Turquoise

Energy Ltd. News #41

Victoria BC

Copyright 2010 Craig Carmichael - July 1st 2011; Happy Canada Day!

http://www.TurquoiseEnergy.com

= http://www.ElectricHubcap.com

= http://www.ElectricWeel.com

Month

In Brief

(summary)

* Motor controllers: problems (no wonder the car

doesn't move!) & solutions

* AKOO Stuff: Hubcap & Weel motors - e-bike - torque

converter design - LED house lighting - battery experiments

* Wind power: costs hit parity with fossil fuel power costs in

2010

* Off Topic Editorial Rant: loss of freedoms; US war crimes

& Wikileaks; failure of our governing systems to evolve.

Electric Hubcap System

* Motor Controllers... A3938 Motor Controller: more failures

* Microcontroller based motor controller: the way to get the

exact

features you want!

* MC33033 controller, e-motorbike: more tests, more failures.

* Back to square 1: IR2130 triple MOSFET driver + 'standard'

logic chips like I was using in 2008/9!

* New IR2133 (with some devious connections!) gets it down to 2

chips, with optimum 'current ramp modulation' control.

* Motor system thinness; Metal protection: "Cold Galvanizing

Compound" spray; First flat magnet rotor.

Electric Weel Motor Project (Electric Wheel

Motor... Rim Motor...)

* Plywood stator base instead of composite mold to speed up

protoypte

* Welded the magnet rotor (finally)

Torque Converter Project

* Spring-loaded MTC protoype - better configuration idea

LED Lighting Project A little

energy efficient home lighting, anyone?

* 10W, 1000 lumens LED... run at just 4 watts as a 3-AA cell plastic

dome light... takes on 3W tungsten,

15W CF and 60W tungsten.

* 4 W hallway globe light - runs on spare 9 V power adapter

plugged into light fixture. (250 lumens? Far brighter than previous 7 W

CF.)

* .9 W "off the shelf" car inside light... lets me read street

names on maps after dark.

Turquoise Battery Project

* Electrode conductivity is now good, but finished cell

conductivity is still low.

* trying other electrolytes

Newsletters

Index/Highlights:

http://www.TurquoiseEnergy.com/news/index.html

(oops - I moved the index in March and neglected to change the link

until now!)

Construction Manuals and information:

-

Electric Hubcap Motor

- Turquoise Motor Controller

- 36 Volt Electric

Fan-Heater

- Nanocrystalline

reflective rear electrodes to enhance DSSC Solar

Cells

- Simple Spot Welder

for battery

tabs, connections

Products:

- Electric

Hubcap Motor Kits, Parts - Build your own ultra-efficient 5 KW

motor!

- Sodium Sulfate

4x

longevity additive & "worn

out" battery renewal.

- NiMH Dry Cell Car

Batteries (please e-mail me to order batteries)

- NiMH Custom Batteries (EVs, E-Bikes, Scooters, etc. - no extra

charge)

- NiMH individual Dry Cells (D - 10 AH, $10 -- AA - 2.5 AH, $2.50)

- Motor Building

Workshops

...all at: http://www.TurquoiseEnergy.com/

June in Brief

June only had 30 days, but somehow this isn't as brief as

expected. It seems like little of note has been accomplished, but

the bowling ball is a little farther down the alley towards the several

pins at the end.

Motor Controllers

Motor

controllers came to dominate the month. It has gradually dawned

on me that they aren't performing well at low speed -- just where lots

of torque is needed to start a vehicle moving.

The variable

frequency current control method that I'd found

in

the A3938 seemed superior to PWM, but my several A3938s all burned out,

and I finally gave up on them. (Turns out they were designed only for

small motors, <1 HP).

Unknowingly, the low PWM

frequencies I chose for the MC33033 greatly reduced low speed torque.

(understandable now, but not mentioned much less explained in any of

the literature)

The first trials with

Tristan's electric motorbike, with a MC33033 controller, showed

it: the bike just didn't draw enough power to start moving,

notwithstanding that it was only a bike with one person on it, and it

had a 4 to 1 gear ratio advantage! The car moved across level pavement

with direct drive to the wheel in 2008 when I used my own "primitive"

design controller. The electric outboard worked fine because the

propeller

has negligible load at low speeds, so the motor had no trouble getting

up to a speed above the low-speed/low-torque effect. I speeded up the

PWM to

'recommended' frequency, but then the controllers started failing.

After a week of blowing MOSFETs, I

finally got a short bike ride on level ground

before the next failure.

I resolved to make a better type of motor controller,

based on the A3938 type "current ramp" modulation.

For a while I

thought I'd

use a

microcontroller for the "brain", with

the same power driver circuits and MOSFETs as in the MC33033

controller. I

started studying Atmel's nice "SAM7S16" ARM chip and how to apply it to

this

application. Then I decided that a microcontroller would take too long

to get going. And

the burnouts seemed to show that better MOSFET interfaces were what was

really needed.

It started to look

like the best choice (of a relatively unsatisfactory lot) was the

IR2130 triple gate driver and some "old standard" small scale chips

- an improved version of what I had made in 2008 before I'd

ever heard of single chip brushless motor

controllers! After designing a tricky circuit that got it down to

just three chips, it occurred to me to

look on irf.com, and I found there's now an IR2133 with a couple of

extra features. By a couple more

'workarounds' on this new device I got it down to a two-chip controller

with the better

'current ramp'

modulation instead of PWM. The month ended with long sessions of

circuit and circuit board design, with the board layout completed July

1st.

If I think my stuff often isn't thought out very well at

first and only gradually improves, I can take solace looking at IR's

chips: the power MOSFET driver parts seem to be second to none but

their chips'

logic functions aren't very well considered. With a couple of different

pins on the IR2130 it could easily have become a single chip high power

brushless motor controller. Instead, the IR2133 has put in one of the

functions - in a convoluted sort of way - kept three rather useless

inputs, improved one feature, and removed a useful

internal timing feature I had planned on using and now must fudge with

resistors and capacitors.

Weel Motor

I continued building the big Weel Motor at the established

snail's pace. I cut two plywood circles for the stator rings, to be

covered in PP-epoxy rather than molded entirely from it. I tack welded

together the two parts of the magnet rotor.

Pieces for the Weel motor.

I can't assign a very high

priority to this project until there are motor controllers to run it

with, and, being short of epoxy to do the rings the day I cut them, I

moved on to

other things.

Torque Converter

I started building a new torque converter before I

realized that a better motor controller had to come first. It had a

pivoting wedge piece to hit the drum to make torque hits, but I wasn't

entirely confident about the arrangement.

A mechanically inclined friend came over and talked about

centrifugal clutches. The converter couldn't grab on like a clutch, but

from that I got the idea of having the wedge spring out centrifugally

into a slot in the output drum rim rather than pivot into one. That

seems like it should have considerably more force, with both the

spring and its own inertial mass going for it, so I'm changing the

design and I'm calling it "most likely one to succeed".

Motorbike Project

Tristan's motorbike project seemed to be stalled. He now

had a job in Vancouver and hadn't made it to Victoria in months to work

on it. There was a prospect of him coming one weekend, and knowing his

time would be limited, I decided to put a few hours into it myself and

give it a jump start. I'd swap him his older version Electric Hubcap

motor that he'd made for the 'modern' one in the shop, which I fitted

onto the bike. Then I put an MC33033 board (working, at least!) into

his motor controller. Lastly I turned

down a motor axle to make a friction fit for the chain sprocket gear

and pounded it on, then I put that shaft into the motor.

Motor (red) & controller (aluminum box) fitted on bike

Motor (red) & controller (aluminum box) fitted on bike

Tristan was only able to

spend the day of Sunday the

19th, but we got it far enough along to try riding it. We found the

aforementioned low low-speed torque wouldn't get it going except

downslope.

Tristan riding his "e-Bike" in the yard (slightly downslope).

Tristan riding his "e-Bike" in the yard (slightly downslope).

3 Ni-MH 12 volt batteries were strapped on the back for 36 volts, but

the amps being drawn were quite low.

LED Lighting

In May I ordered three very bright LED "emitters" meant

for lighting.

