Turquoise Energy News Report #190

Covering

Research & Development Activities of March 2024

(Posted April 12th 2024)

Lawnhill BC Canada - by Craig Carmichael

[CraigXC at Post dot com]

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Month In "Brief"

(Project Summaries etc.)

-

"Everlasting" Cu-Zn

Battery Development - Zinc-Air Batteries for Aircraft! -

Open Loop Air Heat Pumping - Cabin Construction - Gardening

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

* More on Tinnitus & AC Power: Beanie & Pillowcase; EMF

Meters; Car Shields - Scattered

Thots (DST Gripes etc) - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems (No reports)

Other "Green"

& Electric Equipment Projects

* Open Loop Air Heat Pumping

("OLAHP")

Electricity Storage:

Batteries

* Copper-Zinc cells: Experiments, Designs...

Electricity Generation

* My Solar Power System: - The Usual Latest Daily/Monthly

Solar Production log et cetera - Monthly/Annual Summaries,

Estimates, Notes

"Everlasting" Cu-Zn

Battery Development:

Once again I

worked mostly on battery research and experiments - a solid five months

now and headed for six with April. I've long been sure that fantastic,

simple, cheap and high energy everlasting battery designs are possible.

They have eluded everyone so far, but at long last I feel I'm close to

having one. It sure takes time away from other projects, but I

persevere. And after all Edison did [at least] over 30 years of battery

research before he came up with nickel-iron alkaline cells, which were

much the best rechargeable batteries up to that time.

Once again I

worked mostly on battery research and experiments - a solid five months

now and headed for six with April. I've long been sure that fantastic,

simple, cheap and high energy everlasting battery designs are possible.

They have eluded everyone so far, but at long last I feel I'm close to

having one. It sure takes time away from other projects, but I

persevere. And after all Edison did [at least] over 30 years of battery

research before he came up with nickel-iron alkaline cells, which were

much the best rechargeable batteries up to that time.

Over March I had better success with a long, long nagging

problem: apparently all my symptoms are caused by "zinc oxide

passivation"

where migrated ZnO doesn't quite connect and recharge, but lodges in

all the pores at surface of the electrode, blocking the electrolyte and

"smothering" the electrode. As the cell discharges the output voltage

drops and drops not because it's very far discharged, but because of

increasing blockage. And this gets worse and worse without ever a full

recovery by recharging.

Now I still wasn't getting satisfactory performance, but

significantly it stayed the same day after day and didn't keep getting

worse.

The main reason for the improving picture is that now I

have a glimmering of what the problem is. Solutions (technical or

societal) aren't very likely from seeing the symptoms but without

understanding their root cause. I added 10% sodium sulfate to

the electrolyte, and I upped the pH to 13 or 14 (higher than

I wanted and probably higher than necessary - but whatever works) with

7.5% potassium hydroxide so that migratory zincate ions can

(presumably) form. I'm assuming the osmium doping helps the solid ZnO

at the surface to turn into dissolved Zn(OH)4- ions and go back into

the electrode as the cell charges.

As I understand it, during

discharge [in alkaline solution] zincate ions form up

to their solubility limit, which is not high. When that is reached, as

more zinc continues

to be oxidized, excess zincate particles (wherever they are) turn into

the oxide, ZnO. During charge, zinc oxide particles connected to the

electrode and zincate ions when they touch it are turned back into zinc

metal in the electrode. As these zincate particles disappear the

concentration drops, making way for more oxide to dissolve into

zincate - if it will. I think it's the osmium catalyst that helps turn

disconnected -

passivated - zinc oxide back into zincate ions as the concentration

reduces. Herein, at last, seems like a plausible theory of how a

rechargeable zinc

electrode can work, given the strong penchant for

passivation of zinc oxide.

I had wondered if a thin layer of osmium on

the separator was really enough when "the surface" of the powder

electrode is really whatever spaces the electrolyte reaches into, but

just now as I write this, I think that as the zincate ions connect to

the active electrode and charge back to zinc metal, the active

electrode thickens and pushes the passivated ZnO layers out toward the

osmium 'film'. So during charge the outer edge of the passivated oxide

keeps getting converted to zincate, which wanders into the electrode

and charges, sending the remaining ZnO out to the osmium, and this

process continues until the oxide is all converted back into zinc. In a

sense this makes it a "flow" battery, but the "flow" is inside the

mostly solid electrode. Anyway that's my new theory of operation. It

should also have very high potential zinc utilization, perhaps

approaching 100%: 820 amp-hours or just over a kilowatt-hour of energy

per kilogram of zinc. (An equal weight of copper with almost the same

amp-hours for a cell that might be rated 1.1 volts, has low voltage and

adds little to the energy, but two electrodes are necessary so we're

down at most to 500 WH/Kg, less with the non-contributing components.

Other positive electrodes - besides weightless "air", which has its own

challenges - contribute less by weight and volume overall.)

With the SDBS blocking all passage of zincate across

electrodes and zirconium silicate raising the hydrogen generation

voltage, it solves all zinc's four problems: (1) dendrites, (2)

hydrogen generation, (3) amalgamation of zinc particles and shape

changes of the electrode (it's continually shifting, amalgamating and

dissolving!) and (4) passivation. And now I realize I need to get the

acetaldehyde/osmium layer to be right on the surface of the

separator sheet. If I have it right, that should certainly make for a

"forever" working negative electrode.

(BTW Both "sulfonate" and a "heavy metal" layer are in accord

with techniques noted in the 2017 Zinc-Air

Battery paper that have been tried or conceived to potentially solve

zinc's

problems.)

My latest cell in March performed poorly but continued to

work about the same and

even improve some over 2-1/2 weeks. Highest currents (short circuit,

charge current after severe discharge) approached an amp, which is

the target. But the thin separator, thin nonwoven PP fabric ironed onto

parchment paper, eventually let dendrites through and there was more

and more leakage current. So I've gone back to toluene treated thick

watercolor paper.

Earlier I noticed on one separator sheet under the

microscope that the osmium powder was spread rather thinly and

unevenly, perhaps explaining why it doesn't work better. What I will

try next is to make a new pair of electrodes and this time use new

acetaldehyde that I've just bought to replace what I made myself in

~2011, and add osmium powder to it more generously. (That will probably

finish off my ~2011 one gram vial of fine Os powder.) On opening the

acetaldehyde, I note that I haven't smelled that forgotten 'flowery'

aroma in years, which says that my old acetaldehyde has been long since

diluted to nothing by adding too much water.

As we head into April I'm thinking of trying sheets of

copper coated zinc and sheets of cupro-nickel again instead of powder

electrodes. I can't infuse the dopant through a zinc powder electrode

without using a crazy amount of rare osmium, so zinc sheets may work

better because I only need to paint the flat surface, rather than the

effective surface being spread through the whole electrode. For the

plus, I had thought the cupro-nickel sheets worked great at first but

deteriorated, but it was probably the zinc that was deteriorating and

CuNi sheets continue to work fine.

Powder electrodes may seem to provide a lot more surface area to react,

but thin sheets have more surface interaction area with many more thin

electrodes in the same space, which should also multiply current

capacity.

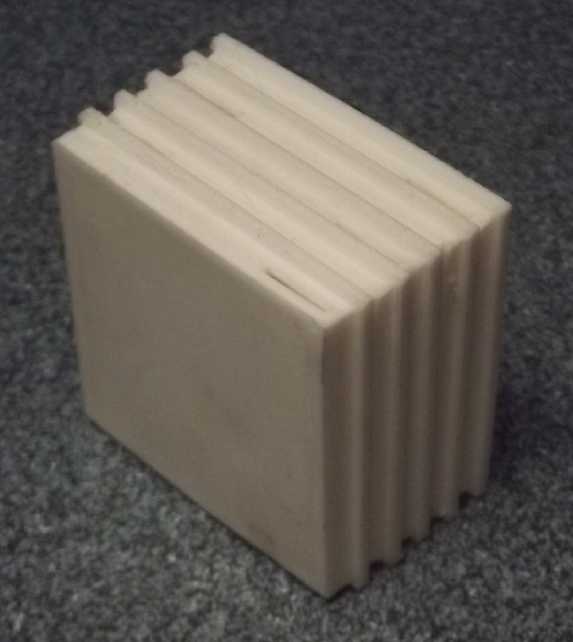

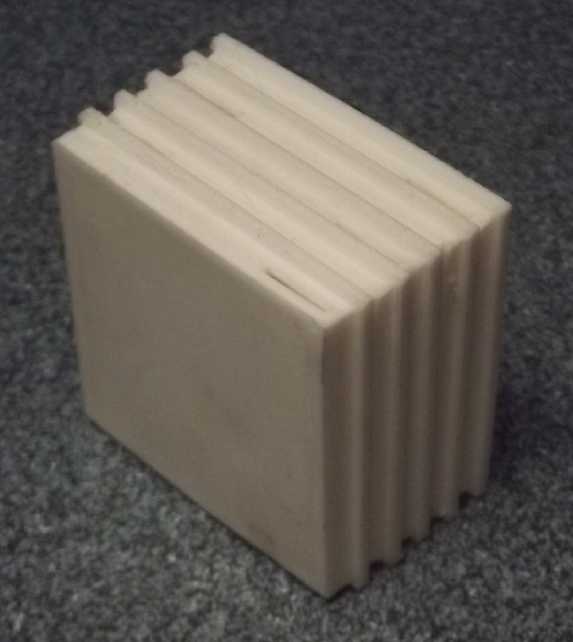

On the construction side

I started making "stacking tray" electrodes, still 50x50x6mm I.D. with

the separator sheet at the bottom of each tray. These are loaded with

exact weights of powder (and the current collector/terminal tab piece)

via the open top and then the next electrode is stacked and glued on

top, alternating Cu-Zn-Cu-Zn... The bottom tray has a solid bottom and

a solid top sheet glues over the top one. This is the compact but easy

to assemble and has just one exact size separator paper between each

pair. Then the stack is turned sideways with the current collectors.

