Turquoise Energy News

#6

Craig Carmichael August 4th

2008

I spent most of June working on the Electric

Hubcaptm car motor and controller, but it

was getting hot and it bounced around a lot. To my surprise making a

new "cooler" motor stator and and an improved mounting

system took most of July.

The new motor turns the car wheel, but the motor

controller needs some redesign to sync to the rotor position.

That's likely to occupy much of August.

Then I hope to give the new Ni-La (3.25v cells)

Turquoise batteriestm more attention. About

all I've done since May is acquire a couple of chemicals, added a new

"component", and done a couple of intermediate battery

chemie things. And I'm waiting for another chemical to arrive.

It occurs to me, having "wasted" June and

July, that if I just change a pulley the wave power unit's

generator will probably spin, and that summer is the best time to be

at the seashore. But I've dismounted the unit to use the trailer for

other things, and for now the car motor and batteries get

priority.

Much of my writing this month is about the motor,

with some fairly in depth (ie boring) details.

Topics Below:

Electric Hubcaptm Drive

Motor Changes - cooling & mounting mods

Revised Turquoise Motor Controller

Cross Section of the Turquoise Batterytm (as currently envisioned)

The Electric

HubcapTM Vehicle Drive Motor

I found these remarks, in harmony with what I've

been saying, on the web site of a company that makes "top end"

custom motors:

"New synchronous motor designs using

permanent magnets make it possible to have low speed and high torque

in one package, eliminating gearboxes and other mechanical

components.

"Eliminating the gearbox saves space

and installation costs, energy, and maintenance, and provides more

flexibility in production line and facility design."

Amen! Then, changing the common radial flux motor

layout to axial flux can provide these advantageous workings in just

three inches "length", thus the Electric Hubcap

design.

Motor Cooling

When I put the voltage up to 36 volts (also as much

as 36 amps - headed for two horsepower) and tested for a while, I

could smell hot polyester. It seemed evident that the motor was going

to overheat when used at full power - perhaps 60 to 72 volts - and so

I did some redesign. Not wanting the complication of a liquid cooling

system, I attacked the problem of better air cooling from every angle

and made a new motor stator.

I discarded the solid cast stator. In its place are

individual cast epoxy coils that have no more cast plastic than

necessary to "pot" the copper coil with its iron strips and

two mounting bolts, into a solid mounting piece. Each coil, exposed to

the air on all sides, bolts individually onto the steel backing plate,

which is a disk brake rotor with heat dissipation vanes.

Washers on the mounting bolts hold the coils off the

backing plate's surface for all around air exposure, while the bolts

and washers carry heat and magnetism from the coil core into the

plate.

The front of a new fairing will have an air scoop so

the moving car blows air onto the motor.

An original cooling system feature remains: the

magnets on the rotor (the car wheel) act in principle as a centrifugal

fan to blow air across the coils, although the RPM is pretty low

except on the highway to move a lot of air. The magnets are mounted on

a solid steel disk bolted to the wheel, which may be expected to carry

off any heat buildup in the magnets.

Then, the coil wires have high temperature

insulation and the epoxy castings and flat black coating have very

high temperature ratings. The stator paint is engine enamel and the

rest is copper and steel, so the coils and stator can operate at

sizzling temperatures without damage.

Finally, depending on summer driving tests, if all

these "passive" cooling features seem insufficient or

marginal, an electric cooling fan - of whatever CFM rating seems

necessary - may be mounted. It would start if the motor temperature

gets too high, much like a radiator fan, to reinforce and provide

airflow even if the car is stopped. The fan's power would be

insignificant compared to the power of the large motor it cools.

It may be that a fan will be found necessary or

desirable but runs rarely -- at least in Victoria's mild

climate.

And again, having efficient motors with no gears

means less overall power and heat, and having two motors splits the

heat there is into two halves. Overall, prospects are excellent that

the motors will run a vehicle at trouble free temperatures in most

conditions. Fans should guarantee it.

An interesting feature of the new implementation is

the individual rather "generic" bolt-on coils. In theory,

they could be plugged into similar motors of various diameters and

ratings, from about 8 to 14 inches with perhaps 6, 9, 12 or 15 coils.

