Turquoise

Energy Ltd. News #43

Victoria BC

Copyright 2011 Craig Carmichael - September 2nd 2011

http://www.TurquoiseEnergy.com

= http://www.ElectricHubcap.com

= http://www.ElectricWeel.com

Month

In Brief

(Summaries)

- Less energy; holidays reduce August working days.

- No time, no work, no reports on Turquoise Battery, Electric

Weel projects.

- New projects: Sprint EV conversion, solar panel for LED

lighting backup power.

- This month's general diatribe: Government Against the People.

Electric Hubcap System

* IR2133 Motor Controller V2 circuit board designed

* Improved Electric Hubcap Motor Molds

* Electric Hubcap Outboard Motor V2(?)

* A thought: Solar panels on electric car roofs can minimize

power grid impact of mass electric conversion

Sprint Car Conversion Project

* Motors, controllers, but no mechanical torque converter yet...

How about a regular electric conversion?

* The "convertable": A small,

light, cheap 4-door hatchback to convert to electric only drive

* Gearing options

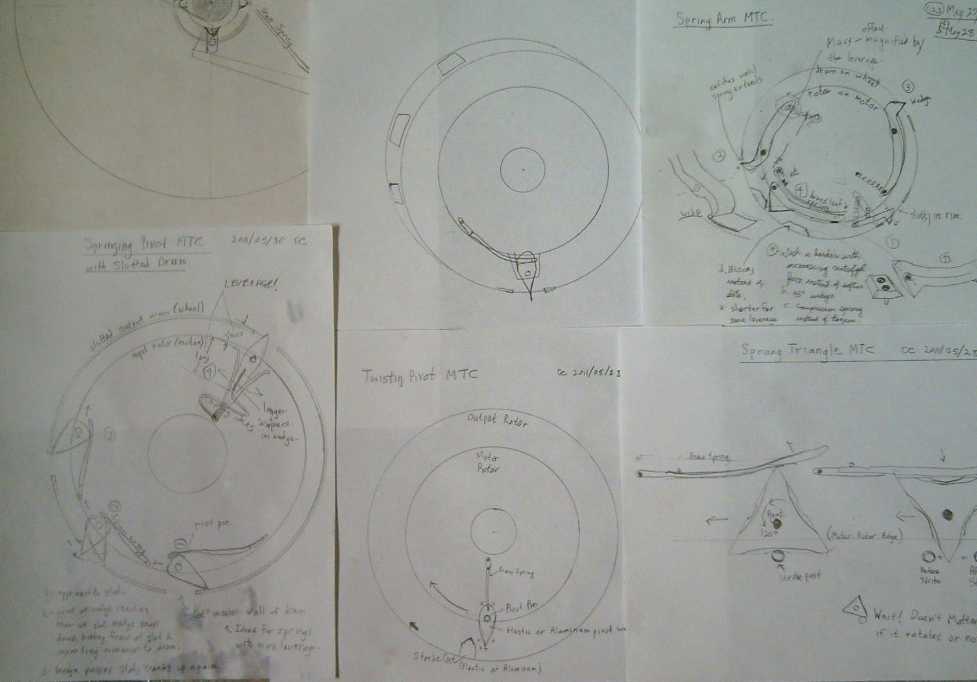

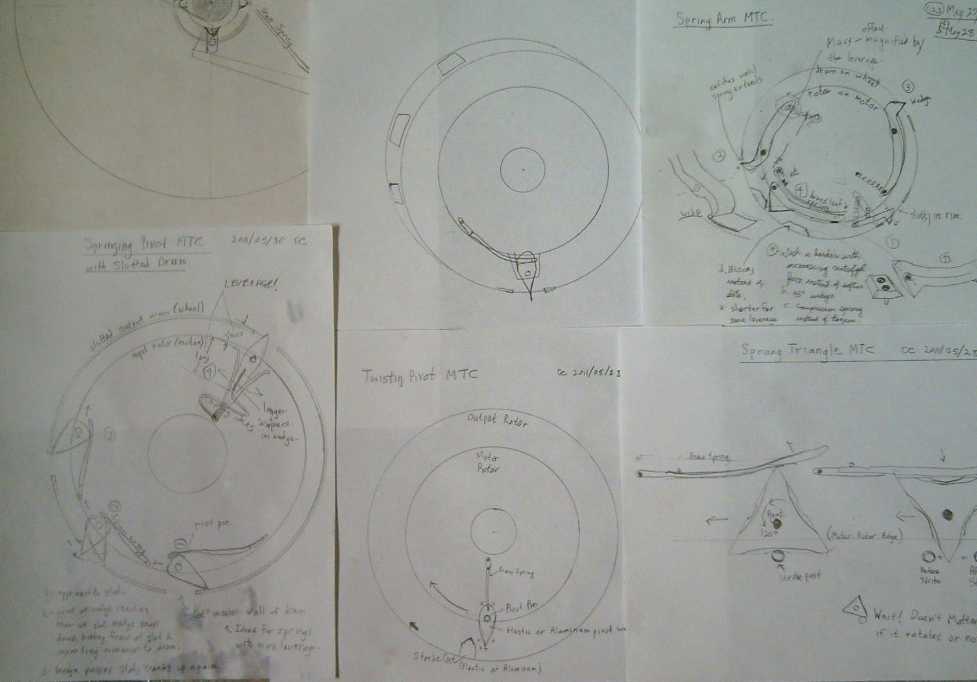

Mechanical Torque Converter Project - fresh plans

* Easier construction to make one for Sprint car under hood

* Less than 1/4 output torque needed than for Tercel wheel.

* Improved idea for the conversion mechanism: narrow slots in

drum give double strength 'reflection' bounce.

NiMH

Battery Project

* Who Killed the Electric Car? -- Hey guys: EV1 used NiMH

batteries, not lead-acid!

* Nickel-Metal Hydride Battery Charging - It's Easy! An essay

* Battery Stick

improvements - light, inside-fit endcaps

allow close stacking of sticks.

LED Lighting

Project - Solar Collector

- Good

emitters with frosted diffusers make what's in the stores seem like

toys.

* Silverware Drainer Project... Huh?

* LED car turn signal & brake lights

* 3 Emitter Lamp with Hi-Off-Low switch: outshines 100 watt

incandescent lamp with same lampshade.

* Installed a solar panel/NiMH battery sticks LED

lighting

backup

power system

* Possibility of using my nanocrystalline titanium borosilicate glaze

as cover glass for silicon - or any - solar panels.

* Idea for solar power: A low voltage DC tie-in system to

save

on

electric bills without a grid tie.

* Best store-bought 120 VAC LED screw-in 'bulb' seen so far: 600

lumens at Costco for 20$.

Newsletters

Index/Highlights:

http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

-

Electric Hubcap Motor

- Turquoise Motor Controller

- 36 Volt Electric

Fan-Heater

- Nanocrystalline glass to enhance Solar

Cell performance

Products:

- Electric

Hubcap Motor Kits, Parts - Build your own ultra-efficient 5 KW

motor!

- Sodium Sulfate

4x

longevity additive & "worn

out" battery renewal.

- Battery Sticks: plastic pipes for making NiMH D cell batteries:

6V (13") and 12V (25")

- NiMH individual Dry Cells (D - 10 AH, $10 -- AA - 2.5 AH,

$2.50)

- Motor Building

Workshops

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

August in Brief

I went camping and had another trip to make 'up island' as

we say here at the south end of Vancouver Island. These trips took a

good chunk out of the month.

In addition, I'm finding that at the age of 56 I have less

energy than when I started in 2008. In 2008 I had about the same energy

and drive as I've always had. Now an afternoon work session is often

replaced

by a nap, and the amount of time I can spend actually working on the

green energy projects

during a day usually seems frustratingly little.

At the beginning of the month I designed 'version 2' of

the IR2133 motor controller circuit board, correcting the problems of

the first prototype. I didn't get it sent off for fabrication -- but

then

I haven't had time even to put the second 'version 1' board together.

Also early in the month I found a circle drill to make end

caps for battery pipes (which I'm calling "battery sticks") that fit

inside the pipe instead of outside, so everything takes less space and

is lighter and cheaper.

In the LED lighting area, I made a 3 emitter table lamp,

got ready-made LED turn and brake lights for the car, ordered more LED

car lights, and got a 65 watt solar panel for charging battery

sticks... if the power should fail, my LED house lighting can still

keep the house bright.

