Turquoise

Energy Ltd. News #35

Victoria BC

Copyright 2010 Craig Carmichael - January 3rd 2011 - Happy New Year!

http://www.TurquoiseEnergy.com

= http://www.ElectricHubcap.com

Contents/Highlights:

Month In Brief

(monthly summary)

3 Years in Review

(a look back at developments: wave power, EH motor and car drive,

batteries, Department of Progress, other projects)

Electric Hubcap System & Motor Building

Workshops

* Metal Stator: had unexpected eddy current losses

* New Plastic Stator: molded composite of strong,

lightweight polypropylene

mat & epoxy

resin - non-conductive so no losses.

* Toroidal Iron Powder Coil Cores: Commercially made

"T200-26B" core is EH's exact size!

Will

greatly simplify making coils, boost efficiency and performance.

* Testing motors to

determine specs.

* Calculations with above improvements indicate EH motors

will attain 95% efficiency.

* Motor making workshop

price reduced with easier to make motors: $650 (Includes

parts/materials for

motor, $300).

* MC33033 motor controller deficiencies uncovered.

* Making new A3938 motor controller (some problems/adjustments

remain, but controller works).

* A3938's current limiting drive works differently to typical

PWM - and more like a gas pedal.

Torque Converter Project

* More mechanical torque converter theory.

* 5-Star Escapement Torque Converter: best design yet.

* Testing Problems: Motor controller deficiencies and sloppy

mechanical coupling to car wheel have been

hobbling torque converter tests.

* simple coupling change for next tests.

Turquoise Battery Project

* 9V battery disassembly shows simple yet exacting construction

techniques

* Ni-MH battery price reductions: for $200 I may replace my car

battery with 30 "D" cells. (If you want some Ni-MH batteries too, a

bigger order would get us better quantity discounts.)

* Latest Turquoise battery design overview (details here)

Newsletters

Index/Highlights:

http://www.TurquoiseEnergy.com/TENewslettersIndex.html

Construction Manuals for making your own:

* Electric Hubcap Motor

(latest rev. 2010/09/xx)

- the only 5+ HP motor that can easily be made at home?

* Turquoise Motor Controller (latest rev.

2010/05/31)

- for the Electric Hubcap. (Probably there are commercial

controllers that would work, too.)

* 36 Volt Electric

Fan-Heater

- if you're running your car on electricity, you'll want a

way to defog the windshield and keep warm.

* Lead-acid batteries: Sodium Sulfate 4x

longevity additive - "worn

out" battery renewal.

* Nanocrystalline reflective rear electrodes to enhance DSSC Solar

Cells.(in TE News #28, 29)

* Simple Spot

Welder for battery

tabs, connections (in TE News #30)

are all at: http://www.TurquoiseEnergy.com/

December in

Brief

Thinking I had the EH motor design pretty much finalized

and having been given some motor equations and techniques, I spent two

or three weeks

trying to measure and derive performance specifications,

hoping to be done with it and move ahead on other projects. But some of

the numbers weren't making sense, and soon a fairly serious deficiency

I'd glossed over

came to light: the steel plate of the stator disk

was causing a rather strong electromagnetic drag load on the motor, so

the

no-load currents were rather high, reducing efficiency and overall

power out. I had expected the distance of the plate from the magnets

(over 1.5") would make this effect trivial, but it didn't.

Putting a 3/8" gap with pieces of plastic between the

stator plate and the coils helped quite a bit, but I wasn't very happy

with the arrangement. Then I unearthed the very first prototype EH

stator, 9 "reduced fill" iron coils cast in a polyester 'donut' ring,

and contrived to

couple it to a new magnet rotor, for the first time with no backing

plate. Now there was no steel except the coil core laminates, and it

was obviously better. With the steel plate, if you give the motor a

good

spin by hand, it stops in about one turn: electromagnetic drag. With

the plateless ring and partly unfilled cores, it would go about a

dozen. A few measurements showed the low no-load currents I was

originally expecting and

aiming at... but didn't actually have with the steel plates.

I decided a new stator design using plastic composites

(polypropylene mat and epoxy resin) would be

necessary.

So much for getting on with other projects! Being able to make a stator

of the exact shape and size I wanted would be an improvement, though.

The

motor is thinner, it protects the coils better (the wires stuck out

past the rim of the metal one), and it's also an end cover

of

the motor enclosure. It's also lighter, and the bare bones motor weight

is down to 25 pounds.

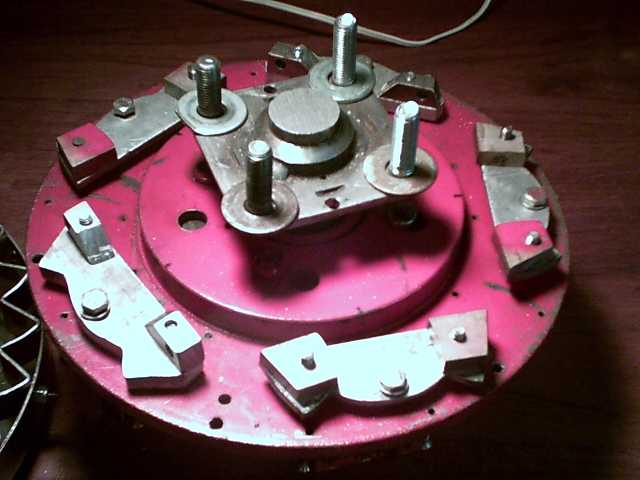

The new lighter, more efficient EH motor with the cast composite

stator.

The new lighter, more efficient EH motor with the cast composite

stator.

(Stator spray painted red with hi-temperature motor enamel.)

The old stator had gained some of its high efficiency from

a special "hollow" core. I also found a source for off-the-shelf

toroidal "hollow" iron-powder cores

of the exact right size and shape. Samples are coming. These will

not only improve efficiency, they'll make the coils, and hence the

motors, much easier to make.

Now no welding is needed to make the basic

EH motor, and the machined bearing hubs, now molded in, are easy to

make on any metal lathe - or for me to supply through the mail -

eliminating a prospective motor builder's need for a lathe. The coils

are also much faster and easier. Only casting the stator - probably -

takes more time than the extra turning of the hub and welding it to the

metal stator did.

I did get a couple of other

things done. One of

them was the small amount of work needed to finish the "5 Star" version

clock escapement torque converter. I took it out to the car and tried

it with the wheel jacked up, but I also took out the current probes now

that I had the DC probe,

and found out the motor controller wasn't letting the motor get enough

amps to develop more than around 1/3 power. In addition, I

finally realized that play in the coupling to the car wheel has been

robbing the wheel of receiving much of the force from the pulses of

torque the converters have put out. It's been

"hobbled" like that for all of the

torque converter tests from day one! When I figured that out I was

disgusted and I disassembled everything and took it all inside,

including un-installing the motor controller. The torque didn't feel

much greater than last time, but later I regretted not at least trying

to move the car on level pavement. I think now it's a very good design

- it might have done something relatively inspiring like take the car

across the parking lot.

Along with that, I started visualizing better more refined

designs for a similar torque converter that would last a long time -

this prototype is probably good for a few miles at best, seeing hte

aluminum dust it emits when it's going.

I burnt out the shop motor controller during motor testing

owing to a motor

short circuit problem, and I put together a PC board with the new A3938

motor

controller to replace it, which was after all on the project list. In

testing it, the

chip got burnt out and I didn't get it working. In light of that, the

controller from the car was needed for further motor

performance testing. More and better motor controllers are now assuming

a high priority. Tristan removed the minuscule dead 38 pin chip and

soldered

in a new one, and on the 31st the new controller was working, but soon

burned out again when highest current was demanded. Some adjustments to

the maximum allowed current seem to be needed.

Another thing I did was to try baking another gooey carbon

pitch/graphite sheet, and I found out that if you cool the sheet off in

cold water, the aluminum that's glued solid to the sheet at room

temperature peels off relatively easily. Putting it

in

the freezer should work even better.

Being able to liberate the pliable sheet

probably makes it a workable electrode contact sheet, and probably much

the best

solution yet. Workable salt electrolyte batteries seem a good step

closer. However,

I didn't have time to try to actually put together a battery, much less

run tests on it.

3 Years in

Review

As I begin the fourth year of the Electric Hubcap and

Turquoise Battery projects, started almost from "Happy new year!" in

2008, perhaps a look behind is in order.

