Turquoise

Energy Ltd. News #59

Victoria BC

Copyright 2013 Craig Carmichael - January 4th, 2013

www.TurquoiseEnergy.com

= www.ElectricHubcap.com

= www.ElectricWeel.com = www.MushroomOutboard.com

Features: New: The Mini Electric Hubcap

Motor

(see "Motor Systems")

Month In Brief

(Project Summaries... and little things not warranting separate

report headings)

- Mini motor, bike rim motor, 3D printing, battery construction, Simple

Ocean

Wave Power!

5 Years In Review (Miscellaneous

topics

and editorial comments)

- 5 years of green energy projects - The coming New Epoch.

Electric Hubcap Motor Systems

* New 6 coils "Mini Electric Hubcap" motor: 24V, 3KW,

0-3000 RPM, 9" O.D. x 4", ~17 pounds.

* Ceramic "Cup Magnets": Cheaper strong motor magnets?, Magnets for

bike "wheel arc" motors?

* Start of arc motor for bicycle

Planetary Gear Torque Converter &

Ultra-Efficient Vehicle Transmission

Project

* Torque Tests (Electric Hubcap is about 1.5 foot-pounds per 10 Amps.)

- Divide by Zero Error?

* An ideal flat drive belt?: Polypropylene or Nylon

Strapping

* Clutch system for Sprint: idler/belt tension wheel (of cast

aluminum), clutch pedal...

Turquoise Battery Project

* Conductive Porous pocket electrode plates

* Filler/airlock cap & complete Mn-Fe test cell

No Project Reports on: DSSC

solar cells, LED Lighting, Pulsejet steel

plate cutter, Magnetic Heat Pumping, Magnetic Motion Machine, Large

format NiMH batteries - take 3, Mushroom Outboard, CNC Farming Machine

(but see 'month in

brief'), Superinsulated 12VDC Peltier element fridge (finished except

for smart solar control... and stocked with food). In future 'Electric

Weel'

motor will be covered in "Electric Hubcap Motor Systems"

Newsletters

Index/Highlights: http://www.TurquoiseEnergy.com/news/index.html

Construction Manuals and information:

-

Electric Hubcap Motor - Turquoise Motor

Controller - 36 Volt Electric

Fan-Heater

- Nanocrystalline glaze to enhance Solar

Cell performance - Ersatz 'powder coating' home process for

protecting/painting metal

Products Catalog:

- Electric Hubcap Motor Kit

- Sodium Sulfate - Lead-Acid battery longevity/renewal

- NiMH Handy Battery Sticks, Dry Cells

- LED Light Fixtures

Motor Building

Workshops

...all at: http://www.TurquoiseEnergy.com/

(orders: e-mail craig@saers.com)

December in Brief

Christmas season occupied a notable fraction of the month.

Still, a new second type of motor, the "Mini Electric Hubcap", is well

under way and a few other things are inching ahead.

Electric Hubcap & Torque

Converter Torque Test

I ran some tests on the PGTC on the bench the 10th. To my

satisfaction, these happened to disclose that the Electric Hubcap motor

was putting out about 10 foot-pounds of torque for an input of maybe

60-70 amps, or 1.4 to 1.7 foot-pounds per 10 amps. Previously I'd been

guessing it was around 1 per 10.

The converter, however, only put out about 10 foot-pounds

with the slipping pulley system. In fact, it did better with about 22

from the locked rotor of the motor pulsed to full power. (This figure

divided by the gear ratio of about 2.2 to 1 gave the 10 for the motor.)

This seemed to fly in the face of the theory of operation

of the converter. I wondered if maybe great ratios were useless if the

car was stopped, since one was dividing by zero. It might work as

expected

once in motion - but it had to get into motion first. The way to do

that seemed to be the flat belt drive with an idler wheel to apply

tension to the belt: ie, with a clutch. I made the idler wheel and

bought a clutch pedal, but have not yet installed either.

Rim-Arc Bicycle Motor; small Electric Hubcap Motor

I decided that if I wasn't going to make the "Mini

Electric Hubcap" motor or the bicycle rim

motor

right away, I'd at least get all the parts lined up. Since I already

had a

steel wheel ring, coils, motor controllers, magnet sensors and

connectors, what was missing (besides minor hardware bits) that I'd

have to purchase boiled down to appropriate magnets. (Missing

components that I'll have to make: mold for arc stator, appropriate

shape magnet sensor board, various mountings and fittings.) It would

take

quite a few magnets to go around the big ring, which was 21.6875" O.D.

and 19" I.D., with the median circumference of the ring thus being

63.7".

After some figuring, 16 magnets would be just under 4"

apart. Since two magnet poles span 3 phases, that would mean the coils

would be 2.65" apart. 2"x1" magnets give the most bang for the buck,

but it's 1/2" of room for the usual 1/2" thickness is cutting the space

too fine. 3/8" should make it as long as the wheel is adjusted

properly, so 2" x 1" x 3/8" magnets. To ensure the coils don't hit the

magnets, I could put in a bearing that would ride on the ring or on the

wheel rim if the coils would otherwise contact.

Then I discovered ceramic "cup magnets" while I was on the

site. The 2.6" diameter ones might work out well for the bicycle wheels

for 1/2 the price of neos, and they'd be easier to use and mount. There

were also 2" cup magnets, and I thought they might be

good for Electric Hubcap motors. The motor might have a plastic rotor

instead of steel, since the cup magnets are already in steel cups that

complete their magnetic circuit without external steel.

I also decided that I would do the smaller 24V, 2.5 to 3

KW, 3000 RPM

"Mini Electric Hubcap" motor and I proceeded ordering parts for both

ideas. That

would make a motor that would fit in the Honda outboard leg, and I'm

pretty sure others will have many good uses for them as well. It's an

especially useful size and voltage for

marine transport that I suspect isn't

commonly found. It could also be used as a 12 steps per rotation

stepper motor for the CNC farming machine, with enough power to till

the soil.

After receiving most of the parts, I decided not to wait

for spring after all. I

made molds and drill jigs and made two complete "Mini Electric Hubcap"

motor bodies. I would have completed and tried out one, but I didn't

yet have the bearings (just one sample), and the waterjet place hadn't

yet cut my 7.5" steel magnet rotors. I also have yet to make a magnet

sensor board.

"Mini Electric Hubcap" BLDC motor test fit

24 V, 127 A = 3 KW, 9" O.D. x 4", 0-3000 RPM

I started in on the bike wheel too. I didn't use the steel

ring and supermagnets. Instead I used the 2.6" cup magnets behind a

1/8" lexan sheet, to be attached with recessed flat heat bolts. If the

coils touched the wheel on bumps or from bad adjustment, they'd contact

the smooth lexan sheet instead of a row of lumpy magnets.

A unique feature of this motor is six unipolar permanent

magnets. Since the cup magnets are (mostly) all polarized in the same

direction, and since spoke spacings on the wheel proved contrary, the

south poles are skipped. This would appear to require optical rotation

sensors instead of magnet polarity switches. I tried several

arrangements with various problems, and I ended up with one with just 6

magnets, all of one polarity, and the 6 coils at 20º spacings. I

hope it provides enough torque not to need revisions.

Magnet ring and coils for 27"x1.25" bike wheel - will probably fit many

bike wheels.

The coils will mount in an arc shaped housing with an indent for the

bike frame in the middle.

On the 12th the awaited thermistors came and I fixed the

3D printer the next day. Attempts to print things didn't go well. The

PLA plastic is easier to work with than ABS, melting at a lower

temperature, and I broke open my shipment of it, which I'd simply

placed in its carton in the closet. It didn't seem to print well, and

suddenly suspicious I found that all 6 spools were ABS instead of PLA.

I probably went to the wrong page when I ordered. The pictures of

spools of plastic look alike, and late in the evening one familiar TLA*

looks much the

same as another.

The ABS, D cell battery cases kept on warping. They'll

probably work in PLA. And trying to print porous battery electrode

pockets with smaller pores was making non-porous surfaces instead. Then

I thought I'd try a NiMH battery case with no bottom. If that

worked without warping, I'd glue a piece of stock ABS onto the bottom,

and it would cut an hour off the print time anyway. It didn't work. It

warped and the whole piece came loose from the bed while printing.

I decided the cases would have to wait for PLA plastic,

and it didn't arrive by month's end. The conductive ABS clogged up the

print head, and I decided I'd have to really want it before I'd use it

again. A new reason I would really want it: Hey! it's carbon fiber!

That makes it strong, desirable material for mechanical parts such as

gears and flat belt pulleys.

* TLA: Three Letter Acronym

CNC Gardening/Farming Machine

The CNC farming machine continues to evolve in my head.

Using polypropylene strapping as flat drive belts makes extremely long

drive belts seem feasible. In addition to providing a secure position

reference to the control computer, this would potentially allow the

main gantry moving motor(s) to mount in a fixed location at one end of

the

track, and the carriage moving motor to be fixed on the gantry instead

of placing it on the carriage, reducing the extent of long, flexing

wiring.

