Turquoise

Energy Ltd. News #55

Victoria BC

Copyright 2012 Craig Carmichael - September 3rd, 2012

www.TurquoiseEnergy.com

= www.ElectricHubcap.com

= www.ElectricWeel.com = www.MushroomOutboard.com

Hilight: Magnetic Refrigeration & Home Heating: vast energy saving potential?

Month In Brief (Summaries)

- 1912 Detroit Electric Car - 12V Fridge - Magnetic Refrigeration

- Sprint

car tests - 3D printer

In Passing (Miscellaneous topics

and editorial comments)

- Wind versus wave power on the sea: immense work to obtain the lesser

energy source.

Our dysfunctional, failing society:

- Einstein Refrigerator 1930. Even

Albert Einstein fell into the "technology death by patent" trap - Self

centered versus love centered training? - Democraship, the kleptocracy,

and state terrorism - an effective cancer cure and why it'll go nowhere

- Widespread crop

failures magnify financial crisis problems - Victims of Bank Fraud.

Electric Hubcap System

* Motor Assembly

* Brake Vacuum Assist - pump & reservoir

* Safety: "Stealth" electric cars should make warning noise when in

proximity to people?

* Sprint car: motor, controller and battery installed. It moved a

little: the motor controller seems to be the problem rather than the

torque converter... makes the motor "wimpy".

* The Planetary Gear Torque Converter Looks Like a Keeper!

* Motor

controller improvements.

* A new type of control modulation: combined CRM + PWM.

Planetary Gear Torque Converter

Project: Converter seems to work acceptably in car!

* 3D Printed plastic planetary gear/torque converter parts?

Solar Electricity Project

* Electricity is already 40¢/KWH in Hawaii, making solar a 3-5

year payback.

* Super battery stick proves less

than super - also beware voltage drops to batteries!

Superinsulated

Thermoelectric Fridge &

Freezer

* Single Peltier cooling works best after all. (Also can work well

without cold-side fan.)

* Better fridge shapes can provide more internal volume with less

exterior wall surface to keep cool - octagon, Low walls and terraced

sunken floor,

geodesic dome.

* Dividing fridge with a wall(s) allows sufficient cooling of a smaller

space in summer heat, ice compartment.

* Magnetic Refrigeration & Home Heating - world's best

research into it: Victoria BC - a design implementation -

rare earths ordered - potential for thermomagnetic motion machines

using gadolinium.

* Regular Chest Freezer used as low energy Refrigerator

Turquoise Battery Project

* Project devolves to assembling 3D printer to make electrode pockets

etc.

* Battery Making Video planned.

No Project Reports on: Magnetic Motion Devices, Weel

motor, DSSC

solar cells, LED Lighting, Pulsejet steel

plate cutter

Newsletters

Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

-

Electric Hubcap Motor - Turquoise Motor

Controller - 36 Volt Electric

Fan-Heater

- Nanocrystalline glass to enhance Solar

Cell performance - Ersatz 'powder coating' home process for

protecting/painting metal

Products Catalog:

- Electric Hubcap Motor Kit

- Sodium Sulfate - Lead-Acid battery longevity/renewal

- NiMH Handy Battery Sticks, Dry Cells

- LED Light Fixtures

Motor Building

Workshops

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

August in Brief

I

was asked to run the August first meeting of

the VEVA - Islands electric car club, as Cam Rawlinson was on the

mainland picking up the 1912 Detroit Electric car for a Victoria tour

to celebrate it's 100th year, making it now a genuine antique. This was

appropriate as the car was bought by a Victorian and it spent most of

its

life here. Running the meeting consisted of telling people that the

Detroit had missed the 5PM ferry but would arrive about 8:15. To my

surprise the midsummer meeting was the best attended so far - owing to

interest in

this car.

I

was asked to run the August first meeting of

the VEVA - Islands electric car club, as Cam Rawlinson was on the

mainland picking up the 1912 Detroit Electric car for a Victoria tour

to celebrate it's 100th year, making it now a genuine antique. This was

appropriate as the car was bought by a Victorian and it spent most of

its

life here. Running the meeting consisted of telling people that the

Detroit had missed the 5PM ferry but would arrive about 8:15. To my

surprise the midsummer meeting was the best attended so far - owing to

interest in

this car.

Its drive arrangement with the motor underneath connected

to the rear differential gears, is essentially similar to today's iMiEV

(available off the lot at Mitsubishi Motors on Cloverdale St). Of

course, performance and style are almost incomparable. The NiFe

batteries regrettably at long last wore out, and have been replaced by

short lived but cheap PbPb's, under the hood and in the trunk.

This Detroit Electric is in admirable condition, and it

won the Oak Bay Mayor's pick at the Classic Car Show on Oak Bay Avenue.

On top of several

more sundry things on my list for the month, I really wanted to get the

motor together and into the Sprint car, get the Peltier cooler fridge

finished, make the magnet machine that's been in

my head for 2 or 3 months now,

and put the 3D printer kit together.

Later on I started thinking

about grinding up some of the

nanocrystalline

borosilicate glaze I made a while back and melting it into 'pebble

lenses'

facing

some solar collector cover glass (using the broken solar collector),

about making a video about making batteries, which someone requested I

do a month or two ago, and about ...yet another... new project:

magnetic heat pumping.

Things seemed to

move at a crawl in early August, with one interruption to the work

after another. I didn't get much

done around the house either, and

the days were into double digits before I got going on much of anything

after the July TE News. I guess

that's summer! Even ordering some electronic parts - mostly for LED

lighting - was put off until it didn't get done at all. Then there were

exciting things on the 30th and 31st that kept me from getting this

newsletter out quickly as September started.

On the 9th someone phoned from Pennsylvania asking about

thermoelectric fridges. Since all I had was the July newsletter

writeup, this seemed to

indicate a hungry market for them, or perhaps for a ready-made

Peltier cooling

system for doing them DIY.

The

cooling system went back to a single Peltier element, which works

better

after all than double. (Oops!) A foam divider wall inside the fridge

allowed it to provide

fridge

temperatures in a smaller space in the heat of summer. With no fan

inside, the inner heatsink would frost up and the temperatures dropped

almost 20º to 4-6... at least near the bottom of the 1/2 fridge.

But I didn't

finish up the fridge itself (yet). Instead, an exciting new type of

refrigeration crossed my radar screen and occupied my time in study:

magnetic heat pumping.

Following TE News #54,

someone sent me a Wikipedia link to magnetic

refrigeration. This has been experimental for quite some time, but

it

seemed to me the

way it was being done, by pumping a fluid or a gas to move heat around,

was (as is so often the case) needlessly complicating the entire idea.

Later I found out that the fluid friction also severely limits the

theoretically very high coefficient of performance.

I soon thought up what I believe should be a better "solid

state" design. As I see it, scientists have created the "vacuum tubes"

of magnetic heat pumping and I have (in concept) the "transistors".

(That analogy is appropriate, but probably overstating the case

somewhat.)

As conceived by month's end, the first main component is

supermagnets aimed down on a horizontal rotor turned by a motor, to

provide the on-off

magnetic field that heats and then cools gadolinium as it enters and

then leaves a magnetic field, by the magneto-caloric

effect (MCE). The other component is stacks of thin, flat solid

plates: stationary copper heat absorber and releaser sheets in a

plastic frame, alternating with loose gadolinium "wafers". Each wafer

may get warmer and cooler by 1/2, 1 or more degrees, and the number of

stacks and wafers required for the desired temperature spread will

depend on the actual

values attained. The magnetic force as a rotor magnet passes by, pulls

each gadolinium wafer up into contact with its upper copper heatsink

within the stack, and also heats it, thus heating the heatsink. When

the magnet has passed, the wafers fall down and contact the lower

copper heatsink, and they cool. It seems to me this should be very

effective at pumping

heat from the bottom of the stack to the top, and [almost] everything

looks simple and straightforward to make.

On the 21st I ordered some

erbium and some

gadolinium - the magic element with a large MCE at 293ºK (room

temperature), its

magnetic Curie temperature. An alloy

of Gd and Erbium (85:15%) has a Curie temperature of 278ºK -

fridge

temperature. [Gadolinium is

"malleable and ductile", so I hoped making ingots into flat wafers

wouldn't

be too hard. Erbium is "malleable".]