I started my 'green energy' inventive career by creating

some

designs to generate power from ocean waves in spring 2006, improved

over designs I'd seen in March, and as usual

in trying to create something new,

I got

enthusiastic lip service from some

quarters, incredulity and scorn from others, and no support at all from

anywhere. You would

think the government would enthusiastically assist, and businesspeople

would grab up, a new type of product that nobody else had previously

made, to be there first. But most of my fine inventions, even when

completed to at least a good demo state, have fallen victim to complete

indifference on the part of

those with resources to help develop, foster or commercialize them. It

seems instead like no one today believes anything really new is even

possible - no wonder the middle ages lasted so long!

However, I made a wave power test unit, and a generator with

supermagnets for it. I got

the idea that the generator would make a great electric car motor.

In January 2008, I decided to pursue the electric plug-in

hybrid

idea, and to make designs that could be made at home or in small shops

so that those who liked the ideas could do them as "DIY" projects,

regardless of the indifference of government or the hostility of

capitalists. For the

first time, great ideas could be published and spread via the internet

and anyone, anywhere, could access and use them. They could

spread despite my personal semi-poverty. Others better placed and more

business oriented than I might turn the inventions into businesses and

then fortunes, and electric transport would grow from the grassroots. The products I

was about to lavish my time and energy on wouldn't go to waste like so

many of my others.

I finished the proof-of-concept wave machine on the cheap

regardless,

but

mechanical defects prevented a successful test. Ironically, the

generator I'd made had heavy magnetic cogging and was part of the

problem. I substantially re-did

the mechanics recently and got a non-cogging lawnmower motor for a

generator, but since then I haven't had time to finish it up

and try testing it.

Dual-float wave power test unit with mechanics mounted on bouncy

trailer -

Dual-float wave power test unit with mechanics mounted on bouncy

trailer -

one of the sources of slack in the mechanism that prevented a

successful test.

As originally conceived, it seemed to me that

supermagnets, used

in an axial flux motor, should have so much torque at such low speeds

that it could drive a car by direct connection to the wheel, and so the

main

components of the system would be the motor, the solid state motor

controller, and, hopefully, some batteries that were better than

lead-acid. But though the first good motor - after some poor but

gradually improving prototype designs over the summer - moved the car

in October

2008, the torque was insufficient to be practical. It finally dawned on

me that it was actually

limited by the weaker field of the electromagnet coils, not by the

supermagnets.

Car moving with directly connected Electric Hubcap motor, Oct 20th

2008

Car moving with directly connected Electric Hubcap motor, Oct 20th

2008

I made a better motor, but by spring 2009 it was evident

that driving a car would take something more than a fairly small motor

running at much too low a speed, and I got the idea of a

magnetic or mechanical torque converter. A workable magnetic design

proved elusive. The oscillating masses theory of mechanical torque

converters and workable mechanical designs

proved to be two different things (also for others who've tried

recently, though Constantinesco's 1926 design worked well), and it

wasn't until the last months

of 2010 I found a workable design concept - the "clock escapement"

inertial masses torque converter. Even then, continuing motor

improvements and tests, and other needs, kept the construction and

testing work down to a snail's pace and prevented a working design

until December 2010. It sits ready to test, a couple of hidden problems

that have been in the test setup all along having just been identified.

One

is 'fixed' for a prototype test, the other will soon be solved by a new

motor

controller using a more advanced motor controller chip (A3938), finally

working December 30th.

On that subject, when I started I didn't realize there

were off-the-shelf 3-phase brushless motor controllers, or chips for

the purpose, so I designed my own from six various logic and driver

chips. I proudly put the design on the web in the fall of 2008, only to

be shown the MC33033 controller chip. I made a new controller out of

that and it seemed great. But a few weeks later I got a message from

Digikey where I'd bought it, saying it was to be discontinued. From

somewhere (web search?) I found the A3938. It turns out the MC33033 has

some quirks, and I belatedly recognized them at the same moment that I

had designed the A3938 PC boards and was ready to assemble the first

one.

In the course of all this I tried a number of layouts and

finally hit on a double row format with the high power components

bolted to heat sink bars and hard wired, with the logic/gate driver PC

board for whatever controller was in fashion bolted on top with

'standard' wire connections to the power components. The bars couple

heat through to bars on the outside with fanned-out thin aluminum

roofing flashing heat dissipation fins clamped beneath them,

eliminating the need for expensive aluminum extrusions.

And I did a complete integrated aluminum chassis layout

wherein all the wiring related to the motor system started or ended.

The controller occupied one side wall and could be removed for repair

without dismounting the box and cable clamps, and the whole box is an

an extension of the heat sink. The transistors hardly get warm.

Motor controller with controls on the chassis, for testing EH motors

in the shop

Motor controller with controls on the chassis, for testing EH motors

in the shop

Concurrently with the car drive system, in early 2008 I

started trying to create nickel-metal hydride batteries that could be

made at home, after finding that economical NiMH batteries big enough

for electric transport have deliberately been made unavailable -

suppressed - commercially. But I also had in mind the possibility that

being

new to the

whole field,

"unindoctrinated" as it were, I might stumble across something great

that others

had missed. In my ignorance I started seeing seemingly great

'overlooked'

possibilities, some of which were impossibilities, but I became

convinced the

whole field wasn't very well explored and that there were much better

possibilities than any current battery technologies.

As time passed my knowledge of batteries

broadened, and my

electrochemistry ideas started coming into line with things that might

actually be possible. I was still trying things nobody else was.

By early 2010 I had the outlines of a fabulous battery

chemistry, novel techniques for doing vital but seemingly very

difficult parts of the work at home, and the outlines of an excellent

battery construction. It seemed I had solved nearly all the issues...

at least in theory.

I decided to use dissolved salt (KCl) electrolyte instead

of acid or alkali, as the average reaction voltages are highest,

including the overvoltages, and it's a fast electrolyte.

I created a way to make -1.4 volt manganese negative

electrodes work, which it appears no one else has ever done, by using

egg albumin to raise the 'hydrogen overvoltage' so it can charge - an

idea gleaned from an obscure piece of 1962 research. By comparison,

iron is -.9 and metal hydride is -.8, and manganese is lighter.

Instead of just nickel for the positive electrode, I put

in a mix of nickel and manganese. The manganese charges from Mn(OH)2

[II] to potassium permanganate, KMnO4 [VII], an astounding valence

change of 5 at +.9 volts for fantastic energy density. The nickel,

charging from Ni(OH)2 [II] to NiOOH [III] or NiO2 [IV], mainly adds

stability instead of being the main ingredient. Graphite powder

increases the conductivity of the oxides, just as with the cheapest dry

cells. A couple of other treatments also prevent the permanganate from

migrating.

Thus the battery's electrochemistry provides a fabulous

2.3 volt cell with incredible energy density from mostly cheap

ingredients (except for the nickel). They should be cheaper than

lead-acid and shrink them at least fivefold with even more weight

reduction - there's the real battery revolution!

The last and most thorny problem - perhaps more thorny

than the electrochemistries - was that with salt electrolyte every

metal I

tried

dissolves - oxidizes - in the positive electrode. The common dry cell

has the same problem and from its carbon electrode rod I finally

realized that carbon/graphite conductive sheets were about the only

thing that would work. Making such sheets and getting a battery that

truly worked properly was

elusive. Again everything came to a near halt in the fall as I grappled

with the motor and motor controller development, testing and

improvement issues, but

before the end of 2010 I had the concept for a somewhat gooey, pliable

carbon sheet that should solve the problems.

Conductive, sealing carbon battery layer

Conductive, sealing carbon battery layer

As time went by working for progress I began to realize

that the chief problems with switching to clean, cheaper, renewable and

non-polluting power, including for transportation, were not technical

but social. Existing, proven technologies that were known to work and

could easily do the vital jobs weren't being employed or further

developed. I identified two main culprits that are preventing us from

rapidly achieving the world of our dreams.

The first culprit was vested interests. In the last

century and more, a very small number of unscrupulous and manipulative

people have

exploited quirks in our social and political structures to seize

economic

power and build giant economic empires. These are, for example, the

less than one percent - and probably far less than one percent - that

"earned" 25% of all income in the USA in 2009. That only left 75% for

2010 for everybody else, and 75% of that 75% for 2011, and so on. These

parasites

control the multinational corporations as pawns in their monopoly game,

and they are sucking the life blood out of our economies. We are at war

with internal enemies we don't understand and only vaguely

glimpse, so they win most of the battles. These people like things just

the way they are, because they know any and every truly progressive

change is going act

to cut their power and influence, and they stoop to anything to prevent

change, including both using the legal system to their advantage and

violent crime if nothing else works. Many people vaguely sense that

something is wrong, but it's hard to put a finger on it. I personally

was oblivious until I started working on electric transport myself. The

documentary "Who Killed the Electric Car?" plus the fact that I

couldn't find the car-size Ni-MH batteries those cars used available

for any

price (much less a fair price), and

subsequently finding Chevron Oil has acquired 125 metal hydride patents

and killed the technology as far as transport is concerned, started to open my eyes.

