Turquoise

Energy Ltd. News #51

Victoria BC

Copyright 2012 Craig Carmichael - May 4th, 2012

http://www.TurquoiseEnergy.com

= http://www.ElectricHubcap.com

= http://www.ElectricWeel.com

Month In Brief (Summaries)

- New Planetary Gear type of Torque Converter - Battery Production,

design - Motor Controllers at last (yay!) - Highlight:

My

Theory of "Thermomagnetism", and

Self

Turning Thermomagnetic Machines -

Electric Cars are happening... so does my stuff have a place? - Black

spots on

a white

background.

Electric Hubcap System

* Motor controller wiring improvements.

* Motor controller IR2133 V2 PCBs arrived; new motor controller made

(works).

* New motor molded; made another new mold to further improve them.

* 13.8 Volt, 5 Amp chargers for NiMH powered systems: 30$ for a 36V, 5A

charging

system.

Mechanical Magnetic Mechanical

Magnetic

Impulse

Planetary Gear Torque Converter Project

* Planetary Gear as a mechanical torque amplifier for indefinitely

variable gear ratios (Eureka!)

* Types of Torque Amp Controls: manual clutch, centrifugal clutches,

magnetic brake, generator brake

* Torque converter for Sprint car

Thermomagnetic drive devices

* Earth's magnetic field rotary device principle checked - but then...

why not

any magnetic field?

* Is that "perpetual motion"?

* Rationale: my theories of "thermomagnetism".

* A test to prove the theory - & a magnetic refrigerator.

* Thermomagnetic Machine ideas, designs, builds & tests.

Turquoise

Battery Project

* ChangHong won't make any NiMn batteries because they have no track

record - Yuk!

* Alternative Negative Electrode Construction - high conductivity,

amenable to DIY.

* New positrode construction too

No Project Reports on: Weel motor, Sprint car conversion,

Electric

outboard

from scratch, LED Lighting Project, DSSC solar cells, Pulsejet steel

plate cutter

Newsletters

Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

-

Electric Hubcap Motor - Turquoise Motor

Controller - 36 Volt Electric

Fan-Heater

- Nanocrystalline glass to enhance Solar

Cell performance - Ersatz 'powder coating' home process for

protecting/painting metal

Products Catalog:

- Electric Hubcap Motor Kit

- Sodium Sulfate - Lead-Acid battery longevity/renewal

- NiMH Handy Battery Sticks, Dry Cells

- LED Light Fixtures

Motor Building

Workshops

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

April in Brief

The path ahead on several valuable projects has at last

become pretty clear, and it's frustrating that there's only the limited

time and energy of a single person to develop and exploit them all.

People say in effect, "Wow, great stuff, how

can

you lose?" Yet getting anything to happen seems to be an uphill

struggle.

And I'm still no salesman - how can all my fine products not sell?

Someone I thought

could be a

partner in the LED lighting has done nothing. I

obviously need to do myself the Energy Star legwork I expected him to

do - two more months have elapsed with no action.

Changhong

batteries too has thrown the ball back into my court until I can

provide

them with long term performance and cycling data on 2 volt NiMn

alkaline batteries - that are all their parts except for the Mn

negative electrodes. This will take me months instead of getting fine

new 2 volt alkaline batteries immediately on the market with existing

production equipment.

Well! Near the end of the month, someone said he wants to

try out an electric hubcap outboard motor, for trolling on a 30'

trawler - a 2 HP "Minkota" submerged motor didn't quite have what it

takes. Since it's low speed travel, the Honda outboard with the new

version motor - and with the low pitch prop - should be suitable. For

later

I'm thinking a toothed belt "outboard from scratch", with two outside

rollers pushing the belt together at the "ankle" of the foot, would

allow a thin profile leg under the water and would be more efficient

and quieter than the chain drive I was thinking of.

Having committed the one good motor to the Honda outboard,

I'm

also making another motor. I made a better stator piece mold and am

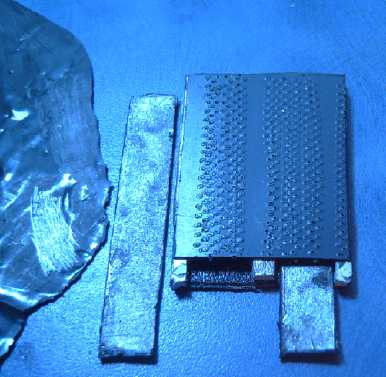

pleased with the new piece (lower left). Each motor gets more

'professional'. (Now if only I could stop the ilmenite in sodium

silicate from flaking off the coils.)

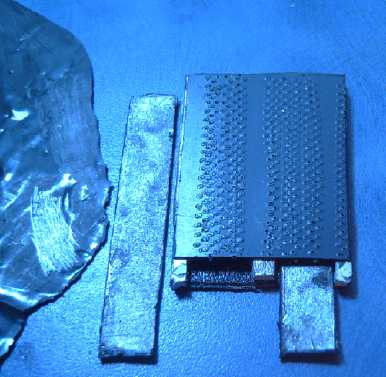

Pieces for the new motor.

Torque Converter - new concept: Torque Amplifier

After disappointing results with the magnetic

impulse converter idea and then with a centrifugal clutch system on the

motorbike, I came up with an idea based on an entirely new

principle. AFAIK no one has ever managed to create a gear with a

variable

reduction ratio.

Surprise! - There is a way to do it, with a common type of gear.

A

planetary gear has three

elements. It can be used as a 'torque amplifier' somewhat akin to

a three element tube or transistor electronic amplifier. The trick is

to drive the sun gear and

(using the ring gear and the planet gears assembly interchangeably as

convenient) let one gear slip 'backwards' (compared to the other) at a

controlled

rate as the other gear turns 'forwards'. This slows the rotation of

the gear that turns the driveshaft, since their ratios all relate to

each other, thus raising the reduction ratio to any

higher

figure.

This allows

both high torque for squealing the tires or climbing gracefully up

curbs and over parking lot

bumpers (where the car will then hang up on its center), down to the

gear's design

ratio

for

highway speeds without excessive motor RPM.

A

planetary gear has three

elements. It can be used as a 'torque amplifier' somewhat akin to

a three element tube or transistor electronic amplifier. The trick is

to drive the sun gear and

(using the ring gear and the planet gears assembly interchangeably as

convenient) let one gear slip 'backwards' (compared to the other) at a

controlled

rate as the other gear turns 'forwards'. This slows the rotation of

the gear that turns the driveshaft, since their ratios all relate to

each other, thus raising the reduction ratio to any

higher

figure.

This allows

both high torque for squealing the tires or climbing gracefully up

curbs and over parking lot

bumpers (where the car will then hang up on its center), down to the

gear's design

ratio

for

highway speeds without excessive motor RPM.

If the slip gear slips

freely,

the output won't move at all. If there's no slip, the designed ratio

applies. If it slips at 3/4 speed, the output 'gear ratio' is

quadruple, eg 12

to 1 instead of 3 to 1. Like the base of the transistor, it

takes little energy to control the slip rate to control the reduction

ratio.

Once this new idea was established, potential ways to

control the slippage of the ring gear soon came

to light. One "magnetic brake" idea would even

reduce the drive ratio towards 1 to 1 at highway speeds - "overdrive".

The various ideas for controlling the slip proceeded in

theory in my head combined with

looking over various items of potentially fitting hardware. Another

project took precedence, but I started construction of the simplest

type on the 29th for the Sprint car, using

a 10" V-belt pulley for a manual gear-slip clutch. A rope will tighten

around it to reduce or stop the slip gear (planet assy) slippage. On

the 30th I carefully ground the end of a 1" round shaft into a pentagon

shape so it would fit into the 30 spline fitting on the ring gear, to

drive the chain drive to the differential.

The sun gear (goes on the motor shaft) will be the most

difficult to fit, as it doesn't quite fit a 1" shaft, and also it has

no spline or alignment key to keep it from slipping on the shaft. Also

I need to finish the new motor to attach it to.

NiMn alkaline Battery Production

The engineer at Changhong

batteries was very interested in my idea for simply making 2 volt

nickel-manganese cells from the

same production line that they use to make flooded 1.2 volt

nickel-iron,

nickel-cadmium and nickel-metal hydride cells.

The engineer at Changhong

batteries was very interested in my idea for simply making 2 volt

nickel-manganese cells from the

same production line that they use to make flooded 1.2 volt

nickel-iron,

nickel-cadmium and nickel-metal hydride cells.

But he wanted

performance and cycling information that I can't supply without

producing a

practical Mn electrode myself, putting it in a Changhong NiFe battery

in place of the iron, and running fairly extensive tests on it and

charting

readings over some months.

