Turquoise

Energy Ltd. News #40

Victoria BC

Copyright 2010 Craig Carmichael - June 2nd 2011

http://www.TurquoiseEnergy.com

= http://www.ElectricHubcap.com

= http://www.ElectricWeel.com

Spotlight: A new high energy, economical battery chemistry: 2.1 volt

V-Ni

salty cell.

Month In Brief

(summary)

* Most inventors are "unemployed"? Well, duh!

* Raising the bar - Mechanical torque converter - battery design

- Hubcap motor production

Electric Hubcap System

* A3938 V2 Motor Controller

* Motor Production Setup

Electric Weel Motor Project (Electric Wheel

Motor... Rim Motor...) (No activity or report.)

Planetary Gears Project

* Disappointing test in April leads to renewed thoughts about

dropping planetary gears, making a torque converter work.

Torque Converter Project

* oscillating planetary gear torque converter: rotary version of

Constantinesco's original design - an idea from chat list "half

bakery.com".

* My version of the planetary gear version

* Types of MTCs

* New idea! A spring-loaded MTC - designs thereof...

Turquoise Battery Project

* Salty electrolyte battery research: stalled since the 1880s!

* But not high budget lithium research!

* Cell with Nickel (+1 v), Vanadium (-1 v) Negatrode

? ... didn't work...

* simply reversed the leeds: +Vanadium, -Nickel cell

...WORKS!, 2.1 volts, should have 200+ WH/Kg!

* Vanadium Pentoxide+: ~ +1v, double electrons: higher energy

than nickel hydroxide or manganese dioxide as a

positrode - works in salt electrolyte only.

* (Potassium permanganate "+" may be even better than

vanadium pentoxide: more electrons, same voltage.)

* Nickel-: ~ -1 volt in salt (!)

* Carbon fiber to improve conductivity.

* "Diesel Kleen" Solvent/Hexadecane": fabulous carbon/graphite

conductivity booster! -

electrode surface turns from "sandstone" to "silver".

* Epoxy with graphite powder to improve conductivity between

electrode and terminal post.

Newsletters

Index/Highlights:

http://www.TurquoiseEnergy.com/news/index.html

(oops - I moved the index in March and neglected to change the link

until now!)

Construction Manuals and information:

-

Electric Hubcap Motor

- Turquoise Motor Controller

- 36 Volt Electric

Fan-Heater

- Nanocrystalline

reflective rear electrodes to enhance DSSC Solar

Cells

- Simple Spot Welder

for battery

tabs, connections

Products:

- Electric

Hubcap Motor Kits, Parts - Build your own ultra-efficient 5 KW

motor!

- Sodium Sulfate

4x

longevity additive & "worn

out" battery renewal.

- NiMH Dry Cell Car

Batteries (please e-mail me to order batteries)

- NiMH Custom Batteries (EVs, E-Bikes, Scooters, etc. - no extra

charge)

- NiMH individual Dry Cells (D - 10 AH, $10 -- AA - 2.5 AH, $2.50)

- Motor Building

Workshops

...all at: http://www.TurquoiseEnergy.com/

Spotlight: A New High Energy, Economical Battery Chemistry

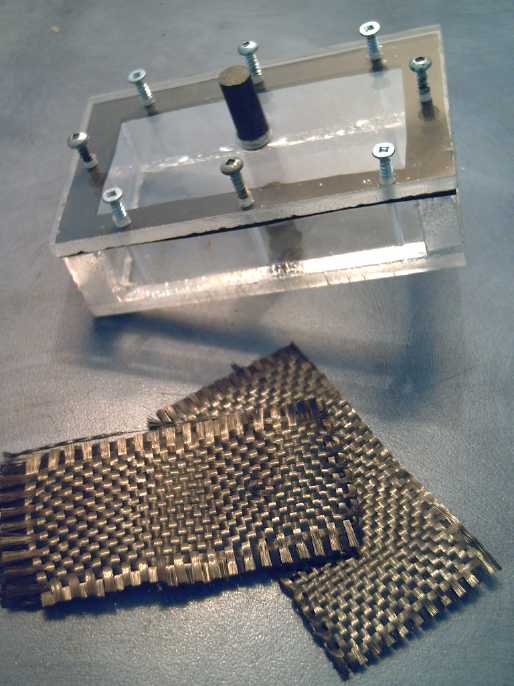

Vanadium-nickel test cell initial charging,

Vanadium-nickel test cell initial charging,

in transparent, openable case, with pressure gauge and adjustable

pressure relief valve,

carbon terminals top and bottom.

It appears I've finally created a good battery chemistry

based on

the designs

and chemistries I've been gradually working out over the past 3-1/2

years. In fact, I

believe it is the highest specific energy working, rechargeable aqueous

cell

made so far.

The fundamental chemistry is vanadium oxide (+) and nickel

(-) in salt solution electrolyte, yielding (to my surprise) a 2.1 volt

cell. Depending on the conductivities and current capacities eventually

achieved, this may translate to 1.75 to 2.0 volts "nominal" voltage

under load.

Vanadium

pentoxide, a somewhat lighter substance than nickel oxyhydroxide and

moving two

electrons instead of one (per metal atom), provides high amp-hours at

about +1

volt, and, rather unexpectedly, the charge and discharge products

appear to be

solids in neutral solution. (V2O5 <=> V2O3) On later inspection

the electrode appeared to be unchanged from when first installed.

The nickel as a

negative in

neutral solution, also unexpectedly, seems to have a higher reaction

voltage

than in

either alkali or acid, about -1 volt. (This seems to be a great

alternative to the manganese negatives I was doing, that seemed to be

just a little too high a voltage (around -1.37) and

consequently had a high rate of self discharge.)

Higher amp-hours times higher voltage means much higher

energy density, both by weight and by volume. Both sides are well

over 500 WH/Kg. Considering the weight of

the water, graphite, and all the things that must surround the

active electrode

materials, I tentatively estimate

that V-Ni cells could be made with a specific energy as high as 200 to

275

watt-hours per kilogram. 200 is

double the best NiMH dry cells. Lithium ion reaches up to 140 or so,

but is

typically less for larger cells that I've looked at actual specs for.

The latest lithium-sulfur cells are about 200-290 watt-hours per

kilogram. They're still experimental (with a chemistry problem yet to

be overcome), and I have little doubt

they're costly.

If for example one wanted 10 KWH of battery in a vehicle,

NiMH AA cells would weigh somewhere over 100 Kg. Lithium ion would be

similar, and lithium iron phosphate would be heavier, perhaps 150 Kg.

At 225 WH/Kg, the

V-Ni battery would weigh under 50 Kg. If lithium sulfate becomes

practical, it

might be a little lighter yet... but surely costly.

The exact workings of the cell were unexpected. It was

intended to try +nickel, -vanadium, the other way around, expecting the

very

voltage that was in fact achieved, about two volts. However, the cell

didn't seem to be

charging well in that direction - the vanadium seemed to be charging

into an

unexpected soluble state, as it appeared to be migrating. (I made this

cell from clear plexiglass and was able to see unusual activity within

the cell -- one of my brighter ideas recently.) So I tried it

the other way

around... and it worked! I didn't think the substances used would

produce such a high voltage charged in that direction, that the cell

would be about 1

volt or 1.5. But the higher energy reaction of two possible vanadium

reactions evidently

applied, and the

nickel negative voltage proved unexpectedly high, yielding exactly what

I had

intended...

and more: the vanadium "+" has substantially higher amp hours than the

nickel would have had, so less of it is required to match the negative.

(

some theoretical positrode values:

V2O5: 576.7 AH/Kg @ ~+1v = ~577 WH/Kg

Ni(OH)2: 289 AH/Kg @ ~+1v = ~289 WH/Kg

MnO2: 304 AH/Kg @ +.55v = ~167 WH/Kg

(standard dry cell)

nickel negative:

Ni: 736 AH/Kg @ -1v = 736 WH/Kg

)

Here then is what appears

to be a much superior, economical, green battery

chemistry.

To make an actually practical battery, I now hope

to

improve

the internal conductivity at least tenfold (preferably closer to a

hundredfold)

for high current EV cells. Here I struggle with the problem that

probably led

past designers to choose alkaline over salt electrolyte: that all

common metals quickly corrode away in a salt based positrode. This is

why standard dry cells have a carbon rod for their positive electrode.

Only conductive graphite and carbon products can be used. The

conductance is generally lower, and unlike metal, graphite and carbon

can't be soldered or welded to make convenient, secure connections.

The current capacities didn't even seem to match the

standard dry cell, though they were creeping into the neighborhood.

But

I've found an exciting new technique of compacting electrodes -

wetting the

substances with "Diesel Kleen" oily hexadecane solvent instead of water

- to create (probably lamellar?) structures of graphite (graphene?) and

electrode powder, creating a conductive network which gives a metallic

appearance to the electrode

surface, and lower resistances.

