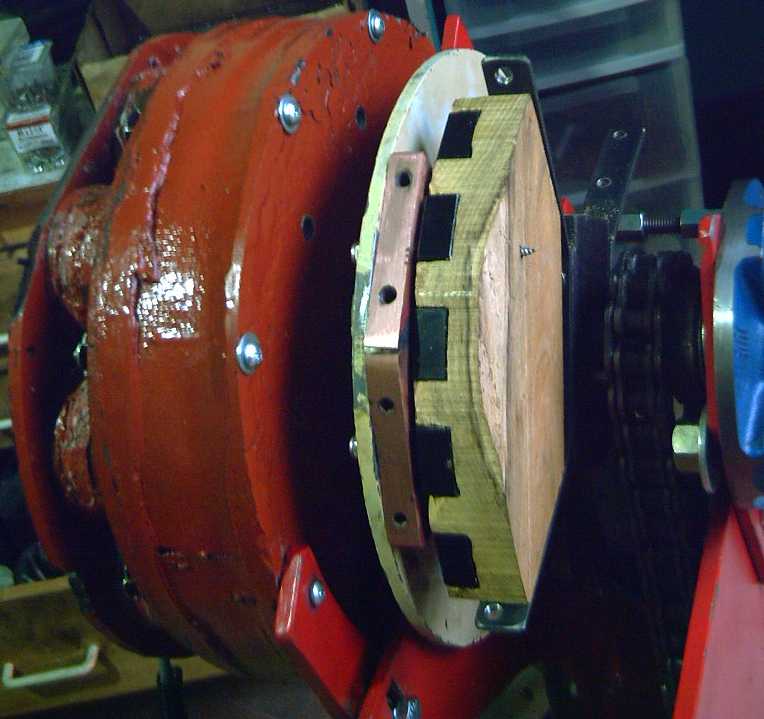

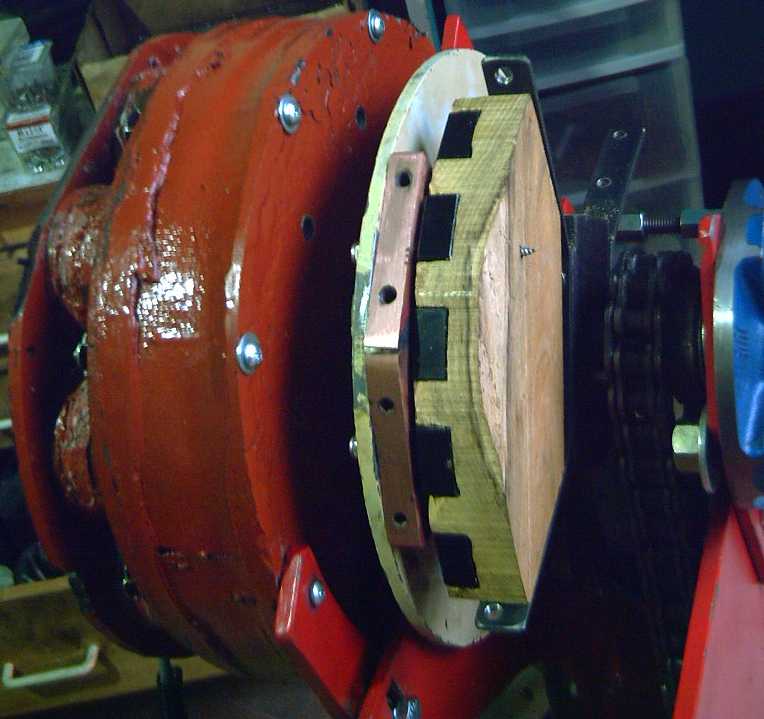

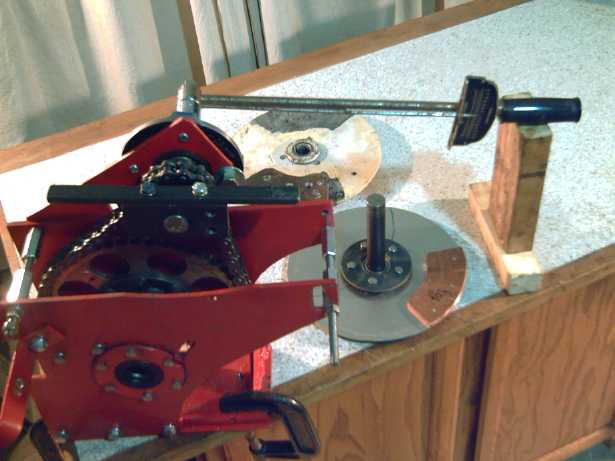

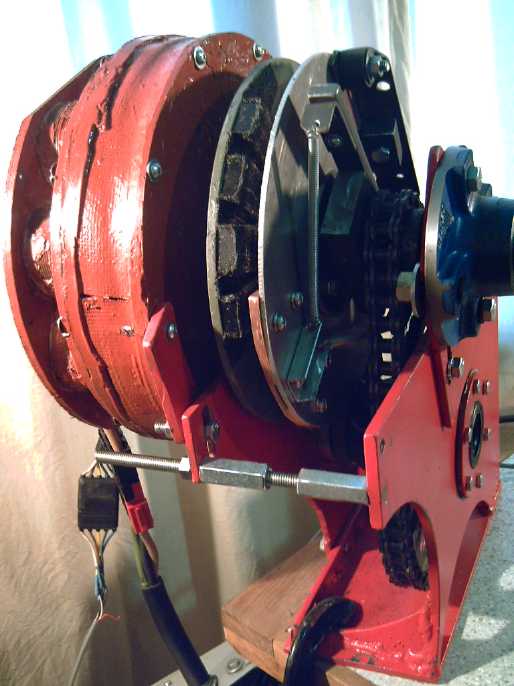

Experimental Version 2: Copper wedge on motor rotor,

and 'wedge' of 5 supermagnets on output "rotor".

I went to a new years eve party/music jam. I noticed the hostess had a

couple of heavy looking presses in the hallway with big "steering

wheel" cranks to tighten them. I wondered if they might be suitable for

electrode compacting, instead of doing up 14 small bolts around the

edges of the compactor box.

I went to a new years eve party/music jam. I noticed the hostess had a

couple of heavy looking presses in the hallway with big "steering

wheel" cranks to tighten them. I wondered if they might be suitable for

electrode compacting, instead of doing up 14 small bolts around the

edges of the compactor box.