They arrived. I made a 3 volt, 4 watt battery operated plastic dome

light

and a 9 volt, 4 watt

hallway globe light that I ran straight off a scrap 9 VDC, 450 mA power

adapter, plugged into a

light socket screw-in plug adapter in the globe light. 4 watts works

out to about 23¢ of electricity per month. The hallway is much

brighter than with the 7 watt CF light that was in there before. They

were about

as bright as 40 or 50 watt regular bulbs and were lovely white color

that I'll call "ultra bright moonlight". I decided I'll gradually

convert many of my house lights over and save

lots of electricity, and have ordered some more. Around 15 watts of

LEDs will probably replace a

100 watt bulb. (I've generally been using two 23 or 26 watt CF bulbs -

about 50 watts. One 23 watt CF seems considerably dimmer than a 100

watt

tungsten

bulb to me. So 15 watts is 1/3 of CF watts for equivalent brightness.)

At 15 or 20 $ per LED and needing two or

three for bright light areas, the initial cost starts to add up

- and with no satisfactory 120V LED installation system in place, so

does the installation

time. There are ready-made screw-in bulbs, which I'll also try out, but

from the sounds of things, they won't have the brightness or be as

satisfactory as the single emitters. There are also small triple

emitters I can try, which a friend is using for his solar panel + NiFe

battery DC power house lights.

Of course, once installed, LED lights may well last longer than me and

I'll never

have to buy or change bulbs again.

4 watt LED globe light.

4 watt LED globe light.

I like the diffuse light from the globe much better than small, intense

points of light.

Turquoise Battery

This month I decided to try Mn & Ni combo again for a

"+", with the same nickel "-" as last month's 2 volt vanadium-nickel

cell, and with the graphite-epoxy electrode glue as well as the "Diesel

Kleen" conductivity raising technique.

The electrodes seemed highly conductive, but cell

conductivity was still poor. I used

lots of graphite in the electrodes and in the glue, though I didn't use

enough Diesel Kleen on one of the electrodes.

I got another surprise: the cell was 1.5 volts instead

of 2 volts.

I was assuming the voltages were:

Ni/Mn+ ... Mn- 2.3 volts (+1, -1.3)?, but high self discharge

from the Mn- side)

V+ ... Ni- 2.1 volts (+1.1, -1)?

So this should have been +1, -1, but the total was apparently only 1.5.

Ni/Mn+ ... Ni- 1.5 volts

Either the Mn was only charging up to MnO2 (though it was

in fact made

with KMnO4, the higher charged state), or the nickel "-" side was only

-.5

volts... what I thought it should be prior to making the V-Ni cell. Did

that mean the vanadium was in fact +1.6 volts and the nickel -.5 ? ...

but if so, why did the vanadium seem to have no serious problems with

self discharge?

Near the end of the month, I started

experimenting with different electrolytes to reduce internal

resistance. Ammonium chloride didn't

help... how about organics?

I tried filling the cell with

toluene instead of water, and the case started cracking to pieces. A

whole corner fell right off! That was it at least until I have a new

case.

Wind Power Cost at parity with fossil fuels in 2010

Adding to the recent North Carolina report that in 2010

solar

power became cheaper (for new plants) than nuclear power, this from

Globalspec Newsletters: "According to the World

Wind Energy Association (WWEA), average installed wind power costs are

now on parity with fossil fuel plants." I don't know how this

compares with nuclear, but the report continues: In 2010, China

installed 19 GW of wind capacity, as did the rest of the world combined

for a total of

38 GW. (Compare with BC's Site C Dam at .9 GW.) Many of the largest

wind turbines are installed just offshore and the current plan - or

dream -

is to go from 120 meter

blade

diameters (5 MW) to 200 meters (20 MW). Offshore is safer and

the noise won't bother people. But I wonder if the requisite number of

windplants wouldn't cost less than the Site C dam and occupy less area

than that to be flooded?

I'm for it, but I must comment that if we're going

offshore around here, 20 MW windplants will surely be harder to make

than small, quiet 20 MW floating

wave power units that won't kill flying birds. The wave power units,

around Tofino, would also doubtless produce more energy per year.

Off-Topic Editorial Rant that really has no place here

I noted some very disturbing related things this month.

More and more we see those we elect to serve us passing

laws and

bylaws that curb individual rights and freedoms in one issue after

another. They wish to try to control and regiment people rather than to

empower them to make their own decisions and live their own lives as

they choose. It's become so prevalent that things that would have

brought storms of protest in past decades now pass without debate,

without much comment, and without any consideration of the overall

effects -- often just to solve one immediate small, perhaps emotional

or

popular, current issue. No attempt is made to educate to prevent

mistakes -- easier just to make something illegal!

As just one example, common chemicals I've wanted for

battery and solar cell development are unavailable or restricted simply

because (and this is just my best guess as to why, as no one seems to

have bothered even to explain the rationale to the public) the medical

profession thinks a few

people may be using them unwisely for health purposes, and wants to be

able to dictate

their medical usage. But making something illegal or unavailable

affects all its

potential uses, not just health. Problem substances include among other

things element #53,

iodine,

needed for electrolyte in DSSC solar cells, and potassium permanganate,

the best positive

battery electrode substance to give cells of the highest energy

density (used as a poultice). But there are more and more examples

of things restricting freedom to live one's own life besides substances

- you can think of

a few.

Now freedom of speech along with freedom of the press

appears to be under serious attack in the USA and

anywhere they touch. It seems any violent act or smear campaign against

any messenger who even might possibly bear unwelcome news is just fine.

The great bastion of freedom is moving towards police state as well as

bankruptcy.

First I watched a Swedish documentary on youtube.com, WikiLeaks

Rebels. In a featured "leak" was footage from a US military

helicopter

attacking and killing Reuters journalists on a street in Baghdad

from the air (2007?). Then, when Julian Osange, founder of WikiLeaks,

couldn't be

located (he's been forced to live at 'no fixed address' for his own

safety), he was

charged with rape of two women -

former girlfriends, neither of whom appeared to have initiated the

action, wanted to pursue it,

or were afraid of him - first to discredit his work by association, and

no doubt "hopefully" to get the Swedes to arrest him. This follows

another

recent multi-million dollar smear campaign I heard of

(though perhaps just a rumor?) by American drug companies to discredit

Michael Moore, who had done an unflattering documentary on the drug

industry. Before that I heard of a carefully prepared TV documentary

news report, an exposé on an unsafe Monsanto product being

injected into cattle everywhere, which didn't air because

Monsanto threatened

the network with suing them if they did. (This story too can be found

on youtube.) Instead the previously much

heralded "hard hitting news" stars who made the documentary ended up

sacked. Then in mid June I read a news report wherein a CIA agent said

someone from

the Bush presidential office had asked him to "dig up dirt - anything"

on

a university professor who was publishing to the web quite a different

view of the war in Iraq to that being put out by the White House, with

reports and footage from first-hand sources including Arabic. The agent

pointed out that it was illegal

for the CIA to spy on American citizens, and reported the incident to

his superiors. (Hurrah, integrity lives!) The White House

spokesman then

proceeded to find another CIA agent, and also made "improper" remarks

about the professor without any evidence whatsoever. The professor,

surprised, felt he was a pretty small fish to be gone after so hard...

what pressure must be on the bigger players? (Those involved were all

named in the news article, linked from a Lycos web search page, but I

didn't write the names down.)

The long and the short of it is, I suspect that killing

the

Reuters journalists (and several bystanders) was no mistake but cold

blooded,

calculated policy. Consider:

independent journalists would be likely to report things "out of line"

with Washington's "clean war" image (like that over 100,000 Iraqis were

killed) - just like the professor they went

after. The pilot first identified "RPG"s. Later

he called them "AK-47"s. The camera equipment became not just "looks

like weapons",

but specific weapons, which surely look little alike, and still

less like cameras. And no one on the ground was paying the slightest

attention to the prowling helicopter - hardly likely for combatants

openly

shouldering weapons on the street. Was the pilot that stupid? Then the

pilot urgently

demanded authority to fire

again on one of the journalists who wasn't dead and was painfully

dragging himself along the ground down the street. When a good

samaritan taking his kids

to (?)kindergarten stopped to help and took the wounded man into his

van, the van

was shot, killing the man as well as the journalist. (The children

miraculously survived. They will probably not think of America very

fondly.) This would make no sense either: a badly wounded soldier is no

threat, and shooting a rescue vehicle is everywhere considered

reprehensible. A wounded journalist, on the other hand, if he lives

will write a terrible story for public consumption: he is even more

dangerous and must be

finished off.