That's the idea. I only stacked two (and filled the rest of the box

with spacers) because they still weren't working great.

On the construction side

I started making "stacking tray" electrodes, still 50x50x6mm I.D. with

the separator sheet at the bottom of each tray. These are loaded with

exact weights of powder (and the current collector/terminal tab piece)

via the open top and then the next electrode is stacked and glued on

top, alternating Cu-Zn-Cu-Zn... The bottom tray has a solid bottom and

a solid top sheet glues over the top one. This is the compact but easy

to assemble and has just one exact size separator paper between each

pair. Then the stack is turned sideways with the current collectors.

That's the idea. I only stacked two (and filled the rest of the box

with spacers) because they still weren't working great.

I also tried ironing the PP fabric-parchment paper

underneath instead of placing it inside. That way no inner lip (or

really, really exact fit) was needed in the tray design.

With 50x50mm area minus the crosshatch and any inside lip,

in figure it's only about 20 sq.cm of interface area between

electrodes. If the target is 50 mA/sq.cm maximum current, that's about

an amp of current between each two trays - or two amps per tray except

the end ones.

I don't think I can iron on PP fabric with thick

watercolor paper, so the papers will have to go inside.

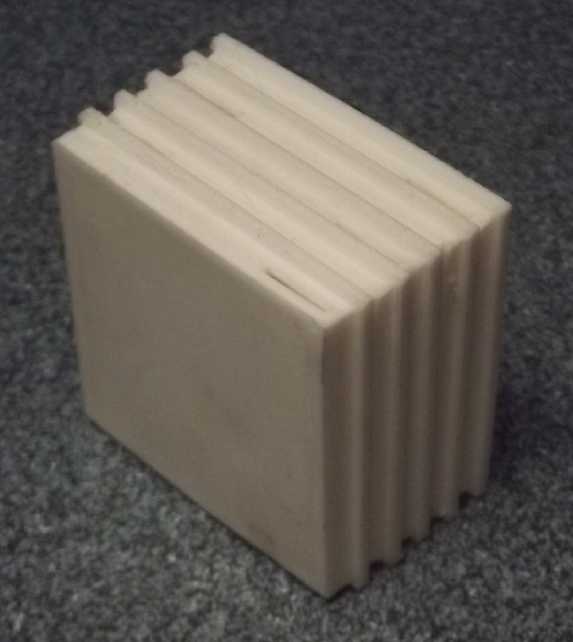

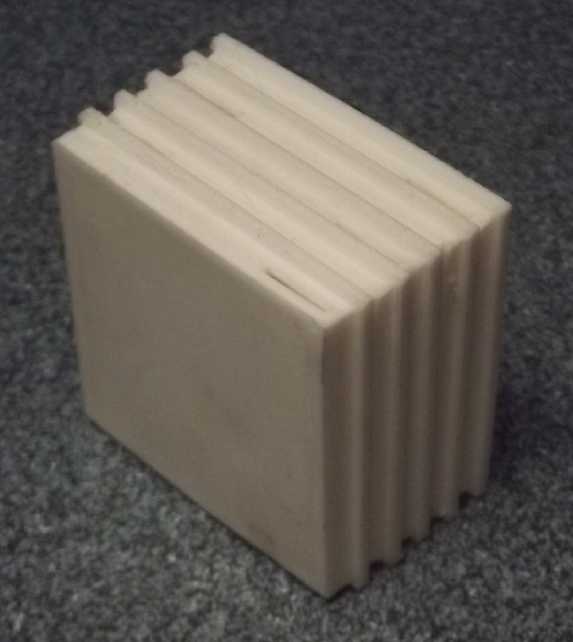

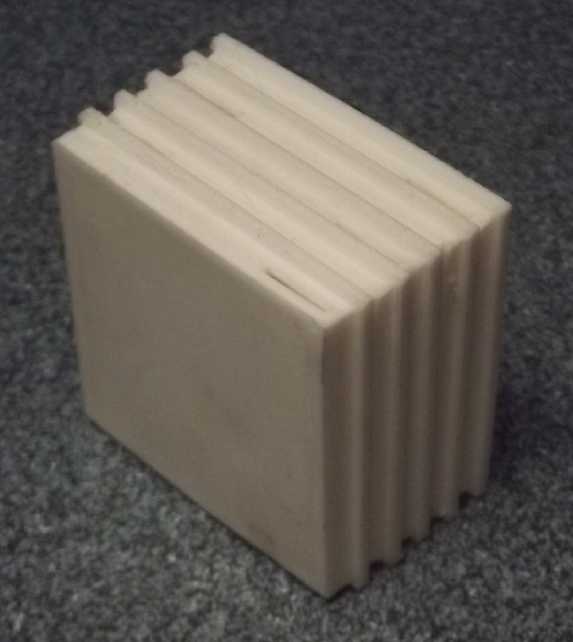

Stack of five trays (there the

PVB filament ran

out)

Stack of five trays (there the

PVB filament ran

out)

In making these I ran out of PVB 3D printer filament and

tried to use ABS. ('Easiest to use' PLA disintegrates in alkali.) After

much frustration (including damp filament that just plain wouldn't work

until dried by the woodstove for a week or two) kept I wondering why it

wouldn't print nicely like with the old RepRap 3D printer, and finally

I realized it: the old Pronterface slicer that I used with the old

printer did .4mm layers of plastic, but Cura does .2 or .3mm. Not only

does it take much longer to print than the old way, but the first layer

of ABS is thin enough to bend and warp, easily warping the print and

coming un-stuck form the bed during printing. I hope for better results

next time by changing the settings. (I think this printer can

do .4mm vertical layers. But it might depend on nozzle diameter.)

Trying to keep the 3D printer bed

warm with a

400W heater and cardboard.

Trying to keep the 3D printer bed

warm with a

400W heater and cardboard.

It didn't seem to help much.

The three ABS prints that worked.

The three ABS prints that worked.

But the bottoms of the corners are curled up.

I also made a

new cell housing, a little wider to hold the extra lip of the trays and

taller to hold terminal tabs inside, all bent over to make the just two

external connections from rows of multiple trays.

I also made a

new cell housing, a little wider to hold the extra lip of the trays and

taller to hold terminal tabs inside, all bent over to make the just two

external connections from rows of multiple trays.

(If this was full with eight trays, each holding about 10

grams of zinc or copper, it might be 30 amp-hours, ~1.1V, 33

watt-hours, in just 150(?) grams.)

Zinc-Air Batteries for Aircraft?

I had sort of cast off metal-air cells as not very

practical. The trouble with air electrodes is that they are exposed to

the environment. Not only O2 but CO2 enters, and CO2 gradually

deteriorates the alkaline electrolyte and the cell, turning hydroxides

into carbonates. (Salt electrolyte with only a little potassium

hydroxide added might be more immune?) H2O too can exit - or enter - so

the cell's delicate balance of hydration changes.

Better then to use a positive electrode like copper and

more or less seal the cell? In general I think so, but aircraft is one

application where cutting the weight of a battery in half again is

probably valuable enough to warrant using cells that need some "looking

after" and even occasional replacement. The much improved flying time

and range that would be provided by super lightweight zinc-air

batteries could open up whole new areas for adoption of electric

aircraft.

Open Loop Air Heat Pumping (OLAHP)

I finished

piping and insulating the indoor-outdoor heat exchanger. I brought it

into the house and connected the cold air intake through an existing

hole in the house wall (from the 2020 experiments). But there it sat.

Maybe it'll be ready by summer?

I finished

piping and insulating the indoor-outdoor heat exchanger. I brought it

into the house and connected the cold air intake through an existing

hole in the house wall (from the 2020 experiments). But there it sat.

Maybe it'll be ready by summer?

Cabin Construction

Work on this consisted mainly of just two things

1) getting the garage door from raw styrene foam to covered with the

galvanized sheet metal from the refuse station.

Start of month

Start of month

End of month

End of month

Broader perspective

Broader perspective

Unfortunately the door weighed about three times as much

with the metal on it as without. When I went to pick it up and put it

in place it took me by surprise and I once again re-injured my "tennis

elbow". Yikes! There are all kinds of things I need to do that I can't

until it heals, and I keep re-hurting it. 10 months now? My right hand

is weaker from three separate injuries of long ago and also being my

non-dominant hand, it can't take up much of the slack. Longer term I

can only live on the acreage if I'm able bodied!