The "Mini Electric Hubcap" BLDC motor (or even the big

one) could be used as a

very large stepper motor. The magnet position sensors provide for exact

stepping to desired position, and at over 3 HP it has the power to plow

or till a field. The fact that it's 3 phase with 12 steps per rotation

can be accommodated in the hardware and software drivers. That should

beat the

cordless 1/3(?) HP brushed lawnmower motors all to pieces.

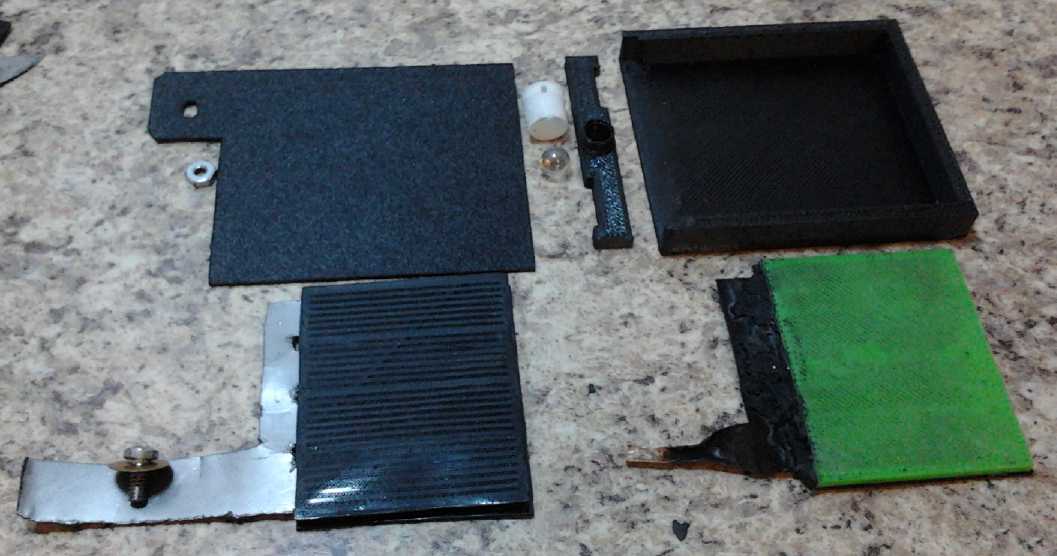

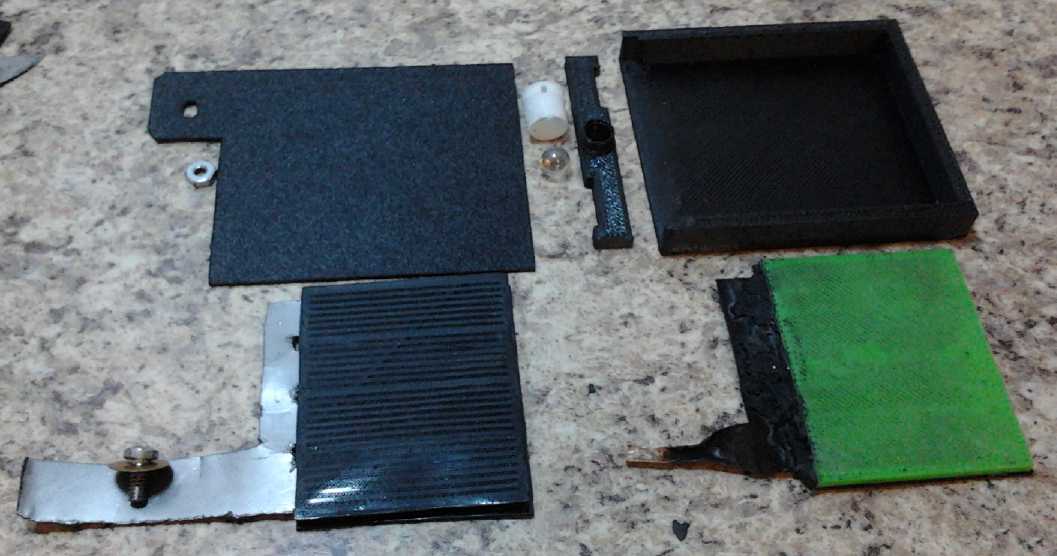

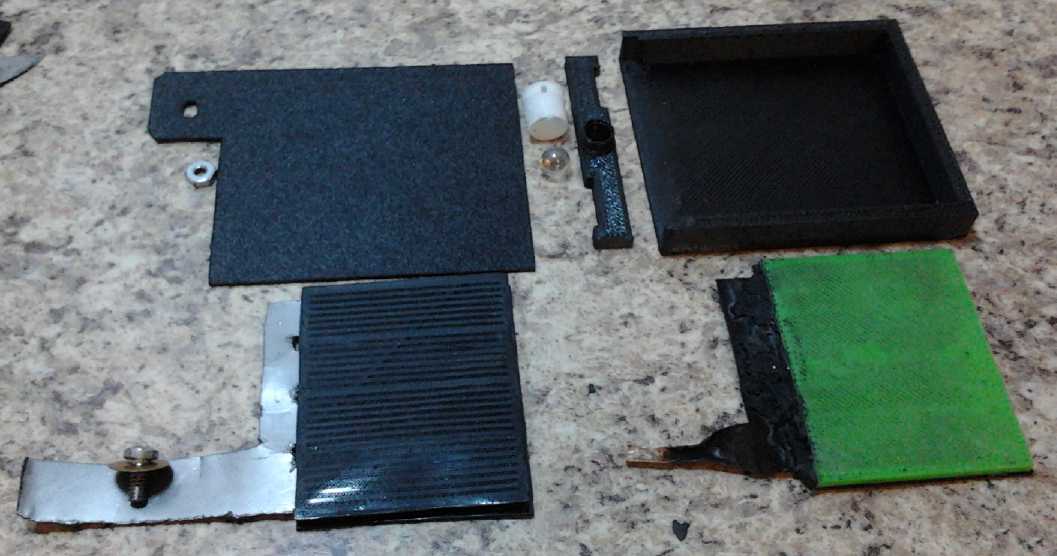

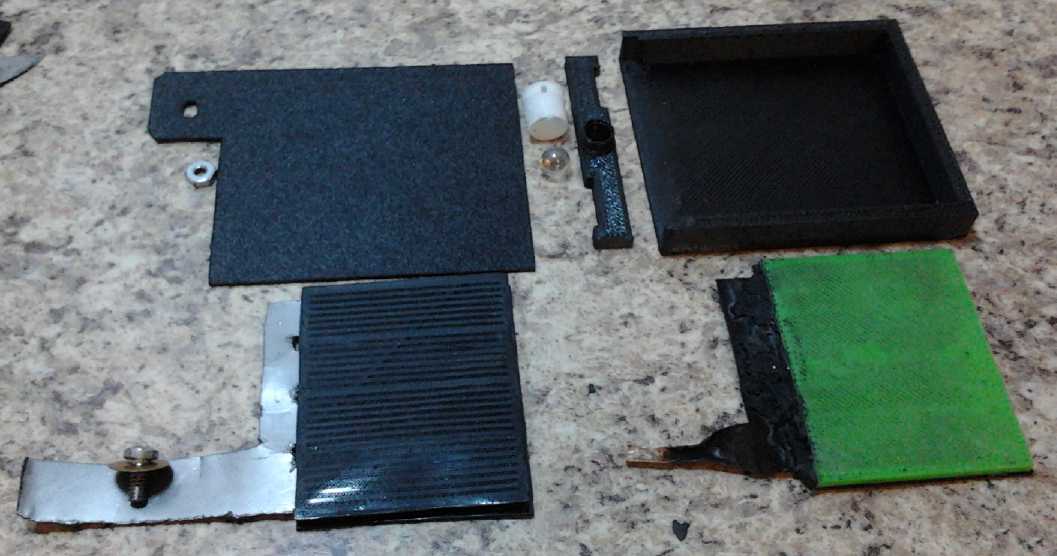

Battery Construction

After printing some conductive porous pocket plates, and

then some filler/airlock battery caps and finding some glass balls to

be the airlocks, I printed some parts and made a test cell. It's

getting close to a design or two that can be produced, perhaps

relatively easily. The

test cell has started with the Fe negode from last month, and a new Mn

(permanganate) posode. But the Mn electrode has low conductivity (not

enough graphite!) and will be improved or exchanged for another, and

then other minus sides - Zn and Mn - will be tried with a working plus.

(I'll probably also try a vanadium pentoxide posode with a Mn minus for

a lark sometime, to see a cell that should be well over 2.5 volts.)

The components of the battery cell.

The working battery.

Since this one is for testing electrodes, I didn't glue the top on, or

seal the terminals with heat glue.

