Turquoise Energy News Report #177

Covering

February 2023 (Posted March 5th 2023)

Lawnhill BC Canada - by Craig Carmichael

(CraigXC at Post dot com)

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Highlight: ZX40 Mini cargo

Truck; Build & Tests of Magnetic Variable Torque Converter (See

February in Brief, Electric Transport, Video Link - 7 minutes)

Month In "Brief"

(Project Summaries etc.)

- Magnetic Variable Torque Converter: Build + Tests, Video Link -

"New Chemistry" Battery Research & Development - Home Solar Power:

4 Years - Plastic Recycling 2.0 Demo

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Scattered Thots - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Magnetic Variable Torque Converter with Planetary Gear: The

Future of the Automotive Industry! Assembling/Installing one for

Miles Truck: working. - wants still more magnetic interaction

Other "Green"

& Electric Equipment Projects

(no reports)

Electricity Storage:

Batteries

* Gelled Ni-Zn: 3D Printed PVB Case - Copper wire strands for zinc

current collector? - Assembly - Keytone wetting for NiOOH: YAH! -

Testing. Mn-Zn cell: Rechargeable?

Electricity Generation

* My Solar Power System:

- The Usual Latest Daily/Monthly

Solar Production log et cetera - Monthly/Annual Summaries,

Estimates, Notes - FOUR FULL YEARS!

February was again largely a "new chemistry battery R

& D" month, and the results were exciting, not yet "perfect,

working!" but at long last all the pieces seem to be in place to

achieve that on some try very soon.

I did finally get the magnetic variable torque

converter in the housing under the truck and working. It ran around the

driveway fine and more than once, but needs still stronger magnetic

rotor interaction. This is achievable and the next step.

I did a sample plate of HDPE plastic molding (Plastic

Recycling 2.0) in the kitchen oven. Some parameters need changing a

bit. 500°F is too hot, 5 or 10 minutes in the oven is too short.

More below.

This month also marks four full years of tracking the

power

from my solar panels. Naysayers say we can't transition to renewable

energy but with all due allowances for difficulties, it is in fact

happening everywhere and if I had around 50 or 60 'sun panes' on my

roofs instead of 18 they would be supplying as much power annually as I

actually use.

Magnetic Variable Torque Converter: Build + Tests, Video Link

Magnetic Torque Converter - February 2023 Tests (Video 7 minutes)

https://youtu.be/MFbFC5YkvTM

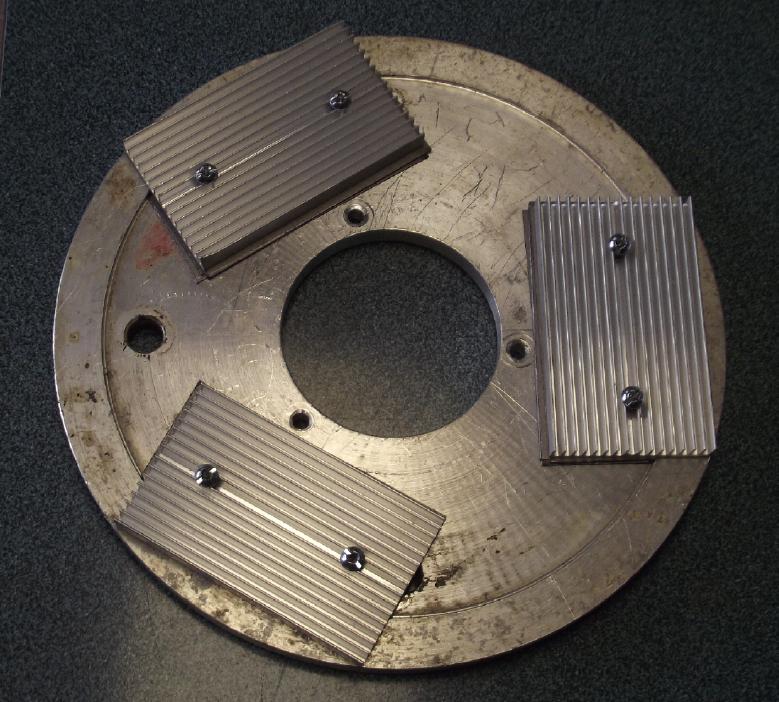

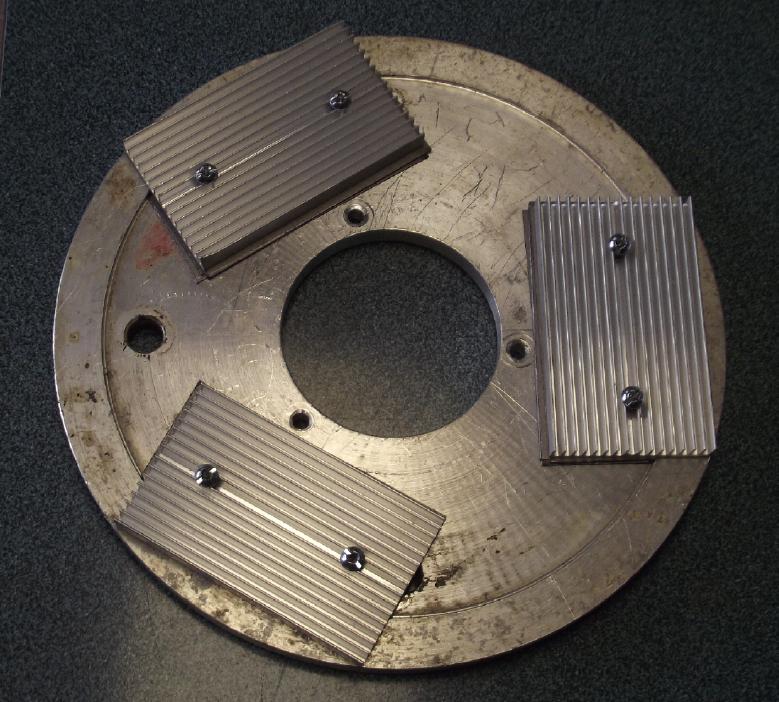

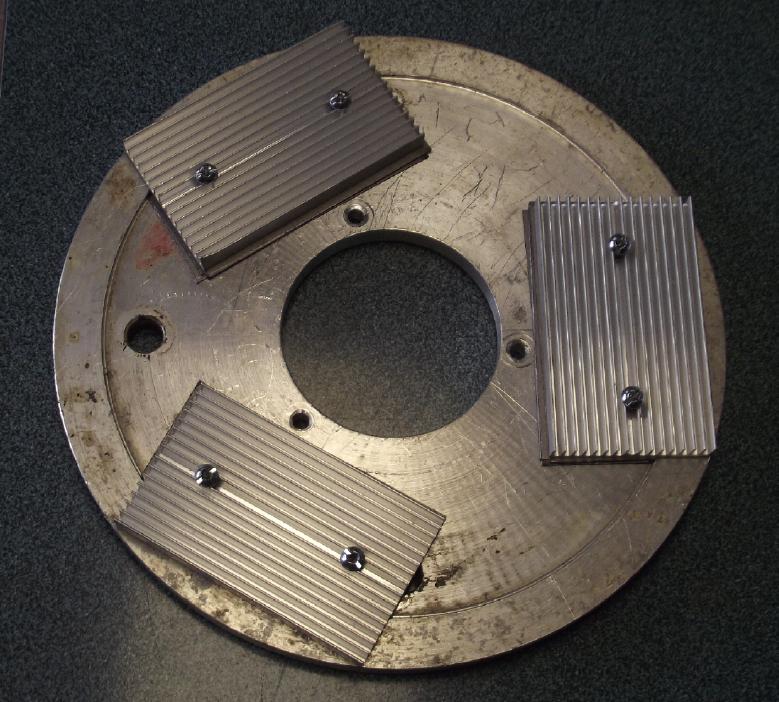

Since the alume disk was getting

too warm, I

changed the bearing

Since the alume disk was getting

too warm, I

changed the bearing

support a little to provide clearance for heatsinks on the disk

Disk with the heatsinks.

Disk with the heatsinks.

Since the back surface of the disk was uneven I built up the middle

with three layers of graphite foil, which is a very good heat conductor.

In the tests in September the theory for this variable

converter was proven to work,

but what was the optimum level of magnetic interaction? I suspected

what I had

was rather light. I added sideways magnets to the magnet rotor to make

it something of a "Hallbach" configuration with more flux, and with

more of the flux coming out the active side to interact with the alume

disk. Did this double the flux? Probably it was at least 1.5 times

more. I tried it out in the garage after I did it and I could tell it

was better.

Then I realized a planetary gearset with a higher

reduction ratio would magnify the effectiveness of the flux and I

ordered a 10 to 1 to replace the 5 to 1 reduction unit I had. At this

point, the effective magnetic interaction between the two disks became

3 to 4 times as strong as in the initial tests.

Now I've reassembled the unit with the "bare bones" of an

enclosure with a steady bearing on the long shaft, and I drove the

truck around the driveway. In general I was pleased, but in driving

over obstacles, or trying to, I realize that the magnetic interaction

should be still stronger. The alume disk shouldn't be turning backward,

really, at any point even in the slowest driving with the total

design reduction when it is stopped being 10 to 1 (planetary) times 2.2

to 1

(at

the differential) for a total of 22 to 1.

I tried to drive one

wheel over a 2

by 4 in the garage. It wouldn't go without a run at it at any pedal

press I wanted to apply.

I tried to drive one

wheel over a 2

by 4 in the garage. It wouldn't go without a run at it at any pedal

press I wanted to apply.

It was revving up too much without moving the truck. I was sure it

should go and I put two large carpentry clamps into the mechanism to

hold the body of the planetary from turning. Thus fixed at 22 to 1

reduction, it hopped over the board easily with a light touch on the

pedal.

It demonstrates that still stronger magnetic interaction between the

disks is required.

