Turquoise

Energy Ltd. News #53

Victoria BC

Copyright 2012 Craig Carmichael - July 2nd, 2012

http://www.TurquoiseEnergy.com

= http://www.ElectricHubcap.com

= http://www.ElectricWeel.com

Hilights:

- The Mushroom Electric

Outboard Motor [Design]

- 3D plastic printing to revolutionize home battery making

Month In Brief (Summaries)

In Passing (Miscellaneous topics

and editorial comments)

- War on Greed - Mercy & forgiveness - How to stop the Peace River

Site C Dam

Electric Hubcap System

* Improved Outboard From Scratch Design: The "Mushroom Outboard"!

* U-joint 90º Drive - socket wrench U-joints - tests show it works

fine.

* Sprint Car: Torque converter is ready; needs motor, controller,

batteries.

* New motor plate drill templates: from hand calculator to...

spreadsheet G-code.

Planetary Gear Torque Converter

Project

* Planetary gear torque converters are already in use! - Toyota Prius

& more.

* Sprint 'clutch' linkage installation.

Solar Electricity Project

* Modules of the "DC Grid Tie" unit.

* Solar Hot Water addition (doubles electricity savings) -

plastic/rubber mat collector, & Pump Control Module.

Turquoise

Battery Project

* RepRap: 3D printing of plastic parts will create battery making

revolution

* Conductive carbon fiberized ABS printing plastic for positive

electrodes ("posodes")

* 3D electrode pockets from Camosun College/VICAMP

* Next Mn negative electrode ("negode") with latest everything

* Mn negode doesn't work in KOH electrolyte (pH 14) -

discharges

spontaneously

* Mn negode does work in KCl electrolyte (at moderately

alkaline pH)

* Cells need seal to keep O2 out to prevent self discharge

No Project Reports on: Magnetic Motion Devices, Weel

motor, LED Lighting Project, DSSC

solar cells, Pulsejet steel

plate cutter

Newsletters

Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

-

Electric Hubcap Motor - Turquoise Motor

Controller - 36 Volt Electric

Fan-Heater

- Nanocrystalline glass to enhance Solar

Cell performance - Ersatz 'powder coating' home process for

protecting/painting metal

Products Catalog:

- Electric Hubcap Motor Kit

- Sodium Sulfate - Lead-Acid battery longevity/renewal

- NiMH Handy Battery Sticks, Dry Cells

- LED Light Fixtures

Motor Building

Workshops

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

June in Brief

I can hardly believe that I've taken on yet another

project, a 'novel' solar electricity system,

following so soon on

starting to explore magnetic systems, and with quite a number of

unfinished

or not quite finished projects still on the go... and when I seem to be

waking up every morning with a boundless supply of lethargy, then

tiring out by mid afternoon. (Perhaps a holiday would help? ...Hmm, B

vitamins seem to help) Yet

all these fields

seem so ripe for the harvest, and the workers are so few, that the

temptations are irresistible.

With western quasi-democratic civilization apparently

being ripped to pieces by ever more heinous financial and political

crimes, I spent considerable time trying to make sense of it all and

encapsulate my view of the big picture in an editorial (below), "War on

Greed".

I hoped I could get the solar collectors mounted in a

week, and

then pick away piecemeal at the electronic and electrical aspects of

the project while I got back to finish or

at least to progress on other things. But safely mounting them on a

south

facing roof with a

45º slope 26+ feet above ground would be no trivial undertaking,

and

the

prep, pursued at first part time and then only occasionally, drew out

for an extended period. Finally on the last day of June I finished a

scaffold-ladder to hook over the peak and lie on the roof of the house.

Most

people with shorter houses and flatter roofs, or a ground area to place

solar panels, would have

a much easier time of it. My south roof is an excellent location and

angle, but putting the collectors at

the base of the house in the tree shadows was looking very attractive.

On July 1st I climbed a hill and overlooked many homes... none with

solar panels. It needs to be made easier and cheaper. The panels are

good enough: The things that go around them need work, and need to be

affordable.

The hot water tank "dump load" idea meant there'd be a hot

water preheater tank, which I decided could go in the upstairs bathroom

next to the regular water tank as part of remodeling that bathroom. In

for a penny in for a pound... I bought a dual 2' x 10' (4 square

meters) plastic mat "swimming pool" hot water solar collector and DHW

circpump for a bill of around 500$. The hot water tube panels should

heat the

tank at least as well as all

four electric panels if not better, doubling the electricity saved for

1/4 of the price. Other motives for

this addition were to cover up the shingles coming apart at the far

edge of the south roof (the first PV panel does the other edge) and

stave off reshingleing a few years (10?), and to

create and test an optional "module" for the DC Grid Tie box: a

differential

temperature pump switch module.

Of course, getting the panels up will just lead to more

work to

get everything running.

Meanwhile

there was the unfinished new motor for the stripped Honda Electric

outboard. But it didn't look like a new Electric Hubcap motor

would fit readily under the Honda hood. I could make a new hood... ugh!

Then I thought up a

"U-joint" design to mount the motor at a 30º angle... and then I

thought:

maybe U-joints could be used to transit

the shaft rotation from vertical to

horizontal down at the prop, eliminating gears or pulleys with belts or

chains. A test with socket wrench U-joints showed it was likely to work

smoothly without much friction. (Contrary, as is often the case, to all

advice on the matter.)

Meanwhile

there was the unfinished new motor for the stripped Honda Electric

outboard. But it didn't look like a new Electric Hubcap motor

would fit readily under the Honda hood. I could make a new hood... ugh!

Then I thought up a

"U-joint" design to mount the motor at a 30º angle... and then I

thought:

maybe U-joints could be used to transit

the shaft rotation from vertical to

horizontal down at the prop, eliminating gears or pulleys with belts or

chains. A test with socket wrench U-joints showed it was likely to work

smoothly without much friction. (Contrary, as is often the case, to all

advice on the matter.)

With this exciting

design idea, I

decided it

would be better to do the "outboard from scratch" which could then be

replicated, and forget putting

time and energy into the "one off" Honda. Unfortunately, this meant

calling the

fisherman to say things couldn't be ready this season, so I was

delaying or perhaps defaulting out of a promising sounding

contract

- rats! Making a mock-up of the design suggested a name - the Mushroom

Outboard. I concentrated on getting the U-joint 90º drive

working nicely and figuring out how to mount its pieces.

In a period starting around the middle of the month, I did

much shopping at odd locations, mostly for the projects. I made several

visits to Camosun

college's VICAMP facility where they 3D printed me some 'perforated'

ABS plastic electrode pockets, and in

general somehow I seemed to spend my days driving around rather than

getting any

work done. The second batch of pockets on the 15th looked quite usable,

so with zinc and grafpoxied carbon fiber current collector plates, I

was ready to try making a decent test cell. Camosun's bill however came

to

325$ and I was glad I had ordered my own 3D plastic printer (and some

ABS printing filaments in several colors). By the

time it arrives and I get it assembled, I'll be wanting to make

electrode pockets, cases

and pressure seal/relief caps.

Having the electrode pockets, I turned some MnCO3 into MnO

to make a 'negode' with a solid sheet zinc (from a dry cell) current

collector. Theoretically

the MnCO3 could be 'calcined' to MnO at the low temperature of

200ºC, but

it didn't work "as advertised" on Wikipedia... nor at 230 or

260º... and in the end I sprinkled the powder through a propane

torch flame 3 times. Hmmf... I could as easily have reduced MnO2 to MnO

by the very same technique!

I put the completed Mn electrode into the Changhong cell

together with two NiOOH electrodes, making a Ni-Mn cell. The

conductivity was much lower than for the sintered electrode... it

seemed to work, but finally I realized the voltage (1.8V) was too

low... the active chemical was actually the zinc current collector and

current raising zinc powder rather than the manganese. The manganese

wasn't charging, and if enough current was applied to force it to

charge, it soon discharged back down to 1.8V, where it stabilized.

So I put together a whole Mn-Mn cell and used KCl

electrolyte. This soon charged up to 2.25 volts, which very gradually

dropped to around 2.15 V idle, notwithstanding liquid leaking out the

top corners. Longer charging (days) brought it up to around 2.4 volts.

Zinc would have been around 1.85 - 2.0 volts, so the manganese had to

be charging. Gradual self discharge over many hours is probably

explained by air leaking into the cell - oxygen discharges alkaline

negative electrodes.

Yes the meter is accurate - it's a whole volt higher than most alkaline

cells.

No the cell isn't on charge. (It was a few minutes previously.)

Yes it's one single MnMn 'moderately alkaline' battery cell.

It seems best now to put the batteries on hold until the

3D printer arrives. Then things should become much easier to make.

Indeed the whole idea of 3D printing homemade battery parts (using any

alkaline type of chemistry) looks so much simpler as to probably amount

to a battery making revolution.

