Turquoise

Energy Ltd. News #45

Victoria BC

Copyright 2011 Craig Carmichael - November 5th 2011

http://www.TurquoiseEnergy.com

= http://www.ElectricHubcap.com

= http://www.ElectricWeel.com

Feature: Battery Technology

Breakthrough!

'Grafpoxy' coated metal grills enable

new salt electrolyte battery

chemistries.

Month In Brief (Summaries -

and - gosh, editorial comment)

* Governments, Oil Companies, to ban electric cars?

* 7 Billion for Halloween & the coming Population Drop

Electric Hubcap System

* Motor contoller finally fixed, tested - works great.

* Motor over-revs at 42 volts and fails violently - analysis of

failure, weak points.

Electric Weel Motor - no report

Mechanical Torque Converter Project

* Gear Reduction in Constantinesco's car - it doubtless had gear

reduction at the rear axle to lighten the job of the mechanical torque

converter.

* A better "centifugal clutch" mechanism

* Sprint is hard to move by hand at 4:1 (chain/sprockets) reduction -

converter

still has a big job

Sprint Car Conversion Project

* Drivetrain pieces come together day by day

* Fit into car and moved car by hand by turning torque converter

drum

* Had main box rewelded, painted it all up with ersatz 'powder coating'

(see TENews #42)

NiMH Battery Project

* Simple constant voltage charger for 12 V Battery Sticks: 15.0 volt

power adapter + 2 diodes drop = 13.8 volts. Small resistor prevents

overloading power adapter.

* Got 5A chargers for 3.99 $

LED Lighting

Project

* LED Lighting: Good for your Eyes?

* BC Hydro subsidies for LED lighting?!?

* "Standard" LED Globe Light Fixtures For Sale

(No wiring necessary. See: http://www.TurquoiseEnergy.com/TEcatalog/

=> LED Lighting Products.)

* Also have a limited selection of 12 volt/car LED bulbs for local

consumption.

* Simple 12VDC Lighting "Grid Tie" part -- 12VDC power adapter for AC

side power supply.

Turquoise Battery Project

* Vanadium-Zinc cell

* Low conductivity: Aha, the culprits!

* Idea: epoxy-graphite coated copper grill current collector

& terminal (turf graphite sheets and carbon rods!)

* Zinc electrodes in salt solution may be much better than in

acid or alkali

*

A

working battery cell made! - no deterioration with cycling

seen

* Grafpoxy

grills work! Breakthrough unlocks the door to new salty

battery chemistries!

* Carbon nanotubes with methylbenzene (toluene) solvent?

* Remaining issues for practical battery cell products

Newsletters

Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

-

Electric Hubcap Motor - Turquoise Motor

Controller - 36 Volt Electric

Fan-Heater

- Nanocrystalline glass to enhance Solar

Cell performance - Ersatz 'powder coating' home process for

protecting/painting metal

Products Catalog:

- Electric Hubcap Motor Kit

- Sodium Sulfate battery longevity/renewal

- NiMH Handy Battery Sticks, Dry Cells

- LED Lighting Products

Motor Building

Workshops

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

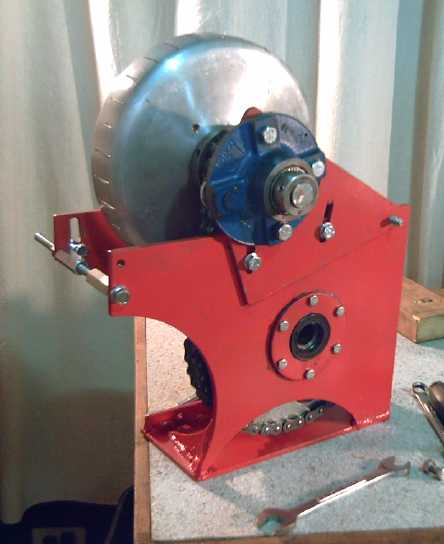

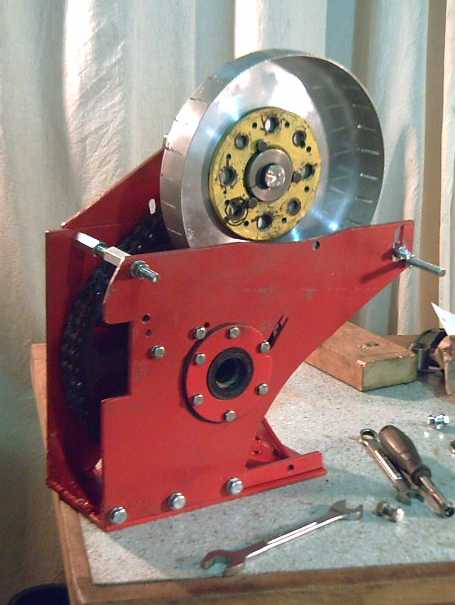

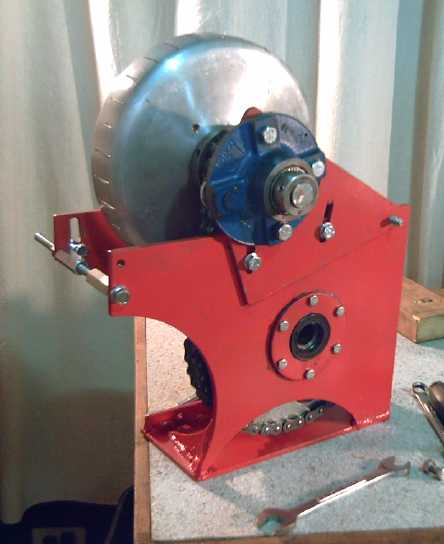

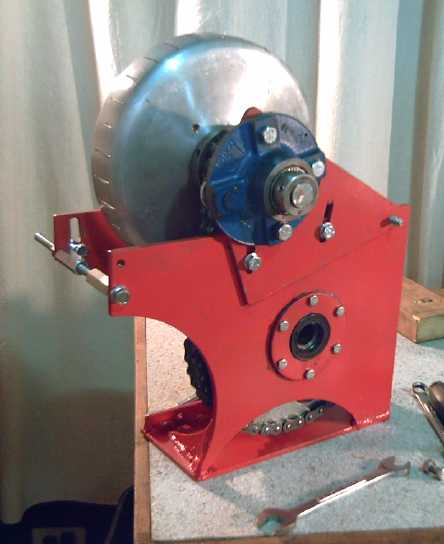

October in Brief

I

thought October would be much like September. For

another week I plugged away day by day at the Sprint conversion,

completing the drivetrain part by part and finally mounting the whole

unit in the car to check the fit.

I

thought October would be much like September. For

another week I plugged away day by day at the Sprint conversion,

completing the drivetrain part by part and finally mounting the whole

unit in the car to check the fit.

And I figured

out a better "centrifugal clutch" wedge system for the torque

converter. Moving the car by turning the torque converter output drum

pointed out what a big job the converter has to do if the

Sprint is going to run well, even with the 4 to 1 chain drive reduction

following it.

The car work didn't stop me

from doing the odd battery experiment... and I figured out where the

high

resistances inside my own batteries were coming from: the positive

electrodes were swelling and losing conductivity - internally too, but

even more they were becoming isolated from their graphite backing sheet

and the carbon terminal post.

Then I thought of

a "grafpoxy coated grill" system for making electrodes. Turf the

graphite sheet and the carbon rod - compact the electrode around a protected

metal grill - the ideal construction! Grafpoxy coatings could do for

rechargeable salt

electrolyte batteries in 2011 what nickel coatings did for

alkaline electrolyte batteries in 1899 - make them practical.

I meant to leave it at that and get back to the Sprint and

the torque converter, but I just

couldn't leave such a promising development on the back burner!

I made a test cell (NiMn-Zn). The negatrode was simply a sheet of zinc

from a dry cell. 5 ohm

resistance readings on the positrode from any point to the terminal

looked promising indeed, and it

did in fact work, apparently with gradual improvement and without

deterioration over a number of cycles over a week.

Adding

toluene to

(hopefully) create carbon

nanotubes seemed to up the current capacity a bit. Here was my first

actual, usable

battery. Open circuit voltage was

around 1-3/4 volts, and it would drive over an amp (1 ohm @ >1 volt)

for about 30

seconds and put out over 1.5 volts at 150 mA for 10 minutes, or 60mA

for around 20 minutes,

holding over a volt (>40mA) for another hour and more. A proper

zinc electrode should greatly improve the running times, like maybe

20-30x.

Adding

toluene to

(hopefully) create carbon

nanotubes seemed to up the current capacity a bit. Here was my first

actual, usable

battery. Open circuit voltage was

around 1-3/4 volts, and it would drive over an amp (1 ohm @ >1 volt)

for about 30

seconds and put out over 1.5 volts at 150 mA for 10 minutes, or 60mA

for around 20 minutes,

holding over a volt (>40mA) for another hour and more. A proper

zinc electrode should greatly improve the running times, like maybe

20-30x.

I also discovered there's a zinc peroxide (ZnO2) which

might - possibly - make a good positrode. It's the first indication

I've seen that such a thing might be possible. A ZnZn salt battery

would certainly be very economical, and it should achieve over 100

WH/Kg energy density if the voltage is reasonable.

I also made a

few more LED lights, and I found out that

BC Hydro is giving rebates to customers who buy approved LED lighting

products. So I tried to get info in order that my LED light fixtures -

which are much brighter than the 'LED lightbulbs' available in the

stores - might become more affordable.

I also made a

few more LED lights, and I found out that

BC Hydro is giving rebates to customers who buy approved LED lighting

products. So I tried to get info in order that my LED light fixtures -

which are much brighter than the 'LED lightbulbs' available in the

stores - might become more affordable.

