Turquoise

Energy Ltd. News #46

Victoria BC

Copyright 2011 Craig Carmichael - December 1st 2011

http://www.TurquoiseEnergy.com

= http://www.ElectricHubcap.com

= http://www.ElectricWeel.com

Month In Brief (Summaries)

* I'm to speak at Discover Tectoria

conference Dec 8th, about Electric Hubcap motor system

* In passing: Nuclear Industry Melting Down; Buying Police Loyalty;

Yet Another GM Dirty Trick

Electric Hubcap System

* Motor repairs (working again) & improvements to rotor compartment

* Polyurethane spray paint "crust" to keep ilmenite coil coatings from

flaking off.

* Motor controller: V2 boards, CRM = direct torque control, great

current

control during regen... but how??

* Cutting shaft keyway slots with a lathe - lathe as milling machine?

Electric Weel Motor - no report (I

did coat the coils with ilmenite. Very flaky, unfortunately.)

Mechanical Torque Converter Project

* New

design: Magnetic Impulse torque converter

- simple, robust, no wear, no internal moving parts!

* Combo magnetic/mechanical design offers higher torque

Sprint Car Conversion Project - no

report

* Working on components - see Electric Hubcap System, torque converter

and NiMH battery projects

New Electric Hubcap Outboard Project?

* An outboard from scratch might be just as easy as a conversion - and

better?

* Production kit version?

LED Lighting

Project

* Bright, cold white emitter fixtures: 1100 lumen/15W

* Electric bills continue lower than expected into winter (yay!)

* Energy Star partnership agreement form file format problems

NiMH Battery Project

* Ultimate Battery Stick? - 4" PVC pipe holds 7 sets of D cells... a 4"

x 25", 12V, 70 amp-hour battery

* Car(s): Musings about using combos of NiMH and lead-acid

Turquoise Battery Project

* Zinc powder?

* Zinc powder from zinc oxide

* Best quality zinc electrodes!

Newsletters

Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

-

Electric Hubcap Motor - Turquoise Motor

Controller - 36 Volt Electric

Fan-Heater

- Nanocrystalline glass to enhance Solar

Cell performance - Ersatz 'powder coating' home process for

protecting/painting metal

Products Catalog:

- Electric Hubcap Motor Kit

- Sodium Sulfate battery longevity/renewal

- NiMH Handy Battery Sticks, Dry Cells

- LED Lighting Products

Motor Building

Workshops

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

November in Brief

I'm to Speak at Discover Tectoria,

December 8th

Late Breaking News for local Victoria BC people: On

December 1st I was invited by phone to speak next Thursday (Dec. 8th)

at the all-day Discover Tectoria conference and trade show

[http://discovertectoria.com/], known in previous years as Island

Tech, on the Electric Hubcap motor system. I'm among

several speakers expected to speak for about 10 minutes each sometime

between 2 PM and 3 PM. I don't have all the details yet, but I'd like

to bring in a motor, controller, a couple of battery sticks and

C-clamps, and run it on a table as a demo and point out features.

Discover Tectoria will take place:

Thursday, December 8th at:

Crystal Garden

713 Douglas Street.

Victoria, B.C.

The entry fee to Discover Tectoria is $20, but

there are supposed to be some free entry coupons in the newspaper this

week.

The Month

In some ways,

the first half of November felt like one of those dreams where

you seem to be trapped in

slow motion and can't get anywhere. There were days when virtually

nothing seemed to move forward. On the other hand, I spent a lot of

time on the internet doing various promotions. Then from the 16th or

17th to about the 20th good things started coming together bang bang

bang. Then it went back into slow motion.

Everything in its

place... I

decided that on the Sprint conversion that the next thing to do was to

fix

the motor. In the process I'd also further the motor development: I'd

make

a mold to improve the rotor compartment rim. It's safer: not only much

thicker and tougher, but the attachment bolts won't be

exposed inside, to be hammered, and bent and ripped out by any

magnet(s) that

might potentially come loose. The last arrangement was too easily

damaged with potential for inflicting serious

injury.

By then

maybe the IR2133 motor controller V2 boards would arrive and I could

make the motor controller. With a working - improved - motor system

again, it would be

time to tackle the torque converter.

Considering installing the Sprint batteries, I came up

with the idea of Super Battery Sticks: a single 4" PVC drain

pipe, with 1-3 struts glued in for battery alignment, will hold

7 parallel strings of D cells, eg, 840 WH at 12 volts. And they'll only

weigh about 30 pounds, mostly the 70 D cells themselves. Three of

these would fit

where the car's radiator was for 36 volt, 2520 watt-hours and plenty of

amps,

for about 1400$ at the current cost of the cells.

And I'd see if I

could convert three of the ten 12.0 volt, 5 amp power adapters I got

(at XS Cargo for 3.99$ each) to 13.8 volts, to constant-voltage charge

them.

It would be even cooler to put three 65 watt solar

collectors on the roof, regulate them to 13.8 volts, and not even have

to plug the car in when I'm not doing a lot of driving -- but that'll

have to await some time when I have money.

For a couple of days

I considered that maybe I should do

some contract work for someone to earn some money. I was thinking

something short term, part-time, but I knew it was more likely either

to come to naught or grow into a lengthy commitment that would pretty

much displace the inventing. Personally I consider the

work I'm doing to be more valuable to all than anything I could do

for some one concern, but it would be nice not to have to wonder how

far

into debt I'll be this year before I get the annual pittance

next spring or summer that society will actually give inventors to work

on new

things, or wonder about how to do increasingly urgent repairs on a low

budget, such as

going up on my high, 45º roof myself to replace "30 year" shingles

that are falling apart and blowing off after only 18.

On the 17th, the day I (finally) finished the rotor

compartment rim mold, I thought up a Magnetic Impulse Torque

Converter. This is in principle a magnetic version of what I was

planning to make mechanically, with supermagnets tugging at aluminum

'spokes' or 'arms' for only a short part of each rotation. It's an

exciting design: no moving

parts, nothing touches anything else to wear out - it's simple and

looks easy to make! An experiment indicated the magnetic forces

strength should be in the right ballpark -- unless things saturated

electromagnetically somewhere below car moving force. I decided to make

one for the

Sprint instead of

finishing the mechanical one. But the torque increase wouldn't be all

that high, and by the end of the month, still before I was ready to

start working on it, I decided on several changes, and then to make it

a combo magnetic-mechanical one that would have more kick to it. I'm

keeping the pieces for the original mechanical converter design just in

case.

The Turquoise battery project seemed to devolve down to

looking for zinc powder. It's there on e-bay and other places, but

American sources don't want to ship it outside USA, and Canadian

sources don't return e-mails. I ended up grinding a little myself,

which was tedious, and then got onto the other things without making an

electrode.

I tried another type of LED emitter, making an 18 watt,

1100 lumen fixture. These ones are 'cold white', which looks rather

bluish. They'll be about the cheapest per lumen price-wise. They're

also 12 volts, so no matter how many emitters I use in a fixture, it

will be that voltage with no need for 6V, 9V or other power adapters. I

may do these, and nothing but four-emitter Cree fixtures (3V each), and

use 12 volts exclusively. Only on the last day of the month, after a

couple of weeks of hassles with some new PDF file format that my older

computer and software wouldn't handle, did I get the Energy Star

Partnership application form off in the mail to begin the process

of obtaining Energy Star ratings and BC Hydro rebates for

potential LED

light fixture customers.

In passing: Nuclear Industry Melting Down; Buying Police Loyalty;

Yet Another GM Dirty Trick

Switzerland is next to eliminate their potentially

devastating ticking time bombs - they've legislated shutdowns from 2019

to 2034 to bring nuclear power generation to an end in that country.

(Now there's a country that could well string windplants like cable

cars between mountains!)

Michael Moore spoke on RT Times - I watched it on youtube.

He said he was setting up

cameras and (IIRC) crime scene tape in front of the bank (a week before

"Occupy Wall Street") to

do a piece on it, when a police officer came up. Michael tried to

tell him they were just shooting for a sci-fi, but the officer wasn't

fooled. He said,

"Go right ahead Michael, they've taken our pension fund too."

Evidently recognizing they'd committed one crime too many,

"the 1%" made a big "gift" to the NYC police dept. When an outraged

public is howling at your door - or occupying Wall street - it's best

not to have the police on the wrong side.