For motors, I improved the center body piece mold with

inner and outer lips, and 'buttons' to hold the coils in exact

position. Between the 'lips', the magnet path runs through a thinner

area, where the magnets are less likely to rub if alignment isn't

perfect.

I started rather hesitantly to put a new version motor in

the electric outboard, but didn't finish getting it installed.

Instead, near the end of the month, increases in the price

of gas got

me back to really wanting an EV of almost any sort. If I didn't have a

torque converter, I had good motors and controllers, so perhaps I

should do a 'typical' electric-only, under-hood conversion. I bought a

1990, light, 50-60 MPG, 3-cylinder Chev Sprint (AKA Suzuki Forsa,

Plymouth Firefly, Geo Metro) for under 1000$ and pulled out the engine,

radiator and exhaust pipe - 250 pounds, and I haven't removed the gas

tank and gas yet - maybe another 50 pounds with a typical level of gas.

The exhaust system alone weighed as much as an entire Electric Hubcap

motor.

The battery sticks will be somewhat over 100 pounds, so

the finished EV should be around 150 pounds lighter - around 1550

instead of 1700. Cars don't come much lighter!

I had hoped for a 5-speed manual transmission, but this

car was a 3-speed automatic. Checking the gear ratios led to the

discovery that a further gear reduction over what the transmission

provided would probably be desirable or even vital. That spoiled the

simple conversion plan! At first I thought I'd put in the 2.8 to 1

ratio planetary gear - that might be a bit cumbersome to do, but should

work out about right.

Then I thought it would be better to replace both the

planetary gear and the fluid torque converter with a mechanical torque

converter. It would need less than 1/4 as much output torque as one

directly on the Tercel wheel, should be easier to make with the sturdy

fixed alignment between motor and transmission, and an idea for an

improved converter mechanism had been brewing in my head. Full circle

from buying a car so I'd need no converter, back to wanting the

converter to make the car into an EV!

The Month's Diatribe: Government Against the People

It seems the present government of Canada has been

interfering with Canada Post, a "crown corporation" (public trust)

that has been serving the public well, to deliberately create

conditions that ensure poor service. It seems they want to drive people

to abandon

the post office so the business goes to courier companies. A recent

strike, no

doubt owing to unfair

treatment, makes the employees look greedy, and every complaint by the

public plays into their plan.

I was surveyed a year ago as to my

business postal needs, and I indicated repeatedly that the economical

shipping was of great

value for shipping lower value, heavy goods such as hardwoods, and

delivery time was rarely an issue. The post office responded, as

if deliberately from my response, by dropping the lower rate parcel

post services and leaving only the fast, more costly shipping services.

Why did I spend 45 minutes on the phone answering the many survey

questions?

Now I'm starting to understand. The purpose of the survey was to find

out how to make the system worse, and they've succeeded.

Canada, and BC, seem to have elected governments actively

working to transfer all the public's assets into the hands of a few

unaccountable people - the people who pay for their lavish election

campaigns and ensure by the most despicable, dishonest tactics that we

elect corrupt schemers instead of leaders. (I shed a tear for Jack

Layton who died of cancer this month, who would probably have been

prime minister years ago in a fair system that elects people instead of

partisan political factions, "parties".) BC Hydro and BC Ferries were

created by previous BC governments only because private companies

weren't

working. Now much of the value of these prize public assets has been

involuntarily donated by the public to the rich.

This isn't free market or anything: it's theft. If these governments

believed

in the "free market, capitalist" system they pretent to espouse, they

would at

least have put shares for these organizations for sale on the stock

markets and the sales from

the

shares into the public treasury. Instead, suddenly the wealth is in

private hands and all the public is left with is government debt and no

assets.

People are fearful, almost

panicked, by the deteriorating economy. These governments promise

"stability" while they steal the remainder of public

wealth and move us all towards poverty and serfdom to the ultra-rich

gangsters to whom they owe their allegiance -- the very cause of the

deterioration. Betrayal of public trust

is a capital offense on more civilized

worlds. Here it has become so prevalent that there's no one left with

the power to prosecute.

The many riots seen around the

world recently may be just the beginning of a dreadful harvest of

politically and economically disenfranchised citizens who have been

until now the middle class, who have no say in their governments,

governments that here can somehow be elected and re-elected but which

have become thoroughly corrupt and are working against the public they

are

supposed to serve. The fields are ripe for the harvest, and upheavals

are in the works. People who a few years ago would have staunchly

resisted change

are becoming ready to embrace it. It is up to each of us to ensure that

our human family makes changes for the better rather than for the

worse. We need freedoms - religious, political, economic, social, and

free time - to live out lives as we choose and fulfill our individual

potentials. not endless petty rules and regimentation. not 8 hour

workdays and "needs" being thrust upon us by clever advertisers. not

pricey garbage being thrust upon us by vested interests, like petroleum

cars, nuclear power, cow hormones, pharmaceuticals and weapons, so they

can make more money at our expense, and at the expense of the planet.

The time is ripe for this to stop. A materialistic summer

is drawing to a close. Those involved in and profiting from such

ventures should take a hard look at

what they're doing to their fellow Sons and Daughters of God and where

they themselves are headed spiritually, and at the misery, death, war

and mob violence their selfish choices are unleashing. "You can't

take it with you", but you do take with you the spiritual fruits of

your life. Dylan's song comes to mind:

"and how many times can a man turn his head,

pretending he just doesn't

see?

the answer my friend, is blowin' in the wind;

the answer is blowin' in

the wind."

Electric Hubcap Motor System

One step I took in August was to get enough #11 magnet

wire for foreseeable needs. Supermagnets have tripled in price since

February (but appear to have stopped rising) and NiMH dry cells

suddenly went up 40% in July. I wish I had purchased more of both.

Might copper pull a similar unpleasant surprise? I felt it was

important to have upcoming needs met, and not with a hodge-podge of

scrap wire. The neighborhood motor repair shop had 40 pounds left of a

50 pound spool bought for a job that was finished, and (as the motor

repair person was too busy to divvy it up) I bought it all for $380,

which is anyway the lowest price I've seen. I think I'm pretty much set

now unless epoxy resin suddenly jumps.

Who would have thought that making an advanced electric

motor would commence with cutting sections of polypropylene landscaping

cloth and then ripping them into strips? Yet cheap polypropylene (PP)

must be one of the toughest things around, stronger and lighter than

fiberglass. Carbon fiber doesn't have PP's tensile strength. I can't

imagine hemp or other organic fibers

having the same strength or the durability. Epoxy is strong and better

than polyester (resin), but even so without support might crack.

Together, PP-epoxy is probably about the best composite one

could mold - the toughest, and economical and relatively lightweight to

boot.

The epoxy resin is nevertheless pricey, and the molding

process is time consuming, tedious and gooey. But I made some good

motor form

improvements this month that couldn't very well be done any other way

but

by molding.

Mold/Motor Improvements

Last month I put together the first motor with a flat

magnet rotor. The rotor (just) fit, but it would have been better if

the rotor

compartment was about 3/16 to 1/4" wider. But the 2" wide black PP

strapping was the widest I'd seen. On a camping trip, someone had

2-1/4" wide yellow PP webbing to fix his aluminum frame rocking chair

(a rather unique item). Aha!

But while molding the second motor, I had the thought to

router out a groove in the edge of the top insert for the center ring,

to make a 1/4" tall lip around the edge. That would add the 1/4", make

the edge stronger, help center the rotor cover better, and leave a bit

more edge exposed on the other side of the ring for fastening the

stator screen to.

Center ring top of mold and ring, a bit thinner but with thicker inner

and outer edge

"lips".

Old uniform thickness ring at right.

Other Concerns: I

also kept thinking about the

warm coil mounting bolts. I've shrunk them from 1/4" to #10, so they're

wasting less

energy, but not zero. They might perhaps be replaced by a plastic

(nylon?) form needing only one bolt instead of two, that the coil fits

over. This could also position the coils more

exactly - they are often a little 'in' or 'out' from each other.

Various designs came to mind, then I had another idea:

what if bumps, "buttons", the size of the hollow core centers were

simply molded into the PP-Epoxy ring? Simply by clamping the two rings

together anywhere, the coils would be fixed exactly in place. And the

clamping bolts could be placed in areas of thick composite to hold more

securely - eg, in the proposed outside lip and another new lip inside.