Then some academic skeptics convinced him it probably

wouldn't work -- and if it did it would have short cycle life. This

double

denouncement is typical unreasoned resistance to anything new by

"experts" who think they already know everything, so

there can be nothing new under the Sun. Evidently this is no different

in China than anywhere else. It's easy to just ignore a new

idea being put forward by - naturally - just one person, and if he

persists in trying to explain it, just put him down as being a quack

without making the mental effort to consider the issue fairly on its

merits. A lot of creative people

with fine new ideas and discoveries are accorded this treatment. If I

pushed hard enough, I might just convince them to make a batch, but

with no belief in it, they'd probably do a shoddy job somehow, eg, of

the zinc plating, and without trying to figure out what went wrong, say

"See, it doesn't work; you wasted our time." and then they'd be almost

impossible to approach again.

It's a vexatious

delay and addition to my workload. All they would have to do is

interrupt production of negative electrodes and make a small batch of

them to see for themselves -- then either they've lost some bit of

production and satisfied their curiosity, or they change the world.

Jungner or Edison, the creators of their battery production system

(they bought it from Varta in Germany), would have dug right in with

enthusiasm.

However, I also still want to make DIYable battery

constructions, and now I expect to be able to make good Mn electrodes

(read on) and get performance and cycling data, so I just said if it

was too hard for them to make any to try for themselves, I'd get back

to them in a few

months when I've done the tests and got the results myself.

I noticed an unusual

type of electrode briefly mentioned in Alkaline Storage Batteries:

copper and iron powders, pressed around a fine wire

screen (a metric ton per square centimeter of pressure), and then

sintered to fuse copper particles together. This made a porous,

sintered iron electrode that

wouldn't fall apart in a flooded cell, without needing a perforated

metal outside casing. The sintered copper throughout gave it higher

current capacity than the pocket cells.

I'm going to try to do

the same thing with zinc and manganese. (or zinc and MnO2?) With the 1%

stibnite that I found makes Mn negatrodes work, of course. Zinc will

need less pressure than copper and can be

sintered in a regular oven. If it works, it would be the easiest for

DIY, including for me, and it should have excellent conductivity. I

ordered fine zinc powder.

If that works, the last main hurdle for usable batteries

will be a positrode with good conductivity. A rolled out sheet of

grafpoxy had puzzlingly high resistance, making me doubt the value of

an idea to make "grafABS" to make

injection molded conductive ABS plastic pockets - square or rectangular

cylinders or

hollow plates, and minutely perforate them with the IR burning laser

diode.

Another idea occurred to me. Use the expanded graphite

sheets I gave up on earlier, but in perf plastic pockets: Make tall,

thin pockets, and cut 'bars' of the graphite sheets that would go along

the back of the pocket from the bottom, out the top, and up through the

lid of the cell. In this arrangement, as they swelled up inside the

pocket after the cell was filled, they would (presumably) compress

against the electrode substance more instead of loosening. The top of

the each bar would get a hole through the lid, and a bolt through

itself above, to

make connections.

Motor Controllers (Yay!)

Mid month the IR2133-V2 circuit boards finally arrived,

beautifully done with solder masks and silkscreened component outlines

and

I.D.'s. I found a mistake (mine) and decided to add another pin

improved for

microcontroller overcontrol, so there'll be a "V3" board. But not

before I've made a few V2

motor controllers - one for the Sprint, one for the Tercel, one for the

outboard, one for the

shop, and three for the big 15 KW Weel motor. (Yikes, that's seven,

plus any I sell!

These 10 circuit boards are going fast!)

Ordering components was another grueling 4 hour session on line.

On the 16th and 17th I re-fitted a previous controller

chassis with

the new board and parts, and on the 18th I ran a motor - *the* motor at

the moment - with it. It worked great.

On the 20th I proposed to a company by e-mail to convert a

small ferry to electric using one of my motors and controllers inboard,

and several solar panels on the roof. (They said no.) The same day a

fisherman from

Port Alberni phoned me asking about putting an electric motor on his

30' trawler for trolling, and I gave him a very similar proposal but

with just two or three panels. The deal ended as an electric outboard

to try out

before committing to anything else.

Someone said there were BLDC motor controllers, 42 volts,

120 amps, in the hobby shop for 220$, so I was wasting my time making

my own. I went and looked. They did. But, first, it was just a small

circuit board with a metal plate and some medium fat but very short

wires. No chassis, no breaker & on-off switch or main fuses, no

cable

clamps... those would all be add-ons. Second, it

was for short duty use, with no serious heatsinks. The seller said

model

airplane flights were maybe 10 to 20 minutes and he wouldn't try

running it for an hour or two. Third, I suspect if it hit 45 volts or

150 amps it would blow. Mine can do to 60 volts, and could probably hit

200 or 300 amps for brief periods. And it's advanced "CRM" or "direct

torque control".

Compared to the hobby controller, the Turquoise BLDC

Motor Controller is easily worth 500$ and more.

My theory of Thermomagnetism - Magnetic Motion

Machines

The project I put the torque converter on hold for - crazy

as it seems at first - was a magnet machine that would keep turning

itself. It stemmed from other ideas -- partly from the magnetic field

drive for spacecraft

idea and partly from an early attempt to make a magnetic torque

converter,

where it seemed my design would create perpetual propulsion. At the

time, I thought surely I must have had something figured wrong. But

here was the same conclusion popping up again when a similar idea was

considered.

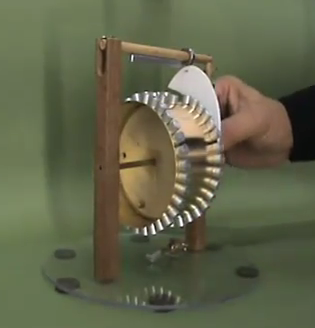

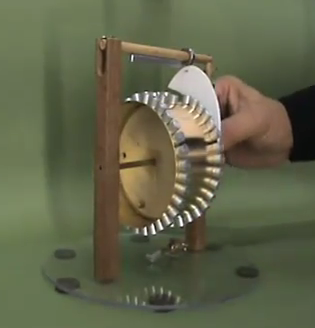

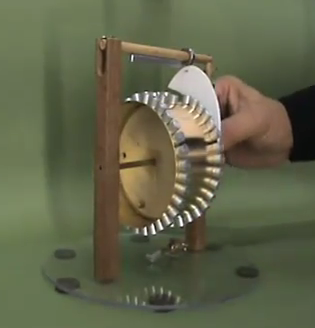

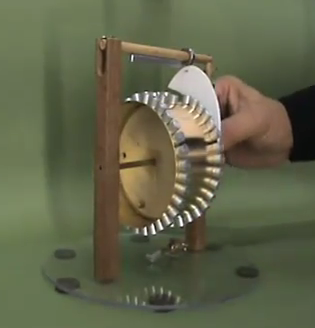

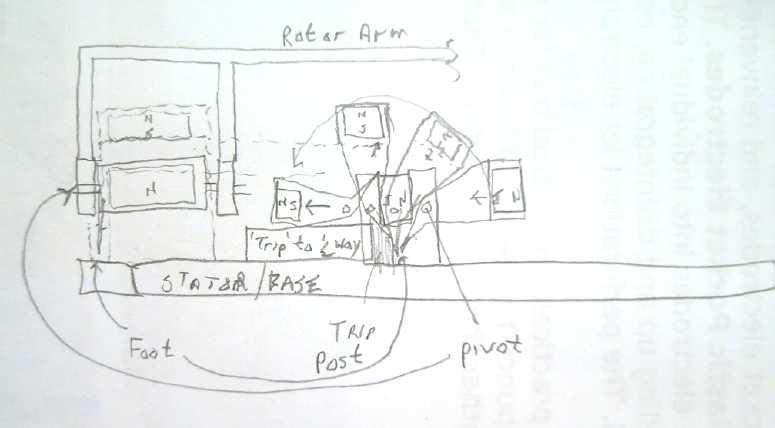

demo seen on the web...

I've always been skeptical of 'perpetual motion', but magnetically

and in theory I couldn't see why this wouldn't work: a push by

magnetic repulsion (or attraction) in one direction, but no force in

the other

direction

owing to mechanically holding each armature magnet above the main

strength of the field until just before or after it passed a stator

magnet.

I've always been skeptical of 'perpetual motion', but magnetically

and in theory I couldn't see why this wouldn't work: a push by

magnetic repulsion (or attraction) in one direction, but no force in

the other

direction

owing to mechanically holding each armature magnet above the main

strength of the field until just before or after it passed a stator

magnet.

Among all the purported magnet machines I found on the

web, most of which were probably phony, one both looked plausible and

was

simple enough to grasp the

workings, and it worked essentially by this very principle. A magnetic

piece, usually a ball, will accelerate down a "V" shaped magnetic ramp,

either by attraction or repulsion, and shoot off the end. There are

lots of videos of magnetic ramps working on youtube. This machine puts

a

"V" ramp onto a circular rotor, and a device pushes the stator magnet

out of

the way momentarily when passing the end/start point of the ramp, just

when it would otherwise create an equal magnetic reverse force that

would arrest the

spinning at that point. Thus the cycle would repeat. As the animation

[taken from a longer movie from which the still image is derived]

shows, a smaller magnet at the bottom also jumps in half a cycle later

- doubtless an extra kick is gained at that

point. I'm guessing it doesn't quite keep turning without that. So,

energetic

as it looks in the animation, this design, assuming it does really work

and isn't a fake, probably wouldn't put out more than a watt or two of

useful energy without stalling, and the light forces only work because

of very

low friction. (Eg, note that the [low friction aluminum?] arm hits on

what

looks like a ball bearing race at the top rather than on the support

itself, for lowest friction.)