Their supporters all the way down the line likewise

instinctively realize that their jobs, businesses and lives will be

changed if they embrace new things, and react against them. Perhaps

typical of this gut reaction is one local business owner - himself an

inventor and in some areas more progressive than most - to whom I

showed the sodium sulfate salt packages for quadrupling the life of

lead-acid batteries, who said "I sell ten batteries a week. Why would I

want this stuff on my shelf?" (Remember that next time you have to buy

a car battery from a smiling dealer!) The factories are all controlled

by the gangster "elite", and every automotive shop I tried sells

batteries. No one in the whole transportation industry wants them to

last longer, or wants better types of economical batteries to come on

the market --

only every consumer.

The other culprit was that there is no department, branch

or agency in government to oversee what is going on, correct problems

or recommend legislation to correct problems, and to work towards

desired change, to foster even the government's own stated long term

goals and the future on behalf of

citizens and the public good. All the departments are concerned with

today and the

immediate future. The effects of the errors in our governing systems

aren't being monitored. No recommendations are made to the legislatures

for fixing loopholes that hinder progress, and that allow power vacuums

to occur and to be filled by greedy and power hungry manipulators.

For example, the patent system has been routinely used to

kill priceless new transportation technologies for over a century. And

inventors usually have no means of

getting paid for their work, either while they work or after

successfully creating a new product or technology. (Less than one

percent ever get paid -- and even more rarely because they took out a

patent.)

The whole idea of the patent publication system was so that inventors

would get paid for their successful work, while their fine new ideas

could

spread rapidly to industry. It has never worked, and it has never been

repaired so that it does. Blatant abuse of a dysfunctional system

continues

unabated, the latest affront

(AFAIK) being the murder-by-patent of a fine new lithium battery

technology, years in the making,

just weeks ago (again with

Chevron as the "hit man").

In addition,

anything that seems too far off is dismissed by government as being

"too visionary", however simple it may be, for example wave power:

That's for the future -- it won't make money or solve problems starting

in the next year or two. No

action is initiated to traverse routes to proceed from the present to

the desired future, even when that future is a stated goal of the

government, and even though developing the routes may in fact cost

pennies today for future rewards of millions. And often that desirable

future

could be much nearer term than anyone thought once the needed

development effort is applied - look how fast everything changed in

world war two, all simply for fear the enemy might get it first. We can

progress in peacetime too. The answers are so often right in front of

us.

What is needed is a "Department of Progress" or

"Department of the Future", charged with dealing with such matters,

working towards the government's long term goals, fostering creative

endeavors if they are deemed worthy, connecting product development

with research and with industry, and making progressive

corrections to the procedures and processes where things aren't working

right.

I first started with an idea for an "Inventors Society"

which

might allocate funds to worthy projects, funded by the government. I

corresponded about this idea with my MP, which led to contacts with the

minister of finance, in which I conceived and developed the idea of the

Department of Progress. I elaborated on it and the reasons behind it.

Finally I realized that, in the absence of the very department I was

now proposing, there was no one in the chain of command between me and

the prime minister of Canada, so I wrote to him with a by now fairly

well developed idea, and urged him to appoint an able minister to start

the department. Unfortunately I have had only an acknowledgment that

the package was received. If he doesn't wish to be the hero, I may have

to send another package to his successor and even the successor after

that

until someone in power understands that there's a gaping void in his

administration - in every administration today - that needs to be

filled.

Along my way, I also digressed into a number of shorter,

seemingly simple projects, and also various techniques that could be

employed in installing the motor systems in cars.

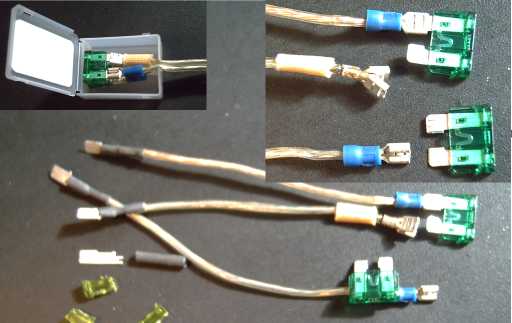

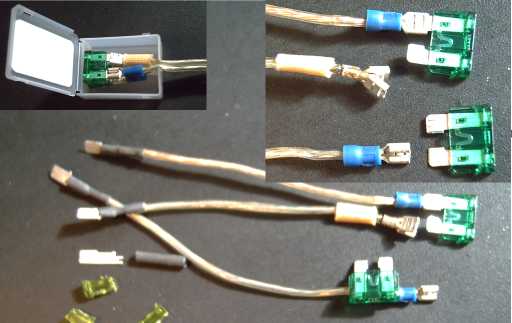

I found that by making a little fuse assembly one could

plug

terminal lugs the same size as fuse lugs into the car's fuse box and

re-route wiring as needed without changing any wiring in the car.

In particular, the turn signals could be run off "ACC" instead of only

with the engine turned on. That, probably an electric vacuum assist for

the brakes, and an electric heater-defroster, seemed to be the main

issues for running my own car with the engine shut off.

I made a 36 volt electric

car heater for the 36 volt

motor/battery system after seeing just one overpriced unit on the web

earlier. When I

had finished it, I searched again and found a number of choices for

lower prices. Perhaps I was wasting my time on that one!

I had an idea along the way

little related to energy: to create a web site where Canadians could

initiate informal 'polls' or 'referendums'. Currently governments claim

whatever they do is what the public wants, but there is no way to find

out what the public does want. Often those screaming loudest about

something are taken or mistaken to represent public opinion. Sometimes

these are just a small, highly opinionated minority. Other times they

are even organized vested interests with their own agenda, as when big

oil puts out one-sided propaganda and claim it comes from 'a concerned

citizens group'. Either way, they should not get their way by claiming

to be the voice of public opinion, and if the more polite silent

majority are allowed to speak, many things might start turning out

differently.

On DIY_EV_CARS@yahoogroups.com discussion list (which last

summer

mysteriously vanished without a trace -- could be innocent, but it fits

an all-too-familiar pattern for most anything to do with non-petroleum

transport), I learned that people were renewing lead-acid batteries

with alum. That sounded weird, but I looked up alum and found it was a

salt of sulfuric acid, which started to make some sort of sense. I

started experimenting, my battery work giving me some knowledge of what

I was doing, and I finally realized that sodium sulfate

was the

'correct' salt, diluting in the acid to sodium bisulfate, a sort of

acidic baking soda to perpetually keep the battery clean.

Alum, the first sulfate salt long ago found to work, also contains

aluminum or magnesium - 'impurities', and may

contain potassium instead of or in addition to sodium.

Battery renewal was

possible and good, but simply adding the salt to a new or near

new battery will make it last 3 or 4 times as long. I

worked out how much to put in. Of my four new or not-very-old

batteries that I added sodium sulfate to well over a year ago now, all

are still working great.

With sodium sulfate in my car battery, I've turned the

idle down very low - the battery is only charging when the car is

moving. Letting it run down a bit while waiting at red lights is now no

problem. This simple step has reduced my car's gasoline consumption

about 10%! (in mostly city driving.)

As mentioned, I found out that the battery

companies have known all about it for many decades, but they don't add

it to consumer batteries - the last thing they want is to sell better

batteries. I found some clever patents for impregnating it into

electrode separator sheets for the highest priced batteries. From there

it dissolves into the acid when the battery is filled. That way, no one

even in the battery

factory knows it's there except a trusted few.

Sodium sulfate additive: battery load/cycling test

Sodium sulfate additive: battery load/cycling test

And somebody

mentioned nanocrystalline ceramic cores for motor coils,

and that they could be better than iron cores. With little knowledge I

attempted to create some in the kiln. I thought I could improve on the

most

promising results and find what worked and what didn't... but I got no

decent results whatsoever to improve on. (I think a reducing or oxygen

free atmosphere is probably required, which can't be attained in an

ordinary electric kiln.) I also tried to buy

nanocrystalline alloy core

strips, but e-mails went unanswered and I got no farther at that than

trying to make the ceramics myself.