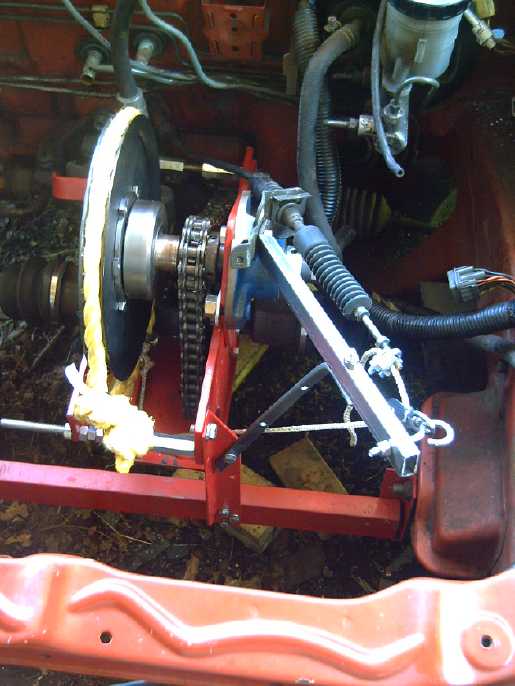

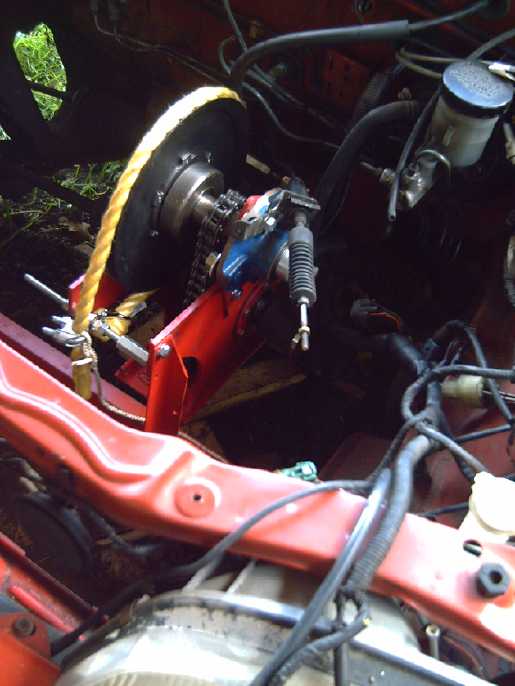

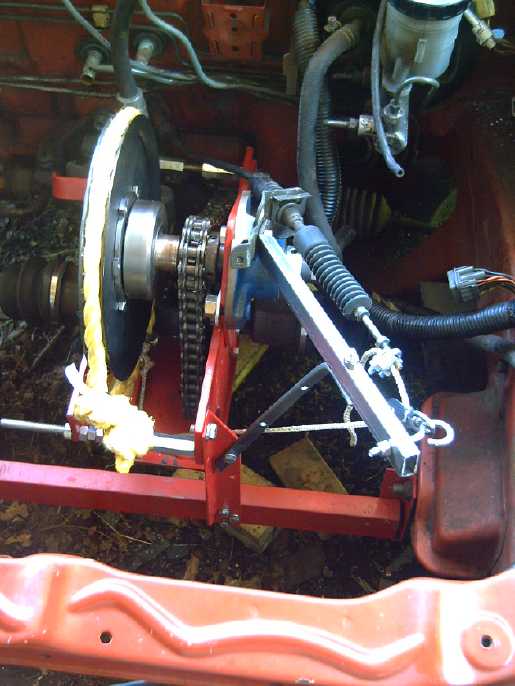

I also got the 'clutch' cable and slip control rope

assembly installed in the Sprint car. I hadn't been sure how I was

going to do this until I finally thought of using a small rope and

pulleys to go between spacially unrelated points 'A' (slip tension

rope) and 'B' (shift cable).

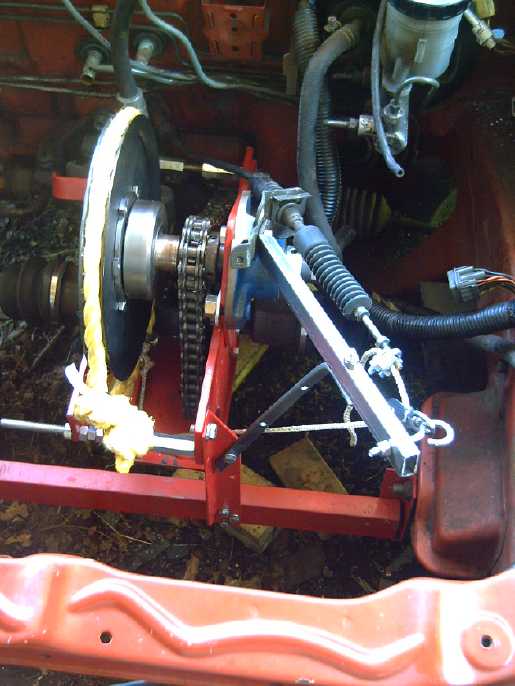

Control Clutch (ex gearshift) cable linkage to Slip Control V-Belt

pulley

via small rope & 2 small pulleys

(Yes, it could be tidied up. I wanna see it work first.)

With the car being now ready to test except for a motor,

controller and batteries, I finally got the stator plate drill template

worked out and drilled the holes in the waiting motor parts just before

month's end. I fooled around with CAD programs and "DXF to G-Code"

converters without much luck. Then I simply entered the text of the

main body of the G-code into spreadsheet cells appropriately

interspersed with the co-ordinate calculations, then just cut and

pasted it into the program file, eliminating most of the grunt work. At

last, a way to simplify it!

I need to put together at least a couple of motors and

controllers at this point. For a guy that wants to sell motor kits and

controllers, I sure don't seem to be producing them very fast!

In Passing

Incidental news, editorials

- Wanted: War on Greed, Corruption

&

Violence - Mercy is the way to peace & progress - Are Universities

Superfluous?

Without a serious enemy in the world, USA's

"leaders" are fond of declaring futile, never ending

wars. At home: "War on Drugs";

"War on Poverty"; "War on Terrorism". Abroad: bribes, threats,

assassinations and other "power plays", and trumped-up excuses for

invading, occupying and plundering weak

countries. For personal gain and power, they

have been

fabricating trouble and creating artificial problems to fight an

increasingly

effective undeclared war on the long cherished rights and freedoms of

their own

citizens.

This cancer has

been festering for a long time, and is now malignant, rapidly spreading

- the perpetraitors are now in almost complete control. They are intent

on turning America into everybody's

enemy, the global bully, enslaving their own citizens at home and

stirring up trouble all around the

world. Psychopathic "major scandal" level offenses by those in economic

and political control have

overwhelmed the defenses of law and order. Canada and

seemingly Britain and Europe are now trotting along beside the USA in

her path to ruin like Italy did

Germany in world war two, eager to outdo her in malicious malfeasance.

But it

would seem

they are all trotting along as the puppets of the

multinational banks

and other entrenched corporate evil empires - the ruling "cleptocracy"

as it's coming to be known.

The earnest attempts of citizens with ideas and ideals to bring about

justice, order and progress are ignored, even branded 'terrorism' and

maliciously suppressed, while far too many thoughtlessly while away the

hours watching entertainment TV, ignorant of the turbulent currents

swirling around them. Western

civilization as we know it has

apparently reached an evolutionary dead end.

With the new

interconnectedness of the internet,

people around the world are just starting to wake up to the fact that

everyone

everywhere is caught in plights to related to their own, and that

except for small agitating and greedy minorities everywhere (mostly in

control), they are

mostly

goodhearted people who have no evil plans for jihad against anybody

else. But no one is safe until everyone is safe. The most powerful

nation can't protect its people against someone who has nothing more to

lose with a homemade bomb strapped to his belt. At some point,

everybody, everywhere, including those pulling the

strings - or their children - will start to sicken of this fools' game

and turn long nurtured energies of fear, hatred and greed to love, to

the

bearing of fruits instead of thorns. There are small signs that

attitudes

are everywhere starting to change.

But even those ultra rich who already want change just

don't

know where to start. The way things

are going, seemingly from bad to worse to worser, what could possibly

trigger favorable outcomes? Unpleasant scenarios of conditions inimical

to progress like widespread rioting and mob actions come readily to

mind. "Those who make peaceful evolution impossible make violent

revolution inevitable." - John F. Kennedy

But the pendulum may

be reaching its maximum swing

because the global currency system seems about ready to crack. Many

analysts have been warning for several years of bank frauds and scams

on the global scale. A rapidly growing number of people have now joined

them in saying financial collapse, whether imminent or staved off until

later, is

now inevitable... and that it's a necessary evil. With western media being beholden to the

corrupt, the only news network covering this, seemingly the biggest

story in the world, is rt.com.

Those in control of the

biggest

banks are now openly manipulating everyone to economically pillage the

world,

stealing every fund including peoples' retirement savings and even from

their bank accounts,

and driving whole nations to economic servitude and ruin. (Canadian

bankers are evidently not innocent, BTW.) Having

acquired nearly all the fiat money for themselves and realizing that

this very fact is making it worthless while also dropping property

values, they're now trying to steal the last things likely to hold

their value - gold and silver. (They seem to have set their sights on

Greece's and Italy's gold now.) And they pay off the leading

politicians

- or in fact are doing what

the politicians want - so (except in Iceland) they aren't being

arrested or reined in. No banker will today invest in a productive

enterprise: stealing money is easier and more profitable.

If the banks close (AKA 'an extended bank holiday'), and

if fiat currency

collapses, along with many destabilizing and perhaps devastating

effects, all the entrenched vested interests will probably lose their

economic stranglehold. An unsettled and turbulent but potentially

fertile period

will likely ensue, when all sorts

of beneficial changes unimaginable under today's repressive conditions

can take place.

Then people can start working together, to

tackle the roots of the real problems: to

find and adopt sustainable social, political and economic systems that

citizens actually have effective control over.