On the 25th I met a retired mechanic who had worked at GM

car dealerships up island in the 1960s-1970s. He told me that one day a

customer brought a brand new car back in, saying the gas gauge wasn't

working, because it still said "full" after driving 250 miles. He

looked under the hood, and where the carburetor usually was was a big

carburetor or something (he motioned over a foot or more square or in

diameter) with all kinds of hoses and connections. They phoned the

factory to find out more about it. Someone flew out from the factory

all the way to Vancouver Island that same day, removed the unusual

carburetor and took it away after installing the regular one.

There was nothing wrong with the gas gauge - the car had just used far

less fuel than usual. It was one of many demonstrations that answers

are all around us, but are being witheld. Needless to say, the new,

super economical

carburetor never made its debut in production cars. This disproves

GM's story that it wants complex cars that need lots of servicing

because that's its "business model". This carburetor was more complex

than the regular one, not less, so according to their own humbug

excuse, it should have been favored. In reality of course the same

gangster families control GM and the oil companies, and maximizing oil

consumption was and still is their goal - contrary to all interests but

their own lust to wrest the money from other peoples' pockets.

The active undermining and sabotage of every

transportation energy economy and alternative has held up vital

technology for a century now and is one of the major forces gradually

ripping civilization apart. It seems obvious to me that natural

resources should be owned by the public and administered on its behalf

by the government or

by a public trust, not owned by private interests for monopolistic

profit at the public's expense. That step and philosophy would get

things under public control, and I think we'd find that would get us

switching off oil - in years, not decades.

I think as the population levels off and competition for

land, housing and goods diminishes, as supplies become sustainably

adequate to the

demand, we have what we need to all be well-to-do with about 4 or 5

hours toil a day. Presently we can't achieve it because of the grossly

inequitable and rapidly worsening distribution of the wealth. That too

should be greatly improved by public ownership of natural resources.

Electric Hubcap Motor System

Motor Renewal and Improvement

On the 6th I repaired the magnet rotor. I made sure there was plenty of

epoxy and that the polypropylene strapping was well stuck down,

including brushing more epoxy onto the remaining seven magnets and the

material around them along with the five that came off like bullets.

It will likely withstand the RPMs that 42 volts can give

it

now, but I think I'll stick to 36 volts unless I find that has

insufficient

power in an actual use. Besides, it's easier charging three identical

12 volt

sections without an extra 6 volt section thrown in.

I was surprised in October's motor failure that the

outside rim of the magnet rotor had ripped open. In the second week of

the month, I started putting together a mold to make molded rims for

the rotor compartments. The molded rims are sturdier because of

thick, solidly molded walls. They're also safer because the wall

encloses the bolts that hold the rotor compartment to the stator, so

even in the event of a rotor failure, loose magnets won't hammer the

bolts to bend them and pry them loose from the stator plate. As one

more bonus, the compartment will be 1/4" thicker, 1.75" inside, and

things will fit more easily. I couldn't readily do that using the PP

strapping

because it only came 1.5" or 2" wide.

The mold has several pieces. Some of them had to be

machined, and what with forgetfully trying to shop for polyethylene on

Rememberance Day and other things (house and porch repairs), it wasn't

ready until the 17th.

The next day I

'retrofitted' an existing rotor cover with

a new rim in the mold. It was tedious, but it was virtually a snap-on

fit onto a stator center ring. Great! It couldn't shift sideways a bit

and line the shaft up slightly crooked like before. It's now pretty

much "well done"

to sell in kits, where it had been a bit "cludjy" before. That didn't

mean it didn't need a bit of touch-up as there were spots of dry

polypropylene here and there. That should happen less for a new rim

than with stuffing cloth in thin spaces beside an existing thinner one

- and the work will go faster. The outside wall couldn't be filled much

and mostly looked the same as before.

The next day I

'retrofitted' an existing rotor cover with

a new rim in the mold. It was tedious, but it was virtually a snap-on

fit onto a stator center ring. Great! It couldn't shift sideways a bit

and line the shaft up slightly crooked like before. It's now pretty

much "well done"

to sell in kits, where it had been a bit "cludjy" before. That didn't

mean it didn't need a bit of touch-up as there were spots of dry

polypropylene here and there. That should happen less for a new rim

than with stuffing cloth in thin spaces beside an existing thinner one

- and the work will go faster. The outside wall couldn't be filled much

and mostly looked the same as before.

I have the idea it'll take about 300 grams of epoxy resin

and 75 of PP cloth shreds to do a rim properly from scratch.

A minor remaining concern is the ragged top of the lip

that fits over the stator center plate. I sanded it down but there are

gaps. For the next one think I'll try getting a 1/8" thick piece of

polyethylene to stuff into the top of the mold around the edge, and

fill the mold well... in other words, mainly just improve my technique

and see how that works.

The thickened rotor compartment rim (before drilling bolt holes through

wall),

and the magnet rotor side of the center plate.

(Previous image shows stator side, with buttons to hold toroid core

coils in exact position.)

With various little things

like cutting a keyway slot in

the shaft, needing different length bolts, etc, it wasn't until the

29th I finally reassembled the motor, and it ran well the next morning

(after finding the coils were rotated one position from the sensors and

swapping phase wires).

I was surprised to find that it hit 1100 RPM with only a

12 volt supply. At 42 volts, that would be headed well up towards 4000

RPM instead of 2000. Yow! I'm starting to see why magnets might rip off

the

rotor. I think I'll take it apart and reduce the flux gap.

Cutting shaft keyway slots with a lathe - Lathe as milling machine

Uncertain about the long-term ability of the SDS

taper-lock shaft bushings not to move under conditions of high torques

and loads with vehicle vibration, and especially when the torque comes

in bursts, I decided it would be wise to install shaft keys. The SDS

bushings and the sprocket gear have keyway slots, but of course the 1"

round shaft, bought and then cut to length, is plain round.

In October(?) I ground a slot into a shaft for the torque

converter output and sprocket gear, and gouged it to final size with a

1/4" square "lathe tool", which itself became the final 1/4" square

key. But I wanted some way to do it properly, more easily, and

repeatably. I thought that properly, this needed to be done on a

milling machine with an end mill bit.

I hadn't even found

a 1/4" end mill on my

previous shopping trip looking for one. But in a "miscellaneous" can on

my own shelves I found

a genuine milling bit, that had

a 1/8" section and then a 1/4" section, bought cheap a few years ago at

a pawn shop to use just as

a

two-step "countersink" drill bit in wood. I cut off the 1/8" section

with the

angle grinder to

leave a 1/4" end mill. The end was a bit rough, but the sides would

mill.

I phoned my

friend

who I'd bought the CNC machine from - never having done any milling, I

wasn't sure of myself. The speed of the router was way too fast, but I

wondered about the drill, if the drill chuck would hold

it square properly. Instead he suggested gouging out the slot with the

lathe using the tailstock and a 1/4" square lathe tool. That sounded

hard to set up and tedious, but I walked into the shop as we were

talking. Looking at it, I suddenly realized how it might be done

"properly" on the lathe.

I phoned my

friend

who I'd bought the CNC machine from - never having done any milling, I

wasn't sure of myself. The speed of the router was way too fast, but I

wondered about the drill, if the drill chuck would hold

it square properly. Instead he suggested gouging out the slot with the

lathe using the tailstock and a 1/4" square lathe tool. That sounded

hard to set up and tedious, but I walked into the shop as we were

talking. Looking at it, I suddenly realized how it might be done

"properly" on the lathe.

I put the end mill bit into the main 3-jaw chuck on the

lathe spindle. This would hold it securely and turn it at a

(selectable) lower speed appropriate for milling. Then instead of a

tool, I put the shaft itself in the tool holder on the turret, square,

lengthwise front to back. I put a 1/8" flat piece of steel under it to

shim it up to line the center of the shaft up with the bit. Left-right

adjustment would set the depth of cut, and screwing the turret

backward-forward would mill along the shaft.

After trying a few things, I found it seemed best to start

at the end of the shaft and mill out the whole 1/8" depth at once. An

end mill that would plunge (drill) properly might use a different

technique, and cut a blind slot that a key can't slide out of. I had to

hammer a crimp into the slot to ensure that couldn't happen. Later I

managed to sharpen the ends. Tho the four flute ends weren't even, this

would allow the mill to drill in for blind slots.

So there's one more motor making thing I don't need to buy

more equipment to produce!

It occurs to me that one might contrive to affix a small

drill

press vise that adjusts X, Y position with two screws, sideways on the

lathe carriage facing the chuck. Parts could then be fed up, down,

forward and back. With the turret to move left and right, one would

essentially have a small, sideways oriented milling machine. I must

remember that in case I have a need for one... maybe to make an

injection mold for making battery cases or LED light fixture bases?

