ma

Turquoise

Energy Ltd. News #47

Victoria BC

Copyright 2011 Craig Carmichael - January 2nd 2012

http://www.TurquoiseEnergy.com

= http://www.ElectricHubcap.com

= http://www.ElectricWeel.com

Four Years of Electric Transportation &

Energy Projects

Month In Brief (Summaries)

Electric Hubcap System

* in the news: A new type of turbine engine, by Robert Mueller at

Michigan State U.

* in the news: Replica of first functional hybrid car, from 1900

Magnetic Impulse Torque Converter Project

* Construction of converter, 10" diameter with springy arms - worked

well at low RPMs only.

* Plan for next version

* Initial tests: the potential is there... how much copper and how many

magnets will it take?

* Theory of Operation

Electric

Weel Motor - no report

Sprint

Car Conversion Project - no

report (see Torque Converter project)

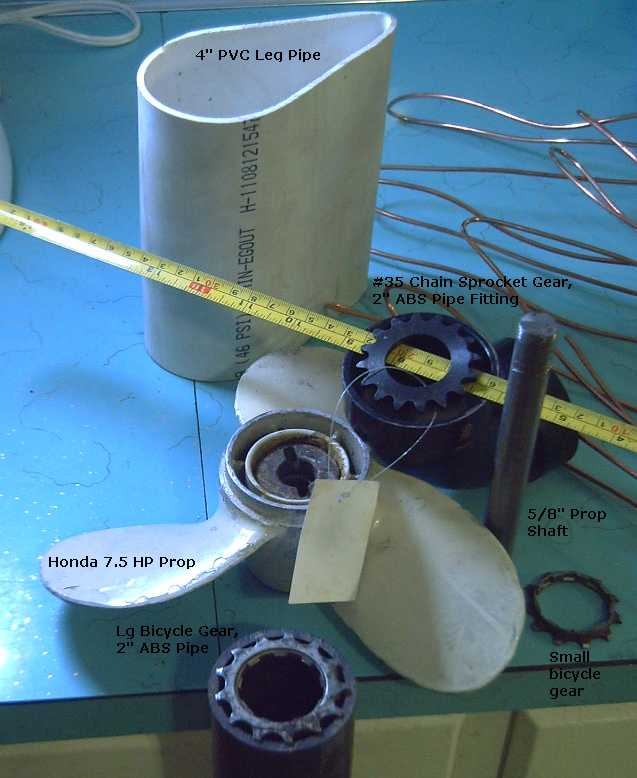

Prospective Electric Outboard Motor from Scratch Project

* Chain drive electric outboard concepts

* Collecting parts

LED Lighting Project

* Wall mounted fixtures: easy as hanging a picture!

NiMH Battery Project

* Second Hand Tip: Vaseline on contacts prevents corrosion, improves

contact.

* First Super Battery Stick made

Turquoise Battery Project

* Of interest: Nickel-Zinc/alkaline 1.6 volt batteries are available

(PowerGenix.com)

but only AA size.

* Zinc electrodes

* New electrode compactors

* Stibnite for manganese negatrodes

Newsletters

Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

-

Electric Hubcap Motor - Turquoise Motor

Controller - 36 Volt Electric

Fan-Heater

- Nanocrystalline glass to enhance Solar

Cell performance - Ersatz 'powder coating' home process for

protecting/painting metal

Products Catalog:

- Electric Hubcap Motor Kit

- Sodium Sulfate battery longevity/renewal

- NiMH Handy Battery Sticks, Dry Cells

- LED Lighting Products

Motor Building

Workshops

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

Four Years of Electric Transportation & Energy Projects

If I had understood

when I started that the idea for turning cars into hybrids might take

half a decade to develop, there's an excellent chance I'd never have

started. However, I did start, and seeing great value in the idea and

progress over time, I've continued. There has also been personal value,

learning

and growth in the process. I haven't made any money so far and live

rather "on

the edge", but things more important than money - "treasures in Heaven"

- have been earned, and

the fruits of the projects are starting to ripen.

I'm sure that, having published all the "how to" (&

"how not to") details

for everyone, my inventive work (especially insofar as it's successful)

will gradually spread and help break the impasse of vested interests

and their dinosaur technologies that have been holding back progress to

a better, kinder age. And when governments finally wake up to the value

of creating their Department of Progress to administer

inventive projects, patents and new ideas on some sort of organized

basis rather than allowing chaos to reign, peaceful progress towards a

utopian society will be powerfully assisted.

Finding no support for the ocean wave power project, I

started January 2008 thinking of just two new projects, ones that

wouldn't succumb to the indifference or hostility of those with

resources: a

supermagnet 'pancake' motor and a solid state motor controller for that

motor, to be

installed into a car. That certainly seemed like a sufficient

challenge! The objective: a simple, economical,

and ultra-efficient

add-on electric drive system to turn typical cars into plug-in hybrids,

that would "catch on", probably with DIYers at first, and eventually

come to dominate the market and move society rapidly away from rampant

petroleum consumption.

L: Stator of first good "Electric Hubcap" motor - 9 coils on a disk

brake rotor mounting plate,

fall 2008

R: Latest composite material motor (steel bracket mounting is for

Sprint car installation)

The motors have progressed in stages from a vague idea

to an excellent, super efficient (~95%), "on wheel" add-on motor, the Electric

Hubcap, to turn any car into a plug-in hybrid. They're easier to

make at home than other motors and boast several contributions to the

motor making arts. As far as I can find, these must be about the best

motors in the world, tho certainly a few rough details could be

improved. (Kit

499$ magnets not included; Motor making Workshop (leave with your own

motor)

800$. That's as cheap as I can do it.)

The solid state BLDC motor controllers went through

a number of design revisions and eventually arrived at an advanced,

compact,

reliable and robust, Direct Torque Control, simple and easily repaired

unit. The aluminum chassis is also the enclosed wiring junction box for

the system. It's just about now

ready for 'beta testing' and then the marketplace. Special feature: no

microcontroller or programming, just hardwired circuits. (499$ complete)

Turquoise Motor Controller in partly disassembled chassis.

(This chassis was cut down to fit a motorbike.)

The same January that I first started, a search for

batteries

disclosed that good alkaline batteries for electric travel such as NiMH

and NiFe apparently had been

deliberately removed from the market and suppressed. It turns out that

somewhat more economical, high energy nickel-zinc NiZn should also have

been available by 2008, but they're only available as AA cells at a

higher price than NiMH. (See NiMH Project article below.) Only

lead-acid and

the priciest

lithium types were available. This put my nose out of joint, and I

started considering how NiMH batteries might

be made at home. I added this third project to my list.

But I soon figured still better batteries must be

possible. I

called it the Turquoise Battery Project, not to get too

specific, since I was trying out

various potential chemistries. Learning as I went, I

eventually found some

workable higher energy chemical reactions, and came up with some

new construction ideas, which turned out to be more important and

tricky than the actual electrochemistry. Details are scattered through

my

newsletters. Although I haven't yet made a practical battery,

important hurdles have been leapt and a practical prototype doesn't

seem to be too far

off.

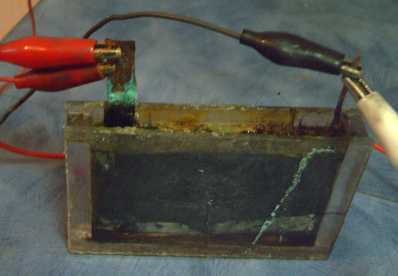

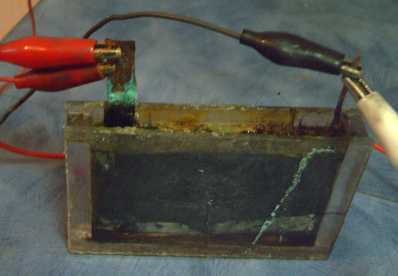

Compacting tool makes powders into battery electrode "briquettes"; a

salt electrolyte test battery with 'grafpoxy' coated current collector

grills

Motor/car testing proved that practical direct drive to a

car wheel would require a very

oversized and heavy motor. For a light wheel motor, "gearing down"

would be necessary. An efficient torque converter seemed to be the best

way if not the only

way my small wheel mount motor could put a car on the streets.

So in the spring of 2009 the

Magnetic or Mechanical Torque Converter project was forced on me

in order to achieve the main objective.

