Turquoise

Energy Ltd. News #54

Victoria BC

Copyright 2012 Craig Carmichael - August 4th, 2012

www.TurquoiseEnergy.com

= www.ElectricHubcap.com

= www.ElectricWeel.com = www.MushroomOutboard.com

Hilights: Peltier Element 12V Refrigerator

Month In Brief (Summaries)

- Solar - thermo-electric fridge - Thermomagnetic theory supported by

ambient heat powered battery.

In Passing (Miscellaneous topics

and editorial comments)

* Machines have increasingly done the grunt work for decades. When will

labor saving devices finally start to shorten

everybody's working hours?

* "Normalcy Factor": populations caught by surprise in changing times.

* Solar PV Kickstart in Germany (next: Ontario Canada): paying

extra for solar power to grid has caused homeowner installations that

eliminate need for other new power plants.

Electric Hubcap System

* Plasticy primer prevents ilmenite coil coatings from flaking off

(yay, at last!)

Planetary Gear Torque Converter

Project

* EDM Machining of sun gear: keyslot made - can now get on with Sprint

car motor/converter installation.

Solar Electricity Project

* Power Price Point (probable power cost increases may soon make solar

economic)

* PV Solar Panel roof mounting, connecting - fuses, isolation diodes,

breaker.

* Spinoff project: Superinsulated Thermoelectric Fridge & Freezer

* Voltage: 24 volts would be great, but most appliances are 120VAC - or

else 12VDC.

* Max Power Point DC to DC converter/CV charge controller/dump load

driver unit?

* Cases for multiple voltages & 3D Printed Plastic 12V D Cell

battery cases?

Superinsulated Thermoelectric Fridge &

Freezer

* Shallow chest format with hinged lid (or lid sections)

* Peltier cooling elements & 12VDC cooler cooling module

* Peltiers in thermal series; peltier module heat pump/heater; two-stage

peltier

makes

frost in room temperature environment

* Exploring Insulation; Construction / Bill of Materials /

Tests during construction

* Conclusions & Product Possibilities: TE temp. control; TE 2-stage

peltier cooling unit; TE Fridges; TE Heat Pumps

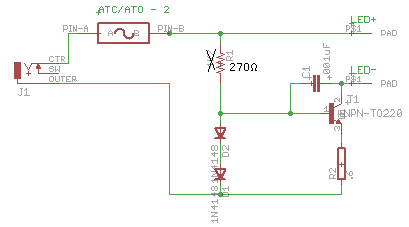

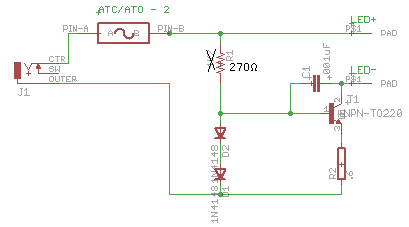

LED Lighting Project

* Linear, low dropout voltage, constant current regulator gives supply

voltage flexibility.

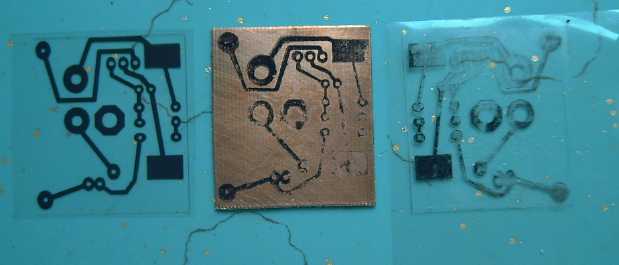

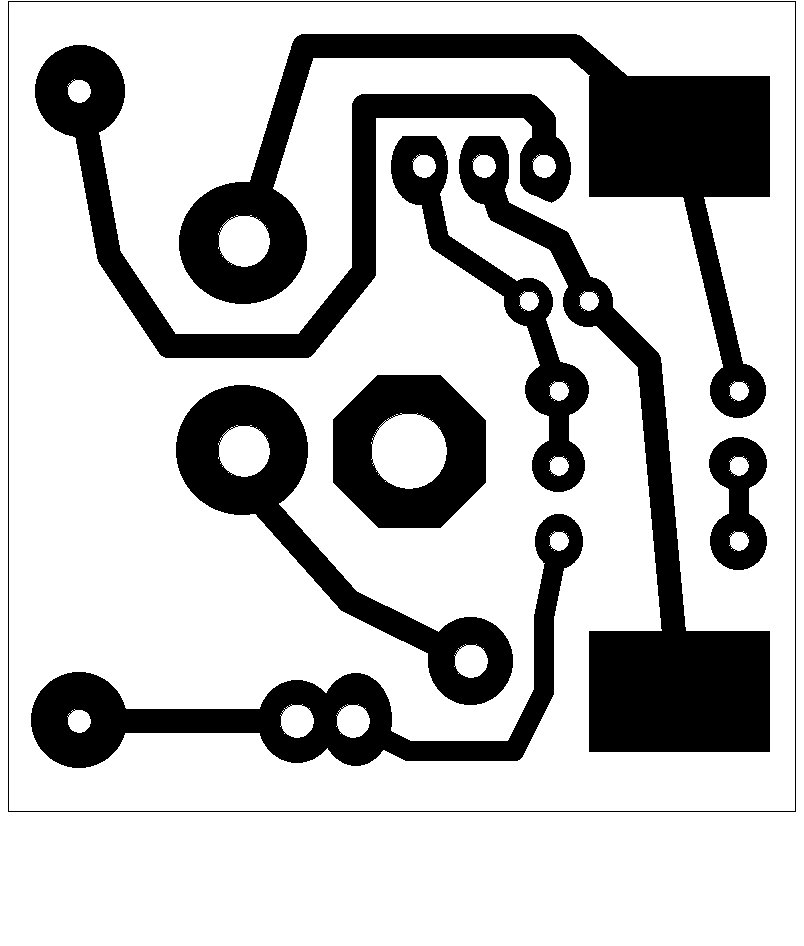

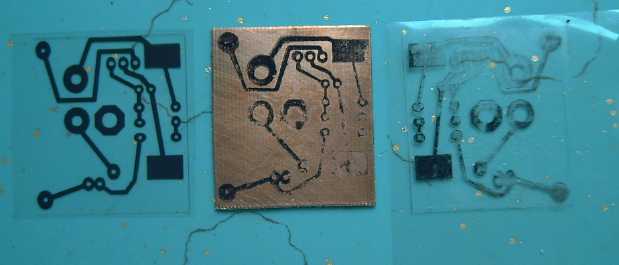

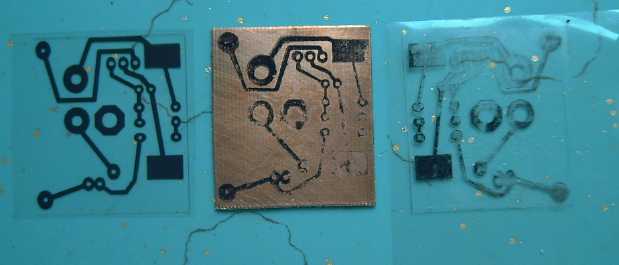

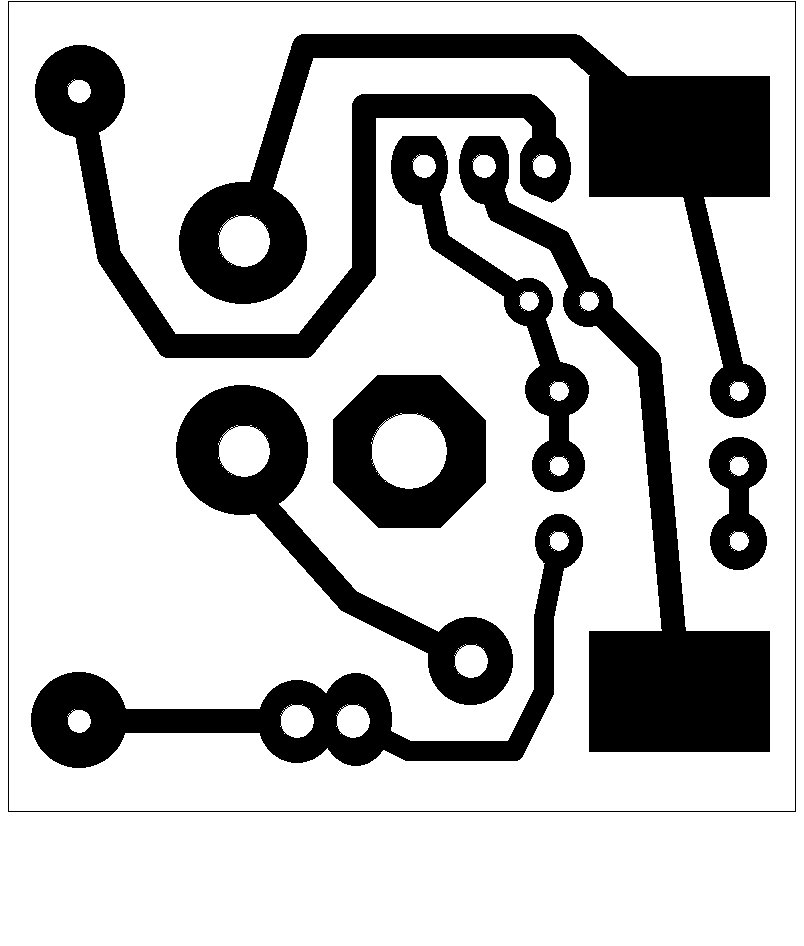

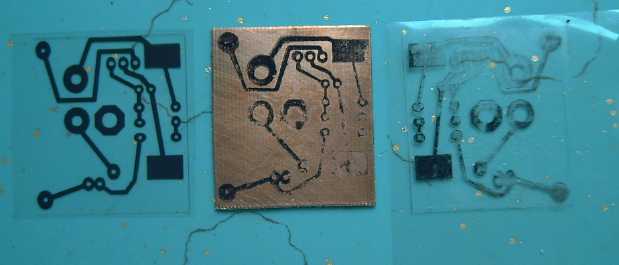

* Circuit board production: laser printed artwork iron onto board;

novel etching solutions.