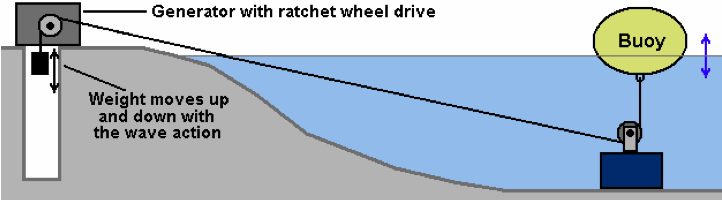

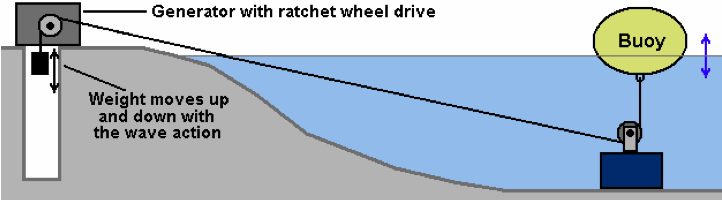

Simple! Ocean Wave Power Device

A friend sent me a link to a web/PDF book on free energy

devices: http://www.free-energy-info.co.uk/

. After Christmas I had a brief look. It has a wide variety of

interesting devices

including magnetic and coil energy machines, but one that struck me

almost instantly was

a simple device for extracting ocean wave power:

At a glance the diagram looks "Mickey Mouse" - a toy for a

theoretical demo. But the simplicity is pure genius! Each feature is

the essence of the matter boiled down to the simplest and most

effective form. First and foremost, a lightweight buoy with a concrete

anchor, pulley and rope are

the only pieces in

the corrosive salt water environment. (There would be a pulley on a

swivel at both ends of course.) Simple, robust parts can more easily be

designed

to withstand storms than more complex things. A foam filled float that

will submerge without lifting its anchor is hardly going to be damaged

by surging waves. The rest of the structure is on solid ground - and

thus isn't rocking adversely in the same waves the power capture float

is in. This makes for the best leverage on the waves.

Next, something has to

run from the device in the water to shore, and rope is cheap

compared to heavy wire cable, especially that made for sub-sea use.

Thus floats can be placed in deeper water farther from shore without

much extra cost. Waves have more power in deeper water before they

incur bottom friction. And they're 'more solid' in the deep before they

start to break.

Third, forget the hole in the ground: the shore

installation would be a tall, enclosed structure. (at least one tall

pole is

needed for the high voltage lines leading away anyway.) The weights

would have a

long range over which they could rise and fall from the overhead drive

shaft to the ground, so tides would be no problem. In fact, differing

tide levels will even out the back and forth pulley wear over different

parts of the rope.

Finally, the entire system uses just one large generator

and one-way "transmission" that ties

it to all the floats. Instead of a unit associated with each float,

there's just one large mechanism to be mounted, wired and

maintained. This is a huge economy. (Note: The 'ratchet drives' shaft

will have to be

considerably geared up to turn a generator at speeds it'll make power

at. It might well take a two-stage increase. Here again the nearly 99%

efficient flat belt drive with plastic pulleys would doubtless make the

best speed converter with the least friction.)

Naturally one would employ a set of floats offset

diagonally from each other and at different distances out to sea,

spanning at least a typical wave length, so that the drive shaft is

being continually driven by fresh waves. A flywheel could help smooth

out

bumps. The maximum power harnessed depends on the volume of the

flotation and the weight of the hanging weights. One person says

sizing the components to resonate with the typical wave frequency will

increase power gained. (I'm somewhat skeptical that the effect will be

pronounced owing to the damping caused by extracting the power, but

even a few percent improvement is an improvement.) My own improvement

idea would be what I've proposed before: longer, thinner, shallower

floats - oval shaped pipes perhaps - that would line up with the waves

to

optimally catch the topmost crests of the most linear meters of

wavefront. (Think of the buoy in

the diagram as being the cross section of a piece of pipe maybe 3 or 4

times as long as the width.)

Any system has its disadvantages as well as advantages.

The ropes would be going back and forth (well) overhead across the

beach instead of having buried electrical cables, and the tall base

structure wouldn't be intrinsically attractive except in the eyes of

the builders. (If the cables are too low overhead at the bottom of the

beach, an

additional tower will be needed down there to raise them, or the main

tower could be placed there.) But most any wave power system is going

to have some basic similarities -

floating components to transfer the power of the waves to a mechanical

or hydraulic system, some sort of shore installation, and power lines

heading for the grid somewhere.

I would think such simple installations could be created

for a

small fraction of the cost of either hydro dams or wind power, and

could indeed satisfy the bulk of our energy needs here

on Vancouver Island. A test installation should surely be tried out.

I'm not favorably situated to attempt the experiment.

5 Years In Review

Incidental news, editorial opinions

When I decided in

January 2008 to try to put a motor or motors on one or more wheels in

my car and make homemade batteries to run them, I little dreamed that 5

years later I still wouldn't have electrically hybridized cars on the

street and still wouldn't be producing batteries. No doubt it's just as

well we don't know such things in advance, or it would be very tempting

never to attempt them. However, ignoring or pushing aside good ideas

isn't the path to progress.

The 36V, 4.6 KW

motors and controllers have evolved into very good equipment, and I've

started a new smaller size 24 volt, 3KW motor that should be running

pretty soon and should prove useful for various applications.

The 2 volt Mn-Mn moderately alkaline battery chemistry has

been proven this year, and just as importantly, means for producing

working battery cells are finally being created, with parts made by 3D

printer such as

airlock caps playing a leading role. Along the way I

discovered sodium sulfate is a good renewer for supposedly 'spent'

lead-acid batteries, that 3 or more banks of 10 Ni-MH D cells make

fabulous, long life car starter batteries, and I devised several ways

to mount these D cells to make them into practical 12 volt batteries.

The fact that a motor that would fit on a wheel couldn't

have both enough torque to get a car moving and reasonable RPM at

highway speeds led to the variable torque converter project, which,

even up until now with the very promising planetary gear torque

converter system, has been the main hold up to getting

'ultra-efficient'

electric car drives onto the street for 3-1/2 years.

And a number of 'incidental' projects have been

undertaken. Some are more along the lines of research, such as the

paramagnetic coil coatings, nanocrystalline titanium dioxide

borosilicate glass to improve solar collector efficiency, and

experiments with diverse magnetic machine ideas besides regular motors,

including magnetic variable torque converters, magnetic "free energy"

designs, magnetic spacecraft propulsion and magnetic heat pumping.

Others projects are more of the nature of applying proven ideas to

development of novel new products, such as the low voltage solar energy

wiring and applicances (12 volt LED lights, 12 volt solid state

refrigerator, CAT standard 12 volt plugs & sockets...), various

applications for the motors and controllers, and the new Peltier

element heat pump. It was discovering the fabulous energy saving

potential of LED lighting that also got me started on installing a

solar PV system and trying to create better parts and equipment for

doing so.

2012 has seen a great increase in the variety of projects,

branching out from the electric transport and battery storage ideas

into other newly developing areas of energy production, conversion and

consumption.

At the start of 2008 I had just four projects: the wave

power machine, a car wheel motor, a motor controller for that, and to

make some sort of battery. I abandoned the wave power early on (which

is well since I've just run across a much better design), leaving just

the three related to electric transport.

A big reason progress is so slow on each of my projects

now is that I now have over a dozen "active" projects.

Of 30

days in a month, I try to do other things Sundays, and there are days

when various things just need attending. Shopping for various often

obscure parts and supplies for each project occupies considerable time.

Then I spend considerable time writing these

newsletters to pass on whatever value and inspiration my ideas and work

may have for others. This not only

takes time but also leads to dangerous new thoughts resulting in more

projects and sub-projects related to a main project... like magnet

machines... solar installations and low voltage

wiring... solid state fridges... light rail vehicles... and CNC

gardening machines.

So for actual work, that leaves maybe a day or a day and a half per

project per month, on average. Sometimes no matter what I'm doing, I

feel like I'm shirking something else. But it's not possible to work on

two things at once, and lately I've grown able to put that feeling

aside and concentrate on whatever I'm doing, without asking myself if

it's the best thing I could be doing once I've chosen something.

I'd like to target specific things and finish

them, but so

many projects seem so valuable or seem to have such technological or

commercial potential that it's hard to let anything lapse for too long.

While the value of putting an ultra-efficient electric car

or (especially) hybrid on the street to show the way can hardly be

overestimated, I

suspect that the best markets for small scale production are really

marine,

and gardening

and farming, rather

than things for cars and solar home equipment. But batteries have

rather universal application, and electric bikes appear to be rising in

popularity. This says that the

Mini Electric Hubcap motor,

the Mushroom Outboard and the CNC Farming Machine are probably the

things

to concentrate on. Then if I'm

making money,

perhaps I can

hire people to work on some of the other things. But naturally I want

to get the Sprint car

going and

do the solar DC wiring in my house, and the CAT plugs and sockets are

about ready to sell - after some more "beta testing", which ties into

my DC house wiring... when I find some time to continue it!