Amazingly, since the 1926 gas sipping, two cylinder Constantinesco

car and railway locomotives until now, no one had made another

successful mechanical torque

converter for motor vehicles.

I had little idea where to start. Many wildly different

directions were possible, both mechanical and magnetic. I had no means

to reliably measure the torque, and I went through

a succession of failed designs

and trials. I finally came up with the idea of a torque converter followed

by a gear speed reduction, eg 2, 3, or 4 to 1. No doubt

Constantinesco's units had even more substantial reduction at the rear

axle, a point I think later attempts including mine overlooked. This

would divide the foot-pounds

the converter would have to produce by the ratio, still without

creating the super-high RPMs on the highway that a single fixed gear

ratio ends up having.

Then with a November 2011 "Eureka!", I came up with a

magnetic impulse torque converter design that applied all I'd

learned in the best way. I was sure it would

really move a car, and in

December I built it. The first version didn't move a car, but the

principle is sound. Bench tests just before year end with a single,

longer wedge of copper (and finally with a means of

measuring output torque; see article below) had more torque, and it

appears that torque to move

cars just needs sufficient supermagnets and copper wedge area for

sufficient force coupling, perhaps in two or more interleaved layers.

The idea and

principle is so simple and obvious in retrospect

that anyone might say, "Aw, he just drew that on a napkin over coffee

one day!" People would feel that any wealth attained from it was

unearned (and the

present patent system ensures there's under 1% chance of an inventor

making money),

discounting the far-reaching value of the idea, the 2-1/2 years it took

me to come up with it, a lifetime

of mostly uncompensated inventive work, and the fact that in spite of

various efforts by many people, no one else had done it.

In the

meantime, just to show my Electric Hubcap motor worked, in

summer

and fall 2010 I converted a Honda 7.5 HP outboard to an Electric Hubcap

motor, reworking the original motor #2 from 2008 that had moved the

car.

Videos of the boat running are on YouTube. I now have ideas for a

better, "from scratch" chain drive outboard, using plastic pipes for

the main body parts. (article below)

In the

meantime, just to show my Electric Hubcap motor worked, in

summer

and fall 2010 I converted a Honda 7.5 HP outboard to an Electric Hubcap

motor, reworking the original motor #2 from 2008 that had moved the

car.

Videos of the boat running are on YouTube. I now have ideas for a

better, "from scratch" chain drive outboard, using plastic pipes for

the main body parts. (article below)

And Tristan Money took my Motor Making Workshop and built

one of the motors at about the same time. It went onto an off-road

motorcycle, but the 4 to 1 chain gear ratio (to my surprise) proved

inadequate. It finally ran up a slight slope instead of only down by

putting 80 amps into the motor, but it was like trying to

start a car moving in third gear. The torque converter should be the

answer for this vehicle as well.

I delved into other things along the way.

I conceived of

a pancake motor that would have the high

torque and low

RPM needed to drive car wheels directly without being ridiculously

heavy and overpowerful as well. The key to torque is forces around a

large

diameter rim - the interior of the motor is largely empty. This motor

was partly insurance in case the dragging torque converter project

never panned out. The 15 KW Electric Weel would simply be the

coils and magnets of three 5 KW Electric Hubcap

motors spread around a 26" rotor and rim, having 9 times the torque,

1/3 the RPM, and still being just 5" thick. I plan to finish it in

2012.

I conceived of

a pancake motor that would have the high

torque and low

RPM needed to drive car wheels directly without being ridiculously

heavy and overpowerful as well. The key to torque is forces around a

large

diameter rim - the interior of the motor is largely empty. This motor

was partly insurance in case the dragging torque converter project

never panned out. The 15 KW Electric Weel would simply be the

coils and magnets of three 5 KW Electric Hubcap

motors spread around a 26" rotor and rim, having 9 times the torque,

1/3 the RPM, and still being just 5" thick. I plan to finish it in

2012.

Nanocrystalline material

seemed to promise better motor coil cores (especially better than my

workable but crude nail gun finishing nail strip iron laminates), and

ceramics was promising and the least explored area in this field. Later

I found excellent low-loss iron powder toroid cores that were doubtless

better

than

anything I could have made even if I'd attained a successful result.

(27 of them are seen here in the Weel motor coils.)

But in the attempt, I came up with two things. One was a

'magnetically conductive' ilmenite-sodium silicate skin for coils that

did significantly improve motor performance.

The other was a

great

nanocrystalline titanium dioxide, borosilicate glaze formula that could

be of service for superior solar collector glass. I developed some

other ideas for better dye sensitized solar cells (DSSCs) as I worked

on the glaze mix and technique. So far I haven't done anything useful

with it except create the

glaze. But only this month did I finally find some iodine/potassium

iodide solution, the required electrolyte for DSSC cells.

Sometime, I found out that lead-acid batteries could be

renewed by replacing the acid with sodium sulfate in distilled water,

and further, that they could be given long initial life - 3 or 4 times

as long - by adding the sulfate salt, and further, that battery makers

have known all about it since before world war two. They don't put it

in regular batteries because (a) short life batteries are a good scam,

and (b) because they'd then be too practical and would make economical

electric vehicles practical.

That led me into a side venture to determine and publish the best ways

to do

it and to figure out what was going on.

I made a 36 volt electric heater for electric cars. (I

finally found some good looking ones on line, but only after I'd

finished making mine.)

I started making a small pulsejet, a type of jet engine

with no moving parts, but I got

sidetracked and haven't finished it so far. Pulsejets spit out pulses

of flame like a cutting torch,

and I thought I could make one to cut steel plate with. But about then

I finally found

two abrasive waterjet companies (a service I had been looking for since

the start).

They do nice, clean, exact cuts and were pretty affordable, which

solved the immediate needs for cutting out steel rotors and parts for

the motors.

About the end of 2010 it seemed nickel-metal hydride D

cells had dropped in

price since early 2008 from 10$ to about 6$. This seemed to make them

more

viable for electric transport. Until and unless I got my own batteries

working and practical, NiMH

dry cells seemed like the most workable EV material.

The currents

listed for the cells and the

great results I was getting with some new NiMH AA cells in January 2011

seemed also to

indicate that NiMHs might be used as car starting batteries for gas

cars. I bought some and found they did indeed start the car. The car

13.8 volt standard charging system turned out to be the ideal constant

charge voltage for (10x) NiMHs, and the cycle life given seemed to

indicate they should surely last for at least a decade if not two or

three as

a

car battery. It apparently hadn't been done before -- the manufacturer

had no idea how long they might last. At the start of 2011 it was just

a theoretical possibility, but since I first tried it in February my

car has been lead battery (-30 pounds) free. 4 different battery

designs

have been tried: with 60 "4/3 A" cells, 120 AA cells (9 pounds), 30 D

cells (most 'oomf', 12 pounds) soldered into a pack, and finally 30 D

cells in

6 - 6V "handy battery stick" pipes. NiMH are proving to be much better

car batteries than lead-acid, saving gas by lighter weight and lower

idle speed, and leaving the lights on for a few hours a couple of times

has had no noticeable detrimental effect.

The currents

listed for the cells and the

great results I was getting with some new NiMH AA cells in January 2011

seemed also to

indicate that NiMHs might be used as car starting batteries for gas

cars. I bought some and found they did indeed start the car. The car

13.8 volt standard charging system turned out to be the ideal constant

charge voltage for (10x) NiMHs, and the cycle life given seemed to

indicate they should surely last for at least a decade if not two or

three as

a

car battery. It apparently hadn't been done before -- the manufacturer

had no idea how long they might last. At the start of 2011 it was just

a theoretical possibility, but since I first tried it in February my

car has been lead battery (-30 pounds) free. 4 different battery

designs

have been tried: with 60 "4/3 A" cells, 120 AA cells (9 pounds), 30 D

cells (most 'oomf', 12 pounds) soldered into a pack, and finally 30 D

cells in

6 - 6V "handy battery stick" pipes. NiMH are proving to be much better

car batteries than lead-acid, saving gas by lighter weight and lower

idle speed, and leaving the lights on for a few hours a couple of times

has had no noticeable detrimental effect.

New this month:

Ventilated NiMH Super Battery Stick

70 D cells: 70 AH, 12 V, 4.5" x 25", just 28 pounds

I found out later that NiMH D cells are popular for hybrid

car batteries, since larger NiMHs are suppressed. Developing them to

make

them good enough for that use, and developing AA cells for the ultimate

possible energy density for small devices, explains their amazing specs.