The thought of possible sales - income! - brought LED

lights to the forefront of effort. I bought more parts and

focussed on defining "production models" such as a 6" globe (image),

updated the Turquoise Energy

Products Catalog to include them (and Handy Battery Sticks), and I

attended a couple of small events trying to promote them. If ASHRAE

engineers specify them for new commercial construction or renos,

savings in HVAC equipment might actually pay for the LED light fixtures

right in the capital cost.

The day of the 17th and some time on the 18th was devoted

to looking through LEDs at

DealExtreme.com and putting together a big order - almost 400 $ worth.

I hope I

can sell a few LED light fixtures or lamps to recoup

some of that, as money is already getting low and tax credits are at

least six months away. In the process, I finished converting the Tercel

to LED lights, except the headlights (haven't found any yet), and

better determined which are the best ones to use. In the order are some

more to do the Sprint.

Later on the

18th I finally tested the motor controller.

It

worked great, but the motor over-revved at 42 volts and came apart

violently. I neglected to consider that the higher top RPM from the

higher voltage would be well above the design intent - maybe 3000 RPM

instead of 2000, 9/4ths the centrifugal force. For a couple of days I

had been mulling over the possibility

of doing the electric outboard before my trailer insurance expired on

the 26th. (I only used it once for the Electric Hubcap Outboard trials

last November 6th. 50$ for one trip is very high priced insurance!) It

didn't seem like a big job to get it running (tho these things tend to

take much more effort and time than expected), but the busted motor

broke the camel's back.

Later on the

18th I finally tested the motor controller.

It

worked great, but the motor over-revved at 42 volts and came apart

violently. I neglected to consider that the higher top RPM from the

higher voltage would be well above the design intent - maybe 3000 RPM

instead of 2000, 9/4ths the centrifugal force. For a couple of days I

had been mulling over the possibility

of doing the electric outboard before my trailer insurance expired on

the 26th. (I only used it once for the Electric Hubcap Outboard trials

last November 6th. 50$ for one trip is very high priced insurance!) It

didn't seem like a big job to get it running (tho these things tend to

take much more effort and time than expected), but the busted motor

broke the camel's back.

Too bad - I might

have actually sold a motor kit or two with an actual application for it

that was demonstrated to work. Who knows for sure how long the Sprint

conversion may drag on for with the untested torque converter plan and

all the other things I'm doing? On the other hand, I now realize the

rotor compartment needs a little more beefing up before the motors hit

the market, and I'll be trying to improve the magnet gluing system a

bit.

AFAIK the controller was still working. On November 1st I

finally ordered some IR2133 V2 motor controller boards, designed in mid

August. On a list someone mentioned iteadstudio.com, and I ordered 10

boards there for half the price of two from APC - wow! High priced

parts are what makes my stuff cost a lot, and this is a good find.

One more motor detail that's been wanting is a better

formulation of ilmenite for the coil coatings, one that won't flake

off. I didn't have time to try out the zinc oxide additive. Until the

coil coatings are improved the Weel motor isn't going to get done.

Governments, Oil Companies, to Ban Electric Cars?

I've just heard a rumour that our (Canadian) government is

planning

to ban conversions of gas cars to electric. This sounds crazy, but it

follows a secret

provincial ban on

registering converted cars last year in Ontario, evidently since

repealed. Since it's virtually impossible to buy an electric car from a

car maker, that would virtually mean a ban on electric cars. If true

such a

move,

clearly at odds with the public interest and the whole planet's, can

have only one real purpose: to prevent the public from making the

switch from gasoline to electricity even with their own hands. This

slow switch

which has

been happening on a small but growing scale with improving electric and

electronic technology, and in the clear absence of any

intent by car makers to produce practical electric cars -- besides a

handful of overpriced units to bandy around and say "See, we're making

them!" They sell one at inflated price

where ten thousand are needed.

Car companies can make a gas car to sell for around

10,000$. Canadian Electric Vehicles (just one example) can convert your

gas car to

electric for around 10,000$ Doing it yourself is cheaper. That's

20,000$ for a brand new electric

car, partly made by hand with Canadian labour in small shops, and with

a

discarded gas engine system left over. From scratch, an electric car is

obviously simpler and easier to build than a gas car. Maybe a basic one

should cost 6000-8000$. Yet a Chevy Volt,

essentially

publicly funded by the billion dollar bailout to GM, costs over 40,000$

-- if they would actually sell you one. They claim

they can't do it for less. Tesla motors, the one seeming bright spot

since Zenn ceased production, is going public, but they're also ceasing

production of their 100,000$ roadster. They plan to make a 50,000$

electric car next year, but there'll be a gap in production. As a

privately owned and funded company it was hard to sabotage, but if

patterns repeat, now that the miscreants are free to buy up the shares

the new model will never be built, and Tesla will cease to supply

electric cars, tho it's so well known now it may be kept "open" to

prevent public outrage at its closure.

Another disturbing rumour I heard this month (from what

seems like a good source) is that the oil companies have bought up

virtually all the battery making companies in China, and forced them

all to sign agreements that their battery sales need to be approved by

them. Obviously, a ban on sales of batteries for electric transport is

the objective.

Oil reserves, CO2 emissions and global

warming would be dead issues were it not for the few actively,

deliberately and cleverly blocking

change. In fact, they might never have been issues. How can the 1%

responsible for this or complicit in it look their neighbors in the

face?

And it would just one more little item in the gradual but

ongoing curtailment of freedoms of we who were a much freer society

within the memory of many. The gangsters that

control the world's economy are now pressing us to the wall.

Winston S. Churchill's "broad, sunlit uplands" for humanity that

followed World

War Two are being rapidly fenced off with "Private Property Keep

Out" signs around them.

The 99%

are beginning to realize that the psychopathic greed and avarice of the

1%

is destroying civilization, and are now

demonstrating in numbers in cities all over. "They continue to block

alternative forms of energy to keep us dependent on oil." is just one

of a long, sickening list of indictments in the Occupy Wall Street Statement

of Solidarity. If nominally democratic

"bought" governments don't

start

doing the things people want and need done, when enough people have had

enough, there may be a revolution. But what then? Military

dictatorships might restore order, and maybe even summarily get rid of

the

gangsters who are lording it over us now. But it would likely be no

freer. Is that what we want?

It's easy to feel the situation is hopeless. But rumours

from a confluence of individually suspect sources going back over 25

years say "Be not dismayed!" - that the troubled times we're entering

are the beginnings of a grand correction, of gradually pulling this

planet back into the main evolutionary sequence. "Communism" showed its bankruptcy 20 years

ago and has largely vanished. Now psychopathic "corporatism" is likely

about do the same. Angels and

other spirits await freewill human decisions, and when we try to do

better, to learn, to educate, to contribute to real human health or

planetary welfare, the results may be better and more far-reaching than

we expect. All things work together for progress.

Seemingly small electoral system changes would lay

foundations for a proper democratic

system. I suggested some of them in my

2003 booklet Fundamental

Principles of Democratic Government . They should result in

real

leaders becoming electable, transfer the real decision making power

from

political partisan ("party") factions to the individuals in the

legislatures where it

belongs, and enfranchise citizens to instigate changes and actions

instead of just

to ineffectively protest someone else's imposed decisions and programs.

The Choice Ranking vote, titled "BC-STV", was chosen as the best voting

system by most of the BC Citizens' Committee on Electoral

Reform in the same year, and Australia already uses it. In Canada (and

Australia), it needs to be enacted along with

direct popular election of the prime minister and provincial premiers.

With the fair voting system where one puts who they really like

best first regardless of preceptions of their electability, and without

the schizophrenic election of two offices with one vote (MP and PM),

the real

ability of the public to elect numerous popular non-party figures who

haven't

worked their way up through a corrupt political hierarchy, would make

the whole system much less open to corruption.

Simply creating the Department of Progress

(mentioned in various issues of TE

News from #21 on) would

provide

an ability to

foster both development and adoption of valuable technologies

and new systems and institutions of governance, where they're needed,

and rein in vested economic interests that attempt

to entrench old and inferior technologies and systems with unfair

tactics against the public interest. Such a department might itself

carefully study and make recommendations for vital political structural

reforms, for discussion and probable enactment by parliament.

And as

another example of things such a department might accomplish, surely it

could come up with a well

conceived national pension system, perhaps formed as a trust, that

would unlock career changes for

the many experienced citizens trapped a decade or more too long in one

job by pension

considerations, and set companies free to hire workers of any age.

To attain to such improved systems we must recognize that

we are one human family on one planet in a stupendous cosmos, spiritual

sons and

daughters of an infinite First Source and Center who encompasses all,

and start to act accordingly. Perhaps John F. Kennedy had the

essence when he said, "We all

drink the same water; we all breathe the same air." We can't

bring peace on Earth and goodwill among men unless our solutions are

fair to everyone, everywhere.

If those who are creating the problems turn and face

themselves, as they must do on the next world if not on this one, they

must recognize inwardly that they're one of a handful of rotten apples

spoiling the whole barrel. They would

do not only humanity but their own souls and psyches a great service by

defecting from this evil - by opening their hearts to the people

they're

oppressing and helping to get long needed changes and advances

implemented.

They might well find themselves living in a better world, and discover

a

couple of things more precious than immense wealth and power - peace of

mind and

a true sense of self worth.