With all that, I strongly suspect the pilots had orders, from the top,

to shoot "unauthorized" journalists, and to report cameras as "weapons"

in case

their transmissions were overheard. The White House "demanded" that

WikiLeaks.org return all the vast evidence of their crimes against

humanity. (The whistleblower was a brave young intelligence officer who

will probably pay a very heavy price.) They got just the unwanted

publicity they were trying to stifle by force. The world needs an

international police force, not a

bullying nation operating in defiance of law and decency and without

the sanction of the international community, for its own ends.

American democracy (not to mention Canadian) is proving

unable to evolve as needed to continue its serviceability to a free

society - only ineffectual if not actively corrupt people seem able to

win

election, shutting out those truly fit to lead. Most emphatically, the

"illiterate's X" voting system, which has never worked right, needs to

be replaced with choice ranking. Australia and New Zealand have it -

and probably most of the civilized universe. And Canada needs to let

the people elect their PMs and Premiers, just as we elect our mayors -

not allow them to be picked by the largest partisan faction ("party")

in the legislature.

The two mistakes give rise to a partisan

faction ("party") controlled system where 'the leader' has all the

power. Canada in particular comes closest to electing a dictator of any

nation. Such "party" systems are open to corruption by rich

vested interests. Decisions on public matters are made privately behind

closed doors -

mainly by the leader of the largest faction - and "rubber stamped" in

the deliberative houses where they are supposed to be openly proposed

by members,

discussed and decided on. In April's federal election, while others had

signs

supporting individual candidates, I made my own political comments

along these lines:

I thought this could be educational not only for what was

said but simply because most North Americans have never even seen a

choice ranking ("STV") ballot. Ideas are scary for being unfamiliar

when

being discussed.

A photo taken from a back row seat inside the US senate

during a recent session showed the 'minority leader' speaking, while

two senators ahead were playing cards on their computers, another was

on

Facebook, and a fourth was doing something else unrelated (texting?),

accounting for all the people nearby in the view. My own member of

Parliament Dr. Keith Martin - who was one of Parliament's

leading movers and speakers - finally threw in the towel in

frustration in the last election, saying the system is so dysfunctional

no one can accomplish anything. Apparently many if not most of the

people

we elect to serve us and improve civilization feel just about as

powerless as the rest of us.

Quoting

from a greater American statesman than those seen recently: "Those who

make peaceful evolution impossible make violent revolution inevitable."

- JFK.

I trust it won't come to that. Change begins with each

individual. Individuals are changed by faith in the first source and

center of infinity - the Universal Father, trust that the universe is

friendly, in recognition of the human family ("We all breathe the same

air." - JFK again), and by

education. The internet is helping people - presumably including future

leaders - learn, by providing open access to previously

obscure (or deliberately hidden) documents and materials, and providing

many previously unthought-of solutions, of which WikiLeaks and

OpenLeaks are just one example type. You can think of more. And the

improving communication is bringing our extended human family together,

as never before.

Electric Hubcap Motor System

I got serious about motor controllers this month. After

trying to get the A3938 controllers to work early in the month without

success, I put together some MC33033 controllers. Tristan came over and

we assembled his "electric hubcap" motorbike far enough to try and ride

it. It wouldn't move except downslope, and it was only after a week and

a

dozen blown MOSFETs that I got it to move along level ground...

and then another MOSFET blew. So, much of the month was unexpectedly

converted to motor controller trials and tribulations, and the MC33033

(as built) proved much more troublesome than expected. I think (maybe)

that over about 24 volts the spikes are making the MC33033 'huccup' and

leave on for too long MOSFETs that are supposed to be off. It doesn't

help that it leaves half of them on regardless of PWM.

Before the end of the month, I finally realized I could

ditch the motor controller chips entirely and use... an LM339 quad

voltage comparator (timings, modulations and on/off gating) and a 4070

quad XOR gate (forward/reverse), with 3 'beefier' half-bridge MOSFET

gate drivers than the present MC33033 board has. Yes, worked down to

essentials, that seemed to be all a brushless motor controller really

needs, and it would give the "current ramp" type of modulation I wanted

from the A3938. On detailed considerations, the IR2130 triple MOSFET

driver seemed like the best choice of drivers, and I could use its

internal op-amp (with a couple of seemingly unrelated pins) and drop

the LM339. On the IRF.com website I found that's been superseded by a

new "IR2133", which, with some creative fanagalling, can do the job

with just one other chip. (the quad XOR gate) So after a long run since

spring 2009 I've come right

around the loop from several general purpose chips to dedicated motor

controller chips and back pretty much to my original chips -- but fewer

of

them, to make a better motor controller.

The very long subsections on motor controllers written

below, something of a 'diary' of events as they unfolded, give

'blow-by-blow' details

of all this. Unless you're really into motor controllers, it's probably

a

good section to skip.

The End of the A3938 Motor Controller?

The

control method of the A3938, ending

with a short fixed "off" period after a variable "on" period while the

coil current "ramps up" to the set current level,

may (possibly) be called "direct torque control" (DTC), "delta

modulation", "delta-sigma modulation", or "chopper control". None of

them seemed exactly

applicable. (See Wikipedia "PWM"

article.) I prefer to call it "current ramp control".

I decided that if I blew

the last A3938 chip, I'd go back

to the MC33033 controllers until some future time. It developed that

the

"is being discontinued" notice only applied to

the DIP package of

the MC33033 (the one I was using), not the chip as a whole. Other

packages remain available,

so

the circuit board would just need a little redesign. I'm glad the DIP

version was there while I was troubleshooting the prototypes! Much of

the trouble and time spent trying to get the A3938 to work has resulted

from the miniscule

packages, that are hard to place and solder and can't be socketed.

I disconnected one pair of transistors from each motor

drive output: Vbb, the output node, and the gates. This was intended to

reduce the load on the A3938 gate drives from 200+ nano Coulombs to

100+ nC per the recently discovered "app note". In all the crowded

wiring I was nervous about doing this, but

I checked everything I could think of and taped off bare wires. What

could go rong?

I turned on the power and turned on the switch. I turned

the motor a bit by hand and BLAM! Two mosfets and the 30

amp fuse were blown. But as I disassembled things I found out why: the

voltage

sense from one of the outputs to the board was soldered to the

disconnected mosfets, so the voltage sense reading for that output was

invalid.

By this time I had removed the six drivers that were in

use, so I reconnected the other six and rewired everything. Evidently

the chip somehow wasn't blown in the carnage. However, the motor still

wasn't getting power. Evidently it wasn't the gate drive timing delays

that were

the problem... so now I knew to look elsewhere.

After getting some shoot-through currents, I had set the

dead time between turn OFF of one mosfet and turn ON of another to the

max, about 5 microseconds. On the oscilloscope I was seeing voltage

spikes

under 1 uSec, so I decided to try some compromise value.

First, to limit potential damage, I put in three 1 ohm

resistors in series with the

three motor leeds to limit the current, and another 1/2 ohm in series

with

the main power.

I tried 100 K ohms, which should reduce dead time to about

2

uSec.

That didn't seem to help either. But on the scope I could now (finally)

see a steady high level voltage on one of the motor supply wires. How

could motor wires be high and low, and yet the motor still drew no

current?

I looked at the plug on the motor. I had made up a special

test plug last month with thin (#18) wires - again to limit

destructive current for

testing - and my memory is of carefully making sure the pins had

clicked

home into the sockets, but there it was: a pin not properly inserted,

and apparently not making a connection.

With that fixed, the motor slowly turned. It was working!

Very soon I

could smell hot resistors. It turned both directions, which meant that

by considerable luck I probably had all three phase wires right. I

removed the 1/2 ohm resistor from the power and tried again. The motor

turned a little faster. My hand came near one of the one ohm

resistors, and I could feel the heat, without even touching it.

Obviously most of the power was being used heating them up instead of

turning the motor.