If there are wars to be declared, they'll be "War on Greed", "War on

Corruption", and "War on Warmongering" - which "wars" will really

just be the long overdue corrective operation of the presently

dysfunctional wheels of government. If institutional and societal

changes create conditions

unfavorable to empowering rogue elements and draw most

everyone over to the same

side, working towards the same goals of a new, sustainable

civilization,

then the world will begin to draw together and become peaceful,

prosperous, and sustainable. The brotherhood of mankind will be

dawning.

The contribution of each individual defines the whole. For

the immediate future, in order to be in

a position to contribute rather than to be in personal or family need,

the advise

of those in the know is to have money in cash, put aside good

food and

other

necessities, and buy some silver and or gold. (eg: there are coin and

bullion dealers in every city, who sell 1 oz pure

silver coins, at about whatever silver is currently valued at plus some

mark up.) I don't

think anyone should do anything rash or irreversible, or panic, but the

more people who

are prepared to weather an initial shock of closed banks and disabled

or empty ATMs, with the likelihood of empty grocery stores, the better

for everyone. Ongoing major withdrawals - gradual

bank runs - are already on in Europe. At the moment, if confidence in

fiat currency

fails and suddenly the banks close, it appears likely to catch 99% of

the population by surprise.

I've heard it said that simply thinking about it and

withdrawing money to prepare will cause it to happen. If the world

banking system is that bankrupt, it can only affect the timing a bit,

and will seem poor logic later if you have nothing to eat.

I regret feeling the need to have written this piece, and

I'm aware that it may possibly be many months premature, or that things

now broken will get fixed and in a year or so I may look like an

overreactive fool. But having seen a glimpse of what appears to lie

ahead and may be triggered imminently, I need my conscience to be clear

if people are suffering for want of preparation, that I passed on the

warnings of many seemingly good judges of finance and economy as best I

could.

---

In the middle of the month, I heard rumors of grand plans to reorganize

the world's

money system when or if the banks shut down. When you bring

in your cash, you'll get to trade it in for the new money. But when you

bring in your six billion dollar bank account, questions will be

asked... like where did you get the money?, and, is it

a reasonable amount for you to possess? This is about the most hopeful

thing I've heard for some time.

If the rumor is true, it might help to explain why so

little seems

to be being done to combat the financial terrorism: many people

have decided that the sooner the whole system crashes, the sooner it

can be fixed. Such a plan, if it really exists, tho it could hardly be

implemented in a day or

a week, could do much to mitigate and shorten the unsettled

period, and to improve the likelihood of good outcomes.

But I fear it sounds like wishful thinking - too good to

be true.

---

Some Egyptians were demonstrating early in June, calling

for

vengeance

against Hosni Mubarak and his family and the people formerly involved

in running Egypt. Yet Mubarak simply 'inherited' dictatorial power when

Anwar Sadat was murdered. As far as I can tell from what little news

ever

reached the west, his long regime was pretty peaceful, even uneventful.

Egyptians who stayed home may be grateful to him for stepping down

peacefully instead

of fighting it out to the end - and maybe winning - with all the

bloodshed, turmoil and ruin that would have ensued.

Punishing Mubarak and those around him will only ensure

that others having power, all around the world, will never dare to step

down and will have to be removed, if at all, by ultimate force. The

protesters want more violence against him than he was willing to

unleash against them. It is the wrong signal to send. Mercy and

forgiveness - especially to those who surely have only tried their best

according to the lights given them - are the paths to peace, progress

and prosperity. "Blessed are the merciful, for they shall receive

mercy." "Blessed are the peacemakers, for they shall be called Sons of

God." - Jesus

Even the corrupt bankers and politicians who are bringing

down civilization are our erring brothers. If we "burn them at the

stake", they can make no repentance of value to the planet, but if we

are more merciful, perhaps many of them will reform, and being capable

people who know the problems from within, they will be glad to help

devise effective systems to counter the growth of such problems in the

future.

---

How to stop the Peace River Site C Dam

The best way to do something positive is to personally

reduce your own grid energy consumption. If your dwelling has no other

major waste of power, LED lighting will reduce the bill significantly.

With the present cost of LED lights, that may seem like more money than

it's worth, but if everyone in BC did it, we'd probably save

substantially more energy than Site C is to produce for far less money.

If the available bulbs aren't bright enough, a "Y" adapter lets you put

two "bulbs" in one socket, space permitting. And of course, I'll

happily sell my brighter LED light fixtures if anyone asks. (The

yellowish 800 lumen Phillips at Home Depot for 30$ are the brightest

LED "bulbs" I've seen locally. They were 20$ with a BC Hydro rebate for

a while.)

One person said he got an electric car and also put in LED

lighting, and his electricity bill went down - the LEDs

evidently save more than the car uses.

The next option is to produce energy yourself: install

solar panels or other green energy source, and or solar collectors for

hot water. Our often overcast west coast isn't the best place for PV,

but wide adoption would again reduce grid consumption more than Site C

will increase production.

And a small grid tie inverter for solar panels is

evidently now affordable, if not economic strictly in dollar payback

terms. (I must look into this - seems to me I was told you can get an

inverter that's on or off grid, so it can switched to power a separate

outlet(s) during a power failure.) With that and BC Hydro's new 'smart

meters', I think it should be pretty simple to put power out to the

grid to reduce your bill - or even get paid.

Perhaps I should look into that as an alternative to the

hot water tank "dump load" idea.

Of course, these things can only work if lots of people do

it, and

it seems a shame so little of that 8 billion dollars for Site C -

around

2000$ per every BC citizen - has been put into incentives to help

people accomplish this. But every bit helps, and if starting now

doesn't stop Site C, it might head off "Site D" or other megaproject.

Electric

Hubcap Motor System

Improved Outboard from Scratch Design (forget Honda conversion)

In considering how to fit the motor under the hood of the

Honda outboard, it occurred to me to mount it at an angle and put in a

U-joint... one from a 1/2" socket wrench set.

Then on the 3rd, it occurred to me that instead of having

a gear at the foot of the outboard, 2 or 3 or 4 U-joints in a string

could

make the 90º bend to the propeller shaft. This assembly, with no

gears or pulleys, could make for the narrowest outboard foot ever. In

fact, perhaps there need be no foot per se except a small bulge where

the prop

shaft comes out, for the seal. The leg would simply end just below the

prop with a skeg.

This started to make doing the "outboard from scratch" sound

easier than trying to fit the motor into the Honda... and it

should make a better outboard motor, eliminating the

unfavorable gear reduction at the foot of gas outboards, probably

with improved efficiency. Perhaps doing the Honda would be less

productive than forging ahead and making this new design, which, once

finished, can be produced. Since

I plan to do an outboard from scratch sometime anyway, eliminating the

Honda 'one-off' actually reduces the extent of the outboard projects

overall.

Once I started thinking about it, by the 4th design

details started coming clearer. A short piece of 12" culvert pipe would

(just) fit over the

Hubcap motor for a housing. Ventilation air would come in the front at

the top, and exit out the bottom near the front, which would be inboard

from the transom. (A splash guard around the outflow might still be a

good idea.) A broad

slot for intake air might also be the wiring entry, allowing the heavy

wires to twist inside for steering, rather than moving a long way side

to side where they entered at the front of the rim.

At the top of the

leg, a toilet flange I bought for an LED lamp base would glue into the

leg and make a good flat seat for the base of the motor compartment,

connecting it solidly to the leg.

If the drive shaft into the leg was made to drop into the

bottom end rather than affixed, the prop shaft assembly could be

lowered diagonally into the leg and then straightened as the shaft

poked out the hole, which could be a screw-on pipe fitting with the

shaft seal. Then the seal would be screwed on and the shaft would be

inserted from above.

The bottom of the leg would simply be glued shut (except

for a threaded in replaceable prop shaft seal/fitting), reducing the

chances of leaks. Oil for the lower unit could be poured in from the

top or a couple of screws could go through the wall in the traditional

manner.

The transom mounting bracket details were still fuzzy.

Potentially the round top end of the leg could simply twist inside

something of slightly large diameter. Or stainless steel clamps

around the pipe could hold a hinge pin at the front. Either way, the

mount would still

need to pivot up to lift the leg out of the water, presumably on a pin

at or above transom level. And there should be a 'straight ahead' latch

for rudder steering installations, and a catch for reverse to prevent

the leg rising up. Another thought was that the farther forward the

pivot was, the less the wiring would need to move for steering. I'll

probably opt for the front pin.

Perhaps the motor controller could optionally mount on the

front side of the transom mount. Optionally because that wouldn't be

the best for vessels using an outboard bracket - the controller should

be within the craft away from waves and spray.

Something that had been concerning me was that surely I'd

never get a long enough piece of PVC pipe in the oven to soften and

bend it. But when I measured against my boat, I found it only needed to

be

20" long. The oven would take 21-22" straight, and perhaps a bit longer

diagonally. Only the lower end gets bent to the streamlined 'teardrop'

profile, since the top is out of the water and also it has to mate with

the round ABS toilet flange. Furthermore, these tubes can be extended

with

another piece having a flange. If I only bolted the top to the leg

instead of gluing it, extension to make it a "long shaft" would require

only another (flanged) piece of PVC pipe and a longer driveshaft -

common 1/2" square steel rod.

The Hubcap motor for the top end is a given, so the first

step in all this, I think, is to create the 'foot' mechanism holding

the

prop shaft, bearings, U-joints, and the socket for the vertical

driveshaft. The size and shape of that unit will determine much of the

lower end geometry.