Finally I experimented by simply mixing graphite powder

with

epoxy, and (again somewhat to my surprise) got much better contact

between the terminal

posts and the the graphite sheets with this "glue".

And vanadium-nickel isn't

the only possible chemistry. The nickel negatrodes seem to

work well and have good voltage, giving them much more energy by weight

than as alkaline positrodes (as in Ni-MH, Ni-Cd, Ni-Fe, etc), and hence

making

the nickel much more

economical as well as smaller. They're a winner!

However, I intend to try the manganese-nickel

mix again as a positrode. If the manganese charges to permanganate as I

expect,

it should work about as well as vanadium or perhaps a little better.

And unlike vanadium, manganese is "dirt cheap", improving economy. If

not, vanadium will remain the choice, at least for vehicle batteries.

May in Brief

Someone said recently in the news - and I confess I can't

remember just who or where - that most inventors seem to be unemployed.

Well, duh! If someone is working at a job, on top of maintaining a

home, perhaps raising a family, when on earth would they be able to put

in the investment of time needed to invent and develop something new?

On the other hand, if they don't have a job, how will they remain

solvent and able to do the work at hand? With no renumeration while

working and virtually no prospect of reward even on successful

completion, most people with ideas aren't free to develop them, even if

they have all the skills necessary.

Ovshinsky had to wait until he retired to create the metal

hydride that made nickel-metal hydride batteries an excellent

chemistry (and made GM's EV-1 fabulous), using his pension as R & D

funding. He was a university

chemistry professor, yet evidently even with such credentials and such

a vision at such an institution, he wasn't permitted to do experimental

work on paid time. Without his work, NiMH batteries today would

probably still be just a scientific curiosity, not a fine product on

store shelves. He did it all

himself.

I'm able to devote my time

to inventing because I've

managed to eke out a solitary existence since 1995 without a job,

mostly by renting rooms in my house, and for several years now my

elderly mother has been sending me money. In the last three years,

Canada Revenue's SR & ED tax credit program has added a vital few

thousand dollars a year -- a partial reimbursement of each previous

year's R

& D expenses -- and having hit 55, I am now deferring my property

taxes, a major relief. (The city can have my house when I go.)

With a Department of Progress in the government, the

nation could work towards its goals of sustainability, soliciting

proposals from would-be inventors and selecting (preferably from those

with good track records) those proposals with the most

promise and seeming to offer the most "bang for the buck". Paying

individual

inventors to invent and develop targeted products would probably cost

the taxpayer far less money

than is today being shelled out for "random" untargeted R & D

funding to "innovative businesses" -- and produce tangible results and

technical

progress visible to the public. The department would naturally modify

the patent system and take other action to recoup its investments and

to see that technical advances don't go to waste. The government would

have a stake in progress instead of in stagnation.

Better motors, a superior green battery chemistry with new

techniques for making

salt electrolyte battery cells more conductive

(after over 120 years with no progress!), and perhaps soon a good

mechanical torque converter design (below) to finally allow a smaller

motor to

give more drive and batteries to go farther than is commonly thought

feasible... In all this, an

overriding goal is to point out that with just minuscule R & D

effort, with a fraction of the resources expended daily in countless

cities all over the world on petroleum engine maintenance and repairs,

the

performance bar can easily be raised significantly in key areas of

transport

technology -- and

then to prove the point by raising it myself with my own R & D.

Somehow I'd got my hopes

up about using planetary gears, but the 2.8 to 1 ratio

planetary gear performed in accordance with my lowest expectations, and

I went back to my 7

to 1

estimate as being

a good minimum ratio to put a car on the street. This would mean giving

up

on planetary gears or having a dual 4 to 1 system good for city

driving only - and even at that, with two motors instead of one, using

almost as much electricity as other systems. Two

motors at 2.8 to 1 and full motor currents just might pull it off, and

perhaps even hit 80 Km/Hr, but

I'm dubious.

I preferred giving up on the gears, and by the 4th had

worked out a new

mechanical torque converter design plus a variant, which seemed very

exciting. Later I realized

that neither would work.

I'd also been sent an idea for a new version

of Constantinesco's original oscillating masses MTC design. It used a

planetary gear! It seemed the most

promising idea. Surely in 2011 Constantinesco's 1923-26

design and product can be duplicated. But it hasn't been done yet!

Then near the end of the month, I thought of another very

simple converter idea, using springs to store potential energy instead

of inertia weights. That

would make for

less "semi-sprung" weight on the wheel. It would also be easiest to put

together, which naturally has a great appeal to me. After a number of

sketches with improving designs and ideas, I'm proceeding with it.

Finally, after last month's successful chemistry battery

cell and a perusal of

vanadium's electrochemistry, I put together one on the 6th with nickel

and vanadium electrodes and found to my surprise, first that it didn't

seem to charge as planned, and second that it not only worked if

charged backwards - not a big surprise - but it that it made a 2.1

volt cell. That was a surprise - I expected 1 or 1.5 volts, depending

on

which reaction the vanadium decided to use. It seemed the nickel

reaction (-1v) was twice the voltage (-.5v) expected from the charts.

In fact it was even better than my plan, with more

watt-hours per kilogram. I had evidently discovered a

superior positive electrode. (...for salty batteries: Vanadium wouldn't

work in acidic or alkaline cells.)

The cell still has "the usual" problems with low

conductivity, but

this month I also created a new technique for enhancing it by

compacting electrodes

with solvent instead of water, and after a promising experiment I'm

about to try out epoxied graphite

powder to connect the terminal posts to the electrodes. The next cell

may well see substantial

improvement. If the present .5 amps becomes 5 or better, it should be a

practical

battery.

The nickel (fried monel-lanthanum-bean sauce) negatrodes

seem excellent. Now I'll try the

mixed nickel-manganese again for the plus side - it seems to me those

must have been charging to potassium permanganate, and so could

work if

coupled with good minuses. This

would be even lighter than the

vanadium as they'd move three or more electrons per Mn atom, and unlike

V, Mn is

cheap... especially from used dry cells such as those currently

flooding the stores. (probably in an attempt to displace rechargeables

from the shelves.)

I didn't have time to look at the big Weel motor in May.

After waiting weeks to have rotors cut by abrasive waterjet and paying

over 350 $ for cutting to date, I'm thinking again that it would be

nice to finish that pulsejet steel plate cutter and see how it works.

And occasionally I think of my ideas for ocean wave power

and for better DSSC solar cells, without having any idea when I might

ever be able to get back to them with all the rest that's on my plate.

Hurrah to Germany for its excellent decision to phase out dangerous

nuclear power generation with its commitment to radioactive waste

storage for longer than recorded history! Hopefully now everyone else

will follow suit.

Electric Hubcap Motor System

A3938 V2 Motor Controller

I decided I really needed to have a good, high current

supply of about 18 volts - high enough to work, but not high enough

that the MOSFETs' 20 volts maximum drain to source voltage could be

exceeded to burn them out. I made a 5 volt, 30 AH NiMH battery of 12 D

cells to add to a 12 volt one to obtain this. Nice to have the lab

power supply to charge this odd voltage battery. Unfortunately the lab

supply doesn't put out quite enough current to run the motors properly

itself.

I swapped in the last A3938 chip, having burned out all

the rest, and tried a couple of times to get a motor running with it.

Mostly no current was being drawn. Some odd things were happening

and it didn't run. But (for once) I didn't get the impression there was

anything

wrong with the chip. There it sat for a while pending some inspiration.

On the 29th, I had the thought that with the slow output

slew rates, perhaps the current limiting was sampling too soon. I had

had to increase the "dead time" to the max to prevent high

'shoot-through' switching currents. "Theoretically" the dead time

should have

been overkill. Perhaps also, although the theoretical blanking time

capacitor was under 50pF and I was using 82pF, it might still be

shutting the cycle off just as it started. 1000pF was the original

value, burning out the first A3938 controllers when turned up too high.

I

put in 330pF as a compromise value.

While I was at it switched the gate resistors back from 18

to 27 ohms, nervous about burning out the A3938's gate drivers again on

my last A3938 chip. They seem to be a weak

point. On the other hand, the first controller was working (until

turned up too far) with 15 ohmers, and longer gate wires than on the

new one.

That didn't seem to do the trick. Probably I'll find

changing some component value, somewhere, will get it going. In

the meantime, perhaps next I'll try it driving single MOSFETs instead

of doubled up. (Single transistors should be fine as long as I don't

put a big load on the motor.) If that works, I'll know the slower

timings owing to the large gate charges are the source of the trouble,

instead of just guessing that's what it is. If not, I should be looking

elsewhere.

Motor Production

My enthusiasm for setting up for motor production wained

owing

to the fact that no one has ordered a fabulous Electric Hubcap motor

kit yet, because I got the flu, other projects (yardwork...

batteries!), and because it

seemed like about a month before some magnet rotors were finally cut by

Victoria Waterjet. Of course I wasn't expecting many sales until

they're pushing

cars

on the

road.