* New way to make printed circuits boards?: artwork is thin

layer of 3D plastic (or wax?), 3D printed

directly onto the PCB?

Turquoise Battery Project

* 3D Printer kit arrives - 3D Printer Software / Conductive ABS

printing filaments / Zinc flakes / Osmium

* Recharge with ambient heat energy?

No Project Reports on: Magnetic Motion Devices, Weel

motor, DSSC

solar cells, Pulsejet steel

plate cutter

Newsletters

Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

-

Electric Hubcap Motor - Turquoise Motor

Controller - 36 Volt Electric

Fan-Heater

- Nanocrystalline glass to enhance Solar

Cell performance - Ersatz 'powder coating' home process for

protecting/painting metal

Products Catalog:

- Electric Hubcap Motor Kit

- Sodium Sulfate - Lead-Acid battery longevity/renewal

- NiMH Handy Battery Sticks, Dry Cells

- LED Light Fixtures

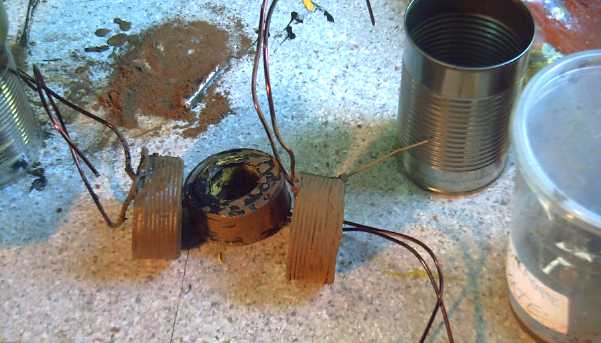

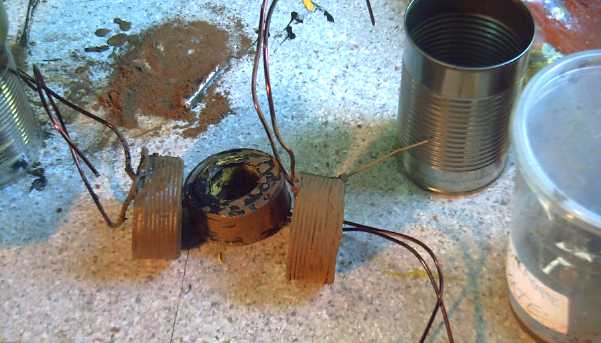

Motor Building

Workshops

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

July in Brief

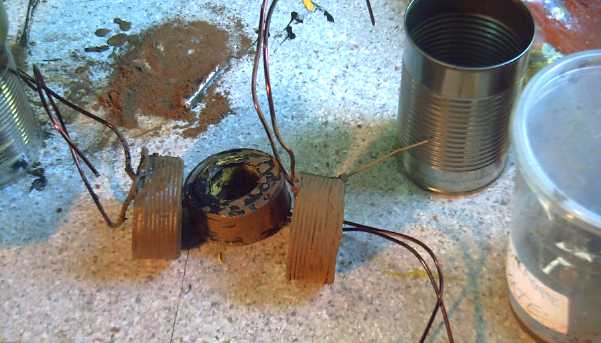

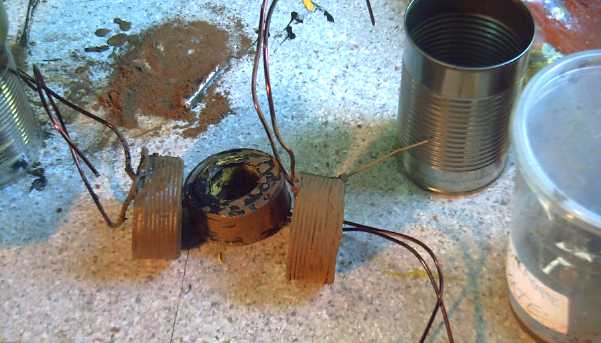

Near the start of the month, I finally found a plasticy

'undercoating' for the motor coils

that the ilmenite in sodium silicate doesn't readily flake off of. I

then thought to put together a couple of motors and controllers and get

the Sprint car going and be ready to power the Mushroom Outboard, but

only one motor got partly done.

I soon got enthused about

the idea of a 12 volt

superinsulated 'shallow chest' fridge using a peltier module for

cooling. The fact that

there are few home products like fridges and freezers made to operate

on low voltage DC is doubtless hindering adoption of off-grid and low

voltage solar energy systems. This would begin an exploration of this

area and the products that might be created to fill the gaps.

Telling

myself that I already had more projects on the go than I could complete

didn't help. I figured it

would be a short project. It won't drag on for years, but it did occupy

much of the rest of the month after the solar panels were up, and it

still isn't finished. I ended up with a camping cooler peltier unit

complete with fans, as it looked tricky to outfit a peltier cooler from

basic parts. Over a few

days I got as far as buying the main ingredients and cutting styrofoam

insulation pieces (R5 per inch) to form the main body. I got

polyurethane foam mix for the inner inch, as it has about the highest R

value (R6-R7) of anything except a couple of unobtainables: vacuum

(R30-R50)

or aerogel ("solidified smoke" - R10). It took much longer than I

expected to foam it in, and if I was to do it again I'd probably stick

with premade sheets and just get one can of polyurethane spray foam to

glue the pieces together. In spite of the great insulation, I could

only get the 4.5 cubic foot space down to 9ºc. This got to be a

puzzle as adding insulation didn't help. It finally proved it was the

cooling unit that would only drop the temperature by about 13 or

14ºc

regardless of what it was mounted in including the original cooler. I

needed to buy or make something better. On the 31st I tried setting up

a 2-stage peltier unit, and It made frost on the coldest part, right in

the warm room. So the temperature is attainable, and the question is

simply how big a unit using how many watts will be needed to cool the

whole fridge - it might need up to 100 instead of 60 or 70.

Fridge with lid and coverings removed, showing the 3+" insulated walls

and floor

The solar panels put out

thirty-odd volts (presumably at up to about 30 amps). On the 14th I was

loaned a 20-48V to 14V DC to DC

converter. The next day I got one of the panels wired up, adjusted the

converter to 13.8 volts, and tried it out with a NiMH battery that

needed charging.

It worked fine as long as the solar panel wasn't

overloaded. It wasn't putting out much power in the overcast, and

pressed beyond its maximum power point, its voltage dropped off. Then

the converter started making scary noises and actually started drawing

heavy currents from the battery. Then I realized that for sure

I wanted to make a flexible, multi-purpose unit specifically for solar

panels that would properly handle all situations. I think that would be

great merchandise, and relatively simple to put together. (There's even

a machine shop near here that is looking for products to assemble,

which is getting into electronics assembly... hmm!)

Further considering solar and battery power for homes

brought me back to LED lighting. My units are very simple, but they

work at exactly 12.0 volts. Battery power can vary from a little less

than that to over 14, which would blow the fuses in the LED lights. I

came up with a simple linear circuit (just one

transistor!) to provide constant current to the LEDs for any voltage

from about 12 up to 15 or 16. At almost 13 volts it's still about 90%

efficient,

which is better than most 120VAC switching power adapters.

That got me going on making

PCBs. I now wanted several simple ones for various things, along with

the more complex ones for motor controllers.

I hadn't done a photo PCB board in 25 or 30 years, and I

had no intention of getting back into that laborious process. I had

heard of printing the artwork on a laser printer and then ironing it

onto the PCB. The first try was crap. The second one, after more

carefully cleaning the copper with solvent, made a somewhat workable

board and I etched it.

Then I got the idea

to try printing etch resist artwork directly onto

printed circuit board copper with a 3D printer. Assuming it works, it

should be a reliable, repeatable in-house board production technique --

unlike anything else I've found

so far.

An e-mail on the

22nd advised me my RaprapPro[.com] Mendel

3D

printer had been shipped. It arrived the next afternoon. It is of

course a fairly

complex kit, yet to be assembled. Once it is, I should be able to start

improving my methods of making various things, starting with alkaline

batteries and circuit boards.

Bases for LED lights, complete with vent holes and

mounting bits for everything, would also be a great simplification and

I could charge less for the lights.

Evidently my theory of "thermomagnetism", that magnet

machines can self power from nothing more than the ambient heat within

the

magnets, has a parallel. Ambient heat in a solution has apparently

been used to make a self powering battery. The vibration of molecules

in the solid magnet is replaced by the travels of copper++ ions in the

solution.

Six cells in series will light an LED, suggesting they're about 1/3 of

a volt each. However, the article leaves much unexplained, and the

author

is somewhat skeptical:

http://www.technologyreview.com/view/427140/graphene-battery-turns-ambient-heat-into-electric/

Graphene Battery Turns Ambient Heat Into Electric Current

"Physicists have built a graphene battery that harvests energy from the

thermal movement of ions in solution"

<snip>

"So the energy generated by this device comes from ambient heat. These

guys say there were able to increase the current by heating the

solution and also by accelerating the copper ions with ultrasound. They

even claim to have kept their graphene battery running for 20 days on

nothing but ambient heat."

Some of the comments underneath the

article showed some keen thought by readers.

For example, "Yes it breaks the laws of thermodynamics but those

laws

may break down

at atomic scales, just as newtonian physics breaks down approaching the

speed of light."

Interestingly, the graphene may be

comparable to my doped graphite positrode current collectors, and I can

easily add copper chloride (their magic electrolyte) to my cells. It's

left over from etching printed circuit boards. Might that make them

charge themselves or give off current even when supposedly discharged?

