Turquoise

Energy Ltd. News #37

Victoria BC

Copyright 2010 Craig Carmichael - March 1st 2011

http://www.TurquoiseEnergy.com

= http://www.ElectricHubcap.com

Contents/Highlights:

Feature: The Electric Weel Motor:

THE

way to

make future cars! - and to do electric conversions today.

Month In Brief

(summary)

New Electronics Lab

* Overcrowded combined shop was getting hard to work in, for

either motors or electronics.

* Room came vacant, so... shops were separated and reorganized.

Electric Hubcap System & Motor Building

Workshops

* Paramagnetic nanocrystalline coil coating: Success! -

lowers no-load motor

currents.

* Toroidal iron powder cores have lower losses than solid

cylinder finishing nail strip laminate cores. (Surprise, surprise!)

* Perfect hub for PP-epoxy stators: regular trailer wheel hub!

PP-epoxy stator is then a flat ring that bolts to the hub. (Too simple!

4 pounds heavier though.)

* EH Motor kits are coming soon!

Electric Weel Motor Project (Electric Wheel

Motor... Rim Motor...)

* Thinking Outside the box: a huge diameter axial flux 'pancake'

motor

with all its force elements out by the rim - an "electromagnetic wheel

rim" motor -

would have the ideal characteristics of immense torque

and low RPM needed for direct car wheel drive.

* Same force components as used to make 3 EH motors, placed

around one 26" rim, would provide 9 times the torque with only 3 times

the

power (15 KW), and at 1/3 the RPM - at car wheel speeds.

* a superior ultra efficient way to

make future electric cars - and to do electric conversions today.

* Spoked rotor and stator provide the size without excess weight.

* Needs heavy axle, bearings, hub - only 6" long but

they weigh 15 pounds.

* Toyota 4runner obtained for conversion to "Electric Weel"

motor EV.

* "ElectricWheel.com" is taken - "ElectricWeel.com" registered.

Spelling will help differentiate product.

Torque Converter Project

* Test shows wheel linkage problem solved.

* But low motor speeds and performance show that

controller, motor and converter problems aren't solved.

* Design flaw: too many teeth! - 5 teeth in ring gear (and 20

'missing') instead of

25 will give motor time to accelerate between pulses - even with low

motor power.

* Motor rotor may want

more weight to give torque pulses more punch.

* Tooth and escapement profiles: quieter, smoother torque pulses.

NiMH Dry Cell

Car

Battery Project - Get

the lead out - of

your car! Reduce vehicle weight! Reduce Fuel Consumption! Green

batteries! from $320. (e-mail me!)

* First D cell battery, Feb 3rd: Starts car without hesitation -

even at -6ºC.

* Sure enough, it's been done... or tried... before. NiCd, too.

* NiMH Battery Tests: NiMH AA cells do actually have 100

watt-hours per

kilogram energy density: best battery for electric transport. ...except

for all

that soldering! (Car battery will be under 9 pounds!)

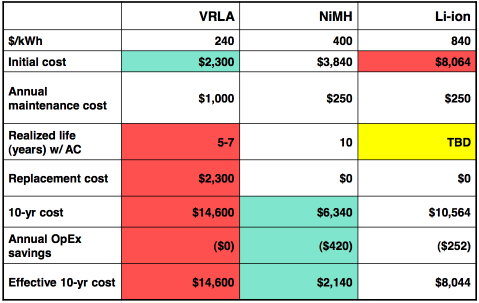

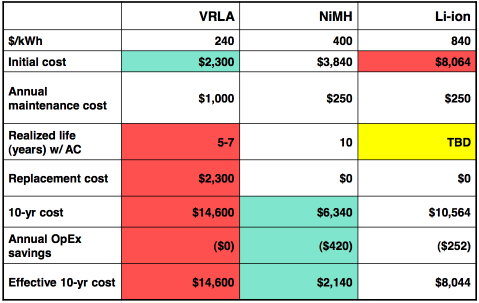

* PbPb, NiMH, LiIon cost comparison (from Ovonics).

Turquoise

Battery Project

* Mn-Fe: Lower voltage (~1.6) than MnMn -- but lower self

discharge.

* Gradual small improvements.

* Better case?: 4" ABS (or 6") - not the pipe, just the flat end

cap!

4.5" inner diameter gives 16 square inch electrode surfaces, 1/2 liter

volume.

Newsletters

Index/Highlights:

http://www.TurquoiseEnergy.com/TENewslettersIndex.html

Construction Manuals for making your own:

* Electric Hubcap Motor Building Manual

(latest rev. 2010/09/xx)

- the only 5+ HP motor that can easily be made at home?

* Turquoise Motor Controller Building Manual (latest rev.

2010/05/31)

- for the Electric Hubcap. (Probably there are commercial

controllers that would work, too.)

* 36 Volt Electric

Fan-Heater

(in TE News #22, 23, 25)

- if you're running your car on electricity, you'll want a

way to defog the windshield and keep warm. (This one I made - but you

can buy them.)

* Lead-acid batteries:

Sodium Sulfate 4x

longevity additive - "worn

out" battery renewal.

(http://www.TurquoiseEnergy.com/Na2SO4.html)

* Nanocrystalline

reflective rear electrodes to enhance DSSC Solar

Cells.(in TE News #28, 29)

* Simple Spot Welder for battery

tabs, connections (in TE News #30 - not the

best

welds, but article remains for ideas.)

* NiMH Dry Cells Pack Car Battery

(TE News #36 -

economical, very long life, green, lightweight: replace your lead-acid

battery!)

are all at: http://www.TurquoiseEnergy.com/

February in Brief

The 100 nickel-metal hydride D cells arrived on

the 3rd. I took 30 and soldered together the second

NiMH car

battery

the next evening. With 30 amp-hours instead of 22.8, it had plenty of

"poop" - the starter turned without the slightest hesitation, as easily

as with a brand new lead-acid, and continued to do so through the

month, even at

-6ºC. Mid-month I put together a second one,which I tried out in a

torque converter test. I'm taking orders now ($320).

Speaking of lead-acid, a reader reports that he

successfully renewed his dying boat winch battery last month with sodium sulfate salt.

There seem to be

surprising misconceptions about nickel-metal hydride batteries out

there, including by people who should know better. An electric bicycle

tech thought they weren't much good - even Chevron in casting odious

aspersions on them never went so far as

to say that! He said they wouldn't handle the

current. He said a 36 volt, 10 amp-hour lithium bike battery delivers

10 amps, has BMS circuits built-in, and costs $1000. I told him that

exact same size in nickel-metal hydride delivers up to 30 amps

continuous, needs no BMS circuits, and costs $320

from me. And I suspect it'll last longer. The only actual advantage of

the lithium seemed to be that it was lighter, 7 pounds instead of 11 or

12. (and for only an extra $680!)

I ran tests on a D and an AA Ni-MH battery, and sure

enough

they both met their amp-hours specs. The AAs are for some reason higher

energy density by weight than the Ds: 100

watt-hours per kilogram versus 75. I also tested a 15 year old NiMH AA

battery and

it still has 80% of its original amp-hours capacity. So I ordered 200

AAs to see how they fare in car battery packs... and how much work they

are to solder together. The small car battery - or bicycle or EV

battery - will weigh 9 pounds instead of 12. When economy is factored

in, NiMH AA cells would seem to be the best electric car batteries

available.

In motor developments, I painted rutile (paramagnetic TiO2

mineral) in sodium

silicate onto the first coils made with the iron powder coil cores.