But on the 23rd to 27th I finally made some new

mold pieces for the

slightly smaller 11.25" diameter size shells, and made the 3 body

ring pieces for another motor. This diameter was

obtained by eliminating the short PVC pipe section (1/2" thick walls)

from the outer wall of the rotor compartment and instead wrapping

around several thicknesses of strong PP strapping-epoxy strapping

composite to form a thinner outer wall.

It's not the complete set of molds to allow me to cast

all the parts for a motor in one session, but it's half way there and I

can cast all the pieces, though one at a time. Between clear acrylic

battery cases and the motor body

molds, I seemed to have to cross town to the plastic supply

shop for something almost every day in this period. I thought I

already had everything, but somehow whenever I went to do something I

seemed to be missing what was needed.

My enthusiasm for the three mold system also wained

somewhat as I discovered that only one would fit in the oven at a time,

and realized that I'd need another 100 dollars worth of C-clamps to

press three at once. I'd rather spend that on epoxy to make more motor

parts, even though more slowly!

Routering the mold base. This is the second pass, deepening the dish

Routering the mold base. This is the second pass, deepening the dish

Pieces for mold(s) with 3" & 4" center posts and plywood

backings, and one finished

motor ring piece.

Pieces for mold(s) with 3" & 4" center posts and plywood

backings, and one finished

motor ring piece.

Stuffing the mold with PP fabric and epoxy resin.

Stuffing the mold with PP fabric and epoxy resin.

The first two ring pieces didn't come out very well and

needed a lot of touching up. I got better by the third one, but I'd

like to figure out a rigid outside wall setup - I end up having to push

protruding pieces in with a chisel or screwdriver just before the

C-clamps close the gap. Nobody makes pipe the right size.

Metal Protection

Finally near the end of the month Victoria

Waterjet had cut the magnet

rotors and other parts I asked for some weeks previously. On the last

day I received back a magnet rotor that I had powder coated to protect

it from rusting. The polyester coating

looked great, and evidently there should be no problem with gluing the

magnets onto it with epoxy & PP strapping as before. I decided I

should

have the bearing holder parts coated as well. That would cover all the

main

metal parts except the axle, the SDS (magnet rotor) coupling, and the

bearings, which

would be hard to work with if they were coated.

But the powder coating place had done the rotor as a free

sample. On inquiry, it turned out it might be around 30 $ per magnet

rotor, and 15 $ per bearing holder, which there are 4 of. Doubtless

there's a lot of prep to turn them from oily and perhaps rusty steel to

spotlessly clean and shiny for coating in addition to the primer and

finish coating, but 90 $ 'extra' - on motor kits I hope to sell for 500

$ - isn't going to work. Even the 30 $ virtually doubles the cost of

the magnet rotor. I wonder if there's any way to do it, or

something similar, myself? Spray paint is probably the simple answer

for the bearing holders and maybe the back side of the magnet rotor,

but I wouldn't want flakey spray paint under the magnets. The powder

coating is good. I think I'll do a little more reading about it...

Planetary Gear Project

The results of the

first experiment seemed rather disappointing. The motor and the 2.8 to

1 planetary

gear turned fine, but it didn't budge the car, and though the motor

power

could have been doubled, it just didn't seem that could be enough to

put the car on the street. The options appeared to be the same as ever:

get a variable rate torque converter working, or the car would need two

complete motor systems even to travel at city speeds -- if even that

proved practical. (Bear in mind that most electric conversions use at

least 15 KW or 20 KW motors rather than 5 KW - only with the

exceptional performance of a mechanical torque converter have I been

expecting to drive a car with such a small motor.)

Planetary gear spin test with the wheel jacked up. This was the only

time it spun the wheel.

Planetary gear spin test with the wheel jacked up. This was the only

time it spun the wheel.

It would no doubt have at least moved the car on level pavement at full

power,

but it surely wouldn't have gone up much of a hill of a hill or

accelerated well enough for the street.

Movie: http://www.youtube.com/watch?v=Zihj3wbPe3A

If a practical mechanical torque converter was already

invented, the

choice would be simple. But it was build the second motor

system or invent the torque converter. Here I've been for two

years, thinking the later would be the superior option, and quite

possibly the faster as well. Well, it hasn't been the faster!

But someone sent me a link to an idea for a rotary

version of Constantinesco's original torque converter -- using

planetary gears! This development seemed so promising, and the

planetary

gears used in the normal way so little promising, that I decided to

try the planetary gear torque converter idea and set the 'regular'

planetary gears system aside.

Torque Converter Project

With the disappointing performance of the planetary gear, I

started thinking again about

the variable ratio mechanical torque converter (MTC), and at the same

time,

someone sent me a link to an MTC design concept someone thought of and

posted to "halfbakery.com" a couple of years ago - just a couple of

months before I started

trying to make one myself. It was essentially a rotary version of

Constantinesco's original design using oscillating planetary gears. The

'engine' oscillated the planet gear carrier back and forth, about a

90º cyclic rotation.

The sun gear shaft had a flywheel, replacing Constantinesco's original

pendulum as the oscillating mass. With my gear, that would have a speed

increase of 2.8 to 1, magnifying the effect of the flywheel's mass by

about 8 over a one to one speed arrangement. Various rotors could be

tried to see what mass works best. On the

outside, the ring gear was connected so that it would turn a one-way

ratchet as it twisted back and forth, moving the car one

direction.

It looked very promising, if a bit complex to build. I

have the gears, but still it would take a lot of

changes,

detailed design effort and work to implement.

And moving the car "one way" would mean forward only. Was

I to turn on the gas engine just to back up?

Another feature of

this converter idea was that it could be a double version, with two

masses, gear

sets, flywheels et al at 90º phase to each

other, which would

balance the load on the 'engine'. I think Constantinesco also used two

90º masses in his production model car engine. But probably for an

electric motor, there's no need to have balanced drive at all points of

rotation.

But I started

sketching and tried again to come up with something simpler. After a

couple of weeks of thinking I was really onto something and being eager

to start building, I realized neither of the two design variations I'd

come up with would work - and that one of them I had thought of before

and already gone through the same process.

Later I thought of a

couple of variations of my other new

design (not

oscillating masses) that just might work. But my confidence

level wasn't high.

At the same time, I was

starting to think of ways to put together the planetary gear type. The

planetary gears were in fact just one of the several components. It

couldn't be a simple in-line form. It would be something like a giant

size

mechanical clock, with all the shafts borne on two parallel plates of

steel and all the gears and levers between, with a few posts holding

everything rigid. Those plates would have to be at least a couple of

inches apart to hold everything, which would do nothing for thinness of

the fit outside the car wheel.

But... it ought to work! I decided I would simply have to

do it - even if it couldn't back up. Perhaps some solution for that

might develop as I worked.

Checking out planetary gear inertial effects: put weight on one

element,

Checking out planetary gear inertial effects: put weight on one

element,

clamp another in a vise, twist the third back and forth with

vise-grips...

and see how much the narrow workbench wobbles.

The biggest sticking point

to getting it to work at all is perhaps the

"one-way valve" or ratchet that takes the oscillating motion and turns

it back into rotary motion at the wheel. Some more recent MTC

implementations have come to grief over this seemingly minor point:

commercial one-way bearings evidently aren't made to handle rapid

oscillations

- they get hot and soon burn out. I'd really like to know what

Constantinesco used in

his 1926 cars! I do however have a couple of ideas for durable

ratchets. One

uses the outside of the planetary ring gear, which is the output piece

and which has grooves... and both use the arms from my aforementioned

sketches. I did up a drawing of a design that looked workable, if a bit

complex.

---

The same person who found the halfbakery.com idea also

pointed me to the NuVinci bicycle hub, an

entirely different MTC design using tilting rolling balls, and the

various diameters attained at different rolling angles. It looked very

complicated to do and needed special 'lubricant', which is the reason

I'd passed the design over

previously.

But now a small version was actually in production, for bicycles.

Should I have another look at that before I started building the

oscillating masses type? A phrase from a blurb on the

site spells out the advantages of mechanical torque converters that

I've been mentioning:

"... it dramatically

improves acceleration, hill climbing and top-end speed while extending

range and battery life..." (www.fallbrooktech.com/09_LEV_Kit.asp)

Those features are why I expect to make a mere 5 KW motor

drive a whole car. But is there any reasonable way to make these

things, big enough for a car, without a whole factory and without

having the special

traction lubricant? (or can the lubricant be obtained?) Somehow, I

can't see trying to scale up their friction-drive unit from the weight

of a person to the weight of a car. I think any version I could build

is virtually bound to

slip and go nowhere.