Intriguing!

In spite of the little time spent working on the Sprint

car, motor and torque converter, another hurdle (besides the ilmenite)

was overcome. The sun gear of my planetary gear set had no splines,

keyslot or other mounting devices - just a 1.064" shaft hole. At a

Saturday brunch I learned someone near me had an EDM machine. That

meant nothing to me. Then, conversing on a list, I learned EDM can

machine case hardened parts such as my sun gear. I took the gear to the

shop at the end of the month and had a keyslot cut into it. I can now

proceed with getting it mounted on the motor shaft and putting the

motor together, and getting the car going.

In Passing

Incidental news, editorials

Shorter Working Hours

I have advocated shorter working hours for almost my whole

career. It has always seemed to me that there are two categories of

people: those who are unemployed and have no money, and those who are

who have no spare time to relax and enjoy the fruits of their labors,

be with family,

or engage in creative endeavors. I've been at both extremes. Where is

the middle ground? Why do we

live these unbalanced lives?

In an advancing age of machines that do more and more of

our "grunt" work for us, we should be actively seeking to address this

imbalance by shortening the work day, perhaps to 6 or 5 hours - maybe

even 4, while we absorb the unemployed but employable into the ranks of

the working. The "unemployable" group is bound to shrink when we

aren't pushing everyone like slaves into working such long days, and

worker productivity per hour over five hours will doubtless be

substantially higher than when people are forced to work eight or

more. Even in the 1970's at my first job, it seemed to me machinery and

technology were liberating people from drudgery, and that it was silly

to be working long hours when there was less of it to do. Every passing

decade has made that more true.

Many grumble that they wouldn't be able to afford to live

if they worked a shorter day. Aside from an aside comment that many

people

seem to live more wastefully than is good for them - often to the limit

of their means when times are best for them, which sets them up for

trouble at the first income glitch - consider that if everyone

is

working shorter hours, then everyone can afford about the same

lifestyle as everybody else. House and other 'big ticket items' prices

will adjust. Taxes will go down when more are contributing and fewer

need assistance.

People will have more leisure time to devote to family, to

creative

endeavors, or to contribute in many ways to an advancing society. We'd

all be much better

off.

Are we there yet?

"To enjoy privilege without abuse, to have liberty without license, to

possess power and steadfastly refuse to use it for self-aggrandizement

— these are the marks of high civilization." - the Urantia Book

The "normalcy factor"

A video on you-tube mentioned something called the

"normalcy factor" or "normalcy effect". When some crisis that hasn't

happened in living memory is looming people tend to say "that's

ridiculous", since it "never has before", or is

something "from history". "Today things are different - it can't

happen." So they don't prepare, and they suffer

needlessly for that lack of preparedness.

The movie gave as an example the sufferings of the jews in

nazi Germany. Of 450,000 jews in Germany in 1933 when Hitler came to

power, 100,000 fled by 1935. Even in the face of everything, the rest

thought it was a glitch, and that everything would surely soon return

to normal. It was impossible Hitler wanted them, good germans all,

dead, or that such a thing would be allowed. It defied 'normalcy'. It

was the factor that kept them from taking timely measures for self

preservation.

Preparing for a fiat currency crisis and grocery store

lineups is much easier than fleeing your homeland, and need not disrupt

normal life. If nothing happens, you've done nothing harmful or

disruptive. If things return to "normal" after a relatively brief

crisis, you've saved yourself from temporary hardship. If 'abnormalcy'

becomes long extended, your preparation buys you time to make new plans

and help work out some new techniques of making a living and doing

business before you're desperate.

The future isn't usually for us to see very far or clearly

into, but

dramatic financial trouble appears imminent and it's said it was just

staved off in 2008. Some European

nations are already falling into a pit. Greece in particular has fallen

under harsh occupation by the IMF and is being pillaged, its assets

stripped for pennies on the dollar, by "financial weapons of mass

destruction". (Steve Forbes was seen there in June, cashing in.) It's

no longer a nation with power to control its own destiny. And the

banksters are working on Spain,

Italy, and Ireland. Even here in cities like Victoria, Canada, it looks

like politicians have been bribed by banksters to facilitate pillage of

local populations via needless "sewage treatment" projects in a manner

similar to Jefferson county, Alabama, which had to declare bankruptcy

last year, and where residents can't afford to turn on their taps or

flush their toilets. Corruption, collusion and fraud at the highest

levels has become rampant and everything is now heading inexorably in

the same direction. Former British PM Tony Blair is now a JP Morgan

Bank executive. Who then will arrest the banksters and reverse this

tide? How can the dam not break? What happens after that is much

less

clear.

From another perspective, societies are as strong as their

families, and family life has been breaking down for decades. Why would

societies remain 'normal'?

Subsidies kickstart conversion to solar energy

(As told to me, later affirmed by a second person...) It

seems Germany has been subsidizing adoption of solar energy by paying

homeowners 10 times the going rate for solar generated electricity. I

don't know the exact details, but evidently the offer has caused so

many conversions that there's now the equivalent of two nuclear power

plants operating on German city roofs. And evidently Ontario Hydro is

now adopting the same incentive scheme. Perhaps BC should do the same

instead of spending 8+ billion dollars (2000+ $/person) on the Peace

River Site C dam?

Electric

Hubcap Motor System

Longstanding motor making problem solved: 'Plastic Dip' "primer

coat" prevents flaking of the ilmenite in sodium silicate

paramagnetic coil coating

The motor coils, after all this time, still needed the

paramagnetic coating to adhere and not flake off. I put small,

occasional efforts into the problem - whenever I put a new motor

together, which was rarely. Since I need at least a couple of motors,

here was another occasion.

Industrial Plastics had a rubbery plastic dip or spray. I

have no idea what it is - maybe some sort of PVC. It stinks of toluene

solvent. I

bought a can of the dip on the 5th and dipped a coil in it. It was too

thick (IMHO)

and made quite a thick, globby coating on the coil, where I wanted a

thin primer coat to paint the silicate onto. I wiped some off while it

was

wet, and it came out pretty nicely. (My main objection to 'thick' is

that it's extra thermal insulation to cause the coil to get hotter

under

load.)

Then I mixed some ilmenite and sodium silicate and painted

it on. It beaded up, just about like on the epoxied wire and the coil

core. Unlike on them, it stayed attached after it dried.

Then I started to think... the general ceramic

recipe is

nanocrystalline magnetic particles suspended in a glassy substrate -

hence the sodium silicate "water glass" substrate. But was it just a

neutral medium for the powder, or was it part of the reason it worked?

If the former, wasn't rubbery plastic also a neutral medium? And the

rubber looked like it was staying on the coil.

Then I started to think... the general ceramic

recipe is

nanocrystalline magnetic particles suspended in a glassy substrate -

hence the sodium silicate "water glass" substrate. But was it just a

neutral medium for the powder, or was it part of the reason it worked?

If the former, wasn't rubbery plastic also a neutral medium? And the

rubber looked like it was staying on the coil.

So I mixed some ilmenite into some of the dip, thinned it

with toluene, and painted

this "plasticized ilmenite" onto a coil. I liked brushing better than

dipping - no fat blobs. (I rolled the brush up inside a plastic bag and

put it in the freezer to keep it soft, since I knew I'd need it again

soon. It worked for a few days.) I wasn't confident the magnetic effect

would work, or

work as

well, as with the sodium silicate, and I wasn't willing to divert into

motor performance testing to find out at this time. It looked good and

wouldn't

flake off, but the next morning I painted a coat

of ilmenite in sodium silicate on top of it. This beaded up, but

somewhat less.

Then I painted a coil with the plasticized

ilmenite, hung it by its wires inside the bag of remaining

ilmenite, closed the top of the bag, and shook it around. Now I had a

coil painted with the plasticized ilmenite and with a dry powdery

ilmenite coating.

Some of the dry particles would be stuck to the plastic but sticking

out,

for the sodium silicate to adhere to. That way, the ilmenite particles

would create a bond between the plastic layer and the silicate layer. I

painted it with the silicate in the afternoon, and it went on very

nicely - no beading or gaps.

Meanwhile, altho the silicate had beaded up on the

previous one, the

coverage was better, and on none of them (even the plastic with no

ilmenite) did the silicate layer tend to flake off. I gave the second

one another coat of silicate, and by evening they were both dry and it

was evident I had two good coils.

So I put another coat of silicate on the first coil as

well. It still beaded up and wouldn't cover. Oh well.

The most intractable problem with making the motors

appears to be solved. There may be any number of good 'primers' that I

haven't tried, but the 'rubbery' plastic coating with ilmenite mixed

in, then preferably dusted with ilmenite powder while it's wet, seems

to work. I'll take it!

Planetary Gear Torque

Converter Project

EDM Machining for Case Hardened Gear

I'd been wondering how I'd get the converter's case

hardened sun gear mounted on the motor shaft. It had only a shaft hole:

no keyslot or set screw holes. It was one reason for "procrastinating"

on getting the Sprint car going.

Then I found out a machine shop near me had

'electromagnetic discharge machining', EDM, which meant nothing to me.

Still later someone told me EDM was the way to modify case hardened

parts.

After e-mailing at the end of July, I took the gear in

August first and had a keyslot machined into it. I swallowed the

machine shop price since it's the most practical way I've found to

solve the dilemma.

Solar Electricity Project

Power-Price Point

In North America, and especially here in BC, we've become

used to reliable, affordable electric power. Whether a backup system

seems justified on grounds of potential power interruptions depends on

your location and your confidence or lack thereof that this good

situation will continue.