They can also be replaced individually if necessary.

July 19th: New Stator with better cooling

airflow completed.

Motor Mounting

After doing my best to stiffen the stator mounting

bracket, increasing the voltage still resulted in excessive vibration,

and finally I realized it would be very difficult to make a

sufficiently strong mounting for the stator in the available space,

with all the braces having to come around from behind the wheel.

The answer dawned on me on July 23rd: a thrust

plate with ball bearings to tie the rotor and stator together at

their centers. That way, the bracket from behind only needs to hold

the stator on and keep it from spinning. It doesn't need to be super

stiff. The thrust plate keeps everything aligned and sets the

stator-rotor air gap.

That evening and the next day, I puzzled with

various bits and pieces, piecing things together and seeing various

problems. Finally, some standard steel pipe end plates, a short pipe,

and a small "lazy Susan" ball bearing plate, brought it all

together.

A running test before supper showed this "platter" had

the desired effect. There was much less vibration, even though I only

had one of the two "arms" attached and it wasn't even bolted

solidly in place.

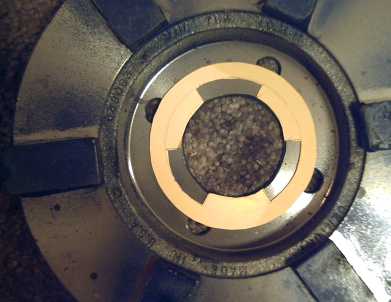

"Lazy Susan" thrust plate

assembly.

Standard pipe fittings have avoided the need

for custom machining.

The square end fits nicely between the four lug

bolts on the wheel.

Thrust plate mounted. The length of the post

was just short, and a flat 5/16" plate placed on the end provides

3/16" gap between the stator coils and rotor magnets. A large air

gap increases efficiency and keeps the magnets from gradually being

demagnetized by coil flux and stator heat.

Another Voltage Possibility

Keeping to very low, and hence relatively safe

shock-wise, voltages, is less practical but not impractical. There are

nine coils in the motor, three per phase in series. If one wired them

separately, 24 volts would provide the same current per coil as 72

volts. They would also draw three times as much total current. (1/3

volts * 3x amps = same power.) One would replace each pair of 100+

volt, 100+ amp rated MOSFETs with three pairs of 50+ volt, 100+ amp

MOSFETs, one pair driving each of the nine coils. The total would be

18 MOSFETs instead of 6, and 9 heavy wires from the controller to the

motor instead of 3. To prevent the range from being cut by 2/3, one

would use 3 sets of 24 volt batteries, either connected in parallel or

perhaps one set per each three coils of phase A, B & C.

However, it would seem easier and more economical to

carefully make the 72 volt system as safe as possible. If the power

was such that it was difficult to drive with single solid state

devices, splitting the coils up with separate drivers might make good

sense.

Electric Hubcap Motor Factoids:

* Only the car's wheel turns. The only moving part in the motor

is a thrust plate centering the stator on the wheel.

* The virtually frictionless magnetic link to the wheel magnifies

useful power by transmitting it all directly to the wheel. There's no

losses from a transmission or gears, it requires no gear shifting or

other attention by the driver, and it's virtually silent.

* Permanent magnet synchronous motors also have the highest

intrinsic efficiency of all electric motor families, further

leveraging the efficient power transfer. As a guess, one might perhaps

expect up to 50% greater range than other electric motor systems from

the same energy, and correspondingly better performance for the same

kilowatts of electricity used by the motor.

* Installation requires no connections with or changes to the

car's existing mechanical components and systems.

* When not in use, the motor has no more effect on the car than

any other 35 pounds of luggage.

* The motor sticks out just 4" from the wheel or a couple of

inches past the fender, less protrusion than the outside rear view

mirror.

* The RPM with 13 inch wheels is about 10 per one kilometer per

hour of speed, that is, 450 RPM at 45 Km/Hour. Most electric motors

prefer much higher speeds, but the "Hubcap" has good low RPM

torque and power. 120 Km/hour is just 1200 RPM, a stately pace for

most electric motors but a good upper range for the

"Hubcap".

