Turquoise

Energy Ltd. News #58

Victoria BC

Copyright 2012 Craig Carmichael - December 4th, 2012

www.TurquoiseEnergy.com

= www.ElectricHubcap.com

= www.ElectricWeel.com = www.MushroomOutboard.com

Features: Peltier Element Heat Pump for

Home & EV Heating (see Month in Brief)

Month In (relatively) Brief

(Project Summaries... and many little things not warranting separate

report headings)

- 12V Peltier element Fridge is cold enuf: probe has been reading

2º

too high! - Peltier Element Heat Pump for home & EV heating - 3D

Printing: a 12V NiMH battery case - Battery Making - "Mini Electric

Hubcap" +

Bicycle Rim Motors - Mushroom Outboard: preparing for 'pot metal'

propeller

casting - aluminum casting

for heatsinks - Torque Converter & Sprint Conversion - Greentech

Exchange Solar Event, Cheap solar heater, & Crowd Funding.

In Passing (Miscellaneous topics

and editorial comments)

- Banking and the Fiscal Cliff: history and beyond it

Planetary Gear Torque Converter

Project

* Balanced ropes + 1 to 1 flat belt + trial with no great results

Mushroom Outboard Motor Project

* Preparing to cast the propeller

CNC Farming Machine Project

* How did I get onto another

project? Don't I have enough unfinished projects?

* 18' Wooden Ladder Gantry: easy to make into a

supported truss - wheels & tracks - motors - drive belts

Superinsulated 12VDC Peltier Element Fridge

Project

* Is colder than measured - cold enough to use

* Commercial & Homemade Aerogel possibilities

Large Format NiMH Batteries - Take 3

* 3D printed, ventilated, stackable 12 volt battery cases minimize size

and added weight.

Turquoise Battery Project

* First porous plastic electrode using my 3D printed electrode pockets

is...

* An iron electrode with improved current capacity, charge rate and

charge retention

* "Graphite Foil" & "Flexible Graphite" likely best solution for

posode current colletors (now on order)

No Project Reports on: Electric Hubcap System, Weel

motor, DSSC

solar cells, LED Lighting, Pulsejet steel

plate cutter, Magnetic Heat Pumping, Magnetic Motion Machine

Newsletters

Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

-

Electric Hubcap Motor - Turquoise Motor

Controller - 36 Volt Electric

Fan-Heater

- Nanocrystalline glaze to enhance Solar

Cell performance - Ersatz 'powder coating' home process for

protecting/painting metal

Products Catalog:

- Electric Hubcap Motor Kit

- Sodium Sulfate - Lead-Acid battery longevity/renewal

- NiMH Handy Battery Sticks, Dry Cells

- LED Light Fixtures

Motor Building

Workshops

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

November in Brief

My September 19th, 2012 Talk at VEVA

(@ BCIT, Burnaby BC)

The Vancouver Electric Vehicles Association

video of my talk at the meeting was

uploaded in October. (I'm just late getting around to some of my

e-mails.)

Craig Carmichael of Victoria BC presents his alternate energy

inventions

Part 1 - http://youtu.be/MPaP8pnRukw

Part 2 - http://youtu.be/a5d3azR8O8Y

Part 3 - http://youtu.be/F_fx4AoLMEE

I confess... I haven't watched it yet.

Solar 12V House Wiring and Equipage

I used the 12 volt plugs and sockets for a convenience

outlet in the main panel (for an LED light to illuminate the dark

closet)

and for the Peltier/solar fridge. They work. I didn't cut a box into

the wall near the fridge yet, so the wire is just hanging there. I keep

thinking there must be some smaller box than an 1110 electrical box, to

cut a smaller hole. Or a surface mount box. Since

I haven't had time to make more LED lights, I bought some sample LED

bulbs at Deal Extreme. One 'cool white' (6500K) one I especially liked

and soon ordered a few more. According to the figures given, it's just

10 watts and 1100 lumens - fabulous efficiency. I haven't measured the

power, but the brightness is there. Some reviewers at DX.com said it

was equivalent to 75, 100 or even 140 watts tungsten. One of the

samples burned out instantly. Later I printed out my order and found

that it was a 12 volt bulb, with a standard "E27" 120 volt base. Rats,

I wrecked the one for the solar power!

The main panel by month's end.

Not much progress, but the voltmeter looks nice

and the 12VDC convenience outlet for the light is the first one

properly installed.

An ampmeter would be a good complement to the voltmeter, but my

matching

one goes to 5 amps instead of 50. (They were bought for testing wave

power.)

The 12V Peltier element fridge

is better

than I thought. The multimeter thermocouple probe was reading

about 1.5 to 2º

too high. When the meter read 8º, it was really 6 or 6.5º. At

the floor near the ice tray, it apparently hovers

around 3 or 4 and gets as low as 2. This was more in line with

expectations

considering the nearby ice tray and the 3" foam insulation.

With temperatures now seeming cold enough, I started

using the fridge for some day to day things. It's unexpectedly nice

to use. The light 3" foam lid opens with a touch, and then you just

drop it the last few inches. It closes itself really quickly, with a

'whuff' of air cushion at the end. Everything is

accessible just as I'd envisioned. Since you're not reaching behind

things to get other things, the time the lid is open is usually very

brief, with little heat gain. And the cold air doesn't dive out the

bottom when it's open like a front door fridge.

I still need find time to make and program the smart solar

control and do

the drain

funnel for under the ice tray.

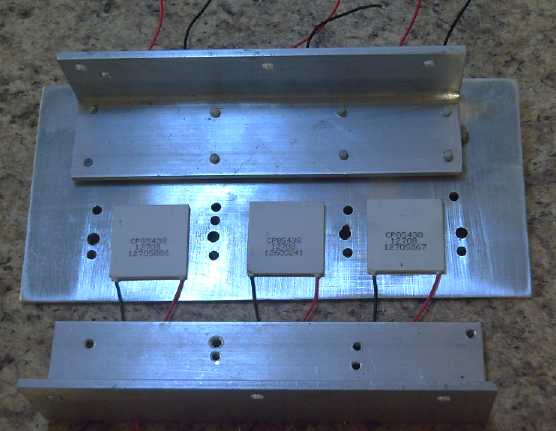

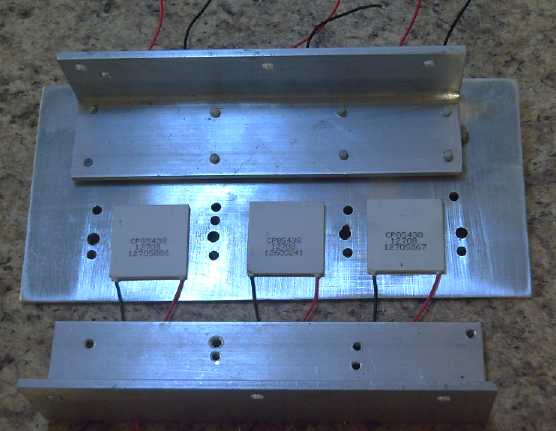

Main hot side plate, cold side angle aluminums.

But on the

25th, I got my nephew to cut and drill holes in

the pieces I'd selected for an experimental peltier element heat pump.

It has 6 peltiers at up to about 100 watts (input) each, in two rows of

three. In operation at full power, each peltier cold side could be

expected to

cool with about 40 watts, and the hot side to heat with 100 + 40 = 140

watts. Thus the total potential was 600 watts input yielding 840 watts

of heat on the hot side.

But on the

25th, I got my nephew to cut and drill holes in

the pieces I'd selected for an experimental peltier element heat pump.

It has 6 peltiers at up to about 100 watts (input) each, in two rows of

three. In operation at full power, each peltier cold side could be

expected to

cool with about 40 watts, and the hot side to heat with 100 + 40 = 140

watts. Thus the total potential was 600 watts input yielding 840 watts

of heat on the hot side.

The EV is the most interesting installation here, as the

heating power has to be supplied by the same batteries that power the

motor, and in winter, driving range is substantially reduced by the

heater/defroster. A heater delivering any extra heat for the power is

thus

highly attractive.

However, a reduction in power bills would mean a peltier

heat pump is also economic for home heating versus electric baseboard

heat. All else being equal (mostly assuming peltier elements have

decently long service life), the power savings will rapidly eclipse a

higher unit cost.