And at BC's electricity rates (residential ~9¢/KWH,

to simplify a complex rate setup), 'going solar' (with only 1000 hours

of

sunlight a year) or 'off grid' appears to make little immediate

economic sense. But other jurisdictions pay substantially more for

electricity, and some get twice the sun. In such situations, a solar

system might already be good economy. Furthermore, the widespread fraud

and trouble in the financial sector which has led to so much poverty

and

high unemployment may well 'spill over' as higher electric rates, as

revenue starved governments grasp at any potential source of funds.

6¢/KWH here became 9¢ overnight, and 9¢ could as

suddenly become 15¢, 25¢, or even 50¢. Electric bills

could potentially skyrocket.

With its abundant hydroelectricity, hopefully BC isn't

likely to face prolonged power outages. But at 40¢/KWH, today's

outlook of a 20 year payback to 'go solar' in Victoria becomes 5 years.

My LED lights, new chemistry batteries, "DC Grid Tie", low power fridge

(below) and other potential products might then be coming along at just

the right time to meet an increasing demand.

Collector Mounting & Installation

Harder than every other aspect

of the work

specifically

for my installation was getting the collectors onto my roof. After a

couple more work sessions and trips to the hardware store, the mounting

boards were finally ready to go, and in an exhausting three hour

session on the 8th my renter and I bolted them onto the roof. The

upper board had four eye bolts spaced along it for clipping the lanyard

of the body harness to, so once it was attached, things got safer. The

ladder I made to hook over the roof ridge was, as I expected,

indispensable for installing the lower board, as were a couple of 'jig'

boards to hold it up and set the spacing between the upper and lower

mounts.

Harder than every other aspect

of the work

specifically

for my installation was getting the collectors onto my roof. After a

couple more work sessions and trips to the hardware store, the mounting

boards were finally ready to go, and in an exhausting three hour

session on the 8th my renter and I bolted them onto the roof. The

upper board had four eye bolts spaced along it for clipping the lanyard

of the body harness to, so once it was attached, things got safer. The

ladder I made to hook over the roof ridge was, as I expected,

indispensable for installing the lower board, as were a couple of 'jig'

boards to hold it up and set the spacing between the upper and lower

mounts.

The next day, we set up a 30 foot ladder and collected the

socket wrench and a small board from a gutter, and cleaned the

full-to-the-brim and more gutters. While up there, I got an idea for

winching up the collectors.

Short of rope,

I went back on the roof on the

10th and

threw 1/2 of a 100' extension cord down each side. Then I set up the

2000# winch on the ground on the north side and tied the cord to the

winch cable. At the peak of the roof the mounting board would prevent

digging into the shingles. I tied the first collector to the end on the

south side of the house. We set up a 32' ladder there (it reached the

eves, but was rather steep). My renter did nearly all the climbing and

got all the shingle burns that day. We got one collector up.

Short of rope,

I went back on the roof on the

10th and

threw 1/2 of a 100' extension cord down each side. Then I set up the

2000# winch on the ground on the north side and tied the cord to the

winch cable. At the peak of the roof the mounting board would prevent

digging into the shingles. I tied the first collector to the end on the

south side of the house. We set up a 32' ladder there (it reached the

eves, but was rather steep). My renter did nearly all the climbing and

got all the shingle burns that day. We got one collector up.

The next day the extension cord "rope" jammed somewhere

and the power of the winch broke it. The second collector fell from the

eaves to the lawn and broke - a zillion little bits of safety glass,

mostly still stuck to the collector surface as a single sheet. There

was a collector with a badly bent up

frame at HES, and I got it for a good discount. I also bought a thick

rope. We got the collector up, but at one point the rope jammed and I

think if it had been the extension cord we'd have lost that one too.

Unfortunately it didn't match the first collector, so instead of two

pairs, there are three types. Beggars can't be choosers.

The next day we were getting

closer to the

point we climb

to the roof from. At the same time, the fig tree was in the way of

winching up the last two (slightly smaller) collectors, and we

decided we could manhandle them up. We got them into place.

The next day we were getting

closer to the

point we climb

to the roof from. At the same time, the fig tree was in the way of

winching up the last two (slightly smaller) collectors, and we

decided we could manhandle them up. We got them into place.

In spite of all the prep, the top board didn't sit flat

and so various things didn't fit as intended and had to be reworked on

the spot, on

the roof. One corner of one collector wouldn't quite latch properly

into

place... I think it'll hold in a gale. We couldn't get at it.

Now I could only wish the collectors' glass surfaces were

covered with my titanium dioxide nanocrystalline borosilicate glass

"lenses" to effectively gather 25-40% more sunlight over the course of

each day. The four collectors would be the equivalent of five to almost

six, gathering more energy earlier in the morning, and especially in

the later afternoon before the batteries have to take over for the

night and house lighting.

(I wonder if there's anything I can do with the broken

collector? It still puts out voltage - so far. Maybe sandwiching it

between two pieces of plexiglass (a clear one on top) can keep it from

disintegrating for a few years of some sort of productive use?)

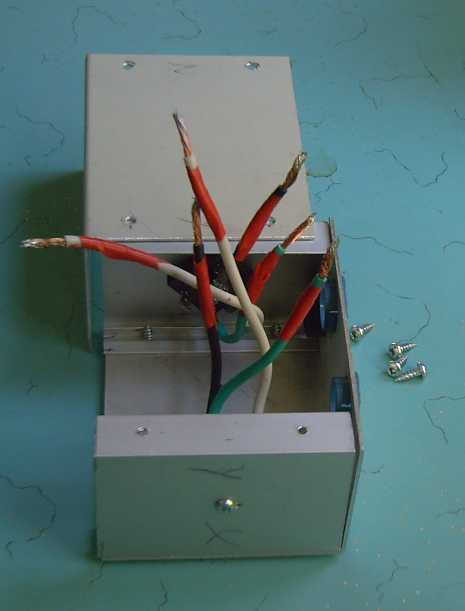

Connections

I spent the afternoon of the 17th wiring up the

collectors, all four in parallel. Where the wire for each collector

came through the roof, I put in a 12 amp in-line AGC fuse holder at the

attic

ceiling. It must be remembered that solar panels generate electricity -

they're live circuits all day and can't be turned off (except by

working at night). And as it turned out, I had to pull the fuses out

not only to do the wiring.

The common connection seemed to be putting out the

voltage of the two slightly lower voltage units, and I surmised that

the two

higher voltage ones must be feeding power into the lower. I removed the

fuses from the higher voltage ones until I could check it out. Someone

confirmed the next day that they should all be tied together with

blocking diodes. My first, smaller, collector had two diodes, built in

in the box underneath. It was only on examining the 'sealed' box on the

broken collector I realized these large panels didn't have any. Thus I

spent the evening of the 18th making an aluminum box and mounting two

30 amp bridge rectifiers with some attached wires inside. On the 19th I

went back in the ucky, fiberglass-dusty attic one more time, ripped out

the wiring box, and put in the new box with diode bridges, using two

diodes from each bridge.

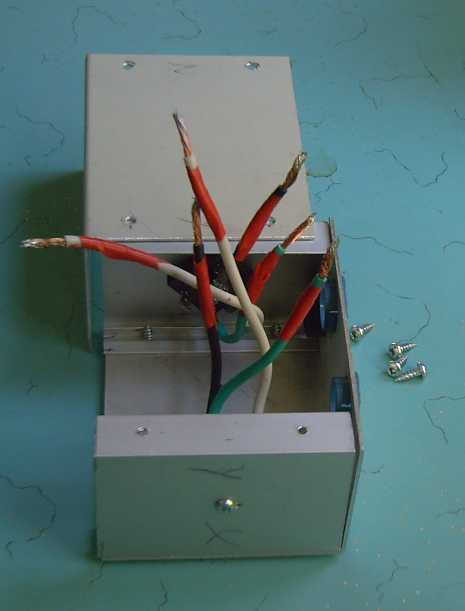

Solar panel junction box with 30 amp diode bridges

Homemade Thermoelectric Fridge & Freezer

I had been lamenting the lack of suitable low voltage DC

appliances at affordable prices. In particular, fridge and freezer are

indispensable items that always have to be on, and consume considerable

energy. It's a big issue for

off-grid and solar living. Plus I've never cared for the

compressor noise of fridges - they make most every kitchen an

unpleasant living

space IMHO, and

the idea of adding a big inverter with a noisy

fan seems much worse.

I tried out the 750 watt inverter with a 12V, 30 AH NiMH D

cells battery, on my countertop apartment size refrigerator. (A 400

watt inverter tripped off on overload

just as the fridge came on.) It

worked, drawing just 12 amps from the batteries and using 120

AC watts. But in addition to the continual howl of the fan, the

converter continued

to draw .6 amps

when the fridge was off. Furthermore, if power is interrupted, the

inverter turns itself off until manually reset - not the best for

running a

fridge or freezer!

It was a setup that could keep some food cold in a pinch,

but I

could hardly see it as a satisfactory long term solution. Low voltage

DC fridges cost a fortune. Sunfrost was recommended, but where a 120VAC

fridge could be had for 300$, I found they were listed at 3000.

I had heard of thermoelectric cooling, but I had been

advised that it

was inefficient and good for not much more than camping cold drink

coolers.

Now I found some low cost fridges that were small, indeed intended for

campers

or boats. One 'Koolatron' unit said it could be fridge or freezer. It

was unique in

using refrigerant pipes on the outside, heated to gas by the outside of

the peltier element and cooled by recondensation. This kept the outside

element cooler for a similarly cooler inside temperature. The units

were also only

around 50 to 75 watts, and not too costly. I could buy one,

or

perhaps two. But they wouldn't hold much food.

Then I had the thought that one could buy the elements

alone, and make a

larger 24 volt fridge of 80 to 150 watts or so. Tripling the size only

doubles the surface area and power requirements, and I started

to think that a decent size fridge might not use more power than a

compressor based fridge after all -- if it was really well

insulated.

