Turquoise

Energy Ltd. News #38

Victoria BC

Copyright 2010 Craig Carmichael - April 2nd 2011

http://www.TurquoiseEnergy.com

= http://www.ElectricHubcap.com

= http://www.ElectricWeel.com

Feature: Electric Hubcap Motor Making Kits:

$499.99

(no where near $500) - Taking orders now.

Month In Brief

(summary)

* Plus opinion... Natural resources: public property?

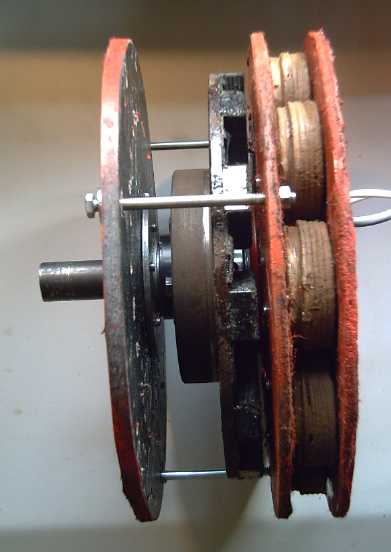

* Plus news item... The End of nuclear

power? A study says that in an ongoing trend, the cost per KWH of

electricity from solar panels has dropped

below that for nuclear plants. (It crossed over in 2010 for new

construction... and that's before Japan!)

Electric Hubcap System & Motor Building

Workshops

* PP-Epoxy Stator Ring Mold - for stator production

* PP-Epoxy Stator/'End Bell' Rings: Same stator for any

configuration of

motor.

* Bearing holders, 1" rod axles

* INSOLUBLE Sodium Silicate coil coating

* "Regular Motor" configuration motor made, CNC setups...

* Ilmenite seems to work even better than ceramic rutile -

even lower motor currents!

* Flat steel rotor disks - cut by abrasive waterjet (it's much

cheaper than I expected). Motor only 4" long.

Electric Weel Motor Project (Electric Wheel

Motor... Rim Motor...)

* Flat plate rotor cut by abrasive waterjet

* more pieces to be cut, taper lock bushing

Torque Converter Project

Sigh, no time!

* Moving escapement pivots from inside the drum to outside: 6"

torque radius instead of 5".

NiMH Dry

Cell

Car

Battery Project - Get

the lead out - of

your car! Reduce vehicle weight! Reduce Fuel Consumption! Green

batteries! from $300. (e-mail me!)

* AA cells arrive, assembled new car battery - sure enough, 9

pounds instead of 12

Turquoise

Battery Project

* Tests: runs for days with 61 ohm load, but at pathetic ever

dropping

voltages - mostly under 1 volt.

* Repeated tests show similar performance: it's rechargeable.

* Improved case: thicker walls, better(?) '+' terminal

connections.

Newsletters

Index/Highlights:

http://www.TurquoiseEnergy.com/TENewslettersIndex.html

Construction Manuals and information:

-

Electric Hubcap Motor

- Turquoise Motor Controller

- 36 Volt Electric

Fan-Heater

- Nanocrystalline

reflective rear electrodes to enhance DSSC Solar

Cells

- Simple Spot Welder

for battery

tabs, connections

Products:

- Electric

Hubcap Motor Kits, Parts - Build your own ultra-efficient 5 KW

motor!

- Sodium Sulfate

4x

longevity additive & "worn

out" battery renewal.

- NiMH Dry Cell Car

Batteries (please e-mail me for batteries)

- NiMH Custom Batteries (EVs, E-Bikes, Scooters, etc. - no extra

charge)

- NiMH individual Dry Cells (D, AA)

are all at: http://www.TurquoiseEnergy.com/

Electric Hubcap Motor Making Kits

499.99 $Canadian - Electric Hubcap Motor Kit

Although I don't have

complete car installation systems yet, I think some people have been

waiting for the motors alone as they can have many uses. The last

details are finally falling into place as described in the Electric

Hubcap topic below, so I think it's finally time to start taking orders

for them as kits, with the caveats that it may be a few weeks before

they are actually shipped, that specs are only roughly determined, and

that the kits may be just a little "rough around the edges". (I will of

course try to minimize unwanted 'features'.) A $100 deposit will put

you

first/next on the delivery list.

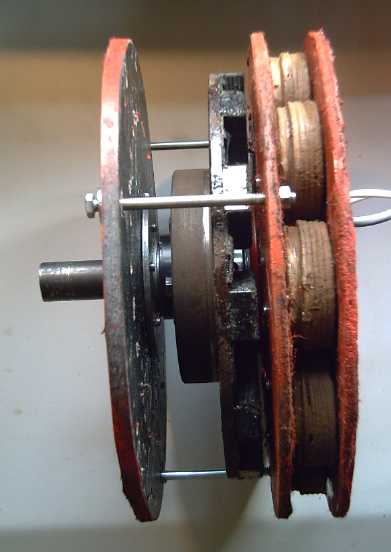

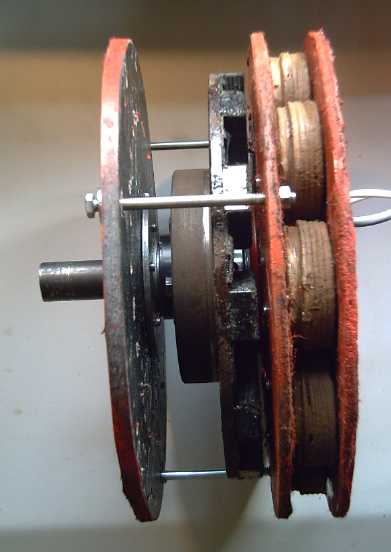

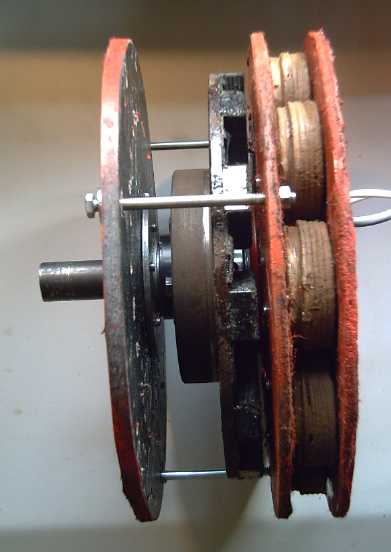

Electric Hubcap kit configuration, Open edge view and closed.

Electric Hubcap kit configuration, Open edge view and closed.

(The disk brake rotor shown is being replaced with a flat plate rotor,

with the main body of the motor just 4" across instead of 5".)

The kits include all the parts to make one Electric Hubcap

Motor except they EXCLUDE:

* the 12 supermagnets (about 2" x 1" x .5" or 50mm x 25mm x 12.5mm)

Purchasers must buy their supermagnets separately - I can't supply them

for the sort of prices they're available at off web sources since

that's where I buy them.

* Epoxy resin. The magnets are glued to the rotor with a small amount

of epoxy resin, and then pieces of polypropylene strapping (supplied)

are glued over them to ensure they don't come loose. Although a cup of

resin is plenty, it's locally available everywhere and I think liquid

would complicate requirements for shipping.

* Brushless Motor Controller. That's a separate item. Unfortunately

mine aren't ready to sell yet.

* Mechanical Torque Converter to hook them directly to car wheels. I

don't have this working yet.

What the kit DOES INCLUDE:

6" x 1" 4110 HT SR machine shaft axle

SDS 1" Bushing (holds rotor to axle)

2 - 1" trailer bearings

2 - 1" trailer bearing races

10" diameter x 5/16" mild steel flat plate magnet rotor (without

magnets)

1 meter of 2" wide polypropylene strapping

Rotor compartment PP-epoxy cover bell (or end plate and ring for walls

- a last pesky detail)

2 - sets of bearing holder parts

9 - pre-made stator coils for 36 volt operation, with:

* low loss iron powder toroid cores

* ilmenite coating to improve magnetics and reduce losses (I

don't think any other motor has this!)

