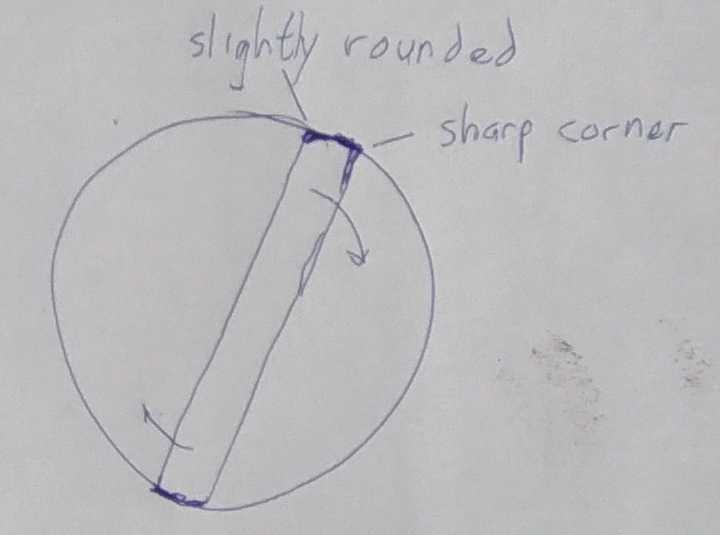

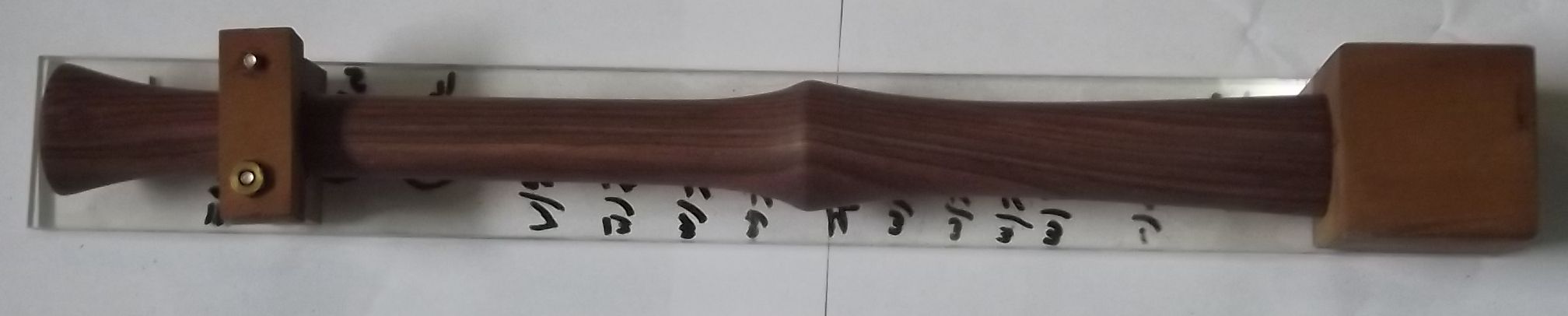

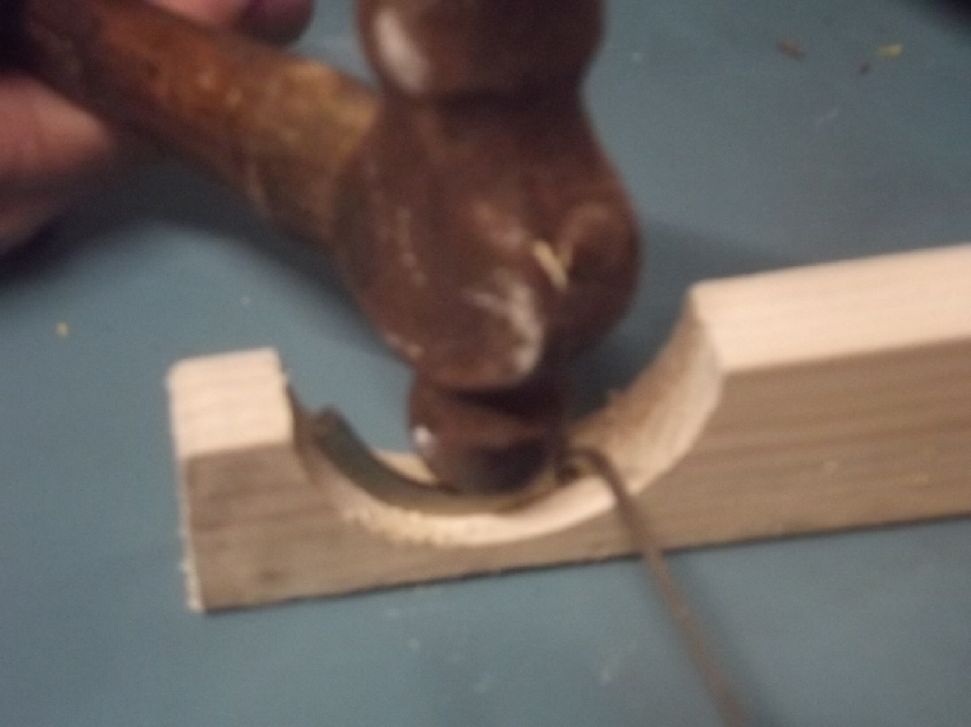

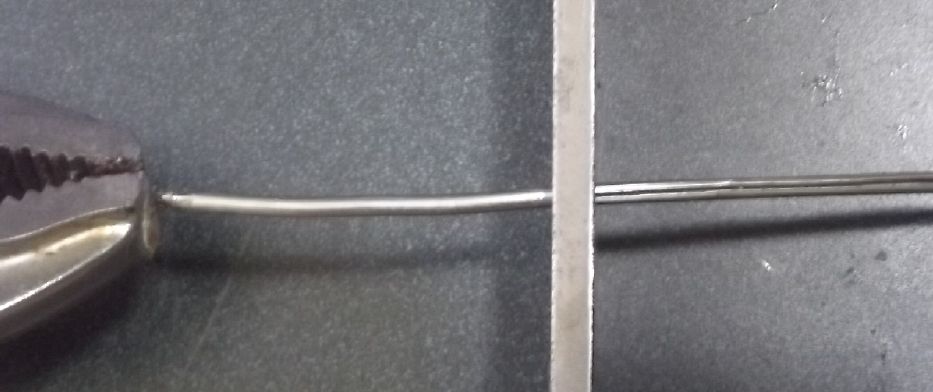

I made the body bore reamer from a

piece of 1/8 x 3/4 inch mild steel bar about 450mm long. From the

slight "shoulder" (image below) the shank part ends and the

reaming part starts. The reaming part is long enough to go right

through the body bore and do the bottom end cleanly. Two corners

along the edge of the reamer are sharpened (at 90 degrees to the

face) to scrape out the bore to the desired profile when one turns

it clockwise. The other two edges are slightly rounded off to

follow the inside curve of the bore, providing enough support that

the reamer scrapes smoothly without "jitter", but not binding.

I made the body bore reamer from a

piece of 1/8 x 3/4 inch mild steel bar about 450mm long. From the

slight "shoulder" (image below) the shank part ends and the

reaming part starts. The reaming part is long enough to go right

through the body bore and do the bottom end cleanly. Two corners

along the edge of the reamer are sharpened (at 90 degrees to the

face) to scrape out the bore to the desired profile when one turns

it clockwise. The other two edges are slightly rounded off to

follow the inside curve of the bore, providing enough support that

the reamer scrapes smoothly without "jitter", but not binding.