But it shows there must be many ways to skin a seal

(relative of

cat)... The NuVinci uses "smooth gears" that can be varied. "CVT"s use

a belt around conical spindles. The Constantinesco type stores up

energy in an oscillating mass. Then I had a fresh idea:

Couldn't energy be stored up by compressing or

stretching a spring instead of in an oscillating mass? Or, couldn't

energy stored in a rotating mass

(rather than oscillating) be rapidly transferred by suddenly

compressing or stretching a spring?

For such an idea to work (and with all-live parts), this

would mean the motor would turn one turn (or some integral division

thereof - 1/2, 1/3... 1/16...), and then at a specific point(s) of

rotation, a

spring would suddenly transfer some of the momentum of the

motor to the output, moving it however much or little that energy had

in it to do. Naturally, the amount of energy would go up with the

square of the motor speed, and below a certain point, it wouldn't

overcome static friction.

Getting the energy transfer at specific points is the

thing. The fewer and stronger the hits, the more the chances of

each one overcoming that static friction. My last "clock escapement"

design

might have worked if there'd been just 2, 4 or 5 hits per rotation

instead of 25. (Unfortunately, with all the progress in motors, I

finally scrapped the old early 2009 motor that had those fittings,

without having tried this.)

Some mechanism would have to disengage the contact to

allow the motor to continue turning (though slightly slowed down) past

the point

of contact, and something would have to "trip" to disconnect the spring

from the output, to prevent it shoving backwards as it decompressed.

The sprung section on the end of the arm, or at the rim of

the rotor, could hit square on and rebound, then twist sideways as it

reversed, bypassing the contact point on the second pass. Once again,

I'm trying to visualize mechanical things that should be possible, but

which haven't been made before. I went off to

the drawing board to try some sketches.

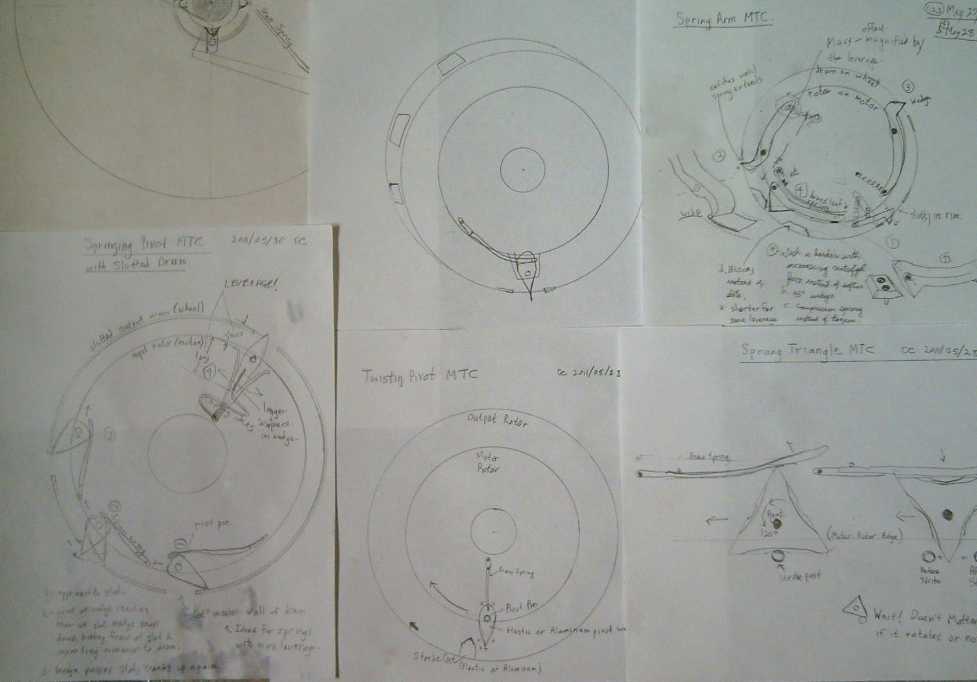

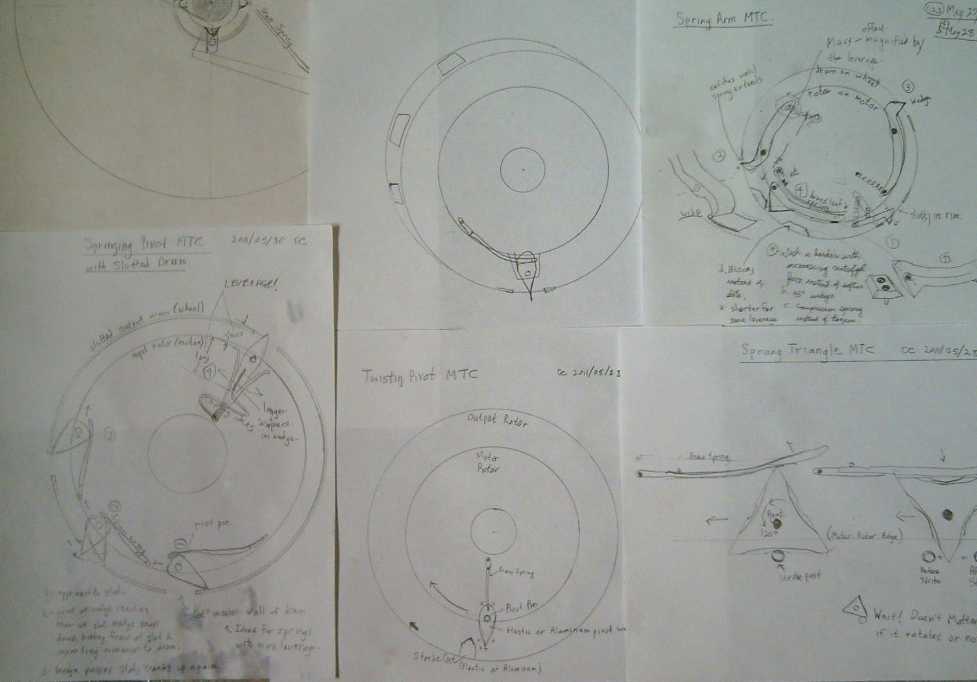

MTC Sketches of May. Top-left is one that wouldn't work from early

in the month;

MTC Sketches of May. Top-left is one that wouldn't work from early

in the month;

the rest develop the new sudden spring compression or release idea,

with spring-loaded wedges.

The first spring activated sketches (top right) seemed

plausible, but a day or two later I realized it would kick backwards

after the forwards kick, as the other slope of the wedge passed the

contact

point. The second used

triangles that would flip just once to the next face at the contact

points. Using curved faces I

tried to get a

design that would turn a little farther than flat to ensure it would

flip to the next face and not back to the first one. Then I noticed

that they would work the same whichever way they flipped! So why bother

with turning triangles? Next was the

bottom center sketch, where it just flicked it and it returned to the

same position.

Then I started thinking that all those ideas compressed

the spring

rapidly at the point of action, but it should be more energetic to have

the spring suddenly release. In the top center sketch, I

simply changed the "strike posts" to "slots" in the rim of the output

drum.

The wedge would be held pushed sideways over most of its

travel, and then

when the point reached the slot, it would suddenly snap down. If the

slot was the right length, the wedge would hit the far side of the slot

at high speed, like the sudden snap of a strong electrical switch or

circuit breaker. Then, as the motor rotor moved on, the wedge would be

twisted up again, compressing the spring, which would remain compressed

until the next slot. Note that the compressing of the spring pushes the

drum the same way as the release and immediately after it, though with

less sudden impact. The

parts will of course be greased, but any slight frictional drag of the

wedge points along the rim will also act in the same direction. None of

the force acts in the wrong direction and almost none is wasted.

In the final sketch at the lower left, I varied the

wedge shapes and spring attachments and shapes, trying to achieve best

effect. After sketching #4 in that drawing, I went from paper to 1/2"

plastic on the 31st:

"Mock up" of sprung wedge MTC.

"Mock up" of sprung wedge MTC.

The number of wedges and slots will of course match so all

wedges act at once. The diameters of the rotor and the drum rim are

going to have

to be pretty close together for the wedges to engage properly. My

current

idea to proceed with is to have two thin (eg, .1") 11.5"

aluminum rotors on the motor axle (via an SDS bushing), with the

pivoting wedges between them. The

drum can be a (thicker) 12" aluminum plate on the car wheel, with the

slotted rim screwed to it. (The prototype plate may be steel as I have

one

the right size - or I might re-use the 12" frying pan for the umpteenth

time.) The axle of the motor should extend to the output

drum, where a ball bearing race will hold it centered on the wheel

center, though free to pivot a little to 'spring' the motor weight a

little vis a vis the wheel. Or (probably preferable) the output drum

may instead spin securely on the motor axle with two bearings, with a

flexible link to the car wheel (similar to last

month's wheel link for the planetary gear).

The spring tension needed to twist the wedges must be

substantially less than the torque the motor can provide to compress

them. (If less torque is required than is needed to twist the wedges,

the motor and wheel rotations will "lock" together.) I will doubtless

do a lot of playing around with the materials, sizes, shapes,

strengths, and numbers of the wedges, springs, and slots. But the basic

idea - as far as I can tell at the moment - seems sound.