Inner stator plate/rotor-stator compartment separator

Outer stator plate

Magnet sensor PCB with 3 hall sensors with 5 pin flat rubber trailer

lights plug for motor controller connections.

APP connectors (70 amp size) for coil connections to motor controller

Angle iron 'feet'/mountings.

Stator vent cover screen

Miscellaneous nuts, bolts, washers.

Some Electric Hubcap Motor rough specs

approx. 12" diameter x 4" body length, rotor 10" diameter, center of

force: 4" radius.

Brushless, 3 phase, axial flux, 120º Hall effect magnetic polarity

switches, air cooled.

5 KW, 36-42 volts (nominal), 0-127 amps. (12-14 volts, 0-380 amps with

parallel wired coils.)

Stator coils (9 of) to rotor supermagnets (12 magnets 2" x 1" x .5", 6

poles) flux gap: 14-18mm / .55"-.7".

Torque and speed vary with flux gap: "adjustable specs" motor. (Nominal

0-2000 RPM; .17 N-m/amp torque constant @ .65" flux gap)

Efficiency: around 95% peak, around 75% at max rated load (these are

both excellent figures)

March in Brief

I put off filling out Revenue Canada SR & ED project

forms, corporate income tax and my Personal income tax until March

20th, then spent many hours on them. (The last item remains to be

finished.) Until the 20th, work on the motors took first place.

At about the start

of the year, a friend took it upon himself to start rebuilding my

rather

primitively formatted website and give it some pizazz, which he had

been threatening to do for some time. He's a great

database and web design programmer. This project started bearing fruit

in

March, and TurquoiseEnergy.com

is getting a new and more professional look. At the same time, the work

has led to

me revise some obsolete info. But so far I haven't been able to pay the

web site revisions the attention they deserve.

Paperwork and web site

aside, the next thing to do was to get set up

for making all the special parts of the Electric Hubcap motors, so I

can offer them as kits.

I made a

polypropylene-epoxy composite

'stator ring' using the plywood mold. It was

gooey

and frustrating work. But if you're trying to do the best motors, they

might as well be

made of the best materials. I made a better, deeper mold with 'butcher

block' HDPE rings that would allow a simpler technique: pile in

shredded fabric, pour in epoxy, put the top on and press it down with

C-clamps. The molds themselves can also be produced and sold. In spite

of that, since the coil making has been much simplified, these 'rings'

are now the most labour intensive part of making a motor.

The new rings are 'universal': a stator made with them can

be used for any configuration of motor. They can bolt onto a trailer

wheel

hub or an axle flange, or hold a bearing race plate or a hub. The rings

can be on both sides of the stator coils, and they can form both 'end

bells' of

the motor. They can be made thick or thin by varying the amount of PP

material and epoxy used.

I decided to offer a 'regular motor' configuration kit,

with

the rotor and stator enclosed in a shell with a bearing at each end and

the axle sticking out one end (or both ends). That meant creating some

small metal plates to hold bearing races at the center of the rings.

Very large washers (4" OD) with CNC drilled bolt holes, one turned to

the bearing race size, turned out to be ideal to clamp onto the plates.

With those parts

done, only

revised tiny printed circuit boards for the magnet sensors and

miscellaneous bits remained. Perhaps I should get a small CNC machine

suitable for PCBs. I haven't made any myself since the cave days with

film,

photoresist and ferric chloride etching fluid, but APC charges just as

much for these simple , almost trivial, boards as for complex ones. On

the last night of the month, I roughed out the board layout.

The new motor had ilmenite coated coils instead of rutile,

and the no-load power drain seemed even lower. I mentioned the motor on

a list. Among several, I got a response from the owner of

SuperMagnetMan.com, who is

involved with the magnet end and has helped

design a fine motor himself.

Among other things, he said: "I am excited to hear about

your advances in this area. [snip] I have worked with lots of people

through this group and other places that are looking for something

similar to what you seem to have operating." And: "I have been wanting

this kind of motor for vehicles for the last 10 years [snip]."

I think customers for motor kits are out there if I can

(a) find them, (b) deliver what's needed (c) with decent quality and

service, and (d) at an affordable price. And doubtless there's some

DIYers who'll make their own, maybe buying some of the parts here -

hopefully after I get around to updating the (now pretty obsolete)

instruction manual, and maybe coming for a workshop to ensure they have

the finer details right (and maybe install the motor in its intended

application).

When the AA cells arrived I did a lighter car battery

- 9 pounds, still 30 amp-hours. It started the car, but it wasn't

as strong as the D cell battery (12 pounds) and I switched back after a

day or two.

But with the high energy storage per weight, NiMH AA cells should make

excellent electric

car/PHEV batteries.

For a week or more, most of the work was nice in that it

required little creative thought - just plug away at it. But there

seemed little excuse or reason to stop between morning and midnight,

and the desire to finish things - especially the motor in its new form

- was strong. Those hours can't be good

for

anybody, and everything else falls behind.

For my own MnMn batteries, I made a new battery cell case

with

thicker sides that I

hoped wouldn't leak. But I didn't get around to filling it. I ran some

long tests on the present cell which

showed that although self discharge is awful and the discharge voltages

and maximum current are pathetic, it will put

out small levels of current for days, and do so again and again upon

recharging, with even slight improvements at times: it has the essence

of a rechargeable battery. A light doping of osmium that probably

didn't contain much osmium on the separator sheet made a minor

improvement. I'll try to ensure more of it gets employed in the next

cell, which will also use salvaged dry cell MnO2 instead of cheap

(impure?) pottery supply MnO2. That might reduce self-discharge.

Opinions: Dropping Solar Power Prices - Natural Resources are a

Public Trust

It seems two people

once entered a nuclear

plant in Ontario to test security, and found that they could easily

have walked out with all the 'spent' nuclear material they could carry

to make dirty bombs or whatever.

Ontario Hydro denied that there had ever been a security breach and

said everything was perfectly secure. The nuclear industry puts much

pressure on politicians and governments to adopt nuclear power plants,

with the same bland assurances that everything is perfectly safe and

nothing could happen, and that the country can't do without nuclear

power.

The USA has hollowed out a whole mountain to store nuclear

waste in. It will need to be

guarded for longer than recorded history at taxpayers' expense. A large

area around Chernobyl including the town is uninhabitable and will

remain that way for a long, long time.

The worst potential

radiation effects - probably alarmist, but who knows? - of the nuclear

plant disasters resulting from

the Japanese earthquake and tsunami appear to be (a) the loss of

mountainous Japan's main agricultural land area, (b) the end of many

Japanese cities including Tokyo, and (c) the end of fishing in affected

areas of the

Pacific. And at times, the Pacific coast of North America is directly

downwind of the dying Japanese reactors via the jet stream. The

Canadian government - before it could possibly have had time to check

out the facts

- quickly assured us there is nothing to worry about and that we should

take no

prudent advance measures, however simple, in case radiation hits us

here.

In case these lessons aren't abundantly clear on their

own, there's now a new reason to phase out nuclear power generation,

and never to build another new station:

The cost of photovoltaic solar panels has gradually but

continually dropped ever since they were first invented, while

the cost of nuclear power continues to rise. In 2010 a milestone

was reached: a report says it is now less costly to build installations

that generate electricity

from solar cells than from nuclear energy. The report may not be

entirely unbiased (any more than pro-nuclear reports), but the ongoing

trend seems clear. Perhaps it is solar electricity that will one day be

"too cheap to meter" - a one-time boast of nuclear power exponents.

(...and all this before Japan, and without my

nanocrystalline borosilicate reflective glaze for DSSC solar cells!)

---

Someone said they had heard on TV that among the 1% top

income 'earners' who now rake in 1/4 or 1/3 of America's wealth each

year are those who feel more at home with Saudi princes than with

citizens of their

own country. It can well be imagined that some of these people would

feel uncomfortable

around the citizens of the civilization they're pillaging, and even be

ashamed look them in the eye. The words

of the song One Tin Soldier come to mind:

Go ahead and hate your neighbor!

Go ahead and cheat a friend!