Regardless of actual efficiency, the Peltier module fridge seemed like

the only practical fridge one could make at home. I decided to

consider making a project of it - hopefully a short

duration one compared to my other long drawn out works - started

looking into it, and was

quickly immersed in it. Perhaps there was potential for salable

products - certainly I wanted one myself. (Project writeup below under

its own title.)

Voltage

If I had a completely free choice, I'd probably go with

about 30 to

36 volts DC. It's low enough to be virtually safe from electrocution

hazard, but currents are only 1/3 of those for 12 volt systems, saving

substantial copper to wire a house.

But large solar

collectors are made for 24 volts - actually putting out about 35 open

circuit and 30 at maximum power, so maybe 24 isn't an unreasonable

limit, indicating a nominal

battery voltage of under about 26 volts. Collectors for 12 volt systems

can be had (at least here)

only at a very stiff premium. I don't understand why this should be,

but unless I get back to the DSSC solar cell project, I'm stuck with it

- along with everybody else.

There's no simple way to get to either 36 volts or 12 volts,

where either would be trivial with 12V collectors.

24 volts should be

a good level to use,

but 12 volt loads are common for automotive, boat and RV use, and other

voltage appliances including 24 are relatively hard to find. 12 volt

LED lighting and 12 volt fridges and coolers are examples. 120 VAC

inverters too are mostly made for 12 VDC input in spite of the high

currents

often necessary. (Eg, 1500W means over 125 amps at 12 V.)

So a 12V distribution is, at least, simple, whereas both

24 and 36

volts are hard to find appliances for.

Perhaps the simplest way to get from 24 volt collectors to

12V is to

have +12, ground, and -12, with two sets of batteries in series. But if

all the appliances are 12 volts, what good is having 24 at all? It just

makes

balancing the two sets of batteries necessary, pretty much manually.

Surely it's better to have all the batteries in parallel and equally

sharing the load. Having just one voltage is a good simplification.

24 V & Other Voltages - NiMH - Cordless Mower - Plastic 12V NiMH

Enclosures

On the 22nd a friend brought me a cordless lawnmower whose

lead-acid batteries (tho one was less than a year old) evidently

weren't holding

a lot of charge. It was 24 volts. Also handicapped scooters are usually

24 volts. These might be charged directly from a 24 volt system. Hmm...

there's probably enough call for a dual voltage system after all. At

least for a 24V solar charging circuit even if the house voltage is 12.

And 36 volts if I want to charge an electric car from it - triple

voltage. Plus of course, there's the inverters to get 120V for power

tools, small kitchen appliances, and other, hopefully temporary use,

loads.

I replaced the 20 AH lead-acids with 40 NiMH D cells to

attain

the same ratings, a 400$ job (~300$ for the actual cells) in trade for

the work he had done and would do to renovate my web site, even tho in

a year and a half we didn't have it up yet. At 6.6Kg they were less

than 1/2 the weight (of 14Kg), and they would outperform the PbPb's -

and last for many years. I did a soldered together pack, because the

"battery stick" pipes made a battery that wouldn't quite fit in the box.

Charging still needs to be set up. I have a feeling the

original charger as is would fry the NiMHs.

It occurs to me as I finish this newsletter up that I can

probably make 10 D cell (2 cells x 5 rows) plastic battery enclosures

with the 3D printer. That should pretty much solve all the problems and

make making battery packs a snap.

DC to DC Converters

I began to realize I should be either buying or making

converters for solar power for both the 12 VDC house and for 36 VDC

cars. (Maybe solar panel makers get kickbacks from DC-DC converter

makers to make the panels 24 volts? Conspiracy is a much copied and

highly successful business model. More money can be squeezed out of

customers to pay for things they shouldn't want or need. Well, that's

probably not it in this case.)

But a single 24 to 13.8 V converter/battery charge

controller on the collectors could make the entire system 12V.

(delivering up

to 13.8 with sunlight and charged batteries.)

I looked on the HesHomeEnergy.com website and found there

was something available closer to what I wanted than I expected.

Specifically, there were Schneider Electric charge controllers for 24

volt collectors for 200-300$ that had 'adjustable' settings for NiCd

(same voltage as NiMH), low voltage cutoff, and a dump load ("eg, an

electric water heater") to make use of any excess power while the sun

was shining. Apparently some of my planned "DC Grid Tie" features are

already commercial. That could simplify my parts. But did the NiCd

charger work the way I want? I've already seen that my 13.8 V "constant

float voltage" charging does a better job than commercial chargers that

charge to 14.2 and then shut off. The cells seem to have more charge,

and they probably will last

longer. And what if I get my MnMn

batteries going and the

'adjustable' charge voltage doesn't quite fit?

What it boils down

to is that I don't trust the present generation of commercial

solar-electronic products. The commercial charge controller I got last

year should have worked great in theory with a diode to drop its 14.4

volts to 13.8. In fact, it had to be tricked to put out anything with

the diode there, and then it put out a high pulsed

voltage averaging 14.4 that would soon have fried my NiMH

cells. I put a

filter capacitor on it to smooth it out, and then the controller itself

soon quit working. Wasting money on crap doesn't help the cause! Then

there's the inverter I got that went up in smoke when momentarily

overloaded instead of shutting

off. It was still within its

supposed momentary overload rating. (I have had better results with

other inverters.)

I tentatively decided to make a buck converter. The

formulae for determining the component values looked complicated.

Then someone loaned me a commercial 18-48V to 14V DC to DC

converter. It used a

control circuit I'd seen on the web with two 555 timers. I was however

impressed with

the number of components and the physical size and heavy wires of the

inductor, tho it

was

only around 15 uH. I can do it with fewer power components, and

otherwise copy the salient features such as the general size and weight

of the coil. But this one did

unpleasant things if the solar panel wasn't putting out enough power.

The specs sounded great, but in practice it just wasn't made for use

with solar panels

in unattended operation - just the reason I want to design my own to be

sure it behaves optimally in all conditions.

31.7 volts from solar collectors through individual fuses, isolation

diodes, yellow wire from attic,

and switch (later replaced by circuit breaker switch [sitting on top]

and ATO fuse)

into Zahn 18-48 V DC to DC converter, putting out 14.1 volts (direct)

or 13.8 volts to charge NiMH batteries (through Schottky diode to

prevent discharging through converter).

80 amp unit should handle up to 30 amps from collectors, delivering

about 60 amps at the lower voltage.

Key features of what I want:

* An enclosed wiring chassis.

* Terminal strips with fuses to connect several solar panels.

* An input circuit breaker/power switch.

* If Vin gets much above MPPt, current goes to the dump load (Hot Water

Preheat Tank) output to bring it down.

* While Vin is at or above MPPt, battery charge Vout is a constant, eg

13.8 volts. (Adjustable ~

11-16V.)

* If Vin drops below MPPt, Vout is reduced to keep it up. Thus Vout

becomes a constant current source putting out as much as it's able to.

* Additionally, if Iout is above its (broadly adjustable) max setpoint,

Vout is reduced to keep it within limits.

* If Vin falls below the minimum required for proper operation, the

output is turned off. There should be a considerable voltage hysteresis

to

help prevent on-off-on-off looping.

* If the converter output is turned off, it draws no current back from

the load. (ie

from the batteries.)

The batteries then must supply current to the house. If the voltage is

a constant 12 volts, the LED lighting doesn't need fancy power

supplies, just a current limiting resistor. Furthermore, if a DC to DC

converter feeds the house, the batteries could be much higher than 12

volts. But a low dropout linear regulator to go from 13.8 volts to 12

might be just fine, too.

Then again, feeding the house straight from the batteries

yields maximum efficiency, and that's probably what I'll do.

Superinsulated Thermoelectric Fridge & Freezer

[This is really long. I was going to do a major hacking and slashing,

but it's the 3rd of August and I want to get this newsletter out, so

you get it as is, with a few pictures added.]

Cooling(?) to the idea of making a peltier effect

thermoelectric fridge on July 2nd, I

realized design options were more flexible than for a

compressor fridge. Instead of a traditional upright shape, one could

make a shallow chest style with a lightweight lid. That wouldn't lose

as much cold when the

door (lid) was opened, and the food would be generally easier to find

and pull out. By

the 5th my head was spinning with ideas for shapes, insulations,

multi sectional lids and internal dividers, pullout cold drawers, and

other design ideas.

Design ideas

A substantial aluminum outer heat sink could spread the

heat from the warm end of the modules, and an inner one would spread

the cold around inside. I thought these should be effective enough to

be

efficient while eliminating the need for a fan.

The outside walls that weren't aluminum might be a light

wood, which would be good extra insulation, or plywood, perhaps with a

melamine 'countertop' lid. The inside surfaces could

be made from rigid plastic sheets of some sort, or PP-epoxy. Custom

smaller inside plastic pieces

might be made by 3D printer. The whole chest could be made heavily

insulated with good stuff, to minimize running time and power

requirements. Perhaps 2, 3 or even 4" of high density styrofoam. (It

would be a bonus to use styrofoam packaging material being thrown out,

but that

rarely has any straight sides. Unless some process were developed, it

would be a nuisance trying to fit it.)

It might be built as a fat table, or as a 'counter' with

drawers underneath. A

freezer could be pretty much the same with a lower temperature setting.

Perhaps they could be dual purpose units - as indeed one of the small

commercial ones was.

Control

A temperature probe coupled

to an LM339 could turn on a

low side MOSFET to supply power when the unit was above temperature.

More exact temperature control could be achieved than with a compressor

fridge. A

light might be superfluous, or it could be an LED light in the lid...

perhaps with a mercury/gravity switch to activate it when the lid was

tilted (open).