Motor Controller

The V2 circuit boards from iteadstudio.com didn't arrive

in November, unlike the fast turnaround from AP Circuits. The low price

makes

it worth a considerable wait: assuming they come. After a month I'm

getting nervous.

On a discussion list, it appeared other motor

controllers

take their time going from forward to reverse, and some were talking

about them failing during braking - so much the better for mine!

Someone wanted one with

fast directional response for a computer controlled unicycle, so mine

was of

interest.

It occurs to me that the "Current Ramp Modulation" (CRM)

control is also "direct torque control", since torque is directly

proportional to current.

On the instant reversal, I've been idly puzzling in my

head why the control potentiometer works properly when the motor is

braking. CRM works by sensing when the current has risen to the set

level. But when it's braking, the current is flowing backwards, into

the batteries. It never occurred to me it might not work when I was

testing it, but the sense voltage should be reversed, negative...

shouldn't it? Yet the control works reliably and smoothly, seemingly

about the same as going forward.

Mechanical Torque Converter Project

New design: Magnetic Impulse torque converter!

On the 17th (just after I finished the Hubcap motor's

rotor compartment rim mold) a friend came by and we talked about some

things... including the resistance of aluminum to magnetic fields and

the potential uses of that. As he drew a thick piece of aluminum across

the magnets on a rotor, feeling the resistance to the motion: Eureka! I

had the

flash of an idea that's surely been on the

fringes of my consciousness for ages.

As I considered, experimented and

calculated over the next day and some, it became evident that it should

indeed be practical -- it appears to be the ultimate torque converter

concept that I've been groping

around looking for for the last 2-1/2 years.

For a mechanical torque converter, I've been trying to

have something impart 'hits' of torque to an output rotor. (I had good

hopes for the latest design.) For a

magnetic one, I've been trying to have magnets interact with aluminum

rotors, other magnets and pivoting magnets. I found various problems

with magnetic "hits" with magnets on

magnets, and magnets on an aluminum rotor causes a steady drag

that never gets up to vehicle moving torque.

I've thought at times of various 'out there' ideas

like

incomplete-circle gears, so that

the motor can pick up momentum in the gaps, then impart that momentum

to the output in the areas where the teeth mesh. But if the mechanism

stops where the teeth

engage, the motor won't be able to start turning. That leads to adding

a centrifugal clutch. It all promised bizarre, complex mechanical units

that would (at best) wear out quickly. (It's how so much of our

technology is cobbled together...)

What finally hit me was the idea of having rotating

aluminum blocks rather than a complete round rotor. The rest

of

the rotation, the motor would spin freely and pick up speed. Since

aluminum isn't attracted to magnets, the arms would only be pulled

forward, just as the magnets passed by them. This gives the

"torque hits" of the mechanical designs, in a smooth magnetic form,

with no

moving parts except the rotors.

It can't be 100% efficient because the magnets do

slip

past the

arms, generating some heat. The higher the torque needed, the more the

heat. But I expect it would be very good overall. (It would be

really hard to make something half as lossy as a fluid torque

converter.)

The strength of the

interaction would vary directly with the relative speed between the

motor and

the output rotor. Since it drops

to nothing at zero speed, there's no force to prevent the motor from

starting

to turn. (Along with making the converter work, this goes a long way to

ensure against motor and controller burnouts.)

If (for example) the output had two opposite arms ending

in big blocks of aluminum, and there were magnets at opposite sides of

the

motor's rotor, the motor could freely pick up speed and momentum for

almost

180º of

rotation. If it tugged on the arms for about 2 inches of rim distance

as the magnets passed the aluminum block,

and then had 12 inches of free travel, it might potentially have about

6 to 1 torque increase.

The idea is amenable

to a number of different

configurations. First, it's reversible. Whether it's the arms or the

magnets that are driven, the coupling effect is the same. The driving

side needs some 'flywheel' inertia. On the motor side, this must be

added. Going the other way, the inertia is provided by the moving car

for regenerative braking.

Second, it can be done radially or axially. Flat magnet

surfaces naturally suggest axial configuration, but with a radial

layout

it might be easier to get a very small flux gap without danger of the

rotors hitting each other. And magnets on the inside of a rim aren't

likely to fly off it.

Then of course the number of arms, the weights, the unit

diameter, the width, the magnets and the interaction materials,

etcetera can all be adjusted.

All the parameters of

operation can be adjusted in various ways. If 6 to 1 isn't enough

torque increase, one could

increase the diameter. That would provide more free turning inches

before the arm and magnet met again, or in other words reduce the angle

where interaction occurred. It would also increase the torque by

putting the force farther from the axle. This ups the torque required

of the motor as well. Another way would be to have one arm and one

magnet instead of

two, so that the motor had a full rotation to speed up instead of half.

Still another way would be to use narrower magnets and aluminum pieces

that would effectively pass by and interact in one inch instead of two.

Then, the heavier

the motor rotors, the

less the motor would speed up and slow down in each rotation. At the

extreme of a weightless motor shaft, each interaction would just bring

the motor down to low speed without imparting momentum to the

output. Then it would speed right back up again. At the other extreme,

a heavy flywheel would impart energy to

the output while hardly slowing at all. It would of course be equally

difficult to regain the bit of lost speed. This is closer to what is

wanted, but how much weight is needed and desirable? The motor already

has a fairly heavy magnet rotor, but at high power this can be

accelerated and decelerated rather quickly. A heavy steel magnet drum

as the torque converter input would about double it - I'm going to try

that

as likely to be a good motor flywheel weight.

The amount of interaction

between the arms and the magnets

is important. If it's too strong compared to the motor torque, the

motor will again be dragged back down to low speed every half

rotation, and it won't be able to pick up good speed and store up

sufficient flywheel

energy between hits. If it's too weak, there might not be enough

interaction to

start the vehicle moving even with the motor running full speed. In

that case, the

motor wouldn't be working hard; it might spin rather freely. There has

to be

a happy medium somewhere. I think I want to see the vehicle start

moving at around 500-700 motor RPM on level ground and maybe 1200-1400

up a fair hill.

I'm not sure how much coupling is useful or

desirable. Reducing the interaction between arms and magnets is simple:

just increase the flux gap. Or use a smaller aluminum block on the end

of the arm.

This is what's needed if the motor just

can't get up much RPM even at a high 'throttle'.

But it seems more likely that even with a small flux gap,

there just won't be enough interaction at reasonable motor RPM. The

output

rotor doesn't get vehicle moving torque imparted to it. In that case,

other parameters need to be

varied.

Easiest, one can put more magnets at each position for

more magnetic poles, with bigger aluminum blocks. If the motor is still

over-revving without making enough output force, more arms and magnet

positions can be tried: four of each instead of two will double the

interaction strength, but will also only allow the motor 1/4 turn to

accelerate instead of 1/2 turn. All these steps reduce the maximum

torque

multiplication.

Another way is to increase the diameter - if the diameter

is doubled, so is the linear speed at the rim at the same RPM, doubling

the force. Of course, a new diameter means all new parts.

Finally there's putting multiple elements at each arm.

This would best be done with an axial configuration - interleaved

'fingers' of motor magnets and output rotor aluminum passing each

other. Two pieces of

aluminum,

one on each side of the magnet, would cause twice the interaction. If

even that fails, a second magnet and a third aluminum block will

further increase it. Any number

of magnet and aluminum 'fingers' can be added until either it works as

desired or the whole unit

becomes too wide

to fit where it's wanted. I don't expect it would require such extreme

proportions as to be impractical, but possibly it might need more space

than I've allowed for in the Sprint mechanism.