I removed the resistors. When I reconnected the power I

thought I

heard a "snap" noise from the circuit board. The power voltages from

the chip

indicated it was fried, evidently without even trying to run the motor

(I tried anyway, to no avail). No evident rhyme nor reason. That was

June 6th.

That pretty much did it. I really hate to give up on a controller chip

from which much was hoped, after so much investment of time and money,

and that was running motors pretty well last fall when first tried. I

finally remembered why I couldn't even duplicate those results: the

initial time when it worked, the motor coils were connected with skinny

alligator clip leeds (and so was the power IIRC). Those were something

like the current limiting

resistors, and I'm not sure it ever worked once wired "properly".

Since it worked with resistance in the lines

and not without it, perhaps I should try putting some resistances or

RC filters in

series with the output voltage sense inputs to the chip to limit

current?

(The app note boasts about how the high voltage section was implemented

with a minimum of silicon - who cares? That means nothing beside

reliable operation. The MC33033 boasts of "industrial ruggedness".)

Another thing I noticed after I switched back to the

MC33033 is that Motorola used an RC filter on the current sense line

(which

I duly copied) while the same raw, spikey current signal connects

straight to the A3938 in Allegro's drawings. I did it their way without

giving it any thought, but that line is certainly a potential source of

chip-blowing transient voltages. Perhaps all four lines coming back

from the motor coils to the A3938 should be filtered.

Filtering the lines to reduce spikes to the chip might

make it work. I may (or

may not) get a few more A3938s for the 5 PC boards I already have. Or

that might just save the chip and blow MOSFETs instead because of

slower voltage sensing times!

Mid-month I started thinking of using a microcontroller,

which can

implement similar control plus regenerative braking - and anything else

I can think of.

A Revised MC33033 Motor

Controller?

After my last A3938 chip failed I

put together a couple more MC33033 controllers just to have some

working controllers, and for a while

considered trying to "trick" them into doing the A3938's "short fixed

off

period" with a bit of additional hardware. Then I decided to just raise

the PWM frequency a lot.

The "current ramp" control

technique of the A3938 is preferable for car drives. It's got superior

low speed torque, lower power dissipation (less heat in the

transistors), and a more familiar "gas pedal" control feel. But in

the time

I've spent troubleshooting I could have put together a few working

controllers of the old type. A controller for

the shop was certainly needed now, and one for Tristan's bike, the big

Weel motor will need three

more by

itself, and to be able to offer reliable controllers known to work with

the

Hubcap motors would doubtless be a big asset for selling them.

"Optimized" controllers would be even better.

The big asset to the MC33033 controllers with the 3

separate IRS2003 half bridge MOSFET drivers was that I

thought I had them working well.

The biggest problem with them is that the main control and

the current limiting control are separate. When the motor is stopped or

turning

slowly, the current will rise quickly. When the maximum current is hit,

the PWM cycle shuts off to avoid exceeding it. But the

cycle is no shorter, so at low speed the motor spends most of each

cycle turned off,

being supplied a low average current overall. Unless the

oscillator frequency is set very high (which brings in needless

switching losses and heat in the controller at all times) this

limits bottom end torque, right where torque is needed most to get a

vehicle to start rolling. This has doubtless been a factor in my torque

converter failures, especially the last 'clock escapement' ones. In

fact, in 2008 with my original multi-chip controller, the car moved

across level pavement, however sluggishly, with the motor tied

directly to the wheel.

That feat hasn't been repeated since making the

MC33033 controllers, presumably because of the low low-speed torque.

And I suspect commercial

controllers use this - "the usual" - PWM type control. This

may help

explain why some bigger motors or higher gear reductions are being used

in

electric conversions than seems to me should be necessary.

Tricking the MC33033 to do "current ramp" control?

But could this unsatisfactory control be modified somehow

on the MC33033 chip?

The signal that says "the MOTOR ON part of the cycle is terminated" is

unfortunately

internal only, but this

condition is indicated if all three low drive signals are off while

running. With a 3

input CMOS (15 volt) NOR gate, a high "MOTOR Power OFF" signal could be

generated. But once again, there's no external input to make the

desired use of that signal. But it could be tied through a diode and a

resistor to

the RC (ramp oscillator) pin. The resistor would be much smaller than

the regular oscillator pull-up resistor, which would cause the RC pin

to rise

quickly to the trigger threshold, rapidly (but not instantly)

terminating the cycle once the motor had shut off, regardless of

whether it shut off by PWM signal or overcurrent signal. The "short

fixed OFF time" of the A3938 would become a "short variable OFF time"

in the

MC33033. The operation would become more akin, and varying the resistor

would allow a range of characteristics.

There's also a similar MC33035 with 24 pins instead of 20,

but on

checking it, it didn't seem like any of the extra signals would be of

much use for implementing the changed operation.

Assembling Controllers

On the 8th I got out an MC33033 controller board, which,

when all wired up turned out to be the blown one (yes, I should have

labelled it "blown" back when it blew), then the other one, which was

rather hacked and

took a while to put into shape. But within 2 or 3 hours I had it

running a motor. (46 W at 500, and 93 W at 1000, no-load

RPM.) I didn't try anything beyond basic operation.

In the afternoon I got out a brand new MC33033 board and

soldered all the components on. (I had to scrounge a couple off old

boards to avoid a shopping trip or (worse) waiting for parts - seems

I'm always out of something!) I

hooked it to the power drivers for Tristan's Bike (a project much

delayed since he's got a job in Port Alberni & Vancouver). By the

end of the day it

was ready to test and, if good, to run.

In this one I bent up the "enable" pin (Hah! Try that with

surface mount components!) and added a resistor and transistor in

series with it to make the external pin "*enable", active low. (That

way the motor will be OFF instead of ON if the operator controls plug

isn't

connected - planned for all future

versions.)

The next morning I tried it out. It worked great. ...from

1 working controller to 3 in a day.

This time, the same motor

seemed to start turning more snappily, and it read about 35 W at 500

RPM

and 78 W at 1000 RPM, no-load. Not bad for a 5000+ watt motor, but

evidently the power needed had quite a bit to do with the controller

driving it. Perhaps it could be even better!

What was the difference? I found that the first controller

had had a 6x larger

oscillator capacitor installed, lowering its PWM oscillator frequency

proportionately. It shows what a difference can be made: if it

had had the "short OFF time" to terminate the cycle after the power was

cut, it should have worked as well as the higher frequency, perhaps

even better - and indeed

it would have been running at a higher frequency under these no-load

conditions - but retaining the much reduced switching rates when high

speed, high

power was being asked for. Even if nothing else, this would reduce the

heat in the controller when it was delivering high power. I

switched it to the smaller capacitor (which also soon proved to be too

big, in the first motorbike test).

Microcontroller Based Motor Controller

Not to go way off on a tangent, as I thought about it

towards the middle of the month, it seemed to me the A3938's problems

were mainly with current and voltage spikes. The MC33033 only gets one

of the problem signals itself, and specifies that it be filtered. The

IRS2003 half bridge drivers seem to handle the rest of the nasty stuff

well - it's their only job. So the key to reliable operation isn't

really the MC33033, it's the little IRS2003's. At the same time, there

were some problems and question marks cropping up in designing circuits

to trick the MC33033 into operating a little differently.

So perhaps it would be preferable to use a microcontroller

chip. Then the control scheme, its adjustments and

timings, and many other features, could be exactly as desired and

tweaked in the software. Including regenerative braking, all

implemented

exactly as I like it best. Plus, any number of "dumb" statuses and

analog signals could be reduced to a 3- or 4-pin serial interface on

the

controls plug/cable to the dash (eliminating the third header

connector, and a second cable to the dash), and the controller could

warn

of motor overheating (even reduce max. power itself), etc. The IRS2003

driver parts of the PCB, and the heatsink assembly and mosfets, could

remain the same.

Though it's rather vexatious to start from somewhere near

scratch (though far better armed with solid experience and knowledge)

and with the need to write some exacting

control software, I decided this

would be the ideal way to go. I selected an ARM RISC chip, the

SAM7S16. This might be thought "overkill" in processing power, but it

should be easier to

program in assembly language than some low performance CPU, and it's

still just 6 $.