Peltier Cooling Modules

The same night I thought of the idea, I went to

Digikey.com and found "Peltier Modules" of various voltages, currents

and wattages. From one manufacturer they were all under 20$. They all

seemed proportional: the more

power, the more cooling. These were probably what the fridges used. I

ordered two 12 volt, 6 amp modules (~72 watts) each capable of

delivering about 40 watts of cooling at Victoria BC room temperature

(18ºC) & refrigerator temperature (2ºC).

And I started thinking about how they'd work and how to

set things up. My intent was to

put them in series for 24 volt operation, or it might be 12/24 with a

plug/jumper or two. That would give about twice the cooling power of

the

little camper/boat fridges... and I'd only spent 50$. If it's excess

cooling I could use it for a freezer and get a couple of smaller ones

for

a fridge, but I suspected it'd take substantial insulation just to get

it refrigerating well.

The power and controls should be pretty straightforward,

so the main concern is to make a nice box that keeps the cold in, and

that one will feel good about putting one's food in. I'd be proud to

have the only homemade fridge and freezer on the block! And they'd

probably save 15-20 $/month of electricity over my present units when

it's sunny; maybe 1/2 that when grid power is needed. It would be more

where electricity costs more than 10¢/KWH.

On the third I thought about the refrigerant

"heat pipes"

of one

commercial peltier fridge/freezer. I probably couldn't do that... but

what

about

attaching the

outside heatsink to a main cold water pipe coming into the house to

keep it cooler, or even 'cold' in winter? That would do even more to

improve the efficiency, for free! That would improve efficiency and

reduce electricity consumption - especially in winter for a fridge!

On the third I thought about the refrigerant

"heat pipes"

of one

commercial peltier fridge/freezer. I probably couldn't do that... but

what

about

attaching the

outside heatsink to a main cold water pipe coming into the house to

keep it cooler, or even 'cold' in winter? That would do even more to

improve the efficiency, for free! That would improve efficiency and

reduce electricity consumption - especially in winter for a fridge!

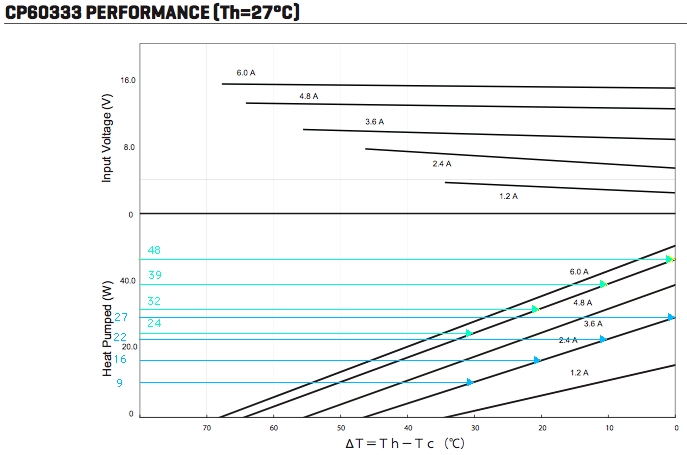

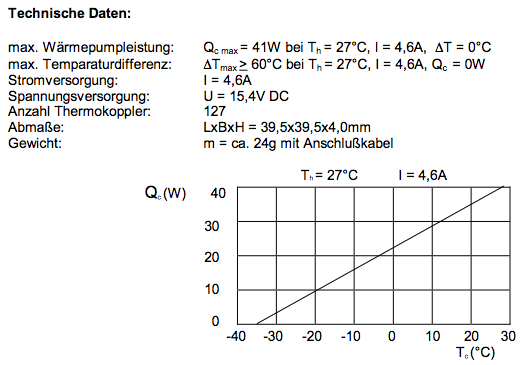

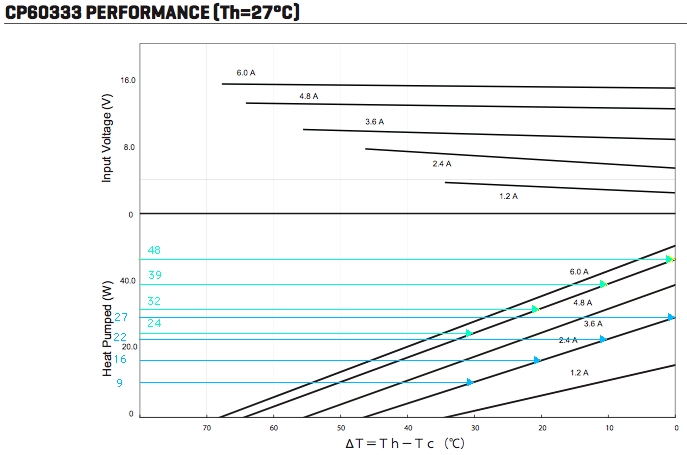

Performance data for the peltier modules

From the graphs, assuming about 13.8 (27.6) volts from the

batteries and 75 watts in, efficiency is double for a fridge in winter

with cold water cooling than for a freezer in summer without it:

0º difference (winter cold water - fridge): ~49 W cooling

power

15º (typical for fridge in air; or freezer with winter cold

water): ~38 W

30º (freezer, summer air): ~27 W

And that's for typical Victoria weather - efficiency will be

worse where

it's hot. 75 watts in yielding 49 watts out is about 65% efficiency. I

believe this rivals compressor fridges, but I seem unable to find any

definite figures. 25 watts out for 75 in is only 33%. This means double

the power for the same cooling effect, and much more than double the

power overall because a greater temperature difference must be

maintained.

The upshot is that

if the heatsink can be coupled to a cold copper water pipe, it seems to

be worth doing so, and indeed it looks like at good way to get at least

acceptable efficiency from a peltier module freezer.

I was also said that the efficiency drops as the power

rises.

When the peltier

modules arrived, I hooked one up to a

power supply. In

about one second one face was quite cold and the other was almost too

hot to touch. A passive heatsink for this was going to need massive

quantities

of aluminum, starting with big cubes of it to get the heat out past the

insulation. If cold water was used, it would have to be flowing.

Peltier Elements in Series (Thermally)

Breaking the narrative sequence, on the 25th, I got an

idea for possibly making the units more efficient. The smaller the

temperature difference between the hot and cold sides, the more cooling

watts they produce per watt of power consumed. (See my yellow lines on

the graph.) For a 30º difference, it pumps only 1/2 as much heat

per amp as for 0º. If instead two peltier units were

placed thermally in series, they'd only be pumping across 15º

each. Then they'd each make 1.5 times as much cooling. They'd use

almost the same amount of power, each, so 2x power, but 3.0x cooling.

With 3 peltiers across 30º, 10º each, efficiency improvement

would be 39/24 = 1.625. The total power could be brought back down by

buying lower current elements drawing 1/2 or 1/3 the amps.

For a 20º temperature drop it's less amazing, but

still significant, two 1/2 current peltiers being 22% improved over

one. A secondary effect would be doubling the thickness and hence the

insulation value at and around the peltier module.

Obvious questions: Why wasn't this being done? Was it

being done but nobody's mentioned it? So I looked for references. As it

seemed when I tried one out with my fingers, the hot side got hotter

than the cold side got cold. This is because it has also to dissipate

the heat of the electricity being used as well as that transferred from

the cold side. This is more

extra watts to cool than the amount saved. (That also explains the

cooler's outside heat sink and fan being bigger than the inside one.)

Peltier Element Heat Pump/Electric Heater

An interesting aspect to this is that peltier modules

could be used as electric heaters, and if the cool side went to a

fridge or outside, they'd make more heat in the house than the amount

of electricity used. Ten 60 watt peltiers, suitably arranged, could

make a heater/heat pump delivering about 850 to 1000 watts of heat into

the house while using only 600 watts of electricity.

That certainly isn't as good as a compressor based heat

pump, but it's a fair improvement over a plain electric heater.

Considering the cost of electricity, the peltier elements might pay for

themselves in one heating season. The heater could be mounted in a

double hung window, or a hole could be made in a wall for some sort of

heat exchange pipes. Since it's a small heater, a hole for a "ground

source heat pump" pipe might be dug in the ground with a shovel. All

depending on climate of course. Here we're typically heating by

10-15ºc much of the time.

Experimenting anyway...

On the 31st, frustration with trying to get enough cooling

led me to try the two-stage thermal series arrangement anyway. I

decided to have the outer peltier running at full power, and the inner

one at maybe 1/4 power (with series resistors), so its resistive heat

wouldn't overpower the cooling of the outer unit. The cold side should

thus get colder - if it had enough power to cool the space it was in.

This time, in order to sense the temperature of the

aluminum block between the two peltiers, I took everything apart, and

held the warm side fan against the heat sink. Direct measurements -

minutes instead of hours to see how cold or warm things would get.

I had already found that the outer heat sink was getting

quite warm, as high as 40ºc. That meant the peltier itself wasn't

trying to cool from (eg) 22º, but from (eg) 35º. So it was

actually cooling by 26º to cool from 22º down to 9, rather

than just the 13º. Now things started to make sense. It cooled

quickly at first because the outer heatsink was still cool. Then that

started getting warm, making the job of the peltier harder. By the time

it hit 26º drop, it was operating in a less efficient range

altogether.

It was about 23º in the room. Neither the inner

heatsink nor the fan was attached to the inner, coldest block of

aluminum. The unit settled down to the following readings:

volts outer middle inner

heatsink

block block

11

34º

17º 0º

12

35

19 0

13 35

19

0

This seemed more satisfying: at last I was seeing

fridge-like temperatures, if only on an aluminum cube. It was, however,

a bit disconcerting that 3/4 of the energy was going to provide a

starting point only a little below room temperature for the inner

element. It shows how much would be gained with cold tap water - or

even strongly circulating room temperature water.