Twice the Gd and no Er arrived on the 31st. Oh well, good

enough to start with, and I got the better bargain in price, Gd for the

price of cheaper Er. It proved magnetic enough to be picked up (about

equally at room or fridge temperatures), but not clamping strongly to

the supermagnet like iron or steel. Perfect! "Rolling resistance" of

the magnet rotor should be low, so a low power motor should work fine

(hmm... where's some old audio cassette deck?)... Just how much cooling

can be effected, from how little power?

Temperature of a chunk went up or down about .3 degrees

entering or leaving a supermagnet's field. Obviously I'll be wanting to

get the strongest possible field and I might review prior designs again

and take note of the ways others got the most flux.

Gadolinium also seemed harder than mild steel when I went

to

cut a piece. Since it also oxidizes readily and has a high melting

point, it may be tough to form it into the required metallic 'wafer'

sheets.

It seems to me magnetic heat pumping has far

more potential than just refrigerators. A 1500 watt electric

baseboard heater might be

replaced, not with a 1000-1200 watt peltier elements heat pump, but

instead with a 300 to 600 watt magnetic one. The

global potential for winter energy saving from this new technology

looks

staggering! It probably has excellent potential for hot weather air

conditioning too.

This was the only 'magnetic machine' that got looked at in

August.

Arriving with the Gd metal was Sm2O3 powder, samarium

oxide, which I think should be about the best substance for raising

oxygen overvoltage in the batteries. It was convenient to get some

while I was placing a rare earths order anyway.

Aside from there being all the other things I was doing, I

had

acquired almost some mental block against working on motors and cars. I

tackled each small step on the motor without enthusiasm and then a day

or two would

slip by before I did one more. Perhaps it comes from 3-1/2 years of not

even getting a car to move. In spite of

ongoing improvements to the motors and the controllers over that time,

finally having what ought to be a working torque converter, and a

lightweight car with a 4 to 1 final reduction gear, I had little faith

that the car would actually move. What would go wrong this time - some

new variety of catastrophic failure, or simple refusal to budge when I

thought there

should be up to maybe 200 foot-pounds of available torque at the wheels?

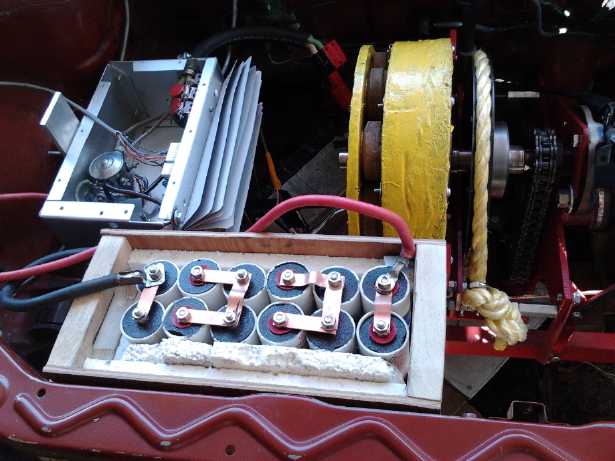

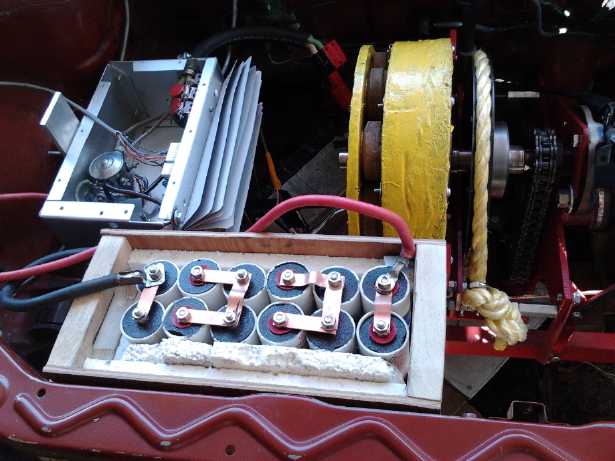

Notwithstanding, the motor was finally done and

mounted in

the Sprint car on the 27th. It looked good and seemed to fit well,

which

seemed

inspiring, so then I put in and wired the controller (29th), followed

by the 36V, 20 AH

NiMH battery box I made a while back (30th), and tried it out.

Notwithstanding, the motor was finally done and

mounted in

the Sprint car on the 27th. It looked good and seemed to fit well,

which

seemed

inspiring, so then I put in and wired the controller (29th), followed

by the 36V, 20 AH

NiMH battery box I made a while back (30th), and tried it out.

The car moved, but not much. The motor controller seemed

to be the main culprit rather than the torque converter. My present

analysis is that the torque converter seems to work, but it takes more

power going to it from the motor than I expected to budge the car.

At one point it did roll forward a ways, but on a slight

downhill slope. It only needed 20-30

foot-pounds at the wheels to do that. The rope tended to jam and not

let the pulley slip, even when it was loose, especially in one

direction. The driver controls in the car worked fine. The motor ran

fine, but in reverse the helical planetary gears caused the

planets assembly with the pulley to push over sideways and rub on the

housing. With the test controls by the side of the hood, I disconnected

the clutch rope and pulled it by hand. At one point, it looked like it

was about to move backwards, which needed 50-60 foot-pounds, but the

motor stalled. Finally, trying to repeat this, I put on near maximum

power to

the motor and pulled hard on the rope. The motor slowed to a crawl and

then the controller made a bang and smelled like blown

transistors. A 'minor' design problem was fixed and the controller

repaired by Sept. 2nd.

On reviewing the videos of the tests on September 2nd, I noticed that

the motor seemed wimpy at times, and that the cause would be the CRM

'direct torque control' modulation. Each time the car started moving or

I put more tension on the slip rope, the motor started stalling, and

one had to be really fast on the 'throttle' to give it more torque. I

conceived of a new combined CRM + PWM control modulation that would

deliver the best of both types. I hope to make an external PWM

circuit and try this out very soon with further car tests - while the

weather is

still nice.

Video of tests uploaded to youtube (click image for video; 'Back' to

return)

Here the car started moving as I applied tension to the rope,

but at the same time, the motor started slowing and stalling.

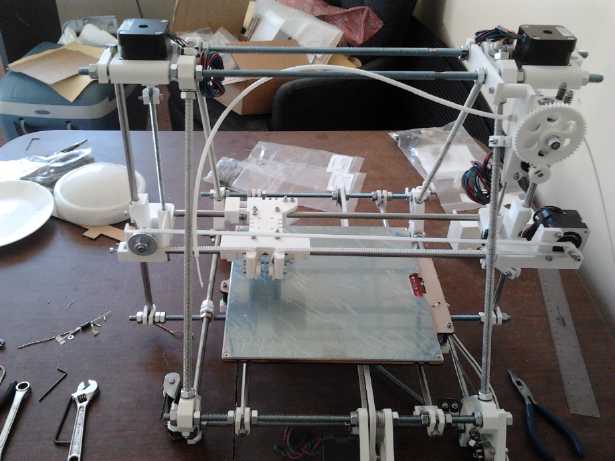

The 3D printer assembly absorbed quite a few hours I would

otherwise have put into the car conversion and other things. It was

well advanced but not complete when I stopped working on it to get

the car installation ready to test.

In Passing

Incidental news, editorials

Wind Versus Wave Power

I watched an episode of "Mega Builders" on Netflix where a

vast field of windplants was being installed on the North Sea off of

Holland. The plants were colossal stuctures, sticking up out of the

ocean on immense pillars. With such immense pieces, the project was

very large in scale. One piller held an electrical substation with a

very high voltage cable to the shore. Much was said about the roughness

of the sea and the hazards and delays it caused in construction.

I think it's amazing how so much effort and expense was

expended to capture wind power, on the sea, when the power of the sea

beneath was doubtless much the greater, and probably more easily

extracted. And if one is going to erect pillars sticking up from the

sea bottom anyway, they'd make better, simpler platforms for wave power

floats, mechanics and generators than floating units as proposed by me

and others.

Perhaps I wasn't thinking big enough in designing floating

wave power structures that could simply be towed into place, the anchor

dropped, and the cable plugged in on shore.

Invention death by Patent: even Einstein fell for it!

Here is just one more

instance of the most common use of patents: to kill valuable

new technologies. (Wikipedia article Einstein.) What a

crooked system the patent system is! If even

Einstein fell into the trap, whoever has a hope of evading it?