A friend who is involved with testing for the New

Energy Congress said he's always fighting off 'perpetual motion'

devices. He

devised a "feather test": If the device stops moving with a feather

rubbing on it, it's rejected as being unable to create a useful amount

of energy. This is a good and pragmatic test, because it sets aside

arguments about whether something is theoretically possible and

separates demos, whether they work or not, from machines that can

actually do useful work. He said that so far, none presented have

passed the feather test.

Back to the topic... here was something that magnetically

looked

theoretically possible - and that had been done and was being used

according

to some - but thermodynamically seemed theoretically impossible. I had

heard no coherent, understandable explanation of where the apparent

energy

was supposed to be coming from. "Zero point energy" was no explanation

for me. If these things worked as seemed magnetically possible, the

energy must

come from somewhere - but where?

Last I heard, we see the effects:

that magnets have force that can move certain materials, and we know

the relationships between magnetism and electricity,

but no one knows just what magnetism is or how it works.

A key is that energy is neither created nor destroyed. So

regardless of single versus 'perpetual' (cyclic) motion, where does

magnetic force and energy come from in the first place?

A stationary object appears energyless -- but it

does have internal energy: its heat.

My

theory of thermomagnetism is that

magnetism is a transfer of force and energy between

the small

scale vibrational motions of the atoms in the magnet - its

heat - and the larger scale directional forces with

the potential for creating large scale motion that we observe as

magnetism. (How it does this I'll leave to the nuclear

physicists.)

If an object is pulled away from a magnet against its

magnetic pull,

or pushed towards it against its repulsion, the energy required to

force that motion is transferred to increased vibrations within the

atoms - in other words, the magnet is heated up.

If an object is

permitted to be pulled towards a magnet by its tug, or if it is

permitted to be pushed away by its repulsion, the energy

expended by the magnet in the

pulling or pushing comes from the vibrations of the atoms: the magnet

cools.

The magnetic energy versus the heat energy would be an

exact 1 to 1

correspondence, energy used pulling an object = heat energy lost within

magnet.

Normally the one time heating or cooling effect is

imperceptible.

But if the theory

is right, I had the thought that one

might be able to measure a temperature drop within the

magnets as a self spinning machine continues to turn, especially if it

was doing

real work. I

chanced to meet a coast guard vessel marine engineer who seemed very

interested in

such

things on the 23rd. He said he

had actually

seen a

small magnet machine that someone pulled out of his pocket. Set on a

table, it

started turning and just kept going. When I told him the theory, he

said that people have observed that working magnet machines get cold,

but that

no

one

understands why. That certainly tied in nicely with the theory. Perhaps

magnets in magnet machines need heat sinks... to keep them warm!

He also

said certain machines he'd heard of "warble" up and down as they turn

horizontally, which

sounded exactly like my "take 3" design. I devised a fairly simple test

for the theory but haven't tried it. (in the detailed project

writeup)

There is precedent

for this 'reversal

of entropy': a refrigerator or heat pump extracts more heat energy from

a cold object, transferring it to a warm object, than the energy used

to effect the transfer. On the face of it, this "overunity" efficiency

too might well sound impossible, and too good to be true. Except that

we're familiar with it and we all know it works. A physicist said it's

been calculated that as much as 1200% heat transfer could theoretically

be gained with present types of systems. (Hmm... could you

run a turbine with the transferred heat and have it power the heat

pump? Yikes! - another potential means of creating 'perpetual motion'?)

A practical magnet machine

with substantial torque and power to do work of course would have broad

implications. Free

energy to make electricity would be always available, day or night,

windy or calm, winter or summer.

There seemed to be nothing for it but to make a machine and find out

whether

I had

something figured out wrong, or if it could actually be made to keep

turning. At least I had a theory to explain how it should work -- and

if I was wrong, it

would seem I at least have quite a bit of company. I figured I

could afford a few days to try a few things out and I did. The design

progressed with half built models which weren't completed to the point

of operating, but which each helped conceptualize something better and

progressively led from things that would have been demos to a design

that attracted the armature pole as it approached a stator magnet, then

flipped it as it passed, and repelled it afterwards. If indeed it

worked, it would be likely to have enough torque to

actually produce usable power. It would take a very large,

stiff feather to stop. But the tricky pivoting parts wouldn't be made

in a day and I thought of several variations on the theme by the end of

the month. Better to work on other things for a bit, play around with

the magnets by hand, and let the forming thoughts be attracted or

repelled in my mind.

Electric Cars(!)

Jim Harrington (doing the diamagnetics experiments on the

Ecosat satellite that somehow got me started on the above), bought a

Mitsubishi iMiEV on about the 12th. This time, they were

right there on the lot - four of them - and he had no

arguments or hassles. It was around 30000$ with a trade-in and a BC

5000$ incentive to buy a new EV or

hybrid car. (I think the BC incentive program is actually working!) I

expect 10,000 $ or more of the price could be attributed to the lithium

ion

batteries.

On the 22nd we drove out to Goldstream Park marina in it

to his electric outboard sailboat, and took a 3 hour cruise to check

the performance of his system with lithium ion batteries in the

sailboat. The car was lovely and had lots of power. The boat motor

ran well as long as we kept the current under 40 amps (@36v=1.44KW=2HP

of electricity), which was the limit of the lithium ion battery

charge/discharge controller. It was a lovely, sunny, rare day's outing

for me. I've never seen seals just floating out in the water sleeping

with their flippers sticking up before. I thought they were two

floating

logs with branches. We were moving right along, but so

quietly that we got pretty close before they lifted their heads and saw

us.

A former co-worker, a retired plumber, visited on the

16th. He had

spent nearly 20,000$ converting an S10 pickup truck into a very nice

electric

vehicle, over a 3 month period with parts from Canadian Electric

Vehicles and assisted by his

son, and

he's enjoying it very much. 4500$ of the cost was for 24 lead-acid golf

cart batteries. He had stronger back springs installed to handle their

weight. He retained the manual transmission. I got a ride. It was

interesting that

there was no need to put in the clutch to start, or while the truck was

at rest, since both the vehicle

and the motor were stopped. The clutch was only for shifting between

2nd, 3rd and 4th. (First gear was only for spinning rubber.) His motor

was over 40 KW,

delivering up to 32 HP. At one point we were drawing over 100 amps

during acceleration per

his handy little dial on the dash: at 144 volts, 14400 watts. He said

it can go up to 300 amps.

At the VEVA.ca Victoria meeting on the 18th, someone

brought

a Nissan Leaf and three of us got a ride. There are evidently

about a dozen of them around town now. The

Leaf is a beautiful car, and very quiet. Stopped at a traffic light

with the windows up, it was eerily silent inside. The acceleration from

0 to 50 Km/hr was astonishing - it would leave typical gas cars in the

dust. The price tag was about 40,000 $.

Also at the VEVA meeting

was a great looking electric tricycle, brought by the maker. It

had bicycle type wheels and a bicycle hub motor on the right rear

wheel. One "feature" I didn't like was 3 "U" brackets going just around

the tire on each back wheel. If he doesn't put on proper fenders to

cover those, somebody's gonna lose or severely maul a finger in one. He

said he doesn't

make a lot of money on them, but he's doing what he likes to do.

My friend and his son also put in an appearance with the

electric pickup truck. (And the owner of the Leaf turned out to be a

onetime plumber who had worked for the pickup owner's father long ago.)

As usual I showed new people my 30 NiMH D cell car battery

(the present six 6V pipes set is now about a year old and still working

like new, which is (iirc) already better than my last lead-acid). And I

showed some 12V LED car lights starting at 1$, a fraction of Victoria

store prices, but nobody bought anything. (Perhaps I shouldn't have

mentioned they were "from dealextreme.com".) Oh well, I'll want many of

the lights for the Sprint and all the batteries I presently have for

whatever car I first electrify.

So if electric cars are taking off anyway, what's my stuff for?

It's really great to see these things starting to happen,

but the costs and the high powered systems, remind me why I'm doing

this work. The torque

converter

alone (at last looking like a pretty sure bet), should eliminate much

of the 30-40% loss of the typical automotive transmission as well as

provide a high ratio to get a vehicle moving, so substantially less

power will be needed for propulsion - 2/3 as much at most. This would

drop the price of cars a by a few thousand dollars in batteries and

motive power requirements as well as improve both low and high speed

performance. For the pickup, it would immediately shave 1500

$ off the lead-acid batteries, and by dropping 1/3 of their weight and

eliminating the transmission, it

might have meant leaving the regular springs in, and a smaller motor

and

all the paraphernalia that goes with it, further reducing the overall

cost.