This would mean not only a motor controller matched to the

Electric Hubcap motors, but a truly superior, "ideal" controller that

will squeeze maximum performance out of a motor at all RPMs, and

maximum range out of the batteries. I wasn't, however, looking forward

to all the study and work.

MC33033 Controller Again (yikes!)

On yet further reflection, I decided something working was

needed soonest, and the only obvious way to get working controllers

soon was to use the MC33033, or the A3938 if it could be tweaked into

working. The MC33033 at least worked, now, and evidently just needed a

circuit board revision because the DIP size chip is no longer

available.

Raising the frequency would give it more low end torque, "workaround"

solution or not.

On the 20th I raised the bike controller's

frequency up about 15x to the "recommended" 25 KHz, and

the controller promptly burned out just as the bike wheel started

turning. That's why I hate experimenting with the controllers

-- if it's working at all, leave well enough alone! Evidently there was

still

a problem with the controller after all, which only became troublesome

at high PWM frequency.

Just two mosfets were blown and I soon had the controller

fixed. But what was the problem?

Was the filter on the current sense line too well

filtered, and sensing of the currents too delayed? I changed the .1 uF

filter to .022 uF, and put in a current sense "resistor" (thinner wire)

that should cause it to trip off at around 30 amps. It seemed to work

well at the high frequency at 24 volts, with currents around 20-25

amps, occasionally 30 and a 40 and once 60 amps reading. That 20-25

amps at 24 volts also seemed to be just enough 'juice' to propel the

bike at a walking pace with no one on it. To ride it (besides

downslope), higher current or higher voltage was needed.

But currents went wild at 36 volts. On the bike with the

current probe attached and the meter bungied to the handlebars I saw

80, 160 and 140 amps flash by, instead of 20-30. There, then, was the

trouble causing the blowouts.

There was the familiar cracking sound, and then another

before I could pull the battery jumper leed off. (No breaker-switch

yet.) The

ultra-reliable 40 amp fuse remained in perfect shape throughout.

(Thanks a lot!) But this one time, the cracking sounds had come from

behind, at the batteries, and it turned out nothing was wrong with the

controller.

I put the .1 uF filter capacitor back in, and at 24 volts

everything was still fine. I got out the 5 volt battery, and at 29

volts, the currents went wild again. If the cause can be determined and

fixed, I think there's controllers that will work acceptably, otherwise

not.

But what was the trouble? Switching shoot-through currents

come to mind - they're not amenable to being controlled, and MOSFET

turn-off time probably increases with voltage. At the lower PWM

frequencies, shoot-through current might be occurring -- but so much

less frequently it makes little heat and does no damage. The IRS2003

has a fixed dead time of 1/2 a microsecond. It seems to me I had to set

the dead time higher than that on the A3938 to eliminate shoot-through

currents. What could be done with a fixed time chip? One technique

that's been used is to put an ultra-fast diode in parallel with the

gate resistor to speed up turn off. But that effect will be minor.

Rechecking its specs, I discovered (rediscovered) that the fixed dead

time of the IR2130 triple MOS gate driver that I used in my original

controller was 2.5 uSec - 5 times longer! Here, then was a big

difference... IF that's what the problem was.

One thing I thought of to help prevent damage during

tests: limit the current by using a single bank of NiMH "D" cells in

series, whatever the voltage. They're rated for 30 amps continuous or

50 amps intermittent, and the voltage drops off rapidly above 70 or 80

amps. This is a good current capacity range for the tests, though the

1200 uF of supply filter capacitors will supply more for brief periods.

I made the battery pack, but it gave me the thought that

perhaps the filter capacitors were insufficient. The rapid switching

might confuse the current probe? Maybe there were no real very high

currents? After all, the 40 and then 30 amp fuses hadn't blown.

I found some 470uF, 200V caps and put in about 1400uF

instead of 1200. (I had to remove some of the 100uFs to fit the 470s.)

Blam! More transistors blew. This time they took out the 30 amp fuse.

So much for "the currents weren't real."

Causes of the problems?

Problem 1 - A3938 Controller: transient voltage rating

Most chip inputs don't want to see voltages much above the

supply or below ground. I knew special precautions were taken for the

motor power signals - IR's half bridges were all "negative transient

tolerant". But the A3938's "absolute maximum" for negative voltage

coming in from the motor phases was only -5 volts... and I found no

mention of spike tolerance. The spikes are 10 to 12 volts. Ouch --

negative 12 volt spikes might well be

what was blowing the A3938s! The belatedly found app notes spoke of

motors only "up to 1 HP".

Problem 2 - IRS2003 half bridge: too short fixed dead times?

Possible the .5 uSec fixed dead time is too short -

at least with the long switching times enforced by their low gate drive

current. One could wish these had the 2.5 uSec of the IR2130, but ALL

IR's many 8 pin half bridges have a similar .5 uSec fixed dead time -

maddening! Shoot-through currents could be why MOSFETs keep on

blowing. At low PWM frequency, the MOSFETs could recover, but at high

frequency, they overheat fast. (I wish I had a spare motor for bench

tests. That should be the next project. I have the parts and it would

only take a day or two.)

I'll have to go to the 14 pin drivers with resistor

programmable dead times.

Counting the resistor, that's double the connections, 16

wires instead of 8! Or I could go back to the 28 pin IR2130 triple MOS

driver. But that chip has separate high and low inputs, and no "output

enable". Two extra logic chips are needed to recombine the inputs and

to

allow modulation, so it saves nothing.

Problem 3 - MC33033: Low drivers stay turned "on".

The MC33033 only modulates the 'high' side drivers: the

'low'

side (as I use them) stays on. That's

okay if everything is fine, but it'll cause extra trouble if there's a

problem. I started thinking about using an external modulation. If the

MC33033 "output enable" was used to accommodate an external modulation

signal, as well as gating on/off (with the PWM voltage held high and

ignoring the MC33033's PWM), it would turn both high and low drivers on

and off. And with external modulation, by LM339 or whatever, it could

run

the

way the A3938's does, with variable current limiting and a short fixed

off period.

Hmm... was the MC33033 even needed for such a system? Some

models of half bridges could perhaps be modulated directly. Ah, the

vast array of possibilities!

Simplify, simplify, simplify!

By June 25/26 I thought a big part of the

key

is in the 3 half-bridge MOS gate drivers. I'd get the type

with one input for high/low select, and

another for "shutdown" (SD), AKA "output enable" or "on/off".

For the simplest brushless motor controller: connect the

hall sensor directly to "in" for each phase, and a modulator to "SD"

of

all three, through an "on/off" switch. The simplest modulator is a 555

timer for a PWM generator. Total chips: one 555 and three half bridges.

Or instead of PWM, one could use an LM339 quad comparator

and use it to do "current ramp" modulation, which compares the current

against the reference voltage from the control. (I haven't worked out a

specific circuit, but I'm pretty sure the LM339 has it in it

somewhere.) Total chips: one LM339 and three half-bridges. This also

(inherently) protects the motor and transistors

against overcurrent to the motor, like the A3938. This is complete: one

comparator does the current sensing, one does the fixed "off" time, and

one interfaces the "on/off" switch.

Those were getting really simple! Unfortunately, I

overlooked that there's a band where they are supposed to be "off".

More inputs are needed to accommodate that. Again unfortunately, the

IR2110 has the required inputs -- but latches the SD input so

the drive

can be turned off, but it can't be turned on again until the motor has

rotated to the next position -- which it won't do as it has no power

because SD is latched off. All these clever ways to make chips

that don't quite work!

IR2130 (IR2133) Motor Controller - back to 2008!

I finally decided that the best solution (of several

unsatisfactory choices) would be to use the IR2130 triple gate driver

(2.5 uSec fixed dead time - 5 times longer) and some "standard" logic

and interface

chips -- about the same as I'd been using before I ever heard of the

MC33033 or other single chip brushless motor controller chips! This

time however, I would make it with 'current ramp' control. It seemed it

could be

done with 4 chips, counting the IR2130.

