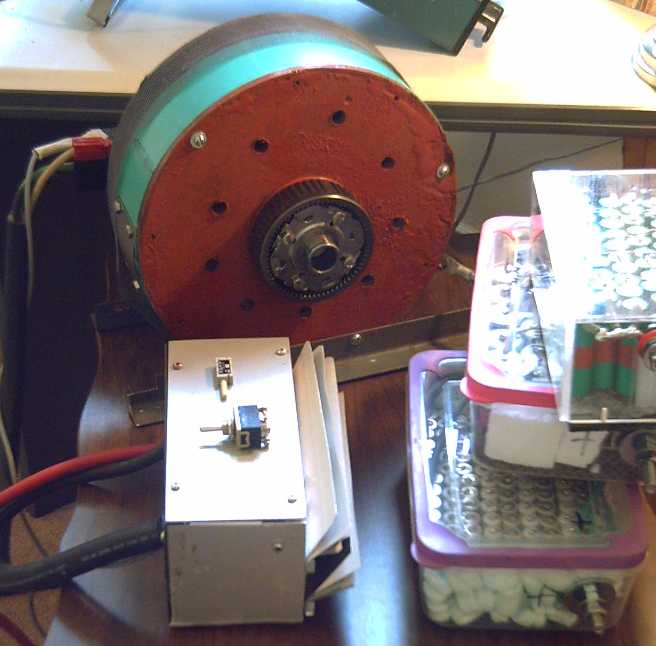

The essential components to electrify a car seem to be coming together at last:

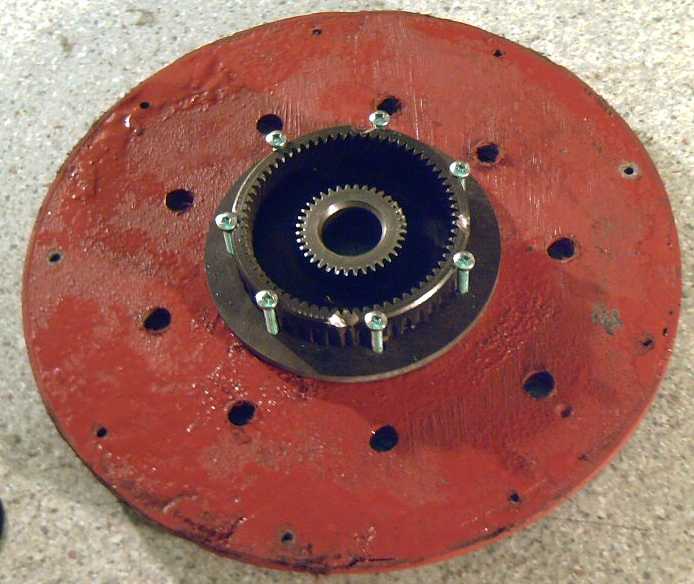

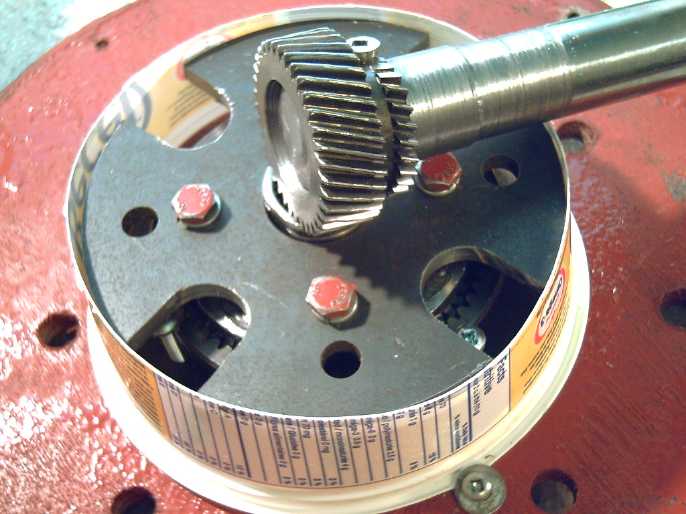

Hubcap motor with planetary gear, Motor controller (finned box),

Forward-Off-Reverse switch and gas pedal potentiometer,

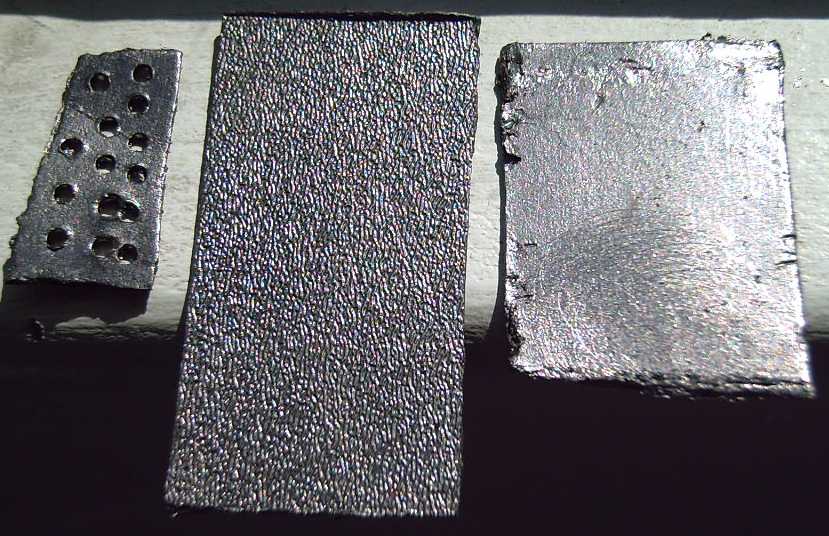

and a few kilowatt-hours of batteries. (The NiMH dry cells shown are about 1 KWH total.)

(Final version of motor will be an inch thinner and 1/2 inch smaller diameter; machine-drilled holes.)