There is one more way to get more magnetic interaction

before going to larger or multiple rotors. The present 10 inch alume

alloy disk is only about 11mm thick. It was just what I had on hand. If

the thickness was increased to 19 or 20mm (3/4+ inch) it would probably

improve by about 1.5 times. Then, if the disk was pure alume

instead of alloy (from last month's conductivity figures tabled for

heatsink purposes), it would be about 1.42 times better. Multiplying

these, the magnetic effect should be about doubled. So that is my next

step. (Where do I get pure alume? alloy seems much easier to come by.

Pure copper of course would be about 2.4 times better than the present

disk even in the 11mm thickness, but too heavy and costly.)

Further, if

the diameter was increased so the rim was 1/4 or 1/2 inch beyond the

magnets it should catch a little more of their magnetism at the largest

radius for a lesser but noteworthy increase, maybe 10 to 20%.

A significant benefit to increased interaction will be

that the

heat generated into the disk should drop by more than half, since less

slip means less power wasted into it.

So... from "it worked" to [I trust] "it's good" seems to

be: original * 1.5 to 2 (Hallbach) * 2 (increased gear reduction) * 2

(better alume disk) = 6 to 8 times more effective flux - headed for an

order of magnitude. Now I'm almost surprised it worked as well as it

did at first in September.

I also noticed that with steel screws holding the

heatsinks on the rotor, there was a bit of magnetic cogging, where the

screws wanted to align with the magnets. It then occurred to me that if

an amount of steel to make the cogging sufficient but not overpowering

was added to the alume rotor deliberately, when less torque was

required such

as cruising along level road, the disks could magneticly lock together

and the mechanism would all turn as one with essentially 100%

efficiency. 90% is great. 100% is better. And the alume rotor would

cool off. When more torque was required

the cogging force would break free, automaticly unlocking them and

going back to variable conversion.

Onward and upward!

"New Chemistry" Battery Research & Development

After 4 consecutive months of efforts I think I'm just about there for

making batteries that work and may be practical to use. Almost. (Still

with horribly labor intensive construction.) I've

made 3D printed cases for externally clamped flat cells and epoxied

them shut so they don't leak. Even more labor intensive? At least it

works!

After 4 consecutive months of efforts I think I'm just about there for

making batteries that work and may be practical to use. Almost. (Still

with horribly labor intensive construction.) I've

made 3D printed cases for externally clamped flat cells and epoxied

them shut so they don't leak. Even more labor intensive? At least it

works!

And I've discovered the way to get much better performance

out of positive electrode powders is to soak them in acetone, which (I

believe) helps build more conductive epitaxial crystal structures at

the nano scale. This follows on discovering that soaking separator

papers in toluene prevents the positive electrode nano-powders from

seeping through to short to the negative side, and that painting the

same separator with sodium dodecylbenzenesulfonate seems to keep zinc

ions from penetrating through from the negative side to the plus.

I'm experimenting with a manganese oxide "+" electrode

(among other interesting "+" side chemistries). Manganese is known for

not recharging well from MnOOH back to MnO2 in alkaline cells. I am

seeing if it will recharge at a pH below 14 when also treated with the

acetone. So far it appears to be working, but it's too soon to be sure.

Manganese-zinc is the well known combo of non-rechargeable dry cells.

If it can be made to recharge, it will open the door to cheap, high

capacity batteries potentially to the scale of grid power energy

storage where a whole power grid can charge with solar during the day

and run off the batteries at least into the evening - maybe even until

morning. They'd be more

than fair for electric transport, too, which would make for

substantially lower cost electric vehicles.

But I found where Ovshinsky et al had not only created the

good metal hydride for Ni-MH batteries, but his team had also improved

the nickel oxyhydroxide chemistry to give it higher capacity - even

above the "theoretical" one electron per nickel atom. This makes

nickel-zinc look really attractive for higher energy and still

relatively low cost EV batteries.

Home Solar Power: 4 years

With the improvements I made to the wiring many months ago

including some new plug-in grid ties, two new solar panels on a pole

and three on the carport roof bringing the total to 18 panes, the solar

production for the fourth full year of operation was almost double that

of each of the first three years - about 3800 KWH instead of 2100.

(1.8x) That is about 1/3 as much as my average total annual usage from

BC Hydro, and certainly much more than my electric car uses.

Certainly one loses a lot with too-thin wires from the

panes, also with grid ties loaded up to near their maximum ratings with

panes instead of, say, to half their rating. ...at least that seems to

be true with cheap plug-in grid tie inverters.

Annual totals are at the bottom of this report. Luckily

the weather isn't usually what the pictures show. (March 3rd)

Solar Panels, Four Years

Solar Panels, Four Years

6 on house roof + 3 just propped up on lawn. (What month is

this again?)

(BTW the 10W solar panel in the window is for my bedroom lamp - ~10

years now, same Ni-MH "D" cells)

4 on cabin roof

4 on cabin roof

2 on a pole (wired to carport)

2 on a pole (wired to carport)

Um, the 3 panels usually facing

south on the

carport roof.

Um, the 3 panels usually facing

south on the

carport roof.

A tremendous wind ripped them out a few days ago and dumped them on the

garage roof.

One is obviously broken (corner of frame is bent). Hopefully the other

two aren't.

I'm waiting for nice weather to go up and put them back -

this time with fat lag screws instead of just deck screws.

Plastic Recycling 2.0 Demo

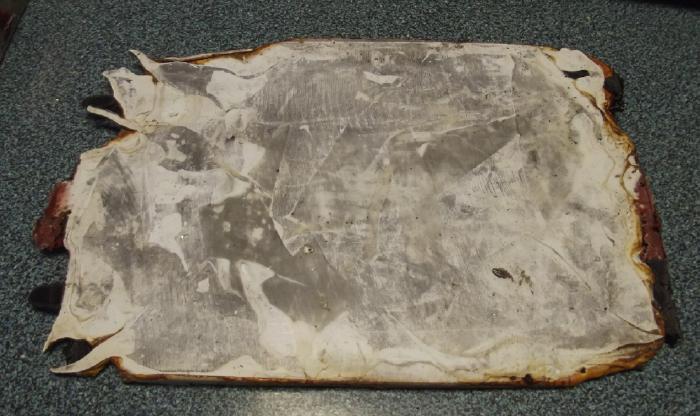

I tried again

to make a little "sample size" HDPE "tile" from a bleach bottle. (I

waited until I was baking and heating up the oven anyway. Not a very

common occurrence!)

I tried again

to make a little "sample size" HDPE "tile" from a bleach bottle. (I

waited until I was baking and heating up the oven anyway. Not a very

common occurrence!)

I'm not sure what possessed me

to change from the previous 9-1/2 pound weight to a 6 pounder. It

wasn't enough.

I'm not sure what possessed me

to change from the previous 9-1/2 pound weight to a 6 pounder. It

wasn't enough.

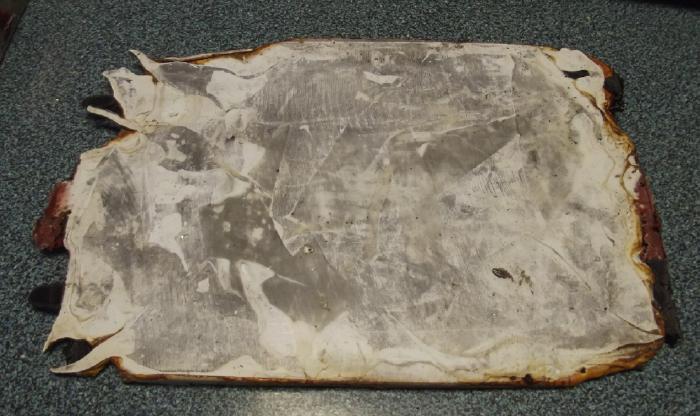

I added some "racing stripes"

from some tear-off strips from 5 gallon HDPE plastic bucket lids. This

time I set the kitchen oven to 500°F but I left the mold in for an

hour instead of just 5 or 10 minutes. The result was that the "tile"

looked scorched around the edges but still hadn't flattened right out

and filled the corners. And it was stuck to the mold quite badly and

hard to separate, especially from the two face pieces without bending

them.

I added some "racing stripes"

from some tear-off strips from 5 gallon HDPE plastic bucket lids. This

time I set the kitchen oven to 500°F but I left the mold in for an

hour instead of just 5 or 10 minutes. The result was that the "tile"

looked scorched around the edges but still hadn't flattened right out

and filled the corners. And it was stuck to the mold quite badly and

hard to separate, especially from the two face pieces without bending

them.

I didn't notice any odor with the HDPE in the oven,

although the window was

open a bit and I didn't sit in the kitchen during the process.

It looks lumpy but these former

pieces of plastic are in fact all melted into a smooth surface top and

bottom. Only the edges are uneven, and scorched. (Too hot, for too

long,

and insufficient weight on top.)

It looks lumpy but these former

pieces of plastic are in fact all melted into a smooth surface top and

bottom. Only the edges are uneven, and scorched. (Too hot, for too

long,

and insufficient weight on top.)

The silver color on the (white bleach bottle) plastic is

polishing compound that was on the mold surfaces. It won't be there

on any subsequent cast.

Conclusions:

1. 500°F (260°C) is too hot for polyethylene. Probably

450°F (232°C) would have been fine; maybe still lower.

2. It does need to be in the oven long enough for all the plastic to

heat up to the desired temperature and to flow. This depends on how

much plastic there is as well as how thick the pieces are and the oven

temperature.

3. 6 pounds of weight on the lid didn't provide enough pressure to

squeeze the melted plastic out to fill the corners, even in this very

small mold. (~14 x 21 cm) (Why did I swap the 9.5 pound weight I used

previously for a 6 pound?)

4. The smaller the cracks around the edges are, the less material needs

to be trimmed off the edges after molding.

5. The higher the sides of the mold, the bigger the chunks of plastic

can be and the less cutting is needed to fit them into the mold. The

low sides of this mold were a nuisance.

6. Spacers in the corners or adjusting screws are useful to make sure

it doesn't come out wedge shaped. (or does for shingles.)