In spring

2011, I ordered some LED emitters to try out LED

lighting. I discovered they really did make a lot of light with very

little

electricity. But one could spend 50$ at Canadian Tire and get just a

450 lumen screw-in 'bulb', barely replacing a 40 watt tungsten

lightbulb. There were also LED light fixtures... with no diffusers,

just glaring little points of intense light. I progressed to making

700, 1050 and 1400 lumen lamps and 6" globe light fixtures that run off

power adapters, and realized they were better than what could be

purchased. I converted my whole house and started saving 20-30$/month

off my electric bills.

In spring

2011, I ordered some LED emitters to try out LED

lighting. I discovered they really did make a lot of light with very

little

electricity. But one could spend 50$ at Canadian Tire and get just a

450 lumen screw-in 'bulb', barely replacing a 40 watt tungsten

lightbulb. There were also LED light fixtures... with no diffusers,

just glaring little points of intense light. I progressed to making

700, 1050 and 1400 lumen lamps and 6" globe light fixtures that run off

power adapters, and realized they were better than what could be

purchased. I converted my whole house and started saving 20-30$/month

off my electric bills.

When BC Hydro started offering rebates on qualified LED

lights - and the available crap qualified - I decided I should make and

sell my superior fixtures - the rebates would make them more

affordable. Over the rest of the year I refined the

design and

worked on getting the requisite "Energy Star" approvals. I've settled

on promoting 15 watt, cold white, 1100 lumen fixtures and maybe 15

watt,

1400 lumen cool white ones (costs about 15$ more). In fact, converting

to these efficient LED lights from incandescent will pay off even the

full price in electricity savings within two years for lights that are

turned on much of the time, and the "cool white" is about the whitest

artificial lighting available. "Cold white" is a bit bluish. Both are

much nicer light than fluorescent, and IMHO nicer than incandescent.

I enter 2012 with the torque converter seemingly nearly

ready to give me an ultra efficient electric car to

hit the streets with, economical high energy batteries hopefully about

ready

to work, a plan for a better DIY electric outboard motor, and

merchandise

ready or about ready to go: motor kits, BLDC motor controllers, NiMH

Handy Battery

Sticks,

and LED

light fixtures.

Not that I've sold anything to speak of so far. Selling

seems to be a different talent than mine.

December in Brief

On the second I had

what seemed like a better and also simpler plan for the magnetic

impulse torque converter: just springy arms would replace the entire

springing mechanism. It looked like a workable converter was just a few

steps away. I started in on the output side, now just a hub holding a

couple of arms with copper blocks on the ends. The rectangular steel

hub block was

fitted on the shaft that day, and the output section was ready on the

6th. I finished it and tried it on the bench and in the car on the 7th.

It seemed great on the bench, but in the car it only had

about 1/4 of the force needed to move the car even on level ground.

Everything worked great up to about 150 RPM, the output torque pulses

'unstoppably' shoving my hand an inch or so at power levels where the

motor rotor (same diameter) can

readily be held stopped. But above that the force didn't seem to

increase with the speed, and even seemed to drop off at high speed.

Evidently non-linearity of force with speed that I'd foreseen as a

potential but (I thought) unlikely problem does occur. In

the days that followed, I tried modifying the force elements. An air

core coil in place of the copper block didn't fare well. Annealing the

copper blocks (5% more conductive) seemed to help some.

Next: A single long wedge/arc of copper, eg 6", with one

magnet set, allows the motor 4/5 of a rev to speed up, then slow

it down more, transferring the maximum force from the input to the

output within that 6" period, which I hope will also prevent

over-revving to

speeds where it ceases working well. I took the electromagnetic

components apart to start over, as I felt such a long wedge of copper

would have to be on the rotor side, with the magnets on the springy arm

- opposite to how I'd done it. On the 30th this did in fact produce

about double the torque with only two magnets. It appears that four or

five magnets

should produce torque values that (with the gear reduction following)

might

push the Sprint car across the bumpy lawn.

On the 13th I got a chest cold. It came out of the blue

within hours of eating a cookie unexpectedly "laced" with two big,

chewy, hidden candied fruits, after playing in a concert. I'm convinced

that candied fruit is the single handed cause of 3/4

of holiday season colds and flus and I try to avoid them.

On the 14th, I decided it was time to quit the machine

shop for a bit and get back to the Turquoise battery project. And I

started working on the battery making manual to eventually put up on

the web.

Noting pinholes in the grafpoxy, I put a second coat on

some grills, which clogged many of the mesh openings, Then

I thought of diluting the epoxy next time to make a thinner coat that

would hopefully cover better. It also appeared I could probably make

sheets of conductive grafpoxy plastic. They might be useful as a common

conductive wall between two cells, so glued-together cells could form a

lighter higher voltage battery. Finer mesh grills would also be

valuable.

Then, having decided to go with small format electrodes

for good, after making a (poorly conceived) "new" compactor for small

electrodes from part of the original one, I did a zinc electrode. Later

I did a better small compactor from the newer large one. The 31 grams

of zinc oxide should theoretically make about 20 amp-hours. The

internal space in my cells is about the same as a D cell, 40cc. Working

it out revealed only around 10 AH of nickel electrode could be fit in.

Oh well, it has a higher voltage than a NiMH D cell.

By the end of the month, I had put a couple of dozen hours

into the battery making manual and it was taking form. The grafpoxy

coated grill electrodes in the new cell seemed to be lasting well, but

the cell itself hardly worked - I tried to re-use a nickel

electrode that had expanded and it had little to no conductivity.

Christmas intervened and I didn't get another electrode or cell made.

I did manage to get hold of some antimony sulfide

(couldn't find any last time I tried) that I hope will raise the

hydrogen overvoltage enough to make a manganese negatrode work. If it

does, it'll be about the highest voltage and highest energy negatrode

ever, and probably very long life.

In Passing: more dirty tricks of the rich

I was hoping to have a month pass with nothing to talk

about but the energy projects, but on the 10th I overheard that some

very rich people - she mentioned Nelson

Skalbania, Peter Pocklington and Donald Trump - "declare

bankruptcy as part of their business plan". By declaring bankruptcy

they avoid

paying income tax, and they can write off all their debts and losses.

They put their assets in trusts, in friends' names, in offshore

accounts, and wherever, so that on paper it appears they don't own

anything.

On the web I read

that Pocklington was arrested in California in 2009 on bankruptcy

fraud, claiming 20000000$ in debts and just 3000$ in assets, but he was

sentenced to just 6 months home detention. (What, he even got to keep

his home?!?!) This info seemed worth spreading. Skalbania may have had

more genuine financial troubles... or was he just better at the game

than Pocklington? I didn't look up Trump.

It seems inevitable that many people must have lost

investment money somewhere, somehow in this, and that these people have

acquired (or spent) it. How many rich people get there by using the

letter of the law to defy the intent of the law, cheating

people and the society that nurtured them as they go? It will give

them no peace.

Oh no, more... I've also heard that the John Deere tractor

company had gone out of its way in the 1920s to buy up all the draft

horses they could get their hands on... and send them off to glue

factories. Shortage of horses

of course forced the largest number of farmers to

buy tractors. Apparently there's no limit to immoral conspiracies and

scams if profits are to be made!

Electric Hubcap Motor System

New Gas Engine

I was sent a link to a news article about a new type of

engine that uses far less fuel and is small and light. Among many

possibilities, this would be great for a small "generator module" to

recharge car batteries while driving, preventing an electric car from

running out of range on long trips. Doubtless it could run on a number

of fuels such as methane (natural gas) or propane as well as gasoline.

http://news.discovery.com/autos/new-car-engine-sends-shockwaves-through-auto-industry-110405.html

I hope they don't fall unsuspectingly into the usual trap

of patenting it. Then

"the 1%" will acquire the patent one way or another and won't let

anybody produce them. You would think that when development of an

invention is funded with public money, either there should be no patent

granted, or the patent should be held by the government and royalties

collected on a non-exclusive license basis. Alas, a private patent that

can easily be bought to kill the new technology is a common condition

for applying for government funding as well as private. No wonder we're

still stuck with "big oil"!