Then I looked closely at the IR2130's internal current amp

and overcurrent shutdown. It occurred to me that since a triple

external gate was already needed anyway, I could 'trick' the

overcurrent shutdown into unlatching. Furthermore, the current amp

could be used to compare the control ('gas pedal') pot with the

current, eliminating the need for the LM339. Also there

was a built-in 9 uSec delay turning back on after overcurrent: the

"short fixed off period", built right in! Now the IR2130 controller

could

be made with just 3 chips: the IR2130, a 4011 quad NAND gate and a 4070

quad XOR gate. (If the motor didn't need to reverse, just the IR2130

and the NAND gate - 2 chips!)

On the 29th I check at IRF.com, and found that the IR2130

has been replaced by a new chip, the IR2133. It had a "FaultClear"

input and a

"ShutDown" input. Together these allowed elimination of the 4011 quad

"NAND" gate (or 4071 quad "AND" gate), reducing the chip count to just

one

IR2133 and one 4070.

The IR2130 (or else 3 half-bridges) would be needed even for a

microcontroller "solution",

so that would be 2 chips, and the microcontroller would have many more

pins than the 4070. Overall the circuit complexity would be about

the same or a bit more complex -- and it would have to be programmed.

The advanced but non-essential features that the

microcontroller could bring can wait. I think simple

logic dictates

that simple logic is the best way to get controllers working

ASAP, and it'll have the main feature: the good current ramp control.

...all assuming I can get them to work well however it's done!

Motor System Thinness

When I see the motor on the car, I realize that the less

it sticks out from the wheel, the more acceptable it'll be. When the

first version moved the car with the motor rotor bolted directly to the

car wheel, it was quite short. Now, a "regular" configuration motor, a

torque

converter, and a flexible coupling to the wheel, each add their bit of

width. As I measure the pieces of the present motor with the disk brake

type magnet rotor and the torque converter rotors, it's about 7". With

the

flat rotors, that'll reduce to 6".

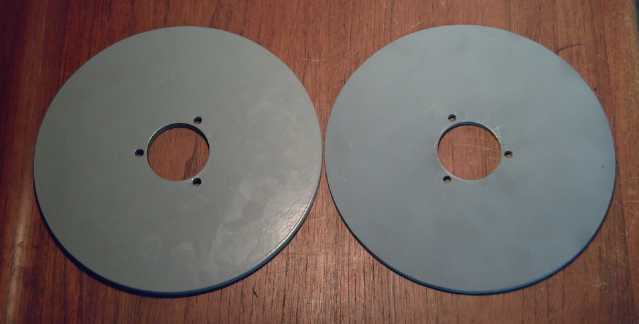

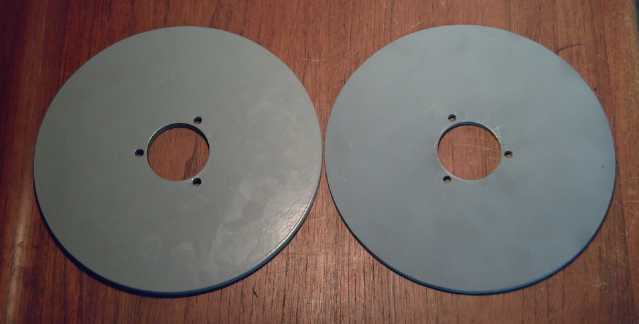

Top: CNC waterjet cut bearing holders for the ends of the motors,

each held to the plate by a thin tab.

Top: CNC waterjet cut bearing holders for the ends of the motors,

each held to the plate by a thin tab.

Below: new flat plate magnet rotor, in a thin composite motor rotor

compartment shell.

(The gray color of the steel rotor plate is polyester powder coating.)

Some bolt heads stick out. If I switch the ones on the

shaft side of both the motor and the torque converter input rotor to

flat-head bolts, the torque converter rotor (an inch thick) can be

almost touching the motor body, saving about 3/8" - so 5-5/8". I think

that'll make it protrude less than than the right side rear view mirror.

Beyond that, there's making the walls and pieces thinner,

but this is probably inadvisable and for small returns.

Here we see an advantage to my previous design with both

shaft bearings on the stator, no inside side wall, and the

motor rotor doubling as the torque converter input rotor: it saves

around an inch of thickness. But the end of the motor has to be open.

The shaft of the enclosed motor is

mechanically stiffer with the greater distance between the bearings. A

combo configuration remains an option, but is probably best avoided

without a

finished torque converter design. Once there is one, the idea can be

re-examined, again using the magnet rotor as the inner torque converter

element.

A possibility for an enclosed motor-converter would be a

concentric axle system: a hollow pipe torque converter output shaft

would surround the motor shaft at the wheel end. All the components

would be enclosed and only the output shaft (with a wheel lug-nut drive

plate

attached) would appear outside. The motor casing would be thicker by

the width of the converter drum.

One other possibility for a small reduction is to use

thinner supermagnets: 3/8" instead of 1/2". The 1/2" ones are more than

strong enough, and the flux gap is also over 1/2". The steel magnet

rotor thickness might well be reduced from 5/16" to 1/4". If using 3/8"

magnets also reduced the best flux gaps by 1/8", total width savings

would be about 5/16" -- and presumably the the supermagnets would cost

less (and there'd be some reduction in their potential to do damage or

injury during handling). But it may be found that the lesser depth of

field of the thinner magnets reduces motor performance. In that case,

thinner magnets might be better matched to thinner coils, eg 3/4"

instead of 1". That would save even more width, but the whole motor

would be less powerful.

I have high grade (N42) 3/8" magnets and the thinner

rotor, and will

give it a try when I have time, comparing one motor's performance with

the two different rotors installed. (However, so far I haven't even

done complete tests on even one motor since improving them! I still

need some sort of mechanical motor test load.)

Lower Power "Electric Hubcap" Motors?

The above thoughts on thinner magnets bring the idea of a

lower powered motor of the same design with the same ~95% efficiency,

with thinner coils and magnets. For example: 1/2 inch thick coil cores,

1/4" thick supermagnets, for a 2.5 KW motor, still 2000 RPM. Everything

including

the body parts would be a little thinner (use less PP & epoxy

each), making a motor of the same diameter but only perhaps 2.25 to

2.5" thick instead of 3.5".

These wouldn't be for cars, but eg for bicycles and

cordless lawnmowers. For a mower, 2.5 KW is still considerably more

power than can be had from a 120 V, 15 A house circuit (120 V * 12.5 A

= 1.5 KW). The 1.5 KW mowers are generally underpowered for tall or

damp

grass. 2.5 KW, with higher efficiency, should make the difference, and

the low voltage (and no cord) eliminates shock hazard. (Now, just need

those better batteries...)

Much as I'd like to try out this mower (with some NiMH

batteries?), I'd need to order the thinner magnets and coil cores, and

I don't know when I'd find time to build it. And it wouldn't cost a

whole lot less than the 5 KW version.

Another option would be to use six 'regular' coils and

eight 'regular' magnets, and make a smaller diameter, 3000 RPM, 3.3 KW

motor. But then new molds for the PP-epoxy body parts would be needed,

so that would take even more setting up.

Such motors would be pretty simple to develop at this

point and might be very useful, but would be just one more

sideline from the main project, hybridizing cars.

Metal Protection

Protecting the steel of the magnet rotors and bearing

holders having entered my thoughts, and the powder coating being very

nice but too costly, I

looked around for a good alternative. I thought perhaps there might be

a spray of two-part thermosetting epoxy that could be simply sprayed

on,

and then set in an oven, essentially working much like the dry powder

type.

Instead, at Industrial Plastics, I found a spray can of

"Cold Galvanizing Compound", "97% zinc". Evidently with "ketone

peroxide" (MEKP?) in the spray, the zinc powder "bonds with the steel"

to form a

galvanized coating. As a plus, even if it's scratched, the nearby zinc

becomes a 'sacrificial anode' and prevents the steel from rusting, or

at least, prevents the rust from spreading underneath the coating. This

sounded

like a reliable bond and about the best possible protection. The guy at

the powder coating

place had mentioned zinc as being their primer coat, too.

I had been impressed by the prep steps for the powder

coating.

There's degreasing and then cleaning the metal to a shine before

coating. I degreased a flat magnet rotor by heating the surface

with the hot propane torch. I thought it was pretty clean to start

with, but one side in particular seemed to become wet everywhere as it

was heated, and this would finally boil off. Not much happened on the

other side, though a few small patches changed color a bit.