Before and after measurements - on two motors to be sure the first

one wasn't just some fluke - appear to show

significantly lower

no-load currents with the coating, which I expect brings the motors

up to the fabulous 95% maximum efficiency target. (I haven't seen any

other motor claiming over 92% so far, though they probably exist.)

This simple but apparently

effective improvement to the state of the art of electromagnetic

materials fully justifies the nanocrystalline ceramic

coil cores project even though no whole cores were successfully made.

(And that's not

to mention the other offshoot, the nanocrystalline DSSC solar cell

reflective rear

electrode and process for making them!) The iron

powder cores - with the coating -

have the targeted low loss core characteristics. They are much better

than the

nail strip cores, with only one watt typical losses per core at 60 Hz

(EH: 1200

RPM) according to the manufacturer's figures.

PP-epoxy stator, iron powder core coils, and painting the coils with

paramagnetic rutile,

PP-epoxy stator, iron powder core coils, and painting the coils with

paramagnetic rutile,

all contribute to very low no-load motor currents and consequent high

efficiency.

Early in the month I started winding motor coils with 20

turns of #11

wire. It became apparent that the $6 I'd paid for the old wire at

Ellice

Recycling would do all 27 coils for the new idea 26" rotor "Super

Electric Hubcap Motor", which I've decided is perhaps better named the Electric

Weel

Motor. ("EW"? "ElectricWheel.com" is taken) This bicycle wheel size,

low RPM, 15 KW

motor with an

order of

magnitude more torque than other motors should make a highly efficient,

direct to the wheel drive (via CV drive shaft) electric vehicle

feasible. This was one of my original design goals in the Electric

Hubcap project. I think it's the future of vehicle design. In

my head I ran through possible designs for the rotor and stator - and

then bought some materials and started building the rotor and axle/hub.

By the third week I

pretty much knew what would be needed and had bought or ordered most

the parts. Some details remain to be worked out.

26 inch rotor rim, stator hub and 2" diameter axle (compare with 1"

on left)

for the Electric Weel,

26 inch rotor rim, stator hub and 2" diameter axle (compare with 1"

on left)

for the Electric Weel,

to be

attached with heavy spokes or rectangular tube.

A few sample supermagnets are in position; coils

for the stator

(which attaches to the big hub on the top half of the axle) are shown

behind.

At the same time a

1988 Toyota 4runner with 446,000 Km on

it was available for a low cost from a friend and I bought it, as it

had sufficient

height under the hood to fit the proposed 28" diameter motor. Too big

for an add-on motor, this

will be a full electric conversion with the motor driving a front

wheel directly via its CV drive shaft. A new project - and a

potentially fabulous new product, tentatively dubbed the "Electric

Weel" - is born.

I am also making progress with making better chemistry

batteries and have some

hope that I might someday be able to give it considerable driving

range.

Otherwise... it's a 3500 pound truck and I'll be removing around 1000

pounds of gas engine stuff, so it can take the weight of some heavy

lead-acids, for potentially 60-80

miles max. range driving.

I might try NiMH dry

cell battery packs... if I can afford them. The spare Ni-MH

car

battery worked fine for a torque converter test in the car (along with

two

lead-acid). I think it would need around 2000 AA cells, perhaps $3000

worth. This would give 6000 watt hours - perhaps around 40 miles

range, with only 60 Kg (under 150 pounds) battery weight.

Perhaps prices will

continue to drop.

I went on something

of a "spending spree" this month, putting out well over three thousand

dollars for R & D supplies (and this follows on recently buying the

$3000 CNC machine) - scary stuff for a person with no steady income.

First there are two very promising new projects that require

significant resources: NiMH AA cells needed

testing as car and EV batteries, and the "Electric Weel"

Motor.

Then I wanted to buy ahead various things I'm almost certain to

need in the next few months for all the projects. I got 240 iron powder

coil cores,

100 NiMH D and 200 AA

batteries for the experimental car & EV battery projects,

72 supermagnets (36 for the Electric Weel motor alone),

electronics for motor

controllers, and a number of smaller purchases. ...not to mention the

truck! The reason for buying some items a little early is that

my corporate

year end approaches, and by buying them now, I get my SR & ED tax

credit a year earlier than if I wait until March or April. (Always

assuming the

projects are

again approved, of course. But are they not truly cutting edge?) I'll

use that to pay off the credit cards, and fortuitously my mother, who

has gone long and far beyond any reasonable requirements of being a

mother, has been able to send me some money at this time. (Thanks mom!)

There are still more things that

will soon be needed as the projects get more 'up-scale': version 2 of

the motor controller circuit boards, 11 AWG wire for winding more

coils,

more epoxy and other supplies, various chassis and frame parts, and

graphite sheets for more battery experiments.

Finally I got some

carbon rods and more (and doubtless purer) manganese oxide for

battery experiments for free (and already mixed with graphite!) by

'raiding' D cells from Rona's battery

recycling drop-off box. Ironic that throw away dry cells seem to be

mainly filled with

half of what it will take to make superb rechargeable EV batteries. I

also abandoned renting out a room to make space for an electronics lab

separate from the machine shop.

So I've gone out on a limb, but 2011 holds the promise of

Turquoise Energy having some

actual very fine products to sell: Electric Hubcap motor kits are

looking very close (though the market will be much larger if and when

the torque converter is working), and it appears that Ni-MH

batteries need only finding the right customers and soldering. Could it

be that one inventor might finally approach solvency through his work,

and

after 15 years of poverty level income?

New Electronics Lab

With the fine CNC machine

taking up 1/4 of the floor space in the machine shop/electronics lab

and a

growing inventory of motor projects and supplies for them, the shop was

getting seriously overcrowded, and the new Electric Weel motors will

take a lot of room. And the CNC router and lathe, though at the other

end of the room, make messes that aren't very compatible with doing

delicate

electronics work. My last renter having left in January, and anyway

having been

collecting rent only sometimes for the last two years from unreliable

people who couldn't pay, I finally decided to move the electronics

shop/lab into the now vacant room, also store some of the R & D

supplies

in it, and thus free up sufficient space in the machine shop to

rearrange it to work there safely and conveniently again. I now have

the garage, which has always been a shop, and three rooms dedicated to

R & D: the machine shop, the battery lab and now an electronics lab.

The difference in the machine shop was apparent the first

time I went to work: I wasn't stepping over things to get across the

room to the tools, and the workbench was clear since there were places

to put things away. I haven't yet found time to do any electronics

(ie, to look at the motor controllers) since the move.

New electronics lab & workstation will be more conducive to

troubleshooting the accursed A3938 motor controllers

New electronics lab & workstation will be more conducive to

troubleshooting the accursed A3938 motor controllers

-- which promise to be excellent controllers once they're working right.

Electric Hubcap System & Motor Building Workshops

Rutile (Titanium Dioxide)/Sodium Silicate Coil Coating

For some time I've had the idea that coating coils with a

paramagnetic

material, even though it's a weak force, could help direct the magnetic

fields coming from the currents in the copper wire to flow more into

the

iron or iron powder of the core.

At the same time, TiO2 is a dielectric that

separates the coil interior from the outside.

It was intended that

such a coating be part of the nanocrystalline ceramic coil cores

project, which didn't get as far as coatings. Recently it finally

occurred to me it could be used just as well on

any coils.

First I tried seeing

if the magnetic

pull from a coil was any greater with the coating applied. It wasn't.