They

would then be outside of the magnet

sweep path, so they would also

have lower eddy currents. And the magnets could never rub across a

piece of metal.

As yet another added bonus, the main body of the ring

could be made a little thinner, shrinking the overall motor thickness

yet a little more.

I worked all the co-ordinates (spreadsheet) and the router

sequence out and started making a new mold. As it was being cut, I got

another idea: to put "lips" around the "buttons" to sandwich the core

securely while exposing the sides of the wires to the cooling air and

removing clamping pressure from the coil wire. It's only a little more

cooling on a very efficient motor, but still heat is the ultimate

limiting factor in how much continuous power a motor can put out, so

anything that improves cooling is a plus. Luckily, I thought of this

while everything was still in progress, so I was able to add the lips

with no misalignment. I did take a chance by routing without being able

to do a test run on a scrap piece, but I got it right. The routing

depth was just slightly greater than I'd planned, but that has to be

set up at the time anyway - a test run wouldn't have helped. It was

close enough, and will make a good air space for best cooling.

New mold and ring with cast "buttons" to mount the coils on (flip side

of ring shown above), old flat ring.

The coils could be shifted back and forth a bit, so on the 31st I put

the mold back on the CNC machine

and made the buttons a little taller, and with solid centers. The mold

is pretty thin in the bottoms of the holes now.

I was thinking it was too late for this motor, but then I

considered that the rotor end was unchanged, so I had two good rotor

ends and one center, which could be fixed up, "good enough", by filling

just the additional hollows and putting it back in the mold. Then with

one new center ring and two new stator end rings, there'd be the parts

for two motors in the new, improved style.

Another item still

needing improvement is the durability of the ilmenite in sodium

silicate paramagnetic coil

coating. The coatings still flake off easily. I intend to play with

"filler" additives including zinc oxide and clay-like substances.

The reader will note that all this has gone from the big

changes and wide range of constructions coming and going over the last

three years, to tweaking the construction details of what is becoming a

pretty finished enclosed motor.

It's the honing away of some rough edges.

International Rectifier MOSFET Controllers: "ITrip"; selection

Most of the IR mosfet drivers have a current limiting

shutoff called "ITrip" fixed at 0.5 volts. I think to myself: Ouch, .5v

* 127 amps is 63.5 watts in the sense resistor! Why did they use such a

high voltage? (not to mention: Why is it a fixed voltage at all?)

Finally it occurred to me... of course, they're thinking

of line voltage motors with much lower currents. The maximum voltage

ratings are 600 or 1200 volts. For example, 5HP at 240 volts is only

around 20 amps, or 10 watts in the sense resistor.

I work around the fixed current limit by using the

built-in op-amp as a comparator between the power control setting and

the actual current, and feeding the output as a digital signal to

"ITrip". For this purpose, the op-amp output might as well have been

tied to ITrip

internally, saving two pins to allow for a forward-reverse input pin.

(I can see doing it as a 24 pin single chip brushless motor controller.

Sigh! Sometimes I wish I could design chips myself.)

I designed and layed out the PCB for the corrected and

improved 'version 2' of the IR2133 motor controller. I was having

trouble fitting the additional components, and finally opted for the

small SOIC version of the 74ALS86 XOR gate. I managed to shrink the

width to 1.65" to allow slightly thinner chassies.

Then (dumb time) I went back to IRF.com to make sure I

hadn't missed any chips that might be better than the IR2133. One

controller (IRS26310) had an RC timeout for overcurrent shutoffs built

in, and safety shutoffs for the high side MOSFETs in the event of a

short circuit. Nice, but it was missing a couple of valuable IR2133

features and the RC actually only saved one resistor over my 'RRC'

design. None of them had the "forward-reverse" pin I wanted (to

eliminate the XOR gate) or any other special advantages. Weeding out

the selections one by one, I ended up back at the IR2133.

In the selector guide (a different one than I found

before) they all said "0.3 to 5 KW" - seems they're the right chips for

a 5 KW motor. 3 of them for the 15 KW Electric Weel is of course still

right.

"Modernized" Electric Hubcap Outboard Motor

Let's see... I have great motors, and I should have great

motor controllers once I get the revised circuit boards. But no means

of coupling them to a car wheel has been proven to work yet. Even the

motorcycle tests were disappointing, the gear ratio evidently being

akin to 'stuck in third gear' inappropriate. What uses could people

immediately

put the motors to that might get a few motors and controllers into use

out there?

Last fall I turned my Honda 7.5 HP outboard motor into an

Electric Hubcap

Outboard. Shortly after that, I started improving the motors in

efficiency and design. It

seems only natural to upgrade the outboard to the new design. The old

motor

was a slightly undersize "open frame" prototype with no case (in fact,

it was the one that got the car to crawl across a parking area

connected

direct to a wheel in October 2008), and it was a good fit under the

hood of the outboard. The new motor, though thinner with a flat rotor

and in the trim final production size (smaller than the initial

production

size), is enclosed in a case. It seems it'll just barely fit with two

sides of

the

stator end ring trimmed off, the coils themselves almost touching

the sides of the hood. The hood might need to bend a little and jam on

if not fit nicely.

With the ultra-efficient Electric Hubcap motor, the

Electric Hubcap Outboard should theoretically take a boat a little

farther, or faster, with the same batteries than an otherwise identical

conversion using any other motor. Boaters might like that.

I decided I'd use the motor I made last month, replacing

the shaft with the one that fits onto the outboard's drive shaft... But

on

the 27th I bought a

very small hatchback car to convert to electric-only via the regular

transmission. Suddenly the outboard motor takes a back seat!

Solar power idea: solar panels on electric cars

At first glance, putting a solar panel on the roof of a

car may seem

like trying to drive spikes with a tack hammer. Even the low-power

Electric Hubcap motor uses up to 5000 watts, and a 'full size' solar

panel

that would take up a car roof area only makes 230 watts directly facing

full sun.

But cars sit a lot, and we may instead look at the figures

in terms of charging the batteries and travel distance. The EV-1 used

around 225 watt-hours per

mile.The

owner of an electric converted Suzuki Swift says he uses 100 to 180

watt-hours per kilometer depending on driving conditions -- average 140?

If we then said the solar panel would average 140 watts,

over an 8 hour sunny day it would collect enough electricity to drive 8

Km free. A larger station wagon just

might fit two panels and double that. It may well be, for example, that

most people won't need to plug in their car at their day job. That's a

lot of energy not

needed from the power grid.

This is also a good argument to those detractors who say

"But where would all the electricity come from if we all drive electric

cars?" That's a silly argument to start with, but here's another good

answer.

'Full size' solar

panels are today over 500$, but

they're starting to

become economical enough for volume production and will continue to

come down as usage increases. (As I write this newsletter I see some

under 400$, at solarpanelsonline.org) I can see doing a solar charging

system on any car with 500$

as the total price in 2 or 3 years.

These panels are around 39 x 65". That's convenient... the Tercel would fit up to around 40 x

78",

and the Sprint 40 x 62". Too wide and you'd bang your head getting in

and out. Length can go over, as long as it's mounted high

enough the tailgate has clearance to open, or it can stick forward a

bit. In hot climates a cover shading the windshield could be a good

thing. Multiple smaller panels might produce a convenient voltage for

charging 42 volt battery systems. Additional smaller panels could also

be located on trunk, hood, body panels and doors if it was felt to be

worthwhile.

Sprint Car Conversion Project

Next Car Plan?

At first I thought my plan for the next try to get a car

going would be to make

two more motors and fit them both to the Tercel with the 2.8 to 1 ratio

planetary

gears. With motor controllers that give good torque at zero and low

speed now, this plan seems more likely to succeed than last

time, at

least with two motors if not one.

Or... an 'under hood' electric motor conversion

But near the end of the month (after thinking I'd better

be very frugal with my remaining money for the rest of the year), I

started thinking that

with good motors and controllers but no torque converter, it might be

better to acquire a very small car (perhaps a decent looking one with a

blown engine?) and do a "typical" electric conversion, with an Electric

Hubcap motor under the hood, keeping the transmission with clutch and

gears in spite of its losses. Surely it

could hardly fail to get moving in first gear and with a clutch?, and

I expect it should be okay for around town even if it proves

underpowered

for the highway.