On the 6th I

put the outer pieces together in a 'mock-up'. Imagining a

domed cap to shed water, the wide, round top with the 4" 'stem' in the

center suggested a name: the Mushroom Outboard.

On the 6th I

put the outer pieces together in a 'mock-up'. Imagining a

domed cap to shed water, the wide, round top with the 4" 'stem' in the

center suggested a name: the Mushroom Outboard.

Also on that day, someone who didn't think highly of the U-joints idea

mentioned looking up "right angle drives". Later "homokinetic drives"

were mentioned. Amongst many ads and info

for beveled helical gears, worm drives, and couplings for misaligned

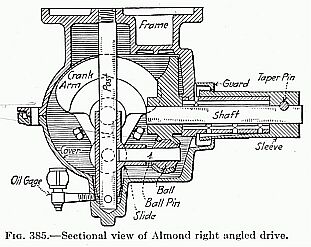

straight shafts, I found this, the "Almond" shaft coupling:

Taken from Wm. Griswold Smith's "Engineering Kinematics"1930.

The drive

shaft ends keyed to a ball joint with integral counterweight. [The ball

joint is similar to that of a rear sway bar end link]

A pin passes through the ball and into the 'trunk' of a "T" shaped

sleeve whose cross bar slides vertically on a fixed post.

The visible "T" actually has a 2nd "trunk" at a right angle to the 1st

[i.e., on the 'Z'axis ] which connects to the pin of the output shaft.

The motion of the pins is helical and reciprocal. The efficiency is

claimed to be 90-93%, [i.e., better than bevel gearing]

The description and diagram seemed clear as mud, so I did

a search on the

specific name, and came up with some you-tube videos showing the

'almond'

and a couple of other types of gearless right-angle shaft direction

changers.

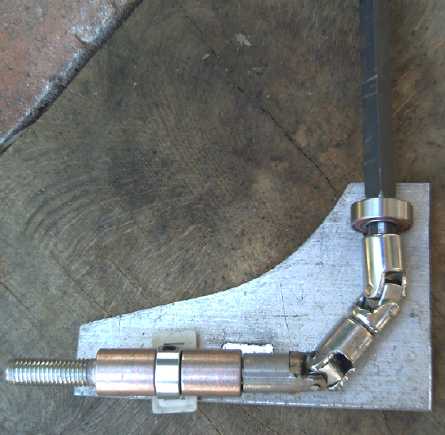

I still

thought the U-joint looked the most promising, but the discussion list

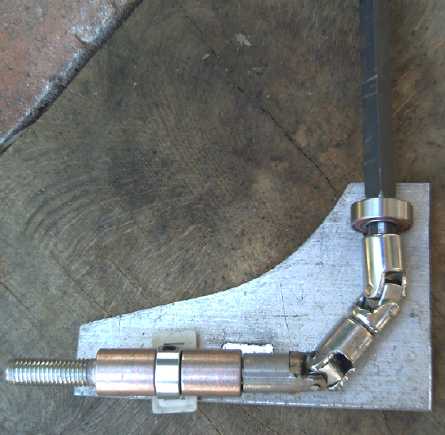

was skeptical. So I made a little test, with a bearing on the input

drive shaft (1/2" square, black), clamped down, and a 5/8" center

pulley "bearing" on the 5/8" propeller shaft (bolt).

I still

thought the U-joint looked the most promising, but the discussion list

was skeptical. So I made a little test, with a bearing on the input

drive shaft (1/2" square, black), clamped down, and a 5/8" center

pulley "bearing" on the 5/8" propeller shaft (bolt).

I simply held the pulley and the prop shaft with one hand

while I turned the drive shaft with the other. If I tried to angle it

more than 90º, eg 110º, the torque to turn it got noticably

"lumpy". But at 90º, it felt

pretty smooth, even when I put some resistance on the prop shaft.

So I think

two U-joints are both the best and the simplest idea. If the socket

set ones wear

out too rapidly,

I'll try to make something better along the same lines. (I can

visualize an 'ideal'. In essence similar, but the center would be a

single piece instead of two pieces pushed together, and the pins would

be beefed up and in line, perhaps with bronze bushings. But I'd rather

not try making it unless I have to.)

Saying it seemed to work well didn't convince everyone

either. A working outboard

might do it, but I'm not so sure - opinion was pretty averse.

On June 9th, I thought of a good way to put it together:

in a "sandwich" of aluminum plate bread. The bearings would sit upright

in rectangular grooves or holes in the the aluminum, like car tires in

potholes. When the two pieces were bolted together with a couple of

rectangular pieces between to hold them straight, the bearings would be

held rigidly in place.

This proved more difficult than expected because I

switched from ball bearings to sintered bronze bushings, and some of

the parts had a greater diameter than the bushings.

Then I

realized I could eliminate one of the moving

parts and make it more solid by making the prop shaft into the final

U-joint segment. (And there was no point continuing with the housing

without having a final shaft configuration.) This needed a stainless

steel pipe of the right inside dimension to slip over the bolt (whose

hex head was ground down to an indented rectangle), cut to end in two

"arms" as the end piece of the U-join. (In fact... all the pieces could

be replaced by 1/2" square rod and other off the shelf stuff.)

Then I

realized I could eliminate one of the moving

parts and make it more solid by making the prop shaft into the final

U-joint segment. (And there was no point continuing with the housing

without having a final shaft configuration.) This needed a stainless

steel pipe of the right inside dimension to slip over the bolt (whose

hex head was ground down to an indented rectangle), cut to end in two

"arms" as the end piece of the U-join. (In fact... all the pieces could

be replaced by 1/2" square rod and other off the shelf stuff.)

While I was working on that, my angle

grinder's right angle drive gear broke, with whole gear teeth going

through the remains of the drive gear. And this wasn't the first angle

grinder whose gears had failed. Hah! A beveled gears right angle drive

has its own

share of potential problems! I took spare pieces from previous angle

grinders to try and make a "new" one, but immediately had the same

problem. The next day I bought a new and somewhat more costly angle

grinder.

When I got this new U-joint arrangement far enough along

to try it, it seemed to turn quite smoothly. However, if the center

socket connection was uncoupled and one piece was turned 90º and

then they were recoupled, it didn't work right. As expected, the

unaligned cross pins had to be set to cancel each other between the two

sets, not reinforce.

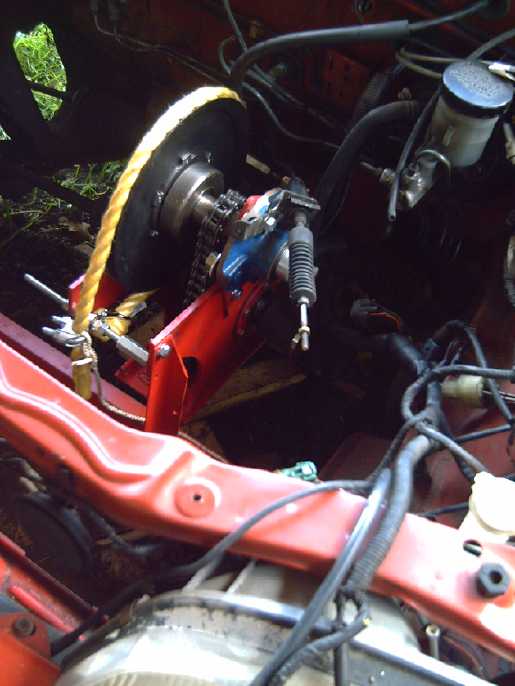

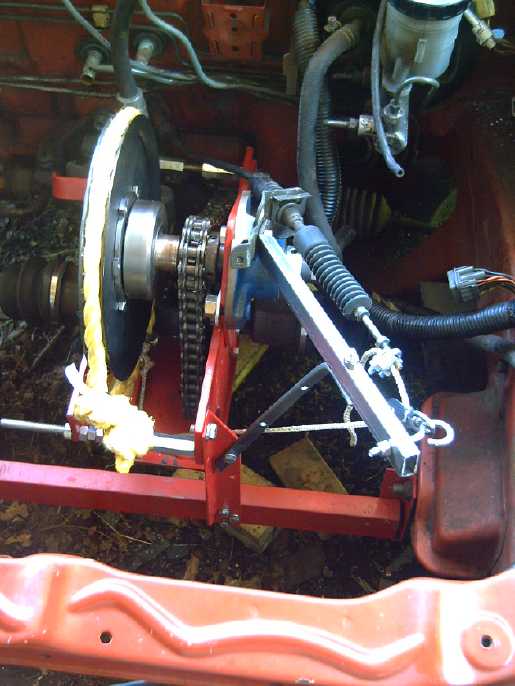

Sprint car conversion

The transmission having been mounted, the linkage between the shift

lever cable and the torque converter slippage control rope (bearing no

particular positional relationship to each other) were connected via a

small rope and two pulleys, as described below.

Once a motor, controller and batteries are installed the

car should be ready to test drive.

New Motor Drill Templates

At first I

used a calculator to calculate X, Y drill co-ordinates from rotor

angles and radii. This grew thin after about the second time I modified

the rotor design. Then it occurred to me to use a spreadsheet, and to

cut and paste the numbers into the G-code drill program.