Outside heatsink fins

In my unit, the heatsink fins go vertically. I'm hoping

the outdoor cooling side can be convection reheated. (Should work on

windy days, anyway. In a car, the car is moving.) The inside will have

a fan. It

could be window mounted (or in my case placed in an existing hole I had

made long ago

in the wall for a passive "Trombe Wall" solar collector, now long

gone), or

installed in a car. I would hedge the bets: for experimentation and

initial use it would use the wall hole and run on a 50 volt, 5 amp

transformer with 5 elements of the 6 in series, to draw just 5 amps for

a 250 watt input, yielding 350 watts of heating power. But with minor

rewiring of the elements into two banks of three, it would become a 36

volt, 300/600 watt car heater (with 420/840 watts of heating).

On the 26th and 27th I started putting it together. The

details of the hole drilling weren't very well thought out and holes

didn't work out or even line up. The warm side heatsink fins were hard

to fit on and then they didn't conduct the heat very well - a critical

problem. I made notes for next time. (I should have had my nephew

assemble it. He'd surely plan out and execute the job much more

carefully next time.)

I also began to realize that some of the "aluminum" fins

were probably some sort of alloy - they weren't attracted to magnets,

but they seemed much harder to bend than aluminum. It has to be pure to

conduct heat well.

3D Printing - 12V NiMH D Cell Battery Holder - out of order

On the 5th I was

printing a D cell 12V battery holder. About 3 hours into the 5 hour

print, things came to a sudden stop and there was smoke coming from the

printer.

On the 5th I was

printing a D cell 12V battery holder. About 3 hours into the 5 hour

print, things came to a sudden stop and there was smoke coming from the

printer.

There was enough printed to put in some batteries and try

it out. It works. Complete cases will be stackable to create large NiMH

batteries in multiples of 12V and 10AH.

For the printer, I had visions of fried circuits, having

to order a new circuit

board, major rebuilding to do, and delays getting projects done.

I had tried successively higher temperatures to get better

results printing ABS, and this one was the hottest try yet, 270ºc.

Fresh plastic lines sagged too much covering over holes and I wouldn't

have gone quite so hot again. Probably 250º as suggested some

places was about right. I was trying to insert bits of cardboard

'insulation' to minimize warping, and evidently I hit the extruder

temperature sensing thermistor wire when the carriage moved towards me.

(Duh

- the printer can be paused!) Somehow this must have shorted

something out - the thermistor blew apart and the

insulation of its wire was scorched all the way along the ribbon cable.

Bad

temperature readings is probably what stopped the printer. It turned

out

that the thermistor and its wire seemed to be the only problems -

otherwise,

everything still seemed to work. Digikey was out of those thermistors

and I had

to back order. (and now they're to be further delayed!) Sigh! With the

3D printer out of order, I turned to

other

things. The magnetic motion machine was out too, as I wanted to print 3

more magnet arms for it.

Battery Making

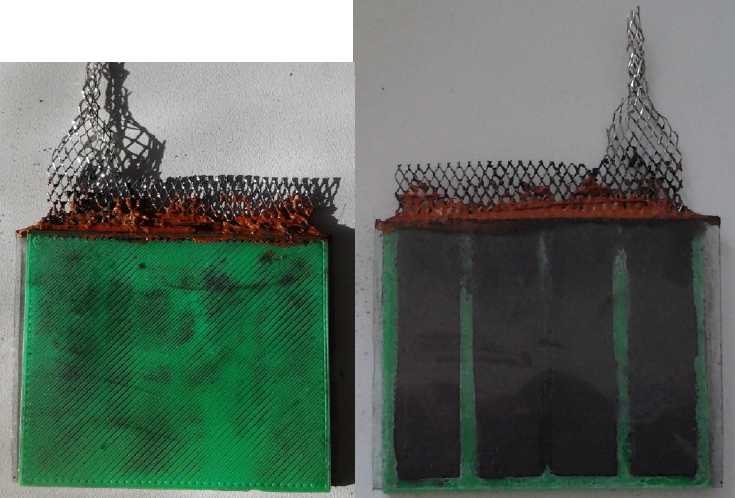

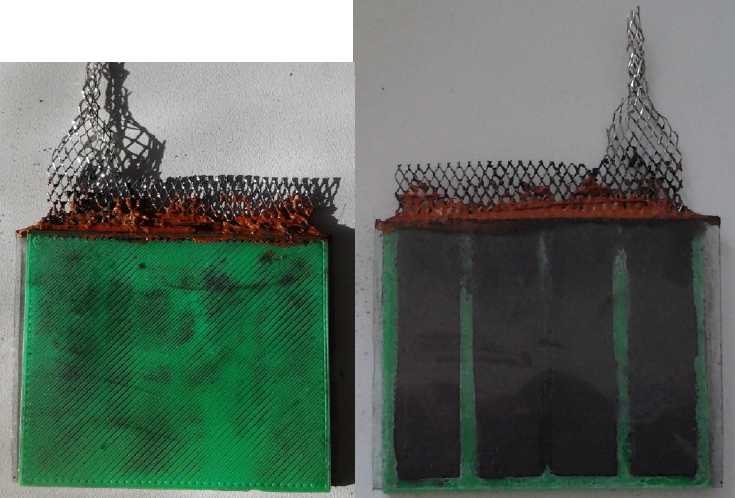

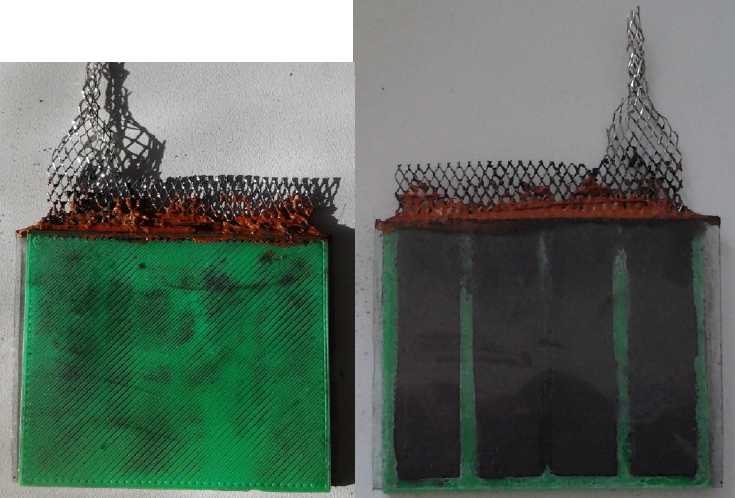

A porous plastic electrode. See-through plexiglass

backing plate shows the active chemicals.

Fine powder on green face leaked through the coarse pores.

Nickel plated copper mesh current collector; RTV silicone to

seal the top (unsuccessful - it turned to goo in the electrolyte).

I took porous ABS electrode

pocket covers I'd

already

printed and made 3 electrodes. Two attempts to make a monel electrode

with the monel mix I made in 2008 plus some graphite were failures.

Only later did I remember that metallic nickel has the unusual property

of not oxidizing in strong alkaline solution. Duh! It should work okay

in my

"moderately alkaline" electrolyte, but the point here was to make a

single electrode and test it in a Changhong Ni-Fe cell with the

original nickel 'posodes', where everything but the test electrode

would be a known, working quantity.

I took porous ABS electrode

pocket covers I'd

already

printed and made 3 electrodes. Two attempts to make a monel electrode

with the monel mix I made in 2008 plus some graphite were failures.

Only later did I remember that metallic nickel has the unusual property

of not oxidizing in strong alkaline solution. Duh! It should work okay

in my

"moderately alkaline" electrolyte, but the point here was to make a

single electrode and test it in a Changhong Ni-Fe cell with the

original nickel 'posodes', where everything but the test electrode

would be a known, working quantity.

The third attempt was a successful iron 'negode'. It

contained 25g of coarse ferrous oxide "sand", 10g of monel

alloy, and .35g of antimony sulfide, and had a copper foil current

collector. I used the coarse powder because the nano powders in the

first two had been leaking through the pores in the plastic. I still

put a piece of watercolor paper across the face when I installed it in

case any came out. Scaled for size, it seems to work a little better

current-wise than the original iron electrodes, despite being twice as

thick relative to the current collector. Theoretically it's 17

amp-hours worth of iron, but it looks like it's attaining around just 2

or 3%

utilization. This is probably because the coarse grit has low surface

area for its volume - most of the Fe is in the interior of the grit

particles where the electrolyte can't reach it. But it has the

following theoretical improvements:

* The monel makes it more conductive. This leads to ability to take

charge faster or more efficiently, and to drive heavier loads with

lower losses. Pure copper powder should be as good or better, but

monel (Ni:Cu ~~67:33% alloy) is what I had. The concentration needed to

attain really good conductivity

needs experiment. Furthermore, I didn't get to see if the graphite

powder would have worked. From the voltages it seems it should, but I

heard from one source that it bubbles hydrogen and discharges the

electrode. The Sb2S3

stibnite just might make the difference to that problem if it

exists. But since Mn-Mn is a wholly

better chemistry, I'm not going to bother perfecting this one.