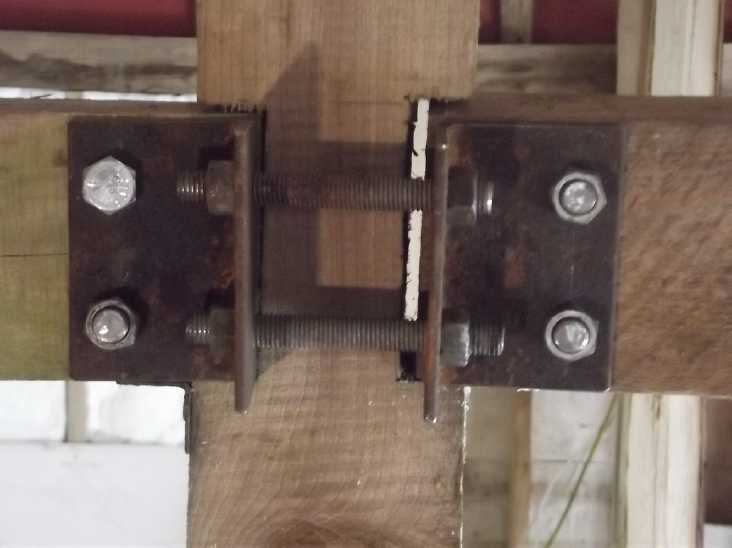

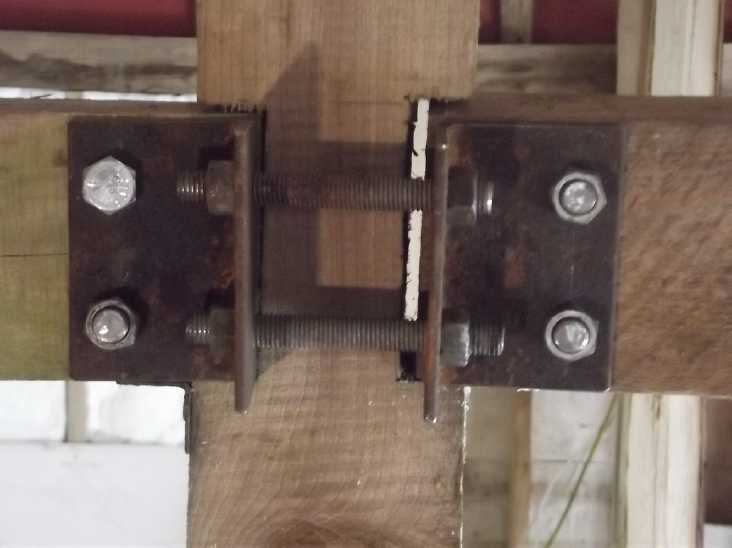

2) The center beam between

the long walls is made of two pieces with a "temporary?" post between.

(It doesn't go to the roof.) I noticed the beam pieces were pulling

apart, bending a light angle iron piece (now removed) originally

holding them to

the post. The roof is pushing the walls apart and will start to sag in

the middle. In ultimate potential, things could collapse. After finding

a very heavy piece of angle iron at the refuse station, I cut and

drilled two pieces, then drilled holes through the beams, put the

pieces on with 3/4 inch bolts, removed the bent piece, and started

tightening to pull it back

together.

2) The center beam between

the long walls is made of two pieces with a "temporary?" post between.

(It doesn't go to the roof.) I noticed the beam pieces were pulling

apart, bending a light angle iron piece (now removed) originally

holding them to

the post. The roof is pushing the walls apart and will start to sag in

the middle. In ultimate potential, things could collapse. After finding

a very heavy piece of angle iron at the refuse station, I cut and

drilled two pieces, then drilled holes through the beams, put the

pieces on with 3/4 inch bolts, removed the bent piece, and started

tightening to pull it back

together.

This had the effect of pushing the pieces of the beam

sideways since the other side had no tensioner. So I've cut two more

pieces for the other side of the beams, but the 6 inch long bolt holes

don't

quite line up. Somehow I have to considerably file out two of the holes

in the metal without wrecking my elbow again. My milling machine won't

run (I'm sure it doesn't like being in the unheated shop) and I'm sure

I would also hurt my elbow again if I tried to drag it into the house.

Without wanting to complain, my elbow is turning into a more and more

serious problem.

Gardening

I bought several "exotic" varieties of seed potatos:

Violet Queens (purple throughout), Russian Blue (mottled purple/white),

Warba (?) and Huckleberry Gold (yellow flesh). This on top of my usual

three varieties to replant of white, red and purple with white eyes

(all with white flesh). I had bought the violet, fingerling, and yukon

gold, before, but I was planting them all randomly and either lost them

in the heavy freeze in February 2023 or ate them all.

This time variety each got its own row, but I found I had

bought too many. I seemed to have nowhere to plant my own old potatos

from last year!

I didn't dump

the lettuce, planted in September, that had got tough and bitter after

all winter under the

LED light. I kept watering it and now it was flowering to go

to seed.

I didn't dump

the lettuce, planted in September, that had got tough and bitter after

all winter under the

LED light. I kept watering it and now it was flowering to go

to seed.

After some months the ~50

'beans' growing on a potted coffee plant were ripening. (Someday I'll

have enough beans to roast and grind for a pot of coffee?)

After some months the ~50

'beans' growing on a potted coffee plant were ripening. (Someday I'll

have enough beans to roast and grind for a pot of coffee?)

...and a lot of the lower leaves were falling off.

Probably from the LED lighting coming from above and not reaching the

lower branches. They're in the south wall bay window and the LED

lighting was intended to be "supplemental", but there's not much

outdoor light in winter.

Per a youtube video (Genius

way to plant carrots) I seeded carrots on a cloth in a plastic

container and when they sprouted I used tweezers to plant one in each

place in cardboard egg cartons, with the bottom punched out so the root

could grow freely. That way presumably they would all be sprouted (no

"duds") and I wouldn't have to thin and weed them. (They were there but

hardly show in the foto.) Carrot roots grow fast, so I put them in the

garden after a few more days. But there seemed to be a lot of empty

spots by then, and I probably put them in too early.

Per a youtube video (Genius

way to plant carrots) I seeded carrots on a cloth in a plastic

container and when they sprouted I used tweezers to plant one in each

place in cardboard egg cartons, with the bottom punched out so the root

could grow freely. That way presumably they would all be sprouted (no

"duds") and I wouldn't have to thin and weed them. (They were there but

hardly show in the foto.) Carrot roots grow fast, so I put them in the

garden after a few more days. But there seemed to be a lot of empty

spots by then, and I probably put them in too early.

I should have been potting tomatos and peppers in

March but didn't get to them.

I have also been reluctant to go out in the gardens and

prepare beds for fear of wrecking my elbow again.

In

Passing

(Miscellaneous topics, editorial comments & opinionated

rants)

More

on

Tinnitus

&

AC Power: Beanie & Pillowcase; Car Shields;

EMF Meter

About the start of March the conductive tuque and

pillowcase, with silver woven into the fabric to help block electric

fields, arrived from "LessEMF.com". (Later Perry found a Canadian

seller of similar goods, SafeLivingTechnologies.com) I started wearing

the tuque all day. At night I put the "pillowcase" on top of my pillow,

lay my head on one end, and folded the other end over my head. on top

of having grounded the metal house roof at multiple points. In a few

days I could hear that things were changing. The loud piercing tone

sort of "broke up" into on and off tones and high frequency noise.

But I was disappointed that with all this the ringing

still didn't really seem to be fading away. On the 13th I tried

checking the volume of the ringing in my ears with the on-line signal

generator and audio meter again. Again it's pretty hard to tell, but I

had the impression it was down maybe around 3 dB from 42 to 39 dB,

which is actually half power. (-6 dB is half perceived sound level.)

As driving on

the highway (right under the 14,400 VAC power lines all the way) seems

to notably aggravate it, I folded and pinned a piece of alume foil over

the sun visor and always keep it pulled down. That way the power line

was much less visible through the windshield. I think that helped a

bit, too. Then I put a smaller piece at the top of the side window for

when the power lines were to the left of the car. (I hardly ever drive

with the windows open anyway as it makes a nasty low frequency pressure

vibration on the highway. If I open one a bit, it's the rear right.) I

was thinking of putting some cardboard on the outside so sunlight

wouldn't flash in peoples' eyes, but the window automaticly opens all

the way with a push on the lever, and I soon accidently crunched the

foil. It will inevitably happen again. No point getting more elaborate,

then!

As driving on

the highway (right under the 14,400 VAC power lines all the way) seems

to notably aggravate it, I folded and pinned a piece of alume foil over

the sun visor and always keep it pulled down. That way the power line

was much less visible through the windshield. I think that helped a

bit, too. Then I put a smaller piece at the top of the side window for

when the power lines were to the left of the car. (I hardly ever drive

with the windows open anyway as it makes a nasty low frequency pressure

vibration on the highway. If I open one a bit, it's the rear right.) I

was thinking of putting some cardboard on the outside so sunlight

wouldn't flash in peoples' eyes, but the window automaticly opens all

the way with a push on the lever, and I soon accidently crunched the

foil. It will inevitably happen again. No point getting more elaborate,

then!