A successful project would demonstrate the

efficacy of the motors and controllers, get a car going on electricity,

and assuming I later get systems with mechanical

converters working, it could provide good data on the improved

efficiency of that system. Especially, one could be mounted on the same

car and the various parameters compared, in particular, acceleration,

driving range, and ease of use.

I decided my priority for the moment is a working electric

vehicle, period!

On the 27th I looked on UsedVictoria.com and saw a 1990

Chevrolet Sprint (AKA Suzuki Forsa, Suzuki Swift, Pontiac Firefly, Geo

Metro), a 1700 pound

hatchback with a 1 litre,

3-cylinder engine, at Fuji Motors. I was somewhat familiar with that

50-60 MPG(!) model, having almost bought one new in their second year,

1986. I think that before this car, Suzuki

only made motorcycles. Fuji

wasn't too far

away, so I went and had a look.

This one was a 4-door automatic.

The dealer seemed to have

some

misgivings about selling the car, which he had on consignment for the

owner - I was warned of several problems. "It runs, but it's not very

good." he said hesitantly. I

said some of them (like the engine burning oil) were no concern because

I was converting it to electric, and that I wanted it because it was

small and light. I had hoped to start the project for under $500; the

total was $812 ($700 + taxes). But except for faded paint and

some bad rust at the very bottom of the sides, the car looked quite

decent inside and out despite the age and mileage (237 Mm). The tires

were good. It was just what I wanted except for the automatic

transmission. I might look long and hard and still come up with

nothing as good for cheaper... unless it was a bigger car. The dealer

drove it home for me on his dealer plates (jump starting it with a

working

battery) since I didn't want to license it for now - Great! No towing

bill! - I didn't even have to ride my bicycle to Fuji. I drove

him back in my Tercel.

Sprint (port)

Sprint (starbord) and "carport"

I only drove it across my own lawn to the back after I got

it,

nose into an open shed "carport" to cover the hood. I used my original

22.8 amp-hour NiMH battery - big enough for this car. I noticed that

the brakes were sticking and the car didn't roll well. It needed new

brake cylinders - and a disk - ugh! What did I expect for $700?

(Another $70 for a front brake caliper and some brake fluid - it's

starting to eat money already

and it's not even on the road yet! I got it at Key-2-Parts -- best

deal, and I think this was their parts delivery car at one time. I

remember seeing it around, and the dealer said it had been a car parts

delivery car. The disk

and the other caliper can wait.

Bonus:

the radio/CD/USB-stick player works and the ashtray is clean!) By

evening it looked a lot clearer under the hood. The next day I rigged

up a winch on the low "carport" ceiling and by evening the engine block

and all

the main superfluous pieces except the gas tank were out.

Some cables, wires and tubes going to the automatic

transmission made me nervous. How did all that stuff work? Would it be

hard

to get it to shift properly? I couldn't even get it out of "park" until

I plugged it in and connected a battery - and even then not until I

figured out you also had to have your foot on the brake pedal to unlock

it. I got a repair manual at the library. Some study showed it seemed

to have going in: gas pedal linkage,

speedometer, and the shift lever. No tach (unless it was an electrical

signal). It would seem it shifts based on vehicle speed, and

downshifts at a high throttle setting. Those wouldn't change (much), so

it should work.

One turn of a wheel turned the transmission input shaft

about 1-1/2

turns, so (counting the opposite wheel not turning) the ratio was about

3 to 1. The fluid torque converter should

make that more like 5 to 1 for starting to roll. I think that was first

gear,

but

nothing changed when I switched the shifter to reverse or to

neutral. It wasn't as high a ratio I was hoping for... from a 5-speed

manual transmission unit.

I took a ring piece of a Hubcap motor and checked the fit.

The new smallest (11.25") diameter motors barely (if at all) clear the

rubber boot of the inner starboard CV joint, which is - barely -

behind. (The transmission wall has an arc cut out of it for this to

fit.)

...The outboard motor and the Sprint, just barely a fit; also

just a

fit on the Sprint's 12" wheels if wheel mounted -- lucky I decided to

make the cases as small as I reasonably could! However, there's no

problem with motor length (thickness?) for this one, so I might use the

spare 10" brake disk magnet rotor with its one inch hub rise, to save

time.

There was however room to spare in front where the

radiator was (and immediately behind it) for the 7 banks of battery

sticks, or even 9 or 10 banks. (I seem to be assuming I'll be donating

my present 245 NiMH D cells to this project.) To reduce electrical

needs a bit, the LED car lights I've ordered will be going on the

Sprint, and the headlights are small bulbs instead of big sealed beams,

so they'll be easy to change.

I weighed the parts coming off the car: radiator, engine,

exhaust piping and muffler. The total of around 250 pounds will be

replaced by only about 150 pounds of electric motor, controller and

battery sticks. That makes it lighter (counting another 50 pounds for

absent gasoline) by about 150 pounds - equivalent to "minus one"

passengers and just 1550 pounds. Of

course, with money, one could easily add that weight back in in

additional batteries for greater range. Or, for least initial outlay,

lead-acids

could easily add 300 or 450 pounds and monopolize the rear luggage area

and/or

one of the back seats.

I'm still somewhat puzzled that the motorcycle didn't

perform better than it did, being

a total load of

only about 350 pounds, with a 4

to 1 speed reduction chain drive. Of course, having only two banks of

batteries at 36 volts limited

the current - at first, briefly, to around 80 amps (when it climbed a

slight rise), and soon to 60 (where it would barely do level ground).

Doubtless I was overloading those first six battery sticks.

The Sprint's tires are about 20" diameter and

the motorcycle's are 27", a ratio difference of 1.35 to 1, so 5 to 1

on the Sprint is equivalent to 6.75 to 1 on the bike, which ratio would

have

produced better results.

I'll try out with at least four banks of batteries on the

car (if not all seven), and 42 volts instead of 36 (equivalent 14

sticks (or 25)), but the car is certainly heavier than the bike. I

thought going through a transmission would solve all the problems, but

the ratio still seems low and at

this point I'm apprehensive about whether it'll

move the car acceptably -- or even at all.

I'll certainly take the best shot at it. If the worst

comes to the worst, there's more options that can be invoked. First, I

could mount the 2.8 to 1 planetary gear between the motor and the

transmission. That changes the total reduction ratio from 5 to 1 to 14

to 1. Should that mysteriously still fail to get the car rolling, or if

it limits top speed too much, there's room for two motors in there on

the same shaft to double the torque - with or without the 2.8 to 1

planetary. Then there'd be plenty of power even for the highway if only

it had the battery range to go somewhere on a highway!

Maybe I'd do it the other way around... install the

planetary gear initially, and remove it if it didn't seem to be

needed. The planetary gear reduction also would doubtless have got

the motorbike going nicely.

But then I started thinking again of the

mechanical torque converter, and that it might be readily applied to

this project. It would eliminate both the fluid converter and the

planetary gear and prove the conversion principle, and it would only

need to supply 1/4 or 1/5 as much torque as driving the Tercel wheel

directly, much improving the prospects for success. Here we're back

full circle to the torque converter project!

Whatever the gears, the next things that need assembly are

the motor, another motor controller, and the 28 battery sticks. - none

of these are ready. (unless I use the motor from the outboard.) Then

they'll need installing, which will mean a custom shaped plate to bolt

the motor to the transmission housing, a main solenoid in the

controller, and brackets and clamps for the batteries. Before the final

motor assembly, I'll need to know exactly what the shaft will fit to

and how:

- planetary gear and fluid torque converter

- mechanical torque converter

- planetary gear alone

- fluid torque converter alone.

(Any change in type will probably mean disassembly and

shaft replacement.)

A potentiometer will need to be mounted for the gas pedal,

and a forward-off-reverse switch, or at least on-off, besides the

ignition key. I want to see how much pressure the brake pedal needs

before I bother getting a vacuum assist unit for the brakes - it is a

really small car and regenerative braking will help. The 42 volt

electric heater/defogger - and a new front left brake piston and any

other repairs - and insurance - can wait a while, at least until it's

running well. It'll be a lawn car until then!

Mechanical Torque Converter Project

On the 30th, having started the Sprint car electric

conversion, I had the thought that if I could replace the

Sprint's fluid torque converter with a mechanical one, the greater

torque multiplication would make using a planetary gear redundant.