* The antimony sulfide raises the

hydrogen overvoltage. This reduces bubbling of hydrogen gas, which in

turn improves charging efficiency and charge retention, reducing if not

curing the most negative characteristics of typical nickel-iron cells.

(Hydrogen evolution may perhaps be reduced to the point where

nickel-iron dry

cells

become practical.)

* The plastic electrode body is cheaper than metal ones. Also it can

touch other electrodes without causing a short circuit, so they can be

more closely packed inside a cell.

All this has allowed me to make single electrodes to use

with existing nickel ones and compare against known iron ones. It's

good

practice, learning, and test of a couple of theories, and has refined

my cell design ideas and led to improvements such as sealing the top of

the electrode pockets with wax. But the similarly long life and higher

energy 2 volt manganese cells are still the main object.

I shot video footage as I made the electrodes, and I

"copied" them onto a Windows PC machine, then erased the camera to free

up the space. But it turned out the computer, despite long clips taking

quite a while to "transfer", had only made "aliases" - links to the

files on the

camera. I discovered this only when I went to edit it all into a

battery making video. Only the names of the file clips remained on the

computer, claiming they were the videos but with no data. Instead of

editing the video and getting it online, I made another electrode and

shot more footage. I didn't get around to making it into a presentable

video.

I read a new term "graphite foil" and on searching for

that found rolls of "flexible graphite" on line. Was this what I've

been missing all this time for positrode current collectors, for want

of which I've been doing carbon (graphite) fiber and the grafpoxy mix?

I ordered some and a large roll arrived December 4th just as I was

finishing up this newsletter. It looks like a thinner version of

"expanded graphite". (And I wish I'd ordered .010" instead of .020".)

But I'll try a few things - in particular chemical surface preparations

- and try it in plastic pocket electrodes, and see what I can do with

it. From their cycle life graphs, it appears Aquion got good results

and long life out of their "graphite foil".

Electric Hubcap Motors

A couple of people were interested in smaller motors for

converting small motorcycles and scooters to electric, as well as the

motor

controllers and new chemistry batteries. I had thought of a smaller

diameter "Electric Hubcap" motor, which would have 6 coils and 8

magnets instead of 9 and 12. To keep things simple, they'd be made much

the same way with the same components. They'd be 24 volts, ~3KW, 3000

RPM, 9" in diameter with about a 7.5" rotor, and ~22 pounds.

In looking at some youtube videos of motors for bicycles I

started to consider (tho not for the first time) a big "partial rim"

motor. This is made in two separate parts. On the wheel, well out

towards the rim (probably attached to the spokes) is a steel ring

mounting supermagnets. The larger the wheel, the more magnets are

required. The wheel becomes the motor's rotor. Attached to the frame

facing the magnets is an arc of coils, a "fender" to the side of the

wheel, rather than a complete circle. This drives whatever magnets

happen to be across from it at the time.

I think 3 "Electric Hubcap" coils might give a minimal

ride on level pavement, 6 would give a good ride, and 9 would

(probably) be overkill on a regular, lightweight bicycle. An

interesting feature is that for magnets at the rim of any wheel, a

small wheel will theoretically perform the same as a large one - the

torque available

is proportional to the torque required for the size.

Mushroom Outboard & Marine

The fisherman who wanted to troll electrically last spring

called again on the 10th, and I still haven't made an outboard. I still

have the Honda outboard leg, but my 'production' Electric Hubcap motors

still won't quite fit under the hood. I talked with Jim Harrington who

has converted a couple of outboards to electric. An appropriate motor

that would fit wasn't kicking around, so we decided to use a sealed 3

HP Leeson DC

motor and controller that he had surplus at AGO Environmental, and

hence available at low cost, and install it as an inboard to drive

his main propeller shaft with a V-belt and pulleys, in order to get him

going for next season.

I like the direction switch on the controller: when

flipped from forward or reverse, it stops at neutral. It can't be

flipped from one direction to the other without stopping and releasing

pressure on the switch at neutral. Where do I get these for electric

cars?

3 HP motor & controller for fishing troller inboard

Along with the battery making, I collected up supplies and

equipment to cast the extra-efficient looking propeller for outboard

motors. Not exactly an invention on its own, but perhaps a product in

itself. And the smaller, higher RPM motors would fit in the Honda

outboard leg, which could make that a good one-off product. In my first

attempted casting on December 3rd, I realized in the nick of time that

zinc-aluminum alloy would doubtless corrode rapidly in salt water.

Melting pure aluminum on the stove worked

out badly, tho it did melt and I'll try it again, and I used the

mini-kiln. The first

propeller blade cast had air pockets and gaps. It wasn't usable.

(...fill the gaps with epoxy?) But since it was my first ever attempt

at metal casting, I sanded and polished up one face a bit for a

picture. I examined it with a friend with casting experience and we

discussed how to get better results.

Along with casting the zinc-aluminum alloy propeller (now

itself pure aluminum), I

started to think it might be nice to cast straight aluminum, perhaps

with fins: for

heatsinks. That had the potential to speed up making several items from

motor controllers to peltier element heat pumps. I was seeing various

ways people were melting aluminum and got so intrigued I forgot about

the

obvious one. I was dubious the hotplate would be practical. On the 25th

I tried melting some in a pottery crucible in the woodstove, but it

didn't get hot enough where I set it. A propane torch did the trick

eventually, but used a buck or two of propane. I read about making an

induction heater to melt aluminum. I

looked up the actual melting temperature (660ºc), and realized my

electric mini kiln could do it. Duh! Problem? No problem! On the 27th

in about an hour I successfully poured a small ingot of aluminum into a

muffin tin

hole, tho with lots of slag left over. It's doable. I couldn't clean

out the pottery crucible - the stuff was stuck

solid into the pores. Then I found one can melt aluminum on a kitchen

stove burner in a stainless steel pot. (See the "Mushroom Outboard"

project report for details.)

On December 1st I found a source of pure aluminum drill

shavings that had been just going into the garbage. I took a big but

pretty light box of them. If I do much casting I'll be back!

Electric Car & Torque Converter

I got the last piece of the new "balanced pull" slip

clutch tensioning system done on the 14th. On the 15th I put the 36

volt battery on charge and since it wasn't raining or too cold, I

started taking things out to the Sprint car and reinstalling them.

Before, I could hardly stop the rope from holding the pulley stopped.

Now it needed far too much pressure to get much drag on the pulley.

Maybe I'll try some kind of noose arrangement.

I didn't get the car to move. I think I was too optimistic

and should have stuck with the 4 to 1 chain reduction drive for now.

With the 1 to 1 belt drive, the converter could be putting out even

twice

the torque now, and still there'd be only 1/2 as much to the wheels.

Belatedly I thought about the elementary step of measuring

the torque on the shaft with the torque wrench, whether the car moves

or not, or even without connecting to them. After all, I ground a hex

shape into the end of the shaft for that very purpose. It proved pretty

useless for measuring pulsed torque, but I should have

been doing that from the beginning of the PGTC to measure results.

Greentech Exchange - Cheap solar heater

On the 29th, after spending the day on brochures and an

ad, I went to a Greentech Exchange Panel Presentation on Solar

Energy. One speaker who couldn't make it in person from Seattle

presented via Skype. His voice and projected face reminded me of

"Hollie" from the Red Dwarf TV show, but it worked.

His presentation was on having black metal with holes or

black cloth facing the sun on a south wall and drawing solar pre-heated

fresh air into the structure through it via a duct near the top. This

meets HVAC fresh air requirements with less energy when the sun is out.

It looked amazingly simple and cheap. I wonder how it would work with a

return air hole at the bottom and solid black material? It sounds so

simple I may just revive my old "Trombe Wall" from 30 years ago, but

needing no glass or transparent plastic on the front. (Of course, the

grape vine and other leaves would still shade it over except in early

spring.)