But there was an unexpected positive result: in trying out

nanocrystalline glazes, I discovered I could make leaded borosilicate

glass

with transparent nanocrystalline titanium dioxide, which could be very

useful for a

reflective rear electrode for dye sensitized solar cells, improving

their efficiency by altering and reflecting back the light that got

through the dye, so it was more likely to be absorbed on the way back.

This could improve the efficiency of DSSC solar cells by at least 25%.

I haven't given up on this idea, but I haven't had

any time to develop better solar cells as they deserve to be developed,

either... or even to make a whole cell.

Nanocrystalline borosilicate glaze DSSC reflector electrode

prototypes

Nanocrystalline borosilicate glaze DSSC reflector electrode

prototypes

I also saw videos of pulsejets in fall of 2010, and I

thought a small one might make a great steel plate cutter that needed

only propane and no oxygen. I started to put one together but only got

it half done before the motor improvements claimed priority over most

everything else.

Testing the motors this fall has led to considerable

improvements, including a composite stator of polypropylene mat and

epoxy resin to replace the steel ones. The steel turned out to be

causing considerable electromagnetic drag.

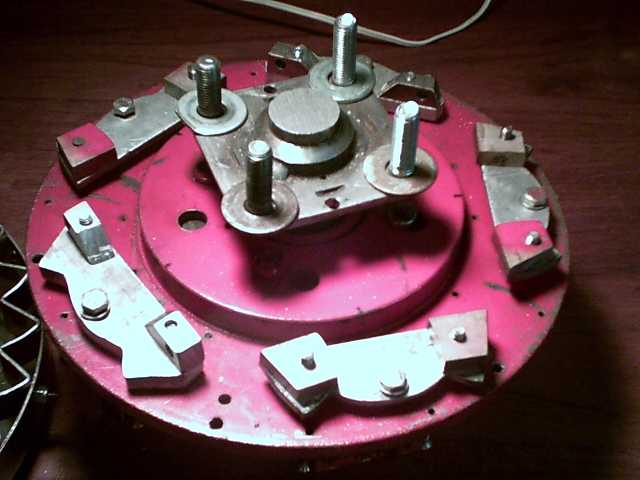

Motor with the new PP-epoxy stator (painted red) mounted on the test

stand

Motor with the new PP-epoxy stator (painted red) mounted on the test

stand

Then in the last days of 2010, I got a link to www.micrometals.com, who

it seemed actually made various cores of various powders and especially

iron powder. I downloaded their catalog and found a cheap,

off-the-shelf core

of exactly the EH motor's outer core dimensions. It was also a toroid

with a

hollow center, but I started to realize from one of the tests that its

shape seemed

beneficial as to flux lines and would have lower losses than a solid

cylinder, and that such an iron powder core should provide great

efficiency

perhaps equivalent to what I expected to get from the nanocrystalline

ceramics. Nine

are currently en-route to me to use in a test motor.

New toroidal iron-powder coil cores - same 2" O.D. x 1" tall size.

New toroidal iron-powder coil cores - same 2" O.D. x 1" tall size.

I started the motor project

(as well as the controller and the battery projects) doing most

everything either wrong or some needlessly hard way. After 3 years of

ongoing improvements, I've changed almost everything about the motor

except the supermagnets and the basic magnet rotor configuration,

having nine coils, and the basic axial flux layout with its resulting

'pancake' motor shape. Copper and core loss figures now lead me to

expect 95% peak motor efficiency with the latest exciting changes.

It'll be a very hard motor to beat - and it can be made at home!

Electric Hubcap System & Motor Building Workshops

A Motor problem and solution

I hadn't bothered to ground the frames of the motors -

after all, they're only 36 volts. No one would be hurt if there was a

short to the frame, and once the motor was mounted in a car, it would

be grounded through the chassis.

It turned out one motor had a short to the frame through a

coil mounting bolt, the coil having been mounted a little off-center,

which there was nothing to prevent. A piece of the ground wire of the

magnet sensors was bare (hey, it's ground anyway, right?) and it

touched the

frame of the in-shop motor mount. Zap! the coil voltage on the frame,

coming along the skinny ground line into the circuit board, fried the

motor controller. Absolutely nothing fries solid state circuits like a

voltage appearing on the 0 volts reference ground line feeding

virtually every component.

Now I'm specifying insulating sleeving over all the coil

mounting

bolts for all motors, I ground the shop's mounting frame to

the controller box... and I may put a small resistor on the circuit

board

feeding both the ground and the 12 volt supply wires to the motor

sensors, to eliminate or at least limit damage from a similar event in

the future. And if a motor isn't to be grounded through a chassis, a

fourth wire on the motor cable, grounding the motor to the

controller chassis, is probably in order.

Later it developed that the stator plates are to be

plastic. It might be a little tough grounding that, but no shorts will

conduct through it, either!

The new A3938 motor controller

In fixing the motor controller, it appeared that the

chips on the PC board were probably toast, along with a few of the

mosfets. Since I had just finished designing and having made the new

A3938 controller PCB boards, I decided that rather than make another

MC33033

board, I'd kill two ostriches with one brick and get the new design

working. But one ostrich tossed the brick back. The tiny chip

blew and I set it aside.

On the 30th, Tristan with his young eyes and fine

soldering skills came over and replaced the minuscule chip while I

worked on motors. Some problems

were found - a mistake in the schematic, and a backwards plug socket.

After some troubleshooting I figured these

out and got the new controller working. It worked great until a mosfet

blew for no apparent reason. After repairs the next day, it worked

again. I saw currents up to 35 amps during acceleration. Then I tried

to turn the control up quickly from a stop, and transistors blew again,

along with the chip. The current limiting should have prevented

destructive currents, but evidently there's something odd at work and

it needs to be set to a lower level.

The A3938's system of operation is interesting. To

compare: the MC33033 essentially provides a constant voltage dependent

on the input control setting. This means one must hold the 'gas pedal'

farther and farther down for faster and faster speeds. This is the

depth of push to go that speed, not the depth for a certain level of

power. But if the load is too high, the current limiting cuts in. This

simply cuts off the rest of each PWM cycle when a

fixed maximum current is reached. It doesn't drive the motor again

until the normal start of the next cycle, leaving however long an "off"

period until then. The switchover between voltage PWM and the current

limiting causes some weird effects, like sudden reduction of power. (I

discovered this as a cause of

low motor starting torque and low power that was going unnoticed in the

torque converter tests: all

the converters were being driven by a motor whose power input was being

stingily "rationed" by the controller. It puzzled me that a few times

in more recent tests, converters seemed to suddenly "take off" and have

surprising torque -- but only once the wheel was spinning, so it didn't

help get the car moving.)

The A3938 works on current limiting alone. A

variable maximum current is set by the amount of press on the 'gas

pedal'. When the motor current hits this value, the controller shuts

off, but only for a short, fixed period. Then it turns on again. The

"PWM frequency" varies in accordance with the current requirements,

dropping for higher currents as the "on" period lengthens.

Thus the average current can be much higher - almost to

the maximum limit, but without ever exceeding that limit (if it's

adjusted right). It seems like

a better system.

It's more like the gas pedal: the depth of push regulates

the flow of current - of gasoline or of electrons. With the current

being

regulated instead of the average voltage, the motor just keeps on

gradually

accelerating until the maximum RPM for the current or for the total

battery voltage is

reached.

Magnetic Friction!

In trying to determine motor performance I found there was

a big discrepancy between the DC and AC figures.

At 500 RPM, 36 volts times 3.0 amps said the motor was using 108 watts

of power... somewhere... with no load. But 6.8 amps squared times .064

ohms is only 6.0

watts of copper losses. Somewhere, it appeared 102 watts was being

eaten. I

found out where.

I already knew the motors stopped pretty quickly if spun

by hand, but not really why. After running some tests for a while, I

discovered

that although the coils

seemed little warmed, the steel stator plate holding them

was very

warm - even "hot"! Most of that 102 watts

of no-load

energy was going into heating the stator plate!

So I took an empty

stator (no coils but with bearing hub) and put it on an axle. I gave it

a spin

and it turned around about 40 times before coming to a stop.

Then I put it on the axle with the magnet rotor, with a

1-1/2" gap. This time, it took only 5 or 6 turns to come to a stop with

about the same starting force. In spite of the considerable separation,

the magnets were slowing it that fast. I turned the empty stator plate

over, which resulted in about a 2-1/4" gap, and it turned about 12

turns, certainly an improvement.