Einstein refrigerator

In 1926, Einstein and his former student Leó Szilárd

co-invented (and in

1930, patented) the Einstein refrigerator. This absorption refrigerator

was then

revolutionary for having no moving parts and using only heat as an

input.

On 11 November 1930, U.S. Patent 1,781,541

was awarded to Albert Einstein and Leó Szilárd for the

refrigerator.

Their invention was not immediately put into commercial production, as

the most promising of their patents were quickly bought up by the

Swedish company Electrolux to protect its refrigeration

technology from competition.

The patents would have expired about 1948, and I suppose my dad was

lucky to find a propane fridge for our cabin in about 1960. By that

time, electricity was available most places and the value of the

technology to the market was very limited. I've only seen 3 or 4 of

these fridges in my life, and two of them were the ones my dad bought.

(The second one was bigger and easier to light.)

Teaching youth: focus on self centered, versus social centered

I remember the class being told in grade 1 (or was it 3 or

4?),

a couple of times, that we needed to get an education, or we'd "end up

digging ditches". We needed an education so we could get a better job

and be more affluent. There was an implicit, and common, hidden message

in this:

that everybody was in life for themself and each should look out for

"number one". (At the same time, we daily recited the Lord's prayer

asking for "Thy will be done on Earth" - but that was just a jumble of

words that didn't even make any grammatical sense, and which were never

explained to us. "Thy what will be done on Earth"? "Our Father

that art in heaven":... did he spend his time painting

pictures? Why wasn't the prayer made of proper sentences?)

Material man must "serve two masters", looking after

material needs while trying to attain meaningful intellectual and

spiritual goals beyond. But "the self" is an insidious focus to instill

in young people. "How can I make more money?" - materialism,

consumerism - is a hollow, unsatisfying philosophy to live by. Often

the best answers found to this shallow question have little to do with

serving one's fellows or improving society, and contribute little to

growth of a dynamic character. Instead the focus may become how to get

the most the easiest way, which may devolve essentially to a mentality

of robbery. At worst people may

progress to the greed and avarice

that are presently running rampant and destroying civilization.

In corporate terms it's called "externalizing": We're here

to make money. The problems our activities inflict on the society we

all live in aren't our problems; somebody else can deal with them -

we'll pay a tax or a fine to allow someone else to deal with them. (but

if you charge us

much, we'll move offshore.) A corrupt culture of scarcity, greed,

abrogation of responsibility and

gangster elitism has arisen.

The attitude that advances true civilization and the

cause of

human brotherhood is of course "How can I best serve my fellow man?";

"How can I

do the most good?". Since one can't contribute while trying to find

one's next meal, making a decent living, hopefully doing things one

enjoys doing, is implicit. So is safeguarding this co-operative culture

by eliminating opportunities for greed and corruption as well as prompt

prosecution and demoting of anyone engaged in it, _especially_ by those

who have been granted positions of power and influence over others. And

when everyone

is contributing or at least prevented from working mischief, everyone

is safe from violence and want, and lives better.

Our present civilization makes no organized effort

to visualize how we want to live as the future unfolds. There are no

"Departments of Progress" committed to and administering working

towards worthy goals. Instead,

people and "for profit companies" are in it 'for themselves' and no one

is left with any power or resources to solve the 'externalized'

problems, or to contribute to the greater good. The "status

quo" powers simply try to put out fires and maintain themselves,

without even trying to remove the

kindling or prevent the fires from starting, without an overriding

plan. Those who conceive plans are locked out of the societal

structures of political and economic control.

Someone likened what's been happening for many decades,

even a century, to a frog in a pan. If he's tossed into a pan of hot

water, he jumps out. If he's tossed into cold water which is gradually

heated, there is no point where the frog realizes the danger and jumps

out, and he dies. Twentieth century civilization, tolerating every

fresh outrage without taking meaningful action, has reached the boiling

point of unbridled corruption and is unraveling before our eyes. In

the last analysis, its unworkable and unsustainable societal

configurations aren't worth saving.

Moving to a brighter future requires a new all-inclusive

morality and higher loyalties, real religious living where the

fatherhood of God and the brotherhood of Man are implicit in one's

daily living, and real courage to face and manage the serious and

perplexing problems just beginning to engulf our planet -- the sort of

courage, perhaps, to risk if necessary becoming eligible for the Julian

Assange

Award for News Reporting, or the Bradley Manning Award for Loyalty to a

Higher Cause. Every person who

stands up and embodies a righteous cause counts for more than he knows

-

the angels await such decisions so they can pitch in and help

co-ordinate people and circumstances in unseen "synchronistic" ways.

BTW I never saw a "ditchdigger". Even in 1960 the few

ditches in town were being dug with machinery.

Democraship, Kleptocracy: the internal enemy

In this century, we have rapidly transitioned from having

marginally useful civil governments to living in "democraships" where

we still

have a vote (so far), but no more control or influence over our

governments than in a dictatorship. The USA's "kleptocracy" is leading

in this. Any

dissent or criticism of the US government is now branded "terrorism" by

agencies of that government, while that government itself is committing

far more acts of terrorism than any other organization in the world.

But the USA isn't alone. Other "western" nations are following right

along.

An Israeli posted a Facebook message "We Love You Iran!"

which was lavishly responded in kind by many more people in both

nations. It touched me. It showed where the sentiments of the majority

really lie. But foreign governments are making economic war on

Iran, starving the people and driving it to desperation. Israel and the

USA especially want to attack it and pillage it, and Iranian society is

being held back.

The US "government" is now also talking about invading

Africa. The pretext is to take out some inconsequential villain,

"Kona"(?), who, according to a Ugandan-American girl in high school,

and

her relatives in Uganda, was most probably killed in a US bombing raid

on his headquarters 6 years ago. He hasn't been seen or heard of since.

In the interview, when the girl mentioned that oil has been found in

Uganda along the border with Congo, the real motive became clear. And

it seems that although Ugandan oil and Iranian oil aren't really needed

with other existing sources filling the demand, and with Canada selling

the USA oil from the Alberta tar sands cheaper than any third world

country sells its oil, the USA in its paranoia doesn't want China

getting oil, so they want to control it all.

US military personnel are also victims: as they start to

understand why they're really there in foreign lands, killing on a

genocidal scale, pillaging and despoiling, they're committing suicide

in record numbers. There are more suicides than battle casualties. The

hierarchy is calling it "stress", but "feeling guilt", not wishing to

participate in these crimes against humanity, might be a more common

reason.

I expect we are today probably looking at the last US

election. As

I've noted the laws are now set up for a dictatorship. The "Republican"

faction "primaries" have shown how little Romney and his gang care for

the democratic process, even making it illegal for Paul supporters to

cast their votes. It appears he'll win the election, and if he does, I

think he'll "delay" - call off - the next one on some "emergency"

pretext.

It's becoming increasingly true, and increasingly

apparent, that it isn't foreign countries but our own

economic-industrial institutions and

governments that have become our worst enemies, the enemies of

peace, prosperity and liberty. They've lost most any merit they once

had, and soon they'll be falling apart along with the global financial

system.

New, effective cancer cure

Dichloroacetic acid (DCA) has evidently been used for

decades to treat a rare disease or two. Last year a doctor in Edmonton

found a previously unnoticed effect and tested it in mice: it's

amazingly effective against cancerous tumors, with few side effects.

Acetic acid is of course better known as vinegar. (Perhaps

instructions for how to chlorinate it can be found on the web?) DCA is

cheap and has been around too long to patent. In our corrupt society,

it'll go nowhere. It might even be outlawed. It's a diabolical process

that eliminates medically effective and cost effective solutions:

* You can't sell something and claim it's good for any medical purpose

unless you can clinically prove it. Even if you sell common things

known to reduce cancer like almonds, strawberries and vitamin D, if you

claim they're effective against cancer without clinical tests, you'll

be shut down.

* The clinical tests cost cost tens to hundreds of millions of dollars.

* If you somehow went to all that trouble and expense for an

unpatentable substance, it gives you no benefit over others selling the

same substance. They can sell it much cheaper because they didn't have

to finance your testing, and would also be able to say "clinically

proven to...".

* Furthermore, if even a patented substance proves too effective, the

patient will be quickly cured and won't be buying it for long enough to

help pay back your costs.