I thought it would be a snap to shine up the metal after

that with a portable belt sander, but it took two belts (they broke

after a while) to do one side. There was some blue-beigey color coated

on

it

that was very difficult to get rid of. Considering it didn't come off

with the torching, I'm wondering if it was some sort of metallic

coating already, and if perhaps removing it is pointless. I decided

that was probably the case and finally sprayed the other "un-silvered"

side too, and then a pair of bearing holder pieces, but I plan to ask

at a metal shop.

The zinc finish looked rather rough and not uniform - like

it was formed from powder and sprayed by hand - but

good.

Two rotors:

(L) powder coated polyester, (R) "cold galvanizing compound" (zinc

powder) spray can.

Two rotors:

(L) powder coated polyester, (R) "cold galvanizing compound" (zinc

powder) spray can.

A couple of spots have scratched off on some bearing

holder "washers". I'm thinking of trying out some sort of heat

treatment to fuse the zinc to the steel better - oven, kiln, torch --

?

Thinner Motor with Flat Magnet Rotor

I gave the motor in the shop over to the motorbike

project, so I needed a new one to continue the torque converter

project. Now that I have the flat magnet rotors, the obvious thing to

do was to put a motor together with one, making one of the planned 3.5"

thinnest motors that I'd already molded two bodies for. I had all the

other parts except one bearing holder set, and assembled motor coils

that were handy, removed as a group from an open format motor. This was

the "first try" set with the rutile instead of the superior ilmenite.

As the sodium silicate was unbaked, I could easily wash the rutile off

and

redo it with ilmenite. This time I'd try sanding the wire a bit to

roughen things up, as the rutile was flaking off badly. Five sets of

bearing

holders were on order at Victoria Waterjet. It boiled down to putting

together the magnet rotor. I did that on the 16th, and the same day

the bearing holders - 10 sets - were ready.

I lightly sanded the magnet side of the polyester powder coated rotor.

It was very smooth and I was just slightly nervous about how the epoxy

would adhere. I think it would have been fine. (Pictures of this rotor

finished and unfinished are above.)

Then I got into motor controllers again and didn't finish

making this motor. It's mostly done and won't take long now. When the

rutile

coil coatings are replaced with ilmenite, it can be

assembled.

Electric Weel Motor

I wasn't looking forward to making a mold for the 27.5"

stator rings for this huge motor, or to the epoxying job to fill that

mold.

And the 27-1/2" ring wouldn't fit in the oven to rapidly set the epoxy

like the

smaller ones. Then I had the idea - at least for the prototype - of

cutting the rings out of 1/4" plywood, and then simply painting on a

couple of layers of polypropylene fabric with epoxy resin to stiffen

it. Since it was

just 5" wide rings fastened to a metal center, that should be strong

enough. I calculated the two rings could just be made from 1/2 a sheet

of plywood (4' x 4'). That worked, however the 1/2 sheet of plywood

cost

only a little less than a full sheet at Rona.

That just left the rotor end wall. That was going to need

more strength, so I might just make it of 1/2" or 3/4"

plywood, again PP-epoxy coated. (Although, being behind the magnet

rotor rather than in front, it could probably be made of metal without

causing drag. Wood or composite will be lighter.)

I'm not sure this can be made under 100 pounds as I hope:

the 27 coils alone weigh almost 25 pounds.

Weel Motor pieces:

- Stator" 18" steel plate with 17" - 27.5" plywood outer ring (a 2nd

ring

goes over the 27 coils)

- 26" rotor, 2 pieces tack welded together, with magnet positions were

layed

out by the CNC waterjet.

Torque Converter Project

I dropped by a recycling place and found a sheet of 1/8"

aluminum for the two input rotor pieces, and perhaps

for the outer rim of an output rotor. I cut them out with a jig saw,

~11.4" diameter, then fitted them to the SDS coupling. Everything was

rough hand

work because they

were too big for the lathe.

(Again I need that pulsejet cutter that I didn't finish making, fitted

to the CNC machine!)

I cut some

5/8" thick pieces to bolt across

between the two, making the rotor 7/8" thick. The center holes were

sized to fit it onto an SDS bushing, which would compress onto the

motor axle.

I thought the plastic pivoting wedge pieces I'd cut were

about the right size for the first try, but that the pivot hole should

be a little higher up. On the 15th I redid them, this time in aluminum.

I then decided I'd put just one on, and cut one square "slot" in the

output drum, and see how that worked.

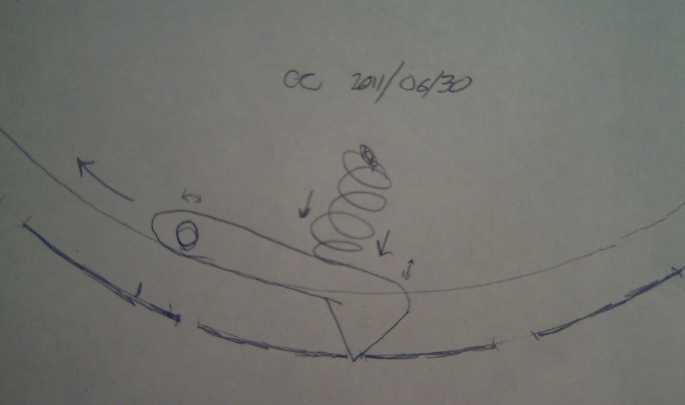

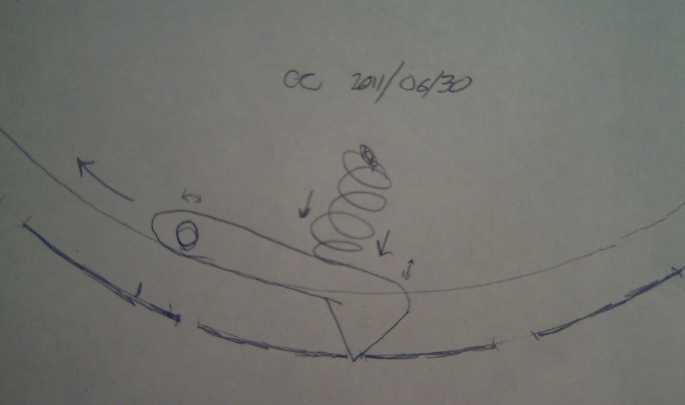

Wedge with spring on input rotor (shown on single disk of double rotor).

The snakey tempered brass spring is much stiffer than you might expect.

(Say... perhaps it should be redone as a spiral coil - the traditional

spring shape.)

A complication arose when

committed the motor in the shop to Tristan's bike project. I was then

without one for the converter until I put another one together. Then

finding that low low-RPM torque from the motor controllers was a big

part of

the problem getting torque converters to move the car, I diverted my

attention to trying to get better performance

out of the controllers, and finally to designing a new controller.

Say... since I have the motorbike for the moment, perhaps

it would be possible to test torque converters on that instead of on

the

car. The torque output of various converters and adjustments that

wouldn't quite move a car might be better evaluated and compared - does

'A' or 'B' climb the steeper hill faster?

On the 29th a mechanically minded friend dropped in and we

talked about the converters. He mentioned centrifugal clutches from

washing machines. I got the idea that instead of pivoting sideways as

above, the wedge might be hinged out on a sideways 'arm' so it would

drop

pretty much straight 'down' into the slots in the rim of the drum,

perhaps as per

this sketch:

Centrifugal wedge torque converter.

Centrifugal wedge torque converter.

That would probably have better force of torque hits than

what I've

started making. It could have both a spring and weight. The mass would

increase the force of each hit as the motor RPM went up. It would

really rumble as the car started moving. At some point of higher speed

and low torque, it might well lock the motor and output rotor together

for silent higher speed cruising.

There are some adjustments to ponder: The wedge has to

have angles both directions to allow

forward and reverse travel. The point of the wedge would start to fall

into each slot as it arrived, pushed outwards by the spring and its

mass. If the slots were wide enough and the wedge angles too shallow,

the wedge would start pressing on the trailing edge as it went in, a

retrograde force, but in a narrow enough slot, it wouldn't be falling

fast enough yet when the leading edge of the wedge hit the far side,

and only propulsive forces would be generated (to the drum rim) as the

falling wedge was suddenly forced to rise again. On the other hand, the

faster it's dropping when it strikes the slot edge, the more force the

hit will have.