But the coil was activated by DC current - the motors were AC. I

decided to try painting the coating onto a set of motor coils and see

if

it had an effect on motor operation before giving up - it was still

possible it might reduce motor currents a bit.

The rutile and sodium silicate seem

to set by themselves with no other ingredients. I had

to break up a solid mass in the jar and add water to the old mixed

batch, and when this was painted on the coils, it seemed to just flake

off. If I mixed fresh rutile and Na2SiO3, they painted on and stuck

much better. However, the sodium silicate is still water soluble and

thus it's subject to washing off if the motor gets wet. Heat treatment

might "desolubleize" it, and I'll try that out soon enough. Otherwise,

perhaps some spray paint overcoating would make it permanent.

When I tested the

motor before and after painting on the

rutile in

sodium silicate, I got the following approximate (and rounded off)

readings

of no load

currents with a 30 volt supply:

500 RPM 1000 RPM Spacers

With the uncoated coils

2.5 A 4.75

A 0 (.55" flux gap)

2.0 A 4.0

A 1 (.675")

1.5 A

3.5 A 2 (.79")

coated coils:

1.5 A 4.0

A 0

1.0 A 3.0

A 1

1.0 A 2.5

A 2

These were very significant reductions! I decided I should

try and repeat the results before I got

too excited. Three weeks or so had elapsed between the 'before' and

'after' tests, and I had

changed the magnet sensor mountings. In the 'before' tests I got

somewhat different current for clockwise versus counterclockwise, which

didn't reoccur in the 'after' tests. (The 'before' figures above are

for the

lower current direction.) Were the results skewed?

Tristan's motor, the

last one made with the finishing nail strips coil cores, was still

here, so I decided to work with it. Again, in the 'before' tests, the

motor drew more current spinning one direction than the other. (almost

double!) The lower current figures are again shown. In the

'after' tests, the current was the same in either direction with the

widest gap, but not with the lesser gaps. I can't say I understand the

discrepancy, but some evening out happened with both motors when coated.

Note that the flux gaps were different before comparing

the absolute currents below to the above figures. (Also, owing to a

crooked magnet rotor, used for all the tests, they are at best an

approximation. The Dexter trailer axle flange is to blame for that.)

I poured some liquid off the top before using the more

pasty stuff

in the original jar for the second attempt.

I didn't want to

remove the coils and un-wire them, so I just loosened the clamps. I

didn't get at the undersides very well with the paint brush. So slight

further improvement should be possible. These coils were dipped in flat

black paint, so I expected the rutile would stick to them much better

than to the

slick epoxy of the new coils. However, there was still a lot of flaking

and crumbling.

500 RPM 1000 RPM Spacers

uncoated coils

2.5 A 5.75

A 0 (.675")

1.75 A

4.0 A 1 (.79")

1.25 A 3.0

A 2 (.9")

coated coils

2.1 A 5.25

A 0

1.5 A 3.75

A 1

1.1 A 2.75

A 2

Evidently, the coating helps as I had anticipated, and the

motors probably now achieve their 95% efficiency target. This would

appear to

constitute a noteworthy advance in the state

of the art, being potentially useful for

transformers and other electromagnetic devices as well as for motors.

Now it's known to work.

What remains to be determined is how thick the coating should be, and

perhaps the optimum composition. Niobium, the element below titanium on

the periodic table, is the most paramagnetic - but also quite costly.

Sticking with rutile, is it

a case of "the more the merrier", or is a micro layer as good as a

millimeter thickness? I can paint another coat onto my motor before I

reassemble it... when I have time.

It's also to be determined whether it would pay to put on

a "primer" to help the mix stick, or an overcoat to protect it from

moisture during operation. But these are just matters of technique.

Also Noted...

A couple of other things were noted in the above tests

besides the coatings.

First, comparing

currents with similar gaps

in both sets of 'before' tests also shows that as anticipated the

toroidal iron powder cores seem to have substantially lower losses than

the

solid cylinder ones made from nail gun finishing nail strips. It is

possible that they would be comparable to toroidal finishing nail strip

cores, but since they're ready-made, I'm unlikely to try the experiment

unless I really want to try out optimizing the shape and amount of iron

rather than just using a toroid. But 95% efficiency will be very hard

to improve on. The law of diminishing returns says "drop it!"

Second, I changed the magnet sensors so their positions

could be shifted easily. However, moving them back and forth made no

noticeable

difference to operation or current - at least not at 500 RPM, which is

1/4 speed.

I've seen writings describing advancing the timing to optimize

performance a bit at one RPM in one direction (and worsen it in the

other direction). I

think they really only apply with high RPMs/frequencies and higher coil

inductances, both of which are very low in the Electric Hubcap motors,

making for wide tolerance.

Series Wound Coils - Epoxy

Until now I've been winding the coils with 60-63 turns of

#14 AWG wire. The three coils of each phase are wired in parallel. I

recently got ten pounds of very old (WW II era? 1950s?) #11 AWG magnet

wire

for a dollar a pound, and I decided to try winding coils from 20-21

turns of this. The three coils of each phase would then be wired in

series to make up the 60 turns. I made a winding spool that put 7 turns

in each layer. The coil turned out just slightly larger in diameter

than the #14s. Part of that is the old fiberous insulation is almost

1/100th of an inch thick instead of 2/1000ths for modern coatings.

With modern #11 (tried when I ran out of the surplus

stuff with an odd number of coils made), I can squeeze in 10

turns per layer and do it in just two layers, which uses the least

length of wire and makes the most compact coils of all, and also proved

to be the

easiest by far to wind.

Coil with 20 turns of modern #11 AWG wire in just two layers (before

rutile

coating).

Coil with 20 turns of modern #11 AWG wire in just two layers (before

rutile

coating).

Most compact, easiest to wind, lightest (360 g), and best heat

dissipation.

These coils were also lighter than the #14 coils - 370

grams versus 425. The overall wire gauge is a bit lighter: 3 #14s works

out a bit smaller than #9. But I expect #11 is heavy

enough: since it's wound in just two layers,

the heat has little volume for its radiant surface area. However,

copper resistance for an EH motor from tables (#11 =

.00413 ohms/meter) works out to .10 ohms instead of .063 or so, so

copper losses at very heavy loads are bound to be higher. The trick is

to avoid working the motor so hard that that matters much. The rutile

will help.

I made a second winding spool so I could have two coils

going at once to make them faster. Then I ran out of the high

temperature epoxy I bought in 2008. I bought a different kind that also

said it was "thermally conductive". That should be still better to get

the heat from inside the coil to the surface for cooling. However,

although it

said it would dry in a 65ºC oven in an hour, the same as the

previous type, it took more like 3 hours. I had to redo parts of four

coils that came unraveled after 'only' 75 or 100 minutes in the oven.

Now even with two spools the speed I can make them at is reduced - ya

jes cain't win! I will of course make more spools whenever I'm waiting

for coils in the oven and have nothing else to do. That last hasn't

been happening to date.

Stators: Back to trailer wheel hubs

In making the polypropylene-epoxy stators, attaching the

bearing hub in the center is one problem, and having the flat rotor

disk bend into a dinner plate shape with the attraction of the coils to

the magnets on the rotor is another. If instead the stator plate were a

ring that bolted onto a trailer wheel hub, both problems would be

alleviated if not solved, and the metal of the trailer hub would be

inboard from the magnets on the rotor and not a significant source of

magnetic drag.