* The best business is thus obtained by marginally effective patented

drugs that keep the patient alive but without affording a real cure.

* In addition, it's in "big pharma's" extreme interest to ban, or at

least stamp out information about, things that will actually prevent or

cure disease better than their offerings. Thus we find many insidious

things:

- The US banning of Laetrille (SP?), derived from almonds in

1969. It's now

available only in Mexico, where Americans in the know go to get it for

cancer treatment.

- The effective banning of DMSO, a 'home remedy' that was

starting to become popular, used effectively by many for various

conditions. (It's not even a drug, it's just a solvent. If paint

thinner cured medical conditions, it'd disappear too.)

- Disinformation campaigns: For example, in a short PNW summer

where hot sunny days can often be counted on the fingers and the

population is chronically seriously deficient in vitamin D, making

cancer virtually epidemic here, on that first rare hot, sunny day that

the public heads for the beaches, "public service" ads appear on TV

reminding everyone how bad sunburn is and advising we all slather on

sunscreen (to avoid getting any of those healthy, vitamin D forming

rays on our skin). Few die of skin cancers - they're mostly easily

treated. Meanwhile, millions die of other cancers because they're too

vitamin D deficient to resist tumor growth.

It's small wonder then that so many are chronically ill

and medical expenses go up and up and up. Health and nutrition are

areas where the individual is well advised to do enough of their own

study to learn some fundamentals. Health care with doctors, healers,

drugs and nutrition have a vital role in society, but ignorant reliance

on an overblown health care system after a careless, unhealthy

lifestyle empowers the greedy to do the things they do to extract

millions from everyone.

Global Bank Fraud, coming food shortages

A UK financial analyst estimated that a hundred million

people have

been driven into poverty since 2007 as a result of bank fraud. Since

people in

poverty aren't living well and often die, he suspected that more people

have been killed by bank fraud than by all the wars since world war

two - perhaps seven million.

(My own very meager RRSP investment was worth 33% less now

than in 1998, 15% less than at the start of 2011, and 6% less than this

January. And that doesn't take inflation into account. It didn't

average 1% a year over 17 years. If I had bought a chunk of gold, it

would now be worth 4x what I put in; silver - 6x. Both have been rising

rapidly in this century and won't suddenly drop like stocks. At 57, my

plan was now 'unlocked' and tho "sell

low" is bad advice in normal times, the writing was on the wall and I

cashed it out. In hindsight it would have been better to have done this

in 2010 or 2011 -- but better now than before it

gets worse or even disappears as many pension funds and futures

accounts have.)

It looks like worse is to come. Corruption

and greed will magnify the problems of poor or failed 2012 year crops

all over the world:

severe droughts across the USA, in Gujarat India, the Sahel and in

South

Korea,

typhoons in China, Taiwan and the Philippines, wildfires in Russia, and

an infestation of crop eating mice in Germany (50% losses) are ones

I've heard of.

Seems to me that at one time the USA kept food reserves in

case of bad crop

seasons. There have been other bad years, but today the larder is bare.

Today there are almost no family

farms to "go back to", and any failure in the food supply chain, or

petroleum to transport food (thanks to corruption preventing and

eliminating electrification of the transportation network), can quickly

result in shortages, hunger, and perhaps famine and epidemics. With the

default (and indeed evident disdain) of governments, responsibility for

stocking enough food to ride out times of shortage devolves on the

individual.

Serious

man caused as well as

natural disasters are obviously in store, and combined with financial

collapse, whole nations, large or

small, could potentially cease to exist as organized entities overnight.

But it's all part of a cosmic plan for progress - a

necessary evil. This world must move forward from its present

evolutionary dead end. The pillars of the corruption are being cast

down,

and in a disorganized time, unhindered by powerful reprobates, the more

enlightened and increasingly spiritual people will learn of and

implement sustainable societal

structures that can adapt and grow. (I expect that my writings, Fundamental

Principles

of

Democratic

Government and the Department of

Progress idea will be among the historic documents and proposals

read and

considered in the processes.)

Electric

Hubcap Motor System

Motor Assembly

By the 13th I had finally cut the keyslots in the shaft

for the sun gear and for the SD bushing to hold the magnet rotor on,

turned a large center hole in a bearing mount plate for the larger

bearing on the

fat part of the shaft, and put together a magnet sensor PCB.

The new, thicker rotor outside body had increased the

motor

diameter to 11.6". With 10" rotors and bolt holes through the walls

instead of within the rotor compartment, those bolt holes had to be

moved out about .1", so a new hole drilling template was needed. On the

15th I made the CNC g-code using a spreadsheet, drilled the template,

and drilled the motor.

I still needed a way to lock the sun gear in place, to

keep it from sliding off the end of the shaft. I didn't want to put a

set screw through it because the only place it could go was through the

gear teeth. Instead I needed to put some fitting on the end of the

shaft. I ended up with this cludjed arrangement:

Motor shaft with SD coupling to hold magnet rotor (hiding stator end of

shaft), bearing,

and sun gear held in place by a shaft key, a sleeve on the shaft, and a

flat-head bolt and bent washer on the outside.

(It may be a saving grace

that the outer washer is only stressed when the car is in reverse. How

can I reinforce it?)

As I was busy with other things, it was the 26th before I

put everything together. Since the rotor holes had been moved outwards,

the holes in the Sprint car mounting plate had to be likewise reamed

out to match,

and I made good use of the mini milling machine for this (still with

hand

cranks, not CNC control - luckily).

I thought of what to do to cover the coils: wrap a narrow

strip of furnace type air filter around the motor and hold it in place

with some small wires. However, I didn't get around to getting the

filter.

I thought of testing the motor, and I thought of checking out its

back EMF voltage levels as this still hasn't been done on the modern

versions. Instead I decided to go for the gusto and mount

it in the Sprint car and try it in situ. Hopefully I might

still get the Sprint running before month's end, if all went well.

After some further fiddling and reaming of mounting holes, it seemed to

fit well, the sun

gear on the shaft centering on the torque converter planet gears.

This is what replaces the car's engine, transmission et al!

Brake Vacuum Assist

One can only get so concerned with "minor details" before

the thing is running, but hey... they're easier to work on than some

aspects of the original R & Development work, and they do need to

be done before hitting the streets. (And the brakes, preferably before

hitting anything anywhere. Although, the Sprint is so small and light

I don't see why it should need a vacuum assist. But it's made with it -

sigh!)

Someone gave me a link to cheap Chinese 12 volt vacuum

pumps, so I bought one. It doesn't have the speed of suction to do car

brake

vacuum assist directly, so the thing to do is to hook it to a vacuum

storage (anti-storage?) tank. What would hold a vacuum without

imploding? It suddenly occurred to me that an empty small propane tank

could work, the kind used for propane torches and campstoves. A great

feature is the price.

The guy who gave me the link thought that would be

overkill on the pressure capacity, and also that it needed to be about

2 liters. Hmm, that would mean two tanks. Well, maybe a 3" ABS plumbing

drain pipe a foot long or so, or a longer 2" one? Or is one liter is

big enough for the Sprint?

I didn't get any of it hooked up, except to mount the pump

under the hood. The mass of wiring that went to the engine will

need sorting out. Perhaps the "fuel pump" wires can be "vacuum pump"

instead.

Safety Warning?

Electric cars are beautifully quiet, however there has

been some concern about their "stealth". A friend recently said he

stepped onto the street and was almost run over by one. He hadn't

bothered to look since he didn't hear any traffic. Another friend

almost hit one on his bicycle. And there's very few around so far.

(Reminds me of Ministry of Transport stations: whenever they added a

second vehicle on a small island, there was always a collision.)

I don't want to make noise unnecessarily, but it occurs to

me that some sort of sensor might be used to start some humming or

buzzing noise if an anything is too close to where the car is headed.

(Something sounding like a hive of angry hornets should grab anyone's

instant attention!)

It could get louder as the danger from the proximity increases. This

would doubtless require computer control to calculate where the danger

zone is and how far it was penetrated based on vehicle speed, power,

steering, etc.