7 Billion for Halloween and

the Coming Population Drop

Officially our family hit 7,000,000,000

earthlings on October 31st 2011, "Halloween" in North America. Most of

my life

I've heard about the "population explosion", the "exponential

growth" of Earth's population and how it just can't take much more. It

had everybody scared like "global warming" does today. In fact, I

think we were supposed to be over 12 billion by now and all starving.

But birthrates in most of the world (with a few notable

exceptions) now are such as to utterly falsify this picture. A couple

of years

ago I saw it predicted that the population would peak in 2055 and then

start

to decline. That was a big surprise to me. Now I'm even seeing 2035

instead.

Halloween evening the 7 billion produced only two costumed kids to come

to the

door for candy, where 30 years ago, there were usually around 40. This

doubtless indicates changing customs and I was late putting the porch

light on, but there certainly are fewer

children around.

We now have an aging population, full of people like me

who lived much of their younger life with the real possibility of

nuclear holocaust, and who bought into "the population explosion" and

thought it might be a service to humanity not to have kids. When we die

off, there are few in the next younger age groups to replace us.

I remember working for the Victoria school district in

the late 1980s when numbers of portable classrooms were being placed on

school grounds. Everyone was asking "Why don't you build additions and

bigger schools instead of this makeshift fix?" But the far-seeing

facilities

manager said "Look at the birth statistics. In five years these

portables will be being hauled away, and if the trend continues, whole

schools will be closing." Thoroughly indoctrinated as I was to the

"population explosion", that didn't make sense to me at the time -

How could more and more people have less kids? But

these things have happened. One high school that had 2200 students at

its peak now has 800. Today, economic times are such that many in their

20s and even 30s are still living with their parents. By the time they

are affluent enough to have a family - if they ever are - they'll be

too old.

While everyone was crying "Blizzard! blizzard!" the

population explosion "snow" simply melted into the ground. It seems

almost

inevitable

there will be substantially fewer people alive in a century than there

are

today, without

any mass starvations, pandemic epidemics, or global catastrophe having

intervened.

But will they be affluent people free to live the lives

they choose in a sustainable, boldly advancing civilization, or will

99% be regimented, poverty stricken serfs of 1%, living in a sick,

polluted

world

and overburdened with

1,000,001 petty regulations against every deviation from arbitrary

social, political and economic "norms" of the day to keep them in line?

A Battery Technology

Breakthrough

Background

There was something that wasn't explained in any battery

reference book: why are standard dry cell positive terminals a carbon

rod, when every other type of battery uses metal?

It took me a couple of years of battery R & D to

figure it out for myself the hard way: every metal I used within the

positive electrode in a salty electrolyte battery oxidized away,

including nickel, which protects the other metals in alkaline cells.

The cells were soon left with a terminal post connected to nothing

because the wire had disintegrated.

The actual electrochemistry is of only secondary

importance beside having cells that don't fall apart.

Why was this nowhere explained? I suffered two years of

failures because of this missing bit of info. Maybe it was so much

assumed to be "common knowledge" by those writing the books that it

didn't occur to them to mention it? Maybe the secret died with salty

battery research in the 1880s? Whatever the reason, I explained it on

Wikipedia in the "carbon-zinc battery" article so others might avoid

this pitfall.

Evolution

Once I understood it, I started using sheets of "expanded

graphite", and carbon terminals salvaged from dry cells. Others have

used graphite impregnated plastic sheets. But there were problems with

this approach. Butting an electrode up against a carbonized sheet

doesn't connect them together very well. My failures now took a

different form: of initially poor conductivity within the battery, that

-

worse - deteriorated further over a few days.

Browsing at (IIRC) GraphiteStore.com for ideas, I noted

that they had "electrically conductive epoxies" with various metal

powders in them, eg, silver, copper or nickel. That obviously wasn't

going to solve the problem: if the metal particles connected with each

other and to the outside, as they must to conduct, they would all

corrode away just like solid metals did.

But if one could do that with epoxy and seemingly with

'any old metal powder', what about with graphite powder, which wouldn't

corrode? I tried it out (TE News #40) and got good results.

Encouraged, I "glued" the offending parts together with

the 'grafpoxy', as I called it, and made a battery. However, the

initially

fair conductivity gradually deteriorated, about like in previous cells.

At this point, I pretty much set the battery research

aside for

a while and worked on other projects.

Invention

In October I disassembled a couple of cells and measured

the conductance of electrodes to the terminal posts. They were good

when

I'd made the cells, but now the resistances were very high - unusable.

This was when I finally realized where the performance had gone.

But having given the issue a rest for a while, a fresh

thought crept in. Alkaline cell metals are coated with nickel to

prevent corrosion. Why not go back to using metal parts, but coat them

with

impervious grafpoxy to protect them? Then salty batteries could be

constructed much the same way as alkalines, but with grafpoxy coatings

instead of

nickel. The problem graphite sheets and carbon terminal posts could be

discarded entirely.

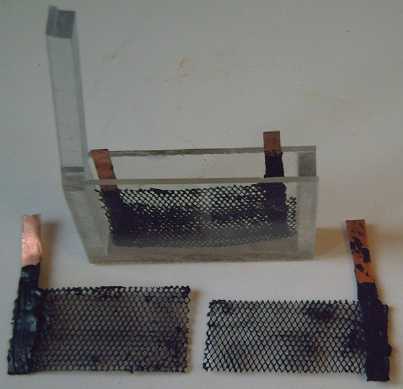

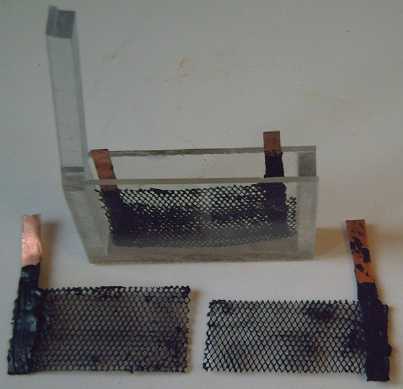

I made up several copper

grills with copper wire terminal

leeds or brass bolts soldered to them... why not solder and brass?

After all, it's protected. Then I realized the 90º posts would be

hard to work with. Doing them that way was perhaps a hangover from

carbon rod thinking. I did some more - and re-did some of the first

ones - with the leeds in the same plane as the mesh so they'd fit into

the electrode compactor.

But having given the issue a rest for a while, a fresh

thought crept in. Alkaline cell metals are coated with nickel to

prevent corrosion. Why not go back to using metal parts, but coat them

with

impervious grafpoxy to protect them? Then salty batteries could be

constructed much the same way as alkalines, but with grafpoxy coatings

instead of

nickel. The problem graphite sheets and carbon terminal posts could be

discarded entirely.

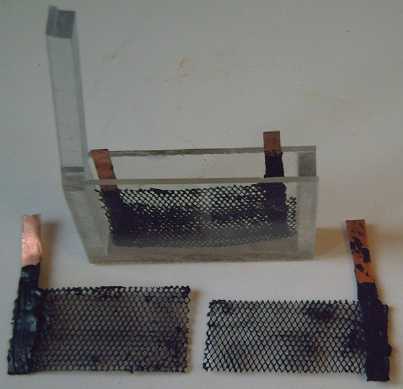

I made up several copper

grills with copper wire terminal

leeds or brass bolts soldered to them... why not solder and brass?

After all, it's protected. Then I realized the 90º posts would be

hard to work with. Doing them that way was perhaps a hangover from

carbon rod thinking. I did some more - and re-did some of the first

ones - with the leeds in the same plane as the mesh so they'd fit into

the electrode compactor.

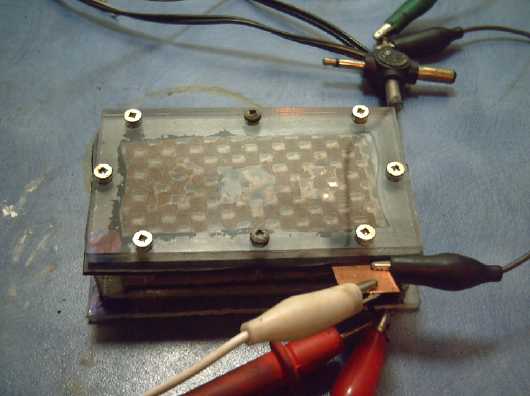

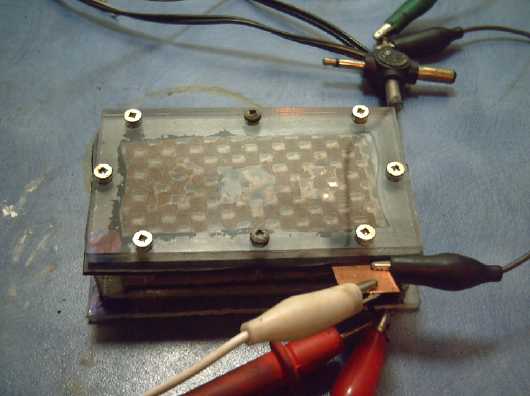

Then of course, I made an electrode (NiMn) briquette

around one grill. The resistance from anywhere to the terminal was only

a few ohms, eg 5 - even better than I'd hoped. I put it in a battery

case and used a piece of zinc from a dry cell for the other side.

