Turquoise Energy News Report #189

Covering

Research & Development Activities of February 2024

(Posted March 9th 2024)

Lawnhill BC Canada - by Craig Carmichael

[CraigXC at Post dot com]

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Month In "Brief"

(Project Summaries etc.)

-

Five Years of Solar Power - "Everlasting" Cu-Zn

Battery Development - Terminology: Anode, Cathode &

Electrodes - Open Loop Air Heat Pumping: Making the heat exchanger -

Better Peltier Coolers Project - Cabin Construction

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Scattered

Thots (Viewpoints, Citizen Participation in Governance) - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

(no reports)

Other "Green"

& Electric Equipment Projects

* Making indoor-outdoor heat exchanger for Open Loop Heat Pumping

("OLAHP")

* Cabin Construction

Electricity Storage:

Batteries

* Much work and several experiments - 'everlasting' Copper-Zinc cell

looks closer

Electricity Generation

* My Solar Power System: - The Usual Latest Daily/Monthly

Solar Production log et cetera - Monthly/Annual Summaries,

Estimates, Notes

February in Brief

On the morning of the 28th it had

snowed overnight (or was it hail?),

On the morning of the 28th it had

snowed overnight (or was it hail?),

covering solar panels - but the more vertical ones under the

eaves were producing.

(It stayed cold and hailed again in early March.)

The steeper ones on the carport

were shedding it,

The steeper ones on the carport

were shedding it,

as were the steep ones on a pole.

as were the steep ones on a pole.

But the shallower angled ones on

the roofs stayed covered until mid afternoon.

But the shallower angled ones on

the roofs stayed covered until mid afternoon.

If it wasn't for the snow, the black panels would have heated up and

melted the snow!

Notwithstanding the last days, this was the sunniest February with the

highest solar collection yet.

Five Years of Solar Power

Readings from five full years of solar power from March

2019 to February 2024 are summarized under Electricity

Generation below. The last year has been the most

successful yet, with 3891.35 kilowatt-hours of solar electricity

generated. That is about half my entire electrical usage over that same

year (partly because living alone now I seem to have used less than in

other years). 'Theoreticly' then 36 solar panels instead of 18 and

battery storage could have supplied all needs, but it doesn't work out

this far north because the highest use is in winter when there is

little production. I am sending excess power to the power grid in the

four summer months, making more than the electric car uses in the

spring and autumn months, and using much more than is made in the three

darkest winter months of November, December and January when there

isn't even enough for the car, let alone electric heat.

The overall annual power bill would be much reduced,

mostly in winter for heating, if I had the open loop air heat pumping

system working as planned and installed in all heated spaces. (I did a

write-up on the theory of operation for that last month. [TENews #188 - search for

"Recap" in Month in Brief]. With the

efficient air compressor-decompressor design, I'm working on the

project again.)

"Everlasting" (Cu-Zn) Battery Development

Over the last four months now I've concentrated heavily on the battery

project, and with freezing weather toward the end of February and well

into March, I kept working indoors on it. And I finally found out what

a problem I've been having for years has been. Right at month's

end and the start of March I thought I had a working battery that

didn't seem to degrade with cycling. Each cycle seemed

roughly comparable in running time. But in fact the initial voltage was

dropping gradually - just

much more slowly than before.

Over the last four months now I've concentrated heavily on the battery

project, and with freezing weather toward the end of February and well

into March, I kept working indoors on it. And I finally found out what

a problem I've been having for years has been. Right at month's

end and the start of March I thought I had a working battery that

didn't seem to degrade with cycling. Each cycle seemed

roughly comparable in running time. But in fact the initial voltage was

dropping gradually - just

much more slowly than before.

The problem that I had been oblivious to all along I

finally discovered in a

paper

specificly covering zinc electrodes: zinc can passivate. More or

less non-conducting zinc oxide solidifies from dissolved zinc ions

during recharge and covers the surface of the electrode substance more

and more densely until it blocks electrolyte flow. That's surely

what's been happening to my cells, so much frustrating me for years

because I didn't know what was happening. I had thought zinc was

supposed to be

"perfect" in this regard and so I continually misattributed the cause

to the positive electrodes (even of different chemistries - including

copper at the start of the month!) and of

course nothing I did to them helped.

There's yet another problem with zinc? I started thinking

I had been doing better with metallic manganese negative electrodes in

2013!

I added quite a lot of graphite powder to the zinc (19

wt%, ~40% by volume) to give it conductivity regardless of its state of

charge, zinc metal or oxide, and the cycle after cycle deterioration

was much less. But not zero.

However, knowing what the problem is makes it possible to

start looking in the right place for the solution.

My cells also still have the problem of very low current

capacity - unit milliamps per square centimeter instead of tens. Zinc

usually has high current capacity. The doped osmium sheet and the SDBS

gel seem to slow current flow down quite a lot, but without those the

cells would

have short cycle life. (...regardless of passivation) The positive

electrode boxes are useful for

making the cells, but the copper oxide being spaced away from the zinc

and behind a second separator sheet surely doesn't help either.

So I started thinking about other ways to put everything

together... ways that are still doable by hand... and in early March

came up with a plan for electrode "trays" that stack together with just

one common separator sheet between trays.

And perhaps a solution to the passivation problem will

entail a remedy to the low capacities at the same time.

Terminology: Anode & Cathode, Negative & Positive Electrode

I took the trouble the actually think about this. (Long

overdue) I've had the concepts of "cathode" and "anode"

reversed in my head. In vacuum tubes the cathode, the negative side,

emits electrons toward the anode, the positive side, which absorbs

them. It only emits electrons. It doesn't absorb them from the

circuit as such, and so I always thought of cathodes as electron

sources. But

that's inside the tube. Inside a semiconductor diode the

cathode also emits electrons toward the anode, the positive side.

However it receives these electrons from the external wire that powers

it, and the anode transmits the electrons that it got from the cathode

to its external connection. In both cases the cathode is the negative

side and the anode the plus. Viewed from the outside the

cathode absorbs electrons and the anode emits them.

In battery usage then the anode also emits the electrons

it got

from

the electrolyte to its external wire but as the negative electrode

instead of the positive since the battery is sourcing power rather

than using it. The cathode pulls electrons from the external circuit

into

the electrolyte as the positive.

But I think the reason people use these otherwise

rather obscure terms instead of the more obvious "positive

electrode" and "negative electrode" has to do with length: "anode" and

"cathode" are each two syllables instead of six. (As in "Metric

System Length Problem: the real reason English Imperial measures are

better", eg, "inch" is one syllable "centimeter" is four. [TE News #125 for more

examples - scroll down from link])

Open Loop Air Heat Pumping (OLAHP)

When it wasn't too cold out I managed to get a bit of work done on the

indoor-outdoor heat exchanger component. I put together the 24 x 60 x

7.5

inch box, cut some

insulation and got together fittings to join the pipes together.

When it wasn't too cold out I managed to get a bit of work done on the

indoor-outdoor heat exchanger component. I put together the 24 x 60 x

7.5

inch box, cut some

insulation and got together fittings to join the pipes together.

There isn't going to be much insulation above and below

the zig-zag rows of pipes. I discounted in my mind how much room

insulation takes up until I actually tried fitting things. The big

faces, front and back, do get 2 inches each - leaving only 3.5 inches

for the finned pipes, which are up to 2.5 inches square - just 1/2 inch

front and back, much less top and bottom.

I suppose when it's warm enough to work on it I won't

really need it until next winter and I'll have many other things to do,

so it might not get done for yet another year. I think I need one in my

shop so I can heat the shop and work in cold weather without it costing

a fortune. (In fact I think I actually need 3 or 4 of them!)

I found I had

a 3-1/4 inch hole saw, and PVC pipe that outer diameter as well. A

building supply store had the matching 90° elbows. So I picked that

size for the uncompressed air ducts through the wall.

I found I had

a 3-1/4 inch hole saw, and PVC pipe that outer diameter as well. A

building supply store had the matching 90° elbows. So I picked that

size for the uncompressed air ducts through the wall.

Future Vision

Obviously many would have these units installed in their

homes to

replace older, energy gobbling heaters, and just as obviously, there

would be similar units designed for air conditioning in warmer climates.

But it also occurred to me that the air intake and outlet

pipes could just as well go through a window with a cover if one was

reluctant to drill big holes through an outside wall.

So ultimately we will probably see 'portable', 'retrofit'

production units: single piece, plug-in OLAHPs with all three main

components in one housing, supplying perhaps 3000 watts of heat with

300 watts

of electricity at freezing temperature outdoors. Bring it home from the

store, drag it into the house

(it will inevitably be bulky), connect the two pipes or

flex hoses through the window fittings, plug it in and go. Not quite as

simple as

a plug-in resistance heater, but not needing professional installation.

Of course, first I need to demonstrate that it works. The

theory certainly seems good. Condensation and water freezing in the

pipes,

especially where the air exits colder than outdoors, is probably going

to be

the toughest issue.

If my six finned pipes don't passively raise the incoming

air temperature enough to get high coefficient of performance (COP) for

3000 watts heat or whatever

amount is required from the system, some larger or longer or more

effective heat

exchanger pipes would, because the same amount of air as comes in goes

out - the exchanger need only reverse their relative temperatures, or

as nearly as feasible.

With a theoretical potential heating COP hitting 20 or

more, if 10

isn't attained, maybe it'll only be COP 7 or 8. OTOH, maybe carefully

designed production units will achieve COP 12 or 14 in freezing weather

- and in weather above freezing but where heat is still needed?

Better Peltier Coolers Project

Well, duh! I searched AliExpress for "nitride ceramic" and came up with

a number of choices of aluminum nitride, .6 and 1mm thick wafers, for a

fraction of the price I paid. Many were quite small and had a hole in

them - they were intended as heat sink insulators for power

transistors. Wow! How could these have made it into power electronics

but not into the absolutely most valuable place for them: Peltier

cooler modules?