Certainly recycling HDPE plastic into "tiles", sheets or

plates, is pretty simple this way - especially if as it seems, one can

just use the

kitchen oven. One only needs to make a simple box mold. Molds for

making tiles up to about 16 by 21 inches will fit in most electric

ovens. In India and elsewhere they make floor and paving tiles in

similar ways. They'd be great for plastic roof tiles or panels. (They

need testing for flammability before use in or on top of dwellings.

Would they light up from a glowing cinder, or just melt a bit? I'm not

sure what test results may already be available. Consider that cedar

roofing shingles plus a woodstove are a notorious combo for burning

down houses.)

In a town in Argentina I saw they were making houses from

plastic "bricks" and the program was slowed by having a hard time

finding enough waste plastic.

For more ideas, look on youtube.

(I'll try in the kitchen again this month - and with PP.)

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Scattered

Thots

* People once thought lichens were a

type of plant. Then someone discovered they were actually two

organisms: an alga that photosynthesized to provide energy plus a

fungus that can scrounge nutrients out of rocks. The biology world was

indignant, but the discoverer presented indisputable microscopic

evidence. They had to create a new word, "symbiosis".

Recently it has been discovered that that too was

incomplete: most lichens are actually an alga and two different

types of fungi.

>>Lichenologists thought that the fungi in the partnership all

belonged to a group called the ascomycetes. Almost on a whim, Spribille

broadened his search to the entire fungal kingdom, and found that in

almost all the macrolichens - the world's most species-rich group - he

[also] found the genes of basidiomycete fungi.

"There's been over 140 years of microscopy" says Spribille. "The idea

that there's something so fundamental that people have been missing is

stunning."<<

That something so major went undiscovered for 140 years

since the original "symbiotic" discovery only surprises me a little. Of

course it suggests that much has probably been missed in many fields,

contrary to the supposition of many that most broader things must

already be well known. Hence my work looking for valuable things that

have been overlooked in areas of batteries, torque converters, BLDC

axial flux motors and so on, where one would expect that anything

simple and "obvious" would have already been found, probably long ago.

* It's hard to realize just

how much the mass media indoctrinates us with incereasingly brazen

American oligarchy

propaganda, a narrative being repeated over and over, often as

presuppositions to whatever is being said:

* It's hard to realize just

how much the mass media indoctrinates us with incereasingly brazen

American oligarchy

propaganda, a narrative being repeated over and over, often as

presuppositions to whatever is being said:

"Putin, who invaded Crimea, and who launched an unprovoked invasion of

Ukraine, has now done this..."

They can't just begin with "Russia has now done this..."

In the oft repeated prejudiced preamble, first everything

is blamed on the leader, by constant repetition making him sound like a

villain, as if none of [whatever] would have happened if anyone else

was in charge. ("Turkey, our staunch middle-eastern allay" suddenly

became "Erdigan's corrupt regime" and "Erdigan's tinpot

dictatorship" in news items in the weeks before the attempt to

assassinate him. I became sure they were going to do so. [Huh? He

wasn't elected? The Turkish parliament suddenly has no power?] But they

failed,

and the repetitious damning references to Erdigan suddenly dropped out

of the news.)

Then, we are supposed to forget all about preceding

causative events like the 2014 American sponsored violent coup in

Ukraine that ousted the elected government for a US hand-picked new one

(who conquered Ukraine?), the ongoing eastward expansion of NATO

contrary to solemn promises, the ongoing nazification of Ukraine (as

reported with concern on BBC more than once in 2015 until they were

apparently told to stop) and totally ignoring Russian concerns and

their

warnings reiterated for many years. The fact that Crimea and the

Donbass and 3 or 4 other "Ukrainian" regions were always Russian except

for the period when they were transferred to Ukraine for internal

reasons within the framework of the USSR, and that when given the

chance they voted to be and

are glad to be parts of Russia again, is never mentioned.

...And even having been repeatedly told otherwise, the

highly paid talking heads will say the same things again next week and

next week until most of us simply assume they must be true. And all

the news is blasted out at a machine-gun pace without a pause between

sentences to assimilate what was just said don't think just accept

the words next topic is __! Goebbels would be proud.

And that's just one subject. But I've perhaps said too

much and instigated too much cognitive dissonance in some readers

already!

* Of the seven core human values/motivators, Equality has to be

right at the top. A society can't be sustainable without equality of

opportunity and treatment. Nobel prize winning economist Joseph

Stiglitz gave a

couple of talks available on Youtube about the social costs of

inequality, and how "rent seeking" (extracting someone else's piece of

the pie from them) became the preferred model for "earning" wealth

rather than "wealth creation" (adding to the size of the pie through

production, service).

Joseph Stiglitz: The Price of Inequality - Talk (2012/06/24 - One Hour)

https://www.youtube.com/watch?v=woerUgtufUo&ab_channel=TalksatGoogle

If an hour video seems too long, here's another talk he gave, obviously

less in depth.

The Costs of Inequality: Joseph Stiglitz at TEDxColumbiaSIPA (Talk

2013/03/11 - 16 minutes)

https://www.youtube.com/watch?v=GYHT4zJsCdo&ab_channel=TEDxTalks

* Something not addressed by Stiglitz is overpopulation. Of course

overpopulation results in competition for resources rather than

co-operation, and this competition is a chief contributing cause of

inequality. There is no remedy for this except a smaller population, a

three times larger planet that can sustain 8 billion people over the

generations being unavailable at this time.

The Club of Rome first sounded the alarm in the

later 1960s after running computer projections that indicated that

continued population growth could only be sustained for a few decades

and would end in a huge collapse. In a recent youtube video Neil

McCoy-Ward

shows footage from an actual 1973 Club of Rome report

projecting declining Quality of Life from around 2000 and a

population collapse starting around 2020. Certainly quality lives have

become much harder to come by lately. The greater majority are now

just scraping by.

Neil McCoy-Ward -- with Club of Rome projections 1973 (50th anniversary)

https://www.youtube.com/watch?v=KyrEZAIjRec&t=108s&ab_channel=NeilMcCoy-Ward

Recent crop and herd reductions or failures and problems

all over the food supply chain globally would seem to indicate we are

headed imminently into the drop. In sub-Saharan Africa hundreds of

millions face imminent starvation, and the Africans are no longer being

helped by nations who used to have surpluses but now are headed into

shortages themselves. In the USA every single county now reports there

being food insecurity, and over 50 million people are turning to food

banks for sustenance. Crime is rising rapidly.

Many giving warnings in recent years are surprised how

long our unsatisfactory state of affairs has continued without

collapsing, but the Club of Rome report 50 years ago seemed to have had

the timing pretty well pegged.

ESD

(Eccentric Silliness Department)

* Notice: no, it's not ice

* Woodchuck could chuck wood... Can a complacent communist economist

excel with "Excel" at tax calculations?

* Quarantine: Being forced to stay at home, read the Quoran and drink

tea.

* The closed caption said Germany was supplying Ukraine with "Leper

tanks". NOW I know why Ukraine is losing!

* And Britain is sending "Sea Cucumber", er, I mean, "Sea King"

helicopters. In Canada these are notorious for falling out of the sky

into the ocean.

* What's this coffee bag at the back of the top shelf? How long has it

been up there?

Egads, is that the expiry date?

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought

of and not tried... and even of how not to do something - why

it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before

publication. I hope they may add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Electric

Transport

Magnetic Variable Torque Converter with Planetary Gear

[22nd] Some kind of

lethargy took over... and battery stuff. Anyway I

cut a piece of plywood to extend the bearing holder out 4/5 of an inch

so I could put three 10mm tall heatsinks on the alume disk. Later I

finally went under the truck and dismantled the whole assembly. Prime

candidate for what was slipping: it looked like the SDS hub wasn't

closing tightly enough on the shaft, which may be a bit undersize. I'll

run a zip disk through the

slot to make it wider and be sure it can close enough.

[22nd] Some kind of

lethargy took over... and battery stuff. Anyway I

cut a piece of plywood to extend the bearing holder out 4/5 of an inch

so I could put three 10mm tall heatsinks on the alume disk. Later I

finally went under the truck and dismantled the whole assembly. Prime

candidate for what was slipping: it looked like the SDS hub wasn't

closing tightly enough on the shaft, which may be a bit undersize. I'll

run a zip disk through the

slot to make it wider and be sure it can close enough.

[23rd] yikes! Now that it's dismounted

and apart and I'm ready to make all the

changes, it's blowing a storm and -5° out there. Not conducive to

working in the unheated shop, and I don't suppose even 3000 watts of

portable heaters would make it anything like warm. Dang, I think I'll

sit by the woodstove instead.

[26th] I've done bits and pieces here and there (while confessing to be

presently much more interested in batteries). It has warmed above

zero... and then gotten

colder and snowed. Most of the detail items on my list are done.

[27th] I finished the list

items and put the heatsinks on the alume disk. The surface wasn't flat,

and I propped them up with 3 layers of graphite "foil", having

discovered that solid graphite is probably a better heatsink material

than alume itself. (or even than copper?)

[27th] I finished the list

items and put the heatsinks on the alume disk. The surface wasn't flat,

and I propped them up with 3 layers of graphite "foil", having

discovered that solid graphite is probably a better heatsink material

than alume itself. (or even than copper?)

Then I reassembled the housing, and the rotating

mechanism. (My back already hurts. I'm I really going to start crawling

under the truck to install it again? Maybe tomorrow!)

Torque Converter 100% Efficiency on the Road?

I had worked out efficiencies once under way to be in the

90%

range. That seemed acceptable as it is apparently better than

"automatic transmissions" even tho they have been much improved during

this century. But an interesting "feature" presented itself. With even

the small steel screws holding the heatsinks there was a noticeable

amount of magnetic cogging between the two disks. It occurred to me

that provided the motor is easily able to overcome that cogging, when

torque requirements are small the alume disk can magneticly "stick" to

the magnet disk and the entire mechanism will turn at 1 to 1 with 100%

efficiency. Perfect! So to get this when torque requirements are lower

- perhaps as when cruising on level pavement - a certain amount of

magnetic steel might well be added to the alume rotor to get it all to

synchronize - automaticly - when conditions favor it.