Turquoise Battery Project

Salt electrolyte battery research: stalled since 1880s!

I think I've said

that

salt electrolyte seems to be about the least explored area of battery

research, much less researched than acid and alkaline. I found an 1891

book

(Primary Batteries - Henry Carhart.pdf) on

primary batteries.

It was a revelation to see the "carbon-zinc"

(manganese-zinc) dry cell, constructed in its essentials the same as

today, which (in combination with the fact that evidently no other type

of salt solution electrolyte based cells are or have ever been

available) means that no important improvements have been made

to salt

electrolyte battery cells in over 120 years! Even

then "sal

ammoniac" was apparently

almost the

only salt that was used.

Small wonder then that an 'outsider' to the

electrochemical field like me might today be able to achieve some fine

results, when it would seem no one else has

done any significant R or D on "mundane" salt batteries since Victorian

times except to improve the packaging.

But no shortage of lithium battery research

A Technology Review article (mobile.technologyreview.com/energy/37632/)

on a new "pumped

sludge" lithium battery project spells out the main problem with

lithiums:

"A big problem with the lithium-ion batteries used

in electric vehicles

and plug-in hybrids is that only about 25 percent of the battery's

volume is taken up by materials that store energy. The rest is made up

of inactive materials, such as packaging, conductive foils, and glues,

which make the batteries bulky and account for a significant part of

the cost."

This is the reason I've always felt that other chemistries

can outperform lithium: other elements theoretically have less energy

per weight, but they can be much less "diluted" in a

cell than appears to be the case with lithium types. I don't think the

"pumped sludge" approach sounds very practical for electric transport,

if for anything... though you never know! The article itself ends on

the same sort of note:

"It's a very clever device," says Dahn. "I don't

know if it will

ever

be more than an idea in a paper, but Chiang has surprised people

before."

For a doubtful "idea in a paper", the project certainly

doesn't suffer from lack of

support, having been incorporated, raised about $16,000,000 and

employed 20 people, according to the article. (I wonder how many of the

20 are actually involved

in the development, and of those, how well their time and talents are

being utilized?)

The money is somewhere around $15,990,000 more than I've

been able to put into this battery project so far. (Like I said in

"month in brief", paying individual inventors - even if they get a real

salary or equivalent plus expenses - should cost much less

than funding "innovative companies" and is more likely to produce

practical technical results. A separate problem is that even if

Chiang's battery proves practical, it is likely to end up as a patent

in

some oil company's drawer (like Chevron's 125 nickel-metal hydride

battery patents), rendered unusable by anyone until the whole

technology has been long forgotten.)

Meanwhile, back at the ranch...

Real, Solid Electrodes

In disassembling recent previous cells, I've been finding

that the electrodes (particularly the negatrodes) have become quite

hard, seemingly much harder than

when installed. They are in line with what is found inside, eg,

commercial Ni-MH or Ni-Cd dry cells. The "sandstone" texture I've been

trying to achieve in

the compactor is finally achieved in the cell itself. Evidently I've

been doing better on this score than I thought.

Vanadium negative?: -1 volts, total 2 volts --- ?

It seemed the main reason for the high self discharging

was that the manganese reaction voltage

[Mn + 2 OH- <=> Mn(OH)2, e= -1.37 V(?) in neutral

solution] was just a little too high, even with the egg albumin to

raise the hydrogen generation voltage, so the discharge reaction

happens fairly

slowly but spontaneously and continuously until the negatrode is

discharged. Iron also seemed to discharge spontaneously.

This was unexpected since it works well in alkaline solution - Jungner

and Edison manufactured nickel-iron batteries, and Ni-Fe dry cells have

recently been created in India. It led me to assume the problem wasn't

in the negative electrode, when in fact it was - with both substances.

What then could be used? Nickel worked, as shown in my

cell at the end of April, but it looked like it would be only 1/2 a

volt. What was between

-.5 and -1.37 volts?

The next element down from manganese seemed to be zinc at

about -1 volt, but the soluble zincate ion causes seemingly insoluble

problems and short life. Chromium looked similar.

Vanadium appeared to have an ideal reaction of about -1

volts with no soluble ions shown for alkaline solution. [V + 2

OH- <=> VO + H2O + 2e-, e= -.975 V(?) in neutral

solution] Drawback seemed to be that like chromium its compounds are

poisonous. But only to people -- to the environment it's "green".

(Well, actually yellow.)

States and voltages of Vanadium - shown as usual for acid and

alkali but not in neutral salt solution -

States and voltages of Vanadium - shown as usual for acid and

alkali but not in neutral salt solution -

suggesting it might be a good negative going between V and VO at maybe

-1 volts.

Wikipedia info suggested it might dissolve into ions, notwithstanding

the insolubility of VO.

In fact, the direct reaction right from valence 0 to 5 isn't seen in

other elements.

I bought a 1/4 pound bag of

vanadium pentoxide at Victoria Clay Arts - 12.95$ ++. This price seemed

similar to nickel oxide - not dirt cheap, but not really rare, either.

(I'm guessing a 10 pound bag will have a better discount than nickel

but I haven't tried pricing it yet.) It must be borne in mind that if

double the energy density by weight is achieved, it effectively cuts

the cost in half as well as the battery size and weight.

I picked up their pound of

neodydmium oxide while I was there, which had been sitting there for

years. (As pottery glazes: intense yellow

(V) and delicate yellow (Nd).) Neo is probably better than lanthanum

for raising

oxygen overvoltage, though not as good as samarium. He had finally put

a price on it, and for 17.95 $ I could

hardly resist - after all I paid over 200 $ for 2 Kg of lanthanum I

bought early

in the project and then had to turn into hydroxide myself. (it made

about 7 pounds of it.) Samarium would doubtless be more.

Next on the

agenda seemed to be to make a new battery in a new case - hopefully

that wouldn't leak. January's ABS case, reused a couple of times, was

split

wide open at a seam. I

decided the case I'd made with a longer rod of carbon inside - and two

holes - was much

too likely to leak and abandoned it. I used clear acrylic

plastic on all sides in case there was anything to see inside the cell

at any time. Also it's harder and stiffer than ABS - perhaps that

would help prevent leaks. The clear case proved absolutely valuable for

seeing things happening inside and

I won't make any other again, at least not for prototyping. In addition

this stiffer material held pressure without leaking. I also

made

this one a little taller so there

could be a pool of water over the electrodes for a sealed (or not) wet

cell.

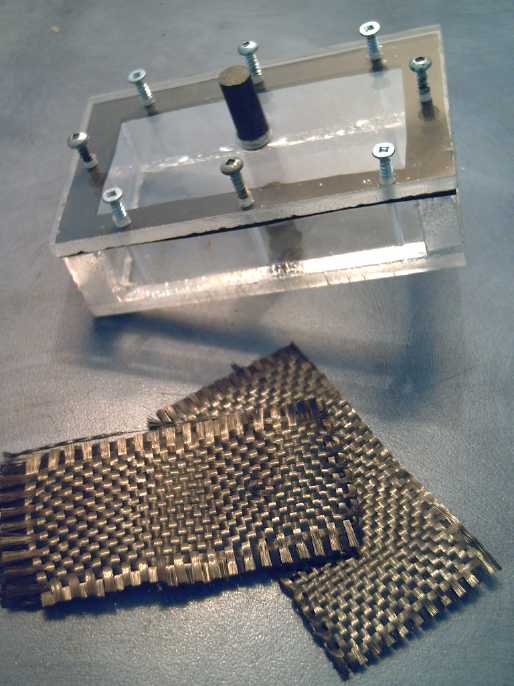

Clear battery cell case with carbon rod terminal posts,

Clear battery cell case with carbon rod terminal posts,

carbon fiber mat to back the electrodes.

For the collector sheets I cut 1.5" x 3" pieces of carbon

(graphite) fiber sheets and boiled them in hexadecane (this time

outdoors, as

it reeks and I have no fume hood). It was still slightly damp with

hexadecane when I put it into the compactor. The hexadecane seems to

act as a "flux" that helps to join the electrode to the graphite for a

better connection and I'll probably continue doing it this way. The

fiber sheets didn't come loose from the electrodes. All or most of the

expanded graphite sheets have done so.

Note: The bottle labelled "Diesel Kleen" that I've been calling

"hexadecane" contains not only

hexadecane but unspecified "petroleum distillates" (from MSDS...

probably Ethylbenzene, Naphthalene, Xylene and 1,2,4-Trimethylbenzene)

and "slick diesel"(?), in unspecified proportions. Whatever it exactly

is,

it seems to work great! (Likeliest best ingredient: methylbenzene?)