I came up blank before, but I did a web search again, this

time on 'nitride ceramic peltier' and came up with a couple of hints

and a company that actually seems to have aluminum nitride Peltier

modules: tec-microsystems.com . They have obviously taken this project

much farther than I ever could. Instead of being the usual 40x40mm

& "12V", they started off 'miniscule' (6x6mm) and worked their way

up to 'tiny' (7x14mm). The ceramic was just .5mm thick instead of about

1mm. Voltages were way lower obviously due to the small sizes and hence

small numbers of thermocouples (known as "pellets"). Thicknesses went

from 1.4 to 2.6mm. (I don't know what the advantages of thinner are,

but the thicker ones had higher "Qmax" ratings.)

They also have aluminum surfaced modules. I had thought

these would be impossible or impractical to make. They have some sort

of flexible, electricly

insulating adhesive inside holding the copper 'buses' (thermocouple

interconnects) to

the aluminum plate. Because of the flexibility they claim a million

heating-cooling cycles of operation, and one of my two main

disappointments

(other than poor overall cooling performance) has been the notably

short life

of the regular modules.

These don't seem to be available from any of the regular

dealers AFAICT - only on their website. I hate to imagine the prices.

(In fact, I think I searched the usual electronic components suppliers

in my previous search rather than a full web search, so I didn't find

makers who don't go through them.)

But if I'm going to do anything now, I'm buying. I was

only going to try to make them myself because previously I couldn't

find anyone who was already making them. (So much for the aluminum

nitride disks I just bought!) I think I could do no better "research"

than to phone them and ask a few questions.

- Which type has the best thermal specs?

- What is the thermal resistance of the flexible adhesive in the

aluminum Peltier modules compared to aluminum oxide ceramic?

- Are they pure aluminum or an alume alloy?

- How much better are aluminum nitride modules than aluminum oxide ones?

- What would you recommend to get a "best performance", that is,

greatest temperature drop, in a Peltier camping cooler?

- Prices

I emailed instead of phoning and asked these questions.

There was a very detailed reply and he said the answers deserved a

book. I may recur to this subject in more detail another time. To

summarize some key points, one consideration I had been especially

ignorant about was the coefficients of temperature expansion (CTE) of

the materials used. One reason for the short life span of typical

Peltier modules is that the CTE of aluminum oxide is half that of the

alume alloy heatsinks they are attached to. (And, I would expect, also

and more criticly,

different

from the copper circuit traces and thermocouples inside.) One reason

tec-microsystems.com's ones with an aluminum outer skin and flex

insulation inside last so long is that the CTE matches that of alume

heatsinks. (And surely, the flex insulation within lets the 'pellets'

inside adjust position minutely with temperature.) Beryllium oxide is

toxic during manufacture, especially the dust, but okay as a finished

product. He said

"Manufacturers like Marlow (II-VI) use it for TEC manufacturing." I

haven't looked up "Marlow".

The aluminum nitride ones do have the best thermal

performance specs of those TEC Microsystems make, with very high

"Qmax"es for their

sizes, but their CTE is only about 4

where the oxide is ~7.1, so they are a worse match for alume heatsinks.

The more power you try to put through the Peltier, the more the thermal

resistance of the skin matters and hence the worse the temperature

drop/rise through it. The aluminum nitride ones can have higher power

in a smaller space.

When the Peltier is turned off, they will all have about

the same heat transfer between the hot and cold sides because the

bismuth telluride (BiTe) thermocouple pellets inside have

substantially lower heat transfer (1.5?) than the surfaces (20+) and so

are the

deciding factor.

Every installation needs to be individually evaluated to

find the best match. He said it's hard to make a Peltier camping cooler

with adequate heatsinks, so it's no surprise that they cool better at 9

or 10 volts than 12 by keeping the hot side temperature from rising as

much.

I was thinking higher voltages didn't help when I used the

fabulous copper heatsinks either, but reviewing TE News #181, I see I

didn't actually try higher than 10.5V - and that's where it got

coldest. I should have tried higher - and still should.) The method of

attachment to the heatsink is also important. (Hence my recently buying

"the best" heatsink compound, also yet to be tried. But when I was

using flex graphite "gasket"

instead of heatsink compound, I was probably allowing the heatsink and

Peltier to adjust separately for CTE.

Since graphite has fabulous thermal conductivity in the

plane (as opposed to across the plane as I was using it, which is good

but only 'pretty good' by comparison), I wonder again if heatsinks

laminated from layers of flex graphite bolted together with their edges

contacting the Peltier might not make the best Peltier heatsinks of

all. It would also have low CTE I expect, to better match oxide/nitride

skin CTEs, perhaps giving them longer life? And it's cheap compared to

copper. It's also something worth trying, and surely easier with the

aluminum nitride

Peltiers owing to their small size. I'll probably get a few and test

both the aluminum and the aluminum nitride ones, and make a graphite

heatsink to match, which may not need heatsink compound at all. When

I'm not busy, ha ha.

Cabin Construction

Fat garage door fitted on the

cabin

Fat garage door fitted on the

cabin

I glued the styrene foam pieces of the garage door together with "gap

filler" foam. The inside got an epoxied coating of light polypropylene

(PP) cloth. It's rather transparent. The outside is to have "galvanized

air duct" sheet metal (new metal from the refuse station). Owing to

hurting my "tennis elbow" yet again in pounding out the bends with a

wooden hammer, as well as the cold weather, I haven't finished

flattening it or tried to put it

on yet.

I glued the styrene foam pieces of the garage door together with "gap

filler" foam. The inside got an epoxied coating of light polypropylene

(PP) cloth. It's rather transparent. The outside is to have "galvanized

air duct" sheet metal (new metal from the refuse station). Owing to

hurting my "tennis elbow" yet again in pounding out the bends with a

wooden hammer, as well as the cold weather, I haven't finished

flattening it or tried to put it

on yet.

I had to grind away a bit of concrete and plane down the

somewhat warped board above to get the door to fit.

I've decided to hinge it to open outward instead of

making a track and having it "roll" up into the ceiling - simpler. I

only think I can

get away with this on such a wide door because it's so lightweight.

(And I really need to get the metal siding on the wall before a wind

rips the Tyvec off!) If only the weather would warm up above freezing!

Earlier in the

month I had made and put in stairs to the room over the garage section.

The mill didn't have 12 foot 2 by 10s and I used 10 foot stringers.

They turned out steeper than I had expected and I put up a temporary

railing. Steep stairs with nothing to grab are very dangerous.

Earlier in the

month I had made and put in stairs to the room over the garage section.

The mill didn't have 12 foot 2 by 10s and I used 10 foot stringers.

They turned out steeper than I had expected and I put up a temporary

railing. Steep stairs with nothing to grab are very dangerous.

(The first step is really big until I get the downstairs

floor put in.)

3 x 5 foot

landing from above. It's one stair step below the floor. ...Needs

safety railings! (Not to mention two whole walls and a door on the

room!)

3 x 5 foot

landing from above. It's one stair step below the floor. ...Needs

safety railings! (Not to mention two whole walls and a door on the

room!)

In

Passing

(Miscellaneous topics, editorial comments & opinionated

rants)

Scattered

Thots

* Someone sent me a link to a video on Bitchute where the maker was

complaining about various sources of electrical noise causing tinnitus.

He especially said that since 2020 when all the "5G" equipment was

being installed everywhere, way more peoples' ears have been ringing.

Maybe it's caused by ANY AC power at any frequency, not just 60 Hz

power lines? This would agree with my original supposition from long

ago (from hearing what appeared to be morse code) that it was from

radio transmissions. At my present location so close to the 14,400 V AC

power lines, any radio signals are drowned out by the loud piercing

tone.

"The Root Cause of Tinnitus - Can we hear electricity?"

https://www.bitchute.com/video/FYei2fN7PZvd/

Later I read a comment under a Youtube video ("WHY THESE

MASTS ARE POPPING UP EVERYWHERE...") about measuring signal strength of

5G, that "My neighbors claim they started hearing annoying tinnitus

like noise even before realizing there was a new mast in the

neighborhood."

* Another commenter under the same video mentioned people getting

headaches, itchy, prickly skin, and more. He said that at one mast he

felt head pain and "pressure" near it. He measured the field strength

and found it was way above Swiss and German legal limits. And he said

he saw a lady go out of her way to walk across a muddy field to a bus

stop to avoid the area of the antenna. And in Daajing Giids someone

said that everyone in the few houses right around a (5G?) mast had

cancer including himself.

Electricity has grown around us over the decades with

hardly a thought to the fact that the fields travel right through us

and the long term - or even the more subtle short term - consequences

of that. There is no question but that electric fields of all kinds and

frequencies warrant far more study than they have ever had.

* I usually walk on the beach at lower states of tide when the big,

flat sandy area is exposed. I should know better than to walk up near

the high tide lines - sometimes I come back with all the bottles and

bits of

plastic waste I can carry. (And there's virtually never a plastic - bag

- to put it all in!) I understand many remote beaches where no people

live to

cart it off are just awash in plastic.

One day I went down with a 5 gallon bucket to get drying

kelp for garden fertilizer. I ended up with half a bucket of plastic

and a big, heavy chunk under my other arm. And some kelp mixed in - all

to be separated again. A couple of days later I repeated that, and had

to leave a very big plastic float behind for later.

Some big beachcombing finds

including the

aforementioned float

Some big beachcombing finds

including the

aforementioned float

and the day's handful of plastic

bits (the hand

not dragging the float)

and the day's handful of plastic

bits (the hand

not dragging the float)

Hmm, no drink bottles or caps today

NOTE TO THE WORLD: I'm tired of picking up your plastic! The water is

no place for it. If it has no other use, remember that most "single

use" plastic, especially PE (LDPE, HDPE, UHMW, plastic bags, many food

containers... also PP) is a simple hydrocarbon that burns the same as

natural gas or propane: no smoke, no ash or residue, just water vapor

& CO2. (It burns hot - just burn a little at a time. But it doesn't

really save much firewood - maybe if I cut up the big pieces with a

saw!)

