Turquoise Energy Newsletter #52

Turquoise

Energy Ltd. News #52

Victoria BC

Copyright 2012 Craig Carmichael - June 2nd, 2012

http://www.TurquoiseEnergy.com

= http://www.ElectricHubcap.com

= http://www.ElectricWeel.com

New: Solar 'grid or no grid' Home Electricity

Project

Month In Brief (Summaries)

- web site - new Hubcap motor; outboard motor (construction delayed

by trying to get CAD/CAM software going... is it worth it?) - Turquoise

Battery development - Making small scale home solar more practical

In Passing (Miscellaneous topics

and editorial comments)

- Dept. of Progress = Dept. of Patent Administration? - A Sodium

Sulfate/PbPb acid battery report - Solectria electric car -

Google search "spying" and search

results "censorship", and a

better, private, search engine (ixquick.com)

- European cars get better

mileage? - France's new president

Hollande...

a real leader? - International finance: a house of cards -

Homelessness amidst a nearly static population and an adequate supply

of housing?

Electric Hubcap System

* New motor, outboard(s)

* Sprint NiMH battery box

* Rotor rim case mold troublesome - improved technique & material

should help rather than new mold

* How much power? - to run a car

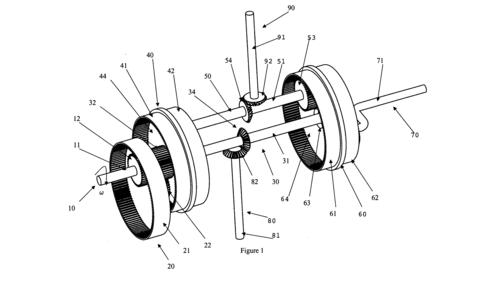

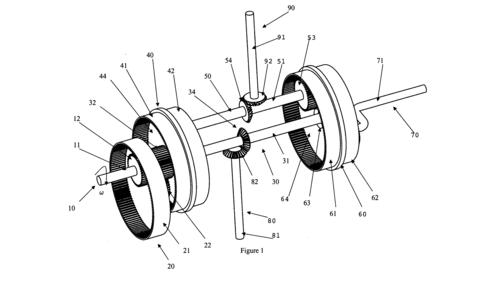

Planetary Gear Torque Converter

Project

* No power is lost by the slipping gear

* Motor/generator with microcontroller control as slip control

* A more ideal planetary gear for torque converters?: large surface

areas, self lube plastic...

* Other types of three element gears would also work: eg, differential

gear

* Review of some other potential types of torque converters (now mostly

redundant)

* Torque converter for Sprint

car: - shift/tension clutch lever

Magnetic Motion Devices

* Temperature drop tests: results negative but inconclusive so far

Solar Electricity Project

* Why? - save energy, cost; grid independence

* How? - The "DC Grid Tie" - electricity grid or no grid, sunshine or

no sunshine

* What? - are good loads to connect - Hot water preheater "dump load"

to utilize any surplus energy

Turquoise

Battery Project

* Positrode current collectors with grafpoxied carbon fiber (best yet,

I expect)

* Simplest zinc electroplating

* MnZn sintered electrodes - brittle but high current - trouble with

using

MnO2 as the Mn

* pure Zn strip current collectors & better Mn pocket negatrodes

* Are 3-D printers ideally suited to make ABS electrode baskets?

No Project Reports on: Weel motor, LED Lighting Project, DSSC

solar cells, Pulsejet steel

plate cutter

Newsletters

Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

-

Electric Hubcap Motor - Turquoise Motor

Controller - 36 Volt Electric

Fan-Heater

- Nanocrystalline glass to enhance Solar

Cell performance - Ersatz 'powder coating' home process for

protecting/painting metal

Products Catalog:

- Electric Hubcap Motor Kit

- Sodium Sulfate - Lead-Acid battery longevity/renewal

- NiMH Handy Battery Sticks, Dry Cells

- LED Light Fixtures

Motor Building

Workshops

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

May in Brief

I had some visitors, some computer problems and some yard

work to do in May and got less done than I hoped to.

On May 4th I published the April news report, and moved

all the newsletters to my safer www.saers.com/recorder/craig/

site (changed this year from www.saers.com/~craig), hopefully for

posterity, most kindly hosted by fellow recorder (the flute) music

enthusiast

Niklas Saers and the Saers family.

From then to the 9th I vacillated about what I was doing

and did bits of work on a test for thermomagnetism, a new Hubcap motor,

positrode current collector experiments for

MnO4-Mn batteries, and the torque converter for the Sprint car. And a

new design of magnet machine emerged. On the 10th I got my SR & ED

tax credit for 2011 and payed off my debts.

On the 12th, I made a large wood box sized to enclose NiMH

battery sticks in the Sprint car where the radiator was and the space

behind

that. Most of what was happening for the Sprint was being included

under other titles, and battery boxes hardly seemed worthy of the "NiMH

Battery Project" title, so I decided to drop the "Sprint Car Conversion

Project" and "NiMH Batteries" headings and put everything under other

specific headings like "Torque Converter" or into the broad heading,

"Electric Hubcap System".

Trying to find an easier way to

create G-code for hole drilling of the new motor, I didn't get it done

at all. Finally at the end of the month, I realized I could simply

enter the exact G-code text as well as the calculations into a

spreadsheet and extract a finished drill sequence, with no special

CAD/CAM software or anything.

Later in the month I made a

sintered manganese electrode

with powdered zinc for a conductive 'sponge' and zinc coated aluminum

grille and leed wire, which was tried on the 22nd.

In doing so I found on the web a great way to do zinc

electroplating with common household ingredients.

(See Turquoise Battery Project heading.)

However, with zinc as a substrate and using

"overdischarged"

MnO2 as the manganese, I had created

a sort of a shorted out MnO2-Zn battery, and the MnO2 oxidized the

zinc. This

left exposed aluminum, which dissolves in alkaline electrolyte, and the

leed dissolved though and fell off in a day. This is probably why the

galvanized nails and bolts used earlier also seemed to not work - in

each case, I think the second electrode post I inserted worked:

because the manganese was by then "discharged" (disoverdischarged?) to

Mn(OH)2.

I studied potential ways and means on the web. It seems

that if MnCO3 is heated to 300+ºC in a closed tube (to keep out

excess oxygen), it'll drive off CO2 and become MnO - unhydrated

Mn(OH)2. That won't oxidize the zinc. Since the sintering requires

heating the electrode above ~450º anyway, it seemed a good fit,

and I bought some manganese carbonate at the pottery supply.

Before it quit, I got some great current readings in load

tests with Ni-Mn in what had been a Changhong Ni-Fe cell in KOH. The

cell

overall was at

least 10 times as conductive as the original Ni-Fe. For the first time

in the whole project, one of my electrodes had conductivity high enough

for demanding

electric transport applications without employing an unreasonable

number of batteries. If the promising positrode current collector

experiments with grafpoxied carbon fiber also work

out well, there should be practical DIY cells.

Sizing up the panels for the "DC Grid Tie" solar project

Near the end of

the month, worrisome international financial news got me thinking

about energy independence. Solar PV

collectors seem the best way to make electricity unless perhaps I get a

working

magnet

machine going. (Even then it would have to be a good size to match the

output of solar collectors.) But how is the

energy generated to be utilized, in a way that provides electricity if

the grid is down? I decided to

expand on the idea of a one-way, low voltage "DC Grid Tie" to supply

power from the collectors and batteries until the voltage drops too

low, then the grid power will automatically handle the load - unless

it's down. Individual

inverters might run things like the fridge, and perhaps excess

collected

energy could be channeled into an electric water preheater tank so

nothing goes to waste. I

think there's potentially a whole range of salable "DC Grid Tie"

products here that

could make small scale home

solar much more practical.

In a closely related area, I didn't do anything on the LED

lighting. You'd think that with what looks like salable products I'd

have been onto this months ago. I have a bunch of emitters, but I

haven't even finished the last few lights that I commonly use in my own

house, and a couple of rooms could certainly stand to be brighter.

Finally, I considered how "Month in Brief" keeps getting

longer with items and editorials sometimes not directly related to the

energy

projects. This month there's more than usual, and I decided to make a

new heading for them, "In Passing".