As invited, I set up some demos of solar 12 volt stuff and

the papers on one of several tables in the lobby. It sounded like most

of the

panelists could really use one or more of the things I've been

developing, and in the question period I said something about that and

to take my card if we couldn't find time to talk.

Rob MacGregor, the BC director of Sun Country Highways

spoke with me

afterwards about batteries. Sun country is building a network of EV

charging stations across Canada so that electric "transportation

appliance" drivers will have somewhere to go to recharge wherever they

are. This addresses the biggest fear about EVs: running out of power

somewhere.

(Someone is presently driving coast to coast, Newfoundland to Victoria,

in a Tesla. But there are many gaps still to be filled for shorter

range EVs.) The

second biggest complaint about EVs is the length of time it takes to

charge the batteries, so a cheap, very high rate cell would be an

excellent thing to have.

I also talked with three mechanical engineering students

who were about to graduate and mentioned my lagging torque converter

project. It seems likely that one of them will contact me after their

final exams.

Crowd Funding?

Something I've noted repeatedly in my inventive career is

that while I work on creating things to benefit everyone, almost no

particular person or body feels it should devolve upon them to

help foster or fund such projects when they are only one of the many

who would

benefit. In "R & D", Development has been the neglected little

brother of Research.

With some products now proven in principle and mainly

needing setup for production, and all these markets for them,

I may

look into "crowd funding", which

I've been hearing positive things about lately. People who wish to

create new

things are being funded not by rich "angel investors" or "venture

capitalists", but instead by a "crowd" of ordinary people who like the

idea and each contribute a small amount. Various terms and conditions

for the funding are specified in advance, so the proponent and

the payers are all clear what is expected.

Thus projects to benefit the many may be funded by the

many, each to a small extent. I could certainly have used something

like that for previous great (IMHO) projects that impressed people and

got good lip service, but went nowhere owing to

lack of investment! But the Crowd Funding idea and implementation

itself is a recent invention.

But there

may be other ways of funding, and there are often ways of setting up

smaller scale production that cost less and reduce or even eliminate

obligations incurred in order to get going.

In Passing

Incidental news, editorial opinions

Banking and the "Fiscal Cliff"

Like most people, I've never paid much attention to the

world of finance - until recently, when it started to look like

catastrophe is looming and lone lunatics predicting the end of the

world were joined by a rising chorus of variously qualified people

predicting such a

terrible financial collapse as might bring about the end of the

civilization we have known for many, many generations. Even the last Globe

and

Mail newspaper I saw had the term "fiscal cliff" in several

Business section articles. I started

to think I should at least try to understand why it's happening.

Youtube seemed like a place to see what "financial

collapse" was all about.

I think The best

overview explanation of hyperinflation and monetary system collapse

I've seen is a short two part video by Argentinian Adrian Salbuchi.

(Search youtube for that name.) He says the cycle of monetary collapse

is shorter in Argentina, and that they have gone through 3

hyperinflations and monetary collapses since the 1960s, whereas for us

in the "first world", all we know of the subject is old pictures from

the 1930s (yes, millions did die of starvation and poverty), and our

"normalcy bias" keeps us from believing such a thing

could happen again here. He held up an old Argentinian Peso and said it

would take trillions of them to buy what one would buy in 1964.

A lady named Ann Barnhardt said she closed her farm

commodities brokerage in 2011 because after MF Global and PG Best stole

all their customers' money ("and John Corzine still walks the streets a

free man!") and then court

decisions and new laws excused such theft, she decided that rule of law

is

gone and she could no longer

guarantee her farmer clients wouldn't suddenly have all their money

stolen.

She advised them all to "get out" and keep their money in cash or

precious metals. Her definition of what money is is worth hearing, too.

One person said that precious metals were an okay temporary

hedge, but that America was becoming a "third world" country and was

likely

to remain so for 5, 10, 15 or 20 years. He had lived in several of them

and thinks that the only real riches in that situation is to have the

means of producing something people need. Everybody needs food, and he

had put all his money into a piece of land, a farm that that he could

grow crops on.

And there are many other points of view on the "fiscal

cliff" and beyond on

Youtube.

Salbuchi's proposal to have the government directly

print money for

specific public works, tax earnings appropriately, and then (hopefully)

destroy any

excess if there's too much in circulation, sounds much better to me

than borrowing it from private banksters, to be repaid with interest.

Where is the money for

this interest to come from if the government can't print money? It has

to come form money already in circulation. And if money can only enter

circulation by a loan from a bank, it becomes a vicious circle of debt

and more debt.

Is it any wonder

then that debts grow and grow until

the Whole World owes far more money than exists, far more than can ever

be

paid 'back', and is now galloping full speed over the cliff of an

incredible financial catastrophe?

We must prepare with reserves of food and other needs, but

ever be mindful there's a tomorrow after that

collapse. The collapse will be a horrific event which may take many

years to straighten out, but the banks have outscammed all the corrupt

businesses through which a few families have controlled 80% of the

world's economy, and hyperinflation or national bank failures will

eliminate their vast monetary wealth. By the time things are

re-starting, the power base of the corrupt will have

been eliminated, and the world will be on a new, more sustainable and

more spiritual track. Many of the

fiscal cliff "prophets of doom" think the long term future will be much

brighter. "The sooner the better." they say. A global change in

consciousness can already be sensed.

A focused bit of American Financial History (an inevitably

slanted view)

There's nothing new in financial collapses, except for the

global extent and the

extraordinary degree of control the main banksters have attained over

governments everywhere and over

everyones' lives and fortunes - their ability to

extract the wealth from most everyone, everywhere, by fraud. They foist

worthless "credit derivatives", "credit default swaps" and

"collateralized debt obligations" - weapons of financial terrorism

rated "AAA investment" by the corrupt ratings agencies, who are

under their control - onto other banks, pension plan funds,

municipalities and other unsuspecting saps, running to trillions of

dollars. Where

in the early 1930's 1600 US bankers

went to

jail for their roles in causing the great depression, banksters and the

ruling "cleptocracy"

caused the 2008 crash with

impunity and continue merrily on

to bigger and worser things.

But the finance

problem was

understood centuries ago.

Britain grew its empire to cover 1/4 of the globe by a central bank

which provided vast sums of

credit to build a navy and army through fractional reserve financing,

which then enforced British rule at

the expense of the colonized people (including the Americans... and not

to mention the common British

people) to pay off the loans. The following is attributed to Thomas

Jefferson.

It seems it's not a real or single quote, but rather contains some of

Jefferson's thoughts and words from 1802 to 1816, liberally appended

to to sharpen and modernize the

points he made. It does well describe America today, especially with

millions

homeless while more dollars worth of foreclosed real estate is in the

hands

of the banks than is owned by homeowners (albeit the bank holdings are

doubtless 2007 inflated "real estate bubble" figures):

"If the American people ever allow private banks to

control the issue

of their currency, first by inflation, then by deflation, the banks and

corporations that will grow up around them will deprive the people of

all property until their children wake up homeless on the continent

their Fathers conquered...I believe that banking institutions are more

dangerous to our liberties than standing armies... The issuing power

should be taken from the banks and restored to the people, to whom it

properly belongs."

The indictments

of Andrew Jackson (US president 1829–1837) sum

up the problems so well they could almost have been written this year

(Wikipedia):

As President, Jackson worked to rescind the bank's federal charter.

In Jackson's veto message, the bank needed to be abolished because:

- It concentrated the nation's financial strength in a single

institution,

- It exposed the government to control by foreign interests,

- It served mainly to make the rich richer,

- It exercised too much control over members of Congress,

- It favored northeastern states over southern and western states,

- Banks are controlled by a few select families.

Following Jefferson, Jackson supported an "agricultural republic"

and felt the Bank improved the fortunes of an "elite circle" of

commercial and industrial entrepreneurs at the expense of farmers and

laborers. After a titanic struggle, Jackson succeeded in destroying the

Bank by vetoing its 1832 re-charter by Congress and by withdrawing U.S.

funds in 1833.

Like

today,

the

bankers

of

1832

threatened

collapse

of

the

economy

if

they

didn't

get

their

way.

Jackson

replied that "You are a nest of vipers"

and to do their worst - he would see them off. (cartoon is from that

time) His veto of their

charter renewal solved the problem, AFAIK until 1913 when the "Federal

Reserve"

corporation was created and usurped the US treasury as the printer of

US dollars.