So when I went out to Thomcat Trailers to get great big

axle bearings for the giant rim motor, I also bought a new hub to try

out with the smaller ones. The PP-epoxy ring stators with trailer wheel

hub will be a project of the near future.

One for motors with in-line torque converters may still

need to be cut down to fit two hubs on one axle, and (not cut down) it

adds four pounds to the motor weight, but as it solves the

PP-epoxy stator mounting problem and (pretty much) ensures proper

alignment, and as I had to turn both sides of the pipe fitting hub -

extra labour -

that (and the $35 price) seems like a bearable trade-off.

Electric Hubcap Motor Kits are getting close

Producing

stators in quantity was the last large question mark in my head - with

trailer hubs and just flat rings of PP-epoxy, now I know pretty much

how every part is to be produced. I can

see the day of offering a complete motor kit drawing close! Of course,

the market for them will be much larger once the torque converter has

them moving cars.

Also the Electric Weel motors, once a couple of prototypes

have been built, shouldn't be too far behind since they use the same

electromagnetic parts - the same coils, magnet sensors and magnets.

Many of what are likely to become production structural parts are also

coming together or have been identified. And the "EW" motor doesn't

need either gears or a torque converter to move cars!

The Electric Weel

- or - Super Electric Hubcap Rim Motor:

The Car Motor of the

Future

Propulsion needs and conundrums

It goes almost without saying that elimination of the

gears and transmission and their 30-40% typical losses would be a major

improvement to vehicle efficiency. But to turn a car wheel directly,

1:1, requires very high torque, and seemingly to get that torque

would require a greatly oversized electric motor with far more power

than is

otherwise actually needed.

For example, the Electric Hubcap motors are quite "high

torque", but still almost an order of magnitude too low. Four of them,

one directly

tied to each wheel,

would give four times the torque of one. It would be 20 KW... and yet

it still

wouldn't be enough torque to accelerate rapidly or start up a hill.

Doubling the rotors and

stators

on each motor would make it sufficient, giving 8 times the torque...

and

would total 40 KW - way overpowered. (and a couple of hundred pounds or

more.)

On the other hand, a simple fixed gear reduction to

sufficiently

multiply the torque of a smaller motor produces serious inefficiencies

in itself, and it creates the problem of very high

motor RPMs at highway speeds - leaving as options small,

high RPM motors, or the nasty multi-gear transmission.

The torque converter, constant velocity transmission (CVT)

or other efficient variable

reduction mechanism is a potential practical solution, but since

Constantinesco's successful 1926 car, practical working units have

remained elusive. (...so far!)

Motors that produce their power at too high an RPM with

insufficient torque for direct car wheel drive, and unsatisfactory

technologies for changing that rotation to lower speed and higher

torque... These are the

problems and

parameters everyone has been grappling with in the creation of vehicle

drive systems. But we have all

unwittingly been thinking inside a cramped box!

Escaping the Box

When we design a motor, we intuitively want to fill

the entire stator and rotor volume with 'appropriately proportioned'

coils and magnets to maximize utilization of the space and power per

volume. There is the

root of the box: implicit assumptions about how to make motors,

limits the size and shape of the motor

we want to make -- to dimensions unsuited to electric vehicle drives.

But why do we care what inner space is 'wasted'? - torque

is

what's

lacking, and the maximum torque is developed by placing the force

elements

out by the rim of as large a diameter of rotor as is needed, maximizing

rotary leverage from the force to the axle. All that needs to happen

inside

from that force producing rim is to connect it to the axle.

The Electric

Hubcap's simple, flexible axial flux design

provides the key to escaping from the box. By simply tripling the

number of the same propulsive elements

and placing them all around the outer rim of one Electric Hubcap

type motor, the torque radius is also

tripled. Three times as many force elements at three times the radius

from the axle provides nine times the torque with only three

times the

power, 15 KW. That's more torque than from all four doubled regular

diameter motors combined (40 KW).

And the maximum RPM of this "bicycle wheel" motor is also decreased

threefold, becoming about the same as that of a car wheel at highway

speeds. The ideal fixed "gear ratio" is thus one to one. This is

the ultimate, simple vehicle drive solution -- it's how tomorrow's far

more efficient electric cars will be made.

Of course, this motor is as large a diameter as a wheel or

larger. How is it mounted so it doesn't drag on the ground? The

answer is of course to turn the wheel via the regular front wheel drive

CV drive shaft. These already attach misaligned transmissions to

front wheels. The motor can thus be mounted somewhat higher up, and

(depending on the

geometry under the hood) could probably even be

mounted at an angle to eliminate the inner CV joint.

Of course, mounting the motor under the hood means converting

the car from gasoline to electricity rather than turning it into a

plug-in hybrid with an add-on motor, so I'll be continuing the

original Electric Hubcap/torque converter project. But this larger

motor will make fabulous conversions, and

it also points the way for new car manufacture.

"Plug-in hybrids" could possibly take the form of a small,

efficient gasoline

generator that can be plugged

into a compartment somewhere in the car to charge the batteries during

long highway

trips.

Electric Weel Truck Conversion

After winding nine coils, I realized that I had enough of

the old #11 wire to wind 27 - the number needed for the big 9 x torque

"Super Electric Hubcap" idea.

This seemed to fit with a friend selling a very high

mileage 1988 Toyota 4runner truck cheaply: it would surely fit such a

motor

easily under the hood for an all-electric conversion. So I decided the

project was ON! I bought it

and wound all the coils. (and I now have 18 extra in case anyone wants

to build a motor, and will make more if

requested - $10 each.)

It seemed like a good project in itself: the regular

Electric Hubcap with torque converter would be a good city motor, but

at only 5 KW would surely at best be a marginal performer on the

highway. The triple would be 15 KW. (Of course, these figures should be

multiplied by at least 1.5 to make them comparable to systems that

drive

the wheels through a transmission.)

It also seems like a good "failsafe" project with the

torque converter project dragging on and on without actual success so

far. In spite of the structural parts 'upsizing' and other needed

changes for

such a big motor, it

has excellent

prospects for moving vehicles using all the 'proven' Electric Hubcap

motor and

controller electronic, electrical and magnetic parts that already work

- just three times as many of each.

Motor construction details started solidifying in my mind

out of a host of possibilities. 1/4" or 3/8" square or round steel

bar/rod

might make nice spokes. For the magnet rotor, the rim could be 1" x 2"

x

70" of angle iron. The 2" face would be cut apart into 18 equal

segments, 3.9"

long. The 1" face (uncut) would be bent around into a 'circle' of 18

straight segments with the 2" flats sticking outward. Thus the inside

of the rim will be a 1" vertical wall to provide vertical stiffness.

The spokes will attach (welded) to that. The eighteen 2" x 3.9" flats

will mount the 36 magnets, 2 per segment. For the hub... [was I really

going to use those 1" trailer axles, and those little pipe coupling

hubs, for

such a big motor, directly turning a truck wheel?!?! Metal fatigue!!]

The 27 coils weighed 10 Kg, 22

pds. That's

almost the whole weight of the regular size motor, right there! I'm

hoping to keep this thing under 100 pounds.

It may seem odd

using such small coils around the rim of such a big motor. This big

motor would fit much larger coils and magnets, for

example one could use 18 larger coils, or 9 huge ones. That's our

habitual 'inside the box' thinking, trying to make a more powerful

motor rather than "waste space". Using

the same

components as the smaller motors has advantages:

- All the forces act as close to

the outer rim of the motor as possible. This maximizes the torque for

the power, giving the "9 x" torque figure with only a 15 KW motor.