* My microwave oven had such a dark grill on the door I really couldn't

see inside. I thought there was a cup of coffee in it that I had placed

there earlier, but I had already taken it. I started it carelessly

without making sure - empty - and

in a few seconds there was a sound and a bright flash. I shut it off.

There was a burned spot on the side. I used it one more time, but then

there was another flash and not knowing much about them, I decided I

had better discard it. Just once, run empty, was a terminal mistake.

I bought a new one. Same brand, even more obscure window.

Worse controls and no reminder signal - in fact no indication at all

that something has been cooked and is still inside. Sigh! (Why aren't

there buttons to turn the light on to see inside? They have the light,

they have a keypad -

how hard could it be?)

* Some have taken to calling birds "avian dinsoaurs" and actual

dinosaurs "non avian dinosaurs". To me this seems like an absurd

mischaracterization.

At least one long extinct line of birds also evolved from

dinosaurs, as did marine and avian reptiles. Dinosaurs also evolved

into mammals more than once, the last time creating the much superior

placental mammals. Dinosaurs themselves

evolved during the Triassic from other early reptiles or amphibians

(frogs & toads; lystrosaurs), which evolved from fish, which

evolved from lower life forms.

If we follow this logic that everything is a dinosaur,

then mammals are also "non avian dinosaurs" of some sort - but also not

extinct. Amphibians must be "hybrid marine dinosaurs" and fish

"unevolved marine dinosaurs".

My point of course is that birds are not dinosaurs any

more than mammals are, or any more than adult frogs are "land dwelling

fish".

* Many negative trends, directions and events that would have been

unthinkable in decades past have been, are, and surely will continue to

be, taking place. I have documented some of them in past issues because

the mass media, now all owned by a very small clique and all in unison

either doesn't cover them at all or presents fictitious views of them,

repetitiously and often word for word alike from every outlet, to

direct the hearer's thoughts in a particular direction and fit a

particular agenda.

We might think of the Urantia Book's well known

example of the image of a filthy, brutish caveman wielding a club -

obviously a savage aggressor who deserves our hatred. Then we broaden

the picture and see there's a woman and child behind him, and a hungry

sabretooth tiger in front. Suddenly we admire him and are sympathetic

instead - same brute! Often the present day mass media only shows us

the first image to arouse our fear and indignation.

It is well to be aware of major civilizational trends and

ulterior agendas as they continue to arise and unfold, and to

search for one's news from multiple sources and broader viewpoints,

mostly

available on line from some of humanity's deeper thinkers who are

looking at broader pictures. The unwary are too

often ensnared by the unscrupulous. Scams abound.

But dwelling on the problems is of little value except

insofar as creative thought may help generate solutions to them.

Citizens should be involved in societal decision making processes, but

in the present era channels through which to do so are are few,

inadequate, and most often negative and "after the fact" - "protests"

coming after politicians with no prior societal feedback have already

made decisions. Being aware of problems, it's better to keep one's

thoughts and actions focused more on the positive side. Negative

thinking and actions (such as protests and demonstrations) tend to

generate negative results and positive thinking good results. And it is

the little things that each of us individuals does during our day that

aggregate to make the whole world a better or worse place. (Remember

that when you think "It doesn't matter!")

IIRC it was Buckminster Fuller who said that to change a

system, one must first envision a new and better system that makes the

present one obsolete. That requires awareness of the benefits and the

inadequacies of the present system -- and then positive creative

thought.

* Hmm... the protocols that run the internet were originally built on

programmers' ideas mutually submitted by "RFC's" - "Request For

Comment".

Nothing was "set in stone" without all the programmers first having had

a chance to provide feedback. Could legislation be subjected to a

similar public prior review process that might modify poorly thought

out or cancel ill advised programs before they are enacted? Proposed

legislation could be posted on a web site for public purview. (Today

governments usually seem to legislate in a near vacuum of public input,

and hence are easily swayed by vocal or wealthy special interests,

ultimately leading to corruption.)

If it would be chaotic to have a zillion individuals

commenting, perhaps legislative proposals could be submitted to (or

simply perused by) citizen "committees", "teams" or "think tanks" for

well conceived, clearly voiced comment as agreed by the group? ...And

then of course, perhaps such "ad hoc" - or perhaps formally

constituted, qualified and recognized citizen organizations - probably

concerned with a particular topic area, could also themselves research

and propose legislation that would be socially valuable but which isn't

high ranking in politicians' thoughts and agendas? (Perhaps they would

be vetted/certified by some organization outside immediate government,

recognized as the "citizen committee qualifying organization"?)

ESD

(Eccentric Silliness Department)

* They say Samuel de Champlain "founded" Montreal, as if perhaps he

had made it in a foundry. "Found" is already past tense. For Champlain

to say "I hereby found Montreal." is nonsensical because it wasn't

there to find, so to use "founded" in present tense, we must find a

different form. So he must say "I hereby finded Montreal" or "Today I

am findeding Montreal."

But when Aleric went to sack Rome, it was already there

and he

found it. (It wasn't hard because "All roads lead to Rome".) However

when he left, Rome was no more. Aleric was the "unfounder" or

"defounder" of Rome. While defindeding Rome, Aleric and his horde

were looking for food. But (at least by the time the city surrendered

and opened its gates) they were shocked to find there was no food in

Rome. Thus in his motive for the confindering of Rome, Aleric was

dumbfounded.

Luckily neither Aleric nor Champlain spoke English. Their

languages probably didn't have these particular grammatical

idiosyncrasies to confound them.

* As seen from BC

- Near East: Alberta, Saskatchewan

- Middle East: Ontario, Quebec

- Far East: Labrador, Atlantic Provinces

- Beyond That: Made in China

"in depth

reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought

of and not tried... and even of how not to do something - why

it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before

publication. I hope they may add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Electric

Transport

Miles Truck Drivetrain

The variable torque is to be controlled by what is essentially a large,

low speed generator with the magnet rotor spinning on the planetary

body and the "stator" spinning on the input gear, which is also the

motor shaft. Where I used a small number of turns of thick wire in the

12 inch "improved Piggott alternator", I want this 10 inch one to go

readily up to about 80 volts to put its juice into the "72 volt" Miles

truck battery. (Let's see... about 75 turns of #15 wire?)

[18th] Whether

or not I do the new version of the variable torque converter, the

vibration in the drive train has to go before it can be used on the

street, much less on the highway. I had to drive the truck out of the

garage to make floor space (for epoxying my new garage door for the

cabin),

so as I've been meaning to do for some time, I put two hose/pipe clamps

onto the rear driveshaft and clamped on a piece of steel bar (150g)

because

it's slightly off-center at the front and so out of balance. (Oh how I

wish I had kept the original transmission, or at least the end "slip

spline" piece that fitted properly into the driveshaft! That's why I

have so much junk around - just in case. In this case I didn't keep it.)

[18th] Whether

or not I do the new version of the variable torque converter, the

vibration in the drive train has to go before it can be used on the

street, much less on the highway. I had to drive the truck out of the

garage to make floor space (for epoxying my new garage door for the

cabin),

so as I've been meaning to do for some time, I put two hose/pipe clamps

onto the rear driveshaft and clamped on a piece of steel bar (150g)

because

it's slightly off-center at the front and so out of balance. (Oh how I

wish I had kept the original transmission, or at least the end "slip

spline" piece that fitted properly into the driveshaft! That's why I

have so much junk around - just in case. In this case I didn't keep it.)

I went around the driveway loop and it seemed

considerably better. Next I clamped another piece on the other side

(30+g) and it seemed better. I found two pieces about 110g and replaced

the 150g, also removing the 30g. That seemed best, fairly smooth to a

higher speed, but at a certain speed a big vibration started up.

I couldn't help but think

that this must be in the motor shaft before the planetary, which turns

five times faster than the driveshaft. But why? It's a long shaft, but

nothing there is out of balance (AFAICanSee) and there's a steady

bearing part way and it ends at the clamped-on planetary gear. What

could be rong?

[20th] I had made the back end of the housing mount "springy" so that

it could shift a bit for any misalignment. I took another video and I

could see the whole housing vibrate. I stuck a wedge in that held it.

It seemed a lot

smoother until that fell out. That seems to be the problem. I need to

attach the rear end of the box solidly to the frame.

Other

"Green"

&

Electric

Equipment Projects

Open Loop Air Heat Pumping ("OLAHP")

Indoor-Outdoor Air Heat Exchanger

I put together

the box then placed the finned pipes

inside. I wished I had made it taller. 30 inches instead of 24 would

have made it much easier to fit the pipes in, all in a vertical

zig-zag, and

it wouldn't have needed to be so deep front to back. Instead, at least

one pair of pipes is going to have to be fitted behind and in front.

OTOH 24 inches is the tallest that can fit between the baseboard heater

that I never use and the window on the dining area wall.

I put together

the box then placed the finned pipes

inside. I wished I had made it taller. 30 inches instead of 24 would

have made it much easier to fit the pipes in, all in a vertical

zig-zag, and

it wouldn't have needed to be so deep front to back. Instead, at least

one pair of pipes is going to have to be fitted behind and in front.

OTOH 24 inches is the tallest that can fit between the baseboard heater

that I never use and the window on the dining area wall.

[19th] I had been shopping around for

some way to connect the pipes. The "zig-zag" arrangement needed very

sharp turns. I had some 3/4 inch PVC pipe which I had found in 2020

that I could heat with an air gun and fit onto the 3/4 inch copper

pipes. I wished there was a plumbing store where I could buy PVC pipe

fittings. I bought some hydraulic hose thinking it might bend sharply

enough without kinking. Finally I got my bucket of plastic plumbing

bits from storage and to my amazement pulled out enough elbows and

pieces to do the job! I should have looked there first.

[23rd] I

started putting insulation in the box. I really hadn't reckoned with

just how much room two inch insulation would take up on every side. It

seemed too shallow to do front and back unless I had almost no

insulation between the pipes, and still almost none between the rows. I

ended up redoing it: no insulation at the top where it would be closest

to room temperature and only one inch at the bottom. That provided

three more inches vertical space to put all six rows in verticly, none

front and back - still with very minimal insulation between rows. On

the plus side, the front and back insulation, the large faces, could

both be two inches, R10, leaving just 3-1/2 inches width air space for

the 2-1/4 and 2-5/8 inch square pipe fins.