"Month in Brief" goes backs to being relatively brief.

In Passing

Incidental news, editorials

- A Sodium Sulfate/PbPb battery report

- Department of Progress = Department of Patent Administration?

- May VEVA: Solectria car; power bicycle

- search

results "censorship" and ixquick.com

search to keep your private info private

- European cars get better mileage than North American?

- France elects...

a real leader?

- International finance: a house of cards

- Homelessness amidst an adequate supply of housing?

A reader reports that he made a solar panel system and

used 4 'NG-31, deep cycle' batteries that 'get drained most days (to

~42 volts)' and recharged 'to ~54'. He saw my sodium sulfate page and

put some in when they were new. They're now two years old and have

worked through all that in hot and cold weather in a shed. For daily

cycling, that would mean 730 charge/discharge cycles, from batteries

that are probably rated for about 120 cycles without the salt.

Depending on actual operating conditions - loads, discharge levels and

recharges - that's a 6 times improvement, and they're still going.

(Keep this quiet - the battery companies don't want people to know.)

A thought occurs to me, that my proposed Department of

Progress might instead be designated the

Department of Patent Administration.

No change of function is proposed, but it has that officious sound that

might appeal more to those in power, and remind that the department's

revenue would come from holding patents and collecting invention

royalties on behalf of inventors. It would still want to support

inventors and ensure they had resources to work with to foster a

continuing flow of new products and technologies. The department would

be keen to

find levels of royalties that would (a) encourage invention (b) not

restrict exploitation of new technologies and thus (c) maximize its own

revenues and value to the government. If Canada were to inaugurate this

department, whatever its name, I predict that soon American inventors

would be taking out Canadian patents instead of the other way around.

The VEVA electric transport meetings were moved to the 1st

Wednesday of each month instead of the 3rd. At the May meeting was a

1996 Solectria, one of about 400 made with GM bodies (Geo Metro?). It

was re-outfitted with lithium batteries instead of the original

lead-acid. It ran great, quiet, and had apparently been driven all the

way from Duncan to put in its appearance at the meeting. Assuming he

was driving it back over the Malahat mountain to Duncan that evening,

it apparently had very substantial range. The owner bought it for

10000$, half the original cost of the batteries. The previous owner had

moved up to a new Nissan Leaf or something.

Someone also brought a "souped up" electric bicycle and I

got to ride it around the parking lot (my first ever electric bicycle

ride, in fact.) The performance was astounding, and I wasn't surprised

to hear it was 1.7 KW.

Did you know that Google Search stores considerable

information

about you? I've been suspicious of them for some time. Evidently it's

the world's biggest database of potentially very personal

information on everyone - and it gives different people different

results for the same

search term. It tries to tailor your results to... to what? (a) what it

thinks

you want to find, or as it often seems to me when I search (b) what it

thinks commercial

interests who advertise with Google would prefer you to find. Either

way,

it may be eliminating things you should be finding, and if someone gets

curious about you (eg, if you some day become a public figure), all the

websites you've ever been to could potentially come back to haunt you.

Someone told me about an internet search engine I hadn't

heard of before,

ixquick.com,

"The world's most private search engine", that simply searches the web

for what you ask for - like Google and all the others used

to do. They specifically go to great lengths not to acquire and record

information about users, and only put the search preferences you

selected and wanted saved (like giving 50 or 100 results instead of a

measly 10)

in one anonymous cookie on your own computer - no tracking cookies. I

am delighted to find

there's such a search engine!

Someone posted a video saying he'd been to Europe and

rented a car there. The European Volkswagon Passat apparently gets 78

MPG where the USA version gets 40-something. He tried to buy the

European version on return but the dealer said that although they were

made in the USA, they couldn't sell them there. Evidently the

'emissions per gallon' were too high to meet US EPA standards. However,

because it used less fuel, the emissions per mile were lower.

It has also been said that the European version has poorer

acceleration. Evidently the European version was probably a diesel,

which generally does do better than gas. It still begs the question of

why the diesels aren't available here - people go to the car lot

wanting to do the right thing, but the existing more fuel efficient

models aren't there. One friend raves about his old VW diesel pickup

truck that gets 65 MPG, but it was one of only a few ever sold in N.

America. Governments use gasoline taxes to fund things, and

instead of finding more creative means, it would seem they simply abet

the

petroleum companies in helping us to maximize fossil fuel

usage, the mentally slothful choice, robbing the future and racing us

down the highway toward extinction.

Of course, a real solution at least for the short term is

to save petroleum or diesel

burning for long trips and use other power sources like economical,

high energy batteries for short ones... that of course is what my new

battery chemies and long running motor project are for.

On youtube I listened (with my meager French) to

the victory speech of

Francois Hollande, France's new president, narrowly elected about May

7th. It was

like a breath of fresh air: He first said he was elected to serve

France, all France (including those who didn't vote for him) -- where

increasingly most politicians seem to think they've been elected to dictate,

to impose their will on the populace, ignoring their own election

promises and the protests of the people. (This is one reason citizens

need to be able to initiate referendums, reasonably easily, which right

has pretty much eluded us in Canada so far.) We might consider a bit of

Urantia Book philosophy: "That government is best which governs least

while co-ordinating the most."

Hollande said his focus would be on

equality, justice and youth. "It's all for the youth." Whatever made

Frenchmen more equal - including more equitable distribution of wealth

- would be his socialist priority. A speech remains to be proven by

actions, and adverse forces may hinder or block the best intentions,

but I had the impression that

France has elected a real leader instead of just a manager or (worse) a

stoogie for commercial vested interests.

From other things I've heard he

evidently wants to quit using American dollars as a trading standard

(as the BRIC countries and others are already doing). He may take

France off the Euro currency owing to its problems. (I remember a

British PM (John Major?) saying Britain was sticking with its Pound

currency owing to "serious flaws" in the conception of the Euro. Those

flaws seem to be coming to the surface.)

Evidently there's also a new currency - IIRC it was called "Virtual

Coin" - which has appeared on the internet, which isn't under the

control

of any nationality. I didn't really check into it, but it seems to be

more than just a silly idea.

If you don't know what the "BRIC" countries are, you've

probably been watching too much North American news. I first looked up

RT

Times, and later Pepe Escobar or Max Keiser (and I'm still branching

out) on youtube, and I found a world of journalism with international

viewpoints,

insights and focuses, sometimes discussing underlying forces, hidden

agendas and motives and providing broader, more international insights

into the events and pressures in the world. Things aren't always as

they're painted out to be in the daily TV news. (Consider the tardy,

biased coverage of America's biggest story, Occupy Wall Street. And

when did you find out that the US president can, since January, sign

something to put anyone away, without even accusing them of a crime,

much less without a trial? The rule of law is gone there. The obvious

next step is dictatorship.)

A considerable part

of the reporting was about, or led me to read things about, finance and

the money system, which is Keiser's specialty. The way it works today,

it seems banks bring "money" into the system whenever someone takes out

a loan.

This develops because they're allowed to loan more money than they

actually

have, since normally no more than a fraction of the loans ever have to

be payed out at once. (If you or I loaned money we didn't have, we'd go

to jail.) Then the borrower has to pay the bank interest with real

money

on this money that never existed. So in fact, the banks bring more and

more debt into the system. Of course, people and governments who borrow

more

and more contribute to the problem. The

end result is there's far more money owed than there is actual money.

It's impossible that the debts can ever be paid off - they just get

bigger and bigger. Around the world, the whole house of cards seems to

be near the point of collapse. Along with all the R & D items, I

finally went out and bought some 1 oz silver coins to buy groceries

with in the event that paper money becomes unstable. (Hopefully by

then, if it happens, I won't be in the market for much gasoline.) At

worst, silver isn't likely to go down much, and investors all say to

diversify. I also found that the dysprosium I bought in 2008 for

battery research and didn't use is presently worth much more than I

paid for it - an unintended 'precious' metal investment. I'm selling it

to pay for solar collectors.