End of the Age - More on Banking

As time passes, I'm becoming aware that the

world is changing forever, at a rapidly accelerating pace. We have

arrived at the end of an age

and are poised at the start of the next. The transition will be

attended by fierce storms and upheavals, manmade and natural, some of

which are already starting to break. The "status quo" attempt to

maintain their positions while a few of the most powerful reprobates,

having attained the choice positions of economic and political power,

seek to enslave the whole of humanity and to destroy vast numbers of

people. Much of humanity sits about, oblivious - and many are deceived

by clever manipulations, or are even deprived of their health and

clearheaded thinking by the heinous food and drug poisons being foisted

on us by the

corrupt. But others in growing numbers are starting to perceive how

misled and enslaved we've been for so long, and are surging forward to

change the ways the world works. And some of the corrupted are

considering their value systems and changing their minds. These new

energies, coming up against the

lingering but ensconced contrary forces of opposition to change, are

bound to brew great storms.

When I started my green energy projects in 2006 with ocean

wave power, I knew little of all the adverse forces hiding in the

background

of what

I'd been taught was an orderly and well run society. But manipulations

that

have pulled the wool over peoples' eyes and been forgotten in past

times are becoming

obvious and persistent on the internet. It seemed things were

dysfunctional, but I

didn't really understand that individuals in strong positions actively

and effectively worked to prevent progress. By the time I'd got very

far on

the car

hybridizing as perhaps one of Canada's most accomplished inventors, and

even my member of parliament could find me no workable

funding source or program, I began to understand that no specific

useful help would be available from any quarter of the 'mainstream'

socio-economic-political system regardless of anything I accomplished

or proved - and that it was best to stay off the radar screens of the

wrong people.

But this long protracted situation is changing. No one

will take unhealthy notice of a new electric car system when big

automakers are themselves starting to make electric cars, and I should

think that what I'm doing is going to fit right in to the beginnings of

the new economy that will inevitably take shape when the storm clouds

lift.

As an addendum to last month's "American financial

history" mostly from the

early 1800's, I've found out a few more things. President John Adams

had a similar view to Jefferson and to Jackson, that there were two

ways to conquer a people: with armies or with debt. And I saw on

youtube that the bankers in Europe were horrified by Jackson's

nationalizing the printing of money, because they couldn't control it

and charge interest on it. And, that in 1906-07 the bankers

orchestrated a financial crisis, and it was this that led to the

"solution" that they proposed and that was adopted, the US federal

reserve act of 1913. Woodrow Wilson, after much political pressure,

signed it

in spite of evidently recognizing that it was a death warrant for

national liberty. Apparently he didn't have Jackson's fortitude. It

took 80 years, but the bankers got their way again. Since then, somehow

this pyramid scheme "financial system" has been forced on the whole

world - and sucked in the national wealth of many nations.

In the USA, congressman Ron Paul has been warning for over

a decade about the housing bubble that was being built up, the housing

bubble collapse, and the coming collapse of America and its "almighty

buck". He was laughed at and paid no more attention than Winston

Churchill during the 1930's, when he repeatedly warned parliament that

unless prudent

action was taken in good time, Germany was going to start another world

war.

The system almost

collapsed in 2008, and a worldwide collapse seems inevitable, most

likely this year, with far reaching consequences... including

freeing humanity from the clutches of all the dying, corrupt

institutions it fostered. That will prepare the way for the new age, to

be built on sustainable foundations.

"But you should be wise regarding the ripening of an age; you

should be

alert to discern the signs of the times. You know when the fig tree

shows its tender branches and puts forth its leaves that summer is

near. Likewise, when the world has passed through the long winter of

material-mindedness and you discern the coming of the spiritual

springtime

of a new dispensation,

should you know that the summertime of a new visitation draws near." -

Jesus

Electric

Hubcap Motor Systems

Mini-Electric Hubcap Motors

Along with rim-arc motors for bicycles, I decided to

proceed with 6 coil regular round "Mini" motors as an expansion of the

Electric Hubcap product line next spring and summer. I first decided to

order

parts to have them on hand for later... but when I'd collected enough I

decided

to start now and not wait for spring.

The Mini Hubcap uses a nominal 24 volts instead of 36, and

6 of the

same coils instead of 9, and the same motor controller with the same

nominal 127 amps max,

making it 3 KW. (Or it could be made 36V, 83A.) RPM is nominally 0-3000

instead of 0-2000.

Electromagnetically considered they are thus identical, with linear

magnet speeds similar to the existing Electric Hubcap motors. Barring

some novel manifestation of Murphy's law, there's no reason to think

they won't work flawlessly and virtually the same except for the RPM

range, at 2/3 the voltage (or 2/3 the current - and hence 2/3 the power

either way), which can only be

easier on the motor controllers.

Dimensions

are 9.25" O.D. and

about 4" long, with 7.5" rotors having 4 magnet poles (with eight

1"x2"x.375" magnets NNSSNNSS). I picked 7/8" shaft size as being

sufficient but not needlessly heavy (based simply on shaft sizes of

other multi-horsepower motors I'm familiar with), and I found nice

flange bearings

for that size at Princess Auto, which seemed to simplify the question

of how to

mount bearings and incidentally of how to adjust the shaft position and

the magnet gap: It can be done from the outside with the motor

assembled, with clamping pieces that come with the bearings. The

bearings in these flanges seem too wide to be roller bearings - they're

probably a better type, ie, roller or needle bearings. That's good

since

this isn't just some 1/4 horse motor.

A 24 volt supply is very attractive for battery

applications. It's definitely not going to electrocute anyone, and two

batteries (with two 12V chargers) makes the system an easy initial

hookup and capital outlay to get started and test.

I bought a length of 4140 HTSR (relatively hard tool

steel, heat treated, stress relieved) 7/8" machine shaft at Metal

Supermarket, and a lighter taper lock coupling than SD ("HX") at

Princess Auto. I took the plan and the HX

bushing to Island Waterjet to have the rotors cut. At the same time, by

planning in advance, motor face mounting flanges will be easily cut

from the pieces left over, as the outside curve of the rotor is also

the

ideal inside curve of the flange.

I ordered a batch of slightly thinner supermagnets, 1" x

2" x .375" instead of 1" x 2" x .5". I've long suspected those will

work just as well, with a slightly smaller magnetic gap and a thinner

rotor (.25"), and will make the motors about 1/4" thinner overall, or

even

5/16". At any rate, I was sure they were good enough for the bicycle

and smaller motors, and I suspect they'd be better for the big "Weel"

motor too, assuming I get back to that sometime. (I may also have some

new ideas for making the Weel's stator body in arc-pieces when I've

done a rim-arc bike motor or two. I'm increasingly apprehensive about

the plywood stator, which has no coil button moldings, which is one

reason I haven't gone any further on putting it together.)

While on the site, I looked around and found some ceramic

"cup magnets". The 2.6" diameter cup magnets had a listed pull of 50

pounds, which was far more than non-cupped ceramic magnets and only 10

pounds less than the supermagnets, and they were 1/2 the price. They

seemed like a good size for the bicycle wheel motors as they'd just fit

between the spokes. 2" diameter ones had 40 pounds of pull, which,

while quite a reduction from about 70 pounds with my usual 1" x 2" x

.5" supermagnets, still seemed like enough to make a good motor from

(with a thinner magnet gap) if the depth of field isn't ridiculously

thin.

A rotor might be made of cup magnets sandwiched between

two sheets of lexan instead of steel, which would make the motor both

lighter and cheaper to make.

Mini Electric Hubcap motor body parts mold - ready to stuff.

The C-clamped mold pressed the PP cloth and epoxy together while the

epoxy sets.

Here it's just come out of the oven, ready to release the new part.

On the 15th I

routered out a mold base with the CNC

drill-router, then a top. Everything considered, it seemed that the one

mold was good enough for all three flat body pieces. The only notable

oddity would be having coil buttons on the rotor cover. I might even

minimize them by filling the button holes with... something.

On the 15th I

routered out a mold base with the CNC

drill-router, then a top. Everything considered, it seemed that the one

mold was good enough for all three flat body pieces. The only notable

oddity would be having coil buttons on the rotor cover. I might even

minimize them by filling the button holes with... something.

The same evening I did up the main g-code sequence for the

hole drilling template. Naturally, since I was using the same coils and

basic design, I was able to borrow heavily from the original Electric

Hubcap

motor spreadsheet and G-code design files.

Finally, before I went to bed I cast the first body piece.

