for their great new mass

production electric car in 1914? Is that why somebody went to a lot of

trouble and risk to burn all Edison's Ni-Fe battery factory buildings

down?

Rational

qualifications and comparisons -- that Ni-Fe's

charge dissipates only somewhat more rapidly over the weeks than

lead-acid's does, and that

it's only

marginally less efficient to recharge -- are never made. Furthermore,

the lead-acid battery

will start to corrode unless continuously maintained fully charged

(it's under charge, using energy, all the time when your petroleum car

is running!) and

it should only be discharged 50-60%,

whereas the

nickel-iron recharges good as new whenever it's next wanted (even years

later) and it can be discharged down to 'empty' with no worries. Also

not mentioned: a battery is most likely to be used within a day or two

of

charging rather than weeks later anyway - self

discharge is a very minor issue.

The overriding truth

is that nickel-iron (Ni-Fe)

batteries, notwithstanding certain weaknesses, are excellent

batteries that last for decades -- and they could be much better and

cheaper if the

designs and manufacturing techniques were updated. New Ni-Fe

developments virtually ceased when Jungner and Edison stopped

developing them a century ago until the above mentioned dry cell work

in 2004 in

India.

The industry has similarly

been kicking away to undermine nickel-metal hydride, notwithstanding

its recent excellent success - nay, because of its success - at

running

electric cars in California:

"Lithium is the 'holy

grail' of battery research." (We smell money! Forget everything less

costly than scarce lithium - we've bought the mines!)

"Yes, those

Ni-MH batteries worked great in the EV-1, but battery technology has

moved on." (Lithiums probably won't last 1/4 as long, and we can use

the high price as an excuse for not making and selling economical

electric cars.)

Actions speak louder than words: Is Chevron's hoarding

(via its puppet Cobasys) of all the patents it can lay its hands on

related to this "worthless",

"obsolete", "too expensive", battery technology, and their point-blank

refusal to

allow it

(in useful car battery sizes) to be manufactured, or to be imported

from

countries where they can't control the manufacturers, consistent with

the 'casually' publicized statements?

Ni-MH batteries are probably 20-30% better than Ni-Fe

overall and evidently of

similar super long life. They probably cost somewhat - but only

somewhat - more than

20-30% more to produce. More important, having the technology and being

able to manufacture and sell it - economically - with a

slimy

oil company

sitting on a stack of relevant patents, are two different things. Even

for small dry cells prices seem to remain fixed at or above 1000 $/KWH

even in bulk - too high to hook up hundreds or thousands of them

economically for an electric

car - instead of dropping below $500 and probably well below.

I keep seeing lithium AA cells in stores now. The whole

idea seems

absurd: the dubious advantage of lithium is that its high reaction

voltage of three volts (theoretically) allows greater energy density.

What is the point

to making it into 1.5 volt batteries? The energy density advantage is

wasted, and they cost more to make and won't last as long as green

Ni-MH cells. I may have a suspicious mind, but this would seem likely

to be a

strategy to quietly phase out the superior, very long life, green Ni-MH

batteries. to

gradually get

them

off the shelves, off the market, while spreading slander about them

that will poison Ni-MH in

peoples' minds and prevent a revolt. Then before the prohibiting

patents all expire everyone will have forgotten there ever could have

been an

economical alternative available, to (deliberately) crappy lead-acid

and to

(pricey) lithium.

Many of them also seem to be single use, non-rechargeable.

If lithium is so scarce, why is it being squandered in single use

batteries? Something's fishy there. And for all the boasting about

"lasting longer" on the packages, they never seem to actually say how

many amp-hours they hold. I bet it's less energy than a single charge

of a typical Ni-MH cell!

http://www.TurquoiseEnergy.com

Victoria BC