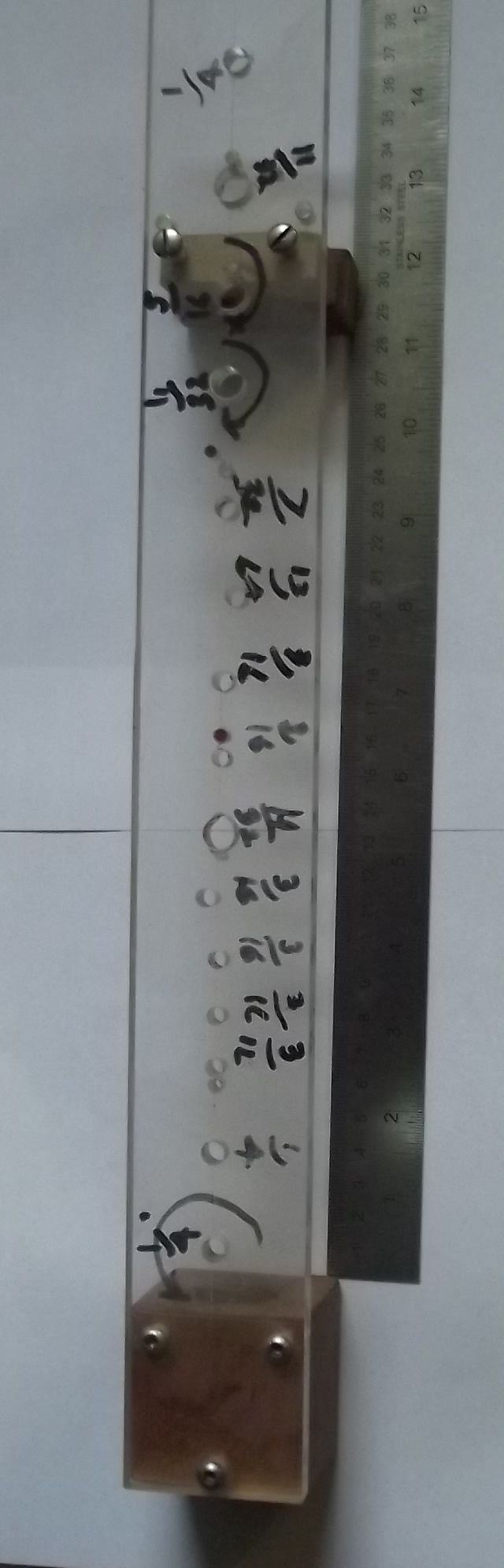

| Measured at: Distance from Shoulder mm |

Width Across mm |

Width Diagonal mm |

| '0' (@2 mm) |

16.80 [17.3] |

17.16 |

| 50 |

16.03 [16.1] |

16.31 |

| 100 |

15.00 |

15.33 |

| 150 |

13.80 |

13.98 |

| 200 |

13.12 |

13.34 |

| 250 |

11.93 |

12.30 |

| 300 |

10.90 |

11.22 |

| 350 |

10.30 |

10.69 |

| 380 |

10.20 |

10.35 |

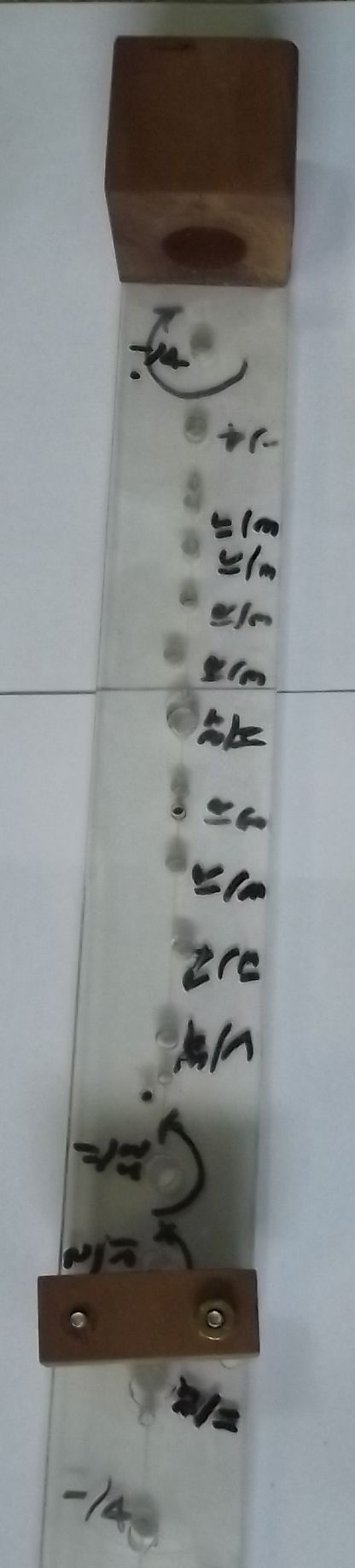

| Measured at: Distance from Lower Shoulder mm |

Width Across mm |

Width Diagonal mm |

| '0' (@2 mm) |

18.00 |

18.52 |

| 50 |

17.47 |

18.16 |

| 100 |

17.35 |

17.83 |

| 120 |

17.15 |

17.75 |

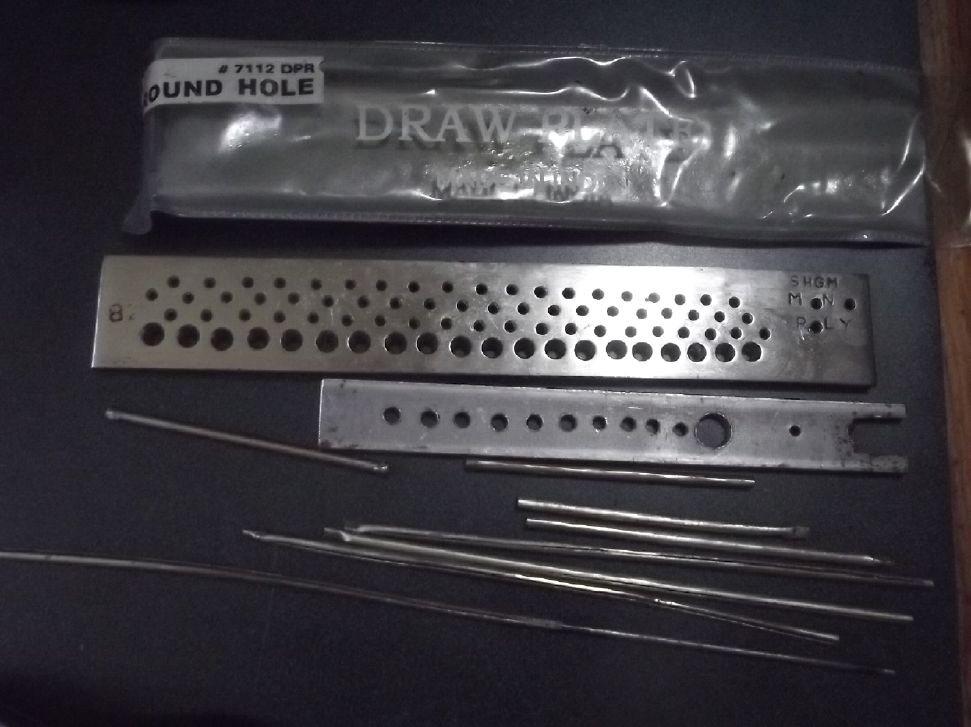

In sizing the hole drills,

it was intended that the holes never be drilled too large, which

would make notes too sharp. Rather, they may be a bit undersize

(note flat) so that removing a bit of surrounding wood will raise

the pitch until it's in tune. Then they can be reamed out bit by bit

from inside with a 'dremmel moto tool' burr bit. The burr bits I

used were small, shaped round and inverse cone. The small burrs fit

though the hole and so are able to ream it from the inside face so

that the outside face of the hole is unchanged.

In sizing the hole drills,

it was intended that the holes never be drilled too large, which

would make notes too sharp. Rather, they may be a bit undersize

(note flat) so that removing a bit of surrounding wood will raise