I used 65g of polypropylene ("landscaping") cloth and 240g of epoxy

resin. I

departed from my usual technique when I found I had poured too much of

the resin too early and didn't have enough left for the remaining

cloth. So I kneaded it by hand. This mixing led to better overall

wetting of the fabric than I usually got, and tangled all the ripped up

scraps of cloth together better, which could only make the piece

stronger. The

result was good. I had vinyl one-use gloves this time, and unlike latex

they held together well in the gooey epoxy. The next morning I did

another one. They were both

hard to remove from the mold - then I remembered I usually wax the

molds. The next one I waxed... and then decided that having clean,

unwaxy parts was better than ease of removal.

I decided taller buttons would be better - the coil bolts

would screw into more thickness of plastic and hence be less likely to

strip. It's a bit of a conundrum that nuts up there would stick up into

the rotor compartment, or if flathead bolts put in from that side came

loose, they'd stick up, and either way, the metal would hit the rotor

magnets and chew things up as they spun by. So only the plastic is

available to screw into.

But once a part is removed from the CNC

machine, that's usually it - they can't be properly lined up again. But

I remembered that when I did the top mold, I had moved the "home"

position of the machine exactly .10" to the left, and it had finished

in home position... so this could be reversed and the previous 'home'

for the base mold regained. Then, if the mold was screwed back

down in the same screw holes, it should be in exactly the same position

it was before. I

decided to gamble on it. The buttons went from just 1/8" deep to 5/16",

and the position turned out to be only about .01 or .02" off.

I cast the third flat piece, and the coils pushed on with,

to say the least, no play to spare, since the buttons, already

carefully sized, were now just that bit bigger.

By the end of the 16th, just two days into the project,

the body assembly only needed the rotor rim... perhaps that could be

done without a mold, or with just a disk mold piece on the inside? Then

I thought to just staple a piece of polyethylene into the shape of a

ring the correct diameter - the body piece would keep it round.

What else? The hole template wasn't made and the body

holes drilled. How to mount the bearings was unclear after it was found

the flanges wouldn't fit, the rotors were still waiting for Victoria

Waterjet to cut them, and a magnet sensor board needed to be designed.

What else? The hole template wasn't made and the body

holes drilled. How to mount the bearings was unclear after it was found

the flanges wouldn't fit, the rotors were still waiting for Victoria

Waterjet to cut them, and a magnet sensor board needed to be designed.

On the 17th I made the trek to Princess Auto and found

7/8" "pressed bearings". The pressed pieces fit the same better

type of bearings as the flanges. But there was only one in the store,

and when I asked I was told they

had been discontinued. I got the one to test fit, and wrote down the

number stamped on it (NBR, PF205) so I could order more via the web. I

was very lucky they had that the one left for me to see,

as it was the

only type I found that looked at all suitable, and I might not have

realized its suitability from a picture. It appeared about as

perfect for the job as anything likely to be found. Bad news for the

day was that the rotors wouldn't be cut until after Christmas - the

waterjet was cutting 3" and 1.5" thick steel, a big job that was

understandably proceeding painfully slowly. (I should have finished

that pulsejet steel plate cutter so as not to be dependent on another

shop's schedule.)

I made the drill jig. One set of 6 coil bolt holes was in

the wrong

place. Since I hadn't moved anything yet, I simply corrected the

program and redrilled. The extra holes can be ignored. Then I drilled

the holes in the

stator pieces. I then used a large drill bit to gouge out dips in the

body

where the inner wire end passed across the coil to get out. It's the

one annoying bit of wire that doesn't fit within the 1.0" height

of the coils because it has to cross over the rest. This arrangement

seemed satisfactory - better than making "foothills" around the coils

buttons on the outer side and

making the whole motor wider by one wire diameter, as per a recent mold

for the larger motor.

Being "on a roll" but unable to continue on the first Mini

Electric Hubcap motor without having all the parts, on the 20th and

21st I

molded the body for a second one. When I get the parts, that'll be one

for testing and one for the Honda outboard. Counting up time spent for

each ring, it seems to take 1/4 hour to rip up the fabric, 1/2 an hour

to mix epoxy, put in and jumble up the epoxy and cloth, clamp down the

mold, and get it in the oven to warm and set the epoxy. Then another

1/4 hour after it's set to get it out and trim it. Somehow that adds up

to 1/2 a day.

The rotor rim is a longer job that's done in two parts.

First two layers of the 3" wide outside fabric are painted with epoxy

and wrapped around the

center ring. (Evidently this 3" strapping is nylon, not polypropylene,

but it seems to work fine.) An inner circular form is used to hold the

shape, and the top of the mold is used underneath This extends down to

cover and protect part of the stator. (A good slot remains for

ventilation.) When it's hard, 1.5" wide PP strapping is painted with

epoxy and wound inside in the rotor compartment until a thickness of

about .5" is reached, which is 7 or 8 layers. Again an inner form is

used, this time pressing it outwards against the outer wall. This time

the mold top is placed over the top to form an exact circle of the

correct diameter.

The rotor end bell bolts go right through the thick wall

to the nuts on the stator side. This leaves the rotor compartment free

of obstructions, and with a very thick outer wall. With the potential

of rotor magnets flying off like bullets, this is necessary for

safety.

The body parts for two "Mini Electric Hubcap" motors,

one set drilled and painted with urethane, the other as cast.

On the 23rd I found a store on line that offered the

pressed bearings and I ordered 9 more, enough for 5 motors total. In

the last days of the month I slapped a few coats of polyurethane paint

on one set of body parts. On the 28th I got some 1/8" "starboard",

black HDPE, with which to form better centers to wrap the strapping

around.

Fit of the coils

Checking the fits... all seems in order.

This is pretty much what it should look like when it's finished.

Cheaper Magnets?

I've been figuring for some time that the 1"x2"x.5"

supermagnets are probably thicker than what's really needed, and I

ordered some 1"x2"x.375" ones this time instead.

And in exploring the feasibility of using electric hubcap

motor coils to make a rim motor for bikes, where the coils only extend

in an arc on the upper side of the wheel but magnets go all the way

around the big bike wheel (18 for my bicycle - and that's leaving

every second space empty), the problem of cost of

supermagnets arose. They've come down substantially after their huge

jump in spring 2011, but are still by no means low cost. I found some

ceramic cup

magnets that seemed to have considerable strength on the active face,

and cost 1/2 as much as the smaller supermagnets:

Ceramic cup magnets are widely used in

industrial

applications such as fastening, holding, hanging or retrieving objects,

etc.

Ceramic Cup Magnets Size: 2.6"

Diameter x 0.37" thick with 0.23" hole

Magnet: Ceramic magnet ring

Cup Coating: Nickel

Magnetized through thickness, poles on the flat surface

Holding power: 50 lbs

Then I started considering whether this sort of magnet might also be

used inside regular Electric Hubcap type motors, and I ordered some

that could possibly replace them to try out. 8 slightly smaller ones

would just fit on the 7.5" "mini" Hubcap rotor and have good force.

Ceramic Cup Magnets Size: 2"

Diameter x 0.3" thick with 0.26" hole (OD 51.5 mm x ID 6.5mm x 7.7 mm)

Magnet: C8 Ceramic magnet ring

Cup Coating: Nickel

BrMax: 3850 gauss

Magnetized through thickness, poles on the flat surface

Holding power: 40 lbs

Note: holding power should be tested for your

specific application

I got 20 large for the bicycle wheel and 10 small for the

small

version Electric Hubcap. I was told they all come glued in with the

same polarity. I hoped I could unglue and

reverse 1/2 of them without breaking more than two of each. There was

also a 3" size and some smaller ones, but the sizes didn't seem as well

suited to 2" coil cores or the spaces available to put them.

When the magnets arrived, after finding the polarity on

most of the magnet was indeed the same (except that the smaller were

the reverse of the larger), I found out by a nasty surprise that four

of the larger magnets did have opposite polarity. Two that should have

repelled snapped together with enough force to give me a considerable

blood blister on a finger that was in the way. Don't believe everything

people tell you! I was being rather casual because they were "only"

ceramic magnets, not supermagnets.

The depth of field is certainly less than with the

supermagnets - the force decreases more rapidly with distance. This is

partly because they're weaker, and partly because they're also thinner.

The choice of sizes is quite limited. A smaller flux gap will help, but

the maximum torque of a motor using them will doubtless be lower. If

Victoria Waterjet doesn't have my steel rotors done soon the first

'mini' motor may have a lexan rotor with cup magnets.

Bike Arc Motors - a Start

On the 24th, I changed the ancient tire and tube on the

back wheel of my bicycle (making it actually fit to ride again

for the first time in some years) and layed out the 2.6" cup magnets to

check the fit. It appeared that if the magnets were placed at about

18-3/8" center diameter, every second magnet would just touch the spoke

ahead and the one behind. So I planned to mount them behind a lexan

ring of about 21.5" O.D. and 15.25" I.D, leaving a ~1/4" margin inside

and outside the magnets.