This month I played around with a CAD program, LibreCad,

which made 'standard' ".DXF" files. I did the design after a while, but

then I had little luck with "DXF to G-Code" converters. Then I simply

entered the text of the main body of

the G-code into spreadsheet cells appropriately interspersed with the

co-ordinate calculations, then just cut and pasted it into the program

file, eliminating most of the grunt work. At last, a way to simplify it!

On the 29th I finally got the stator plate drill template

worked out, drilled it,

and drilled the holes in the waiting motor parts. Using the template

and a hand drill is easier than setting up the CNC machine each time a

rotor or two is to be drilled. It also generally gets the holes better

aligned, since the line-up of template and part is easy to see before

holes are drilled, instead of after.

Planetary Gear Torque

Converter Project

Planetary Gear 'Torque Converters'

are

already in use(!)

It seems that Toyota Prius hybrid cars, and drive

systems from another company, already use planetary gears effectively

as torque converters. In both cases, electric motors or generators are

being used to control the slip - or instead, variable forward drive -

of the third element, in ways that aren't very clear to a casual

glance.

(http://prius.ecrostech.com/original/Understanding/ContinuouslyVariableTransmission.htm

[2001]) And it seems the GM Volt uses a planetary gear to connect two

motors to the wheels, each running at half speed above a certain

vehicle speed, to limit RPMs to the 3000's range instead of 6000's.

Although the Prius has been around for over a decade, I've

only been hearing that "2012 hybrid cars

are using CVT's" in recent months. Even then, the term "CVT" instead of

"torque

converter" made me think of

split pulleys and steel drive belts per typical past CVT's. The

difference in terminology kept me from checking very hard when I didn't

readily find any info on the web.

So it would seem my big planetary gear "Eureka!" is a

reinvention of something

already invented. At least it validates that the operating principle is

sound - it's in use. And sure

enough, the Prius's engine

is said to be only about 70% of the size it would be if the car had

step

gears, also validating my "2/3 the power" or "half again better"

estimate.

I wish I'd known about

these systems 3 years ago when I started the torque converter project.

It could have saved much of that time period - assuming I'd been able

to wrap

my head around the seemingly complex

implementations to understand the working principles. It seems

surprising that little

excitement ever seemed to be aroused about such a breakthrough

technology, and

that it isn't finding its way into all cars... except maybe that

improved

fuel performance probably may still not be what the oil barons want...

or maybe it's still not understood that it could be used with any

motive power: The more complex idea of driving two of the three gears

has distracted from the simpler one of simply allowing one gear to

slip - just set up the ratios accordingly.

My mechanical brake or

clutch idea for controlling the

slip still appears to be new, or at least a new implementation.

(...although at this point I wouldn't be surprised to learn something

like it had been done a century ago.) If it proves to work well - that

is, that the driver can control it easily and smoothly - then it's

surely the simplest way to do it.

"Clutch" tension linkage installation

Something that

had been puzzling me for a couple of months

was how to get the gearshift cable to line up with the friction rope

around the V-belt pulley. The positions and angles were all wrong, and

the cable certainly wasn't very flexible. Towards the end of the month

I had the thought

that by clamping a small rope between the big rope and the shift cable,

and installing some strategic small rope pulleys, the positions and

directions of pull could be altered as convenient. Having a plan is so

much better than not that I got onto the job.

Something that

had been puzzling me for a couple of months

was how to get the gearshift cable to line up with the friction rope

around the V-belt pulley. The positions and angles were all wrong, and

the cable certainly wasn't very flexible. Towards the end of the month

I had the thought

that by clamping a small rope between the big rope and the shift cable,

and installing some strategic small rope pulleys, the positions and

directions of pull could be altered as convenient. Having a plan is so

much better than not that I got onto the job.

I came up with an

arrangement for the pulley end. Then I looked for my old stainless

steel boat hardware including some pulleys that should do the job...

and realized I must have given it away a few years ago when I thought I

had no use for

it. Sigh!

I also started to think that a foot pedal clutch might

be better than the hand operated "parking brake ratchet" idea. It would

be like the traditional manual clutch pedal, except that it would be

engaged and modulated by the foot for longer periods as the car gets

moving. But there'd be no gears to shift, so it was "hands free" and it

might actually be

easier. I decided to see about getting a clutch pedal and cable next

time I was near an auto wreckers, since my automatic car didn't have

them. On the 23rd I went there at 1:30 PM, only to find they close at

1 PM on Saturdays. Sigh!

By Monday I

had changed my mind again and decided to hook

up the gearshift lever as originally planned. It has the advantage that

it can be set to some intermediate tension and left there, which might

be best for low speed travel. I started to consider that the clutch

idea might prove to be a nuisance.

By Monday I

had changed my mind again and decided to hook

up the gearshift lever as originally planned. It has the advantage that

it can be set to some intermediate tension and left there, which might

be best for low speed travel. I started to consider that the clutch

idea might prove to be a nuisance.

I bought a couple of pulleys and clamps to join the ropes

and shift cable. On the 26th, after some perplexing but imaginary

problems rectified by reinstalling the part of the cable inside the

car, the shift cable came out to near its original position under the

hood (gosh!), and I used its original fastening plate, slightly

modified, to fasten it to the new 'transmission' box.

I put one pulley under the V-belt pulley on the

'transmission' frame base. It seemed the pulley to the shift cable

would have to be mounted near the left headlight. This seemed fine and

I mounted a pulley there. Then I remembered that the frame of the car

wasn't rigid to the shock mounted transmission and motor assembly, so

the rope would tighten and loosen when going over bumps, jerking the

motor and mechanism. All the pulleys had to mount on the assembly. The

stiff cable stuck out past the assembly, so I'd have to make a big

tripod out of square steel tube or angle iron to have a place beyond it

to anchor the pulley to the cable - sigh!

I set to it and made the main piece of .5" x 1" square

tube. Then a support piece of 3/16" x .5" solid steel, twisted and bent

to fit, that was virtually in line with the direction the rope would

pull. I decided that was sufficient without a third leg unless proven

otherwise.

Of the various alternatives for how to make the slipping

gear mechanism work, I'm starting to think this may in fact be the best

of any of the simple ones, in spite of the manual tensioning lever. (If

it needs a new 2' rope every 6, 12 or 24 months, so be it.) The second

motor-generator system, under computer control, might be superior, but

at a much higher cost and with considerable development needed.

Solar Electricity Project

Wooden Collector Mountings

There was an aluminum frame mounting system that HES

evidently makes. Evidently it's a good one. I decided to save the money

and do a wooden mounting system. The four panels were to mount beside

each other in a single row. 14 foot 2"x4"s bolted to the steep roof

would be long enough. With the top one, I planned the collectors to

slightly overhang the peak of the roof to keep much of the water from

going under. The bottom one would give a bit of support for traversing

the steep roof while putting them up.

I didn't want to have to cross over any of the panels to

their far side during installation. The first one would have a 40 foot

drop inches from the far side. The rest would all have the previous

mounted panel in the way. So I came up with a hooking system by which

the "L" shaped panel edges would be swiveled into place, "clipping"

them on at the top corners and on the far side near the bottom, and a

lag bolt on an outward facing "L" bracket across from that would fasten

the fourth corner.

Solar Panel cross section:

_________________________

|_

_|

<--

inward

"L"

aluminum

angle

edges

Thus the panel could be maneuvered and twisted into place

and then bolted down at the bottom near corner, with a single lag bolt

and without having to cross the roof to the other side of the panel. I

didn't look at the aluminum bracket mounting system, but I bet you

couldn't do that with it! I could be wrong. The 2x4's and their

associated wooden "clips" were put together, and everything including

the wiring was tested for fit on the ground to give the best chance

that everything would go smoothly on the roof.

Hot Water Collector (What does this have to do with electricity?)

I figured if I was going to have a hot water preheater

tank, and since the shingles are wearing out and coming up just along

an edge of my roof where the wind evidently was catching them, I should

put up a solar hot water collector to cover that edge. (in spite of

some afternoon shade from trees.) One thought was to simply have fat

plastic pipes on the roof that would hold the hot water themselves. No

pump would be needed. The other idea would be to have an unpressurized

drain-down system that would pump water through a pipe in the preheater

tank. That did need a pump, but solved winter water freezing problems.

Either way, PVC pipes, not

available in 1980 when I

made my previous solar hot water collector system, would be cheaper and

easier to install than copper.

I went to a plumbing store

to check out options and

prices, and they suggested Van Isle Water Services. They had ready-made

collectors

of rubber mat with small tubes molded into it "for swimming pools". I

had first heard of this in

the early 1980s or so. There were two brands. One cost just 245$ for a

kit of

two 2' x 10' collectors, plastic rather than rubber. (I had only been

planning ~18" x 10'.) It didn't fit

any vision of what I'd been

thinking of, but as I drove home it dawned on me that it was the ideal

choice, and I bought it the next day. They'd make a lot of hot

water, and the plastic mats should make good roofing! The solar hot

water would save substantial electricity for a fraction of the cost of

equivalent solar PV panels... and help put off reroofing, hopefully by

a decade.

It seemed a natural to find a 12 or 24 volt pump and power

it

from the DC Grid Tie system. To control the pump, a 'differential

thermostat' would use two temperature sensors to see if the collector

was warmer than the tank, at least by a degree or two, with the outdoor

air above freezing. I made one of

these in about 1995 for someone else's solar water system. (LM339,

AD590's or LM335's) Whatever

collection was available could continue even in

winter, whether rarely or often.

And I'd have another useful module that can be added to

the

DC Grid Tie system!