- The electrical systems are exactly

the same as with the regular motor. The tested, working components are

all simply triplicated. This saves working out whole new sets of

component values and operating parameters.

- Using identical components also

avoids having to design and stock multiple versions of everything - the

same coils, magnets, motor controllers, wiring, plugs and everything

will fit any of

the motors.

- I wouldn't want to have to deal

with bigger supermagnets by hand.

A 1600 Kg/3500 pound truck may seem a pretty big vehicle

for an electric conversion. But once I've ditched the engine,

transmission, rear drive shaft, muffler and exhaust pipes, gas tank and

fuel pump, radiator, and a couple of heavy underside protection plates

that won't be needed, it should be headed for 1000 pounds lighter.

That'll give it carrying capacity for 100 pounds of motor and

triple motor controller... and whatever weight of whatever batteries

are installed.

On the 17th I bought 26 pounds of steel at Metal

Supermarket to make the main

structural components from. I couldn't get 1" x 2" angle iron, so I got

2" x

2". Just as well - 1" would have been rather feeble by proportion. On

the 20th I

cut 20º angle wedges from it with the angle grinder zip disk and

bent it into a circle. Originally

I was going to

have the vertical on the inside, but then I realized it would be

stronger with it on the outside and easier to weld the spokes on, and

also

that the other way, it could severely injure one's fingers if they

accidentally contacted the ragged outside of the spinning rotor. The

angle

joins could also be welded solid, and even loose they couldn't bend

around.

The change meant

the piece I bought wasn't quite long enough, so I got a

little piece to weld in, courtesy of Urban Iron.

The 26" diameter rim of the magnet rotor: a 2" x 2" angle iron

The 26" diameter rim of the magnet rotor: a 2" x 2" angle iron

divided into 18

sections, each bent 20º to form a rim - to be welded.

The stout axle in the middle is 2" diameter and 6" long.

Hub & 2" axle, turned on the 26th to fit the 5000 pound, 1-3/4"

I.D. trailer

bearings.

Hub & 2" axle, turned on the 26th to fit the 5000 pound, 1-3/4"

I.D. trailer

bearings.

(Regular motor hub & 1" axle are shown to its left.)

I'm leaning towards six pieces of 1" x 2" tube (rusty piece shown) for

spokes

rather than many pieces of small stuff.

Also of note: 36 supermagnets, represented here by some

supermagnets,

and the 27 coils as they'll be spaced, but which of course will go on

the as yet unmade stator, not on the rotor.

The next day I found some pieces to cover the axle (the exposed

bottom half here),

and weld the inside ends of the spokes to.

Mechanical Torque Converter (MTC) Project

I finally tested the "5 star clock escapements" converter

version made in December. It barely moved the car.

The videos showed the linkage to the wheel was much better

- no more of the output rotor bouncing back and forth.

Something is still amiss with the motor and

controller. Running in reverse, the motor drew under 20 amps and didn't

get up much speed. In forward, it often had to be pushed to get it to

start spinning. Then it would read 40, 50 or even 60 amps, and yet

seemed to have even less power and speed than in reverse. This

asymmetry between directions really leaves me scratching my head, and

this time is by far the worst ever. (Could I have connected the phases

wrong?) I'm going to see if I can

get the new stator to fit with the

rotor and axle that have the torque converter, and see how that

performs.

Notwithstanding all that, even with lower motor power the

car should move. I began to realize the design was still violating one

of the basic operating principles of the mechanical torque converter.

All five escapements now operate in unison and that's much better than

staggered. But there are 25 teeth on the outer gear - continuous all

the way around. What it needs are 5 evenly spaced teeth that work in

unison... and 20 'empty spaces' where no torque is developed, where the

motor gets to build up its speed freely between torque pulses --

whether or not it has all the power it should have.

The simplest thing to try is to remove the ring gear and

replace it with five triangles evenly spaced around the rim of the pan.

I no longer see either the escapement shapes nor the layout as anything

like optimum, but it has a very good chance of working. (A more optimum

layout would put the escapements on the outer drum and the fixed points

on the inner.)

Now that I've thought of it, it seems silly. When I had

the teeth sideways, which caused more vibration than torque, I had this

aspect right: four sudden hits per rotation, all four pins hitting at

the same time. When I oriented the teeth on axis and changed the

masses to escapements, somewhere I lost the whole principle!

It seems that the

motor slows down quite a lot with

each hit. Another thing I want to try is to add weight to the motor

rotor so it has the inertia to barge right on through.

Things to try next:

1. Change the stator to the new one and hope for more power. If fitting

it proves to be simple, it's the thing to do first. It's more

efficient, but it may or may not provide much more actual power.

2. Make a 'ring gear' with just five teeth - 20 'missing'. Giving the

motor more slack time to gain speed is likely to be effective even

without

more power, and should be the next thing to try. I might have made it

in February but the weather turned cold - even the shop in the house

was too cold to work in for a week or so.

3. Change the motor controller

for more power. This requires getting the A3938 motor controllers

working properly.

4. Add inertial mass to the motor rotor. However, the resulting

improvement is likely to relatively minor: the hits won't slow the

motor as much, but it'll also be harder to speed it up again between

hits. Item 2 is the thing!

At the same time, I've been playing in my head with designs for

improved tooth

shapes. A concave shape, like the front side of a

water wave, would cause the escapement to accelerate continuously as it

moves up the slope. This would be smoother and quieter than 45º

'impact' hits. And it would wear more slowly.

Ni-MH Dry Cell Car Battery Project

NiMH

dry cell battery #2 (as initially mounted) under the hood: 30 AH, 30 D

cells.

This is the best

performing battery I've ever put in the car - starts great even at

-6ºC!

It's under 12 pounds - the

car is 30 pounds lighter!

I simply used a plastic food container to keep the weather and dirt out,

and stuffed in some styrofoam around the edges as it was too large in

all dimensions.

These work great, so I'll start off with a Car Batteries for Sale

ad:

30 AH (210 amps cranking, small car) - $320

40 AH (280 amps cranking, mid size car) - $420

Custom configurations (any voltage, current) - $proportional, nothing

extra for being custom.

Individual NiMH cells:

10 amp-hour D cells: $12 each

2.5 amp-hour AA cells: $3 each

(End of advertisment.)

Correction #1: Last month

I reported that someone had used NiMH dry cells to

rebuild his Toyota Prius hybrid battery. Evidently the correct story

was

that

the person disassembled his Prius battery and that's what was already

in it,

straight from the manufacturer. So! Long lived NiMH hybrid

batteries

consist simply of a string of 120 or more (depending on voltage) NiMH

dry

cells, evidently some are 7 AH to 10 AH "D" size - the very cells

I'm using!

This lends great support to the idea that the same cells will have

very long lives as car batteries. And it's worth noting that these

[dangerously] high

voltage batteries simply have (AFAIK - I *could* be wrong) two

terminals at 0 and 144 volts

- there are no extra "battery management systems" regulating each 12

volt section as is evidently required with lithiums.

Correction #2: A reader of the

last TE News told me

he himself had experimented with making a NiMH car battery 15 years

ago. I just knew I couldn't have been first with something so obvious!

But I still can't find any references to the subject on the web.