[23rd] I

started putting insulation in the box. I really hadn't reckoned with

just how much room two inch insulation would take up on every side. It

seemed too shallow to do front and back unless I had almost no

insulation between the pipes, and still almost none between the rows. I

ended up redoing it: no insulation at the top where it would be closest

to room temperature and only one inch at the bottom. That provided

three more inches vertical space to put all six rows in verticly, none

front and back - still with very minimal insulation between rows. On

the plus side, the front and back insulation, the large faces, could

both be two inches, R10, leaving just 3-1/2 inches width air space for

the 2-1/4 and 2-5/8 inch square pipe fins.

[26th] About the outer

holes for the non-compressed air? I found I had a 3-1/4 inch hole saw.

That would be much nicer than roughly cutting a hole out with a jigsaw.

I drilled the two holes in the box... but what would fit into them? I

looked on a shelf with pipes. I knew I had 4 inch PVC. Lo and behold,

hiding inside that was a 3 inch piece. It was a perfect fit for the

holes I had just drilled. I might have a really hard time finding an

elbow and other fittings, but at least something went into the box.

(Hmm... If I cut the pipe at 45° and glue it on the other way, it

would be a 90° corner. Worst case choice.)

[26th] About the outer

holes for the non-compressed air? I found I had a 3-1/4 inch hole saw.

That would be much nicer than roughly cutting a hole out with a jigsaw.

I drilled the two holes in the box... but what would fit into them? I

looked on a shelf with pipes. I knew I had 4 inch PVC. Lo and behold,

hiding inside that was a 3 inch piece. It was a perfect fit for the

holes I had just drilled. I might have a really hard time finding an

elbow and other fittings, but at least something went into the box.

(Hmm... If I cut the pipe at 45° and glue it on the other way, it

would be a 90° corner. Worst case choice.)

I'd have done more work on it but it was too cold. Maybe I

should do the test install in the workshop instead of in the kitchen

& dining area? That also would have the advantage of not having a

fridge periodicly at random adding other heat into the space, which

made good measurements tricky in 2020.

[27th] I unsoldered and soldered

fittings onto the finned pipes in order to let me connect them the way

I want in combo with attaching PCV elbows and pipe bits by heat gun.

3/4" PVC pipe is a bit to small to go over 3/4" copper pipe... unless

you heat it. Then it slides over and shrinks again as it cools, making

a tight fit. A pipe/hose clamp makes sure of it. Same with 1/2" and

1/2". Using plastic fittings at al the bends creates thermal barriers

to stop heat transfer along the copper pipes. (FWIW)

Then I went into town. By some miracle the building supply

store had 3" PVC elbows and I found them. It looked like they only had

4" PVC, all laid out in a bunch of shelf trays, but as I was about to

give up, I spotted a box of 3" fittings across the aisle, all jumbled

together. I'd guess they aren't getting any more. (No discount, tho -

12$ each!)

Cabin Construction

Styrene Foam Garage Door

At some point

I put in the stairs, then concentrated on making the one-piece pull-up

garage door.

At some point

I put in the stairs, then concentrated on making the one-piece pull-up

garage door.

At some point I glued the

extruded styrene foam sheets together with expanding "gap filler" spray

cans. (I remembered this worked well with my "superinsulated Peltier

fridge" around 12 years ago.) With the 2 inch foam the insulation value

of the door is R10. Pretty good for a door!

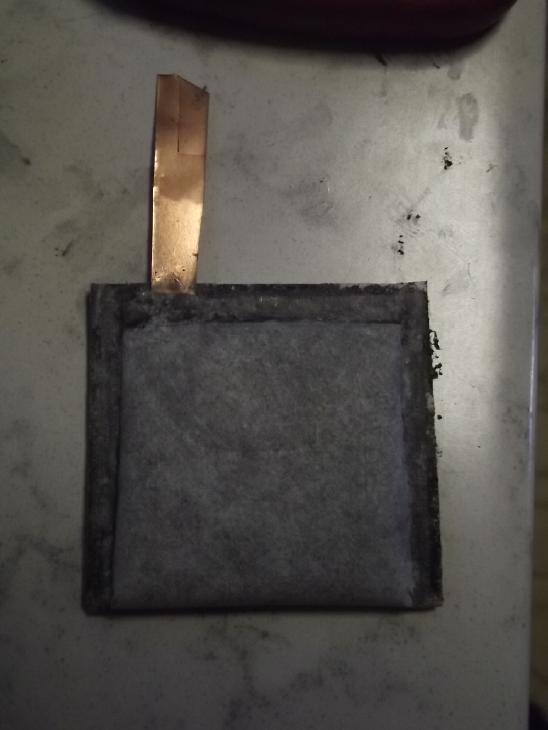

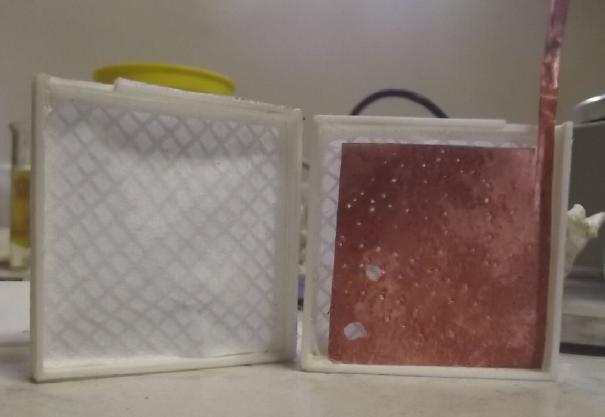

[20th] Yesterday & today I epoxied white polypropylene (PP)

"landscaping" fabric onto one face of my extruded styrene foam garage

door, which I had finally glued together with "gap filler" spray in

recent weeks. (I finally finished off a ten year old gallon of "West

System" epoxy and its hardener.) I suppose I should paint it.

For this I drove the electric truck outside and used the

heatable and relatively clean garage. I did my best, but it didn't turn

out perfectly. As I suspected, everything shows through the thin layer,

even the printing on the styrene. The plastic picked up some spruce

needles and things by static and I missed some little bumps of the "gap

filler" foam that I glued the sheets together with. They're all under

the PP, visible and making bumps. But overall pretty good effect. I

used my usual technique of putting the left over epoxy in the freezer

overnight so it wouldn't set and I could continue in the morning with

what was left and the same roller.

My ideas for how to attach the door are still rather vague.

[25th] I took the door from the heatable garage to the cabin and set it

in place to check the fit. I had to cut the "overhang" part off the

bottom. It wouldn't quite go in as the outside frame wasn't quite

square. I figured I'd have to cut the door down a bit.

[26th] I

looked at it again and decided to change the frame instead: I ground

off some cement where it rose up a bit at the bottom in one corner, and

I planed off some wood from the 2 by 4 along the top, which was warped

and bent down a bit in an area in the middle.

[26th] I

looked at it again and decided to change the frame instead: I ground

off some cement where it rose up a bit at the bottom in one corner, and

I planed off some wood from the 2 by 4 along the top, which was warped

and bent down a bit in an area in the middle.

Then I decided it would be

easier and maybe better to hinge the door, opening out to the outside

wall instead of having it roll up into the ceiling. It's very wide for

hinging but also very lightweight. But the weather turned freezing cold

and I haven't wanted to work outside, so there it has sat.

Electricity

Storage

Everlasting Copper-Zinc Cells with Plastic Pocket Electrodes

Blended Copper-Nickel Hydroxides Positive Powder & Electrode

[6th] I decided that if copper by itself didn't want to recharge -

except it seemed to to some extent as contained in cupro-nickel sheets

- I should try and make a mixed nickel-copper oxide similar to the way

I had for so long been trying to do with nickel-manganese oxides (AKA

nickel manganates). Except now I know to dissolve them in acteone to

form into epitaxial crystals as the acetone evaporates, and I realize

that I should only charge to copper oxides voltages, not high enough to

turn the nickel component into nickel oxyhydroxide.

I decided to make the ratio 60:40 copper:nickel, a 3 to 2 ratio,

without bothering to

try and count copper and nickel atoms. So with 21 grams of copper

hydroxides in a jar, I would try something along the lines of:

Ni(OH)2 - 14 g

Mixed copper hydroxides (with graphite) from my own previous electrodes

- 21 g

A bit more graphite - .5 g (Actual: .6 g. The scale settled .1 g above

where it read when I finished adding. Grr! Still, not far off.)

I measured them into a 100cc beaker and added acetone. As

I stirred the hard lumps disintegrated, the colors blended to dark

gray, and

it made a thin paste. I put it on the hotplate at the "60°" mark to

evaporate the acetone faster and hence presumably grow smaller crystals.

In a while it was "burping" occasional bubbles that came

up from beneath, and there was a thin layer of liquid on top. I poured

off most of this little bit of excess. By bedtime it seemed powdery

again and I turned off the heat.