I considered

garden and marine supply DC pumps, until the people pointed out that

most of these

weren't made for continuous operation, were less energy efficient than

AC, and

were all made for cold water, not hot. The higher flow rate and

pressure of the AC pump was also desirable, and to top it off, the one

I found had

three settings to find the best speed and flow after

installation. I could have found

a separate DHW pump and used my DC lawnmower motor with it. But the

quiet AC

pump should last many years with no maintenance. The differential

temperature unit would have to be just a switch to activate a solid

state relay (SSR ...or maybe could include a power MOSFET for 12 VDC

pumps regardless.)

An inverter can still run the pump off the DC unit

if desired, but I admit I'm becoming distressed by the number of simple

things I can't get for 12 or 24 volts, or which cost far more or don't

work as well. Such factors mitigate against adoption of low voltage DC

home systems and solar systems.

Turquoise Battery Project

I'm shortening my self made terms 'positrode' (positive electrode) and

'negatrode' (negative electrode) to 'posode' and 'negode'. I think they

have a better chance of catching on to replace the unintuitive and

ambiguous terms 'anode' and 'cathode', which reverse in meaning

depending on the direction of current flow.

3D Printers for Plastic Parts Production

Long ago when the first laser printers came out, I noticed

that they laid on so much PVC(?) toner that the printing could be felt

with the fingers. Others evidently noticed this too and took it to

another level: printing on top of printing, layer on layer, could make

a solid 3D object.

After visiting Camosun College's VICAMP prototyping

facility and seeing their equipment in May, I started to consider

that

3D-printing of ABS plastic would be uniquely suitable for making

perforated plastic pocket electrodes, because they could simply be made

with the perforations built in, instead of having to burn or punch them

out afterwards. In looking up these rather new (and various) 'additive

machining'

technologies on

Wikipedia, I found this insight about their general application:

"Three-dimensional printing makes it as

cheap to create single items as it is to produce thousands and thus

undermines economies of scale. It may have as profound an impact on the

world as the coming of the factory did....Just as nobody could have

predicted the impact of the steam engine in 1750—or the printing press

in 1450, or the transistor in 1950—it is impossible to foresee the

long-term impact of 3D printing. But the technology is coming, and it

is likely to disrupt every field it touches."

—The Economist, in a February 10, 2011 leader

The question was means. I figured I wasn't going to find

such a micro-factory on Used Victoria or eBay for an affordable price.

But as I

read on, to my surprise I found 3 digit prices mentioned for kits

instead of 5 or 6 digit,

so I

started checking them out. Sure enough, they were affordable. Their

revolutionary nature has had a huge

impact

on the machines themselves: their custom formed plastic parts are made

on other 3D printers, so they're easy to reproduce in

small quantities. If

they needed injection molds, we'd still be waiting for them to drop

under that 5 digit price barrier. The first manufactured item

"disrupted" by 3D printers is 3D printers!

Instead, an open source 3D printer revolution was started

by a developer in London about 2007, and it started catching on.

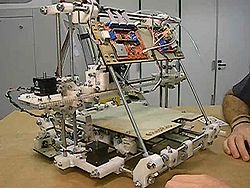

reprap mendel 3D ABS/PLA plastic extruder-printer

I also read about a plastic I hadn't heard of before,

"PLA" or "Poly Lactic Acid", made from plant material such as corn

starch, tapioca or sugar cane instead of petroleum products. The

machines I'm interested in can use either ABS or PLA.

SO! Forget injection molds entirely: the plastic parts for

my version of the Turquoise Battery can be made with 3D printing

technology. The writer in The Economist was right - certain

things that were hard until now have suddenly become a LOT easier.

Battery making may be the second thing revolutionized by 3D printers.

Regardless of chemistries, printing electrode containers

and other battery parts will make homemade batteries practical for the

first time. After all, a battery is just chemical powders, crammed into

"+" and "-" housings, with some sort of current collectors connecting

the chemicals and all immersed in or containing some sort of

electrolyte. Cramming chemicals is simple - appropriate structures and

current collectors to cram them into constitute the hard part.

In fact, the thing will have other uses as well: for

example, custom made LED light fixture bases for various styles of

diffusers would simplify LED light construction and they could be made

easy to screw into walls and ceilings without even removing the

diffuser. For another example, anchors and mounts for various things

like the terminal blocks in the motor controllers and in the "DC Grid

Tie" units.

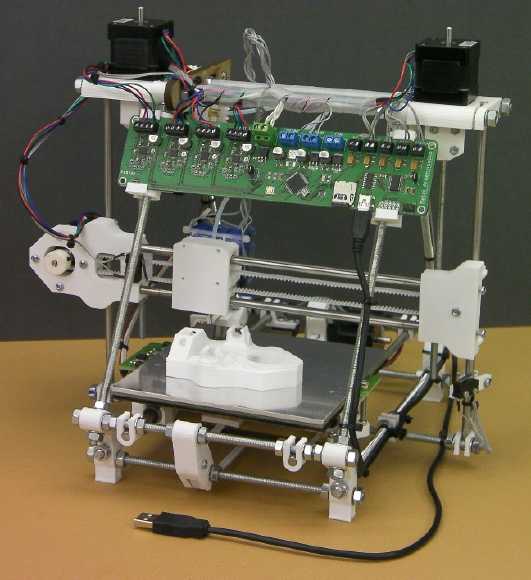

On the 9th I ordered a complete kit for a somewhat smaller

model, www.REPRAPpro.com/Huxley . It's expected to ship July 20th. Work

area is 140 x 140 x 110 mm.

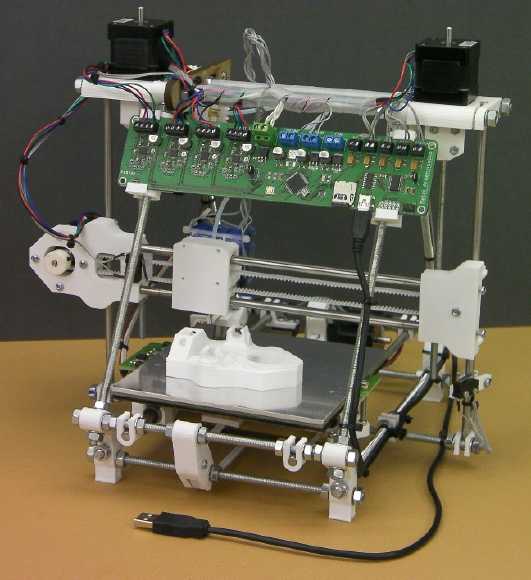

REPRAP Huxley as made in kit form by RepRapPro

I seem to usually be in the next-to avant guarde in

printer technology. Interestingly, The Huxley is similar in dollar

price to the first mass market dot matix printer, the Epson MX-80

(1981?), and to my first color inkjet, the original Epson Stylus Color

(1992?). And half the price of my first laser printer IBM4029, similar

to original HP Laserjet (1993?)

(My first color laser printer, the Samsung CLP-300, was much less than

any of the others above - I must have been late getting in.) Back then,

each dollar was worth

substantially more than it is now, so in effect, 3D printing is the

cheapest new printing technology yet - and look what it does!

There were also additional recent designs: the Ultimaker

(Holland) and the Solidoodle (USA). Ultimaker is evidently

faster but costs more, and it looked like Solidoodle (cheapest... and

pre assembled) isn't ready to ship yet.

3D printing can make parts that previously only injection molding could

- and more.

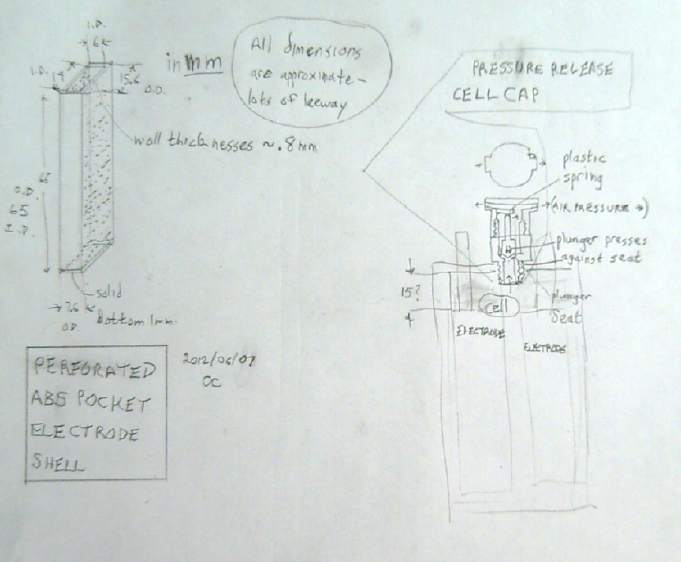

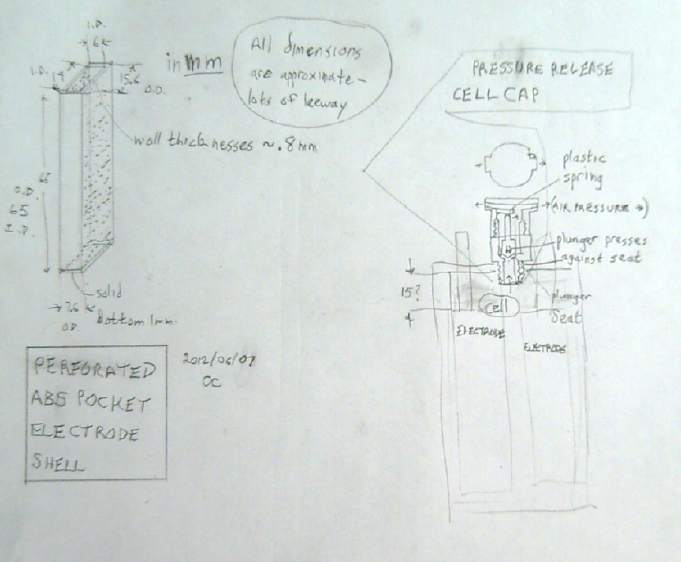

Electrode Pockets from VICAMP

Meanwhile, I had contacted VICAMP about making some

ABS electrode pockets with their machine, both as potential alternative

production and to get some soon instead of maybe by next fall. The

REPRAPs have a heated table. The VICAMP machine keeps the part in an

enclosed 'oven' space closer in temperature to where the plastic

softens, which makes parts that stick together better and warp less. It

can print polycarbonate and ?"ulton"? - similar to nylon) as

well as ABS and no doubt PLA. (Polycarbonate and Nylon... I start

thinking of planetary gear/torque converter parts!)