Pos (Neg):

- 15g of the monel/La(OH)3 mix

- 10g of MnO2/graphite mix (from a dry cell)

- 5g more graphite powder

- .25g Sb4O6

- 1.5g Sunlight

- bit of HOH

(No MnO2 2nd cell)

This 'trode was compacted onto the treated carbon fibre,

painted with lime, dried in the oven for 40 minutes at 250ºF,

torched for 10 seconds, and then

placed in the bottom of the new cell case.

I was in a bit of a hurry and only dried it in the oven

for 2/3 of an hour. In the torching, a chunk popped out. They get the

full hour drying in the oven from now on!

Neg (Pos):

- 12g V2O5

- 9g graphite

- .15g Sb4O6

- 1g Sunlight

- bit of HOH

The "intense yellow glaze" vanadium pentoxide made a

yellowish electrode

instead of the usual dark gray to black.

For the separator I used only a sheet of cellophane, doped

with osmium in acetaldehyde. If it's too thin and shorts out, I'll have

to dig out the vanadium electrode and replace with cellophane and art

paper, but thin should make for great ion flow - gotta get that

internal

resistance down.

As an aside, there were separator sheet materials/textures

I was thinking of long ago (and probably won't use now), that I

couldn't think what it was I was thinking of. One of them I

finally realized was coffee filter paper. The other was polypropylene

non-woven fabric, which I didn't know is also called "landscaping

fabric". However, the fabric is too

porous and the electrodes would short. Coffee filters remain possible,

but are probably not as good as the Arches watercolour paper... though

it may depend on brand. So does the watercolour paper.

Using clear plexiglass for the case was quickly

vindicated. A visual inspection of the cell after a few hours revealed

that some vanadium oxide had gone through to the lower electrode in one

corner - leaked or fallen over the edge of the cellophane "tray". The

rest of the negatrode had lost its yellow colour and turned black over

a few hours, presumably as it charged to lower oxides or to vanadium

metal, but

distinct yellowish patches were there around the edge spreading

from that corner. If this battery has any self discharge, fast or slow,

there was the first item to suspect. Perhaps that was part of why it

seemed to be charging so slowly, and why the voltage rapidly dropped

off if the charge was removed.

How many previous cells might I have seen and solved

problems in if I'd made them all clear?

It didn't seem to want to charge. After a while I took it

apart and put

in another sheet of cellophane, but that didn't help - the yellow edges

spread.

Perhaps there was something odd going on, with all

vanadium's odd soluble reactions spoken of on Wikipedia? The redox

chart did show a reaction straight from valence 0 to 5, which seemed

unique. Perhaps it became some dissolved ion form not shown, went

through the separator, and recharged at the positrode to valence 5?

That

might explain the migration seen

at the edges.

But if it wouldn't work as a negatrode, could vanadium

make a good positrode? With all the strange "+" oxidizing reactions of

vanadium in "strong acid" and "strong base" forming various soluble

ions, it didn't seem very

likely, but as usual there's no redox charts of vanadium in neutral

salt

solution. Vanadium pentoxide is "the most stable and common compound of

vanadium", which "upon heating reversibly loses oxygen". I also gleaned

from one item that the tetravalent state is, or at least

sometimes is, V2O4 rather than VO2, and the trivalent state is V2O3. It

is perhaps noteworthy that the

cation in the main positive states of charge should be "V2", suggesting

a

good stability between charge and discharge.

Conceivably in salt solution it might discharge and charge

between V2O3 [III] and V2O4 [IV], moving one electron per reaction, or

(better still) V2O3 and V2O5 [V], a valence change of two electrons?

This last reaction, illustrating

the "reversibly losing oxygen" property of V2O5, looked on the chart

like it might occur at

about the desired +1 volts, which would make vanadium an excellent

positrode material. There are also various transition oxide forms

between

V2O3 and V2O5, such as V3O5 and V3O7 that vanadium can take... as well

as various soluble ion forms. But it seemed more likely the V2 form

would

remain intact as two oxygen ions came and went, and solubles might well

only

occur in acidic or alkaline solutions - not in neutral salt and with a

"+" charge.

So I tried what I tried with the

previous battery (and once in a long distance phone call): I reversed

the charges. I now knew that the nickel

works as a negative. This seemed to charge! After 12 hours, a bit of

yellow

colour seemed to return, so evidently it was charging back to valence

five -- perhaps to V2O5 in accordance with my fondest hopes. And the

cell voltage had risen to around 1.7 volts and was still rising.

This was another surprise. It had seemed to me the most

likely reason the previous cell was 1.5 volts was that the manganese

was charging to potassium permanganate (+1v) and that the nickel

hydroxide to metal would

be -.5 volts, midway between the base (-.72v) and acid (-.28v) levels.

But for the vanadium at about +1 to cause the cell to rise

to

a

higher voltage meant that to explain the previous cell's 1.5 volts, the

"-" side must have accounted for more of the voltage. The "+" then was

actually charging to only MnO2 (+.5), and the

nickel-manganese-lanthanum side in salt had to be about -1. There is,

eg, a redox reaction for NiS <=> Ni that's -.99 volts, but it's a

far cry from

anything shown on the chart for oxides/hydroxides.

Nothing in the chart hints that Ni(OH)2

<=> Ni is apparently -1 volt in salt solution,

Nothing in the chart hints that Ni(OH)2

<=> Ni is apparently -1 volt in salt solution,

instead of being be the average of the acid and alkali levels.

In vanadium, seemingly I've stumbled across an excellent

battery

positrode

substance. How good? Wow!:

(a) The only reaction suggested by the voltage would be V2O5 <=>

V2O3. Theoretically this reaction moves two electrons per vanadium

atom. It looks to me likely it will actually

approach this value in practice. Manganese dioxide is said to move one,

and

nickel (with the best mixes - which significantly dilute the actual

nickel content) moves about 1.5,

so 2 (and without additives) is a major gain.

(b) V2O3 (@4.87

g/cc) is a little more dense than nickel hydroxide (@4.10), and it is

only slightly less dense

than MnO2 (@5.03), but it has the lightest atomic weight, so it packs

in

more atoms -- more amp-hours -- both by weight and by

volume. Even if NiOOH, MnO2 and V2O5 each moved just

one

electron per metal atom, the amp-hours of the vanadium both by weight

and volume would still be highest.

NiOOH <=> Ni(OH)2 - 102<=>103 g/m, 1 e- (1.5 e- with best

mixes charging some to NiO2)

MnO2 <=> MnOOH - 87<=>88 g/m, 1 e-

V2O5 <=> V2O3 - 91<=>75 g/m, 2 e- (grams/mole &

electrons for each "V")

(c) With the dual vanadium

center, it may prove to be the most stable and have the longest cycle

life - if it has any cycle life limit at all.

(d) It's "the max" +1 volts instead of

some lower voltage. (Though, in neutral solution, nickel should also be

+1. V2O5 and NiOOH might even make a good mix, if there seems to be any

reason not to use just V2O5.) The higher the voltage, the higher the

energy density, and +1 and -1 seem to be about the limits in salt.

Thus vanadium looks excellent for a "regular" type

battery,

ie one with solid electrodes, in salty electrolyte. (It's also used in

the "vanadium redox

battery" in liquid form.)

I don't know what vanadium's problem is as a negative -

perhaps with the right treatment that could work too, but I didn't seem

to be getting good results. Or perhaps like nickel, and maybe iron, the

hydroxide to metal voltage was

higher in neutral salt solution than expected, which could make it too

high. (Could this be the general case? It would explain

why salt water is so corrosive, and why "low voltage" nickel is -1

volt.)

If the nickel is about -1

volts, it's higher than in either acid (-.28) or alkali (-.72). But

that would seem to be the best explanation for getting about 2 volts.

It can't be the lanthanum, and copper has no reactions that look like

any sort of match. I added no manganese to the nickel mix in the

second cell, so it wasn't the manganese.

What a round-about way to arrive at my "ideal" 2 volt salt

solution battery cell - one reaction unexpectedly without soluble

products in charge or discharge, and one

reaction whose voltage in salt is quite unexpected, neither really

hinted at

or suggested in the charts and literature! But the result is the thing

- a better battery chemistry! I'm going to make a preliminary estimate

that it's good for 200-275 WH per Kg. Only the newest, experimental,

lithium-sulfur

cells (220-290) rival that,

and it should be far more economical to produce than those.

Also, batteries have specific causes for eventually

wearing out or failing, and I haven't identified any so far except for

potential eventual drying out of the electrolyte through poor seals.

Since it's a flooded cell type, it can be refilled by drilling a tiny

hole in the top, adding water, eg with a syringe, and putting in a

plug. That means I'm guessing they should go until the plastic case

finally

cracks or the separator disintegrates. (I should probably put in a

combo filler/relief cap that releases gas above a certain pressure.)

After charging the cell, I let it sit and found it

discharged overnight to about 1.1 volts. I charged it again and did a

50 ohm load test. The internal resistance was higher than previous

recent cells and it didn't fare well.