He mentioned

problems that cropped up in his trials, which

I think

won't happen now because of improved cells since NiMH's early days and

because I cross wire, parallelling at least every second group of cells

to

support any weak ones, now for the D cells version parallelling at 0v,

1.2v, 3.6v, 6.0v, 8.4v, 10.8v and 12v with an alternating up-down 5 x 6

cells layout that needs no additional wires for that. (see images

below.)

The worst of the problems occurred at low temperature. He

mentioned -6ºc. Most new cells are rated to -10ºc, and

-30ºc cells are available. High temperatures seem to be no

problem, except gradual self-discharge increases with temperature, as

it does for most types of batteries.

(Someone else also

reports having used just two banks of 12 Ni-Cd 5 AH D cells to start a

car with a dead battery out in the middle of nowhere, and that just 1/2

dozen would start a VW Beetle.)

Large Flooded NiMH Cells

He also mentioned Ovonics flooded NiMH batteries, and gave

me a

link to some info. It's the first time I've ever seen a price for

Ovonics batteries, and if correct that 223 $/KWH price

definitely puts the

lie to

the assertions of those who killed it that "nickel-metal hydride is a

great

technology, but it's so expensive." These things should be all

over at Wall Mart and Canadian Tire, since 2005 or so, displacing

lead-acid and propelling the shift to electric vehicles.

Ovonics liquid filled 13.2 volt (11 cells) NiMH

battery: 85 AH, 1120 WH, 60 WH/Kg.

Said to be $250 list price, but never available to the public before

'big oil'

murdered it.

So far it's nearly twice the cost for this capacity in NiMH dry cells -

but still price competitive with lithium-iron phosphate, and

dropping.

A good thing that may gradually emerge from this is that

the dry cells are actually better:

1. higher energy density for

greater driving

range.

2. maintenance free

3. safer - no potential

spills of caustic alkali

NiMH dry cell prices are likely to drop substantially as

they spread into

more automotive applications, finally, we may hope, attaining a similar

price range

to the

flooded cells. They would never achieve the sort of sales volumes

necessary for this if the flooded cells were available. "All things

work together for progress."

I do see flooded

NiMH cells available on one web site for the first time, from China: www.ChangHong.com .

These seemed to have similar energy densities to the Ovonics. I didn't

ask about the price since the dry cells are better. The dry cells are

also made in China, though I'm

ordering them from a US company. India is experimenting with NiFe

(even cheaper very long-life chemistry) dry cells for telephone

exchanges. Again we

see the Far East forging ahead with advanced battery technology that

has been stifled and suppressed here in the West. And lest we think the

suppression of batteries is anything new, someone has told

me that nickel-cadmium dry cells were kept out of North America for

over half a century by the well known makers of non-rechargeable dry

cells here. The Germans used them in submarines in world war one.

30 AH D Cell Car Battery

Meanwhile, back at the ranch... I put together the first

30

AH D cell battery on the 4th

after the cells arrived on the 3rd. I made a frame to hold them in

place, and again I simply soldered them. (this time wearing safety

glasses just in case. Not only potential bursting of a cell, but a

solder splash in the eye would be very bad, and I did have a wire

spring up and flick up solder as it melted.) I decided to wait and see

how many batteries I

actually end up doing before going to the trouble of making a discharge

welder and setting up the CNC machine to weld tabs. Also, with the high

currents of starting cars, it seemed prudent to use heavy, copper wire

and plenty of solder to ensure good, strong connections, rather than

thin nickel-brass tabs. All bets are off for the AA cells,

though - all those little cells will take a lot of soldering, and the

currents through each

cell are much lower. On the other hand, smaller, stranded wires and

small cells are much

easier to solder.

I terminated each of the three banks with a wire soldered

to a "_n_" (or "Ω") shaped piece of copper bar. A nut tightened the

copper bar's

"n" center between the head of the 3/8" bolt and two washers, one

inside the plastic case and one outside. The rest of the bolt stuck out

to attach the car cables to with another nut and washer. (Yes, a

close-up would have been nice!)

New 30 AH D cell battery

L: In cell holding frame of Garry Oak sapwood

R: Bottom view shows the rest of the connections.

As I now had the first Ni-MH battery to carry as a spare for a couple

of weeks in case of any problem with the new one, I finally carted the

old lead-acid battery away to renew it. It weighed 43 pounds, so the

new Ni-MH battery makes the car over 30 pounds lighter!

One thing I didn't think about is that while

they'll work fine in the car, and jump starts from a running car should

work fine,

'intelligent' lead-acid battery chargers are unlikely to give

good results, since they expect very specific voltages at specific

states of charge and will most likely shut off without giving the

NiMHs much of a charge at all. In lieu of an actual 12 V Ni-MH (or

Ni-CD) battery charger, any "dumb" charger, or even an unregulated 12

volt power adapter (these are usually closer to 15 volts), is likely to

give

better results. I bought a "semi dumb" one that the salesman said was

"dumb". It works but it isn't as good as "dumb". It charges them at the

full 2 or 6 amp selection, but never reduces it and has to be shut off

manually since it can never raise the voltage to the 15 volts it wants

to see before it says "enough!" With the really dumb ones - if any

still exist - the current drops off as the battery approaches 14 or

14-1/2 volts.

D & AA Cell Performance Tests

Somebody said they didn't think they were getting the

rated amp-hours out of their NiMH AA cells. On the 16th I decided to

test a D cell to see if the performance specs were exaggerated. I

started at 8:00 PM with a .5 ohm load. That would be 2.5 amps at 1.25

volts. Since the voltage drops off after about 90% discharge, I

expected it should drop below 1.00 volts out (the usual cutoff point)

between 11:30 and 11:45. But it took until 12:34, an hour longer than

I'd anticipated. It would have run a lighter load still longer.

It appeared it had put out 11 amp-hours, but later I found

that the alligator clip leeds had considerable resistance, making the

total load perhaps .575 ohms. This would make it about right for the 10

AH rating.

But perhaps in the competitive quest for sales, AA cell

ratings were exaggerated? After all, I had seen two 120 volt motors

with ordinary 15 amp plugs the same day I tested the D cell, and one

earlier, all claiming to be "3 HP". It is impossible to get more than

about 2 HP (rarely that much counting motor inefficiencies) from a 15

amp, 120 volt outlet without blowing the breaker, so those claims must

be extreme exaggerations, not to say false or misleading advertising.

The ratings on the AA cells gave them up to 100 WH/Kg,

versus 75 WH/Kg for the D cells. What was the actual case for the AAs?

If in fact they were no better than D cells, that would eliminate the

idea that using AA cells could provide the highest energy density for

electric cars at the cost of a lot more soldering. Would all that

soldering prove to be for naught?

The way to find out would be to test a new AA cell, which

I did on the 20th with a 2 ohms load. Disappointing performance turned

out to be a high resistance (.1 ohms or worse) on the battery holder

connection. So I started again with another cell, this time with the

tab wires soldered on so that only the clip leeds were wild cards. (I

finally determined they were around .1 ohms too.) The test ran 3-3/4

hours and showed the cell did indeed have the rated capacity.

This means that the AA cells truly are the best for

electric transport, offering 100 watt-hours per kilogram for about the

same cost per KWH as using D cells. With a large surface area per

volume, they weren't likely to need any form of cooling either. The

only drawback is the amount of soldering needed for all those tiny

cells.

I've heard of electric cars being done with "3000 AA

cells" and wondered why D size wasn't chosen. Evidently the builders

did their homework!