I had had the idea of making the pockets lying down, in

two halves to butt together and glue. (For that, the heated table

should

be sufficient.)

______

| |

|_____|

The VICAMP maker came up with a slightly more elaborate

design where ideal alignment was assured:

First batch of open ended "boxes with lips" pockets from VICAMP.

pocket 'boxes' as assembled showing closed bottom end.

The mesh of the ones on the right seemed too coarse - the chemicals

might come out.

Only the narrower one (@ 1/2" vs 3 @ 5/8") one on the left was stiff

enough to consider using.

From this design, I came up with the idea to have one half

fitting over the other:

______

| |

|____|

These would glue together along the 'verticals'. The sum

width of the adjoining vertical walls could still be strong even when

made narrower than the walls butted together or in the first 'box'

form, wasting less plastic and adding less size and weight to the cell.

A second batch of pockets all looked usable, altho several

different patterns, wall thicknesses and internal thicknesses had been

created. The thin ones looked almost like my text drawing above.

I wrecked one of the boxes. I put too much methylene

chloride on to glue the halves together, and some spread onto the mesh.

The perforations in the mesh filled in, and simply touching the mesh

while it was wetted broke it and left two jagged holes. This however

led to

the realization that the slightly porous printed parts, to use them for

cases and pressure caps, could be sealed simply by a quick application

of, or a dunking in, methylene chloride.

I think the cases can be printed square "U" shaped bottom

and

ends, while the wide sides can simply be pieces of flat ABS sheet glued

to the "U"s. The fairly precise control of dimensions printing the "U"

and

the matching glue-on lid will make the cases relatively simple to

fabricate and assemble.

Or the whole open top case might be printed as a unit.

However if it needs to be saturated with methylene chloride to seal it,

it might not be as much easier as expectable. This might still be a

good place for an injection mold.

Next Mn Negode

Having obtained pockets for electrodes, zinc collector

plates, and manganese carbonate, I decided to to make the manganese

monoxide with heat:

MnCO3 → MnO + CO2 - at 200-260ºC.

As an aside, another way to convert the carbonate would be

by making the electrode and soaking it in [dangerous] NaOH or KOH. This

exchange reaction makes Mn(OH)2 + Na (or K) CO3 - a contaminated

electrolyte to dispose of. (as garden fertilizer?) The heat method is

preferable IMHO if it does an acceptable job.

The surprisingly low temperature can be had in a kitchen

oven set to 450ºF or 230ºC. The one problem with it is that

without an inert gas facility, the MnO readily absorbs oxygen from the

air to form

Mn3O4 or Mn2O3. That's at least less oxidized than MnO2, but I could

derive it from MnO2 with a higher temperature. I put it in a

crucible and put aluminum foil over the top. Perhaps the CO2 would

drive the oxygen out of the crucible?

I put 100g of MnCO3 [valence II] in the crucible. The

results should be indicated both by the color and the weight after the

CO2 is driven off:

MnCO3 - [II] light pink - 100g

MnO - [II] green or "dark colored" - 62g

Mn(OH)2 - [II] white - 77g

Mn3O4 - [2.33] red or brown - 66g

Mn2O3 - [III] dark brown or black - 69g

MnO2 - [IV] black - 76g

Short duration

heating in the kiln (on the 17th, 15 minutes?) with the powder in the

crucible and

aluminum foil over the top resulted in 97 grams with brownish powder

around the outside, still pink in most areas.

I decided to put it in a small stainless pot in the oven

at 425ºF/220ºC, still with aluminum over the top, for 90

minutes. It looked about the same and weighed 97 grams.

I tried again with the oven at 460ºF. This time, the

whole mix turned a medium-light brown - perhaps about right for Mn3O4.

But it still weighed 96.4 grams. Surely it should at least drop below

70!

Next try was at the oven's highest setting,

500ºF/260ºC. 260ºC is where it's supposed to start

forming Mn3O4 or Mn2O3 instead of stopping at MnO at all. But I'm

beginning to think the oven temperature is a little below the dial

setting, at least up near the high end. But the weight was still 95

grams.

On the 19th I tried putting it in the new crucible and

torching

it. (It was so windy on the 18th I waited a day.) The top glowed

red, but I realized it wasn't heating very deep in. So I dumped it out,

aimed the torch into the crucible, and started sprinkling the powder in

with a teaspoon. The torch not only heated the crucible, but also the

powder as it fell past the flame. This time the powder, still medium

brown, was down to 85 grams. I repeated the process and got about 72. I

repeated it a third time and it was down to 59 grams. I figure probably

about 2-4 grams was lost in all the handling and sprinkling. However,

in the reducing propane flame and seeing the low end range of the

product weight, I figure it probably formed either MnO or Mn3O4, or

some of each, rather than higher oxides. Or it may in fact even have

formed some metallic Mn. To my eyes it's medium-dark brown with no hint

of green, but I'll call it a success. (Would it turn white in

water, converting from MnO to Mn(OH)2)? Hmm... not in clear water.) I

was surprised that in all this torching, the torch flame didn't seem

to be blowing any notable amount of powder away from or out of the

crucible.

If I'm going to torch it anyway, I might as well be

starting with MnO2, which should also reduce to MnO in the torch flame.

With either substance, if this is how it's to be done, I should set up

a stand for the torch and some sort of funnel pouring system that'll

automatically drop out an 'hourglass' sort of fine sprinkle of powder.

Without 'clumps' of powder going by it'll probably just take a single

pass through the flame.

With that at last ready to go (on the 20th), the negode mix could be

formulated:

MnO active chemical - 80% (32g / 32.6)

Zn conductivity enhancer - 20% (8g / 9.4)

Sb2S3 hydrogen overvoltage raiser - 1% (.4g)

For the electrode pocket, I selected the (only) 4.5mm

thick one from batch 2, with .042" (1.05mm) thick faces, 4.65 grams. It

was quite stiff with little flex. The 'lid' sides were all the same

shape, but I forgot there were a couple of non-perforated ones until

after I'd glued it on. Nevertheless, it seemed to be 'microporous'

(evidently typical of printed ABS parts), which is probably good enough

-- maybe it's even better, saving the trouble of putting in a separator

sheet or spacers. I can hardly wait to get my own 3D printer to try out

variations.

I had cut the

zinc current collector (2.25g) about the end of May;

now I made a 2mm thick aluminum spacer to put in while the first side

was filled. The next day I made the mix, wetted it, and stuffed it in.

I had no particular system set up, and it must have taken an hour of

dropping a bit of mix on the zinc plate and stuffing it in with a

'plunger', ad infinitum, then repeated for side two. The zinc current

collector 'tab' was bent a few times and the tip broke off in all the

stresses. The mixture, with no binding agents, was loose and not

amenable to good compaction. It mushed out around the plunger, even tho

it wasn't very wet. Zinc makes initially very fragile electrodes; this

seemed as bad or worse, and worse than the sintered one.

I had cut the

zinc current collector (2.25g) about the end of May;

now I made a 2mm thick aluminum spacer to put in while the first side

was filled. The next day I made the mix, wetted it, and stuffed it in.

I had no particular system set up, and it must have taken an hour of

dropping a bit of mix on the zinc plate and stuffing it in with a

'plunger', ad infinitum, then repeated for side two. The zinc current

collector 'tab' was bent a few times and the tip broke off in all the

stresses. The mixture, with no binding agents, was loose and not

amenable to good compaction. It mushed out around the plunger, even tho

it wasn't very wet. Zinc makes initially very fragile electrodes; this

seemed as bad or worse, and worse than the sintered one.

Starting with 10 grams, I had less than 2.5 remaining, so

about 7.5 must have gone in. The MnO was about 79% of that, so 5.9g of

MnO. The "O" dilutes pure Mn's .975 AH/g, yielding about 4.4 AH

theoretically. If the bulk of that proves accessible for discharge, it

should be quite good, but for production I'd like to see more Mn

compound and less extraneous structure if possible.

I put the electrode into the Changhong cell with its

nickel electodes, with a piece of watercolor paper folded over it. The

leed barely stuck through the top to make connection to, and that by

pulling it up a bit. Initial voltage was 1.7 something. After a few

hours charging at ~50mA, it sat at 1.84.