the pitch until it's in tune. Then they can be reamed out bit by bit

from inside with a 'dremmel moto tool' burr bit. The burr bits I

used were small, shaped round and inverse cone. The small burrs fit

though the hole and so are able to ream it from the inside face so

that the outside face of the hole is unchanged.| Finger (Notes when hole is the top open hole,

closed) [Rotation from in-line with other fingers - degrees] |

Distance in mm |

Hole size in inches |

| Left Hand |

||

| Thumb (G, F#) [180] | 18.5 |

1/4 |

| 1 (F#, E) |

44.5 |

1/4 |

| (E, Eb) |

68 |

3/16 |

| 2 (Eb, D) |

82 |

3/16 |

| (D, C#) |

97.5 |

3/16 |

| 3 (C#, C) [left ~ 4 mm but usually drilled

straight down] |

114 |

3/16 |

| Right Hand (mostly!) |

||

| "4" - index finger (C, B) (B, Bb pipe) |

131.5 |

11/32 |

| (B, Bb) (B, Bb pipe) |

152 |

3/16 |

| "5" (Bb, A) |

173.5 |

3/16 |

| "6" (A, G#) [may be in-line or ~4 mm right

(see text), but drilled straight down] |

196.5 |

13/64 |

| "8" (G#, G) [0° - in line] (LEFT little finger, double key) |

220.5 |

7/32 |

| "7" (G, F#) [75°(?) right] (RIGHT little finger, bottom lever double key) |

255 |

5/16* (?jig says 11/32?) |

| (F#, F) [75°(?) right] (RIGHT little finger, top lever double key) |

280 |

5/16* |

| "8" (F, E) [0] (LEFT little finger, double key) |

310.5 |

11/32 (Try 5/16*, undercut? |

| BELL STOPPED (E, Eb, or E, D with "D"