Altho only a 10" diameter converter drum would fit instead of 12",

there's more length

to work with than on a car wheel - the motor shaft can be any length I

want really - and the 3 to 1 gear ratio to the wheels following the

converter means it only needs 1/3 the output torque. And the wheels are

a little smaller and the car is lighter, so it might really be more

like 1/4 to 1/5 the torque. And I have in mind a modified torque pulse

mechanism that should be better and easy (relatively) to make.

Alignment is simplified by the fact that the motor is held

rigidly in place. It doesn't pivot as it must for suspension on the

wheel. The

'odds' on acceptably making what I have in mind and having it work seem

favorable.

I came

up with a good plan to put the output shaft/drum on bearings around the

motor shaft to keep it lined up: by clamping an SDS (or SD) 1-15/16"

taper lock shaft bushing with the

drum onto two tapered trailer bearing cups, sandwiching two bearings

back to back, perhaps with a short spacer between them. (Or it might

have

to be a 2.0" shaft size SDS, with the slot ground a little wider with

an angle grinder -- the bearing cups are slightly under 2 inches.)

Thus the layout would be: motor with about a 3" shaft

sticking

out, an SDS coupling clamped onto the shaft holding the input rotor,

and a second SDS (or SD) coupling, on bearings, holding the output drum

outboard from that. Somehow the output rotor needs to attach to the

splined shaft in the transmission. When the motor is attached to the

transmission housing, the output rotor will have no room to slide off

the end of the motor shaft.

I'm reluctant to chop up the fluid converter to extract

the spline fitting - in case this doesn't work, I'll need that fluid

converter.

I couldn't find the spline fitting, but the next day I

thought: an SDS coupling of the right inside diameter, holding the

slotted output drum, will clamp on and likely work just fine - yay, a

plan! That will replace the above SDS holding the drum on bearings, and

shorten the mechanism.

I'll want one smaller bearing on the protruding tip of the transmission

shaft, with a tenon over it on the motor shaft, to align the motor and

transmission shafts.

The bottom

couple of inches of a 10" aluminum saucepan with fairly thick walls

could be used for the torque converter drum.

The torque plan is to slot the drum with about 30 narrow

slots, stuck by pivoting wedge arm pieces, pushed outwards by springs,

along the lines of those in the top-right drawing from May (ignore the

other drawings), which I

think are the best design idea:

The narrow slots are a new feature of the plan. With

narrow slots, the wedges on the arms are still traveling downwards when

they strike the far edge of the slot, with the back side of the wedge

still in contact with the leading edge of the slot - unless the

difference in rotational speed causes them to lose contact. That,

within limits, will only increase the downward force. The bounce

reflection gives the hit twice the force it would have if it was

bottomed out and hence vertically stationary when it strikes the far

edge.

The number of wedges can be theoretically anywhere up to

the number of slots. They should all operate simultaneously... as long

as the motor can push the wedges out of the slots from a stop. Tho I'm

not sure how many will needed or optimum, the more the simultaneous

hits, the stronger the pulse of torque. If I make the rotor with 12

wedge holders (or places to mount 12 - if they'll fit), it can have 2,

3, 4, 6, 8, 9, 10 or 12 wedges applying symmetrical rotational forces

around the drum.

With a few techniques and key pieces, I think the

construction seems doable, and I have good hopes for the wedges and

narrow slots making sufficient torque. Ironic that I started the Sprint

car

conversion because I don't have a working converter yet; now it may

lead to making one. I

hope I can find time to get to it

in September.

On September first I ordered an SDS 7/8" bushing to hold

the torque

converter output drum to the spline shaft in the transmission, and I

bought a 10" aluminum saucepan and cut it down to make that drum.

Nickel - Metal hydride Battery Project

Battery Sticks V2, 12V & 6V.

I'm repeatedly amazed that

most people who say they've

watched Who

Killed the Electric Car? seem to think those EV-1's ran on

lead-acid batteries. They've missed one of the key points of the movie:

that the cars became sporty, popular cars instead of so-so slugs when

they switched from lead-acids to nickel-metal hydrides in 1997 -

batteries that

looked as though they'd outlast the cars. Ovshinsky, who was

interviewed in that movie, created the metal hydride that made the

batteries great, at home, after he retired from being a

chemistry professor at a university, using his pension for research

funding.

And of course many or most hybrid car batteries are NiMH.

Evidently newer ones are composed of NiMH D dry cells, now - the same

as what I'm using. They're lightweight, electrically excellent, and

readily available.

Ovonics recently estimated they

could (if they were permitted by Chevron) produce NiMH car/EV batteries

to sell

for about 200 $/KWH, which isn't so much more than lead-acid. And with

recycling of batteries, that could come down further.

Charging NiMH Batteries - It's Easy!

There seems to be a lot of confused information about

charging of NiMH dry cells on the web. Much of it would lead you

to believe that NiMHs are a finicky chemistry and that charging them is

an

exacting science. Nothing could be farther from the truth. Some writers

appear to be exaggerating minor characteristics to make them look like

major problems in order to promote other chemistries for financial

gain: lead-acids need much more frequent replacement, and lithiums have

a higher selling price - NiMH makes the seller - and costs the buyer -

the least amount of money over time. (Nickel-iron batteries have been

similarly

maligned and worse for a century. The writers, usually lead-acid

battery sellers, play on peoples' unfamiliarity with nickel-iron to

make these fine, exceptionally long life, batteries sound utterly

worthless. At a battery conference this year, keynote speaker Peter J.

DeMar, known as "the lead-acid battery guru", shocked everyone with his

talk "Edison Had It Right" [with his NiFe batteries, lasting a

century].) The known high self discharge of typical high-rate NiMH

(and NiFe) cells is a case in point: "experts" make it out to be a

major problem, for all practical purposes ruining the chemistry. But

how

often does your car sit for weeks between uses... and then need to

drive it's maximum range? Even

then, would you not simply keep it plugged in and "topped up" when it's

idle? The electricity to do so is pretty trivial. And the low

self-discharge NiMH cells

available for (eg) battery clocks and smoke detectors are rarely

mentioned.

NiMH cells will take

charge rapidly, and they can be randomly partly charged or discharged

at will and left sitting in any state of charge (except totally

discharged) with no ill effects. Newer D cells are good for 20-50 amps

discharge rates, and high rate AA cells can replace short lived NiCds

in applications such as cordless power tools, and give longer

running times as well as long service life. NiMHs only lose a certain

amount of their permanent capacity if they're discharged to under about

1.0 volts - that's over 90% discharged. Until about 80% discharge,

expect them to be stable at about 1.25-1.15 volts under any reasonable

loads. They can really only be killed by being short circuited or very

seriously overcharged.

But a clear distinction must be drawn between fast

charging, say in under an hour to 3 or 4 hours, and regular

charging in maybe 8 or more hours.

In rapid charging, there's little problem until the cells

near full charge. Then oxygen starts bubbling rapidly from the positive

electrode. The faster the charge rate, the more furious the bubbling.

The cells are made to withstand a certain amount of this, but that's

greatly exceeded in fast charging. The oxygen diffuses over to the

negative electrode and spontaneously discharges a hydrogen ion (proton)

from the hydride, a chemical burning reaction creating water and heat.

At such fast charge rates, the oxygen gas diffuses over to the negative

electrode faster than the regular liquid electrolyte transfer of ions,

creating a lowered internal resistance and the charge voltage (but not

the cell voltage after removal from the charger) actually drops instead

of continuing to rise. Thus the usual voltage-rise indication of 'end

of charge' is

inverted, and only battery temperature is truly a reliable guide that

it's being fried.

In addition, fast charging multiple cells in parallel can

result in

problems. One may reach full charge first and overheat and fail before

the

other one is fully charged.

And

the faster the charge, the higher the voltage that needs to be applied

to obtain it and the less efficient the charging becomes. Unless the

cells are needed urgently, rapid charging as a standard charging

technique is to be avoided, since it is likely (IMHO) to shorten the

life of the cells, and charging problems have a good chance of

immediately

destroying them. For large batteries, eg for EV use, the extra energy

used for charging so rapidly may perhaps also be significant.

NiMH cells can however take rapid charge up to the point

of

getting near full charge, so they are excellent for automotive

applications like regenerative braking where some charge is restored

very rapidly, but they'll never be overcharged that way because more

energy is lost in driving than is gained. (unless of course you start

at the top of a mountain with fully charged batteries.) The much talked

about supercapacitors are superfluous with a NiMH battery.