Spokes are a subject of special interest with hub motors -

often regular spokes wear out and break rather quickly, and thicker

spokes are desirable. The forces operate over the length of the spokes.

With this motor, the forces act out near the rim, which is what is

being driven. Obviously if they were at the rim or virtually there,

there should be no extra forces on the spokes. But pushing sideways in

the middle area just might be worst of all. How they'll hold out I

won't try to guess. The more even the forces the better, and I'll do

what I can to connect the lexan ring to each spoke on its side of the

wheel. If it's a serious problem, I might look for a way to attach it

to all the spokes, or more directly to the rim. For now, I may print

some special spoke-slot clips to screw the lexan securely onto the 18

spokes on its side.

9 N and 9 S magnets didn't leave enough space for the coils, so they

had to be spread out.

Even with interleaving the two sets of 3 by reversal of polarity on one

set, it occupied more of the rim than I'd hoped.

Then I tried a different arrangement of 9 unipolar magnets, but the

coil spacing didn't change much.

It still stretched way back past the supporting frame, and I wasn't

keen on having a coil under a strut where it might not have room to

adjust properly.

I ended up with this arrangement of just 6 unipolar magnets, which

spacing resulted in the coil arrangement I wanted.

The question now is, will so few magnets so far apart have enough

magnetism to provide sufficient torque?

On the 21st, someone phoned about the Hubcap motors. He

hopes to convert a minivan with a blown engine, and has bigger plans

too.

Of course I had to say that while the motors and controllers are

operational, I still haven't created a successful variable transmission

and got a car going. Evidently he has considerable mechanical

experience and that didn't seem to phase him.

Planetary Gear Torque Converter (PGTC) Project

Toyota Prius Planetary Gear 'Torque

Converter'

Someone gave me this great

link to an interactive animation of how the Toyota Prius's "Power Split

Device", a sort of planetary gear torque converter that combines two

drive inputs with a third on the drive shaft. http://eahart.com/prius/psd/

Applying the animation to the PGTC is a little tricky. The

Electric Hubcap motor is in the position of "MG1" (sun gear), which

unfortunately

can't be moved directly. "ICE" is the amount of slip on the planets

assembly, governed by the slip-clutch-rope-pulley assembly. "MG2" is

the output drive shaft. Move "MG2" to -2 MPH (-130 RPM), and with no

slip (ICE=0), the motor (MG1) is doing 338 RPM. The slip ("ICE") can

only

be set either to 0 or above the top of the red line to 998 RPM (call it

1000). There, the motor ("MG1") is doing 3930 RPM to go that speed,

instead of 338. There's a reduction of almost 12 to 1 from the motor to

the output shaft.

This is actually a pretty high RPM for 2 MPH. The 130 RPM

of MG2 versus the car speed indicates that there's around a 4 or 5 to 1

gear reduction from MG2 to around 28 RPM on the wheels, depending on

the wheel diameter. So the total reduction is 338/28=12 to 1 with no

slip, or 3930/28=140 to 1 with 1000 RPM slip on the planets assembly.

Double the slip to 2000 and the motor will be at its maximum RPM

without hitting 2 MPH.

There's how it's supposed to work.

I also looked up some variable transmissions on youtube.

One called the "D" drive had a number of gears including planetary

gears, but I wasn't entirely convinced it did essentially more than my

PGTC, with a lot of extra complexity. On the other hand, my system

too appears to need a little more complexity to make it work as planned.

How not to test - Torque tested: yuk!

I (finally!) took the unit apart and restored the 4 to 1

chain drive for the time being. It took all of an hour. Then I thought

about putting the torque wrench on the converter output shaft. Then I

thought, "Why am I taking this thing out to the car and trying to move

the car at all, without knowing in advance how much torque it has? I

can simply C-clamp it to the bench and see what it puts out with the

torque wrench. If it doesn't have about 30 or more foot pounds to give

at least 120 at the wheels, there's little point installing it in the

car."

I guess when I started I had high hopes, and the obvious

thing was to connect the transmission to the gear shift lever to

tension the rope. Then I found I could tension it by hand at the unit,

but I just kept taking it out to the car and installing it to try out

each modification, repeating the pattern without thought.

So when I got the unit reassembled with the chain drive

(needlessly) reinstalled, I set it up on the bench. Even with all the

improvements, the PGTC didn't have 30 foot-pounds: it had 9 or 10

maximum. If I clamped the pulley for zero slip, the stalled motor gave

it about 22 foot-pounds, pulsed with what was probably 60 or 70 amps

for a second

or so. (With the planetary gear ratio being about 2.2 to 1, this

indicates about 10 foot pounds from the motor - somewhere around 1.4 to

1.7 foot-pounds per 10 amps. This is actually higher that the 1

foot-pound per 10 amps I had estimated. It shows the value of

definitive spec testing... that hasn't been attempted since early

prototype

motors and even then was never complete.)

What kind of a torque converter is putting out less torque

than the straight gear ratio? Do I have the whole theory all mixed up

in my head? Is this really better than the magnetic converter idea? At

least that one could conceivably be built up to quite high

torques

with enough magnets and copper.

Could it be a case of reduction "ratios" being somewhat

meaningless

when dividing by zero? - the whole operation doesn't work with the

wheels

stopped? Or from another viewpoint, power = torque * speed, and speed

was zero. Evidently lugging the motor more and more heavily with the

slip pulley

only reduced the motor speed.

I take some heart in the fact that on the occasion in

September when I got the car moving while standing at the hood, once it

started moving, it seemed to surge ahead unexpectedly strongly. At that

moment, I was sure I had it. In that case, how would I get the output

shaft turning before the car starts moving? This is starting to feel

like that old "catch 22" problem - you can get it moving if it's moving.

Final Drives: Flat Belt (99% efficiency)... and Clutch?

If the torque

converter doesn't work until everything is turning, perhaps what's

needed is a clutch? If the shaft has lots of torque once it's rotating,

it'll

definitely work - and even an idling speed gas

engine creating little torque will

start a car moving if the clutch is engaged slowly enough. It's

another sort of gearing down. If the clutch is popped quickly, even an

engine considerably revved up may stall.

So a second thought

was to put a clutch on the flat belt drive, using a loose drive belt

and

a roller that comes in from the side to put pressure on the belt to

gradually engage it. Of course it's a whole new complication to the

system and for the driver... but not ridiculously difficult or complex.

It might "do the trick".

(Another way to do the clutch could be to move one of the

two pulleys in and out to loosen or tighten the belt, with no 'idler'

pulley at all. This could be pretty easily arranged on my unit except

that the motor shaft wouldn't move with the output drive shaft, causing

misalignment in the planetary gear. Oh well!)

I did do a bit of experimenting with letting the belt slip

last month. But tho it tracked well if it didn't slip, it would run off

the side of the lower pulley if it did. It would seem the idler pulley

had best have side walls, and it might need another guide on the other

side, too. Come to think of it, it may need an idler wheel on

each side - for forward and reverse.

Another thing... if the PGTC output shaft has to be

turning to work, I can't use the torque wrench on it. I can only test

it by installing it in the car and seeing what happens... just like the

previous tests up to now. ...unless I can find things that fit in the

spline shaft sockets of the differential, lock one side, and connect

the other to the torque wrench.

I found this info about flat

belts. (I omit "irrelevant" sections. URL: http://machinedesign.com/BDE/mechanical/bdemech1/bdemech1_11.html

)

Flat belts

Recent developments

in flat-belt technology have overcome their previous drawbacks of high

tension and mistracking. New designs and advances in materials have

made both low and high-power transmission practical and cost efficient,

and at speeds that usually exceed other belt designs.

Higher power flat belts.

Developments here include sticky yet abrasion-resistant rubber

compounds that eliminate the need for high tension to grip pulleys.

These materials also allow lower shaft and bearing loads to transmit

significant power. The strongest flat belts now transmit over 100

hp/in. of belt width.

Different flat belt

surface patterns serve different transmission requirements. For

example, in high-power applications and outdoor installations,

longitudinal grooves in the belt surface reduce the air cushion that

flat belts generate when they run at speed onto a pulley. An air

cushion reduces friction between pulley and belt. In addition, the

longitudinal profile nearly eliminates the effect of dirt, dust, oil,

or grease. Furthermore, the grooves reduce the noise level of an

already quiet power transmission design even more.

Perhaps the most

significant advantage of flat belts is their high efficiency -- nearly

99%; about 2.5 to 3% better than V-belts. Three factors account for the

good efficiency: lower bending losses due to the thin cross section,

low creep because of special friction covers and high modulus of

elasticity traction layers, and no wedging into pulleys like V-belts.

Without the wedging action as in V-belts, flat-belt and pulley wear is

minimal.

Flat belts offer

greater design freedom than standardized designs because they are

available in most any width and length, in increments of 1/16 in. This

means drives can be sized closer to optimum rather than the next size

larger.