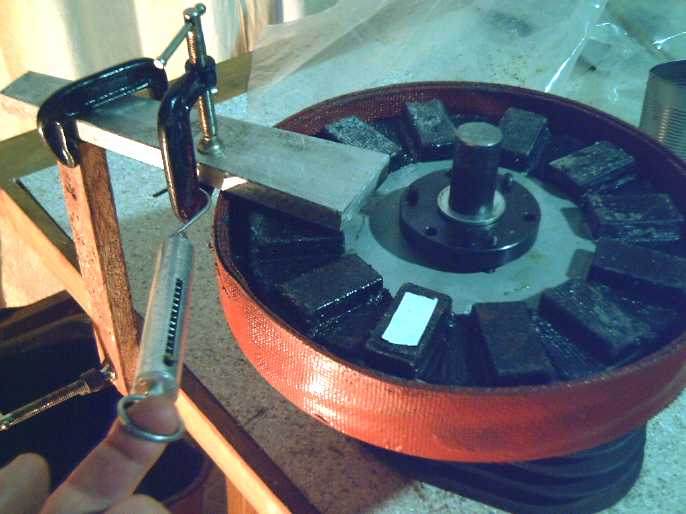

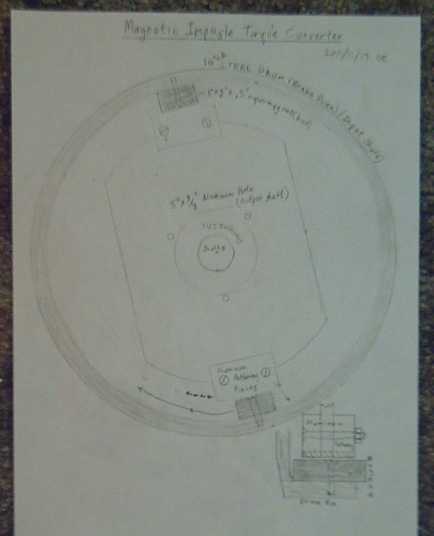

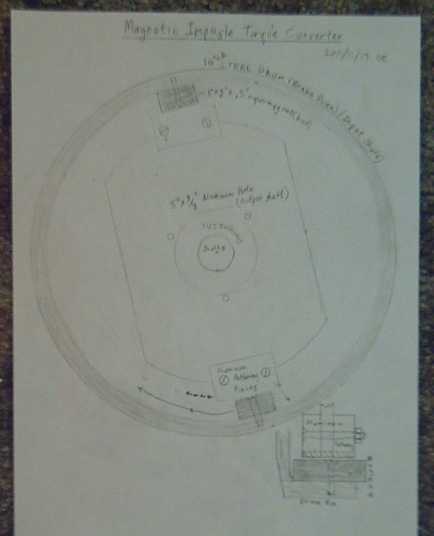

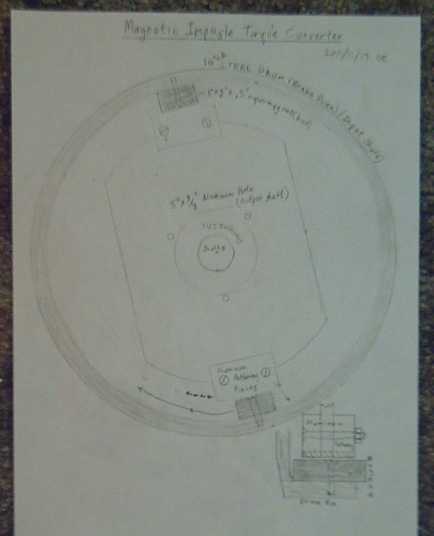

I did a drawing (below) using a radial flux design with a

brake drum rotor bought for a previous torque converter design that

will fit on an SDS bushing on the motor shaft, and a

piece of 5/16" x 5" aluminum bar for the output.

I wanted to do

experiments, and I was thinking of making

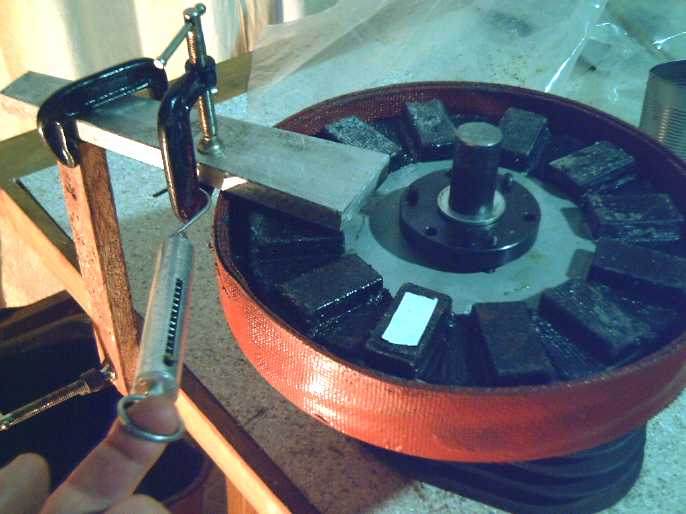

jigs for them, but I came up with a simple way to test the

interactions. I set up the motor's magnet rotor (the motor still being

disassembled) in its casing so it could spin on one bearing with the

magnet side facing up. I put a piece of white tape on one of the 12

magnets

so I could see when it had done one revolution. With C-clamps and a

piece of wood, I set up a fat bar of aluminum (.75" x [1" to 2.5"

tapered] x 10") to sit right over the magnets on the rotor. I used the

fish scale to measure the pull on the bar, and the noisy wall clock,

ticking off

seconds, to estimate 60 RPM - one rotation per tick. I spun the rotor

by hand at roughly that speed and measured the forces.

I wanted to do

experiments, and I was thinking of making

jigs for them, but I came up with a simple way to test the

interactions. I set up the motor's magnet rotor (the motor still being

disassembled) in its casing so it could spin on one bearing with the

magnet side facing up. I put a piece of white tape on one of the 12

magnets

so I could see when it had done one revolution. With C-clamps and a

piece of wood, I set up a fat bar of aluminum (.75" x [1" to 2.5"

tapered] x 10") to sit right over the magnets on the rotor. I used the

fish scale to measure the pull on the bar, and the noisy wall clock,

ticking off

seconds, to estimate 60 RPM - one rotation per tick. I spun the rotor

by hand at roughly that speed and measured the forces.

I found that for good effect, the aluminum bar had to span

about two magnets width (~2.5"), presumably to span the north-south

transitions for rapid magnetic field changes as it passed over. The

thin end of the somewhat wedge shaped bar, still an inch wide, caused

surprisingly little drag. This suggests that two magnets should be

placed in each position in the drum rather than one, and the aluminum

blocks need to extend a little farther around the arc than I'd

expected. And the smaller the flux gap, the more the drag - it needs to

be pretty small, eg, preferably .05" rather than .15".

With the thick (2.5") end of the bar and a smallish gap,

the pull was about 2 pounds. It didn't seem like much. But that would

be 20 pounds at 600 RPM, and if there are two sets pulling at opposite

sides of the rotors, 40 pounds - we'll just round that off to 39. The

intended radius being 4", 1/3 of a foot, that would be 13 foot-pounds.

13 foot-pounds times four with the chain reduction is 52 foot-pounds

torque to the wheels.

That's enough to move the Sprint on level ground -- the

torque wrench test indicated 30-40 would do it. At 1800

RPM - if the motor will deliver that speed under the load - the

calculated 156 foot pounds should overcome most any normal obstacle and

get the car moving.

The conclusion to the experiment is that the forces of

interaction appear to be in the right ballpark with the 10" steel rotor

on the motor if paired magnets, a somewhat larger block of aluminum

than expected, and the smallest flux gap that doesn't cause collisions,

are employed. Because copper is more conductive than aluminum (1.72*10-8

ohm-meters vs 2.82*10-8 Ω-m), switching to annealed copper

blocks should provide

282/172 = 1.64 times the forces.

Two conceivable problems could be (a) if there's some

electromagnetic saturation level that the interactions hit, preventing

the development of force beyond a certain point that's less than what's

needed with the intended components, or (b), if the flywheel effect is

insufficient and the motor gets slowed down considerably in the

interaction zone, limiting forces by reducing the effective speed in

the zone. However, I'm optimistic that neither of these conditions will

occur with the selected components up to the limits of the required

torque. Even if they do, it only means

up-sizing the converter and its active elements, and again I'm

confident that it wouldn't have to grow beyond a size that makes a

practical converter -- certainly smaller and lighter than a vehicle

transmission

even if it won't fit into the allocated space in the Sprint.

A third possible problem (c) could be that the torque

multiplication isn't high enough for the torque of the motor. It's not

overly high unless the interaction zone can be made thinner than I

expect. It seems workable but it's not overkill by any means.

Hmm... Where'd the image rez go? You were supposed to be able to read

this!

Outside, the 10" O.D. drum rotor rim with magnets, on shaft "A"

Inside, the aluminum 'rotor' and pieces, with a small flux gap to the

magnets, on

shaft "B"

About the 22rd I decided axial flux would be simpler. The

problem with radial is the the two shafts would have to be pretty much

perfectly concentric. I'd have to add a common bearing or

something to ensure that. With axial, approximate shaft alignment is

good

enough as long as the plates are parallel. I could use any one of the

rotors I'd had made for motor magnet

rotors.

I cleaned and torched one, sprayed it with zinc, heated it

to 225ºc to sinter the zinc (zinc melts at only 420ºc), and

then sprayed on a coat of polyurethane for a finish.