* The rotor is a 10 inch steel disk brake disk mounted on the

wheel lug bolts, 6 poles using 6, 12 or 18, .5" x 1" x 2"

NIB supermagnets, glued and-or bolted on.

* The stator is a similar 10 inch brake disk (but with cooling

vanes), with 9 epoxy cast coils bolted to it, each of 60 turns of #14

wire, in 3 phase "Y" configuration. Magnetic flux is

axial.

* A unique design breakthrough is that the stator coil iron is

strips of regular nail gun finishing nails in the coil cores instead

of custom die cut iron laminate sheets. With this and no axle or other

moving parts, the motor is simple enough to make at home, or the coils

could be wound by machine and cast, for super economical mass

production. Individual coils can be easily replaced.

* The motors dissipate their waste heat via air cooling, avoiding

the complexity of liquid cooling systems. There's maximal coil air

exposure and heat sinking with the magnets blowing air in front of

them, an air scoop on the front of the fairing and air guide vanes,

plus a temperature actuated electric fan in case all else is

insufficient at low motor RPMs that don't move much air and high power

(eg, climbing hills and mountains).

Turquoise Motor

Controller

I've been pleased that the solid state motor

controller with the high power MOSFETs actually drives the motor and

nothing blows up until I do something wrong. It's only been tested up

to 36 volts so far, but this testing has shown that lower voltages

should be used - perhaps 60 to 72 volts instead of 120 - so 36 volts

is actually at least half way (and 1/4+ of full power). Though heavier

wires are required for the same power, this allows choosing 100 volt,

120 amp MOSFET transistors, more economical than the 200 volt, 65 amp

parts. Bonus: the lower voltage is less likely to electrocute anyone,

though anything over about 40-50(?) volts or so must still be treated

as potentially dangerous.

However, I've finally realized that the "lumpy"

torque that leads to some of the vibration, and the "fragility"

of operation - a tendency to suddenly stall when the load gets a bit

too much - mean that the drive signals can't simply assume the motor

will synchronize to them: the driving power has to synchronze to the

actual magnet positions, somewhat like a DC motor with a

commutator.

Now that I'm addressing the issue, I see this can

actually simplify the controller circuit as the phases can be

generated simply by the optical shaft position sensors. But a slotted

disk, optical elements and additional wiring for them have to be added

to the motor itself, and the controller will of course need mods, so

the changes are likely to take up a good part of August.

Say, a cardboard cutout slotted disk should be

much easier to check for fit than a real metal one!

Will it slip on without disassembling the

thrust plate assembly?

Best to cut it so it will!

To the left: a convenient old mouse PCB with

four pairs of LED + phototransistor. This needs just three sets, one

per phase.

With the revised controller, which will have PWM

like most controllers, the gas pedal "must" (simplest) go

back from being a "speed select" pedal to a regular

"accelerator" pedal. In my view this is largely a negative

thing, but it's how we drive now anyway. And it does open the way for

a front wheel drive car to become an all wheel drive with electric

rear and gas/mechanical front drives, both on at the same time.

Speaking of which, a differential can let one wheel spin,

eg in mud or on ice, while the other is stopped and providing no

thrust. Both hubcap motors provide torque at all times: it's a better

two wheel drive.

Motor Controller Factoids:

The controller converts the DC power from the

battery to a variable frequency approximation of three phase AC power,

on three power wires that go to the motor to create a variable speed

rotating magnetic field in the stator, the motionless part of the

motor. That field pulls the permanent magnet rotor on the wheel around

with it and hence rotates the wheel.

Optical sensors tell the controller the

position of the magnets to time the pulses. The amount of torque is

controlled by pulse width modulation proportional to depression of the

accelerator pedal. Torque to slow the motor is provided by differently

timed pulses proportional to the depression of the brake pedal. A

reverse switch switches the signals to reverse the rotation of the

magnetic field.

In accelerating, the motor uses energy from the

battery. In decelerating, the motor generates energy, which goes back

into the batteries.

Turquoise

BatteryTM

Here's details of the Ni-La bipolar flat plate

battery cell as currently envisioned. There are some uncertainties

that may necessitate a change or two.