tube) |

347 |

1/4 |

| Pillar Key Set |

Distance Down (top hole, mm) |

Distance Down (bottom hole, mm) |

Angle from in-line with finger holes

(degrees) |

| Eb - Db |

63 |

158.5 |

90° to right |

| G - E |

135.5 |

318 |

90° to left |

| F# - F |

231 |

287 |

25° (?) to right |

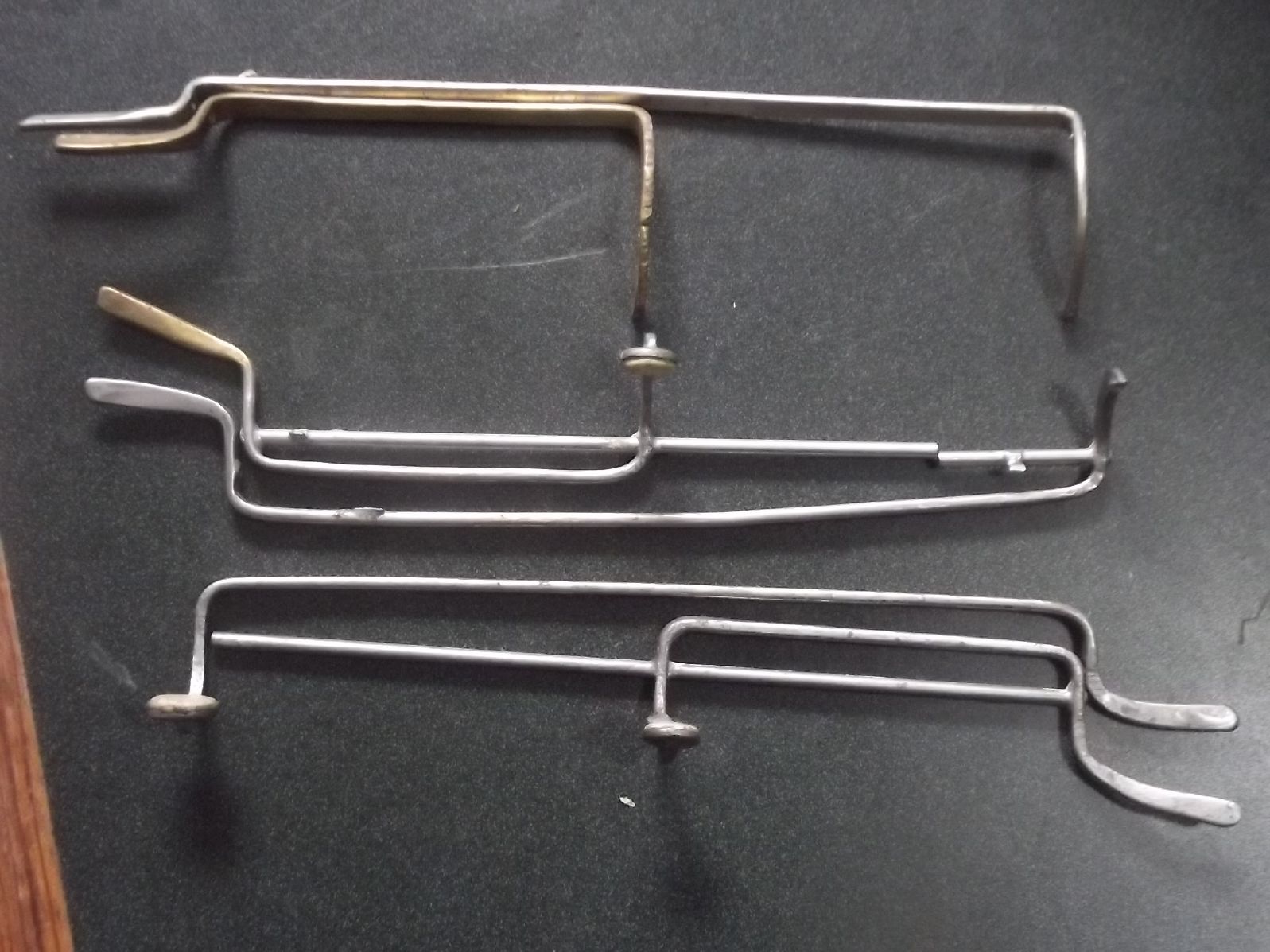

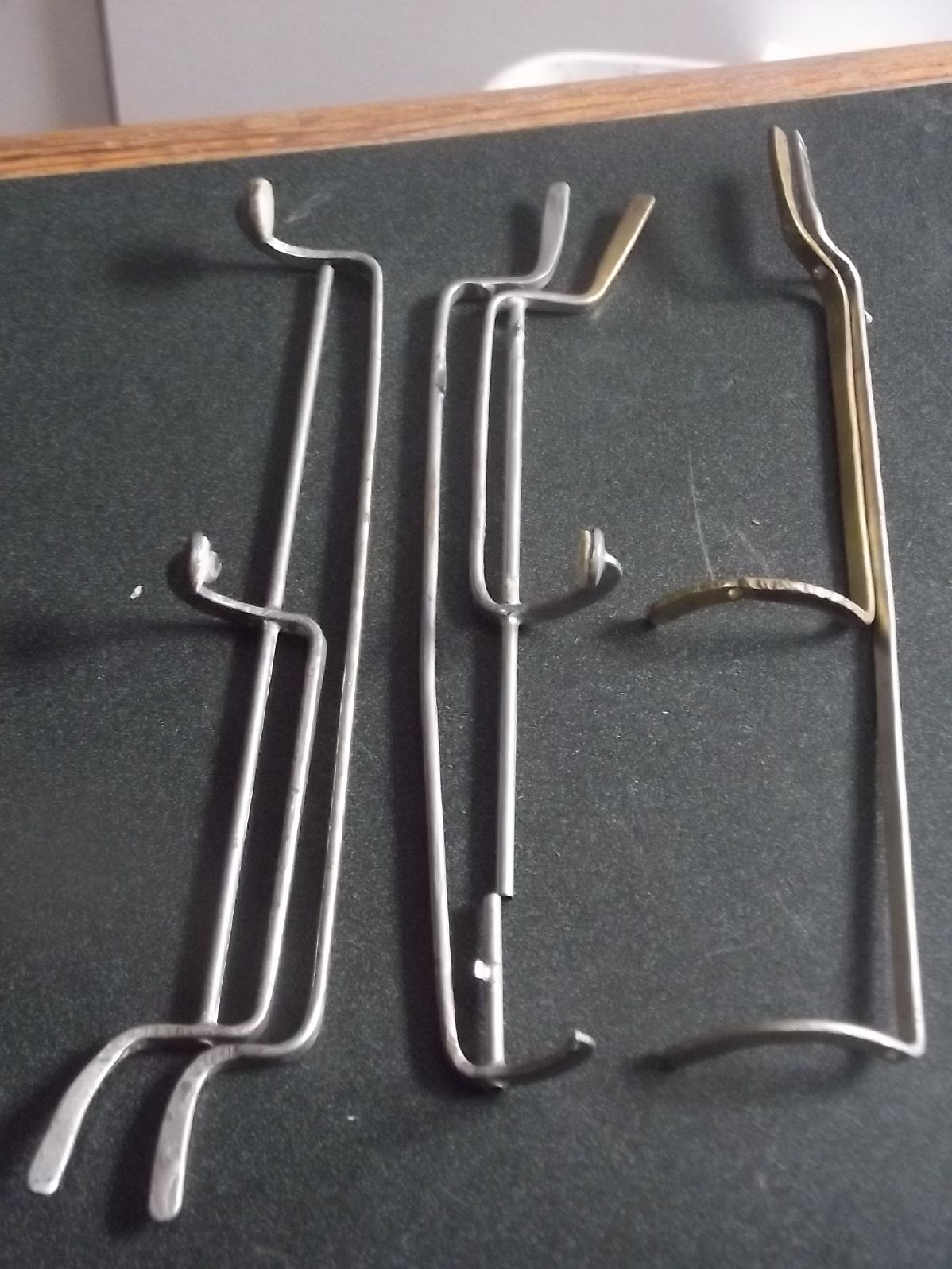

But after that I started forming the

moving part of the keys out of just four pieces - the axle tube,

the pad cap, the spring rest, and a single "bracket" piece

something like a "U" (or "[") with a finger rest tail, bent around

in three dimensions to form the finger rest and the rest of the

parts between and holding the pad cap. This takes all the twisting

strains. With this arrangement the tubes have no tendency to

twist, and the two or three soldered joins take very little

strain. So I just used soft solder - the "modern" "silver bearing

solder" (tin alloy) often used in electronics. (Eg, Sn:Cu:Ag

93.6:4.7:1.7%), with resin core. Not to be confused with much

harder, high temperature "silver solder", made of various mainly

silver (Ag) alloys.) I did try to make a large common surface area

of solder join and to get more solder built up around the edges,

especially for the ring keys, whose finger pieces do take some

strain.