Of course mixing with a substantial percentage of nickel

hydroxide notably dilutes the copper hydroxides with their fantastic

amp-hours density. Making cells that work cycle after cycle without

deterioration takes priority! [Later note: totally unnecessary]

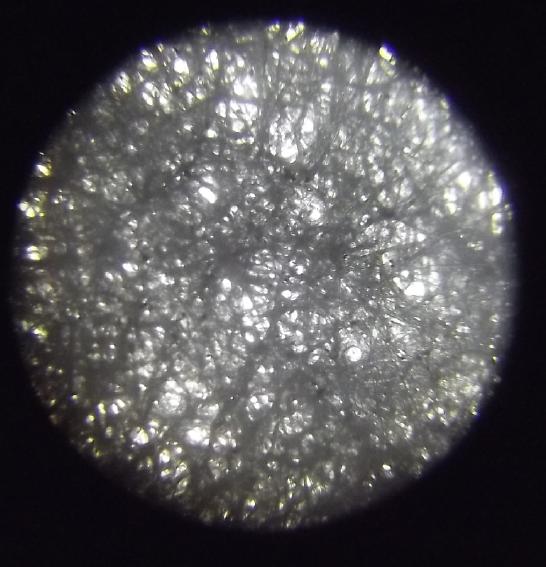

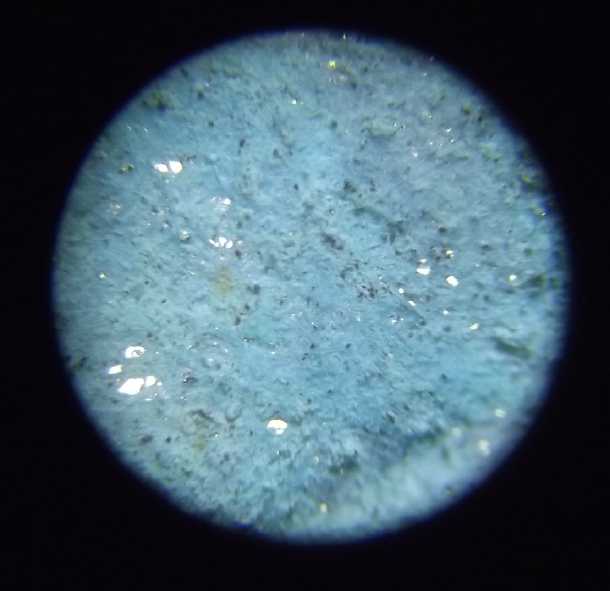

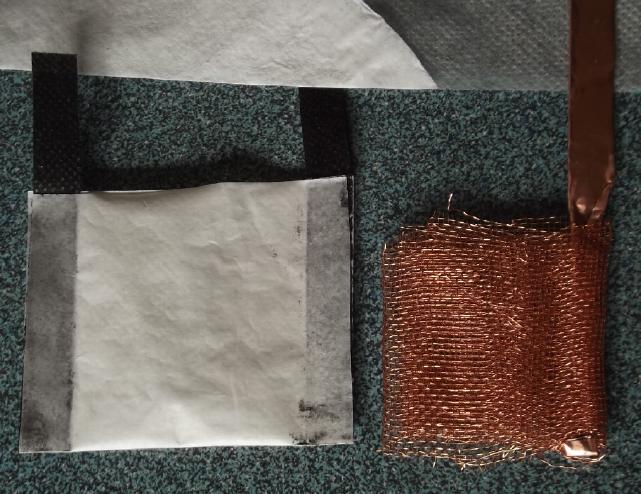

Sky blue copper II hydroxide

[Cu(OH)2] made by

electrolysis in sodium nitrate solution

Sky blue copper II hydroxide

[Cu(OH)2] made by

electrolysis in sodium nitrate solution

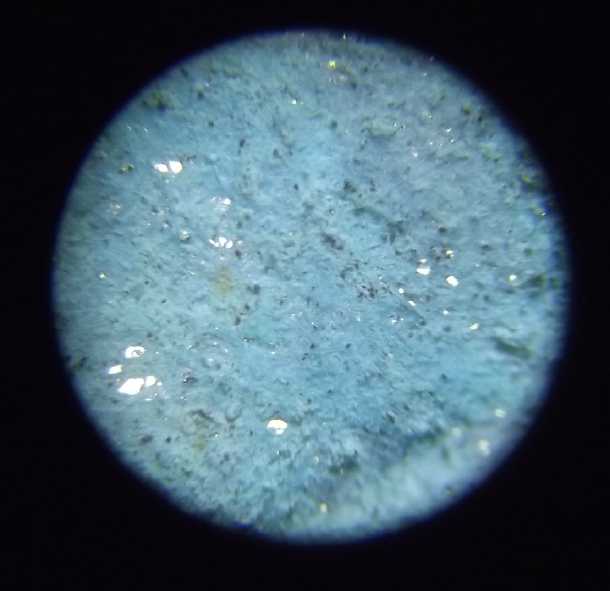

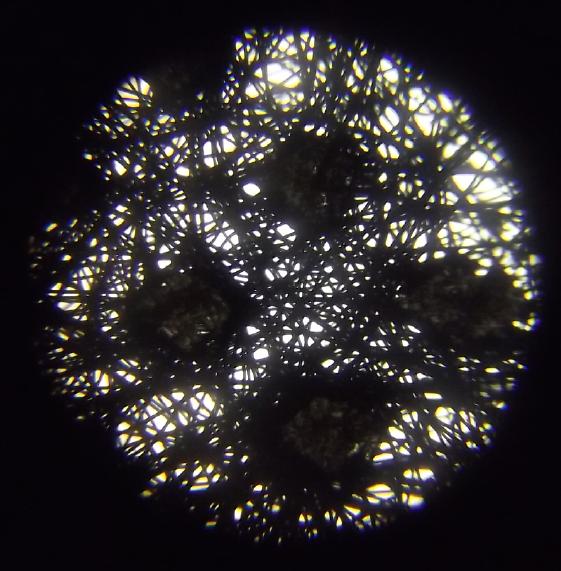

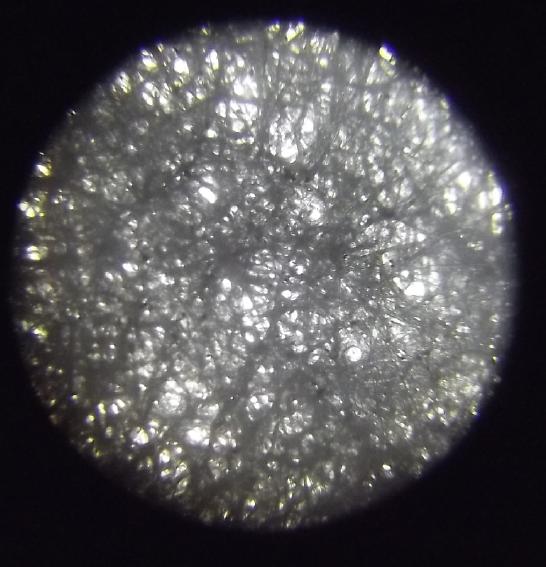

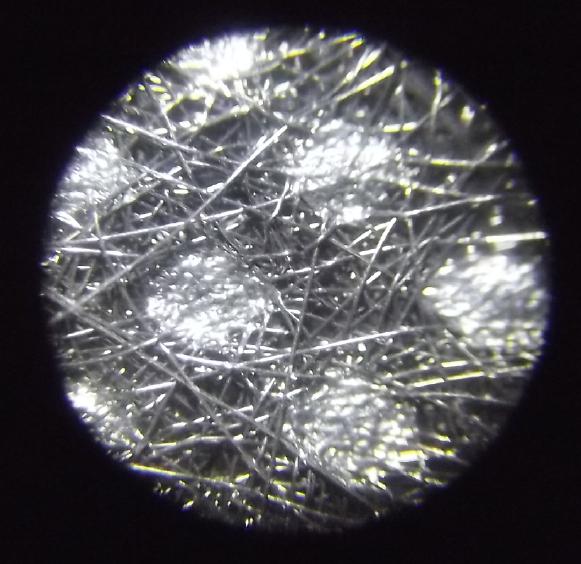

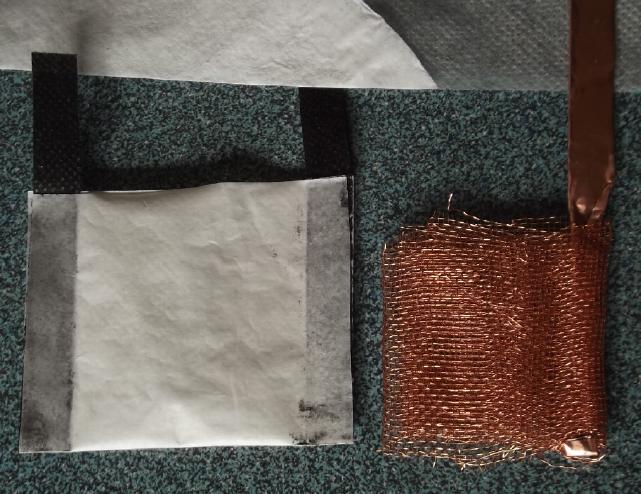

Parchment paper under microscope:

very fine

holes

Parchment paper under microscope:

very fine

holes

[Later note: actually the best]