Like

today,

the

bankers

of

1832

threatened

collapse

of

the

economy

if

they

didn't

get

their

way.

Jackson

replied that "You are a nest of vipers"

and to do their worst - he would see them off. (cartoon is from that

time) His veto of their

charter renewal solved the problem, AFAIK until 1913 when the "Federal

Reserve"

corporation was created and usurped the US treasury as the printer of

US dollars.

Later (1834?), someone attempted the first

assassination of a US president, saying Jackson's banking policies were

keeping him poor.

(His two pistols both misfired but later both worked reliably.)

He was

pronounced insane, but a disgruntled banker or two may well have put

the

ideas

that Jackson

was to blame for his ills into his weak mind - and then given him the

pistols. It would seem likely that there's also nothing new about

bankers and other vested interests trying to eliminate leaders that

don't knuckle under to them.

I've mentioned that I think America might dissolve into

chaos and civil war after the collapse. Now hundreds of thousands from

many different

states have "requested that [their state] peacefully secede" via a

federal

government web site. Texas soon had over 100,000

who think they want it to be the lone star state again. (In fact it

went from

21,000 to 70,000 petitioners in a couple of days after RT[.com] did

a news article

on it. Do so many Americans get their news from RT?) Doubtless it's

largely people who didn't like the federal election results, but the

numbers and the Texas "Secede!" bumper stickers indicate considerable

disquiet. This movement

could gather momentum rapidly, as the central government seems to be

doing so little of real value for the wellbeing of its citizens and

seems so out of

control.

The USA is next door from here, has had great influence

over the world, and is well documented. What of the rest of the planet?

Every country and region is different and has different conditions, but

the more I see, the more it looks like the financial collapse will

leave no land untouched. For example, China's industrial economy

was partly built on selling goods to the west, which is now broke,

so suddenly vast unemployment and abandoned construction works are

spreading there too. Hyperinflation

and bank runs too keep rearing their ugly heads in surprising places.

Water is starting to gush through leaks all across the dam.

Over long time periods geography is the biggest determiner

of administrative regions. Might a looser

North American union of the entire continent eventually come into

being? with the component regions having more independence, being

better governed, and providing people more freedom, than exists today?

Of course, all intermediate regions including continents are of

relative value only insofar as they improve peoples' lives. The whole

planet will eventually

be unified in some way as best seen fit at the time - it's the final

way to end wars

and have true, complete human brotherhood. But I think I've said such

things before in Fundamental

Principles

of

Democratic

Government - Towards Utopian Systems of

Governance.

Planetary Gear Torque

Converter (PGTC) Project

I left the project for a

while, with the last piece being some way to attach the

clutch/tensioning rope so it could tension around the big pulley with

balanced forces.

I was trying to straighten a scrap piece that looked about right for

one side of some sort of bracket but was bent 90º, and it attained

a bit of an "S" shape. I thought that might be useful, so I took it and

I eyed everything up together. The

bend

put

the

end

in

about

the

right

position

relative

to

the pulley.

"Some sort of bracket" was thus reduced to this simple bar of steel

attached at one end with two bolts (instead of one and a separate

diagonal piece to keep it from twisting) with an eye bolt sticking out

to attach the rope to. If it bends in use, I'll use a still stiffer

piece.

At the other end of the pulley, I ended the friction rope

ends pretty short, clamping them to two thin ropes which go over two

smooth cylindrical 'slides' and then clamp together into one that goes

through two small pulleys to the gearshift/tension cable.

Originally, I could hardly stop the rope from locking up

the clutch-pulley. Now when I tried it out, I couldn't get enough

tension on the ropes to put much load on the motor - the pulley just

spun. I took a small grinding wheel and (at risk of considerably

shortening the life of the rope) roughened up the inner surface of the

pulley as best I could. This helped some, but somewhere it needs more

leverage. Maybe some kind of noose. A mechanical student I talked to

later asked about steel "bands" that have been used with planetary

gears, which I've heard referenced before. Perhaps I should look into

that.

I finally ended up

grabbing the clamps on the ends of the rope (with my fingers just too

close to the

pulley) to tighten it. The car didn't move regardless of heavily

loading down the motor. After some fiddling around

and trying variations, I gave up.

Evidently I was too optimistic about the torque it would

produce. I still don't see why it shouldn't be hundreds to one. But

with

the one to one belt drive, the converter now needed 4 times as much

torque as before. Even if it now had twice as much as before - surely

it has more than it did - it would now be 1/2 as much at the wheels and

might not move the car.

I took it all off the car again to disassemble and

re-install the 4 to 1 reduction chain drive. Better to have limited top

speed than none at all. If it moves, it can be tweaked. If it doesn't,

it's too hard to see what's happening.

...Come to think of it, I should be able to measure the torque on the

output shaft with the torque wrench regardless of how it attaches to

the drive shaft, or even if it's not attached at all. That's why I

ground a hex nut shape onto the end of that shaft. Duh! That would

be a good step. I wish I'd thought of it while everything was

assembled, and even more, for each trial from the beginning.

Another thing I should do is make a bigger 36 volt battery

than 20 amp-hours. This one will only supply 50 or 60 amps without

losing voltage, placing a limit on the torque of the motor. (Let's

see... 36V/30AH is: 3 * 3 = 9 battery cases at 5 hours each is 45 hours

of 3D printing. Up it to 70 AH and the Sprint should be able to run

around Esquimalt.)

But with the weather being mostly cold and wet, and having

lots of

indoor things to do, that's about all I got done on the car or torque

converter.

Mushroom Outboard (Outboard Motor from Scratch) Project

For the moment, this seems

to have become "The More Efficient Propeller Casting Project". I

started looking into

casting the plastic propeller blades in metal. It seems "sand casting",

as one might suspect, involves more than just sand, which would

obviously crumble. "regular" sand is mixed with very fine sand so the

pores are smaller. The simplest binder to hold the sand grains together

is bentonite clay. This is thoroughly mixed and water is added.

I thought a zinc-aluminum alloy would be easy to do

because it can be easily melted on a stove burner. I could get a good

hotplate

and do it all outdoors. A web page [www.baldwinmanufacturing.com/zinc_AL_alloy.html]

indicated

this

alloy

would

be

a

great

choice

for

more reasons than I

suspected. Another web page I mentioned before talked about the

zinc-aluminum "stovetop metalcasting". [www.gizmology.net/stovetop.htm]

On

that

site

is

the(?)

formula

for

ZA-27.

I

presume those are weight

%'s rather than volume %'s. He said:

I melted a handful of post-1982 (copper coated zinc) pennies.

Once the zinc melted, I dissolved a bit of aluminum into it, to produce

an

alloy similar to the various ZA alloys. ZA-27 (71% Zinc, 27% Aluminum,

and 2.2% Copper) is on par with cast iron for strength, but melts at a

much lower temperature and is only two-thirds as dense.

|

Gray Cast Iron |

ZA-27 |

ZA-12 |

ZA-8 |

| Compressive Yield Strength |

65,000 psi |

42,400 psi |

33,400 psi |

36,500 psi |

| Ultimate Tensile Strength |

40,000 psi |

60,900 psi |

39,900 psi |

54,200 psi |

| Density |

0.258 lb/in³ |

0.181 lb/in³ |

0.218 lb/in³ |

0.228 lb/in³ |

| Melting Point |

2795°F |

709-903°F |

711-810°F |

707-759°F |

I say the alloy I made is only similar to ZA-whatever

because I didn't measure anything - this run was just to see if it was

possible at all. To get a near perfect ZA-27 alloy would require $1.99

in post-1982 pennies, one pre-1982 penny, and 100 grams of aluminum.

This assumes that the copper on the pennies won't oxidize, which is a

stretch - to make sure there's enough copper, I'd add two pre-1982

pennies.

The pennies took about 15 minutes to melt from a cold start,

and the aluminum took perhaps another 15 minutes to dissolve. Then I

turned the burner off and let the blob cool.

I hoped I could stick the

propeller blades in a sand casting mold and simply pull them out,

leaving the cavity behind to pour molten metal into. Then I'd add a

cylinder on top as an

attachment piece, and

maybe a bit of a funnel to pour into above that.

I learned more

about "cope" and "drag" sections of a mold, slightly improving the odds

it'd work and learning vaguely known procedures. I bought sand,

fine sand and bentonite clay, the essentials for 'sand'

casting. On the 21st I made a small wooden box to pack the mix into. On

the 22nd I bought a 120V hotplate.