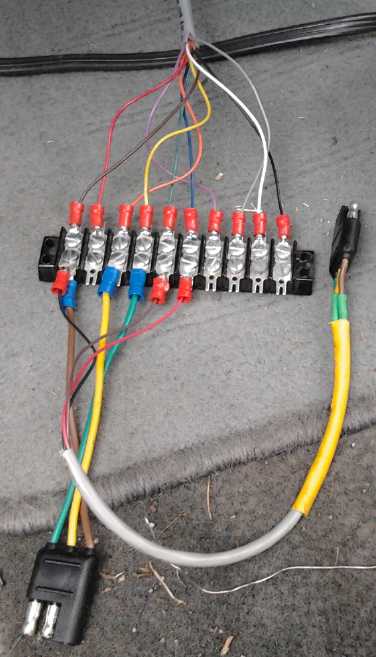

Motor Controller: Operator controls wiring

The motor & controller under the hood. There was lots of room, but

many obstructions and no flat surfaces to mount anything on.

I bolted an aluminum bar where there were two threaded holes together

on the fender and bolted the motor controller to the bar.

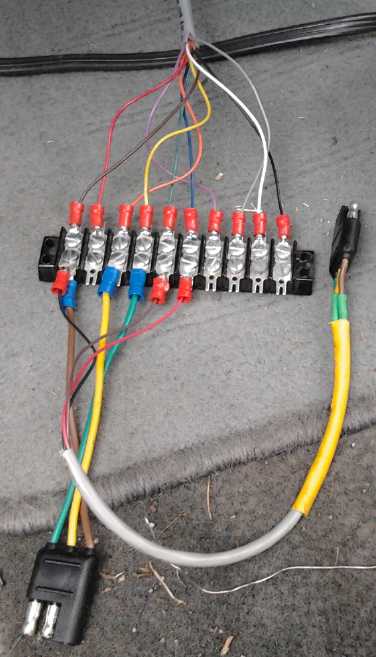

I had decided

on a single 10 pin "operator

controls"

header connector in the controller. But what would be on the other end?

The Tercel and two arrangements in the Sprint were a bit of a

hodgepodge of wires, even with just the Fwd-Off-Rev switch and the

'electron pedal' wired.

I had decided

on a single 10 pin "operator

controls"

header connector in the controller. But what would be on the other end?

The Tercel and two arrangements in the Sprint were a bit of a

hodgepodge of wires, even with just the Fwd-Off-Rev switch and the

'electron pedal' wired.

I got an idea to screw on a 10 position screw-down

terminal block under the dash in the car, and run a single 10 pin cable

to the connector in the motor controller. That way, a mechanically

solid connection point in the cab was an exact extension of what was in

the controller. The individual 'device' wires could go straight from

the device to the terminal block, ending with crimped (& soldered)

fork lugs to be screwed to the block. In the Sprint I left the rubber

Pico trailer plugs I'd already put in, but they should be a bit

superfluous in future installations.

One improvement would be to have 2 or 3 extra positions on

the block to clamp more ground wires, since most everything has a

ground wire.

Sprint Car Tests

On the 30th I installed a 36 volt battery in the Sprint,

having put in the motor and controller in the preceding days, and tried

it out. On the lawn where and as it was sitting (slight slope), a

torque

wrench on the front wheel nuts showed it took around 20 foot-pounds to

move it forward, and 60 to move it backwards.

The motor ran fine. But there was notable hesitation and

little torque starting from a stop - a persistent controller problem.

The slip clutch rope, tho loose, also tended to jam and not let the

motor start turning. Evidently it needs a bit less rope angle wrapped

around the pulley... or maybe the motor just needs its starting torque

improved. In the reverse

direction, the helical gears pushed the planets assembly sideways

(about 3/16") where the attached slip clutch pulley rubbed on the

housing. Simple to fix. The driver controls in the car

worked fine. The motor temperature sensor, properly hooked up for the

first time ever, gave no reading.

I had to disconnect the clutch rope and pull it by hand to

avoid the jamming, and use the test controls at the hood. The car

didn't seem to move as easily as was hoped. It consented at one

point to roll forward, with much force required. It looked a couple of

times as though it was was about to start rolling backward, but it

didn't. I wasn't very impressed by the torque converter at the time,

but on reviewing the videos I took, I think it works well enough, and

that the motor controller is the real problem.

Theoretically the car should have

rolled even with the jammed slip clutch. The motor theoretically has

around 10 foot pounds torque with 100+ amps of current, and with 1.8x

speed reduction in the planetary gear and 4x in the chain drive, that's

72 foot-pounds to the wheels to overcome 20 to roll forward. But since

the motor is held stopped with no clutch, this would

presume good motor torque at startup instead of a hesitancy to start

spinning even with no load.

I put together a short video typical of the tests from

clips I took, and

uploaded it to Youtube.

( http://www.youtube.com/watch?v=BsW66_lnzFg&feature=plcp

)

Here car is rolling forward as I pull on the slip clutch rope to apply

tension.

Motor Controller Improvements (sigh!)

Then in one test, giving the motor high "throttle" and

pulling hard on the rope, the heavily loaded motor (probably drawing

over 100 amps) slowed to a crawl and there was a BANG! from the

controller and the smell of toasted transistors. (luckily just 2, phase

B low.) On inspection, the phase A power wires ran right alongside

the phase B high gates control wire for about 4cm, an ideal layout for

spurious phase B high-side MOSFET turnons and shoot through currents in

phase B -

but only at very high current loads owing to most of the gate run

now being a twisted pair, a 'balanced line'. I repaired it and moved

the gate wires farther away.

Additionally, the hesitancy of the motor to start is

obviously a separate controller problem that needs addressing. I've run

into it before. It's caused by the

capacitors of the floating high side gate drivers discharging in less

than a second in the phase being driven high if the motor doesn't

quickly get turning. Once it's going they get recharged as the motor

turns. I switched from .5uF to 2uF ceramic capacitors. It

doesn't seem to have done the trick. And the higher the power, the

faster they discharge, so 'giving it the boot' doesn't seem to help

much.

New type of motor modulation control

I started to

think of going back

to something I did with the motor controller that moved the Tercel with

direct drive in 2008: pulsing the controller on and off at a few hertz

until it reaches some set RPM, then allow normal control. The charge

pumps will get reset in the

'off' periods, and the highest currents at very low RPMs won't be

continuous.

Reviewing the videos, I noticed also that the motor seemed

wimpy under load. Then I divined the cause.

"CRM" modulation - "direct torque control" - is much more prone

than "PWM" to letting the motor stall under load, since the torque

doesn't automatically increase as the speed drops. Once the

motor starts slowing down, it keeps doing so and rapidly comes to a

stop unless you're very fast to "hit the gas". This in fact seemed to

be the main reason the results weren't better in trying to move the car.

This suggested making a combined control: Use the CRM,

perhaps always at "full throttle", and modulate that with low frequency

PWM. The CRM will come back on after the short fixed off period, so the

PWM can be as slow as desired, even 20, 10 or 5 Hz, without loss of

power. Switching transients and losses (= controller heat) are still

minimized with the low PWM frequency. Hopefully the PWM "off" period

will allow the charge pumps to recharge and eliminate the low starting

torque problem. I suspect the combined control will probably make the

best system ever. 4-1/2 years later, I'm still finding better ways to

do things that most makers think are already optimized, 'standard

practice'... and then having to redesign my circuit boards yet again!

But I can try out the system with an external single chip

PWM generator tied into the 'electron pedal' in the car, sending a

pulsed 'max. throttle' setting to the CRM controller.

If everything works well in the controller, motor, and

converter, it seems

to me the 4 to 1 chain reduction could be reduced, even to 1 to 1. That

would allow the Sprint to do 100+ Km/Hr without over-revving the motor,

if it

can get going that fast.

Planetary Gear Torque

Converter Project

The first converter tests

are covered above as a component of the total system in the Sprint car.

3D-Printed Plastic Planetary Gears?

At the end of July (28th) I went to the Victoria Maker

Fair. I was mostly interested in the 3D printing, and I got the

names of some software and a person or two doing home 3D printing in

Victoria. Among

the displays was a planetary gear with straight teeth, about 2" wide

and 5" in diameter. The parts seemed huge compared to their metal

counterparts. I was about what I had envisioned to replace metal gears

with, to spread the loads over large areas and to avoid needing an oil

drip. Would such a construction stand up to automotive stresses?

(If 2" wasn't enough, maybe 3", or 4"?) I was told its ratio was about

5 to 1. I should have got the name of the person who made it (who

wasn't the person at the table). Maybe the design is on line somewhere.