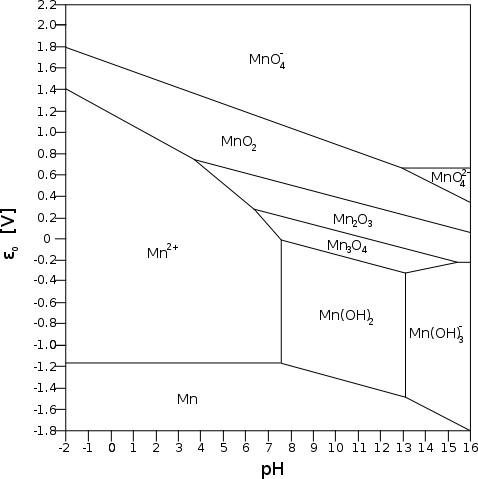

Zinc is

usually considered to

have the highest usable

negatrode voltage, -1.05 volts in salt solution. Manganese is perhaps

the next voltage up of

the usable elements. I was

guessing that its potential in salt was

the average of acid and alkali, -1.37 volts. I knew that was risky but

had nothing else to go on.

Zinc is

usually considered to

have the highest usable

negatrode voltage, -1.05 volts in salt solution. Manganese is perhaps

the next voltage up of

the usable elements. I was

guessing that its potential in salt was

the average of acid and alkali, -1.37 volts. I knew that was risky but

had nothing else to go on.

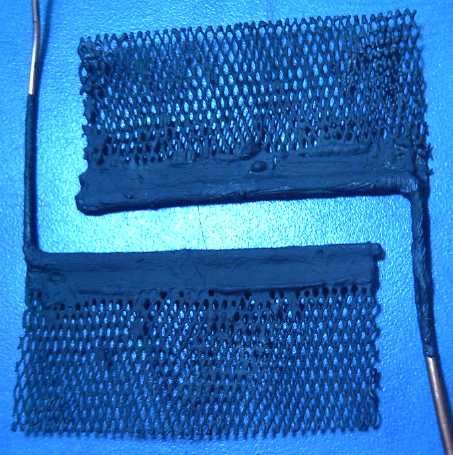

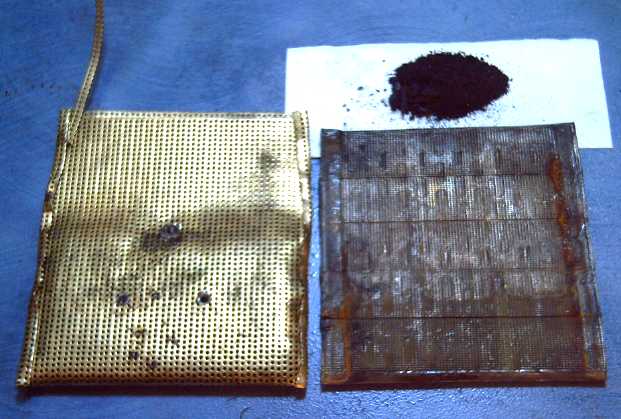

On the 22nd I tried to dig the

iron out of an iron pocket

electrode to replace it with the manganese, but it was tough going.