The Electric Hubcap wheel drive system as a whole would

allow sizing still smaller batteries and the minimal 5KW motor size -

for a typical day's city driving rather

than a maximum range (since the gas engine can take over for longer

trips and on the highway), further reducing the battery cost and added

weight.

Then of course a cheap, high energy density battery would

be just the thing for any EV system and for off-grid storage as well.

Presently NiMH dry cell battery sticks are little if at all cheaper

than lithium types.

Nickel-manganese from ChangHong looks very promising as a first

offering using one of my chemistries if I can get them convincing

performance and cycling data from homemade electrodes. Those might

cost about 300 $/KWH - not a lot more than

lead-acid for a much lighter battery that should last much longer, and

about 60% of the price of NiMH dry cells or lithium ion types. Mildly

alkaline permanganate-manganese will be best of all and cheapest if I

get good electrode constructions, and if the permanganate positrodes

prove to have have a long cycle life. (Nickel manganate-manganese would

also be pretty economical if the permanganate has problems.)

And then, if the magnet machine proves to work and to be

practical, it changes everything again. Not to think of all the other

potential uses, a car needing no external power may need only a few

batteries for when a surge of power is required - or maybe even none at

all. Could it even replace the electric drive motor? (Hah! NO WAY will

it replace the torque converter!)

The White Background

The seemingly perplexing lack of action on renewable

energy and electric transport got me going on the green energy

projects. That started waking me

up to the evil forces frustrating the progress that everybody wants in

principle, tho so many seem indifferent to. Only a few are deliberately

hostile. The

black spots often get me indignant, but

it must be remembered that they're just black spots on a white

background, not the other way around. And lights are being shone on

them, exposing them to

increasing public scrutiny and criticism for eventual correction.

Forgiveness, mercy and enlightenment to those who today foolishly

perpetuate the problems without a thought for others, the future, or

their own real best interests. Let's all start pulling together.

("Do you not realize that the hope of a better nation — or a better

world — is bound up in the progress and enlightenment of the

individual?" - Jesus)

From a

broad perspective,

evils of a century

ago, or farther back, could hardly take place again in a similar way

because we've evolved beyond them. In the 1960's fish

returned to the Thames river after a century's absence due to

pollution, and

I hear lake Erie has largely returned to health. (thanks largely to the

invasive Black Sea mussels filtering the water.) Recycling is replacing

open ended dumping and use of materials leaving deleterious wastes is

decreasing.

Spiritual, cultural, scientific and technical progress can

be thwarted for brief periods, even a century, but they continue

progressing even unseen and arise again to be adopted in new forms. Our

vast and accumulating knowledge base can hardly again be burned and

lost with worldwide dissemination and storage of information. Let us

transcend present problems with all the newly appearing sustainable

technologies and with new, superior organizational structures.

Various

means of harvesting energy are proliferating and, along with the

upcoming world population decline, there will surely be abundance for

all.

Today's evils will be gone in another fifty years or a century and the

races will have moved far

towards social and physical sustainability and human brotherhood. Often

in fits and

starts, and often

painfully, the world progresses.

The universes were created to evolve towards perfection; that isn't

their starting condition.

Electric Hubcap Motor System

The motor on the motorbike, a 2011 prototype, didn't seem

to run very well for the magnetic impulse torque converter test at the

start of the month. A couple of days later, I tried swapping phase

wires around. Yep. That was the problem. It ran great once they were

right. It's funny it can run well enough to fool you in two of the six

possible combinations of wires.

That means the magnetic converter didn't really get a very

proper test. At first I thought I might try it again sometime with a

modified design, but the planetary gear torque amplifier would seem to

be the way to go. There may be some magnetic way to accomplish the same

thing, but I haven't figured anything like it out.

The prototype motor got munched by sudden transverse force

in the next test with a centrifugal clutch. The molds for future

motors had already been improved. I made a couple of additional

improvements - a better mold already planned, and a change to the rotor

compartment so the 'corner' where magnets were getting out if they came

loose was now the sealed side, with the joint in the outer corner,

behind the magnet rotor.

I have a couple of prototype motor shells, but I guess I

won't use them. I might be able to cut down some of their plates to the

new slightly smaller size and use them as rotor ends since they'd be

the same (except for having oddly placed [but usable] vent holes). That

would reduce the waste of pricey epoxy.

Motor Controller: Battery Wire Clamp Assembly

I had made a copper bus with a clamp to connect from the

fuses to the main supply bus inside the motor controller. But before

the power would get to that point, it was now bothering me that for the

motorbike unit with (so far) no internal breaker or solenoid that the

power wire bolted to, unless the battery wire was clamped to the motor

controller chassis, it was only held in place by the fuses connecting

it. If the fuses pulled out (and there was nothing but friction to

prevent it), the main battery wire, unfused, could touch anything -

BLAM! I didn't want to use it any longer in that condition, much less

supply such units to anyone else.

Even where there was a breaker, switch or

solenoid/contactor relay terminal to clamp the battery leed to, the

connection at the fuses, albeit short and internal, was floating

around loose. So I set out to make something better.

After considering things like making a copper plate (that

would need a

torch to solder the fuse holders to), I simply unsoldered one of the

four fuse holders, drilled and threaded a hole in the plastic under it,

and put a machine screw through the hole in the copper bar into the

plastic. Three 40 amp fuses instead of four is plenty for the

motorbike. Good enough!

For the next one, however, I made flat #18 guage

nickel-brass plates, with

the heavy wire clamp on one end, and with two more holes (total 6) for

four

fuses and two hold-down bolts. Nickel-brass is stiffer than copper, so

the #18 wasn't too thick to solder to.

IR2133 V2 Circuit boards arrive, & 'new' motor controller

After not hearing again from the circuit board company, in

March I had had a new idea: Since they couldn't seem to read the

attachments in my e-mails, I gave them the web link to the design where

I had posted it on my web site. They had no trouble with that. I wish

I'd thought of it long ago.

On April 10th the long sought boards arrived. I had only

asked for double sided, but they did solder masks and a silkscreen

layer with the part outlines and numbers as well. Beautiful and very

useful! There's less chance I'll make a mistake putting on the parts.

Since the boards are so much cheaper from this Chinese maker, I'll have

them

done that way from now on...and stop putting text on the top copper

layer.

A couple of

days later I decided I should make one up.

First I put some parts on the board to see what I needed to order

besides

the 74ALS86 SOIC XOR gates. Then I did a little editing of the PC board

- already I can see a version 3 will be desirable. Worst feature: a

trace I hadn't re-routed after moving a part was shorted to a pin.

Rats! I'll just cut the traces and hard-wire it for these 10

boards. Anyway, nice to notice it before trying to run it!

A couple of

days later I decided I should make one up.

First I put some parts on the board to see what I needed to order

besides

the 74ALS86 SOIC XOR gates. Then I did a little editing of the PC board

- already I can see a version 3 will be desirable. Worst feature: a

trace I hadn't re-routed after moving a part was shorted to a pin.

Rats! I'll just cut the traces and hard-wire it for these 10

boards. Anyway, nice to notice it before trying to run it!

Then I got on line for a grueling 3-1/2 hour session

ordering parts at Digikey Electronics. I was somewhat perturbed to

discover the IR2133 MOSFET gate drivers are now over $15. Maybe

somebody's using my

design and the demand is high? - there was interest on a motor

controller

list, and I did put the design on the web. Perhaps I'm not even the

first to make my own PC boards?

I spent the 16th,

and a little time on the 17th, putting the new controller together in

an old chassis. Most everything had to be moved, redone or just done,

so I didn't save much work over

building a new one from scratch except the sheet metal fabrication.

(Even there, a chassis side piece had somehow gone missing.) I

made new style wire clamps and a

fuse "platform" on plexiglass. On the 18th I tried running the one

working motor, and after a few hiccups, it worked great. (2

diodes that went bad, and

crossed phase

wires. I threw out the rest of

those diodes. Someone gave them to me long ago. Always look gift

components in the mouth.) I didn't do extensive tests. For a change I

checked the RPM. With only 24

volts instead of 36 I could get the motor over its design speed of 2000

RPM.

Yikes! What horrendous speed was the one going that flew apart at 42

volts?

Someone said he thought I was reinventing the wheel: the

hobby shop had similar motor controllers for 220$. I went and looked.

The largest controller they had was indeed rated 42 volts, 120 amps for

large model airplane motors. However, the salesman expressed doubt that

it would work for driving a car. He said the airplanes might fly for 10

or 15 minutes - he wouldn't try running it for an hour. "Hobby use

versus industrial." he shrugged. Nor would I trust such a small unit on

the road. In addition, while I'm calling it "40 volts at 130 amps",

I've used 48+ battery volts, and they'd probably take well over 250

amps momentarily. There are enough unpleasant external surprises on the

road without adding internal ones. I wouldn't be surprised if the hobby

shop board would blow in a moment at 45 volts or 150 amps, and it

didn't have a heat sink capable of dissipating the heat of sustained

high power operation.