A decade ago I had noticed an increase in my tinnitus on

the city streets very soon after I started driving my first electric

car, the silent, converted Mazda RX7 EV. I had wondered if it was

something electrical in the PWM motor drive circuits (in spite of the

unit being in a metal housing behind the metal firewall), but obviously

it was the power line fields coming right through the windows, never

really noticed before when driving noisy petroleum vehicles.

As the weather warmed I

started gardening and other outside work. The first day I was out I was

using the angle grinder, so I took my conductive threads tuque off and

put on safety glasses and ear protector "headset". After a while the

ringing in my ears was returning from "high frequency noise" to being a

loud "whistle" again. Of course for short periods I was also making

actual loud noise which can cause temporary tinnitus, but I did have

good ear protection on. I start to realize that not only the tuque but

having grounded the metal roof of my house at several points (as well

as having covered one wall with 2" mesh chicken wire) has been really

beneficial. It's been quieter but not by any means going away. (It's

too bad I can't ground the tuque.) Now being outdoors more it's getting

worse again. The house and my whole yard are definitely much too close

to the power lines. I have 5 acres, but only the part near the highway

is cleared - the rest is trees. (Chicken wire on the house east wall

facing the power lines is probably the best next step. And get the

grounded metal roof & sides cabin (with grounded chicken wire over

the windows) finished so I can occupy it much of the time. I found one

more roll of old 2" mesh chicken wire and brought it out front. But the

"CLACK" of the staple gun, or nailing staples, will re-injure my tennis

elbow. Now what? Screw it on with short screws and the electric drill,

I suppose.)

On April 3rd, after having had the conductive pillowcase

folded over my head pretty much all night (I think), the ringing was

"the usual" very loud with each heartbeat, but much quieter in between.

But before I got up it had quit being louder then too. Then I get up

and feed the chickens in the front yard and being in the kitchen just

inside from there, and it gets worse again fairly rapidly and stays

that way (even with the beanie on). It just shows how variable it can

be, how strong the EMF from the power lines is, and how long (at least

for me) it takes to quiet down.

Also this day,

Matt had ordered and received two EMF meters, both "S8602" (from

"Temu"?). Since he offered and they were only 15$ I bought one of them

from him. In my front yard nearest the power line it was reading

between 50 and 100 volts per meter, flashing its LEDs, beeping and

displaying "Harmful". If I held it up with my arm stretched out, it

read upwards of 200 V/m and only somewhat higher standing on a chair

with outstretched arm. (I saw a "238" at one point.) Perhaps I should

mention that there's a steep ten foot bank from the highway and so the

front yard is "ten feet up the power poles" - about 1/3 of the way up -

already at ground level.

Also this day,

Matt had ordered and received two EMF meters, both "S8602" (from

"Temu"?). Since he offered and they were only 15$ I bought one of them

from him. In my front yard nearest the power line it was reading

between 50 and 100 volts per meter, flashing its LEDs, beeping and

displaying "Harmful". If I held it up with my arm stretched out, it

read upwards of 200 V/m and only somewhat higher standing on a chair

with outstretched arm. (I saw a "238" at one point.) Perhaps I should

mention that there's a steep ten foot bank from the highway and so the

front yard is "ten feet up the power poles" - about 1/3 of the way up -

already at ground level.

I remember a few times my tinnitus was just so bad

I was lying in bed awake. That was probably when I was working on the

carport, especially the roof, and later when I put solar panels up

there. I hadn't done anything that was noisy and I just couldn't

understand why it was so bad - not that I understood even having it at

all. Now I went up and measured. Sure enough, it was over 20 V/m at the

west side and around 100, flashing and beeping "harmful" at the east

end by the solar panels. The power line is more horizontal than

vertical distance from there, and maybe 30 feet away.

Indoors it got above 50 V/m right by power outlets with

wires plugged in. By the wall & windows facing the highway I

couldn't get a steady reading. It mostly sat at "0" but as I moved it

around it would jump to values in the 30s or 40s and even start beeping

"harmful" occasionally.

Standing on the highway, at head level it was around 55

and beeping on the powerline side and 30 on the far side. That

certainly explains why driving anywhere notably aggravates my tinnitus.

However, in spite of being advertised as "0 to 1000 volts

per meter", whenever the reading falls below 20 V/m it just stops and

reads 0. (and says "Safe") That's most places. To determine how loudly

my ears will eventually be ringing I'm sure I need to know whether it's

1 V/m or 10 V/m, so this particular meter is pretty useless. For no

apparent reason it will only tell you about the worst extremes.

But it gave me the idea. I checked out "EMF Meter" on

AliExpress.com and found one that showed "005.00 V/m" in the pictures

for around 27$. That should be much better, so I ordered it. The

cheaper EMF meters from popular outlets are much more affordable than

those from LessEMF and SafeLivingTechnologies.

Grounding roofs and putting up grounded chicken wire on

wall is helping, but a meter would be able to quantify the improvements

and to point out the next worst area to tackle.

Going beyond into April, Rolph sent me a

link to a youtube video Electrosmog

Radiation - Effects on the VDR (and beyond) by DrTevorMarshal. It

was a lecture about radiative effects including on the immune system

and bacteria within the body. Much of it was biology far from my

knowledge base, but one special take-away for me was that the cloths

with copper and silver in them aren't very effective at low

frequencies, ie, AC power frequencies. I was really figuring as much

from the disappointingly little improvement the tuque seemed to be

making. He showed a slide of some Faraday cages, one of conducting

cloth and others of "special aluminum foil" sheets, all hung from the

ceiling and completely covering beds. He said the alume ones were much

better. (Measuring the tuque, resistances can be measured - sometimes -

between very nearby points. We really need a cloth that measures pretty

much a short circuit across any two points, from one end to the other.

I haven't seen anything like that.)

Somehow I never thought of metallic "walls" hung from

horizontal sticks, which are hung by wires from the ceiling around the

bed. The idea seems promising, but it would take a lot of tinfoil

(which would soon get crinkled and wrecked)!

Now I see another video (Is Your DNA an EMF Antenna?

by ScottiesTech.Info - youtube) where the presenter says over 1000

studies over the decades show that electricity has negative effects on

our health. He describes a study indicating that our DNA molecules are

"fractal antennas" which are affected by electric fields, which

register as stresses. He also mentions a book, The Invisible

Rainbow, A history of Electricity and Life wherein the author,

Arthur Firstenberg, relates the incidences of new electric

infrastructure development to outbreaks of new diseases or ailments.

Which suddenly reminds me... When I was 3 or 4 (1958 or

'59), my parents moved me from the back bedroom to a front one. The

upstairs front was probably about level with the trolley bus wires, at

maybe 16 meters distance. (On Google streetviews, the house looks the

same but the trolley lines and poles were removed 1968-69 when we were

gone for a year. I can't remember if there were power lines 10 meters

from my window before or not.) I started complaining about persistent

ringing in my ears when I was 5 or 6. (I wonder what the voltage of the

trolley wires was?)

I'm liking adoption of 36-40 volts DC as the prime power

source for homes more and more!

Scattered

Thots

* There are atomic clocks with precision to picoseconds. This exact

time is available on the internet to the whole world. So how is it that

here on Haida Gwaii our clocks have once again moved from nearly an

hour

ahead of the actual time to two hours ahead?

* The increasingly protracted length of so-called "daylight savings

time" ("DST") or as I call it "get up in the dark time", is another

example of legislatures not being qualified or not giving sufficient

study to the subject in passing the laws they do. I remember when it

was lengthened - for about the third time - to be well over half the

year. A US

congressman argued passionately that we needed to extend it "to save

energy". AFAIK he presented no evidence to make his case, just

implicitly

assumed that somehow forcing everyone to get up earlier would somehow

"save

energy". The only statistical evidence we actually have comes from a

couple of US states that didn't adopt DST with the rest until the

federal government mandated it. Their annual energy consumption rose

marginally when they started using DST. Obviously he was ignorant of

these statistics. Surely he had resources and staff who could have

looked them up if he had asked. And nobody else in congress challenged

him - none of them knew or bothered to check either. The whole US

congress

passed the bill in ignorance, and Canada followed suit like robots!

Thus the change achieved the opposite of its intended

purpose. Statistics probably show slightly increased energy consumption

if anything, if anyone has ever investigated - as should have been done

to follow up on the new rule. It has only worked harm, most notably in

accident statistics mostly in the first week of people having to get up

before dawn again even as the days lengthen, and go to work an hour

earlier than usual. (And sleep deprivation is statisticly worst at the

western ends of each time zone, where the sun goes down almost an hour

later than at the eastern ends so people stay up later, but are

expected to get up and go to work with the clock.) Congress should have

soon retracted

this legislation with red faces. It never happens, does it? Us "night

owls" end

up "burning the candle at both ends" year after year. Not being on any

politician's special agenda now, this mistake has never been addressed

and

is still with us, now for many years.