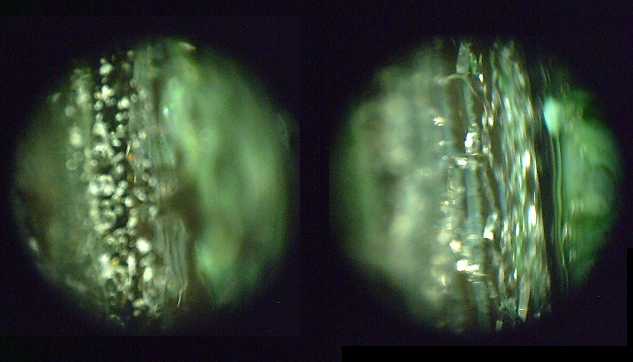

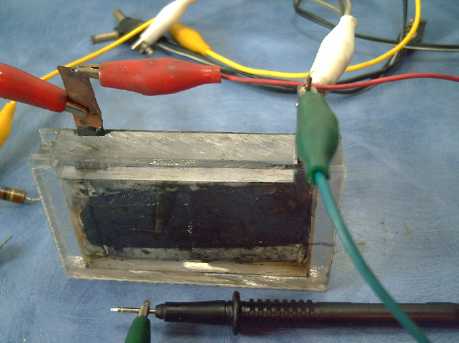

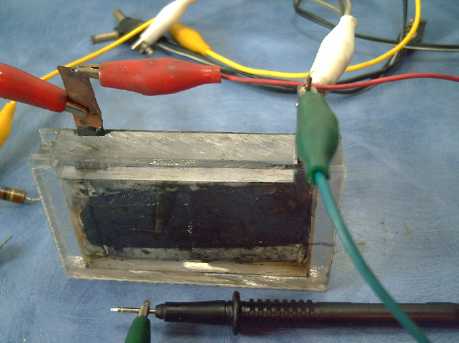

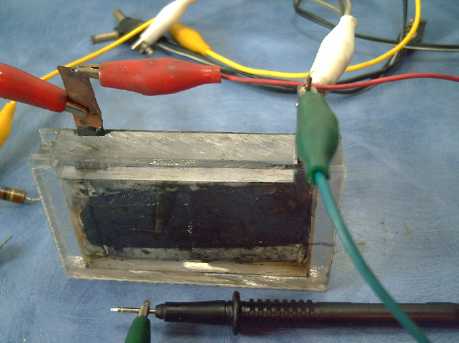

First grafpoxied electrode cell, and my first really

working battery.

It worked! It

was a real battery, and roughly equivalent

to a standard dry cell in current performance per electrode area.

Better yet, it continued

to work through several charge and discharge cycles with actual (though

minor) improvement with each cycle.

It worked! It

was a real battery, and roughly equivalent

to a standard dry cell in current performance per electrode area.

Better yet, it continued

to work through several charge and discharge cycles with actual (though

minor) improvement with each cycle.

Further Development

That was the initial success and, it would seem, proof of

concept. But the mixture and application procedure needed improvement.

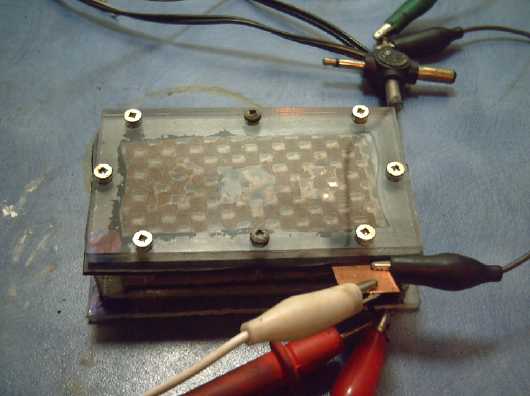

A

sheet of zinc was a crappy rechargeable electrode. An ill-fated second

battery hardly lasted a day before the positrode structure crumbled and

the leed wire came loose. Evidently there was a gap in the coating by

the

wire (tiny gaps were visible on some of the grills) - or compacting

the electrode scraped some epoxy loose and left a gap.

Cell #2. I put it edge up fearing it might leak at the terminals.

I think I'll make them all this way up, and liquid filled.

For best adhesion and coverage it may prove necessary to

thoroughly clean the metal with several complementary treatments,

similarly

to if it was to be electroplated.

If good results aren't forthcoming with that, I'll try two

coats, hoping the second one will bring stiffer protection and fill any

small gaps. If all other techniques should fail, I'll make molded

grafpoxy grills with no metal in them at all except a terminal post

cast inside a thick housing and - again only if necessary - pretty much

outside the cell. But I'm pretty sure the epoxy is impervious and by

good technique the grill can be made tough enough that extremes won't

be necessary. The metal grill provides better current capacity, in a

much thinner grill that leaves mainly active electrode substance for

high energy density.

For a third try, I used copper foil and riveted it to the

grill, since the solder seemed to be a weak spot.

For a third try, I used copper foil and riveted it to the

grill, since the solder seemed to be a weak spot.

Copper grills with riveted terminals

I put up to

four applications

I put up to

four applications

of

grafpoxy on to try and

eliminate tiny bare spots.

The structural parts for battery #3

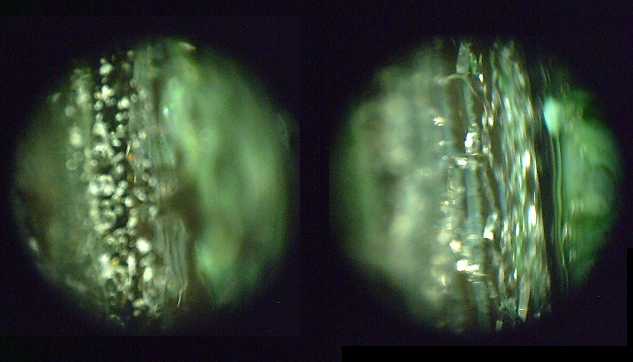

A thick positrode, compacted around one of the grills.

The painted calcium hydroxide coating picked up some purple from the

potassium permanganate.

Finished cell. The top was just set in place, not sealed.

This cell also had some

problems, but the positrode appeared to remain solid over a week or so.

Then the cell was disassembled.

The essence is there - it

can be done. The door is opened

to batteries of various new chemistries in salty electrolyte that were

previously inaccessible owing to there being no really good and

practical way to

construct a salty electrolyte rechargeable battery. Some of these

chemistries

are exciting in that they hold promise for probably higher energy

density than lithium ion and long or indefinite cycle life, and all for

the price of cheap dry cells, or of lead-acid -- without its hazards

and environmental problems.

If and when economical electric cars and trucks have a

day's highway

driving range, gas vehicles will lose their monopoly. And when weeks of

electricity from solar collectors or windplants can be saved up

on-site in batteries, perhaps too the electric grid will no longer be

such an

indispensable part of modern living for everyone.

Electric Hubcap Motor System

Motor Controller

After making the fuses bar clamp at the end of September, I wasn't

happy with it and made another the next day, that supports the bar with

a couple of plexiglass pieces when the fuses are being inserted, and

holds the

copper bars apart (thin strip

glued on beside bar after photo)

so the fuses can't accidentally be bypassed. Still

lots of room for improvement - next unit!

Fuses Bar: Clamp (arrow, right); Support (arrows, left)

Busted Motor. One magnet punched a hole through the particle board

table it was clamped to.

I hadn't considered that going from 36 volts to 42 would

up the maximum RPM the motor would attain, and I wasn't measuring it.

The motors had already been going up to 2200-2400 RPM instead of the

intended 2000, and 42 volts might take it as high as 2600-3000 RPM,

with double the centrifugal force I had intended it to withstand.

I'm thankful I wasn't in the line of fire. Thinking of the

guy doing the flywheels to store energy in the late 1960's, whose ideas

for powering even buses from flywheels were

featured in several Popular Science and Popular Mechanics magazines

until he was killed by a big flywheel that flew apart spinning 50000

RPM in his lab, of jet engine failures, and of my own previous magnet

glue

failures, I've gotten into the

habit wherever feasible of mounting motors vertically and being face on

to it rather than edge on. (The researcher's death was the end of the

idea of using flywheels to store energy until very recently - over 40

years later.) One magnet made

a 1" x 2" rectangular hole (and the exit was much larger) right through

the table the motor was clamped to. (It was a cheap particle board end

table... but still!...)

I collected the five loose magnets from around the room. Three of them

were badly chipped on one end, but I didn't see any holes or gouges in

the walls

or ceiling. They're probably what bent all the bolts inside, ripping

them out of the PP-epoxy center plate.

Analysis of the failure

The first thing that was virtually a given was that a

magnet must have come loose from the rotor. This would have become an

obstruction in the rotor compartment, hitting other spinning magnets.

It appeared that the five magnets that came off had separated from the

epoxy, rather than the epoxy from the powder coating paint, or the

paint from the undercoat or from the metal.

They also separated from their polypropylene strapping, or

(with two of them) the strapping separated from its epoxy on the rotor

and stayed with the magnet. The strapping was mostly but not entirely

intact, unripped. Examination of the rotor disclosed areas where not

much strapping area was well embedded in the epoxy, especially near the

inner ends -- with one such weak spot on each side of the same magnet.

This

could cause the magnet under stress to pull strongly away from the

rotor on the inside. Once it broke free of the rotor behind, it would

have swung out, ripping the rest of the strapping from the epoxy, and

become a projectile.

Better workmanship

might have prevented the failure... or just delayed it until reaching a

bit higher RPM. Improving the strapping configuration

might be helpful if I can think of a simple way to do it. It's easier

in theory than when you've got a bunch of gooey epoxied strapping that

doesn't want to stay put. If I'd tried inserting a screwdriver under

the strapping at various points, it might have disclosed the weak

spots.

But screwdrivers and supermagnets don't mix very well either. Maybe

something plastic.

The rotor

compartment's outer cover, made of four winds of PP strapping, was

ripped in one place. It looked like a magnet probably flew out from

there. The point was near the top of the motor, so it wasn't the magnet

that made the hole in the table underneath. It may have been the two

magnets I

found across the room stuck together. The strength of the PP strapping

is impressive, but not unlimited. A thicker outer wall appears to be

required. But then the outer wall will be so close to the rotor it may

hinder ventilation. I also note that the outer strapping wind was

delaminated from the others. Making the outer shell by casting it

should also be stronger.