The first thing to try would be to get the stator plate

farther away and measure the idle currents again. Presumably they would

drop significantly. I got longer bolts, dismounted the coils and

replaced them with 3/8" of flat nylon spacers stuffed under them,

adding that much gap to

the stator plate. This was a considerable improvement in no-load power

consumption, and the motor would spin 2 or 3 turns by hand. But now I

was sure it should be better yet.

Meanwhile, it occurred to me that the pancake motor

(minimum 2-1/2" thick in my original theoretical concept) was

already getting

fatter, with 1/2"+ flux gap. If I had to add another, say 3/4"

more

space between the rotor and the stator plate, it might be more like a

cake cake rising than a pancake! Was there a another approach?

Both the wide flux gap and the need to move the stator

plate back are a result of the large depth of field of the 1/2" thick

supermagnets. Thinner magnets would have a lesser depth of field.

That would mean both a narrower flux gap and a reduced effect from the

stator plate "only" 1-1/2" away from the magnets. As a bonus, the

magnets and rotors would be *somewhat* less dangerous to handle. On the

other hand, would this be enough magnetic force without going to 18

magnets?

I decided to buy twelve 1" x 2" x 3/8" magnets and try out

rotors made

with that magnet thickness. The 3/8" thick size

cost more than the 1/2", but the prices will come way down for whatever

the chosen size is when lots of the motors are being made.

Another technique would be to build the stator plates from

transformer laminates where they cross the magnet sweep. Fine for a

factory, but not for DIY.

Finally, one could make them from an insulating substance,

perhaps a high temperature plastic like bakelite or nylon. What would

that do to the magnetic fields? I decided to try this instead and never

took the pricey thinner supermagnets out of the shipping box.

Stator Losses and improvements

That seemed to help. I calculated efficiencies up to 68%.

It was still way below my expectations. But now the plate didn't get

very warm, nor did anything else, so it seemed there were no more

'outstanding' problem areas.

The 'best compromise' stator plate gap, between perhaps

1/4" and

3/4", remained to

be worked out. More 'radical' solutions were conceivable: the thinner

supermagnets will

give less depth of field. But that might mean less power from the

motor. They might well be better matched by shorter coils, eg 3/4"

thick instead of 1". Then a gap to get the stator back to 1" distance

might be required!

Or the opposite: thicker coils might be employed. This

would move the stator farther away, but the magnetized coil iron would

on average be farther from the supermagnets, again reducing the power.

But perhaps that's all thinking inside a box? Another way

to change everything, and just by making a

mold, would be to make a stator plate out of entirely non-conductive

material.

This would be the ultimate of low-loss materials.

Composite plastic stator with no steel backing plate

However! With this thought, it occurred to me that the

very first Electric Hubcap stator prototype had the coils cast in

polyester resin, a polyester donut ring like the windplant generators

it was originally derived from. Although the coils had minimal steel

laminates, I could run it long enough to measure some of its

performance characteristics to see whether the idea was great, not

worth

trying, or a 'maybe'. During the night of the 18th-19th, I came up with

a way to set it up: Turn a wooden piece to make a center for the stator

"donut", with a hole in the middle for a bearing hub, and turn a

bearing

hub to match. This occupied much of the 19th, but finally it was ready.

I gave it a spin by hand and it went a dozen turns (instead of

one with the original setup or two with the 3/8" spacers under the

coils). I used the hall effect sensors Tristan had wired up, removed

from their mountings and screwed to the stator. It wasn't perfect, but

it ran. Boy, did it run! I didn't need any more tests to tell me that

it was a vast improvement, but I took some readings anyway. The flux

gap was perhaps 17mm, a bit wider than in the earlier tests before

spacing out the plate (16mm), and considerably wider than the

13mm in the tests with the spaced plate. Reducing it would have

required more wood lathe turning, and with a new lathe setup.

Even allowing lots of room of error in comparing different

varieties of apples in the various tests with somewhat different coils,

wiring, and flux gaps, the figures seemed conclusive: It took about 22

watts

from the DC supply to turn at a steady 500 RPM instead of the original

108, or 72 with the spacers. The AC motor current (total) was 4.1 amps

instead of 9 or 10 amps. At 1000 RPM, it needed 52 watts instead of 259

(original) or 206 (spacers) and again the AC current was way down - 6

amps instead of 13 or more.

Here I thought again of the polypropylene cloth with resin

that made such a nice, strong cover for the rotor magnets - whether

used with polyester or epoxy resin. (It would take a lot of resin, and

epoxy is pricey.) As a bonus, the stator could be sized and shaped

exactly to suit. I wasn't quite sure about attaching the bearing hub.

It

could be done by welding a flat steel plate to the hub, say 5"

diameter, that the plastic plate is bolted to. But it would be nice to

figure out a way that would eliminate welding to the hub piece. That

would require that the center of the plastic piece be strong enough to

simply press in the shaped hub... or to simply press the bearing rings

into.

Another nice touch might be if the stator plate was sized

to cover everything and fit in or on the outer shell-ring, hence

forming the outer end wall of the motor. I went with this idea, and

with molding the bearing hub into the plastic. as part of making the

stator.

This led me on another quest for polypropylene cloth on

the web. Searches showed that it seemed to be used for everything and

present everywhere (including those re-usable cloth shopping bags) -

except for sale as cloth. A zillion third-party

advertising sites with no products of their own begging you to take

their useless links to nowhere utterly dominated the results. (Simply

saying ' -alibaba ' in the search reduced the number of supposed "hits"

by over 500.) Finally I found it's used as landscaping fabric and could

be had as cloth or nonwoven mat for low cost at any local hardware or

gardening store. The only problem was that the material isn't

identified on the package. The "landscaping fabric" could have been

made of fibreglass, PVC, rayon, or hemp for all I knew or anyone in the

store could tell me. It should be identified 'PP' for recycling

purposes if nothing else.

Mold

Mold

Laying sheets of PP mat in the mold

Laying sheets of PP mat in the mold

Pressing the stator - PP mat and epoxy resin, with bearing hub in

the center, in the mold with plywood above and below.

Pressing the stator - PP mat and epoxy resin, with bearing hub in

the center, in the mold with plywood above and below.

I did the first ten layers of mat and the lower half of the hub, then

the second 20 layers and the top part of the hub later.

Later I finished by slopping on the rest of the thickening resin (kept

in the freezer 2 days) and spray painting with engine enamel.

I found that it took 30

layers of polypropylene

"landscaping" mat to get a 3/8" thick stator plate. When I got it

molded, it seemed considerably less stiff than I had hoped. It seemed

it would need 'ribs' at right angles to impart some stiffness to it.

But when I checked it again the next day, it had become very stiff and

seemed okay to use as-is. Perhaps a good idea anyway, but I'll skip it

for now - it's not vital. It's a prototype and the design may change,

which might make

any new jig immediately obsolete.

The amazingly light new stator, after discounting the cast

metal bearing hub which is molded into it, replaces the 6 pound disk

brake rotor with under 2 pounds of plastic composite. That should

bring total motor weight down to about 28 pounds.

Stator before painting

Stator before painting

Now it's tempting to think

of shaving off another 4 by

changing the magnet rotor to plastic as well, but the rotor's inertia

and solidity are needed for the torque converter and probably for other

motor applications.

The motor case outer barrel (whose 1.3 Kg isn't accounted

for in the current 32 pounds measure), could be lightened by a switch

from PVC to lightweight PP/Epoxy, saving at least a pound - even two by

making the wall thinner.

On the 30th I got the holes

drilled and assembled the

motor with the new stator and ran it with the A3938 motor controller,

also completed that day. Somehow, the bare bones motor weighed only 25

pounds.

New motor runs great!

New motor runs great!

I drilled the holes with the CNC drill program. I painted

the rotor with high temperature motor spray enamel. I'll also be adding

washers and a layer of tarpaper between the coils and the plastic

stator plate.

It seems excellent, so I'm now putting together another

one. In the middle of cutting out all those PP mat circles, it occurred

to me that if I 'marked' the circles with an xacto knife instead of a

pencil, it would save a lot of snipping with the scissors. I zipped off

another 18 circles that way in under 15 minutes. By the nature of

molded composites, I can probably use the (PP) bag of PP mat scraps for

another stator, too.

I've also turned the bearing hub, so It's ready to mold.

The first bearing hub wasn't quite straight though (I'll even the gap

by adding washers under each coil to suit), so I'm trying to come up

with a good jig to hold it perfectly centered and straight.