Potential drawbacks: 1. The pedal will have to be pressed

far enough to overcome the cogging to start moving from a stop. Then

the vehicle may "lurch" into motion. 2. There may be some vibration

when the converter isn't running at 1 to 1. How serious these potential

objections would be needs to be determined. There may be a reasonable

amount of steel to make them trivial yet still get the 100% in most

cruising. It's something for future "fine tuning" experimentation.

[28th] Heating garage up to 13° so I can work in it. It clicked

"on" the instant I moved it up from 5°.

Weight: housing (before epoxy) 13 pounds. Rotating

mechanism: 23 pounds. Heavy enough to lift... but I should be thankful

I can handle them separately, and I don't need a chain hoist, jack or

something!

The housing went on okay, but the mechanism wouldn't push

into the splined socket on the motor, which had always gone easily

before. The shaft didn't quite line up. It seemed the housing had

become slightly trapezoid. I took out some screws to loosen things up,

and worked it in, but it still wasn't straight. Good enough for the

test, but to avoid premature wear I'll want to address that before I

epoxy up the housing. Then one of the heatsinks was nicking one of the

2 by 6'es as it went by. Rather than do it all over again I let it

click. Again the trouble was probably the trapezoid.

When at length I had a camera on underneath and drove out

of the garage... it worked! I went quite slowly and the result was

"catching" on every little lump or root in the grass and when going

upslope, having to press pretty hard on the pedal to get moving again.

But move it did. Pushing through the snow required some extra torque

too. The alume disk still got pretty hot - I got just a whiff of the

heat from in the cab.

I had only a video of the mechanism, and somehow the

camera was aimed too far forward and didn't show the rear driveshaft.

Having no cameraman I set another camera on a tripod. I made another

circle of the driveway and got the footage of both the mechanism and

the moving truck. I drove a little faster this time and it went quite

smoothly. I didn't smell heat from the disk. It was probably pretty

warm, but even at a still pretty low speed I didn't have to press the

pedal so far, so it probably wasn't as hot. And doubtless the spinning

heatsinks made a difference. But as I think about it, there isn't any

good place for the air to enter near the center to be thrown to the

outside by the heatsinks for good air circulation. I can drill a few

holes in the bearing holder plywood. (Start of new list!) I still like

the idea of venting the disk to the windshield to help defog, but it

would be a considerable job.

In my rough driveway, I estimate that even with the 10 to

1 reduction planetary, the hallbach rotor magnet configuration and the

disks almost touching each other, the magnetic coupling was barely

adequate; by no means excessive.

Things that could help increase it would be a thicker

(than ~11mm) alume rotor, using pure alume instead of alloy, and making

a more optimized hallbach magnet rotor. (Pure copper is still better,

but it's heavy and costly. Again, conductivity ratios: Alume alloy 167

/ Pure alume 237 / Pure copper 401. Pure alume 237/167= 1.42 times

better than alloy. 401/237= 1.69 times better than pure alume, or

401/167= 2.40 times better than alume alloy. A 3/4 inch thick pure

alume disk would probably be about twice as good as the alloy one I

used.) Beyond that, it would have to be larger diameter rotors, or even

multiple rotors. (The Chevy Sprint with the already-bought 7 to 1

planetary straight to the wheel is likely to want 12 inch rotors, the

best I can make or get.)

Later I took a third trip around the driveway for no

special reason. I also tried to drive over a 2 by 4 behind one wheel on

the level garage floor. Using a fair amount of pedal, it wouldn't go

from a stop, without a run at it. Just like with the 5 to 1 planetary

in my original concept tests, except this 2 by 4 had all square corners

and so was a bit more challenging. For sure still more magnetism would

be helpful. This sort of a torque converter was surely entirely

impractical before the creation of powerful rare earth magnets.

Magnetic Torque Converter - February 2023 Tests (Video 7 minutes)

https://youtu.be/MFbFC5YkvTM

[March 1st] I thought that with the 10 to 1 planetary reduction times

the 2.2 to 1 rear differential reduction, 22 to 1 should easily drive

over a 2 by 4. I put in a couple of carpentry clamps to keep the body

of the planetary from turning. Sure enough, the truck hopped over the 2

by 4 in both directions with a slight touch of the power pedal. (The

disadvantage to such a fixed ratio being, of course, that the motor

would be

over-revving even at a quite low speeds. With the variable torque

converter it

wouldn't run too fast even at 200 KmPH on the highway. ...BTW, I don't

think I would dare run this truck at over about 60.)

Conclusion: The magnetic coupling surely isn't as strong

as would be desirable. When the ground is dry I'll have to try it on

hills. But it should be good enough to drive around, and my next step

is to epoxy up the housing and make it really solid, and fill in the

open walls so as to keep road dirt out.

But to finish I think I want that 3/4 inch thick pure

alume disk, which should be around double the magnetic coupling of the

present ~11mm alume alloy disk. That should be at least close enough to

an "ideal" strength of magnetic coupling. And, the magnetism doesn't

stop right at the edges of the magnets. I'm sure making the alume rotor

at least 1/4 inch, or better 1/2 inch or more larger radius than the

magnet rotor, would be just that much better. (Egads, that would make

it an 11+ inch rotor instead of 10 inches! I'd have to expand the

housing.)

(And while I'm at it, another 12 inch diameter disk for

the

Sprint. With a 12 inch magnet rotor, that should be around 2.6 times

more torque than this one... which without the truck's 2.2 to 1

differential reduction means only about a 1.18 times torque improvement

to the wheel. But the Sprint is lighter. Or again maybe a 13+ inch size

to catch more outer edge magnetism. Hmm... can I actually fit this in

under the hood?)

Other "Green" & Electric Equipment Projects

No Reports

Electricity

Storage

New Chemistry Batteries

Here we are on the fourth

consectuvie month of battery R & D, and I think I'm awfully close

to making cells that actually perform well. A couple of vital new

things were learned, and a 3D printed case designed.

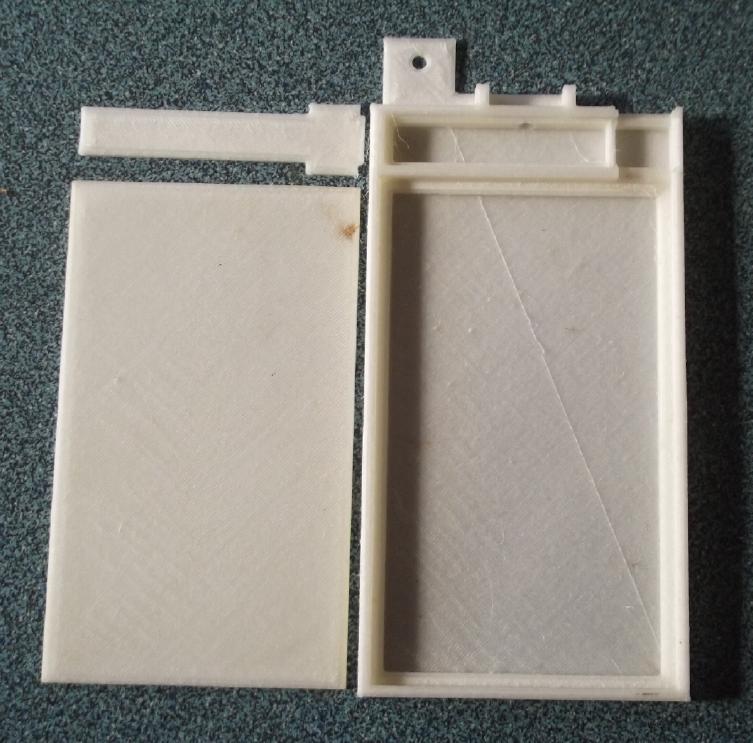

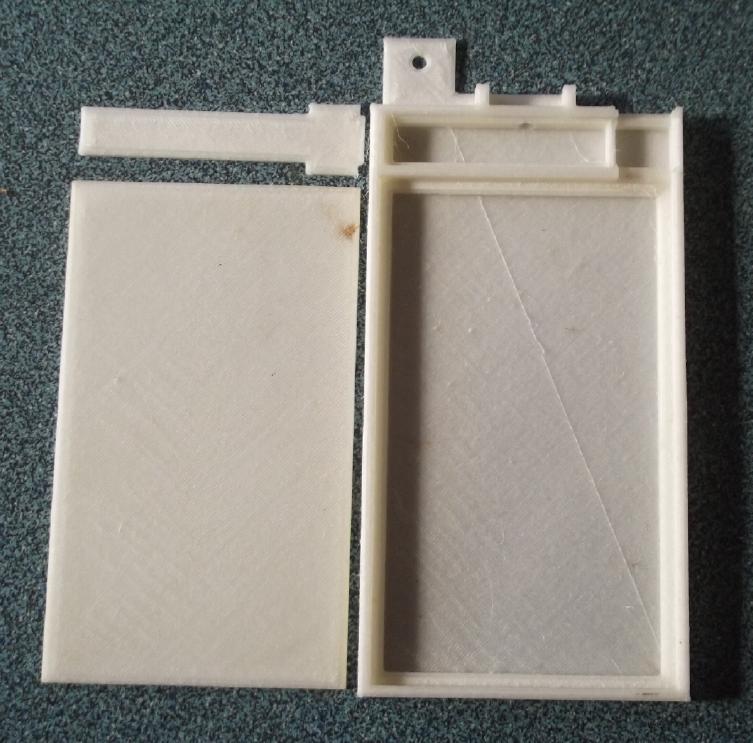

3D Printed Battery Cases

[13th] I went through my

old 3D printed battery case designs and found

one from 2013. Solid plastic might be heavier than packaging tape, but

other than that it (unsurprisingly) seemed to have most of the things I

wanted: in

particular a divider to keep electrolyte materials away from the edges

of the separator papers and a small reservoir at the top for liquid.

Why wouldn't I just use that design?