May they wake up and

see how shallow and unfulfilling is the obsession with wealth for its

own sake, and how destructive it is to their own personality and sense

of self worth when it's knowingly and willfully gained by manipulating

and exploiting others. "The love of riches all too often obscures and

even destroys the spiritual vision. Fail not to recognize the danger of

wealth's becoming, not your servant, but your master." - Jesus

---

Other than the need

for patent reform and for the missing government

Department of Progress, one outstanding societal structural flaw

promoting gross inequity would

seem to be the permitting of private ownership of natural resources,

such as oil, before they are extracted and processed. I believe the

principle needs to be established and made sacred that natural

resources are public property, to be under the control of a public

trust

or perhaps (in Canada) a crown corporation.

Private contracting

corporations may extract

resources from the ground and process them as called for by the trust,

but they will not own them. The

trust will sell the end products without discrimination to whoever

needs them, and of course some products like oil and gold can help the

government fund services with less taxation. This rather obvious step

should eliminate some of the unaccountable vested interests and their

obscene wealth, and their oppressive economic power to prevent progress

and keep civilization static and stagnant.

Electric Hubcap Motor System

Polypropylene-Epoxy Stator

Rings

I made another

stator with the plywood stator mold, this one as a flat ring to which

would attach to some sort of metal center. It was frustrating and gooey

work.

One change was that instead of

cutting 30+ circles of polypropylene, I took some of the scrap pieces,

and I took some bigger pieces, of both the nonwoven mat and the cloth,

and cut and ripped them into smaller

pieces. This was intended to eliminate the tedious cutting, and to

mingle the layers so it couldn't delaminate, as I had to a small extent

experienced earlier. Only a top and a bottom circle were cut. But in a

sense this was like starting all over again. I had no idea how much

cloth or how much epoxy would be needed, and there was no way to get a

good estimate except to see what came out of the mold.

I used 150 grams of epoxy on the first try, and I

neglected to weigh the cloth. The proportions seemed good, but the

piece was only 1/8" thick. Next there was just 150g of that epoxy left,

so I did it again. This time I used 72g of fabric. This ended up still

under 1/4" thick. Proportion was okay - it might have used a little

more cloth. Then I used around 235 grams of new epoxy and "some" more

fabric. It came out the desired 3/8" or so.

I had a problem weighing the epoxy as the digital

scale turned itself off twice while I was pouring it slowly in. (I also

went

months before figuring out how to turn this same scale off manually:

you have to hold the "On/Off" button down for about 3 whole seconds.

Another poorly designed product: the hardware is fine but the software

sucks!)

Anyway! It seems it took about 400-450 grams of epoxy and

200-250 grams of shredded fabric.

Old ring mold (not a fungus)

Old ring mold (not a fungus)

The next day (6th), I made a second ring. For this one I used

360 grams of epoxy and 120 grams of PP fabric, and it came out just

under 1/4" thick, and seemed to have good proportions.

It was still gooey and frustrating work. One problem was

that the fabric wouldn't lie down and kept coming out of the shallow

mold while I was trying to put it in. Then, in spite of waxing them,

the epoxy stuck to the plywood

and to the wooden center I made. I decided to make a new mold out of

1/2" high density polyethylene 'butcher block', that the epoxy wouldn't

stick to. I spent the afternoon of the 5th at my brother's near

Industrial Plastics, waiting for them to cut my piece of HDPE.

There was no way I was going to try cutting these somewhat

pricey pieces by hand. I had just learned the programming and technique

for routing

curves and circles with the CNC drill/router, so that was the obvious

way to go. I cut a 6" length of 300 mm PVC pipe (same as for the

motor bodies) for the outside edge of the mold, to solve the

fabric flopping out problem. Instead of brushing on the resin to wet

down the fabric and

get it flat enough to work with, I'd simply throw in fabric and pour

in resin, then cram the top ring on it and clamp it down with C-clamps.

Then I realized I'd need gigantic C-clamps to fit over the

6" sides. I trimmed the pipe down to 4-1/2", and bought 3 more 4"

C-clamps that would fit over that. The mold had now cost $60 and

several hours work, exclusive of an unexpected $40 and more time to fix

my air compressor, which the CNC machine needs to raise and lower the

tool.

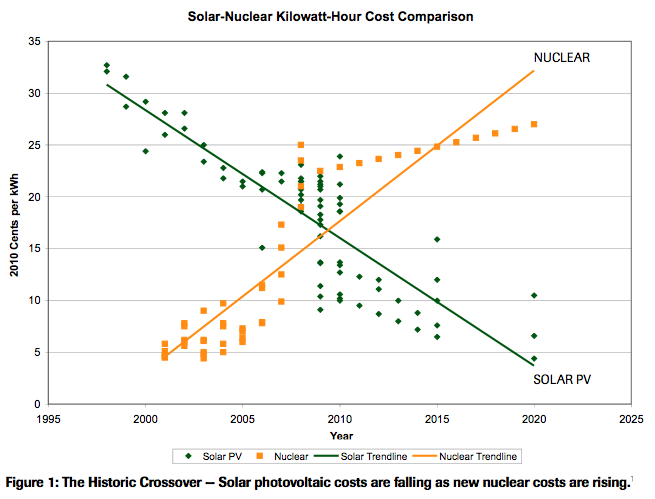

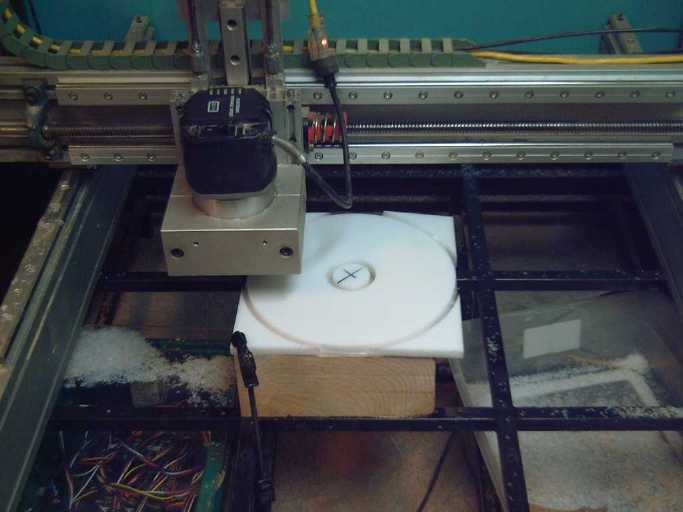

CNC machine with router, cutting HDPE stator mold piece

CNC machine with router, cutting HDPE stator mold piece

The final piece was a 2.75"

OD center pipe. A 4" piece of aluminum pipe 2.85" OD was found and

given to me at Smith Bros. That at least didn't cost a lot, but I spent

a couple of hours on the lathe shrinking it to 2.77". (partly because

my cutting tool was dull - it really helped when I finally

thought to try another one.)

New ring mold

New ring mold

Drop in bottom mat (left), then some shredded pieces of fabric, some

epoxy and repeat, then place top mat,

top mold ring over that, and compact it down with C-clamps.

The first ring I made with this new mold had 150 g of

fabric, 450(?) g of epoxy, and came out 1/4" thick and was a little dry

in

spots. The next one used 150 g of fabric, 510 g of epoxy, and took 45

minutes from start to putting it in the oven - a bit laborious, but

much less so than previously.

That seemed fine, but when I took it out, it had large dry

sections at the outer edges and it was .33" thick on one side to .42"

opposite. Since I used no more cloth and more epoxy yet had bigger dry

areas, it would seem one must pay very close attention to distribution

when piling in the fabric, distribution when pouring in the epoxy, and

the tightness of the C-clamps, which I had done up less tightly this

time, fearing I might be bending the plastic mold pieces.

I'm getting better at this, but I think the real answer is

to find still more improvements to the technique.

I calculated co-ordinates for the coil mounting bolts and

some others - lots of sines and cosines on a calculator - entered them

into a CNC drilling program, and made two PP-epoxy rings into a stator

and one into an end bell for the other end of the motor. Some other

holes I drilled by hand and will add to the CNC program later, and

differentiate between the inner ring, outer ring, and end bell pieces.