I think my ideal would actually be aluminum sun and ring

gears and a steel planet gears assembly with plastic planet gears -

probably of the higher temperature nylon-like plastic whose name

escapes me at the moment. With the slight porosity of printed plastic

parts, the plastic gears could hold lubrication and some grease should

do for lubrication. I doubt I'd find 2 or 3" wide, large diameter

aluminum planetary gears, and that's too wide for abrasive waterjet to

cut, so it would probably devolve down to a nasty machining job needing

fairly special CNC & cutting tools. If printed plastic for all the

gears works, it'll be the simple choice.

Furthermore, for under hood conversions, a plastic part

could easily be printed as a ring gear on the inside and toothed belt

pulley on the outside, to drive a similar toothed pulley

at the differential. This would make the torque converter/transmission

unit very compact.

Solar Electricity Project

Price is already there some places...

A couple I know bought a half finished cabin in Hawaii

(Oahu?). Evidently the price of electricity there is already

40¢/KWH, and it gets a lot of sun year round. Payback on a solar

system might be 3-5 years. This would already be a good place to market

solar system, LED lighting and refrigeration equipment... for which I

have concepts

but not as yet products.

Super battery Stick not so Super

I hooked my 70 cell "Super Battery Stick" in the 4" PCV

pipe, with 7

rows of D cells in parallel, into the solar collector system. I thought

it should run the 4 amp fridge all night. Instead, it was crapping out

after 4 hours. I shook it and the voltage went up. Of those 7 rows, how

many were actually making reliable contact? And there was no way to

test individual rows.

I decided that the "Super Battery Stick" idea wasn't

really a very

good one. Individual pipes of 10 cells can be tested individually and

proper operation of each ascertained.

However, another factor to be considered was voltage drop.

Voltage

started at 13.8 out of the DC to DC converter from the collectors, but

through the

alligator clip wires it became 13.4 at the battery (thus it didn't stay

at full charge even during the day) and 13.1 at the plug of the fridge

unit. And, since I was measuring... the long, thin cord supplied with

the cooler lost another whole volt to 12.1 before it hit the circuit.

The moral of this is to put the batteries close to the charge

controller with short, fat wires, and to keep all wires thick enough.

Additionally, I have the idea to make compact plastic 10

cell/12

volt D cell battery holders using the 3D printer. These are likely to

be the most practical general solution, at least where 26 or 14 inches

length of space isn't available for the long 12v or 6v sticks.

Superinsulated Thermoelectric Fridge & Freezer

Single Peltier Cooler Again

On looking over the datasheets, I

decided the two-stage cooler didn't really look any better than the

single stage. The heating of the warm side element by the cool side

element essentially seemed to cancel out the benefits at refrigerator

temperatures.

So I tried the same arrangement as had given me freezing

temperatures but with the single original peltier, and got better

results: it hit -13ºc. With the heatsink attached but no fan, it

still managed to hit freezing in a warm room. (or even -2,

depending on the orientation (& hence airflow) of the heatsink.)

Keeping the warm side a few degrees cooler would also cool the cool

side a bit, but the desired temperatures were in fact attainable by the

unit

itself as made.

At the flip of a switch, the cooler unit could become a

warmer. That didn't seem very useful at first, but it defrosts the cold

side heatsink in minutes, before the fridge itself warms much. A

rectangular 'funnel' under the inside heatsink would carry out the

drips through a

plastic hose. I was wondering if 'defrost' should be left as a manual

operation, or if the temperature control should have it built in. Then

I put it on defrost and forgot it a couple of times, and the fridge was

warming instead of cooling. Now I'm sure it should be

automatic!

The

funnel might well be a custom 3D printed plastic part.

It also occurred to me that the unit should shut off, or

at least the inside fan should shut off, when the lid is opened, to

avoid blowing the cool air out.

Evidently I had been wasting my time with the double

peltier. Logically then the fridge should just need more watts, eg, two

cooling units... but I still suspected a problem in the cooling unit,

perhaps in its layout, because it attained about the same temperature,

8 to 10ºc, no matter how much insulation I added to the fridge, or

even back on its original cooler. Why was it hitting a "wall" at that

temperature? A second identical unit would double the watts, but might

get it little cooler.

So I wasn't quite ready to give up. About the only thing I

could think of to try was to

separate the warm and cold sides more, to place them entirely outside

and inside the thick insulation of the fridge, by putting in a longer

block of aluminum through from the peltier to the inner heatsink. (If

I'd known I was going to do this, the fridge would have just needed a

small square hole through the insulation instead of a giant one to

mount the whole original unit as it was.) Copper transfers heat even

better, but it's both costly and heavy. If there was much temperature

rise along the length, a fatter piece of aluminum is probably a better

answer. (Seemed pretty good.)

I added a couple of chunks of aluminum and extended it

over 2", but the fridge insulation is over 3" so the inside was still

well recessed into the wall. Without a fan, the cool side heatsink went

to -6 and the fridge to about 12 (seemingly somewhat stratified -

cooler at the floor below the unit than up at the lid). With a fan, the

heatsink rose to +5 but the fridge stayed at 12, less stratified. With

the peltier cold side 10º warmer, it should have been delivering

notably more cooling. It was still hitting that "wall" where it simply

didn't want to further cool the space, for no readily apparent reason.

It would need about an added 2.5" to 3" block of ~42mm x

~44mm aluminum to have the inner heatsink sticking out in the inner

space. The next morning I was passing a recycling place. I stopped and

found a 3/4" thick slab. I cut a piece to fit. With no fan, the inside

heatsink, now exposed properly to the inside air - vertical with the

fins up-down, hovered at about zero. It seemed to reduce or eliminate

the need for an inside fan, but the fridge space didn't get any colder.

I finally concluded the obvious, that the unit simply

didn't have

enough watts of cooling power to attain the desired temperature in the

space being cooled. That means the unit will inevitably run all the

time, and a temperature control is virtually superfluous. I also

finally realized that a temperature reduction on the warm side doesn't

mean an equal reduction on the cold side, just a few more

cooling watts. A bigger heatsink, stronger fan, or water cooling of the

warm side just might make 1-3º difference inside, but it would be

the 'law of diminishing returns', much effort for a small gain.

Of course, the lowest temperatures already attained, 8 to

10º, are much better for food storage than room temperatures. Some

might even say "Good enough for me." (Someone wrote that 3-5º is

optimum where I thought 2-4º... one less degree to cool to) In the

winter in my cool kitchen

it would get lower. I decided I'd consider 6-7º or under (with a

23º room temperature) to be essentially food worthy.

I decided to

replace the peltier in the cooler with the highest power 18$ peltier

element available at Digikey, tho it's only incrementally higher power

than the

original. It might just make it 2 or 3 degrees cooler without needing

more hardware - heatsink and fan units. If that didn't hit 6º, a

bigger heatsink on the outside might just make the remaining

difference. But a new plan (below) came to light before

I got to ordering it.

Meanwhile, although it was

too late to shape the fridge

for minimum exterior surfaces per volume, eg, as an octagon shape with

shorter walls and a terraced saucer floor (so that tall objects could

fit in the middle and shorter ones around the edge), I put some wedges

of foam in the corners (making a slight octagon of the inside).

Meanwhile, although it was

too late to shape the fridge

for minimum exterior surfaces per volume, eg, as an octagon shape with

shorter walls and a terraced saucer floor (so that tall objects could

fit in the middle and shorter ones around the edge), I put some wedges

of foam in the corners (making a slight octagon of the inside).

It also occurred to me I might still shorten the walls a

bit and make a domed lid, or a lid with less insulation inside in the

middle for tall objects, in lieu of the saucer floor. (The almost flat

floor is done. I could take a jigsaw to it - ugh!) Every inch

of

shortening of the walls is 3/4 of a square foot less surface to cool.

(Rectangular interior surface area of 18" x 36" x 12" walls is 18

square feet.)

I suppose the ultimate shape to minimize the exterior

surfaces of an

object with flat sides, would be a geodesic dome.

Considering it gets close to fridge temperatures, such

little things as minimizing surface per volume, sealing the lid, and

putting on the outer skin, should make notable differences to the

temperatures attained with the same tiny cooling

unit. There's another possible expedient...