The bolts holding the rotor compartment to the stator side

of the motor were all bent, having been hit by the loose magnets. (This

is probably where the magnets got chipped.) These bolts pass through

the rotor compartment just inside the outer cover. If the

cover shell were thickened so that the bolts passed through holes

within it,

the damage to the bolts would probably have been avoided and the case

might not have failed. To enclose the bolts is a second reason to

thicken the outer wall, and to cast it. But there's not

much room between the bolts and the rotor since I minimized the

diameter of the motor. I'd really rather not redo all the molds and

everything unless there was no other way!

The center ring/plate between the rotor and stator

compartments protected the coils and stator side from damage, except

pieces of

the ring itself ripped/broke apart at the bolt holes, allowing the

motor to come apart. This was the first ring made with the new mold

casting technique, and I knew it had some dry spots without epoxy.

These weakened it.

Furthermore, I hadn't expected any real trouble, and only

six of the nine bolts were installed. All nine might just have made the

difference. But it may be that the magnets ripped the bolts out one by

one, and there would simply have been nine rips instead of six.

Corrective Actions:

1. Make a careful inspection of

every rotor after magnet & strapping installation. Try to insert

something flat under the epoxied strapping and otherwise hunt for weak

points. And maybe paint on an extra layer of epoxy after it's otherwise

finished.

2. Try to figure out a better configuration for the strapping that's

inherently stronger. I think casting it should stiffen it.

3. Recess the magnets in a bit from the edge of the rotor - maybe .1".

4. It might pay to rough up the bottoms of the magnets a bit with

sandpaper or scotchbrite before applying the epoxy. On the underside,

the magnets separated smoothly from the epoxy.

5. Thicken the outside wall of the rotor compartment, and drill holes

through it for the bolts. Or maybe just the area in line with the

magnets? (better for ventilation?) On second thought, I think I'll mold

the outer wall.

6. Always install all nine bolts to hold the rotor compartment together

and to the stator compartment.

7. Snip the tines short on the T nuts so they don't cut into the

plastic center plate so much. Or bend them over. (In some places, the

center plate ripped at the tines.)

8. Use the new shaped center plates with thicker outside edges to hold

the nuts/bolts. Ensure no dry areas after molding.

9. Make a motor controller with a microcontroller that monitors (among

other things) motor RPM and reduces power if it hits max.

10. Going back to 36 volts instead of 42

would pretty much eliminate the potential of serious over-revving. That

would make battery charging details easier too -- three 12 volt

chargers,

three 12 volt solar collectors on the car roof (800$ option), and no

single 6 volt units that have to match the 12s in current.

Mechanical Torque Converter Project

Someone gave me a washing machine clutch mechanism to

examine. With my last designs, the motor would have to get up enough

torque to overcome the springs holding the wedges in the slots before

it could start moving. I was only hoping that the maximum pressure for

starting the motor was also at least sufficient pressure to develop

good force to the output. But this is backwards. Ideally the stopped

motor should be free, unloaded, and force developed should be

proportional to motor speed.

I've decided to modify the design, and use centrifugal

force to push the wedges into the slots. This implies that the wedge

arms must be given a certain amount of mass to push them out with some

'optimum' amount of force as the motor spins. Instead of having the

springs push the wedges into the slots, they'll hold them away from the

slots, retracted, until the motor gets up some speed, somewhere in the

upper 100's of RPM.

Thus the unit will act as a centrifugal clutch that will

cut in when the motor is going fast enough to develop some force - the

sort of force that might start to move a car on level pavement. The

mass of the arms and the strength of the springs can be varied to see

what works best. It'll be unlike a centrifugal clutch in that it will

neither solidly 'engage' nor 'slip', but the greased wedge will freely

slide across the flat areas, bumping against the edge of each slot as

it comes to it.

The force of each hit will largely be proportional

to the

square of the motor speed. The frequency of the hits will

depend on the relative speed between the motor and the output rotor,

which depends on the amount of torque required. The torque will

I think be the motor torque times the total distance between slots,

over the distance for which the drum is driven at each slot - around 18

to 1.

Since I haven't made the wedges/arms/springs part of the

mechanism yet, design changes - so far - don't require any reworking of

things

already done.

Looking at the washing machine clutch, I note that the

arms could be on the outside of the output drum. In this case they

would pivot in the middle, with the weight on one side and the wedge,

facing inwards, on the other. However, I'm not sure if this would have

any particular advantage, and there isn't room to fit it without

redoing important parts of the frame, since I hadn't planned on

anything larger.

Seems to me that if the diameter is to go up, it should

probably be

the output drum that's made larger and the arms and wedges should be

kept inside it. It also occurs to me that the drum and slots could be

made wider - if not an inch, then two or three or four inches - to

distribute the force of the hits and so prevent damage from relatively

powerful forces.

Constantinesco's car & converter: gear advantage

Although Constantinesco eliminated the entire transmission

of his cars with the torque converter (which was built into a two

cylinder engine in his production model), there was a gear at the back

axle for forward-neutral-reverse. It belatedly occurs to me that this

gear probably was also a reducing gear. Given the higher RPMs of a two

cylinder gas engine and the fact that 40 MPH was probably a good top

speed in the 1920s, it wouldn't surprise me if it was as much as around

10 to 1 reduction. This means that his torque converter had a much

easier job to do than I what was thinking. That might explain why his

oscillating masses converter was successful but no one since has

managed to duplicate his success.

Doubtless the chain drive I've put in the Sprint, or

a planetary gear reduction following the torque converter before a

vehicle wheel, reduces the converter's job.

Test Setup?

I thought of making a test setup using the sprint car

drivetrain C-clamped to the workbench. Instead of hooking the input

rotor to the motor, I could hook it to a hand crank. I could mount a

fish

scale at a 6" radius from the output drum and measure the output

torque. I'd have to estimate input RPM and torque. I had another cut

down trailer axle for bearings for the same 1" shaft as the motor,

so the input rotor could be moved from the crank to the motor without

modifications (except maybe stronger springs so it'll engage at a

higher RPM).

A few days later it occurred to me that all I had to do

was put a longer axle on a motor, so that it stuck out the back end.

The handle could then go right on the motor shaft and nothing extra

except the handle need be constructed.

I hope in this way to get more of a feel for how it's

working and what gives it more or less effect and how much effect. On

the other hand, I can't duplicate motor RPMs by hand.

What's needed now is time to get to the job!

Sprint Car Conversion Project

Fittings

On the 2nd, I fitted a plastic plate on the hole in the

floor where the gearshift lever was, a plastic plate on the console,

the console back into position (with a couple of new brackets to mount

it), and the

key "Park" release cable and the forward-neutral-reverse switch into

the plate. Around the switch I put an aluminum shroud to make it simple

to shift to where you mean to shift and prevent accidental shifting.

I've had this shroud safety idea in mind for well over two years, and

now it's finally taken form, albeit with some rough edges. I'm leaving

the cable in as another safety feature: to switch into or outof "Park"

(which now only allows the key to be removed and locks the steering),

you have to pull the cable. Takes two hands. I'll probably fancy it up

with a lever to pull the cable at some point.

A means for having to press on the brake to go from

neutral into "Drive" (forward or reverse) would be tricky, but I don't

think it's necessary since the car won't start to move until you press

on the electron pedal.

Of course, the parking brake becomes vital, since there's

no other way to lock the wheels.

On the 3rd, I fitted the speedometer gear to mesh with its

gear on the differential, using a short bit of angle iron as a mount. I

don't want to do an electric car and not know how fast it's going or

how far it's gone! I wonder if it should have an oil drip too, seeing

the gear teeth and the bushing are no longer running in an oil bath. It

does turn slowly - perhaps grease would do.

On the 4th I fit an axle mounting for the small sprocket

and the torque converter drum -- a cut-down trailer wheel bearing hub

from an early motor. This required making another large hole in the

mounting plate, which I tackled with the same technique as the

differential bearing holes. On seeing how it all fit, I saw I'd have to

cut new slots for adjusting that side, do a new axle to fit... and move

the speedometer gear.

The next day I found a slightly better bearing hub and fit

it, and cleaned up some details, including cutting an axle rod,

extending the slots and moving the speedometer gear. All this stuff

takes a lot of time when things aren't ready made for you. It's one

thing after another, one little job at a time (inevitably taking much

longer than anticipated), all adding up.

On the 6th I got chain and fitted it in. It turned out

that the bulk chain was the long-lasting sealed chain. Cranking the

unit around by hand showed that all those little rubber seals on the

links really do give it a lot of resistance to turning. I suspect it'll

reduce efficiency enough to show up clearly in reduced performance and

mileage. I'll definitely try out some other chain as well once things

are working, to compare and see if that's the case.

I took the unit in to see how long the chain needed to be,

and the merchant at Victoria Motorcycles offered to redo my amateur

welding free. His good TIG welder could do a much better job, just to

help out. True, I would

hate to have the welding fail on the road, but I didn't think it would,

and this being the main unit

that everything else fitted onto, I couldn't give it to him without

stopping work myself.

In the next couple of days I made some brackets and bits and

fit the unit onto the original engine and transmission mounts, and I

cut a keyway into the shaft. I'd been told I could do this properly

with an end mill using the drill in my CNC machine. But someone else

said the mills should only be used in a collet chuck, not a drill

chuck, and anyway Western Equipment was out of 1/4" end mills. Instead

I

bought a '1/4" lathe tool', which was the square shaft key I

wanted... but made of tool steel with sharp beveled edges on the ends.