Aside from that, the Turquoise Motor Controller comes in a

heavy duty aluminum chassis wiring box and includes a breaker-switch,

fuses, and optionally a solenoid to turn on the power remotely. Theirs

is just a circuit board and all the other parts have to be added

externally - it would all add up to maybe 400$ plus labor. This makes

500$ for my heftier premade unit seem like quite a reasonable price.

New Electric Hubcap Motor - With Layout Improvement

By the 23rd, with two working motor controllers now on

hand, I started getting concerned that if I managed to sell a system, I

would have no working motor. Soon someone did in fact want to try out

an Electric Hubcap Outboard, which has pre-empted this motor. I was up

in the air whether to work on the

torque converter or the magnet machine. Instead I molded a new stator

end piece for a new motor and thought about the next steps on the

others. (150g PP cloth; 600g epoxy. This is the plate that takes the

stress of the magnets pulling towards the stator, so I'm making them

pretty thick.)

Then I made a new mold for the center ring piece,

with

bumps for the coil centers but no shoulder around them. The coils will

definitely be affixed in place on both plates, and the slight overhangs

of

wire will face out, while the cores will butt right up against the

center ring as close as possible to the magnet rotor.

New inner stator plate outer face mold

1" thick x 12" x 12" 'butcher block' UHMW polyethylene, made on 26th

I think I'll use for both stator plates - it'll hold the

heavy #11 wires on the coils better.

Some

reinforcement ribs might also be feasible... hmm, another new good

idea! Will I ever have a final design? But I couldn't see anywhere

substantial ribs would fit on this inside piece. On the outside of the

outside piece might be a good place. If it had some stiff ribs, I might

trim 100 grams off it in thickness and still have the desired stiffness.

On the 27th I made the piece in the new mold, using 100g

polypropylene "landscaping" cloth and 400g of epoxy - thinner than the

outer piece because it takes less stress and because its thickness sets

the minimum distance the magnet rotor can be from the tops of the

coils. Since the present motor can easily be overrevved, it would be

nice to reduce the gap, decreasing speed and increasing available

torque. This piece should allow a gap as thin as is magnetically

practical anyway,

about 1/2".

I found a magnet rotor already zinced and polyurethaned.

Among some plywood reinforcing pieces for the molds I

found also a rotor end piece I must have made a while back. That's two

more little motor making jobs done. So the last molding job is the

outside circumference of the rotor

compartment, and in fact it will be the first one done from scratch

with the mold setup made for that.

Pieces for next motor

First I have to decide where to locate the holes in the

stator plates. Originally, the coil holes went at left and right inner

edges

of the toroid cores to keep them in place (at least left and right - in

and out there was some undesirable free play). Now with the composite

buttons

keeping the coils in exact position, the bolts could be closer to the

centers of the cores, and the extra thickness of the buttons gives more

material to screw them into. (Metal nuts by the spinning rotor magnets

are undesirable.) A few more bolts at the inside and outside edges of

the plates wouldn't hurt either, if space can be found to place them.

Then I have to calculate all those hole positions and set

it all up as a CNC drill program. Sigh - I could use some CAD/CAM

software.

Remake of the Honda Outboard motor

A fisherman was interested in putting an Electric Hubcap

motor on his 30' trawler. But if it proved to have insufficient thrust

for trolling or the project otherwise proved unworkable, it

would be a considerable wasted investment in time and effort to install

and remove.

Instead we decided I should put the electric outboard back

together, and he should make an outboard mounting on the back of the

boat.

If it didn't work out, I'd still have the outboard and he'd have a

mount for any small outboard.

A glitch to the program was that the original motor had a

9" rotor and was a little smaller than the later units, and it was an

open frame with no case. It just fit under the Honda hood. The new

motors don't quite make it.

Somewhere in the process of trying to fit the motor, I

found that most of the surprisingly strong gear noise in the

previous version was because the motor was pressing down on the drive

shaft. If it didn't press down, it was quiet.

5 Amp NiMH Battery Chargers!

A

while back I bought ten 12 volt, 5 amp power

adapters with 'cigarette lighter' output cords at XS Cargo for 3.99

$ each. One thought was to use them for 12V LED lighting. Another was

to convert some to 13.8 volts for 12V NiMH constant voltage battery

chargers.

A

while back I bought ten 12 volt, 5 amp power

adapters with 'cigarette lighter' output cords at XS Cargo for 3.99

$ each. One thought was to use them for 12V LED lighting. Another was

to convert some to 13.8 volts for 12V NiMH constant voltage battery

chargers.

This month I opened one, found the specs on a tiny surface

mount "shunt regulator" IC inside (that I didn't even see at first - a

"programmable zener diode" I'd call it) on the bottom of the PCB, and,

seeing how it worked (praise the web), I changed a resistor for one

with a slightly lower value. That changed the voltage to 14.1. Bingo!

I bought a package of resistors to give the exact voltage and made

three on the 28th. I put a .27 Ω resistor

in the output to limit current for quite discharged batteries so they

don't shut it

down or blow it.

I think I'll cut off the cigarette lighter sockets and put

on small (30 A) APP plugs, where plug and socket are identical and the

pins on both sides, battery and charger, are recessed. (The APP parts

cost me slightly more than the power adapters themselves did.)

Three triple 12 V chargers for three 36 volt, 5 amp

Electric

Hubcap system/NiMH battery charging units will use up 9 of the 10. I'll

want them all - nothing left to sell. One for

house LED lighting will finish them up. All for 45$! At the

time I didn't know if I really could change the voltage. If I'd checked

into converting them right away, I'd have known I wanted them and

bought about 30 while the opportunity was there.

Mechanical

Magnetic

Mechanical

Magnetic Impulse

Planetary Gear

Torque

Converter Project

The Motorbike Centrifugal Clutch Test

The installation of the

centrifugal clutch with the 10 tooth sprocket gear went amazingly

smoothly in just one afternoon on April 4th. I ground a bit of a slot

in the axle to accommodate the built-in shaft keys on the clutch with

the angle grinder without taking the motor off the bike. That went

well. I left the output drum slightly off-center. A steel tube I

happened to have handy proved to be the exact size and wall thickness

needed (!) to make a shim for the input, and in a can I even found the

right size shaft collar to hold the assembly on. And I finally figured

out how to adjust the chain - by moving the back wheel ahead or back a

bit. I became uneasy about how well and smoothly the making was going.

That surely meant something would go wrong in the test. Was I becoming

superstitious?

Anyway it looked good

Centrifugal clutch assembly on motor.

The black output drum was mounted slightly off center.

Then I spent a day (6th) improving the motor controller

and making a nice battery box and more 6v battery sticks to have two

banks of 36 volts. (See NiMH project.)

The test on the 7th was a disaster. The motor was turning

faster than

I thought it should need to before the clutch cut in. That's probably

because it was made for high RPM gas engines. Suddenly everything

jammed to a stop. The motor was broken and 9 of 12 magnets had come off

the rotor. This was the oldest prototype motor having the

polypropylene-epoxy housing pieces, and it had an old car disk brake

rotor

instead of a flat rotor, dating back to the lossy metal stator plate

designs.

I pieced together the most likely scenario the next day.

The clutch probably suddenly grabbed and the chain yanked tight,

pulling the axle sideways. I've been a bit nervous about using this

earlier prototype motor with the culvert pipe outside cover - if it's

yanked sideways hard enough, the cover and axle could be shifted

off-center,

enough that the magnets would hit the stator. Of course, a chain drive

does exert sideways force (duh!) and letting out a clutch engages that

drive suddenly. Examining the scrapes in

the stator ring and the paint from that ring on the top of some magnet

surfaces indicates that this is probably what happened. The

newer molded rotor ring casings solve this problem, so it shouldn't

happen again. But I'll have to make another motor (or two) because now

I only have one.

So far, principles of operation for a torque converter

had consisted of trying to create momentary high torque pulses with

little or no torque between, wherein the motor recovers its speed. Some

of these means have been mechanical, others magnetic. A major problem

has been finding a system where the motor isn't held stalled if it

moves too slowly into a "torque pulse zone" or comes to rest in one.

Thoughts about centrifugal clutches as a means of

obtaining momentary high torque that would disengage if the motor

couldn't keep its speed up, continued and branched

out, and I came up with more than one new plan for coupling motors to

wheels. Then a fantastic idea emerged: a torque converter based on a

different operating principle entirely.

Planetary Gear as Torque Amplifier!

First, an example of an amplifier that everyone is

familiar

with: the triode vacuum tube. This has three elements: cathode (or

filament),

grid, and anode. A big flow of power, of electrons flying through the

vacuum between the

glowing cathode and the anode, is controlled by varying a low voltage

using almost no power on the third element, the control grid between

them.