(No doubt I've said all this before.)

We can all screw up at any time of the day, but only

politicians would knowingly screw up the time of day itself.

* And in cities politicians are setting lower and lower road speed

limits. Do they think they're doing it to save energy? Petroleum

vehicles use the least fuel per mile traveling between 60 and 70 KmPH.

At lower speeds simply running the engine becomes an increasing

percentage of fuel use. What does reducing speed limits to 40 or 30 on

major streets accomplish besides driver frustration and wasting

petroleum? Again we seem to be seeing unqualified political decisions

not based on reality. (I'm so glad I got out of the city!)

* With all the "labor saving devices" that have been created in the

last century, why do working hours not decrease? All else being equal,

should we not be able to do the things necessary for life maintenance

in, say, 4 or 5 hours a day instead of 8 or more? Then we should have

full employment and more time for more creative activities. (Partly I

suspect this is one

symptom of the ever growing overpopulation. We wouldn't, for example,

need a continuously expanding supply of housing if the population was

stable. In Japan, where the population has been gradually shrinking for

some time, houses are CHEAP! And we wouldn't need to log and extract

resources from ever

more "remote" areas, despoiling the last intact forests and ecosystems.)

* I've had this 2003 iMac (with

the earliest USB-1 system and one of the first ever big LCD screens)

for 21 years now - long past its "best before" date. Without "security

updates", it doesn't connect to websites any more but I still write on

it. I've just discovered that if you select an image file and then

press "space", the image will pop open to view. And vanish again with

another press. Wow! (hmm, HTML files too) And if you select several

files and press space, arrow keys appear and you can cycle through

them! Those are really handy features. Too bad about the last 21 years!

ESD

(Eccentric Silliness Department)

* Electric fields can cause tinnitus and other subtle or long term and

not readily identifiable health problems. Could "tinfoil hat wearing

conspiracy theorists" know something we don't?

* When Bill Waterton created the comic Calvin and Hobbes, he

wouldn't let anyone do merchandising and produce stuffed "Hobbes" dolls

or anything. But I don't understand why no one ever came up with a

breakfast cereal called "Chocolate Frosted Sugar Bombs"!

"in depth

reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought

of and not tried... and even of how not to do something - why

it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before

publication. I hope they may add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Electric

Transport

No

Reports

Other

"Green"

&

Electric

Equipment

Projects

Open Loop Air Heat Pumping ("OLAHP")

Indoor-Outdoor Air Heat Exchanger

[12th, 13th] The weather being warmer, I put in some work on this,

arranging fittings to connect the pipes including some soldering. Dang,

I went into town and forgot I needed pipe/hose clamps.

[14th] Went to town, got

the clamps. Clamped or glued all the ends

together. I'm really glad I put a pipe union half way. Lifting sections

of three pipes wasn't bad. The pipes could all be supported evenly with

two hands in the right places. All six at once would have needed a

cradle or something. With so little vertical space in the box, I put a

single divider of 1" insulation half way up, to force the air to go to

the far end and back just once on its way through. Other than that,

I'll have to count on convection to take the warmest air upward to the

exit passages. This unit may not be as effective as I was originally

thinking. I fear I may have to come up with other construction ideas

and go through several iterations to get a really good result. But much

depends on the rate of the air flow. It's easy to transfer heat if it's

slow, but with the OLAHP system the more heat it is to make, the more

air the compressor needs to draw. I don't know how the requirement

compares with the actual case. As usual I haven't tried any modeling or

calculations before I building, because there are so many variables I

wouldn't know where to start.

[14th] Went to town, got

the clamps. Clamped or glued all the ends

together. I'm really glad I put a pipe union half way. Lifting sections

of three pipes wasn't bad. The pipes could all be supported evenly with

two hands in the right places. All six at once would have needed a

cradle or something. With so little vertical space in the box, I put a

single divider of 1" insulation half way up, to force the air to go to

the far end and back just once on its way through. Other than that,

I'll have to count on convection to take the warmest air upward to the

exit passages. This unit may not be as effective as I was originally

thinking. I fear I may have to come up with other construction ideas

and go through several iterations to get a really good result. But much

depends on the rate of the air flow. It's easy to transfer heat if it's

slow, but with the OLAHP system the more heat it is to make, the more

air the compressor needs to draw. I don't know how the requirement

compares with the actual case. As usual I haven't tried any modeling or

calculations before I building, because there are so many variables I

wouldn't know where to start.

Indoor-outdoor heat exchangers (usually called ERV's is

it? HRV's?) using

a stack of squares of coroplast in alternating 90° directions seem

pretty effective but one can't run compressed air through those. If

they didn't burst entirely the pressurized ones would bulge and loose

contact surface

with the other ones.

I took the heat exchanger into the house and ran the air

intake through the existing hole in the wall, but there it sat.

A small reality check

In the dollar store there was an operating heat pump. The

louvers that could be aimed electricly simply oscillated back and

forth so the air wasn't always blowing in the same direction. I thought

the air coming out seemed pretty warm, so I bought a thermometer and

checked it.

It was only 35°C - just what I had estimated would be

about the minimum temperature needed for blowing air to effectively

heat a space. (If one can bring that down to 30° in "just cool"

weather the COP can be even higher! Can we pass 15?)

Electricity

Storage

Everlasting Copper-Zinc Cells

New Construction Plan

[3rd] Much as I like being able to assemble each 'trode separately and

to be able to test one against another whose character is already

known, that leaves two separator sheets, and in present construction a

gap, between electrodes and one of the two worst problems now seems to

be low

currents.

I came up with

a new plan for stacking electrodes. They

would be identical box frames with socket and tenon (are those the

right words?) or "telescoping" fit together, a "lip" sliding over the

other side by about 2mm all the way around. They would be glued

together. A hole or slot half way across for the terminal tab. Instead

of a "basket weave" plastic grill outside the paper, the grill would be

inside and the parchment paper+PP cloth ironed onto the outside,

fitting into the next one. Thus only the one separator sheet would be

between 'trodes. These could be easily filled from their open face and

the materials packed in before gluing to the next one over.

I came up with

a new plan for stacking electrodes. They

would be identical box frames with socket and tenon (are those the

right words?) or "telescoping" fit together, a "lip" sliding over the

other side by about 2mm all the way around. They would be glued

together. A hole or slot half way across for the terminal tab. Instead

of a "basket weave" plastic grill outside the paper, the grill would be

inside and the parchment paper+PP cloth ironed onto the outside,

fitting into the next one. Thus only the one separator sheet would be

between 'trodes. These could be easily filled from their open face and

the materials packed in before gluing to the next one over.

Obviously this would be for

production with confidence the

electrodes will all work properly. It should be a good system for hand

assembly and not prone to leaks of powders. The amount of material

going into each 'trode will have to be carefully controlled, because

there's no sponge rubber spring at one end to push all them together if

the powders are loose. (unless the boxes aren't glued together and

they're slightly overstuffed -- but that would be prone to leaking

powders out of the boxes.)

At some point

I tried ironing together the thin PP cloth

and parchment paper, and then ironing a piece of that onto the outside

of an electrode face grill. I cut a little alume block to fit inside to

iron against. It seemed to work. So far so good! With the separator

outside of the "basket" grill instead of inside, it didn't add a gap

between trodes, and the outside face of a single separator was the

inside face of the next.

At some point

I tried ironing together the thin PP cloth

and parchment paper, and then ironing a piece of that onto the outside

of an electrode face grill. I cut a little alume block to fit inside to

iron against. It seemed to work. So far so good! With the separator

outside of the "basket" grill instead of inside, it didn't add a gap

between trodes, and the outside face of a single separator was the

inside face of the next.

[The parchment paper proved too thin. It didn't hold

enough SDBS to prevent zinc dendrites, and watercolor paper is too

thick to iron through. So back to exact size watercolor paper

separators inside the trays.]

And I ordered some

acetaldehyde from Sigma-Alderich as I'm

about out - 165$ in preference to making it myself as I did in 2010 or

so. (It's sure nice having this "OAP" as an R & D budget!)

[10th] I ran into an unexpected hitch printing the stacking electrode

trays: I was virtually out of PVB 3D printer filament, so I tried ABS

filament. (PLA would probably disintegrate inside the cell.) While my

old RepRapPro 3D printer printed ABS quite nicely in smaller sizes, I

couldn't get the i3Mega to print it, nohow. The first time it went a

couple of layers, then a corner lifted, caught on the extruder, and the

whole print came loose. Every try after that was worse. I tried all

kinds of settings, I put cardboard over the printer with a 400 watt

radiant heater inside and got it up to about 45°. I tried Kapton

tape on the glass per one recommendation on line. Nothing worked. I

couldn't even get it to print the first layer before the whole thing

fell off the bed.

I looked for PVB filament and Filaments.ca was "out of

stock" on all PVB. I didn't like the look of importing - all pretty

costly. I must have a dozen spools of ABS already, and I would rather

use ABS anyway.