[13th] I went through my

old 3D printed battery case designs and found

one from 2013. Solid plastic might be heavier than packaging tape, but

other than that it (unsurprisingly) seemed to have most of the things I

wanted: in

particular a divider to keep electrolyte materials away from the edges

of the separator papers and a small reservoir at the top for liquid.

Why wouldn't I just use that design?

I doubled the height of the cell (making it like the ones

I've been making lately) and tweaked various other dimensions, then

printed a sample one in PLA plastic. Just a model to inspect: PLA will

disintegrate from the alkaline electrolyte and it is aggravating that

the "new"

printer won't print ABS properly. However, I should think PVB will work

okay. I printed the back (the bottom on the printer bed) in just three

.3mm layers and discovered that I could put my mouth up to it and force

air through it. But it was half the weight of the ones made from

purchased ABS

sheets and much better adapted to the job. I will likely wrap them up

in packaging tape to keep them from leaking anyway. (Doesn't work.)

As one new innovation I may put in a thin frame after the

separator papers are put in, to keep the upper electrode away from

their edges during assembly as well as the lower one.

Then, and more importantly, I will make a front piece with

ridges (or a thick, lightweight "hollow" piece) that fits just

inside the rim. It can be pushed into the box to compact the

electrodes as much as is useful, the ridges or thickness making it

stick out from the box and against the alume clamp regardless of exact

thicknesses of the materials within. This seems like a much better plan

than anything I've come up with before. Again wrapping in packaging

tape may be the simple way to prevent leaks.

[14th] The next day I tweaked a few

things and then had a hard time

with the 3D printer - again. (It worked so well yesterday!) I looked on

line. Hairspray was recommended as a possible fix to get things to

adhere better. Or glue stick. Of course you don't want the plastic

adhering so well that it's hard to get off, so it's a tradeoff. The

heated glass bed is great if it sticks, because the part just comes

right off once the bed is cool. But the parts lift too easily during

printing. Clean glass (rub with acetone) and warm, dry filament are

vital. I might try printing ABS with the hairspray idea. (...worked

well with the PVB.)

The entire complex shaped case less the main front cover weighed

31.35g, but the front cover, 3mm thick, weighed 31.6g and actually took

longer to print! That makes the whole case 63 grams. That front cover

just can't be good for energy by weight! (Hmm, I forgot about the idea

of printing a thinner sheet with ridges - maybe to look like a heatsink

with fins?)

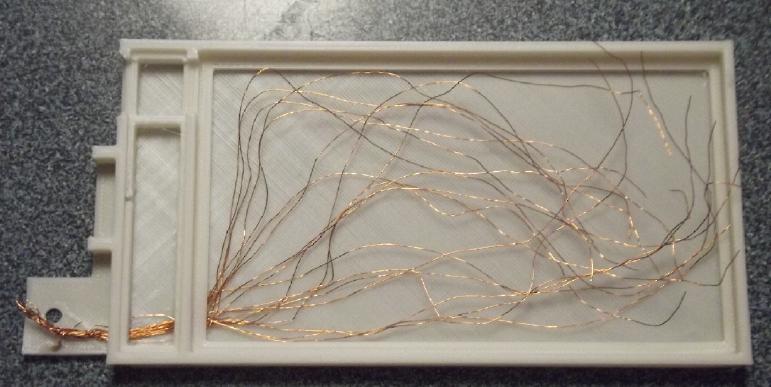

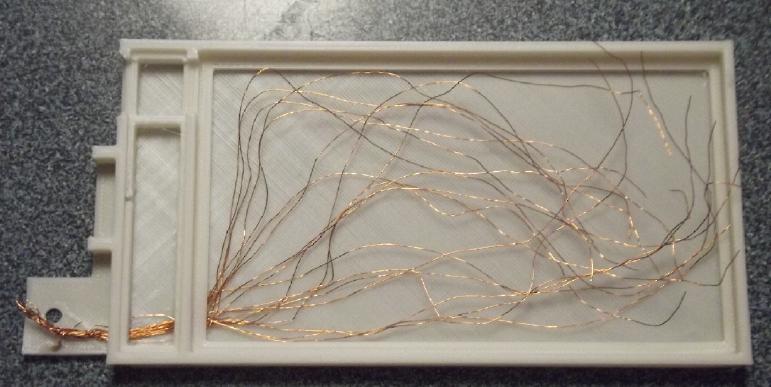

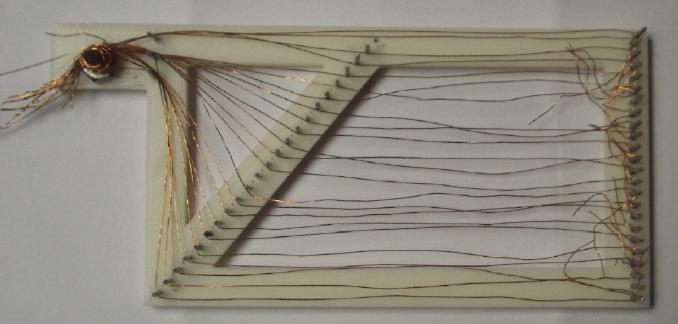

Copper Wire Strands Current Collector?

I had also

been thinking that expanded copper mesh for a

zinc current collector was nice, but not very common or cheap. But what

about

fine stranded wire? I cut open a short length of a #6(?) wire from "cab

tire"(?). It came apart into 7 bundles of fine stranded wires.

I had also

been thinking that expanded copper mesh for a

zinc current collector was nice, but not very common or cheap. But what

about

fine stranded wire? I cut open a short length of a #6(?) wire from "cab

tire"(?). It came apart into 7 bundles of fine stranded wires.

I took

one bundle, about 7 inches long, and combed it out. It was just 2

grams. (The copper mesh was 4-5g.) A bit of a mess, but if one had a

system, it could be well spread out without big gaps. And the zinc

itself would plate onto the copper in charging and do a lot of filling

in.

I took

one bundle, about 7 inches long, and combed it out. It was just 2

grams. (The copper mesh was 4-5g.) A bit of a mess, but if one had a

system, it could be well spread out without big gaps. And the zinc

itself would plate onto the copper in charging and do a lot of filling

in.

[16th] I bought some hairspray and some glue

stick. (They still sell

glue stick!?!)

[16th] I bought some hairspray and some glue

stick. (They still sell

glue stick!?!)

I didn't see anything I didn't like in the second model. I

changed the upper cap a bit to cover two gaps at the upper electrode

terminal strip. I printed that and adjusted a dimension slightly so it

fit better.

I cleaned and sprayed some hair spray onto the printer

bed, then I printed a "for real" cell case with the rather costly PVB

(poly vinyl butyrate) filament. None of it lifted off the bed during

printing - Yay!

I decided to go for the main cover just 2.1mm (7 layers of

plastic) thick. If it goes all the way in I'd have to add some extra

posode material.

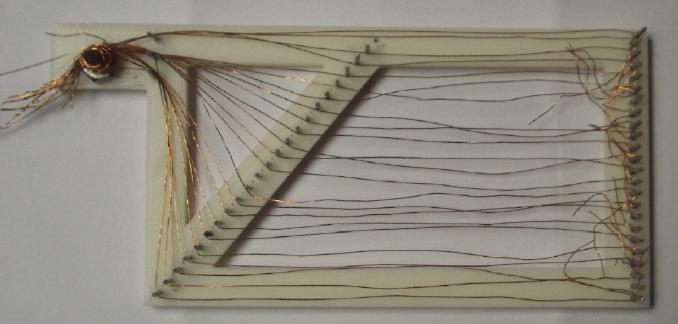

[17th] For the copper wires current

collector idea I had been thinking of

drilling holes in a piece of plastic for small nails in a pattern to

string the wires across and cover the whole electrode with even

distance between wires. That sounded tedious... wait a minute! I can 3D

print a piece of PLA complete with the holes!

[18,19th] I printed the

"pin toad". I had envisioned the wires stung

across taut like on a harp. It didn't really work out that way. and I

didn't

get

them interlocked at the bottom. And it took too long. (It would have

been easier and doubtless neater with one long strand instead of a

bunch of short ones.)

[18,19th] I printed the

"pin toad". I had envisioned the wires stung

across taut like on a harp. It didn't really work out that way. and I

didn't

get

them interlocked at the bottom. And it took too long. (It would have

been easier and doubtless neater with one long strand instead of a

bunch of short ones.)

When I took it off, it was just a mess.

I suppose one could weave some strands across, making it a loose

"window screen" weave. Or wrap long strands around the

zinc sheet, although that would leave half on the wrong side of the

sheet to make indents into the separator paper. Perhaps best to use

the extruded mesh until I run out, and meanwhile hope for an

inspiration.

When I took it off, it was just a mess.

I suppose one could weave some strands across, making it a loose

"window screen" weave. Or wrap long strands around the

zinc sheet, although that would leave half on the wrong side of the

sheet to make indents into the separator paper. Perhaps best to use

the extruded mesh until I run out, and meanwhile hope for an

inspiration.

I used the mesh and put a

zinc electrode into the 3D

printed case. Then I prepared separator papers and put them in place.

Keytones! (Epitaxial crystalline growths?)

[20th] I wetted my nickel hydroxide mix [TE News #176] with

methyl

ethyl keytone and put about 30 grams into the cell. Then I cut a

cupro-nickel current collector, painted the active face with calcium

oxide, and set it on top. I closed the top and wrapped the whole cell

with packaging tape, then put it in the clamps. The clamps seemed to

press the front fully down to the sides, and it was only charging at

30mA. (But it didn't leak - yay!) I took it out, slit the tape, pulled

the top off, and added another 10 grams of Ni(OH)2 mix. (Now around 3.6

amp-hours) This time it definitely didn't press right down. In fact, it

had "too much" material at the bottom and I had to get a couple of

longer screws. Then the re-wrapped cell leaked, badly. So I took it out

again and wrapped another layer of tape on. Then it only leaked a tiny

bit, and I left it. Shining a flashlight through it from behind and

tilting it, I could see there was only a bubble of air in the top

reservoir. But I should have made the filler hole bigger - to see in

and

also so a pH paper strip would fit in - so I adjusted the 3D print

design for next time.