(This electron beam is of course the origin of

the term

"electronics".) The electrons would happily flow from the cathode to

the positively charged anode, but if the grid has sufficiently negative

voltage, it

repels the cathode's electrons back, and there's no flow. If it's not

negative enough, or is positive,

the electrons are attracted

to the much higher positive voltage of the anode beyond, and flow to

it.

In between "off" and "on", small changes to the suppressing grid

voltage, using trivial power, make large

changes to the main current flow - amplification.

Planetary gear: Left: Sun Gear; Center: Planet Gears Assembly (may have

3, 4, or 5

gears); Right: Ring Gear.

Planetary gears also have three

elements: Sun gear, Ring

gear, and Planet gears assembly. Usually one of these is held in fixed

position, and a fixed ratio of torque conversion is attained between

the other two. With my Chrysler transmission planetary, if the

sun gear is driven and the ring gear is stationary, the planets

assembly turns 1/2.8 times as fast as the sun gear. If instead the

planets assembly is held fixed, then the ring gear turns 1/1.8 times as

fast as the sun -- and in the opposite direction.

Planetary gears also have three

elements: Sun gear, Ring

gear, and Planet gears assembly. Usually one of these is held in fixed

position, and a fixed ratio of torque conversion is attained between

the other two. With my Chrysler transmission planetary, if the

sun gear is driven and the ring gear is stationary, the planets

assembly turns 1/2.8 times as fast as the sun gear. If instead the

planets assembly is held fixed, then the ring gear turns 1/1.8 times as

fast as the sun -- and in the opposite direction.

However, there is another possibility, in between these

two: if the ring

gear is permitted a limited constant backwards slip with some sort of

variable clutch or brake, the output gear (planet assy) will turn...

but more slowly

than the indicated

ratio.

The energy to control the slippage should be

small compared to that being controlled.

I haven't figured out the losses.

If the ring gear is allowed to turn backwards freely,

there's no

energy loss. Also none transmitted to the planets assembly - it (and

the car) remains stopped. The

electron beam is

"off". If the gear is held stopped, there's also no energy loss. The

beam is full "on", and the planets assembly turns at the

2.8

to 1 ratio. Half way between is perhaps the largest frictional loss

owing to slippage. But the slipping gear is being permitted to

slip backwards. I don't think the energy loss will be large. Then,

depending on the design ratio and when the ring stops

slipping, those losses might well only apply to start the vehicle

moving and during more rapid acceleration below about 20, 30 or 40

Km/hr.

The slipping of the third element is the control voltage

on the

grid of the tube. Controlling the negative slip controls the gear ratio

of the

main power transmission anywhere between approximately a zillion to one

and the fixed ratio. Either the ring gear or the planet gear assembly

can be the slip gear, and the other the output gear, as is

convenient. For one, the motor will run in reverse direction to the

other. So

what?

Unless I have something figured entirely wrong, herein is

the essence of a fantastic torque converter! This will move

cars. (It may have taken me 3 frustrating years to figure it out, but

AFAIK nobody else has done so. Persistence pays. I see nothing like it

on the web.)

Planetary gear as it previously attached motor to Tercel wheel, planets

assembly set to move it via turning the wheel lug nuts.

It should have worked, and may yet work, by allowing a controlled slip

of the ring gear

to provide an infinitely variable ratio instead of a fixed 2.8 to 1.

There's one more

mode of operation:

if any two of the gear elements are locked together, none will turn

relative to each other, so they turn as a single unit at 1 to 1 drive

ratio. This becomes significant for certain forms of slippage controls.

Applying a controlled slip to one 'output' gear (planets

or ring gear) to use the other as the drive shaft output, can

be done in a number of ways.

Ring gear slip techniques

manual clutch

First I think I'll

try the simplest and probably surest design on the Sprint car: a manual

clutch/brake that releases the slip gear to spin freely, or tightens to

hold it stopped.

This has no slippage and the exact design gear ratio when

the gear is held stopped, as it would be above perhaps 20, 30 or 40

Km/hr except during rapid acceleration in city speed ranges.

If as I expect I can spin the

wheels on the Sprint or if it lunges into motion when I hit the

electron pedal,

it'll probably also be sufficient for the Tercel wheel even without the

Sprint's 4 to 1

reduction. (And the Sprint's reduction can be reduced or even made

unity.) If somehow I have it figured out wrong and it's another

failure,

or if the implementation needs improvement to make it work... well,

I'll find that out with the least amount of building - I think.

(I keep wishing I had finished making that pulsejet steel

plate cutter to make new steel rotors and odd shaped parts at will

instead of taking the design somewhere out of town, putting the project

on hold while it's made for me, and then driving back again to pick it

up. Then repeating the process when I find it doesn't fit quite as

expected.)

centrifugal clutch

The next step up

might be to use a centrifugal clutch. But a question is: between what

and what? A centrifugal clutch to a fixed drum is going to have slip at

all times, since as it latches it slows, the centrifugal force reduces,

and it's

released again. The gear would always be slipping backwards

proportionally to the torque required. Putting it between the sun gear

(motor, with the

centrifugal part) and the ring gear (as the slip gear, with the drum

part), with the planets assembly as the output, would have them

slipping until everything was turning at 1 to 1 speed. This would be

good with a bigger, lower RPM motor, but either leaves the units

slipping most of the time or limits motor speed more than desired,

unless a further 2 to 1 or so reduction follows the converter. A

reduction is already done under the hood on the Sprint, but would be

tricky for a wheel mounted motor.

An alternative could be to mount one element on another

gear , so that at the desired ratio, both elements are spinning the

same speed. This would be complicated.

Thus the seemingly obvious choice of a centrifugal clutch

seems to break down under scrutiny - except maybe in the Sprint or

similar conversions. There it might be worth a try at some point.

magnetic brake

After figuring out these mechanical means of controlling

the slip of the ring gear - manually or centrifugal - I thought that

the same thing might be accomplished magnetically, with a magnetic

brake. Here the loads should be lower than for using magnets directly,

making it feasible. Interestingly, this would harken back to my first

attempted magnetic torque converter and could even use the same

aluminum braking plate. Undesirably unless it proves to have trivial

loss for most driving, there would always be a certain amount of slip.

For the 'simple clutch', one element - the braking plate

or the magnet rotor - could be fixed with the other on the slipping

gear. But if they were mounted

on two opposite turning elements, at high speed and low torque the

entire assembly

could be moving forward, the ring gear element slipping back less than

the output speed. This would provide a reduction ratio headed for 1 to

1, smaller

than the fixed ratio of the planetary gear. This again might load the

motor more than desired.

As the results are less certain than for the manual

clutch, I'll save these ideas for later.

controlled generator

On the 10th

having coffee with friends, someone had a brilliant idea: use the

slipping gear to turn a generator, which would put the waste

energy back into the batteries. I wasn't sure there would be enough

waste energy to worry about, but it sounded simple enough mechanically.

Electrically, the rate of generation, controlling the

amount of slip, has to balance the desired conversion ratio at

different speeds.

Somehow I still

have the Sprint's alternator, and a loose engine pulley for it (that

fits over

the planetary's ring gear).

These take a ribbed belt. Again it would be tricky to mount on a wheel,

but on the Sprint it might work fine. It's another variant to try at

some later date, after proving with the manual clutch that the

conversion system works in the first place. And after seeing if

the slippage losses are significant enough to worry about.

The planetary gear torque converter now seems like the

obvious

way to use the Hubcap

motors to drive any wheeled vehicle. Unless I've missed something it

seems it can hardly fail except via poor implementation. (I do find

implementation of mechanical designs tricky - witness some of my

failures.)

Sprint Car Test Model

Checking the fit. Great... say, where'd the motor go?

On the 29th I found an

appropriate 10" V-belt pulley at

Princess

Auto - one with a single steel plate for the body, so it could be

bolted to something next to it. I drilled 6 holes in

this, and 6 (threaded) holes in the planet assembly of a different

model of planetary gear (the Chrysler transmission had two different

ones). This

gear seemed a good pick for this because

the planet assembly had six tabs that stuck out beyond everything else,

to drill holes in and bolt to.

It also had a closed end on the ring gear.

The pulley was thus the easy part. The output

shaft attachment is for a splined shaft. I actually have the shaft, but

it won't fit anything else except the gear. There are 30 splines, so I

thought I might be able to grind the end of a 1" shaft to a pentagon

and insert

it, if I was very careful to get it perfect. I accomplished this on the

afternoon of the

30th, spending quite some time fitting it.

At the other end, the sun gear isn't quite the right inside size for

the 1" motor shaft, and doesn't have a key or splines or anything to

lock it onto the shaft. That'll be the trickiest part.

And finally a rope, fastened at one end, has to loop

around the pulley and

then go somewhere to some clutch lever or pedal. Being (formerly) an

"automatic", the car has no clutch pedal for it... auto wrecker?