After all the frustration it finally occurred to me that I

had had the same trouble with PLA a year or two ago. My spools had been

stored out in the damp in the shipping container since I moved here. If

filament is the least bit damp it doesn't work worth a [choice of

expletive here]. This spool had been in a sealed plastic bag and now

had been inside for some time, but it had also been stored out there

for years. I set it near the woodstove and hope it will work properly

for these small parts in a few days or a week.

I decided to see how much I could still print with the

remaining strands of PVB. I did one tray, then tried putting it against

a "non tray" electrode box and realized that half of them should have

the terminal slot on the other side so the "+"es and "-"es weren't all

mixed together on one side. So I mirror image'd the design and printed

another one. The inside corners "round off" as the filament goes around

the corner, so to fit them together I cut a bit off the outside

corners. After that it was a great fit, first try! (If I'm doing a lot

I'll have the the outside corners rounded in the printing.)

Okay, two

trays for a line of 'n'. The line also needed a

starting tray with a solid 'bottom' instead of a grille and separator

sheet, and a solid cover over the 'top' tray. I thought the filament

might run out, but luckily there were still enough winds on the

spool... 17, 16, 15... 11, 10, 9. Yay!

Okay, two

trays for a line of 'n'. The line also needed a

starting tray with a solid 'bottom' instead of a grille and separator

sheet, and a solid cover over the 'top' tray. I thought the filament

might run out, but luckily there were still enough winds on the

spool... 17, 16, 15... 11, 10, 9. Yay!

That made three electrode trays with ends. Possibly enough

filament for one more. Great, except they seemed too precious to risk

using!

They're still 50x50x6mm trodes inside, but making them to

stack they occupy 57x57x6mm; 8mm for the top one. The PVB in each

(central) tray weighs 3.25 grams. That's a fair bit of overhead for

about 10 grams of zinc or copper hydroxide mix, but the separators are

ironed on and can be trimmed after, and the ingredients are open face

loaded into the trays, which are then immediately stacked together. It

should be much the easiest way to assemble electrodes & cells by

hand.

In the meantime I mixed 20

grams of fine zinc powder, 5

grams of conductive carbon black, and (around) .125 grams of zircon,

then added acetone to make a thin paste. Hopefully "co-depositing" to

mix the crystalline forms will work better than just mixing the

powders. As it was drying, I discovered it was getting lumpy so I

stirred it and broke up the bigger ones.

And I needed

more copper hydroxide for the next trodes, so

I mixed some more sodium nitrate and put in a couple of chunks of

copper in a jar. At about 4.6V it drew about 1.5 amps. For whatever

reason NaNO3 makes nice pure blue Cu(OH)2 where

other

salts make CuOH, CuOOH or mixed substances.

And I needed

more copper hydroxide for the next trodes, so

I mixed some more sodium nitrate and put in a couple of chunks of

copper in a jar. At about 4.6V it drew about 1.5 amps. For whatever

reason NaNO3 makes nice pure blue Cu(OH)2 where

other

salts make CuOH, CuOOH or mixed substances.

Potential?

[11th] I printed two more

trays to use up the last of my PVB filament.

(I was surprised to get one, much less two, out of nine winds of

filament on the spool.) The set weighed 19.0g. Each center one was

3.25g, so a "cube" of eight trays would be 28.75 grams. That would

contain about 40 of each powder for ideally maybe 25 amp-hours. Add 5g

x 8=40g for current collectors/terminals and 41.25g for a light outer

case and miscellaneous... 28.75 + 80 + 40 + 41.25 = 190 grams. At 1.1

volts, 27.5 watt-hours. 27.5 WH / .190 Kg = 144 WH/Kg. If actually

achieved in a homemade battery cell, that would be excellent.

[11th] I printed two more

trays to use up the last of my PVB filament.

(I was surprised to get one, much less two, out of nine winds of

filament on the spool.) The set weighed 19.0g. Each center one was

3.25g, so a "cube" of eight trays would be 28.75 grams. That would

contain about 40 of each powder for ideally maybe 25 amp-hours. Add 5g

x 8=40g for current collectors/terminals and 41.25g for a light outer

case and miscellaneous... 28.75 + 80 + 40 + 41.25 = 190 grams. At 1.1

volts, 27.5 watt-hours. 27.5 WH / .190 Kg = 144 WH/Kg. If actually

achieved in a homemade battery cell, that would be excellent.

Another possibility would be to 3D print water reservoirs

as upper sections of the trays and eliminate the outer case entirely.

This would shrink and lighten the cell considerably. And require that

the trays glue together perfectly - no leaks including no "porosity" in

the printed walls themselves. (160 grams, maybe? 27.5 WH / .160 Kg =

172 WH/Kg.) My confidence in this for prototyping isn't high enough to

try it.

[12th] I made a new outer

case. With the extra couple of mm for the

overlapping edge lips, the old one was a bit too narrow. It was also

too

short to put a cover on when zinc trodes stuck up a bit. I made it long

enough to accommodate a string of 8 trays. (That was probably a mistake

since there'll be a lot of excess space to fill in for testing two

trodes at a time.) [Yes, I had to cut several filler pieces.]

[12th] I made a new outer

case. With the extra couple of mm for the

overlapping edge lips, the old one was a bit too narrow. It was also

too

short to put a cover on when zinc trodes stuck up a bit. I made it long

enough to accommodate a string of 8 trays. (That was probably a mistake

since there'll be a lot of excess space to fill in for testing two

trodes at a time.) [Yes, I had to cut several filler pieces.]

(Image: A little bar to keep the housing bottom, ends square while

gluing.)

Solving Zinc's Problems

In addition to describing the four basic problems with

rechargeable zinc electrodes, the paper linked last month (Electrically

Rechargeable

Zinc-Zir

Batteries:

progress,

Challenges and Perspectives)

describes things that have been tried to ameliorate them and get longer

cycle life. (As far as I'm concerned, if one gets less than a few

thousand cycles or a decade of use out of a battery, why bother?

Everyone will keep using lithiums... and if that was the case, maybe

I'd have been better off sticking with manganese as a negative?) The

best result they report on is someone mixing zinc and aluminum as

hydroxides, 75:25%, in alkaline solution. This gave 1000 cycles with

little deterioration. It didn't sound like the authors wanted to invest

in that. I suspect they thought mixing them would take a lot of

equipment and effort, because they didn't know about acetone, which I'm

(fairly)

confident would mix the substances properly.

From the book Alkaline Storage Batteries it sounds

to me like the most successful zinc battery cells were the old style

flooded alkaline cells with perforated metal pocket electrodes. What

did they have that newer designs don't? The metal "pocket electrode"

current collector was on the outside of the electrode.

Passivated oxide

couldn't build up on the outside surface because the outside is where

the electrode was connected. And there was a gap between electrodes.

Fine dendrites that tried to build up in the gaps were probably

"zapped" with current during recharge. The cells (it was said) would

work until simply too much zinc [as zincate ions] had migrated right

out of the electrodes, clogging up (or "poisoning") the positive

(nickel) electrodes with zinc [as oxide] while reducing the capacity of

the zinc side too much. Still they probably only got hundreds of

cycles, which isn't my definition of a real success for future

batteries.

According to the paper, one technique for "ameliorating"

zinc problems then is to put "heavy metals" at the outside surface.

There's no metal heavier than the osmium doping I've been using with

acetaldehyde, painting it onto the inside of the separator sheet.

Another thing was adding sulfonates to the separator

sheets. I've been soaking the whole electrode in sodium

dodecalbenzenesulfonate. But if zinc ions can't pass the separator

sheet, they can't deplete from the electrode nor form dendrites that

short out the cell. So probably saturating just the separator sheet is

sufficient,

and doing the whole thing may be one reason for poor currents. So next

I'll just do the separator. I'm not sure these two things - sulfate and

heavy metal - have been

combined before, and especially not these two specific ones.

Then of course there's adding something like graphite or

conductive carbon black ("CCB") to improve the internal conductivity of

the trode at all states of charge. Single digit percentages of carbon

black were mentioned. Also mentioned was the likelihood that

"co-precipitation" of the mixture would probably work better than

simply mixing them. This is what I believe I'm achieving when I

dissolve the powders in acetone to have them form epitaxial crystals as

the acetone evaporates, as I have done with the latest mix (10% CCB)

for the next zinc trode.

And of course everyone adds something to raise the

hydrogen overvoltage. I'm sticking with .5% zirconium silicate

(ZrSiO4), also "co-precipitated". It seems to work quite well if the

charge voltage isn't too high. (And hey, 3% of it plus 1% stibnite

(Sb2S3) even worked with

manganese, which "theoreticly" shouldn't even hold a charge!)

I skimmed the rest of the paper (about air electrodes) and

found some more useful info at the bottom, then decided I could stand

to read the entire section on zinc over again!

[13th] I soaked the ironed-on separator sheet in SDBS and then painted

the inside of it with osmium doped acetaldehyde. I folded up a copper

screen with a terminal of copper foil, then I painted that with calcium

oxide/hydroxide. Then I fitted it into the electrode tray.