The cell started off with somewhat higher charging

currents than usual - maybe double, but not that order of magnitude

I've been after. 55, 60 then down to 45mA after an hour. With 4

amp-hours of Ni(OH)2 to charge it was still going to take 4 days to

charge. When I put a load on, the voltage would drop down to some

level, but it didn't continue dropping and dropping from there the way

all my previous cells have done ever since I started experimenting and

had learned enough to get battery-like results. In fact, it even seemed

to rise up 10-20mV after 20 or 30 seconds under load. What an

improvement! It could hardly be anything but the ketone - that was

really the only thing different. Like wetting the separator paper in

toluene (or varsol), wetting the positive electrode with a keytone was

unintuitive but vital. It certainly took too many years to figure it

out! (No doubt there are many other workable processes to do similar

things, and I'll just take the first ones I've found, but one must

realize that some process for something seems to be required in the

first place. Perhaps these things aren't required in pH 14 alkaline

solution, and since everyone doing rechargeable aqueous cells until now

has gone with pH14 KOH, that explains why such aren't mentioned in the

literature - not that I've found, anyway. Separators are much

discussed, but it didn't seem related to electrode powder leakage.)

It still leaked a bit. In a few hours there was no water

in the reservoir and the currents were dropping - probably drying out.

(Initial charging was proably using water, too.) I slit the tape and

took it apart, down to removing the top current collector. The nickel

electrode was about 3 to 4mm thick. I'll remark that that's a pretty

thick electrode, to match only a thin slice of zinc - the reason to

find some other positive elctrode element(s). I didn't see that any had

been converted from turquoise Ni(OH)2 into black NiOOH yet, although

there was probably a little, perhaps hidden under the surface.

About half the

electrode substance stuck to the

cupro-nickel current collector and half stayed in the box. I had been

looking them up and thought methyl-methyl ketone (AKA acetone) should

be better than methyl-ethyl keytone, and I availed myself of this

fortuitous opportunity to let it all dry out and wet the outside

portion stuck on the current collector with acetone, with no chance of

it affecting the separators or the other electrode. When I put it back

together there should be enough difference to notice any significant

further performance improvement.

About half the

electrode substance stuck to the

cupro-nickel current collector and half stayed in the box. I had been

looking them up and thought methyl-methyl ketone (AKA acetone) should

be better than methyl-ethyl keytone, and I availed myself of this

fortuitous opportunity to let it all dry out and wet the outside

portion stuck on the current collector with acetone, with no chance of

it affecting the separators or the other electrode. When I put it back

together there should be enough difference to notice any significant

further performance improvement.

[21st] I put the electrode back. It went nicely back into place without

any of the powder crumbling or falling off and jamming things up. I

taped it up, put it back in the clamps, and filled it. It started

charging at only about 45mA - again 4 days to charge all that NiOOH.

[22nd] Performance seemed to be up which

was great news, but my plan for

sealing the cells simply by wrapping them in packaging tape seems to be

a failure. They often seem okay at first but leak worse and worse as

the

hours pass. Supposedly PVB can be solved with alcohol, and it should be

easy enough to seal up the top reservoir area. As for sealing the main

front cover, my confidence level is low, and even the thin back wall

could be slightly porous and electrolyte seep out.

Maybe what I need to do is "pot" them - dip the whole cell

in some kind of epoxy or something? Hmm... one might perhaps epoxy them

into sets, like 12 volts worth, going thick on the ends for rigidity,

and

forget the alume clamps?

[23rd] Having at long last found this ketone/acetone method of getting

more out of nickel oxyhydroxide, it occurred to me to look up the

subject on line. Sure enough, more info! The article (May 2020) said it

was standard practice "in the scientific literature" to heat the nickel

hydroxide to 300°C. That converted some of the hydroxide to oxide.

Hmpf! In all I've read none of it bothered to mention this small but

apparently vital preparation detail. Perhaps that's why my electrodes

have always had such poor conductivity and performance. (What if I just

started with nickel oxide?)

But the article spoke of heating the hydroxide to 900°

for an hour instead. It was said that in theory that would break it

down and ruin it. They tried it anyway and found that the electrode

made from it generated 50% more electricity than usual even after 6000

cycles! Their focus was about using the nickel hydroxide electrode as a

cheaper catalyst (than platimum or paladium) to hydrolize oxygen out of

water, but they also tried it as a battery positive electrode.

That should mean that instead of 90 amp-hours per

kilogram, it would yield about 135. The theoretical limit of 289 AH/Kg

is still a ways off. How about if I heat some up - maybe just to over

300° (about 500°?) for a first try - and after it cooled wet it

with acetone? Could it do even better? After all these years, suddenly

I find two performance improving techniques in two days!

Fortuitously I've just bought a controlled temperature

electric furnace for melting metals! It goes up to 1100°. The

larger crucible should hold quite a lot of the powder. (Since I haven't

potted the cell yet, I think if it comes out easily I'll take out the

Ni(OH)2 and heat treat it (complete w. the monel & samarium oxide

powders), then acetone again. Then I'll treat a new batch of just

Ni(OH)2 powder.)

This time most of the electrode stuck to the metal current

collector. It didn't stick to the separator sheet, so it all came out

easily. There was just a bit of black (presumably NiOOH) right on the

current collector. Not much charged! I put it in at 500° for 25

minutes, then ground

it back to powder and re-did the electrode. Most of the powder had

converted into black nickel oxide, and there was only 27 grams instead

of near 40. (Why am I starting with nickel hydroxide instead of just

nickel oxide from the pottery supply shop, again?) Let's see:

Ni-OH-OH (59+17+17=93) => NiO (59+16) (59+16=75) + H2O (18) boiled

off, or .8 times as much weight. "Should" have been over 30 grams left,

but it might not really have been 40 to start with, and I lost a little

on the way.

Tub of black nickel oxide. A bit

of the source

material, turquoise

Tub of black nickel oxide. A bit

of the source

material, turquoise

nickel hydroxide, is seen around the edges of the cell above it.

If it gets 150 AH/Kg, that's 4.05 amp-hours instead of

3.6, and with less material. (One can always dream!) A little acetone,

grind it with mortar & pestle. (it became fine powder again almost

at once - black powder.)

The rest of the jar of NiOHOH: 78 grams. Put it in crucible, in metal

melting oven @ 500°C for 25'. It "boiled over", strewing powder all

around the lid area. (Yuk!)

I mixed a little epoxy

(25g) and smeared it all over the cell except the top, and with a

couple of pieces of sheet polyethylene to keep the epoxy from the

alume, screwed it into the clamps. I set it by the woodstove to set and

put the remainder of the cup in the freezer to keep for a day or two in

case it needed touching up.

I mixed a little epoxy

(25g) and smeared it all over the cell except the top, and with a

couple of pieces of sheet polyethylene to keep the epoxy from the

alume, screwed it into the clamps. I set it by the woodstove to set and

put the remainder of the cup in the freezer to keep for a day or two in

case it needed touching up.

On line again, I found a

patent by Stan Ovshinsky & crew (company "Ovonics".) Ovshinsky not

only

created the thin film transistor (TFT) that gives us our flat screen

monitors & TV's, but the nickel-metal hydride flooded batteries of

GM's EV-1 fame, that first made electric cars sporty, long range and

long lasting in the late 1990s. Some of these batteries lasted 20+

years. I knew he had formulated the metal

hydride that made these batteries possible, but I didn't know they had

made important improvements to the nickel oxides side as well. Combos

of 3+ elements mixed by special techniques to give more than

one electron valence change per nickel atom... ooh! This is going to

take some reading to get the gist of!

From Ovonics Patent: (Think GM EV-1 battery):

Nickel hydroxide positive electrode material exhibiting

improved conductivity and engineered activation energy

[0051] This discrepancy between theoretical capacity and the capacity

achieved by the prior art can be explained by

the fact that nickel hydroxide has an enormous number of available

sites for hydrogen storage, but that many or most

of those sites cannot be effectively utilized. This is because:

* the NiO-H bond is outside the thermodynamic window accessible for use

in a sealed, alkaline electrolyte cell;

* the competing O 2 evolution reaction;

* poor conductivity where highly charged nickel oxihydroxide material

cannot be fully discharged or is at least severely

* rate dependent, or pockets of charged material may exist even after

discharge due to such poor conductivity;

* the inaccessibility of those sites because the surface of the

particles does not allow electrolyte penetration, and the

* unoptimized crystallite size make the conductivity and "active

surface area" of the crystallites insufficient.

[0060] The benefit of using dopants in addition to, and as a substitute

for cobalt,� cannot be over emphasized. Cobalt

is very expense relative to the other battery materials, and therefore,

significantly influences final NiMH battery cost.

Cobalt also is uniquely capable of being almost completely substituted

for Ni and soluble within the nickel hydroxide

host matrix. The instant inventors believe that nickel hydroxide

materials modified only with cobalt have a tendency to

be single phase. Because these materials avoid becoming "multiphase",

and disordered, they cannot provide the following

desirable properties:

* formation of a spectrum of NiO to H binding energies

* formation of small crystallites (improving accessibility)

* increased conductivity

* multiple electron transfer per Ni atom resistant to swelling and

operable over a wide range of temperatures

* engineering local and intermediate range order

[0061] The instant inventors have found that combinations of elements

(such as Ni-Co-Zn-Mg-Ca or

Ni-Co-Zn-Mg-Ca-Mn-Cu) show synergistic behavior relative to the

expected electrochemical effects

from just the individual elements alone.

Anyway, this cell is sealed in epoxy. How or whether it

works is in limbo, and I don't think I'll be taking apart to make any

changes, but it's less likely to leak than any previous cell!

I filled it to the brim with weak KCl solution (thinking

there's probably enough CuCl2 in it already and some KCl) but of course

it took time for it to penetrate into the zinc electrode and then

across the separator sheet, so I filled it several times until it

stayed full.