On the 23rd and 24th I started thinking about the limited

torque increase the converter would make. If I put 4 magnets on the

rotor in the usual places for a motor rotor, that would be 8 magnets

not installed, and thus, in simple terms, the motor would be free to

accelerate for 2/3 of its travel, for a 3 to 1 torque increase. It

would probably be better than that since the maximum force transfer is

only achieved where the magnets and arms are aligned, but I'd prefer to

see larger figures that would ensure the car can start moving even if

it has to climb out of a pothole or over a board or a rock.

I then started thinking of making the arms on the output

have a limited pivot angle, with springs, instead of being fixed. They

would pick up a speed and travel (with some slip) along with the

magnets on the input rotor, freely at first and then against increasing

spring pressure, which would be pushing the output rotor body and the

car. If

the torque increase required was higher than the maximum spring

pressure, they'd

reach the end of their travel and strike an end stop - perhaps a rubber

pad. Then either they would be brought to an abrupt

halt, or the rotor would turn from the sudden force of impact (moving

the car), or of course, part of each. After hitting and after the

magnets had passed, the arms would spring back to center, ready for

the next pass.

Then I considered whether or not, despite unbalanced

forces, to have a single set of elements instead of two - just one

position per rotation where force is developed. This gives the motor

almost a whole turn to regain its speed after imparting some torque to

the output.

After all the failures I've had, for the first tries I'd

rather have excess torque coming too seldom to give good street speed

than insufficient torque to move the car.

On the 28th I did another experiment with some

supermagnets and a block of 3/4" thick aluminum. It seems maximum force

is generated with opposite magnets either touching each other at the

edges or with a small gap. That is to say, one magnet has its north

face to the aluminum and the adjacent one its south face. A 3/4" gap

between the two magnets

considerably reduced the force. For 3/4" thick aluminum, the 1" x .5" x

2" seemed to be a good size - Four .5" x .5" x 2" would probably have

had a shallower field depth and less force. But three 1" x .5" x 2" (eg

N-S-N) would be almost double two owing to

the two field reversals.

3" long magnets, or two 2" long touching ends for 4",

might help a bit, but they and their forces would be getting rather

close to the center of the rotor.

Magnets clamped together on their faces with the edges

facing the aluminum delivered very weak force. Presumably, most of the

magnetic field lines went straight between the two magnets and had no

depth into the aluminum.

Four 1" x 1" x .5 magnets, tho cut from 1x2 magnets by

angle grinder and considerably weakened thereby, had a very good effect

with N-S-N-S faces - three field reversals. However, that made the

length four inches across,

which would only allow a small (2 or 2-1/2 to 1?) torque increase if

they covered 4" at opposite ends of the rotor, as so much of the

passage

would be against drag with little free-spinning angle for the motor.

A single strong 2" x 2" x .5" magnet, having no field

reversals,

exerted surprisingly light force on the aluminum.

A bunch of small magnets, in several different

arrangements, also created very light forces. They would have had less

depth of field.

Then I decided that I should probably use copper instead

of aluminum for the output side to maximize the force

from whatever magnets were used. On December first, finding no large

blocks of scrap copper, I bought 4 pounds of

bare wire from Ellice Recycling for 11$, thinking of melting it into

blocks in my mini-kiln. I was a bit worried about certain aspects of

the idea, from getting big air bubbles inside the blocks, to the

container cracking and having liquid copper pouring out, to potentially

ending up with just copper oxide. Then I decided

to check at Smith Bros Foundry. A 1/2" x 3" x 6" block of copper (3

pounds) was "only" 50$, so I bought it.

To my surprise, the effect wasn't 1.64 times the force of

aluminum: it was more like five times. Wow! If you drop the magnets

flat onto the copper from an inch or two above, the effect is so great

that

they slow as if on a cushion of air, and do a soft silent landing. The

aluminum then seemed like a cheap, third rate imitation. Now I'm

certain

the coupling between the

rotors will be adequate, and indeed will probably have to be reduced,

with a larger flux gap or by cutting the copper pieces smaller than 3"

x 3".

On November 30th I started getting the parts together. The

plan is:

* axial flux with two pairs of magnets on opposite ends of the 10"

diameter input rotor disk,

* acting on two copper blocks on opposite ends of a single 3" x 10"

steel output

"arm" (acting as two opposite arms in unison), which will pivot on a

center bearing on the shaft.

* The arm will be free to pivot about 45º forward or backward

with weaker springs returning it to center

* The ends of the arm will strike two heavy springs at the ends of

their travel, compressing them and bouncing back.

* The heavy springs are heavy enough that compressing them provides

sufficient

torque to turn the part of the output rotor connected to the shaft,

starting the car

wheels rolling.

(Details "subject to change without notice" as they say. ...The copper

is so much more interactive with the magnets than the aluminum.)

Thus, the magnetic interaction will pull on the pivoting

arms and fling them forward. Their weight, hitting the heavy springs,

will knock the output rotor ahead, moving the car. Here is a very large

torque multiplication. The rotating magnets will continue past the arms

as they stop, and the arms will

return to center. This repeats

each 1/2 revolution of the motor relative to the output. As the output

rotor (and the car) speeds up, the hits will become fewer and less

forceful as less torque is needed. (Phew!)

A New Electric Hubcap Outboard Project?

The Honda outboard motor

that I converted to electric had a built-in two-to-one gear reduction

down at the propeller shaft in the foot. That's fine for a displacement

hull boat

and 5 or 6 knots, but it's a frustration for a powerboat, because at

half the motor RPM, the propeller RPM is too low to get the boat

moving very fast. I was also quite surprised by the amount of noise the

bottom gear made: the electric outboard was certainly quieter than gas,

but it

still had that characteristic outboard whine.

The RPM would be about right at one to one, but an axial

flux

pancake motor is exactly the wrong shape to try to mount in a sealed

pod under the water to direct drive the propeller. For an outboard, it

has to be

above the water at

the top. (An inboard Electric Hubcap motor to a fixed prop shaft should

be easy.)

Having done a chain drive for the Sprint car conversion,

it occured to me that an outboard might have a chain drive with small

sprocket gears, avoiding

the

use of meshing tooth gears entirely. This would allow adjusting the

gear

ratio, and bring construction of the entire drivetrain into the realm

of DIY potential. Perhaps the chain drive would have no more losses

than the usual 90º gears down at the propeller? (It could hardly

make as much noise!)

This would mean making the whole outboard from scratch.

How hard would that really be? - an outboard isn't that complicated,

especially an electric one where forward, neutral and reverse are just

a switch. Main drive components would be:

1. motor - it would be mounted vertically with the sprocket gear at the

rear.

2. cover for motor (Aha! 30cm PVC culvert pipe should just fit over the

motor!)

3. pipe for leg. If the sprocket gears were 2" diameter, the pipe might

need to be

3".

4. cowling to streamline the pipe/leg

5. cavitation plate

6. bottom housing - 3" pipe "T" fitting, holding: bearings, bottom

sprocket

gear, prop shaft, some oil, rear seal, and the propeller

Mounting components would include:

7. transom clamp

8. pivoting leg holder with prop insert to hold leg up

9. leg swivel

10. steering handle

The first thoughts of aluminum or stainless steel pipe

bring visions of welding, cost, lots of difficult and time consuming

work, and problems with seals. But what about plastic pipe, perhaps

with a flat plastic strut front to back, inserted for stiffness? Or as

a wide fin glued to the back on the outside? The propeller foot could

be attached with - or could simply be - a 90º "T" joint piece,

with a dome endcap at the front and reinforcing 'fairings' to the leg.

Plastic is easy to cut, the pieces glue together, and sealing... well,

it's made to seal. Only where the propeller shaft comes through

would the seal be any sort of issue - all the rest below the motor

would be glued and sealed.

A short section (7"?) of turquoise 30cm PVC culvert pipe

should just fit over the motor, and it should glue to the other pipes,

tho the join would need reinforcement. A plain piece of flat ABS or

acrylic plastic could cover the back side - tho it might need to be

bolted instead of glued to

allow access to the top sprocket and motor shaft. Somewhere above the

waterline the pipes should slide to afford chain tension adjustment.

An inch or two of oil in the bottom would keep the

bearings and chain well lubricated - no different from most outboards,

and better lubrication than most chain drives get. There would have to

be some sort of cover at the top end to keep it from spraying around at

the motor end and being used up.

This should be much lighter than an equivalent gas

outboard. At the top, it wouldn't stick out backwards beyond the leg -

mainly just to the sides except for the steering handle. The motor

would have to be above the clamp and transom in order to have room to

turn. (unless it was mounted ~7" behind the transom to miss it when

pivoting, in which case it

could be placed lower.) It would have a small "nuisance footprint"

compared to a gas outboard.