When this is all ready and programmed into the CNC machine

I can sell not only finished rings, I can sell the

CNC-made molds - and manual drill guide templates - to help others do

more of their own

making of

motors as well. This is part of the counter-intuitive business

strategy: If this catches on, there are

250 million vehicles in North America almost desperately needing

electric propulsion. The more molds, etc, that I can produce, the

faster it'll spread, and it will take many years to saturate the market

no matter how many people start making them. To paraphrase a famous

saying, sell someone a motor and you have one electric car - sell them

means to make motors, and they'll grow a whole crop of them.

Or perhaps some sort of franchise system could be worked

out.

Metal Ring Centers - bearing race holders

Next, what goes in the hole in the middle of the ring? For

motors with a bearing at each end, I had been trying

to come up with some sort of plate. I went out and bought some huge

washers, and ended up using two that were 4" outside diameter, bolted

together and sandwiching the plastic ring between them. The center of

one was turned on the lathe to fit the bearing race, while the other

prevented the race from pushing right through.

Next I set up the CNC to drill 5 holes

in the washers for 5 bolts to hold them together. Using the machine is

the only way the holes will all line up properly, and they can be

cranked out easily when and as required.

For the thicker

rings, center washer spacers

that fit are

necessary to prevent the race from falling in between the big outer

washers. Unfortunately the best spacers I've found still require work -

grinding 5 indents where the bolts go through to accommodate them, as

the outer diameter is just a bit large on the size where the inner

diameter

is good.

The Form of the Motors -

"ordinary motor" type

I got a trailer hub - the new stator ring would bolt right

onto it. Then I started thinking about shapes and forms. My axial flux

motors have both bearings at the stator, whereas most motors have one

at each end of the body - one on each side of the rotor.

Mine can exist and run without having a body

over the working parts, which, as I stop to think about it, is rather

unusual.

But whatever form is best for a motor with a torque

converter, for an ordinary motor that spins a shaft, the shaft will be

stiffest with bearings at opposite ends. I'm going to use

the new 'stator rings' also as 'end bells', with the turquoise PVC tube

for

the bodies as originally planned.

Electric Hubcap in an enclosed "ordinary motor" guise.

Electric Hubcap in an enclosed "ordinary motor" guise.

This was a first "mock-up". Then I asked myself why it needed two

layers of outer case over the rotor, and eliminated the outer one.

This will be one more of several unique EH

rotor-stator-axle-bearing configurations that may be adopted for

various purposes - one of general utility and familiar to most motor

users. By making the

stators as flat rings, one standard design of rotor and one of stator

can now be employed to form any of the configurations.

Axles: 1" Steel Rod Shaft

I couldn't fit the rotor and stator properly onto a

trailer axle. But after trying the encased motor layout, I realized

that an

axle end nut wasn't needed, and that the optimum axle for it would be a

simple 1" hard steel shaft such as "drill rod", which could be cut to

any desired length, with the "SDS" taper lock bushing to hold

the magnet rotor and provide a base for the bearings. At Metal

Supermarkets I got a hard steel rod

called "heat treated, stress relieved, 4140 machine shaft", which

sounded like the best and was also (unlike drill rod) economical. It

only

needed to be 6" long, with the bearings at 0" and 4" leaving a 2"

projection. Such a short axle is inherently very hard to bend, so I'm

confident the strength is more than adequate.

Once I had this piece along with the others I'd made or

gathered, the steps for putting together a motor fell into place.

The new motor without the rotor cover

The new motor without the rotor cover

The stator and the rotor form two separate compartments

Cooling air flows by the coils from the rim to the interior, through

holes to the center of the rotor,

is flung outwards by the rotor magnets ("fan blades"), and exits

through holes in the left hand cover.

All assembled

All assembled

March 28th: I had a steel flat plate rotor made by abrasive waterjet

cutting.

I re-assembled the motor with it to check the fit. The motor body is

just 4" long (or is it 4" thick?),

The rotor cover will be just over two inches across.

The thickness of the SDS bushing that clamps the rotor to the shaft

prevents a further 3/4" reduction.

The main thing left to do before I can sell these motors

as kits is a revised circuit board for the magnet sensors, and I layed

it out on the night of March 31st. I would also like to change the

shaft

end bell to a one-piece bowl shape with integral sides. This will

better ensure proper alignment, and also that the motor can't be run

without the protective cover over the rotor the way it's seen in a

couple of pictures here.

I think I'll also sell the kit sans supermagnets. I don't

do anything with them here, and I would just have to import them, and

then in many cases re-export them, all at extra expense in taxes, fees

and shipping. People will can just as well order their own. It lets me

knock off around 125$ from the kit price for around 75$ in magnets. The

price of the complete motor kit (without magnets) will

be about 500$.

INSOLUBLE Rutile (Titanium

Dioxide)/Sodium Silicate Coil Coating

The rutile in sodium silicate coating on the coils

definitely improves the

efficiency of the motors. But the water soluble sodium silicate medium

seemed to portend poor durability of the coating.

In trying to figure out ways to make the rutile/sodium

silicate coil

coating insoluble, I had been forgetting one of sodium silicate's most

interesting properties - when heated to 99-105ºC, it loses its

water of hydration... and thereupon becomes insoluble, all by itself.

Problem solved! The coating doesn't look any different, but it no

longer will dissolve in water.

The wire insulation and the epoxy are rated for about

200ºC, but it does mean taking the coil cores above their

70ºC rated temperature for a few minutes to do it. The

manufacturer says that's no problem - the coils degrade, but slowly

over time, if

they're

too hot. A once-only overtemperature is thus different from having it

as a continuing or repeating condition while running the motor.

The other problem, the coating flaking off, is a bit more

tricky. Painting on a stiffer mix (less water) seems to help, but it

really doesn't bond to the cores. Perhaps I should rough them up with

sandpaper?

The other experiment, painting on 2 or 3 coats to see if a

thicker layer helps even more than thinner, also remains to be tried.

Ilmenite...

As a further experiment, on the coils for the next motor

(seen above) I

tried using ilmenite, a mineral blend of titanium and iron. (FeTiO3).

The TiO2 alone (rutile) is much better than air, but perhaps the mix of

nano-size

paramagnetic and ferromagnetic attributes would create a still better

magnetic path from the outside of the wires into the core.

Ilmenite responds weakly to a magnet, suggesting (along with the oxygen

content) that the iron is in more of a ferrous (FeO) valence state than

ferric (Fe2O3).