First, the cell in cross section:

1. Nickel-brass plate cell wall (AKA nickel-silver but actually

has no silver so the name is misleading). The current flows through

the thickness of this plate across its entire length and width

straight into the next cell, so it's good for zillions of amps. The

two ends of the battery are extra thick pieces with bolt terminals

silver soldered to them, which should handle, say, many hundreds to a

couple of thousand amps.

2. A conductive layer of zinc mixed with the positive electrode

powder. This zinc is not added but leached from the surface of the

nickel brass cell wall sheet by electrophoresis.

3. The positive electrode powder/paste. This is the familiar

nickel beta [oxy]hydroxide, with a bit of cobalt trioxide added

(becomes cobalt hydroxide on first charging) to improve conductivity.

Pretty much the same as in Ni-Fe, Ni-Cd, Ni-MH...

4. The electrode separator sheet.

5. Ferric oxide (or osmium) powder layer. Smeared onto the

separator sheet, this acts as a hydride to store protons, hydrogen

ions. Os should have better performance, but though only a bit is

needed, Os is very expensive. Note that that gives us the basics of a

Ni-MH battery cell. The difference is that this is just a thin mid

layer. It won't hold many protons, but they just pass through to the

negative half of the battery.

This layer is important because it splits the cell

voltage into two parts: the positive side (1.38 volts per Ni-MH usual)

and the negative side (-.83v MH - 2.90v La/La(OH)3 = 2.07v). Water

based electrolyte starts to break down above around two volts, which

is why lead-acid batteries (2.1v) are the highest voltage cells

besides lithiums, which use a non-water-based (but very slow)

electrolyte. So splitting or "ramping" the voltage permits

creating the Ni-La cell, of 3.45v theoretical voltage.

6. Zirconium silicate (zircon) or zirconium oxide (zirconia)

layer. This is an electrical insulator that freely passes ions. It

insulates the ferric oxide layer from the negative electrode powder

while letting the protons and hydroxide ions freely pass.

7. Another electrode separator sheet. I'm not sure I trust the

zirconium to have 100% coverage!

8. The negative electrode powder/paste. About 6mm thick. This is

a 3 to 1 mix of monel and lanthanum [hydroxide], with a little cobalt

chloride thrown in for better conductivity. These ingredients are

mixed in a bean paste to add thiamine mononitrate, rolled out thin,

dried, and fried until the bean paste catches fire and burns off.

(about 90 seconds. This is definitely an outdoor job - the smoke is

awful! I turned an electric barbecue into a special oven.) The

"sintered" amalgamated powder is scraped off the sheets into

containers for later use.

9. An aluminum grid next to the cell wall to improve

conductivity.

10. The cell wall of the next cell. There's only one wall between

cells.

There are also the ingredients that aren't bound by

the layers. The first of these is Lemon Fresh Sunlight dishsoap

(accept no substitutes), which is mixed with the electrode powders and

turn into semi solid pastes. The second is the electrolyte, which is

poured in as water with potassium chloride (sodium free table salt), a

"tincture" of methyl-ethyl-ketone (nasty solvent), and

acetyl ester (AKA ethyl acetate).

The chlorine ions and odd organic ingredients in the

electrolyte [should] allow the reversible La <===> La(OH)3

electrochemical reaction for charging and discharging the negative

side of the battery. I did see almost three volts in one test, but

that was without the rust or zircon layers and the water discharged it

quite quickly. (That continuous discharge, increasing rapidly with

voltage, is perhaps why it didn't get up to 3.45 V.)

I'm hoping for many hundreds of amps capacity, even

1000+, in a battery whose maximum actual drain/charge will be under

200 amps with two hubcap motors at full power. (Pushing things to

extremes, just think: a 50 amp-hour battery could be charged in just 3

minutes at 1000 amps, a 72 volt battery drawing around 300 amps at 240

VAC. How big is the main breaker on your house?)

Now I've told you all the secrets... so what do you need me for?

Well, maybe you should hold off until I've actually got one

working.

http://www.turquoiseenergy.com

Victoria BC