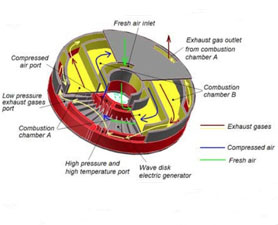

From the article:

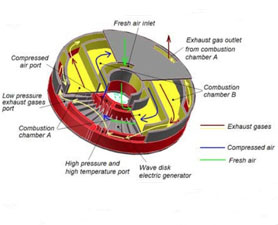

"Researchers at Michigan State University

have built a prototype gasoline engine that requires no transmission,

crankshaft, pistons, valves, fuel compression, cooling systems or

fluids. Their so-called Wave Disk Generator could greatly improve the

efficiency of gas-electric hybrid automobiles and potentially decrease

auto emissions up to 90 percent when compared with conventional

combustion engines.

"Researchers at Michigan State University

have built a prototype gasoline engine that requires no transmission,

crankshaft, pistons, valves, fuel compression, cooling systems or

fluids. Their so-called Wave Disk Generator could greatly improve the

efficiency of gas-electric hybrid automobiles and potentially decrease

auto emissions up to 90 percent when compared with conventional

combustion engines.

"The engine has a rotor that's equipped with wave-like channels that

trap and mix oxygen and fuel as the rotor spins. These central inlets

are blocked off, building pressure within the chamber, causing a shock

wave that ignites the compressed air and fuel to transmit energy.

"The Wave Disk Generator uses 60 percent of its fuel for propulsion;

standard car engines use just 15 percent. As a result, the generator is

3.5 times more fuel efficient than typical combustion engines.

"Researchers estimate the new model could shave almost 1,000 pounds

off a car's weight currently taken up by conventional engine systems."

Norbert Mueller holding his prototype. The foto doesn't look like the

drawing, but details are scanty.

According to Mueller's web page at MSU, he works with

'turbomachinery', 'centrifugal compressors', 'wave rotors'

and several related areas, that would seem to make him a natural to

invent such a new machine.

Replica of Porsche Hybrid from 1900

How long have hybrid cars been around? Evidently this one,

recreated by an unnamed hobbyist, was the first functional one, in

1900. It appears the two 2.5 HP gasoline engines are behind the front

seat. They charged batteries and powered the electric hub motors in the

front wheels. A single ratio gear in each hub was probably all that was

needed for the speeds you'd want to go on the rough roads of 1900:

faster than a horse or a bicycle - cool!

The turbine engine above would have left more room for

luggage and used less fuel. Great batteries would have let it go over

100 miles without any engine. A magnetic impulse torque converter would

have let it do 100 Km/Hr -- ooh, scary!

www.treehugger.com/cars/riding-the-worlds-first-hybrid-car-1900-porsche-semper-vivus.html

The outside profile of the front wheels isn't dissimilar

to what I hope to do with the Electric Hubcap system on rear wheels,

but evidently these motors and wheels weighed 200 pounds each, where

the Electric Hubcap system should weigh under 50.

Motor Controller

The IR2133-V2 circuit boards still didn't arrive. I

e-mailed to ask what's going on. Turned out I'd sent a wrong file and

they hadn't communicated that back to me. Hopefully it's on track now.

Magnetic Impulse Torque Converter Project

Construction

By Dec. 2nd, I'd figured out what I hoped was a better

plan for the converter. To implement the heavy springs, I would simply

mount the copper blocks on the ends of somewhat springy arms. There

would be no other mechanical moving parts, and in fact no output

"rotor" per se at all - just a hub on the shaft to hold the springy

arms, and the copper blocks on the ends of those.

The spring effect would be less dramatic, but it would

smooth the magnetic hits, which might be pretty abrupt with copper

blocks even tho nothing would physically touch, and still provide a bit

of boost to the torque. The rotating magnets would still pull the arms

forward, against the spring pressure. That would put considerable

pressure on the shaft, more and more as the arms became under more

tension, and added to that, the forward inertia of the blocks as it was

arrested. At some point, the magnets would reach the front of the

copper blocks and let go. When they did, the arms would spring back,

the rebound inertia continuing to push on the shaft for a further short

distance.

There needed to be a hub to attach the arms to. Since the

arms would be straight(?) pieces of steel, it seemed reasonable to have

a square or rectangular hub instead of round, so they could simply bolt

along the edges. I found a bar of mild steel 2" x 4" x .75" in my

stock. That seemed a good size as-is.

I couldn't make a 2-1/8" hole for an SDS bushing in a 2"

wide piece even if I could somehow drill it, so it would have to go

directly on the shaft with a slot for the shaft key. To make a 1" hole

through the center for the shaft I would need a 1" drill bit. The pawn

shops having none, I had to buy it new for 35$ (Best price in town, at

Canadian Tire - ouch!) I reasoned I'd surely want to drill more 1"

shaft holes at some point, since that's my "standard" shaft size. I got

the hole drilled the same day, drilling up a bit at a time from 5/16"

with 9 drill bits. It'll suffice, but it wasn't quite straight - what's

with the drill press?.. It looks straight.

Making the slot for the key seemed a different prospect.

In November I'd found how to mill slots into the shafts, but the end

mill bit wasn't going to go inside a hole sideways. Neither was the zip

disk on the angle grinder. This seemed to leave the dismal prospect of

filing it out. Or perhaps it could be chiseled/gouged out with a

1/4x1/4" lathe tool? Finally I got down to it and it only took about an

hour, using the edges of a couple of files and the lathe tool to square

up the inside corners. Then I drilled and tapped a hole on the side and

put in a set screw. The square block was fit on the round shaft - one

job done.

Evidently no one sells spring steel in Victoria, so I

decided to try regular steel - a .125" x 1" steel strip. If this went

straight out from the center to the copper block, it would only have 2"

of spring length. That didn't seem like much. Then looking at the block

hub on the shaft, I thought of using 2 pieces of .125" x .75", one from

each

side of the hub, to each side of the copper. That would keep the copper

lined up parallel to the magnets at the desired gap much better, and

pretty much the only flex would be along the travel axis, the desired

direction. I could attach it 1" out from center on each side, and at

over 3" and just under 5", and bend a little bow in between for flex

length. I bought the steel and cut, drilled and mounted the arms on the

hub on the 4th.

Last detail of the output side construction was - how big

to make the copper blocks? I had bought a 3" x 6" block, but that

didn't mean 3" x 3" was the best size. The two magnets were 2" x 2". I

decided on 2" x 3", with the 2" along the arc of travel so that the arm

would try to follow the magnets for only a short period to attain the

maximum torque increase. But if that seemed light on the interaction, I

could turn them sideways

for a 3" run. If that still wasn't enough, 3 magnets N-S-N on the 3"

copper would surely move anything - if the motor could handle it. I cut

the copper blocks on the 3rd, actually before the arms, so I had all

the main bits to lay out on the bench to determine details. Owing to

the 3" length of the blocks, the copper stuck out an extra 1/2" beyond

the 10" rotor diameter. But there

was room.

To keep the steel arms, which are of course attracted to

magnets, at a bit of distance from the input rotor, I decided to use

spacers of aluminum, so the copper would stick out 3/8" from the steel.

With these 1/8" thick spacers, and two 1/8" steel pieces clamped over

the main arms at the hub, I realized that if they were all on the

inside, a natural gap would allow the arms to spring without having to

bend them, so I arranged it that way.

On the input side, the only real variable was how thick a

rotor to use: how much flywheel effect was desirable? I had a 1/4",

some

5/16", and a 3/8", all made to fit on an SDS bushing and all 10" in

diameter. Two magnets went at each end, 180º apart. Once they were

glued on, it would be hard to change it. But excess weight - if it

really mattered - would work against the brakes for stopping the car,

and more weight could easily be added. On the 7th I got the magnets

epoxied to the 1/4" rotor. The new magnets from the cupboard seemed to

be about time and a half as strong as the old scratched ones I'd used

in the tests.

This seemed to augur well.

Testing

I assembled

the unit and tried it on the bench with just

12 volts on the 36 volt motor. Essentially it worked, pulses of torque

pushing the output arms around each time the magnets went by. It slowed

down but didn't stop as I squeezed the shaft coupling to try and stop

it, and it speeded up as I reduced pressure.

I assembled

the unit and tried it on the bench with just

12 volts on the 36 volt motor. Essentially it worked, pulses of torque

pushing the output arms around each time the magnets went by. It slowed

down but didn't stop as I squeezed the shaft coupling to try and stop

it, and it speeded up as I reduced pressure.