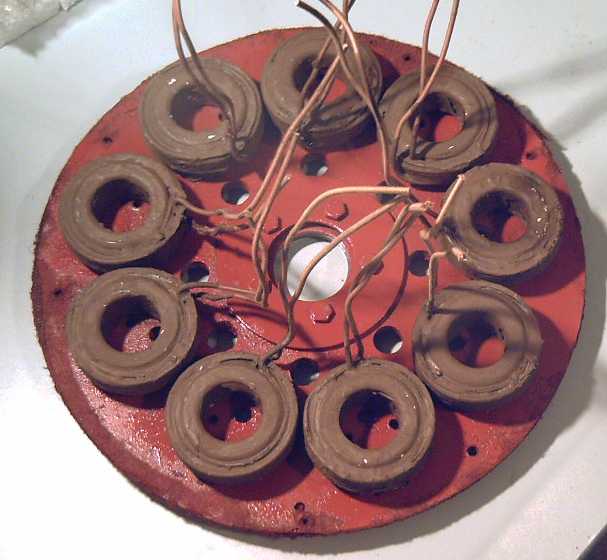

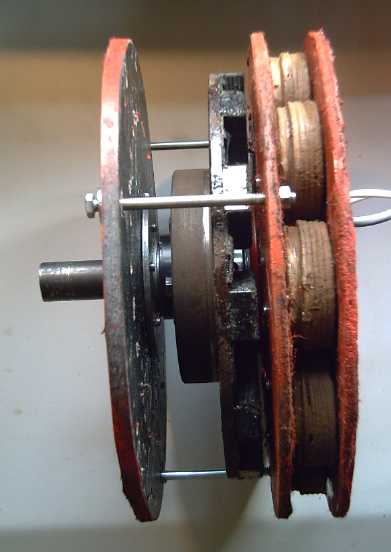

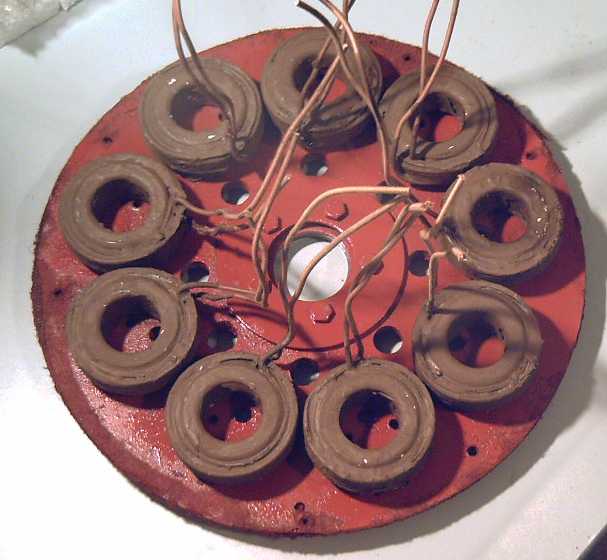

The ilmenited coils on the new (painted) stator ring. The

center hole holds a bearing race.

The ilmenited coils on the new (painted) stator ring. The

center hole holds a bearing race.

The rotor magnets, acting as a fan, will be right behind this

ring. Another ring will enclose the coils,

and the vent holes will pull cooling air in from the stator outside

edge,

across and through the coils.

That ilmenite might well work even better than rutile was suspected...

just look at that

rich,

creamy chocolate color! (doubtless supplied by the iron content.)

When the new motor was

finished on the 19th,

I measured the no-load currents. The gap was about .6", and the

coils are 20 turns of old cotton insulated #11 wire (3 phases with 3

coils in series) whereas the previous motor is 61 turns of #14 (3 of 3

in parallel), and the flux gaps were different. In addition, the

bearing setup is a bit different with one bearing now on each side of

the rotor. So some difference in

figures may have other

causes than ilmenite versus rutile.

I'm not making enough motors (so far) to try out just one

small change per motor as they've so rapidly evolved.

Interpolating last month's rutiled coil results for a .6"

gap estimates

38 watts at 500 RPM and 105 watts at 1000. The new motor, with the

ilmenited coils (and the comparison-disruptive factors mentioned),

produced the

table below. Power was two NiMH dry cell batteries providing about 26

volts. Results compare favourably with the previous, at 31 and 88

watts, a further 15-20% idle power reduction.

RPM

|

Current (Amps)

|

Watts (A * 26 volts)

|

500

|

1.2

|

31

|

1000

|

3.4

|

88

|

1500

|

5.4

|

140

|

The coils felt cold after the tests,

but the 1/4" x 2" coil mounting bolts (at least, their heads) were

noticeably warm. Zounds! Perhaps I should use thinner or

non-metal bolts, too! I think I'll try #10's next time. With the double

ring stator, they should be stiff enough.

Iron Powder Cores Info

I called Micrometals and found out that (a) the iron

powder size is on the order of 100 microns, and (b) that it is

pre-coated before making it into cores so that the particles don't

short into one big iron conductor, with all the nasty eddy currents

that would result in.

I should think that

having nano-size iron particles would be theoretically optimum, though

improvement on

near perfection may be a bit academic. Problems with producing iron

nano particle cores would be: (a) getting iron particles so small. It's

easier to get 'nano' with oxides, but iron metal is best. (b) coating

such tiny particles to insulate them. And even if they were coated, it

would have to be a nano-thin coating as well or it would be mostly

inert coating with little actual iron.

The glassy ceramic substrate I was trying to do with

ferrous

(FeO) and paramagnetic TiO2 particles might work (if successfully made

- in a reducing atmosphere kiln), but I'm not confident it would be

better - it would be better than air, and almost 100% lossless, but one

might need substantially more core to do the same job, meaning a bigger

motor for the same power.

The Electric Weel Project:

The Car Motor of the

Future?

I decided this giant diameter motor should have a solid

steel plate for the

rotor after all - if only a thin base. I'd hate so much to have a weld

give way and see a

huge spinning rotor fly to pieces! I thought I could really use that

pulsejet steel plate cutter that I didn't finish making last fall -

cutting out a 26" round steel disk with the angle grinder has very

little appeal.

Instead, I called Waterforce abrasive waterjet cutting in

Sydney, and found the price for cutting such disks is much less than I

feared. So I asked for a 26" disk of 1/8" mild steel.

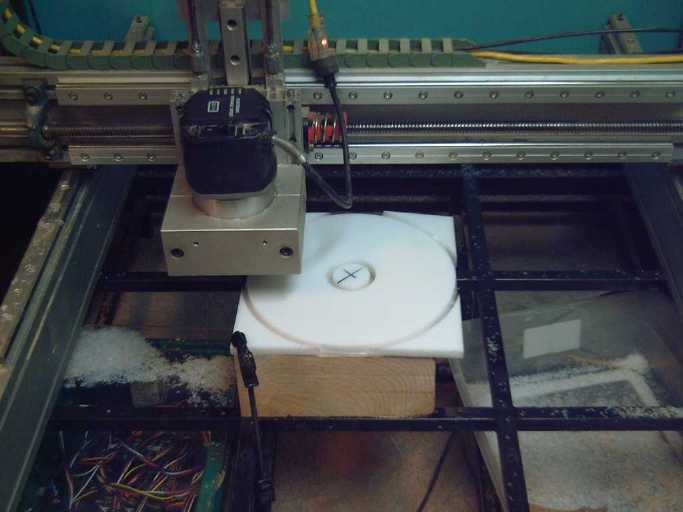

26" diameter rotor disk of 1/8" steel (20 pounds)

with 10" EH disk and chair for comparison.

Next (latest plan), I'm

having a 26" steel ring cut 2.125" wide from

3/16" stock. This will go around the rim as a stiffener, a thicker base

to mount the magnets on, and to carry the magnetic flux between

magnets. The inside piece left over from that ring is to be the

center of the stator, which needs to be non-metallic in the outer area

under the magnets. I hate to think of the mold it'll need and all the

epoxy it'll take to do the giant 'stator rings'!

And it occurs to me that with the SDS taper-lock bushing

attaching the 10" rotor to the 1" axle seeming to work so well, all

that's needed for the bigger motor is bigger SDS tackle. SDS bushings

for shaft sizes up to 2" are in fact available so I bought one.

When I have the steel pieces - and some time - I can

continue the project.

I still think the pulsejet steel cutter would be a cool

tool to have!

Mechanical Torque Converter (MTC) Project

I decided to change the torque elements, and to have three

curved 'strike' teeth 120º apart on the motor rotor, that would be

'hit' first at a very shallow angle, that gradually steepens so as to

operate quietly and produce a smooth pulse of torque. Then three

'escapement' arms to strike them, on the output drum.

Variants of two, three, five and six teeth and arms can be

tried

pretty easily. Near the end of the month, I realized I could put the

pivots on the outside of the drum and just have the points sticking in

- this would give the largest radius of force, about 6" instead of 5"

or 20% better torque from the same pulses.

I may also put springs on the escapements, causing one

hook to try to stay down. This isn't in accord with the oscillating

masses operating principle, but it could help transfer more force from

the motor to the output during each pulse.

I also looked at a truck this month at Canadian Electric

Vehicles, with an electric motor

driving a set of planetary gears whose output turned the drive shaft to

the rear differential. That motor must really rev up on the highway.

Speeds of single gear ratio electrics are evidently often limited to

about 80 Km/Hr.

The value of a torque converter is again brought home: to provide the

required torque at low speeds yet keep the motor revs down on the

highway - and to do it all with greater efficiency than the gears.