The fan sped up with voltage, so the outer heatsink didn't

get much warmer with increasing voltage and power. The three 5 watt,

1.5 ohms resistors (=4.5Ω) limiting power to the inner element got

quite hot (but they were away from the cooling unit). Current to the

inner peltier was about 1.5 amps out of about 5.5 total. It was using

maybe 6 watts.

Obviously the original unit isn't good enough because the

warm side heats up too much. If that didn't happen, it would get down

to freezing. Instead of using extra power for a two stage cooler, a

self-circulating water system to keep the warm side of the peltier

element cool might be optimum. Aluminum is attractive, but copper can

be soldered, and is an even better heat conductor. And there's lots of

copper plumbing fittings and radiators available. If the warm side of

the single peltier could be kept down even to 30º instead of 35,

the cooling limit would be about 4º - within acceptable fridge

range - instead of 9.

A water cooling system plus a two stage peltier should

give sufficient temperature drop for warmer climates, or to make a

freezer. But as I write this it's the end of the of the month and I

have yet to try out the two-stage unit in a cooler or fridge. The

second peltier uses only around 25% additional power, and I can play

around with how much power gives the best results. It might work great

as-is with only a slight power penalty - if the second peltier, running

at 1/4 power, delivers enough cooling watts for the space. If not,

total power will have to rise, maybe to 100 or more watts.

Peltiers in Series (Electrically) - sort of

On looking at the graphs again, I noticed that the watts

of cooling apparently depended on the current input, not the power

input. 4.8 amps with a 20º drop needed 12 volts, which is 57.6

watts. 2.4 amps with a 20º drop needed a little over 6 volts -

only about 15 watts. That's 1/4 as much power, but giving 1/2 as many

watts of cooling, or twice the cooling per watt of electricity. Two

parallel pairs in series would give twice the cooling for the same

power input. Was this for real, or was there something non-obvious that

would negate this supposed effect? Why wouldn't the electric cooler and

fridge makers make use of this? How could such a thing possibly be

overlooked? Were they simply all too cheap to put in two peltier

elements instead of one, in order to cut the power almost in half?

If the theory was correct, twice the cooling could be had

for 2/3 the power with two banks of three peltiers. The ratios are

however temperature dependent, and the peltiers aren't cheap when you

start talking about a half dozen or more. At some point, peltiers

thermally in series might also be employable to advantage, especially

in a freezer.

I decided to try the 2 identical peltiers I had,

physically in parallel, electrically in series. That would, according

to my reading of the charts, be half the electrical power but probably

about the same cooling power at 20º drop. If this worked, then two

more peltiers should give twice the cooling power with the same amount

of electricity.

Reality cut in when I tried it. It seemed this arrangement

provided about 1/2 as much cooling for 1/2 the power, as the cooler

dropped by 7 degrees instead of 13. That figures.

Commercial Thermoelectric Cooler

Meanwhile back on the third, I had coffee with a friend,

and he told me

there were thermoelectric coolers at Canadian Tire. I thought I might

as well look. There were 35 litre ones for 130$ and a 45 litre one with

wheels, almost the size of the small fridge I'd looked at on the web,

for 160$. These were the height for my shallow tray idea, albeit 1/4

the capacity overall and not as well insulated. I bought the

large one. It draws 5 amps (x12v = 60 watts), is supposed to cool by

"up to 20ºc", and has no

thermostatic control. Would this replace making my own?

I tried it out. It cooled glacially slowly to about

4ºc. The 120V

power

adapter drew .55 A. (x120v = 66w) and got very hot. The regular

countertop fridge drew

1.2 A (x120v = 144 V-A) but it has twice the capacity, and it only runs

maybe 1/4 of the time. (And since it's a motor, the V-A may be higher

than the actual watts.)

As the inside got

cooler - very gradually - the outside surfaces also started to seem

cool. Was it

just my imagination, or was this

thing not very well insulated?

Maybe making the larger but better insulated and thermostatically

controlled fridge was still a good idea - but using this pre-made

peltier cooling unit.

The cooler uses 60 watts. If it ran full time, it would

use 44 KWH per month. If I'm not being too optimistic, hopefully it

would run 1/2 the time and use 22... or even less. My present fridge

says it uses 75. Newer more energy efficient ones claim as little as 35.

So even if it does it by super insulation and smaller

shallow chest layout, I think a peltier fridge might be energy

competitive (or even save energy) rather than, as is commonly said, be

too inefficient to consider for anything bigger than a cooler.

On the 23rd I took the unit apart to have a look. The

outer fan pulled air though a duct shrouding a considerable heatsink

with about 3/8" thick alumimum where it contacted the peltier element.

The inner fan blew air through a lesser heatsink, which, being just

used, still had condensation where the element was beneath. I was

wondering if that one should have had more fins to blow the cool away

faster. It was plain that my originally envisioned arrangements for the

loose peltier elements I bought would have been quite inadequate -

except maybe for the idea of having cooling water. Even that would have

needed to be flowing water, or to circulate well. The beauty of

I tried to remove the heatsinks, but even with the screw

out they wouldn't budge. I suspect they were glued to the peltier

element. I really wanted to see in there, but I considered that the

peltier element itself might rip apart before the glue came loose, so I

quit while I was ahead.

Later it developed that this cooling unit would only cool

by 13 or 14ºc, regardless of what it was mounted in. I took it

apart again, this time completely. I couldn't fault the design or

construction. There was a temperature sensor in the cold side. I pulled

it out of its hole and simply set it in the warm side so it wouldn't

decide the unit was too cool, and put it back together with just a few

screws. That didn't seem to help. (It probably simply shuts the unit

off, at a temperature it never reaches.)

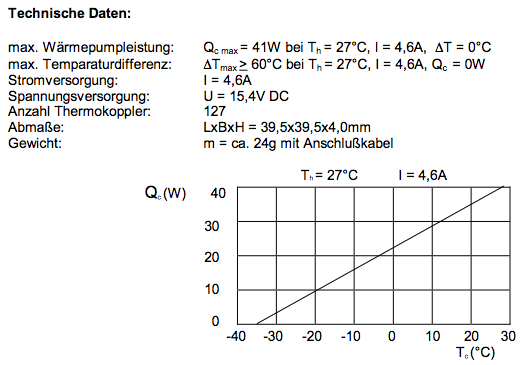

But I wrote down the number off the peltier, and now

looked it up. It didn't seem as good as the ones I'd bought from

Digikey. With null temperature difference, it delivered only 41 watts

of cooling for 71 watts of electricity, where the others put out about

48 watts for about 65 watts in. The apparently improved specs

looked like a good reason to replace the one in the cooler. However,

there's theory and reality, and the new element seemed to work about

the same.

Form of the Fridge

To make a fridge using

the

pre-made

module of this cooler with its fans and all as the cooling unit

started to look more promising than my passive heatsink design.

I

could also copy a couple of the cooler's ideas: first, make the lid in

2 or 3 separate sections. And to further refine

that, put vertical dividers at the joins to limit air into the closed

section(s) when one is open. Second, make them open right to vertical

so they'll stay open (better than a prop), and lightweight so they

don't slam shut. That's very different from my old freezer that tries

to eat you when you stick your head in and slams shut hard if your

hands are too full to lower it gently.

Finally, a section needs to be 12" tall for tall

containers, but the whole thing doesn't need to be so tall. If that was

a small section with only 3" insulation top and bottom, the next

section could be 10" with 4" insulation. The far end could either be

just 8" tall with 6" of insulation, or it could be a 4" tall pull-out

tray with a 6" space underneath.

A further sub option to this, if it could be done without

wrecking the insulating value or the seal, would be a 6" pull-out

drawer under the 4" section... or two drawers. I rather like that:

instead of "opening the fridge", one simply pulls open a "cold drawer"

to access small items. That might lose still less heat, as the back and

sides of the drawer could still pretty much close off the remainder of

the fridge

from the open drawer. Lid sections, however, would be simpler than a

drawer or drawers, any any air leak or insulation gaps around a drawer

would cause serious cold loss.

Insulation

So if the critical thing is insulation... how good was the

insulation on the cooler? The main body had no apparent way of opening,

but the lid pieces screwed together. I took the large side (with no

equipment) off and took it apart. The insulation was a chunk of

'extruded' styrofoam molded to shape and inserted between the plastic

faces. Except for a couple of thin spots around the power adapter

holding compartment, it was mostly about 1.25" to 2" thick. There

wasn't much

to criticize. The only big improvement could be thicker or better

insulation, and maybe "aluminum foiling".

I worked out that for 18 x 36 x 12", the inner surface

wall area was 2.2 times that of the cooler. I had got the cooler down

to 4ºc. The insulation needed to be over twice as good to attain

the same temperature.

So then, what insulation would be

best? R8 (per inch) would do in 2" what R4 would need over 4" for. Some

materials seem to degrade a little with age. I found a

couple of tables, of which this seems typical:

| Urea Terpolymer Foam |

R- 4.48 |

|

| Rigid Fiberglass (>

4lb/ft3) |

4.00 |

|

| Expanded Polystyrene

(beadboard) |

4.00 |

(I have lots... but it's only R4!)

|

| Extruded Polystyrene |

5.00 |

(~75$)

|

| Polyurethane

(foamed-in-place - or sheets) |

5.5-6.8

5.5-7

|

Sheets: 500$

enuf pour foam mix: >100$

|

Polyisocyanurate

(foil-faced) [AKA "polyiso"]

|

5.6-7.20 |

>100 $ per 2" sheet?

|

Aerogel

|

10

|

VERY costly - hard to get

|

Vacuum

|

30-50

|

costly - hard to get

|

From one source: "Polyisocyanurate

is an evolution

of polyurethane. It is stronger and has greater thermal resistance. In

fact, PIR offers the highest R-value of any material per thickness."