It seemed very promising. I put up a video of it: http://www.youtube.com/watch?v=Z73XZE4lnPo

But the astute viewer will notice the output stopped

gaining force with the motor speed at some none-too-high RPM.

Then I took it out and tried it on the car. The car showed

no

sign of wanting to move, but after minimizing the gap, the arms flailed

back and forth heroically about 10-15º as the magnets shoved them,

with the springing arms and also owing to a bit of slack in the chain.

Furthermore, above a certain RPM, the arms stopped flailing and

smoothed out, but there appeared to be less force than at low RPM.

The motor seemed able to accelerate and attain high speed without

working very hard: the coupling force seemed good at low speeds, but

almost nil at high speeds.

It appeared that the non-linearity and possible

saturation of interactive forces that was my biggest potential concern

actually occurred, and not far above the speeds and forces I'd been

attaining by hand in my November experiments. Two pounds force at 60

RPM certainly didn't seem to become anything like twenty pounds at 600

RPM.

It seemed it would be best to load the motor down so that

it couldn't readily attain higher speed than where maximum torque pulse

forces occurred, probably under 200 RPM.

In order to get sufficient interactive forces for that

purely from

magnetism as built, it seemed it would be necessary to go to multiple

interleaved

magnets and copper blocks, or to use a substantially larger diameter

and have several sets of magnets and blocks around the circumference.

For the latter there isn't room in the Sprint mechanism and

advisability of large diameter for 2000 RPM is doubtful, and the former

is beyond my

construction techniques and patience even if there was enough room - as

with doing gear transmissions, a properly equipped factory would be

best.

Remembering that evening that I had found a way to measure

torque to

the wheels on the Sprint, the next morning I jacked up a wheel and put

the torque wrench on the center nut. The torque went up to only about

10 foot-pound pulses - only 1/3 or 1/4 of what was needed to move the

car even on level ground. Seemingly contrary to all logic, torque

dropped off to

about zero as motor speed increased towards 1000 RPM, and stayed there

at any higher motor speed. How could the

magnets have less pull - even none - on the copper blocks at high

speeds than at lower speeds?

That afternoon was my talk at the Discover Tectoria

event. I ran the motor and mentioned several projects, but about the

torque converter I was less certain. I only said I had been on the

project for 2-1/2 years

now and had learned a lot. The talk was deemed a success, but I wished

I had been able to say I had solved the last problem and had, or would

soon be able, to move a car.

On the morning of

the 9th I realized what it probably was: at

low frequency, big circles of looping electrons would run around inside

the copper block. The whole copper block would be a big countermagnet,

as expected. But as frequency increases, they run around in

smaller and smaller

loops, canceling each other except at the outer surfaces. This "skin

effect" where current only flows near the surface of a conductor is

well known in higher frequency circuit design. That would decrease the

magnetic

field in the copper until it didn't interact well with the deep field

of the supermagnets. And without getting more thrust at higher

speed, the magnets would go by the blocks too fast for the low thrust

to overcome the inertia of the output and get the arms moving.

Perhaps something more sophisticated than a block

of copper was required on the output side? How about a big loop of

thinner copper, forcing the electrons to travel around the loop? Or

several thinner loops? This would be more like a shorted coil, so

effective at loading down a generator! That sounded right: for high

frequency coils, thinner wires are required because of the skin effect.

The 1/2" thick block of copper would only be good for the lowest of

frequencies - the sort made by hand motions for my simple tests. A 1" x

3"

loop 2" wide, or several thinner ones to total 2", with 1/8" thick

copper, should be good for a much higher frequency. In fact, loops of

heavy magnet wire might be best.

Another thought was that it could be given a laminated iron core - or

maybe simply solid iron - to increase the flux density.

The more I considered it over the day, the more certain I

was that this was the solution to the dropout of thrust at higher

speeds. What has more electromagnetic resistance to motion than a

generator with the output shorted? This was the same thing in reverse -

the coils would have great resistance to not following the

magnets spinning on the rotor, and shouldn't drop out at any

frequencies likely to be attained. Let's see: 2500 RPM (top speed and

more) is 42 cycles per second. Multiply by two because there's two

magnets on opposite sides of the rotor making two cycles per

revolution: 84 Hz. Now multiply by 10 because the entire cycle occurs

just when a magnet passes an arm - nothing like a sinewave: 840 Hz.

That's higher than I was thinking, and helps explain higher speed

dropouts of the solid copper blocks. It may even indicate thinner

magnet wire should be used.

The next logical step was simply to try a motor coil,

shorted out - hey, I wouldn't even have to make anything! But trying to

hold one near the rotor, the iron

powder core grabbed onto the magnets so strongly it prevented getting

any sense of

whatever else was happening.

Since I didn't have a way to mount a motor coil, I made

a coil to fit onto the arms to

try out, using the first bit of my 400$ spool of #11 magnet wire. I

decided to try a non-magnetic core first. I cut some black locust (a

hard dense wood) into

two appropriate size blocks, drilled holes to fit them onto the arms,

and wound a wire coil around one. It hardly worked at all. With the air

core and much less copper than the solid blocks, the force transfer

effects were slight. Worse, force seemed to stop increasing with speed

at about the same RPMs as the solid blocks.

It would seem air core coils would only work if they

contained as much copper near the magnets as the solid blocks. Another

thing that could be tried along

these lines would

be simply to split the copper bar into insulated 'laminates', either

flat or radial, to

try to get better higher frequency performance. I'm dubious this would

work any better, or even as well.

That leaves iron powder core coils again. Perhaps worth

trying.

But the next thing I did try, on the 11th, was annealing the

copper blocks. Copper is usually sold hardened so the rods and bars

don't bend in the stores, but hardened copper is about 5% less

conductive than annealed copper. Copper being 1.64 times as conductive

as aluminum seemed to translate out to about double the electromagnetic

coupling effect, so perhaps 5% would be 10% improvement. Of course,

that seemed pretty minor. Low-speed torque did seem better on the

bench, but that might just as well be attributed to the smaller flux

gap I think I got.

After the thought about the short duration of the

interactions of the blocks and magnets, I thought I'd turn the blocks

sideways so the magnets dragged along them for 3" instead of 2. (At

that point they'd go around enough of the circle that a wedge shape

might be noticeably better.)

The next step would be to use three magnets instead of

two. Two magnetic reversals instead of one would almost double the

force applied to a 3" long block. I had positioned the magnets for two

on the rotor, so the third would have less than ideal placement. But I

didn't try these things.

The next morning I woke up with the idea of using a single

wedge, a copper arc around the rotor, 5, 6 or 7 inches long at the

outside edge, working

against 2 or (more probably) 3 magnets, or even 4 if required. This

would:

* allow for increasing the coupling force with more magnets and copper

as required, similarly to interleaved fingers but without the

mechanical complexity (with the drawback of reducing the maximum torque

ratio),

* lengthen the time over which the coupling force was applied, which

would slow the motor more while applying torque to the output for a

longer period - hopefully long enough to overcome 'spring' in slack

mechanism, car springs and rubber tires.

* and double the time the motor had to freely pick up speed, giving

more impetus to each hit.

The circumference of a 10" diameter rotor is 31.4", so a 6" wedge

would occupy almost 1/5 of the circle, for a maximum potential of 5 to

1

torque increase. Of course, such a long wedge would be best be mounted

on

a rotor instead of on springy arms, to keep it straight. On the other

side, two or even three magnets might well be mounted on the springy

arms, suggesting that I should reverse the positions: copper on the

input

rotor and magnets on the output. That meant somehow getting the solidly

epoxied magnets off the rotor and redoing much. I might have to chip

them off. Oh well, that's what inventing's about. The hub and arms, and

the rotor itself, should still be employable.

Loosing the magnets turned out to be easier than expected:

the paint underneath detached from the zinc undercoat too easily and

they popped off with a hammer and chisel. As no magnet had flown off to

cause injury or damage in the tests, this was convenient, and a warning

not to use enamel spray paint. The polyester

coating of the genuine powder coating on the motor rotor hadn't come

loose even in October's magnet disaster. I don't have that, but I'll

try polyurethane spray next

time instead of enamel.