Then at a recycling place I got some old corroded pieces

of ship anode for a few pounds of zinc. The surface looked awful, but

inside was bright, shiny zinc. The corroded surface should just

become excess slag on top.

I could also see wanting to melt pure aluminum for casting

heatsinks, which could be easily molded. But to melt aluminum evidently

required

a lot of propane. I found a site with what look

like good instructions for making an induction heater: http://inductionheatertutorial.com/

Then I remembered my mini-kiln could melt it. I tried it

out. It took an hour - 15¢ of electricity - and I poured a little

ingot from a pottery crucible into a muffin tin. Gosh, liquid aluminum

- it actually works!

I tried to melt some in a pot on the hotplate, then on the

kitchen stove, but the thick bottomed pot turned out to be

laminated not solid. On the stove, the base layer detached and warped,

holding

the rest of the pot off the burner. Notwithstanding that the bottom of

the pot glowed dully red, none of the aluminum in it melted.

Later I watched a

youtube video of someone doing his own

first aluminum casting, and learned a few things to do and not to do,

improving my odds for success. (My wooden mold box had

to be remade.)

When I went to

cast the prop on December 3rd, at the last moment I decided it should

be pure aluminum - wasn't zinc used as sacrificial anode? Why would I

think it would last in salt water? I pulled the zinc out of the thin

bottom stainless steel pot on the large stove burner before any melted,

and put in only aluminum - drill shavings and some fat chunks. It did

eventually melt the aluminum. But between the thin shavings of aluminum

(I had thought they'd disappear into the zinc) and I kept taking the

lid off the pot to check it, it ended up with more oxidized slag than

aluminum. Some bright aluminum was melted and would run across the

bottom of the pot under the slag if it was tipped. This demonstrated

that It Can Be Done! Then I made the fatal mistake of stirring it with

the tongs. This mixed the oxide into the liquid aluminum and everything

turned into mush that wouldn't run or pour. (Oxides melt at much higher

temperatures than pure metal.)

When I went to

cast the prop on December 3rd, at the last moment I decided it should

be pure aluminum - wasn't zinc used as sacrificial anode? Why would I

think it would last in salt water? I pulled the zinc out of the thin

bottom stainless steel pot on the large stove burner before any melted,

and put in only aluminum - drill shavings and some fat chunks. It did

eventually melt the aluminum. But between the thin shavings of aluminum

(I had thought they'd disappear into the zinc) and I kept taking the

lid off the pot to check it, it ended up with more oxidized slag than

aluminum. Some bright aluminum was melted and would run across the

bottom of the pot under the slag if it was tipped. This demonstrated

that It Can Be Done! Then I made the fatal mistake of stirring it with

the tongs. This mixed the oxide into the liquid aluminum and everything

turned into mush that wouldn't run or pour. (Oxides melt at much higher

temperatures than pure metal.)

I'll try melting

aluminum on an

electric stove again. Next time I'll pay

attention to the following points:

1. Use a big stove burner rather than a small one.

2. Use a flat bottom stainless steel pot with a lid that fits well. The

lid is all the more important as the aluminum is spread in a shallow

layer over a broad area, and thus is quite subject to oxidation.

3. Don't open the lid any more than necessary. It lets in oxygen as

well as letting heat escape. It'll probably take at least 1/2 or 3/4 of

an hour to

melt say 200 grams of aluminum, so frequent checks are pointless. (The

1500 watt mini-kiln takes an hour or more.)

4. Use big chunks of aluminum (eg, 1/4" or thicker pieces) rather than

drill shavings or thin sheet metal. The thin pieces end up mostly as

oxidized slag.

5. Don't put in borax flux. It's commonly used, but it seemed just to

be trouble both on the stove and in the kiln.

6. Put the mold close by on the stovetop, perhaps on another burner.

Lay out metal - perhaps cake pans or cookie sheets, anywhere the pot of

melted aluminum passes over. Be very careful. Always wear safety

glasses. A full face shield and leather gloves are better when you lift

the pot. Watch out your pot and lid handles aren't getting burned or

melted - especially, you wouldn't want to drop the pot. I'd much rather

do all this outdoors, but that's not where the stove is. The hotplate I

bought for that purpose

doesn't get hot enough. I don't think it has the 1000 watts it says on

it - seems more like 600 or 700. It was good for burning off some smoky

oils (or ?) on the aluminum outdoors before

bringing the pot into the kitchen, but that's all.

L: Removed top "cope" part of mold. (The little vent hole to the right

didn't flood with aluminum no matter how much I poured on.)

R: Breaking away the sand/clay mix

Prop freed of sand.

I poured in aluminum (melted in the kiln), to the extent

of making a big puddle of it on top. None came up out of the tiny air

vent where I expected it to. I

had an experienced friend over, who arrived just in time for the

pouring, who had a couple of misgivings about my mold and technique.

The bottom, the outer end of the blade,

filled nicely but seemed rather rough, and the tip (bottom) was quite

rough. The upper zone didn't fill completely and had some hollows and

gaps. It didn't appear to be appreciably smaller than the original part.

We discussed the probable reasons for this and what to do about them:

1. The roughness at the bottom was probably from pulling the prop out

essentially sideways to the surface. This may have roughened the sand

surface, and bits of sand probably fell into the bottom, explaining

some bottom voids. And I may not have tamped down the sand sufficiently

to press it well enough. (I did want to be able to pull out the blade!)

Other than to change the orientation of the mold entirely, I could try

oiling or greasing the surface of the prop so it (hopefully) slips out

with less disturbance, and tamping harder.

2. This is guessing... With the tiny air vent, made by strategically

poking in a wire, the aluminum quickly froze around the vent and

prevented air from coming out. This caused the aluminum to build up air

pressure and stop filling the upper area, causing the voids.

3. The aluminum may not have been hot enough, causing premature

freezing. But I'm not convinced this was the problem since I poured a

good puddle on top, and the aluminum in the crucible was still liquid

as I set it down, and after a few moments, thinking the pottery

crucible might crack from temperature strain (not to mention the wet

grass, soon burning), picked it up again with the tongs and put it back

into the kiln.

4. (I thought of this

afterwards) These factors didn't seem to completely explain it. It

wouldn't do to pour too slowly and have aluminum touching the wet clay

freezing up faster than the pouring, but think I poured too fast, and

aluminum slopped up into the air vent (and froze) before it should have

reached that height. I was surprised how fast the mold was full.

In fact, the cast blade weighed 76 grams and the puddle on top was 111

grams. The crucible full of melted chunks could easily have cast all

three blades for a prop.

5. I should have built up more of a

"funnel" in the sand at the top while forming the mold, so that the

puddle of aluminum would have more height to exert more pressure in the

top part of the mold. This is indeed the part that was full of gaps.

6. Once the prop (and a plastic funnel) were removed prior to casting,

I should have avoided disturbing the sand, as grains would tumble into

the mold. I might even turn the bottom half upside down to dump out any

loose grains.

These improvements I'll soon be trying and I'm optimistic

I can make a good propeller(s). I've thought of casting the entire prop

in one piece, but I'm not very confident about getting good results

from such a complex shape, so I think I'll stick to casting separate

blades and hub. As a bonus, the pitch will be adjustable.

I'll make a

hub with a 14mm hole and shear pin slot to fit my Honda outboard. When

I get some motor in that, I can test times, amperages and speeds

between

the shallow pitch prop, the steeper pitch prop, and this new propeller,

perhaps on a couple of different size boats. (Or maybe I can give it to

someone else to try out while I make molds to make the "mini-electric

hubcap" motor and do one to put in the Honda. Or make a whole "Mushroom

Outboard". Hmm!)

Notwithstanding that it doesn't look usable, I roughly sanded and

polished up my first ever metal casting.

CNC Farming Machine Project

A first thought for the

faming machine was to involve someone else, who has more experience

than me in both CNC and farming. He seemed less enthused than I

expected and had other ideas, citing the high cost of mechanical parts

for such an undertaking. But we might still accomplish some things

together.

The second thought was that I should do a small unit and

test things out on my own garden. And then, that an 18' wooden

extension

ladder section might make an admirable 'bridge' or gantry to go over

the

garden: Build a strong double "roof truss" shape out of more pieces of

wood. Screw it all to the inside of the rails, leaving the rails and

outside clear for the wheels

of the carriage (made of 3D printed plastic?).