Let's see... Since the 'clutch' will be in 'some slippage'

mode at low speeds, perhaps it would be better if it could simply be

set to any given position rather than having to modulate it with the

foot. Maybe I'll put the automatic transmission lever back in and

connect it to the cable to tighten the rope. I'll change it so it can

be pulled back (tighter) readily, but will only move forward (looser)

if the button is pressed. I think this sounds like the ticket. (No

linkages to ignition key or to brake... then again, maybe it should

have...?)

Drive Belts

For the motorbike, the Sprint car, and the electric

outboard from scratch, it occurred to me that instead of chain drives, belt

drives (maybe toothed) might be better. On the outboard,

potentially a smaller pulley might be used, narrowing the leg. The

Wikipedia article on

belt drives says

that

improvements in belt engineering now allows belt drives where

previously only chains or gears would suffice... like, maybe, in

automotive drive

units, where they could make everything more efficient. Nobody seemed

to have any special 'high power' V-belts.

The high efficiency figures surprised me: "90-98%, usually

95%". They have

high tolerance for

misalignment (ideal for DIY), and are inexpensive. Clutch

action can be had by releasing belt tension. Different speeds can be

obtained by step or tapered pulleys. Toothed synchronous ('timing')

belts need the lowest tension and are generally the most efficient.

I've never thought before except in terms of gears or

chains, knowing that V-belts on small diameter pulleys have

considerable friction -- despite recently seeing the timing belt in the

Sprint engine, and knowing how much better those are than the old

timing chains. Why have belts not revolutionized automotive

transmissions? It's probably inertia - so many parts of the

transmission would have to be changed at the same time. It can't be

approached piecemeal, since present parts run in oil and belts can't be

in oil. Funny how slow we so often are to

catch on to real opportunities created by advancing technology! The

ever innovative bicycle world is first as usual. (see foto)

My original thought had been a flat, ribbed or multigroove

belt that could use an idler wheel for a clutch. Thus a clutch on the

belt, probably manual, would replace the centrifugal clutch. Toothed

belts would be better in general, but aren't amenable to being clutched.

Another thought, on reading the Wikipedia article, is to use a "flying

rope". The ends of a wire cable could be silver soldered(?) together to

make it a loop. Polypropylene rope might be good if the ends can be

fused together well. The diagonal strands in the cable would grip a

textured pulley without slipping (like the teeth of a toothed belt),

but would more easily slip to be clutch driven. I'd have to look into

pulley diameters versus cable diameters versus load capability. The PP

rope would flex better. (I adapted this idea for the slipping gear

clutch system.)

In fact, couldn't textured pulleys be used to prevent

slippage of belts having any flat bottom surface? -- or would that just

cause fast wear?

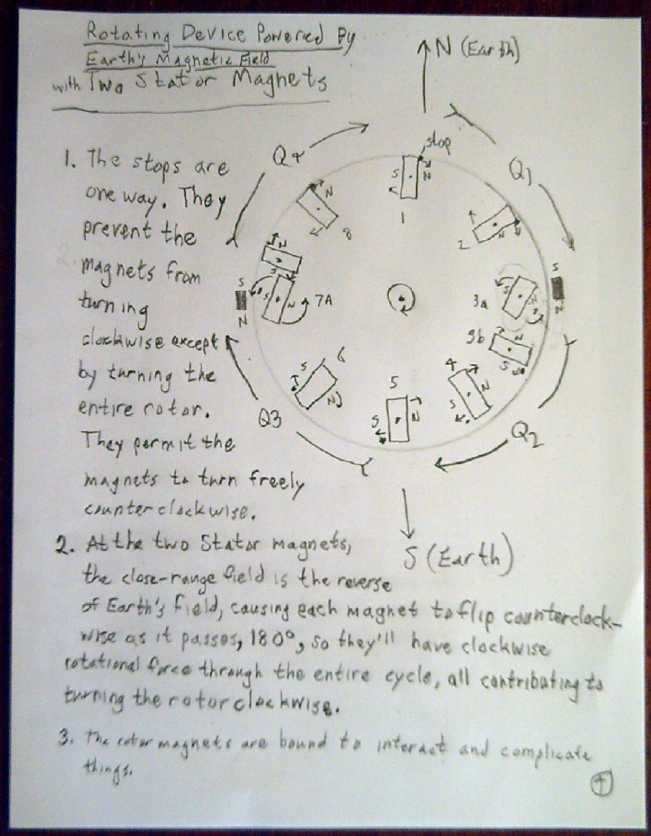

Magnetic Motion Devices

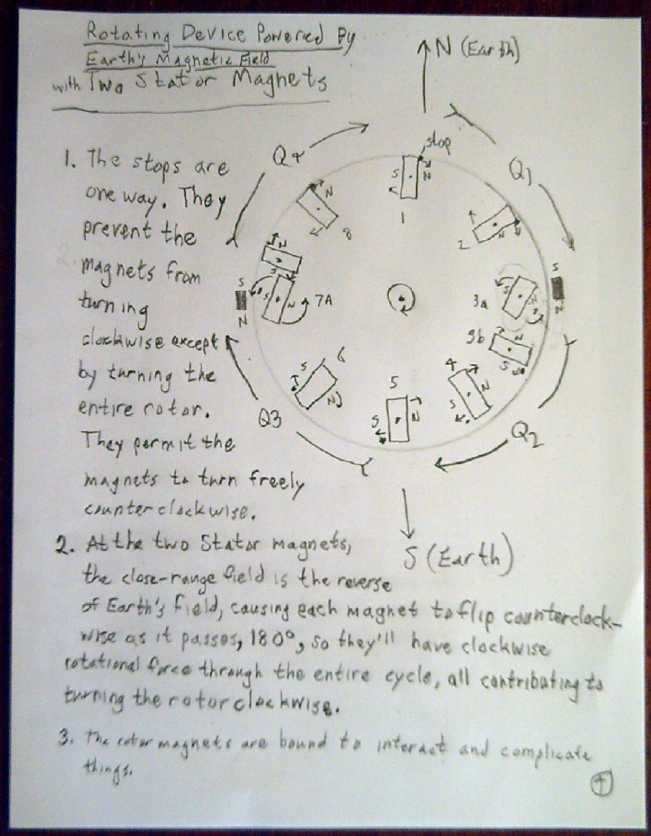

The drawing

last month showed how if a rotor had magnets facing so they would all

try to turn clockwise, the entire rotor would try to turn clockwise. In

order to keep them thus oriented, they had to be flipped around half

way between north and south on both halves of their journey.

The drawing

last month showed how if a rotor had magnets facing so they would all

try to turn clockwise, the entire rotor would try to turn clockwise. In

order to keep them thus oriented, they had to be flipped around half

way between north and south on both halves of their journey.

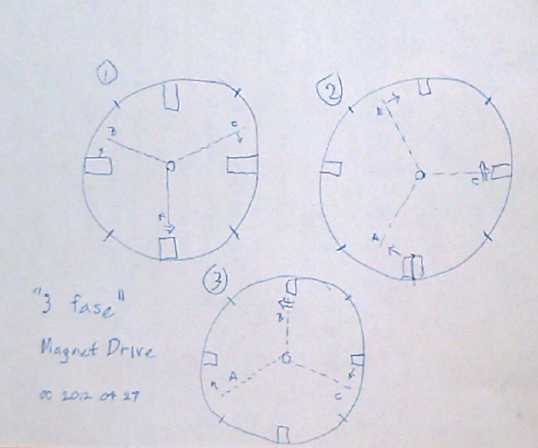

I cut a light 12.5" diameter disk of thin acrylic plastic

and scored the center point with a drill. At 120º from each other

I hung three magnets by putting a steel bolt on the top of the plastic,

which attracted the magnet and held it in place.

I drilled a hole in a piece of wood and stuck a drill bit

in it, but the device didn't work. Then I took out the drill bit and

stuck in the compass I'd marked the disk outline with, sharp point up.

This gave better results.

When one of the magnets between magnetic north and south

was turned around, the disk rotated 1/6 of a turn. Then the one on the

opposite side was midway, and reversing that one caused another 1/6th

turn. Then the next magnet was half way on the first side again, and

the process repeated. Sure enough, each magnet was being reversed half

way between north and south as it arrived at that point, and except for

having to

reverse the magnets by hand, the disk would have had continual

rotation. That demonstrated the first, and rather obvious part of the

operating theory.

The next part would be harder: have the magnets flip

around by themselves at the half way points. The forces being slight,

friction would have to be almost nothing, and the force needed to flip

the magnet would have to be very small to prevent it from stopping the

rotor.

Origin of the Theromomagnetic Theory

But what if, instead of the Earth's linear field, magnets

were placed all around the rotor with their north faces facing the

rotor? Then essentially, north would be coming from the outside and

south from the inside, and with

all the magnets on the rotor facing the same way, they would all be

trying to twist the same

direction. It started sounding more and more like perpetual motion...

but why

wouldn't it work?

Someone named Howard Johnson took out a patent for a

perpetual magnetic

motor in the 1980's, and indeed he took out several related patents. In

the patent he was ranting on something about unpaired electrons from

which energy could be extracted, and ferromagnets being a form of

superconductor. It was either BS or way over my head - I'm suspicious

that it was probably the latter.