For regular car batteries, I'll have to cost out the

economy of spending about 3 times as long soldering versus any savings

in cell costs -- but also factor in the appeal of a 9 pound car battery

instead of 12 pounds. Compared to 30 or more pounds for lead-acid it

seems a bit academic, yet "1/3 the weight" or "30%" sounds better than

"2/5 the weight" or "40%".

Finally I decided to test one of the NiMH AA cells I

bought in 1996 to see how close to it's rated 1.6 AH it would come

after 15 years. (The digital camera I bought them for is long gone!) It

has been much abused by overdischarge in battery clocks. The clocks run

fine until the battery is down to about .5 to .7 volts. That means

every time the battery runs low it runs for weeks or months way under

the 1.0 volt recommended minimum voltage.

Again I used the 2 ohm load. The test showed that the cell

has at at least 80% of its

original amp-hours, but that its ability to supply heavier currents at

rated

voltages has been much reduced. (I would have to run a test at a lower

discharge rate to ascertain amp-hours more exactly.) Evidently it'll

run a clock

as long or nearly as long as new, but it's no longer very good for

heavy loads.

In car use the batteries don't get left run down for months like

that, and in

spite of occasionally having to put out a lot of current, they'll

probably fare better. "Life of the car" is what Ovonics says of NiMHs.

Finally, here is a sample cost graph from Ovonics. It's

probably reasonably representative, with the cost of NiMH being not far

below the bulk AA cell price. The life spans given would be for

heavier

cycling rather than for gasoline car battery use. The annual

maintenance cost of dry cells is about zero.

Turquoise Battery Project

While it was thrilling to replace my lead-acid car battery

with 1/3 the weight of NiMH dry cells, I was also encouraged by further

tests on January's second try at my own new chemistry battery, which

showed I finally had a real cell, even if the specs were abysmal owing

to high internal resistance. I ran it for 24 hours on the 5th/6th with

a 26 ohm load. The voltages were very low and got worse (from 1.6

volts, 50 mA at the start, to 1.1 volts/40mA after an hour and ending

at just under 1/2 a volt/17mA after a day - headed for an amp-hour

altogether). But the voltage drops were very gradual and it continued

putting out current the whole time, and would have continued probably

for another two or three days - at ever lower voltages.

It also charged back up in a day or so, and a second load

test produced much the same results.

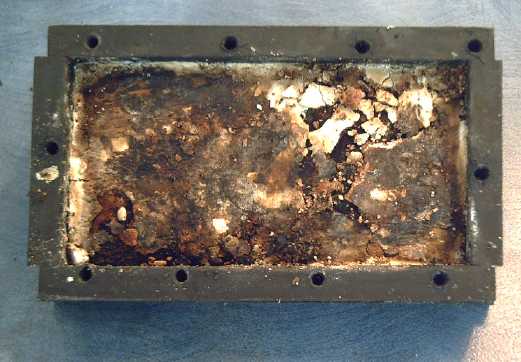

After that, I opened it. I remember putting in enough

water to pretty much flood it, but as I suspected, it was more of a dry

cell. I added water, flooding the top part (which may or may not soak

into the bottom electrode leaving it still un-flooded), cleaned the top

graphite sheet, and put it together again. Charging voltages had been

going up beyond 2.5 volts, now they were a little lower.

But it occurs to me that much of the resistance of carbon

terminals is contact resistance. I think I need to make "ligatures" or

find little pipe clamps to go around the whole carbon rod and make

contact at numerous points.

February's Battery Cell

I emptied and

cleaned the other 1.5" x 3" cell case, cleaned graphite sheets with

hexadecane and epoxied "D" cell carbon rods to them when I had mixed

epoxy for doing motor coils.

On the 7th I mixed the positrode: 30g "B mix" and 6g

graphite. Recalling that

cobalt oxide was used to improve conductivity of nickel

hydroxide/alkaline

electrodes, I added 1.1g Co2O3. (I only meant to add .3g, but the first

lump was 1.2 and I couldn't seem to extract much of it from the mix.)

On probing the loose powder, it typically gave readings in

the range of 15,000-50,000 ohms. This time, I would have some vague

idea whether that sort of loose powder reading might turn out to be a

5000 ohms electrode after compaction, or 50 ohms, so I might better

estimate the amount of graphite necessary for next time. I added 2g

Sunlight and about 4-5g water, mixed, and compacted. Contact

resistances were around 100 ohms. 50 would have been better, but 100

seemed alright.

Later, after I had it in the battery, it read 35-50. I got

out the commercial Ni-Cd electrodes, still in jars in the cupboard for

comparison. A Ni one read mid 1s of ohms, a Cd one under 1 ohm

everywhere. These were very thin electrodes sintered onto perforated

nickel foil, which was welded to the terminals - that's why those tiny

cells would put out 20 amps! If only some metal would last in the salt

electrolyte! It drives home the very low resistance requirements for

getting high current cells.

Of course, I can add all the graphite I want to bring the

resistance down to the teens or even ones. What's optimum? And I can try

adding monel to the negative mix. Perhaps I'll do that by pulling out a

graphited negatrode and replacing it with one having monel instead.

That can bring the negatrode resistance down to 1s of ohms, if it

lasts. which it might. On the other hand, carbon is light, fluffy and

cheap; monel is dense, heavy and while not prohibitive, it's less

economical.

For the negative, I ground up an "old" one (early January)

that read

around 500 ohms and hadn't been used for that reason. The loose powder

read

megohms. I added 2.5g graphite and the readings were 10s to 100s of KΩ.

I added another 2.5g and they were down to lower 1s of K. Then I added

2g Sunlight and 4g water. The mix was clearly too damp, and I added 4g

manganese powder. Total was 47 g of material. When compacted,

resistances were in the desired 50 ohms range. I painted in some

eggwhite and water, and cooked it in the oven for 75 minutes at

110ºC/225ºF.

Then I took the positive, which had also been drying in

the oven, and quickly ran the propane torch over it to sinter the

surface. (I don't think that's necessary with the negative.)

Both electrodes were about 5mm thick.

I remembered how long the last negatrode had bubbled when

the water was added, so this time I decided just to put it in a bath of

water. And the positrode too while I was at it. The "+" started

crumbling from the corners, and the "-" swelled up like a sponge.

Evidently this wasn't a good idea for either one of them! I took them

out. I put the "+" into the battery, scooping up the powder and filling

in the corners with it, and set both in the sun (there was some! for a

while.) to dry. After that I re-compacted the negatrode, and put the

calcium hydroxide layer on the positrode.

Additions

Was there anything besides cobalt I'd forgotten about that

might be useful? I started checking past notes and ran across the

reference to zirconia again, and

realized the zircon layer had got dropped somewhere in all my

un-methodical

experimentation. A layer of zircon(ia) on the separator sheet evidently

helps prevent migration of cations - one more technique that can be

applied - as in this V-Fe alkaline

(non-rechargeable) cell:

Given that most battery researchers simply avoid all

soluble materials for rechargeable cells, and hence cast away many

valuable and energetic reaction possibilities, the reader must forgive

me for throwing up all the roadblocks to electrode cation migration I

can think of or find in each cell. Basically I think chelation,

binding dissolved cations into a matrix, should allow the use of

soluble ions. Even so, potassium permanganate is only slightly soluble.

I wasn't quite sure where to put it amongst all the other

layers. I finally decided to paint it on bottom of the separator paper

with acetal ester, that is between the positrode calcium layer and the

paper - perhaps separated with cellophane. The

Fe2O3 could go on the top (negatrode) side.