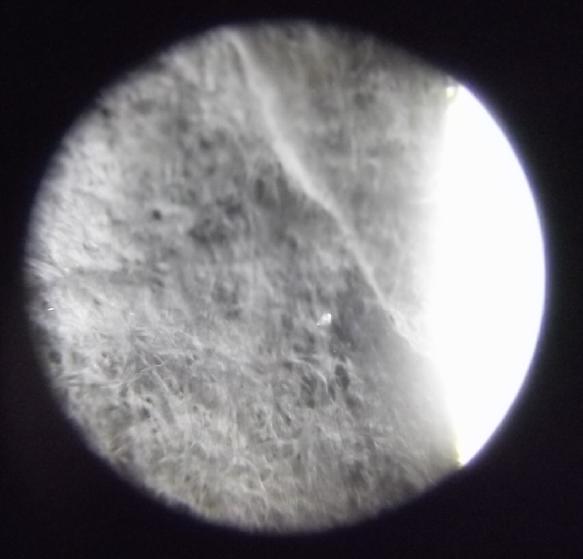

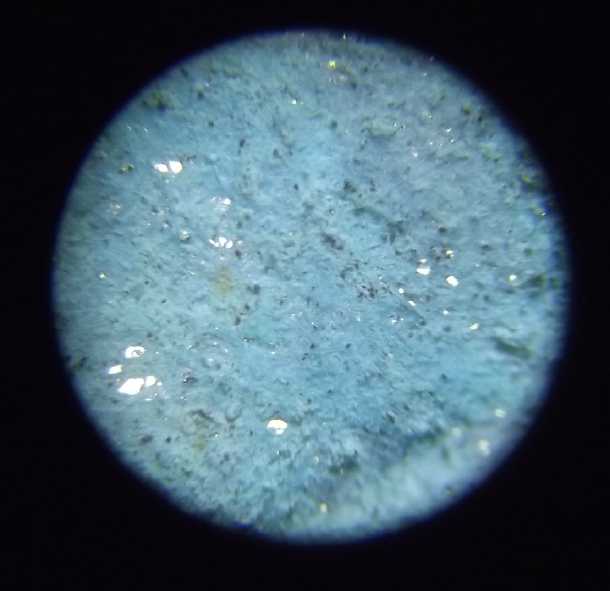

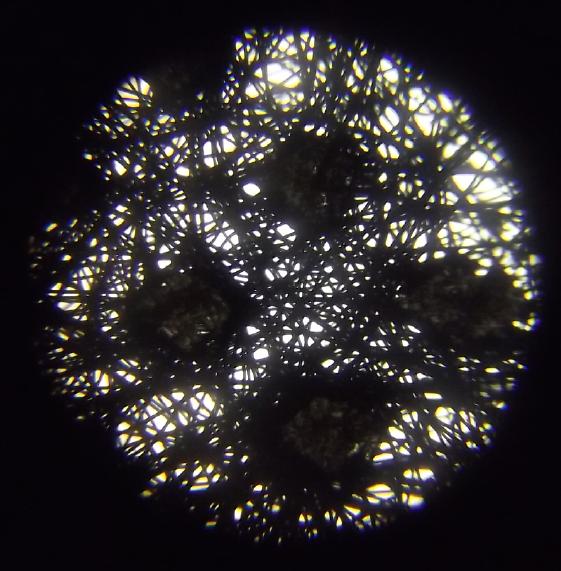

Coffee Filter Paper

Coffee Filter Paper

Used coffee filter paper showing

holes (lit

from behind)

Used coffee filter paper showing

holes (lit

from behind)

where powder would have been getting through. It's too coarse.

Cone coffee filter: very coarse

and fuzzy.

Cone coffee filter: very coarse

and fuzzy.

At some point I made a zinctrode.

Compacting a

zinc "briquette" works poorly.

At some point I made a zinctrode.

Compacting a

zinc "briquette" works poorly.

[7th] The powder still smelled a bit of acetone in the morning. I put

it on the woodstove for a couple of hours to drive off the remnant. In

the meantime I printed a new electrode box, this time mirror image to

have the terminal on the other side.

I cut & put in a coffee filter paper then 9.30 grams

of powder, filled in loosely to the rim of the box. I scrubbed the used

current collector and set it in, then the box back. When I pressed it

down pretty heavily with my hands it went down until it was slightly

recessed in the box. Then I bleached it in a jar lid of water and a

tablespoon of bleach for ten minutes. I figured the liquid would soak

into the dry electrode so I didn't bother to stir it. After that I

rinsed it in the same lid with water, but I agitated it because it was

already wet and the liquid might not circulate very well. All this gets

out any remnant sodium nitrate, too. ...and some grains of the powder.

I reglued a bit of the back that wasn't stuck. I could see powder

drifting out there.

The cell started off saying .151 volts. (Isn't bleach

supposed to charge it? Or was that hydrogen peroxide?) Usually the

voltage starts rising or drifting, but it sat exactly there. It started

charging at just 52mA with the power set to 1.5V. 47mA after 10

minutes. 12:27, 38mA. Voltages briefly off charge, O/C and 50Ω load are

rising. So it seems to be charging.

12:09: 52mA

12:11-12:17: 47mA

12:27: 38mA, 1.1V, .86V (Ante Meridian until ~12:48 here)

13:32: 25mA, 1.2V, .97V

As it got a bit more charged I changed the procedure. Instead of very

short and unmeasured times, I paused the charge and measured the open

circuit voltage after 30 seconds, then immediately turned on the load

and read the voltage after 30 more seconds. Once again, at these

disappointing charging currents, it's going to take a long time to get

to a few amp-hours worth of charge.

15:32: 16mA, 1.261V, .972V

15:52: 16mA, 1.245V, .981V

16:22: 16mA, 1.262V, .986V

17:54: 12mA, 1.290V, .944V Ouch, this doesn't look good! New

tack: switching to 1.8V charge. Started at 72mA, soon down to 35.

Higher and higher open circuit voltages, lower and lower

drive voltages and currents... I suddenly realized the problem was

nothing I had been thinking about. The CuNi current collector was

becoming higher and higher resistance, losing connectivity to the

electrode substance!

The back of the box was well glued, but I managed to pry

it off with a small knife without wrecking it. I removed the CuNi

current collector. Resistances didn't seem high on an ohmmeter, so I'm

puzzled. I cut out and installed a graphite foil one. It was much

worse. But it does illustrate that connectivity to the current

collector seems to be the problem. Or at least, something in the

connectivity within the electrode. Maybe it's the powder itself

expanding and losing connectivity, but pushing on the back to squeeze

it against the zinc trode doesn't seem to help at all. Well, I'm

totally frustrated now. I don't know what I haven't tried but I keep

having the same or similar problems over and over again. [Later note:

It was zinc passivation - not the copper side at all!]

[8th] I think it might have something to do with the charging and

discharging. If you run it down to .5 volts with a 10 Ω load, it seems

to strengthen it a bit. Then if you leave it charging at low current

for too long, it weakens it and load voltages drop. There may be some

charge-load cycle that will strengthen it for an initial formation -

which I then hope wouldn't have to be repeatedly done. I think I'll

have to make that microcontroller based automatic battery cycler I've

been meaning to do for so long. When charge current drops to a certain

point, stop charging and turn on the load. When it drops to .5 volts,

stop and recharge. Repeat.

[9th] I made a zinc

double-face trode. (at last.) I took the old

single-face one out and put in the new one. For the two "plus" end

electrodesI used the "current" copper-nickel hydroxides one and the

previous copper-only one on the other side. I charged this for a while

at almost double the current of the single one, and then ran a 10 Ω

load. Unexpectedly it ran for for 27 minutes from over .7 volts down to

.500 instead of, like 3 or 6 minutes.

[9th] I made a zinc

double-face trode. (at last.) I took the old

single-face one out and put in the new one. For the two "plus" end

electrodesI used the "current" copper-nickel hydroxides one and the

previous copper-only one on the other side. I charged this for a while

at almost double the current of the single one, and then ran a 10 Ω

load. Unexpectedly it ran for for 27 minutes from over .7 volts down to

.500 instead of, like 3 or 6 minutes.

Has the zinc side been

deteriorating? All this time I've considered the problems must be with

the copper side. In charging the cell, the new trode made lots of tiny

soapy [presumably] hydrogen bubbles, since I made it with metallic zinc

powder so there was no zinc oxide to charge.

Looking at the previous zincode, the face watercolor paper had absorbed

a

lot of copperish 'goop', probably bits of powder escaped from one

electrode after another as I tried new copper electrodes. Or else, the

copper stuff has been dissolving and migrating. (If so that would

suggest the need for a higher pH than the 6.5 it seems to be working

well at. Either way... Like a clogged funnel that won't drain, perhaps

all that powder covering the face was the unsuspected, unexpected and

previously unseen cause of the declining current capacity?

Looking at the previous zincode, the face watercolor paper had absorbed

a

lot of copperish 'goop', probably bits of powder escaped from one

electrode after another as I tried new copper electrodes. Or else, the

copper stuff has been dissolving and migrating. (If so that would

suggest the need for a higher pH than the 6.5 it seems to be working

well at. Either way... Like a clogged funnel that won't drain, perhaps

all that powder covering the face was the unsuspected, unexpected and

previously unseen cause of the declining current capacity?

After charging (?)an hour and more, the cell ran the 10 Ω

load from .9x V down to .50 V in 50 minutes.

[

Later Note: Wikipedia solubility table says

CuOH: .0000007 g/100cc

Cu(OH)2: .0000017 g/100cc

CuOOH: no figure given

Unless CuOOH is greatly different, those really aren't very soluble!

]

[10th] After charging

overnight, oodles of bubbles and I refilled the

water. It ran the 10 Ω load from .9x V down to .50 V in 95 minutes.

Currents were a little higher at a given voltage too. (The 'Charge' -

'Off' - 'Load' switch is crap. (I got ten of these switches off

AliExpress. "15 A, 250 V". They have burned out in every power

application I put one in, and the switch's resistance changes even just

running battery tests in mA! But I digress.)

[10th] After charging

overnight, oodles of bubbles and I refilled the

water. It ran the 10 Ω load from .9x V down to .50 V in 95 minutes.

Currents were a little higher at a given voltage too. (The 'Charge' -

'Off' - 'Load' switch is crap. (I got ten of these switches off

AliExpress. "15 A, 250 V". They have burned out in every power

application I put one in, and the switch's resistance changes even just

running battery tests in mA! But I digress.)

So:

1 - 27 minutes

2 - 50 minutes

3 - 95 minutes

and by night

4 - 110 minutes

It looks promising!

It definitely seems that

running copper cells down to .5

volts (or so?) after charging strengthens them. This is probably only

in the initial charging. After running a load, charge currents are high

until the current drawn is replaced, then they get slow again. So once

charged and then discharged it's "working" while the portion of the

electrode's substance still in "initial state" doesn't charge very

fast. So it looks like copper probably makes a viable electrode after

all. It just needs special treatment, several or many "forming" cycles,

after fabrication.

Running it down to .5 volts must reduce the copper to the

lowest oxidation level it will achieve - perhaps to metallic copper

particles. OTOH in the electrode mixed with nickel hydroxide, it may

not get quite get to metal. In fact after the discharge it recovered -

eventually - to just 1.05 V. That too suggests the copper's oxidation

state was pretty low, maybe mostly Cu and some CuOH - or equivalent in

the mixed oxide one.