For slower charging, the fast charge problems disappear

and everything is much more casual. With a ten hour charge rate, the

batteries can withstand a few extra hours of charge, and at 20 hours or

more, they can be left in for extended periods and only get a little

warm. At a rate of perhaps 50 or more hours, charging voltages are

lowest and trivial stress is placed on a battery even if it's left on

indefinitely. Of course, no one wants to wait days for their cells to

charge. 8, 10, 20 and 25 hour charge currents are common. Constant

currents do work -- but there's a better way to charge NiMH batteries.

A constant voltage charge IMHO is optimum: at first the

cells charge very rapidly, even a two hour rate or faster for the

first

few minutes if they are quite depleted. As they charge, and the battery

voltage comes up, the current drops gradually and naturally, at each

moment being, IMHO, about optimum for the present state of charge. At

full charge, the rate has dropped to a 50 or 100 hours rate and below.

What is the best constant voltage? First I must point out

that this voltage must be a steady DC level, not the pulsing

voltage put out by many chargers that merely averages out to

the desired voltage. The cells will respond to the peak voltage of the

pulse and continue to charge, resulting in overcharge.

One circuit I saw on the web used 1.35 volts per cell.

Currents will certainly taper off to nothing at that voltage, and the

charging will be quite efficient, but the cell may end up with perhaps

10% less charge when 'full' than using a somewhat higher voltage. In

addition, the higher the constant voltage, the faster the un-full cells

will

charge. My feeling is that optimum voltage is around 1.37 to 1.39

volts. 1.395 volts is about the upper limit: above that, the currents

will stay too high once the battery is charged, and that steady-state

current rises

rapidly with small increases in voltage. (Note that for 10 cells, the

automotive standard of 13.8 volts is not only acceptable but ideal,

making NiMH D cells excellent replacements for lead-acid car batteries.

Older vehicles, using light bulbs for voltage regulation, are likely to

rise to 13.95 volts with NiMH cells installed - still just within

limits.)

With this constant sort of constant voltage charging,

cells placed in parallel will all charge fine and any that are more

discharged

than others will charge faster at first, so they may all finish

charging fairly close to the same time. If not, it still isn't a

problem.

Admittedly much of my more recent and extensive charging

experience is with Tenergy brand NiMH cells. They appear well made, put

out a lot of current when needed, and met their claimed amp-hours specs

when I tested an AA and a D. Certain "off-brands" are known not to meet

their claimed specs, and there's some I'm suspicious of. Other brands

may have slightly different optimum voltages... but I suspect that for

1.38 volts charging, all common NiMH cells would be within limits.

Temperatures below -10ºc (typical rating) may pose a

problem for typical cells. There are cells rated to -30. Coldest I've

been able to try here was -6ºc last winter. The car started

smartly, much the same as when it's warm, and no problems were

encountered during the slightly sub-zeroºc weather periods.

Prices

The 40% NiMH price increases during July seem typical of

Chinese advanced technology products and are unlikely to affect NiMH

dry cells alone. (Then near the end of August there was a "15% off"

sale.) It also occurs to me that although only AA size NiMH

cells are available in Victoria stores for small volume uses, car

makers have

evidently been using NiMH D cells in their hybrid batteries. Since that

would mean 120 or more D cells per hybrid car, production volume of

NiMH dry

cells may be much greater than I had expected, which in turn means the

prices aren't likely to drop quickly "as more people use them".

On the other hand (assuming price increases were across

the

board and not just for NiMHs from Tenergy) the wholesale price of

lithium ion cells (from Thundersky) is higher than NiMH retail. And,

though lithium ion claims longer cycle life than NiMH, several thousand

cycles versus 1000 cycles, laptop computer users have been reporting

opposite results - that computers with lithium ion batteries need new

ones more frequently than those with NiMHs.

Improved Battery Sticks

The Problem: find a practical and reliable way to make many

small cells (at least half again as many as here - preferably double

or triple) into one big battery for electric transport. Soldering them

all together is tedious, and I found that stressed joins can acquire

metal fatigue

with road bumps and vibration in actual vehicle use.

The Solution: I found a great way to make a battery case last

month -- by simply putting batteries into plastic plumbing pipes.

The "1-1/4 inch" PVC irrigation pipe has about the right

wall thickness - enough to make it stiff but not needlessly heavy -

though it's a bit of a sloppy fit on the inside. D cells are a little

over 1-1/4" diameter, but this pipe size actually has the same O.D. as

"1-1/4 inch" pipe with thicker walls rather than the same I.D, so that

the same outside-fit fittings can be used. It is actually about

1.5" I.D.

The more objectionable parts were the bulky and somewhat

pricey plastic end fittings, which held the tubes apart and added

considerable weight. This month I looked in Rona at some big

hole/circle drills. These make both a hole in the outer piece and on

the inside a slightly smaller disc with a 6mm hole in its center. I

checked out the 1-3/4" and 1-5/8" sizes against the pipe end. The

1-5/8" looked about right, so I bought one ($20 - but then I had just

spent $50 on pipe end fittings) and tried it out. They were a good

match -

slightly loose if the drill edges were clean, all but made for the job.

A disk of 3/8" ABS couldn't pivot sideways inside the tube, though 1/4"

thick one could be twisted around.

I glued a 1/4" one in with airplane dope (with MEK) but it

didn't seem to stick to the PVC. Then I tried methylene chloride with a

3/8" thick piece. That seemed to work quite well to join the ABS and

PVC. The other end I

attached with three small screws so it could be removed to check each

battery cell, or the fit adjusted.

Battery Sticks V2 with inside fit ends:

lighter, slimmer, cheaper.

I also decided to try gluing both ends, though that

wouldn't allow access to the cells later except by cutting the battery

open. In some I put in a little "U" shaped spring at one end to be sure

that

any slack was taken up, since there would be no way to adjust them

later. I did six 6-volt pipes this way to make a car battery, which has

worked fine in my car for some weeks now.

Pipes slip into vertical holder assembly to hold them upright.

5 pound steel weight on short steel pipe pushed top down while glue set.

Car battery with 5 of 6 pipes is seen at right.

Copper sheets connect the paralleled terminals.

Of course that was twice as much work as three 12v sticks,

and it still didn't fit in the car very comfortably. Next choice would

have been three pipes with 4 cells and six with 3 cells - total nine -

to make it shorter. Ugh!

Plastic tray with styrofoam prevents 6V end from touching any metal.

In spite of the poor fit, it did seem to work fine. If even one stick

didn't connect well, I think the car would be hard to start.

12 volt, 10 amp-hour, D cell Battery

Sticks (25" long, 325g,

1900g full)

1 - 2 | 11 $

3 - 5 | 10 $

6 - ? | 9 $

6 volt, 10 amp-hour, D cell Battery Sticks (13" long, 225g,

1045g full)

1 - 2 | 10 $

3 - 5 | 9 $

6 - ? | 8 $

LED Lighting Project

Reading up a bit, it appears that the Cree XM-L LED

emitters I've

been getting have about the most light per watt of any, over 100 lumens

per watt. They'll run at up to 1.5 amps with good efficiency, so I

could go up a bit from 1 amp. (A 1600 lumen, 100 watt tungsten bulb is

about 16 lumens per watt. A 26

watt CF may be around 35-50.)

Then there's the

color... I notice it mainly when doing dishes: they come out much

whiter than before I put the LED lights in the kitchen - they seem to

practically glow!

Dish Drainer Project

Perhaps this doesn't really belong in a green energy

projects newsletter (even less under "LED Lighting"), but saying that

reminds me of another little project I did a year ago... I'd been

trying for over 10 years in many stores to buy a silverware holder for

the dishrack, but repeatedly came up empty. Any that looked even 1/4

decent were only sold with a new dishrack. Really nice ones only come

with a whole dishwasher. I don't see what should be so unusual about

wanting a silverware holder/drainer, but I finally took some of the

flat ABS black plastic I'd got for battery cases and made my own:

The old, disintegrating silverware drainer and the new one

More pics of the new one

If I was to do it again, I'd make it just a bit taller yet

(5+" instead of 4-1/2" - old one was just 4"), and I'd put a solid

center divider in instead of just pieces at the top and the

bottom, as teaspoons (especially) get across the divide and fall inside

at an angle. (I wouldn't put "butcher block" maple around a sink again,

either.)