I hope I can find some time in April to work on it!

Ni-MH Dry Cell Car Battery Project

NiMH

dry cell battery #2 in a better fitting enclosure under the hood: 30

AH, 30 D

cells.

NiMH

dry cell battery #2 in a better fitting enclosure under the hood: 30

AH, 30 D

cells.

Starts great even at

-6ºC! Under 12 pounds - the

car is 30 pounds lighter!

(Strap is aluminum. ...though duct tape might work fine if you

can wrap it on somehow!)

Best Charging Voltage?: car

alternator's

13.8 volts not

only works: it's Ideal!

For a typical battery charger, charging up NiMH cells from

low to

full, voltages up to perhaps 1.41 or 1.42 volts may be used. Then the

charger

shuts off. In the car,

the battery usually doesn't get

discharged very far, and driving continues until a destination is

reached, not just until the battery is charged. But NiMH cells don't

stay up

at 1.4+ volts, they discharge to between around 1.37 and 1.33 in a few

hours or in a day or two - even lower after some days or weeks unless

they're the 'low self discharge' type. Let's call them 'overcharged' if

they're above that. If a cell keeps getting strongly charged for

extended

periods when it's already full, it may shorten the life, and anyway

it's doing no

good. My first in-car test showed that the car alternator's 13.8 volts

is

acceptable, but what really is the best constant voltage to

charge at if a battery is going to be left on charge for long

periods such as while driving?

I ran a test to find out. I charged one of my NiMH car

batteries (sets of

10 cells in series, so voltages are *10) with the lab power supply at

14.10 volts. The current gradually settled to about 4 amps and stopped

going lower.

I reduced it to 14.00 volts. Since the battery was charged

nearly to 14.10, the current stopped. But when checked a couple of

hours later, as the

'overcharge' reduced, the battery was again drawing abut two amps to

hold it at 14.0 volts.

I reduced it again to 13.95 volts. Again the battery

stopped drawing current for a time, but 3-4 hours later, it was up to

400 milliamps - much better, though still a higher trickle charge than

desirable (and a needless 5 watt power drain).

Then down to 13.90 volts. This time as the voltage dropped

the

current came up to only about 80 milliamps. Divided amongst 3 banks of

D cells (or 12 banks of AA cells), this is a very acceptable continuous

trickle charge current.

Next test was at 13.85 volts. It took longer for the cells

to drop from 13.90 to 13.85 since they were much closer to staying up

there by themselves. The current to keep them at 13.85 was trifling -

the current meter needle on the power supply barely moved.

Then down to 13.80 volts. It took longer for the cells to

drop down to the new voltage with each drop, and this one was took some

hours. I would have had to connect a milliamps meter to read the

trickle current.

It took overnight to drop from 13.80 to 13.75 volts. This

might mean it was a few percent below 'full charge', eg 97%. Not much

in the overall scheme of things!

It took about a day to drop from 13.75 to

13.70 (temperature around 12 to 15ºC), so considering typical

self-discharge rates, one suspects that could mean at 13.70 it's not

quite fully

charged, eg, it might sit at around 90-95%.

Conclusion: for a constant voltage charge of

indefinite duration, a good voltage to charge at is about 13.75 to

13.90. This will keep the battery 'topped up' to 100% without

overcharging it. By some fluke of chance, car alternators put out 13.8

volts as a standard, making NiMH batteries ideal car batteries. And

they are more ideal than lead-acid, because until they're considerably

discharged, they sit up over 13 volts, so headlights will hardly dim if

the engine is

off. This will be especially useful for a car running on

electricity

instead of gas.

Continuous

Charge

Voltage:

13.65 - too low, won't be well charged

13.70 - okay, might stay slightly undercharged, eg 90-95%

13.75 - good: virtually no trickle charge. If undercharged, it's only

by a very few percent

13.80 - good: trivial trickle charge (10mA?) <-

standard car alternator voltage!

13.85 - good: trivial trickle charge (20mA?)

13.90 - okay: draws an allowable trickle charge (eg, 80mA)

13.95 - okay but a bit high: a considerable trickle charge (eg, 400mA)

stays on

when battery is fully charged

14.00 - too high: keeps drawing a couple of amps when fully charged

On measuring, I've discovered that MY car's alternator is

putting out 13.95 volts. It may well be that on older cars, the voltage

is really regulated by the current, so it probably rises to give the

NiMH

battery the same current as it would give a lead-acid battery. It's

still workable. I expect that newer cars made in

the solid state era have better regulation.

Speaking of Chargers...

Okay, so how do you charge NiMH 12 volt batteries that

aren't connected to a car alternator? I found a good 6 or 2 amp charger

for $40 in the automotive department at Canadian Tire, model 11-1526-8.

It's said to be for lead-acid batteries, but inside are two trim pots

that can be adjusted. The one towards the rear changes the voltage at

which the green LED comes on saying it's charged and the current to the

battery shuts off. With the nearly charged battery connected, turn it

clockwise to reduce the shutoff voltage to about 14.1 to 14.15 or maybe

14.2. It takes about 20 seconds to react - not to mention you have to

wait until the battery charges to the right voltage - so patience is

required. (The other trim pot more towards the front seems to adjust

the 2 amp rate current setting.)

NiMH dry cells technical advances: Improving EV energy densities?

The first NiMH AA dry cells I bought in 1996 were an

impressive 1.6 amp-hours - over triple the last NiCd's I'd had. Today

2.3 to 2.6 is the norm. With 2.5

AH AA cells, GM's EV-1 could

have had about a 200 mile range instead of 100 miles, with the same

total weight of batteries.

I recently saw a

NiMH AA cell with some odd

brand name

claiming to

hold 2800mAH of charge. It weighed 27 grams, 10%

lighter than most. I couldn't take it and run tests on it, but

taking the specs at face value:

2.8 AH * 1.2 V / .027 Kg = 125 watt-hours per kilogram.

That's over 20%

higher than the previous best, and well up into the range of the high

density lithium ion types. It's also over double the energy of NiMH

flooded cells I've seen specs for such as those used in the GM EV-1.

These sound like

great EV

batteries. If 2.8 AH, 125 WH/Kg, is the coming standard, in the choice

between

lithium ion and NiMH, it may boil down to price, cycle life and

performance: which

is really better value? Here, eg, the 7 pound, 10 AH electric bicycle

L-ion pack at $1000 would have to last a very long time or come down a

long way in price to outdo a 7-1/2 pound, 11.2 AH $300 or even $400

NiMH

pack. And the NiMHs are inherently good performance, and

environmentally nontoxic at the end of their

long life.

The chemistry? One surmises

the positrode must have manganese in it,

charging to permanganate, or that much of the nickel charges to NiO2

[valence IV] - or both. Otherwise it's pushing the limits of the nickel

to an amazing

degree. The traditional nickel charge from Ni(OH)2 [II] to NiOOH [III]

is

theoretically only 289 AH/Kg, and it really only attains around 217. So

the weight of the Ni(OH)2 powder alone would have to be 13 grams - half

the total weight and probably 3/4 of the bulk, which doesn't seem to

leave enough for everything else.

The alloy of the hydride must be very good, too, one of

the best sort of 1000+ AH/Kg types. This is about the same in theory as

my Mn

negatrode, but at a lower voltage. The overall chemistry is obviously

getting very good.

If the positive is charging to MnO4 and probably NiO2

(both at almost the same voltage), it's the same 'mixed valence' Ni-Mn

system I'm using, except mine is in neutral (KCl salt) solution where

the reaction voltages are double what they are in alkali (KOH), and

I've added gas recombining catalysts to reduce pressure and chelating

agents. Except for the lower voltages (of both electrodes) and hence

lower energy

density, higher operating pressure preventing large cells, and the

higher materials costs, it would seem the latest NiMH

dry cells accomplish - in miniature - much of what I've been hoping for

from my own 2 volt

cells.