It didn't seem to leak. But the charge jumped right up to

the supply voltage and it only started charging at 10mA. In an hour it

didn't go higher. It would go up a little for a bit if I drew some

current off it, but was soon back to 10mA. It seemed really

disappointing. Had heating the nickel hydroxide to oxide wrecked it

instead of improving it? Did I do it too hot or for too long? There was

nothing to do but leave it overnight and see how it was in the morning.

I suspect another cause of low currents is painting the

separator sheet with osmium dopant instead of painting it directly on

the zinc.

With zinc granules and powder it seemed like it would use way too much,

but

now I'm putting in actual zinc sheet again, and I should coat that

instead. (Too late for this cell, now epoxied shut!) The zircon can be

put in with the zinc powder, and the 'extra' parchment separator sheet

can be done away with.

[24th] In the morning the cell charge was up to 17mA. The voltage

wasn't staying up yet and quickly dropped under 1.5V - not too

surprising since it was taking so little charge. I tried a 60 Ω load.

It was less than impressive except for one thing: again, unlike all my

previous cells, the voltage didn't quickly start fading. It fell from

1.4xx to 1.038V when I put the load on, but after 20 minutes it had

risen to 1.110V instead of falling off. After 25 minutes it was still

1.109V. When I removed the load it rose in 1/2 a minute to 1.309V, and

1.314V by one minute. When I put it back on charge it started out

drawing 90mA and only gradually worked its way back down while making

up for the load energy, being still 34mA after 10 minutes. A few

minutes later a 10 Ω load started at .600V and rose considerably in a

minute to .651V. Then 1 Ω started at .100V and rose to .126V, then

dropped to .125V at the 1 minute mark. Again charging started at over

90mA.

I can only hope the cell continues to improve bit by bit for quite some

time. In mid afternoon, then late afternoon, performance was creeping

up marginally but perceptibly.

Manganese Dioxide?

The remarkable change in the performance of the nickel

oxides from wetting the powder with acetone got me thinking about MnO2

again. MnOOH or Mn2O3 (valence 3) is known to not recharge (to MnO2,

valence 4)... but that's in pH14 alkaline solution. What would happen

in salt solution at a lower pH, and if it was treated with acetone? A

friend said he had once tried recharging an ordinary salt dry cell (pH

6?) and it had recovered 70% of its charge. Surely at least some of the

MnOOH or Mn2O3 had to recharge to MnO2 to do that? (He said on the

second recharge, it leaked. Probably the zinc can was weakened and

there would be pressure inside during charging.)

A perpetually rechargeable manganese zinc cell would be

very low cost (in principle) and very high energy by weight: dynamite!

(It could even be made by recycling old dry cell materials.) I decided

it was worth trying. If it worked it would be, at least, the obvious

choice for power grid level stationary energy storage. And it would be

a cheap EV battery too, and quite lightweight even if not "the

ultimate".

Having thought of it, in spite of the many things I should

be doing, I just had to try it. I had another 3D printed battery case.

I had some MnO2 from dry cells. One more expanded copper mesh grill.

One more cupro-nickel sheet cut. And some varsoled watercolor paper

separators. I had the epoxy in the freezer, which would soon harden if

not used...

I put the copper mesh (4.25g) in the case, and a zinc

sheet (13.6g) on that. I painted the osmium dopant straight onto the

zinc. Then I mixed some zinc powder with a bit of zircon

(3.0g+13.6g=16.6g Zn) and spread it around on top. Then I painted a

separator paper with SDBS.

[25th] I took the dry cell MnO2+graphite and added a little Sm2O3 to

raise the oxygen overvoltage. I put in lots of acetone and mixed. I

filled the cell to the brim with this. I painted the current collector

with CaO (=> Ca(OH)2) and put it on top.

Then I got the epoxy and made a horrible mess. I turned

the cell over to do the back first and the front came off and spilled

powder. I did finally put it together, with epoxy and powder all over

the counter. I got some polyethylene sheets into the clamp and screwed

everything down. I set it near the woodstove to set and managed to

clean up the counter with many paper towels and a fair bit of acetone.

My black fingers (in spite of one plastic glove and "I can keep the

other hand away from the epoxy" -- ha ha) were another story. Next...

mid afternoon! Time to get on with my day.

When I unclamped it to look, it was still a mess. An area of the

back had powder all over it and the case was sunken in. The remaining

acetone in the MnO2 evidently had melted the back. Still, it didn't

look hopeless and after I scraped the powder away I filled the cell. It

didn't seem to leak. (fyew!)

When I unclamped it to look, it was still a mess. An area of the

back had powder all over it and the case was sunken in. The remaining

acetone in the MnO2 evidently had melted the back. Still, it didn't

look hopeless and after I scraped the powder away I filled the cell. It

didn't seem to leak. (fyew!)

Then I clamped

both cells -- first time there've been two cells in the clamp!

Then I clamped

both cells -- first time there've been two cells in the clamp!

It read 1.05V right off the bat. Let's see, MnO2-Zn at pH

11 is about +.35 - -1.15 = 1.5 volts. About the same as at any pH. I

set the power supply to 1.60V

and charged through 0.1 Ω. I must have got more things right this time,

because the charging current started way over 100mA - maybe 200. It

soon dropped to 110-125mA... and stayed there! There, at least, was

something with an order of magnitude improvement, at least, over 10 or

20mA.

A few hours later it seemed to not be performing well, but

it was leaking after all. (Sigh!) I figured it was that messy back

area, but the leak was actually around the edge of the front face. I

left it overnight by the woodstove for the cracks to dry out before

smearing some more epoxy on it here and there, and put the Ni-Zn cell

back on charge.

Black powder

seeped through

the poorly "toluened" separator

[26th] The Ni-Zn cell,

however, right from the start hadn't seemed to hold charge. I was

hoping it was just the slow charging, but right from the start, the

more it was charged, the faster it discharged until it was down around

1.3 volts. This time it had actually reached 2 volts where it should

have sat happily, but the charging current was up instead of down, and

as soon as the charge was disconnected it began its relentless and

rapid drop in voltage. I guess somewhere in the compacting the

separator sheet must have ripped at the edge or something. Being sealed

with epoxy I can't take it apart. At least not without totally

destroying it. I suppose it's worth sawing open if I can figure out

what's wrong. Or I could just assume I know what's wrong, and just

lower the lip inside (another millimeter?) so the bottom zinc electrode

area is thinner and the separator doesn't touch the lip until it's

being squeezed in by the upper electrode.

[26th] The Ni-Zn cell,

however, right from the start hadn't seemed to hold charge. I was

hoping it was just the slow charging, but right from the start, the

more it was charged, the faster it discharged until it was down around

1.3 volts. This time it had actually reached 2 volts where it should

have sat happily, but the charging current was up instead of down, and

as soon as the charge was disconnected it began its relentless and

rapid drop in voltage. I guess somewhere in the compacting the

separator sheet must have ripped at the edge or something. Being sealed

with epoxy I can't take it apart. At least not without totally

destroying it. I suppose it's worth sawing open if I can figure out

what's wrong. Or I could just assume I know what's wrong, and just

lower the lip inside (another millimeter?) so the bottom zinc electrode

area is thinner and the separator doesn't touch the lip until it's

being squeezed in by the upper electrode.

I got the last of the epoxy out of the freezer and touched

up the Mn-Zn cell. In the -25°C freezer it still wasn't hardening

much yet after 3 days.

But the Mn-Zn cell is doing the same thing as the Ni-Zn

one, but with higher currents. I supposed it was because the zinc

material doesn't fill the whole cavity, so when the powder is put in

and compacted, it pushes into the voids at the edges and rips the

separator. Nope! I chiseled the Ni-Zn cell apart at the seams and

didn't see any signs of ripping except what I caused opening it. What I

saw instead was a bit of black on the wrong side of the separator

sheet. Some of the nickel oxides nano powder had seeped through it,

creating a short.

I knew I wanted toluene (methyl benzene) and not varsol!

(Maybe the Co-op Home Centre or Home Hardware would order me some

toluene if I asked? Looking it up on line, I found that naphtha was

mainly xylene (dimethyl benzene) and trimethyl benzene. Maybe naphtha

camp stove fuel is the best thing I can get right now? That, and

treating the paper more than once. I had two treated sheets left and I

doused them with varsol again. Then I found some Coleman camp stove

fuel. 3rd time lucky? I doused them with it. But "Naphtha" is an

ambiguous term of various formulas. The methyl benzene ones are

"solvent naptha". But Coleman camp fuel is evidently "petroleum

naphtha" which is quite different. But none of them guarantee specific

chemicals or in specific percentages. Hmm... Varsol is largely "solvent

naphtha", ie, di- and tri-methyl benzene.

[27th] I looked on line and found toluene in 1 liter cans at Home

Hardware. I phoned Home Hardware in Masset. They had it! Apparently I

had somehow neglected to phone the one place of three on this island

that might - and did - have it when I was looking for it 2 or 3 months

ago. I bought it over the phone and called Port Air Cargo to deliver it

to me. (Sigh, 40$ instead of 20$. But it's too far for the Leaf and

there's a brake sticking on my Toyota Echo that needs fixing before I

try going anywhere in it again. That's likely to cost much more than

the toluene! Repair will have to wait until it stops snowing and is

warmer.) It came Wednesday, March 1st and I doused the two separator

sheets once more, this time in the desired stuff! Between that and 4

dousings, hopefully I can start making battery cells that actually work

properly and last a long time!

[28th] I 3D printed two new cell cases. The second one was because

somewhere the devious software had switched itself to "print support

structures" and it filled in the lower slots and the filler hole - ug!

Why would it do such a thing on a printer it knew had just one extruder

and no soluble filament? It had been printing the slots just fine with

almost no sag. (to my initial surprise) I could drill the hole out, but

it would be difficult to cut the two thin slots where they need to go

without wrecking the whole print.

To be continued...

My

Solar

Power

System

I think maybe I like "photo panes" as a (somewhat) short

form for "solar panels", or "panes" for "panels".