And some of the reporting got me thinking about

homelessness... One

thinks of all the work that goes into making a dwelling, and thinks,

well, isn't it right that someone buying one to live in should pay for

all that? But a house can stand for 100 years or more (mine is over

130), and someone may only live in it for 1, 5, 20 or 50 years. Is it

right that each new owner should pay for all the work the house

initially represented, over and over? When they also pay for the

upkeep? Homes used to stay in families for generations, and each new

generation inherited it. They didn't have to buy it over again.

As population swelled, towns and cities grew, there

weren't enough houses, and in effect each new generation did have to

buy all the work of building to get a house, especially a new one. Yet

here we are now with a leveling population, to start dropping sometime

around 2035-2055, yet more and more people are homeless. At the same

time, a few individuals own more and more dwellings or land as

investments, and some of them are empty. Why shouldn't people who need

homes have them if there are enough for everyone?

One solution, rather dictatorial, would be to simply

forbid owning more accommodations than a person or family can be

reasonably expected to make use of, or more land than seems reasonable

for a farm, eg, limit everyone to owning no more than a square mile or

whatever and stop huge

operations (and a few wealthy individuals) from monopolizing ever

vaster tracts of land. That would

estate-enfranchise far more people than the number who would be

marginally inconvenienced by having to

sell off their multiple holdings.

Another solution (put simply) would be to allow one

(reasonable) dwelling unit as a primary residence with no tax. The

second unit, or farm land in excess of some maximum, would be taxed at

the going rate. The same owner holding a third property would have it

taxed at 1.5 times the rate, the fourth unit at double, the fifth at

2.5 times, and so on. Holding real estate in great excess of personal,

family, corporate or farm needs would simply become a poor investment,

and if the greedy insist on tying up houses and land they don't need,

they can at least pay for the privilege.

Electric Hubcap Motor System

Outboard(s) & Motor for it

First a side note: Since I found the excessive gear noise

of the previous incarnation was from the motor pushing down hard on the

shaft and wasn't an intrinsic problem, I think that for an outboard

from scratch I'll go for the traditional shaft and right angle

gears rather than either chain or belt drive. I've seen 45º angle

gears available that are used to get a 90º angle, and they always

have 1 to 1 ratio, solving the problem for higher speed boats of the

unwanted speed reduction in gas outboard feet. An aluminum or stainless

steel angle iron piece might hold the bearings and align the gears. The

electric of course needs no gear shifting for neutral and reverse.

On the 11th I thought I should get

going on the outboard motor for the salmon boat. I decided to use the

Honda again since the system wouldn't be for high speed travel.

However, I got bogged down in trying to use CAD to get the positions

for the bolt and ventilation holes, and although I did some more work,

things mostly ground to an unintended halt. I didn't finish making the

motor, let alone get it mounted in the outboard.

As the rotor and stator are

reversed from the old motor, the shaft needed a shaft key in a

different spot. I tried to

make a key slot in the [car transmission] shaft with the square end

that I made in 2010, but the steel was so hard it took two milling bits

on the lathe to make a short slot, breaking the first one and dulling

them both. I'll use a short key. I resharpened the second (brand new)

mill, but whether it'll work well again is doubtful. I wish I had at

least roughed out the slot with the angle grinder. That's how I did the

slot the first time, before I figured out how to do the milling.

But it didn't seem the motor would fit under the hood. On

the 23rd I finally decided to see if I could put a U-joint in the shaft

and put the motor in lower, at an angle. It might just make it. The

next

day I bought a U-joint coupling for 1/2" socket wrenches. Now I'll be

using a different shaft from the one so painstakingly prepared.

Sprint Battery Box

I had

envisioned mounting the batteries for the Sprint

in some sort of racks where the radiator used to be. Now I decided that

an open frame

mounting was probably not a good idea. Better to have the many contacts

enclosed in a box, as shorts would be dangerous. So I essentially

copied the idea of the wooden box I recently made for the motorcycle,

but long enough to lay 12 volt (2' long) battery sticks in

horizontally. I'm not quite sure how I could conceive of putting

gorgeous figured lombardy poplar together with used 1/4" degrade fir

plywood.

I had

envisioned mounting the batteries for the Sprint

in some sort of racks where the radiator used to be. Now I decided that

an open frame

mounting was probably not a good idea. Better to have the many contacts

enclosed in a box, as shorts would be dangerous. So I essentially

copied the idea of the wooden box I recently made for the motorcycle,

but long enough to lay 12 volt (2' long) battery sticks in

horizontally. I'm not quite sure how I could conceive of putting

gorgeous figured lombardy poplar together with used 1/4" degrade fir

plywood.

I cut the pieces to the maximum size that would fit in the

space: 9" deep by 13" tall by 28.25" long, with a figured lombardy

poplar top. That let it fit 12 volt

handy battery sticks arranged as:

* 4 rows of up to 7 columns tall (28 - 280 D cells, 3360 WH) with

styrofoam padding on the sides

* 5 rows of up to 7 columns (35 - 350 D cells, 4200 WH) with no padding

* 3 super battery sticks with 4 handy battery sticks beside each one in

a skewed arrangement (33 - 330 D cells, 3960 WH)

(Yikes - it could weigh up to 150 pounds with so many

batteries!) These storage figures should be good for local driving

range - not a lot more. I don't know yet how low I can get the WH/km

figure. They're also more D cells than all I have so far. I ordered 50

more on May 11th. They were "on sale" at 12% off. Impulse shopping.

A minimal setup for general testing would be 15 sticks, 5

parallel sets of 3 in series, since 3 gives 36 volts, and 30amps * 5 =

150 amps (max. continuous), while the maximum motor draw is under 150.

(As far as range, that should at least get to the grocery and back.)

An 'extra' stick or two will go on the lowest 12 volt

section, in preference to having a separate 12V battery for the lights

et al. The mostly LED lights don't use much power, and as I'm charging

each 12V section

separately, the arrangement raises no charging issues except that the

lower 12V section might take just a bit longer to 'top up' than the

other two. Big deal.

Terminals will be provided for ground, +12V and +36V.

Three APP 30 amp charging plugs to mate with the 5 amp power adapter

chargers will be on one end. Hmm... for 100 AH, it could take up to a

day to charge at just 5 amps. Oh well!

New Hubcap Motor - Rotor rim case mold & molding

L: Stator end with coil cores

R: Middle (coil top 'buttons'), and rotor compartment.

I'm not happy with the

rotor rim mold, which I used

"properly" for the first time. The result was less than beautiful, and

it took me a whole day of fiddling around and touching up after the

initial molding to finish it. Spending that kind of time on one piece

is counterproductive. However, the remedy may not be a new mold but

improved technique.

I'm not happy with the

rotor rim mold, which I used

"properly" for the first time. The result was less than beautiful, and

it took me a whole day of fiddling around and touching up after the

initial molding to finish it. Spending that kind of time on one piece

is counterproductive. However, the remedy may not be a new mold but

improved technique.

One thing I was sure was needed was 2-1/2" wide PP

strapping,

which I hadn't found to buy yet. That would give it a smooth one piece

outer skin. Three layers/winds of it would give that plus a uniform

upper tab to keep the end cover centered. If I also found 1-3/4" wide,

I could put an inner skin on it. If not, I could cut 2" down to 1-3/4"

with scissors. Finding 2-1/2" strapping was key, however. I've seen it:

in light colors in aluminum frame patio furniture. Buying it alone has

proven to be another matter.

Given the strapping, there'd be just a thin interior left

to stuff PP cloth strips into to finish up. The sides of the mold would

hold the strapping straight and rigid. Small gaps in the fill would be

unimportant and also unseen.

On the 16th I found 3" PP strapping at a tent & awning

place. It went from 2" to 3". But 3" can be trimmed down, so with a

certain amount of aggravation, it solves the problem.

Instead of spray paint, I found polyurethane enamel in 1 litre tins. I

figured that would make a much thicker coating, so I bought it. Of

course, paintbrush isn't as beautiful as spray. And when I bought it, I

was thinking yellow would be a good rotor color, not about the case

color. But I'm certainly not changing back until the 70$ tin is empty,

if at all!

While on the subject of the new motor, here are the

pictures I took at the beginning of May for the motor making manual,

showing the epoxying of the magnets onto the rotor:

The first six magnets are easy. The placement jig sets the spacing and

alignment.