But after that I started forming the

moving part of the keys out of just four pieces - the axle tube,

the pad cap, the spring rest, and a single "bracket" piece

something like a "U" (or "[") with a finger rest tail, bent around

in three dimensions to form the finger rest and the rest of the

parts between and holding the pad cap. This takes all the twisting

strains. With this arrangement the tubes have no tendency to

twist, and the two or three soldered joins take very little

strain. So I just used soft solder - the "modern" "silver bearing

solder" (tin alloy) often used in electronics. (Eg, Sn:Cu:Ag

93.6:4.7:1.7%), with resin core. Not to be confused with much

harder, high temperature "silver solder", made of various mainly

silver (Ag) alloys.) I did try to make a large common surface area

of solder join and to get more solder built up around the edges,

especially for the ring keys, whose finger pieces do take some

strain.

The tube surround, lever and Bb pad cap I sometimes made

from one piece, sometimes using one of the pad cups. These (as

best I can remember) were all cut and shaped by hand. An 8 mm

clarinet pad seems good; use 8 mm oboe pad for thinner.

The tube surround, lever and Bb pad cap I sometimes made

from one piece, sometimes using one of the pad cups. These (as

best I can remember) were all cut and shaped by hand. An 8 mm

clarinet pad seems good; use 8 mm oboe pad for thinner. At first I cut the slot in the pipe

from the bottom. It does the job of preventing the key from

popping off. This particular tube stops when the spring is fully

compressed, which is just about the right point where the Bb key

closes. Great!...

At first I cut the slot in the pipe

from the bottom. It does the job of preventing the key from

popping off. This particular tube stops when the spring is fully

compressed, which is just about the right point where the Bb key

closes. Great!... The tube surround, lever and Bb pad cap I sometimes made

from one piece of thick sheet metal, sometimes using one of the

pad cups. These (as best I can remember) were all cut and shaped

by hand. I probably punched or drilled the hole for the tube

first. I was using an 8 mm clarinet pad (or an 8 mm oboe pad for

thinner).

The tube surround, lever and Bb pad cap I sometimes made

from one piece of thick sheet metal, sometimes using one of the

pad cups. These (as best I can remember) were all cut and shaped

by hand. I probably punched or drilled the hole for the tube

first. I was using an 8 mm clarinet pad (or an 8 mm oboe pad for

thinner). Okay,

something new! Being unsatisfied, I've just worked out a new

way: screw a retainer piece to the body of the instrument that

covers the top of the slot in the pipe. (The screw is 2 mm x 6

mm.) It could be made as I've done this one, or with a slot so

that it pivots one way to keep it closed and nearby direction

to open the slot to remove the key. Or (tolerance being tight)

it could be a "washer" with an off-center hole, to be rotated

until it covers the slot without rubbing on the tube. There's

not much room, but it seems better.

Okay,

something new! Being unsatisfied, I've just worked out a new

way: screw a retainer piece to the body of the instrument that

covers the top of the slot in the pipe. (The screw is 2 mm x 6

mm.) It could be made as I've done this one, or with a slot so

that it pivots one way to keep it closed and nearby direction

to open the slot to remove the key. Or (tolerance being tight)

it could be a "washer" with an off-center hole, to be rotated

until it covers the slot without rubbing on the tube. There's

not much room, but it seems better.

One day I read that some bamboo

flutes were brought into tune by making a hole in the side near

the labium to sharpen the pitch. I made a mechanism, a push-lever

with a spring, pressed by the lower lip to open such a hole. This

was one of the two special, original inspirations for making the

supercorder, along with the dual B-Bb pipe/key. It worked,

which was exciting, but it was somewhat awkward. It didn't have a

really fine feel that a player wants.

One day I read that some bamboo

flutes were brought into tune by making a hole in the side near

the labium to sharpen the pitch. I made a mechanism, a push-lever

with a spring, pressed by the lower lip to open such a hole. This

was one of the two special, original inspirations for making the

supercorder, along with the dual B-Bb pipe/key. It worked,

which was exciting, but it was somewhat awkward. It didn't have a

really fine feel that a player wants. I thought about making a hole

directly closed by the lip, but it seemed like it would be an

awfully long hole. Was it even close enough to the labium to work?

Recorder windways (for alto size) are generally a couple of inches

long, and a quarter circle curve shape underneath. Obviously the

curve was just tradition and had no bearing on the sound. Did they

need to be so long? I cut that in half to an inch and changed the

outside shape to "squarish" so the lower lip could conveniently

cover a much shorter hole. It worked! Very nicely!

I thought about making a hole

directly closed by the lip, but it seemed like it would be an

awfully long hole. Was it even close enough to the labium to work?