Charging voltage, instead of rising, started at 1.92 and

dropped to 1.905, and stayed around that level some hours even as the

off-charge voltage rose... then it dropped further to 1.895 with an

off-charge voltage of 1.85. Hopefully, that meant that the electrode

was building current bridges and oxide was becoming more conductive Mn

metal.

With a 2.2 ohm load, output dropped below about 1.2 volts;

1.25 volts after a few hours; then almost 1.3 when the day was done.

The next morning, it had improved to 1.87V open circuit

and 1.4V with the load. But I opened the cell and found an 'erupted'

pile of light gray material had oozed out of the electrode. Well, it

made sense that Mn(OH)2 should take up more room than MnO, and white

Mn(OH)2 would explain the light color. Perhaps I shouldn't compact it

much at all, and just let this swelling do its work? I scraped it off

and let it fall into the cell. I'd have liked to look at the whole

electrode to see if the sides were bulging or if it was also oozing out

the perforations, but that would have meant disrupting everything, and

I also dislike working with caustic KOH, so I left it for later, when I

would also change the electrolyte, since it might have a fair bit of

carbonate in it by now from any leftover MnCO3, plus the sludge on the

bottom. If any was oozing out, the paper I had put in should prevent

shorts. The nickel electrode was bubbling (oxygen) since it was already

charged and the charging current continued. The Mn side only bubbled a

bit.

After another couple of hours, the charging voltage

started going up, and I had to reduce the current to 50mA again. It

seemed much too soon. Was the zinc plate disintegrating? I had pulled

it out a bit when I inspected, and it came up disturbingly easily

through chemicals it was supposed to be in minute contact with. Would

this electrode deteriorate and become useless like so many others I'd

made? No load voltage was up to 1.87, and a 2.2Ω load test delivered

above 1.5 volts -- but dropped off with passing seconds, indicating

poor connections through the electrode. Probably disturbing the current

collector upset things?

1.88 volts seemed too high to be zinc [+.49 - -1.28 =

1.77V], but not really there yet for manganese [+.49 - -1.56 = 2.05V].

On the 23rd I

opened the case and removed the electrodes. More mix had evidently

oozed out the top around the edges of the pieces of plastic I inserted

to prevent this, and seemingly also through the tiny perforations - but

only on the side with the intended perforations. The 'microporous' side

was clean. Evidently, the powders being very fine, microporous is the

way to go - and a good fitting glue-on lid would be a definite asset.

In fact, it seems to me Alkaline Storage Batteries mentions a

special Ni(OH)2 mix for flooded pocket electrode cells - I bet it's a

specially coarse mix to minimize oozing. And they do anyway. They have

to have it rinsed off before final assembly. Being able to print very,

very fine perforation - more like 'pores' - will be a definite 3D

printer technique asset over punching holes in solid pieces.

On the 23rd I

opened the case and removed the electrodes. More mix had evidently

oozed out the top around the edges of the pieces of plastic I inserted

to prevent this, and seemingly also through the tiny perforations - but

only on the side with the intended perforations. The 'microporous' side

was clean. Evidently, the powders being very fine, microporous is the

way to go - and a good fitting glue-on lid would be a definite asset.

In fact, it seems to me Alkaline Storage Batteries mentions a

special Ni(OH)2 mix for flooded pocket electrode cells - I bet it's a

specially coarse mix to minimize oozing. And they do anyway. They have

to have it rinsed off before final assembly. Being able to print very,

very fine perforation - more like 'pores' - will be a definite 3D

printer technique asset over punching holes in solid pieces.

After rinsing the electrodes and knocking the stuff off, I

put the battery back together. (I didn't change the electrolyte.)

Obviously this not so well compacted 'loose fill'

electrode was nothing like as conductive as the previous sintered

electrode, but it did gradually improve over the hours as it charged.

I'll be thinking of how to do this all better. The 'microporous'

plastic side may (just possibly) have limited ion flow to that side.

Perhaps a good way to make Mn(OH)2 would be electrical

reduction of MnO2 - to discharge it as a negative battery electrode

reaction, but stopping when it hit -.15 volts instead of trying to

charge it to -1.56. The Mn(OH)2 at least shouldn't expand after the

electrode is assembled.

I finally woke up to the fact that the 1.8 volts that

seems to be as high as wants to stay charged to is roughly the voltage

of NiZn, not NiMn. Reaching 1.9 volts can be done, but the Mn doesn't

stay charged and it drops back to 1.8.

At this point, I began to think that Mn negodes don't work

in KOH electrolyte because the voltage (-1.56) is too high even with

antimony sulfide added. They do seem to work in my 'moderately

alkaline' cells, perhaps because the voltage decreases more rapidly

than the alkalinity to -1.18V. (Zinc drops to under a volt in these

conditions. But NiOOH and KMnO4 both go up faster with falling pH, so

the overall voltage is higher.)

I also keep looking at that zinc pourbaix diagram that

shows no soluble state between pH 8 and 13 - the desired alkalinity

range. Accoring to theory, that should mean zinc won't form dendrites

at those pHes, in which case it would make a very good negode material

producing roughly 2 volts open circuit. I'm not convinced it would

actually work that way and make very long life electrodes... but it

looks like it on the chart, so it might.

That the Ni-Mn/KOH cell won't charge Mn to metal meant the

next step should be to make a complete Mn-Mn/KCl cell to repeat for

verification the successful chemical results of February, but with the

new current collectors/terminal leeds to hopefully get better

conductivity.

I used

the KMnO4 posode from April (with one pocket nibbled off and tiewraps

to hold it closed) and the Mn negode pulled from the Changhong cell

(still oozing stuff). Another bit of the zinc terminal tab broke off

and I had to make do with such a short length that even coming close to

sealing the cell looked problematic. I did what I could.

I used

the KMnO4 posode from April (with one pocket nibbled off and tiewraps

to hold it closed) and the Mn negode pulled from the Changhong cell

(still oozing stuff). Another bit of the zinc terminal tab broke off

and I had to make do with such a short length that even coming close to

sealing the cell looked problematic. I did what I could.

Conductivity was very poor and the water turned purple

(sigh!), but sure enough, even with only 8mA charging current, in KCl

it immediately started charging to well over 2 volts, too high to be

accounted for by the permanganate-zinc (~+.95 - ~-1 = 1.95). Only

permanganate-manganese (~+.95 - -1.18 = 2.13) would explain the high

voltage. After a while it hit 2.25 volts. There was still some self

discharge, whereas it seems to me that in February I had pretty much

eliminated it.

Then it occurred to me that with the cell being poorly

sealed, oxygen would get in. If oxygen would discharge MnO to Mn3O4, it

would surely discharge wet Mn to MnO or Mn(OH)2 in spite of the

antimony. In fact, it discharges cadmium and metal hydride - that fact

is used to keep dry cells from bursting on overcharging or too rapid

charge. That probably explains all residual self discharge. It would

seem that alkaline cells must be essentially sealed to hold

their charge, with of course the high pressure release.

Evidently I've been wasting my time

thinking that Changhong could make the chemistry work with their

existing flooded KOH alkaline cell production line. It seems to need

the carbon parts, salt electrolyte... and likely a somewhat better

sealed case than theirs. Again it seems fortuitous that somehow I

didn't convince them to try it out. When I can send them a finished,

working battery I'll do that and see what they think.

It's probably time to set

the battery project aside until August or September when the 3D printer

arrives and is assembled (except maybe for a bit of preliminary 3D

electrode pocket computer modeling). Then I'll be able to easily do

things that have proven difficult - even problematic - so far: ideal

plastic pockets, and 'slight-pressure' cells with caps that don't

leak... or even cells that don't leak.

Conductive perforated plastic electrode pockets!

Since I had ordered the 3D printer, I started looking into

sources of ABS plastic. I was informed there was a conductive

ABS printing filament! I explained that it would have to be conductive

carbon or graphite based for the positive electrodes, or conductive

zinc

based for the negatives, and that nothing else would work.

It turned out the conductivity was based on carbon fiber!

This could revolutionize the position. Instead of grafpoxying a thin,

narrow 'sheet' of carbon fiber for each electrode and sticking it into

the middle, then having to compact powders on each side of each one

separately, the electrode can be printed as above but with a connection

tab to stick up through the case. Stuffing would be one simpler

operation instead of two more fiddly ones. In fact, a whole set of

pockets forming a plate with a tab could all be printed at once.

It would all depend on how conductive the ABS really is --

or could be made to be with toluene, osmium/aldehyde, grafpoxy or

whatever. Of course I put some on the order - it was just becoming

available, a new product. But it would probably arrive before the

printer.

In addition, the person said he would consider trying to

make conductive zinc ABS filament as well. This doubles the excitement!

Certainly one couldn't pull the terminal leed and disturb the

connections if the basket was the current collector. 3D

printing, with conductive printing filaments of the exact

formulations required, might just solve nearly all the battery

production problems at a stroke! However, I might have to pay something

up front as an inducement, and of course the endeavor might not

successfully produce a practical material.

The big advantages would be:

* The pockets would be printed automatically, sizes, shapes and

material as desired. This alone saves a heck of a lot of work. (If

printing 3D parts is too slow for production needs... get or make some

more printers!)

* The printed pockets would have attached printed terminal leeds

exactly sized and positioned for the holes in the lid of the cell, with

all the pieces liquifyable by methylene chloride. The cell would thus

be much simpler to assemble and to seal.

* The mass of these non-reacting 'extraneous supporting structures'