With high energy density batteries, such a motor could be

used on quite a small boat without making it too stern-heavy, and give

it lots of oomf and range. Or it could be an extended running unit for

a larger displacement boat, even with heavy batteries.

Another thought, thinking the plastic might not be strong

enough, would be to add a shell to the outboard body of tough

polypropylene-epoxy, painted over the plastic. Or (or 'and'), an

aluminum pipe might fit just inside the plastic one for strength, and

extend into the foot to hold the front and rear bearings.

More thoughts: use 4" ABS for the leg, soften it to "limp"

in the oven at 300ºf, and form it into the streamlined teardrop

shape. That would at least be stronger than round 3". If that still

wasn't strong enough: use 4" aluminum pipe and bash it into the

teardrop shape with a maul on an anvil (or a big rock). Of course, this

would make aluminum welding of an aluminum foot necessary, and that's

out of my DIY department.

A steel pipe of the right diameter inside would prevent

forming the pipe (ABS or aluminum) too small to fit the chain. The top

of the pipe above the waterline might be left round as the steering

pivot.

Hmm... that's a far cry from a conversion and having to

work around an existing outboard with inappropriate shapes and

mechanisms.

I think I like this! Where is my team of

production engineers to work out the details?

LED Lighting Project

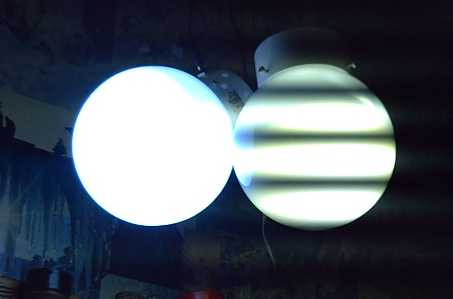

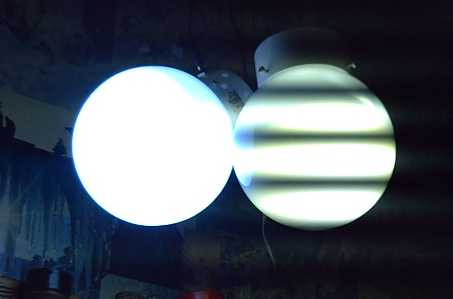

Two

LED lights hung up in the kitchen: on the right is the original. The

strobe effect so common with fluorescents, here interacting with the

camera to make dark stripes, is what I've since avoided by adding a

filter capacitor or using a 'modern' regulated power adapter. (I do

plan to add a filter capacitor to this one - running water in the sink

below looks weird.)

Two

LED lights hung up in the kitchen: on the right is the original. The

strobe effect so common with fluorescents, here interacting with the

camera to make dark stripes, is what I've since avoided by adding a

filter capacitor or using a 'modern' regulated power adapter. (I do

plan to add a filter capacitor to this one - running water in the sink

below looks weird.)

The left hand light is the new 1100 lumen "cold white" one. Tho I

reduced the exposure, the bluish color only shows at the top where it's

not quite so bright, and a bit in the dark strobe areas on the other

light.

LEDs

I got my big order from Deal Extreme and on the

16th(?)

put together a

two emitter light with the "20 watt, 1500 lumen, 15000K cold white"

emitters. These cost about 40% more than the Cree XM-LAWTs but give 50%

more light, using somewhat higher energy. They have an added attraction

of being 12 volts, so fixtures with any number of emitters (in

parallel) can be run from a 12 volt system. With the

usual deratings from the maximums to run cool and get or exceed "energy

star" spec performance, two emitters at 7 watts each should be giving

about 1100 lumens.

The 'cold white' light seemed bright and rather bluish,

but it's funny how the eyes adapt. After a while of that, all my 'cool

white' lights, that I think of as being relatively pure white, seemed

yellowish.

Still, 3 and 4 emitter fixtures

of this

type (~1700 and 2200 lumens, 24 and 32 watts) will need 3 amp power

adapters instead of about 1.5 amp, so it doesn't let me order only one

type of power adapter.

Of the several types I've

tried so far, these and the Cree "X-Lamps" seem the most suitable.

These

appear to be made the same as the 32 volt one I bought and used for the

shop light, but smaller.

I found a spool of #26 Ni-Chrome resistance wire at Queale

electronics to use instead of buying 5 watt resistors in packs of two.

I thought I could cut the pieces a bit long, test them, and add solder

along the

wire to effectively shorten them to suit. A second objective of using

resistance wire is to try and get a positive temperature coefficient of

resistance to counteract the strong negative change of forward junction

drop of the LEDs with temperature. I find I'm having to put in

considerably larger resistances than work well at room temperature, and

the lights get brighter and draw more current as they warm up. If the

resistances increased substantially with temperature, more of a steady

state brightness might be achieved.

To my chagrin however, I discovered that nichrome wire

can't be soldered. I guess the solder won't stick to the chrome. This

makes connecting the strong but fine wire difficult. I might just go

back to resistors.

Electric bills continue low

According to my electric bill, from mid October to mid

November I used 32 KWH of electricity per day, including a certain

amount of electric heat. Last year it was 49 KWH/day. It was 20-30$

less than I anticipated. Taking a median figure of 25$ and figuring the

darkest winter months are yet to come, and that there are no more bulbs

to replace, that's probably around 300$/year being saved by having

mainly LED lights instead of some incandescent (2/3 of them?) and some

compact fluorescent (which I found dim and didn't like the light of).

My investment in various parts and LED emitters for doing

the house lights myself (estimating the various lights without actually

adding up all the bills) was around 400$.

I don't leave every light on, but I do have a large house

and I don't flip them on and off as I go from room to room, either. The

kitchen lights (now around 25W) are often on, and either the machine

shop, the livingroom or my office lights, or maybe two of them, will be

on depending what I've been doing. The lights in the dark hallways (now

8W and 5W) are usually on.

Replacing at least lights that are turned on a lot with

LEDs is a good investment!

Energy Star

After a couple of weeks I finally looked into getting

Energy Star approval for the LED light fixtures. Then their PDF

application form on the web wouldn't open properly. I e-mailed and

eventually got sent another copy of the same unusable form.

Several days went by between each response from Energy

Star. Selling LED light fixtures had promise, but the cost seems too

high without the Energy Star approval and consequent BC Hydro rebate to

purchasers.

I finally asked for a copy on paper in the mail. While

waiting for a reply to that request, I thought to send a friend the

file and have them try. It worked fine for them, and they sent me back

a copy re-saved using an older PDF program. This worked fine. By then

it was the end of the month.

I should have been

onto the application

earlier, but I wanted to have at least "pre production" fixtures made

and be sure what I was doing first. I didn't expect it to take weeks

just to get the forms.

Nickel - Metal hydride Battery Project

Ultimate Battery Stick?

As I

considered mounting the batteries in the Sprint, I thought it

would be good to enclose them in one big housing so there weren't a

bunch of little pipes with live ends sticking out. But that would be

putting batteries in

cases into a case.

As I

considered mounting the batteries in the Sprint, I thought it

would be good to enclose them in one big housing so there weren't a

bunch of little pipes with live ends sticking out. But that would be

putting batteries in

cases into a case.

Then I thought of making making long thin square ABS

plastic boxes to

enclose 4 or 8 strings of ten cells, with the contacts on the inside

except for two terminal posts.

Then I thought of using a bigger pipe. A quick mental

calculation suggested seven strings might fit nicely into a 4" I.D.

pipe. I tried it out, and this proved true.

At 6.50$ per cell, the cost of each pipe works out to

about 475$ (my cost). I preferred last July's sale price of 5$ - they'd

be under 400$. (Perhaps I could make and sell the pipes as cases, and

let other people buy their own D cells to fill them.)

With a strut or two to prevent the strings from

twisting, one end with a flat metal plate, and one end with seven bolts

that could be adjusted for contacts, a 70 amp-hour, 6 or 12 volt

battery stick

should be easily made. The 12 volt one would weigh about 30 pounds.

Three 12 volters should put out plenty of current to run an Electric

Hubcap motor, and would fit nicely in the Sprint radiator area.

4" diameter pipe holds the batteries of 7 small pipes:

70 D cells for 70 amp-hours at 12 volts.

The 2.52 KWH should be

good enough for testing and short trips - plenty of amps. But it won't

give a car

(even a Sprint) a lot of range, so I'll doubtless want to expand on

that once it's on the road. Doubling it would be great, but owing to

the cost, I might just add a single string or two at a time. Or maybe

there's a good pipe size for

70 x AA cell (17.5 AH/210 WH) pipes?