The second six want to glom onto the other magnets and must be clamped

down before the jig is removed.

All twelve magnets must be the correct way up for the motor to work

right: NNSSNNSSNNSS.

About to start putting the polypropylene strapping onto the magnets.

(I took more pictures. Where did the rest go?)

How Much Power?

I found a site with some 'typical' EV conversion motor

power figures (below) and

thought it

might be nice to compare estimates, with a ~2400 pound car like the

Tercel, but with the 33% less for the anticipated efficiency gain with

the torque converter instead of a transmission.

I'll start with my main conclusion: With the torque

converter offering infinite reduction ranges and a single 5 KW Electric

Hubcap motor, one might expect a small car to make quite a zippy start

from a stop, but with performance dropping off with vehicle speed. It

should be adequate around town, but probably not on a highway unless

it's pretty level with few starts and stops. (Ie, not on our

mountainous

BC highways, and it's likely to be sluggish regaining highway speed

after a stop.)

The rest of this section is just tedious details.

To do 50 MPH/80 KmPH we use their estimating equations otherwise as-is.

These

show that two Hubcap motors would be required for good highway

performance. This isn't unexpected.

[1 HP/1000# @ 2400# = 2.4 HP] + [Cd of .3 = 3 HP] + [2% grade, 4.8 HP]

= 10.2 HP.

Driving around town takes less, and the add-on motor that allows

switching to gas on the highway gives the flexibility to avoid needing

that 10 HP of electric power. Assume 55 Km/H is the max, and that

above that you would switch to gas. Estimate of rolling and hill

climbing resistance would be about 2/3 of highway speeds, and wind

resistance would be half.

[1.6 HP] + [1.5 HP] + [3.2 HP] = 6.4 HP.

This is still a little above our nominal 5 HP rating. What it would

mean is

somewhat slow hill climbing and acceleration at street speeds. Some

slow-down on steep hills is common for gas cars anyway.

I may up

the amps settings a bit in the controllers and allow up to maybe 160

amps,

which would be 5760 watts, well over 5HP. Above 100 amps I get more and

more nervous about the controller and about motor heat. On the other

hand, I haven't tried and it might be found that higher figures pose no

problem at all.

To estimate for the Sprint, I'll simply call it 2/3 of the above,

since it's only 2/3 as heavy: Highway 6.8 HP, City 4.3 HP. Conclusion

is it should perform pretty well around town, probably even on level

highway. (Avoid Malahat Mountain!) Probably to get these favorable

results, I

should

replace the chain drive with a belt.

(Note: I've neglected to add the weight of the motor and batteries to

the vehicle in these calculations.)

The

basic equation for determining the hp required for a drive system is:

Required Hp = Hp (Rolling Resistance) + Hp (drag) + Hp

(Hill Climbing) + Hp (acceleration)

- Rolling

resistance is typically 1% of the vehicle weight. It takes ~1.5

hp per

1000 lbs of vehicle to maintain 50 mph at 0% grade and no aerodynamic

drag. So a 4000 lbs vehicle is 4 times as much ~ 6 hp for rolling

resistance.

- Aerodynamic

Drag is a function of speed squared and frontal area. If you

double

the speed, the aerodynamic drag increases by 4! With a Drag

Coefficient of 0.2 (Cd=0.2) very aerodynamic vehicle, is approximately

0.7 hp at 25 mph and approximately 3 hp is required at 50 mph. With

Cd=.4 approximately 7 hp is required at 50 mph. This is based on a

frontal area of about 18 sq ft.

- Hills are a major obstacle. A 1% grade is a 1 ft rise in

100 ft. This is

the same amount of energy as rolling resistance. A 5% grade (5 ft

rise

in 100 ft) is five time rolling resistance. That means that it

takes 5

times rolling resistance (~8 hp) for a 1000 lb vehicle. For a

4000 lb

vehicle, 30 hp is required for the same 5% grade. This is why

designing a vehicle for Colorado is considerably different than

designing an EV for Florida.

Typically, when we size motors for on-road EV applications, we assume a

2% grade

and 50 mph. For a 4000 lb conversion, this would be another 12 hp for a

total of 25 hp. Our rule of thumb has been it takes 6- 8 hp per

1000

lbs. That would dictate 24-32 hp. You can see that we

are within the

range.

- Acceleration

can become the dominant requirement. Looking at the totals above

for a

4000 lb vehicle with a Cd=.4, approximately only 13 hp is required

to

maintain 50 mph and 0% grade. A Corvette requires ~ 20 hp at 60

mph

and 0% grade. With a 430 hp engine, acceleration is the

predominant

requirement for the 2010 Corvette.

Planetary Gear Torque

Converter Project

No power is lost in the slip

This is a bit tricky to figure out, but it is of course a

very important point.

Ignoring friction

etc, one's first thought would be that if the slipping gear is going

1/2

speed and the drive gear is also going 1/2 speed, 50% of the power is

going into the slipping gear. But this isn't true. The slip

gear isn't an inert

load - without restraint, it wants to go full speed rather than to stay

stopped, and when it does, no power is transmitted at all. If the slip

gear is stopped, all the power is being transmitted to the drive gear,

so again no power is being lost. If it has a controlled slip, the motor

uses less power to maintain the same speed by the amount of the slip.

Thus it takes no power to hold it stopped or

to let it slip - freely or any amount. All the power that the motor

puts out goes to the drive shaft.

Only if the slip gear is

pushed in the

opposite to the slip direction does it take

power to turn it. In that case, which isn't part of normal operation,

it would be doing work. It would then be similar to a car wheel

differential, where

some of the power goes to each wheel. And the car differential is

similar to

the torque converter when

one wheel is slipping in the mud: no power is needed except

to overcome the weak friction, and stepping on the gas even a little

will just rev

up the engine and wheel and splatter the hapless

pushing volunteers with mud.

Thus, if the slip gear is turning 1/2 speed, it's losing

no power, but the speed of the drive gear is cut in half. Power =

Torque * Speed, so the motor can turn with the double the speed,

and the torque is doubled for the same output speed. From another

perspective: for a

given torque, power needed drops as the variable reduction ratio is

increased. A puny motor could slowly move the car.

Except for frictional losses, all the motor's power is

being

transmitted to the driveshaft, at any gear ratio.

Motor-generator with microcontroller as slip gear control

Someone mentioned new car variable transmissions and said

they used a motor under microcontroller control to control a shaft

turning rate that controls the reduction ratio. I couldn't find much

info. While it's possible the car manufacturers have figured out the

planetary gear's torque converter potential, I've found no mention of

it. I suspect rather that they've found needlessly intricate ways of

doing much the same thing, as shown in a recent patent (see 'other

types of torque converters' below).

However, the idea of using a motor and microcontroller

might be a good one, considering that the various mechanical means of

control

look trickier than expected. The slippy rope "clutch" around the V-belt

pulley could be replaced by a V-belt going to the control motor. The

microcontroller would monitor main motor RPM, current, electron pedal

position, and vehicle speed, and decide how much slip would be best.

The slip control motor presumably would take very little

power, since it only holds back the slippage. It might even generate a

bit.

A more ideal planetary gear for torque converters

My thought is that a physically large, very wide planetary

gear with aluminum sun and ring gears, and self-lubricating plastic

planet gears, would be more ideal than the typical steel planetary gear

with case hardened teeth seen today. It could be used without

lubrication, with the large contact surfaces spreading the load and

heat to run cool. That way, no oil bath, oil drip or frequent

greasing would be necessary.

I've seen aluminum gear teeth (for a timing belt type

pulley) being cut on a homemade CNC lathe with a "flying cutter" in a

drill chuck, so it's doable. (The inside of the ring gear might be

tricky. ...Or, I may yet have a good use for Camosun College's VICAMP

facility with their 3-D plastic fabrication machines.)

My ideas of "large" and "wide" are flexible. I'm starting

at maybe 5" diameter and 1.5" wide and going up to as much as 12"

diameter and 6" wide - whatever seems needed for reliability and long

life.