I roughed out the keyway slot with the angle grinder, then used a

hammer and the 'lathe tool' to finish gouging out the inside corners of

the slot. This, plus the close fit in the sprocket gear and in the

torque converter drum hub, gave the desirable close machined fit,

albeit with some rounded outer corners on the shaft. On the 9th, I

tried out the assembly in the car. It was a bit too far to port - the

inner CV boot end fitting slipped off its place on the starbord CV

shaft when I put it in. Later I moved one bolt hole that positioned the

rear

end 1/2" over and the shafts seemed to fit okay.

In the next couple of days I made some brackets and bits and

fit the unit onto the original engine and transmission mounts, and I

cut a keyway into the shaft. I'd been told I could do this properly

with an end mill using the drill in my CNC machine. But someone else

said the mills should only be used in a collet chuck, not a drill

chuck, and anyway Western Equipment was out of 1/4" end mills. Instead

I

bought a '1/4" lathe tool', which was the square shaft key I

wanted... but made of tool steel with sharp beveled edges on the ends.

I roughed out the keyway slot with the angle grinder, then used a

hammer and the 'lathe tool' to finish gouging out the inside corners of

the slot. This, plus the close fit in the sprocket gear and in the

torque converter drum hub, gave the desirable close machined fit,

albeit with some rounded outer corners on the shaft. On the 9th, I

tried out the assembly in the car. It was a bit too far to port - the

inner CV boot end fitting slipped off its place on the starbord CV

shaft when I put it in. Later I moved one bolt hole that positioned the

rear

end 1/2" over and the shafts seemed to fit okay.

I tried moving the car by turning the

torque converter output drum. It was easy enough on level lawn, but

slight hills were much harder, and I couldn't get it to go forward

(uphill) from its little depression at all. The torque converter is

definitely going to have to perform in order to drive the car readily

across the lawn! 4x motor torque out (for a total reduction of

16x) may

be minimal.

There was nothing to attach the torque wrench to so I

couldn't get actual figures of the forces needed. It would be nice to

rig something up.

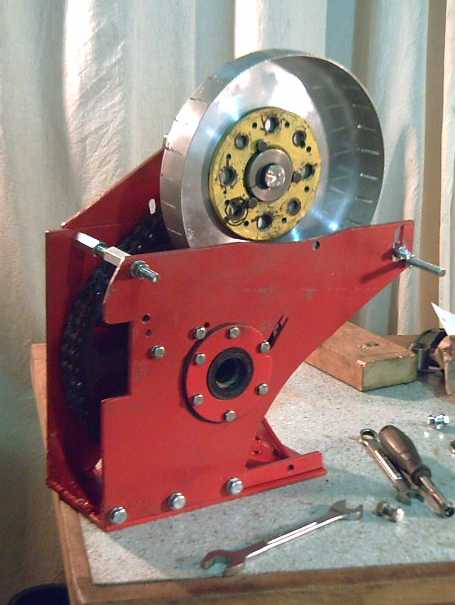

On the 16th and 17th, after having done

little on the car conversion

for over a week, I galvanized and painted the drivetrain unit using the

"ersatz powder coating" technique I developed (TE News #41). Looking at

the main piece before zinc spraying it, I finally decided I should take

Jim up on his offer to re-weld it before I did it. Jim was only

marginally happy with his welding, but it looked great to me. It was

1000% better than mine. I had interesting conversation with Jim and his

next door neighbor, who had been involved with the original development

of gas concentrating solar collector tubes for hot water. He was doing

lovely rockwork landscaping in his large back yard. Jim was also very

creative with machinery, and together they had made a big wire tumbler

for sifting soil. The soil came out underneath, and it dumped the rocks

and roots out the far end.

The next

day I tested the repaired motor controller (it worked great) and

promptly damaged the motor by over-revving it. The car won't go

anywhere until the motor is repaired or a new one made.

Not wanting to tackle it the next day, I just did a bit of

wiring in the car. I wired the forward-neutral-reverse switch, ran the

cable from the console out to under the hood for the controller, and

one from the "electron pedal" to the console. I used rubber 3-pin

trailer light plugs for the pedal and the switch, since they're

reliable and automotive. I decided none of the controls would be

soldered onto the main cable to the motor controller - it would all be

plug-in.

4runner Truck Conversion Thought

It occurs to me that keeping the original differential was the right

thing to do on the Sprint, and it will probably also be the right way

to do the

truck with the big Weel motor. That'll make the truck a front wheel

drive with both wheels driven, and all that heavy 4 wheel drive

transmission stuff can be eliminated except of course the rear axle.

(The Weel motor should have 9x the torque of the Hubcap

motor, but it won't fit under the Sprint's hood.)

Nickel - Metal hydride Battery Project

12 volt, 10 amp-hour, D cell

Handy Battery

Sticks (~26" long, 1900g): $105

12 volt, 10 amp-hour, D cell

Quintos Battery

Sticks (~7" long, 2200g): $120

6 volt, 10 amp-hour, D cell

Battery Sticks (~14" long, 1045g): $55

12 volt, 2/6 amp NiMH charger (adjusted for NiMH): $60

What's with Prices?

Canadian Tire had a NiMH cordless drill on sale for 35$.

It was 18 volts, 3 amp-hours, which is 54 watt-hours. It works out to

only about 25% more than I'm paying per watt-hour for D cells. I guess

they're throwing the drill in for free! Furthermore, I found a retail

price on line for that drill's battery alone: 78.46 $. Go figure!

Simple NiMH Constant Voltage Battery Chargers!

I've written (plenty) about how 1.38 volts per cell or

13.8 volts for a 12 volt battery is an ideal constant voltage to charge

NiMH batteries at. It's not the fastest way to finish the charging to

100%, but if there's no big hurry it doubtless puts the least stress on

the cells,

maximizing their cycle life. It seems ideal for the car, scooters,

solar, and

any batteries that are normally left on charge for long periods. But

the thought of producing such a charger for sale with the batteries

seemed rather daunting.

In Quealle Electronics on the 11th, Fred pointed out as I

considered LED power sources that the newer switching power adapters

are an exact voltage (±5%), unlike the

older very approximate ones (a

fact that had only gradually been working its way into my brain while

doing LED lighting), and that quite high current models were available

(and in stock!) at 12.0 and 15.0 volts.

Lets see now... a 5 amp adapter at 15 volts, with a 1.2

volt drop from two diodes or a darlington transistor, is a 5 amp, 13.8

constant volts charger! There's my 'ideal' NiMH charger, and doubtless

cheaper than most any lead-acid charger!

And the 12 volt models... there was an off the shelf

component for the line side of the "LED lighting grid tie"! (Per my

plan in TE News

#43)

After thinking about

it, I went to Quealles and bought a 15 volt adapter, 1.3 amps. To

charge the car

I'd want three 15 volters (and one 7.5 if using 42 volts) in as high a

current rating as

was available... I thought they'd still be much cheaper than chargers

intended for lead-acid, but the price did go up with amps.

I used a diode bridge for the two diodes. It

seemed to drop about 1.5 volts instead of 1.2, but the power adapter

was about .2 volts high anyway. I tried to charge a 12 battery stick

that was quite low - down to 11 volts. (I drained it for several hours

on an LED light.) The battery wanted more current than 1.3 amps, and

the power adapter pulsed on and off, not doing a lot of charging. I put

a one ohm resistor in series to limit the current. That did the trick!

The battery charged up overnight. It seems like a good arrangement. As

the battery voltage

rises, the current drops and the resistor drops less and less voltage

until it is trivial. It does slow charging somewhat, especially when

currents are high... but then that's what it's for.

Higher current supplies would handle lower value

resistors, perhaps 1/4 ohm for a 5 amp adapter. All assuming the

batteries aren't even flatter than the one I tried - to handle really

dead ones they might possibly need higher values. But I'll go with this

for now. The one I've got will charge the odd battery stick if the sun

isn't shining on the solar collector (which does over 3 amps). It seems

I've found a simple way to constant-voltage charge my electric

car batteries and any scooter/e-bike batteries I sell.

Later someone sent me a foto of some 12 volt, 5 amp power

adapters at XS Cargo for 3.99$! (Taken with his phone/GPS/...) I went

down and bought ten. It turned out they had a cigarette lighter socket

for an output. No matter - that can be changed! (Maybe APP 30 amp

connectors from Queale Electronics.) They open, and I have little doubt

I'll find a 12 volt reference part inside that I can change to 13.8.

Then three could charge the three banks of 12v batteries for the

electric Sprint - or even two or three trios in parallel. That's sure a

cheap setup to charge 36 volt batteries at 5, 10 or 15 amps!

LED Lighting Project

"Standard" 6 inch globe fixture

LED Lighting Fixtures are now For Sale - from $80 ($62 without

wall power adapter)

I've put several LED ceiling/wall light fixtures in the

Turquoise Energy Products Catalog, with options for brightness and form

from parts I have or have on order. At up to 1800 lumens they're about

the brightest LED lighting around, and the 90 lumens per watt ones

must be the most efficient lighting available, far surpassing minimum

"Energy Star" requirements. (I also have a

limited selection of

automotive LED lights for local consumption.)

www.TurquoiseEnergy.com/TEcatalog/

=> 6. LED Lighting Products

It seems the cooler the LED runs, the brighter it is, and

the longer it will take to dull. As well as using lower currents and

external power adapters (with their heat outside the fixture), I'm

maximizing the efficacy of the heatsinks in these fixtures, using the

roofing flashing fanned fins construction I

developed for the motor controllers. It seems the ambient air

temperature also plays a big part, so good ventilation is also a

feature. In what I've measured so far, air temperature has been below

50ºc and the heatsinks at the LED below 70ºc. Under those

conditions, projected life before dulling to 70% of the original

brightness is around 100000 hours - over 11 years of running time; 80

years if run 3 hours a day.