I took it apart and added sheets of expanded graphite,

sanded to roughen and cleaned with hexadecane, and hexadecane

brushed onto the carbon fibre cloth, which did come apart from the

electrode briquettes on disassembly. The brushing seemed to loosen the

fibres - perhaps that will improve conductivity. The graphite parts

were still wet with it when I put them back together with the 'trodes,

which may also help.

But I didn't put the vanadium positrode back in. Instead I made a new

one, adding some nickel hydroxide and neodymium oxide in hopes of

reducing the self discharge.

Pos):

- 9g V2O5

- 9g graphite

- .10g Sb4O6

- 4g Ni(OH)2

- 2g Nd2O3

- 1.5g Sunlight

- bit of HOH

This upped the current capacity to about what I had with other cells,

but it didn't seem to do a thing for the self discharge. Had I in

vanadium oxide picked another element and reaction that was just a bit

too

high in voltage? Considering how close it must be, with the potential

not only of almost double the voltage of manganese dioxide, but also of

moving two

electrons per metal atom instead of one, that would be frustrating.

Days later I realized I'd forgotten the calcium layer for

overvoltage improvement, as well as the idea of adding cobalt oxide to

increase conductivity. I should really get into a better habit when

doing electrodes - post procedure notes on the wall and check them as I

proceed!

A load test before and after seemed to show that the

voltage stayed higher longer for half an hour or so, but then dropped

off to even lower levels thereafter.

I took it apart and put in a calcium layer and torched it

(in fact I did two, unthinkingly placing one on the nickel electrode

instead of the vanadium one... well, that was the original "+" side, on

the bottom of the cell where I put the "+"es... and I had the flu.),

but by this time the briquettes were crumbling and there was little

hope of better current capacity or performance. I also replaced the

cellophane separator sheet (ripped) and added some more osmium powder

to the acetaldehyde mix before coating it.

The reassembled cell seemed to have higher self discharge

and took considerably longer to charge than before. A positive note to

that is that the self discharge, being higher, seemed to be something

I'd done

rather than to be an intrinsic property of the materials.

The chemistry seems good, and (for once!) the cell holds

pressure: the

conductance simply has to be improved. That may well solve the self

discharge and the low utilization of the electrode substances. It's got

under 20mA/sq.cm. even through 1 ohm, which is nearly a short circuit

with such low values. Ten times that figure would be a great

improvement. I could add bits of carbon (graphite) fiber to the

electrode as well as the powder, but I hate working with it - it's

worse than fibreglass and I end up itchy from the fine fibers every

time I use it. I can also add cobalt oxide, but that's supposed to form

a conductive network "in solid solution" with nickel hydroxide, in

alkaline solution. There's no guarantee it'll help simply mixed with

vanadium. There may be many possibilities for improving salt

electrolyte cell characteristics, but salt solution batteries and ideas

for them are hardly in the literature.

On the 13th I chopped up some carbon fiber mat into small

individual strands, maybe .05" to .25" long, and immersed it in

hexadecane. I realized I could probably use hexadecane to wet down the

electrode mix as easily as water. It would evaporate, and it seemed it

might improve contacts - and also keep the lightweight fibers from

becoming airborne while working.

I suspected that nickel hydroxide might either complement

the vanadium oxide or raise its oxygen overvoltage. So Vanadium

Electrode Mix #3 was:

10g (66%) V2O5 (active)

5g (33%) Ni(OH)2 (overvoltage/active)

.15g (1%) Sb4O6* (O2 H2 => H2O recombinant catalyst)

5g graphite powder (conducts)

"a 3g wad of" carbon fiber (conducts) [much of the mass of the "wad"

was hexadecane.]

1g Sunlight (glue)

?? hexadecane (flux)

*I want to try Sb2S3 (Sb4S6?), stibnite

- might work better - but I haven't found a cheap and convenient source

for it yet. It's sold by pyrotechnics supplys, but I couldn't find a

Canadian source, and the shipping from the USA was much more than the

price of the merchandise. I could make Sb2(SO4)3 by boiling the Sb2O3

in sulfuric acid - perhaps

that might reduce to Sb2S3 in the negative electrode? Yuk!

This electrode was compacted

on a sheet of expanded graphite. Taking off the graphite sheet revealed

an amazing working of the Diesel Kleen solvent: what would normally

have a

fine

"sandstone"

texture instead had a smooth metallic sheen and very low electrical

resistance, adjacent points reading as low as 4 ohms. This appears to

be

a fabulous technique for improving conductivity! I suspect it's forming

random lamellar

structures of graphite (graphene?) and electrode active substance(s) as

it evaporates, a random conductive network through the electrode.

(Perhaps I can dispense with the nasty chopped carbon fibers?)

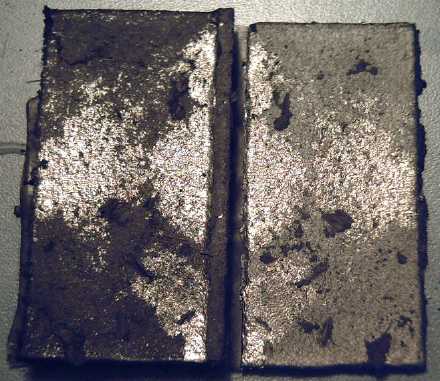

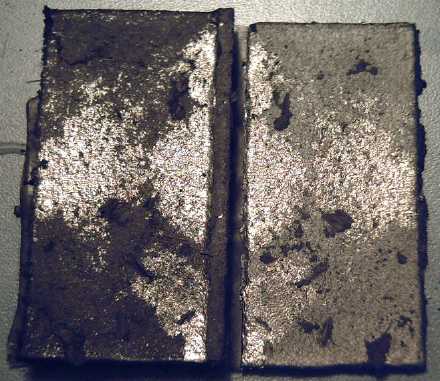

Backside of vanadium electrode briquette, with a metallic sheen, and

fuzzy with conductive carbon fibers (left),

Backside of vanadium electrode briquette, with a metallic sheen, and

fuzzy with conductive carbon fibers (left),

with its expanded graphite

backing sheet (right), illustrates the effect of the solvent/hexadecane.

A more usual electrode surface texture is seen in the thin area

along the top, which protruded past

the backing sheet.

The rest has a metallic sheen to it and quite low

electrical resistance.

(Note: The backing sheet is somewhat lumpy and the worse for

wear after 3 compactions. The first 2 compactions failed because the

briquette was too damp with

hexadecane and oozed out of the form. "Diesel Kleen" seems to evaporate

considerably slower than water.)

Top face of the hairy electrode. A few surface spots had a silver

shine to them.

Top face of the hairy electrode. A few surface spots had a silver

shine to them.

With the addition of nickel hydroxide to the vanadium pentoxide,

electrode color went from ecru to camo.

However, with only 5 grams of graphite powder in the mix,

the resistance from the top face to the bottom seemed to be in the mid

tens (~50) of ohms. I should have used more powder. Next

time I will -- and that'll be soon if the cell doesn't perform well.

So Vanadium Positrode Mix #4 (barring further adjustments) will

be:

10g (66%) V2O5 (active)

5g (33%) Ni(OH)2 (overvoltage/active)

.15g (1%) Sb4O6* (O2 H2 => H2O recombinant catalyst)

8g graphite powder (conducts)

"a 3g wad of" carbon fiber (conducts) [much of the mass of the "wad"

was hexadecane.]

1g Sunlight (glue)

?? Diesel Kleen (solvent/flux)

Next the layer of calcium

hydroxide was painted on, then it was dried in the oven

for about 90 minutes at 225ºF, and then torched for 7 or 8

seconds or so with a swirljet (very hot) propane torch, moving the

flame around the surface to hit it all.

For the negative, I used the Ni-Mn-La mixture at the top of this

article except I used 7.5g graphite, .15g Sb4O6, and a ~2.4g wad of

carbon fiber, and wetted it with hexadecane instead of water. Only

about 3/4 of the mix seemed to fit into the compactor, so some was left

over.

This time

I was afraid to add too much hexadecane, and it came out of the

compactor rather dry. The metallic sheen covered only a portion of the

back surface. Unsatisfied, I dabbed on some more hexadecane and

re-compacted it. This time, the briquette had to be pried away from the

graphite sheet, and the whole surface was silvery. (A couple of silvery

briquette surface spots broke away and stayed adhered to the graphite

sheet - they weren't 'missed'.)

Left: First try - too dry. Not enough hexadecane, and silvery

surface coverage was incomplete.

Left: First try - too dry. Not enough hexadecane, and silvery

surface coverage was incomplete.

Right: Added a few drops to the bad areas and re-compacted. This

completed the coverage.

The front surface, also looking a bit silvery. Resistances were

quite low,

The front surface, also looking a bit silvery. Resistances were

quite low,

around 10 ohms from surface points to the graphite backing sheet.