Come to think of it, the offer to borrow 3 KWH @ 36 volts

of lithium ion batteries is doubtless still good. They might fit in

under the hood somewhere, with a battery switch to select between them

and the NiMHs.

Lead-acid EV battery options

Other than that, I might put in some lead-acids, with a

battery switch

to select NiMH, or PbPb if the NiMHs run out of juice. Lead-acids with

sodium sulfate should last quite a while if they're only occasionally

used, essentially as backup batteries. It looks like there'll still be

room for 3 under the hood. Of course, even three 100 amp-hour units

would be 135-150 pounds - plus 3 more (PbPb) chargers. That's like

lugging around an extra passenger, but valuable when needed. And having

to switch gives warning that you're hitting the range limit and need to

recharge soon.

Of course, you won't

actually get anything like 100 amp-hours out of them. Derating for

PbPb, and at the higher discharge rates of electric driving, suggests

about 25 to 30. (How "cheap" is lead-acid when everything's taken into

account?)

Arbitrarily continuing this somewhat off-topic train of

thought, if one were

to use lead-acid more, or entirely, two banks in parallel would drop

the currents in half and each bank would be more productive, perhaps 30

to 35 amp-hours for a total of 60 to 70, thus 270 to 300 pounds

yielding similarly to the 70 AH (probably should derate the NiMHs to 60

for high currents as well?) from

the 90 pounds of NiMH dry cells.

Six 6V golf cart

batteries should do

somewhat better than the six 100AH/12V cells, maybe 80 to 90 AH... but

they weigh and cost

proportionately more, 370 pounds and 960$. Three parallel banks of

100AH/12V (405-450 pounds) should

yield still better results (with the currents being divided by three),

35 to 40 AH each, 105 to 120 AH total... and also make the Sprint

heavier than it was with the gas engine system in it.

Two 70 AH banks of

NiMH D cell pipes would be at least as much available energy as that,

much longer lasting, and just 180 pounds - reminding

us why lead-acid isn't a very popular EV choice. They would also cost

3000$ instead of 1000$

- reminding us why the owners of big oil should

be relieved of their strangleholds over better economical battery types.

Yet another - and simpler - way to use lead-acids to get

sufficient batteries with less expense would be to use them in series

with NiMHs. Charging each 12 volt

section independently allows this.

One would want the lead-acids to have at least as many effective

amp-hours as the NiMHs if they are to last at all. One could put in

(eg) two NiMH "Super Battery Sticks" of 70 amp-hours for 24 volts, then

finish with two 100 amp-hour lead-acids in parallel for the third 12

volts, making 36V, 70 AH and 150-160 pounds. Or if three NiMH

supersticks were used initially as I'm planning, one could later add

one more (paralleling two pairs for 24 volts) and use four lead-acids

in the last position to get double the above energy and almost double

the range.

Still better of course would be to get my own economical

chemistry batteries working to the point where I could use them in the

car.

Turquoise Battery Project

Making Zinc Powder

I was sure

using some zinc metal powder rather than just

starting with yellowish zinc oxide would make a better electrode. I

can't seem to

find it in town. I can't think who might have it. I tried ordering some

on the 6th, but the e-bay seller wasn't sure he could ship it outside

the USA. I e-mailed two potential Canadian sources but got no replies.

Sigh!

I was sure

using some zinc metal powder rather than just

starting with yellowish zinc oxide would make a better electrode. I

can't seem to

find it in town. I can't think who might have it. I tried ordering some

on the 6th, but the e-bay seller wasn't sure he could ship it outside

the USA. I e-mailed two potential Canadian sources but got no replies.

Sigh!

I tried grinding some from a zinc rod I had. It was very

slow going. At one point (foto) I made a block to hold the zinc rod,

but held like that it quickly got too hot. By the 10th (after

several 10-15 minute grinding sessions) I eventually decided I had

enough

powder/flakes for an electrode, but it was more flakes than powder -

the powder would build up on the grinding wheel and then flake off.

Doubtless the particles comprising the flakes were all fused - melted -

together.

I was dubious about using it.

Zinc from zinc oxide

Then I got the idea to try and reduce some zinc oxide to zinc powder

electrically. I got a round "basket" of perforated brass sheet from an

older experiment.

Then I got the idea to try and reduce some zinc oxide to zinc powder

electrically. I got a round "basket" of perforated brass sheet from an

older experiment.

But wouldn't it just electroplate the brass with zinc? I

mixed 60g ZnO and 25g graphite powder to keep the zinc from

conglomerating into a solid piece or plating. About half of it tamped

into the basket.

Knowing salt electrolyte would corrode the basket, I used

potassium hydroxide for the electrolyte, and I used a piece of graphite

sheet for the positrode.

I attached a power adapter and got 2.3 volts with a

current of .27 amps. Since there was no real positive electrode to

oxidize, the oxygen from the zinc oxide should bubble up from the

graphite sheet. Soon it was in fact bubbling merrily with small, rapid

bubbles.

If I had used a nickel or grafpoxy plated positive

electrode with nickel hydroxide, I'd have made a nickel-zinc alkaline

battery. Many have tried to get good cycle life out of such a cell. I

only needed it to charge once.

Unfortunately, I left it a few minutes, and when I came

back, the substance in the basket had frothed up and spilled all over.

Of course! - 2.3 volts was too high and the zinc filled negatrode would

be generating hydrogen. The trapped gas puffed up my nicely compacted

basket of zinc/graphite. I limited the current to reduce the voltage to

about 1.5 or less, but by then it was a mess in a tub

of caustic hydroxide. It did however seem to be charging.

I read over means of making zinc electrodes in Alkaline

Storage Batteries by Falk and Salkind. I noted that they were

usually immersed in a tank of electrolyte, left to sit for a day, and

then charged against a 'dummy' positive electrode, and maybe run 3

charge-discharge cycles. Soluble impurities would leach out of them.

Then they were dried. It occurred to me that even if I was making salty

batteries, I could use the same procedure. The mobility of zinc ions

when cycling in alkaline solution should be an advantage for a few

cycles, forming conductive zinc pathways within the electrode to

improve the current capacity.

I also noted that zinc electrodes were said to be very

fragile before

'forming' with initial charges and discharges - exactly as I had

discovered. Another possible means of making them was by sintering zinc

oxide at

around 750ºc for 20-80 minutes (I presume with a collector screen

enclosed). Those would be more solid, but might be less amp-hours by

weight. Seemingly, it would be an easy thing to try out - simple

ingredients! But for use in salty electrolyte, the collector screen

needs to be grafpoxy coated. That would burn up at 750º. Not so

simple after all! Zinc metal powder sinters at kitchen oven

temperatures (over 200ºc), as I had found doing the 'ersatz powder

coating'. That might make nice pre-charged electrodes, but it's still

too hot for the grafpoxy.

Another thing mentioned was 1-4% mercury oxide to raise

the hydrogen overvoltage. No thanks. I'll stick with the

environmentally friendly antimony oxide, and maybe the eggwhite, maybe

a rare earth.

Anyway, it should be less prone to hydrogen generation in salt solution

- after all, standard dry cells stay charged for years with nothing but

zinc sheet metal... unless that's actually an alloy with some small

additive for overvoltage.

On the 27th I took the remaining zinc oxide and graphite

and tried again, adding a bit of antimony oxide to the mix. This time I

limited the current, and the voltage started a slow rise from 1/2 a

volt. On a whim I replaced the graphite "+" with a flat nickel

pocket electrode from a nickel-iron pocket cell. A Ni-Zn alkaline cell

should charge

up to about 1.75 volts, without the oxygen bubbles unless the nickel

became completely charged. In fact, after 3 hours or so the zinc was

making dirty hydrogen bubbles with the cell at 1.72 volts. The zinc

couldn't

possibly all be charged so soon. Of course!, I had just tamped it into

the basket: it wasn't properly compacted, so resistances away from the

basket metal were bound to be high, allowing some zinc to charge

fully without getting to the rest.

I tried shorting the cell, twice. It put out just over an

amp, which quickly dropped off. Not bad, considering the poor interface

between electrodes, and all the work I go to to get an amp out of a

salty cell! No wonder everyone went to

alkaline cells and abandoned the the harder job of trying to make

rechargeable salty cells.

I decreased the

current to eliminate the bubbling, and went over things from the

battery book... oh ya,

'immersed and left to sit for a day'. I removed the charge.

Even 2 or 3 hours later, when the voltage had dropped to

1.1 volts, it still put out over half an amp when shorted.