The Usual Daily/Monthly/Yearly Log of Solar

Power Generated [and grid power consumed]

(All times are in PST: clock 48 minutes ahead of local sun time, not

PDT which

is an hour and 48 minutes ahead. (DC) battery system power output

readings are reset to zero

daily (often just for LED lights, occasionally used with other loads:

Chevy Sprint electric car, inverters in power outages or other 36V

loads), while the

grid tied readings are cumulative.)

Daily Figures

Notes: House Main

meter (6 digits) accumulates. DC meter now

accumulates until [before] it loses precision (9.999 WH => 0010

KWH), then is

reset. House East and Cabin meters (4

digits) are reset to 0 when they get near 99.99 (which goes to "100.0")

- owing to loss of second decimal precision.

Km = Nissan Leaf electric car drove distance, then car was charged.

New Order of Daily Solar Readings (Beginning May 2022):

Date House, House, House, Cabin => Total KWH Solar [Notable

power

Uses; Grid power meter@time] Sky/weather

Main

DC East Cabin

January

31st 4233.39, 7.05, 7.71, 1.79 => 5.78

[4666@17:30]

February

1st 4234.63, 7.19, 8.50, 2.38 => 2.76 [55Km;

4713@17:30]

2d 4236.10, 7.29, 9.46, 3.10 => 3.25

[4751@18:00]

3rd 4236.96, 7.38, 9.85, 3.45 => 1.69 [90Km;

4797@17:30]

4th 4238.16, 7.45, 10.56, 4.04 => 2.57 [50Km; 4840@17:30]

5th 4239.53, 7.56, 11.33, 4.60 => 2.81 [4880@17:30]

6th 4241.88, 7.65, 13.13, 5.89 => 5.53 [60Km; 4919@18:00]

7th 4244.94, 7.75, 15.03, 7.57 => 6.74 [4952@18:00]

8th 4245.74, 7.82, 15.37, 7.87 => 1.51 [60Km; 4995@18:00]

9th 4247.36, 7.93, 16.75, 8.80 => 4.04 [5029@18:00]

10th 4249.96, 8.06, 18.90, 10.11 => 6.19 [90Km; 5071@17:30]

11th 4251.09, 8.09, 19.49, 10.60 => 2.28 [50Km; 5112@18:00]

12th 4253.22, 8.15, 21.28, 11.95 => 5.33 [5146@17:30]

13th 4257.76, 8.23, 24.74, 14.57=>10.70 [5174@18:30]

14th 4260.40, 8.34, 27.21, 16.15 => 6.80 [5211@17:30] SNOW!?!

15th 4261.01, 8.46, 27.59, 16.49 => 1.65 [60Km; 5255@17:30]

16th 4264.66, 8.55, 29.60, 18.29 => 7.55 [35Km; 5294@18:30]

17th 4266.49, 8.66, 30.67, 19.18 => 3.90 [5339@20:00]

18th 4268.18, 8.77, 31.64, 19.95 => 3.54 [55Km; 5371@18:00]

19th 4269.15, 8.87, 32.17, 20.38 => 2.03 [5404@18:30]

20th 4272.59, 8.97, 35.00, 22.46 => 8.45 [5422@18:30]

21st 4275.27, 9.05, 37.42, 24.00 => 6.71 [5454@18:00]

22d 4279.99, 9.23, 41.07, 26.92=>11.47 [60Km; 5480@18:00]

MINUS -2° and gusty winds? (probably -5° last night?)

23d 4282.27, 9.31, 41.95, 27.94 => 5.26 [5542@18:30] -5°

Today, powerful wind gusts blew over carport solar panels.

24th 4284.16, 9.42, 42.30, 28.80 => 3.21 [5586@18:00] -0°, snow.

Fixed roof, didn't get sunpanes back up. One is bent, must be broken.

25th 4286.92, 9.50, 43.00, 30.33 => 5.07 [55Km; 5631@18:00]

26th 4288.24, 9.59, 43.84, 31.06 => 2.98 [5667@18:00]

27th 4288.94, 9.67, 44.59, 31.45 => 1.92 [5706@18:00] Snow covering

most of the panes.

28th 4292.58, 9.75, 45.81, 34.26 => 7.75 [5745@18:30] Snow melted

off panels.

March

1st 4294.21, 9.86, 46.09, 35.00 => 2.76 [5781@18:00] Snow melting in

rain. Didn't get carport panels fixed yet.

2d 4296.29, 10.0, 46.94, 36.48 => 4.55 [50Km; 5817@18:30] More

snow! Some sun too.

3rd 4296.92, 0.09, 47.32, 36.84 => 1.46 [85Km; 5861@19:00] Still

snow on panels.

4th 4303.26, 0.21, 48.70, 41.14 =>12.14 [30Km; 5895@19:00] Snow

musta melted.

5th 4310.38, 0.30, 50.05, 46.08 =>14.40 [5921@19:00]

Chart of daily KWH from solar panels.

(Compare FEBRUARY 2023

(left) with January 2023 & with February 2022 - but note number of

solar

panels differs from last year.)

Days of

__ KWH

|

February 2023

(18 solars)

|

January 2023

(18 solar panels)

|

February 2022

(15 s. panels - 2

mostly in shade)

|

0.xx

|

|

5

|

2

|

1.xx

|

4

|

8

|

4

|

2.xx

|

6

|

7

|

8

|

3.xx

|

4

|

2

|

3

|

4.xx

|

1

|

3

|

2

|

5.xx

|

4

|

2

|

5

|

6.xx

|

4

|

|

3

|

7.xx

|

2

|

2

|

1

|

8.xx

|

1

|

2

|

|

9.xx

|

|

|

|

10.xx

|

1

|

|

|

11.xx

|

1

|

|

|

12.xx

|

|

|

|

13.xx

|

|

|

|

14.xx

|

|

|

|

15.xx

|

|

|

|

Total KWH

for month

|

132.46

|

93.79 |

102.14

|

Km Driven

on Electricity

|

713.1 Km (odo 92583)

(110KWH?)

|

811.9 Km

(~130 KWH?) |

893.8

(~130 KWH?)

|

Things Noted - February 2023

* Nothing much

Monthly Summaries: Solar Generated KWH [& Power used from

grid KWH]

Month: House system (+ DC system at house) + Cabin system = KWH made

[used from grid]

2019

March 1-31: 116.19 + ------ + 105.93 = 222.12 KWH - solar [786 KWH

used from

grid] (10 solar panels

total)

April - 1-30: 136.87 + ------ + 121.97 = 258.84 KWH [608 KWH]

May - 1-31: 156.23 + ------ + 147.47 = 303.70 KWH [543 KWH] (11th

solar panel connected on lawn on 26th)

June - 1-30: 146.63 + 15.65 + 115.26 = 277.54 KWH [374 KWH] (36V, 250W

Hot Water Heater installed on 7th)

July - 1-31: 134.06 + 19.06 + 120.86 = 273.98 KWH [342 KWH]

August 1-31:127.47 + 11.44+91.82+(8/10)*96.29 = 307.76 KWH [334 KWH]

(12th solar panel connected

on lawn Aug.

1)

Sept.- 1-30: 110.72 + 15.30 + 84.91 = 210.93 KWH [408 KWH]

(solar includes 2/10 of 96.29)

Oct. - 1-31: 55.67 + 13.03 + 51.82 = 120.52 KWH solar

[635 KWH used from grid]

Nov. - 1-30: 36.51 + 6.31 + 26.29 = 69.11

KWH solar [653 KWH used from grid]

Dec. - 1-23: 18.98 + .84* + 11.70 =

31.52

KWH, solar + wind [711 KWH + 414 (while away) = 1125 from grid]

2020

Jan. - 6-31: 17.52 + ------* + 10.61 = 28.13 KWH,

solar+ wind [1111 KWH from grid]

Feb. - 1-29: 56.83 + ------* + 35.17 = 92.00 KWH,

solar + wind [963 KWH from grid]

* The solar DC system was running the kitchen hot water

tank. Now it's only running a couple of

lights - not (usually) worth reporting. So there's just the 2 grid tie

systems:

house and "roof over travel trailer" (AKA "Cabin").

One year of solar!

March - 1-31: 111.31 + 87.05 = 198.37 KWH solar total

[934 KWH from grid]

April - 1-30: 156.09 + 115.12 = 271.21 [784 KWH

from grid]

May - 1-31: 181.97 + 131.21 = 313.18 KWH

Solar [723 KWH from grid]

June - 1-30: 164.04 + 119.81 = 283.82 KWH Solar [455 KWH

from grid]

July - 1-31: 190.13 + 110.05 = 300.18 KWH Solar [340

KWH from grid]

August- 1-31: 121.81 + 83.62 = 205.43 KWH Solar [385KWH

from Grid]

Sept. - 1-30: 110.68 + 65.09 = 175.77 KWH Solar [564

KWH used from grid]

Oct. - 1-31: 67.28 + 42.55 = 109.83

KWH Solar [1360 KWH from grid -- Renters!]

Nov. - 1-30: 35.70 + 20.79 = 56.49

KWH of Solar [1301 KWH from grid]

Dec. - 1-31: 19.78 + 11.31 = 31.09

KWH Solar [1078 KWH used from grid]

2021

Jan: 25.47 +

18.58 = 44.05

KWH Solar [1185 KWH used from grid] (1

solar panel moved to DC system only -- 11 panels)

Feb: 47.18 + 33.22 = 80.40

KWH Solar [1121 KWH used from grid]

Two years of solar!

Mar: 81.73 + 55.22 + 2.2 (DC) = 139.15 KWH

Solar

[1039 KWH grid]

April: 161.83 + 112.35 + .44(DC) = 274.62 KWH

Solar

[680 KWH from grid]

May: 156.25 + 97.22 + 1.29(DC) = 254.76

KWH

Solar [678 KWH from grid]

June: 197.84 + 112.07 + 2.21(DC) = 312.12 KWH Solar

[& 448 KWH from grid]

(Connected

12th solar panel -- 13 panels total but one goes to DC system