LED Car Lights

I figure that if it costs 10¢/Km to drive with gas,

and less than 1¢ with electricity, then electricity made from the

car

alternator, with the friction and slippage of the fan belt, probably

costs us over 1 $/KWH instead of 8 or 10¢. You can often hear how

much

turning on the headlights, or a low battery while charging, slows the

car's idle. Watt for watt, I'm sure there's no bigger savings in

electricity costs to be had than what's saved during driving a gas car.

The total value of monetary (gasoline) savings, of course, has to be

balanced

by how much the car is used and what lights are on and for how long.

At DealExtreme.com, I saw "LED turn/brake/reverse lights,

12V" for around 9.60 $US/pair, and I bought a pair just to see. (SKU

71625)

They

fit in the car in the rear and seemed to be about the right brightness.

Tho they would have been rather bright, I tried them in the running

lights, but the

bayonet socket pins are different than the brake lights and they

wouldn't fit. (Evidently the

polarity of the pins also matters, being backwards for a positive

ground vehicle.)

Previously, the tungsten/incandescent turn signals would

go from off to on (and on to off) over, say, 1/4 of a second, not

instantly. With the LED lights, they blinked crisply on and off. There

was another effect: although they were similar in brightness, they used

so little electricity that they blinked very rapidly, as usually

happens when one of the signal bulbs is burned out. Ironically, I'm

sure the car makers go to some trouble to do this deliberately so

you'll know when you have a burned out signal bulb. I left them in

anyway. There was no speed-up of the emergency flashers.

Turn signals spend little time lit, but in city driving

the brake pedal is pressed much of the time, with the brake lights on

during all the waiting at red lights. With a lead-acid battery and the

idle turned up so it doesn't start to discharge at red lights, extra

gas is used all the time. With the Ni-MH battery and the idle

turned down to a minimum, the battery may discharge somewhat at the red

lights, and the electricity used is made up by charging once moving

again.

More or all LED lights would allow the idle to be turned down some even

with a lead-acid battery, since less electricity is needed. All the

lights add up, but LED headlights would be the most valuable.

I looked for 5" x 7" sealed beam LED headlight

replacements in

July but didn't see any. I tried again, and also looked for

replacements

for all the running lights. I did the dome light previously from a

local source, Industrial Plastics (2nd floor) - .9 watts and much

brighter than the old dome light; it's great! I found various running

lights I wasn't sure were the right ones for various spots around the

car -- amidst almost 2000 choices (a few of which looked like

duplicates to casual inspection), but most of them were cheap and I

ordered several types. I

didn't find any LED replacements for sealed beam headlights, but I

ordered some 450 lumen 'brake lights' that might mount in a plastic

headlight body (yes, some of them are plastic) if I cut a hole in the

back where the terminals were, to mount them. I'll see if this is

workable when I try it. Each one will theoretically need two emitters,

for high and low beam. Conversion kits I saw at other sites for halogen

headlights were the better part of $100 each.

It seems I'll now be using most of the LED car lights for

the Sprint EV project and will have to order more for the Tercel. I

just might find LED headlight bulbs for the Sprint, since it takes

small bulbs.

For more house lighting and some lamps for gifts or sale,

I ordered a few of another type of LED emitter that probably aren't as

bright as the ones I've been using but were half the price - from a

slate of around 1400 "LED Emitter" search results. I want to do a four

emitter light, to run off 12 volts with substantially lower than an amp

current. It's a common power adapter size as well as a common battery

voltage. Finally I ordered a

4000 lumen emitter - potentially as bright as a 'regular' 200 watt bulb

- for the machine

shop, for $24.

The total order, 30 various individual LED bulbs

and emitters, came to about $105. So except for the 4000 lumen one, the

other 29 were only ~$80.

3-Emitter Table Lamp

The one LED light construction project for August was a

3-emitter lamp. I cut and bent a piece of aluminum so it would:

- jam into the 3" PVC pipe for a friction fit

- hold the emitters at a 45º horizontal spread from each other

- allow the diffuser to fit on top without hitting.

The main spread of the light was about 180º. Lamps

are usually against a wall, and why brightly light the wall behind? I

used a

beefy 9.5 volt, 1.5 amp power adapter. A .47Ω resistor provided about

an amp, but I had used an "on-off-on" switch, so I put five 180Ω, 1/4W

resistors in parallel, making 36 ohms at 1.25 watts for the third

switch position. This gave quite a soft light. Three ohms proved much

too

bright for a "low" setting - the power adapter voltage just rose as the

load lightened and it was still supplying over 1/2 an amp.

The three position

switch was a

fluke, scrounged from my old parts bin, but I like having the two

settings and I think I'll keep making them this way.

It was a beautiful, bright lamp. On looking at it, I

decided the mushroom diffuser was inadequate: it really needed a

lampshade. I need to find plastic globe or mushroom diffusers: In

plastic I can drill a top hole to mount the lampshade. (I ordered some

in the last week of the month by e-mail, but I haven't heard back yet

and must write again.)

I can also drill a couple of small vent holes near the top

(and a couple more down on the tube). This unit runs warm on high

power, and I'm also going to double the heatsink from 4" x 5": on this

unit by attaching a second piece of aluminum, on future ones by using a

10" long piece that goes farther down the tube. (I added this piece

later but it still runs too warm for comfort. The vent holes would

really help.)

On the high setting, set near an incandescent lamp with an

identical lampshade set on it, subjectively, facing forward it appeared

somewhat brighter than the 100 watt lamp, and somewhat dimmer from the

back side. And of course, the light was white.

The three emitter LED lamp with 180º light dispersion looked

to me

somewhat brighter than the 100W incandescent lamp from the front,

and much whiter, but behind it didn't light up the blinds behind as

much.

Power consumed:

- Off 5W

- Low 5W (fractions of a watt are too low for my clamp-on AC ampmeter

to discern)

- High 15W

I was a bit shocked to find the unit drawing .04 amps when

it wasn't even turned on. Evidently the power adapter itself isn't a

negligible power consumer. It stays warm as long as it's plugged in.

The LEDs on high should be about 9W. But

considering that it looked brighter than a 100 watt tungsten

bulb with an identical shade, the whole 15 watts might almost be called

negligible.

For installed lighting, the power adapter goes off with

the light. For a lamp, it stays on unless the lamp is unplugged or

turned off from a power bar. Now in addition to not overloading a power

adapter, it would seem it's most efficient to get one that's not too

much bigger than necessary either, since bigger transformers consume

more watts at idle.

Solar/Battery Lighting Backup System

There's one fabulous thermonuclear power source at a safe

distance from all human habitations, with no cost for its one kilowatt

per square meter radiance delivered direct to our planet's surface.

I haven't made DSSC solar cells yet, and I'm not sure what

possessed me to start on a somewhat "mundane" solar panel project,

but it seemed like a natural: low power LED lighting can run from a

system that produces a little electricity and saves it in batteries...

and I was already doing the lighting and the NiMH battery sticks. All

it seemed to need was a solar panel to enable off-grid lighting.

But once I got into it, I came up with a couple of ideas

that seemed less "mundane".

First it occurred to me that my nanocrystalline titanium

borosilicate glaze mix could make a great cover glass for silicon, or

any, solar

panels as much as for DSSC. So I may at some point get a very

small panel and start experiments with the glaze again, comparing power

output with the original cover glass.

The other idea was a potential simple way to tie the solar

system

and grid power together to power LED lights and any other low voltage

DC loads and save a bit on power from the mains without worrying either

about running out of battery/solar power or about power failures,

written up

below.

Back to the current project... I bought a smaller solar

panel to put up on the roof,

which has a 45º south slope face. (65 watts ~ 17v 3.7a, $224, 31"

x

26", at HomeEnergy[.com]

on Mary Street in Vic West... I could fill the south roof with

collectors and sell power to the power company, but cloudy Victoria is

an poor climate for solar much of the year, easily doubling the already

lengthy payback time.)

I planned to run this through a 13.8 volt voltage

regulator and keep a 12v NiMH battery stick, or even several of them,

and a couple of 6v sticks, charged up. (They'll be AA sticks once the D

cells are in use for transport unless I get more.) These can then be

used to power LED lamps in place of 6v and 12v power adapters, either

in the house during a power failure or outside or camping.

CTI-65 65 watt solar panel, a less popular model for 200$ discount

price at Home Energy in Vic West.