Other Three-element gears that could be torque converters:

differential gear

Other three-element gears besides planetary gears could

work. A

differential, for example, could have the left or right "wheel" gear as

the slip element, and the output drive would have a 90º angle from

the

input. An interesting feature is that with no slip, the ratio is

actually a speed increase (torque reduction) of 1 to 2. An amusing

thought is that I could have done this in the Sprint, giving a

one-wheel drive. It would have had to be always slipping to get the

needed ratios.

Or, right and left could be the (in line drive, anything:1

to 1:1

ratio) input and output, with the "drive" gear as the slip. This

probably could have been done with the Sprint and one wheel too, but in

this case the planetary gear with the 2.1 to 1 reduction is very

similar and more appropriate.

Other types of torque converters

While the planetary gear converter appears to be an

excellent type

of torque converter and I've decided to go with it, I'm not convinced

that there aren't other potential types of torque converters waiting to

be discovered or developed, so I think I'll summarize the ones I know

of or have thought of here.

I omit belt driven CVT types and a bizarre converter used

for bicycles that looked likely to be hard to scale up to car size.

There are also 2 or 3 (expired?) patents for torque converters. None

looked very promising to me. One was for bicycles, and I confess I

don't see how it could possibly work. (I'm not saying it doesn't. I

wrote a letter to the inventor but got no reply.)

A recent patent (WO2009039590) for a "CVT" comes from

Australia. Perhaps it has some advantage(s), but in essence, to me it

looks like he's created a complex converter

with several gears to do about what the planetary gear converter does.

From somewhere

I gather a microcontroller and a motor are used for computer controlled

"modulation" (slip) in some new car transmissions, which may or may not

be based on this design. This seems similar to the idea of putting a

generator on the slip gear, except for the computer control.

Constantinesco's oscillating masses converter (1923)

obviously worked well,

especially if two masses were used oscillating at 90º to each

other, which canceled out vibrations. He was making whole

transmissionless cars with such converters built into the two cylinder

engines by 1926. (They used 1/2 the gas of other cars.) After GM

tricked him into shutting down his car production, he used

them for railway locomotives in Eastern Europe into the

1930s.

The magnetic impulse type would have worked if the forces

had risen linearly with speed. They don't. As it is, with NdFeB

supermagnets and copper, it appears somewhat too much magnetic material

would be needed to be practical, and the reduction ratios attained will

be

small, eg, 3, 4 or

5 to 1, with considerable speeding up and slowing down of the motor as

it crosses the interaction zone.

Superconducting materials with very powerful fields and

interactions could change that picture, and 28ºC superconductors

have recently been identified. This type might especially become

practical if the fields

can be varied or switched on the fly, which could once again offer an

infinitely variable reduction ratio. Of course, motors using

superconductors might themselves have the torque to make torque

converters redundant.

My ratchet drive converter was proven to the point that

with a ratchet wrench on a nut on the car wheel axle, I could easily

move the car around by stepping on the horizontal handle of the wrench,

then ratcheting it back up to horizontal again. Since I weighed around

150 pounds and the handle was about 10" long, I was applying about 125

foot pounds of torque to the wheel.

However, the idea had several smaller but vexing

challenges. First was a limited range of reductions. Then it really

would need the motor mounted elsewhere than on the wheel, in order to

have a push-pull rod to the ratchet on the wheel axle. At least, I

couldn't think of a simple way to mount it on the wheel. Mounting it

elsewhere isn't necessarily bad, but it would have to be level with the

wheel to avoid problems with interactions with the vehicle's

suspension. I didn't really come up with a good place on my car. Then,

the car would only move one direction - no matter

how it was propelled - unless the ratchet could be reversed like a

socket wrench, or at least disengaged. (At least it couldn't roll

downhill if parked facing uphill.) The ratchet wrench I found that was

strong enough for the job didn't have that feature - to go the

other way you were supposed to turn it over.

Also notable is that the weights of the oscillating pieces would cause

vibration unless they had counterweights.

I had previously conceived of it with some centrifugal

mechanism on the motor to change the distance of the drive pin from the

axle to alter the reduction ratio. I didn't come up with a satisfactory

idea for making this either.

Recently I had the thought that instead, there could be a sliding

control on the ratchet side, perhaps operated by the driver through a

shift mechanism attached to a cable. Shaft/slide projections and

detents would prevent shifting during the power stroke.

Still there's the nagging suspicion that if all those

details were taken care of, the ratchet or one-way bushing would wear

out quickly with continual operation at hundreds of RPM. I mention the

design only for posterity, having figured out enough of the details

that it looks like it would work. (I did a drawing, but didn't bother

to take a foto.)

The "clock escapement" type converters - a variation of

oscillating masses - didn't get a car moving for me, but the car wheel

budged a bit with the last one every time the motor turned, suggesting

it was making 10 or 20

foot-pounds from a motor producing maybe 4-6. (motor controller problem

back then.) At the

time I had no means of measuring torque,

or of how much was in fact needed to move a car. I'm sure it had too

many

transitions per rotation loading the motor down, and I'm not convinced

the idea wouldn't work with the right configurations and escapement

masses for stronger, higher speed torque hits.

And I half made but didn't finish or try the centrifugal

clutch with the 45º angle bouncing/ratcheting "pads" hitting into

transverse slots in the outer rim. It has promise. A really nice wide

slotted outer rim - I'm thinking 3 to 6 inches wide slots on a 10 or 12

inch

diameter drum, and wide wedges to match, would reduce loading and

stress at each

point to levels where aluminum and plastic parts would work without

quickly wearing out.

These last two types again both provide infinitely

variable

reduction, down to 1 to 1. Note that the forces all need to be on axis

(radial) and balanced, or the motion product is mainly vibration. In

particular, any axial forces simply shake the entire unit and

motor.

If a system needs a gear and a

torque converter, perhaps it might as well be the single unit planetary

gear converter. For a system that doesn't otherwise need a gear, one of

these

other forms might be worth trying.

Then of course, if one makes a motor with enough torque, the torque

converter becomes at least somewhat redundant. I got a link to "Yasa"

motors. I assume this is the commercial development of the Oxford UK

axial flux

motors mentioned a couple of years(?) back. They're very impressive:

750 peak

newton-meters (566 foot-pounds. and there's a 400nm/295 ft-pd model),

and the efficiency is high.

Then of course, if one makes a motor with enough torque, the torque

converter becomes at least somewhat redundant. I got a link to "Yasa"

motors. I assume this is the commercial development of the Oxford UK

axial flux

motors mentioned a couple of years(?) back. They're very impressive:

750 peak

newton-meters (566 foot-pounds. and there's a 400nm/295 ft-pd model),

and the efficiency is high.

On the other hand, to get that torque, it

uses up to 100 KW at 700 volts and needs liquid cooling. With the

torque converter, the air

cooled Electric Hubcap at 5 KW and 36 volts will have almost unlimited starting torque, though it'll drop

much more rapidly with speed. I

know which one will make

a car go 0 to 60 MPH really fast and which one probably won't even hit

60 going uphill. I also know which one I'd rather work with, and buy

and charge batteries for.

With the torque converter, the 5KW will have almost

unlimited torque to get the car moving, still plenty at low speeds,

and overall, I expect, should perform decently at city speeds. Highway

trips need gas anyway unless the car is to be stuffed with batteries.

So far, it seems to me that's less economic, partly owing to the high

price of batteries.

Construction: Axle for Sun gear

On the 4th and 5th I turned

a (trailer stub) axle for a motor on the lathe, a fatter one with a

1-1/16" diameter end for the

sun gear of the torque converter. I used a carbide cutting bit that I

bought recently. It seemed to go considerably better than with steel

tools, but it wasn't a miracle cure. I had to sharpen it more than

once. The shafts I use for motors are of course pretty hard steel, and

it still doesn't pay to try to take off very much at once. If there was

water dripping on the tool point to cool it, things might go

considerably faster, because it was capable of taking off much bigger

shavings - until it overheated and quickly got dull.