Powder Cores

I'd been wanting to find a way to avoid having to piece

together those cores of nail gun finishing nail strips - they add a

serious amount of labour to making a motor.

In talking in a discussion group I learned a bit more

about powder coil cores, and there was a link to micrometals.com, who

appears to be (or to own) the chief manufacturer of ready-made cores of

various

compositions. I downloaded a catalog, and discovered that although

there was no cylindrical powder core around the EH's 2" diameter and 1"

length, there were toroidal cores of exactly that size, "T200". I

decided that a big hole in the middle of an otherwise perfect core

shouldn't stop me from trying them out.

I phoned for technical assistance, and it sounded like the basic "26"

iron powder would be, though perhaps not the ultimate in permeability,

high saturation and low loss, a good compromise - quite serviceable and

economical. (And doubtless better than the nail strips.) I was asked

if I wanted a couple of samples of 26 and a couple of 52, which had a

little higher permeability. I said I needed 9 to make a motor. He said

he'd send 9 "T200-26B" cores. It turned out these are only $1.88 in

single lot pricing. I wouldn't be ordering less than 50's (only 5

motors worth), I'm sure.

If these work okay - and there seems no reason to

doubt that they will - the coils will be far easier to make. I envision

mounting the core on the coil winder with 3" diameter non-stick plastic

side 'washers' to hold the wires in place, mixing some epoxy and

winding all nine coils in well under a couple of hours, painting the

epoxy onto each layer of wire as it's wound. I might wrap a layer of

polypropylene around the outside. The entire coil would be dismounted

from the winder chuck complete with the center bolt that holds it

together and left for the epoxy to set, and there'd be nine sets of

winders to do all the coils with the same batch of epoxy.

An additional, and large, benefit is that the powder cores

appear to be very efficient (the manufacturer's specs are in the

catalog), where the nail strip cores were "good enough" but had

significant losses. The composite plastic stator and these cores

together with the other design advantages should boost the EH motors

into the singularly ultra-efficient (95%+) category I didn't previously

dare hope to achieve.

There's one more twist: Considering the magnetic

interactions, the toroid form of coil core may actually perform

better than a solid cylinder. The copper will magnetize the core in

an area more concentrated towards the sides - closer to

where the lines of force from the magnets actually are as they approach

or leave the coil's

vicinity. When the magnet pole is right over a coil, that coil is

turned off

anyway. And, the hollow core has 40% less iron to have iron losses

from. As long as the 60% iron that remains doesn't saturate, that's a

further considerable efficiency boost.

As an additional bonus, the toroidal cores will weigh only

220 grams

each where the

laminates weigh 265 plus whatever the motor varnish adds. The motor

will weigh about another pound less. Bare bones, the motor to

drive a car (now just 24 pounds) will weigh about the same as a typical

mounted 13" car tire.

The one thing I think I

need to watch is that evidently the iron powder cores are only good for

70ºC, so there's not a lot of point using high temperature motor

varnish to allow 150º or more. (In fact, baking varnished coils in

an oven at 225ºC with 70º rated cores seems like a very bad

idea.) I

will use a high temperature rated epoxy, though. If temperature does

prove to be a problem, they have the same toroid cores made from higher

temperature

spec materials. A motor that can go up to 175ºC can run at higher

power

longer than one that only goes to 70. On the other hand, the ultra high

efficiencies will make this a very cool running motor, so 70º

parts may well be just fine. And

with the toroid shape, cooling air gets to the inside of the coil as

well as around the outside. The polypropylene stator's epoxy is also

only good for

70ºC, but the coils will be mounted slightly off it with tarpaper

and washers, which again allows cooling air under the coils.

$1.88 each, super

high

efficiency and performance! ...and all that work I did earlier trying

to make

nanocrystalline ceramic cores! The professionally made iron powder

cores have very low losses per cc at EH motor frequencies, and the

toroid form would

appear to reduce cc's and further increase its efficacy, probably

accomplishing as

much as I had hoped to get with the ceramics. And they'll also

accomplish the other vitally important part of the job: making the

coils, and hence the motors, way easier to make.

Motor testing and performance categorization

I did considerable measuring of Electric Hubcap motor parameters in

late November and the first part of December, and

through the wonders of math and equations came

up with some seemingly bizarre and highly suspect figures for

efficiency and power (which also resulted in the plastic stator

mentioned

above). I've heard brushless motors can have "over 90%

efficiency" and had high expectations, but I wasn't seeing anything

like that for the EH motors. Here I thought I had created a great

motor, and I was embarrassed to find I was calculating efficiency

figures

like 55%

and even 45%.

My test setup was primitive, and I only tried a couple of

(unknown) loads at few RPMs, usually 500, 1000 and 1500. The "load

tests" were done by pressing my foot against the spinning rotor and

increasing the 'throttle' until I read some considerable DC amps coming

from the battery to maintain roughly the same RPM. Other

than being unsteady, providing no torque readings (to compare with the

theoretical), and the smell of burning

rubber from my running shoe, it seemed to work okay. It was expedient

but

not elegant.

But upon reading more 'stuff' on the web, I started

realizing some things that were good to keep in mind. The first was

that efficiency was so high only under the best conditions, and that

motor manufacturers evidently usually

rated their

motors at the peak point of efficiency: at the ideal high RPM and light

load. (Why

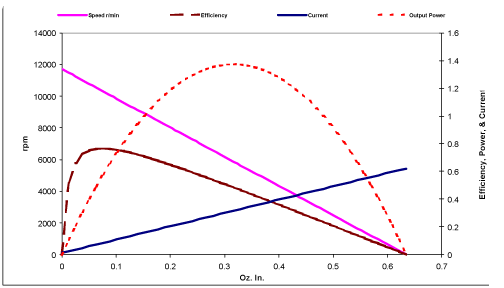

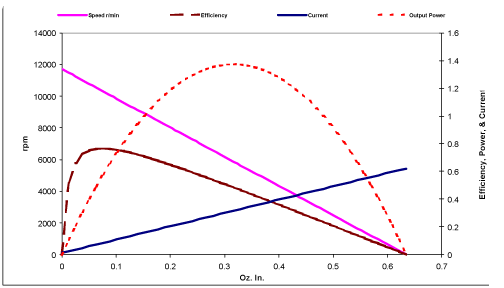

wouldn't they?) I found a document and graph that showed more real life

conditions:

Sample: performance graph of a small commercial DC PM motor.

Sample: performance graph of a small commercial DC PM motor.

Efficiency is highest, 75%, at very low torque, eg 10% of full.

At the highest output power - at about 1/2 speed, 1/2 torque, 1/2

current

- efficiency is 47%.

(Source: http://www.micromo.com/n390432/n.html)