Tristan visited the day after I got the collector and he

thought a charge controller would be better than the linear regulator

and economical, so we went back to Home Energy and looked. (I had

thought they'd be too costly to consider and didn't bother to ask.)

There was one intended for lead-acid batteries, "SunSaver6" supplying

14.1 volts, 6 amps, for 42$. It had no adjustments, but I thought I

could make it work for the NiMH's. If I needed to charge the most

batteries at once, it would use the full 65 watts of the 224$ panel

instead of about 80% of it. Hmm... fart around with hacking a ready

made "best solution" for $42 or fart around for a longer time to make a

more lossy voltage regulator design of my own? I bought it.

266$ somehow got to be a ways off from my original

minimalist, low-cost intent: to scrounge or buy cheap an old solar

panel from my neighbor (who it seems is away for a month) or else find

a banged up or used one at Home Energy (weren't any), and cobble

together the 13.8 volt regulator (or a 6.4 volt one if I ended up with

one of my neighbor's 6V panels). And then mount it on my

high, steep roof, and wire it through to downstairs.

I put a schottky diode in to reduce the output voltage by

about .3 volts - from 14.1 to the ~13.8 volts the NiMH constant voltage

charge needs. (It turned out to be more like .4 volts drop. The system

tended to be a bit under voltage.) This however tricked the unit into

thinking no battery

was attached and it wouldn't turn on. I put a 1K resistor in parallel

with the diode so the battery voltage would appear on the terminal.

Somewhat to my surprise, this worked.

That didn't solve everything however - the batteries

continued to draw large currents even when they were well over 13.8

volts, as if the diode had no forward drop at all. It turned out that

the so-called "14.1 volts" consisted of short pulses of higher voltage,

merely averaging 14.1. I tried several capacitors to smooth out

these spikes and ended up with a large one, 4700uF @25v rating, across

the BATT output. That dropped the charge currents to the expected

levels. I feared that it might destroy the unit - at once or over time

- since it wasn't part of the design, but it has been operating fine. I

charged some batteries.

I noticed that the "14.1" volts drifted considerably with

temperature, from 14.06 (warm) to 14.17 (cool), which naturally

affected charging considerably. In the manual, it seemed this was

deliberate - must be something to do with lead-acid battery foibles. Oh

well!, it was still within essential limits. I also noticed that the

unit continued to work fine in the shade for the couple of watts still

being asked of it after the sun left the area.

Testing and tweaking the 6 amp charge controller to charge two 6V NiMH

battery sticks

I used a 6 volt battery stick I'd charged (one of two in

series) to power my 6v LED lamp that evening, unplugging its regular

power adapter. Drawing an amp, it should have run up to about 9 hours.

I

would recharge the cells with the collector the next day.

That same day the August power bill arrived. It was 15%

lower than July's 30(?) year record low. (A big part is that I'm not

renting out any rooms now.) Unless I stop taking showers or doing

laundry,

it can probably only get a little lower now with more LED lights, but

now it bothers me to turn on high power lighting for any extended

periods. By October I'll be back to running electric heaters (and

burning wood), but summers - and all the lights on those long winter

nights - should now be almost free!

The next day I got the collector up on the roof (and

cleaned some gutters and the chimney while I was up there) and ran a

#12 wire down into the house - doubtless overkill but it's what I had

on

hand.

65 watt solar panel looking a bit lonely on the ideal 45º slope,

south

facing roof.

On further playing with the charge

controller and charging, I found that if maximum amps were needed, the

collector voltage was dragged down to the charging voltage. The

collector had good sun, and it should have had something like 17.5

volts and 3.7 amps input from the collector (65 watts) and 14.1 volts,

4.1 amps output (65 watts) - or less volts and more amps (still 65

watts) - but instead the collector was loaded to 12.5V and the output

was 12.4 volts at only 3.95 amps (47 watts). I could have saved my $42

- it was no more efficient and had no higher output than the linear

voltage regulator I had originally planned to make - and still might.

Solar to Grid Low Voltage DC Power Tie-In with NiMH Batteries

Tying a PV solar

system into the power grid is an enticing idea, but the investment is

high and the payback long, especially in our local cloudy-all-winter

climate. It has to be done in a big way (for an individual) to be worth

doing at all. 20 'full size' 225 watt panels at 500 $ and the grid tie

inverter, permits et al would doubtless run at least 15,000 $ and

probably more. That would produce only around 6-12 MWH/year or 600 to

1200 $/year at 10¢/KWH.

Short of that, is there some way to tie the

solar system and the grid together, even one-way only: to power LED

lights and any other

low voltage DC loads from solar power if it's available, but from the

grid if it isn't? That could save on the power bill even if that bill

could never be negative.

This would mean storing solar energy on site, which would

mean batteries. Here the NiMH batteries, or NiFe batteries, are key -

they have

it all over lead-acid. Lead-acid need to essentially be kept fully

charged or they deteriorate. It's a crappy chemistry for solar

power where the batteries are drained and recharged on a daily basis,

and may sit discharged overnight after using lights all evening. The

NiMH, or NiFe, can sit at most any state of charge and be drained and

charged random amounts, and they don't mind. The battery sticks make

the NiMH dry cells easy to make into higher voltage batteries.

So the solar panel charges the battery sticks. Then what?

Here's the idea:

1. I've been making LED lights of 3, 6 and 9 volts so far, but

unfortunately we have to pick one system voltage. Probably 12 volts is

the best choice - there are few solar PV panels with lower voltage.

Four lower current emitters can be used to make bright 12 volt lights.

Going higher means getting constant current drivers for the LED lights.

They're available, but I note there are many 12 volt LED lights

ready-made for campers, car and boats - far more choices than for any

other voltage or power supply.

2. The batteries are connected direct (but with fuses or breakers) to a

wiring bus that carries the power around the house to the desired

points for lighting. This wiring is probably the most labour intensive

item if it's to be done nicely. (Easy in a new house during

construction!)

3. A 13.8 volt power supply connects the collector to the batteries.

The power supply should be designed so that if there isn't any sun,

power won't go backwards from the batteries into the supply. (Note:

My collector has two diodes. If the power won't get back from the

batteries to the collector, they aren't needed - the voltage will be a

bit higher without them. Oh, no!, it's way up on the steep roof and the

wiring box with the diodes is underneath it!)

4. An 11.75 volt (rough estimate of best voltage) power supply comes

from the mains to the batteries. It also is designed so that power

won't go into it from the batteries on the load side if their voltage

is above 11.75 volts. As long as the battery voltage is above 11.75,

this

supply is at idle.

Now the solar collector supply puts up to 13.8 volts onto

the system if it's able to. (Of course, if the sun is shining, use of

lights will be minimal.) With the collector off, eg at night, the

batteries, with any reasonable load, will run at about 13 to 11.75

volts

from fully charged to almost 90% discharged. As long as they're above

11.75 volts, they'll supply

all the power. Once they drop too low, 11.75 volts will be supplied

from

the mains.

When the sun comes out, the batteries will recharge.

Once installed, this system

would be entirely automatic, nothing to do or to worry about.

Of course, with just my 65 watt panel, it's going to take

a couple of days to make 10¢ worth of electricity, or 3 dollars a

month. Around here, count on only about 6 productive months per year -

$18. To get my $224 back for the panel, even ignoring other costs and

any power going unused, will take 12 years.

But really the storage is the main problem with the

concept. 50 NiMH D cell batteries for 50 amp-hours/600 watt-hours, at

$7 each, would cost more than the collector ($350), and being

cycled daily, they might have to be replaced within ten years or even

five. (or just add 10 more at a time as needed - evidently only the

capacity drops, and after the rated 1000 charge cycles they still have

75% capacity.)

Now add more panels and batteries and get a 12 volt

fridge, make a solar hot water system and get a clothesline, and you're

pretty much off grid!

I think I'll leave all that out of my plans as the power

bill is already low. I may not make even the system described for the

65 watt panel.

The fact that more economical, super long

lasting batteries would make this system much more practical would

indicate that it would be better for me to put my energy, time and

inventive skills into creating

those batteries.

Just for effect tho, I've been charging a pair of 6V

battery sticks and using them to power the 2-emitter LED lamp in the

evenings. It runs 3 or 4 hours, tho gradually dimming as the current

drops from an initial 1.35 amps to .5 amps, as the cells drop from

about 6.5 volts to 5.9 volts. The voltage drop is a little faster than