Slip Gear Clutch Control

All the centrifugal or magnetic clutch arrangements I

thought of either

leave some slip even at high speeds or else create a 1 to 1 reduction

ratio instead of the design ratio of the gear. The magnetic ones might

allow too much slip based on experiences so far. So unless 1 to 1

(centrifugal type) is the

desired ratio, the manual clutch or brake for the slipping gear may may

in fact be the best of any reasonably simple arrangement. In the

Tercel, 2 to 1 makes 2000 RPM at 100 Km/hr on the highway (maybe 90 in

the Sprint with its smaller wheels), so that's about the minimum

desired

reduction ratio with the Electric Hubcap motors. Any less just reduces

power for no reason, from a motor that's certainly not oversized for

driving vehicles.

I think the best manual control would be a ratchet lever

like a parking brake - pull up to tighten, push the button and lower to

release. However, the parking brake on the Sprint is the only means of

holding the car stopped.

I decided to try the original gear shift lever as the

clutch tension control. (and I almost threw it out when I removed it!)

It's made, it fits the car, and it's in a good position to operate

while driving. "Park" (which won't hold the car stopped) is loose,

disengaged, and the successive stops are each stronger tension than the

previous for higher speeds:

P R N D L2L1 = O

1 2 3 4 5.

The stick gives the cable about 2 inches of motion. If

that's too much and it won't travel to 5 from loose in 0,

a stiff spring in the link will give it more give - and probably more

steady tension control.

I wanted to make it so that except for going from P,

the lever could be pulled back freely like a parking brake, but the

button would have to be pressed to go forward again so that it wouldn't

shift itself looser. But confronted by the existing logistick on the

6th, I

filed detents into 4 and 5, and bolted on a piece of

steel to make one between D(3) and N(2). The button now

has to be

pressed for all shifts except going from R(1) to N(2).

In the install, I also reconnected the key interlock so

the car won't turn on except in P. There was also an interlock

to prevent it from being shifted out of P unless the foot brake

was applied, but that's no longer desirable since pulling gradually

back on the stick from P with the foot on the 'gas' will be the

way to start the car

rolling.

Since I had mounted the F-N-R switch where the

shift lever was and had made that point a minor 'wiring central', on

reinstalling the

lever I had to relocate it and reroute the wiring. I

put the switch on the dash to the right of the ignition, and wondered

why I hadn't put it there in the first place.

Then I got caught up in other things and had to let this

project sit.

Magnetic Motion Devices

Magnet temperature drop tests:

results negative but not conclusive

On the 6th I decided to put together the test to see if

the temperature of a magnet dropped measurably when it was expending

energy. I rigged it up pretty fast with a hinge from "take 2" magnet

machine, a motor coil, and C-clamps and a vise. The first thing that

became apparent, while operating simply by touching and untouching the

wire to the battery, was that the wires were getting hot too quickly to

go on long. The coil was drawing quite a few amps to give sufficient

repulsion, and any small switch would have fried. I decided instead to

try rotating a permanent magnet with a small motor to alternately

attract and repel the target magnet.

A separate problem was that the meter read in unit degrees

C. If the temperature dropped perceptibly but less than 2 or 3 degrees,

the result would be uncertain. If it was less than a degree, I might

well not even know it had changed. The short test showed nothing

reliable, tho the meter went from 16 to 15 a couple of times during

operation. I would have to rig up something better.

So much for the quick test!

On the 10th I put my old wavepower gen rotor on an axle

and put it in a vise - 12 alternating polarity magnets. I again mounted

the flapping magnet from the

"take 2" design with C-clamps, so that when the rotor was spun by hand,

the arm flapped back and forth as the opposite polarity magnets went

by. I also wired up an AD590 temperature probe with a power adapter and

a 1K resistor so that 1 mV = 1ºK.

After a minute or so of turning, the magnet had dropped

about .2º. That looked promising, but it didn't drop more, and it

didn't seem to go back up while sitting at rest again. A subsequent

test showed no change. It certainly wasn't sufficient

evidence to validate the

theory - it seemed more to disprove it. A control sensor measuring room

temperature would have been helpful. Measuring the magnetsº on the

rotor might have shown something but would be hard to do. The test

setup was adequate to show larger scale results if they had presented

themselves, but not subtle ones.

I tried holding the magnet arm back with my hand to cause

it to resist the motion, and the magnet went up .5º after some

cranking. That seemed at least somewhat consistent with the theory, but

again it's a small rise could have other causes as well. Even the

proximity of my hand to the wires (an inch or more) might possibly have

heated

up the wires and hence the sensor by that amount.

A surer way

would be to build a magnet machine that ran.

If

its magnets cooled down while running, it would be a pretty safe

conclusion that the energy came from the temperature; if not, vise

versa. Even if that were the case, I

suspect more and more that the force-energy that is

magnetism

must be derived from nuclear force-energies within the substance, and

that when magnetism does work, the energy is somehow being derived from

the energy within the atoms, whether an object is being moved once or

in a repeating cycle. Somehow it must be nuclear energy, available as

magnetism via electron flows without splitting atoms. And I'm by no

means thinking it's not thermonuclear at this point. Here we

come to the edge of known quantum

physics.

A surer way

would be to build a magnet machine that ran.

If

its magnets cooled down while running, it would be a pretty safe

conclusion that the energy came from the temperature; if not, vise

versa. Even if that were the case, I

suspect more and more that the force-energy that is

magnetism

must be derived from nuclear force-energies within the substance, and

that when magnetism does work, the energy is somehow being derived from

the energy within the atoms, whether an object is being moved once or

in a repeating cycle. Somehow it must be nuclear energy, available as

magnetism via electron flows without splitting atoms. And I'm by no

means thinking it's not thermonuclear at this point. Here we

come to the edge of known quantum

physics.

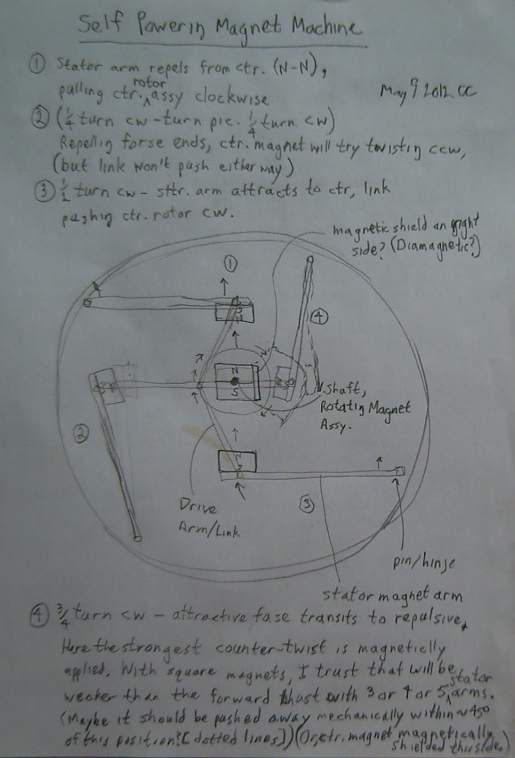

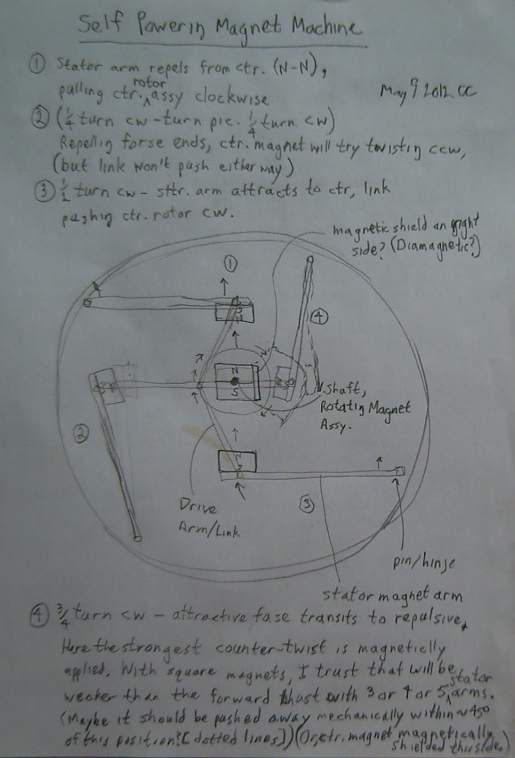

Magnet Machine Take 5

I drew a diagram of this new type on the 9th. I considered

that in just one position of the circle out of four the magnetic forces

would be contrary. But it was where the arm magnet was closest to the

rotor magnet, so the force would be strong. I considered having the

magnet rise vertically to be out of the field at that point, but that

looked mechanically difficult to do. Then I considered that if I offset

the center

magnet, it could be farther away at the contrary time and closer where

the twist was the right direction.