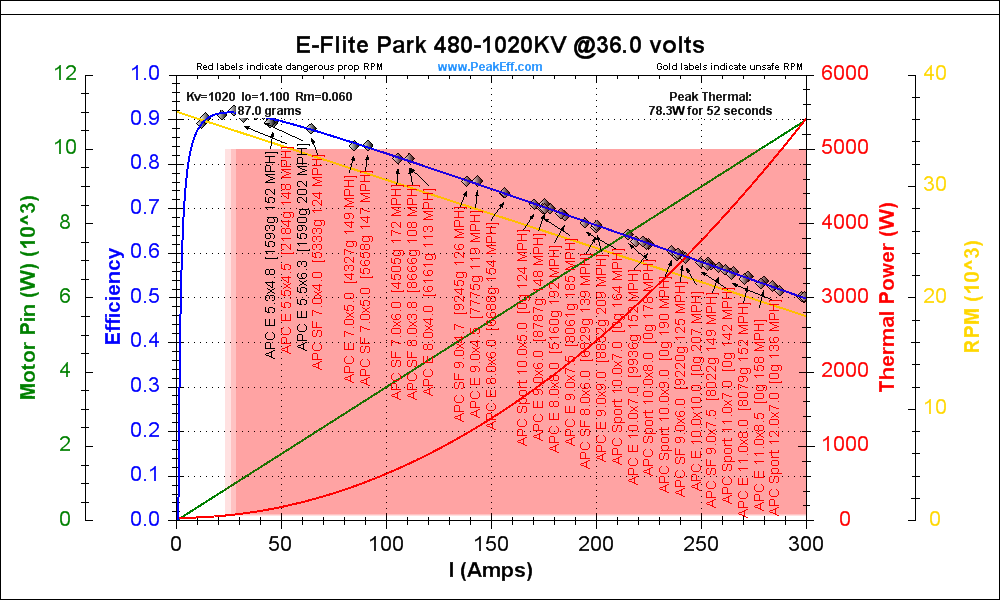

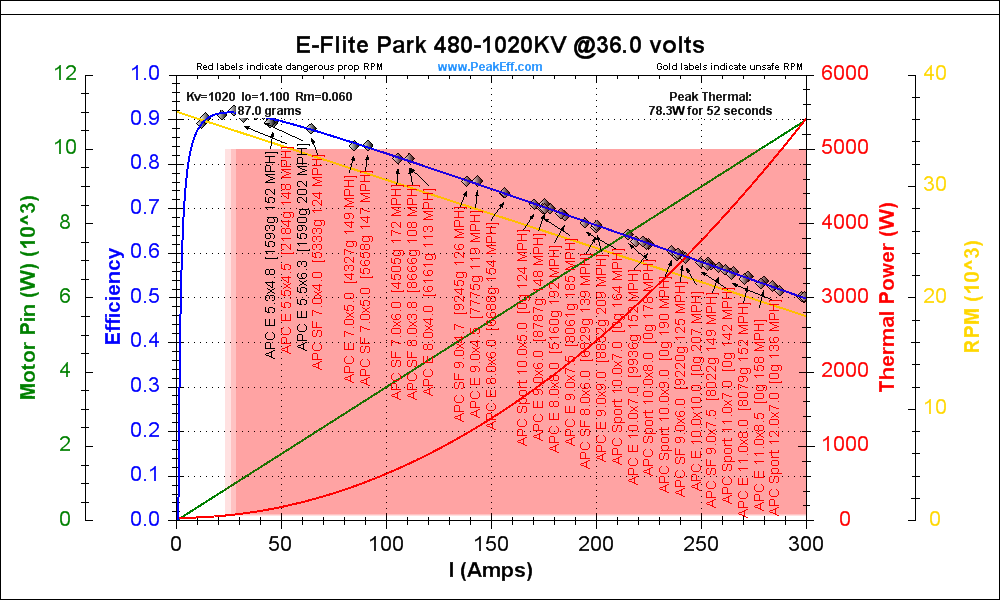

Later I found this performance graph,

Later I found this performance graph,

probably the most similar graph to what's now expected from the EH

motors except for RPM range.

It's a 36 V brushless DC PM model airplane motor (with just .06 ohms

motor resistance!).

At very light output power the efficiency is 92%.

At very high power where push tries to shove, it's just 50%:

almost 11000 watts in, under 5500 watts out.

EH operation will be restricted to the left half of the graph - under

5000 watts in -

with 95% peak efficiency, dropping to 75% at full load.

After seeing the graph and accompanying stats, the figures I was

getting began to look more

understandable - and reasonable.

At no load, a motor's efficiency is de facto

0% - whatever energy is used is used just to keep the motor

spinning. On the EH

motors, the current at no load with a steel stator was high enough to

prevent approaching great efficiency figures at light loads. At high

loads, the same extra current becomes part of a heavier I^2

loss figure, causing considerable extra copper

resistance

losses. The EH with the new PP/epoxy plastic stator is much more

satisfactory, and with the iron powder coil cores it will attain the

highest possible

efficiency standards.

Another problem was that "power in" is

battery volts times battery amps, and the DC current clamp was wildly

off at low currents and still reading 15% high at 10 amps, above which

point I have

to pull the Fluke DVM amp meter out of the circuit before it fries

(which is why I bought the clamp in the

first place), so

I have no other comparison.

Also

someone on a list said that with PWM you had to use meters with a high

bandwidth - that low frequency meters could read "wildly" off -

possibly

the problem with the DC (& AC) current clamp, although it also

reads higher on AC currents compared to the other clamp and to the

Fluke

meter on amps. At first I was

also just assuming the battery voltage was 36 volts, but at high

currents it was often under 33 volts - 10% lower. Power out is

calculated from the

motor AC amps times the torque constant times the RPM: it doesn't care

about the DC supply. If the figure for power in is, eg, 20% high, and

the output power figure is right, then an efficiency of 95% reads as

75%, and around 55% comes

out as being around 45%. The error is further compounded if the AC and

back EMF readings are on the low side. Without a motor load that will

tell how much torque the motor is

actually producing, I have no good check that the Power Out side

readings are consistent with the

Power In side.

I have an idea for a magnetic brake to give me this load:

take

an EH magnet rotor and get it near to the rotor end of the motor, in

line with it. Put a 2 meter long stick on it, sticking out 1m each side

- balanced. The magnets will attract to the back of the rotor and will

try to spin with it, but this rotor can't spin because of the sticks.

Put a weigh scale under one end of the stick. Each 102 grams the scale

weighs is one newton-meter of torque the motor is putting on the rotor.

An aluminum plate 'coupling' near the load rotor magnets (spinning with

the motor rotor) may work best, and will drag but not grab to the

magnets. Adjusting the gap adjusts the loading.

Having the essential idea and taking the time to figure out all the

construction details and make it may however prove to be to different

things. Without even looking it up, I doubt I could afford a ready-made

test brake.

Another person has suggested a simpler "prony brake",

simply

an adjustable circular clamp around the rotor with an arm sticking out,

with a scale on the arm as above. The work done heats the brake, so it

may smell as bad as the running shoes.

While having no figures for other motors of similar size

and construction to compare with, and figures of suspect accuracy for

the EH motors, after some weeks of all these frustrating

measurements, calculator banging, and frying a motor controller, I had:

a) actually improved the motor's efficiency by changing to plastic

stators, and made it more reliable by putting sheathing on the

coil bolts. (Now the sheathing will be made redundant by the toroid

coil cores.)

b) found that now nothing was getting even very warm, indicating there

were no more exceptional losses (and certainly saying nothing bad about

the

magnets as cooling fan blades - you can feel the air they blow).

c) a bunch of actual performance figures and calculations, done in the

first half of the month. These were to follow on next, but the change

to the plastic stator, not completed until after Christmas, makes most

of them obsolete, and the new ones will soon be obsoleted by the iron

powder cores. Hopefully I'll have some excellent figures next month.

Performance measurements and calculations

One calculation isn't rendered obsolete by the changes:

The coil resistance between motor terminals is a

crucial

parameter and measurement, and I measured it with a power adapter to

supply a small

power across the coils. The measurements were plugged into R = E / I:

.070 V / 1.10 A = .064 ohms... virtually the same as the

calculated resistance

based on tables of the resistance of #14 copper wire, the coil

connections, and the lengths of wire in the coils. Evidently one simply

measures the resistance between any two of the three terminals to get

"Rm". They all read about the same, but what happens with the third leg

when you only measure across the other two, is unspecified. Should the

resistance be multiplied by the square root of two like the current...

or should it be divided by the root of two because the legs are in some

sense in parallel? I think

and infer that one just uses the actual

reading, but it would be good to not

be left guessing about these

things!

I also think the EH motor is best here: lower than others

of the same

power and size because of the round 'donut' coil windings, magnetizing

the most

nearby iron, in closest proximity to the rotor magnets, with the least

length of

copper wire. The resistance would have been .072 ohms for square coils,

and more on

standard coils with "overhangs". The copper

losses - the biggest efficiency loss - are directly proportional to the

resistance -- motor resistance

times the square of the current.

95% Motor Efficiency

The

change to the plastic stator, and the coming change to iron powder

cores, pretty much blots out the meaning of most of the

figures measured earlier, except insofar as those figures actually

prompted those

improvements. Supermagnet motors often peak at over 90% efficient and

axial flux is the best, and we can calculate or estimate the following

factors that will make the Electric Hubcap's newest design better than

others:

* low loss iron-powder toroid cores that will also put the

maximum magnetic flux right where

it's needed.

Eddy current losses in powder cores are trivial, only the

hysteresis losses being significant.

Iron losses, based on the manufacturer's printed specs,

will be only about 10 watts at 1500 RPM.

* the new composite plastic stator eliminates most of the magnet rotor

drag caused by metal parts

Only internal nuts and bolts, and more distant mounting

hardware, remain.

* the wide (and adjustable) magnetic flux gap is known for high

efficiency (the axial flux advantage).

It also prevents gradual demagnetization of the

supermagnets, making the motors 'everlasting'.

* The lowest coil

resistances attainable for the voltage and size, .064 ohms.

At low loads, the copper losses are again only 15-20 watts

at 1500 RPM.