Probably it was charged to iron particles that would be sintered -

electroplated - to the pocket walls. Fully discharged to Fe3O4 it

should have been easier.

On the 22nd I tried to dig the

iron out of an iron pocket

electrode to replace it with the manganese, but it was tough going.

Probably it was charged to iron particles that would be sintered -

electroplated - to the pocket walls. Fully discharged to Fe3O4 it

should have been easier. I started

imagining a number of possible

molded plastic shapes, lightweight "pocket" cages with the vertical

bars and

perforated sides, or a grid lattice holding in paper sides, to hold the

electrodes and prevent them from

expanding once inserted into the cell, which appears to be my ongoing

main problem. These, or perhaps even a bezel, might also make handling

and inserting the electrodes simple, including for DIY production. And electrodes with internal grafpoxy coated

grills - or even nickel plated grills - should be cheaper to make than

nickel plated pocket cells. This construction could be applied to any

fillings chosen, so it should be

well

worth it for somebody to set up some sort of production line to make

batteries in that form without waiting for any other battery success in

my research. (Making a mold(s) for this seems like a fine job for my

new milling machine!)

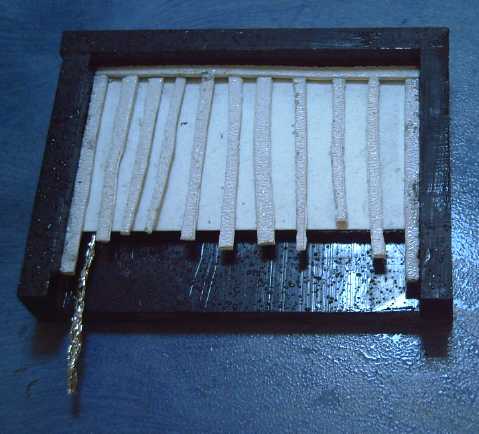

I started

imagining a number of possible

molded plastic shapes, lightweight "pocket" cages with the vertical

bars and

perforated sides, or a grid lattice holding in paper sides, to hold the

electrodes and prevent them from

expanding once inserted into the cell, which appears to be my ongoing

main problem. These, or perhaps even a bezel, might also make handling

and inserting the electrodes simple, including for DIY production. And electrodes with internal grafpoxy coated

grills - or even nickel plated grills - should be cheaper to make than

nickel plated pocket cells. This construction could be applied to any

fillings chosen, so it should be

well

worth it for somebody to set up some sort of production line to make

batteries in that form without waiting for any other battery success in

my research. (Making a mold(s) for this seems like a fine job for my

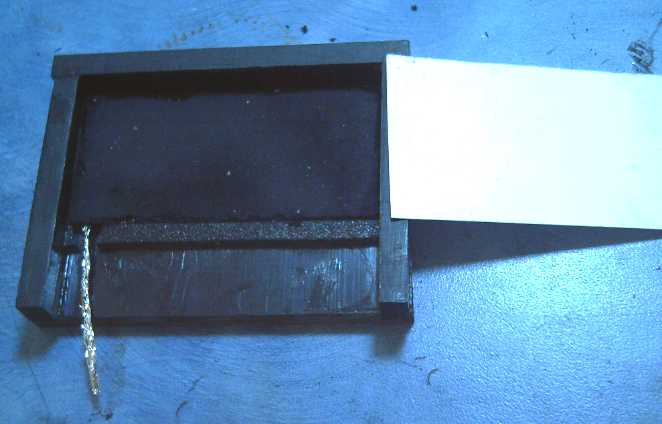

new milling machine!) On further

consideration, I decided that maybe making the

cases to exact 'bezel' size but leaving one side off might be the

simplest. The bottom electrode, exact size separator paper, a frame of

bubble path bars (glued around the edge), another separator, the top

electrode, and something springy if any space remained, would all be

layed gently into place without the likelihood of breaking the

electrode briquettes, then the

other side would be clamped on top and glued. Then it would be set

upright and the top glued on. The more of the four plastic pieces that

were pre-molded, the

easier it would be, but it could all be glued flat pieces.

On further

consideration, I decided that maybe making the

cases to exact 'bezel' size but leaving one side off might be the

simplest. The bottom electrode, exact size separator paper, a frame of

bubble path bars (glued around the edge), another separator, the top

electrode, and something springy if any space remained, would all be

layed gently into place without the likelihood of breaking the

electrode briquettes, then the

other side would be clamped on top and glued. Then it would be set

upright and the top glued on. The more of the four plastic pieces that

were pre-molded, the

easier it would be, but it could all be glued flat pieces.