[14th] I sprinkled in 5 grams of the zinc mix and put the solid cover

on the back. (I hope that's enough - it seemed a bit light. But it will

expand a bit as it discharges to ZnO.) I put on four adhesive strips of

foam rubber (weatherstripping) to press against the cell case

(with the right thickness of spacers) and hold the cover on. I didn't

glue the cover on

in case I want to add more electrodes to the stack later - or even to

check inside the electrode to see what the zinc mix is doing. (If it

leaks, the zinc goes outside the stack and can't get into the nickel

tray.)

I found the electrolysis a few days ago had produced 26g

of blue Cu(OH)2. I added 1.7g of graphite to this, about 6.5%, then

poured in some acetone and mixed to make a thin paste, to

"co-precipitate" epitaxial crystals. I set it by the woodstove to

evaporate out the acetone.

[15th] I made a CuNi

current collector, painted it with calcium oxide,

and added about 5 grams of the Cu(OH)2 mix, now dried and crushed back

to powder. Before the mix it weighed 17 grams, so 22 grams. Much more

supporting structure than active powder - that's certainly no way to

get high specific energy! (I really need thin monel, not

heavy cupro-nickel "plate" for current collectors. If it has holes in

it to

eliminate some of the metal, so much the better! But it needs to be

more than "foil" or "window screen" because the outside oxidizes.)

[15th] I made a CuNi

current collector, painted it with calcium oxide,

and added about 5 grams of the Cu(OH)2 mix, now dried and crushed back

to powder. Before the mix it weighed 17 grams, so 22 grams. Much more

supporting structure than active powder - that's certainly no way to

get high specific energy! (I really need thin monel, not

heavy cupro-nickel "plate" for current collectors. If it has holes in

it to

eliminate some of the metal, so much the better! But it needs to be

more than "foil" or "window screen" because the outside oxidizes.)

I put the empty tray with a paper ironed onto the front on

top (to cover the open top of the nickel tray) and bleached it for 5

minutes in diluted bleach and then rinsed it for the same period. I

dried the outside of the tray off and glued the two trays together with

ABS cement.

I cut some ABS

spacers to fill in the extra cell length

since I had made the case to hold a stack of up to eight trodes. About

35cc of 10% KCl electrolyte filled above the tops of the trays.

I cut some ABS

spacers to fill in the extra cell length

since I had made the case to hold a stack of up to eight trodes. About

35cc of 10% KCl electrolyte filled above the tops of the trays.

This time the cell was tall enough to put a cover on. Because of that I

didn't have to keep refilling it as the days went by.

This time the cell was tall enough to put a cover on. Because of that I

didn't have to keep refilling it as the days went by.

It started about like

usual. It said ~.9 volts and dropped

to .4 if I tried a 10 Ω load. With 1.35V charge it started charging at

17mA which soon rose to 19. After a while I tried some more brief load

tests, with slightly rising voltages as charging proceeded. After each

load, the charge would jump up from 19mA to 30, 40 or 50, depending how

much I had run it, gradually dropping back to the original low value.

There was no visible bubbling at least in the first hour. One type of

pH paper seemed to say pH was around 10-11 while another one claimed it

was about 6.5. (?? I'll try again later.) In an hour or so momentary

short circuit current was 350mA. Well, at least that's 1/3 of the amp I

hope for rather than 10-15%. Presumably it'll charge up. Then comes the

main question: does it degrade with each cycle or continue working?

[16th] It was degrading. I was at my wit's end. I thought of what very

different results I had got making copper hydroxide in KCl, MgSO4 and

NaNO3 salt electrolytes. Perhaps I should try something different. I

had already tried sodium nitrate. It hadn't seemed better... maybe a

different anion? I had a jar of K2SO4 from neutralizing the acid in

lead-acid batteries years ago. I mixed a 10% solution, dumped the KCl

liquid in the cell, and filled with this. It seemed to help. Then I

started thinking: what if the reaction voltage from Cu(OH)2 to CuOOH

was higher than I expected? What if the cell needed more than 1.4 volts

charging voltage? After all, in the earlier results that had got me

interested in copper, I had been seeing voltages around 1.3V.

So I turned the charge voltage up to 1.6V as I had been

using before. I meant to leave it for a couple of hours but was away

for about nine. In the evening it was charging at just 7 mA. I did a

load test and the results seemed incomparable. Off charge it held to

1.400V after one minute and the drop was very slow. While again it

started at under .8 volts with the 10 ohm load, the voltage started out

by rising for about 3 minutes (to .813V) instead of falling swiftly. I

wonder if the osmium helped convert passivated ZnO at the surface of

the trode into dissolved zincate, if not preventing passivation then at

least reversing it during discharge. I ran it for an 45 minutes at

which point the voltage had fallen under .6V. It recovered to a much

higher value (over 1.1V instead of ~.9V) and when I switched the charge

on it hit 212 mA, much the highest value yet, and was doing 70 mA after

a minute. (Momentary short circuit current had been down to about 235

mA at one point. It now passed 400.) After a little charging a quick 50

Ω test started out above 1.2 volts and 100 Ω was at 1.25 - up where

they had been in the best of the early tests using cupro-nickel sheet

as the copper and before the zinc started passivating.

[17th] It didn't seem to last. In the morning it held 1.435V open

circuit, but as soon as I put the 10 ohm load on it dropped to about

.7V, then rose over 5 minutes to just 7.23V - 90mV below the previous

evening. Well, what was the salt that had made the nice blue copper

hydroxide? Sodium nitrate. It seemed more "aggressive" than the other

salts. If sodium nitrate wasn't the thing, how about potassium nitrate?

How to make? The baking soda worked well for the sodium version, but

there's no potassium bicarbonate. I guess it'll be potassium hydroxide

& nitric acid. (Or what about that "instant cold pack" with

calcium-ammonium nitrate? I'd have to look the video up again.)

In a nickel-whatever alkaline cell, nitrate is an impurity

that causes self discharge via the "nitrate-nitrite shuttle". At the

negative, the nitrate is reduced to nitrite, discharging an electron.

At the nickel side, it is oxidized back to nitrate putting the electron

in to discharge that side. Obviously the zinc is way more negative than

needed to cause the reduction. My question is, at what voltage

does the nitrite oxidation happen? Obviously nickel oxyhydroxide is

high enough, but copper hydroxide or oxyhydroxide has a lower voltage.

Might the nitrate not turn back into nitrate? In that case we

would end up with a stable potassium nitrite electrolyte. On looking

that up, it is poisonous, a strong oxidizer and also incredibly

soluble: at room temperature, over 300 grams of it can be dissolved in

100 grams of water.

Current seemed awfully high, sitting around 35mA and not

dropping. Was it because of (a) nitrite doing a much better job of

charging the cell's electrodes?, (b) charging of the nitrate into

nitrite?, or (c) the nitrate-nitrite shuttle, wherein the charge

current would match the self discharge and never reduce? A few hours

would probably tell. Well, altho the charge current gradually dropped

over the day, it wouldn't run a load properly. It held charge more like

a leaky capacitor than a battery. Sigh!

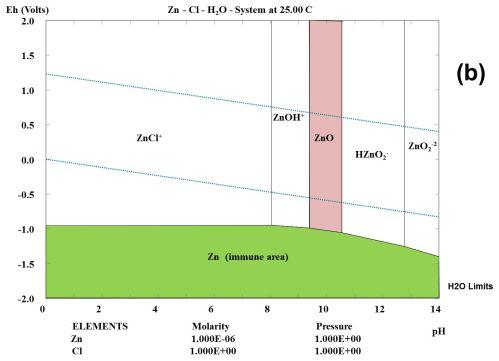

Zincate?

Okay... if we're going out on limbs... how about soluble

"zincate" anion? This is variously described as or composed of:

ZnO2-- (Forms only at highly alkaline pH'es?)

Zn(OH)4-- (shown in some diagrams in place of ZnO2--. It's about the

same thing + 2 H2O)

Zn(OH)3- (shown in some diagrams. might be more likely to form in

a more neutral

solution)

HZnO2- (Shown on right diagram - in place of above?)

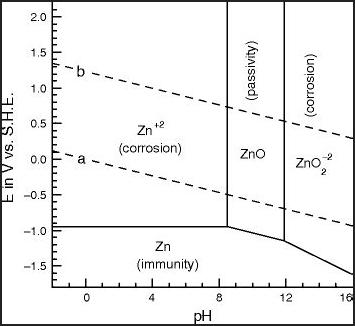

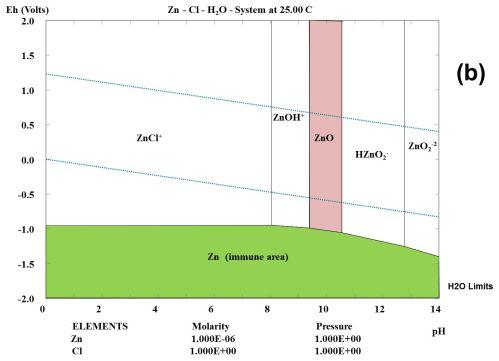

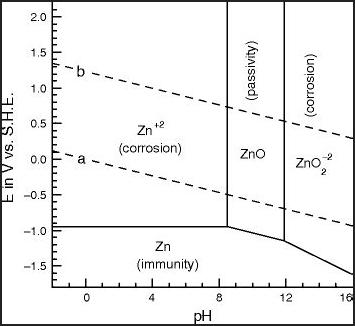

One Pourbaix diagram shows these different

electrochemical results for zinc in chloride at different pH'es and

voltages. And then there's at different concentrations, the right

diagram having only a little zinc.