(source: Cree LED manufacturer graphs)

The external power adapter

plugs into the original light

socket via a screw-in receptacle.

Reasons to use LED lighting

1. White LED lighting isn't sunlight, but it's the whitest artificial

light available with a broader, more even spectrum than any other type.

With similar light levels, you'll help your eyes, and potentially save

your

kids from needing glasses.

2. Save money. LED lighting is costly up front, but it pays for itself

in electricity savings within a few years - at best within a

year. The electricity saved helps the environment.

Reasons to use Turquoise Energy LED lighting

1. It's the brightest LED lighting around. Most of what's available

isn't really bright enough to replace common lightbulbs.

2. It's diffused into a white, even glow. Too many LED lights have

intense pinpoints of light

that leave spots in front of the eyes. This may in fact be a long term

visual health hazard, and some LED emitters are bright enough in the

blue spectrum to cause retinal damage if viewed directly from close

range.

3. It's the most efficient - more light for less watts gives the

biggest electricity savings. At

10¢/KWH, a 100 watt, 1600 lumen bulb uses 88$ of electricity if

left on for one year. The 15 watt, 1400 lumen LEDF5 fixture or lamp

uses 12$. And it looks brighter - visually, the 11 watt (9$/yr), 1050

lumen LEDF3 is a closer match for the 100 watt bulb than the LEDF5. A

26 watt compact

fluorescent (which seems dimmer than either) is 22$/yr, and other

typical

LED lights are perhaps around 15-20$.

4. It doesn't flicker. Many bulbs don't have room internally for a

proper filter capacitor and go on and off at 60 Hz. TE fixtures use

regulated switching plug-in power adapters or internal filter

capacitors to smooth out the DC power.

600 lumen, 9.5 watt Lights of America bulb (left) versus

Turquoise Energy 1050 lumen, 11 watt LEDL3 lamp with plastic jar

diffuser,

with identical lamp shades on both.

800 Lumen, 12.5 watt Phillips bulb (left) versus the LEDL3 lamp.

The LEDL3 is brighter on the left because its light is somewhat aimed,

and it's pointing to the left, away from the wall (and in this case,

mirror).

A friend had bought two of the best screw-in 120V LED

bulbs

presently available. I took the 3-emitter LED lamp and (in his only

dark room, the bathroom) we compared it with his bulbs, with the same

lampshades. It seems these

commercial bulbs don't flicker like

some do. (The other bulbs seem

brighter compared to mine in the fotos than they did in life... or was

I just prejudiced?) I prefer the "cool white" to the orangey "warm

white". I

think we're just so used to orangey incandescent lights - and perhaps

instinctively know we're bothered by whiter fluorescent lights - that a

"friendly" whiter

light seems strange at first.

How much electricity is going to be saved?

According to an LED lighting web site, 3.7 terrawatt hours

of electricity (presumably worldwide) was saved in 2010 by LED

lighting. That's getting up towards the whole output of BC's planned

Site C Dam.

And LED lighting hadn't replaced very much other lighting yet - it's

just the beginning.

BC Hydro Rebates on LED Lights! - Nope. - Maybe.

One day I remarked to a friend that if BC wanted to get

serious about saving electricity, it would encourage LED lighting

manufacture with the "Innovative" Clean Energy fund, or have BC Hydro

subsidize LED lighting products or production. The very next day he

showed

me a flier he was looking at, in

which very substantial BC Hydro rebates were available on LED light

bulbs.

I thought "Hmm, I'm making much better LED lighting

products than those, but they're expensive.

Surely they would qualify for the program." So, after some difficulties

trying to navigate the BC Hydro web site or contact anyone who knew

anything, I wrote (twice) to ask if there was an application form.

The information was utterly discouraging. I found that

having better, more efficient products than anyone else evidently

wasn't good enough. They wanted references

from five previous corporate customers, I had to offer a full

range of lighting, not just LED, and a 2,000,000 $ liability insurance

policy with BC Hydro as a beneficiary would be required. If I could

miraculously meet or get around the first two requirements, It seemed

likely to me that if any insurance company would even touch something

like this, it would be at a premium I'd never recover in sales. I put

BC Hydro approval out of consideration.

Then I got another e-mail from another person, answering

my previously

unanswered first e-mail of the previous week that I'd given up on,

saying if the lights got "Energy

Star" approval, they'd be listed on the

BC Hydro website. The first person to reply hadn't mentioned that vital

detail. After some confusion about the requirements I found out that

"Energy Star" wasn't part of BC Hydro and they sent me a link to it.

They should easily surpass Energy Star requirements and

I'll be making submissions. Thus prospects seem good of at least

getting

them listed at BC Hydro. Whether or not that means the customer can get

the rebates I'm not sure at this point... Probably. It would sure help!

"Standard" Ceiling Fixture

I decided I'd

better make exactly what I wanted

to sell and have it on hand. Lamps are great, but I also wanted

installed light fixtures. I

thought I'd put together a couple of 6" globe ceiling lights before

breakfast on

I decided I'd

better make exactly what I wanted

to sell and have it on hand. Lamps are great, but I also wanted

installed light fixtures. I

thought I'd put together a couple of 6" globe ceiling lights before

breakfast on

Thanksgiving day - and not install at least one, to have

as a portable sample. By 4 o'clock I had one done, after various small

problems, breakfast, lunch, etc, and the other was ready to wire.

What goes inside the light is somewhat flexible. This

light was 7 watts (~.8 amps at 9.0 volts), but the AC amp probe said

.11 amps going in at 120 volts, which is 13 watts. Not very efficient

for a switching type power adapter - and it does indeed run warm. The

emitters themselves weren't

much better - the lamp runs much warmer than those with the Cree

emitters. I drilled some extra ventilation holes. These were the

same LEDs as I used in the first light in the upstairs hall (ceiling

now filled and painted), and I've never opened that globe up to check

the temperature. It stands to reason, however, that if one LED converts

75% of the energy to photons, and another converts only 50%, the second

one will generate twice as much heat as the first. I got seven of these

warmer-running emitters, but I

probably won't get any more.

I'm almost out of emitters, but the friend with the bulbs

spotted a 12 volt emitter that seems a good deal amongst the high

brightness ones at

DealExtreme.com , and I ordered some. Three of them should make a good

1600+ lumen light. Lumens per watt is an important measure of

efficiency

-- lumens per dollar is an important measure of economy.

I made a couple of drill templates (so far: for 6" globes

and 7" low profile mushrooms) for the heatsinks. Those'll do for

occasional orders. If I actually get quantity orders I should set the

CNC

machine to drill the holes. Hopefully

I should be able to get the rebates, and the time and the parts cost

down, so it

all becomes worthwhile to make them and sufficiently economical for

customers.

I also have a plan for a CNC machine addition to hold and

rotate the plastic fixture caps so their holes can be automatically

drilled. Evenly spaced vent holes would look better even for single

unit orders.

LED Car Lights

I finally got around to doing the lights on the front half

of the Tercel - the car is now LEDs except the headlights. You'd think

a 5" x 7" standard halogen headlight would be about the easiest thing

to find of all, but I haven't seen one yet (except for a horrendous

price), and I have yet to see a

plastic 5" x 7" one I could cut the center out of. And I sold the 450

lumen, 12

volt bulbs I was going to try with that idea, to someone living

off-grid with 12 volt power. I've ordered more. The Sprint should be

easier as the bulbs are separate from the fixture.

The one hitch in the proceedings was the front turn signal

lights.

The LED 'bulbs' had a PC board projecting outwards, right above the

socket, and the sockets had a restriction there. They wouldn't quite go

in. So I tried the ones I'd put in the rear, and they fit. I put the

ones from the rear in the front, and the new ones in the rear, where

they did fit without trouble. Now I know which type to reorder of two

quite similar bulbs.

I also found which model of small bulb spreads the light

which way. One is better one place, the other seems better in the

other. Both are quite passable, and cheap.