This makes for a carriage that can roll from one side to

the other, with wheels on top and underneath the track so it can't come

off or tip. That should be sturdy

enough to hold a rototiller and run it back and forth through the soil.

I have two cordless lawnmowers someone gave me, and in fact three such

24 volt motors. These and optical position sensing devices might be

used in place of stepper motors for motive power. Other details are

more vague.

For rails, I considered that one could screw angle iron to

4x4 wooden beams as rails, similar to my sawmill rails, which use angle

iron and aluminum 3" x 3" tubes. (or even use my sawmill rails... hmm!)

I bought 2 wheels that run on angle iron edges. (The other side gets

plain wheels that run on the wood: only one side guides. Otherwise the

slightest misalignments between rails would cause trouble.)

This is another project for which I think flat drive belts

(with barrel shaped pulleys) would be ideal. They would have to be made

in custom lengths far longer than typical pre-made belts from a store.

This is really a traditional situation where flat belts would be chosen.

I'm trying to decide whether the gantry should operate at

a fixed height with the tools moving up and down, or should itself be

able to raise and lower. A low profile would be best for the stresses

of plowing, rototilling or raking, but passing over tall corn, or a few

other things, needs a lot of clearance... Okay, I think I just decided

the gantry needs the "Z" axis. A stepper motor at each end driving an

identical screw (like the Reprap 3D printer's Z axis) is probably a

simpler arrangement than linking two raise/lower screws mechanically

over such a long distance.

(My sawmill does 4 screws with bicycle gears and chain.) No lawnmower

motor for "Z"!

12 Volt Solid State Refrigerator Project

>It's Colder than I Thought!

The Peltier element fridge cools better than it seemed.

Belatedly

comparing the convenient multimeter probe I've been using all along, I

find its readings are too high. In a typical location it said 7º,

but two

regular thermometers in the same place said 4º and 4-1/2º.

Near the

top, it said 9 and the thermometers both said 6. Duh!

At the

floor near the ice tray, it apparently hovered

around 1 or 2. This seemed to be more in line with expectations

considering the nearby ice tray and the 3" foam insulation. Then I got

some more thermometers and started dipping them in the tray of ice and

water to calibrate them. It turned out the truth was somewhere in the

middle, about 1.5 or 2 degrees colder than the meter's reading. But

it's the difference between being nervous that things might spoil and

reasonable confidence.

It just goes to

show you shouldn't believe everything you read without verifying it,

even if it didn't come

from mainstream media. The floor near the ice tray is typically 2.5 or

3º to

4º.

Operation

I'm finding the fridge needs to run about 11 or 12 hours a

day.

Less and the ice completely melts and temperatures start to rise.

Otherwise, since the cooling is accomplished by an ice tray that's

always about 0ºc, the temperature is pretty constant, varying only

by a degree or so.

I still need to make

the smart solar control and the drain funnel for under the ice tray. I

now have what's needed and just need time to get to these details.

Use

With temperatures

inside now seeming to me to be just cold enough, I started using the

fridge for some day to day things. I put things most likely to spoil

near the ice tray end where it's coldest. Lettuce at the other end.

It's unexpectedly nice to

use. The

light 3" foam lid opens with a touch, and you can lean it open against

the wall if desired. After you lower it part way you just drop it. It

closes itself with a 'poof' of air cushion just before it hits.

Everything is very accessible

just as I'd envisioned. Since you're not reaching behind things to get

other things, the time the lid is open is usually very brief, with

little heat gain. And the cold air doesn't dive out the bottom when it

is open like with a front door fridge.

I think it's just as well I went for the simple single

hinged lid and didn't bother with multiple sections or compartment

drawers. They'd really have been superfluous as well as a nuisance.

Commercial Aerogel - Home Made Aerogel?

Aerogel at R10 is the best thermal insulation besides a

vacuum. But it hasn't been available. Now it comes in flexible matt

rolls

and in small strips for facing 2x4s in house walls, to reduce heat loss

through the wood itself. The structure of these products is to have

some

sort of solid or flexible web for strength (think perhaps of green

nylon pot scouring pads), and then fill in the space with highly

insulating but flimsy aerogel. The strips are costly; I didn't enquire

about the rolls and have apparently lost both URLs.

Then I got yet another link, to how to make aerogel: http://www.aerogel.org/?p=990

.

I don't think I'm about to follow up on aerogel insulation

myself at this point,

but it sounds exciting. An R20 fridge with 2" walls would be more

compact yet better insulated than R15 with 3" polystyrene foam. Or

larger inside with the same exterior

dimensions, eg 5.7 cubic feet instead of 4.125. A 4 or 5 amp peltier

element could replace

my ~7.2 amp one or it could run fewer hours during the day, reducing

electrical consumption.

Large NiMH Batteries - Take 3

The first basic type of large NiMH

battery, of necessity built up from small dry cells owing to

suppression

of the large sizes by corrupt interests, was soldered together cells

placed in plastic food containers. In cars, the solder joins tended to

eventually vibrate apart. The second design was to put them end to end

in PVC 1.25" (for D cells) irrigation system pipes. These work very

well, but are needlessly bulky and the sizes are often inconvenient.

The third

major variation is to 3D print custom ABS plastic cases to fit 10 D

cells (12V) in

minimal space. This of course is only possible now

that I have a 3D printer.

I

decided to design the NiMH 12V D cells battery case

while I waited for another hour long printout. Hah! With all the

various intricate little desired features, it took the whole day. Then

it took the better part of an hour for Pronterface to make the g-code

file. Then it took 5 hours to print just one.

I

decided to design the NiMH 12V D cells battery case

while I waited for another hour long printout. Hah! With all the

various intricate little desired features, it took the whole day. Then

it took the better part of an hour for Pronterface to make the g-code

file. Then it took 5 hours to print just one.

In fact, the base layer alone took almost an hour.

Printing directly on the

glass is done very slowly in order that traces don't curl up as they

print. Since

for this object the base layers covering the entire area only make for

a solid side wall and aren't needed structurally, it would seem

reasonable to use a solid piece of plastic and glue the complex part of

the frame to it, to cut an hour off the printing time. Furthermore, the

corners warped up as it printed. If there was no bottom, might I hope

for less of that?

But it looked nice as one solid part. The top will be flat

plastic. It seemed obvious that it should be simply cut from a flat

piece. But to get the holes for the screws lined up by hand looked

tricky. It would be slow, but easier, to print even the flat tops!

...or maybe just make one flat top to use as a drill template.

I

misjudged or mismeasured the

first one - it was 3mm too

short to hold two cells in series. The other dimensions and sizes were

perfect. Nevertheless, I found and scribbled out a half page of small

changes and

fixes. When I printed the second one, I tried stuffing some pieces of

cardboard around the partly printed object, hoping if it was kept

warmer with insulation it would warp less. A hot wire touched another

when I touched a wrong place with the cardboard. The printer instantly

stopped and started smoking. I pulled the plug. Enough of the holder

was printed to try it out and even to use it, as seen here. It seemed

only the thermistor

sensing the extruder temperature was fried, and a wire going to it, but

the printer was out of action until another could be found.

I

misjudged or mismeasured the

first one - it was 3mm too

short to hold two cells in series. The other dimensions and sizes were

perfect. Nevertheless, I found and scribbled out a half page of small

changes and

fixes. When I printed the second one, I tried stuffing some pieces of

cardboard around the partly printed object, hoping if it was kept

warmer with insulation it would warp less. A hot wire touched another

when I touched a wrong place with the cardboard. The printer instantly

stopped and started smoking. I pulled the plug. Enough of the holder

was printed to try it out and even to use it, as seen here. It seemed

only the thermistor

sensing the extruder temperature was fried, and a wire going to it, but

the printer was out of action until another could be found.

Then I read the the way to reduce or prevent warping is to

cool the bed temperature. But I've found that the white ABS

plastic,

specifically, has a tendency to break loose from the glass except at

the

highest bed temperatures. Next time I'll use another color for anything

large. Or PLA plastic. I ordered 6Kg of PLA plastic.

I'll try such battery holder design variations as mentioned when the

printer is running again.

Turquoise Battery Project

An Iron Electrode - Ni-Fe

I decided to try and

make an electrode this month after having printed several porous

plastic electrode pockets on the new 3D printer last month. I bonded a

porous plastic electrode plate cover to a solid ABS back piece to form

a plate with 4 porous ABS plastic electrode pockets, about 57 x 15 x

2.4 mm, porous only on one side. I cut out a flat copper

foil current

collector and fitted it in.