Another item to consider

was that afterwards I'd have to dig the mix out of the basket and

properly compact it into the desired electrode form. Why wouldn't I

make the desired electrode first, then 'form' and charge it in the

alkaline solution, and then simply rinse it and use it in the salty

battery? The zinc should migrate to form great dendrite 'tentacle'

connections during forming in the alkali, and they'd become fixed in

place in the salt battery with every prospect for a super long life,

highly conductive electrode. I could make some sort of little basket or

compartment so the electrode could be inserted and removed with little

stress.

All this seemed very good. But I was still wondering why I

couldn't seem to buy something so simple as zinc powder. However, I did

a bit more research, and found that something I was doing was making it

into better oxide than it started as. Not what I thought, tho...

Best Zinc Electrode!

Back to the basics... it seems that not only zinc powder,

but zinc

oxide powder will absorb carbon dioxide from the air and form zinc

carbonate. Zinc carbonate is passive in the battery. Perhaps this is

partly why results from my first zinc powder electrode didn't seem so

great? One can heat zinc carbonate to produce "calcined" zinc oxide and

CO2, but it seems that for batteries there's a better way.

Simply putting zinc carbonate into alkaline solution

causes it to become fine, high surface area zinc oxide. This is

sometimes

termed 'active' zinc oxide. 'Fluffy' high surface area chemical is

ideal for

batteries, yielding the closest to the theoretical amp-hours of the

substance.

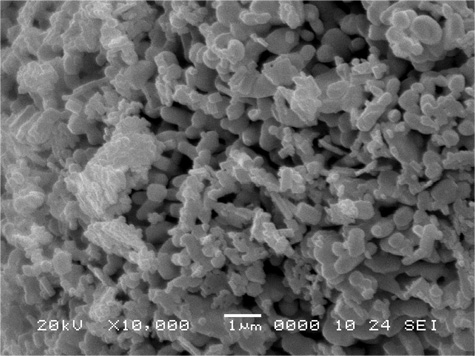

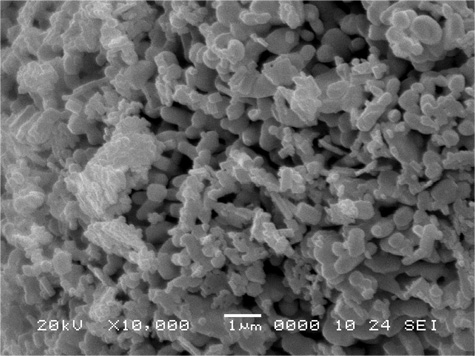

"Active" high surface area zinc oxide

(ZnOxide.org)

So all I have to do to get an ideal zinc battery electrode

is to make the electrode, immerse it in potassium hydroxide solution

for a while (like the alkaline battery makers), then rinse it

off - probably no electrolyzing or anything. And then - presumably - no

dendrites in salt solution to deteriorate the electrode and limit the

battery's cycle life. It appears I've stumbled onto the best form of

zinc negatrodes!

It looks like the only thing that might be a better

electrode is if

the hydrogen overvoltage with manganese can be raised that extra .3

volts so that a manganese negatrode works properly. The eggwhite didn't

seem to do it. I think that's worth more research, but I'll go with the

zinc because it's well known to work well as is.

http://www.TurquoiseEnergy.com

Victoria BC

The next day I

'retrofitted' an existing rotor cover with

a new rim in the mold. It was tedious, but it was virtually a snap-on

fit onto a stator center ring. Great! It couldn't shift sideways a bit

and line the shaft up slightly crooked like before. It's now pretty

much "well done"

to sell in kits, where it had been a bit "cludjy" before. That didn't

mean it didn't need a bit of touch-up as there were spots of dry

polypropylene here and there. That should happen less for a new rim

than with stuffing cloth in thin spaces beside an existing thinner one

- and the work will go faster. The outside wall couldn't be filled much

and mostly looked the same as before.

The next day I

'retrofitted' an existing rotor cover with

a new rim in the mold. It was tedious, but it was virtually a snap-on

fit onto a stator center ring. Great! It couldn't shift sideways a bit

and line the shaft up slightly crooked like before. It's now pretty

much "well done"

to sell in kits, where it had been a bit "cludjy" before. That didn't

mean it didn't need a bit of touch-up as there were spots of dry

polypropylene here and there. That should happen less for a new rim

than with stuffing cloth in thin spaces beside an existing thinner one

- and the work will go faster. The outside wall couldn't be filled much

and mostly looked the same as before.

I phoned my

friend

who I'd bought the CNC machine from - never having done any milling, I

wasn't sure of myself. The speed of the router was way too fast, but I

wondered about the drill, if the drill chuck would hold

it square properly. Instead he suggested gouging out the slot with the

lathe using the tailstock and a 1/4" square lathe tool. That sounded

hard to set up and tedious, but I walked into the shop as we were

talking. Looking at it, I suddenly realized how it might be done

"properly" on the lathe.

I phoned my

friend

who I'd bought the CNC machine from - never having done any milling, I

wasn't sure of myself. The speed of the router was way too fast, but I

wondered about the drill, if the drill chuck would hold

it square properly. Instead he suggested gouging out the slot with the

lathe using the tailstock and a 1/4" square lathe tool. That sounded

hard to set up and tedious, but I walked into the shop as we were

talking. Looking at it, I suddenly realized how it might be done

"properly" on the lathe. I wanted to do

experiments, and I was thinking of making

jigs for them, but I came up with a simple way to test the

interactions. I set up the motor's magnet rotor (the motor still being

disassembled) in its casing so it could spin on one bearing with the

magnet side facing up. I put a piece of white tape on one of the 12

magnets

so I could see when it had done one revolution. With C-clamps and a

piece of wood, I set up a fat bar of aluminum (.75" x [1" to 2.5"

tapered] x 10") to sit right over the magnets on the rotor. I used the

fish scale to measure the pull on the bar, and the noisy wall clock,

ticking off

seconds, to estimate 60 RPM - one rotation per tick. I spun the rotor

by hand at roughly that speed and measured the forces.

I wanted to do

experiments, and I was thinking of making

jigs for them, but I came up with a simple way to test the

interactions. I set up the motor's magnet rotor (the motor still being

disassembled) in its casing so it could spin on one bearing with the

magnet side facing up. I put a piece of white tape on one of the 12

magnets

so I could see when it had done one revolution. With C-clamps and a

piece of wood, I set up a fat bar of aluminum (.75" x [1" to 2.5"

tapered] x 10") to sit right over the magnets on the rotor. I used the

fish scale to measure the pull on the bar, and the noisy wall clock,

ticking off

seconds, to estimate 60 RPM - one rotation per tick. I spun the rotor

by hand at roughly that speed and measured the forces.

Two

LED lights hung up in the kitchen: on the right is the original. The

strobe effect so common with fluorescents, here interacting with the

camera to make dark stripes, is what I've since avoided by adding a

filter capacitor or using a 'modern' regulated power adapter. (I do

plan to add a filter capacitor to this one - running water in the sink

below looks weird.)

Two

LED lights hung up in the kitchen: on the right is the original. The

strobe effect so common with fluorescents, here interacting with the

camera to make dark stripes, is what I've since avoided by adding a

filter capacitor or using a 'modern' regulated power adapter. (I do

plan to add a filter capacitor to this one - running water in the sink

below looks weird.) As I

considered mounting the batteries in the Sprint, I thought it

would be good to enclose them in one big housing so there weren't a

bunch of little pipes with live ends sticking out. But that would be

putting batteries in

cases into a case.

As I

considered mounting the batteries in the Sprint, I thought it

would be good to enclose them in one big housing so there weren't a

bunch of little pipes with live ends sticking out. But that would be

putting batteries in

cases into a case.

I was sure

using some zinc metal powder rather than just

starting with yellowish zinc oxide would make a better electrode. I

can't seem to

find it in town. I can't think who might have it. I tried ordering some

on the 6th, but the e-bay seller wasn't sure he could ship it outside

the USA. I e-mailed two potential Canadian sources but got no replies.

Sigh!

I was sure

using some zinc metal powder rather than just

starting with yellowish zinc oxide would make a better electrode. I

can't seem to

find it in town. I can't think who might have it. I tried ordering some

on the 6th, but the e-bay seller wasn't sure he could ship it outside

the USA. I e-mailed two potential Canadian sources but got no replies.

Sigh! Then I got the idea to try and reduce some zinc oxide to zinc powder

electrically. I got a round "basket" of perforated brass sheet from an

older experiment.

Then I got the idea to try and reduce some zinc oxide to zinc powder

electrically. I got a round "basket" of perforated brass sheet from an

older experiment.