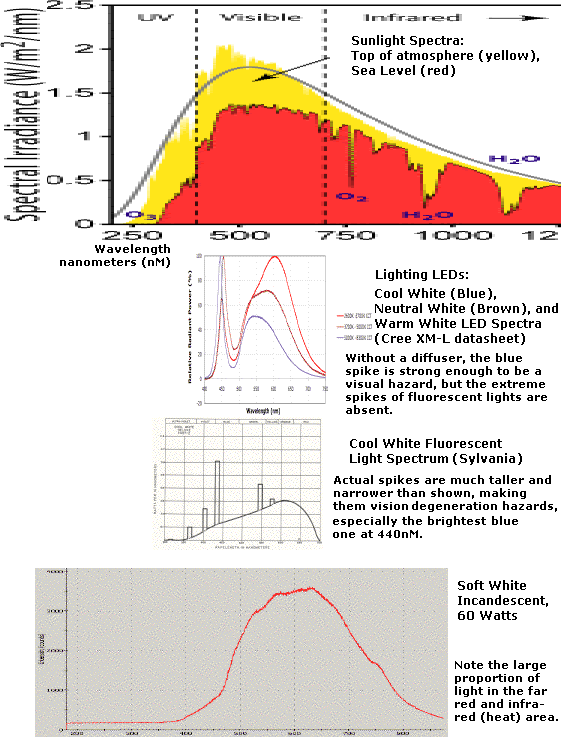

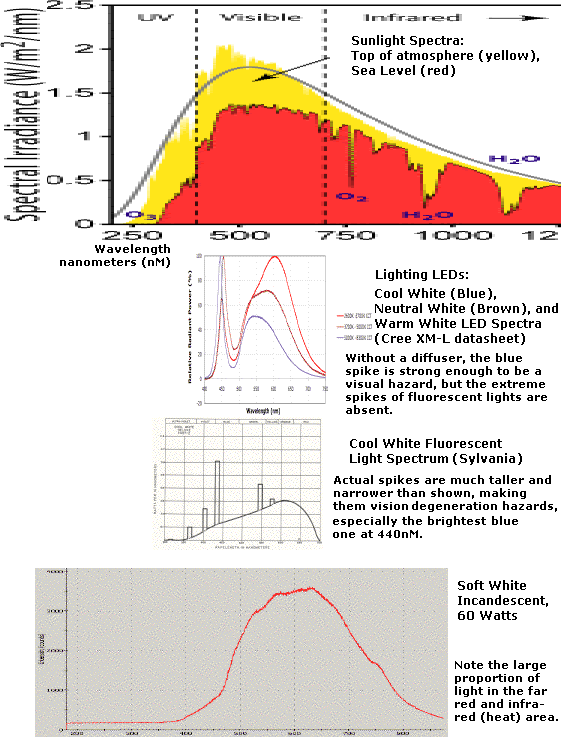

What's White in Light?

Looking at a spectrum of a "cool white" LED emitter, I had

the thought to check it against other spectra rather than just to

assume the the ideal was a straight horizontal line. Ordinary sunlight

is perhaps the ideal - kids who

get out in the sun an extra hour a day or more are less likely to end

up wearing glasses (and are less prone to getting cancer because

they're getting more vitamin D).

But sunlight isn't entirely a straight line spectrum even in the

visible range.

All the lights look

different than sunlight. The violet and blue end of the spectrum is

missing in the incandescent. Evidently all fluorescents have a nasty

big blue spike right at 440 nM (mercury vapour) and some other spikes.

(Cool white fluorescent has been banned in some jurisdictions,

especially in school classrooms.) Then the main range tends towards

reddishness.

LED lighting is of course quite new. It doesn't have

fluorescent's spikes. Ultra-violet and violet are missing, then the

blue of the actual emitter is prominent. But then it's weaker in the

cyan from around 475 to over 500 nM. Above that, the phosphor gives a

broad band, then the far red end is very weak.

But I tried looking at some reddish objects under an

incandescent and an LED light. One in particular, a tab of the colour

from a magenta toner cartridge box, looked rather brownish under LED

and brighter red under the tungsten. Aha? However, the next day I found

it looked brownish in daylight - even here the LED was the truer colour.

I ordered a few coloured emitters (red, green, blue) to

experiment with, to try and fill in weaker bands and see how I like the

light. However, those seem to be colors already well covered by the

white. An indigo (far red) emitter (eg, 675 to 725 nM) might make it

extra pleasing, and perhaps with a cyan at 500 nM the spectrum would be

very even through the visible range except in the far violet. I see a

cyan emitter listed at Cree in the XLamp7090XR series, but not indigo.

I also didn't see the cyan at DealExtreme.com, so I'd have to track

them down.

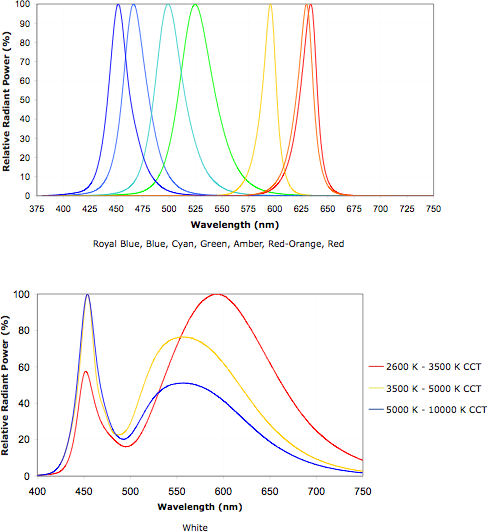

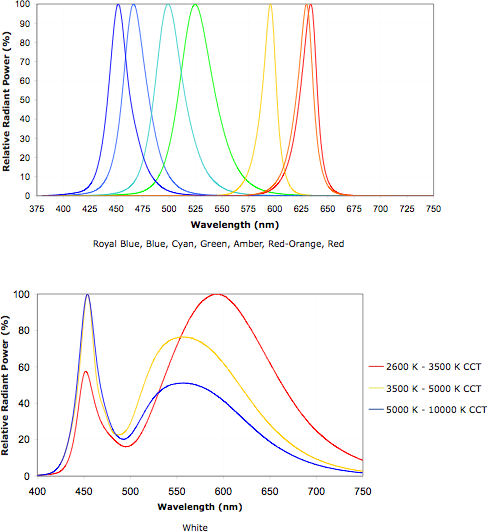

Some coloured and white LED emitter spectra

But I must say that it appears any improvements would be

minor. White LEDs through a white diffuser are the most even, whitest

artificial light available. An incandescent light now seems a touch

drab and orangey to me beside a good LED one, even if it does activate

my solar powered calculator from about the same distance.

Turquoise Battery Project

I gave up on the first permanganate/nickel - zinc cell.

The

case was all cracked up, and it wasn't performing or improving. I

decided to re-use a previous case, which was in good condition, and

dug out the electrodes. On something of a whim, I decided

to try out the vanadium electrode from that case (which I extracted

mostly intact) with the zinc.

The culprits in poor conductivity

Trying to measure the resistance of the used vanadium

electrode, if it didn't read as being open or negative resistance, it

was

many kilohms. When I made it it measured around 50 ohms. Here may be a

good

clue

as to the poor conductivities: perhaps either with wetting or with

charging, or both, the positrode (or both electrodes) swells and the

conductivity

drops drasticly. Perhaps I need to put more graphite powder in these

electrodes to account for this, perhaps compaction is insufficient, or

perhaps there needs to be nowhere in the cell for it to expand to once

wetted. With dry cells there's

nowhere for the compacted powder to expand to, whereas I just have some

sponge rubber pushing the electrodes together. One or both can "fluff

up" if they want to, inevitably losing their good conductivity. This

would indicate that I should modify my construction.

Measurement of the nickel/permanganate electrode disclosed

that it was megohms from the surface of the electrode to the terminal

post. That must be the reason for the poor cell performance.

Measurements from one spot on the electrode to another varied wildly

(as usual), from ones of kilohms to megohms. The nickel negative,

however, still had very low resistance, tens of ohms. (As it was

removed from the cell, measurement to the separated post wasn't useful.)

Evidently the positrode is the problem, but in this case

much worse owing to poor connection to the post rather than just

swelling.

This was the electrode where I'd coated the surface of the plexiglass

with grafpoxy, then pressed the post in from the outside and the

graphite sheet onto it on the inside, expecting great conductivity,

which it had when made. If I pressed on the electrode where the post

was, resistance would drop to about 1K ohm. Evidently something has

delaminated - so this aspect of the construction also needs to be

modified.

Later I did more checks on the vanadium. I pounded it with

a hammer to try to "un-fluff" it. It didn't seem very fluffy. I found

that the new meter was giving pretty weird results, and the

conductivity within the electrode probably wasn't as high as it seemed.

Then I found that like the other one, the resistance to the terminal

post was high, tho not as bad.

V-Zn cell (~~2.3 volts)

Notwithstanding the high readings on the vanadium, the

cell performed far better than the previous one, and on a par with

previous best results. 25x better? Another 50x again and it would be a

real battery.

Open circuit V-Zn cell voltage was around 2.3 volts.

It's hard to be exact as it still had high self discharge and dropped

from 2.4 to 2.25 over a few minutes while I watched. Less Sunlight

dishsoap in the positive next time, and none in the negative!

Grafpoxy 'plating' of metal electrode structures

Another idea struck me as to electrode construction: if a copper or

other metal grille were simply coated with graphite-epoxy, would it not

be immune to the electrolyte? The part of the terminal inside the case

would also be coated, and of course the opening sealed. This might

provide a better electrode collector and terminal post, of simpler

construction. It could be to a salt electrolyte cell what nickel

plating is to alkaline cells. This construction would count on the

'grafpoxy' being completely impervious to the electrolyte, and on

obtaining 100% coverage that didn't get scratched or abraded away at

any point. Epoxy is very sticky and tough, so for the moment, I'll

assume these conditions can be met and try it out. I've become

convinced this is the way to do it if it works.

Some Conclusions

By October 3rd, I figured I had a pretty good idea of

where the main problems lay. After running a discharge test that day

for seven hours, I remembered how running off to record the latest

battery every little while reading disrupted the process of working on

anything else. (An automated data logging system would be most

helpful!) So I decided to drop the battery experiments for a while and

work on other things.

I need some way of making cells that can hold the positive

electrodes compacted as well as hold pressure and not leak. Doubtless

better initial compaction is required. Probably metal structures coated

with grafpoxy can serve as electrode elements, which will simplify

things and - I trust - provide good conductivity.

I might end up with something like cylindrical cells with

wrapped up electrodes after all, as is done for NiCd and NiMH dry

cells. I'll pause and consider all this, and perhaps some

inspiration(s) will strike as to improved ways of achieving the several

goals. Or I can see making cylinder cells with coated grills and the

ingredients simply forced [pounded?] in like cheap dry cells. A 5" long