I really wanted some smaller, square profile magnets,

especially for the center magnet. Then it occurred to me simply to use

the magnets I had cut in half a while back, doubled up to make 1" x 1"

square instead of .5" x 1". No new money spent, and I got what I wanted

- square profile magnets that were weaker for safer handling.

Despite some difficulties with

structural strength versus magnetic pulling foreseen in the

construction, I decided to build it. But it takes longer to build

something

than to draw it, and I didn't get to it during May.

Solar Electricity Project

Why?

Solar panels have been dropping in price year by year.

Solar electricity became cheaper than nuclear in 2010, and according to

my calculations solar installations by BC Hydro would cost less than

their Site C Peace River dam project, with no flooding of land.

Some solar PV panel making companies have recently been

bankrupted by

the falling

prices. The price drop may continue more gradually, or at some point

(barring some technology breakthrough), gradually start to rise. I

suspect that

whenever the inclination strikes is probably a pretty good time for an

individual to invest in solar PV.

Individuals can make a huge dent in the total amount of

power needed

from the utilities by being more efficient, as with LED lights (and

electric cars that take less energy as I've been working on), and by

utilizing energy available on their own doorstep - solar, wind, flowing

water, waves, tides, geothermal or from waste heat as applicable. Solar

seems most practical for the most people.

But a solar system with a

grid tie inverter doesn't provide

independence from the power grid. If the grid goes down, the inverter

stops, so as not to electrocute linemen repairing the line. One might

also want independence from the grid in a mobile unit such as a camper

or a boat. In another situation, the "grid" may be replaced by a fossil

fuel burning generator or other device.

With only 1000 hours/year (out of 8766 hours in a year)

full sunlight equivalent in Victoria, electricity at 10¢/KWH, and

a 225 watt solar panel at around 500$ plus tax, panels

alone will take

20 years to pay for themselves - if the energy is being

effectively utilized. Without a grid tie to sell the energy to the grid

as it's made, reasonably full utilization of the energy and its

opposite, not running out of power when the energy is used up, are the

tricky parts. The energy generated has to either

be immediately used, or it must be stored. All I've been doing with my

one panel so far is charging 12 volt NiMH batteries and using them to

run LED lights or for motor tests. Most of the potential electricity is

going to

waste.

But if utilization can be attained with minimal investment

and maintenance, and if the work is mostly DIY by

the homeowner, there'd be the satisfaction of being more independent,

and of seeing smaller monthly power bills. And then, when the

inspiration and finances come together, or

if panels get cheaper or are found used or whatever, the system can be

gradually expanded to some optimum size. Some sort of system might

start (assuming all new equipment) as low as around 2000$, and expand

to 5000 or 10000$, with substantial savings off the monthly electric

bills, which might even be zero in the sunny months.

How?

The question then is how to make grid-independent small

scale solar

electricity accessible for everyday use in a practical and economical

way - to (1) fully utilize the collected energy and yet (2) not have

problems or inconveniences at the times when it runs out.

My key idea is to expand the one way "DC Grid Tie" idea

that I envisioned

earlier from 5 amps to 50 or more and adding some flexible options. It

would be a central wiring unit to replace more than one single purpose

unit.

One function would be a programmable or adjustable charge

controller with a maximum power point converter supplying voltage to

batteries. It might even incorporate two such units, optionally from

two sets of collectors, perhaps with different MPPt voltages, also

optionally supplying two banks of batteries, potentially even of

different voltages.

Connecting loads to the Tie allows it to solve problem

one: to utilize the solar energy, as it's generated or stored in the

batteries. (An idea for ensuring all of it gets used follows.)

The one-way DC tie-in to the grid solves the second

problem: if the solar energy runs dry, the regular house power simply

takes over. This might operate off a heavy duty battery charger, for

example. The intent is not (necessarily) that it charge the batteries,

but that it runs the connected lights and appliances when the solar

runs out, without having to do anything or worry about it.

What is the output voltage? Ideally this too could be

programmable, and perhaps as with 120/240 VAC, there can be more than

one voltage. 12, 24 and perhaps 36 volts DC are the most useful around

the house. The higher voltages allow thinner wiring

to high current appliances.

What?

What will be powered? To run 12V LED lighting almost goes

without saying - 12 V LED lights are readily available, made for

vehicles, campers and boats. But it seemed to me the user could also

run some heavier

wires,

and install individual inverters to output 120VAC for selected

appliances that are

on a lot such as the fridge, freezer, computer and TV systems.

Electric stoves, heaters, water heaters and dryers are probably out

without a considerable system, but an electric water preheater tank

might make less work for the grid tank while using any excess solar

electricity not otherwise used. It could also be connected to non

electric heat sources.

Vis: "DC Grid Tie" circuit breaker (or AGC/AGO fuse) => heavy 12 (or

24 or 36?) volt cable to kitchen => DC outlet => Inverter =>

Fridge.

Each piece costs some money, but not a major investment,

and only once. The monthly bill for each connected appliance goes away,

at least in sunny months.

This seems practical enough to think of a "DC Grid Tie"

as a potential salable product. It should be easy to make it

programmable or adjustable as to charge and output voltages and

currents. Two units could be combined to accept "maximum power point"

input from two power sources such as two separate PV banks, or solar

and wind. An aluminum

chassis with circuit

boards, power transistors, low voltage DC circuit breakers or fuses,

and wiring

terminal connections wouldn't be very different to put together from my

motor controllers, and could be sold by itself (ie no motor), making it

a relatively simple product to produce and to market. The 120VAC to

12VDC

converter and any

inverters employed would be external (CSA approved I trust) and not my

concern.

In the cloudy winter, an electric heater may use up all

the energy from the collectors and energy storage isn't required. For

the other times I consider that I (personally) can use (a) cheap

renewed lead-acid

batteries and or (b) NiMH D cells (preferred) to store up energy. But I

now see these as temporary measures until I have (c) a sufficient

number of working Ni-Mn (from Changhong) or Mn-Mn (homemade) cells.

There's where sufficient, economical storage lies.

And there's another

practical way to store or use 'excess' energy: a "dump load" straight

from the collectors that comes on whenever the batteries are fully

charged and the other loads are satisfied, but the collectors have more

to offer. An electric heater could be a good dump load in the winter.

I myself want instead to put in a hot water

preheater tank ahead of the main hot water tank. Any excess power will

be

directed to that tank, storing energy as heat, and the 120V tank will

have that much less to reheat when hot water is used. I have a 30

gallon copper tank that has sat around here for

some time, and I trust I'll find a suitable heating element for 12

(24? 36?) volts at some suitable watts. (This special output might

supply variable voltage and current.) The dump load will absorb all

collector output unless you simply

aren't using as much energy and hot water as they can supply.

In lieu of a copper

water tank, I visualized simply an insulated fat copper pipe "tank",

eg,

4" or 6" diameter, running floor to ceiling, with the heating element

in an "L" at the bottom. I haven't worked out how many gallons you'd

get, but it should last as long as any of the other plumbing in the

house. Or perhaps a suitable stainless steel tube with end fittings

would be

available. A couple of phone calls to check prices of pipes put a quick

end to this idea. A cheap water tank, easily replaced, would be

feasible, or perhaps a PP-epoxy tank would be a long lasting item.

Another option might be to have a larger single hot water tank and heat

only the top half by having grid power to the top element only. The

bottom half would then effectively be an attached preheater tank.

It may seem odd to use solar PV panel electricity to heat

water, but having

once done it the other way long ago, I'd say that plumbing up an extra

tank indoors is a lot less plumbing and work than doing an entire hot

water

solar collector system on a high roof. There's no water outdoors to

freeze, and it's still replacing grid power with solar power.