I had good hopes, but the battery didn't perform as well

as January's second attempt, and the case sprung two leaks. I set the

project aside to work on other things.

Self Discharge

My batteries still have serious self discharge problems.

Whatever their voltage is supposed to be, they drop rapidly to around a

volt, and thereafter only slowly.

It's the other main remaining problem besides high internal resistances.

One day I raided Rona's battery recycling box and

collected discarded alkaline cells to get the manganese-graphite mix

out of them, suspecting they would be more pure than the MnO2 from the

pottery supply. Still, I don't know the true source of the problem.

Would the self discharge be cured by purer manganese? Probably not but

it's something to try.

I took apart a square lantern battery, and found it

contained

four 1.5 volt F cells. The cells were connected with soldered wires:

exactly what they tell the public never to do! Two of the cells and a

previously opened D cell made 120 grams of MnO2 and graphite. I soaked

them and poured off the water 3 times to dissolve out the ammonium

chloride electrolyte. (The zinc was uncorroded, which means the battery

had never even been used.)

Lantern battery - at last I know where "F" cells ("stretched D") are

used!

Lantern battery - at last I know where "F" cells ("stretched D") are

used!

Perhaps I could narrow it

down to the positive or the

negative. On the evening of the 19th I decided to try replacing the

negative in the leaky cell with iron (without disturbing the Ni-Mn "+"

underneath), though the only FeO I've managed to obtain is quite a

coarse powder. I didn't expect much performance, but it puts out (best

case) over 300mA into 1 ohm, almost on a par with others.

I used: 20 g FeO, 4.5 g graphite, 1 g Sunlight, 1.5 g water. This

wasn't terribly solid when compacted - more pliable than most instead

of brittle. "Pliable" and "doughy" is how the Indian researchers

described their iron electrodes - I thought it was because of their

PTFE binder, but it seems it's the FeO itself. The electrode was maybe

3mm thick. It read around 30-40 ohms.

What would the voltage be? Two very different acid

voltages were given

for Fe, and as usual none for neutral pH. It seemed to be around 1.65

volts, predictably somewhat higher than Ni-Fe in alkali. It self

discharged down to 1.4 volts quickly as always, but took a day to drop

to 1.1 and then, as usual, the discharge became slow, taking a couple

more days to drop to 1 volt.

Over the next days, however, I started finding things that

changed the rate. First, having lots of electrolyte was necessary. I'm

not sure why that should be since dry cells ("starved electrolyte

cells") are known to work fine, but it works much better soaked with

plenty of

water. Second, having the "sandwich" of materials pressed well

together, eg by foam rubber, helped. Third, sealing the cell seemed to

help - I put some screws in from the underside where it was leaking to

press the bottom against the sides, and re-glued the top terminal with

RTV cement, which was also leaking.

On the 22nd, it suddenly occurred to me that the acetal

ester probably wasn't polymerizing very well, and that the reason for

that was about the same as the epoxy taking forever to cure at room

temperature -- it probably needed to be heated.

On the 28th I tried making a separator sheet impregnated

with it

and put it in the oven at 110ºC for an hour.

I bumped and pried the negatrode out of the other battery.

The calcium layer, with a bit of very degraded cellophane, was seen:

I fixed it up by painting a bit more calcium on instead of

shaking the dry powder on. That made a thinner layer, somewhat absorbed

into the electrode.

I replaced

the separator sheet in the battery with the 'cooked' one. Much to my

surprise when I tried to bend up an edge of the dry paper it snapped.

It folded fine when wet. There was just enough area left to fully cover

the electrode.

The battery seemed to work better - at least, the

conductivity was considerably higher. This is likely more the result of

adding water and perhaps the thinner calcium layer than the sheet. It

takes time to charge

up and run tests, so this report can't go any farther. I'll be doing

more testing in the coming days.

Next battery I'll try using acetal ester to wet the

electrodes instead

of water, and then of course cook them.

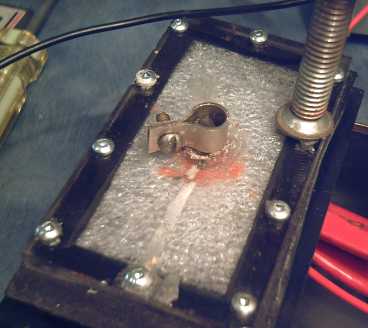

Better Connection?

The trouble with the graphite and carbon rods seems to be

contact resistance rather than internal resistance. I made some

"ligatures"

to clamp all the way around the carbon electrodes, which would surely

contact at several points. The dry cell makers crimp a piece of metal,

the "+ button" over the carbon rod - the origin of having a button at

the "+" end of the cell - but I don't have such a crimping

tool. So far the ligatures haven't solved the low conductivity problems

- but at least you can solder a wire to them!

Perhaps one way to approach the problem would be to line

the outer face of the graphite sheets with plasticized graphite that

wouldn't let electrolyte through. Then a wire mesh could be placed

behind in the dry area, in contact with the plastic all over (which is

in contact with the graphite all over), and soldered to a metal

terminal.

Nickel-brass ligature clamp to get best connection from carbon rod

electrode terminal

Nickel-brass ligature clamp to get best connection from carbon rod

electrode terminal

(The foam plastic was put in to push the electrodes together.)

Best Case Scenario?

With all the battery cases I've made that have leaked

under

pressure, I keep wanting something like a tub with straight sides -

just like people make for battery cases, but not to sell in stores. On

the 24th I thought of ABS pipe again, and how a flat end plate on a

piece of pipe could

leak, but how much plastic and weight a regular end cap on a pipe has.

Then I thought, "What about just the end cap itself?" A flat end cap is

a round tub

with straight sides, and it's 1/2" bigger inside diameter than the

pipes. I zipped off to Rona and bought one for 4" pipe to inspect. It's

a little

shallow (47mm) for a 6-cell, 12 volt battery, but good for 6 volts (3

cells), at least. 6 cells could work with thinner electrodes. I worked

out

that the 4.5" I.D. gave 16 square inches of electrode surface, just a

little smaller than my planned 3" x 6" rectangle size, and the volume

of 13 D cells - almost half a litre.

The next day I went to Bartle & Gibson for a cast pipe

coupling for the Electric Weel motor, and since I was there I also

picked up a

6" pipe endcap.

That size gives 34

square inches and a volume of 1-3/4 litres. That would make fantastic

batteries, but somehow I can't see making electrodes that big.

Especially compacting them.

Only the top will have a seam to leak, and the two

electrode terminals will of course have holes. Being round, the seam

will be uniform and won't tend to bend out under pressure like the

middle of a rectangular side. That's about the least amount of

potential trouble it's possible to have. The top could be both glued

and screwed on. Or, a recessed top could have a ring of 4" pipe glued

over it to help seal it.

Of course, a round electrode compactor of the right size

will be required - another tool to make. And round will be somewhat

wasteful of graphite sheets. The shape would at least be amenable to

use with a 45 ton(?) hydraulic press for faster

production than my bolt-down-edges type compactor. But I'll have to

stick with the 1.5"

x 3" rectangle test size until and unless I get to the point of having

practical, working batteries.

2", 4" and 6" ABS drain pipe end caps.

2", 4" and 6" ABS drain pipe end caps.

The 4" might make nice EV batteries.

The 6" is probably just a pipe dream - it would take a tremendous press

to compact such huge electrodes,

and they would be hard to install intact unless I can make them much

stronger or more pliable.

http://www.TurquoiseEnergy.com

Victoria BC