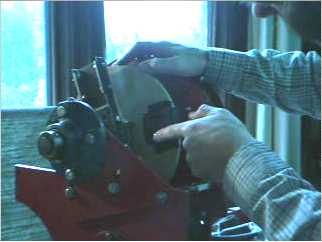

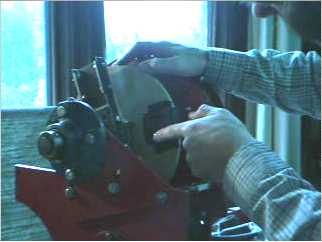

Front: Hex-nut shaped end of shaft with 22mm socket on torque

wrench.

(The wrench handle needs to be clamped down before I accidentally use

it with the motor in reverse.)

Rear-left of torque wrench handle: rotor with silver soldered copper

'wedge'.

(It needs a counterweight. Borax flux still covers some areas of the

copper.)

On the 13th, I decided I'd go work on battery making and

laid off the torque converter a week. But on the 21st, I cut two of the

copper pieces to form (roughly) the wedge. I tried to silver solder

them together

to prevent a sudden electromagnetic 'glitch' in the middle, but with

the thick slabs of copper and the December weather (2ºC), I

couldn't heat the copper up enough with the propane torch, even having

warmed the propane bottle in the house. I tried to switch to MPS gas,

but it hadn't been prewarmed and hardly burned at all.

The next day I decided to try the mini-kiln. I used the

potassium fluoride flux that I'd been sold with the silver solder (then

I read what it was and the dangers and said "augh!), and I clipped some

short sections of silver solder and laid them on the seams. I didn't

put it on for long enough, but after adding borax powder with a long

spoon for more flux and after going 10 more minutes and 10 more minutes

and 10 more minutes... the copper glowed red and the solder finally

melted into the seams. It was a solid block with the essentials of the

wedge shape, tho the seams really weren't properly filled.

Measuring Torque

I had finally (after having nothing for the first 2-1/2

years of the project) found a means of measuring torque, at the Sprint

car wheels: by putting a torque wrench on the center nut of a front

wheel.

It then occurred to me that if I ground the end shaft

collar into a hex shape, I could put a socket on it, and again with the

torque wrench, measure the torque right on the output shaft - including

for tests on the bench... assuming the shaft collar didn't slip.

Finally I realized I had enough shaft length free to slide

it over 1/2" and grind a hex shape into the outer end of the shaft

itself - that couldn't slip or come loose. This I did on the 28th,

buying a 22mm socket especially for the job and carefully filing the

hex down to its exact dimension and shape by fitting it on and filing

where it jammed.

Now if only I'd thought of this before I took the first

magnet/copper block arrangement apart, I'd be able to measure

improvement with the new arrangement. Trying to apply the desired 30 or

40 foot-pounds of force to the output arms steadily by hand shows what

a lot of force is needed. I couldn't get to 40. It was however not hard

to get the indicator to bounce to a 40 or 50 foot-pounds reading by

hitting the arm with a hammer. While such fluctuating readings can't be

trusted since the wrench's indicator arm bounces too, herein is the

torque converter theory: short, intermittent pulses of sufficient force

to move a car (at least after a final reduction gearing), with recovery

of lost motor momentum in between.

Second Trial

I was pretty sure it'd take at least two magnetic polarity

reversals (three magnets) along the copper wedge to get anything like

sufficient force, so I wasn't going to try one. (two magnets) More

likely it'll take three or four (four or five magnets). Beyond that,

the magnets would be spread out past the ends of the copper block and

no greater force can be attained.

roughly balanced rotor with copper wedge.

Copper is denser, and the block is thicker, than the steel plate.

On the 29th,

after having spent much time on batteries and

then all the Christmas diversions, I decided I couldn't let the month

expire without trying to finish the first 3-magnet version and try it

out. That day I got the copper wedge bolted onto the rotor, and since

that was heavy and unbalanced the rotor (the problem I'd hoped to avoid

by using two opposite-end sets of magnets and arms), I started on a

steel

counterweight for the other side. It wasn't heavy enough, so I bolted

it on offset to leave room for another one. I had them both on by

afternoon the next day. It still wasn't very well balanced, but was

good enough to run the motor at lower RPMs.

On the 29th,

after having spent much time on batteries and

then all the Christmas diversions, I decided I couldn't let the month

expire without trying to finish the first 3-magnet version and try it

out. That day I got the copper wedge bolted onto the rotor, and since

that was heavy and unbalanced the rotor (the problem I'd hoped to avoid

by using two opposite-end sets of magnets and arms), I started on a

steel

counterweight for the other side. It wasn't heavy enough, so I bolted

it on offset to leave room for another one. I had them both on by

afternoon the next day. It still wasn't very well balanced, but was

good enough to run the motor at lower RPMs.

Thinking about the magnets on the arm, I then figured I

could

hold two on the arms with a C-clamp without making anything, and

measure the torque (without the output actually having to rotate). So I

C-clamped

the magnets on and attached the motor with the newly outfitted rotor.

It seemed to give about 5 foot-pounds. With the 4 to 1

chain reduction, that would be 20 foot-pounds to the car wheel, which

would be half enough to move the car on level ground. That's double

what I had on the car with the two sets of two-inch lengths of copper

and double

magnets. Furthermore, it was attained with only a 12 volt battery.

What's next

The motor itself can put out (IIRC) over 10 foot-pounds of torque, but

that's with maximum amps, maximum heat in the coils and the motor

controller, and waste of energy. It might move the car on level ground.

Extrapolating (somewhat safer here multiplying elements than the

previous one, which assumed that force would increase linearly with

speed), roughly we might expect:

Magnets - Converter Torque Out (foot-pounds) - Torque at Car Wheels

following 4 to 1 chain drive

2 - 5 - 20

3 - 10 - 40

4 - 15 - 60

5 - 20 - 80

That was with about a .1 inch gap, which might be narrowed

a little. But not by much by the time an epoxied polypropylene fabric

covers the magnets to fix them in place and allowing for less than

perfect alignments.

So it would seem that evidently with 3 magnets the unit

just might move the car (30-40 ft-pds), four should traverse level

ground, and with

five it might even accelerate some or go up a bit of a slope. But with

five, the magnets would extend beyond the copper block on both ends.

Only for about 1/2" of the travel would all four

north-south-north-south transition edges be over the copper. The torque

would rise "gradually" in four steps and fall off again in four more.

(So much for the 'sudden' pulses of force.) No more than 5

magnets can face the copper at once.

If the magnets have to extend farther around the arc than

the copper block, I might as well have left the magnets on the rotor

and the blocks on the arms. But they all had to be rearranged anyway,

and that rebuilding makes figuring out the best

configuration tedious.

The copper block

could be extended a little farther. At 7.6" around the outside edge, it

could take 6 magnets, and would still have up to 4 to 1 torque

increase, and (in theory) 100 foot-pounds at the

wheels.

That's still not a lot, unless minor things like minimal

gap and double polarity reversals cause more force increase than

expected. (thinking wishfully...) The one item that might improve

things somewhat is raising the motor from 12 to 36 volts. The extra

motor power might just give sufficient extra torque with the present

copper arrangement and the four or five magnets. But the coupling of

the motor's force is still key and extra RPM obviously doesn't help.

However, if there were copper blocks on both sides of a

two faced cast PP-epoxy

magnet rotor, the forces could be about doubled. I'm no auto expert,

but I think

somewhere between 120 and 160 max foot-pounds at the wheels would give

the lightweight Sprint streetworthy performance. That seems attainable,

tho only with the 4 to 1 chain reduction, which would limit it to city

speeds.

First I'll try the simple path of putting 4 or 5

magnets on one of the arms and measuring the force attained. If it

seems worthwhile, I'll try it on the car. If it's good, great! If it's

"not bad", I'll try extending the copper and adding magnets. But if

it's just not enough "zip" for hills and the street (likely), the

double sided magnet rotor with copper blocks on both sides on the

output is next. It'll be more elaborate and time consuming to make, but

should be doable - the opposite copper would just "hook over" the

magnet rotor. More layers than that starts getting tough to put

together, but it looks like they probably won't be needed - at least

for this lightweight car.

Magnetic Impulse Torque Converter Theory

1. The motor has a 10" diameter rotor on on its shaft, the input shaft

to the converter. This rotor

and the motor's internal magnet rotor act as a flywheel to store up

kinetic energy as the motor rotates.

2. The rotor has a 6" long (O.D.) by 2" wide by .5" thick wedge of

copper on the side facing out.