Fridge Size Experiments - & without inside fan

It occurred to me on the 16th to cut and insert a piece of

2" styrofoam to divide the space. Thus I obtained a variable size

refrigerator. With a room temperature of 25-26ºc (scorching heat

for my house), the whole fridge (with the cooling unit reconfigured to

go through the 3" of insulation, but no proper duct over the cold side

fan and heatsink) was attaining 13-14º. Divided in half, the

cooled side reached 17º while the virtually uncooled side settled

to 19-20. Huh? Something was definitely rotten in the state of Denmark.

I found a rusty alligator clip wasn't making connection from the

converter to the battery. The 30 AH battery, having delivered about 5

amps for nearly 5 hours, was down to 3 volts. That was serious

overdischarge, even for NiMH, and it certainly explained the poor

cooling performance. Probably on

reconnecting the low battery, I found the "25 amp" fuse from the solar

collectors to the DC to DC converter was actually 7.5 amps and was

(understandably) blown.

I waited for the current

(charging the battery) to drop below about 6 amps and tried again,

making a note to replace the rusty clip that evening. This time it

reached 11, still with the uncooled side about 19. (The outer heatsink

read 40º. The inner one was 7º, but the peltier was 1 to

2º, showing poor thermal coupling from the element to its inner

heatsink.) Cooling only 1/4 of the space, the temperature hit 9 -- a

16º cooling. It wasn't a whole lot cooler than 13 considering it

was 1/4 the space, but it probably shows the physics: the higher the

temperature difference, the harder it is to attain and maintain.

Later (20th) I tried without the inside fan. Evidently

there are more air leaks than I thought or something, because it worked

better instead of worse. Cooling about 1/3 of the fridge, temperature

was 3 in a 22º room. The 19º was the largest temperature

differential attained. A still smaller space hit 2º. The inner

heatsink, at -7º, was heavily frosted up after a few hours.

Obviously

either the heatsink should be enlarged or the fan is needed. I'll

probably make a small ice

compartment right around the cooling unit.

I turned the setting to "heat" and again defrosted and

dried the

cooler in 5 minutes - what a great defrost unit! The tray beneath

collected about a tablespoon of water.

A little later I

found that the temperatures were considerably higher near the top than

near the floor of the unit, the temperature stratifying. Either the

cooling

unit should be at or just below the lid instead of mid wall height, or

the inside fan is needed to circulate the air.

By the expedient of making the fridge smaller with an

inside wall, a certain amount of food can be kept cold even on warm

days, while in the winter the whole space will be available if needed.

On the other hand, around 38 KWH a month (since it runs all the time,

so far) was as much juice as a good energy star full size fridge to

cool around 1/3 to 1/6 of the space. That's about a whole solar

collector's worth and more in the summer, and unless it shut off part

time it probably couldn't be powered continuously all winter.

Well, I can't say I wasn't warned Peltier cooling wasn't

very efficient. Coefficient of performance is typically .3 to .6

(Wikipedia), or around 1/2 watt of cooling for every watt of

electricity used. A compressor based fridge, or a heat pump, might be

1 to 1.5. A home heating heat pump might be only one at sub freezing

temperatures, but the electricity used is also heat, so one becomes two

for heating but not for cooling.

Magnetic Refrigeration

But it does cool, and... "Seek and you shall find." - and

not always what you expect to find (or you'd have already found it).

Soon after the July newsletter someone sent me a Wikipedia link to

magnetic refrigeration, which I

hadn't heard of. The potential coefficient of performance is perhaps 5

or

higher! Seemingly in accordance with my 'thermomagnetism'

theory, some substances heat notably when exposed to a strong magnetic

field, and similarly cool when removed from the field - The

"magnetocaloric effect" (MCE). If they're

cooled back to room temperature with a heatsink while within the field,

they get notably cooler when the field is removed. The fields employed

are in the range of 1 to 7 teslas. 1 or 2 is attainable with

supermagnets. Potentially there are a number of ways the heat could be

transferred from the fridge to a heatsink via the substance being

heated and cooled.

Development is in experimental stage and it looks very

promising. The most promising research cited is in my own

town, Victoria BC. A 2009 paper said it was potentially more

efficient than compressor + gas refrigerant refrigeration: 30-60% of

theoretical carnot cycle, versus 5-10%. And it uses one of my

favorite things: magnetism! The

best substances (which change magnetic state) at about room temperature

include gadolinium (Currie point 293ºK), alone or in an alloy with

europium (I think the document is in error - it seems it's erbium, not

europium. Currie point 278ºK).

How complicated would it be

to do well? I decided to try and contact the researchers and look into

their latest system and ideas. Peltier was the only viable

refrigeration idea I initially found, but it's not very efficient per

se and I'm not wedded to it. I'll jump horses in midstream at the drop

of a hat like a scared rabbit rather than throw good money after bad if

there's some other bandwagon I can put before the horse - if it

proves reasonably simple to do. After all, much of my effort went into

building the enclosure. That can be cooled any practical way that can

be found. Perhaps adequate cooling can be accomplished with fewer watts

instead of more, by building on the UVic research?

An 'autoreply' said the chief researcher was away. He

didn't respond to my e-mail when he was supposed to have returned. Then

I noticed he had started a company looking for funding to commercialize

his complex designs. By that time, I had read a paper surveying

existing designs, worked out my own simpler idea, and ordered

gadolinium.

If the performance is good, perhaps really efficient small

scale heat pumps and air conditioners can also be made without typical

compressors and refrigerant gasses. If a practical unit can be

produced, the potential for small size, lower energy heating and air

conditioning units is enormous. The peltier heat pump might do 1.3

times better than a regular electric heater - significant but not Earth

shattering. And it wouldn't make an effective air conditioner.

Something that could provide two to five times

the heat per watt of an electric heater, in a small plug-in size unit

(and maybe cooling too), would be a real game changer. Decentralized,

individual

room furnace replacement units using maybe 300-700 watts instead of

1500

would be worth putting a hole through the wall for!

But, even if it's practical and much better than peltier:

is it worth it for me to get involved in developing it? I only

started out to make a refrigerator that would work with a low voltage

DC solar power system. On the other hand, my winter electric bills are

high, and lots of people pay much more than me. To cut heating bills in

half, or by 2/3 or 4/5, is potential to drool over.

I decided to order

some Gd. I

saw it for about

1.0-1.5 $/gram in 100 gram lots on e-bay, then I phoned HEFA Rare Earth

in Richmond BC: 490$/Kg or 54¢/g for smaller amounts. Then: So an

alloy of Gd:Er

might be tailored to a specific Curie point? What about one with

a low point (erbium?) alloyed to one with a high point (iron,

nickel...?) in varying proportions? I

ordered some erbium too (35¢/g), but I'm not sure how I'll

accomplish

any alloying without oxidizing any rare earths.

Gleaned from Literature

I read a 32 page paper that was a survey of all magnetic

refrigeration experiments and prototypes prior to 2010, including th

eUVic ones. (wenku.baidu.com/view/8dd4353410661ed9ad51f3f8.html###)

Evidently an alloy of Ni:Mn:Sn has a reverse

magnetocaloric effect: it cools on entering a magnetic field, and

warms again as it exits it. Some alloys (eg, Gd:Si:Ge) have a "giant

magnetocaloric effect".

Curie temperatures:

Gd - 100% - Curie = 293 K (20ºC)

Gd:Tb - 74:26 % - 285 K ??

Gd:Er - 85:15 % - 278 K (5ºC)

La:Fe:CoSiB - Bal:10.97:.78:1.05:.2 % ??

Ni:Mn:Ga ??

About 50 watts of cooling power is supposed to be sufficient for a

typical refrigerator. (In which case why can't I cool the

superinsulated fridge with around 20 watts?)

Typical magnetic field strengths were .9 to 2 teslas, with a few

superconducting electromagnets supplying up to 7 teslas.

Typical cooling cycles were around .2 to 4 Hz, mostly under about 1 Hz.

The gadolinium needs time to magnetize and time to transfer the heat.

(Thinner pieces at a higher frequency of operation should pump the same

amount of heat while requiring less gadolinium.)

There were heat conducting fluids employed including

helium, water, air, pH 10 'basified' water, and olive oil, but in 41

prototypes described, none used solid state heat transfer. Personally,

I suspect that the first researchers used a gas or fluid, and while

varying much else, the rest have just copied that. But solid contact

between flat copper or aluminum faces is surely the fastest way to

transfer heat, and the fact that gadolinium is attracted to the magnets

provides a very convenient means for shuffling it back and forth

between cold and hot sinks at (surely) just the right times. (If a MCE

alloy isn't

heavy enough to make good thermal contact with the lower heatsink,

perhaps a bottom facing of copper foil could add weight.)