LED Lighting Project

Okay, it's not the most amazing or exciting research

project -- but it is brilliant, dazzling! No new inventions, but I'm

exploring practical ways to use these devices. Perhaps commercial

possibilities lurk therein, or improvements for hybridizing cars.

In fact, by the time I'd done a couple of lights, I

started realizing that what's holding back LED usage for lighting isn't

so much the LED cost - that'll come down when usage goes up - as the

need for more practical and more attractive lighting products based on

them. Few people are

going to try to do wiring and to figure out electrical current

supplies, heatsinks, and light diffusers and fixtures from scratch, and

such bulbs as exist seem to emit nasty, bright pinpricks of light.

Especially,

they need good diffusers.

In May I ordered three different bright light emitting

diodes (LEDs), for about $10 each. They arrived on

June 9th. These "emitters" are literally blindingly bright and can

damage your retinas - one reviewer described them as being "like

welding arcs". (Somewhat like some of the newer "always glaring" car

headlights?)

I got mine from "DealExtreme.com" (Hong Kong). A solar

power/LED lighting enthusiast mentioned

another source, "LedSupply.com" (USA). (Any economic Canadian sources?)

I tried them out clipped to the regulated, current limited

power supply, clamped in a vise and facing away from me. It was after

dark. I put one up by the window and went outside. I could see the

illuminated window area. Then I got far enough back that I could see

the LED emitter itself. WOW it was a brilliant point of light, too

dazzling to look at even from way out at the street!

The next day

I went to Canadian Tire to find frosted fixtures to put them in. I

found some battery powered plastic dome lights for $5 and bought

two. You press the front dome to turn it on or off. I mounted the 10

watt, 1000 lumens emitter in one on a piece of

aluminum for a heat sink:

Left: LED emitter (DealExtreme.com #51989.

XMLAWT-0-1A0-T60-00-0001 ...?) installed on a heat sink cut from a

scrap

piece of

aluminum. The #4-40 machine screws go through (a) slots at the edge of

the LED base

(b) the aluminum sheet (threaded) and (c) thread into the plastic.

Observe battery polarity when soldering the wires.

Right: the unmodified light with frosted tungsten (incandescent)

"flashlight" bulb at center.

For battery power, three NiMH AA cells give more than the required

3.0 to 3.5 volts. So I put in a resistor in place of the fourth

cell to limit the current. LEDs need a specific current rather than a

specific voltage, and either the voltage drops until the current is

okay, or the LED burns out. I chose .5 ohms because it was the lowest

value resistor I had. I bent

the leeds around so it would make the connections in place of the

fourth cell

without falling off:

Battery/resistor arrangement. The bottom sides of the aluminum

heat sink (center, bright) and the machine screws can be seen.

All that was left to do after that was turn it on. The

voltage across the resistor turned out to be .5 volts, so the LED was

drawing one amp. The three cells made a battery of about 4 volts, so

the power was 4 watts. (1/2 a watt went into heating the resistor, so

the LED was actually only using 3.5 watts - about 1/3 of its max

power.) With a

smaller resistor, the

current would be increased. Since it's supposed to be a 10 watt LED,

the limit would be about 3 amps, at which point it should be putting

out around 1000 lumens of light - more than a regular 60 watt bulb

(~850 lumens).

But it's non-linear: at 3.5 watts, it probably puts out 400+ lumens.

Here's how it fared at 4 watts (apologies for the overexposed bulbs):

15 Watt compact fluorescent bulb in glass frosted shade versus 4

watt

LED light in translucent plastic dome shade. Even at 4 watts, the LED

light is so

bright that the whole lamp assembly glows - the sides and even the back

as well as the front dome. The CF bulb was rather orange. The LED was

brilliant white. The translucent plastic does a very good job of

diffusing the "much too bright" point source of light.

Left: 60 watt incandescent bulb (850 lumens) in the frosted glass shade

Center: 4 watt LED

Right: The unmodified plastic fixture with the original ~3 watts

incandescent bulb. (Yes, it is on!)

Rear: Daylight!

The dazzling LED is using only slightly more power than

the feeble glow of the original tungsten bulb unit.

Note: The LED is radiating light only 180 degrees, towards

the camera, while the incandescent and CF bulbs are sending it all

directions, which makes the

LED seem brighter by comparison. The LED could be made three times as

bright, but I hear they do actually burn out in a few years if run at

full power, whereas they'll last for ages at 1/2 or 1/3 power, and

they're actually most efficient in that range. At 1/2 power, they give

somewhat more than 1/2 as much light as at full rated power. And they

won't get very hot.

Even at 1/3 power, the AA batteries will only last a

couple of

hours before they need recharging. It seems odd that the makers chose

to use 4 AA cells rather than 2 D cells, which would last twice as

long. But lucky for this project, since 3 cells are required for the

LED.

This particular light would be a good car/camper dome

light, closet light, trouble light, or a light for a shed or garage

without electrical wiring, for about $20 counting the batteries.

Since it's portable, I tried it out in an outdoor shed and

in various rooms in the house. Even in rooms with a 100 watt overhead

light, this extra 4 watt unit made a substantial contribution to both

the quality of the light and the brightness of the room, and in a

hallway with 28 watts of CFs, it was about half the

light. I like the light. I didn't expect to, but now I want to add it

wherever I want bright, working light. Perhaps the cool quality could

be described as "ultra-bright moonlight". But there are various

flavours to try out.

My chief conclusion so far is that LED lighting can give

you nice light using very little electricity. If it's not

bright

enough, turn them up; add more; add varying colours - the electricity

will still be almost nothing. In the winter certain incandescent bulbs

help heat my chilly house, providing some light with the heat on those

long winter nights, but I think it would be very nice to switch all the

ones where that's not a consideration from tungsten, or from CF when

and as these mercury bearing bulbs burn out. (AFAICT, CFs don't really

seem to last longer than incandescents.)

For electric transport, all LED lights would make the

range running at night with all the lights on virtually no different

from daytime running with them all off.

LED Lighting with 120 VAC Power the Simple Way

For home use, changing batteries in lights will wear thin

quickly as a regular operation, even if they can be recharged

indefinitely. In

addition, slip-in battery connections aren't very reliable, and in

these lights in particular the cells fit too tightly and the springs

can't push them together to ensure any connection - after a while the

LED light would go bright and dim, flicker, even shut off. It worked

more reliably after I chopped some of the offending plastic supports

from the battery compartment with sidecutters to loosen things up.

I wanted to find a simple way to power LED lights from 120

volts AC to replace household lights. For the next experiment I wanted

to try various stray power adapters left over from

long obsolete equipment, and find emitters that work well at their

typical voltages, eg 9 VDC, 12 VDC... (or put, eg, three or four 3-volt

emitters in series.) The power adapters could be plugged into those

screw-in adapters that turn light sockets into plugs, in order to put

plug-in LED lights where lights are supposed to go. (What a devious,

twisted plot!)

I took the 9 volt, 10 watt, 500 lumens white-yellow LED

(Great product, DealExtreme #05876 says it's 12 volts - buyer beware!),

and found an old 9 VDC, 450mA power adapter. I found the power adapter

was putting out 13.8 volts with no load. I used two 1 ohm resistors in

series to limit the current, and the LED drew 370 mA. I cut that down

to one ohm, and it went up to 420 mA. With no resistor at all it went

up to 440mA, and the voltage was about 9.1 volts. That's 4 watts - a

little under 1/2 power (good for longevity) -- and the full power

capacity of the power adapter. In essence, the tendency of the

adapter's voltage to drop with increasing load made it a great current

limited LED power supply well matched to the ~9V LED. I have a whole

box full of various adapters that people have given me over the years.

(even after throwing a bunch out once and giving some away. Once I saw

a used computer store with a good selection, too, or perhaps any

secondhand store would have some.) Now many of them can be put to

productive use,

saving the purchase of many LED drivers!

I had more than one idea about what light to put it in,

but a frosted globe light in the upstairs hallway looked like the