120 AA Cell Car Battery: Tenergy D

cells prove better than Tenergy AAs for starting cars

I got 200 AA cells, ordered in February. I used 120 to

make a 30 amp-hour car battery. This would theoretically operate the

same as the 30 D cells battery. But it weighed 9 pounds instead of 12,

each AA cell being less than less than 1/5th the weight of a D but

holding 1/4 as much energy.

AA: 100 WH/Kg (energy density by weight)

D: 75 WH/Kg.

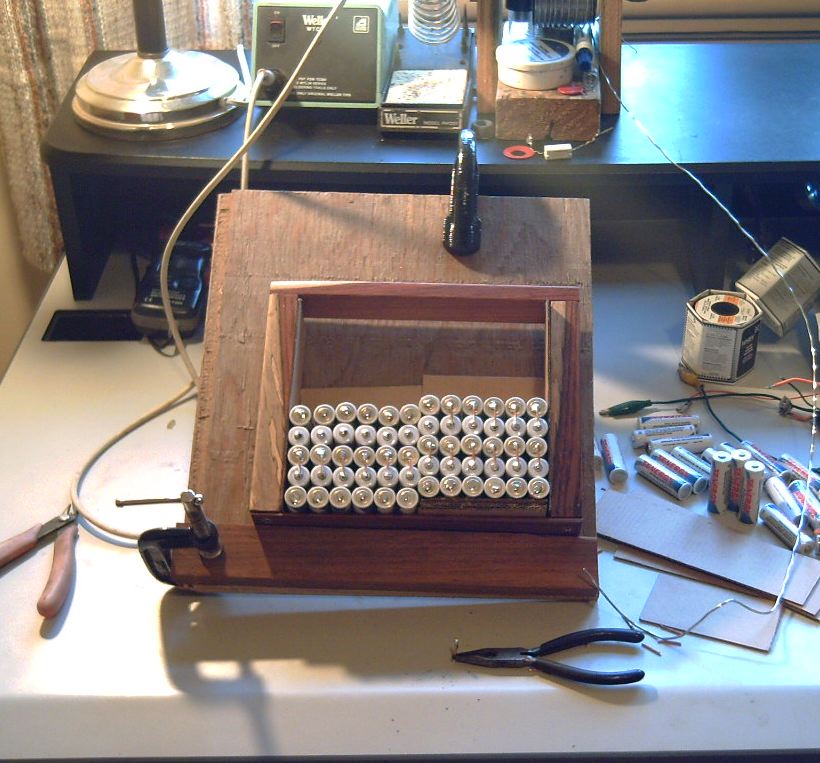

120 AA cells soldering jig

120 AA cells soldering jig

The skew at the center was to make room for terminal bolt heads in the

smallest possible case.

The cells kept getting out of place, falling over, etc, so I put the

jig on a slant.

Having now soldered together many hundreds of cells in my long

career without

ever having any resulting problem or battery trouble, I

suggest that no one who solders should hesitate to solder together

batteries from dry cells. I think reluctance to solder dry cells has

been a major unrecognized factor

holding back

utilization of the best small cells such as these for greater purposes.

As assembled, the 360 WH

battery weighed 4.00 Kg and was thus down to 90 WH/Kg. Using lighter

wire,

skimping on the solder, and having no enclosure are probably not the

best options. Smaller, lighter terminal bolts could shave off 40 or 50

grams - I've been using big 3/8" ones whose big washers can clamp down

car battery

cable

clamps, but that's unnecessary for EV use.

In operation however, the

AA battery delivered lower voltage supplying the 200 amps to the

starter motor. Voltages down to about 8.2 volts were caught on the DVM,

versus 9.3 volts and up with a D cell battery. And sometimes the car

hesitated to start although it was cranking over fine. Although it's

hard to get better than a rough

approximation of a very short duration minimum voltage with a simple

meter that

samples the voltage at a 'random' time, it would seem a D cell can put

out the same high current as 4 AA cells with 10-15% less voltage drop,

even though the amp-hours ratings add up to the same. Perhaps that

extra weight in the D cells goes into heavier internal conductors. (It

probably also needs a thicker case to hold the same pressures in a

bigger cylinder.) To

get the same performance as the 30 D cell battery, the AA would need

around 150 cells instead of 120, bringing the weight up to 11 pounds

(and the amp-hours to 37.5) and costing more. Of course, it's possible

this may apply only to "Tenergy" brand cells, which is the only brand

I've tried, and maybe even to these two specific models, so a

hard conclusion of "a D cell provides more current than four AAs" may

be premature.

With what I have though, I've decided that the D

cell battery is more practical for a regular car battery, and switched

my own car back. Three 'extra' pounds means little -- 12 pounds is

still 20 pounds lighter than lead-acid.

The situation is different for EVs and PHEVs, however. In

that case, enough cells are needed to provide a desired electric

driving range - say from around 2000 AA cells up. With so many

cells - and an efficient drive system - the current demanded of each

cell isn't so high. Instead, it is probably more important that the

2000 AA cells weigh 60 kilograms (132 pounds), versus 500 D cells at

81.5 Kg (180 p). Increasing from that minimum to 24 KWH to push the

driving

range up to perhaps 150-200 miles shows more significance: 530 pounds

for 8000 AAs is almost 200 pounds lighter than 720 for 2000 Ds.

Those new(?) 2.8 AH, 27 g AA cells would be only 193 Kg/425 pounds -

another 100 pounds off.

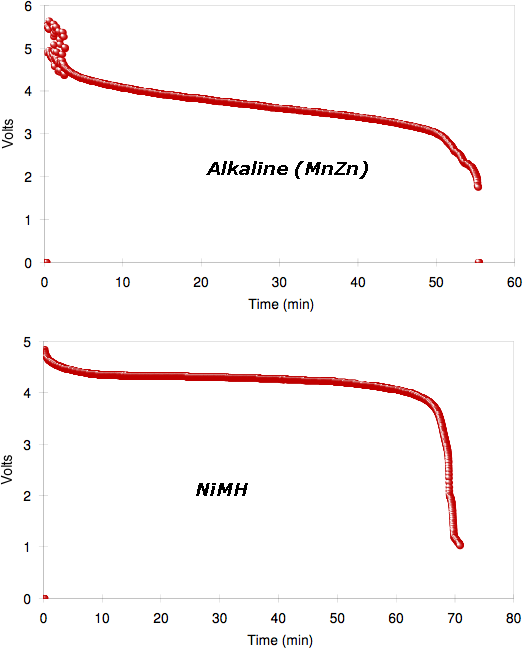

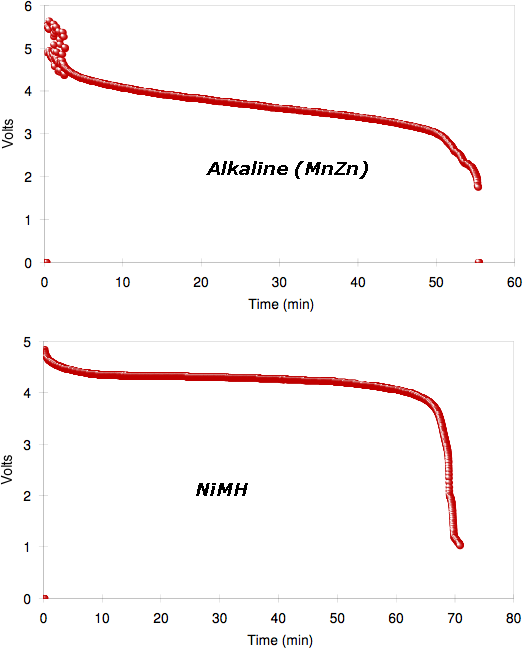

Versus Single-use Alkaline

On a list someone said he had discharge tested 4-packs of

single use alkaline batteries versus nickel-metal hydride. His graphs

show the NiMH to be superior in every way - and they can still be

discharged 999 more times, while the MnZn alkalines are spent.

The only value of the MnZn type is that the self discharge

is very low. It can be kept around for a long time without attention

until needed.

4 AA cell packs of same brand tested with 2 ohm load (note that the

voltage and time scales are unequal):

At this heavy load, one charge of the 2450 mAH NiMH battery ("5 volts")

outperforms the single use ("6 volts") alkaline battery's only charge,

not only in total run time but also in voltage and current output over

virtually the whole discharge period.