Furthermore, the report states that while the promise is

there for 20-30% efficiency improvement over compressor/gas systems,

substantially higher performance is being prevented by the pressures

needed to overcome friction and drive the fluid or gas sufficiently

through the system. Such extraneous power demands are largely

eliminated in the solid state system, so it *should* prove far more

efficient. If I get 1.5 times what compressor & gas refrigeration

gets, it'll be an advance over the fluid systems. Double would be even

better.

Gd & Magnetic Motion Machines

I also wonder if there's some role for gadolinium in

ambient temperature powered magnet machines? Surely the heat and the

motive force are

reciprocal forces.

Related to this, I found the following video, where a

paperclip hanging from a metal "string" is attracted to a magnet, which

lures it into a candle flame. The flame heats it up to the curie point

of the steel, at which point it loses its magnetism and falls back.

Soon it cools off until it's attracted to the magnet again, and the

process repeats itself repeatedly until it becomes repetitive.

The curie temperature, BTW, is also the point iron has to

be heated to in order to anneal or harden it.

fueloptimisers.com/magnetic-heat-engine-curie-effect.html

"Curie Point Magnetic Heat Engine

How it works

The heat engine uses a

principle of magnetism discovered by Pierre Curie. He studied the

effects of temperature on magnetism. Ferromagnetism covers the field of

normal magnetism that people typically associate with magnets. All

normal magnets and the materials that are attracted to magnets are

ferromagnetic materials. Pierre Curie discovered that ferromagnetic

materials have a critical temperature at which the material loses its

ferromagnetic behavior. This is known as its Curie Point. As an

example, a piece of iron (Fe) at room temperature is strongly attracted

to a magnet. Heat the iron to a temperature of 770 C, which is its

Curie Point, it loses its ferromagnetism behavior and it is no longer

attracted to a magnet. If we let the iron cool, it regains its

ferromagnetic behavior and is attracted to the magnet again."

This was hardly a perpetual

motion machine. The energy of the paperclip going back and forth was

minute compared to that of the candle flame. But the curie temperature

of iron is 770ºc. Even slight heating and cooling would put

gadolinium above and below its room temperature curie point, but the

magnetism doesn't seem to change as far as I could feel.

My Plan for a Magnetic Cooling Unit

I came up with an idea for a cooling unit that uses solid parts only,

no gas or fluid:

A rotating disk of supermagnets would pull on 2 or 3 stacks of

gadolinium wafers (each faced with epoxied copper foil to protect the

reactive gadolinium from air and moisture), interleaved with aluminum

or copper heatsinks. Each stack of wafers would "shiver" up and down as

the

magnets passed, heating as the magnet approaches while being pulled up

to the upper, warming heatsinks, then cooling after the magnets pass

while the stack drops back to the lower heatsinks, pumping heat through

the stack from bottom to top. Each individual wafer cools by 2 or 3

degrees.

In my first plan, the (epoxied, copper foil faced)

gadolinium wafer stacks would have been be held together by a framework

along two opposite edges. The interleaved copper heatsink pieces would

be framed along the other two edges, creating two interleaved stacks.

On the 24th I came up with the idea of framing the copper

heatsinks on all four sides, which would simply trap each loose

gadolinium

wafer in a thin box between two heatsink pieces. Nothing would hinder

the wafers from

jumping up when the magnet arrived and falling back afterwards, and

making good, square contact with both the heatsink above and the one

below. They only need to go up and down a fraction of a millimeter -

good square contact - very flat surfaces - is the key.

Naturally I thought of making the stack frames of plastic

with the 3D printer, but for a prototype that would probably just be a

luxury. They could just as easily be glued up from sheet plastic. If

each gadolinium wafer can be in a tiny sealed

compartment with minimal retained air and moisture, it shouldn't be

necessary to epoxy them and face them with copper foil, simplifying

everything, shortening the stacks, and maximizing heat transfer.

The reason for multiple stacks is to attempt to balance the magnetic

forces acting on the motor's rotation, so as one magnet is approaching

and being pulled towards a stack, another is leaving a stack and being

pulled backwards. It'll also be necessary to put stacks thermally

in series to get sufficient difference between hot and cold ends while

keeping the stacks short to keep the gadolinium wafers close enough to

the magnets.

Recap:

* A rotating disk of supermagnets (should provide sufficient magnetism,

but stronger is probably better).

* A stack of copper plates (Cu sheet metal heatsinks) with narrow

spaces in between them, sealed around the edges to protect the Gd from

air and moisture.

* Each space is loosely filled by a wafer of gadolinium. (Even Gd dust

would work, but single flat pieces will transfer heat best.)

* There may be two or more such stacks, with copper or aluminum

connecting the cold side of one to the hot side of the other, to double

the number of cooling units in series. (Since the wafers all have to be

as close as possible to the magnets, the stacks will be at most an inch

long.)

* An outside/hot side heatsink with fins and (probably) a fan. (must be

thin at the end to allow magnet rotor to pass closely to stack - fins

aim the other way.)

* An inside/cold side heatsink (large or with fan) inside the fridge.

That seems quite simple and straightforward - in fact,

much simpler than gas refrigeration.

One likely

complication, especially for

production, is how to form the gadolinium ingots/chunks into sheets.

I'll

fudge a few some way for test prototypes. Even gadolinium powder or

filings

should essentially work, tho not transfer heat as fast as a solid

sheet.

If it needs to be heated, it would have to be done in an inert

atmosphere, and Gd's melting point, 1312ºC/2394ºF, is at the

extreme limit of my kiln temperatures. (I wonder if one can create a

sealed steel box and, say, keep argon flowing through it while heated

to high temperature? It seems welding places do have tanks of argon -

200$.)

Considering the incredible potential benefits, I can

hardly see walking away from it. (Sigh!) The project is On!

Chest Freezer As Refrigerator

Someone wrote of a chest freezer being used as a

refrigerator for off-grid use. This seems like a brilliant idea! A unit

designed to cool to -10c naturally cools to fridge temperatures very

easily and stays there longer. (If it isn't super energy efficient to

start with, putting a couple or 4 inches of foam in the bottom and on

the lid as I did with my freezer should help considerably.)

Energy use is evidently minimal and the owner is quite

pleased with it. I might try it myself except instead I want to try the

magnetic cooling, which should be even better.

Turquoise Battery Project

The battery project, LED lighting project, and aspects of

other projects came down to assembling the 3D printer kit, with which

device I plan to make various battery parts, LED light bases, and PCB

artwork. I did 3 hour

sessions on several days or evenings, and assembled the frame, "Y" axis

carriage, "X" axis carriage, heated printing surface, hot plastic

extruder head, ...

About the only other things that happened were the arrival

of the osmium ordered last month, and

some samarium oxide - in an order with some rare earth metals for

magnetic refrigeration experiments. Sm2O3 should be a bit better trace

additive for raising oxygen overvoltage than Nd2O3, which I have about

a pound of, so it wasn't exactly a critical purchase. But here was the

time and place to get the best.

The osmium is indeed dense. The 10 gram blob of bluish

metal is only 1/2 a cc in size, like a fat shirt button. A kilogram

would be just 45mL. But there's no way one could afford a kilogram of

it, cool tho it would be to feel its heft.

http://www.TurquoiseEnergy.com

Victoria BC

I

was asked to run the August first meeting of

the VEVA - Islands electric car club, as Cam Rawlinson was on the

mainland picking up the 1912 Detroit Electric car for a Victoria tour

to celebrate it's 100th year, making it now a genuine antique. This was

appropriate as the car was bought by a Victorian and it spent most of

its

life here. Running the meeting consisted of telling people that the

Detroit had missed the 5PM ferry but would arrive about 8:15. To my

surprise the midsummer meeting was the best attended so far - owing to

interest in

this car.

I

was asked to run the August first meeting of

the VEVA - Islands electric car club, as Cam Rawlinson was on the

mainland picking up the 1912 Detroit Electric car for a Victoria tour

to celebrate it's 100th year, making it now a genuine antique. This was

appropriate as the car was bought by a Victorian and it spent most of