A vacuum would obviously be

best. But foaming in place a bunch of thermos bottle liners wasn't

going to give a lot of insulation value. Aerogel (AKA "solidified

smoke", made by NASA) probably couldn't be had for any price, and I'm

sure must be daunting to make. I'm sure square sheets of 1" vacuum

cubes, or else commercial aerogel panels, ought to be developed for

refrigeration uses, but I'm not gonna touch those myself. (Hmm...

actually, 2 sheets of plexiglass with reinforcing rods every 1" could

be evacuated...) That leaves 'foams', in order of preference by 'R'

value.

Contrary to the chart and statement above, Wikipedia rates

"polyiso" below polyurethane, and part of it's value is ascribed to the

foil face... One could

'foil face' polystyrene, too - would that make it a 5.5 or a 6? - and

it's

readily available at building supply stores.

What about kiln bricks? They weren't on any list (they're

not even mentioned on Wikipedia!), but they're

almost as light as foam and insulate kilns at well over 2000ºF. I

finally

found info (on the very last click as I was giving up): http://www.traditionaloven.com/articles/81/insulating-fire-bricks

"In

refractory

air

is

the

best

insulation

and

this

is

why

insulating

firebricks

have

excellent

insulating

properties.

Their

body

is

made

of

tiny

air

spaces

similar to honeycomb effect."

- Thermal Conductivity 300°C : 0.2 W/m.°K

- Thermal Conductivity 750°C : 0.28 W/m.°K

- Thermal Conductivity 1000°C : 0.32 W/m.°K

Guessing around .15 at room

temp, that's maybe 3-4x higher than

extruded polystyrene, making kiln bricks under R2/inch. I thought

they'd be

better. No magic bullet there!

Then I decided to check out paper... and found a great

table. Wikipedia had a similar table (if not the same one):

http://www.engineeringtoolbox.com/thermal-conductivity-d_429.html

"Cotton wool insulation" beat polystyrene by a

very slight margin. On the other hand, that

wouldn't be much of a backing for thin plastic, and how could one

ensure a consistent result? And where would you get it? On the market

it's been replaced by polyester fiberfill AFAIK.

The inside insulation is the most critical. The outside

dimensions get larger and larger as the R value drops, using

disproportionately more material for each added inch of insulation, at

the same time making the volume to be cooled larger. For

an 18" x 36" interior space, with 2" of insulation the exterior

dimensions are 22" x 40". With 4" of insulation, that becomes 26" x

44". And you have to lift a larger, heavier lid and lean over farther

to get food. (And that lid will be above lightswitch height if the

fridge

sits on a countertop.)

If even the inside

1/2" could be R10/inch instead of R5/inch (making R5), the fridge could

shrink an

inch on all sides and still retain cold better. More practically, R6-7

(with polyurethane foam), 20-40% better, is probably worth some extra

money for the

innermost inch or so. I checked the web site of industrial plastics and

found sheets of polyurethane, but on the phone found that even a 4' x

4' x 12mm sheet was 166$.

That's just 0.44 ft^3, and not enough area to cover the whole

inside. It seemed prohibitive.

I thought about that then called back and asked about

expanding polyurethane foam pouring mixes. Enough for nearly 2 cubic

feet was 70$. The rep thought it was R7/inch.

That was much better. It would do over an inch all around the inside.

And presumably it could be done solid, with no cracks except

at openings. I decided that was, after all, the way to go for best

insulation effect, inside a 2" or thicker polystyrene (1/3 the price)

box

to add thickness around the outside. (If one poured the foam stuff at

reduced air pressure, or in a vacuum, I wonder if it would be even

airier and higher R value? Maybe it would be as light as aerogel?)

By the time I had the main pieces and materials I'd spent

390$. This was well beyond what I'd intended, but I think it's breaking

new ground - not in terms of absolute invention or discovery, but in

attempting to produce an all around more efficient 'shallow chest'

fridge design, and in the use of peltier elements and the very best

insulations for a low power, low voltage home fridge - one especially

suitable for solar homes.

Size of the Fridge & Requirements

For interior size 18"w x 36"L x 12"t and with 3"

insulation all around

(R17), it appeared there'd be 6 cubic feet of insulation surrounding

4.5 cubic feet of food capacity. In practice, I'd add more insulation

pieces where there were shorter containers, so it would be even less

space and more insulation. A more cubic shape could improve the ratio,

but utilization of the space would doubtless be poorer unless food was

stacked on food or multiple pullout shelves were employed. Or if the

lower

area was in pull-out "cold drawers" - but I decided to avoid that

complication.

How big were my other fridges and freezer? I did some

measuring and came up with these approximations of cubic feet:

Unit

|

CF actual

|

CF usable

|

Main fridge

|

14

|

10

|

Countertop Fridge

|

4

|

3

|

TE Cooler

|

1.5

|

1*

|

Freezer

|

21

|

10

|

Proposed TE Fridge

|

~4.3

|

4

|

* For camping, things usually get stacked on top of each other and the

entire space is well utilized. This is awkward for everyday use.

Another fridge-freezer I checked has 15 cubic feet of

fridge (18"w x 27"d x 54"t), and while I would have said it wasn't all

conveniently usable, the owners certainly have it stuffed to the gills

much of the time.

In giving typical "usable space" figures, I don't mean

holding that many cubic feet of food items, just that there are some

spaces typically almost entirely unoccupied, where it's hard to put

anything. Shelves

usually have unused space above the food, or else it's too hard to

access the food at the back. If the freezer was half filled, you'd

never find - or get at - the stuff at the bottom, so in practice a

shallow chest

holds as much food as a deep chest. (I've seen a deep freezer fully

packed. I'm sure some of the food underneath had been in there almost

since it

was purchased.)

It's evident that better utilization is a good bonus.

Still, the new TE/solar fridge wouldn't have 1/2 the usable space of

the big fridge. But it could fill the essential need for ongoing cold

food storage.

Igloo cutting

Eskimos take a

big knife and cut snow blocks to

make an

igloo. On the 9th, I took a couple of them (and a tape measure and a

carpenter square) and cut styrofoam blocks to make the fridge. Another

inch of polyurethane foam goes inside the 2" thick pieces of

polystyrene. Obviously it's much more than just a camping cooler. True

it's substantially smaller than a 'regular' fridge, but food can be

more efficiently packed in. It takes up more floor area, but

surprisingly only 12% more, being a foot broader but 6" less front to

back - in fact, regular counter width if the lids are hinged or pinned

for flush mounting. There's room for some storage underneath, cupboards

above, and in a narrow passage, the absence of a door swinging out

could be an advantage.

Eskimos take a

big knife and cut snow blocks to

make an

igloo. On the 9th, I took a couple of them (and a tape measure and a

carpenter square) and cut styrofoam blocks to make the fridge. Another

inch of polyurethane foam goes inside the 2" thick pieces of

polystyrene. Obviously it's much more than just a camping cooler. True

it's substantially smaller than a 'regular' fridge, but food can be

more efficiently packed in. It takes up more floor area, but

surprisingly only 12% more, being a foot broader but 6" less front to

back - in fact, regular counter width if the lids are hinged or pinned

for flush mounting. There's room for some storage underneath, cupboards

above, and in a narrow passage, the absence of a door swinging out

could be an advantage.

I was wondering how to attach the foam pieces. I was

thinking epoxy - yuk. Hmm, how bout white wood glue? I glued two scraps

together with it. It worked well, tho it took a long time to dry.

Freezer Compartment

Strangely, it didn't immediately occur to me I could be

making a combined unit, a fridge with a freezer compartment. This may

be because my regular fridge has nothing more than an ice cube

compartment. Perhaps I should set aside 9 or 12" of the 36" width for

one. And if I added another inch of urethane foam inside, it'd have 4"

and be R23 or R24.

It would necessitate a dual temperature control: If the

freezer needed cooling, the peltier unit would come on. If the fridge

needed cooling, a louver could open, or a fan could come on, between

the freezer and fridge compartments. (Someone who once worked in

appliance repair says he's seen old fridges with a bimetallic strip

louvre between the freezer and the fridge parts.) This is assuming, of

course, that the cooler's 60W peltier cooler would be adequate to the

job. It's asking a lot of it.

Construction

I had to let it sit for a week or two while I did other

things, but on the 18th and 19th I glued the main body of foam together

and carved out a hole to fit on the cooling unit, in the right side. I

left the glue to dry overnight with the left side still separate. It

still wasn't dry, but I couldn't resist trying it out, empty, with just

the 2" of styrofoam, not very well sealed. With the inner inch missing

on all sides, it was 6.2 cubic feet. I tried it out - see Tests,

a

ways

below.

Doing the Urethane Foam Insulation - Hindsight: urethane spray

can foam is

about the same price as the two part liquid, easier to use, better...

and a great glue for the polystyrene sheet joins.

Applying the

urethane anything like evenly proved impossible. It starts frothing in

about 20 seconds while you're mixing it, and after about 45 seconds

total, it won't flow any more. I tried spreading it around by hand, but

it mostly stuck to my latex or vinyl glove. As a means to fill the many

voids, I bought a spray can of expanding urethane foam and started

filling them with little squirts of it.

Applying the

urethane anything like evenly proved impossible. It starts frothing in

about 20 seconds while you're mixing it, and after about 45 seconds

total, it won't flow any more. I tried spreading it around by hand, but

it mostly stuck to my latex or vinyl glove. As a means to fill the many

voids, I bought a spray can of expanding urethane foam and started

filling them with little squirts of it.

I think the liquid foam would best be

poured, a bit per application, between two walls that are held stiffly

in

place, ie, as into a mold. Surely there are 1/4" sheets of polystyrene

that could be used to be smooth inside walls? It'd pretty much need a

plywood frame inside to hold them stiff for PU foaming.

The "max expansion" spray urethane foam took far longer to

harden, and continued expanding and hardening a bit even overnight.