The Car Batteries for Sale

ad:

30 AH (210 amps cranking, small car) - $300

40 AH (280 amps cranking, mid size car) - $400

50 AH (350 amps cranking, V6?) - $500

60 AH (420 amps cranking, V8?) - $600

Custom EV, PHEV, cycle battery configurations (any voltage, current) -

$proportional, nothing

extra for being custom.

Individual NiMH cells:

10 amp-hour D cells: $10 each

2.5 amp-hour AA cells: $2.50 each

Turquoise Battery Project

Wasting Time Plugging Leaks

Salt encrusts leaky test battery

Salt encrusts leaky test battery

I decided it might be nice to try using 2" ABS pipe

endcaps for small test battery cells since my square glued together

ones nearly always seem to leak, and on the 4th I went to make an

electrode compactor for it. I couldn't get pipe and steel rod that

matched in diameter, so I had to make my own, turning plate steel into

round bits on the lathe.

I spent

some hours making it, getting everything just right - only to find when

I fetched

the ABS pipe cap that I'd made it all 1/4" too small - the pipe size

instead of the cap size. Back to the leaky

glued rectangles!

Wasting time making a compactor that doesn't fit!

Wasting time making a compactor that doesn't fit!

It then occurred to me that

I had found some 3/8" thick

ABS sheet a few months ago. Before that, I thought the thickest

it came was 1/4". If

I used 3/8" thick for side walls, there was a much better chance of

getting cells that don't leak: more glue, less flex, wider gaskets.

Along the same lines, I had earlier tried making a

transparent

acrylic plastic cover for one cell, but immediately inside that goes

the graphite sheet or sponge rubber, blocking any view of the

internals. This time I made two of the sides of 3/8" acrylic, so that

two cross sections can be seen. This may not show much of visual

interest either, but there's more chance than with either end face!

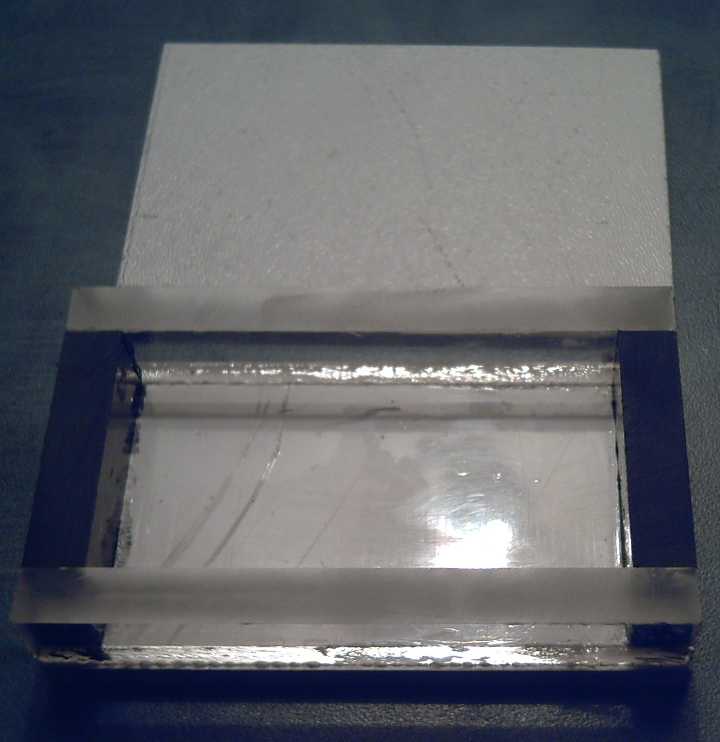

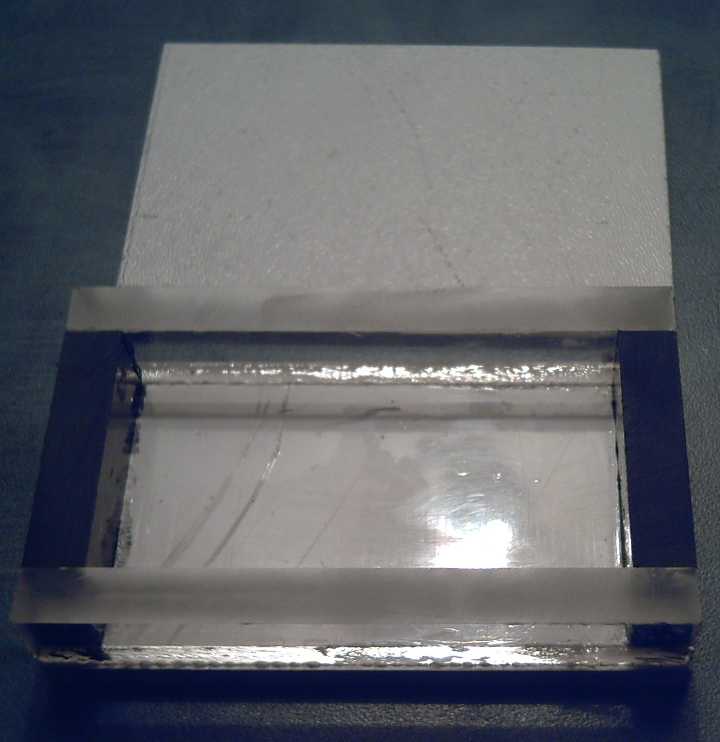

Thick walled battery cell case

Thick walled battery cell case

white and black ABS, and clear acrylic sides.

With graphite sheet and carbon rod with large contact area -- trying

to get lower resistance connections.

With graphite sheet and carbon rod with large contact area -- trying

to get lower resistance connections.

Osmium: a better dielectric?

I bought a gram of osmium powder well over a year ago now

as

a dopant for the separator sheet. It's over 100 $/gram and forms osmium

tetroxide, which evaporates as a poisonous vapour. I hadn't dared break

open the

container. Instead I've used ferric

oxide, but I think osmium will work better - with

luck a half an amp might become ten. Osmium is quite volatile, reacting

with air and water, and it is one of only three elements attaining a

valence of

plus eight, usually as osmium tetroxide. (The other two are ruthenium

and xenon - which is evidently less noble than the other noble gasses.)

Osmium will absorb protons and could be a good metal hydride if it

wasn't for the fact that it is so rare, and that it reacts with

alkali, the usual metal hydride battery electrolyte. Of course, I'm

using salt instead of alkali.

By its chart, it appears it could perhaps also make a

great positive electrode in spite of its high atomic weight,

potentially moving a whopping 8 electrons per reaction (at almost a

volt in acid... reacts with alkali... ??? for salt):

Of course, I just want it

as a dopant on a thin film in the separator. Near the end of March, I

finally opened the

tiny bottle and sprinkled a bit of the powder into a small test tube

with a few cc's of acetaldehyde. I hoped it was enough to have an

effect. A bit of this mix

I painted onto a piece of cellophane with a q-tip. (The rest went in

the fridge with a rubber stopper on it.) I took the battery I'd been

testing (leaky, above) apart and placed the new film next to the

positrode layer.

By using the same battery, changes of performance owing to the film

should be more

readily apparent than by starting fresh. It appeared to be a 15 or 20%

improvement, with slightly higher (but still pathetic) voltages and

currents - not the sort of "night and day" change I was hoping for. On

the other hand, it was a tiny fraction of a reservoir of acetaldehyde

with a fraction of a gram of osmium in it. Perhaps it wasn't enough.

Also, I shook it but didn't really stir it, and as I think about it,

the osmium (the densest element of all, at s.g. 22.6) may have mostly

settled to the bottom. The Q-tip only reached down to the top of the

liquid. Next test cell I'll sprinkle in some more osmium, and dip a

small paintbrush down to the bottom and stir.

I'll also use the MnO2 salvaged from the dry cells, as

that from the pottery supply may not be very pure - that could be part

of the high self-discharge problem.

http://www.TurquoiseEnergy.com

Victoria BC