I connected the two "+" trodes only with an alligator clip

leed. That way I could readily disconnect them. While the copper-only

electrode seemed weaker initially, I checked during recharging after

the 95 minute test and it drew current about equivalent to the

copper-nickel one. In a short 10 Ω load test the mixed oxides one held

.85 V after one minute while the pure copper held only .71. (Both

together were .94 V.) This would seem to validate the higher

conductivity of the spinel crystalline structure. But if conductivity

and higher current drive is the only object, perhaps the pure copper

one could be brought up to a higher level with a few more percent

graphite powder, rather than diluting the copper to 60% by adding 40%

nickel substance. Certainly the amp-hours should be higher.

[11th] I didn't have time until afternoon. By then it had been charging

so long that the voltage started out lower, at .85V and rising in one

minute to .90V. But far from meaning the cell was weaker as I had kept

assuming, under 10 Ω load the voltage dropped still more slowly than in

test 4. By ~30 minutes the voltage was equal to that test (.86V), and

from then on, higher. But it only lasted 5 minutes longer. The next

test was shorter: I don't think I recharged it long enough.

5 - 115 minutes

6 - 90 minutes

Short circuit current is only 280mA. This is pathetic and

only 5.6ma/sq.cm of interface. To get to 50 that order of magnitude of

improvement is still needed. A recent try had been over 15mA/sq.cm,

which here would have meant 750mA. What happened?

[12th] After overnight charging the load voltage started even lower,

.75V, but it was soon over .8 and it crept up to almost .85 over the

first six minutes under load. In an hour it was similar to other loads

at an hour. I turned it off there, .64 volts, thinking discharging to

nothing every time might not be strengthening it.

Something I've been noting all along is lots of bubbles

from the negative and having to refill with a bit of water a couple of

times a day or even before or during a load test. It would seem that I

should make the cell housings with lots of room above the trodes for a

water reservoir. Presumably it will stop needing more once it has been

fully charged and if there's a cover over it.

The more I see, the more I realize I have been taking the

problem of separators much too casually. Some kind of membrane? But

what?

If I use a woven PP cloth ("landscaping fabric", "cloth

grocery bags") it will doubtless have holes for powders to seep

through. If I iron it, it will turn into a solid sheet of plastic.

Maybe if I iron a coffee filter into a piece of PP cloth it could make

a good separator that will let ions pass but not powder, however fine.

But it can't be as fine as the parchment paper, which didn't let ions

pass freely enough and reduced current flow.

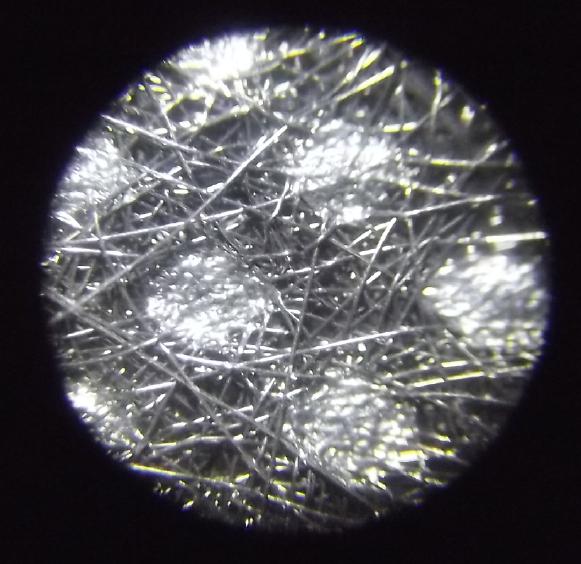

[13th] Under the microscope I see there's a subtle difference in hole

sizes between different brands of basket coffee filters. I'm going to

use white "GK Connoisseur" brand. They seem to have smaller holes than

"Great Value" or (I didn't check any brown filters.)

I also belatedly thought to look at parchment paper under

the microscope. It does have tiny holes and I'm surprised it doesn't

work better. Maybe it too cloggs with nano powders?

Under a microscope the black PP fabric that looked rather

like

woven cloth turned out to be a random non-woven with regularly spaced

tiny spots fused by heat to make it "solid", if that's the right word -

to keep all the fine strands in place.

Front Lit

Front Lit

Back Lit

Back Lit

t

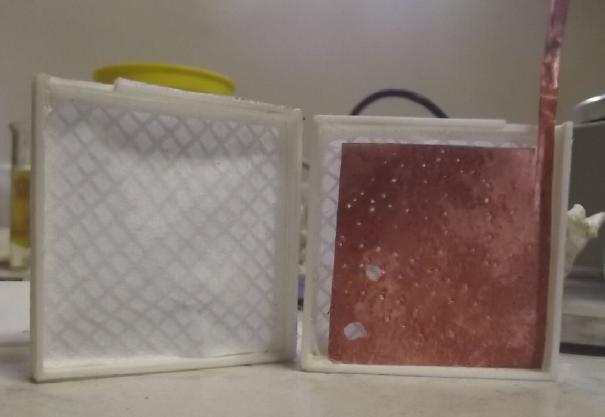

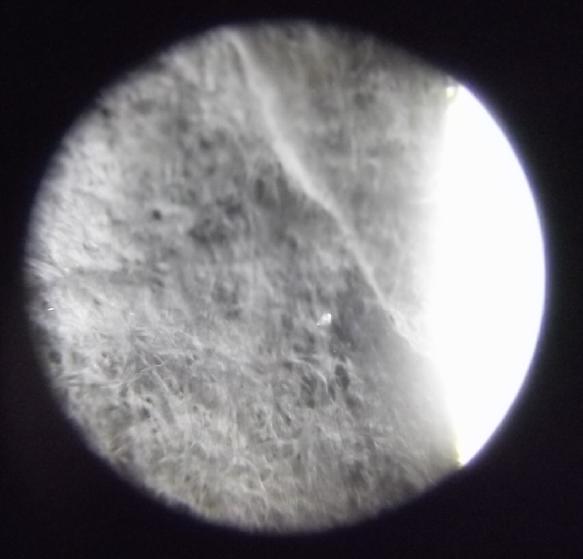

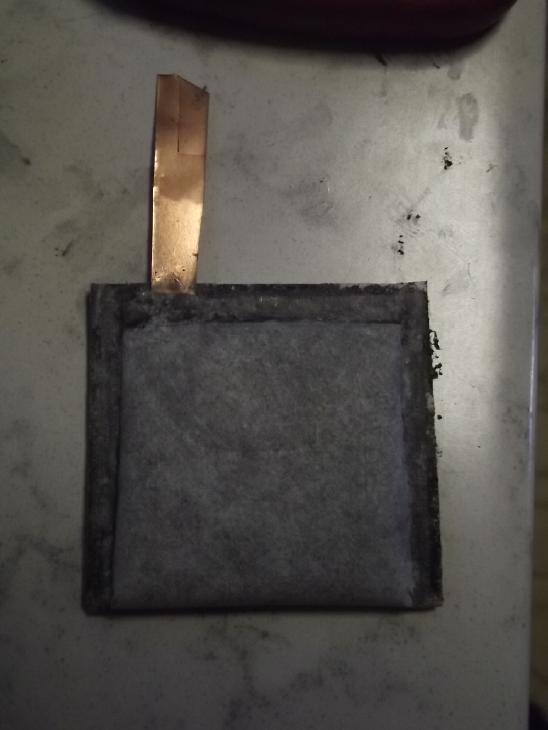

I decided to

make a sheet with PP in the middle and coffee

filter paper on both sides, with the iron set to "Extra Steam"; but I

didn't use any steam. I had to do each face separately because the heat

didn't go through the cloth. Holes showing light through in the

finished "membrane" were small, few and far between, and even so they

had fibers crossing them.

I decided to

make a sheet with PP in the middle and coffee

filter paper on both sides, with the iron set to "Extra Steam"; but I

didn't use any steam. I had to do each face separately because the heat

didn't go through the cloth. Holes showing light through in the

finished "membrane" were small, few and far between, and even so they

had fibers crossing them.

Pieces cut 50x50mm for new

electrode(s)

Pieces cut 50x50mm for new

electrode(s)

But even before trying a new electrode, I decided to try

cutting the "clogged" watercolor paper off one side of the zinc and

replace it. It turned out to be "rip" off rather than cut, exposing the

doped cellophane paper. I decided to try it with just the cellophane.

It too was soaked in sodium dodecylbenzenesulfonate (herein "SDBS") and

might by itself stop zinc dendrites. I

put one of the copper electrodes in with it. (Three electrodes were

really hard to get in and out. Two is easier.) It started out around

1.15V and dropped to .9x with a ten ohm load. Short circuit current was

420mA - a considerable improvement with just half the interface area...

under half really, as the paper I peeled away wasn't the whole 50 x 50

mm face. Maybe I need to ditch the watercolor paper entirely?

But even before trying a new electrode, I decided to try

cutting the "clogged" watercolor paper off one side of the zinc and

replace it. It turned out to be "rip" off rather than cut, exposing the

doped cellophane paper. I decided to try it with just the cellophane.

It too was soaked in sodium dodecylbenzenesulfonate (herein "SDBS") and

might by itself stop zinc dendrites. I

put one of the copper electrodes in with it. (Three electrodes were

really hard to get in and out. Two is easier.) It started out around

1.15V and dropped to .9x with a ten ohm load. Short circuit current was

420mA - a considerable improvement with just half the interface area...

under half really, as the paper I peeled away wasn't the whole 50 x 50

mm face. Maybe I need to ditch the watercolor paper entirely?

It started charging at over 100mA which soon dropped under

80.

I had replaced the switch

that had poor contacts, and now

in checking the short circuit current I found another poor connection

that has probably been degrading my readings: the bolt and nut on the

terminal. I tightened it. With charging that current rose to as high as

530mA. If we call it 20 sq.cm of interface that's hit the 25 mA/sq.cm

"good enough" mark, or 1/2 way to the more desirable target of 50 per,

instead of the previous best of 17. If there are no zinc dendrites I'm

definitely ditching the watercolor paper. But any leakage of powder

from the copper side, however slight, will have to be eliminated.

With some charging, discharge into 10 Ω started at a bit

over a volt, 95mA current, and that's with just one copper trode and

half the interface area. Things are looking up!