Recorder windways (for alto size) are generally a couple of inches

long, and a quarter circle curve shape underneath. Obviously the

curve was just tradition and had no bearing on the sound. Did they

need to be so long? I cut that in half to an inch and changed the

outside shape to "squarish" so the lower lip could conveniently

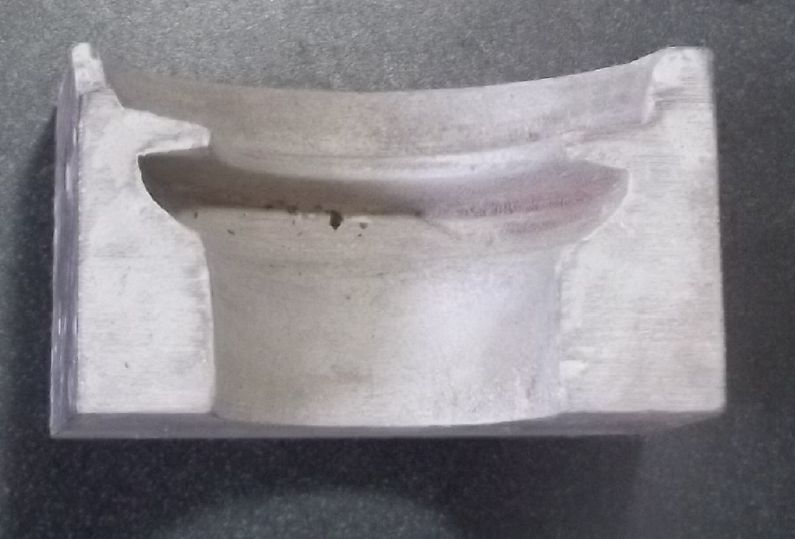

cover a much shorter hole. It worked! Very nicely! I made molds to shape the

porcelain beaks and blocks. In coming up with the shape of the

beak, I considered how to fasten it to the wood. I made it to be

held against the head by the "U" shaped "retainer" piece of brass,

which I threaded on both ends and then had to make special nuts

for.

I made molds to shape the

porcelain beaks and blocks. In coming up with the shape of the

beak, I considered how to fasten it to the wood. I made it to be

held against the head by the "U" shaped "retainer" piece of brass,

which I threaded on both ends and then had to make special nuts

for.

Here is a mismatched beak and block. The

beak sagged a bit because the sides spread out a bit before or

during firing (probably in pulling it out of the beak mold), and

the center of the windway is too narrow. Yet in my collection is

at least one block that matches this beak. How well that pair

matches the curve of the edge of the labium is another guess,

and the labiums are pretty uniform between instruments. In an

assembled & properly adjusted instrument held up to a light,

one should be able to look along the block and see a thin line

under the labium. It's best if it's uniform all the way across.

(that's easiest to see with the block in place, beak removed.)

Here is a mismatched beak and block. The

beak sagged a bit because the sides spread out a bit before or

during firing (probably in pulling it out of the beak mold), and

the center of the windway is too narrow. Yet in my collection is

at least one block that matches this beak. How well that pair

matches the curve of the edge of the labium is another guess,

and the labiums are pretty uniform between instruments. In an

assembled & properly adjusted instrument held up to a light,

one should be able to look along the block and see a thin line

under the labium. It's best if it's uniform all the way across.

(that's easiest to see with the block in place, beak removed.)

As previously mentioned, I used steel

'dremmel mototool' burrs to

As previously mentioned, I used steel

'dremmel mototool' burrs to  enlarge tone holes

by undercutting them, reaming them from the inside without

enlarging the outside. (The burr has to fit through the hole.) I

don't remember if I got as refined as this or if it's actually as

useful with burrs as with a knife, but I would think that if the

upper octave is sharper, probably enlarge inside toward the top of

the hole to help raise the lower one more. If the upper octave is

flatter, I would enlarge toward the bottom so as to raise the

pitch of the lower note less. I more remember going around the

whole inner edge, a bit at a time, to raise both pitches.

enlarge tone holes

by undercutting them, reaming them from the inside without

enlarging the outside. (The burr has to fit through the hole.) I

don't remember if I got as refined as this or if it's actually as

useful with burrs as with a knife, but I would think that if the

upper octave is sharper, probably enlarge inside toward the top of

the hole to help raise the lower one more. If the upper octave is

flatter, I would enlarge toward the bottom so as to raise the

pitch of the lower note less. I more remember going around the

whole inner edge, a bit at a time, to raise both pitches.