I can't find much of anything about the solubility or

properties of these various substances on Wikipedia. I have heard that

"the solubility of zinc is lowest around pH 9". That means that

contrary to the diagrams it is at least somewhat soluble at any

pH. At how low a pH can there be some form of zincate anion? It looks

like 12 or higher should do it. What would

form in a neutral salt environment? Suppose we assumed that given a bit

of free potassium a very limited amount of dissolved KZn(OH)3 - or

K2Zn(OH)4 would form? The "free" potassium would be its hydroxide, ie:

KOH + Zn(OH)2 => KZn(OH)3 or 2 KOH + Zn(OH)2 => K2Zn(OH)4. Would

such salts or hydroxides be neutral or basic? How much would be

dissolved if the main salt was KCl (or K2SO4)?

My thought is that some form of zincate is the one form

that might dissolve passivated ZnO off the surface of the zinc trode,

and thus essentially prevent it from happening. At least, it's an idea

that might have that potential. I decided to go back to potassium

chloride add just a bit of potassium hydroxide. Would it convert to

some sort of potassium zincate and stay near neutral pH, or would it

just remain KOH and make it alkaline - without improving the

performance? Or maybe I should let it become somewhat alkaline in order

to form zincates, and that might improve the performance?

[18th] A little flake of KOH (.15g) raised the pH to 11-11.5 or so and

it just stayed up there. The cell didn't seem to work any better. If I

can't figure out some way to prevent the zinc from passivating then the

whole idea of using zinc, with all the things I've done to prevent

dendrites and other problems, will have been for naught. I'm sure there

must be a way, and probably more than one way - can I find one?

Hmm... According to some Pourbaix diagrams pH has to be

over 12 to make zincate. So I added another flake. pH 12? Later I added

another. (I found no figures on the solubility of zincates, but I

suppose if I had raised the pH to over 12 with calcium like I usually

have done, CaZnO2 instead of K2ZnO2

might well be essentially insoluble and if so probably wouldn't help

eliminate passivation.)

It didn't seem to help, just to raise the pH. Well, was

zincate really forming? What about some actual zincate? I had some

sodium zincate solution in a bottle. I added a couple of drops. Nothing

seemed to change. But I thought zincate should form by itself and

didn't continue.

[19th] I added some more KOH, eventually to about 1.65 grams - around

5-6%. pH went up to around 13. It seemed to be having an effect. Load

voltages with 10 ohms were still only around .6 volts and gradually

dropping from there, but they weren't getting worse with each

passing

cycle. That was a significant result.

[20th] I took the (yay, not

glued!) back off the zinc tray. The zinc had

settled into the lower part of the box, maybe 60% full. Certainly no

compression/compaction in there. I added another 3 grams of the zinc

mix. It didn't do much when I first put it back in, but after just a

minute of charging - at higher currents than before - I tried the 10

ohm load. The voltage hardly dropped. Off again it hardly rose. On

again, very slight drop. I thought I had a bad connection or something.

Then I looked at the current. Sure enough, instead of the voltage

dropping way down, it was supplying over 110mA starting at about 1.25

volts -- 5+ mA per square centimeter of interface area with hardly any

voltage drop -- just like it should have always worked but never has!

It didn't last. With the short charge (@ 1.6V), load

voltage soon started dropping back to .6V levels. And it didn't come

back up. And charging currents got ridiculously low for something that

needed charging. And yet, when charge was stopped the open circuit

voltage only gradually fell from 1.6 volts, suggesting that it didn't

actually need charging. And why should it? - it had charged all night

and the new material was zinc metal, not oxide.

It still didn't seem like a lot of zinc. I added another

2.6 grams; total now 10.6 grams. That might actually be filling the

tray and have a bit of pressure from the foam rubber behind it. I got a

similar result to the previous adding - great for a few seconds.

Putting another piece of plastic filler in to press the foam rubber

against the back of the tray harder didn't seem to do much. But the

load voltages were up toward .7 volts - a little less. A little more

charging and they passed .7.

What could need charging?

Perhaps new conductive pathways

have to form between the carbon black particles and the zinc dust? How

could it work great for a few seconds but only once? I certainly don't

have the answers! What can charging at unit milliamps do?

But I do have one answer: The fact of great performance

(even

just once for a moment) after working only on the zinc trode suggests

that the copper hydroxide side works great already. Only the zinc side

has troubles, and if it works right twice, why can't it work right

always?

[21st] pH still about 13. Steady-state charging is now at 12mA, up from

9. (@ 1.6V. No bubbles.) Doesn't seem to work any better. Will keep

charging. By evening 13mA. And it drops pretty quickly to 1.140V when

taken off charge. These don't seem like good signs - incrementally

worse? A 10 Ω load started at .65V and worked its way up over .7 over a

few minutes. (Ran it about 15 minutes.) Momentary short curcuit current

is over .5 amps. After that charging current was over 200mA when first

started. Those things seem incrementally better. As noted some recent

time back, it seems to charge painfully slowly, but after running a

load it returns to its previous state of charge quickly before dropping

off to almost nothing again. At such low long-term charging currents,

if it ever gets to good performance it's because it's not deteriorating

over an extended period. Let's give it another day? or ten? I lowered

the charge voltage to 1.5. It doesn't hold above 1.3 and 1.6

seems a little high, even tho there's no bubbling evident.

[22nd] Still at 13mA in morning. Open circuit drifted down to over

1.17V instead of 1.14V. I don't know what, if anything, could actually

be "charging". With a 10 Ω load the voltage still starts a little over

.6V and creeps up over several minutes to almost .7V - 2/3 of what it

should be, if. In fact, it was still rising for over 12 minutes, twice

as long as ever before, hitting .694V before starting to drop. After

this short circuit current was still well over 400mA. Maybe something is

still "initially charging" at this low, low rate? Copper hydroxide to

oxyhydroxide? Ten days may not be an underestimate to get a fairly full

charge.

There's somethin' happening here....

What it is ain't exactly clear....

It's too bad the copper tray is glued shut. It would be

nice to see the color of the compound within:

Nickel hydroxide: Turquoise; Copper hydroxide: Sky blue (dark blue-gray

mix with graphite powder)

Nickel oxyhydroxide: Black ; Copper oxyhydroxide: Black ?

By evening the steady charge current was up to 14mA. It

still drops to lower .6 volts when the 10 ohm load is started (rose to

.686 in 3 minutes). However, at least it isn't notably deteriorating -

it's not dropping to .5XX, .4XX and .3XX on successive days. Short

circuit current current remains high as do charging currents after a

load. I think making it alkaline enough to form zincate ions, perhaps

pH 13(?), has been key to preventing zinc oxide passivation. I used:

10% KCl

5-6% KOH

That's more alkaline and more KOH than I like, but if it

works and a lower pH doesn't, I'll run with it. It's not as caustic as

more concentrated KOH solution. I can run experiments later to see if

it's more than what's needed.

[23rd] Steady charge was up to 18mA. When I took it off the voltage,

instead of drifting lazily down, dropped to 1.061V in a matter of

seconds, then went up a bit to 1.065 - as if it was driving a light

load. I suspect a zinc dendrite may be causing a low resistance path

between electrodes. A dendrite(s) through the supposedly protected

separator sheet would be most unwelcome - I thought I had that solved.

It may be on the outside of the trays, as I noted black zinc dust

coating the outsides of the white PVB a couple of days ago. (That's the

down side of not gluing the back on the end tray.) Or the sheet isn't

well enough ironed onto the tray and there's a gap at an edge.

Loads ran about the same as previously - meaning voltage

drops way too much, and then starts rising again but is still way lower

than one expects. Why doesn't it drive even 5mA/sq.cm at a little under

its open circuit voltage? Short circuit current seemed to be down, to

about 400mA. Charging currents after a load remained much higher than

previously starting at over 1/4 amp and staying higher longer.

[24th] In fact, any "exercising" of the cell, running and charging for

short periods, increases every aspect of the performance. Especially at

higher currents, which now means low hundreds of miliamps rather than

mid-upper tens. Charging for hours at the low rate (now up to 18mA)

makes if worse, even as it gradually runs longer and longer.

I suspected the glued sides between the two trays were

leaking and powder was bridging the electrodes. I took it out and

brushed the sides off, removing quite a bit of powder especially around

the terminals. It was soon holding higher open circuit voltages again.

(Not dendrite(s) across the separator - yay!) Presumably the "steady

state" charging current would drop. (Yes - down to 15mA in an hour or

so, another hour, 12.)

[25th] By morning charging was up to 19mA again. I took the electrodes

out, brushed the fresh coating of black powder off the top, and noted

that the whole top seam had water going in and out as I touched it. I

left it out to dry off, then smeared heat glue around the outside seam

on all four sides. I hooked it back up and it was very soon down to

10mA, and when disconnected, drifting down from the 1.5V charge as by

parachute instead of like a rock.