Nickel-iron

batteries keep coming up in discussions, and I decided to make an iron

electrode. I

thought of SAFT's making of highly conductive sintered copper-iron

'negodes' in the 1950s, as mentioned in Alkaline Storage Batteries.

I

didn't

have

any

fine

copper

powder,

but

I

had

monel

powder:

nickel

and

copper

alloy.

Both

elements are compatible with an iron

electrode, having lower reaction voltages.

Then again, I thought, why not make a nickel negode with

the monel

mix that I started with in 2008? To 30 grams of the monel mix I added

15g of

graphite powder to make it more conductive (15-20 ohm readings), and I

stuffed

it into the electrode, ramming it in with a little piece of plastic to

compact it. When

it was full I glued a printed plastic cover over the top. There was a

bit of a crack over each pocket, but I didn't think much about it.

The plan was simply to use it with a couple of Changhong

nickel hydroxide 'posode' plates in their NiFe cell case. It should be

1.21

volts open circuit. (= +.49 - -.72) I put it all together and filled

it.

It started out at .6 volts, but charged steadily. However, it didn't

pause long around 1.2 volts but continued up to 1.5 and started

bubbling audibly. Performance was poor and short lived. When I

disassembled the cell, I found that much of the substance of the

electrode had been percolated out of the little cracks at the top by

the bubbles. And a little powder had apparently also made it through

the perforations in the face of the pocket. Maybe I should have used a

little coarse iron oxide powder and made an iron electrode, after all.

Being stubborn, I tried again with the monel mix. This

time, I used

(nickel plated) expanded copper mesh for the current collector and

acryllic plastic for the back of the pocket plate. The powder inside

could now be seen through the back. I filled the pockets with powder,

ramming it in as

best I could, and it looked good through the plexi.

This time, I got out some

silicone RTV cement and caulked

the top shut. Now the only way out for the powder was through the

perforations or to burst something. In assembling the cell, I put a

piece of Arches 90# watercolor paper in front of the porous side -

between

it and the metal positive plate facing it.

To make a long story short, it was another failure. And on

disassembly, I found that the silicone had turned to gooey mush in the

potassium hydroxide solution.

Only later did I remember that metallic nickel is the one

metal that simply

won't oxidize in pH 14 alkaline solution, so the monel was never going

to work at that pH. Duh!

Installing with paper and plastic spacer,

with the Changhong nickel 'posodes'.

This time I went with 25g of the grainy

or 'sandy' Fe3O4 'black iron oxide' powder [pottery supply], 10g of

pure

monel powder

(not the mix) [micronmetals.com] - this time just to improve the

conductivity of the iron - and

.35g of Sb2S3 [american pyro supply]. Adding a bit of water I mixed and

pressed these together

in a press, dried the flat (but not very coherent if touched) 'cake',

then I torched it with a small propane torch for about 10 seconds to

sinter the powders together. (On the next one I torched it too long,

and there was a large patch of reddishness that would have been iron

oxidized to Fe2O3 - rust. This won't charge because it's an electrical

insulator.) Then I scraped the material (loose powder

again with a few crumbly clumps) into a small plastic container.

Resistance measurements were in

the megohms. That didn't seem very encouraging, but it wasn't open

circuit and I decided to try it anyway. (In fact, it worked better than

the original Fe 'trodes.) I wondered if the hydrogen

bubbling in the last two was caused by the graphite and didn't want to

add any this time.

I mixed in a few drops of sunlight dishsoap and water and

mixed again, then used it to refill the first electrode (which had been

removed and easily emptied by running water through it). It took

virtually all the material with hardly a gram left over.

This time, I sealed the top with sticky casting wax. Later

inspection showed this to be intact. Again

I used the art paper to mask the pocket perforations.

I calculated that

25g of Fe2O3 should have about 17 amp-hours. It turned out to be more

like .2 amp-hours - 1% utilization. This would be owing to the coarse

particle size having far less surface area for the volume than a

nano-powder.

After an hour to soak I

started charging slowly at 40mA. Since .04 * 24 = .96, that meant that

the number of days it took to charge was virtually the number of

amp-hours it had. It didn't take a day.

Yet it was soon evident that this electrode was working

better

than the previous attempts, as the voltage rise was gradual. At first,

it only

wanted to put 1/2V, 1/2A into a 1 ohm load. After a couple of hours,

that was up to 3/4 and it dropped much more slowly with the discharge.

Charging voltage rose from about 1.30V to 1.33V in that time, and the

rise or drop as the charge was put on or removed decreased from 50mV to

25mV: the resistance was dropping as the monel, somewhat oxidized by

the torching, charged back to metallic form.

But when the voltage hit 1.5 before bedtime (after 5

hours), I got nervous and took it off charge for the night. In the

morning it was 1.25 volts. I tried a load test. It put out over a volt

into a 10 ohm load (>100mA) for nearly 1/2 an hour and looked like

it would continue for hours at very gradually decreasing voltage just

under a volt. But I wanted to charge it further, not discharge it.

Probably 1.5 volts was a fine charging voltage since the theoretical

Ni-Fe is 1.43. The antimony sulfide should prevent

hydrogen gassing below maybe 1.7 volts. So I put it back on charge,

this time at 90mA until it got back up to 1.5V.

Towards the end of the day after 16 hours of charging, the

charge voltage was up to 1.6, and it would deliver over .9 amps for a

bit into 1 ohm, and almost 3 amps if momentarily short circuited. With

the

effective electrode surface/interface area being about 5.2 x 5.5 cm or

28.6 sq.cm, that was 31 mA/sq.cm current density for the 1 ohm load or

around 100 for the short. Scaled for 1/6 the interface surface area,

the short

circuit figure is better and the resistive load similar to an original

Changhong Ni-Fe cell. In evauating this, we must take into acoount that

the

electrodes are about 2mm thick instead of 1, with a current collector

of smooth, solid copper foil at the back rather than a mesh or with

holes or

coarseness to increase its surface area contact with the electrode

substance, and that it has quite low amp-hours capacity. Thus its

current performance seems considerably better than the original iron

electrodes.

I left it on charge overnight and in the morning I ran a

load test. For 1.5 hours it had a 10 ohm load. It ran most of that time

from about 1.1 volts down to .9 volts. I decreased the load to 20 ohms

and ran it another hour, after which it was again under .9 volts.

Doubtless it would have run somewhat longer at still lower voltages or

lighter loads. It was

working, but it didn't seem notably good or practical. But late in the

evening, after hours of recharging, I tried again (10 Ω) and it ran

over 1/2 hour above 1.3 volts/130mA. This was into real, practical

battery territory, and much better than the first discharge where it

sank under 1.3 volts before 2 minutes were up. It probably probably

shows why flooded batteries get cycled a few times when they're first

made.

I consider it's probably worth trying a straight monel

nickel negode again in a lower pH electrolyte just to prove it works.

Of course, the voltage will only be about -.65 volts at pH 12. If the

one I still have still doesn't work, I may try one with the pure stuff

and no graphite, and

torched to oxidize some and to fuse particles into larger

agglomerations. (With maybe a little nanocrystalline nickel oxide or

'fluffy' nickel hydroxide thrown in to up the surface area per volume.)

Nickel-iron batteries are known for their long cycle life, yet Fe3O4

gradually gets converted to Fe2O3 and the capacity gradually decreases

once there's less iron capacity than NiOOH capacity. Nickel may be .2

volts lower than iron, but it's more conductive - especially as monel

with its copper - so it loses less voltage under load. So the

difference may be less in practice than in theory. Plus the reactions

are reversable even if overdischarged, so it has indefinite life span

without loss of capacity. Still further, it's more dense than the Fe3O4

and so a lot of monel fits into a small electrode, making lots of

amp-hours in a small space.

All this wasn't getting my Mn-Mn chemie going, but it was

a simple way to assemble and test the plastic electrode construction on

single

electrodes, while trying out the copper and stibnite improvements for

Ni-Fe that nobody else was doing, just to prove the

point.

I learned the

need to seal the entire pocket plate very carefully and figured out to

seal the

top with wax but not with RTV silicone. In fact, I started to think

about new electrode and cell construction ideas and techniques.

I also used it as an opportunity to shoot some video about

battery making. Doing a video is something of a project in iteslf, but

it should really bring it to life for a lot of people who want to make