Still, a water preheater tank can

also be

connected to a woodstove for winter water heating, which is very

effective, and or to a pumped or (if it can be mounted above the

collector) thermosiphoning hot water solar collector. A pumped system

that drains down could easily be turned off for the winter. These

things do definitely cut down on electricity usage. Personally I don't

use the "solar dryer" (clothesline) because of allergies to pollen, so

the clothes dryer will remain a big electrical load. I used to hang out

my wash and get terribly itchy.

I planned to use 12

volts as it's common, with many inverters

and appliances available, and it's the usual voltage of my LED lights.

I

decided to get a larger number of "left over" smaller 12 volt solar

panels (65 or 80 watts) made

for charging batteries at that voltage.

But the 'left over' panels were gone. I couldn't get 12 volt

panels at an effective price. I had to get the large panels made for 24

volt systems. 24 volts

allows 3 AWG gauges lighter wiring

for the same power. A friend says he was going to put his panels in

series to get 80 volts for still lighter wires, but got such a shock

while connecting them that

he

changed his mind and made it 40 volts. (He used Changhong Ni-Fe

batteries and runs LED house lights 24 hours almost year round. This

led to a profitable

association with Changhong, which led to my contacts with them.)

12, 24 or 36 volts would be my choices as far as

voltage is concerned. Personally I think 48 is a little high, with two

solar panels in series to attain it being over 70 volts with no load.

36 volts

is then the lightest wiring but there's fewer things available for 36

volts, and with the solar panels being 24, the choice is virtually

forced. I would prefer 12

volt panels that could be put three in series. So the choice boils down

to 12 and or 24. In fact, my unit should probably output both. For that

I suppose I'll need to create a hefty 24 to 12 volt DC-DC converter.

Another potential option would be to have +12 volts and

-12 volts, with 24 volt units across both. This would almost be

like the 120/240 VAC of regular house wiring, but there are some

limitations owing to grounds being different. Three wire cables would

be run to each outlet. Outlets would be APP plugs with four terminals:

+12, ground, ground, -12. 12 volt loads would plug into either the

+12:Gnd

pair or the Gnd:-12 pair. (They would need to be distributed so as to

discharge the two batteries

relatively evenly.) 24 volt loads would plug into the outer two

terminals, +12:-12, and possibly with chassis ground from one of the

center pins. I decided this seemed like the practical way to go, to

avoid a high power 24VDC to 12VDC converter with its cost and losses.

On the 29th I opened a Turquoise Energy account at Home

Energy Systems and bought four panels. They offered me

discounts on some marred or damaged panels, so I took four Sharpe

panels that weren't quite matched:

1. 240W (with gash on back plastic)

2. 235W (slightly bent aluminum frame - these two look

identical)

3. & 4. 208W * 2, still in box together (6" shorter. One had a ding

in the frame.)

Looks like these should have just enough room in line on the roof.

On the 30th, I bought a 1000 watt inverter (75$, a reduced

price) at Princess auto. I hooked it up to a NiMH 'car' battery and

plugged in my refrigerator. I went upstairs to get meters to monitor

performance. While I was up there, I guess the fridge happened to come

on by itself. Something that sounded like an alarm went off. By the

time I got back, thick smoke was coming out of the inverter. It should

have been plenty large enough to handle the fridge, and the manual

claimed it had overload protection. It shouldn't have blown. But the input

section had

fried and there were burned out transistors and circuit board. If this

was any indication, inverters weren't really a viable way to run

anything with a motor. (I took it back and got my money back.)

Equipment that can be purchased: two 12 amp, 12 volt

battery chargers for the 24 volts grid power to the system, a 400 and a

750 watt inverter, plugs to mate with the solar collectors, and APP 30

amp plugs. Evidently there is no standard for 12 or 24 volt plugs and

receptacles (except car cigarette lighter sockets), so I'm adopting

these.

Equipment that can be purchased: two 12 amp, 12 volt

battery chargers for the 24 volts grid power to the system, a 400 and a

750 watt inverter, plugs to mate with the solar collectors, and APP 30

amp plugs. Evidently there is no standard for 12 or 24 volt plugs and

receptacles (except car cigarette lighter sockets), so I'm adopting

these.

Missing: a piece of equipment to tie all these things together.

The next day, the 31st, a Canadian Tire store had a "Grand

Reopening"

sale. I decided to give inverters another try. I bought two 12 amp

battery chargers (@40$), two 400 watt inverters (@25$), and a 750 watt

inverter (50$), along with a long overdue shop vacuum cleaner (30$)

and a couple of much needed 33 drawer small parts drawers (@15$).

I tried the 750 watt inverter on the fridge. It was rated

for 1500 watts surge, but it shut off almost instantly when the fridge

came on: "E03" = overload. This was a big improvement over going up in

smoke, but it still didn't get the fridge going on batteries.

Additionally, the unit has a loud fan blowing a lot of air in a small

space. I couldn't have lived with that in the same room I was in.

Stalling the fridge gave a reading of about 19 amps. Sure

enough, it was over 1500 watts - theoretically it should blow the 15

amp house breaker every time it started, but of course it doesn't draw

that much for long enough to have an effect except on a fast responding

unit like an inverter.

12 and 24 volt fridges cost far more than 120 volt

fridges. Maybe if I get a cheap enough Wall-mart fridge, it would have

a smaller motor and would work with the 750 watt inverter. On their web

site it looked like they start at about 200$ - substantially less than

the 1500 or 2000 watt inverter evidently needed to run the fridge I

have, and a tenth the price of a 12 or 24 volt fridge.

The two 12 amp battery chargers would be the 120V grid tie

for the +12 and -12 volt supplies. 288 watts is only 1/3 of what the

solar panels put out, but the price was good and they should be

sufficient for now. (Best of all, they don't have fans.)

On June 2nd I saw some 70W inverters at XS Cargo for 10$,

made to plug into car cigarette lighters. I don't know what possessed

me not to buy a couple.

I had realized after buying the panels that I'd need

some of the mating plugs/sockets. Then I heard that I should get

aluminum mounting rails for

the collectors rather than attaching them straight to the roof. This

would cost all the money saved by finding discount panels.

The "minimal investment" project costs were starting to

mount. I decided to

make my own mounting system with wood, and I got the raw plugs to put

my own wires on. Without the pricey crimping tool, I could still solder

them.

Turquoise Battery Project

I didn't do a great amount of work on this, but

everything's been good progress and next month may bring Mn-Mn cells

that can actually light light bulbs and things.

Positrode Current Collectors

The positrode construction was still up in the air. There

were many possible ways to do them, none of which had proven very

practical so far.

So I started some experiments for

grafpoxy positrodes while I was doing epoxy in making the next motor.

First I made another sheet of it using fresh epoxy. It

got too hot in the oven. The PE melted and the epoxy bubbled up. But

the resistances were substantially lower, and didn't change much with

probe separation beyond a small distance. At the same time, I noticed

the first sheet was at least slightly flexible - it didn't seem it

would snap suddenly with a bit too much pressure. This was starting to

look

more promising.

Then I tried simply painting epoxy onto some polyethylene.

It spread much better than with the graphite mixed in. I sprinkled

graphite onto that and 'dusted' it around with a brush. I then mixed

the rest of the epoxy with graphite, and spread this grafpoxy onto the

top face of two pieces of the .03" PVC I've been perforating. Onto one

of

these I 'dusted' on more graphite. These all went into the oven at the

same time.

The first piece read very high to open. The first piece on

the sheet PVC was in the 100s of kilohms. The second was in the 10s of

KΩ, lowest where there were crusty clumps of graphite at the surface.

I took the two PVC pieces and put on another layer of

grafpoxy, then threw them (separately) into a jar with a little

graphite and shook it up. Then I glued a small square of sheet copper

with a hole in the middle onto each and put them back in the oven, as

terminal points to be above the cell. That

finished the gigantic 12g batch of epoxy I'd mixed. They were down to

3-5 KΩs range. Putting one probe on the copper only dropped it a KΩ or

so. It still seemed a lot higher resistance than the expanded graphite

at under an ohm. But I still don't trust that stuff not to degrade.

Each layer seemed to drop the resistance, but evidently it was going to

need quite a few layers. It would be better if it could simply be a

coating on a good conductor, but mostly the electrolyte seemed to get