After compaction, resistances from any surface point to

the backing sheet seemed to be about 10 ohms. In these silvery surfaces

I felt, for the first time since being forced to adopt carbon instead

of metal backings and conductivity additives, that high current

densities might be within reach. ...as long as the electrodes haven't

become more or less impervious to the electrolyte (unlikely), and as

long as those nasty carbon

fibers don't poke their way through the separator sheets and short out

the cell! I suspect the fibers are now superfluous, though.

After a day of charging the cell, it was up to almost 2.2 volts, and it

would source around 3/4 of an amp into a one ohm load, only a small

improvement over previous cells. That would be maybe 30mA/sq.cm of

electrode interface. An order of magnitude more would be better. It

wasn't as good as a new regular manganese-zinc D cell (1.275 A), but it

was headed the right direction. The D cell would be about 50 sq.cm

instead of 29 though, so 26 mA/sq.cm. (I found it was capable of 40

mA/sq.cm while delivering above one volt. What a far cry such numbers

are

from NiMH D cells, delivering 70 amps at almost a volt to start the

car!)

I was hoping for better. Doubtless it would have done

better with a little more

graphite in the positive to reduce those 50 ohm readings, and probably

if I hadn't split the carbon sheets away from the electrodes to peek in

between. In a future cell I can also try using metal (expanded copper

mesh?) in the negatrode structure to provide lower resistance in that

side.

After a second day's charging, green material had formed

around the edges on the negatrode and started creeping its way up the

folded separator sheet to the positive. It could be nickel hydroxide or

copper chloride - they're virtually identical blueish green. On the

other hand, nickel hydroxide shouldn't be moving, and copper chloride,

even if it formed,

should have converted to hydroxide (or dissolved). Furthermore, both Ni

and Cu should be reducing

to metal with charge, not oxidizing. Whatever it is, I don't like the

way it's trying to do an end run around the separator!

By the end of the day, black lines were forming at the

tops of the green. Best guess: it was Ni(OH)2 and it had now touched

the positrode, and was charging up to black NiOOH on top. A bridge

around the edge of the separator sheet -- it's a sure setup for rapid

self discharge! I let the cell sit overnight and charged it during the

day, and sure enough, on the second night, the voltage in the morning

was lower, 1.3xx versus 1.6xx volts.

I disassembled the cell. The positrode came out without

damage, and I wrapped it almost all up in new paper except where it had

to contact the terminal post. Not only was this better insulation with

less chance of a bridge, it turned out to be easier to fold than

forming a dish

around the outside. It did use a 3x4" piece of paper for a 1.5x3" area,

but paper is neither pricey nor heavy. I added a couple more sheets of

rubbery stuff, hoping a stronger press would get everything connecting

together better inside.

The old paper was green not only around the edges; much of

it was impregnated with green, in many areas black on the positive side

surface. If this was copper chloride, it could possibly be an

advantage, just as

zinc chloride proved to be a better electrolyte in standard dry cells,

and it then became a specific additive to improve performance. If it

was nickel, either hydroxide or chloride, it was probably bad news.

Nothing for it but to put it back together and see what happened. And

maybe figure out some chemical test for copper or nickel on the old

paper.

How could I have made all those cells without clear sides

to see in!?!

I put a pressure gauge on this cell, but I unscrewed it

and let the pressure out whenever it hit about 3 PSI. I think a flooded

type cell with an air reservoir on top and a pressure release valve

will be optimum, especially for DIY construction. Somebody else can try

completely sealed cells (dry or wet) later. This will also be about the

safest battery going: it can't pressurize and explode, and salty water

isn't

corrosive to human flesh if it gets out. Short of actually ingesting it

- or perhaps leaving it short circuited until things start to melt -

it's unlikely to injure anyone.

On the 19th I finally bought an adapter fitting for

the adjustable pressure relief valve I had bought along with the

pressure meter, well over a year ago now, and I installed the valve.

Now it could do its own pressure reliefs when and as needed, at maybe 5

or 10 PSI.

V-Ni cell in clear case with pressure meter and pressure release

valve.

V-Ni cell in clear case with pressure meter and pressure release

valve.

Greenish layer is nickel negatrode, white is vanadium pentoxide

positrode wrapped in watercolor paper.

Brown is spongy rubbery stuff to push the two together.

5/16" carbon posts top and bottom (from standard "D" cells) connect the

electrodes to the outside world.

On the 20th the voltage had

dropped overnight again to 1.64 volts. I thought of opening the cell

and adding eggwhite/albumin to the negative. But it already had the

thiamin - surely a good amine itself. When connected, the voltage rose

to 2.1 in a couple of minutes, more like a commercial battery. It

seemed the 'intermediary' additives had been charged out and all that

was left active was the intended chemicals.

Something seemed to be changing, and one must expect very gradual

results when charging a cell that's several amp-hours at 25mA. I

decided to give it another day of charging and see what happened on the

fourth night. It could take the rest of the month to really see

results, but I'd rather take it slowly. If it appeared to be working I

might make my 'full size' 3" x 6" cell.

The next morning the voltage had dropped even more, to

1.54 volts. All that green stuff around the edges... it came to my mind

that I hadn't added the zircon ion shield layer, at least not to the

second separator sheet. In the afternoon I opened it and painted some

zircon on. (I'd better not forget the zircon if I try the

manganese-nickel mix for permanganate again!) I also added yet another

sheet of rubbery mat stuff to push the electrodes together more.

It didn't help. Conductivity seemed to be gradually

dropping. It would only source 1/2 an amp into 1 ohm, and the following

morning the voltage was 1.46. I decided to charge it backwards and see

what happened, this time not to attempt to use it that way, but only to

change or move chemicals that might have charged up on the wrong sides

or in a wrong way. I charged it much of the day that way, then reversed

it again.

There was improvement - after 8 hours sitting the cell was

still 1.65 volts, and 1.5 volts after 18 hours. At least it was back to

how it was. I let it rest the whole of the 23rd.

On the 23rd also, I was given a PDF copy of Battery

Reference Book 3rd Edition by T.R. Crompton - a 774 page tome.

Imagine working on making batteries for 3-1/2 years, doing web searches

and looking at library catalogs, and not discovering that such a

comprehensive reference work exists! Could it have saved me countless

hours of work? Or would I have been "indoctrinated" with "standard"

assumptions and not tried some of the things that are now starting to

yield great results? Starting with a "clean slate" (also known as

complete ignorance) and perhaps discovering some thing or things

overlooked by previous battery research was after all one of my ideas.

However, as I perused some of the pages, I found practical

design and construction seemed to be about the least covered aspect. In

particular, I could find no mention of why only carbon and graphite

were used for common dry cells - that every metal placed in the

positive electrode would corrode away. Essentially it didn't seem to

contain any revelations that

would

have really speeded up my work.

On the 24th, it finally dawned on me that it might simply

take a few charge, rest, and discharge cycles to get everything

into proper balance. I'd done lots of charging but until now little

discharging or resting on this cell. Having rest it over 24 hours (it

was still about 1.4 volts), I shorted it out for a few hours until the

current dropped to almost nothing, then let it rest some more, and

charged it in the evening. On the 25th it still wouldn't source more

than 450 mA into a one ohm load, and a load test didn't seem very good,

notwithstanding that it wasn't very fully charged.

The Conductivity Problem: Epoxy-graphite experiment

The chemistry (and probably more than one chemistry) seems

great, the electrode conductivity is surely much improved by compacting

with Diesel Kleen. The external metal clamps seem to contact the carbon

posts quite well. Where then is the performance problem? No amount of

charging and discharging seems to improve conductivity, nor restore it

from its slow decline in each cell. There seemed to be just one likely

culprit: the contact between the graphite backing sheet and the carbon

terminal post. These two pressure-contact-only joins, where the

graphite sheet would gradually saturate, surely deform and get looser

under

pressure, were now the one unvarying "worst feature" of all the

cells I've been making, which are all two or three internal ohms to

start and which all only put out 1/2 an amp or so, and that get very

gradually worse.

I visited graphitestore.com on the web and started

wandering around the pages. After looking at a few things of marginal

interest, I found some "conductive epoxy" glues with metal particles in

them - silver, nickel, or aluminum. But if the electrolyte soaks

through the graphite sheet and comes into contact with a metal at the

positive electrode, it'll oxidize into a low conductivity oxide. If the

metal particles contacted each other - as they must to conduct - they

would all eventually oxidize.

Okay then, how about epoxy with carbon or graphite

particles? What about simply mixing graphite powder with epoxy? Mixing

graphite into pitch gave poor results, but I hadn't tried epoxy.

As a preliminary experiment, I mixed a little epoxy, 3.65 g, and then

stirred in a gram of graphite. It turned black, but the consistency was

little changed. I added a second gram, and it became a little thicker.

With a third gram it became a thin paste, and with a fourth, a thick

paste. With a fifth gram it all stuck to the stir stick and came out