On the other hand, I haven't heard that anyone has

successfully repeated the results... except... someone told me one

magnet motor in a patent office successfully ran for 30 years. This was

reputed to have obtained

its energy from very gradual demagnetization of the magnets. But for a

machine

to continue working for so long from such a minute energy source

stretches credulity as much as the idea of magnetic perpetual motion.

I know a

lot of people have tried and failed to produce something that works,

and especially something that one can extract useful energy from. A

dozen

youtube videos later and seeing no one intelligibly explain where the

energy is supposed to come from or demonstrate a credible working unit

could understandably leave one skeptical.

And yet... there just might be something there, somewhere.

Some

source of nuclear energy in the 'superconductive', 'unpaired electrons'

within ferromagnetic materials that could be harvested. Or was that

just like saying a diode should generate electricity because it only

pushes electrons through one way?

Then I found, or

someone send me a link to, a video of a spinning magnet machine that

looked genuine. As described in Month in Brief above, it seemed

to have the essential elements, carefully constructed.

Magnetically it

looked like it should work, and the video looked good, but nothing so

far had comprehendably

explained to me where the

energy would come from to move a rotor and keep it moving. I finally

came up with my own theory:

We see an apparently inert object, and conclude that it

has no

energy that can be harnessed. But its atoms are all vibrating. The

extent of this vibration is proportional to its temperature - is

its temperature, its internal thermal energy. Vibration stops only at

absolute

zero. My theory that magnetic actions take these

vibrations and convert them to large

scale directional force, magnetism, with the potential we observe for

the movement

of magnets and magnetic objects, is expanded above in April in Brief.

The rotation of the rotor in a magnet

machine is simply a cyclic repetitive motion of the same forces and

energies that are always invoked when magnets act.

A test to prove the theory

If this is the case, the magnets should drop in

temperature as they continually turn a rotor. It might, or might not,

be enough to measure.

Someone who seemed to have looked at and studied magnet

machines said it was indeed the case that they got cold when running -

and also that no one understood why.

Thus a test to prove the theory suggests itself: Take a

supermagnet and put a temperature sensor on it. Then take an

electromagnet with a core that's magnetically attracted. Set it up with

the magnet swinging on a

hinge, with a proximity sensor so that as it gets very

close to the electomagnet, the coil turns on for a moment and repels it

away.

The electromagnet (I'll use a motor coil) will heat

electrically in

excess of any other factor. The supermagnet will be expending energy

moving in both directions, so its temperature should

drop proportionally to the amount of work it has done.

At first I thought this suggested a new way to make a

refrigerator. Put the magnet inside, and the electromagnet outside, of

a thin, nonmagnetic fridge wall. Then I realized a fridge could

probably

be made to generate electricity instead of using it: just put a magnet

machine inside.

Let it run a generator and convert the heat in the fridge into

electricity. Electricity from a quieter fridge with no ozone depleting

gas that runs for free - it can't get much better than that!

The drop in temperature in a magnet machine would of

course be made up from

the surroundings, which are heated by the sun. Thus, the energy of the

magnetic machine is, indirectly, solar energy.

If the theory was right, the question was still, did I

have or could I come up with, a

workable magnet machine? It

seemed there was nothing for it but

to try it out.

Take 1

For the 'all north magnets' design idea, that wouldn't be

hard

- in fact, much easier than

trying to have magnets pivot. My three magnets on the plastic disk with

the compass point would be a fair test armature. In the end I simply

placed the outer magnets all around in a circle, "Magnethenge".

For the 'all north magnets' design idea, that wouldn't be

hard

- in fact, much easier than

trying to have magnets pivot. My three magnets on the plastic disk with

the compass point would be a fair test armature. In the end I simply

placed the outer magnets all around in a circle, "Magnethenge".

It didn't work as I made it. Motive force at the stator

magnets turned to anti-motive force between them and everything

canceled out. (including with a prime number of surrounding magnets,

and regardless of the flux gaps.) I think that with no south pole in

the center, the flux lines from the north poles all facing in probably

bend around and come out again between magnets.

Take 2

What would happen if the armature magnets could pivot up

and down on arms, so that in the forward propulsion area they were in

line, but in the repelling zone they were above or below the strong

flux zone?

Then there should be net rotary motive force - if it didn't happen to

make an equal or greater slowing force to fling the magnets out of the

magnetic path. This was similar to an idea I worked on in a couple of

versions for a magnetic torque converter early on, with interacting

supermagnets. I wanted them to pull the output ahead, but not back

again, as the motor rotor passed, so I held them back with springs

(first type; not finished) or twisted them 90º (second type; was

built) to prevent attraction until they were right across from each

other. (Although it worked in essence, it didn't provide car moving

torque, and it wasn't constructed with turning itself in mind.)

As I did the first one of these converters, I realized

there was

motive force in one direction but not the other. That sounded like

"perpetual motion". Since I didn't believe in perpetual motion, I

figured

I must have figured something wrong, even tho I couldn't see what it

was. How many people have done that, I wonder, and missed the

opportunity? If you don't

believe something is possible, chances are pretty remote that you'll

take the

trouble to design and build a working model to demonstrate it.

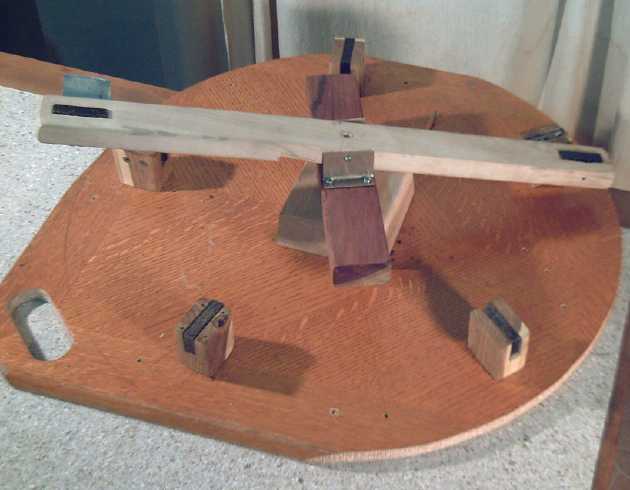

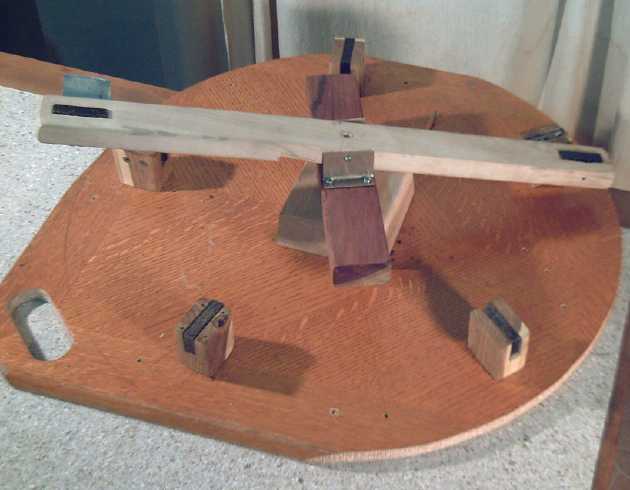

The 'take 2' unit was made in a marathon session occupying

the whole day and evening of the 13th. Woods are good materials for

this sort of prototype since they are beautiful, structural, easy to

fashion, and have little magnetic effect.

The 'take 2' unit was made in a marathon session occupying

the whole day and evening of the 13th. Woods are good materials for

this sort of prototype since they are beautiful, structural, easy to

fashion, and have little magnetic effect.

The body was a piece of eastern oak veneer

particleboard that used to be a coffee table top, cut round 2' in

diameter, except a corner was left to form a carrying handle. From the

3/4" hexagonal fir plywood center

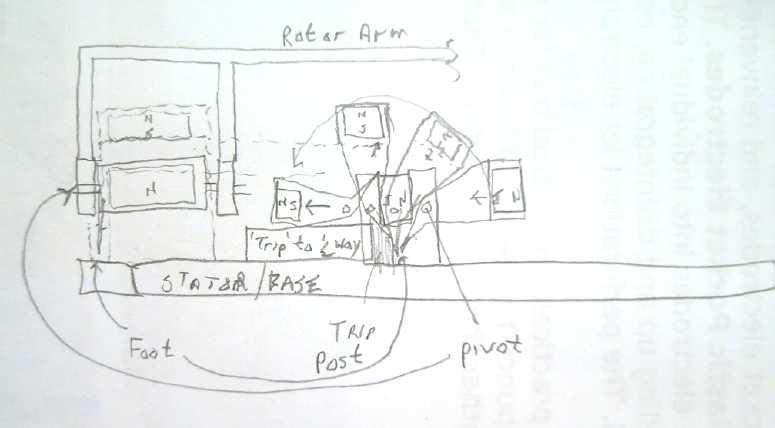

hub, it had