Pulley alignment is

equally important to flat belts as it is to other styles. Crowning at

least one pulley, usually the larger one, improves belt tracking. Flat

belts are forgiving of misalignment; however, proper alignment improves

belt life for any drive.

And by typing enough descriptive words, I finally started

to find places selling flat belts on the web, hidden between all the

hits on "Alibaba and the 40,000 fake hits" and many kindred search

results thieves. One place will make you any length and width of

urethane flat belt, in thickness from 1/16" to 1/8": http://ebelting.com/ . But the stretch

figures seemed high, several percent, and it turned out they were only

for low power use. So far, the one I got at the car parts place is the

best. What luck it was just the length I needed!

Besides it being the most efficient, and being amenable to

clutching, another reason for the 1 to 1

flat belt drive is that the motor RPMs through the planetary gear (with

no slip) will allow highway speeds. The 4 to 1

chain drive makes a useful test, but the motor would be revving too

high at too low a speed to be practical on the street. (My original

plan was to change the chain sprocket to get 3 to 1 or less once I had

something working, and then only drive it in town.)

Polypropylene or Nylon Strapping for Flat Belts?

After I wrapped polypropylene strapping around the rotor

compartment of the new Mini Electric Hubcap motor, I occurred to me

that PP strapping would make a fantastic flat belt. It's very strong

(like the yellow PP ropes), thin and so flexible it would go around the

smallest pulley virtually without frictional loss. The ends could be

melted, glued or sewn together to make a continuous belt. It comes in

long rolls in widths of .5", .75", 1", 1.5", 2", and 3" (and probably

more sizes). The narrower sizes are under a dollar a meter. My 1" x 38"

belt for the Chev Sprint would be around 1$.

If as seems likely the plastic proves too slippery, the

belt could be sprayed

or painted with urethane or some sort of rubbery substance having more

grip. Or the pulleys could be so coated. Or both.

In combination with printed plastic pulleys, here we have

potentially

not only the most efficient possible drive system, but the cheapest and

easiest to do belts for.

Clutch Mechanism

Salmon tin casting in two pours.

I had to cut off and then cut a slit in the remaining stainless pipe to

get it out. I won't do it that way again!

On the 11th,

after deciding a clutch is probably what the

whole thing needs, I thought about the idler pulley. Could I find what

I wanted? Skeptical of that, I didn't try. Instead I cast an aluminum

pulley in a salmon tin (while I was casting an aluminum propeller

blade), and then machined it to shape on the lathe. (Much later,

someone pointed out that you can buy round aluminum stock in various

diameters.)

On the 11th,

after deciding a clutch is probably what the

whole thing needs, I thought about the idler pulley. Could I find what

I wanted? Skeptical of that, I didn't try. Instead I cast an aluminum

pulley in a salmon tin (while I was casting an aluminum propeller

blade), and then machined it to shape on the lathe. (Much later,

someone pointed out that you can buy round aluminum stock in various

diameters.)

The casting didn't go well. The aluminum didn't seem to

want to pour, and I didn't get the tin half full. So I did another

crucible of it and poured some more. It still didn't get it as full as

I wanted or expected. It's wide enough for the 20mm belt, but if I get

a

much fatter one, it's too thin. (It might manage 1" if I turn the

sidewalls really thin.) I thought the top pour would would stick to the

bottom half, but I had two

separate halves. Rather than do it over, I drilled holes and bolted

them together with flat head 1/4" bolts, recessed in for the machining.

Next time I'll use a stainless steel pot that holds more aluminum than

a small pumice pottery crucible.

It's the first aluminum thing

I've machined on a lathe, and I must say it's far easier to shape

than steel. With the thin and uneven casting, it has some defects -

pits and

voids - but it should suffice. I turned the center to fit two sealed

bearings I had in a drawer that I thought were for a 1/2" shaft, but

they turned out to be 14mm. Sigh - good luck finding metric bolts

around here! I did find some 15mm bearings with the same outer size,

which happens to fit a 5/8" bolt.

My Sprint had been an automatic. On the 12th I went out to

an auto wrecker and got a Sprint clutch pedal and cable. I

then considered that maybe the clutch could be activated by linking it

to the same lever as the PGTC slip pulley, since they did essentially

complementary things. Then I decided again to go for the pedal.

But by the end of the month I hadn't found any time to

start putting the pieces together.

Mushroom Outboard (Outboard Motor from Scratch) Project

Bottom of prop sand (& clay) casting mold

Top of mold

The second propeller

casting, trying to do two blades at once, came close to disaster. I

guess I poured the

aluminum too fast, the sand was too wet, and the air vent was too

small. It got a steam bubble and blobs of molten aluminum erupted 2 or

3 feet into the air. By some small miracle, none of them hit me or

anything important. The burned pieces of wood on the sand casting form

are a reminder. The prop itself (nothing flowed into the second

chamber) was essentially hollow.

The second propeller

casting, trying to do two blades at once, came close to disaster. I

guess I poured the

aluminum too fast, the sand was too wet, and the air vent was too

small. It got a steam bubble and blobs of molten aluminum erupted 2 or

3 feet into the air. By some small miracle, none of them hit me or

anything important. The burned pieces of wood on the sand casting form

are a reminder. The prop itself (nothing flowed into the second

chamber) was essentially hollow.

For the third casting on the 11th, I made a bigger air

vent to ensure it didn't get clogged, and I poured slowly and evenly.

This time, the result was mostly good, but the aluminum froze before

filling the thin trailing edge areas of the blade, so I must have

poured too slowly. And some lump of

sand must have fallen into the bottom because there was a large void at

the tip of the blade. (I also poured a pulley for the Sprint

transmission clutch in a salmon tin, and then switched to working on

that project.)

Breaking open the sand/bentonite clay mold.

First prop blade (lower - blackishness is polishing compound) &

third one.

Both 'close but no banana' so far.

Then I found on youtube

where someone did "lost PLA"

casting. He made the parts he wanted on his 3D printer, and used a

mixture of 50% sand and 50% plaster of paris (by weight or by volume

wasn't specified). He burned out the PLA plastic and then poured in

aluminum. The result was so good he didn't need to do any machining.

Instead of sand grain texture, the surface detail was so fine it showed

all the texture the 3D printer had put in the original plastic. Wow,

that's for me for the next try! I even have some plaster of paris.

When I have one good aluminum blade I'll probably use it

to form a

polyethylene mold to cast props in PP-epoxy. But for December, other

projects and Christmas intervened.

Turquoise Battery Project

A person who

contacted me about Hubcap motors was also interested in manufacturing

batteries. I told him about the Mn-Mn chemistry in moderately alkaline

solution. I also wrote a lengthy e-mail about battery construction to

the "Edison_NiFe_Batteries@yahoogroups.com" list in response to someone

who was trying to make a battery and had some fundamental flaws in his

design.

Few people seem to have have a good grasp of all the

essential principles of what makes a good battery, and then even those

who get it figured out need to find or create practical,

workable constructions and manufacturing techniques. And those who may

have all this don't seem to be sharing in a manner that might enlighten

most people. These hurdles have so far

stopped most everyone from making practical, marketable cells, ie

beyond experimental prototypes, and from expanding in new directions.

After starting with the common ignorance myself and having learned a

few necessary things about the subject over five years of time

consuming, hard won experience, I now hope to give others a head start.

When the printer was running again, I 3D printed a porous

electrode plate with the somewhat conductive ABS plastic. Regardless of

printer settings, I couldn't seem to make it porous. The problem with

all of them is that the first layer of plastic spreads out against the

glass and tends to join up with the bead next to it, and the carbon

fibers in the conductive type made it a little fuzzy, and the plastic

filled in everything even if printed quite thinly.

Coming back to the problem on the 23rd, I decided I should print

a first layer of vertical lines with spaces between them. The porous

front face would print on top of that. Then the 'pixels per mm' printer

setting should do a pretty good job of determining the porosity. The

exterior vertical line spaces would also be a passage for gas bubbles.

But when I went to do it I had a frustrating time. When it

was finally printing the bars, and then printing porous instead

of solid (by setting the print density from 980 down, down, down, down

to 300), the result was a globby piece instead of smooth and even, with

"pores" that were either filled in solid or gaping holes. Flexed

slightly, it started to break up. I thought I'd have to give up on the

conductive ABS, but further experiments the next day showed that a

setting of 430 gave decent results.

But again, the pores looked big enough to leak electrode

substance. Even as I worked, my thoughts drifted back to watercolor

paper or other microporous material being the right sort of consistency

for electrode separators. But if they were external to the pocket,

essentially one didn't have self contained electrodes any more. If they

were inserted inside, they'd surely be torn to mush as the electrode

substances were being compacted. That left putting the paper in its own

pocket between two porous plastic walls. In this case, the pores could

be very large, just fine enough to ensure the paper wouldn't rip during

construction. That would make the electrodes thicker and put more space

between them, increasing battery size and decreasing current capacity.