3. The output rotor has several supermagnets arranged in a similar

wedge, oriented to cause rapid transitions from (eg) null to north to

south to north to south to null as the magnets spin past along the

copper wedge.

3. The magnet block is on the end of a stiff but slightly springy

arm, which is attached to a hub affixed to the output shaft. An

opposite arm has a counterweight.

4. The copper block is oriented so that its flat face almost touches

the flat face of the supermagnet block as it spins past, with a small

flux

gap.

5. This is the key part: As the copper wedge spins past the magnets,

most

especially at their sharp north-south magnetic transitions, the magnets

generate

electricity into it. The electrons looping though the fat copper

short circuit create an equal and opposite magnetic field, which

resists the motion of the magnets across the block. Since the rotor is

a flywheel and the copper won't slow down easily, the arm with the

magnets gets a

powerful tug, the force of which varies linearly with the motor speed

relative to the output speed (up to a rather low RPM point). The choice

of copper for

the block is

important: copper is only 1.64 times as conductive as aluminum but the

interaction effect this creates seems to be about twice as strong, and

the

heat losses will be lower. (Pure silver would be even better but it

costs a lot - it looks like a silver wedge would be pushing 1000$ (Dec

2011). Even with pricey lithium batteries, any efficiency gain could

hardly be worth the expense. Room temperature superconductors (where

are they?) would be super interactive and losses would be trivial.)

6. This is the mechanical helper part: Owing to the slightly springy

arms, the magnet block starts to move forward, freely for the first

instant, with the copper before

exerting force on the shaft, giving the arm a bit of inertia as well as

the continuing magnetic force. The resistance to

this motion quickly increases, linearly with the distance of flex

(Young's modulus), and the deceleration of the arm is added to the

magnetic force. The blocks rebound as the end of the copper wedge

passes. This increases the last shove of torque that the arms apply to

the hub and the output shaft. The flex also makes the forces somewhat

more smooth and gradual, as the magnetic impetus

otherwise would start and end more abruptly and might set up a fair

vibration in the car when high torque was needed.

7. The average radius of force is 4" from the center. For 4/5ths of

each

rotation, the motor spins freely and the flywheel picks up speed, then

the

magnets and copper wedge cross each other, slowing the flywheel down.

The wedge occupies a 6" O.D. arc around a 360º

circumference of π*10"=31.4". If we assume that the distance over which

the motor is slowed down is 6" (a rough approximation at best), then

for the other 25.4", the motor can

freely pick up speed. 31.4/6=5.23. This is the approximate maximum

torque increase over the

motor's torque. Since the magnets and block actually have at least

some interaction for several more inches, but peak interaction is in

much less

than six inches, and also because the spring action increases the peak

torque, it can only be a rough approximation.

For the Sprint, with the 3x or 4x chain reduction

following the torque converter, that should be sufficient torque

increase for practical use, overall speed reduction and torque

increase

being as much as 20 to 1, provided the actual output torque

from the rotor is sufficient, which depends on effectively coupling the

motor's torque.

For a direct on-wheel converter with no further reduction,

a 12" diameter system would give about 6 to 1, which might well be

insufficient. For larger rims, a 14" system with the same magnets and

6" wedges would give 7 to 1, and 16", 8 to 1. Those just might work,

but it's asking a lot.

Otherwise, the

2.8 to 1 planetary gear following the torque converter might be needed

to attain sufficient total force. Turning 5 to 1 into 14 to 1 should

enable the 10" diameter again.

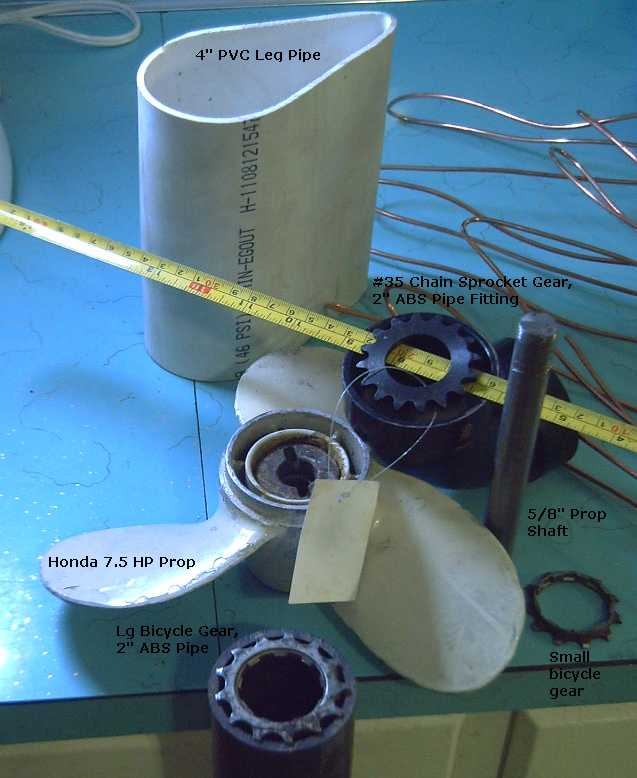

Prospective Electric Outboard Motor from

Scratch Project

I had seen Princess Auto

"weld-to-hub" sprocket gears on line in the fall when I was looking for

some for the Sprint. You buy the sprocket gear by the number of teeth

and chain type, then the hub in the desired shaft size, and weld them

together. This way, the number of types they need to stock is

minimized. They were low cost, and I thought of the hypothetical

outboard project.

I had hoped there might be some that would fit in 2"

width/diameter. The sprocket-with-chain diameter set the minimum

possible width of the outboard leg at its widest point, since it had to

run down transverse to the propeller shaft. If it fit in 2" width, I

could use 2" plastic drain pipe for the prop shaft compartment.

In November a Princess Auto store opened near Victoria,

and on December 10th I went out with a friend to see it - especially

these sprocket gears. The smallest gears were a 12 tooth for "#40"

chain and a 16 tooth for thinner "#35" chain, both the same size. That

would take at least 2.5" inside width. I bought just one of the

16 tooth gears (3$, slightly smaller with the lighter chain on it) to

size up. Aggravatingly, the hubs for this size sprocket ended at 7/8"

shaft size, just a bit too small for the 1" Electric Hubcap motor

shafts, or I might have bought two with hubs. As it was, my thoughts

went towards bicycle gears and chain - perhaps they were smaller. The

"#35" chain looked about the same thickness as bicycle chain but was

wider, the sprockets being fatter, and the segments were shorter -

doubtless better for small diameter sprockets.

When I got home I checked out my bin of scrap bicycle

sprockets. There was only one that was a smaller diameter than the one

I'd just bought, and some of the 13 teeth had been damaged by a

cyclist, never mind a 5 horsepower motor. And even it would take a

little over 2" diameter space. A couple of others were the same size as

my new one, but looked much flimsier, and again one had teeth damaged

by just a cyclist. It seemed the "#35" set was the way to go, at least

for a motor over a horsepower.

Let's see... I could perhaps drill out a 7/8" hub to 1".

On second thought, better to turn down the end of a 1" shaft to 7/8".

Monday I went back and bought the other sprocket and two hubs,

5/8" and 7/8". I wasn't going to get bearings for the prop shaft, but

there were some 15mm ones for just 2.5$ each, so I did. I didn't get

chain. At least two people have told me to use motorcycle chain rather

than 'machine shop chain' in high speed applications.

A

2" ABS pipe fitting, that fits over the 2" pipe, should be

about 2.5" inside. That should just take the sprocket, and would also

be just about right for the prop off the

Honda. Any bigger and I'd have to go to 3" pipe for the foot. 2.75 to

3" O.D. would fit the prop better than 3" I.D.

I had a 7" length of 4" PVC drain pipe left over from the

first "Ultimate Battery Stick" - a great little piece to try out. I put

it in the oven at 300ºF for about 7 minutes. By then it had sagged

and was quite soft. With a 2.5" wide aluminum channel piece inside to

set the inner width, I shaped it into approximately the streamlined

teardrop shape while it was soft and pliable. Trying to make the sharp

back edge proved tricky, and when I squeezed it hard enough, the nearby

sections went concave. While I pushed them out again, it cooled and

became stiff again, so the back edge came out more rounded than I

wanted. So "by hand" does the main job and might be deemed acceptable,

but some sort of former(s) to closely

establish the teardrop cross section would be ideal. One could try a

slightly higher temperature to soften the plastic more. My experience

with this is pretty limited - in fact, I knew ABS would work at about

300ºf, but this is the first time I've tried PVC. Don't get it too

hot - fumes from liquid PVC are known and serious occupational hazard

carcinogens. The widest

width, for the chain, came out just right. It seems to me it's strong

enough to take the force of the prop with a 5 HP electric motor, which

should deliver substantially more thrust than 5 HP gas. I doubt I'd

want to go much higher with these components tho.