The total no-load losses at 1500 RPM will thus be only 10

or 20

watts (Cu) plus 10 watts (Fe) plus bearing friction plus air friction,

just a few

tens of watts. By contrast, they rose to several 100's of watts at that

RPM with the steel stator and nail gun strip coil cores.

15 or 20% load is likely to be the most efficient range.

15% load is 700 watts and losses should be only about 35 watts, so it

seems we can expect 95% peak efficiency. At my intended

maximum watts, about 4600, 75% might still

be attained, where other motors show graphs dipping to 50% or less at

their maximums. This is partly the built-in efficiency, and partly

that I'm limiting the maximum power to the best operating area so as

not to

generate too much heat or drain batteries needlessly quickly. (The

second graph above ("E-Flite") would also be minimum 75% efficient at

full load as shown if they limited full load to 150 amps of current.)

Mechanical Torque Converter (MTC) Project

More Theory

The oscillating masses torque converter is something like

a rotary version of a hammer

striking a nail. There is a longer period where kinetic energy is

gained,

the down swing, and then a shorter period where that gained energy

moves the load: hitting the nail.

In the torque

converter, the energy is imparted in such as way as to not stop the

motor each time but only to slow it a bit so the rotary motion can

continue - a 'glancing blow' or slip, which may either be a sudden

'impact', or

a relatively rapid but non-instant change.

Like simply pressing a hammer against a nail, the average

torque

of the motor isn't enough, eg, to start a car rolling up a hill. But

that average is divided into longer periods of little or no torque, and

shorter periods where that accumulated energy is spent to produce much

higher torque. The high torque hit starts the car moving, and each

subsequent hit gets it moving a bit faster.

In this, one must consider the periods and magnitudes of

the forces. If

the unit were, for example, to have a 20 second period to build up

momentum and then a 2 second period where that built up force is

applied to turn the wheel, no one would question that the car would

start moving, and indeed it might well be doing 'street speeds' after

the

two

seconds was up. But to store up this much energy the unit might have to

do something like

start a massive flywheel spinning and then let out a clutch to

engage it.

If on the other hand the unit had just 20 microseconds to

build up speed and then 2 microseconds to dissipate it, perhaps all

that would be noticed would be a high pitched vibration. The minuscule

stored force would be averaged out with the same effect as a steady

force,

perhaps too little to start the car rolling. On the other hand, no

heavy parts would be needed to hold the minute, short period energies

generated within such a system.

Something in between is needed. The smaller the forces and

the shorter their time periods, the tighter everything has to fit. At

some point, even the rubber tire will absorb the tiny torque hits and

present to the road the average, too small, force. We need forces of

sufficient magnitude and length of period that the car actually budges

with each hit of torque, but not so large and slow that excessive

masses have to be employed, with the car moving in perceptible lurches.

Hidden torque converter testing

problems

I've become aware that there are at least a couple of

problems in the torque converter tests that aren't the fault of the

torque converter.

The first one is the coupling between the torque converter

output rotor and the car wheel. A while back, I made a plate for the

car wheel with four 'extra' holes and some tapered pins for the output

rotor that would fit into them. But when I changed from the smaller

steel drum to the 12" aluminum drum, those pins didn't fit and I used

four 12mm bolts. They fit in the holes, but there's a lot of loose

play. I can see it in the videos I've taken: The

output rotor bounces back and forth relative to the car wheel, when

they should move as one. The

escapements must 'hit' the output rotor, but then

the bolts hit the edges of holes in the coupling to the wheel, then

bounce back. Larger, longer

period torque hits than I hope to employ would be required to overcome

all that slack. (The new "5 Star" escapement converter design has

the strongest, longest period escapement hits so far.)

On the 23rd, I took the plate off the car wheel and set it

on the converter. On looking it over, I realized it could easily be

made to

work. I had in fact drilled 12mm holes that just fit 12mm bolts. The

original sloppy, oversize holes were coupled to the converter. If I

simply bolted the plate tightly to the wheel using the oversize holes

instead of the small ones, the small holes would be left for the

pins to the converter, and the play would be virtually eliminated.

The second problem I discovered on the last test, on the

15th. On a whim, I took out the AC current

probe and the new DC current probe to check the motor currents.

(...along with all the heavy things I have to lug out and set up for

each test.)

Much to my surprise, the highest the AC motor current

readings got was 40 amps, and the DC supply 25. I've seen 80 amps AC on

the same motor with my original motor controller. (Multiply

reading by square root of 2 for actual

3 phase motor current: 40->57 & 80->113 amps.) I got another

battery and

boosted the voltage from the usual 36 volts to 48 - a bit risky with 60

volt transistors and having seen 12 volt spikes coming from the coils

on the oscilloscope. Even more to my surprise, the maximum AC reading

was still just 40 amps, and the unit had no more power!

The motor controller was set up to limit the current to

'150 amps'. But that's peak amps. It seems that the average

amps is far lower. 40 amps instead of 80 means 1/2 the torque,

and 1/2 the torque means lower speed with the same load. I'd noticed it

didn't

seem so energetic before with various torque converters for a load, but

with all I was trying to do whenever I ran a test, somehow it never

occurred to me to check the motor performance out. Thus my EH car

motor,

ever since I put that controller in, has been distinctly limited in

maximum

power. Since that was before I started on the torque converter project,

all the torque converter tests from day one have been done with

unduly

limited motor power!

It's funny how things like these can affect everything

for so long. I should of course have tested the new motor controller's

operating parameters when it was first working, and I should have

looked into some sort of tighter coupling to the car wheel. My only

excuses are that

that's what can come of having too many things on the go at once!... and that I didn't have a good meter for high

DC currents.

Now

I'm putting together the new A3938 motor controllers. It seems like a

better chip,

and the low current problem is likely to disappear. And I'll probably

head out on a new quest for a

better flexible coupling system between the converter drum and the car

wheel - I still don't see the four pins as being optimal. Some sort of

spline system might be better.

The new version of the converter is surely still the best

design... but

none of them had really fair trials.

The "Five Star Clock Escapement" Torque Converter

In the escapement torque converter, the motor rotor starts

to spin, spinning the escapements at its rim along with it.

EH Motor Rotor with 5 Escapements

EH Motor Rotor with 5 Escapements

But owing

to the points on the escapements meshing with the teeth on the output

rotor, they have to oscillate

back and forth in order to spin.

Output Rotor (behind) with 25 'Teeth'

Output Rotor (behind) with 25 'Teeth'

'5 Star' version finished December 13th

At low speeds they move freely and easily, but as

speed increases they have exponentially more and more

resistance to being

oscillated. They are continually pushed in one direction or the other

as they spin, a bit like pendulums on steroids.

All five escapements now operate at the same time: they

move alike, in unison along the 25 rotor teeth. In the previous

version, six escapements around the rim all operated 60 degrees out of

phase with each other. The new way gives a single quintuple strength

torque pulse (the total 665 escapement grams) just 1/6 as often as the

previous six single strength

pulses (133 g each) - a longer period with correspondingly stronger

hits: the better to couple the peak

force to the tire and road with less averaging out of the torque.

Where one or

the other end point of the escapement hits the next fan tooth is where

their direction of swing,

the oscillation, suddenly

reverses. For most of the oscillation, nothing happens and the motor

spins freely, but at this point five hammers hit the nail. The average

torque of the output rotor is the same as the motor's torque, but it's

divided into the free swings with no torque, and the sudden "5 hammer"

torque "bumps", hopefully at least ten times stronger than that

'average'. It's a better approach to "gearing down" the motor than

gears, because

it's continuously variable depending on torques and speeds.

Ways to improve on this basic design now are:

(a) make it a larger diameter. This is much the best improvement,

giving all the forces more leverage. It also makes (c) or (d) (below)

more feasible.

(b) reduce the number of teeth. This reduces the number of hits

per revolution. Changing from 25 to 20 teeth (if practical, still with

5 escapements) would mean

20% stronger hits, 20% less frequent. (I'm pretty sure reducing to 15

would be impractical. Then again...)

(c) increase the number of escapements. (with the number of teeth

being a multiple of the number of them so they're in phase.) This

increases the mass of the hits.

(d) increase the mass of each escapement. Wear to the unit from

heavier hits needs to be considered.

As the car starts moving with the repeated strong 'hits',

the output rotor speed starts to catch up to the motor speed, and the

torque hits (and noise) strength and frequency are gradually reduced as

less torque is needed. One could add a spring to one or more of the

escapements so that below a certain torque, the converter would lock to

the motor speed.

The Test