Even as I finally started getting conductive ABS

pocket plates that looked like they might be usable, I started thinking

again of abandoning the pocket electrode construction. But other types

have their own problems, and I hadn't been very successful with them so

far! In particular I have trouble making electrode briquettes that stay

together long enough to put them into a cell - that's the biggest

attraction of the pocket electrodes. Hmm... what about that stainless

steel form to feed in and compact stuff from the end with a press?

Note: Later I found that the carbon fibers of the conductive ABS had

clogged up the extruder head around the outside of the nozzle and the

teflon cone. That caused other filaments to stick to the head and ruin

each print, and it took disassembly and a considerable cleaning with

acetone, methylene chloride and several cotton 'Q-tips' to render it

useful again.

Filler/Airlock Caps

One thing needed for flooded cells regardless of inside

details is caps to fill the cell through, that will block air passage

once closed except to allow excess pressure to vent off. On the 27th

and 28th I designed and 3D printed a few attempts at making a two part

cap. I didn't however have little balls to put in them.

The base part of the bottom piece will insert and glue

into a hole in the top of the cell. A small ball is placed on this as a

sealing piece. The top piece is a friction fit over the bottom, and has

a small plastic spring to exert pressure on the ball to seal the cell

unless the pressure is too high.

I was thinking of some sort of twist lock, but the pieces

are a close fit, and they print slightly oval with forces on the

plastic. They "twist lock" together just fine without making anything

special for it.

I couldn't think of where or what I might use for sealing

balls. Ball bearings come immediately to mind, but I suspect they'd

quickly corrode and lose their seal. I'd think soft rubber ones would

be ideal, but where would they be found? More likely prospects would be

glass or plastic. I thought of some small size marbles I'd had when I

was a kid. Even those would have been larger than I wanted.

The most

likely idea my brain could come up with was Michael's Crafts store, and

I swung by there en route to a Christmas social destination. They

indeed had small (~9mm) and cheap clear glass spheres, in bags of what

looked like a couple of hundred, for flower arranging. I'd found my

marbles! The surfaces weren't however flawless, with a few pits and

indented swirl patterns on the surface visible under a magnifying

glass. I decided they'd probably be good enough if the seat was well

done and matched the lower curve of the sphere. For that job, I'd

either heat the glass sphere and drop it into place to melt into the

seat a bit, find a router, drill or sanding wheel that would make the

right shape... or perhaps best, drop the glass sphere (or still better

a smooth ball bearing the same size) into place and drip some methylene

chloride on to soften and shape the plastic.

The most

likely idea my brain could come up with was Michael's Crafts store, and

I swung by there en route to a Christmas social destination. They

indeed had small (~9mm) and cheap clear glass spheres, in bags of what

looked like a couple of hundred, for flower arranging. I'd found my

marbles! The surfaces weren't however flawless, with a few pits and

indented swirl patterns on the surface visible under a magnifying

glass. I decided they'd probably be good enough if the seat was well

done and matched the lower curve of the sphere. For that job, I'd

either heat the glass sphere and drop it into place to melt into the

seat a bit, find a router, drill or sanding wheel that would make the

right shape... or perhaps best, drop the glass sphere (or still better

a smooth ball bearing the same size) into place and drip some methylene

chloride on to soften and shape the plastic.

The ball size was larger than my larger design. In fact

the larger diameter piece seemed just about right for use as the

smaller. So the size went up again, and got too large for the planned

thickness of the top of a cell. This could be accommodated with larger

pieces but with a smaller bottom stem that fit in a workable size hole.

Then I conceived that if I changed the cell top design a bit,

permitting an upright print orientation, I could print cell tops

complete with the lower filler cap as a single piece, allowing a bigger

hole and improving the 3D build accuracy, albeit adding a bit of

sanding or filing to flatten the faces that get glued.

After making caps to fit the glass balls, I had the thought that the

lower piece of the cap could be printed as a part of the cell cap

itself. So I made that, and tried to print a complete surround. But I

had trouble and (after cleaning the extruder) I finally printed a top

piece with integrated cap piece, and a cell surround complete with one

printed

face. I cut a piece of plastic for the other face, and I used a cap top

I'd already made. I put these together with the iron electrode that

worked, and a new one with conductive ABS and flexible graphite current

collector that had yet to be filled, to make a cell.

The components of a cell.

The flimsy flexible graphite gets pressed against the tab on the face

for connection.

The copper foil will be treated similarly in future.

The top edge will be modified with thinner stops at the terminal base

slots, to stop glue from running though into the cell.

1. glue the cap on and stack the internal pieces, then glue on the

second face.

2. glue on the second face, slip the components in from the top, then

glue the top on.

The second way is great for pocket electrodes. The first

way would be used to drop in current collectors, loose electrode

briquettes and separator components, then an expanding foam, forming a

stack.

After filling, heat glue is to be used to seal around the

terminal posts. (If it reacts, it may have to be wax or something.)

Electrolyte is added, and finally the ball covers the opening and the

cap covers and holds the ball.

The cell as it will appear before heat glue seals the terminal posts.

It's getting closer to what might be considered

reproducible, but now I think once I have working electrodes, even if

they're still pocket electrodes, they'll be glued directly to the cell

walls instead of being separate internal pieces, saving 3mm thickness

and some weight. So this 15mm thick unit is still a test cell and it

gets clips to hold the top of the walls together and modeling clay

instead of heat glue around the terminals.

But I'm thinking of a new, fast way to compact briquette

electrodes from one end, probably with a screw press such as the book

press. It's going to take many cells to do a solar installation, and

hundreds to do an

electric car, and any too-tedious steps to making them are going to

make them

impractical.

Finally on

January 2nd I decided I couldn't just leave it there almost

finished. I took a concoction of 25g KMnO4, 17.5 g graphite powder, a

gram of Ne2O3 and a gram of Sunlight dishsoap (that had been sitting

open on the counter for months), and added 10 g of nickel hydroxide and

a bit more dishsoap. Then a bit of water to make it into a dryish

paste, and I stuffed about 13 grams of it into the pocket plate with

the conductive ABS. I sealed the top with wax. I had a hard time

getting the sticky casting wax to stick. Finally I found the problem

was that the bristles of the paintbrush were pretty much dissolved or

melted off in the wax.

Finally on

January 2nd I decided I couldn't just leave it there almost

finished. I took a concoction of 25g KMnO4, 17.5 g graphite powder, a

gram of Ne2O3 and a gram of Sunlight dishsoap (that had been sitting

open on the counter for months), and added 10 g of nickel hydroxide and

a bit more dishsoap. Then a bit of water to make it into a dryish

paste, and I stuffed about 13 grams of it into the pocket plate with

the conductive ABS. I sealed the top with wax. I had a hard time

getting the sticky casting wax to stick. Finally I found the problem

was that the bristles of the paintbrush were pretty much dissolved or

melted off in the wax.

In the process of handling to fill and seal the electrode

some more of the terminal and another part broke off. Much more loss of

material would have been a problem, but everything still connected.

I then assembled the cell with a piece of watercolor paper

(hopefully) blocking the entire space between the two electrodes. The

top got some duct seal. It took about 40cc of electrolyte to fill the

cell with a 6 or 8 mm reservoir above the pocket plates. The color

turned purple from the permanganate.

The cell charged up but didn't seem to have a lot of

current drive. It could drive about 50mA without excessive voltage drop

(but preferred 25mA or less), and it put less than .4V/.4A into a 1Ω

load. Since the same Fe negode sourced over an amp in the Changhong

cell, the weakness is either the electrolyte or (much more likely) the

posode. For one thing, I should have added more graphite powder when I

added the nickel hydroxide. There seems to be a sort of "critical

concentration" of conductivity additive powders, around which the

resistance drops or rises rapidly with a relatively small increase or

dilution.

When the charge is removed, the cell begins a slow but

continuing discharge from 1.7X volts with no load, to 1.2X volts

overnight. (Theoretical voltage for the cell at pH 12 looks like about

1.55 volts from the pourbaix diagrams.) Either something touches,

there's something in the electrolyte causing discharge (perhaps an

impurity from the new electrode), or there's enough air leaking in the

top to do it. Some extra modeling clay around the top seemed to help...

or was it the additional charging since the last check?

A check the next morning revealed that the pH was low,

just 8. There might perhaps be some solubles forming and causing the

trouble. It seemed I hadn't added enough calcium hydroxide, or that it

had been consumed. In addition, the purple color had vanished and the

electrolyte was clear. The water level was also low, whether from

leaking or from internal consumption I don't know, and I had to add

some.

At any rate, the cell doesn't leak and liquid isn't

wicking up and out like with previous recent cases. The design seems

quite usable and is likely to be the final form except for dimensional

adjustments for electrode sizes and thicknesses. Except for the lid

with the tricky airlock/filler cap and the slots for the terminals, the

cell could be made equally easily from flat stock plastic or by 3D