But I figured powder would leak and clog the cellophane

and so the whole thing would start deteriorating again. And in fact by

later afternoon it wasn't quite as good. So I took it apart. It was

worse than I thought. The cellophane not only was starting to

accumulate gunk, it was ripped across the middle. And the coffee filter

had disintegrated, leaving half the box weave wide open! The watercolor

paper around the zinc was disintegrating too. Apparently I needed to

re-think the whole system of separators, not just the one.

And this in fact was what I saw as the biggest benefit to

the separate tube electrodes in a jar: if powder leaked out, it would

mostly just fall to the bottom of the jar. But I suppose while good for

testing, anything that isn't "perfect" is going to deteriorate over

time one way or another, so "perfection" needs to be achieved.

[14th] To do

the zinc side, I ironed a coffee filter onto one side of

the PP fabric. I set the iron a little hotter (to "cot") and everything

melted together quickly. The shrinking PP fabric made it curl up. Then

I set it up so I could iron the edges, and glued the PP fabric with the

iron to form an envelope.

[14th] To do

the zinc side, I ironed a coffee filter onto one side of

the PP fabric. I set the iron a little hotter (to "cot") and everything

melted together quickly. The shrinking PP fabric made it curl up. Then

I set it up so I could iron the edges, and glued the PP fabric with the

iron to form an envelope.

It was really a "double" size envelope but I just managed

to get a single sided zinc trode into it. The inward curl grabbed at

the doped cellophane and tried to keep it out. (I should have made a

metal spacer to keep the top wide open.)

When it was in I ironed the top shut and trimmed off the

excess.

Then of course I soaked it in SDBS for an hour - "again"

for the innards but first time for the new cloth/paper cover.

[15th] The cell didn't perform very

well, and even less until I

squeezed the electrodes together. Now I'm starting to think the problem

is the zinc side. I have assumed it will charge from oxide to metal

readily. But the last cell, with the negative made of zinc powder,

worked better. This cell has the same substance, but I've noted that as

it dries out when leaving it on the counter, it seems most of the zinc

turns to oxide in the damp saltiness. And it swells up quite a lot.

Whereas the zinc metal had a ziilion tiny hydrogen bubbles when

charging the previous cell, in this one the water is placid since the

oxide is charging back to zinc. So along with not being very well

charged I don't think the connectivity is as good so the currents are

lower. I could add a conductivity additive like graphite powder, but

it's probably better just to never let all the zinc turn to oxide:

always keep the electrode submerged and never let it dry.

So... new

zinc trode. Maybe half zinc, half zinc oxide. (And of course half a

percent zirconium silicate.)

So... new

zinc trode. Maybe half zinc, half zinc oxide. (And of course half a

percent zirconium silicate.)

Breaking up the lumps, on closer inspection they aren't

"mostly oxide". A considerable surface layer is, but inside is more

metal. But when I used the lump pieces it was the oxide that went

against

the current collector. This time I ground these up before reusing them

so there would be some metal throughout. Then I added 5% graphite to

improve conductivity regardless of state of charge.

Breaking up the lumps, on closer inspection they aren't

"mostly oxide". A considerable surface layer is, but inside is more

metal. But when I used the lump pieces it was the oxide that went

against

the current collector. This time I ground these up before reusing them

so there would be some metal throughout. Then I added 5% graphite to

improve conductivity regardless of state of charge.

Looking at the

copper box, the fab new fabric was colored

with blue again. It had to be copper dissolving and getting through

rather than powder getting through cracks. [Later note: apparently

wrong. Holes; powder.]

Looking at the

copper box, the fab new fabric was colored

with blue again. It had to be copper dissolving and getting through

rather than powder getting through cracks. [Later note: apparently

wrong. Holes; powder.]

But when first made,

performance was good even at the lower pH of about 6.5. Two things to

try?:

1. raise the pH to 12 with calcium hydroxide, or

2. block dissolved ions from getting out of the positrode box.

Raising the pH might just mean the same thing happens much

more slowly and the cell lasts a long time. But not 'forever'.

[16th] So I decided first

to try the latter. A while back I ran across

a pricey 30x30cm sheet of Nafion that I must have bought years ago. (It

seems to me it fell apart in an alkaline environment. Since that's

where I was working, I only used one little piece.) I cut a 50x50mm

square and put it in the window of a new box. I scooped the copper (or

was it copper-nickel?) mix from a previous electrode into it.

[16th] So I decided first

to try the latter. A while back I ran across

a pricey 30x30cm sheet of Nafion that I must have bought years ago. (It

seems to me it fell apart in an alkaline environment. Since that's

where I was working, I only used one little piece.) I cut a 50x50mm

square and put it in the window of a new box. I scooped the copper (or

was it copper-nickel?) mix from a previous electrode into it.

So, now we have dissolving zinc ions trapped by SDBS soap

and dissolving copper ions [hopefully] trapped in a solid box with an

ion blocking membrane in the window. Come to think of it, how could

ions that dissolve and re-solidify, but can't migrate anywhere while

they're dissolved, do any degrading during charge and discharge cycles?

I had to make a new CuNi

current collector - the terminal

had corroded off at about the waterline/top of box. I think it was too

much charging at 1.6-1.8 volts instead of 1.5 or less. (Why can't I get

monel?) I think I'll

extend the plastic of the box to above the waterline around the

terminal tabs. That will also ameliorate the effects of any leakage

around the terminal. (But leakage will still eventually cause trouble,

I'm sure.)

[17th] The new cell - both

electrodes - put together in the evening,

was disappointing. It started charging at just 25mA or so and overnight

dropped to 11. Discharge into 10 Ω started out hardly above .5 volts.

Well, so much for Nafion!

[17th] The new cell - both

electrodes - put together in the evening,

was disappointing. It started charging at just 25mA or so and overnight

dropped to 11. Discharge into 10 Ω started out hardly above .5 volts.

Well, so much for Nafion!

But it seems to need something if the copper ions want to

migrate. [Later: wasn't the problem] I decided to try the same thing as

in the zinc: SDBS. (After

all, when the ions came out of the copper trode, they seemed to stop at

the SDBS impregnated paper around the zinc.) I just soaked the previous

electrode with the coffee filter/PP separator in the window for an

hour. (Same as before: a tablespoon of SDBS powder in a 200(?)cc drink

bottle of pure water - a refill because it was about empty and dirty

with zinc.)

That was much more gratifying, having similar performance

to the initial performance of previous cells, with several tens of

milliamps of charge current (@1.5V) and 360mA short circuit drive. I

note the zinc wasn't well distributed inside its envelope, having

tended to fall toward the bottom when it was turned upright. It seemed

there was almost none at the top, so it was probably well over

15mA/sq.cm in practical terms. (Now, how do I uniformly fill zinctrodes

when 'briquettes' just crumble?) And putting in spacers to squeeze the

trodes together, more especially to squeeze the zinc envelope,

definitely improved the current drive. I did it while running a 10 Ω

load and the voltage crept up from ~~.85V to ~~.93V as I added more.

Now the 64 thousand dollar

question is, will it continue

to perform, or deteriorate? As well as having many other things to do,

I think I've just about reached the limit of my frustration and

patience with this project for this winter if I don't have a really

working battery or at least a clue why not.

[18th] I pried the last box apart and replaced the Nafion with the new

composite fabric. I cleaned the current collector and sprinkled &

smeared a thin layer of graphite onto the copper substance before

putting the current collector back on. Maybe that will help the CC

connect to the powders better? Then SDBS for an hour.

The zinc is double sided and I put both copper boxes in,

one on each side. The new one initially gave around 330mA sort circuit

current, but after a while of charging was down to 275 or so. The other

one was around 225. Both together were around 425. This suggests that

the zinc side is probably partly responsible for the low currents.

[19th] Discharge voltages and currents dropped with charging and time

again. Two things occurred to me. One was that I had forgotten to

bleach the new electrodes. The second was that 1.5 volts might be too

high a charging voltage for cells that are fully charged at around 1.3

V. 1.6 or more seemed to degrade the CuNi current collectors, but

perhaps there was still something causing a problem at 1.5V? Worth

exploring. I dropped the charge to 1.4V, then to 1.35V. Charging

current didn't drop much. It didn't help. Output voltages/currents

continued to decline.

[20th] I took out the electrodes. I put the zinc in water so it

wouldn't mostly discharge. I dried the copper ones on the woodstove,

then bleached them: each separately, a tablespoon of bleach in a cup of

water for 10 minutes or more.

[21st] Maybe SDBS was the wrong gel for the plus side? I heated a

little bowl of water and mixed in a teaspoon of agar. I put in one of

the copper trodes and let the mix soak in. Then I reassembled the cell

with just the zinc and that one copper. As usual it seemed to be

working okay, but currents were lower. I finally put the other one (now

bleached) in instead.

As the zinc was fuller at the bottom than the top, I pressed the

top of the zinc in a bit with extra spacers and the discharge current

rose notably. Obviously it pays to have the zinc well "squashed"

against its current collector - and I probably haven't got it very well

yet. How can I make a zinc with flat faces if it settles to the bottom

of its "envelope" before it gets into the cell? In fact, I'm starting

to think that's the main problem with the cells.

AHA! The more I think about it, the more sense this makes.

When I opened the big flat cell last month, the zinc metal had largely

turned to oxide and it had swelled from 4-5mm to 7mm or more - 1.5x to

almost double. So as the cell charges the zinc oxide returns to metal

and shrinks, and in doing so with no added compaction it loses

connectivity between particles and to the current collector. So the

more the cell charges, the worse the performance gets - exactly the

symptoms I keep seeing. nothing to do with migrating copper ions. Then

when I push added spacer pieces in, the ever dropping load voltage and

conductivity go up again. So it would seem that the thickness of the

zinc electrodes needs to expand and contract with charging and

discharging. And the copper ones would probably do likewise, except

expand with charge and contract with discharge. But it might not be

even between the two sides.

[22nd] I think I'll try redesigning the electrode boxes so that they

slide together like a cardboard box with separate top and bottom, with

the faces having the mesh, and use them for both electrodes. The layers

will be assembled into the bottom and then the top put on. Enough