Some alleged parts for hypothetical DIY Electric Outboard Motor project

My idea for the outboard leg would be that it would be

shaped towards the bottom for underwater streamlining, but left round

towards the top, where it could be used with 4" pipe fittings as the

pivot for steering. Another idea would be to have two skinny legs, one

on each side for each side of the chain. These could potentially be

just 3/4" wide - at least below the waterline where it counts. There'd

be two, but they could be even thinner than one having the usual shaft

and gears. The sprocket size would matter less, too.

Hmm... the prop shaft had better be stainless

steel.

With no need for a number of things that gasoline

outboards need, like a forward-neutral-reverse system, the critical

parts would be:

* The propeller "foot" compartment with shaft, lower sprocket and

seals, and filled with a little oil to lubricate the chain.

* The waterproof join(s) of the foot to the leg(s).

* attachment of the motor compartment and motor at the top of the leg,

with chain tension adjustment.

* steering pivot, leg raising pivot, and transom attachment clamps for

the entire outboard.

There are a few other sundry things: steering arm or cable

attachments, speed and direction controls, preferably a catch to stop

it from kicking up in reverse, skeg extending below prop,

anti-cavitation plate, and a little cover over the chain and sprocket

at the top end to catch the oil that flies off and drip it back down

into the leg.

A minor issue is that it's likely to be front heavy and to

want to flip up by itself. But this depends on the placement of the

hinge, etc, and anyway might be solved by a spring or even a bungy cord

or two. Having the motor behind the chain instead of in front would

work too, but lengthens the wiring. For that, perhaps the motor

controller should be mounted right in or on the outboard. That would

make it

a single complete unit, too.

Issues with the leg are (a) that it might be hard to find

an oven big enough to hold the actual leg piece to heat it to

300ºf softening temperature (especially for a 'long shaft'

outboard), and (b) it's almost 3" wide. How much of an issue that'll be

for friction in the water, I don't know. I suspect that low speeds

should be fine, but at higher speeds, it may prove a significant drag.

It's the main problem I see with chain drive, and with the smallest

readily

available sprockets being bigger than I'd like. There's always 6" PVC

pipe for a longer but no wider teardrop profile, or the two leg idea.

I'm thinking the total weight would be under 50 pounds,

including a 30 pound Electric Hubcap motor. Many motors could of course

work acceptably. Using a highest efficiency Electric Hubcap motor is

valuable anywhere something's being run off batteries and maximum range

or duration is desired.

In concept I very much like this whole project - partly

because I don't see anything that doesn't look readily doable, or that

should take too long. On the other hand, new designs always take longer

than one expects, and unexpected snags are to be expected.

But I think I'll collect the rest of the parts, and work

on it now and then when I'm fed up with other projects or not sure

what's next on them... or (gasp!) finished some of them.

I thought instead of getting a 5/8" stainless steel shaft

for the propeller, I'd just buy a 5/8" stainless steel bolt, 8" long.

And that would have a threaded end to hold the prop on. Gasp! The bolt

and nut cost 29$, more than all the other parts so far put together.

Being near Industrial Plastics one day, I thought of 2.5"

I.D. (2.75" O.D.) plexiglass tube instead of ABS or PVC plumbing pipe.

I found a 10" piece in the 'offcuts' bin - 8$. That solves the main

propeller housing body - it's just about the right size for the bottom

sprocket gear, and pretty much matches the base end of the propeller.

Being able to see what's happening inside is a bonus, especially on a

prototype. But even on a production unit it'd be nice to be able to see

if any seawater has gotten into the oil.

Another day I bought a longer piece of 4" diameter PVC for

the leg, at the same time as buying some for more Super Battery Sticks.

LED Lighting Project

Light fixture on the wall? - easy as

hanging a picture!

I took the

cold white light made in November, took the globe off it, and mounted

it on the kitchen wall in a corner by the table that has always been

rather dark, with one screw. An outlet was nearby at table height. I

didn't get fancy - just plug in the adapter to turn it on.

I took the

cold white light made in November, took the globe off it, and mounted

it on the kitchen wall in a corner by the table that has always been

rather dark, with one screw. An outlet was nearby at table height. I

didn't get fancy - just plug in the adapter to turn it on.

Then it occurred to me that if I changed the small

mounting holes in the back to large holes with a slot, as is so common

on electrical box covers, that one could simply hang the light fixture

on a wall from a nail or a screw anywhere, like a picture, without even

taking the globe off - Buy it, put it on the wall, and plug it in. If

you don't like the location, put in another screw or nail and move it.

(Try that with 120 volt light fixtures!)

Energy Star

After waiting some weeks for a response to my application

(on paper in the mail) to Energy Star, I finally e-mailed them.

Evidently I signed my name on the wrong dotted line and I had to start

all over again, a month later. Ouch!

But the document actually had no place for a signature. I

queried that.

Nickel - Metal hydride Battery Project

The connections inside the battery sticks seem very good,

but someone told me that if you put a bit of vaseline on each

connection, the contact is improved, and it prevents corrosion. He said

vaseline is a conductor.

My ohm meter doesn't seem to think it's a conductor.

Nickel and stainless steel don't corrode readily, still, it might help

prevent corrosion, especially if the nickel plating eventually wears

through with vibration when in use.

I pass on this tip FWIW and will try it myself. (If I like

it, what am I going to do with all those battery sticks that are glued

shut?)

First Super Battery Stick

Feeling a need

to actually complete something (besides a battery compactor I didn't

like and a couple of LED lights for Christmas presents), on the 18th I

made the first 12 volt, 70 amp-hour Super Battery Stick. I wasn't

tracking the time, but it probably took around 3 hours initially, then

on the 22nd I modified it. It should theoretically source 210 amps

continuous (the Electric Hubcap motor draws less than 150 max), and

would probably put out over 600 amps if it were shorted. I think I like

like the terminals being on opposite ends rather than set to short if a

wrench or piece of metal bridges them.

Feeling a need

to actually complete something (besides a battery compactor I didn't

like and a couple of LED lights for Christmas presents), on the 18th I

made the first 12 volt, 70 amp-hour Super Battery Stick. I wasn't

tracking the time, but it probably took around 3 hours initially, then

on the 22nd I modified it. It should theoretically source 210 amps

continuous (the Electric Hubcap motor draws less than 150 max), and

would probably put out over 600 amps if it were shorted. I think I like

like the terminals being on opposite ends rather than set to short if a

wrench or piece of metal bridges them.

It swallowed all my remaining D cells from the cupboard

and I had to take some from a couple of existing single set battery

sticks, too. It was a good time as the charge on some of the cells

sitting in the cupboard since July was getting rather low. It took a

while just to unbox and unwrap the 70 cells and slide them all in. I

checked the voltage on each set of ten to make sure I hadn't put any

cells in backwards - even one would create a big problem. Since the

cells were at different levels of charge, including differently charged

cells in series, I charged it pretty slowly, limiting the current to a

couple of amps until the voltage eventually hit the 13.8 volt limit.

Initially, I wasn't sure whether to keep the pipes nicely

enclosed to keep them clean inside, or drill ventilation holes. But

even with low charge currents, I could feel a couple of the cells or

strings getting warm through the PVC pipe. I recalled a friend saying

that at UVic, they'd wrecked some lithium batteries by overheating

them. They had planned a ventilation system but hadn't installed it

yet, and all the batteries' heat together in one place were too much

during testing of their EV project.

These weren't lithiums, but learning from someone elses'

mistake is cheaper than from your own, so I drilled ventilation holes

in the pipe. They are after all going to be protected under the hood of

the car, and I can put moisture guards above and below them. They are

also going where the radiator was, and I should be able to direct air

flow across them. I suspect they won't even get warm except maybe

during charging, but better safe than sorry.

You can buy this pipe as perimeter drain pipe with some

holes, but not enough of them for good air flow, so even in that I'm

drilling more.

Getting 70 more cells for the next Super Battery Stick

will involve unsoldering one of the earlier battery packs, and for the